Method for preparing graphene/fullerene hybrid material and application

A graphene and fullerene technology, applied in the field of materials science, can solve the problems of high energy consumption, cumbersome preparation process and high cost, and achieve the effects of large specific surface area, simple preparation method and high energy storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Ultrasonic dispersion of 40 mg of freeze-dried graphene oxide into 10 mL of N-methylpyrrolidone solvent to prepare a graphene oxide dispersion with a concentration of 4 mg / mL, and high-shear mixing to make the dispersion uniform.

[0026] 2) Disperse 5 mg of fullerene into 5 mL of diethylamine, and sonicate for 2 h.

[0027] 3) Mix the graphene oxide dispersion liquid and the fullerene dispersion liquid uniformly, and magnetically stir for 1 h.

[0028] 4) Put the mixed solution into a polytetrafluoroethylene reactor, then put the reactor into an electric blast drying oven for high temperature, set the temperature at 180°C for 9 hours, and cool to room temperature after the reaction.

[0029] 5) Finally, the product obtained in step 4) was washed with deionized water three times, and freeze-dried for 48 hours to obtain a graphene / fullerene hybrid material.

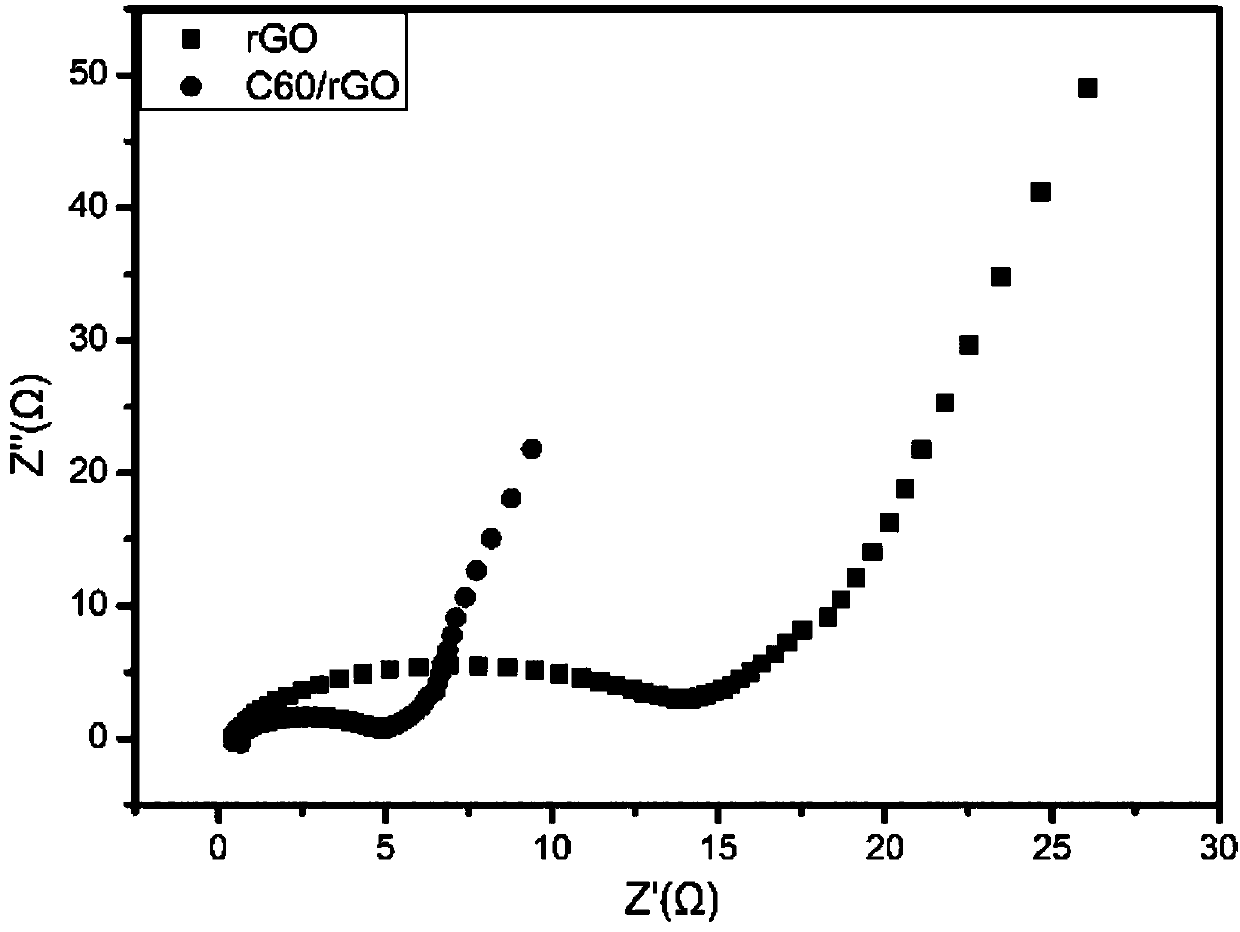

[0030] The graphene / fullerene hybrid material is sliced and pressed with a tablet machine at a pressure of ...

Embodiment 2

[0032] 1) Ultrasonic disperse 40 mg of freeze-dried graphene oxide into 10 mL of ethylene glycol solvent to prepare a graphene oxide dispersion with a concentration of 4 mg / mL, and magnetically stir to make it uniformly dispersed.

[0033] 2) Disperse 8 mg of fullerene into 5 mL of acetonitrile, and perform high-shear mixing treatment for 2 h.

[0034] 3) Mix the graphene oxide dispersion liquid and the fullerene dispersion liquid uniformly, and magnetically stir for 1.5 h.

[0035] 4) Put the mixed solution into a polytetrafluoroethylene reactor, then put the reactor into an electric blast drying oven for high-temperature reaction, set the temperature at 200°C for 12 hours, and cool to room temperature after the reaction.

[0036] 5) Finally, the product obtained in step 4) was washed with deionized water three times, and freeze-dried for 30 hours to obtain a graphene / fullerene hybrid material.

[0037] The graphene / fullerene hybrid material is sliced and pressed with a ta...

Embodiment 3

[0039] 1) Ultrasonic disperse 80 mg of freeze-dried graphene oxide into 10 mL of a mixed solvent of ethylene glycol and deionized water to prepare a graphene oxide dispersion with a concentration of 8 mg / mL, and ultrasonically disperse it evenly.

[0040] 2) Disperse 8 mg of fullerene into 5 mL of deionized water, and treat with magnetic stirring for 2 h.

[0041] 3) The graphene oxide dispersion liquid and the fullerene dispersion liquid are mixed evenly, and magnetically stirred for 1 h.

[0042] 4) Put the mixed solution into a polytetrafluoroethylene reactor, then put the reactor into an electric blast drying oven for high-temperature reaction, set the temperature at 160°C for 12 hours, and cool to room temperature after the reaction.

[0043] 5) Finally, the product obtained in step 4) was washed with deionized water for 3 times, and dried in vacuum for 20 hours to obtain a graphene / fullerene hybrid material.

[0044]The graphene / fullerene hybrid material is sliced and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com