Patents

Literature

432results about How to "Complete restoration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for cathode material Na3V2(PO4)3/C of sodium ion battery

InactiveCN105140468ARestore fully and evenlyMix well and evenlyCell electrodesSecondary cellsSodium-ion batteryReducing atmosphere

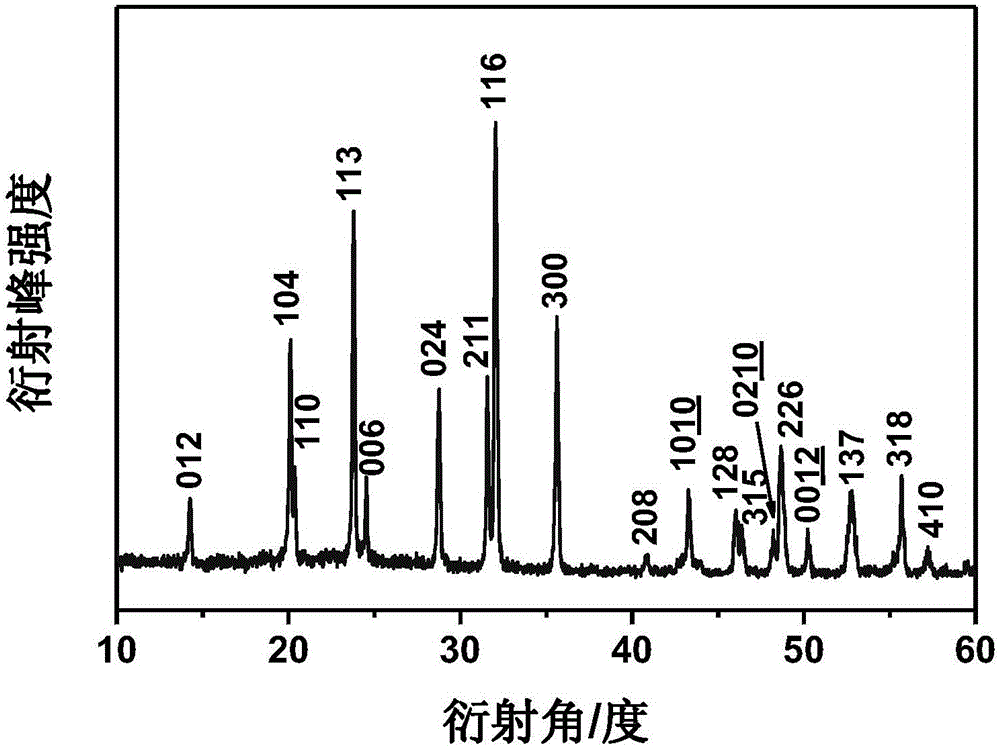

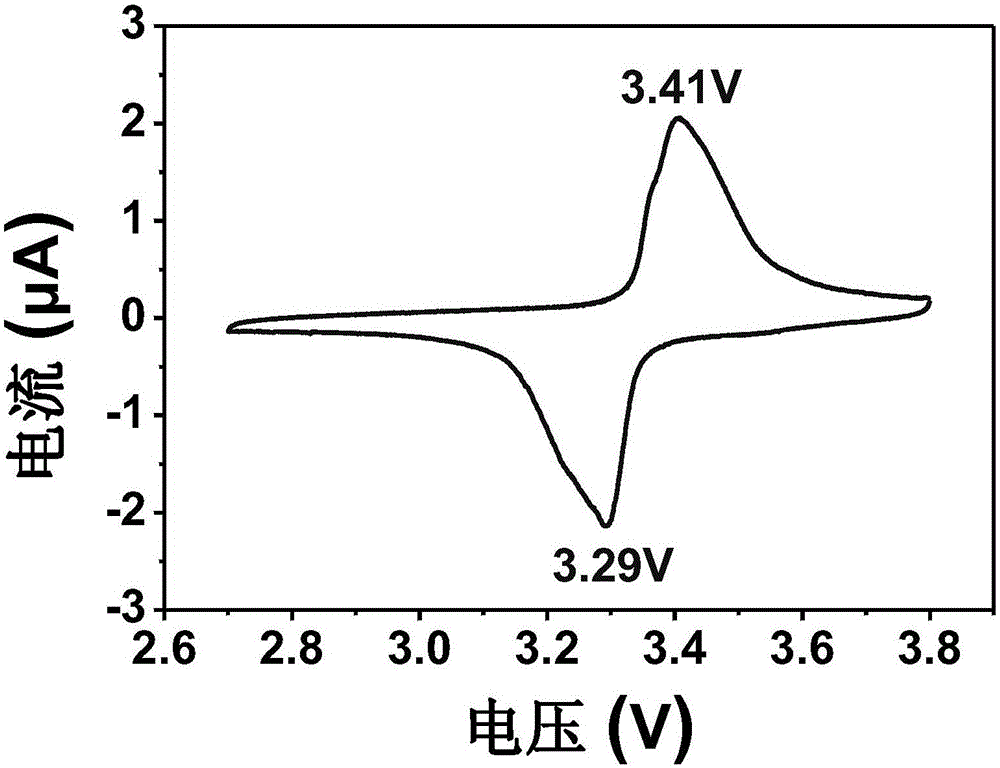

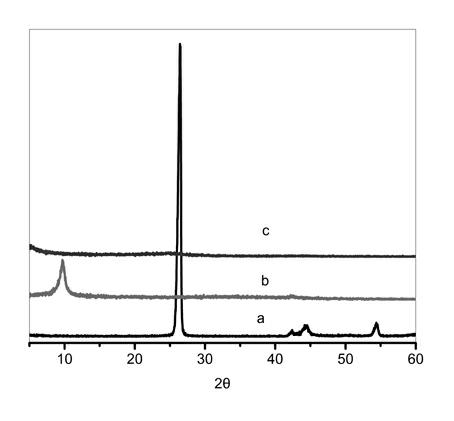

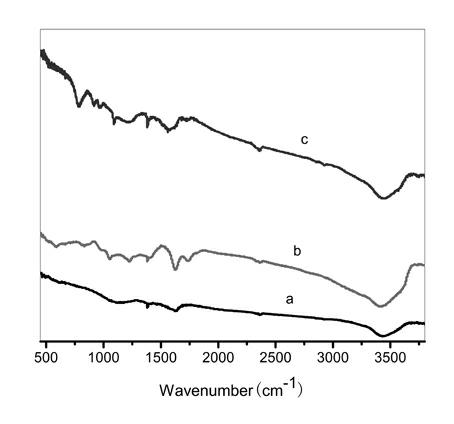

The invention discloses a preparation method for a cathode material Na3V2(PO4)3 / C of a sodium ion battery. The preparation method comprises the following steps of: (1) taking a high-valent vanadium source compound, a sodium source compound, a phosphorus source compound and a reducing agent as raw materials, weighing the reaction raw materials according to the molar ratio of a sodium element, a vanadium element and a phosphorus element of being 3:2:3 and the molar ratio of the reducing agent and the high-valent vanadium source compound of being 3:1 to 15:1, carrying out mechanical ball grinding for 2 to 20 hours, and reducing high-valent vanadium into low-valent vanadium at a normal temperature; and (2) forwarding a precursor obtained through ball grinding in the step (1) into an inert atmosphere or a reducing atmosphere, and carrying out heat preservation for 4 to 20 hours at 600-900 DEG C to obtain the Na3V2(PO4)3 / C. The method has the advantages of short flow and low cost, and is easy to control, the prepared Na3V2(PO4)3 / C is high in purity and crystallinity, and the production of the cathode material Na3V2(PO4)3 / C of the sodium ion battery at a large scale is easy to realize.

Owner:WUHAN UNIV

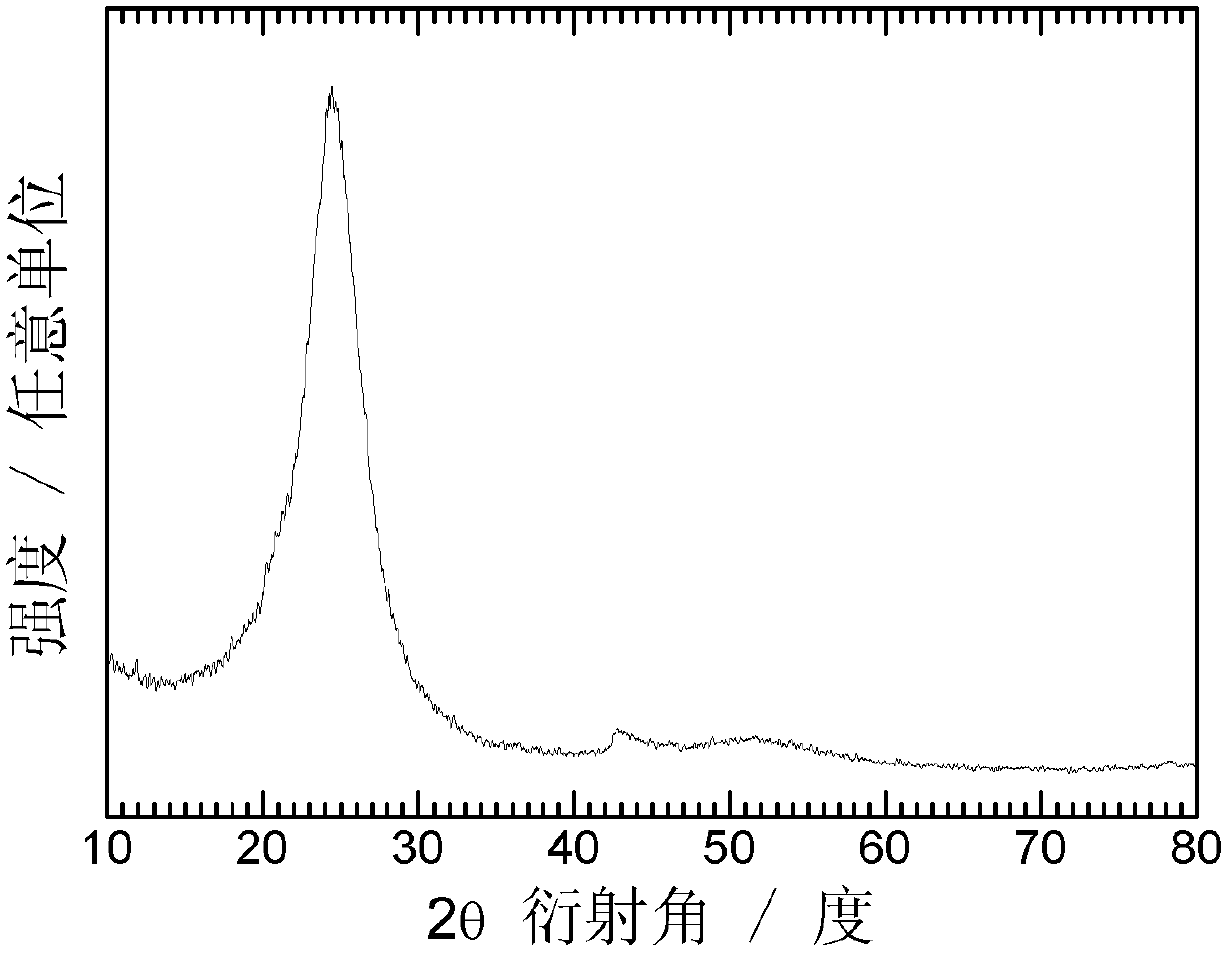

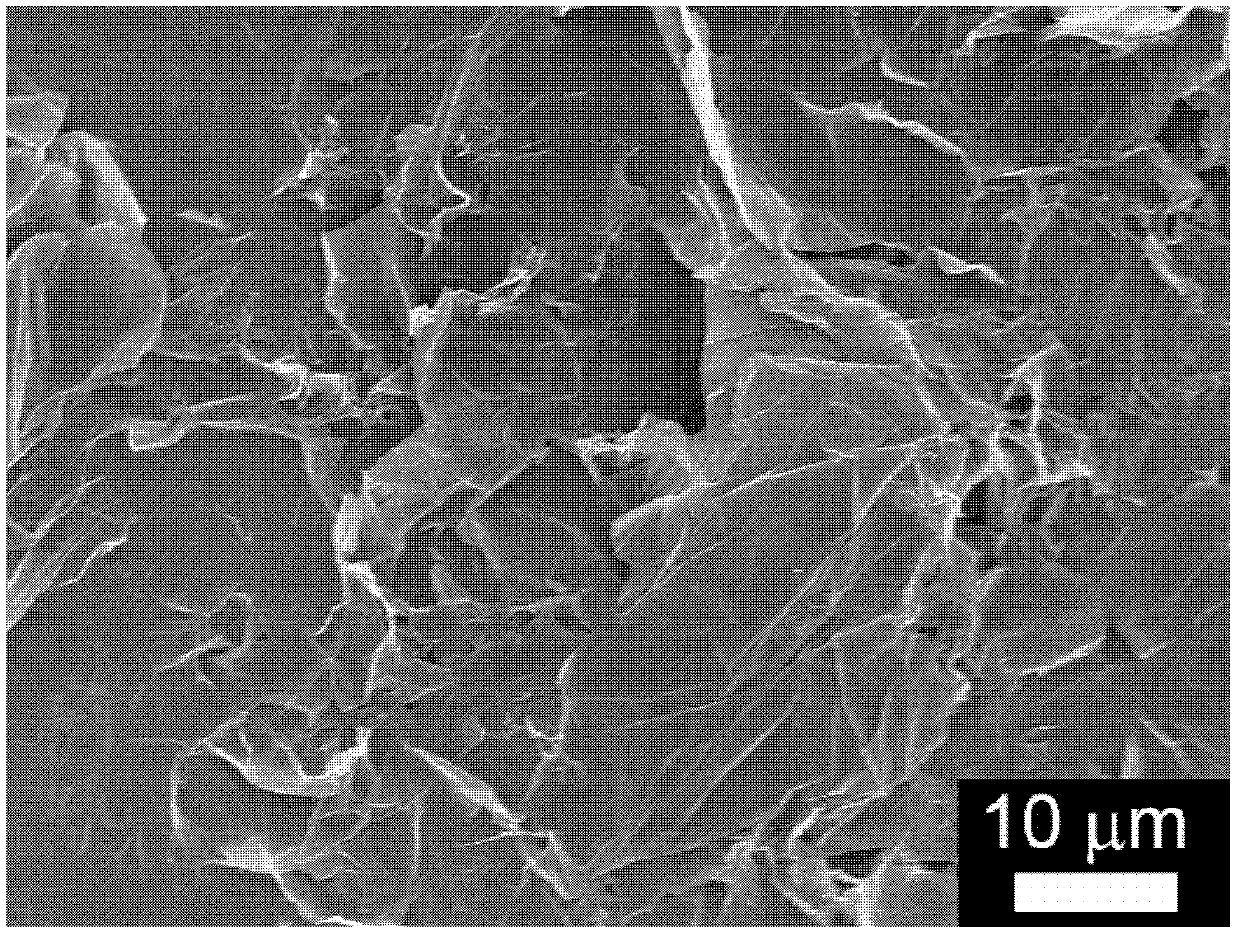

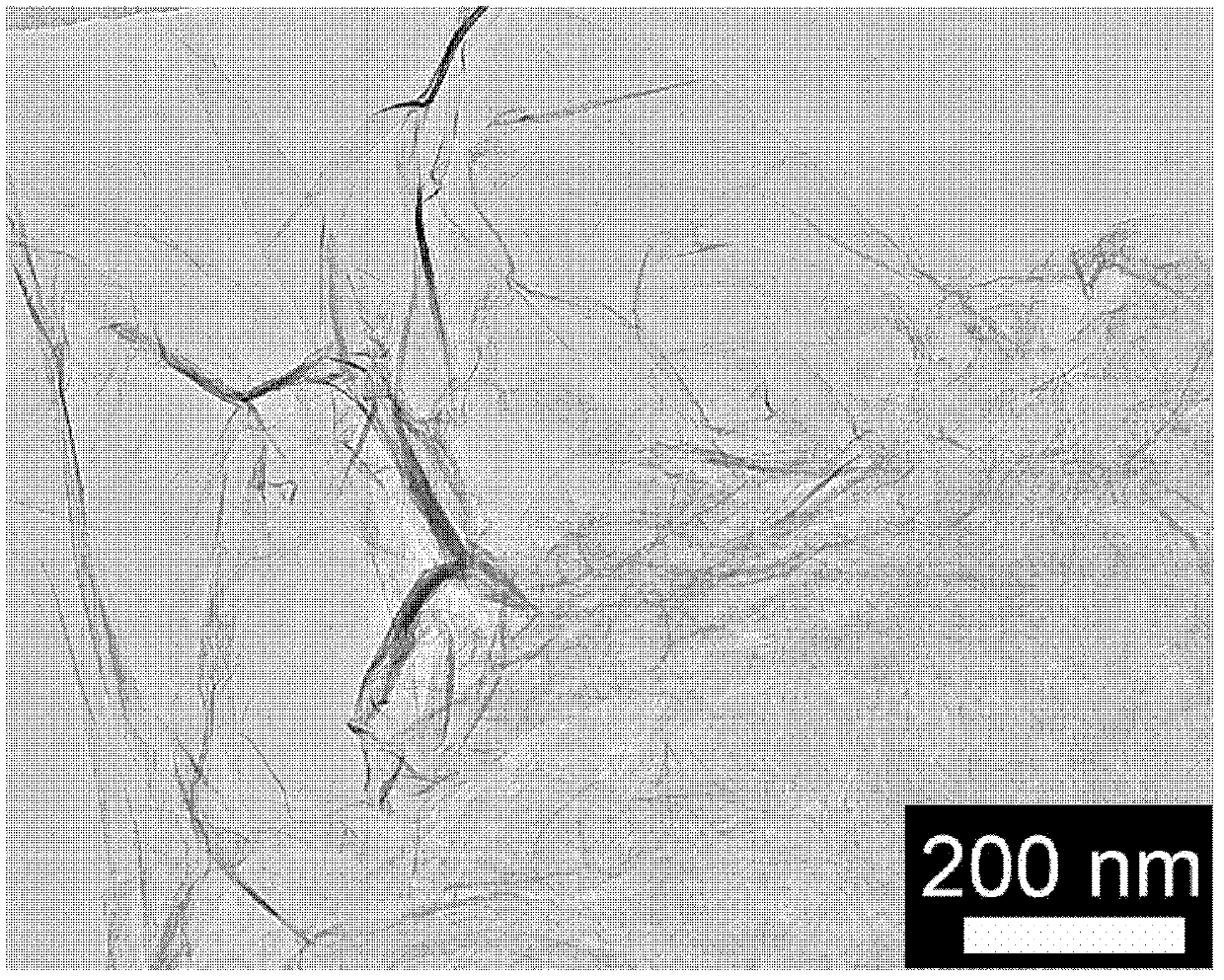

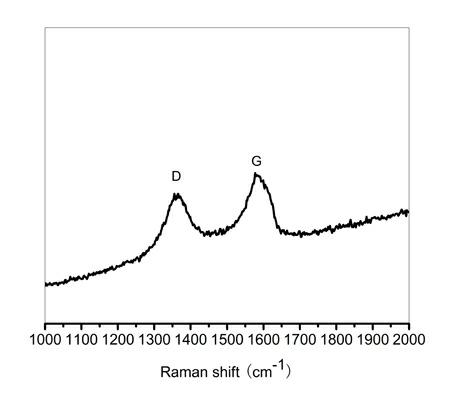

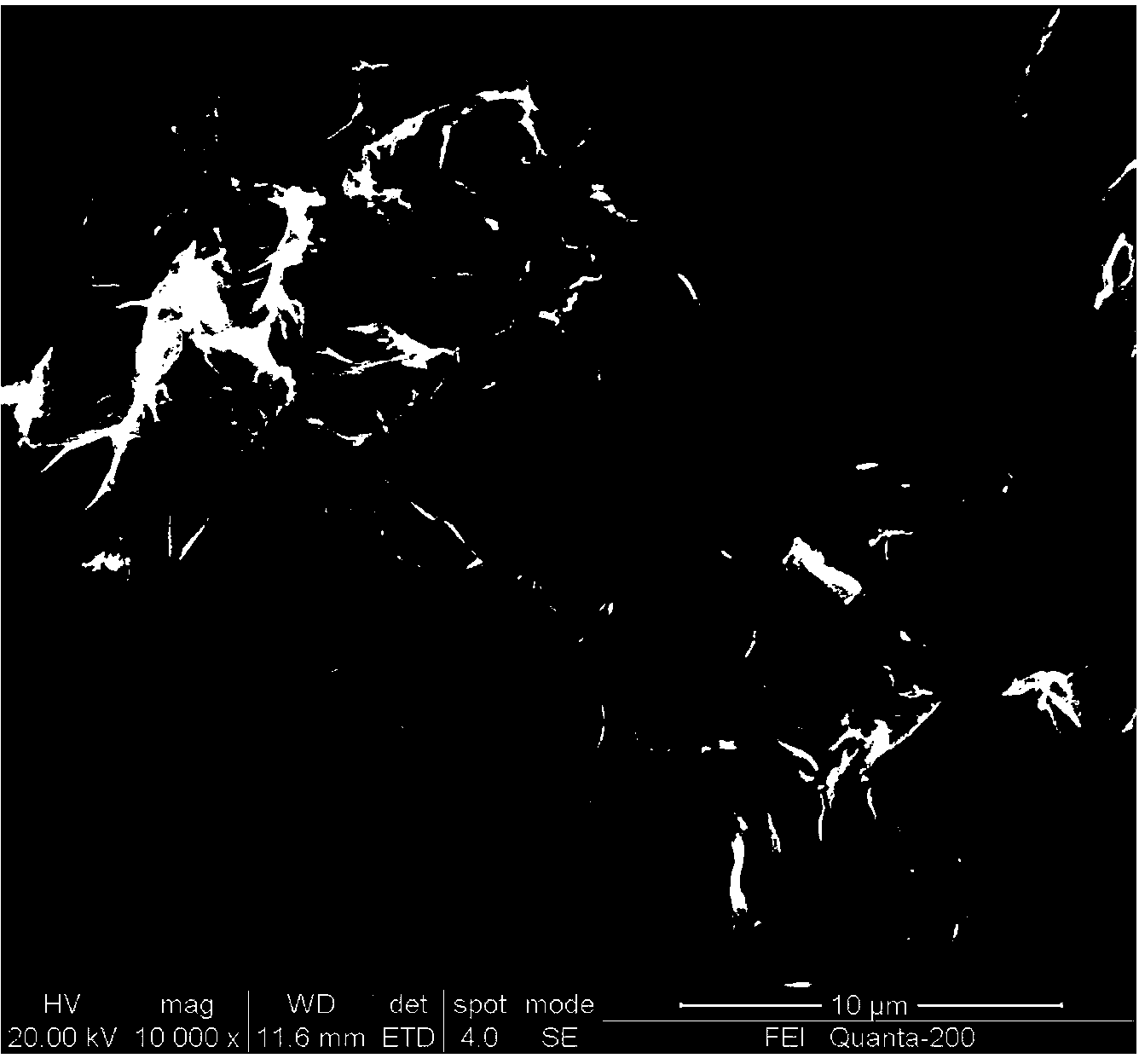

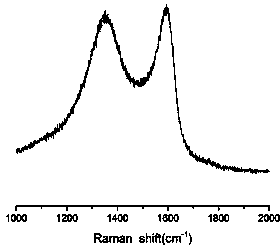

Graphene conducting film and application of graphene conducting film to electrochemical capacitor

InactiveCN103077766AComplete restorationSolving Cohesion ProblemsConductive layers on insulating-supportsHybrid capacitor electrodesLaser scanningOptoelectronics

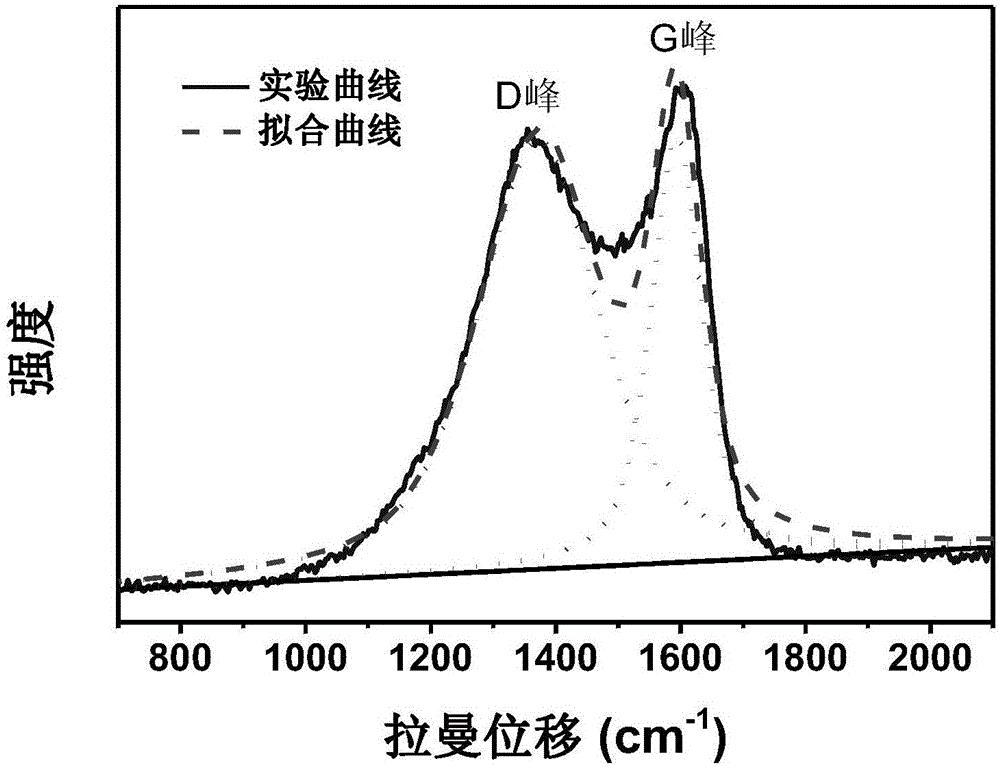

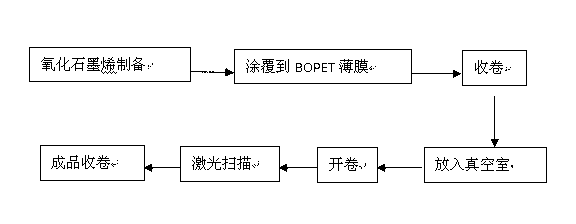

The invention relates to a graphene conducting film and application of the graphene conducting film to an electrochemical capacitor. The graphene conducting film comprises a substrate and graphene oxide attached on the substrate. A production method of the graphene conducting film comprises the following steps that a, graphene oxide water solution is coated on the substrate, the water solution concentration is 0.1 to 5mg / mL, and the costing thickness is 10 to 100mum; b, the coated liquid on the substrate is dried; c, the steps a and b are repeated; and d, the substrate obtained in the step c is put into a vacuum chamber, the graphene oxide is subjected to laser scanning after being cooled, and then, the rolling is carried out.

Owner:QINGDAO ZHONG KE HAO TAI NEW MATERIAL SCI & TECH

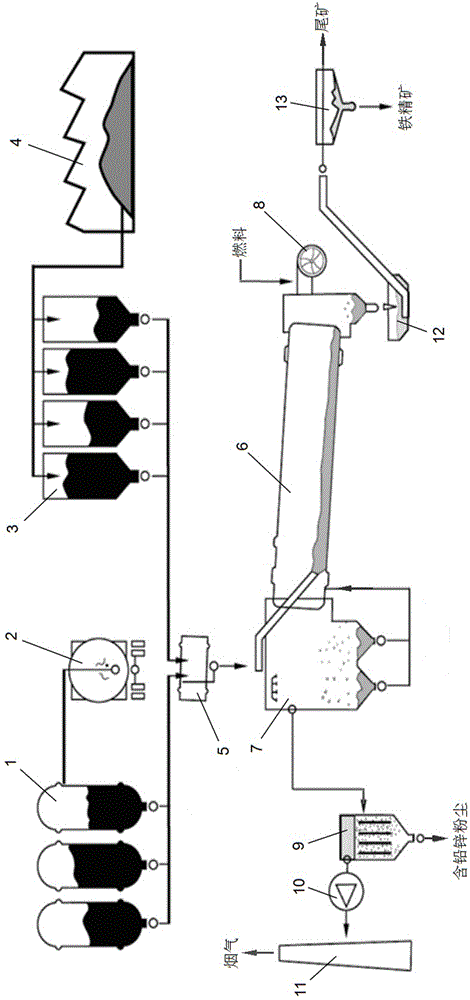

Iron-containing zinc powder recycling process

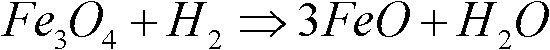

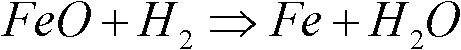

InactiveCN104073649AComplete restorationImprove thermal efficiencyProcess efficiency improvementShaft furnaceSteelmakingHigh energy

The invention discloses a recycling process of iron-containing zinc powder generated in an iron and steel process. The process comprises the following steps: mixing dried iron-containing zinc powder with a binder, and pelletizing by a pelletizer to obtain green balls; feeding the green balls into a shaft furnace and heating to 1100-1300 DEG C; reducing iron in the shaft furnace to sponge iron; converting reduced zinc at high temperature into zinc steam which is discharged out of the shaft furnace with coal gas and enters into a two-stage dedustor; and feeding dedusting mud obtained from the dedustor into a settling pond, and filtering, settling, thickening and drying to obtain zinc powder. The iron-containing zinc powder mainly comprises blast furnace gas ash, gas mud, dedusting ash, converter steelmaking dust and continuous casting steel rolling scrap iron generated in the iron and steel production. By adopting a treatment mode of the shaft furnace, the problem such as large rotary kiln equipment, low utilization ratio of in-kiln volume and high energy consumption is solved. Coal base is directly reduced at a high speed, and meanwhile, zinc in dust is further recovered.

Owner:WISDRI ENG & RES INC LTD

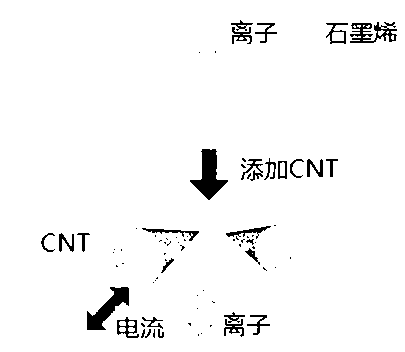

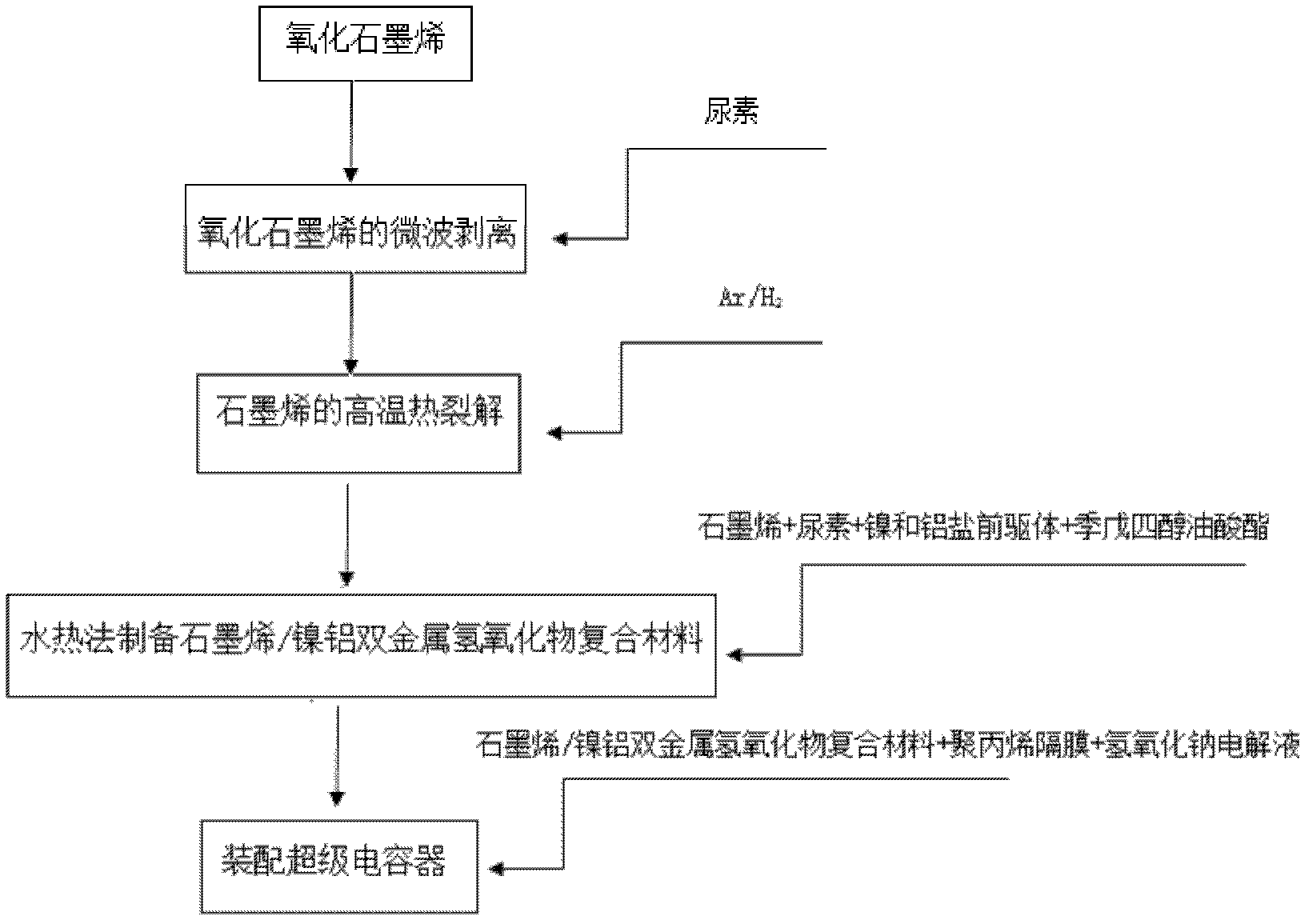

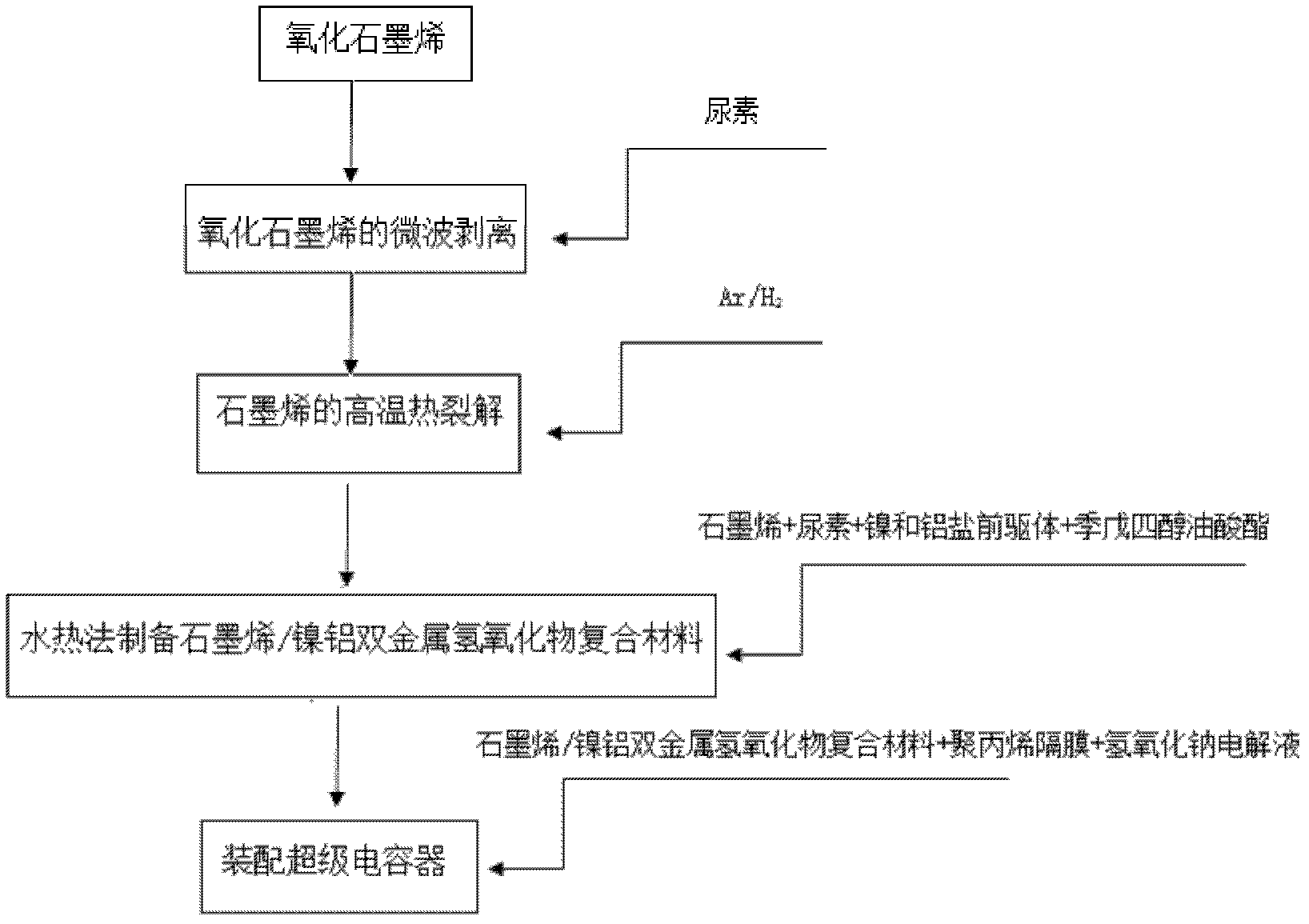

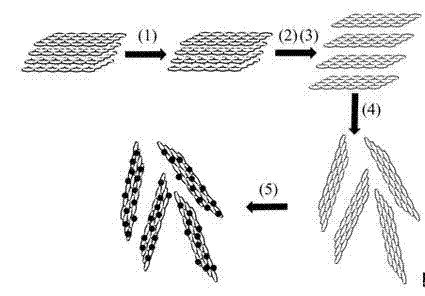

Preparation method of graphene/nickel-aluminum bi-metal hydroxide composite material and application thereof

ActiveCN102496480AGood electronic conductivityGood conductivityElectrolytic capacitorsCvd grapheneEnvironmental chemistry

The invention discloses a preparation method of a graphene / nickel-aluminum bi-metal hydroxide composite material and an application thereof, belonging to the technical field of electrochemistry. The preparation method comprises the following steps of: preparing a mixed solution by a stripping enhancer, oxidized graphene and deionized water, dispersing the mixed solution by ultrasonic wave; decompressing and filtering the mixed solution to obtain a filtering cake, and arranging the filtering cake into a household microwave oven to radiate; placing a graphene filtering cake into a tubular furnace, charging Ar / H2 mixed gas, and executing high-temperature thermal cracking; and adding an alkali source compound, nickel and aluminum salt precursors, a medium regulating agent and the deionized water to prepare a reactant mixing solution, and transferring the reactant mixing solution to a high-pressure reaction kettle to carry out a hydrothermal reaction, and finally obtaining the graphene / nickel-aluminum bi-metal hydroxide composite material. According to the preparation method of the graphene / nickel-aluminum bi-metal hydroxide composite material, disclosed by the invention, toxic chemical agents are not used at two steps of reduction of the graphene, thus damage on the health of a human body and environmental pollution because a large number of harmful chemical agents such as hydrazine hydrate and the like are taken as a strong reducing agent in a chemical reduction method can be eliminated fundamentally.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

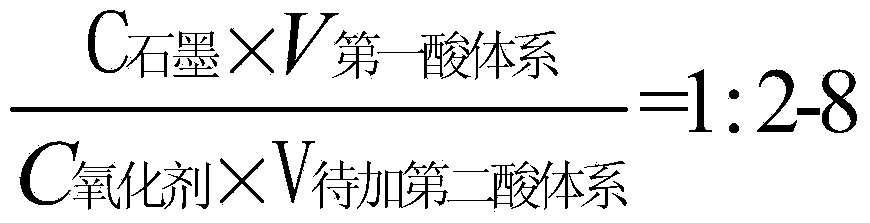

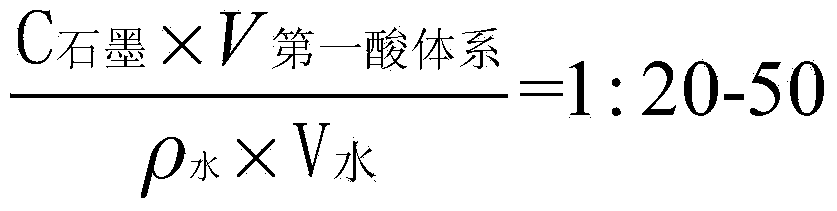

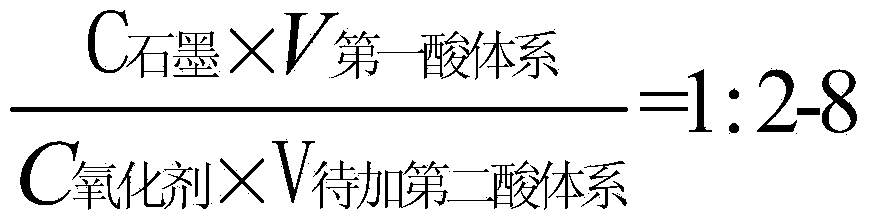

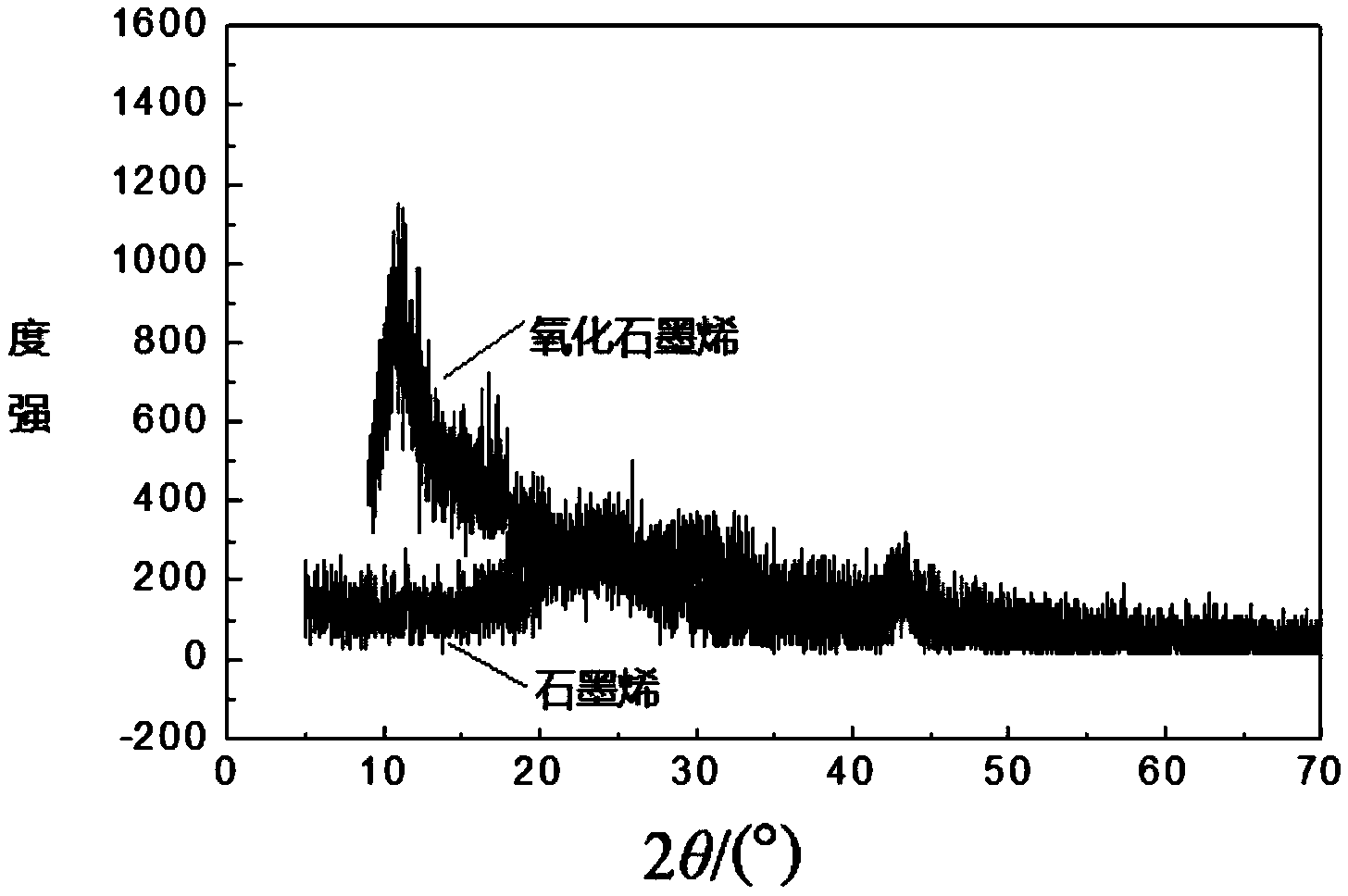

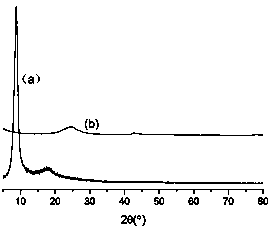

Oxidized graphene based on mixed acid system and preparation method of graphene

The invention relates to a preparation method of oxidized graphene based on a mixed acid system. The method comprises the following steps: a, preparation of graphite powder; b, preparation of a first acid system turbid liquid; c, preparation of a second acid system turbid liquid; d, preparation of oxidized graphene. The invention further relates to a method of preparing graphene by the oxidized graphene prepared by the method. The method comprises the following steps: e, preparation of an oxidized graphene dispersion liquid; f, reduction of oxidized graphene; g, ultrasonic stripping treatment; h, separating and drying to obtain graphene. By adopting the methods to prepare oxidized graphene and graphene, the use level of strong acids is reduced, and corrosion to reaction equipment and heat generated by reaction are reduced, so that the reaction efficiency is higher. The prepared graphene product is more excellent in performance, and can be applied to industrial production on a large scale.

Owner:SINOPHENE NOVEL MATERIALS

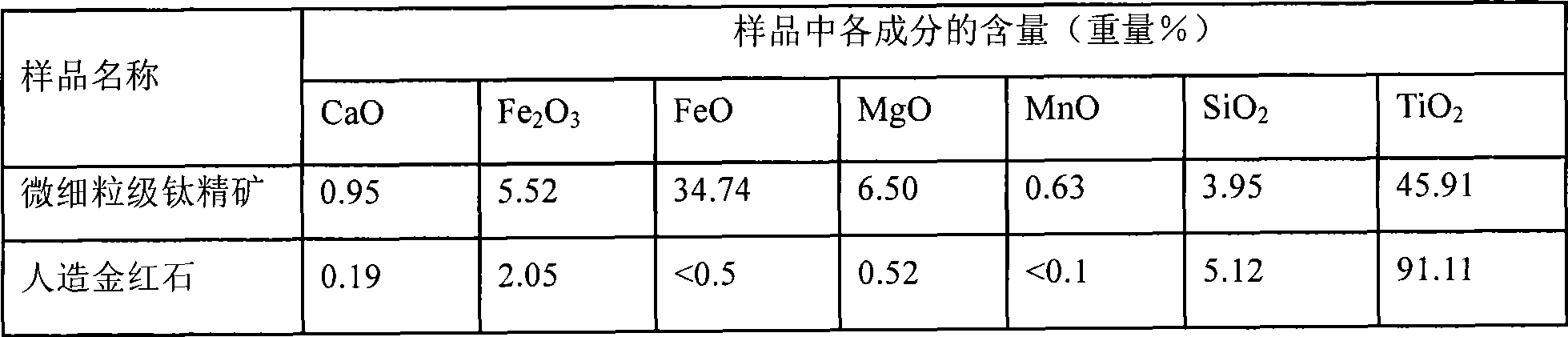

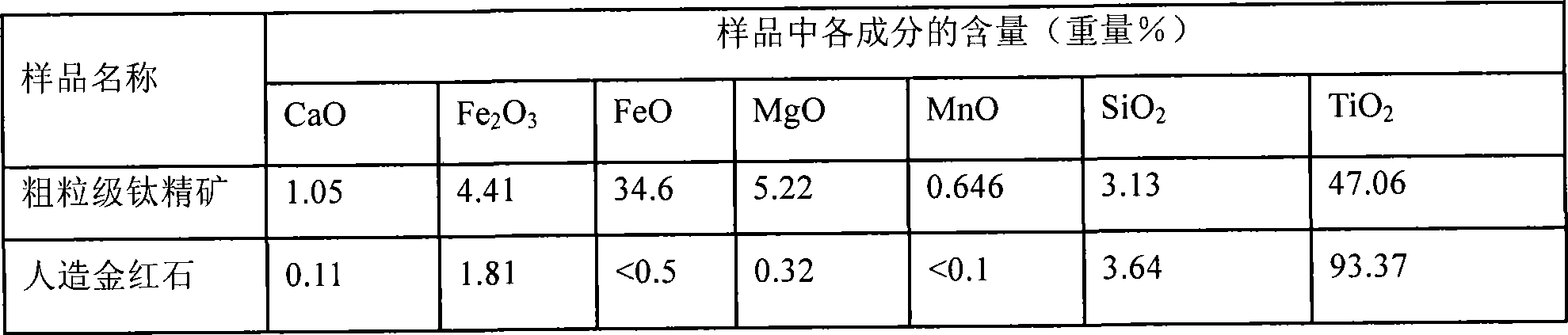

Preparation of synthetic rutile

The invention provides a method for preparing artificial rutile. The method comprises the following steps: titanium concentrate is subjected to oxidizing roasting and reducing roasting for removing impurities in oxidizing roasting products; and the products of which the impurities are removed are calcined, wherein the oxidizing roasting is performed in the presence of oxidizing gas, the reducing roasting is performed in the presence of reducing gas, and the oxidizing roasting and the reducing roasting are performed in a fluidized bed reactor. By adoption of the method, the high-grade artificial rutile can be prepared by adopting coarse fraction titanium concentrate as a raw material and can also be prepared by adopting micron-sized fraction titanium concentrate as the raw material.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Method for preparing graphene

The invention discloses a method for preparing graphene. The method comprises the following steps of: adding natural graphite, persulfate and phosphorus pentoxide into concentrated sulfuric acid, and reacting with stirring to obtain pre-oxidated graphite; adding pre-oxidated graphite, nitrate and potassium permanganate into concentrated sulfuric acid sequentially and reacting to obtain graphite oxide; and dissolving the graphite oxide in alcohol to prepare solution, performing ultrasonic dispersion, reacting in the sealed environment at the temperature of between 120 and 220 DEG C for 4 to 48houhrs, and then performing centrifugal washing until the pH is 6.5 to 7.5, and performing vacuum drying to obtain black graphene powder. No reducing agent is adopted in the method, the reducing capacity of a solvent is used to reduce the graphite oxide, and the method has the advantages of low cost, and light pollution, and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

Preparation method of graphene

InactiveCN102320598AComplete restorationThe reduction system makes the graphite oxide fully reducedNanotechnologyElectrochemistryCvd graphene

The invention belongs to the technical field of nano-materials, and particularly relates to a preparation method of graphene. Graphite oxide is added into a liquid ammonia solution with dissolved reductive metal for reaction, and graphene is obtained after subsequent separation. The method provides more fully reduction of graphite oxide; the product is easy to separate, and the purification process is simple; in the preparation process, no stabilizer or dispersant is added, and the prepared graphene contains less impurity elements; the using amount of the reducing agent is few, and the process is controllable; the low-temperature reduction condition prevents the easy generation of the agglomeration phenomenon; the reaction period is short; a normal pressure condition is required; and the equipment is simple. The prepared graphene has wide application prospects in the electrochemistry field.

Owner:HENAN UNIVERSITY

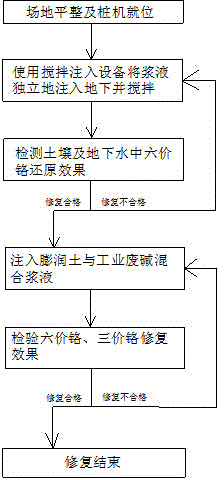

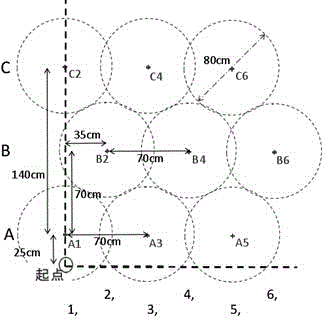

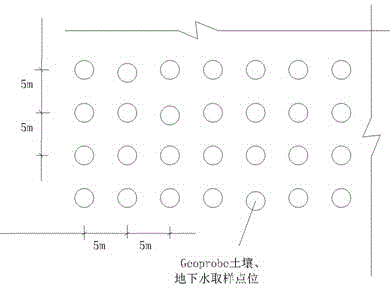

Remediation method for hexavalent chromium polluted soil and underground water

ActiveCN104624632AComplete restorationEfficient removalWater contaminantsContaminated soil reclamationSodium BentoniteInjection equipment

The invention discloses a remediation method for hexavalent chromium polluted soil and underground water. The remediation method comprises the following steps: step (10): putting a pile machine in place; step (20): independently injecting acidified bentonite slurry loaded with active carbon powder and bentonite slurry loaded with zero-valent iron powder into the ground by using stirring and injection equipment and stirring; step (30): detecting the reduction effect of hexavalent chromium in the soil and the underground water; step (40): injecting bentonite and industrial waste alkali mixed slurry; and step (50): detecting the remediation effect of hexavalent chromium and trivalent chromium. By virtue of the remediation method, remediation chemicals can be in direct and sufficient contact with the soil and the underground water to react, so that the hexavalent chromium in the soil and the underground water can be completely reduced; meanwhile, an indissolvable stable compound is formed by the trivalent chromium and the useless loss of the remediation chemicals can be reduced; the potential of hydrogen of a stratum is balanced; and the remediation method is suitable for the large-area hexavalent chromium polluted stratums different in potential of hydrogen and moisture content.

Owner:SOUTHEAST UNIV

Production method for organic fertilizer

InactiveCN103304283ANon-perishableRoot Rot PreventionBio-organic fraction processingOrganic fertiliser preparationSludgeRoot rot

The invention discloses a production method for an organic fertilizer. The production method can be used for mixing excrements of herbivore animals and plasters or plant ashes and coal ashes which are obtained by combusting lime sludge of a sugar factory or manioc waste and bagasse of a starch factory and quickly converting organic waste into available organic fertilizers by a zymophyte ecological method. According to the method provided by the invention, the stack fertilizer preparing time can be shortened, and the labor and the time can be saved. By using the organic fertilizer produced by the method, a perfect root environment can be constructed, so that rot diseases can be avoided; plants can fully realize the functions of absorbing the fertilizers, and crops can quickly grow up; the physical property and the chemical property as well as the microbial state of the soil are thoroughly balanced, so that the soil can be forever kept in an optical state for culturing crops. The organic fertilizer produced by the invention can be mixed with other trace elements, a plant growth promoter, chemical fertilizers and the like to prepare a composite fertilizer. Beneficial microflora can be added for further treatment; the non-toxic and harmless microorganism fertilizer can be compounded.

Owner:WUZHOU CITY YIYUAN FERTILIZER CO LTD

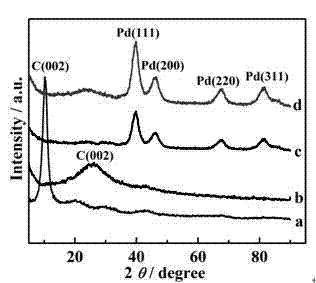

Preparation method for synthesizing graphene loaded noble metal catalyst in organic phase

InactiveCN102198398AEasy to operateAvoid overlappingCatalyst activation/preparationNanotechnologyCvd grapheneStructural stability

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

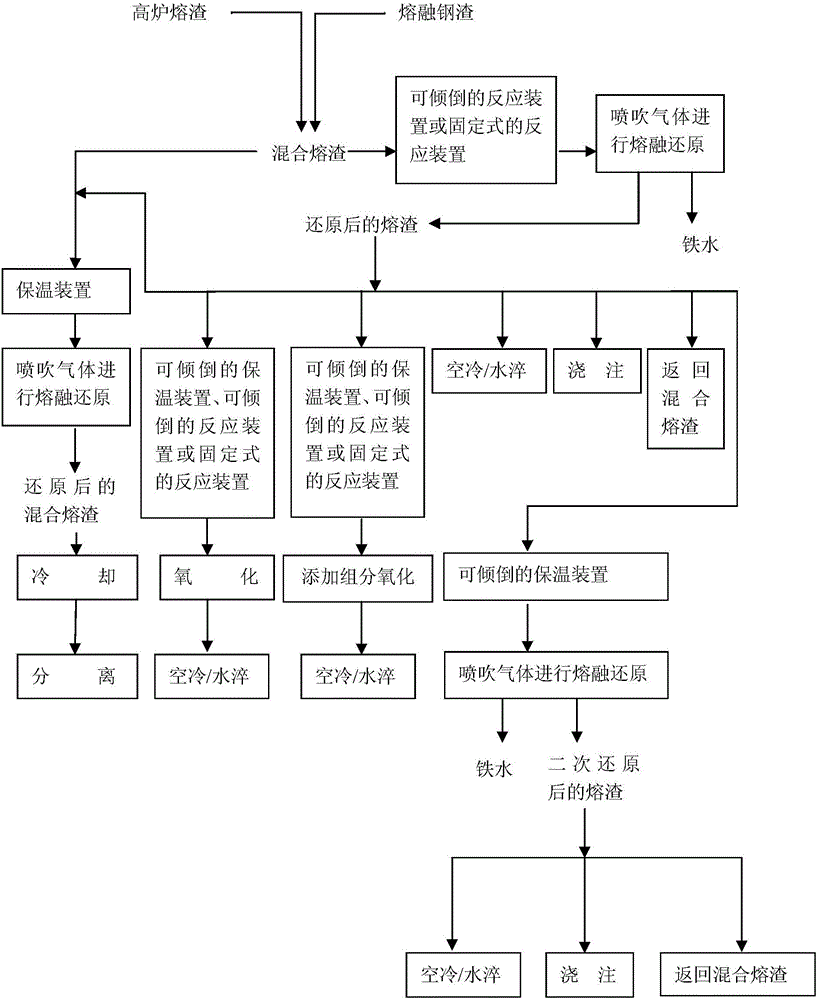

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

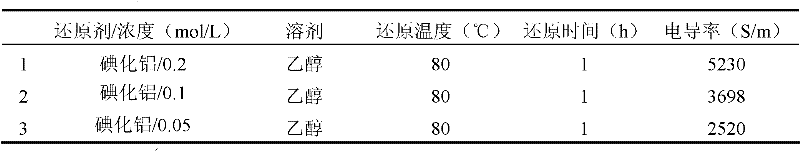

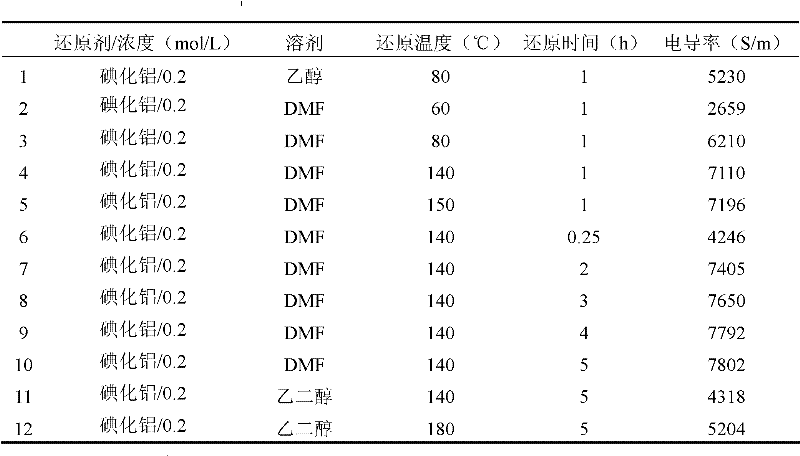

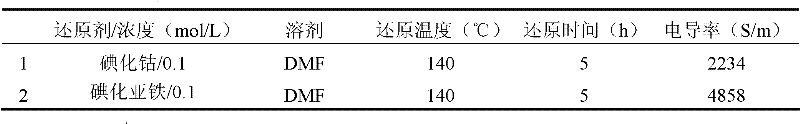

Method for preparing graphene by low-temperature chemical reduction method

The invention discloses a method for preparing graphene by a low-temperature chemical reduction method, which belongs to the technical field of chemical composition of graphene. In the method, graphene oxide prepared by chemical oxidation is used as a raw material. The method comprises the reduction reaction step of reducing the graphene oxide into graphene; in the reduction reaction step, aluminum iodide is used as a reducer; the reduction of the graphene oxide is realized by controlling the concentration of the reducer and a solvent type at 60 DEG C to 180 DEG C; oxygen-containing functional groups (epoxy group, hydroxyl group, carboxyl group and carbonyl group) on the graphene oxide are removed; the electric conductivity of the graphene is recovered more thoroughly; and the graphene isprepared. The method provided by the invention is a method for preparing the graphene by a low-temperature chemical method, which is suitable for large-scale industrial production. The method has theadvantages of low reduction temperature, mild and controllable reaction, more thorough reduction, environmental-friendly performance, suitability to industrial production, etc.

Owner:TSINGHUA UNIV

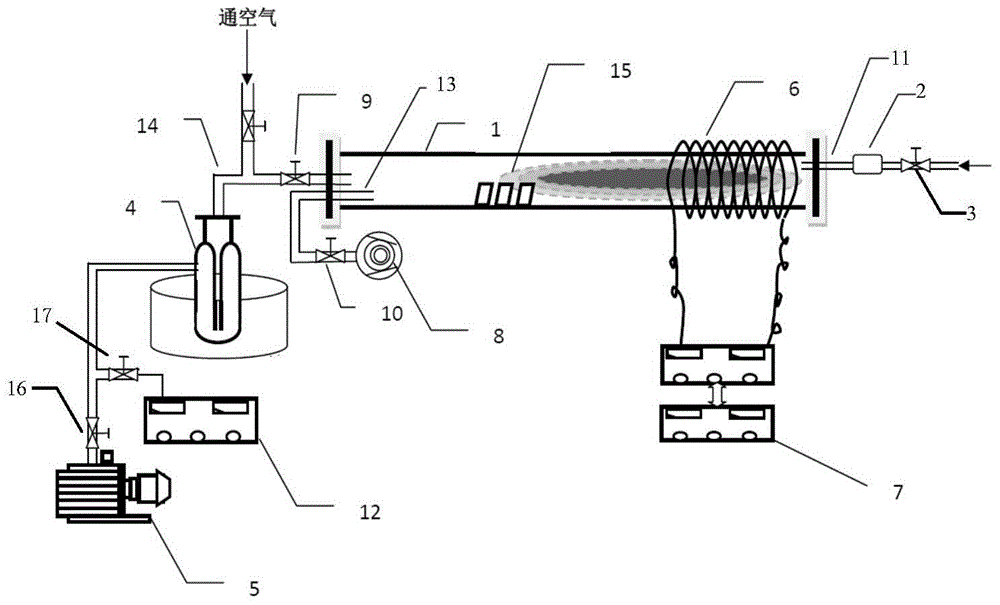

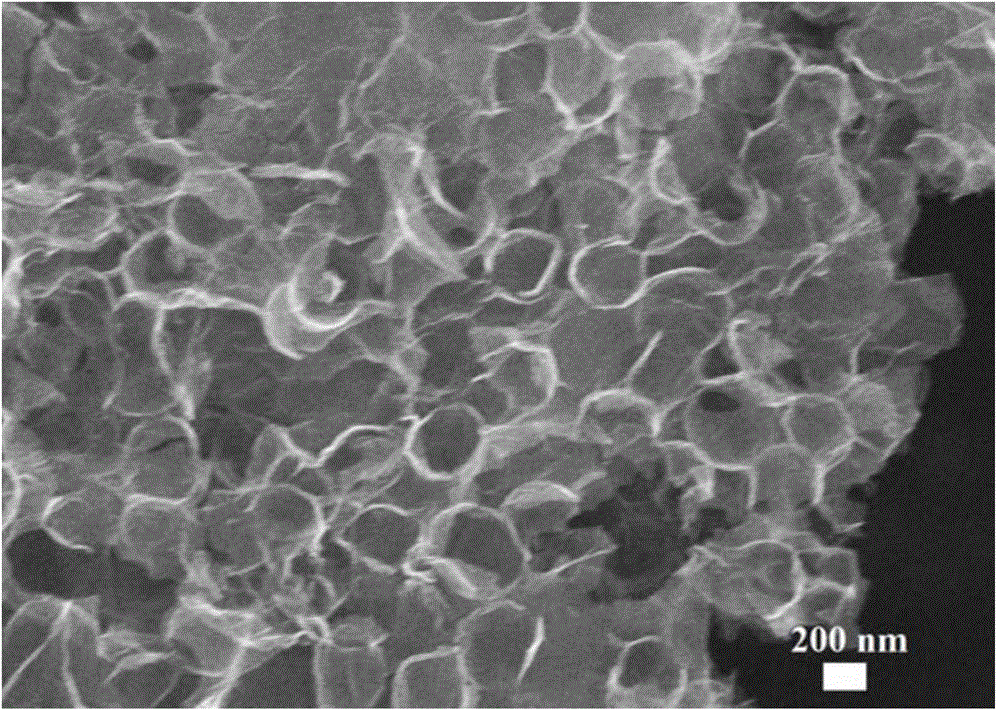

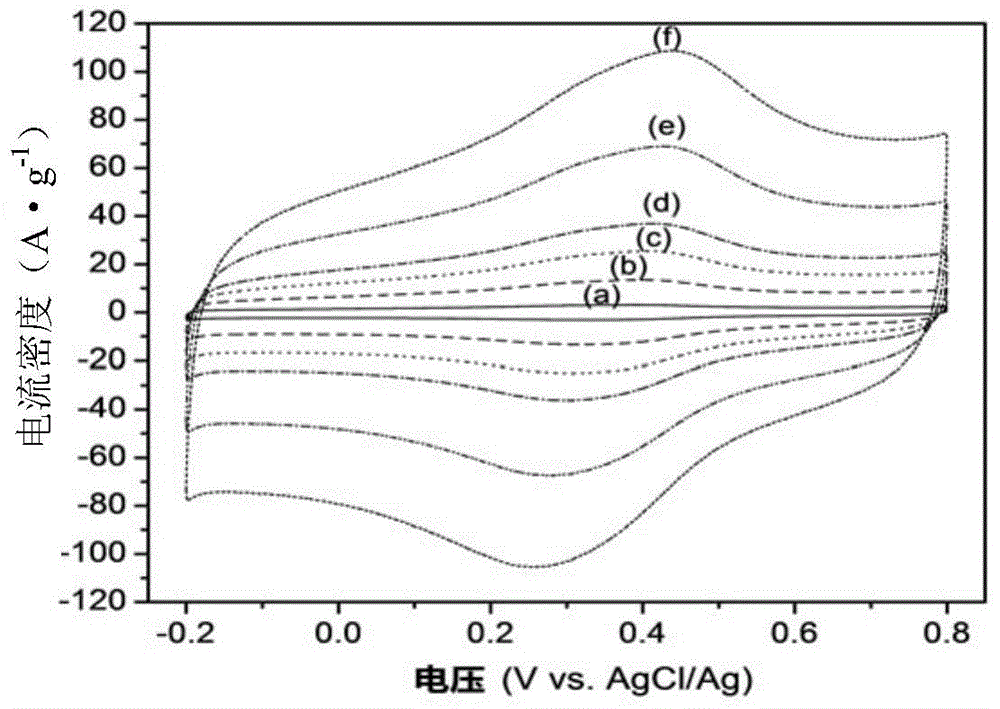

Hetero atom-doped hollow spherical grapheme composite material, and preparation method and applications thereof

The invention belongs to the technical field of carbon material and electrochemistry, and discloses a hetero atom-doped hollow spherical grapheme composite material, and a preparation method and applications thereof. The preparation method comprises following steps: styrene, polyvinyl pyrrolidone, and 2,2'-azobis(2-methylpropionamidine) dihydrochloride are mixed with water, and positively charged polystyrene spheres are prepared under certain conditions; a graphene oxide aqueous dispersion and a positively charged polystyrene sphere aqueous dispersion are stirred for reaction so as to prepare a graphene oxide@polystyrene sphere compound; a hetero atom-doped sourced compound and a solvent are added into the graphene oxide@polystyrene sphere compound, and an obtained mixture is subjected to mixing, coating, and freeze drying so as to obtain solid thin films; a substrate loaded with the solid thin films is delivered into a plasma high-temperature tubular reactor for reaction so as to obtain the hetero atom-doped hollow spherical grapheme composite material. The hetero atom-doped hollow spherical grapheme composite material possesses relatively high specific surface area and relatively excellent electrical properties, and can be applied to the field of supercapacitor.

Owner:SOUTH CHINA UNIV OF TECH

High-compressibility water atomization iron powder and preparation method thereof

The invention relates to a method for preparing high-compressibility iron powder with a water atomization process. In the method, scrap steel is used as a raw material; and through the control on the content of alloy element impurities during the selection of the raw material, control on the components of smelting molten steel and control on the factors of atmosphere, time, temperature and the like in the secondary reduction process, the purity of the iron powder is improved to more than 99.5%, the micro-hardness of the powder is reduced, and the powder feature is changed, thus the compressibility of the iron powder is improved, i.e. the compressibility of the processed iron powder reaches more than 7.20g / cm<3> (by single-axial pressing under 600MPa). According to the invention, the scrapsteel or unqualified water atomization iron powder is used as the raw material, thus the produced high-compressibility iron powder can be widely used for producing high-density and high-strength powder metallurgy members.

Owner:CENT SOUTH UNIV +1

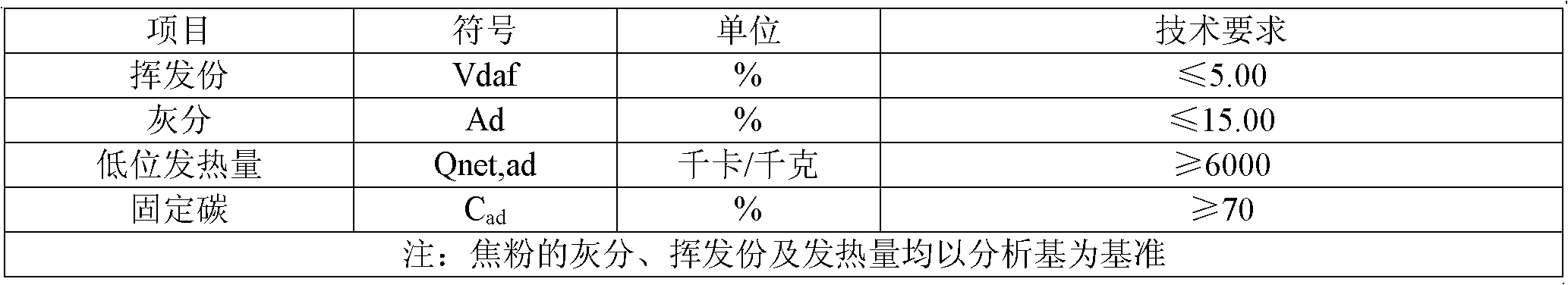

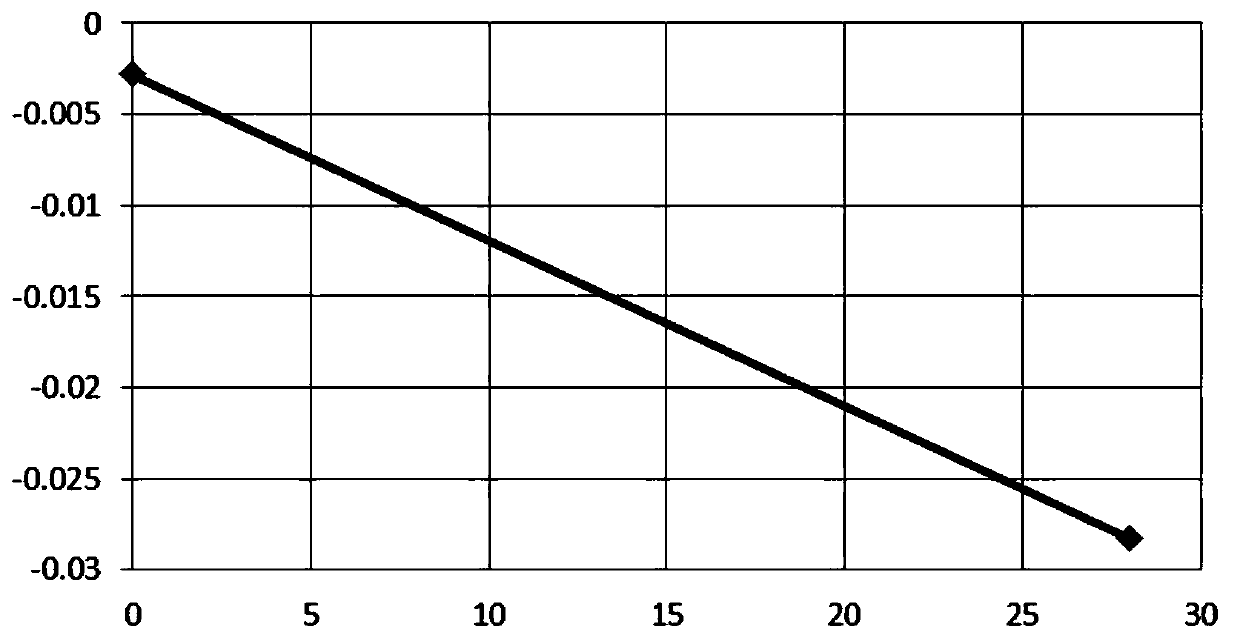

Technological method for extracting zinc by roasting blast furnace gas mud by virtue of rotary kiln

InactiveCN102127645AReduce in quantityReduce mass ratioRotary drum furnacesProcess efficiency improvementSlagZinc

The invention discloses a technological method for extracting zinc, in particular to a technological method for extracting zinc by roasting blast furnace gas mud by virtue of a rotary kiln, belonging to the technical field of metallurgy production. By applying the technological method provided by the invention, zinc oxide in the gas mud can be thoroughly reduced, and the production cost is low. The technological method comprises the following steps of: a) burdening, namely adding coke powder with the mass ratio of 16-20% into the gas mud and mixing to be uniform; b) checking, namely carrying out a sampling test on the calorific value of mixture of the gas mud and the coke powder which are uniformly mixed, wherein the acceptable calorific value is 1600-2000 kcal / kg; c) roasting and reducing, namely directly sending the qualified mixture of the gas mud and the coke powder into a kiln body of the rotary kiln to be roasted and reduced, thus zinc oxide particles and metallized slag are generated; and d) collecting, namely collecting the zinc oxide particles at the tail of the kiln and discharging residual metallized slag from the head of the kiln.

Owner:PANZHIHUA GANGCHENG GROUP

Method for preparing graphene through reduction of oxidized graphene

The invention discloses a method for preparing graphene through reduction of oxidized graphene. The method comprises the steps of under ultrasonic-assisted stirring, reducing the oxidized graphene with alkali metal or alkaline earth metal as a reducing agent and iodine as an initiator, and separating and purifying to obtain the graphene. The method has the advantages of short reaction cycle, simple operation, high efficiency, no pollution, low cost, good product quality and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Process for preparing graphene by cryochemical method

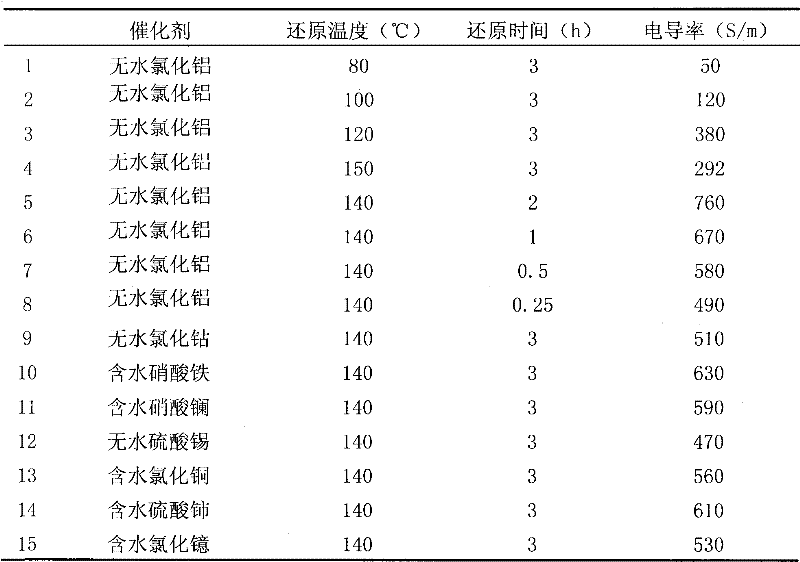

ActiveCN102452650AConductivity recoveryLow reduction temperaturePhysical/chemical process catalystsGrapheneEpoxyChemical synthesis

The invention discloses a process for preparing graphene by a cryochemical method, belonging to the technical field of chemical synthesis of graphene. The process uses graphene oxide prepared by chemical oxidation as a raw material, and comprises the step of reducing reaction in which graphene oxide is reduced into graphene. The reducing reaction step implements reduction of the graphene oxide at80-150 DEG C by using sodium borohydride as a reducer by the aid of a catalyst, oxygen-containing functional groups (epoxy group, hydroxy group, carboxy group and carbonyl group) on the graphene oxide are removed, and the electric conductivity of the graphene is thoroughly recovered, thereby preparing the graphene. The process disclosed by the invention is suitable for large-scale industrial production. The process has the advantages of low reduction temperature, mild and controllable reaction, thorough reduction, environment friendliness and the like, and is suitable for industrial production.

Owner:TSINGHUA UNIV

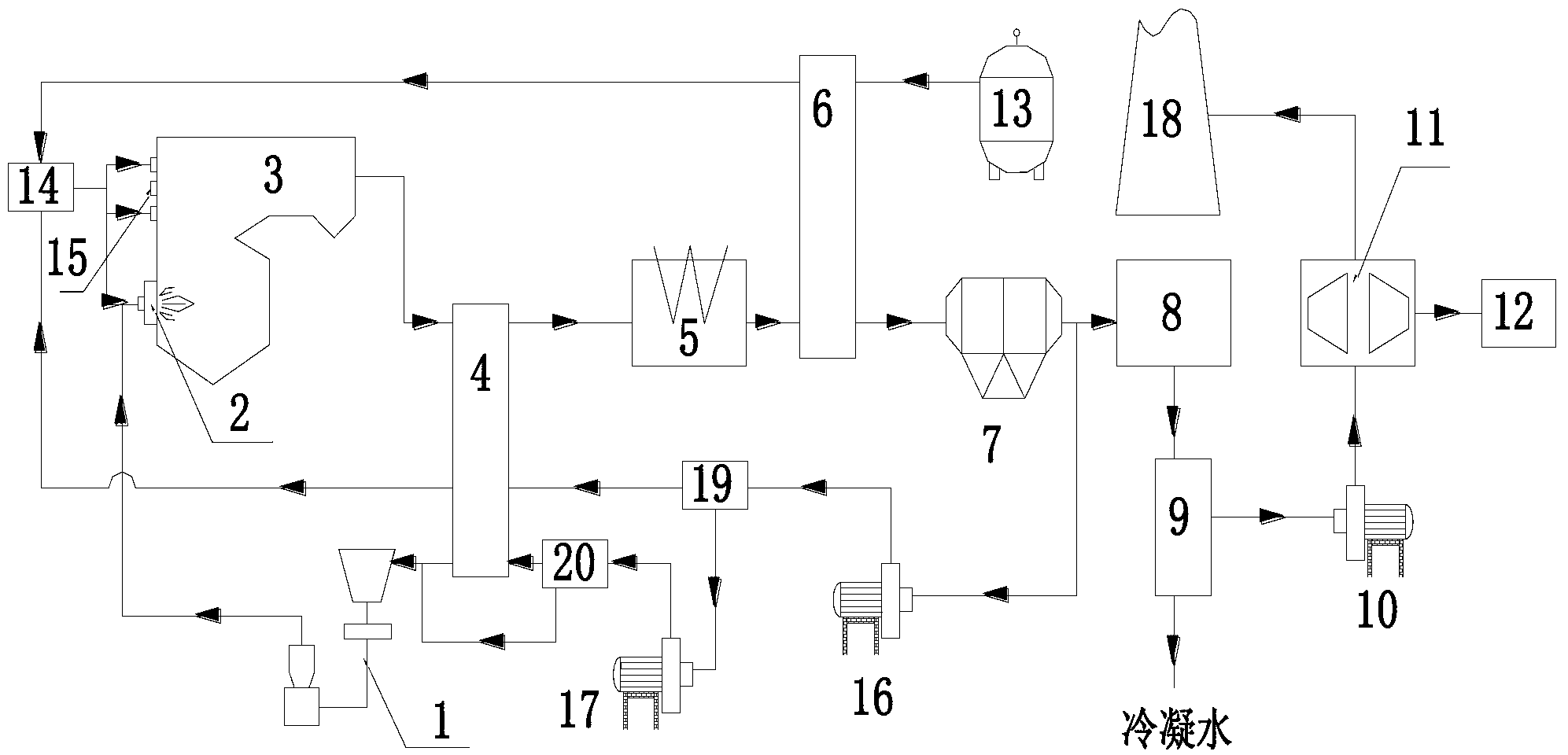

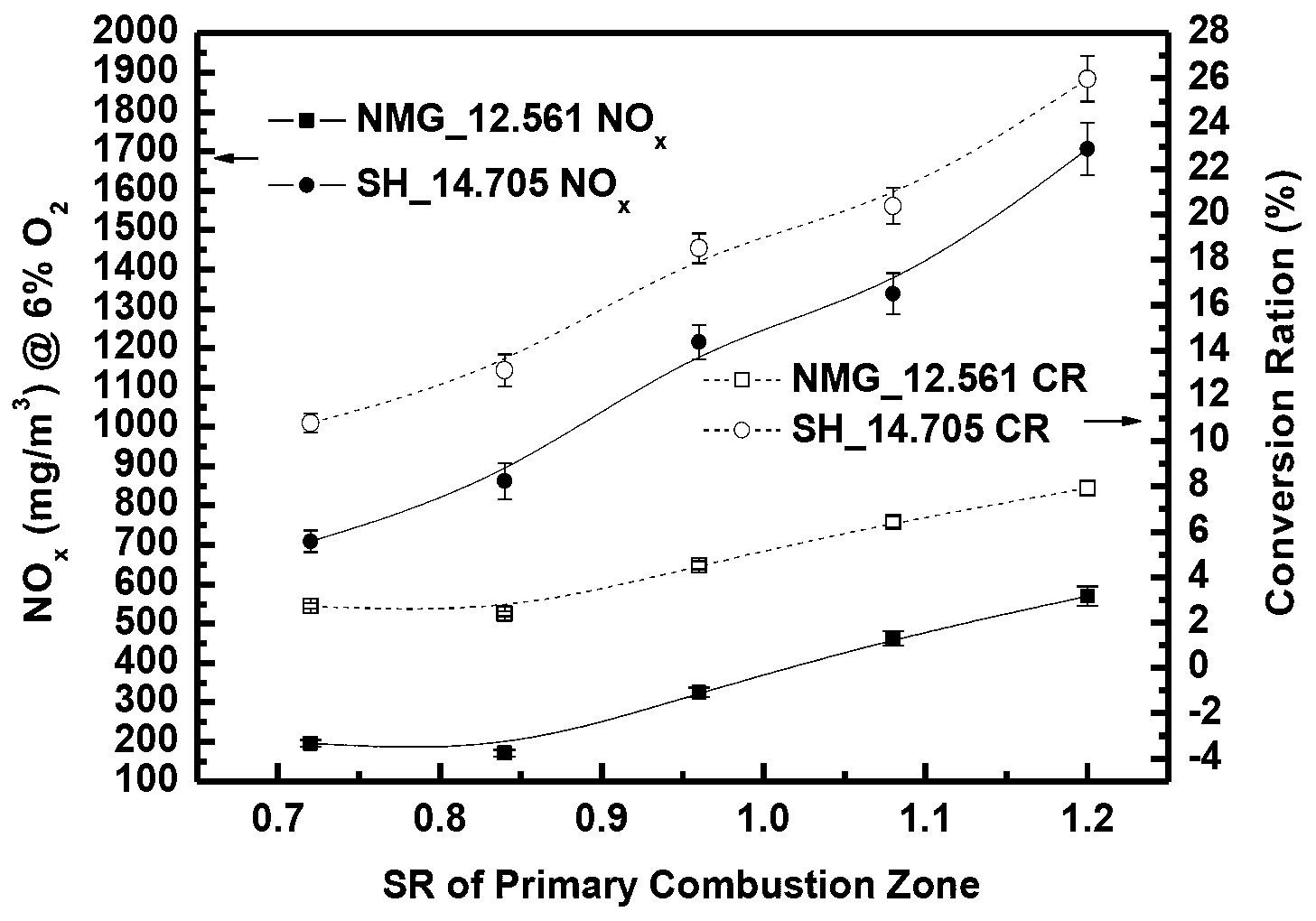

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

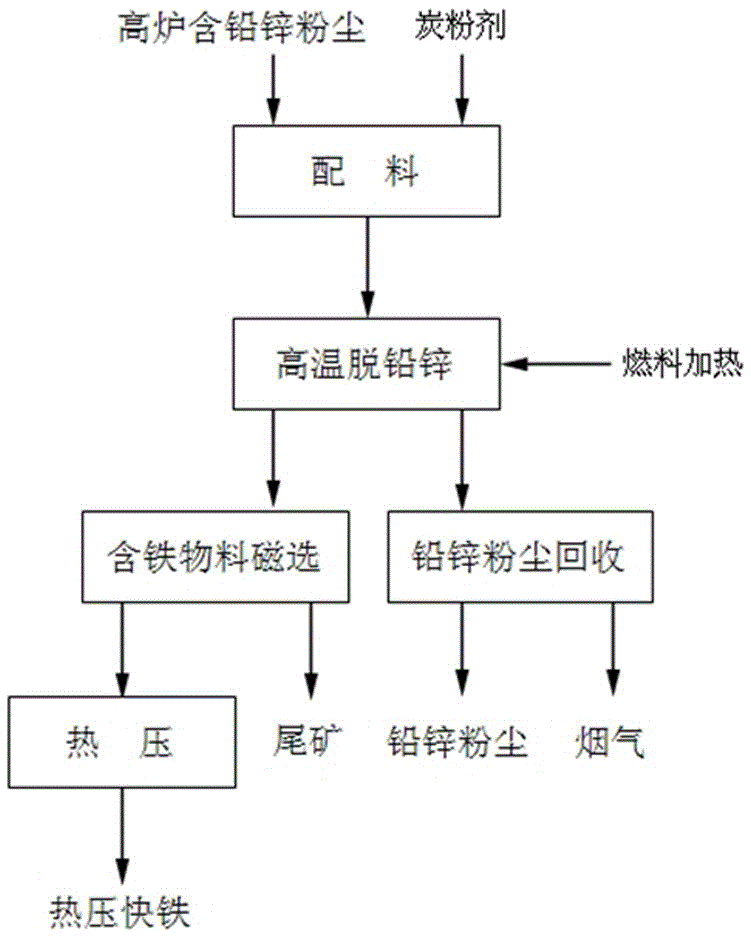

Method for comprehensively recycling lead and zinc containing blast furnace dust

ActiveCN105483371AComplete restorationAvoid secondary pollutionProcess efficiency improvementZincCyclonic spray scrubber

The invention discloses a method for comprehensively recycling lead and zinc containing blast furnace dust and belongs to the technical field of iron and steel smelting. The method comprises the following steps: the step of batching: evenly mixing reclaimed lead and zinc containing blast furnace dust and a carbon powder agent according to the weight ratio of 10 to 1-3 to prepare pellets; the step of removing lead and zinc at a high temperature: adding the pellets into a rotary kiln from a kiln tail, spraying fuel from a kiln head to heat the pellets to reach the temperature of 900 to 1300 DEG C and smelting for 30 to 50 min, after smelting, discharging an obtained lead and zinc removed iron containing material from the kiln head and cooling to reach a normal temperature, and discharging dust and gas from the kiln tail; the step of lead and zinc dust recycling: collecting and sending the gas and the dust discharged from the kiln tail of the rotary kiln into a cyclone dust collector to obtain lead and zinc containing dust through catching, and externally discharging residual smoke; and the step of magnetic separation of an iron containing material: carrying out magnetic separation on the lead and zinc removed iron containing material so as to obtain iron ore concentrate and tailings. The method provided by the invention is characterized in that the process is simple, more than 90 percent of lead and zinc in the lead and zinc containing blast furnace dust can be effectively removed, iron containing dust, lead and zinc can be comprehensively recycled, and energy conservation and emission reduction can be achieved.

Owner:红河钢铁有限公司

Microwave heating type cracking furnace

InactiveCN101633847AEvenly heatedLarge heat radiation areaBiofuelsSpecial form destructive distillationMicrowavePositive pressure

The invention relates to a microwave heating type cracking furnace for saving fuel resources in a production process. The invention adopts the technical scheme that the microwave heating type cracking furnace comprises a closed heating furnace body and a matched heating, pressure-maintaining and pyrolysis atmosphere maintaining mechanism and adopts a structure integrating pyrolysis, carbonization and activation. The structure comprises the furnace body and a sliding sealed cover plate which is arranged at the furnace top; the pyrolysis furnace body comprises a pyrolysis furnace chamber which uses a microwave heat source and an activation chamber arranged below the pyrolysis furnace chamber; wherein the pyrolysis furnace chamber is in a positive-pressure, nitrogen-atmosphere and movably sealing-type structure; the sliding sealed cover plate at the top of the pyrolysis furnace chamber is provided with a reverse V-shaped groove rail made of sealing material and a sealing-type friction pair; the reverse V-shaped groove rail is made of embedded sealing material; and the sealing-type friction pair slides with the matched reverse V-shaped groove rail arranged at the upper end of the pyrolysis furnace body. The structure comprises a shell-type stand, and a space in the furnace body is separated into the pyrolysis furnace chamber and the activation chamber by the match of a sealing separator II and the elastic sealing material arranged on a shell in match with a movable sealing matching part. The invention integrally realizes four-in-one operation and has simple structure and strong reliability.

Owner:深圳市兖能环保科技有限公司

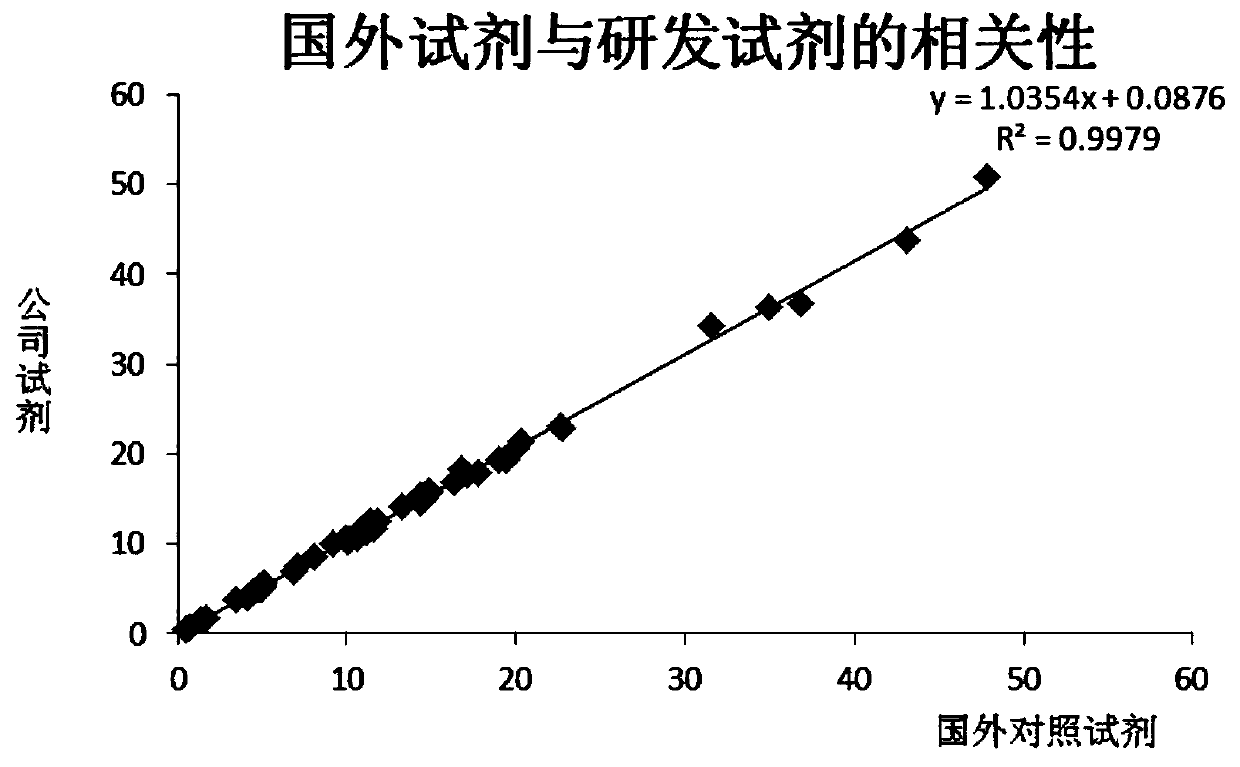

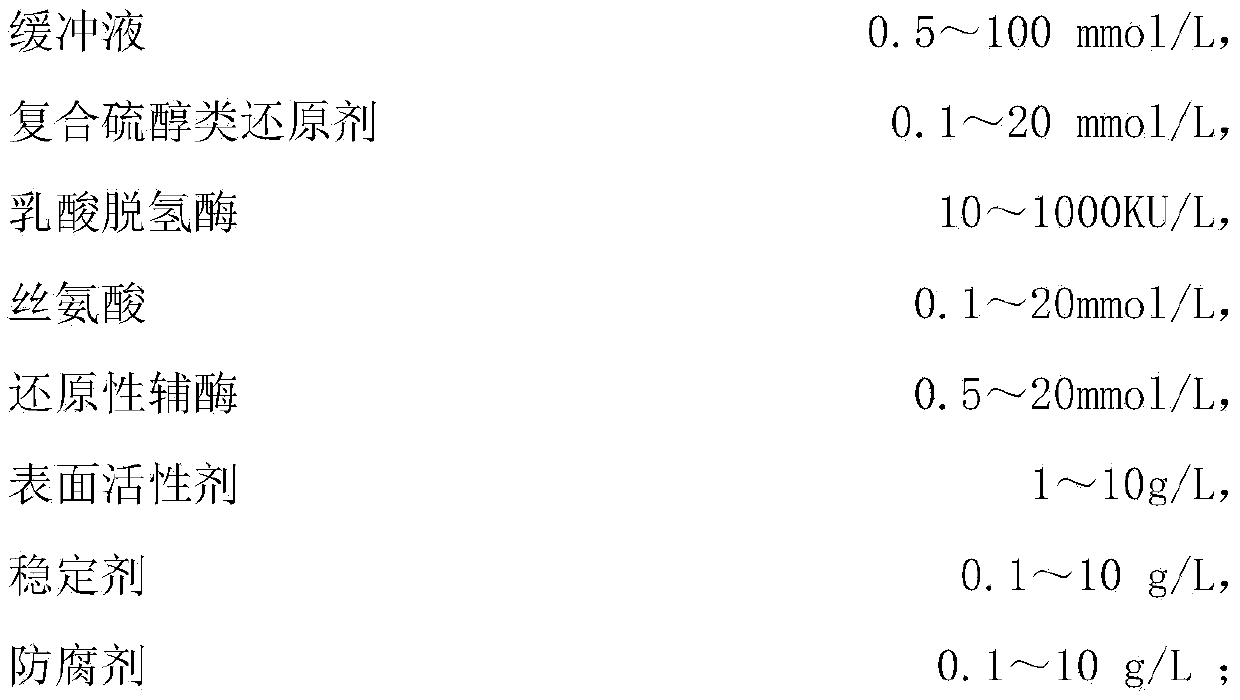

Stable kit for detecting homocysteine

ActiveCN104198726AThe test result is accurateHigh sensitivityBiological testingPreservativeSurface-active agents

The invention provides a stable kit for detecting homocysteine. The stable kit consists of a reagent R1 and a reagent R2, wherein the reagent R1 comprises the following components: a buffering solution, a mercaptan reducing agent, lactic dehydrogenase, serine, reducing coenzyme, a surface active agent, a stabilizing agent and a preservative; and the reagent R2 comprises the following components: a buffering solution, cystathionine beta-synthase, cystathionine beta-synthase, a surface active agent, a stabilizing agent and a preservative. The stable kit provided by the invention can detect the homocysteine in serum by utilizing an enzymatic cycling method, is easy to operate, and is fast, accurate, sensitive and stable.

Owner:上海睿康生物科技有限公司

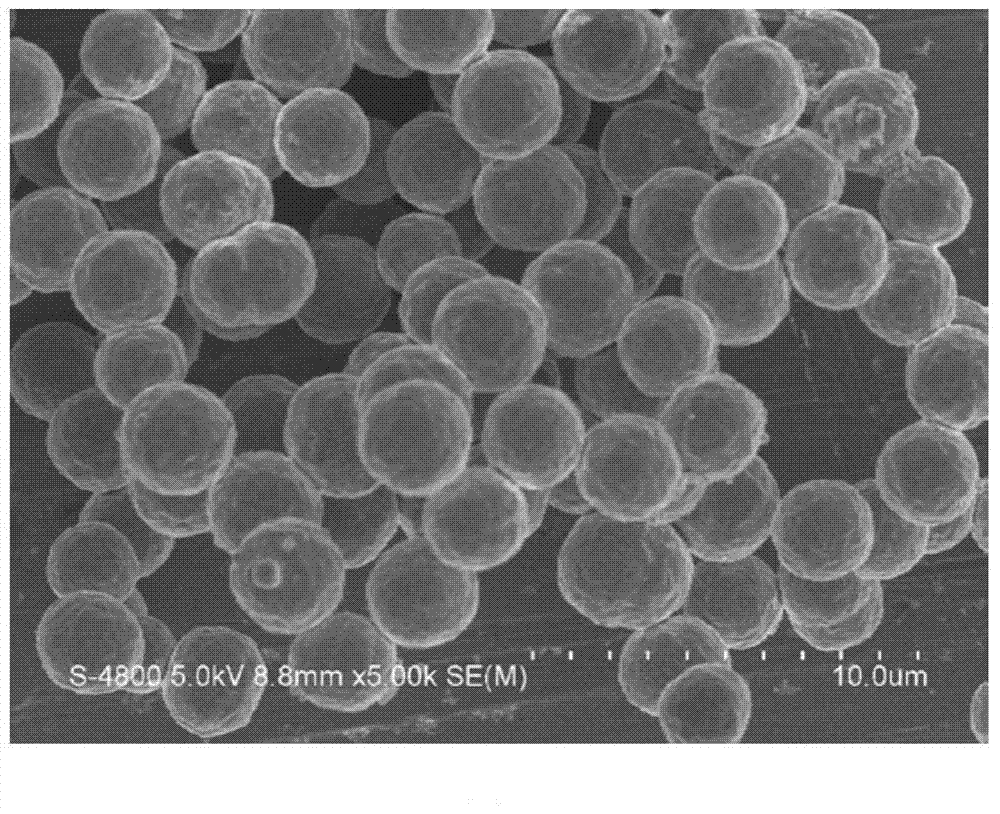

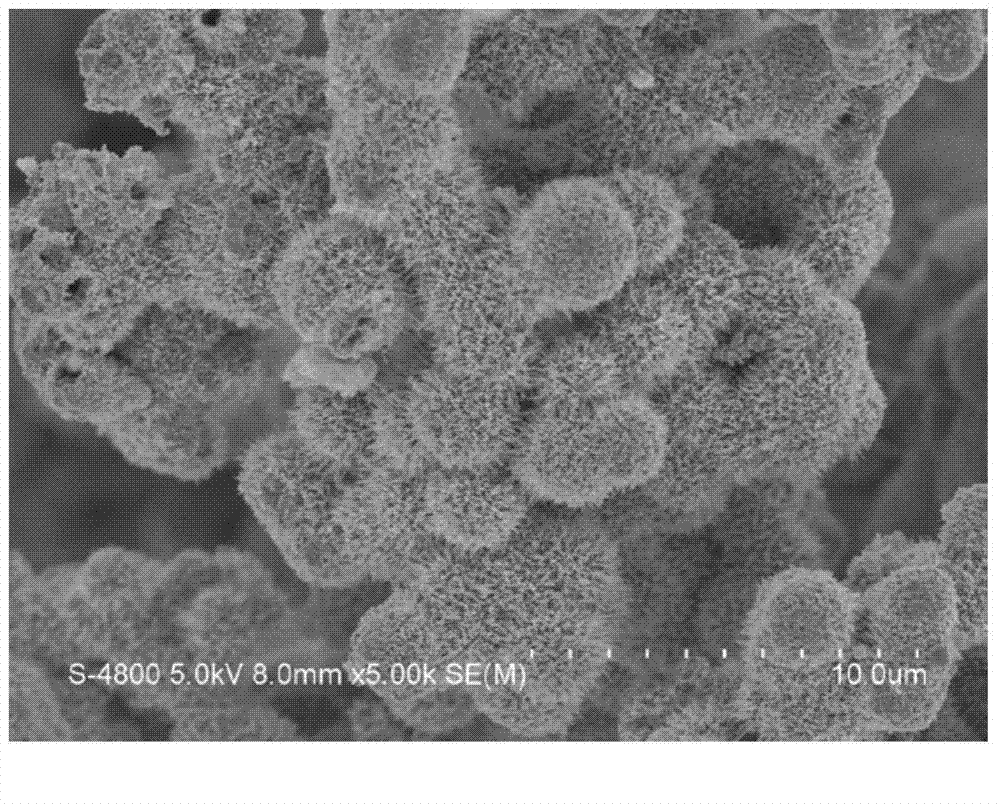

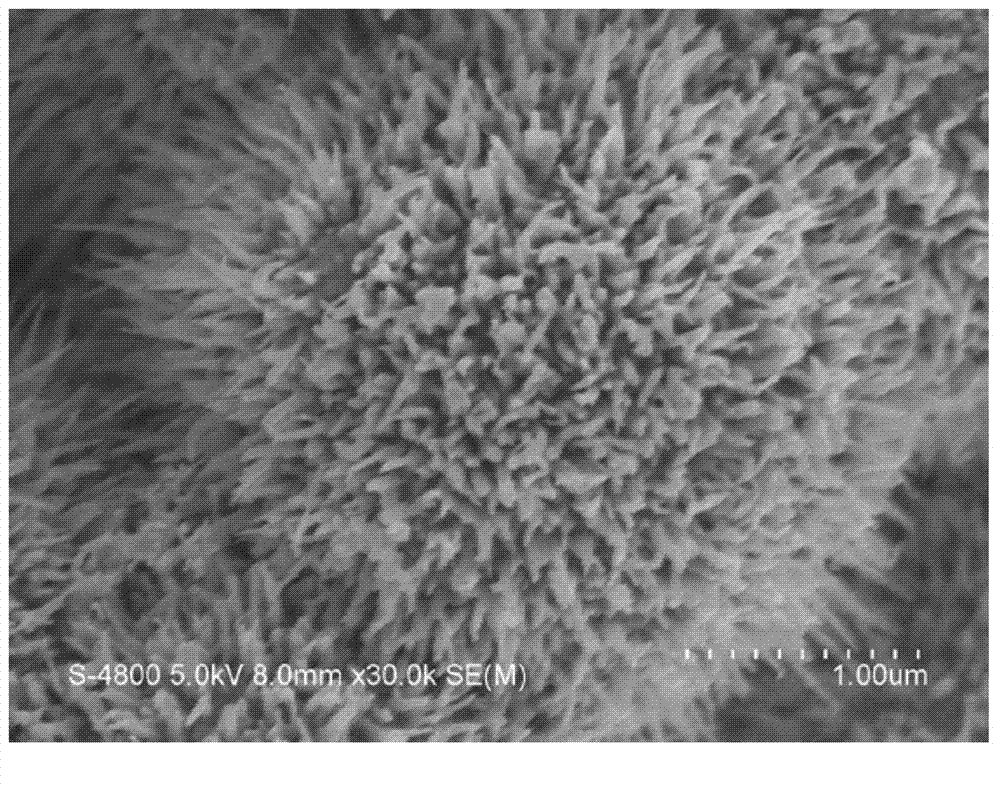

Micron-size nickel phosphide material as well as preparation method and application of micron-size nickel phosphide material

ActiveCN103566956AMild preparation conditionsImprove responsePhysical/chemical process catalystsOrganic compound preparationNitrophenolNanotechnology

The invention relates to a micron-size nickel phosphide material, as well as a preparation method and application of the micron-size nickel phosphide material. The micron-size nickel phosphide material takes the shape of a hollow sea urchin, and the nickel phosphide is a compound of Ni2P and Ni12P5. The preparation method comprises the steps of synthesizing a ball-shaped Ni simple substance and synthesizing the nickel phosphide. The nickel phosphide synthesized through the method is a sea-urchin-shaped hollow superstructure material, has a very large specific surface area and has a better catalyzing effect on reduction in catalyzing p-nitrophenol, the preparation condition is mild, and the reaction is simple.

Owner:ANHUI NORMAL UNIV

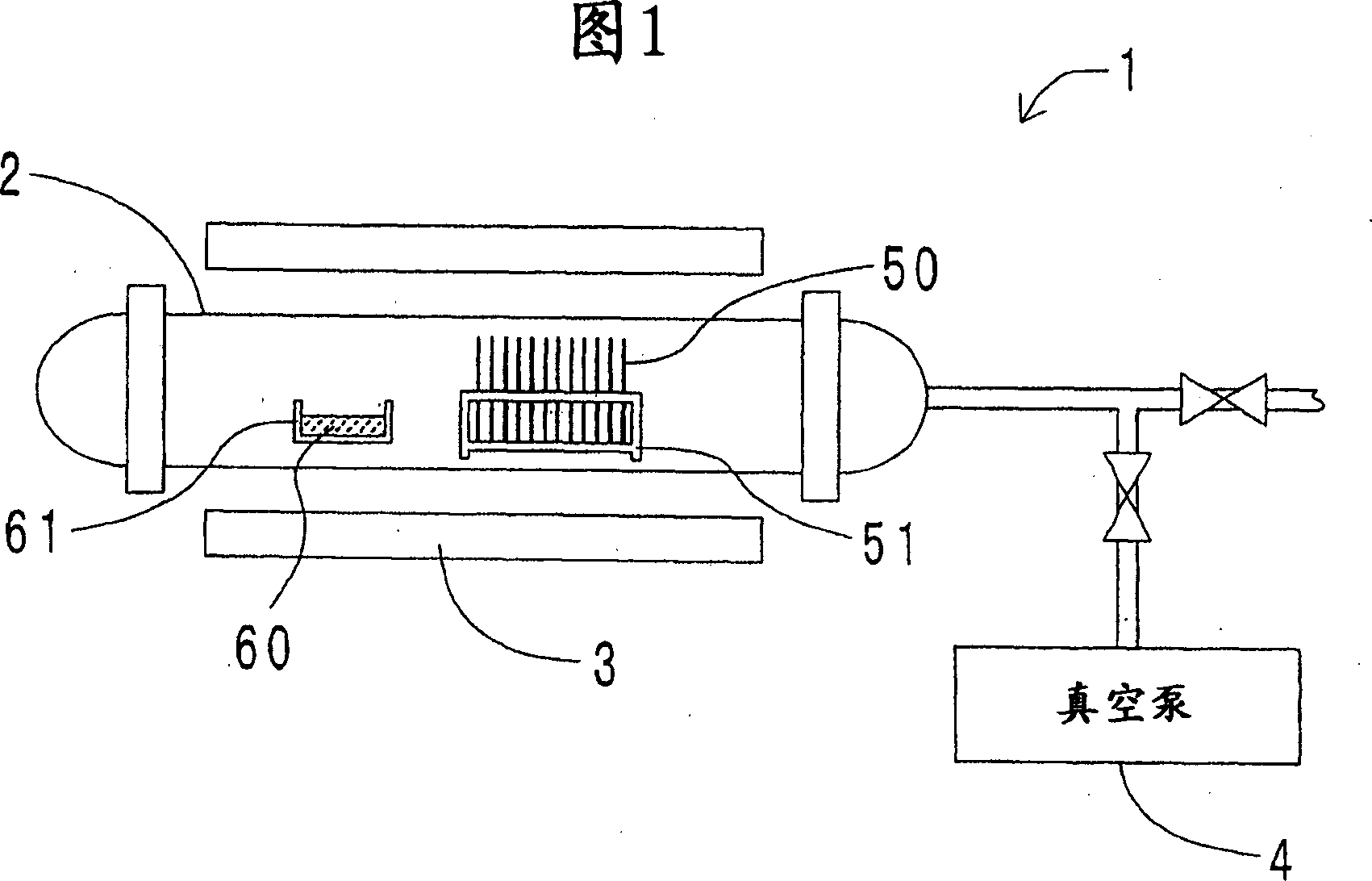

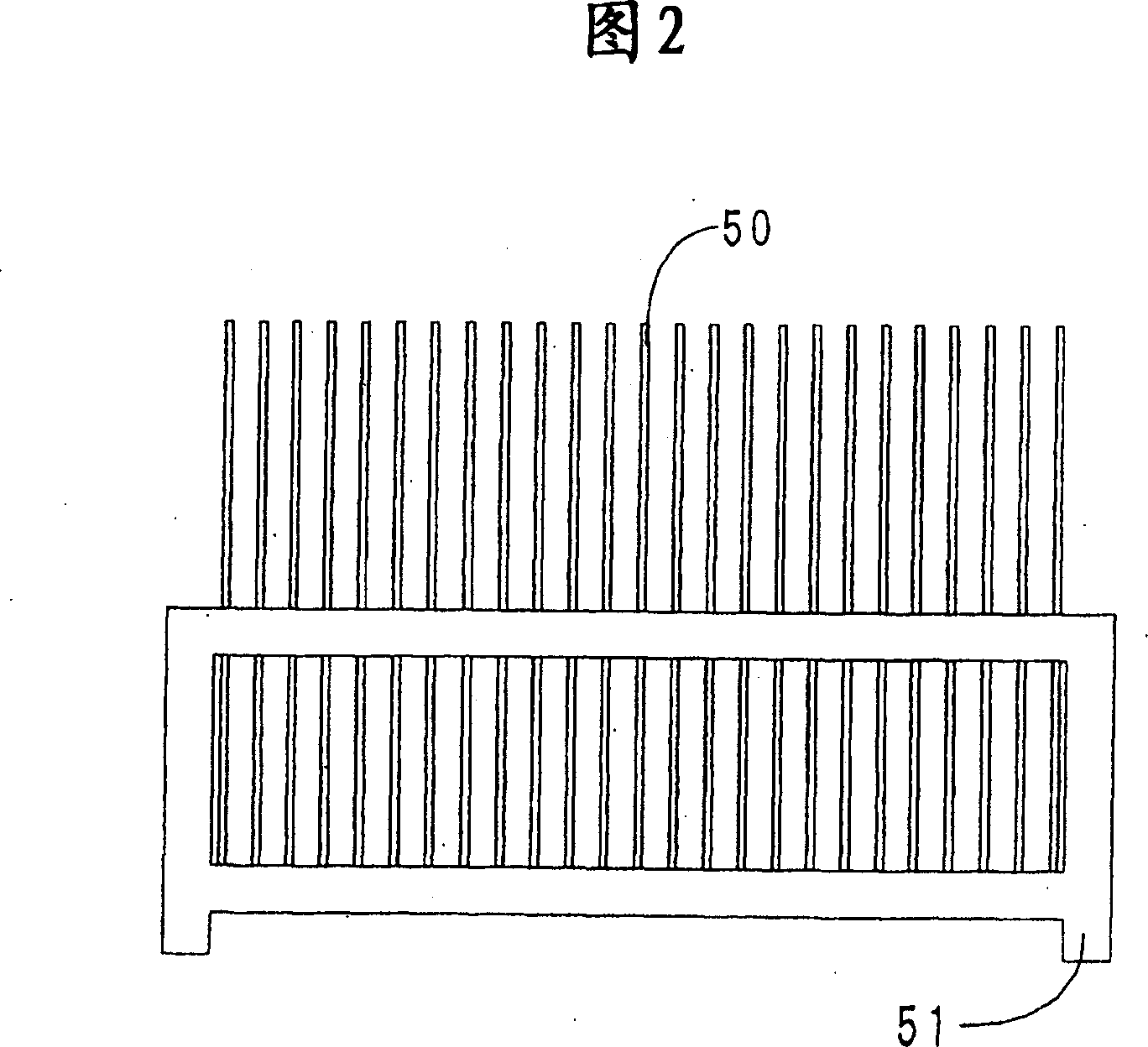

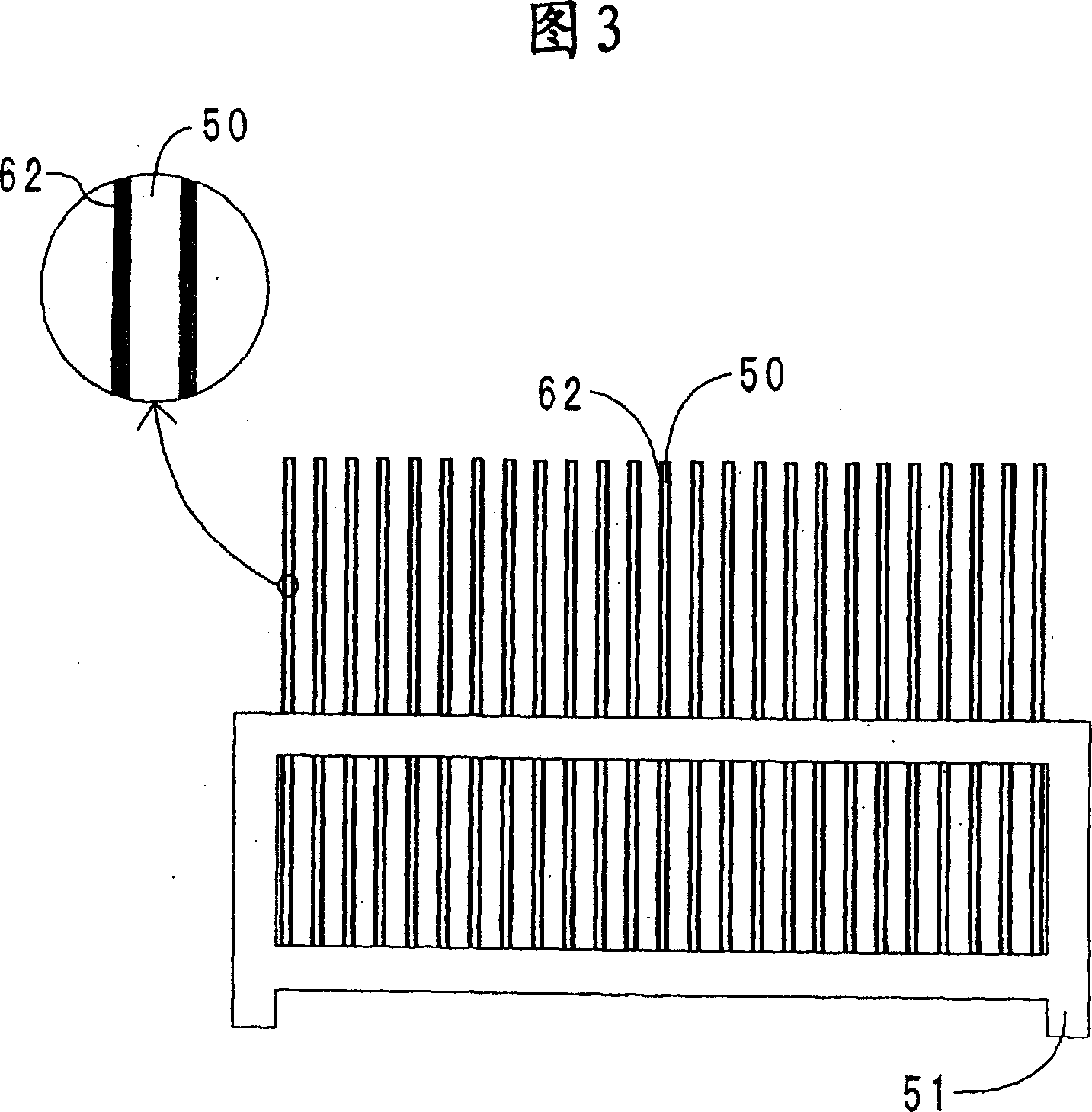

Charge restraining method and apparatus for piezoelectric oxide single crystal

InactiveCN1950549AEasy to operateControl the degree of restorationPolycrystalline material growthAfter-treatment detailsSingle crystalPiezoelectricity

To provide a processing method which can restrain the charging of lithium tantalate single crystal or lithium niobate single crystal without impairing the piezoelectricity. Moreover, to provide a processing apparatus which can carry out the processing method simply and easily. It is characterized in that a wafer 50, made from a lithium tantalate single crystal or a lithium niobate single crystal, and a reducing agent 60, including an alkali metal compound, are accommodated in a processing tank 2, and the inside of the processing tank 2 is held at a temperature of from 200 °C to 1000 °C under decompression, thereby reducing the wafer 50.

Owner:YAMAJIYU CERAMICS

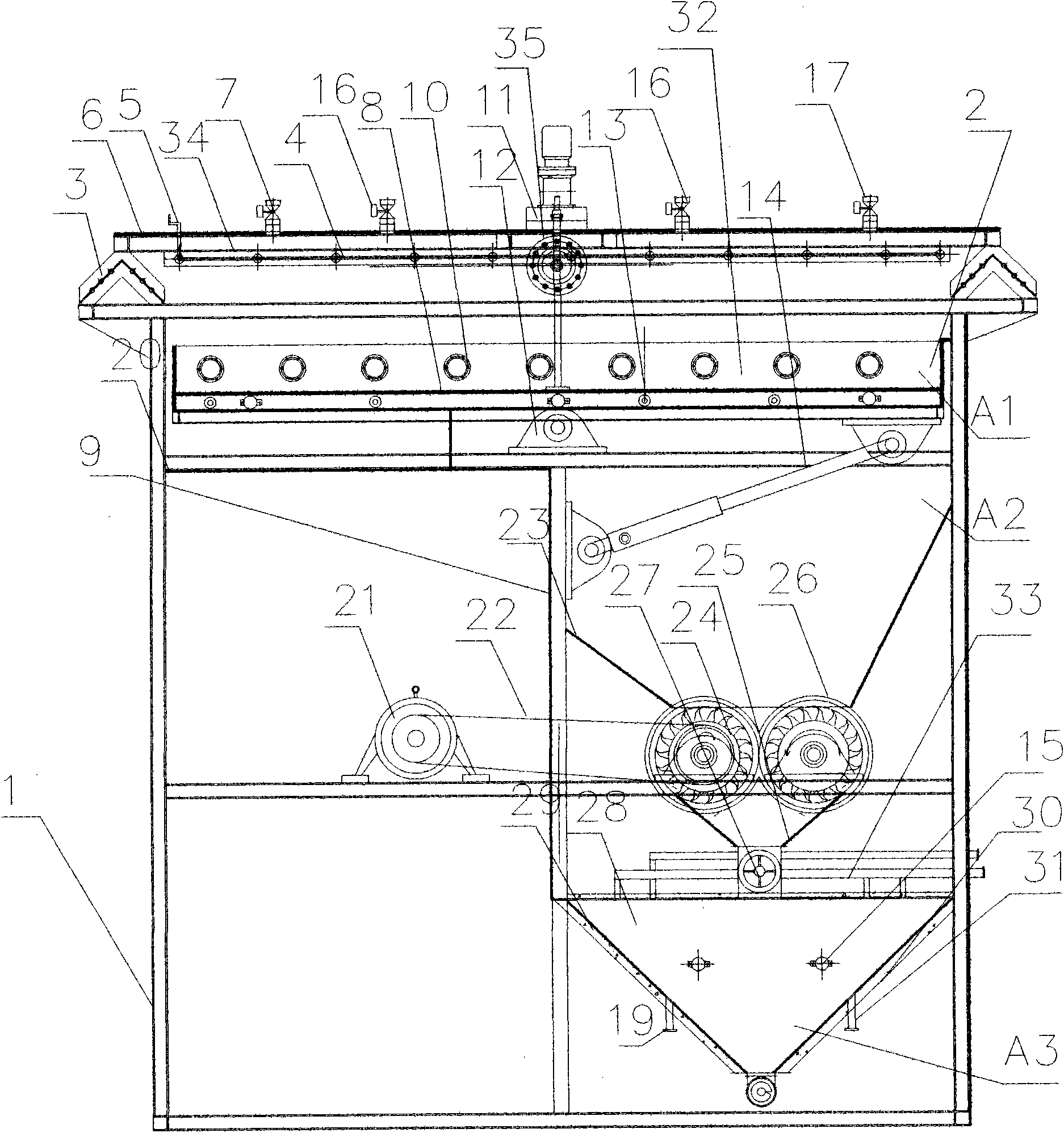

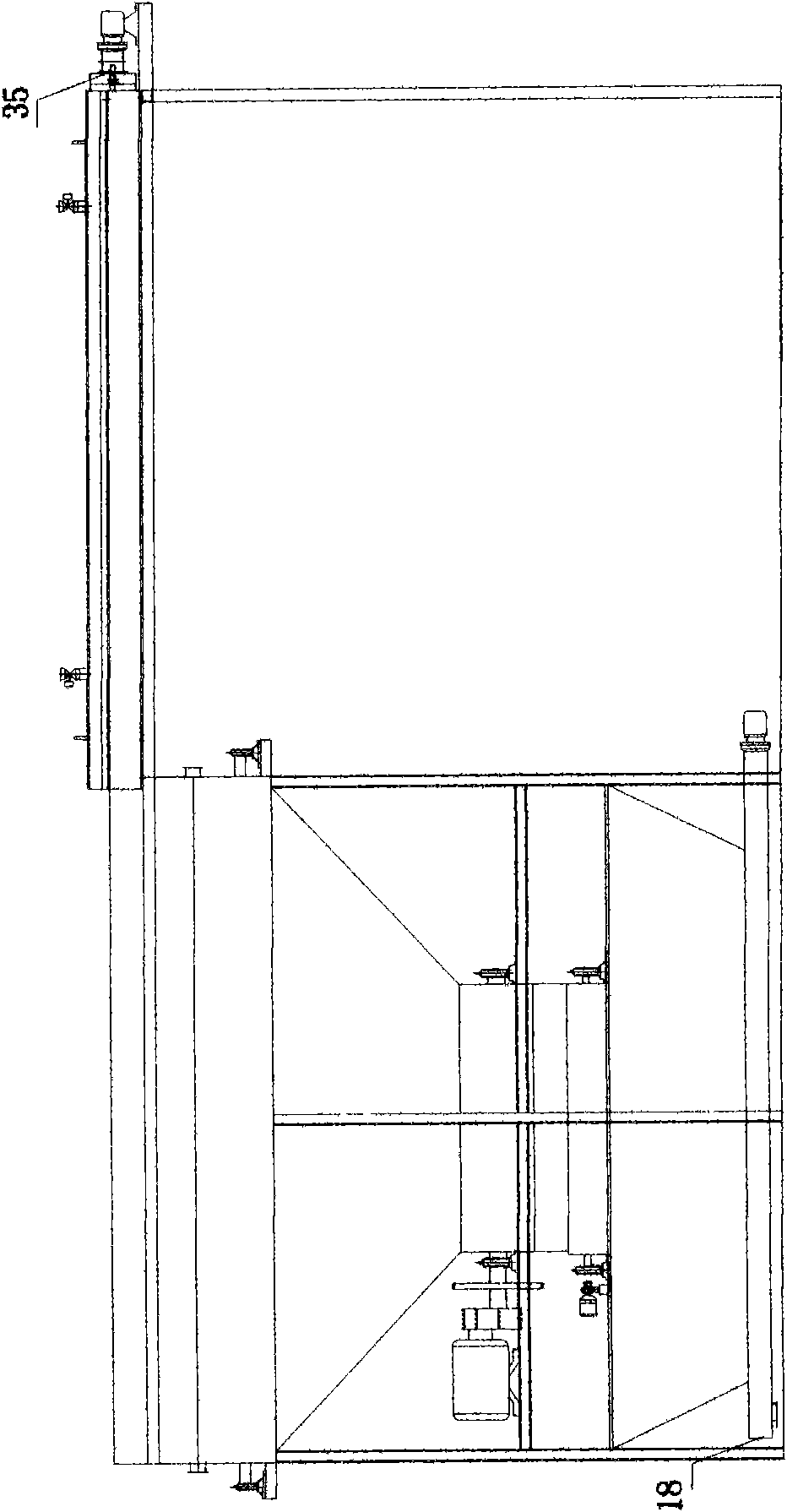

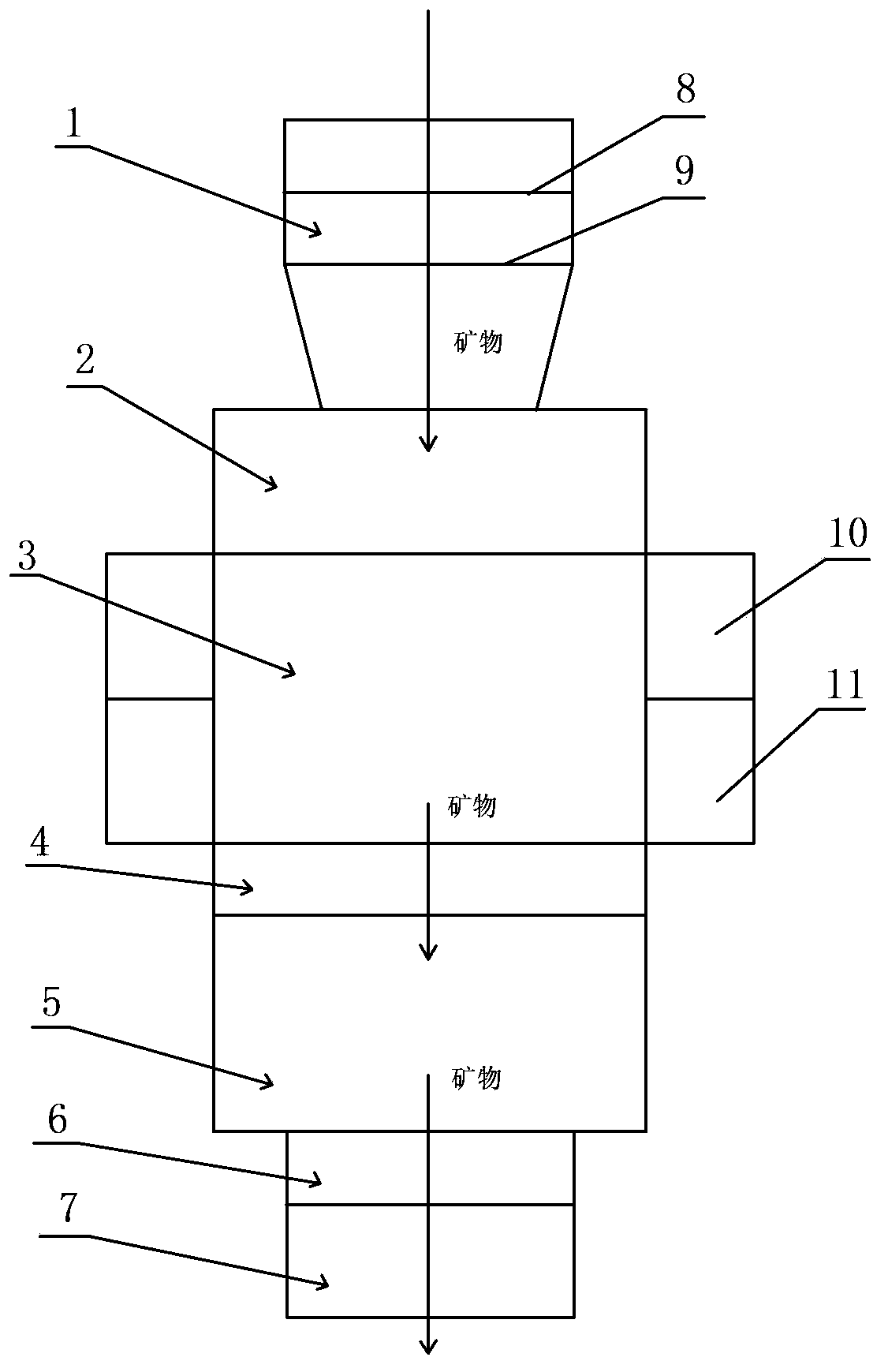

Mineral roasting reduction device and application method thereof

The invention discloses a mineral roasting reduction device. The device comprises a feeding zone, a drying preheating zone, a roasting oxidation reaction zone, a pressure-regulating zone, a reduction reaction zone, a discharging zone and a water-sealing cooling zone, which are arranged from the top down and communicated with one another, wherein the feeding zone is provided with an automatic sealing device; the drying preheating zone is provided with a directional pressurizing device for vacuum-pumping; the roasting oxidation reaction zone is provided with an incendiary agent adding device; the pressure-regulating zone is provided with a plurality of pressure-regulating air doors; the reduction reaction zone is provided with a reducing agent adding device. The mineral roasting reduction device is provided with the directional pressurizing device, so that negative pressure can be generated in the inner part of the device; molecular flows of both an incendiary agent and an reducing agent are in uplink, while mineral is in downlink, so that a convection current movement is formed to ensure conversion affinity of the solid phase and the gas phase; in the device, the mineral sequentially is subjected to drying, preheating, heating, resolving, reducing, water quenching, cooling and discharging from the top down, and all processes are performed in an air-free state thoroughly to complete roasting reaction.

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

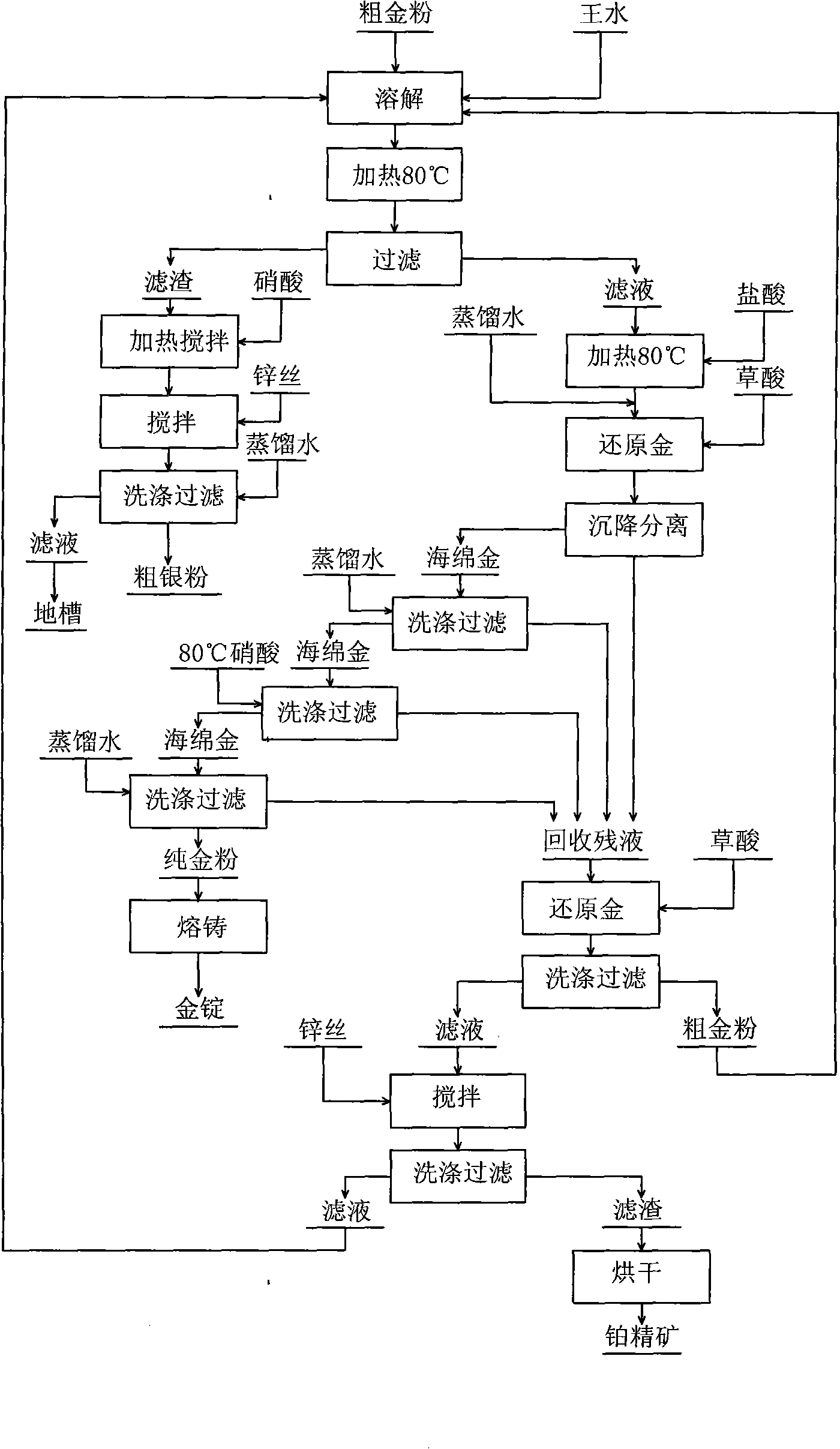

Gold wet purification process

The invention relates to a process for purifying gold by the wet method. Firstly, aqua fortis is used to remove silver; secondly, nitric acid is used to remove impurities such as bismuth and copper, etc.; the separation is performed by filtering; in the richly contained gold solution, the gold is reduced to gold powder deposited by an oxalic acid reducing agent with strong reducibility, and the impurities such as platinum, the bismuth and the copper, which are reduced simultaneously, are redissolved by nitric acid added later and enter the solution, and the solution is subjected to the filtering separation to obtain pure gold powder; and the pure gold powder is made to be ingot-shaped by fushion casting, and the finished gold ingots with a gold content of 99.99 percent are obtained. In the invention, the reduction reaction is made by oxalic acid at a low temperature, so that the process of the invention has the advantages of not causing environmental pollution, favorability for the heath of operators, lowering cost, shortening the period and obvious economic and social benefits.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Graphene preparation method

The invention discloses a graphene preparation method. The mixed solution of thiourea dioxide and soluable alkali or carbohydrazide and the soluable alkali is taken as a reducing agent to perform reduction-oxidation on the graphene aqueous solution, and evenly dispersed graphene powder is obtained after washing and drying. The graphene preparation method, disclosed by the invention, solves the problems that hydrazine hydrate and other existing reducing agents are high-toxic and not thorough in reduction, and the graphene is liable to gathering in the graphene preparation process. The preparation method is simple and feasible, is rapid in reaction process and moderate in reaction condition and has no special requirements to equipment, and the prepared graphene is of high quality.

Owner:吴江市华诚电子有限公司

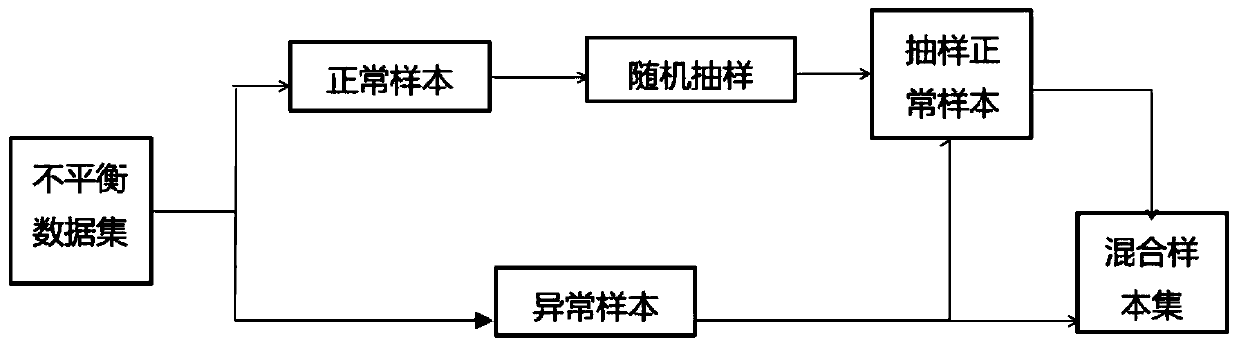

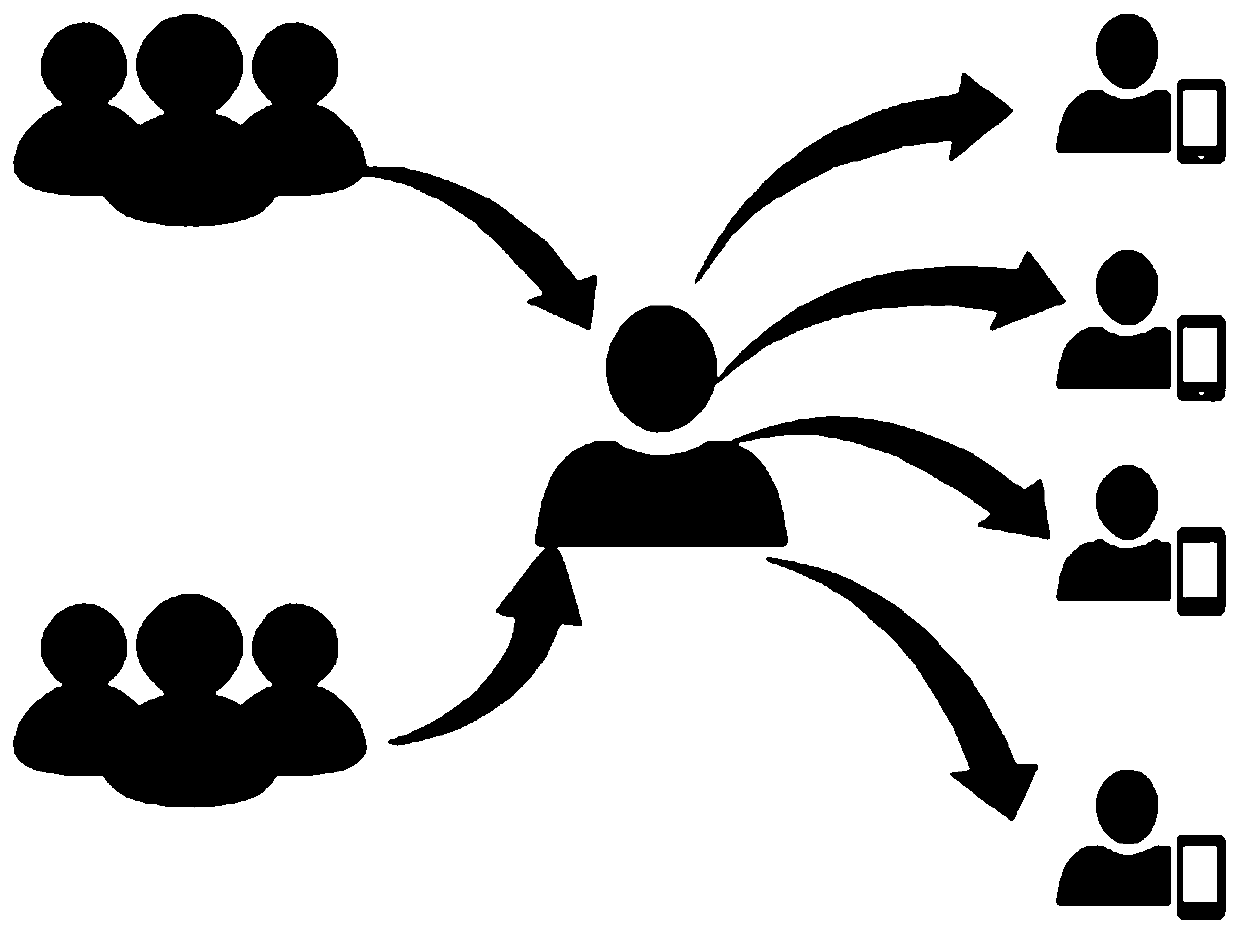

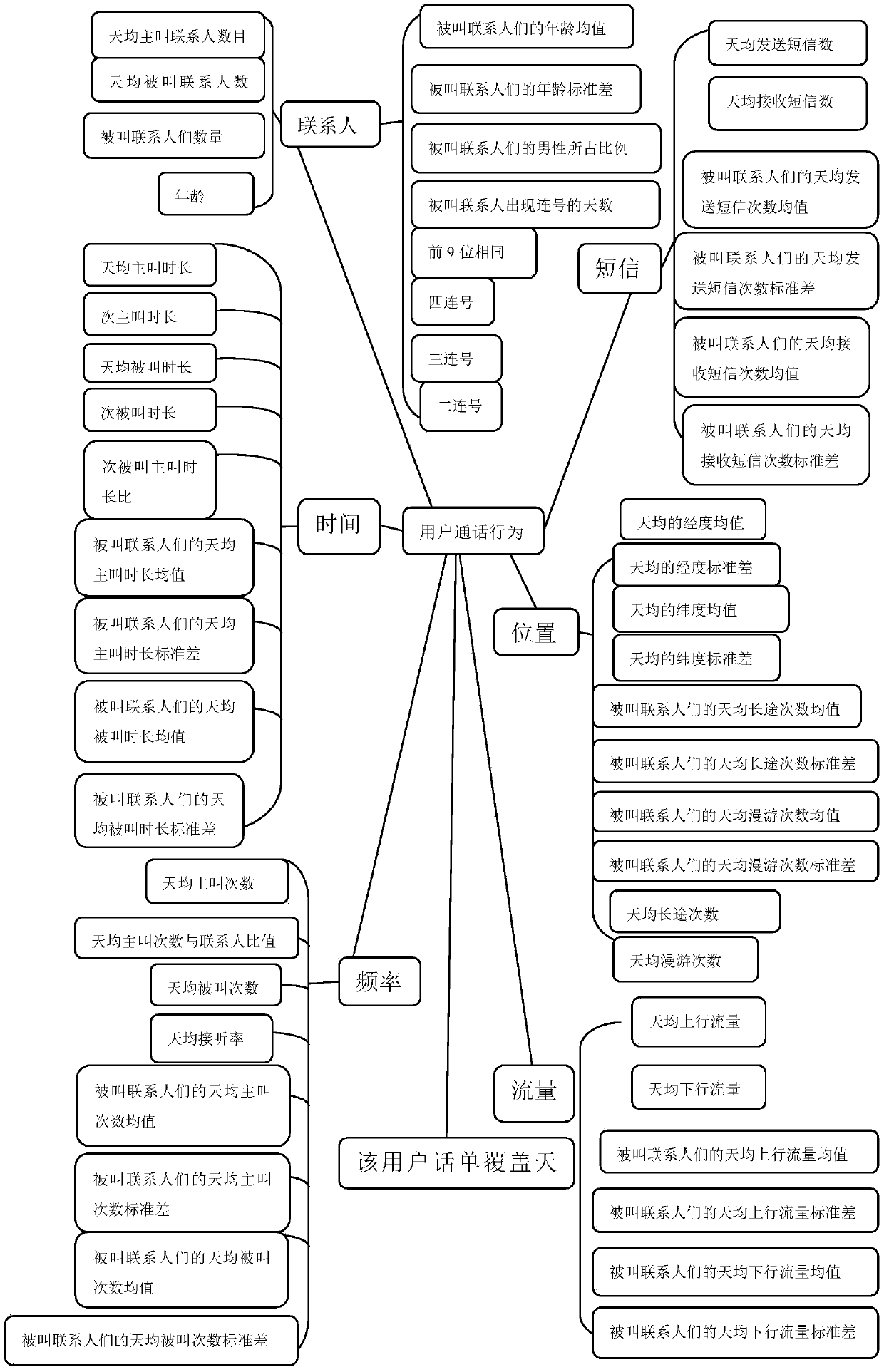

Abnormal telephone recognition method and system based on feature selection and integrated learning

PendingCN110072017AComplete restorationImprove forecast accuracyEnsemble learningSupervisory/monitoring/testing arrangementsFeature miningData set

The invention discloses an abnormal telephone recognition method and system based on feature selection and integrated learning. The method comprises the steps of constructing a mixed data set; miningsample characteristics through historical call behaviors of the user in a window from the starting time to the ending time; combining and optimizing the characteristics based on the user call behavior, and mining the characteristics with behavior information from the aspects of time, frequency, short message, flow, position and contact person; performing oversampling based on user call behavior samples, increasing the number of few samples, and reducing the influence of sample imbalance on the model; performing feature dimension reduction processing on the user call behavior sample; and establishing a model by using the integrated learning training data set, and carrying out abnormal telephone identification. According to the method, the original information of the sample is fully restoredin a feature mining combination and dimensionality reduction mixing mode, so that the prediction precision is improved.

Owner:UNIV OF JINAN

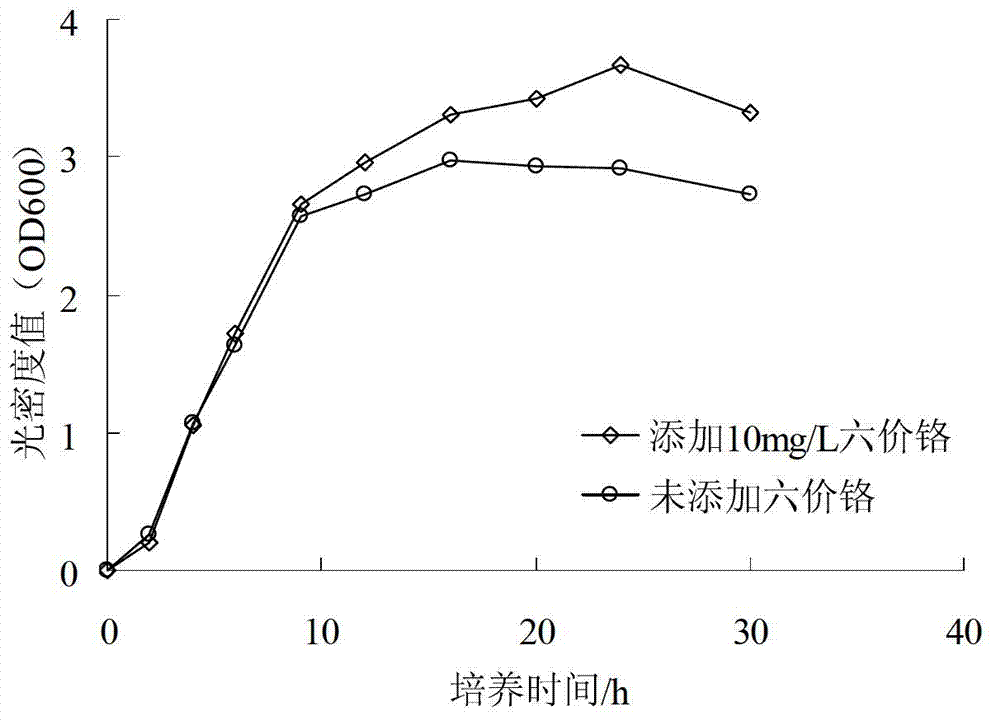

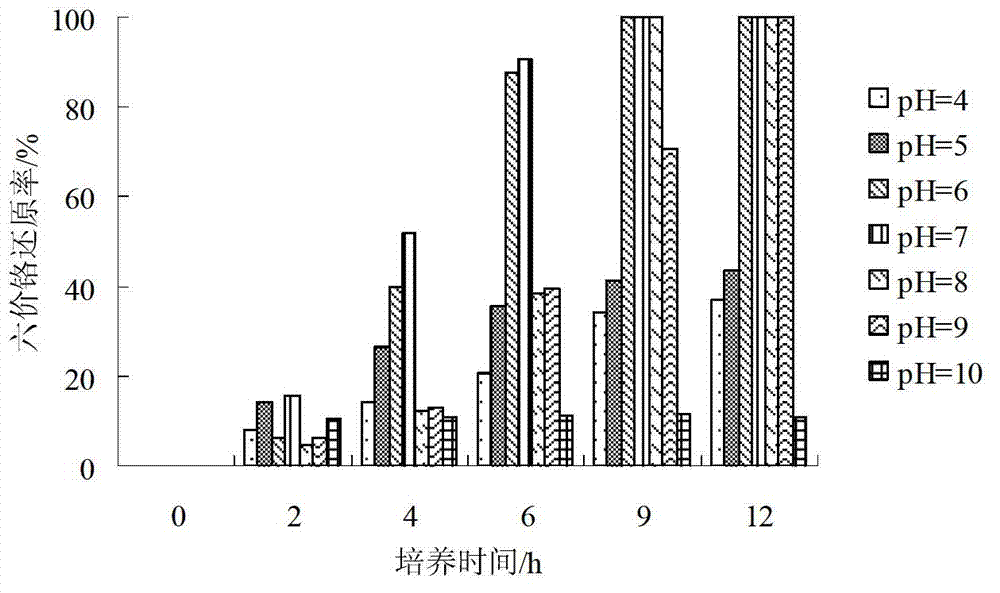

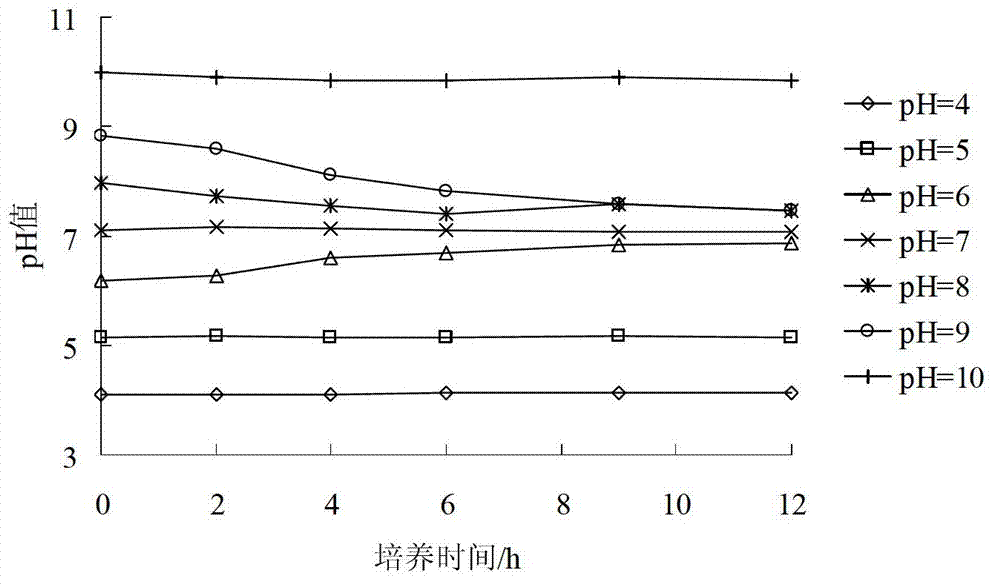

Application of Lysinibacillus sp Cr-6

InactiveCN103395893ASolve the problem of restoring technologyComplete restorationWater contaminantsContaminated soil reclamationMicroorganismEconomic benefits

The invention provides an application of Lysinibacillus sp Cr-6. The Lysinibacillus sp Cr-6 is used for reducing Cr6<+>, so as to reduce the Cr6<+> into Cr3<+>. In an anaerobic environment, the Lysinibacillus sp Cr-6 is used for reducing the Cr6<+> into Cr3<+>. When the pH value of the Lysinibacillus sp Cr-6 is 6-9, the Cr6<+> is reduced into Cr3<+>. Under the condition that Zn2<+> ions and Cu2<+> ions exist in the Lysinibacillus sp Cr-6, the Cr6<+> is reduced into Cr3<+>. The concentration of the Zn2<+> ions is 1-10mg / L; the concentration of the Cu2<+> ions is 1-20mg / L. According to the application of the Lysinibacillus sp Cr-6, the technical problem of reduction of hexavalent chromium in a natural environment is solved, so that a degrading bacterium for the reduction of the hexavalent chromium is provided. The Lysinibacillus sp Cr-6 is strong in survival ability, complete to degrade and short in required time; microorganisms are degraded completely. Thus, the Lysinibacillus sp Cr-6 has good social, ecological and economic benefits.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing olefins by using dehydrogenation of light alkanes with sulfur-containing substances added in raw materials

ActiveCN102910997AAvoid rapid deactivationEasy to useHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The present invention discloses a method for preparing olefins by using dehydrogenation of light alkanes with sulfur-containing substances added in raw materials, comprising: the dehydrogenation catalyst, which is a platinum group metal-supported catalyst, is not subjected to a reduction and sulfurization before use; and a small amount of sulfur-containing materials are added in the dehydrogenation raw materials for a dehydrogenation reaction directly, wherein the concentration of the sulfur-containing materials in the dehydrogenation raw materials is 5-100 [mu]mol / mol. Compared with the prior art, the method of the present invention improves the stability of the dehydrogenation catalyst, and can effectively prolong the service life of the dehydrogenation catalyst and reduce the carbon deposition rate of the catalyst, thereby improving the economic benefits of preparing corresponding olefins by using light hydrocarbon dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com