Method for preparing graphene through reduction of oxidized graphene

A graphene and graphene suspension technology, which is applied in the field of preparing graphene materials by using graphene oxide, can solve the problems of reducing the electrical properties of graphene, the toxic price of a reducing agent, and a long reduction reaction period, and achieves large-scale production, The reduction effect is good, and the effect of accelerating the reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

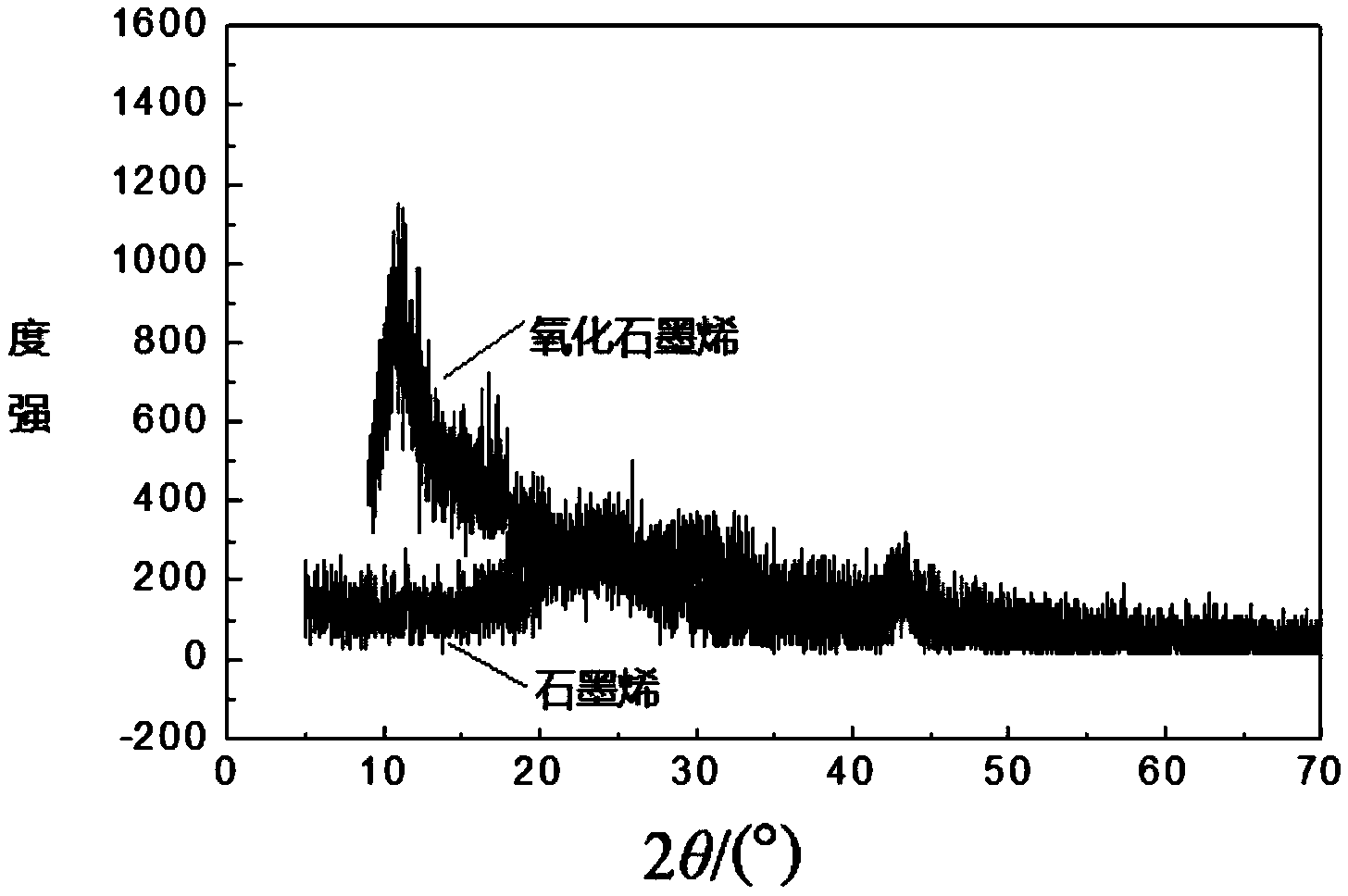

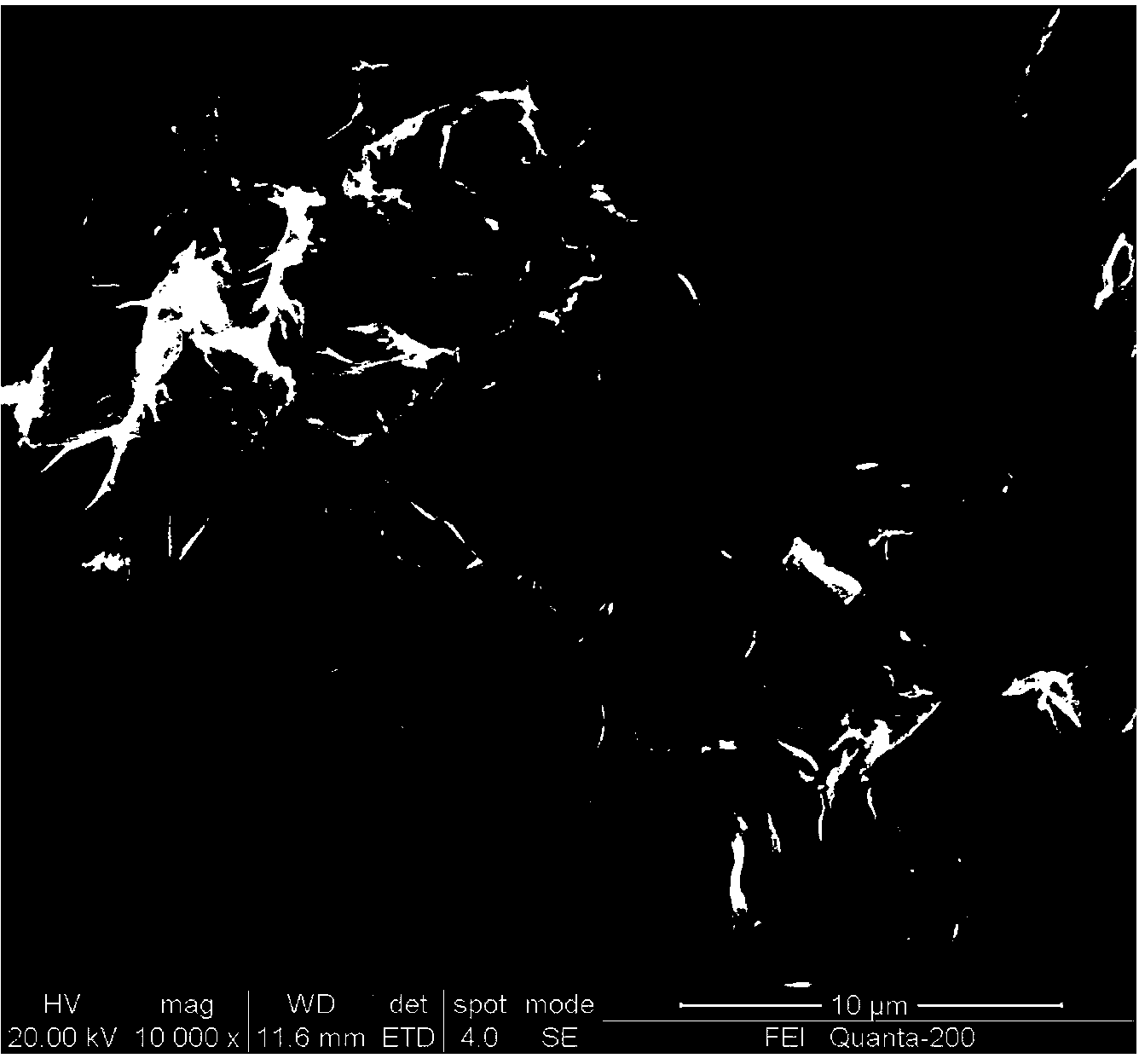

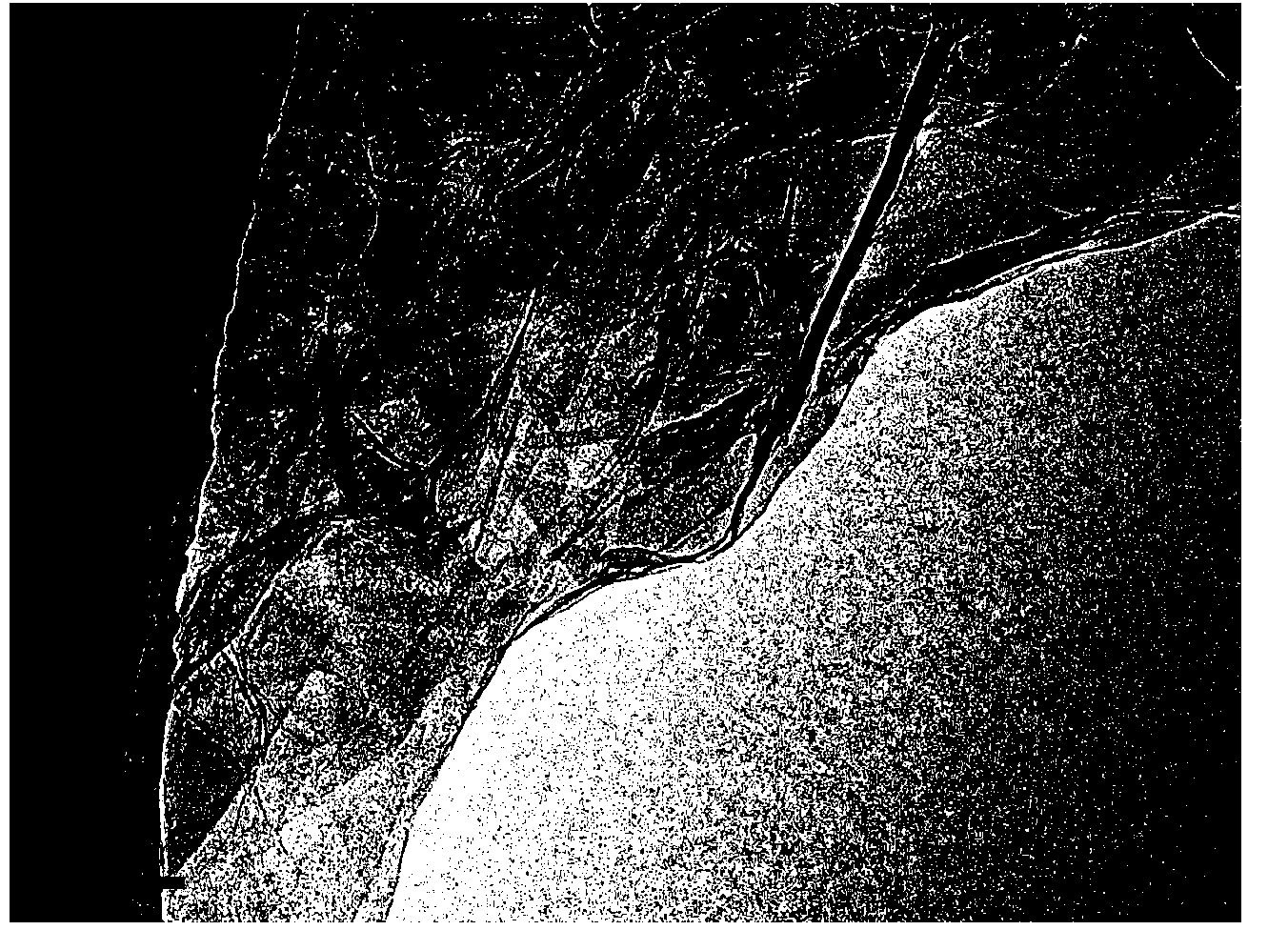

[0035] A method for preparing graphene by reducing graphene oxide according to the present invention, which uses an alkali metal as a reducing agent and iodine as an initiator, and under ultrasonic-assisted stirring, graphene oxide is reduced, and then separated and purified to obtain Graphene specifically comprises the following steps:

[0036] 1. Preparation of graphene oxide: Assemble a three-neck reaction bottle in an ice-water bath, add 48ml of concentrated sulfuric acid and stir, and keep the temperature at (0±1)°C, add 2g of natural flake graphite and 1g of sodium nitrate in sequence, and then add slowly in batches 6g strong oxidant potassium permanganate, react at (10±1)°C for 2h, then react for 2h under stirring in a constant temperature water bath at (35±3)°C, slowly add deionized water to raise the temperature to (98±1) ℃, keep it for 1h, then add hydrogen peroxide to oxidize the unreacted strong oxidant, turn the solution into bright yellow, stop the reaction, let ...

Embodiment 2

[0042] A method for preparing graphene by reducing graphene oxide according to the present invention, which uses an alkali metal as a reducing agent and iodine as an initiator, and under ultrasonic-assisted stirring, graphene oxide is reduced, and then separated and purified to obtain Graphene specifically comprises the following steps:

[0043] 1. Preparation of graphene oxide: Assemble a three-neck reaction bottle in an ice-water bath, add 48ml of concentrated sulfuric acid and stir, and keep the temperature at (0±1)°C, add 2g of natural flake graphite and 1g of sodium nitrate in sequence, and then add slowly in batches 6g strong oxidant potassium permanganate, react at (10±1)°C for 2h, then react for 2h under stirring in a constant temperature water bath at (35±3)°C, slowly add deionized water to raise the temperature to (98±1) ℃, keep it for 1h, then add hydrogen peroxide to oxidize the unreacted strong oxidant, turn the solution into bright yellow, stop the reaction, let ...

Embodiment 3

[0048] A method for preparing graphene by reducing graphene oxide according to the present invention, which uses an alkali metal as a reducing agent and iodine as an initiator, and under ultrasonic-assisted stirring, graphene oxide is reduced, and then separated and purified to obtain Graphene specifically comprises the following steps:

[0049] 1. Preparation of graphene oxide: Assemble a three-neck reaction bottle in an ice-water bath, add 48ml of concentrated sulfuric acid and stir, and keep the temperature at (0±1)°C, add 2g of natural flake graphite and 1g of sodium nitrate in sequence, and then add slowly in batches 6g strong oxidant potassium permanganate, react at (10±1)°C for 2h, then react in a constant temperature water bath at (35±3)°C for 2h with stirring, slowly add 96ml of deionized water to raise the temperature to (98±1) )°C, keep it for 1 hour, add 10ml of 30% hydrogen peroxide to oxidize the unreacted oxidizing agent, turn the solution into bright yellow, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com