Patents

Literature

58results about How to "Affect electrical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

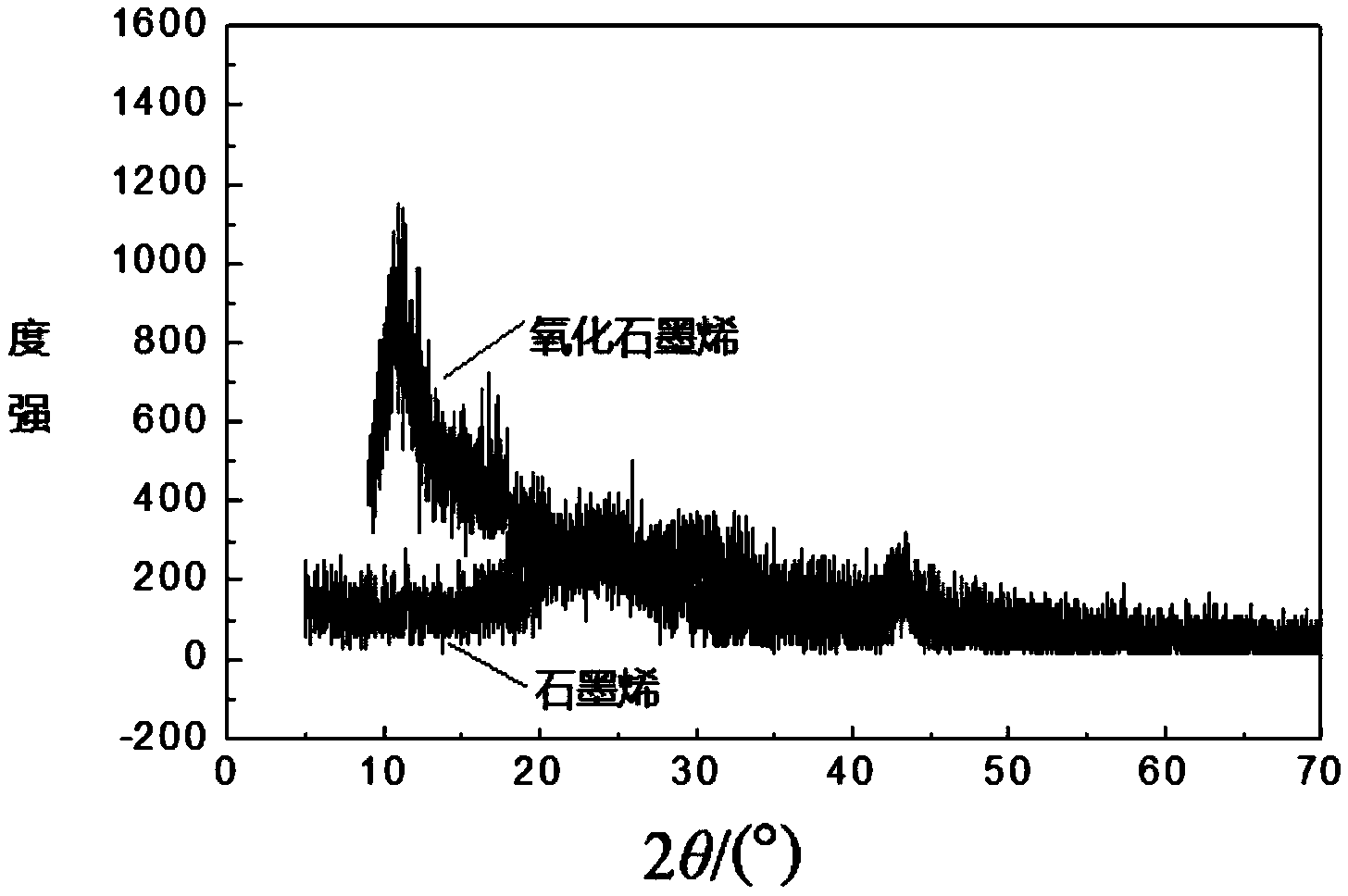

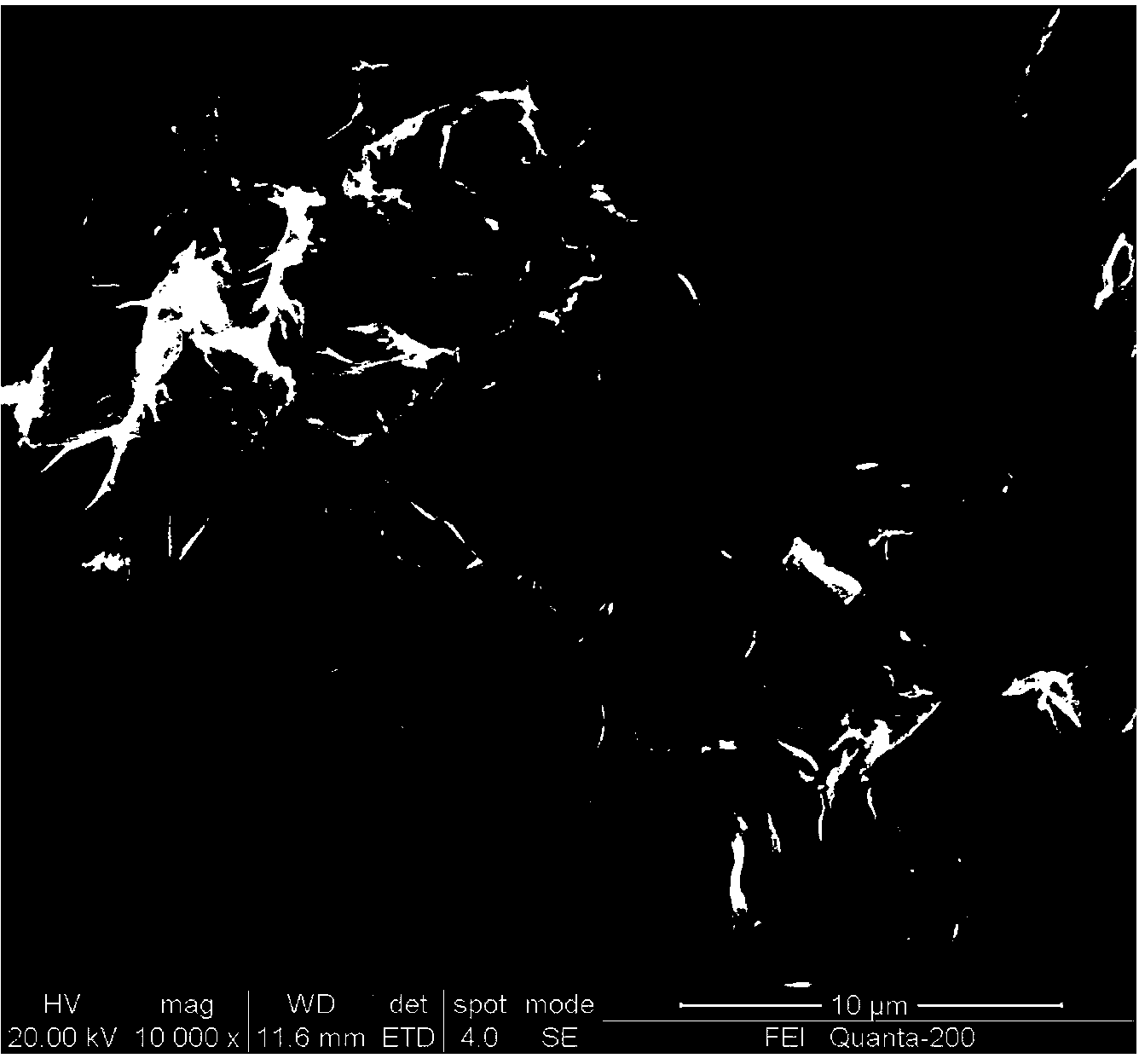

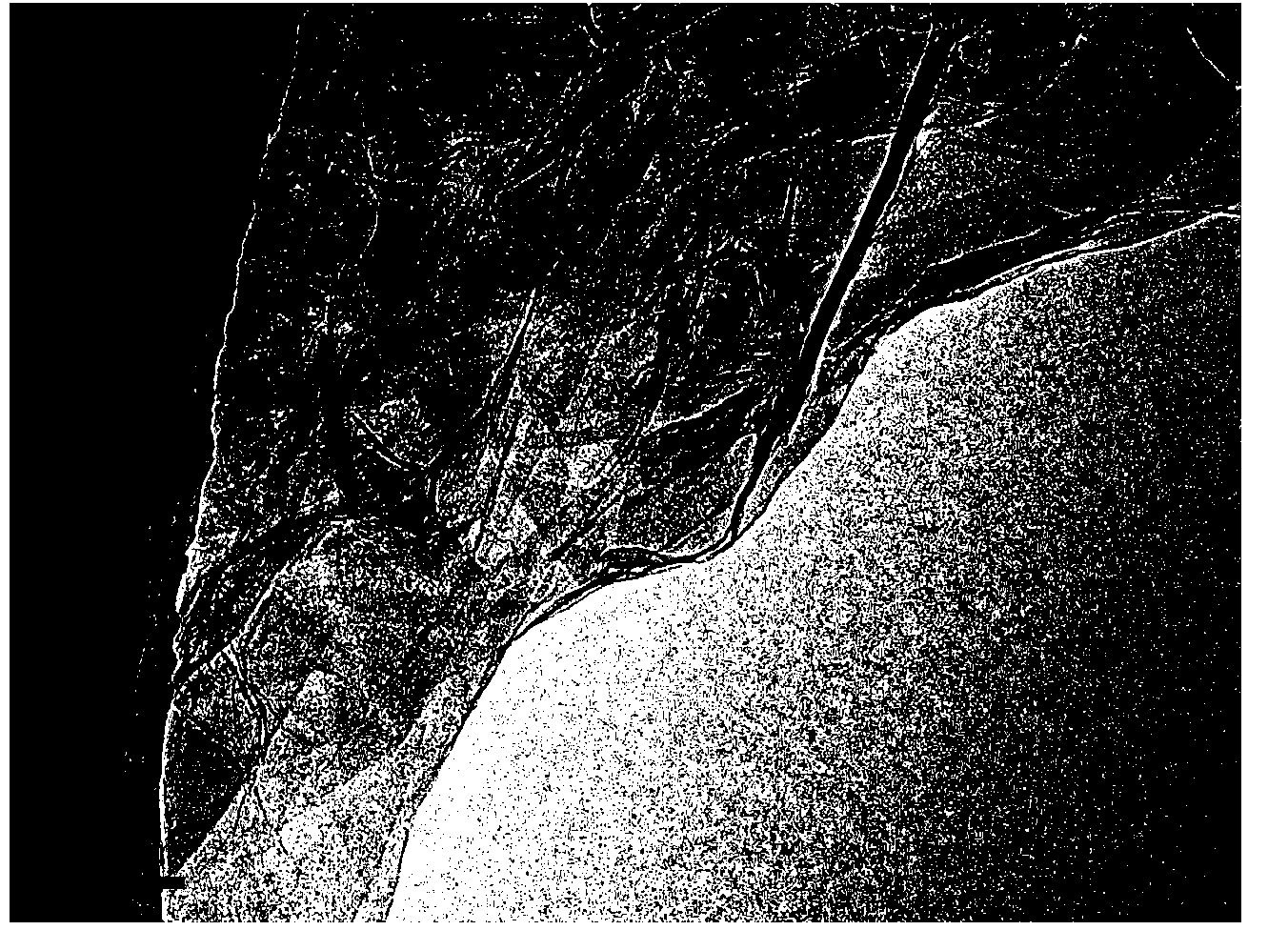

Method for preparing graphene through reduction of oxidized graphene

The invention discloses a method for preparing graphene through reduction of oxidized graphene. The method comprises the steps of under ultrasonic-assisted stirring, reducing the oxidized graphene with alkali metal or alkaline earth metal as a reducing agent and iodine as an initiator, and separating and purifying to obtain the graphene. The method has the advantages of short reaction cycle, simple operation, high efficiency, no pollution, low cost, good product quality and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

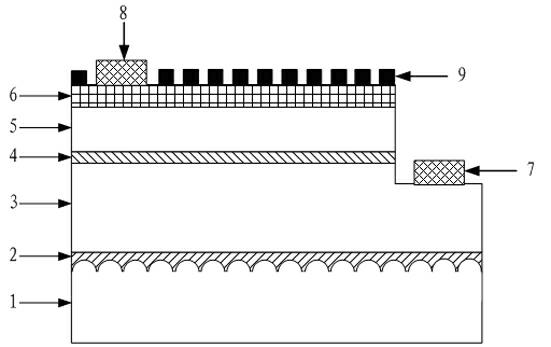

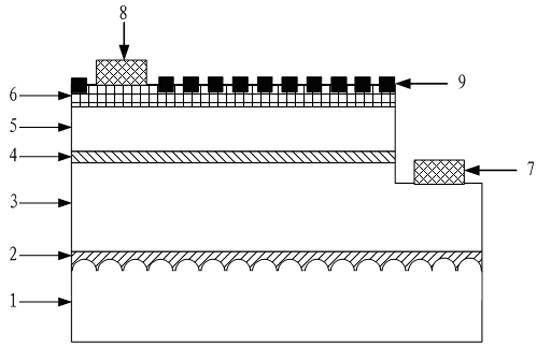

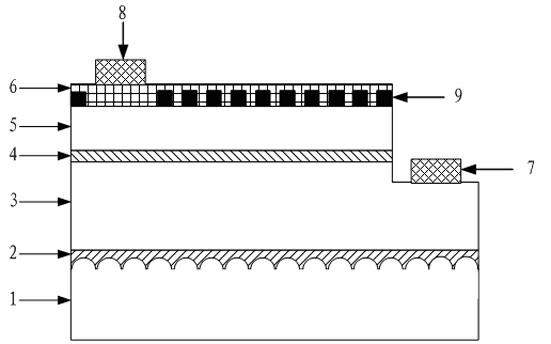

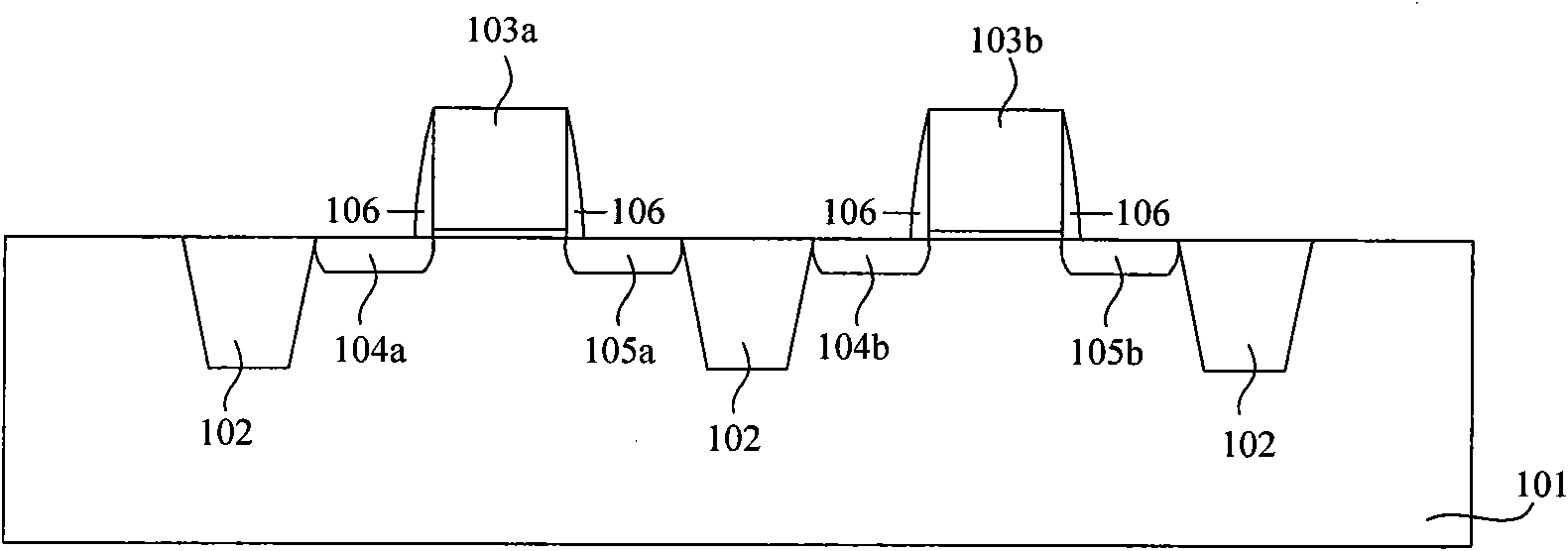

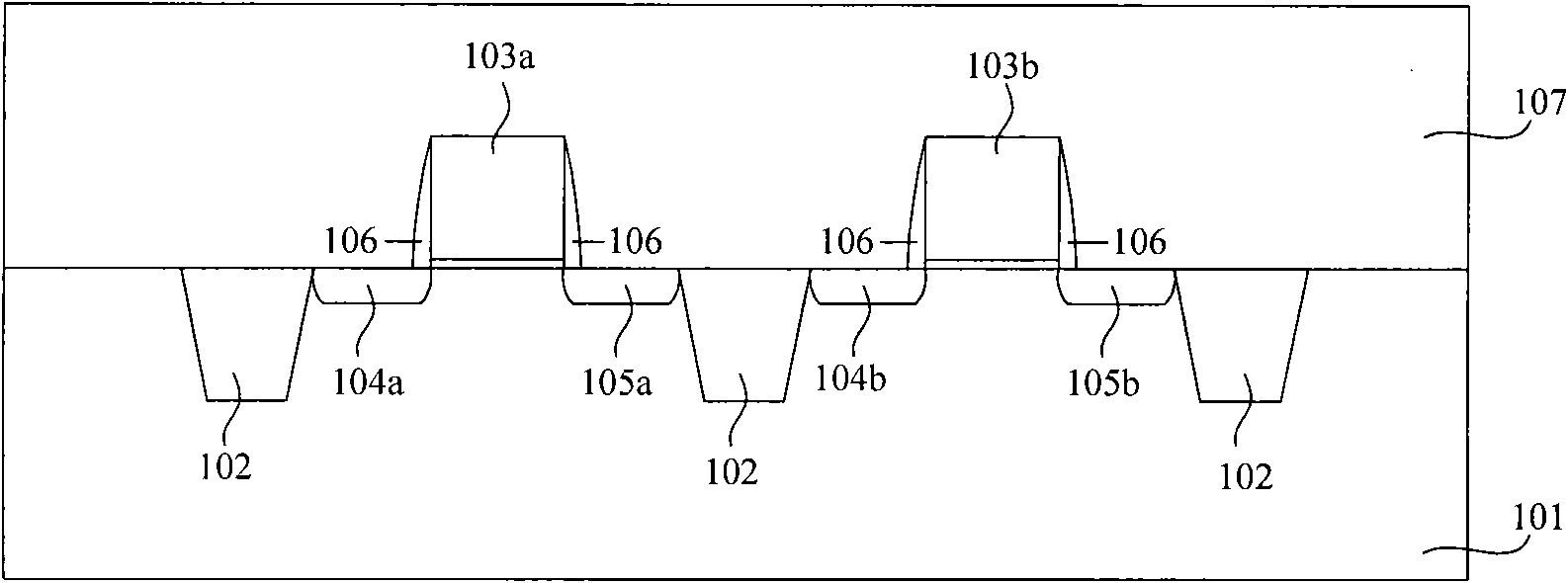

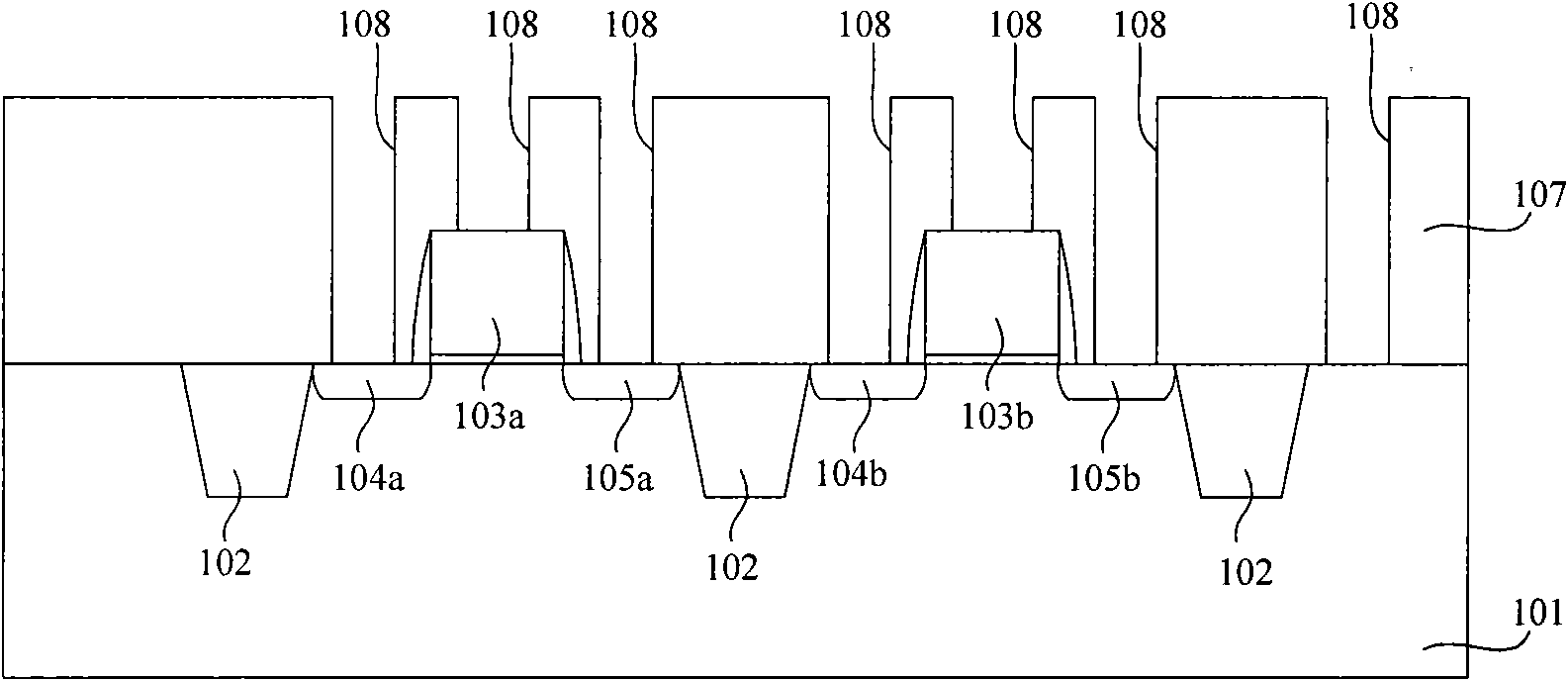

Light emitting diode with oxide nano array structure and preparation method thereof

InactiveCN102097568AReduce the effect of total reflectionImprove light outputSemiconductor devicesTotal internal reflectionReactive-ion etching

The invention relates to a light emitting diode (LED) with an oxide nano array structure and a preparation method thereof. The LED comprises a transparent conductive layer deposited on the surface of the LED, and oxide granules covered on the surface of the transparent conductive layer or embedded in the transparent conductive layer and distributed in array. The preparation method for the LED comprises steps of spin coating, stamping, ultraviolet (UV) irradiation, stripping, reactive ion etching (RIE), deposition and lift-off, and can also comprise an etching step between the RIE and deposition steps. The oxide granule structure distributed in array in the LED can cause scattering of light and destroy the light of original total internal reflection to allow more photons to escape from the LED so as to reduce the total reflection influence of the LED and improve the light emitting rate of the LED. The preparation method does not refer to plasma etching of an active layer and a p-type GaN at the same time of improving the light extraction efficiency of the LED, so plasma damage is not caused to affect the electric performance of the LED.

Owner:AQUALITE CO LTD

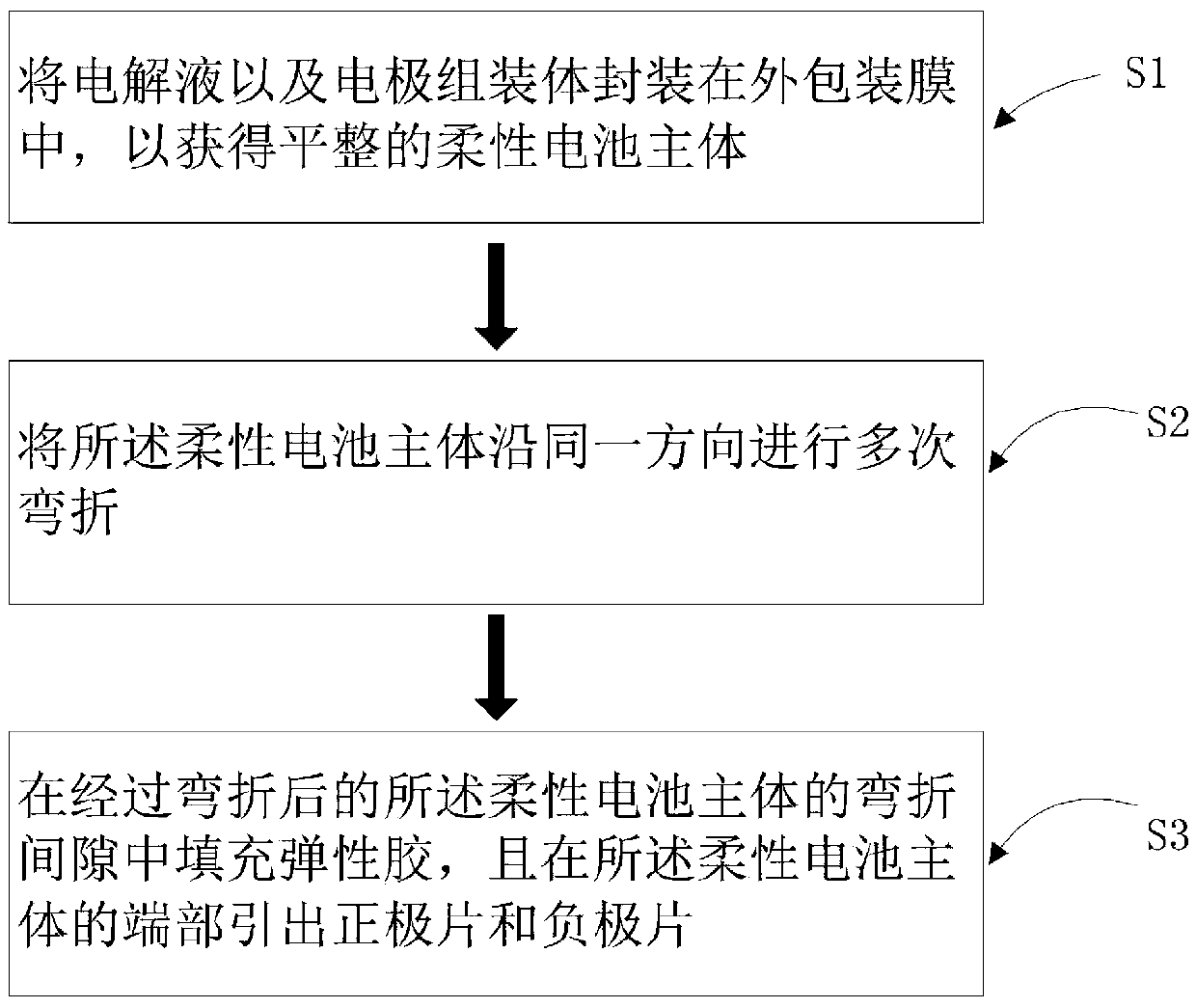

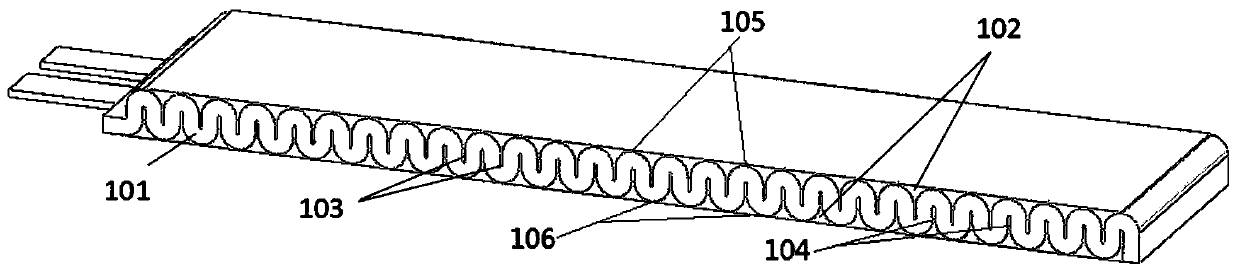

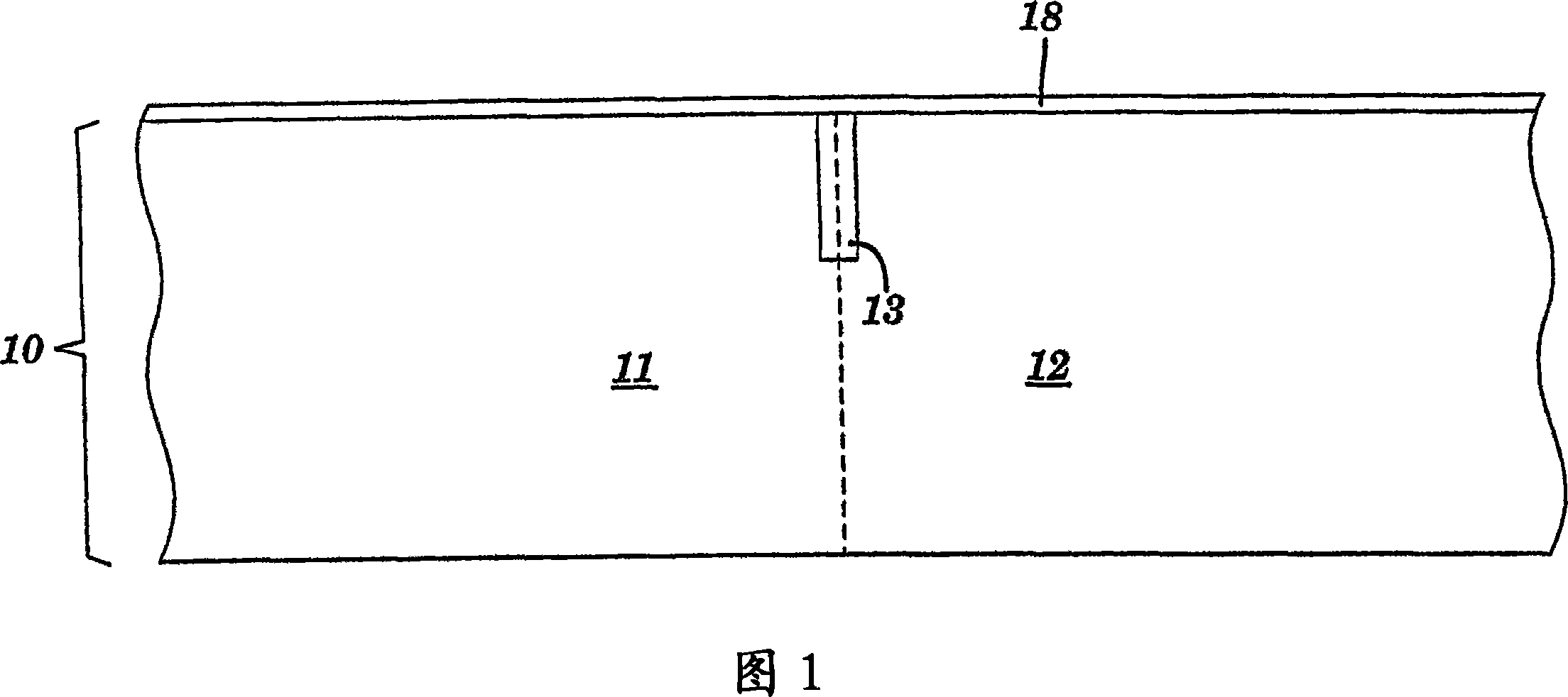

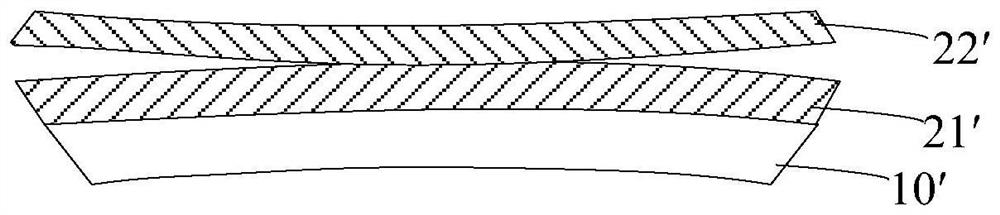

Flexible battery and preparation method thereof

PendingCN109713376AExtend your lifeAffect electrical propertiesFinal product manufactureSecondary cells manufactureElectrical performanceEngineering

Owner:柔电(武汉)科技有限公司 +1

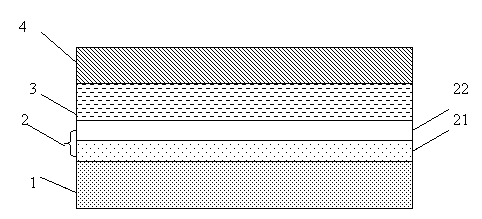

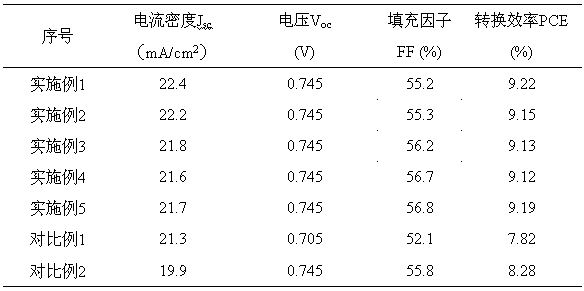

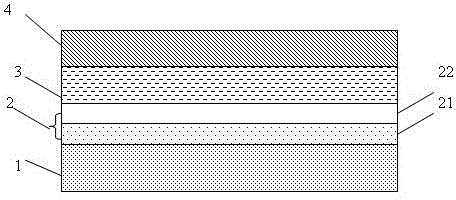

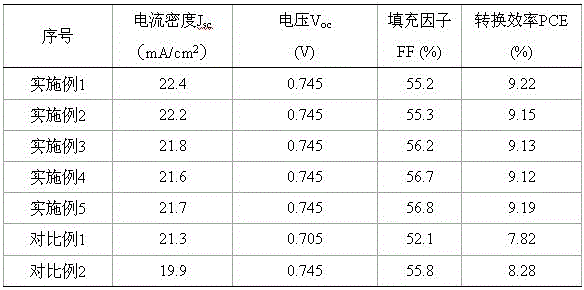

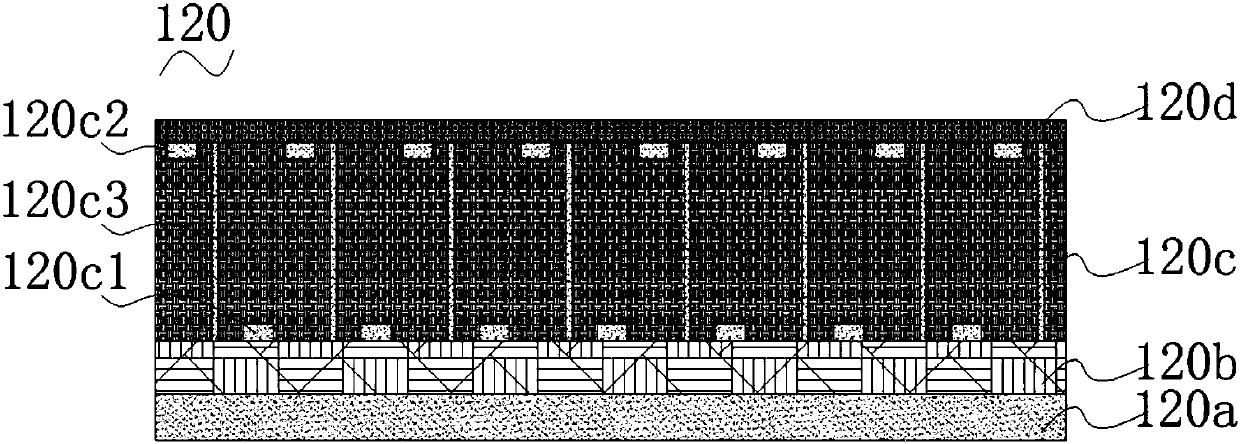

Polymer solar cell and preparation method thereof

ActiveCN103325945AAffect electrical propertiesNo reduction in open circuit voltageSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerOhmic contact

Provided are a polymer solar cell and a preparation method thereof. The cell comprises a transparent positive pole, hole transporting layers, an optical active layer and a metal negative pole, wherein the hole transporting layers comprise a first hold transporting layer and a second hold transporting layer, the first hole transporting layer is arranged on the surface of the transparent positive pole, and metal nano materials are doped in the first hole transporting layer; the second hold transporting layer is arranged on the surface of the first hole transporting layer; and metal nano materials are doped in the optical active layer. According to the polymer solar cell and the preparation method, the exposed metal nano materials in the first hole transporting layer are coated, the exposed metal nano materials in the first hole transporting layer and the optical active layer in the cell form good ohmic contact, the electrical property of the cell are prevented from being influenced due to leading-in of the metal nano materials, the fact that open-circuit voltage and filling factors of the cell are not reduced is guaranteed, and meanwhile photoelectric conversion efficiency is improved by more than 10%.

Owner:CHINA LUCKY FILM CORP

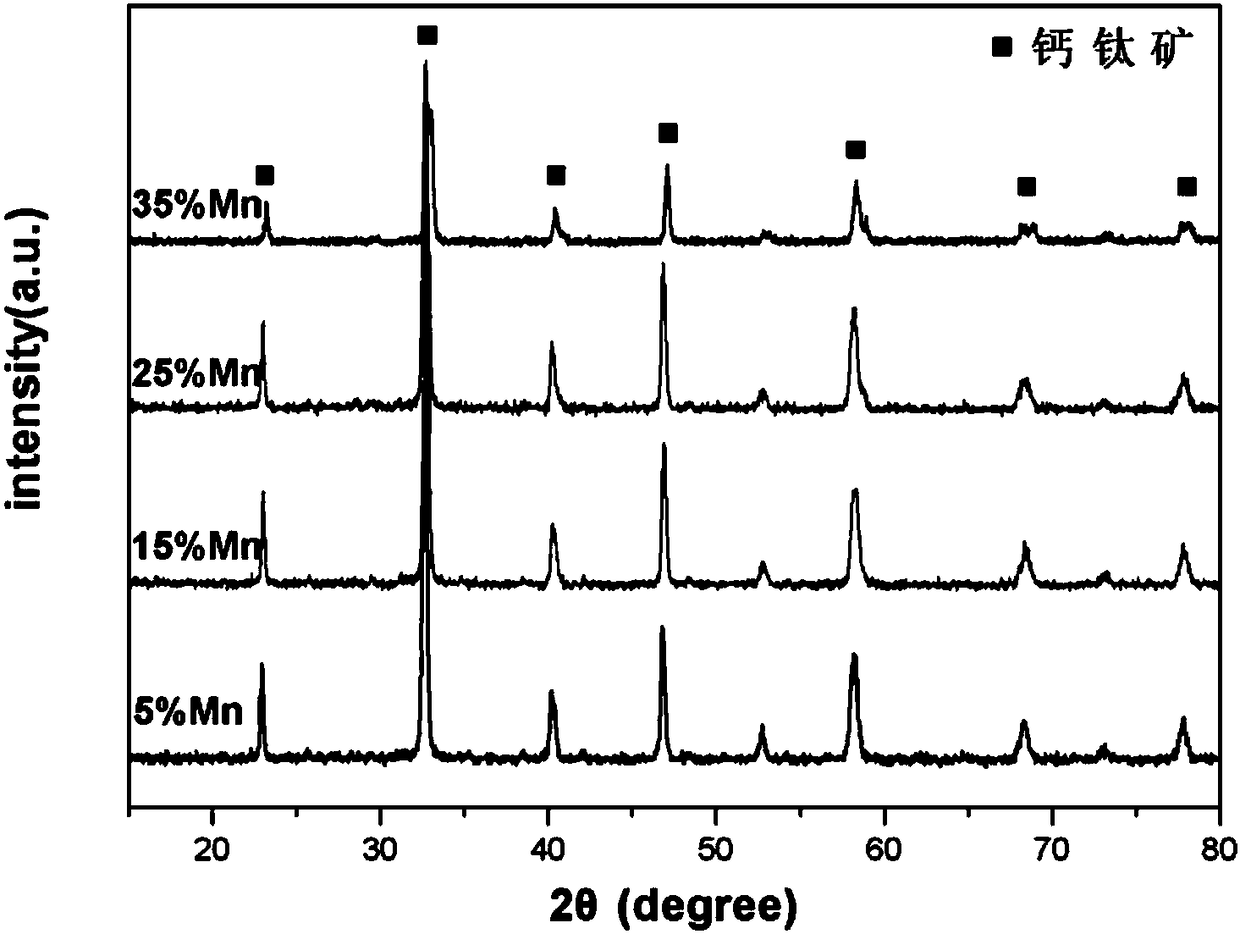

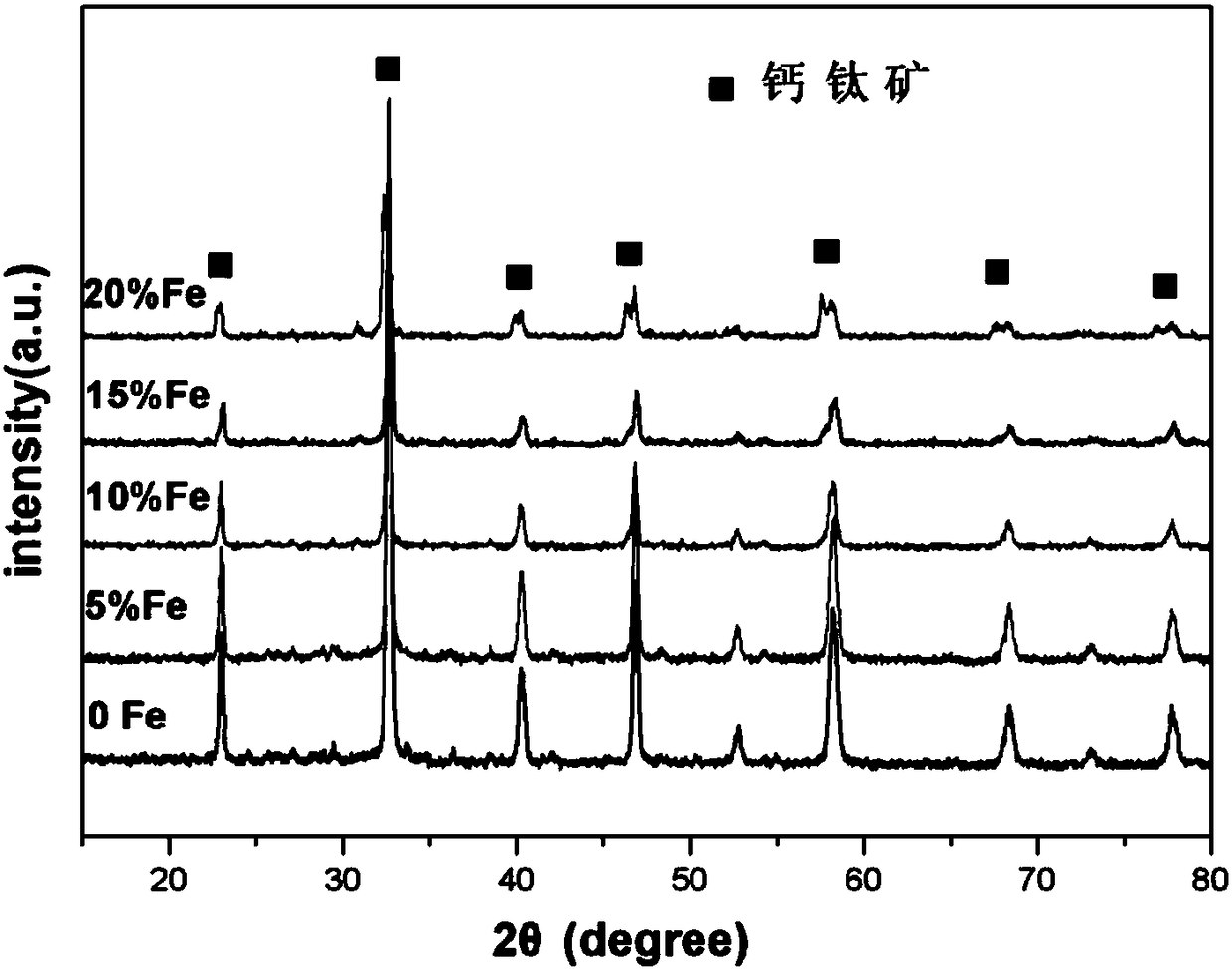

Chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material

InactiveCN108585794AUniform particle sizeImprove ball milling activityNegative temperature coefficient thermistorsHigh resistanceManganese

The invention provides a preparation method of a chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material. The method comprises the following step: weighing the following raw materials: 20-55% by atom of La, 5-75% by atom of Cr and 5-40% by atom of Mn; performing wet milling to obtain slurry; drying and grinding the slurry to obtain powder; roasting to obtain perovskite-phase La(CrMn)O3 powder; preparing the powder into block materials; performing two-step sintering method; cooling with the furnace to obtain the chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material. The chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material prepared according to the method has the advantages that electrical parameters are that rho25 DEG C=15.2 omega.cm-13823.2 ohm.cm+ / -2%, B25 / 50=2688-3942K+ / -1.5%; the material has the characteristics that the high-resistance, low-B and low-resistance and high-B parameter combination is realized; the consistency is high; the stability is high; the material is recyclable; the material is applicable to measuring and controlling of temperature in wide temperature range, circuit compensating and inhibiting of surge current.

Owner:UNIV OF JINAN

Method for enhancing pressure resistance capacity of chip in packaging process and chip thereof

ActiveCN101834153AImprove reliabilityProtection from collapseSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectInsulation layer

The invention relates to a method for enhancing the pressure resistance capacity of a chip in the packaging process and the chip thereof. The method comprises the following steps of: additionally arranging patterns used for forming through holes in a redundancy region of each metal interlayer insulation layer mask and a redundancy region of each metal interconnect mask, wherein the pattern additionally arranged in the redundancy region at the nth metal interconnect mask corresponds to the pattern additionally arranged in the redundancy region of the nth metal interlayer insulation layer mask, and the pattern additionally arranged in the redundancy region of the (n+1)th metal interlayer insulation layer mask corresponds to the pattern additionally arranged in the redundancy region of the nth metal interconnect mask, wherein n is 1, 2, 3 till N. The method for enhancing the pressure resistance capacity of the chip in the packaging process and the chip thereof can improve the pressure resistance capacity of the chip, thereby improving the manufacturing reliability of the chip.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A kind of polymer solar cell and preparation method thereof

ActiveCN103325945BAffect electrical propertiesImprove utilizationSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerOhmic contact

Owner:CHINA LUCKY FILM CORP

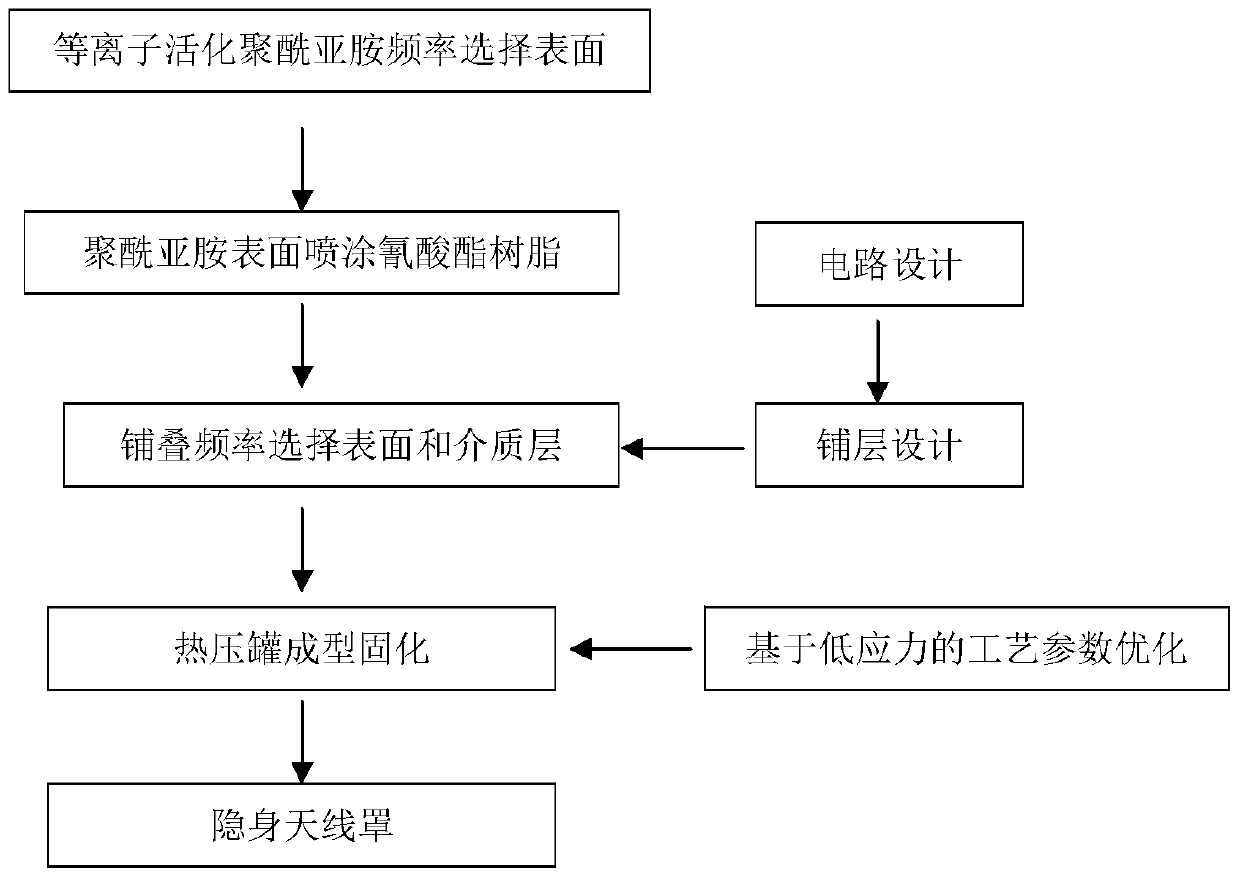

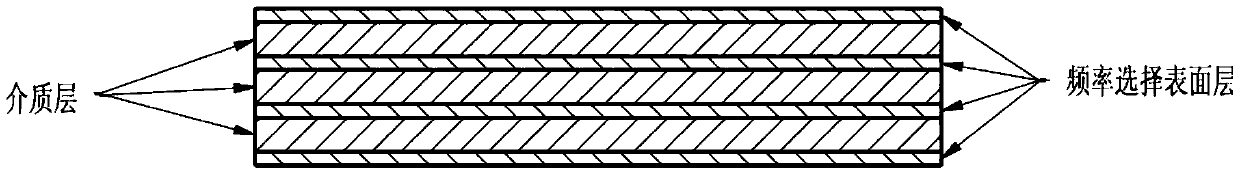

Preparation method for anti-dielectric substrate delamination of multi-layer fss radome

ActiveCN105186131BAvoid the effects of differences in expansion coefficientsImprove selection featuresRadiating element housingsRelational modelDielectric substrate

The invention discloses a preparation method for anti-dielectric substrate delamination of a multi-layer FSS radome. Before the radome is laminated, the polyimide frequency selective surface is plasma activated and the cyanate resin is sprayed for viscosity-increasing treatment; Quantitatively describe the influence of curing process parameters on the internal stress, establish the relationship model between the internal stress of the multilayer frequency selective surface stealth radome and the curing process parameters, and then make the polyimide frequency selective surface into prepreg; select according to the multilayer frequency The circuit design of the surface stealth radome requires the frequency selective surface and the layup sequence design of the composite material dielectric layer, and the layup is carried out according to the layup sequence; after the layup is completed, the autoclave is formed and cured. The invention makes up for the defect that air bubbles are easily trapped when the polyimide frequency selective surface and the dielectric layer prepreg are laminated in the traditional method, and solves the problem that the air bubbles cannot be excluded due to the barrier of the frequency selective surface when the dielectric layer is formed, and separation will occur. layer problem.

Owner:10TH RES INST OF CETC

Iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material and preparation thereof

ActiveCN108585854AUniform particle sizeImprove ball milling activityGrain boundary migrationNegative temperature

The invention provides a preparation method of an iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material. The method comprises the following steps: weighing rawmaterials according to a La-Cr-Fe atomic percent of 30-55 to 10-65 to 5-35), and performing wet grinding to obtain slurry; drying the slurry, and grinding to obtain a powder; calcining to obtain a perovskite phase (LaCrFe)2O3 powder; preparing a bulk material from the powder, adopting a two-step sintering method, and performing furnace cooling, so as to obtain the iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material. According to the preparation method disclosed by the invention, the two-step sintering method is adopted, grain boundary diffusion is positioned in an active state while inhibiting grain boundary migration, and the aim of completing sintering on premise of not growing grains is achieved; the finally prepared ceramic material is smallin grain size, uniform in distribution, high in resistance, wide in adjustable range, small in value B change, high in stability and excellent in consistency.

Owner:UNIV OF JINAN

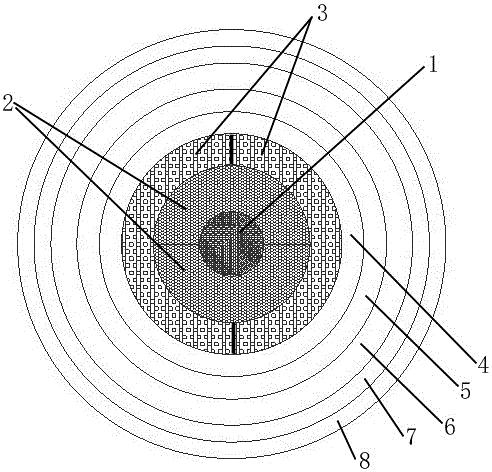

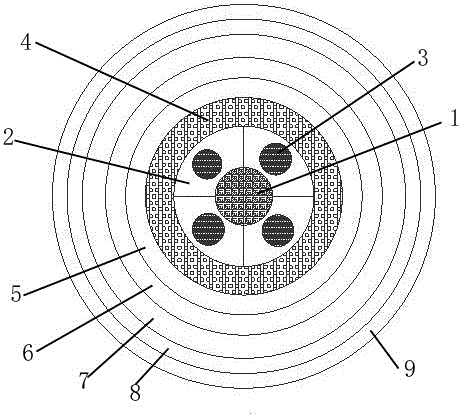

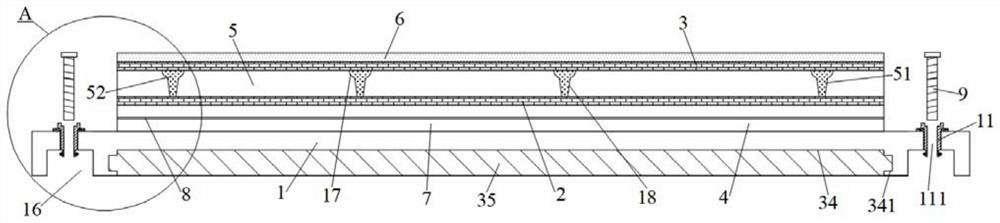

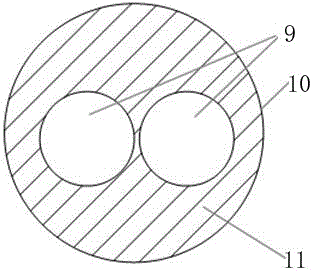

Insulation low-voltage power cable

InactiveCN106504824AGuaranteed bending performanceGuaranteed air tightnessInsulated cablesPower cablesInsulation layerElectrical conductor

The invention discloses an insulation low-voltage power cable. The insulation low-voltage power cable comprises a solid aluminum conductor, wherein the solid aluminum conductor is arranged at the center of the cable, two semi-circular first solid aluminum lines with same shape structures are transversely extruded outside the solid aluminum conductor, two semi-circular second solid aluminum lines with same shape structures are longitudinally extruded, a low-density polyethylene insulation layer wraps the second aluminum lines in an extruded manner, dual layers of water blocking tapes wraps in a lamination way, a corrugated aluminum sheath is welded outside the water blocking tapes, asphalt is coated on the corrugated aluminum sheath, and finally, a middle-density polyethylene sheath is extruded at the outermost layer of the cable. The insulation low-voltage power cable has the characteristics of good water resistant performance, corrosion resistance, oxidation resistance, good heat resistance, no mechanical damage and the like.

Owner:WUXI JIANGNAN CABLE

0.6/1 kv waterproof tensile power cable for shallow seas

InactiveCN106531306AGuaranteed bending performanceGuaranteed air tightnessPower cables with screens/conductive layersFlexible cablesElectric power transmissionWater block

The invention discloses a 0.6 / 1 kV waterproof tensile power cable for shallow seas. The 0.6 / 1 kV waterproof tensile power cable comprises a cable core, wherein the cable core is formed by twisting three fan-shaped phase line cores, a circular ground line and a filling water-blocking strip together; a wrapping belt is wrapped outside the cable core, a low-density polyethylene inner sheath is firstly extruded outside the wrapping belt, and then a thick steel wire armoring layer is tightly wound; two wrapping belts are wrapped outside the thick steel wire armoring layer, then a medium-density polyethylene isolation sleeve is extruded, two water-blocking belts are wrapped outside the medium-density polyethylene isolation sleeve in a stacked manner, a corrugated aluminum sheath is welded outside the water-blocking belt, asphalt is coated on the corrugated aluminum sheath, and finally a medium-density polyethylene outer sheath is extruded on the outermost layer of the cable. The 0.6 / 1 kV waterproof tensile power cable has the characteristics of structure stability, low skin effect, large carrying capacity, good water-blocking performance, corrosion resistance, oxidation resistance and the like, and is widely applied to power transmission between a mainland and an island and between islands as well as power transmission traversing bottoms of rivers, lakes and seas.

Owner:WUXI JIANGNAN CABLE

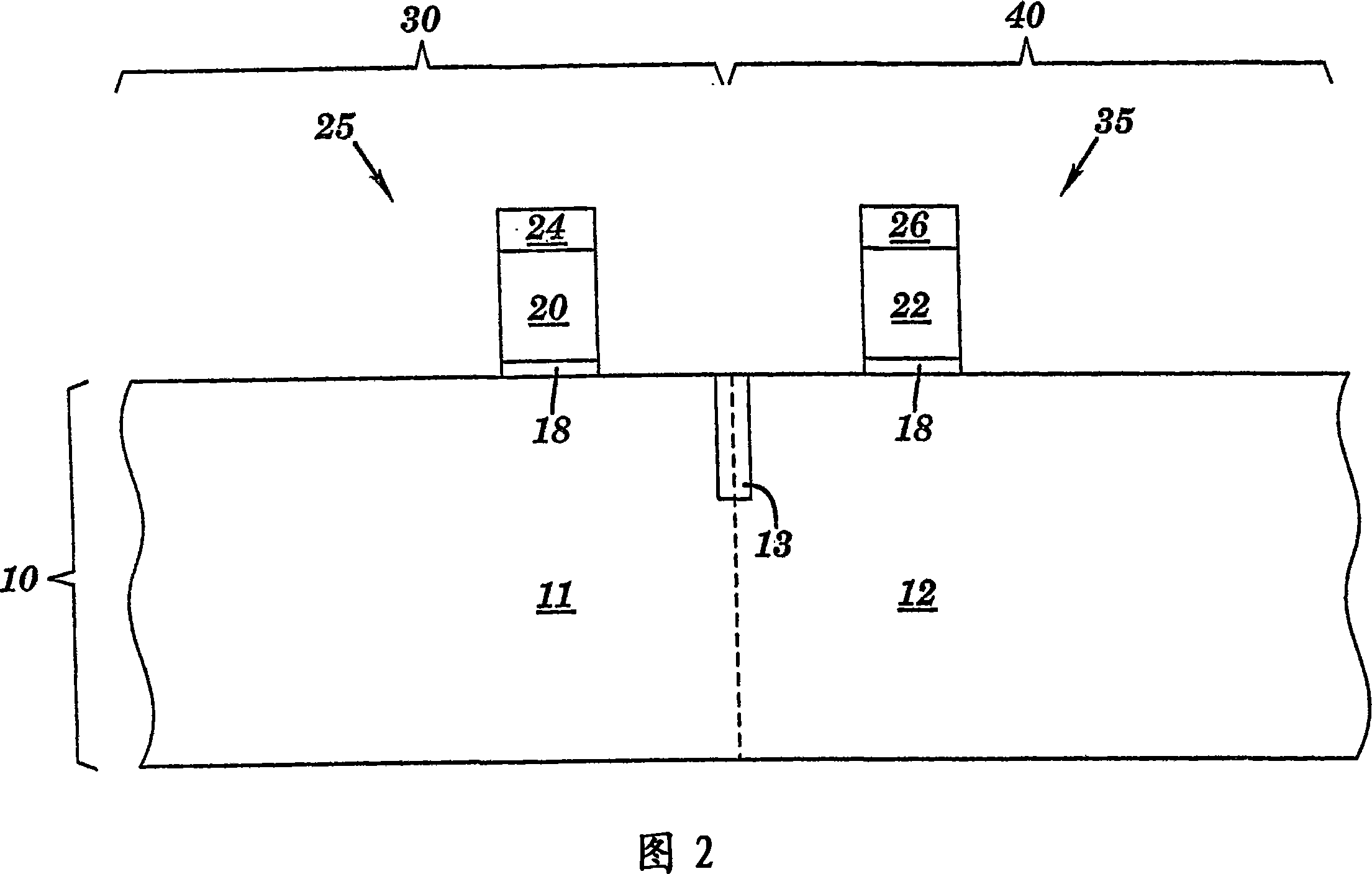

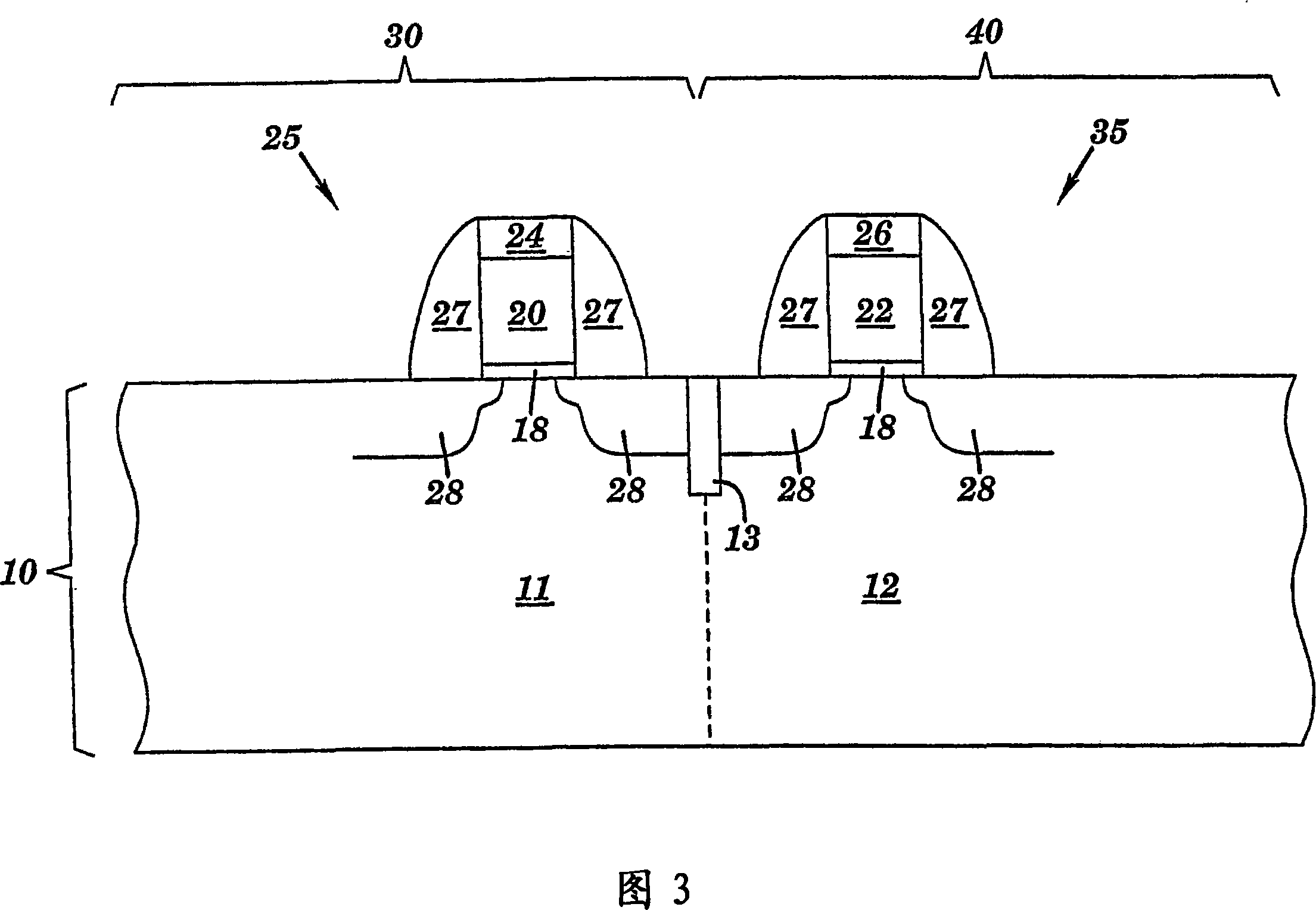

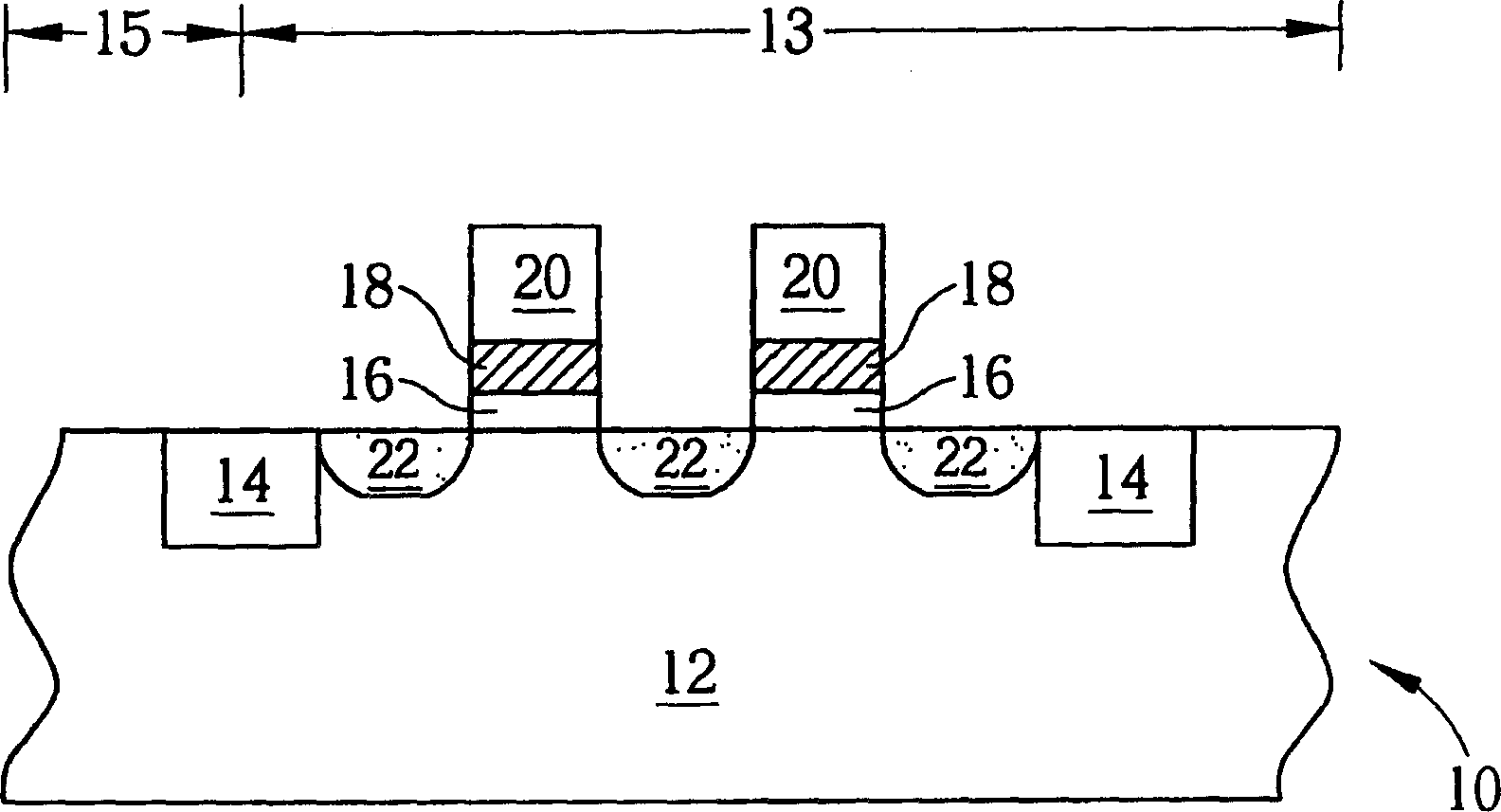

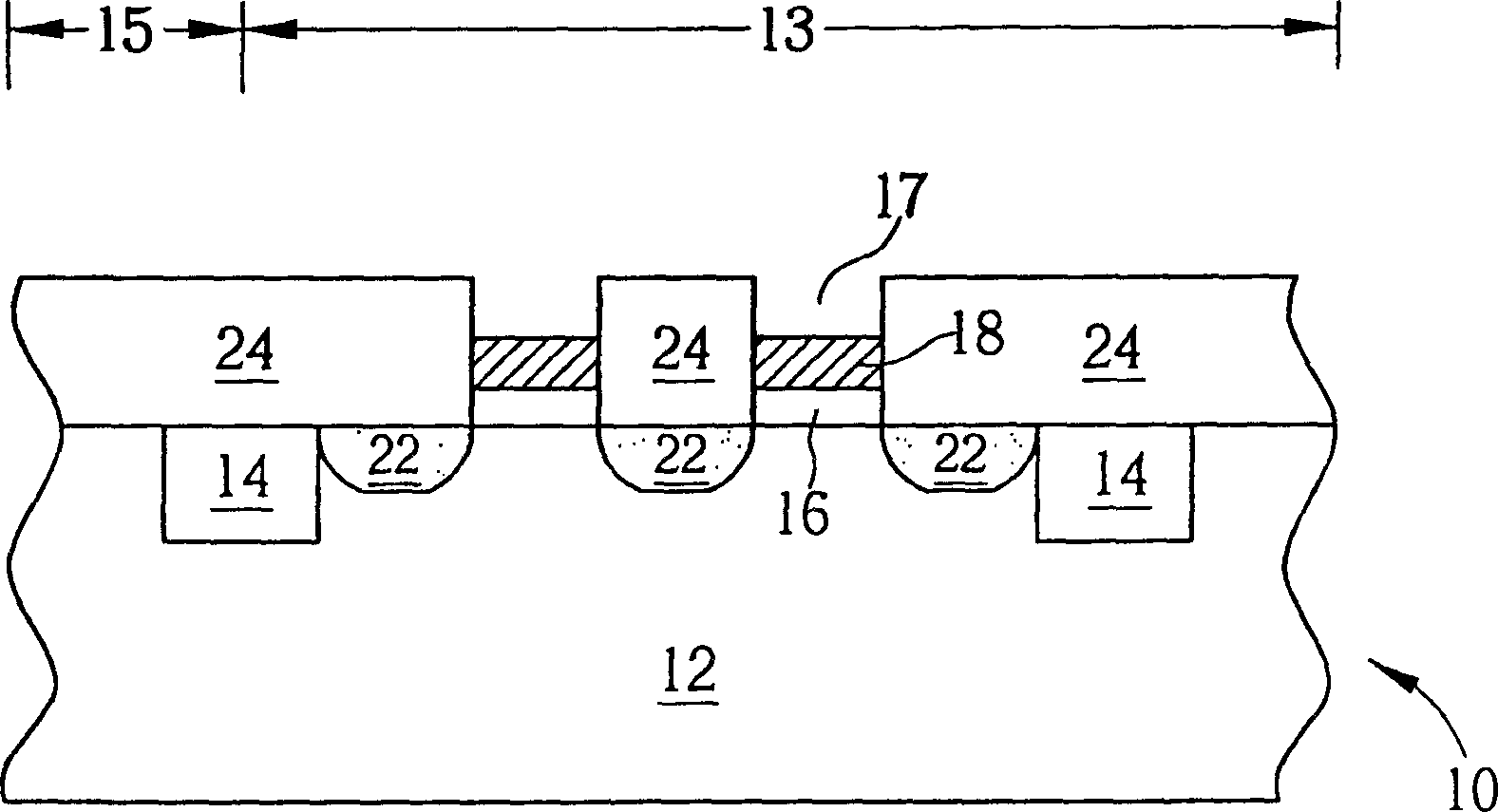

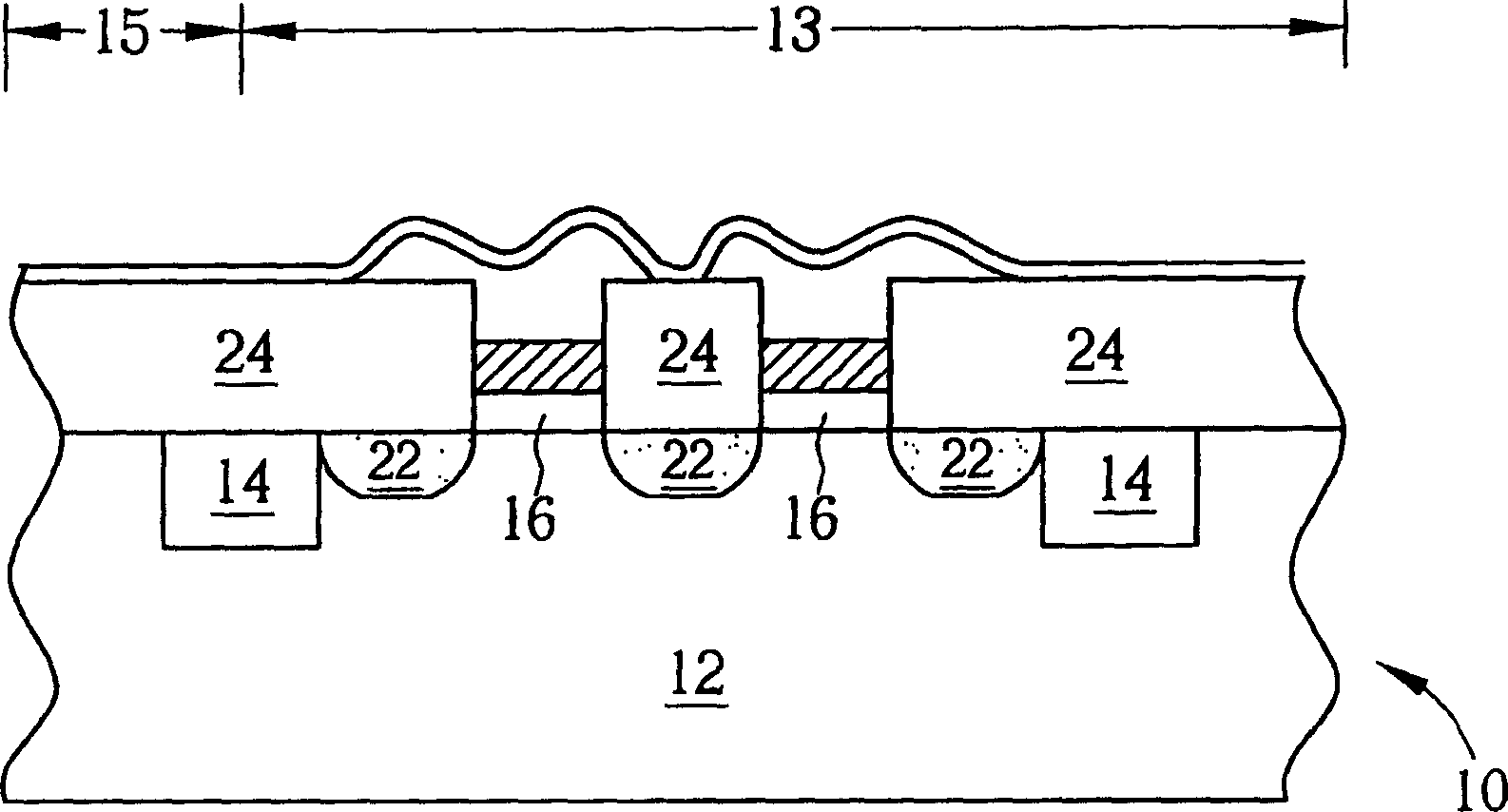

Metal gate mosfet by full semiconductor metal alloy conversion

InactiveCN101233611ADoes not interfere with electrical propertiesAffect electrical propertiesTransistorSemiconductor/solid-state device manufacturingMOSFETMetal alloy

Owner:INT BUSINESS MASCH CORP

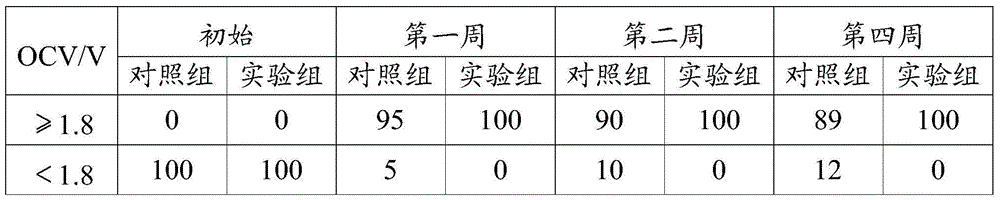

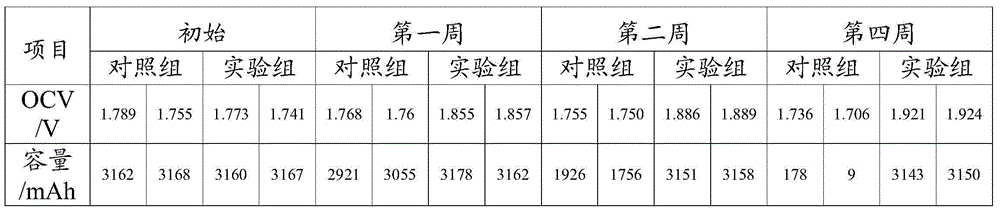

Impurity removal method for positive active material of lithium-ferrous disulfide battery

ActiveCN105161719AWon't happenAffect electrical propertiesCell electrodesSecondary cellsOrganic solventPhysical chemistry

The invention belongs to the technical field of primary lithium batteries, and discloses an impurity removal method for a positive active material of a lithium-ferrous disulfide battery. The method comprises the steps as follows: the positive active material containing ferrous disulfide powder is provided; the positive active material is extracted by an organic solvent; impurities are removed from the positive active material; the active material is subjected to vacuum drying; and an organic solvent is glycol dimethyl ether and / or 1,3-dioxolame. The impurities in the positive active material of the lithium-ferrous disulfide battery are extracted directly by a solvent component for preparing electrolyte, so that a new impurity is not introduced into the battery; the positive active material does not contact a lot of water to generate a Fe<2+> or Fe<3+> impurity; the extracted positive active material can be directly used after being dried; the problems that the electrical property, the storage property or the safety performance and the like of the battery are not affected by adding an additive to the battery are overcome; and the impurity removal method is relatively economical and applicable.

Owner:EVE ENERGY CO LTD

Electronic-grade low-dielectric glass fiber cloth treating agent and preparation method thereof

The invention belongs to the technical field of glass fiber treating agents, and particularly relates to an electronic-grade low-dielectric glass fiber cloth treating agent and a preparation method thereof. The electronic-grade low-dielectric glass fiber cloth treating agent is prepared from the following raw materials in percentage by weight of 0.6 to 1.2 percent of a coupling agent A, 0.3 to 0.8 percent of a coupling agent B, 0.01 to 1.5 percent of a coupling agent aid, 0.1 to 0.5 percent of alcohol, 0.1 to 0.5 percent of acid and the balance of water; the coupling agent A is a coupling agent containing vinyl; the coupling agent B is a coupling agent containing vinyl benzyl; and the coupling agent aid is salt of a maleic anhydride grafted modified copolymer. According to the treating agent, on the basis of meeting the low dielectric property, the bonding property of glass fiber cloth and low dielectric resin is improved, and meanwhile, the mechanical property and the heat resistance of the low dielectric glass fiber cloth are enhanced.

Owner:TAISHAN FIBERGLASS ZOUCHENG

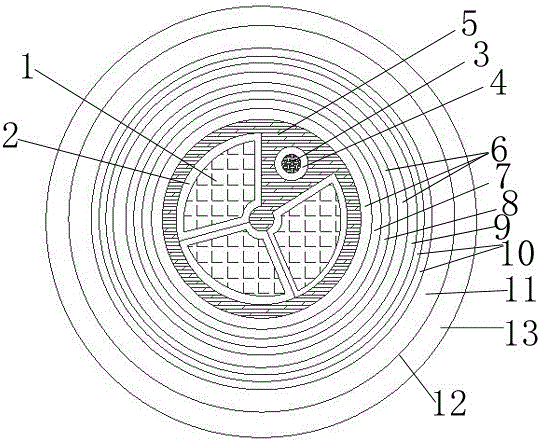

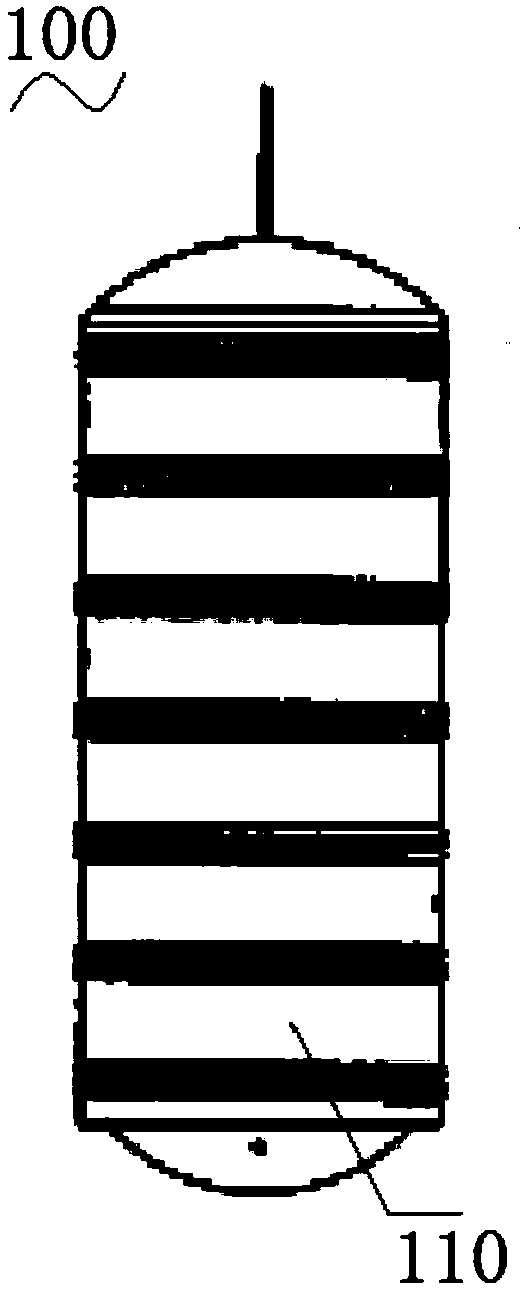

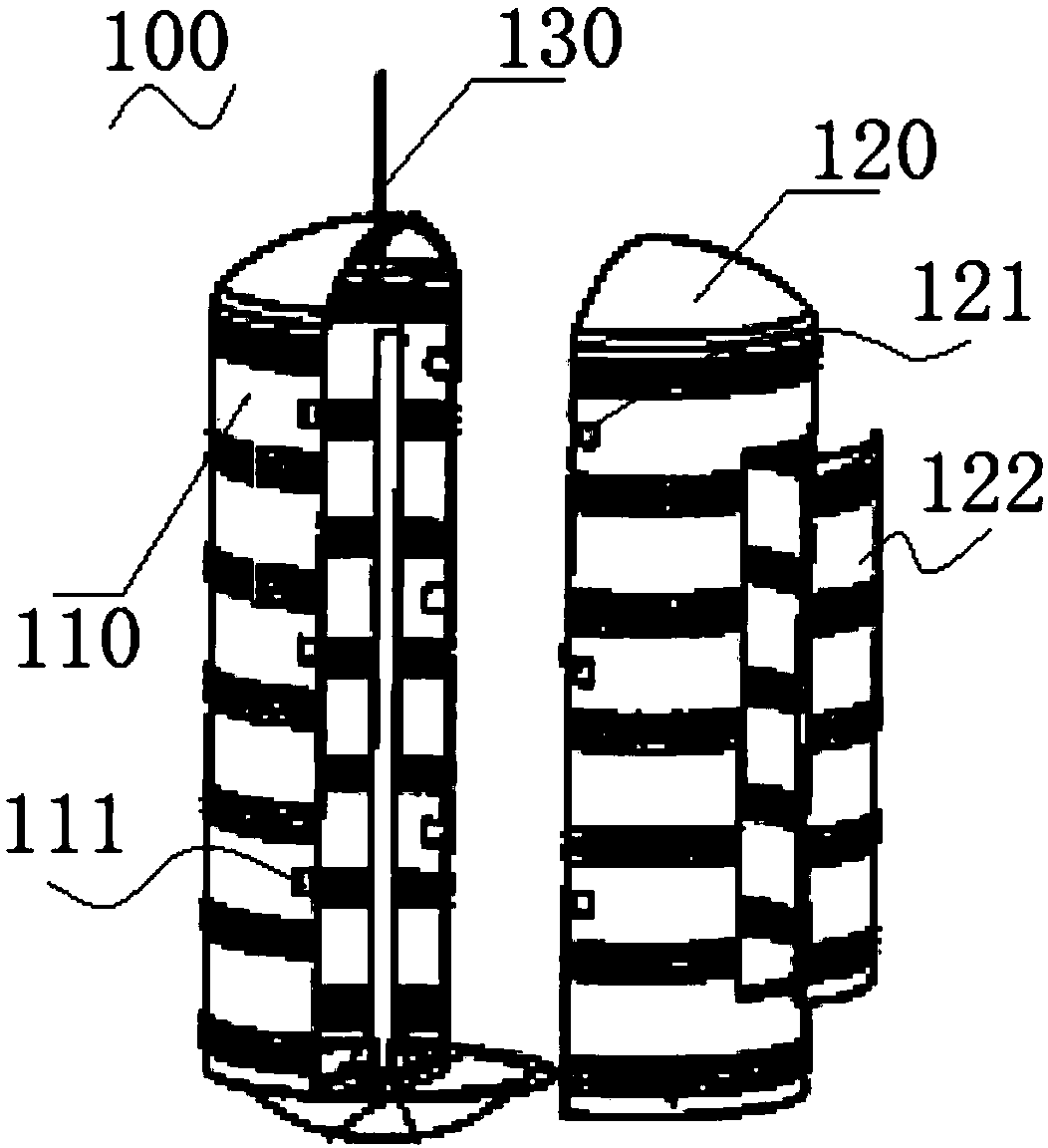

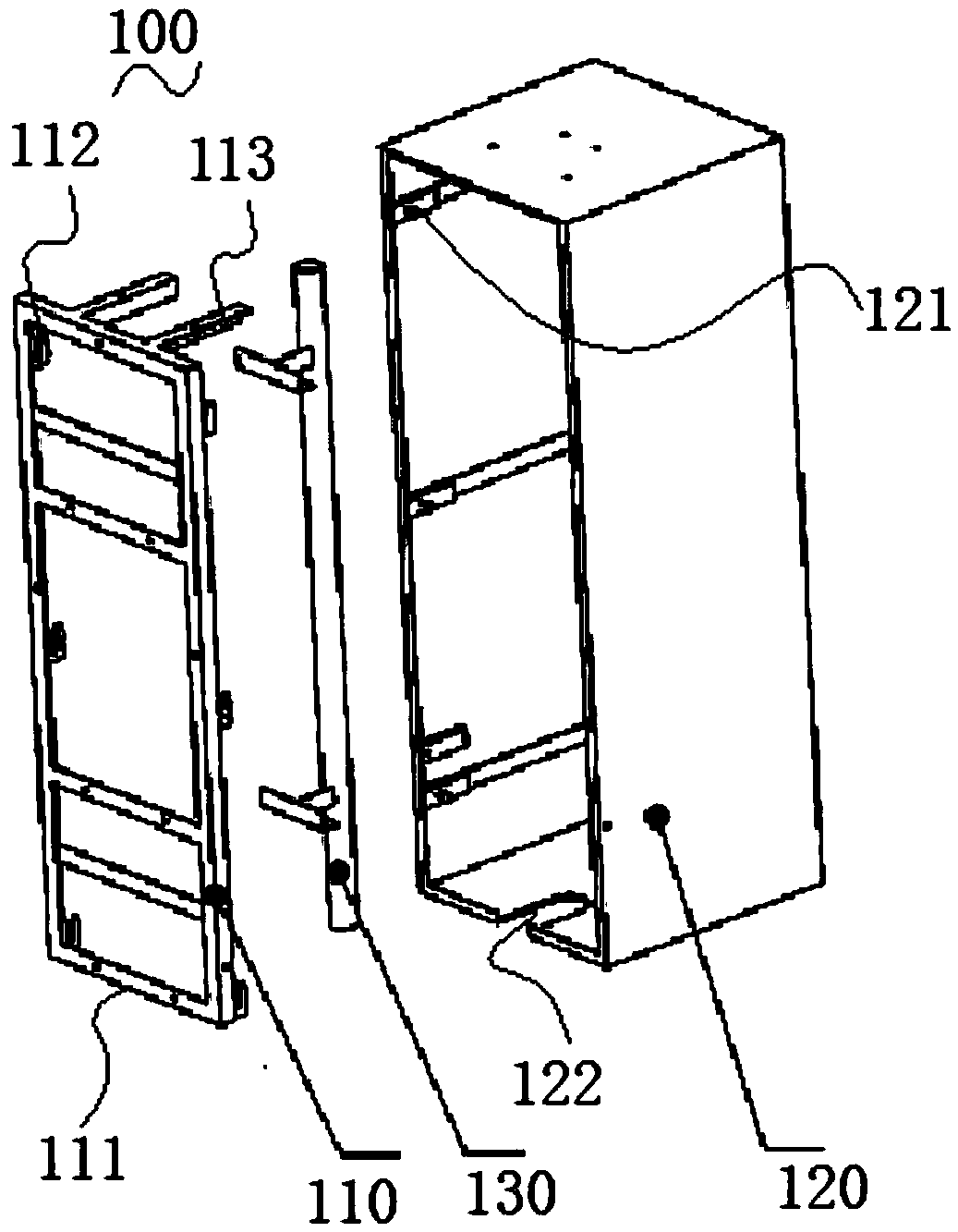

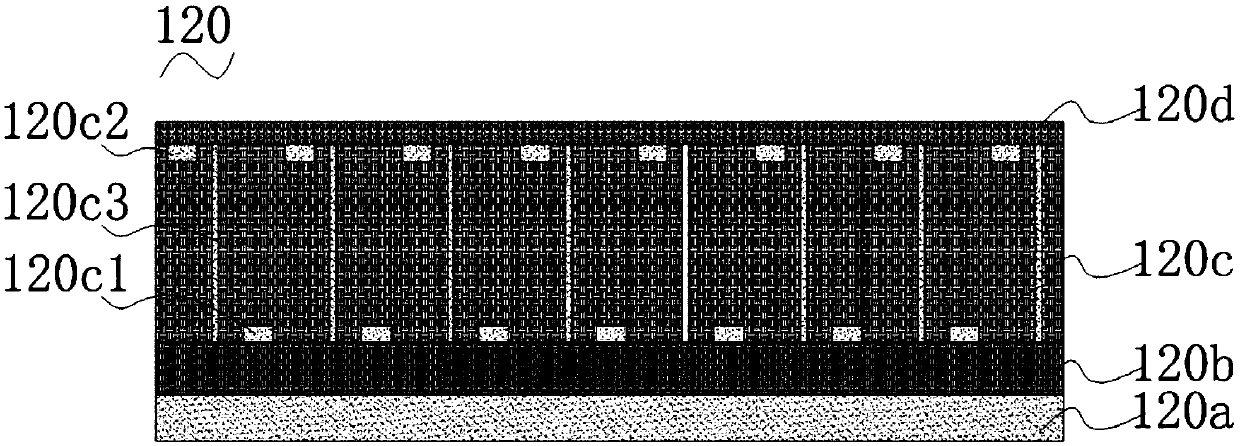

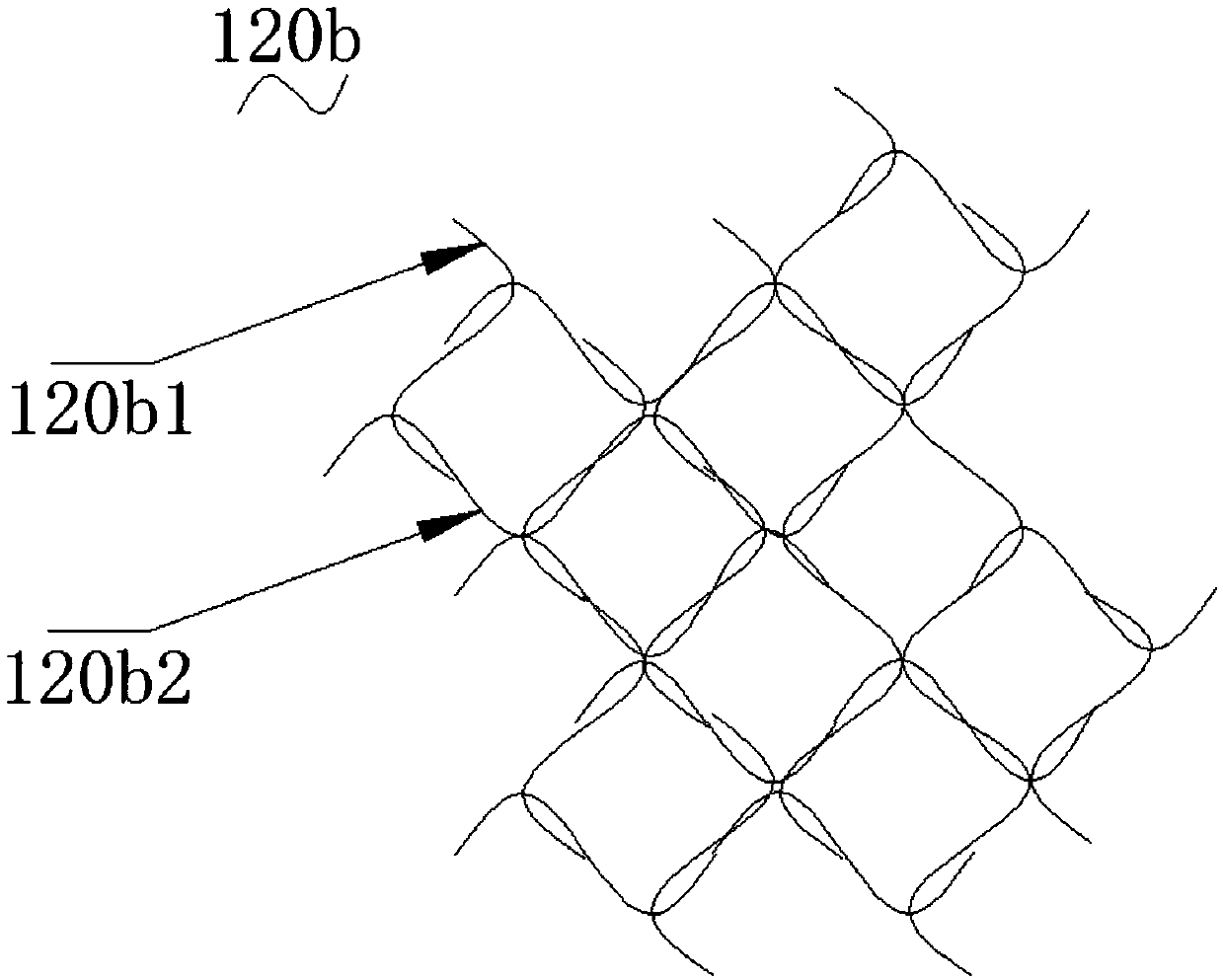

Low-density glass fiber reinforced plastic radome and production process thereof

The invention relates to the field of radomes, in particular to a low-density glass fiber reinforced plastic radome and production process thereof. The radome comprises a first protective cover and asecond protective cover which enclose a hollow water tower shape, and an antenna holding pole arranged in a hollow water tower-shaped cavity formed by the first protective cover and the second protective cover; the first protective cover is provided with a first clamping piece, and the second protective cover is provided with a second clamping piece corresponding to the first clamping piece of thefirst protective cover. The first clamping piece and the second clamping piece are connected so that the first protective cover and the second protective cover can be detachably connected to define ahollow water tower-shaped structure, and an openable and closable window convenient to overhaul is formed in the surface of the second protective cover; the high-wave-transmission fiber cloth layer comprises composite core-spun gauze formed by weaving carbon fiber core yarns and glass fiber weaving yarns and curing resin cured outside the composite core-spun gauze. The glass fiber reinforced plastic has the advantages of the low density, the light weight, the small dielectric constant, the good wave permeability, the high mechanical strength and the long service life.

Owner:DONGGUAN YANCHUN IND CO LTD

Insulated high-voltage optical fiber composite power cable

InactiveCN106531340AGuaranteed bending performanceGuaranteed air tightnessInsulated cablesPower cables including optical transmission elementsElectrical conductorAlkali free

The invention discloses an insulated high-voltage optical fiber composite power cable, comprising a solid aluminum conductor in the center of the cable, wherein four first solid aluminum shaped wires and then an annular second solid aluminum shaped wire are extruded outside the solid aluminum conductor; a low density polyethylene insulating layer is extruded outside the second aluminum shaped wire, a double-layer water blocking tape is superposed and lapped, a corrugated aluminum sheath is welded outside the water blocking tape, an alkali-free glass fiber tape is lapped outside the corrugated aluminum sheath, and a medium density polyethylene outer sheath is finally extruded at the outermost layer of the cable; and an optical fiber is arranged in each first solid aluminum shaped wire. The composite power cable has the characteristics of good water blocking performance, good corrosion, oxidation and heat resistance, no mechanical damage and the like, the temperature and the transmission load of the power cable can be monitored in real time, and the power cable can be used for 'three-network fusion'.

Owner:WUXI JIANGNAN CABLE

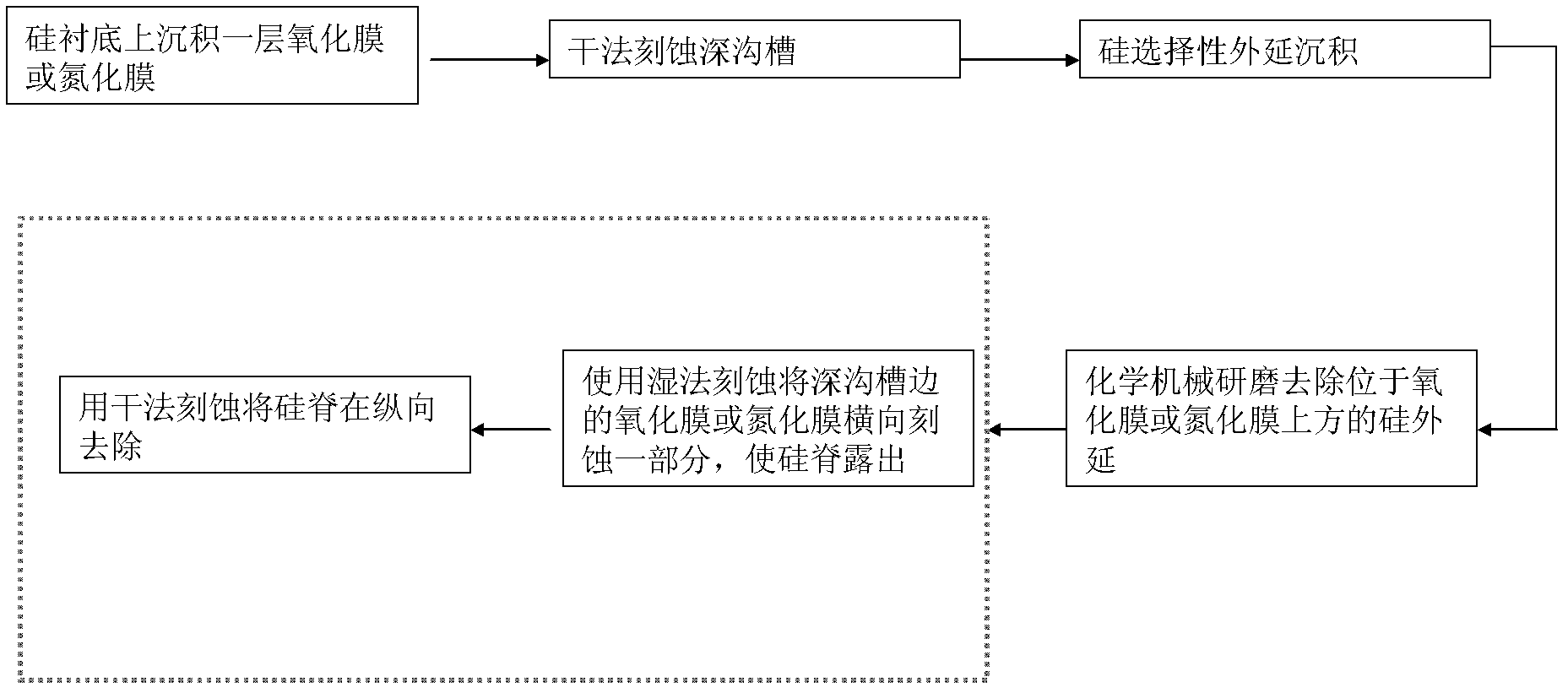

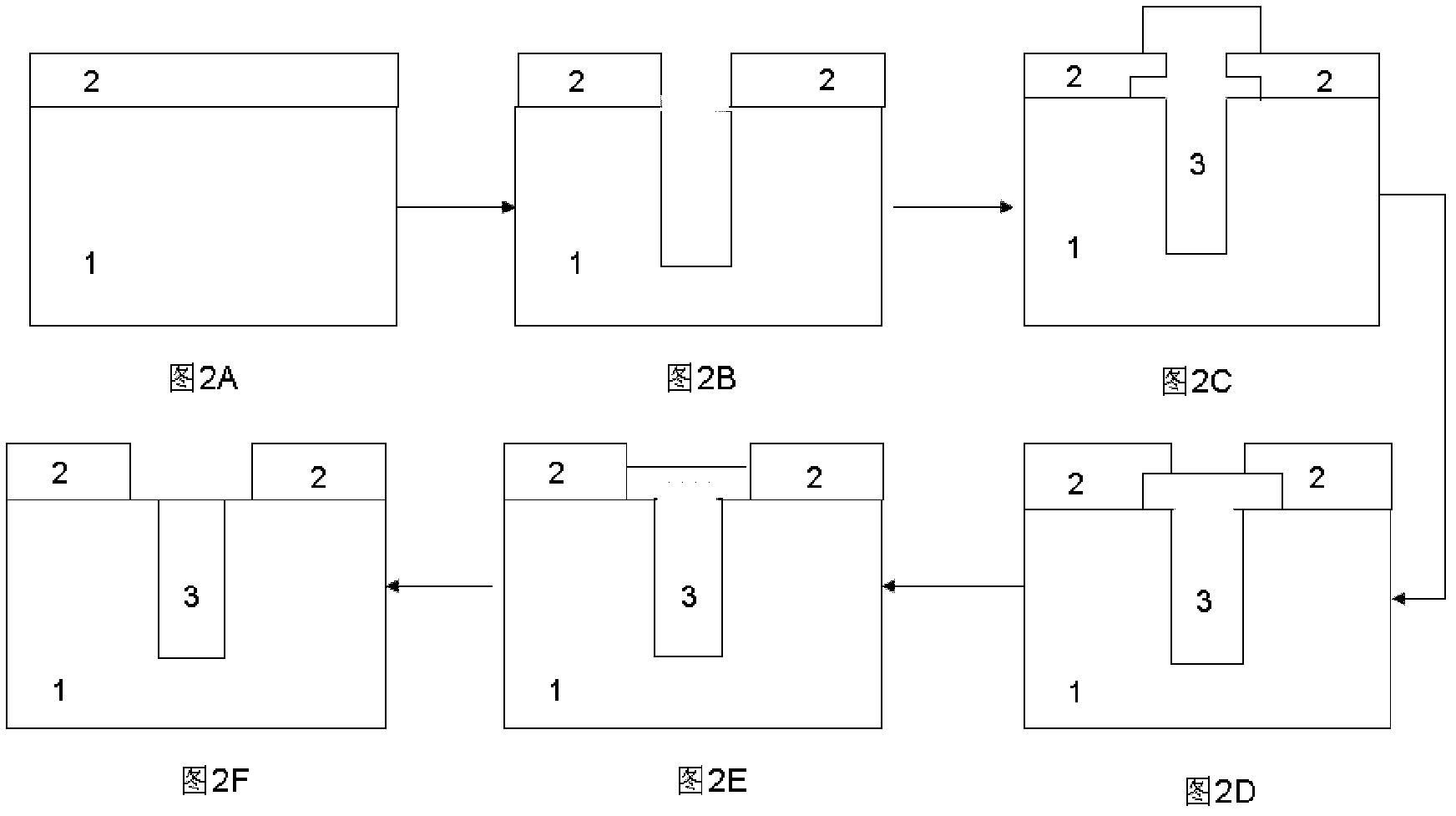

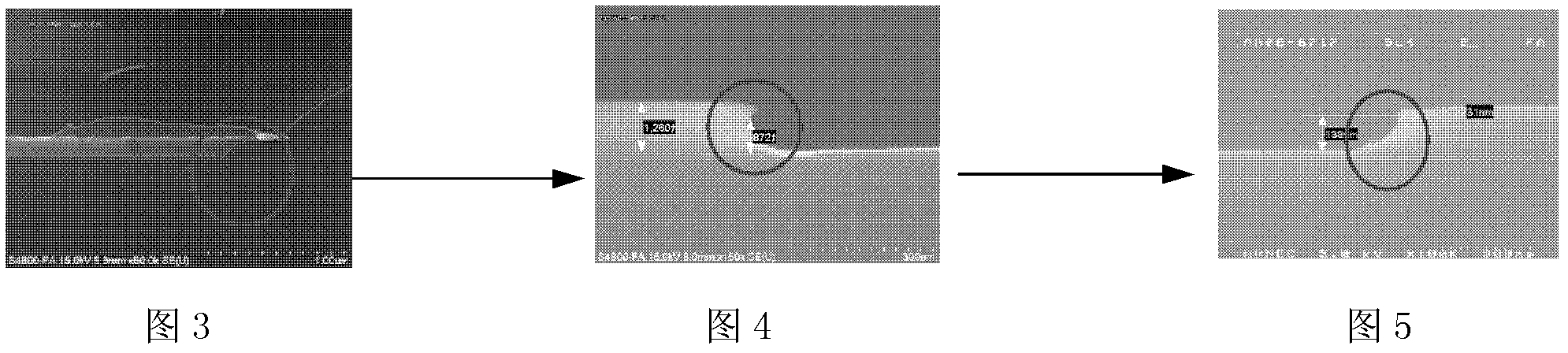

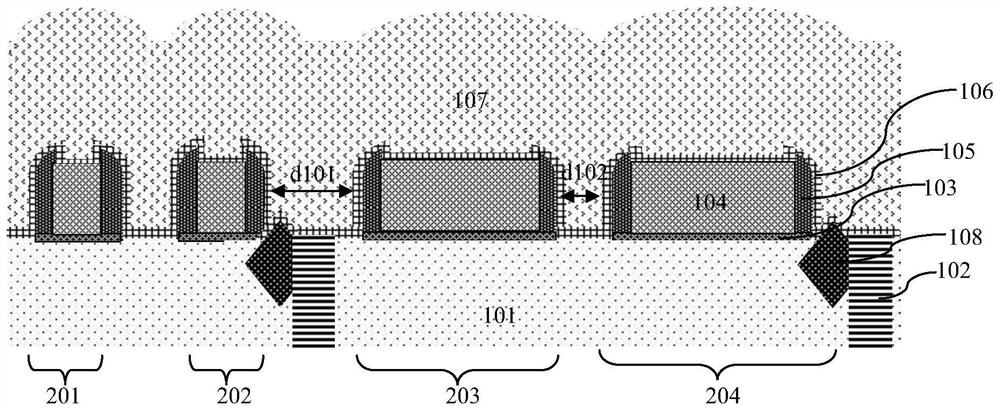

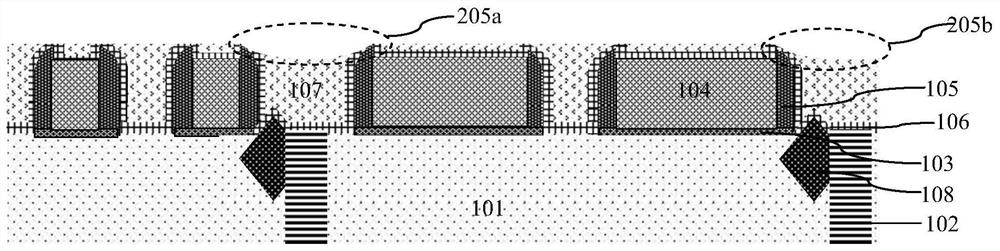

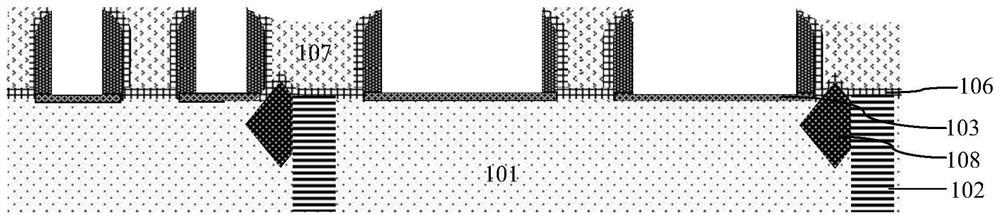

Method for removing silicon ridge produced in epitaxial deposition of super-junction high-pressure device

ActiveCN103000519AAffect electrical propertiesAvoid Process EffectsSemiconductor/solid-state device manufacturingHigh pressureSilicon chip

The invention discloses a method for removing silicon ridge produced in epitaxial deposition of a super-junction high-pressure device. The method includes the steps of firstly, depositing a layer of oxide film and / or nitride film on the surface of a silicon chip; secondly etching a deep groove on the silicon chip; thirdly, filling the deep groove with monocrystalline silicon or polycrystalline silicon; fourthly, performing planarization to the surface of the silicon chip by chemical mechanical grinding process, and using the oxide film and / or nitride film as a grinding retaining layer; fifthly, performing back-etching to the part of the oxide film and / or nitride film on two sides of the deep groove by etching process to expose the silicon ridge; and sixthly, etching the silicon ridge to remove by the etching process. The monocrystalline silicon in a bottom cut produced in an oxidation layer due to the fact that etching gas is guided in the epitaxial process can be removed, and accordingly the following gate polycrystalline silicon and the gate oxidation layer are provided with fine surface appearance, the following processes can be prevented from influence of the silicon ridge and certain electric performance of the device is free of influence.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

High-wave-transmission high-strength carbon fiber glass fiber composite glass fiber reinforced plastic radome and production process thereof

ActiveCN110534867AGuaranteed uptimeEasy to install and maintainAntenna supports/mountingsRadiating element housingsYarnFiber

The invention relates to the field of radomes, in particular to a high-wave-transmission high-strength carbon fiber glass fiber composite glass fiber reinforced plastic radome and a production processthereof. The high-wave-transmission high-strength carbon fiber glass fiber composite glass fiber reinforced plastic radome comprises a mounting based mounted on a wall, a protective cover arranged outside the mounting base in an openable and closable covering mode, and an antenna holding pole located in a cavity defined by the mounting base and the protective cover. The glass fiber reinforced plastic base layer comprises in parts by mass: 50-80 parts of unsaturated polyester resin, 5-20 parts of glass fibers, 2-15 parts of carbon nanotubes, 0.5-4 parts of 1, 3-butanediol, 5-30 parts of a heat-resistant modifier, 5-10 parts of a low shrinkage agent, 1-5 parts of a release agent, 5-15 parts of a coupling agent, 1-5 parts of fluorinated graphene, 1-5 parts of an initiator and 1-5 parts of athickener. The high-wave-transmission fiber cloth layer comprises composite core-spun gauze formed by weaving carbon fiber core yarns and glass fiber weaving yarns and curing resin cured outside the composite core-spun gauze. The glass fiber reinforced plastic has the advantages of the small dielectric constant, the good wave permeability, the high mechanical strength and the long service life.

Owner:DONGGUAN YANCHUN IND CO LTD

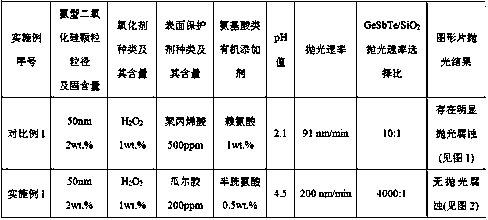

Chemico-mechanical polishing solution for phase-change material GeSbTe

InactiveCN108129991AAchieve mechanical removalEfficient removalPolishing compositions with abrasivesWater basedPhase-change material

The invention relates to a chemico-mechanical polishing solution for a phase-change material GeSbTe. The chemico-mechanical polishing solution for the phase-change material GeSbTe is prepared from anammonia type nanosilicon dioxide grinding material, an oxidizing agent, a water-soluble polymer surface protecting agent, an amino acid organic additive and a water-based medium. The chemico-mechanical polishing solution provided by the invention is applicable to a chemico-mechanical polishing process of the phase-change material GeSbTe, is high in polishing rate reaching to 200nm / min and high inGeSBTe / SiO2 polishing selection ratio reaching to 4000:1, and has no polishing etch defect.

Owner:浙江晶圣美纳米科技有限公司

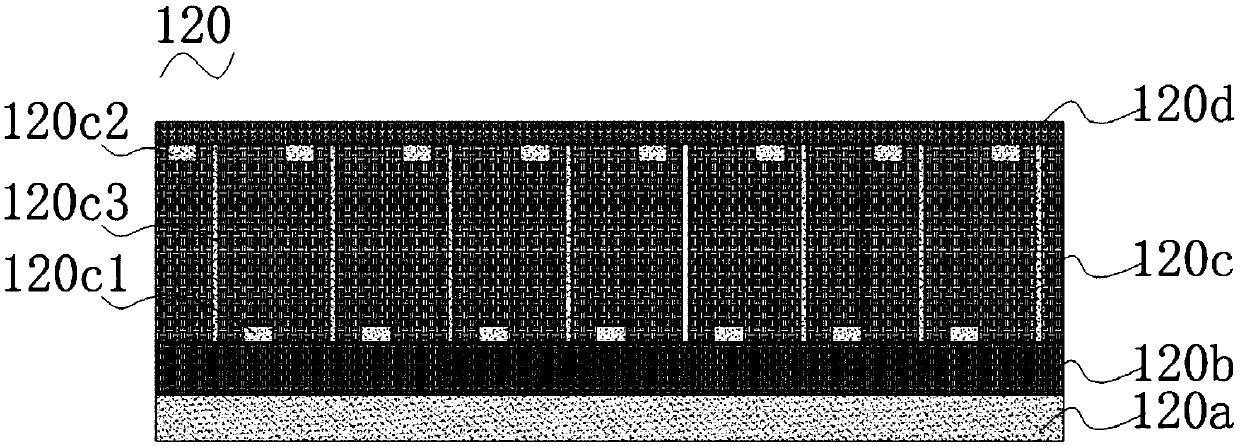

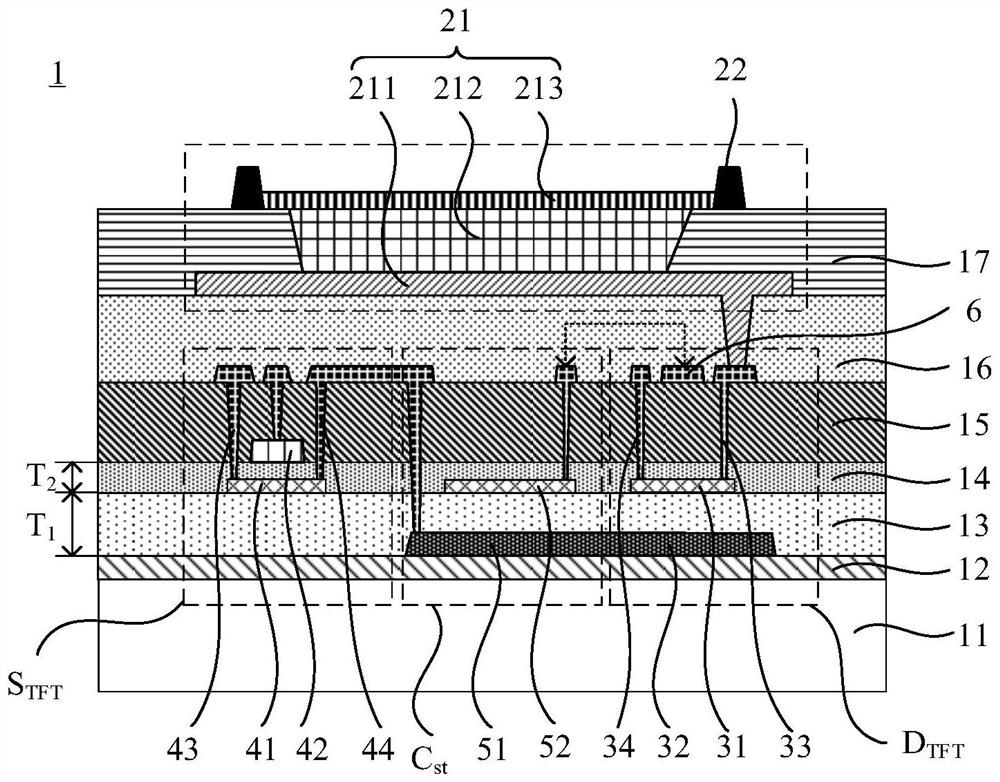

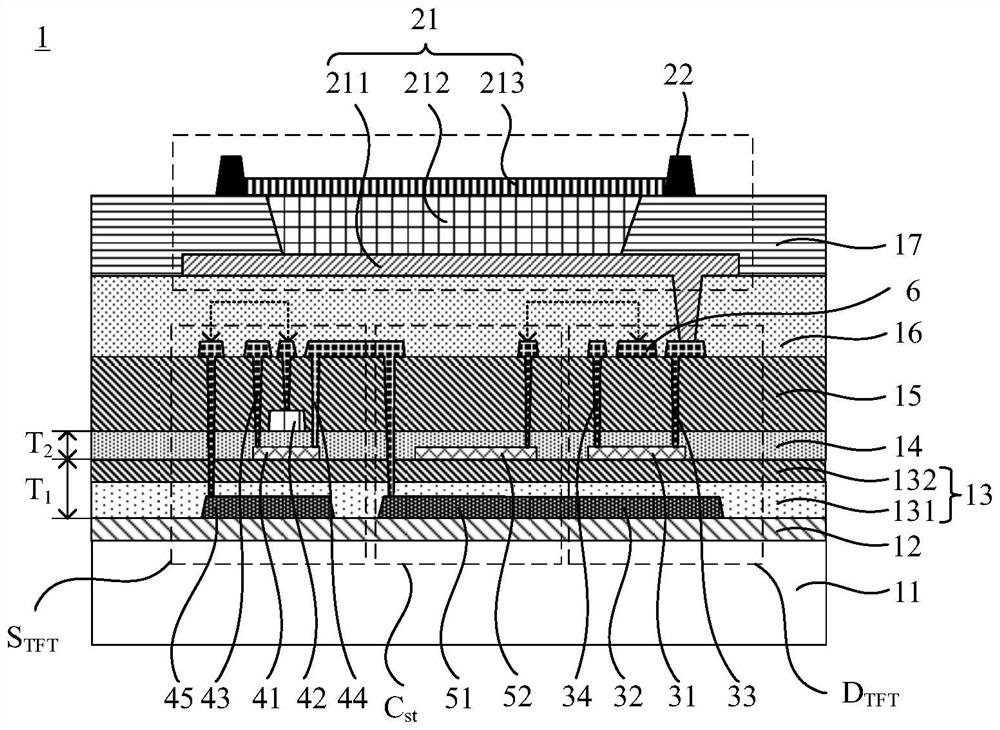

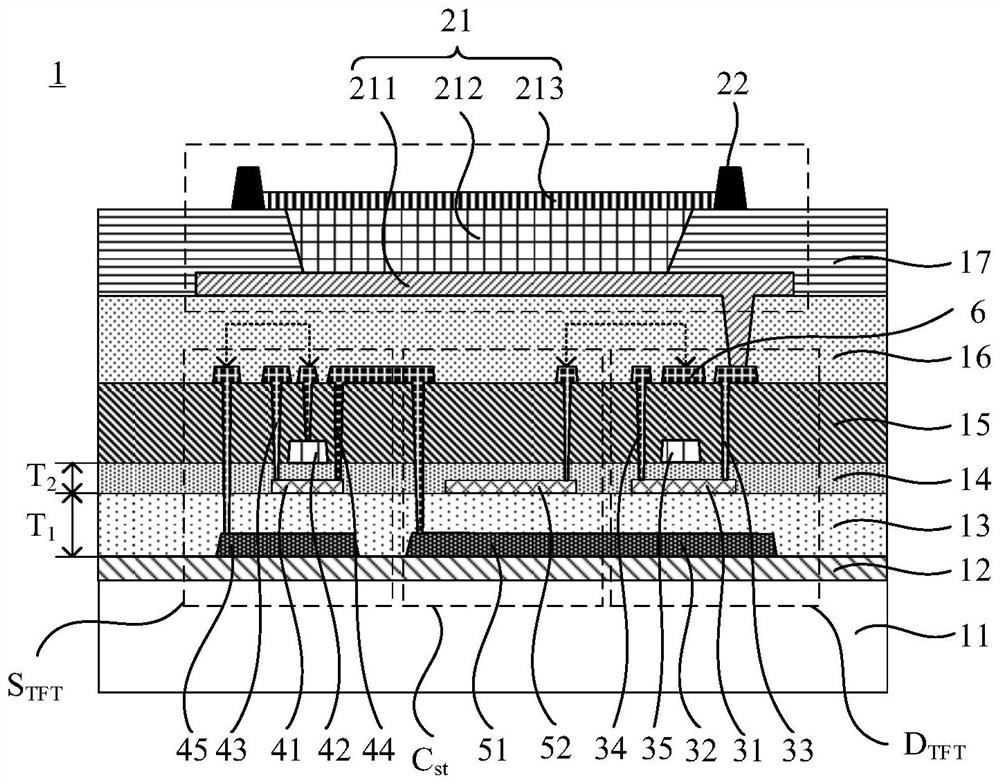

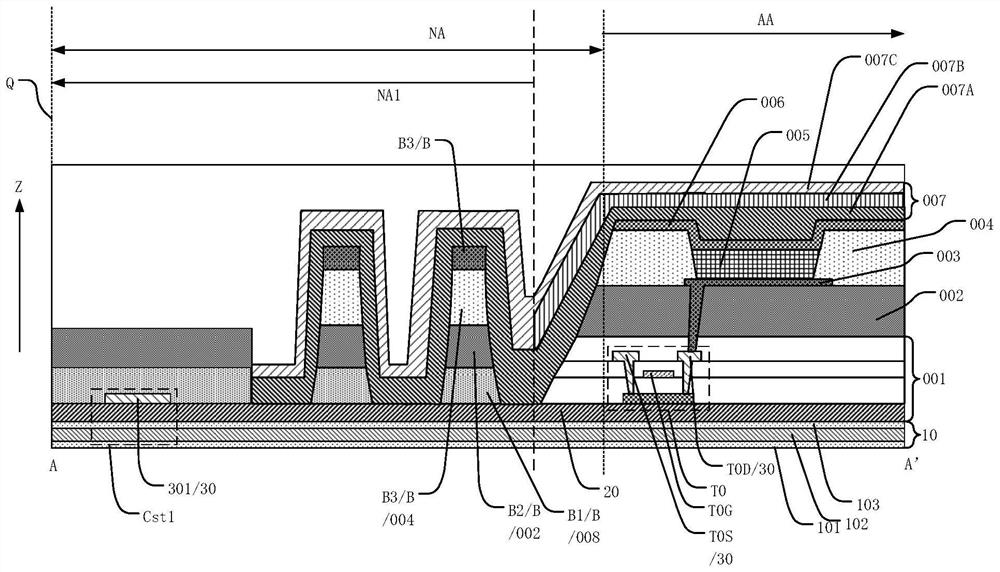

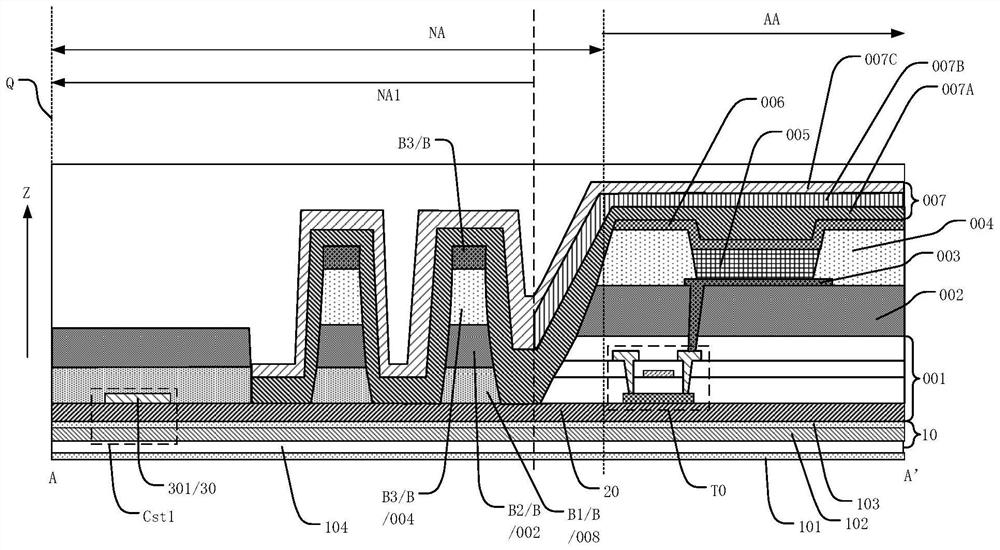

Display substrate, preparation method thereof and display device

PendingCN114256314ASimple processReduce or eliminate floating body effectSolid-state devicesSemiconductor devicesDisplay deviceHemt circuits

The invention relates to a display substrate, a preparation method thereof and a display device. The display substrate comprises a substrate and a plurality of driving circuits arranged on the substrate. The driving circuit includes a driving transistor and a switching transistor. The driving transistor comprises a first active layer and a first grid electrode located on the side, close to the substrate, of the first active layer. The switch transistor comprises a second active layer arranged on the same layer as the first active layer, and a second grid electrode located on the side, away from the substrate, of the second active layer. According to the display substrate, the preparation method thereof and the display device, the display performance of the display substrate can be improved, and the manufacturing process of the display substrate is simplified.

Owner:HEFEI VISIONOX TECH CO LTD

Method of reducing microparticle residue and defect

InactiveCN1459845AIncreasing the thicknessAffect electrical propertiesSemiconductor/solid-state device manufacturingResistElectrical conductor

A process for decreasing the residual microparticles and defects includes providing a semiconduct chip containing the first area covered by a oxide-nitride-oxide (ONO) layer and the second area covered by the second and the first polysilicon layers, an oxide layer, and said ONO layer, generating a photoresist layer on ONO layer to cover the first area, dry etching on said ONO layer and two polysilicon layers in the second area, removing the photoresist layer, flushing with a buffer oxide layer etching liquid for removing oxide layer, and flushing with SC-1 solution and then with SC-2 solution.

Owner:MACRONIX INT CO LTD

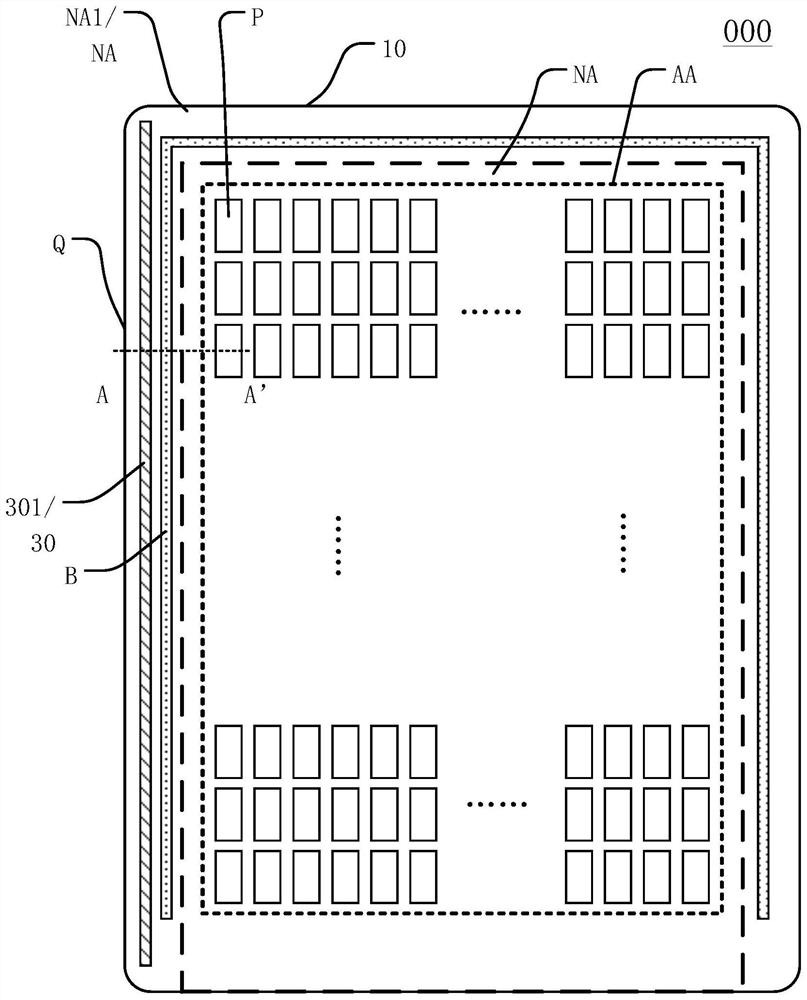

Display panel and display device

PendingCN114784016AAvoid enteringShorten speedSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

The invention discloses a display panel and a display device, and belongs to the technical field of display, the display panel comprises a display area and a non-display area at least partially surrounding the display area, the non-display area at least comprises a first non-display area, the first non-display area comprises a cutting edge and a retaining wall, and the display panel comprises a first substrate, the first substrate at least comprises a first substrate, a first conductive layer and a second substrate which are arranged in a stacked mode, the first insulating layer is located on the side, away from the first substrate, of the second substrate, the first metal layer is located on the side, away from the first substrate, of the first insulating layer, and in the first non-display area, the first metal layer comprises at least one first part; the first part is located between the cutting edge and the retaining wall in the direction from the first non-display area to the display area. The display device comprises the display panel. The speed of static electricity entering the screen body can be effectively reduced, the electrostatic protection capability is improved, and the product yield and the display quality can be improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

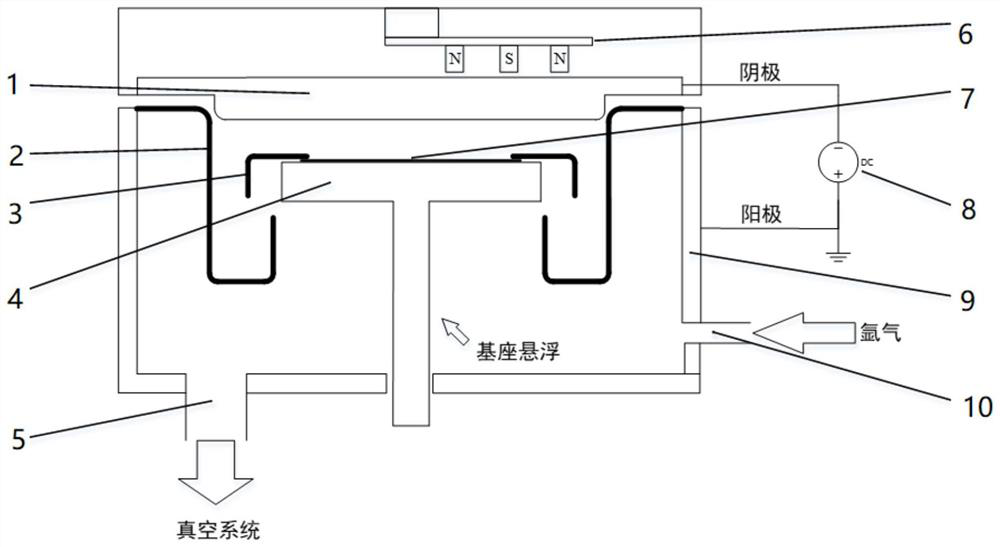

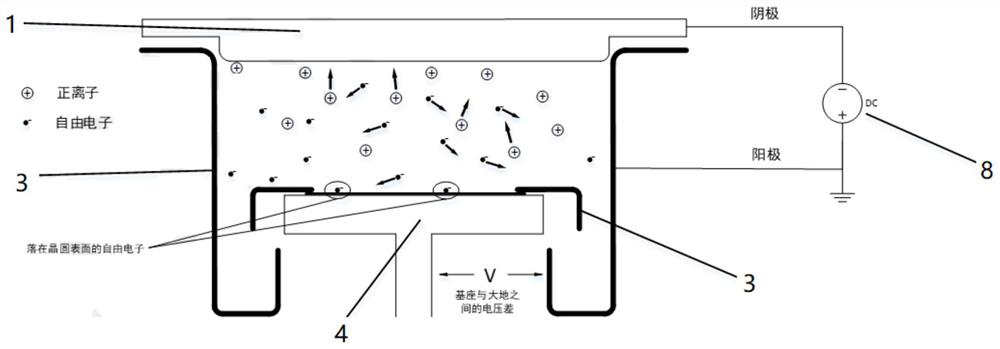

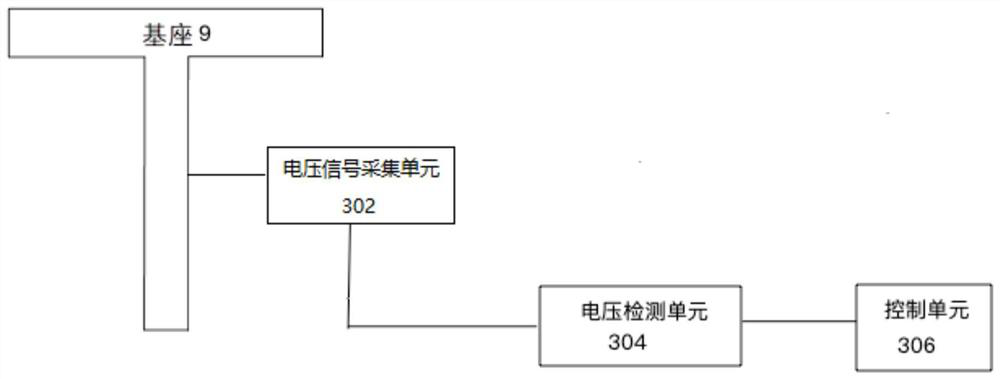

Pedestal grounding detection device and method

PendingCN114355244AAffect electrical propertiesAvoid affecting product qualityVacuum evaporation coatingSputtering coatingOvervoltageWafer

The invention relates to a pedestal grounding detection apparatus and method. A voltage signal of a base is acquired through a voltage signal acquisition unit, and a voltage detection unit determines whether to take a first signal indicating that the base is grounded as an output signal or not according to the voltage signal and a preset voltage signal; and once the control unit receives the first signal, the control unit immediately indicates the semiconductor equipment to stop executing the process and sends out an alarm signal, so that the grounding condition caused by short circuit between the base and the chamber wall or the lining and the like can be found in time, and the accidents that the electrical performance of the wafer is seriously influenced and the product quality is influenced because the wafer is broken down by current are avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

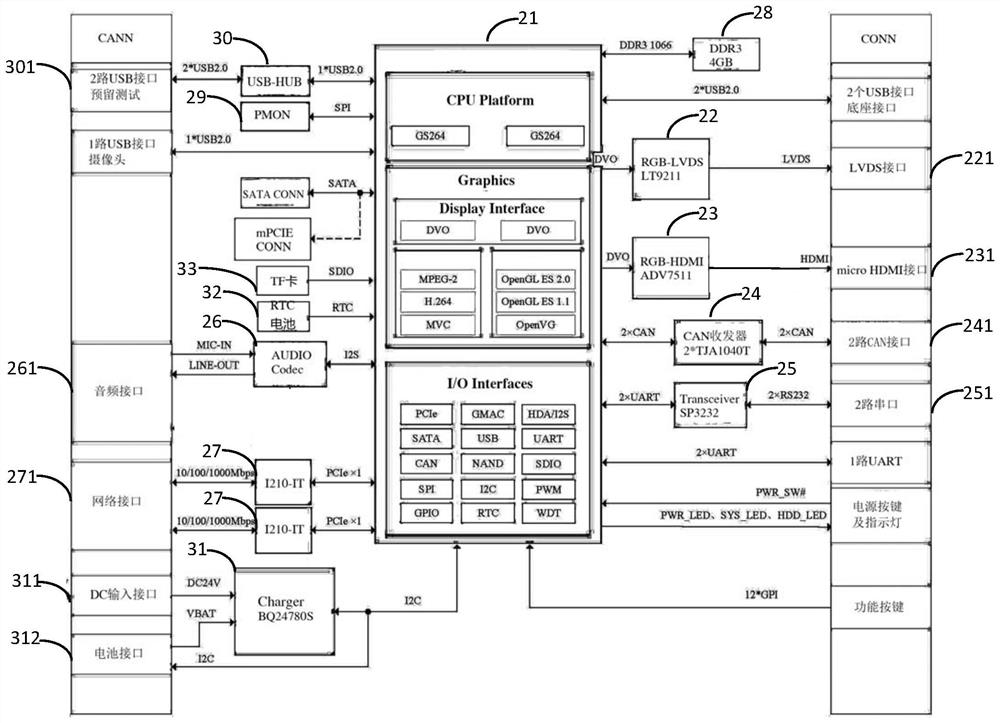

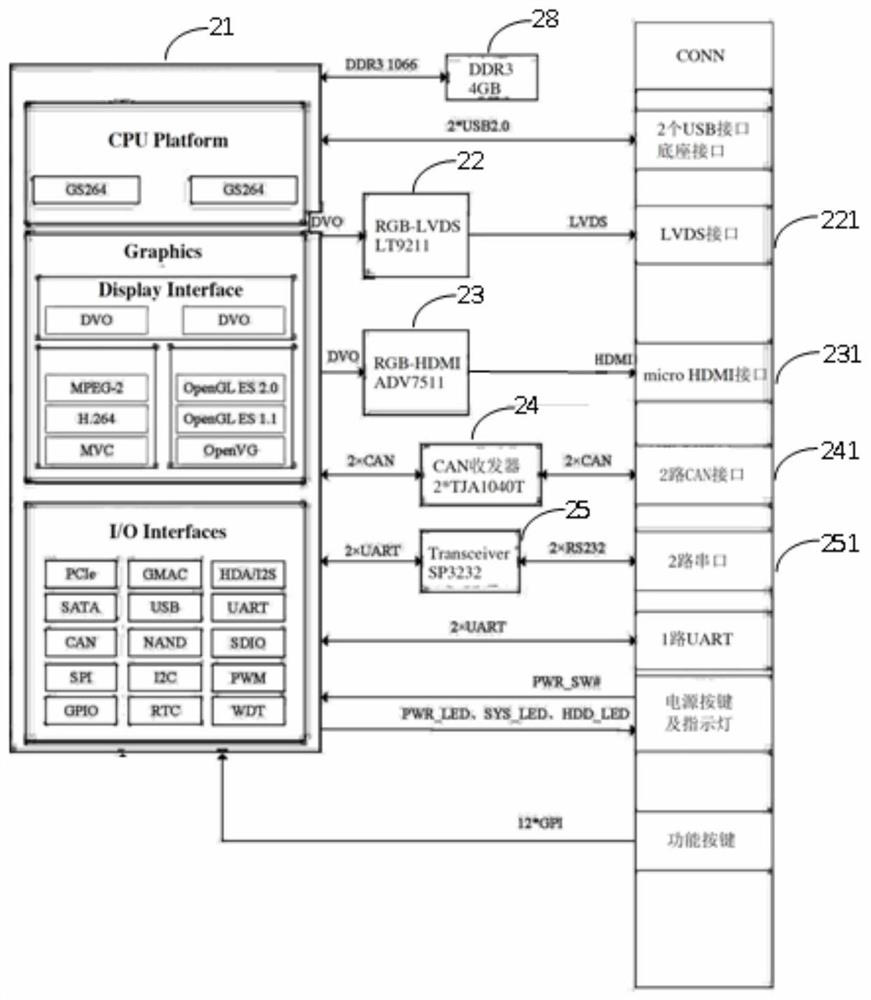

Domestic control mainboard based on Loongson 2K

PendingCN113056096AAffect electrical propertiesImprove protectionPrinted circuit non-printed electric components associationCircuit thermal arrangementsTransceiverEngineering

The invention discloses a domestic control mainboard based on Loongson 2K. The domestic control mainboard comprises a Loongson 2K chip, a video bus conversion module, a format conversion module, a CAN transceiver, a level conversion module, an audio conversion module, a network chip and a memory used for information storage, which are installed on a PCB. A plurality of blind holes used for connecting a first conductive pattern layer and a second conductive pattern layer are formed in a second dielectric layer, a heat dissipation block with clamping blocks at the two side ends is embedded into a mounting groove of an aluminum substrate, and the clamping blocks of the heat dissipation block are embedded into clamping grooves of the mounting groove; and a plastic sleeve with a through hole allowing a bolt to be embedded in is embedded in a mounting through hole, the upper portion, located above the aluminum substrate, of a plastic sleeve is provided with a wide-opening extension portion, the lower portion, located below the aluminum substrate, of the plastic sleeve is provided with an outer protruding portion, and the blind hole is composed of an arc hole and a conical hole communicated with the bottom of an arc hole. According to the invention, the resistance is reduced, the reliability is improved, efficient real-time acquisition, processing and transmission of signals and battery management are also realized, and the functions of products are conveniently expanded.

Owner:苏州匠致电子科技有限公司

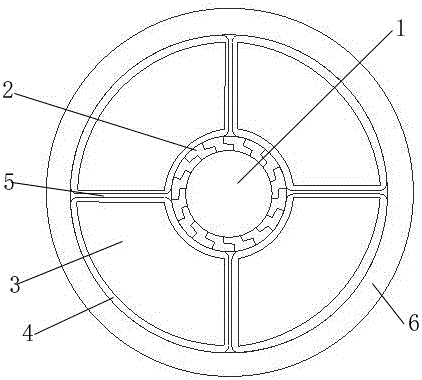

Water-blocking super-large section hollow split conductor

InactiveCN106782826AIncrease conductor cross sectionIncrease transmission capacitySingle bars/rods/wires/strips conductorsInsulated cablesBlocking layerSkin effect

The invention discloses a water-blocking super-large section hollow split conductor. The center of the conductor is provided with a hollow layer or a filled water-blocking layer; a single conductor single-line layer is arranged outside the hollow layer or the filled water-blocking layer; a plurality of corrugated conductor blocks are arranged outside the conductor single-line layer; a corrugated water-blocking layer is arranged outside each corrugated conductor block; a gap among the corrugated water-blocking layers is provided with a water-blocking filling strip; and a water-blocking layer is arranged outside the plurality of corrugated conductor blocks. The water-blocking super-large section hollow split conductor has the characteristics of being low in characteristic requirements on a tooling mold and equipment, stable in structure, low in skin effect, high in carrying capacity and good in water-blocking property, corrosion resistance and oxidation resistance, and the difficulty of the production technology is reduced.

Owner:WUXI JIANGNAN CABLE

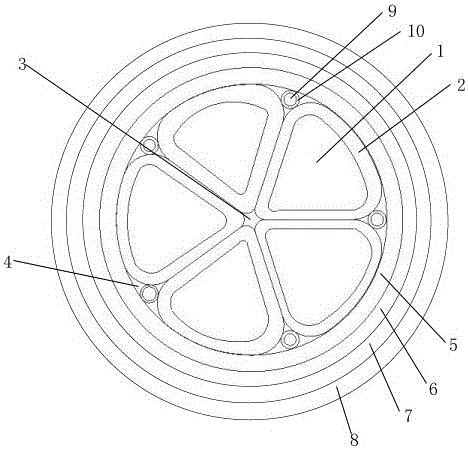

Multilayer segmented conductor type water-blocking power cable with built-in cable

InactiveCN106531305AWon't hurtNo lossPower cables including optical transmission elementsFlexible cablesFiberAlkali free

The invention discloses a multilayer segmented conductor type water-blocking power cable with a built-in cable. The center of the cable is equipped with a segmented conductor layer. The segmented conductor layer is formed by assembling a plurality of segmented fan-shaped conductor strand blocks and a fan-shaped strand block water-blocking layer arranged out of each segmented fan-shaped conductor strand block. A water-blocking rope is filled in a center gap after the plurality of fan-shaped strand block water-blocking layers are assembled. A round conductor is arranged in each fan-shaped conductor strand block. A round water-blocking layer is arranged out of each round conductor. Water-blocking blocks are filled in the gaps among the fan-shaped strand block water-blocking layers, a water-blocking tape and silk thread bundles. A polyethylene insulating layer, a vertical structure water-blocking layer, a metal armored layer and an alkali-free glass optical fiber tape are extruded out of the segmented conductor layer in sequence. According to the cable, the conductor water-blocking structure and the external water-blocking structure are combined mutually, the conductor is not oxidized and corroded due to water immersion, the electric performance of the cable is prevented from being influenced and an abnormal cable breakage event is prevented from occurring.

Owner:WUXI JIANGNAN CABLE

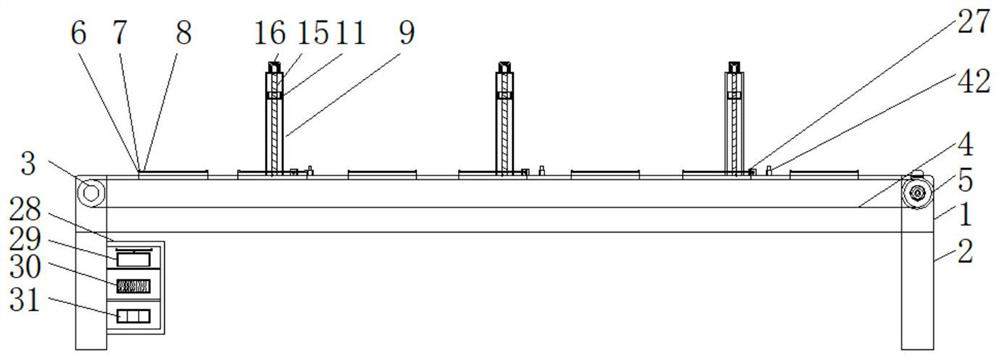

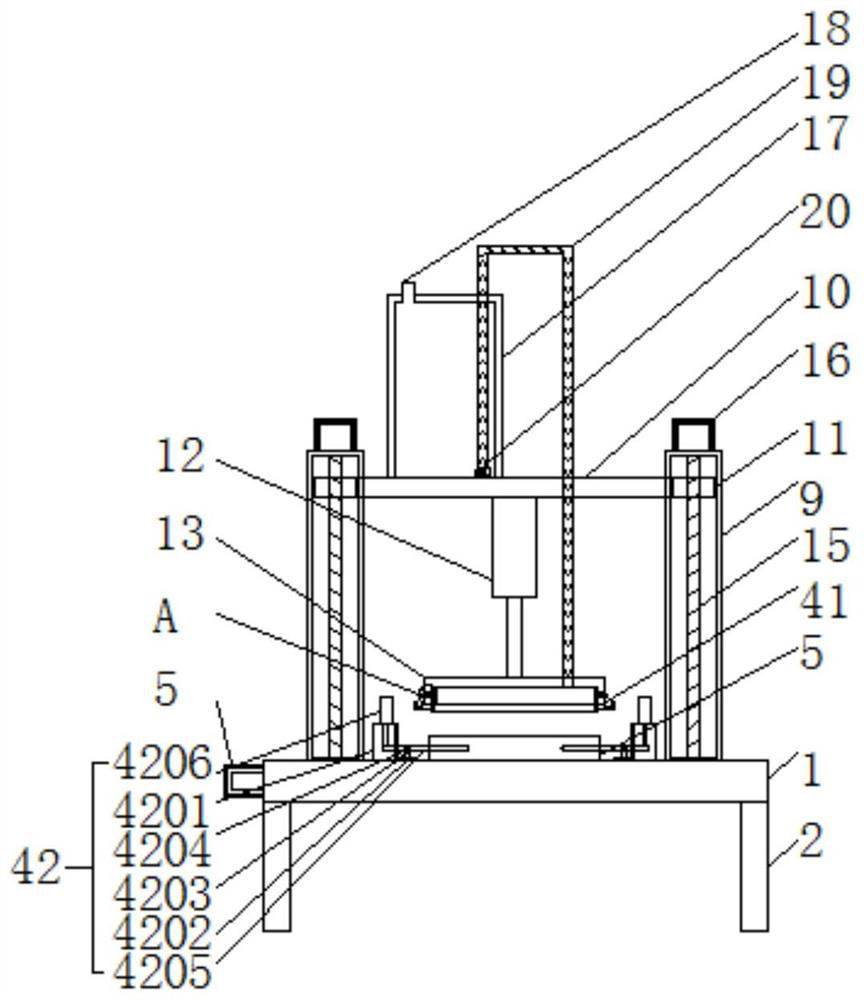

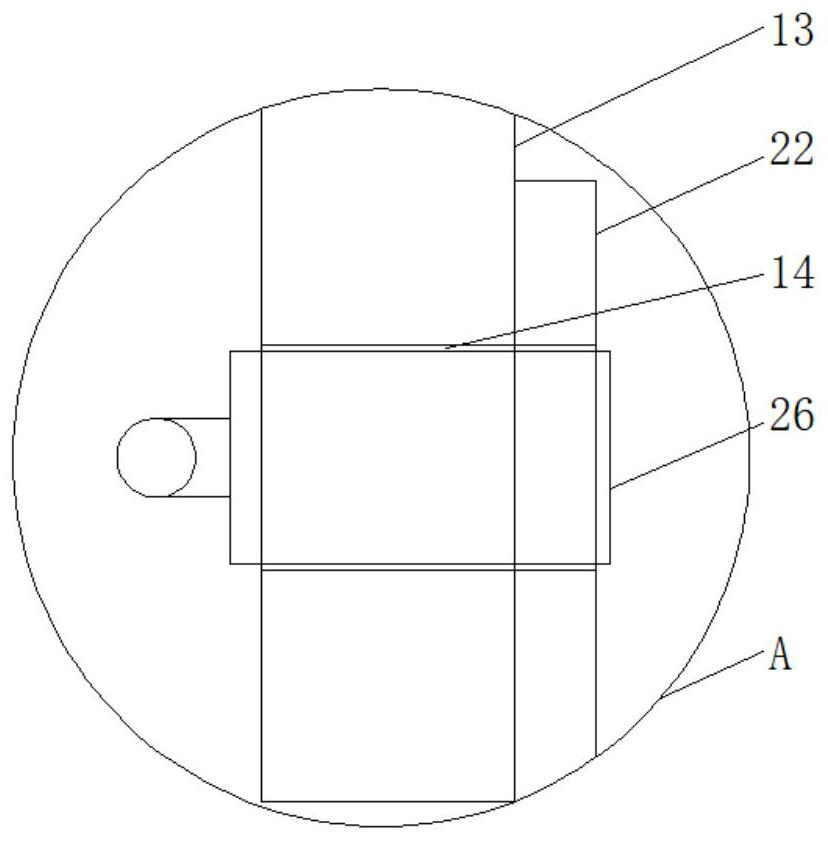

A step-by-step printing device for photovoltaic crystalline silicon cells

ActiveCN112937082BAvoid Duplicate PrintingReduce the use of electrical performanceFinal product manufactureScreen printersGratingSilicon cell

Owner:徐州中辉光伏科技有限公司

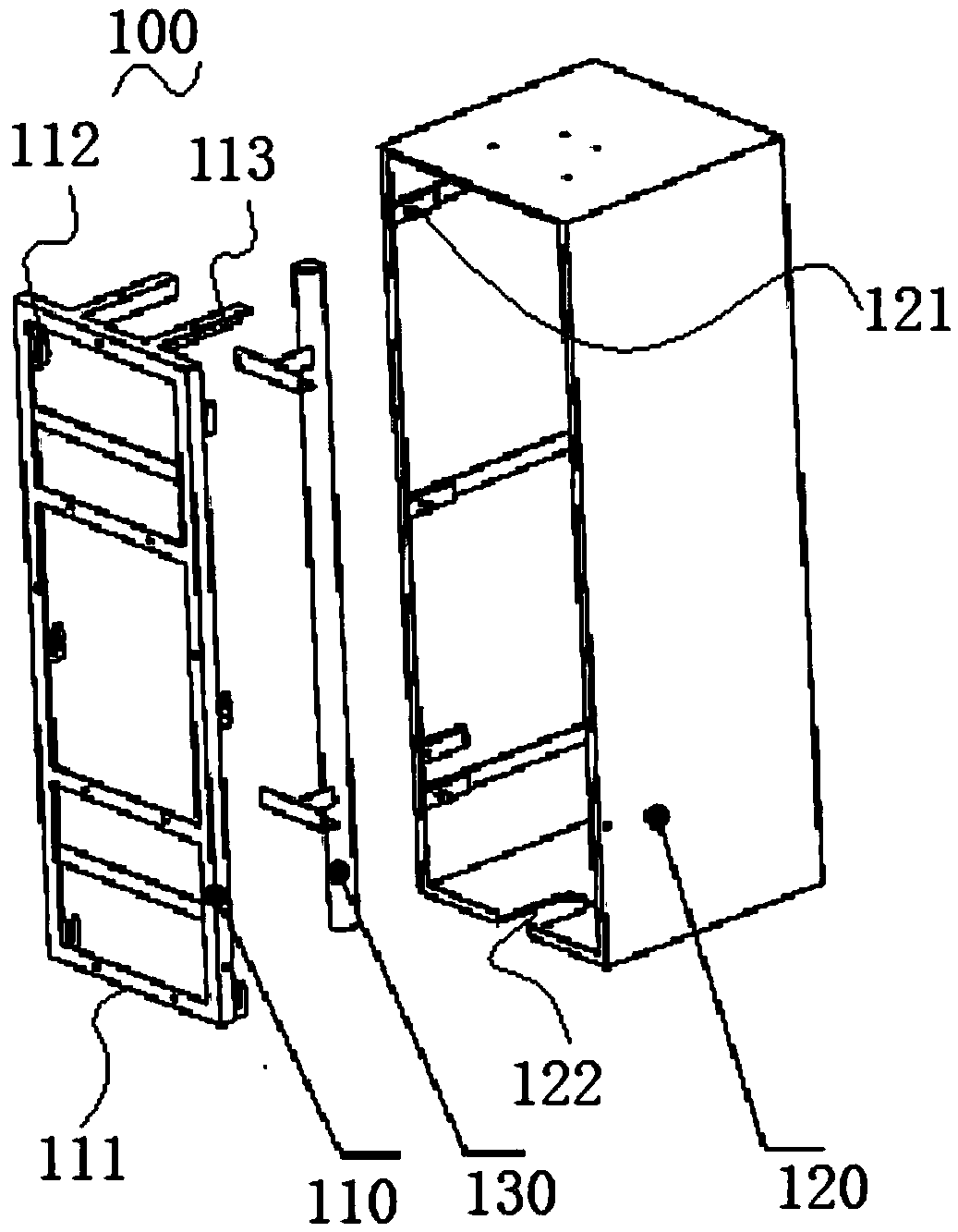

Low-dielectric-constant glass fiber reinforced plastic radome and production process thereof

ActiveCN110534895AGuaranteed uptimeAffect electrical propertiesRadiating element housingsGlass fiberCarbon nanotube

The invention relates to the field of radomes, particularly to a low-dielectric-constant glass fiber reinforced plastic radome and a production process thereof. The low-dielectric-constant glass fiberreinforced plastic radome comprises a mounting base mounted on a wall, a protective cover arranged outside the mounting base in an openable and closable covering mode, and an antenna holding pole located in a cavity defined by the mounting base and the protective cover. The glass fiber reinforced plastic base layer comprises in parts by mass: 50-80 parts of unsaturated polyester resin, 5-20 partsof glass fibers, 2-15 parts of carbon nanotubes, 0.5-4 parts of 1, 3-butanediol, 5-30 parts of a heat-resistant modifier, 5-10 parts of a low shrinkage agent, 1-5 parts of a release agent, 5-15 partsof a coupling agent, 1-5 parts of fluorinated graphene, 1-5 parts of an initiator and 1-5 parts of a thickener. The low-dielectric-constant glass fiber reinforced plastic radome has the advantages ofa small dielectric constant, the good wave permeability, the high mechanical strength and the long service life.

Owner:DONGGUAN YANCHUN IND CO LTD

Display substrate and preparation method thereof, and display panel

ActiveCN109192737BPrevent mutual separationHigh bonding strengthStatic indicating devicesSolid-state devicesThin membraneEngineering

The invention discloses a display substrate, a preparation method thereof, and a display panel. The display substrate comprises: a base substrate; a first insulating layer and a second insulating layer are arranged on the base substrate, wherein the first insulating The film stress direction of the layer is the same as the film stress direction of the second insulating layer. The display substrate is beneficial to improve the display uniformity of the image, avoid display defects such as white spots, and improve the display effect of the display image.

Owner:BOE TECH GRP CO LTD +1

Manufacturing method of interlayer film

ActiveCN108878288BIncrease grinding rateGuaranteed thicknessSemiconductor/solid-state device manufacturingDevice materialMembrane surface

The invention discloses an interlayer film manufacturing method. The interlayer film manufacturing method comprises the following steps: step one, providing a semiconductor substrate on which a pattern structure of a semiconductor device is formed; step two, forming a first insulating layer on the bottom surface and side surfaces of the pattern spacer and the surface of the pattern structure outside the pattern spacer; step three, forming a second insulating layer to completely fill the pattern spacer and extend outside the pattern spacer; and step four: performing chemical mechanical polishing on the second insulating layer and the first insulating layer with the pattern structure as a stop layer, and forming the interlayer film formed by stacking the first and second insulating layers filled in the pattern spacer. The interlayer film manufacturing method can reduce or eliminate dishing defects on the interlayer film surface at the top of the pattern spacer, can improve the flatness of the entire interlayer film, and can improve the electrical properties of semiconductor devices.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com