Chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material

A negative temperature coefficient, perovskite type technology, applied in the direction of resistors with negative temperature coefficient, non-adjustable metal resistors, resistors, etc., can solve the problem of lack of high precision, achieve the suppression of grain boundary migration and expand the application The effect of uniform range and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

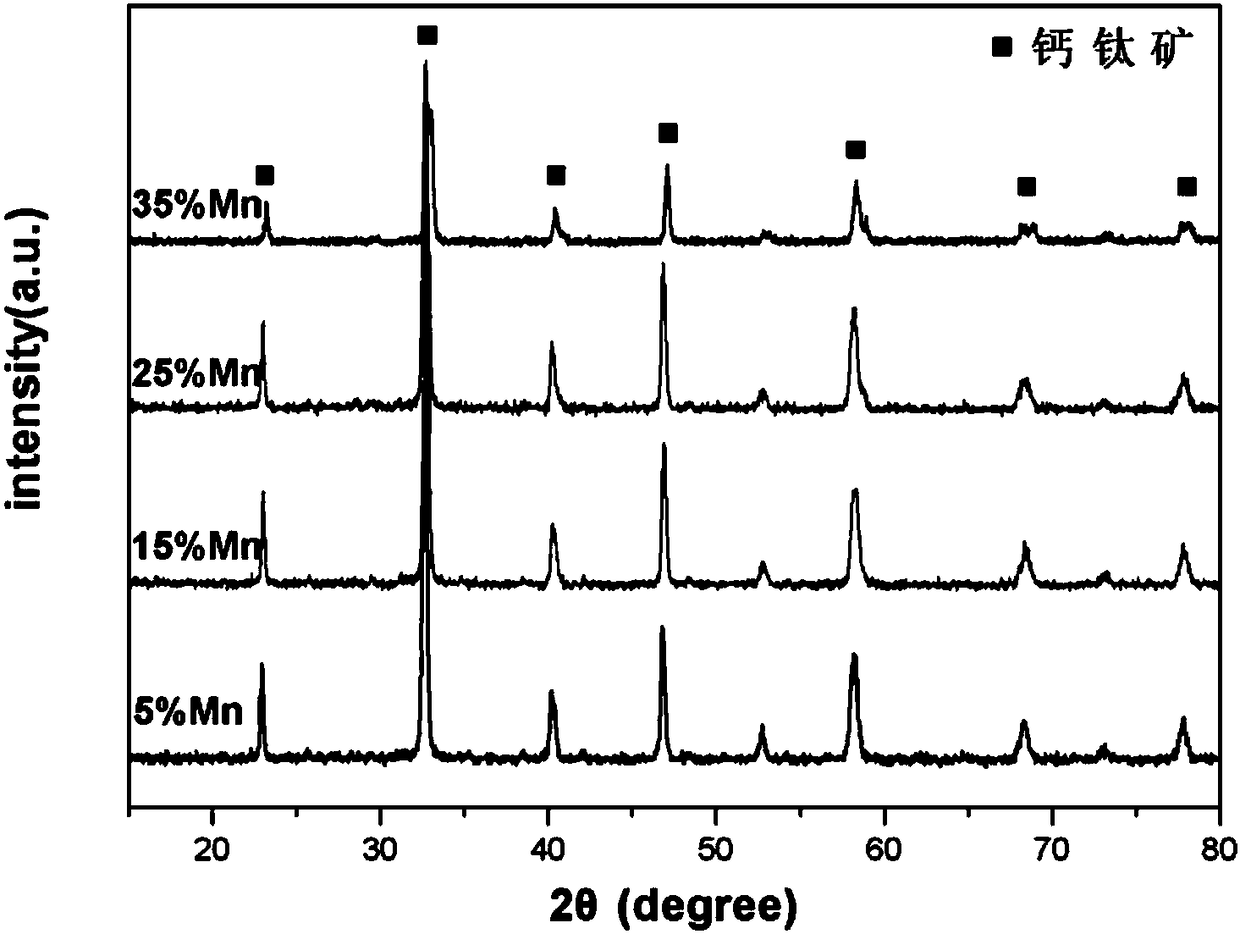

[0029] (1) First use La 2 o 3 、Cr 2 o 3 , MnO 2 As raw material, according to the perovskite phase La(CrMn)O 3 The atomic percentage in the middle is La:Cr:Mn=50:45:5 Weigh each oxide and place it in an agate ball milling jar, use agate balls as the ball milling medium and absolute ethanol as the dispersion medium, wet mill for 15 hours, and control the amount of each substance in the ball milling jar The mass ratio is: agate ball: material: absolute ethanol = 2.5:1:1, ball milling is carried out alternately clockwise and counterclockwise, with an interval of 30 minutes clockwise and counterclockwise;

[0030] (2) Dry the wet-milled slurry in step (1) in a vacuum drying oven at 80°C, and then grind for 1 hour to obtain a powder;

[0031] (3) Calcining the powder obtained in step (2) at 950°C for 2 hours to obtain the perovskite phase La(CrMn)O in step a 3 Powder, the particle size of the powder is 0.746 μm; then it is placed in an agate mortar and ground for 4 hours to o...

Embodiment 2

[0036] (1) First use La 2 o 3 、Cr 2 o 3 , MnO 2 As raw material, according to the perovskite phase La(CrMn)O 3The atomic percentage in the middle is La:Cr:Mn=50:15:35. Weigh each oxide and place it in an agate ball mill jar. Use agate balls as the ball milling medium and absolute ethanol as the dispersion medium. Wet mill for 20 hours to control the amount of each substance in the ball mill jar. The mass ratio is: agate ball: material: absolute ethanol = 2.5:1:1, ball milling is carried out alternately clockwise and counterclockwise, with an interval of 30 minutes clockwise and counterclockwise;

[0037] (2) Dry the wet-milled slurry in step (1) in a vacuum drying oven at 80°C, and then grind for 1 hour to obtain a powder;

[0038] (3) Calcinate the powder obtained in step (2) at 1000°C for 2 hours to obtain the perovskite phase La(CrMn)O3 powder in step a, with a particle size of 0.417 μm; then place it on agate Grind in a mortar for 4 hours to obtain a powder material ...

Embodiment 3

[0043] (1) First use La 2 o 3 、Cr 2 o 3 , MnO 2 As raw material, according to the perovskite phase La(CrMn)O 3 The atomic percentage in the middle is La:Cr:Mn=50:35:15 Weigh each oxide and place it in an agate ball mill jar, use agate balls as the ball milling medium and absolute ethanol as the dispersion medium, wet mill for 24 hours, and control the content of each substance in the ball mill jar The mass ratio is: agate ball: material: absolute ethanol = 2.5:1:1, ball milling is carried out alternately clockwise and counterclockwise, with an interval of 30 minutes clockwise and counterclockwise;

[0044] (2) Dry the wet-milled slurry in step (1) in a vacuum oven at 100°C, and then grind for 1 hour to obtain a powder;

[0045] (3) Calcining the powder obtained in step (2) at 900°C for 2 hours to obtain the perovskite phase La(CrMn)O in step a 3 Powder, the particle size of the powder is 0.128 μm; then it is placed in an agate mortar and ground for 4 hours to obtain a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com