Patents

Literature

161results about How to "Guaranteed bending performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

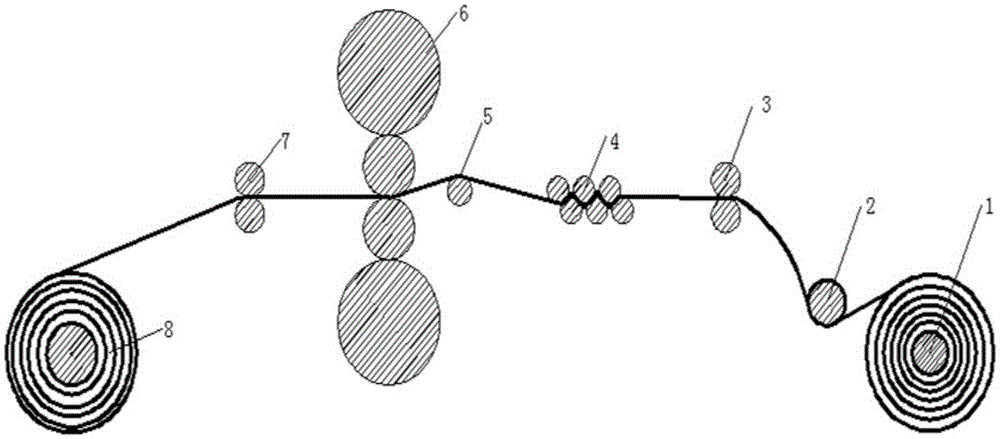

Leveling method for cross break defects on surface of hot-rolled and acid-pickled plate

ActiveCN105268746ACross-fold defect eliminationReduce uneven forceProfile control deviceEngineeringStrip steel

The invention belongs to the technical field of steel making and discloses a leveling method for cross break defects on the surface of a hot-rolled and acid-pickled plate. The leveling method comprises the steps that constant-rolling-force control is adopted by a hot-roll leveling unit, and a leveling and straightening mode is selected; a strategy of segmented pressure control over a deep bending roller is adopted, and the pressure of the deep bending roller is adjusted according to the cross sectional area of strip steel; and the elongation of the strip steel is controlled to be 3%-3.5%. By the adoption of the leveling method for the cross break defects on the surface of the hot-rolled and acid-pickled plate, the cross break defects are effectively eliminated; meanwhile, leveling operation is simplified, the probability of secondary leveling is lowered, and thus the product quality is improved.

Owner:BEIJING SHOUGANG CO LTD

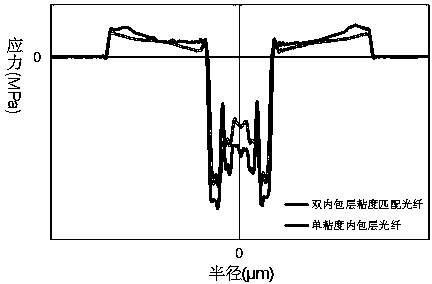

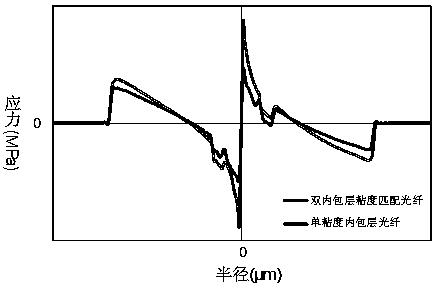

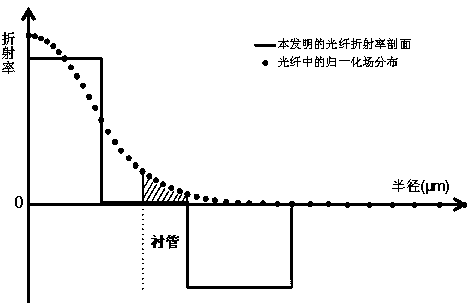

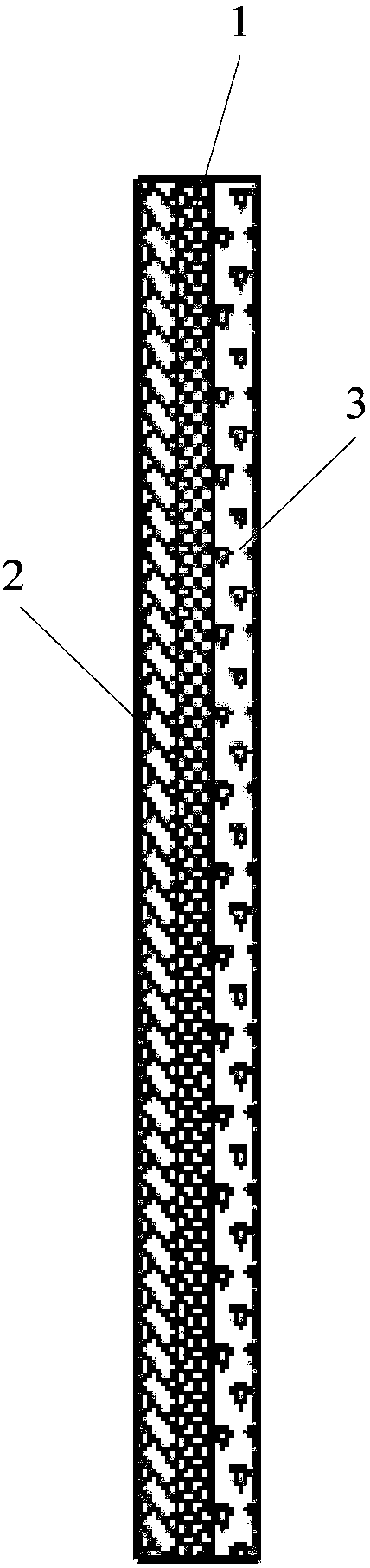

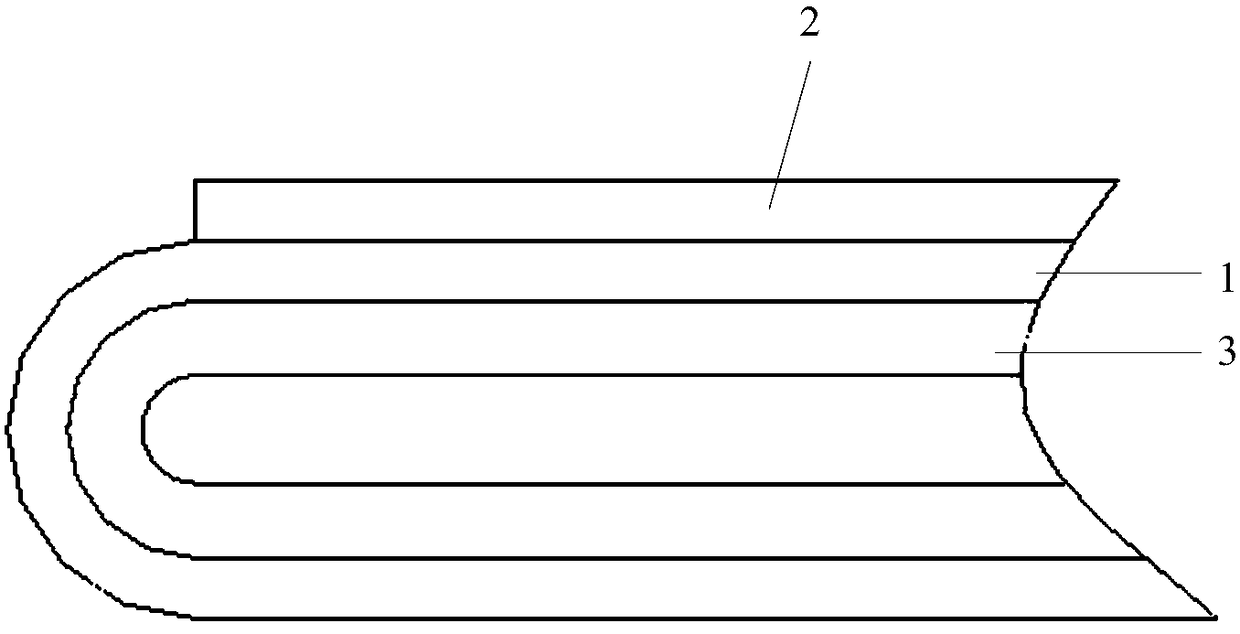

Low-attenuation bending insensitive single mode fiber

InactiveCN104316994AGood attenuation performanceDelay decayOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationMicrometer

The invention relates to a low-attenuation bending insensitive single mode fiber which comprises a core layer and wrapping layers. The low-attenuation bending insensitive single mode fiber is characterized in that the relative refractive index difference delta1 of the core layer ranges from 0.30% to 0.38%, the radius R1 of the core layer ranges from 3.5 micrometers to 4.5 micrometers, the four wrapping layers are arranged outside the core layer, the first wrapping layer is a first inner wrapping layer tightly surrounding the core layer, the relative refractive index difference delta2 of the first wrapping layer ranges from -0.02% to 0.02%, the radius R2 of the first wrapping layer ranges from 6.5 micrometers to 8.5 micrometers, the second wrapping layer is a second inner wrapping layer tightly surrounding the first inner wrapping layer, the relative refractive index difference delta3 of the second wrapping layer ranges from -0.02% to 0.02%, the radius R3 of the second wrapping layer ranges from 8 micrometers to 11 micrometers, the third wrapping layer is a downwards-concave wrapping layer tightly surrounding the second inner wrapping layer, the relative refractive index difference delta4 of the third wrapping layer ranges from -0.5% to -0.2%, the radius R4 of the third wrapping layer ranges from 12 micrometers to 20 micrometers, and the fourth wrapping layer is an outer wrapping layer tightly surrounding the downwards-concave wrapping layer and is a pure quartz glass layer. The low-attenuation bending insensitive single mode fiber can be completely matched with a G.652.D optical fiber, and therefore the low attenuation, the large effective area and the bending resistance can be better unified.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

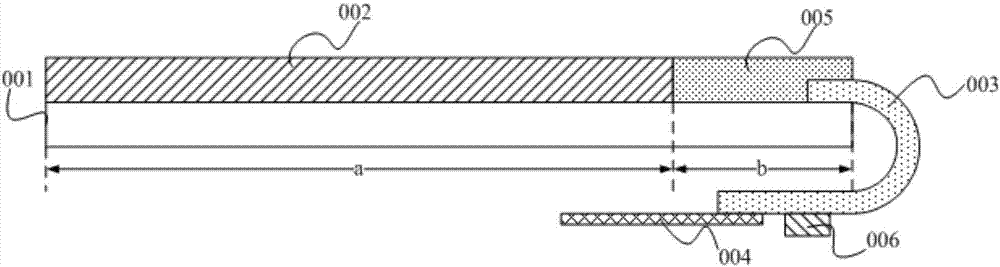

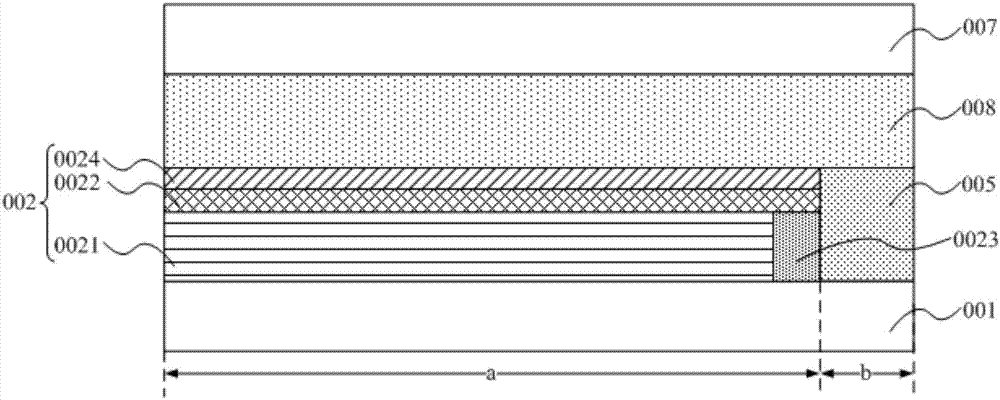

Flexible display panel and flexible display apparatus

ActiveCN107316881AGuaranteed bending performanceGood flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

The invention discloses a flexible display panel and a flexible display apparatus. The flexible display panel comprises a flexible substrate with a display region and a bonding pad region, and multiple display elements arranged on the display region of the flexible substrate. The display region and the bonding pad region of the whole flexible substrate are covered with a protection film, and a bonding layer is directly arranged in the space between the protection film and the display elements and in the space between the binding region of the flexible substrate and the protection film separately, only single adhesive exists in the welding region between the flexible substrate and the protection film; when the flexible display panel is bent under stress, it is ensured that a strain neutral layer in the welding region of the flexible display panel can be positioned in the bonding layer, so that the risk of line breaking caused by cracks of a signal trace in the welding region due to overhigh stress can be avoided; and by virtue of the bonding layer, the elasticity modulus can be controlled within a range of 0.5-10MPa, so that the bonding layer has relatively high flexibility, thereby ensuring the buckling performance of the flexible display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

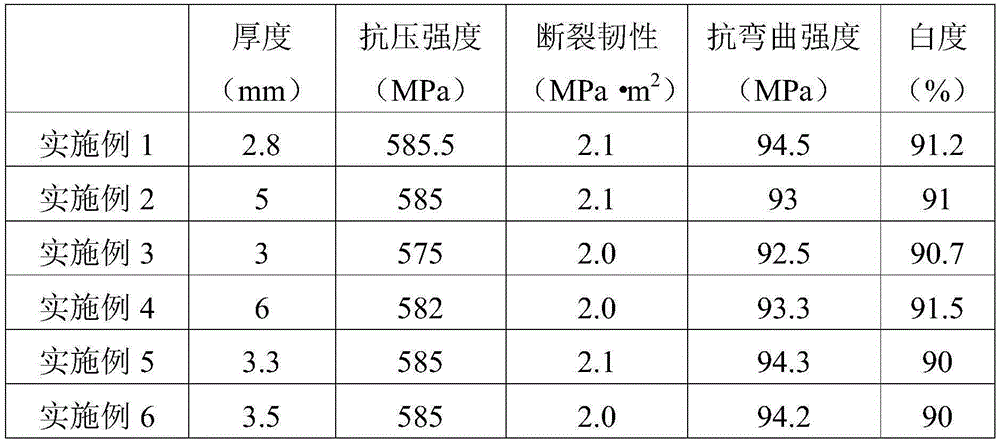

Preparation technology for glass ceramics sheet

ActiveCN105271642AImprove bending abilitySolve technical problems that are easily deformedGlass rolling apparatusFlexural strengthNucleation

The invention discloses a preparation technology for a glass ceramics sheet. The preparation technology includes the steps that 1, SiO2, Al2O3, K2O, Na2O, CaO, MgO, F and a clarifying agent are weighed to obtain batch; 2, the batch is added into a melting furnace, the melting temperature is controlled to be 1510 DEG C-1520 DEG C, and the melted batch is clarified on the stirring condition to generate glass melt; 3, the glass melt enters a three-roll roller press to be rolled and calendered to form a glass plate; 4, the glass plate enters a roller kiln, and a glass ceramics sheet is obtained through primary nucleation, intensified nucleation and crystallization; 5, annealing, cooling, polishing and trimming are carried out on the obtained glass ceramics sheet to obtain the glass ceramics sheet product. The thickness of the glass ceramics sheet prepared through the preparation process according to the component content is 2-10 mm, the technical effect of bending resistance of the sheet in the production technical process is achieved, bending resistance and compressive strength are high, industrialization of the glass ceramics sheet is achieved, and market promotion is easy.

Owner:JIANGXI XINFENG MICROCRYSTALLINE JADE CO LTD

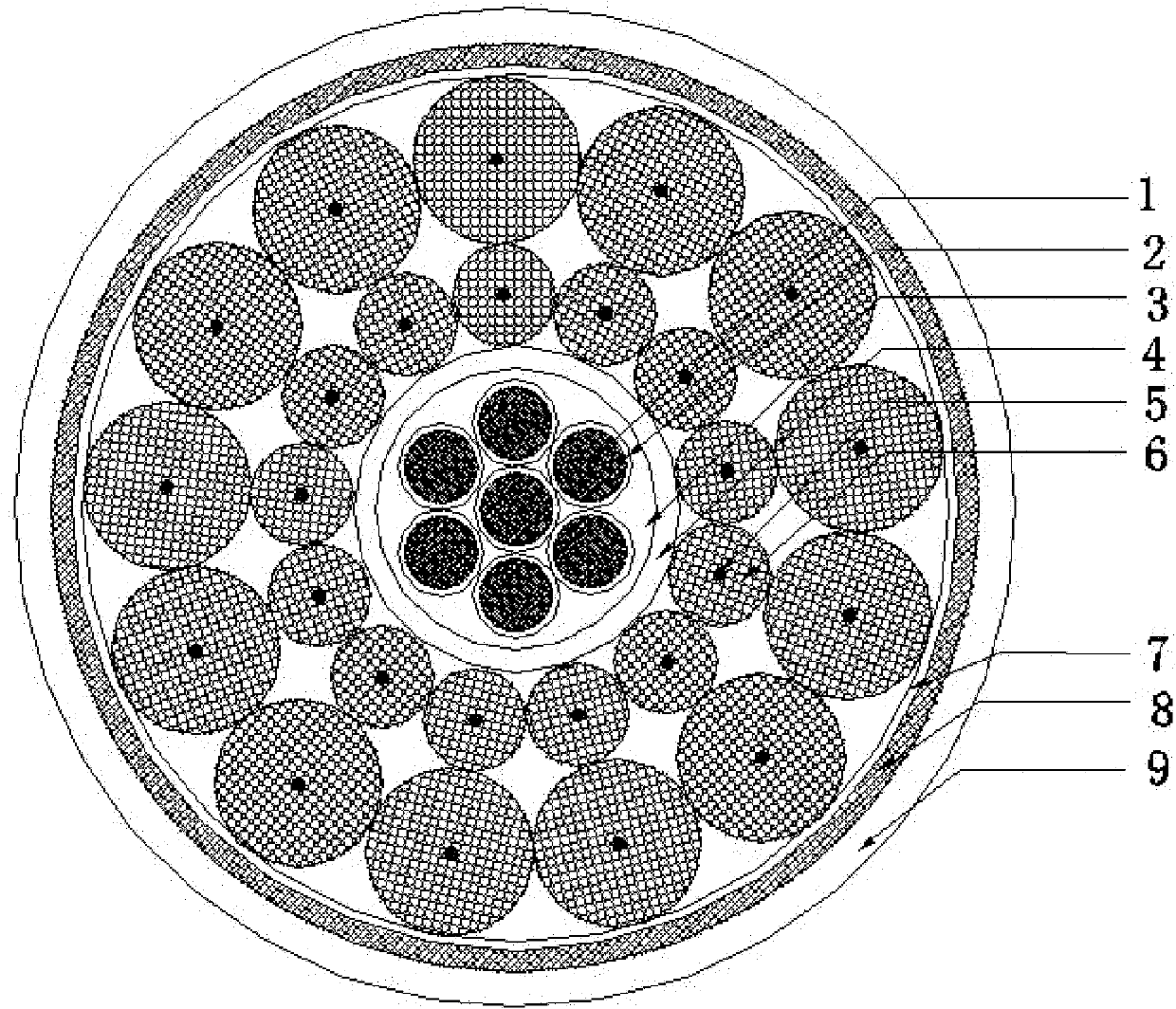

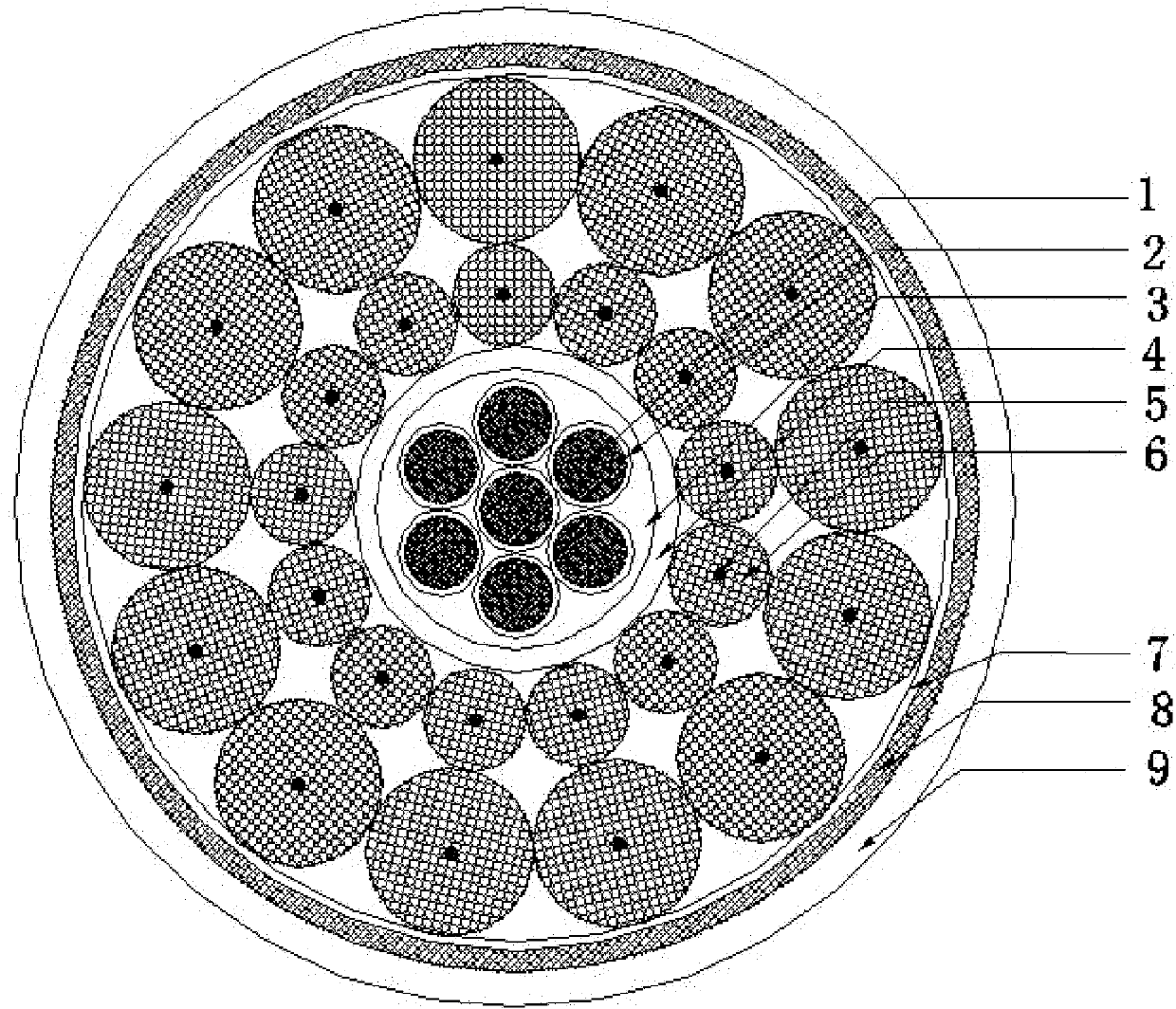

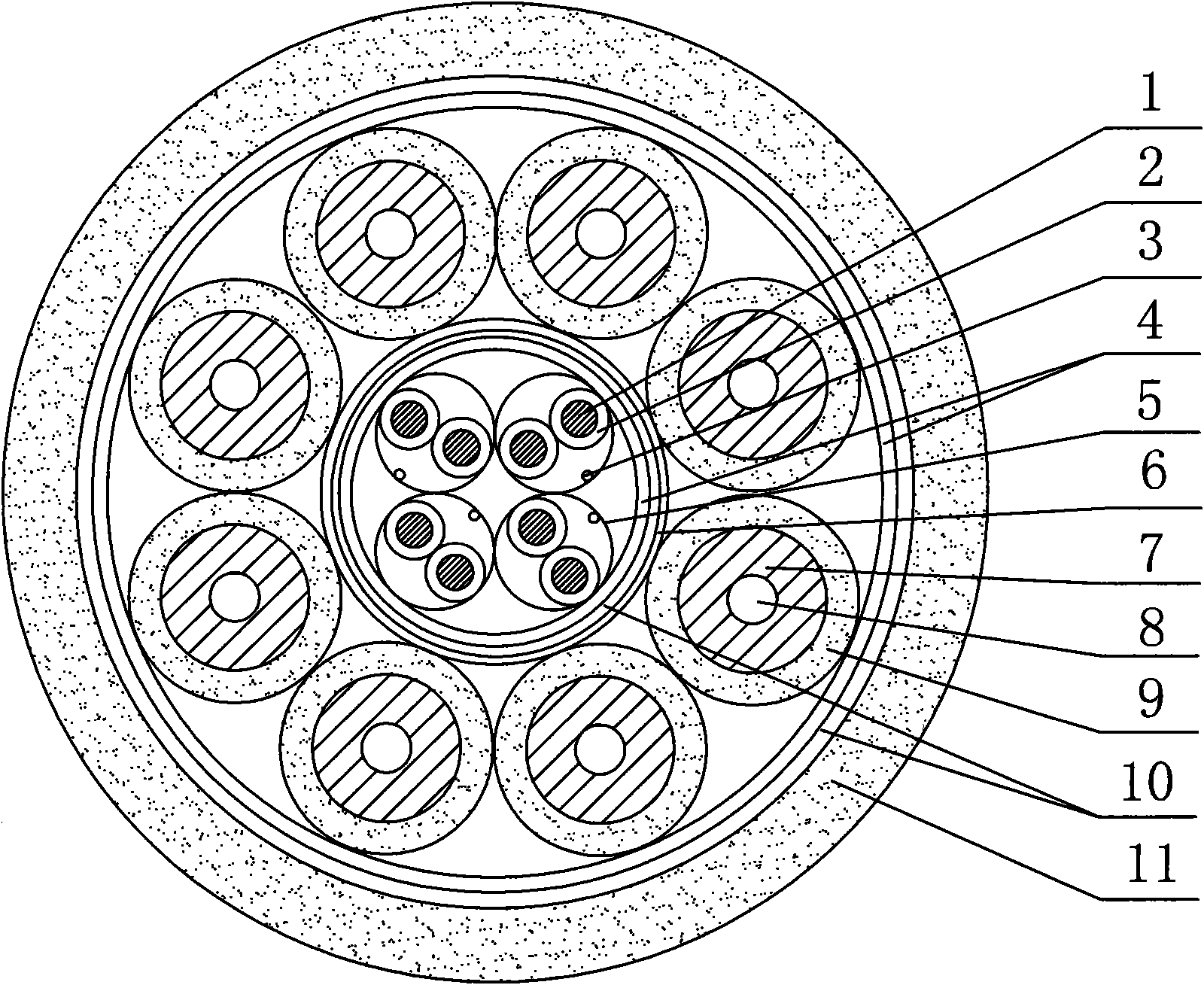

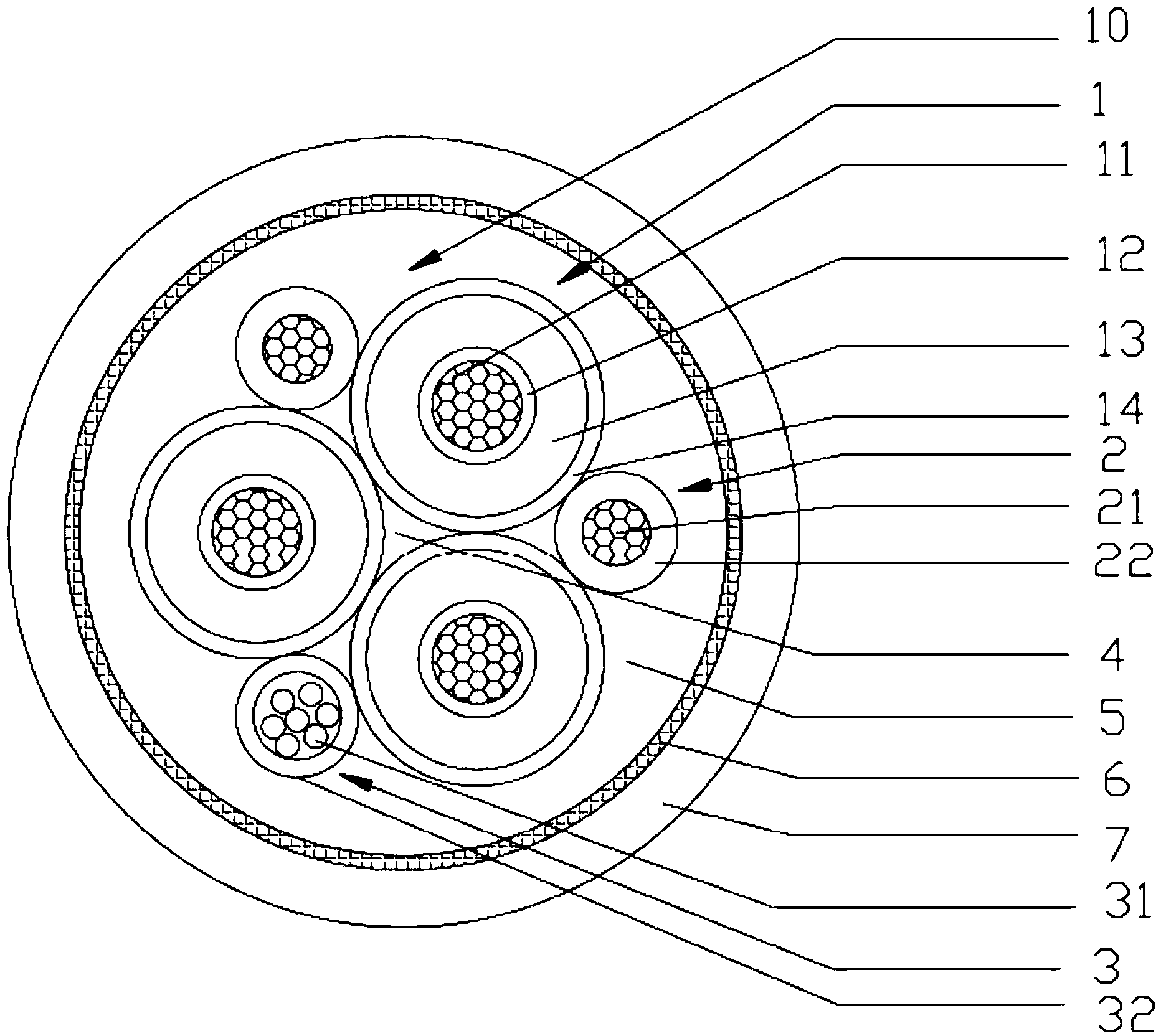

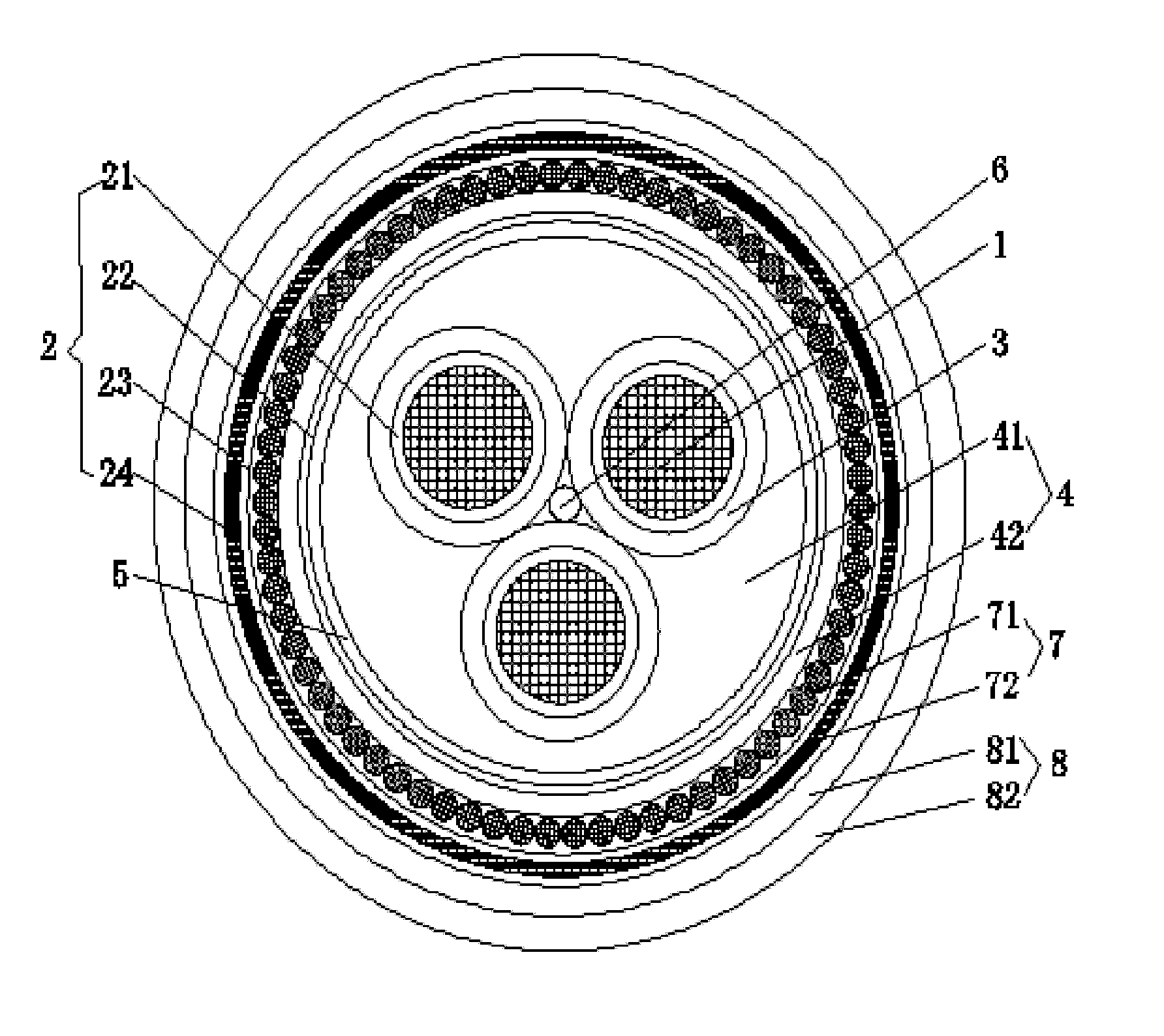

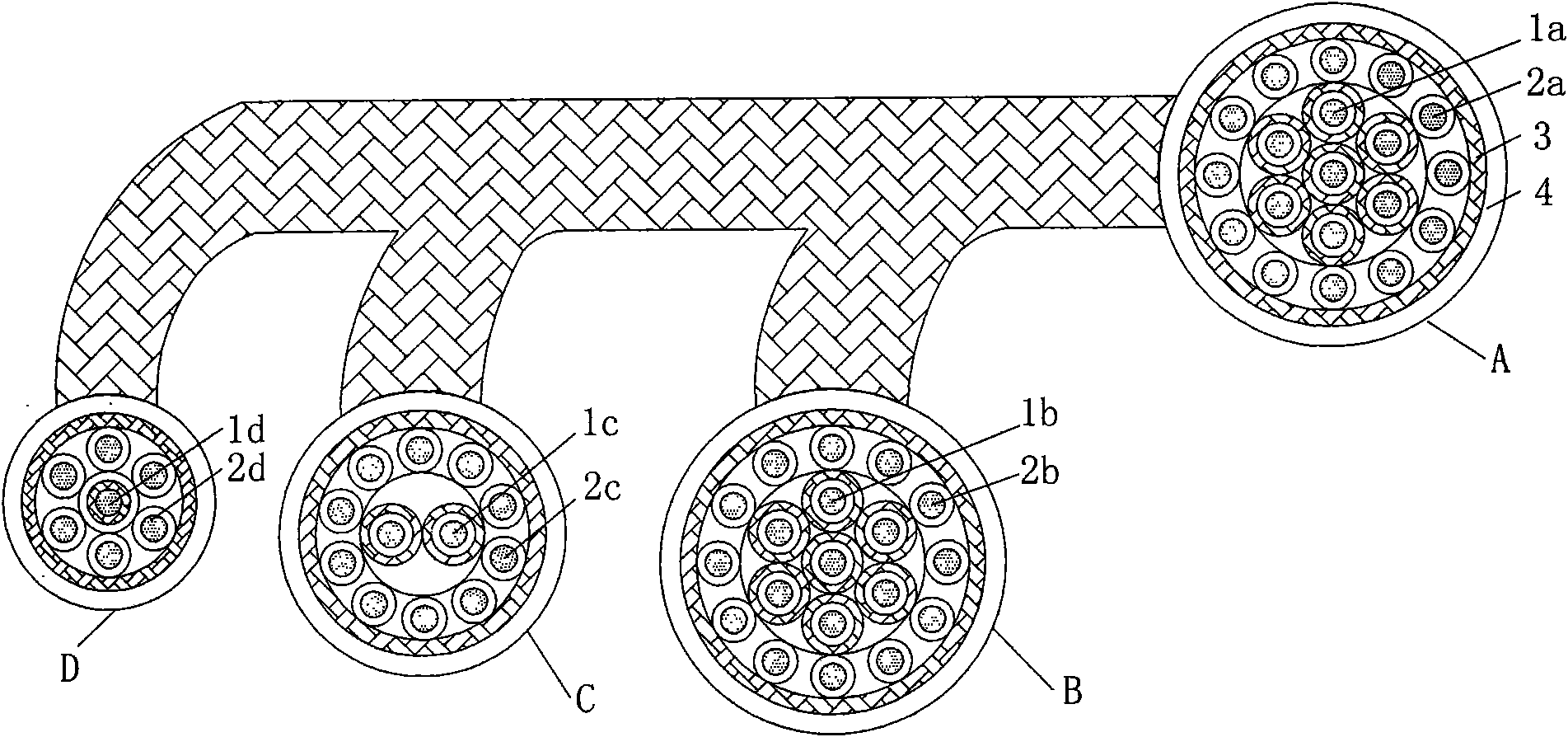

Offshore floating wind power generation cable

ActiveCN101996708AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFloating cablesPolyolefinElectrical conductor

The invention discloses an offshore floating wind power generation cable, which comprises conductors, insulating layers, an inner lining layer, an inner protection layer, tensile components, floating components, a waterproof layer, protective layers and an outer sheath, wherein the conductor is coated with the insulating layer by way of extrusion so as to form insulating wire cores, and a plurality of insulating wire cores are stranded into a cable core; the cable core is respectively coated with the inner lining layer and the inner protection layer by way of extrusion; two protective layers are wound outside the inner protection layer, each protective layer consists of a plurality of protective elements which are arranged in the shape of circle, and each protective element is formed by coating the tensile component with the floating component by way of extrusion; the two protective layers are respectively coated with the waterproof layer, the protective layer and the outer sheath by way of outward extrusion; the insulating layers and the inner lining layer are made of thermoplastic elastomeric materials by way of extrusion; and the insulating layer is made of thermoplastic polyolefin (TPO) materials in thermoplastic elastomer (TPE), and the inner lining layer is made of toughened polystyrene (TPS) materials in TPE. The wind power generation cable of the invention has the advantages of low temperature resistance, bending resistance, torsion resistance, abrasion resistance, water blocking, corrosion resistance, weather fastness, high tensile strength, and capability of effectively preventing the damages of stormy waves and other floaters over the sea to the cables.

Owner:FAR EAST CABLE +2

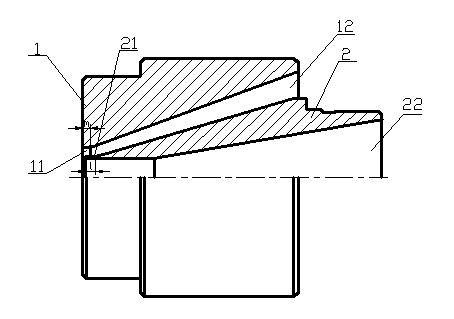

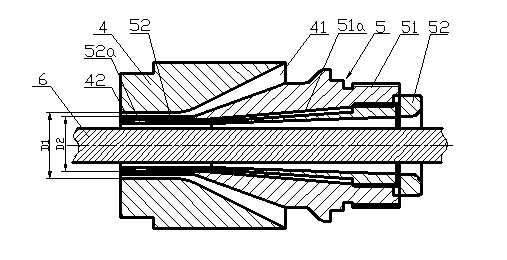

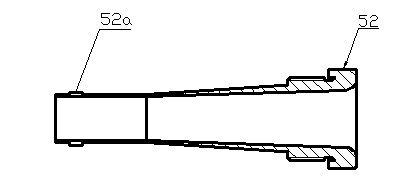

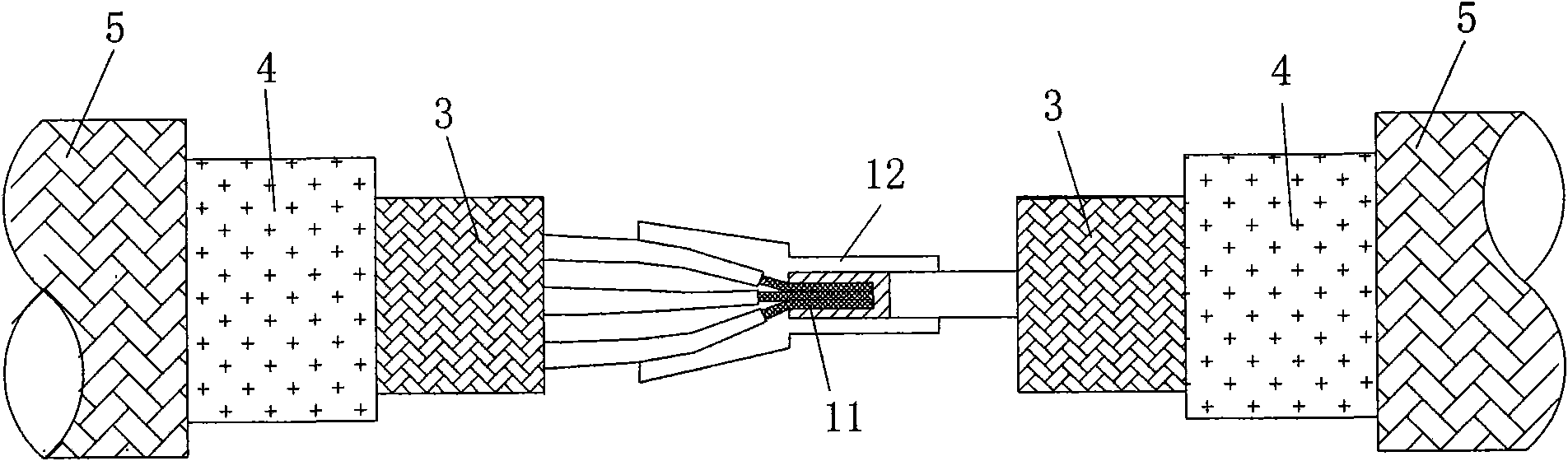

Method for producing sheath of nylon cable and extrusion die thereof

ActiveCN102096163AStable peel resistanceQuickly adjustable eccentricityFibre mechanical structuresGlass fiberPore diameter

The invention relates to a method for producing a sheath of a nylon cable and an extrusion die thereof. The method comprises the following steps of: predrying, forming a primary polyethylene (PE) sheath, forming a primary waterproof tape, forming a glass fiber layer, forming a secondary waterproof tape, forming a secondary PE sheath, and the like, wherein the secondary PE sheath is molded by a semi-extrusion die; a cable core covered by the secondary PE sheath is dried and preheated; and the nylon sheath is molded by a double-core inner die. In the semi-extrusion die, the axial length of an inner die extrusion part is not more than 5mm, and the axial length of an extrusion hole of an outer die is not more than 3mm. An inner die of the double-core inner die consists of a cable core heat-insulation supporting tube and an inner die core, wherein the cable core heat-insulation supporting tube is supported in a supporting hole in the center of the inner die core through a plurality of supporting ribs which are distributed on the circumference of the front end; the extrusion part at the front end of the inner die core passes through the extrusion hole to extend out of a corresponding end face of the outer die for 1 to 1.5mm; and the difference between the pore diameter of the extrusion hole and the outer diameter of the extrusion part is 2.8mm to -4.0mm. The invention has the advantages that: the adhesive strength between nylon and the PE sheath is greatly improved; therefore, the bending index and other properties of finished products are effectively improved.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

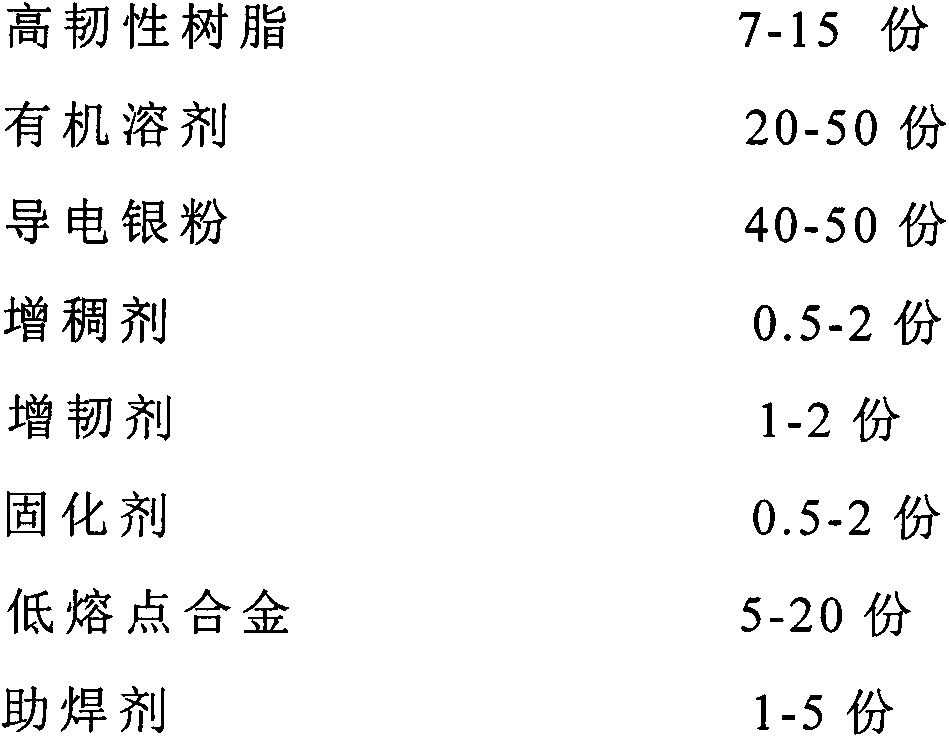

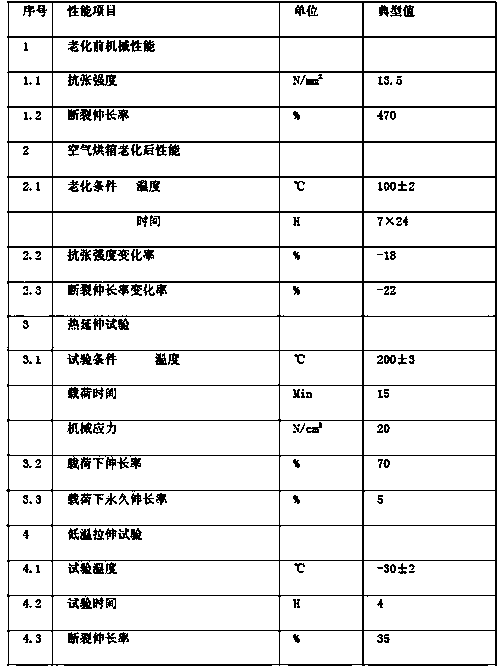

High-conductivity low-temperature sliver paste and preparation method thereof

ActiveCN106297949AUnique designReasonable compositionNon-conductive material with dispersed conductive materialCable/conductor manufactureMembrane switchAlloy

The invention discloses a high-conductivity low-temperature sliver paste and a preparation method thereof. The preparation method comprises the steps of successively mixing a high-toughness resin, a thickening agent, a flexibilizer and an organic solvent; successively adding a low-melting-point alloy, a soldering flux and conductive silver powder, and performing high-speed mixing for obtaining paste; and grinding the paste to the paste with fineness of 5-10 mu m, and obtaining the conductive sliver paste. The conductive silver paste prepared by the invention has advantages of high conductivity and high mechanical property. After the low-melting-point alloy is added, conductivity performance and hardness performance are greatly improved. Through adding appropriate amount of thickening agent and flexibilizer, diffusion performance and bending performance of a sliver strip can be effectively controlled. The low-temperature sliver paste prepared by the invention has advantages of effectively reducing silver content, improving conductivity and mechanical performance and greatly saving cost. The high-conductivity low-temperature sliver paste can be widely applied in the industries of a thin-film switch, a capacitive electrode, a touch screen, etc.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

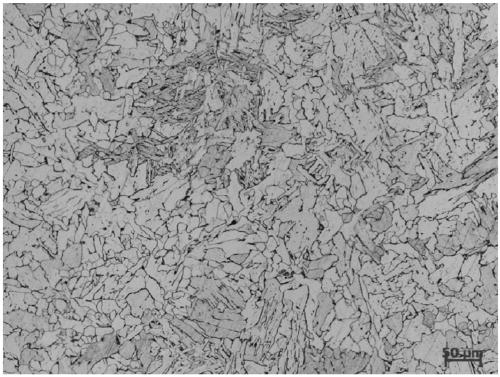

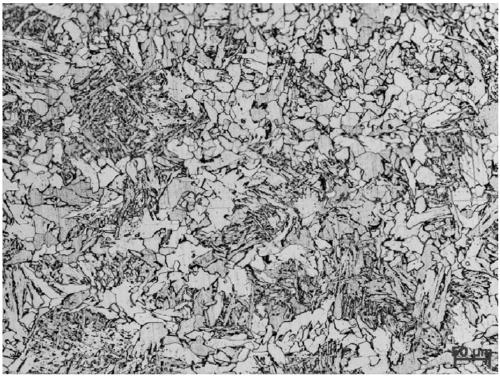

Strip-casting 550-MPa-level weathering resistant steel and production method thereof

PendingCN109881084AReduce C contentGuaranteed bending performanceMetal rolling arrangementsSuperheatingImpurity

The invention discloses strip-casting 550-MPa-level weathering resistant steel and a production method thereof. The method comprises the steps of 1), smelting: the chemical components of molten steelcomprises C lower than 0.03%, 0.20-0.80% of Si, Mn lower than 1.0%, 0.03-1.50% of P, S lower than or equal to 0.008%, N lower than or equal to 0.008%, 0.40-1.50% of Cu, 0.05-1.50% of Cr, Ni lower than0.10%, 0.05-0.20% of Nb and the balanced Fe and unavoidable impurities; 2), strip casting: continuous casting is conducted on molten steel on which qualified smelting is conducted by a pair of coppercasting rolls which are rotated in the same directions to produce a casting strip with the thickness of 1.4-2.5 mm, and the superheating of the molten steel is controlled to be lower than 80 DEG C; 3), casting strip online hot rolling: the hot rolling pressing amount is 15-65%, the temperature of pressed strip steel is 950-1050 DEG C; 4), cooling and winding: the temperature of strip steel on which hot rolling is conducted is cooled down to 450-600 DEG C through atomizing cooling to obtain fine and uniform ferrite and less amount of pearlite tissues. The 550-MPa-level weathering resistant steel has the advantages of short production procedure, low production cost, good strip steel shape and easy welding.

Owner:SHAGANG GROUP +2

Anti-torsion data power composite cable and manufacturing method thereof

ActiveCN101562062ASimple structureAdvanced technologyPlastic/resin/waxes insulatorsInsulated cablesCapacitanceEngineering

The invention discloses an anti-torsion data power composite cable and a manufacturing method thereof. The composite cable comprises a cable core, an outer jacket, and is provided with a data line core and a power control line core; wherein, the data line core is formed by stranding of quad and positioned in the center of cable, the quad is provided with two insulated cores and drainage lines, and wounded and wrapped with a plastic-aluminum composite strip sub-shielding layer, the data line core is provided with a main shielding layer, the power control line core is formed in a manner that multi-assemble reinforced cores are mounted on the periphery of the data line core, the data line core and the cable core are provided with a composite cushion layer respectively. The invention has the advantages of simple and reasonable structure, advanced technique, high mechanical strength of products, low capacity and low attenuation. The invention is also characterized by strong anti electromagnetic interfere property, shock resistance, fine torsion bending resistance property, oil proofness, chemical solvent resistance, hard wearing, high / low temperature resistance, water erosion resistance, environmental leaching and loss resistance, ensuring stable property of cables in various severe environments so that cable property is reliable and safe.

Owner:BAOSHENG SCI & TECH INNOVATION

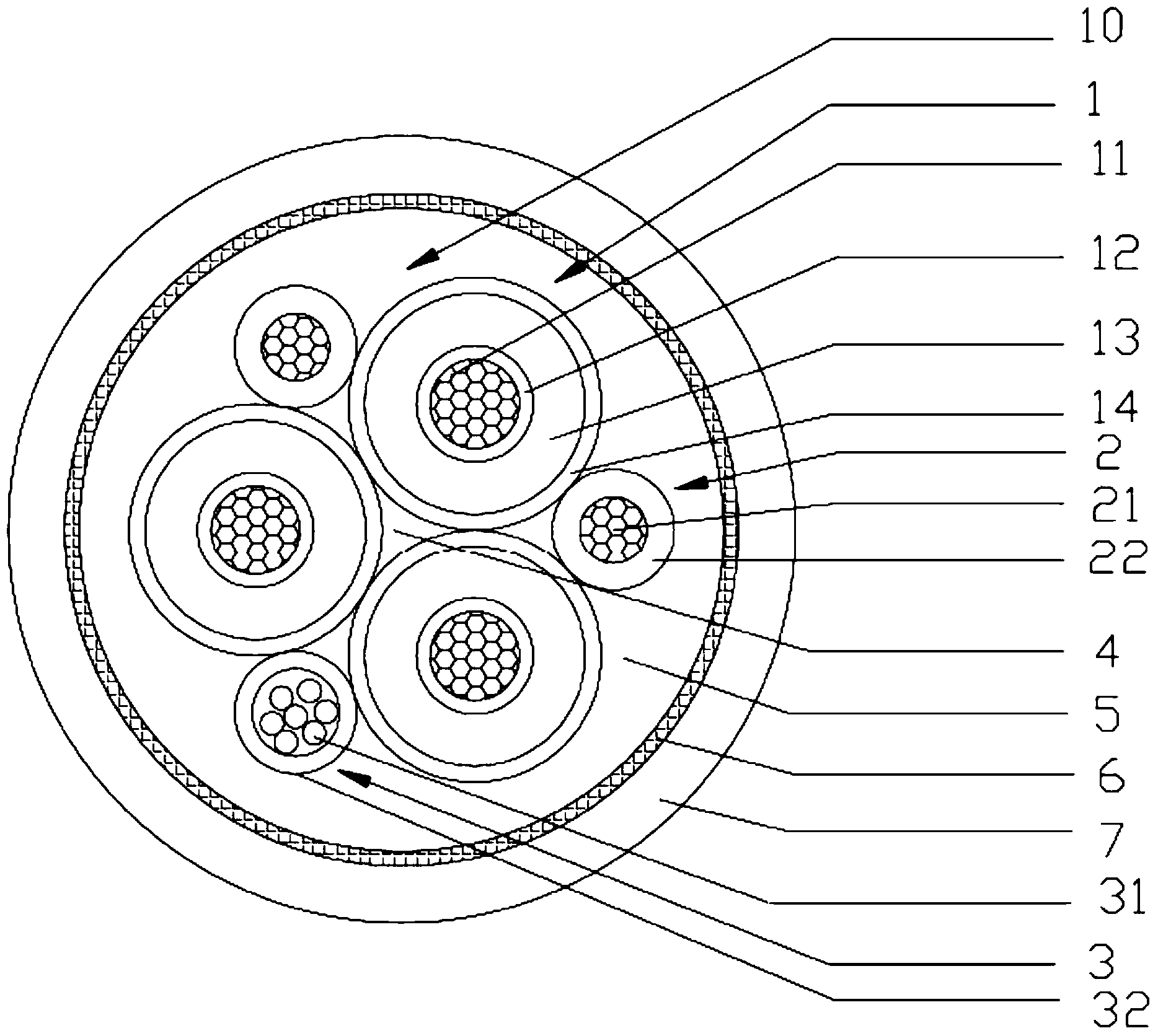

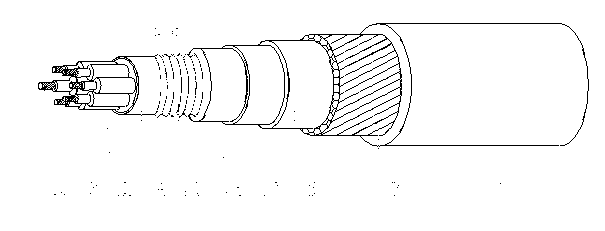

Torsion resistant photoelectric composite medium-voltage drum cable

ActiveCN104036859AExtended service lifeExtend your lifePower cables with screens/conductive layersInsulated cablesYarnPolytetramethylene terephthalate

The invention discloses a torsion resistant photoelectric composite medium-voltage drum cable. The torsion resistant photoelectric composite medium-voltage drum cable comprises a plurality of power line cores and a plurality of ground line cores which are twisted together to form a cable core, as well as at least one optical unit, a special chloroprene rubber inner sheath wrapping the cable core, a reinforcing layer which is woven at the exterior of the special chloroprene rubber inner sheath and is embedded in the special chloroprene rubber inner sheath, and a special chloroprene rubber outer sheath wrapping the reinforcing layer; in power line core conductors and ground line core conductors, the stranding directions of two adjacent layers are opposite, and the stranding direction of each layer is opposite to the stranding direction of strand lines in a corresponding layer; the reinforcing layer is a terylene wire-woven reinforcing layer; insulating layers in the power line cores are ethylene propylene rubber layers; loose bushings are made of polybutylene terephthalate plastics; water-resisting yarns are made of water-resisting aramid fibers; thixotropic composites are made of factice; and nonmetallic reinforcing members are made of aramid fibers. With the torsion resistant photoelectric composite medium-voltage drum cable of the invention adopted, the special chloroprene rubber sheaths are adopted as the inner sheath and the outer sheath of the cable, and therefore, the torsion resistant photoelectric composite medium-voltage drum cable has excellent low temperature resistance, wear resistance, oil resistance and other properties, and the service life of the cable can be prolonged.

Owner:JIANGSU HENGTONG POWER CABLE

Method for manufacturing photoelectric composite medium-voltage drum cable

ActiveCN104036885AImprove performanceExtended service lifeCable/conductor manufactureRubber materialQuinoline

The invention discloses a method for manufacturing a photoelectric composite medium-voltage drum cable. The photoelectric composite medium-voltage drum cable comprises power line cores, ground line cores, at least one optical element, a special neoprene inner sheath wrapping a cable core, a reinforcing layer which is woven at the exterior of the special neoprene inner sheath and embedded in the special neoprene inner sheath and a special neoprene outer sheath wrapping the reinforcing layer; chlorinated polyethylene rubber materials include the following components of: a chlorinated polyethylene raw rubber, magnesium oxide, dibasic lead sulfate, lead sulfate tribasic, paraffin, chlorinated paraffin, antioxidant, namely, poly(1,2-dihydro-2,2,4-trimethyl-quinoline), a reinforcing agent (carbon black), flame retardant (antimony oxide), a filler (talcum powder), a filler (calcium carbonate), a reinforcing and filling agent (white carbon black), a vulcanizing promoter (triallyl isocyanurate), and a vulcanizing agent (dicumyl peroxide). With the method for manufacturing the photoelectric composite medium-voltage drum cable of the invention adopted, the cable can still keep excellent insulation performance under high temperature burning and humid conditions, and it can be ensured the cable can work normally for a long time under burning, mechanical percussion and water spraying situations.

Owner:JIANGSU HENGTONG POWER CABLE

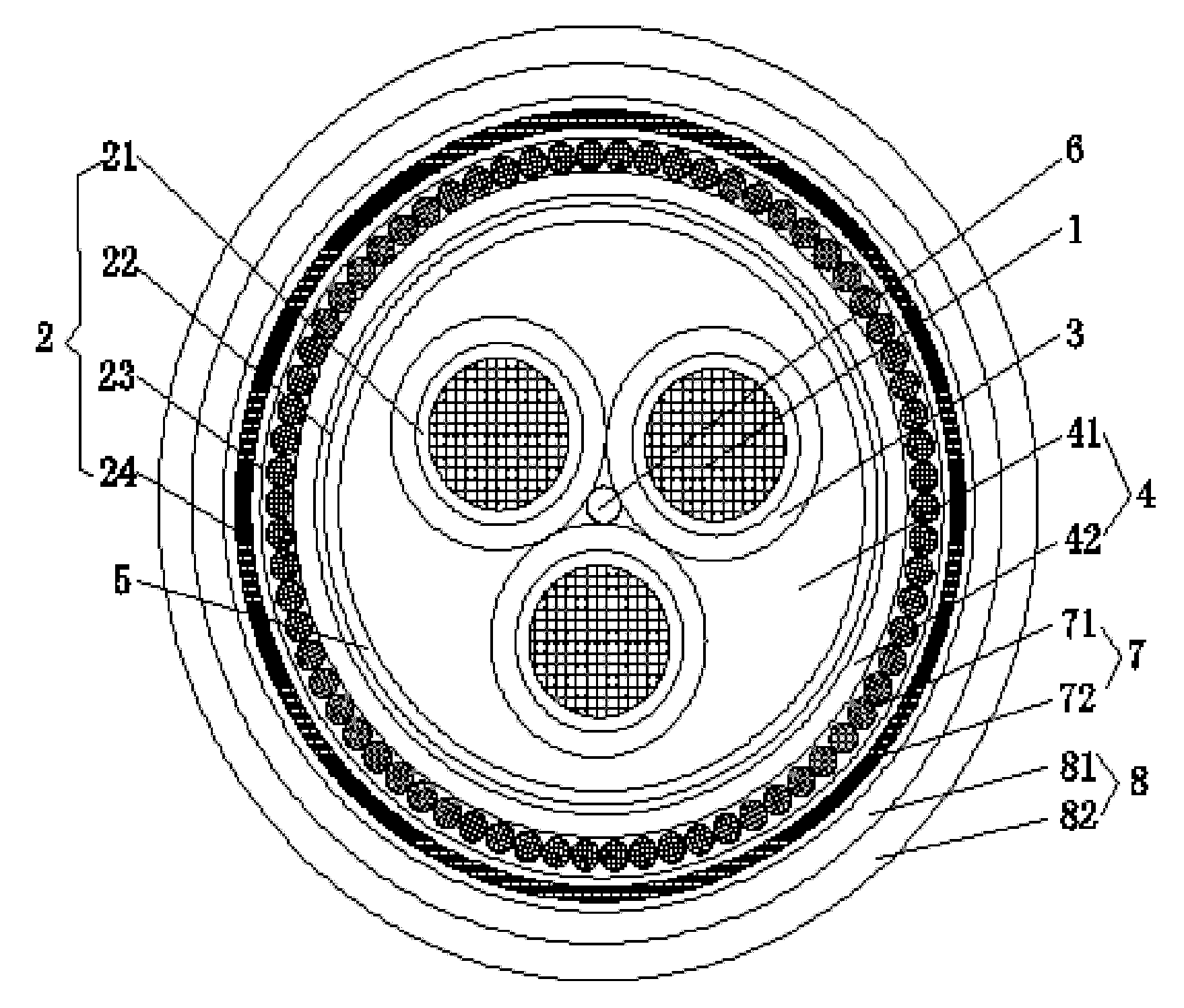

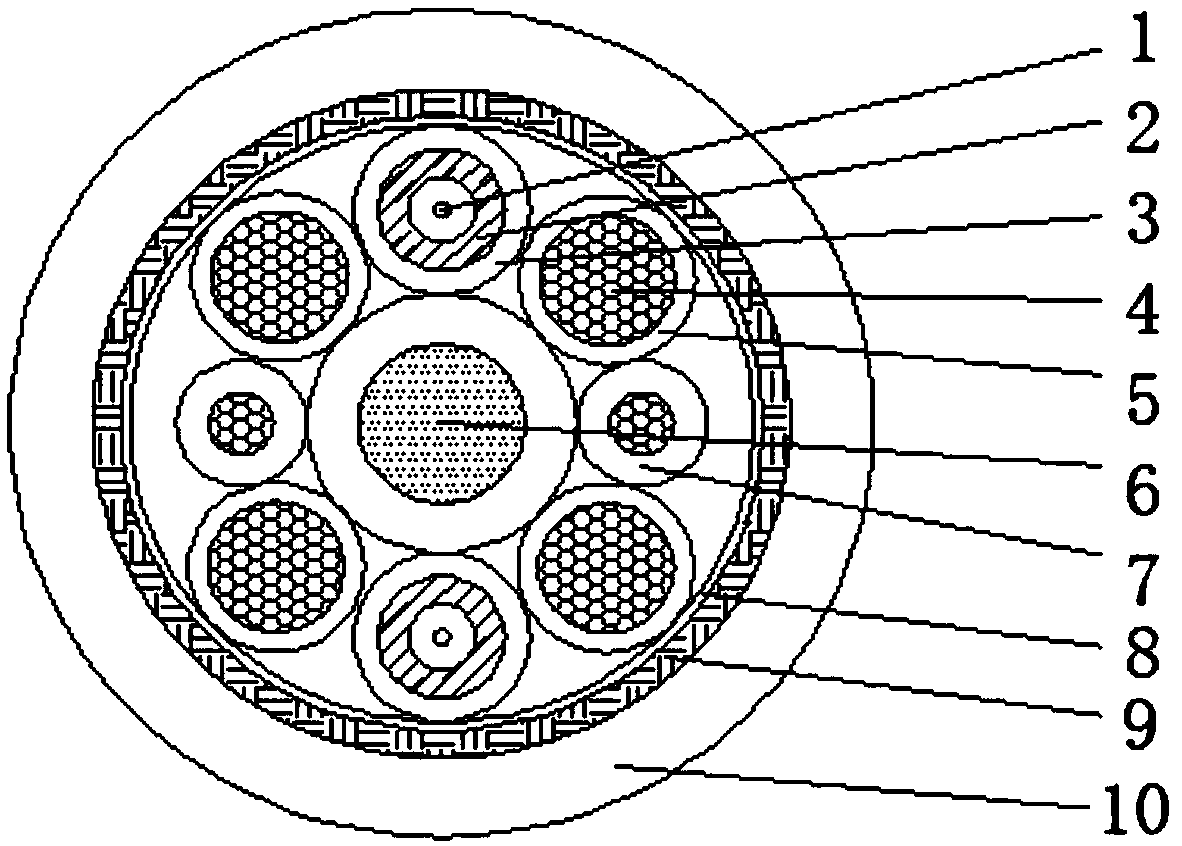

Intelligent anti-interference low-smoke halogen-free flame-retardant loadable monitoring type medium-voltage cable

ActiveCN110504066AIncrease loading capacityIncreased payload securityFlexible cablesFlexible conductorsToxic gasPower cable

The invention discloses an intelligent anti-interference low-smoke halogen-free flame-retardant loadable monitoring type medium-voltage cable. The intelligent anti-interference low-smoke halogen-freeflame-retardant loadable monitoring type medium-voltage cable comprises an outer sheath, a steel wire load layer, an inner sheath and a cable core, wherein the outer side of the cable core is extrudedwith the inner sheath, the steel wire load layer is wrapped on the outer side of the inner sheath, and the outer side of the steel wire load layer is extruded with the outer sheath; and the cable core comprises elastic fillers, a fixed support, 6 elastic guide belts, 3 power cable cores, 3 monitoring cable cores and an optical transmission cable core. According to the invention, the inner sheath,the steel wire load layer and the outer sheath are sequentially wrapped outside the cable core, and the fixed support arranged inside the cable core is used for improving the structural strength andthe bending performance of a cable, so that the cable can be conveniently laid and used in a complex mine, the real-time monitoring picture information of an underground production site is effectivelytransmitted, the loading force of the cable is improved, the safety of the load is ensured, the cable can be effectively prevented from burning when a fire disaster occurs, the cable is prevented from burning to generate toxic gas, and the pollution to the environment is reduced.

Owner:ANHUI LINGYU CABLE TECH

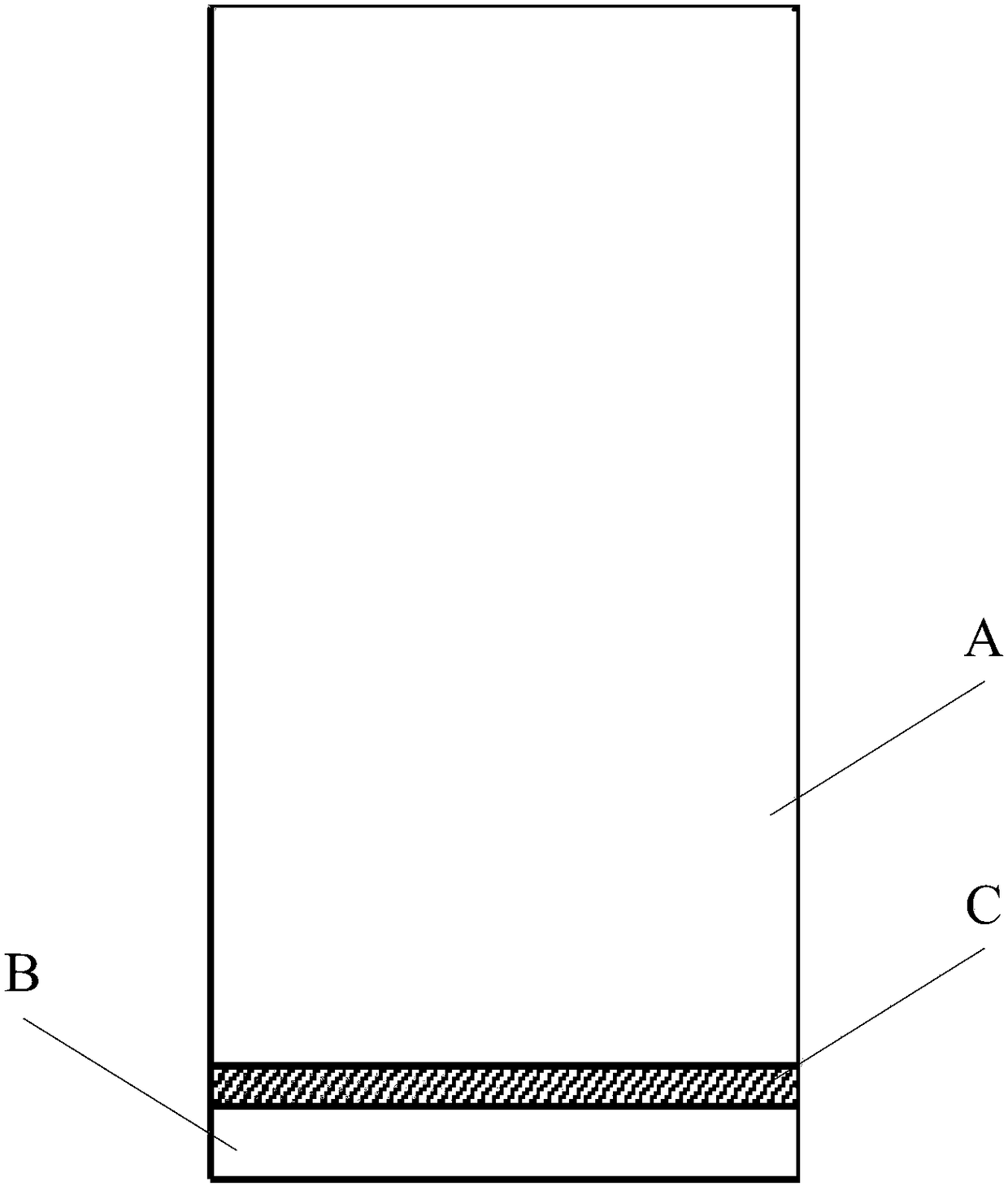

Support membrane for flexible display panel, flexible display panel and preparation method thereof

InactiveCN108598263AImprove stiffnessGuaranteed stabilityFinal product manufactureSolid-state devicesFlexible displayBiomedical engineering

The invention provides a support membrane for a flexible display panel, a flexible display panel and a preparation method thereof. The problem that the flexible screen body is hard to bend since the support membrane is adhered at a bending area of the flexible display panel in the prior art is solved. The support membrane provided by the invention comprises a support area and a tear-off area adjacent to the same, and a cutting line is formed between the support area and the tear-off area.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Cable for shallow sea wind power generation

ActiveCN101937738AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFlexible cablesElectricityElectrical conductor

The invention discloses a cable for shallow sea wind power generation, which comprises a conductor, water-blocking tapes, an insulating layer and lining layers, wherein, the first water-blocking tape and the extruded insulating layer are wrapped sequentially outside the conductor to form insulating wire cores, and a plurality of insulating wire cores are twisted together to form a cable core; the first lining layer and the second water-blocking tape are wrapped sequentially outside the cable core; and the insulating layer and the first lining layer are formed by extruding a thermoplastic elastomer (TPE). In the invention, the insulating layer is made of a thermoplastic olefin (TPO) material in the TPE and the first lining layer is made of a thermoplastic starch (TPS) material in the TPE, wherein, the TPE has good electrical property, good mechanical property, excellent low-temperature bending property and excellent torsion resistance, high long-term working temperature up to 125 DEG C, better water resistance and excellent salt-fog resistance, and especially the TPE can still maintain good flexibility at -60 DEG C; and TPO has more excellent electrical property, and TPS has better water resistance than that of the TPO.

Owner:FAR EAST CABLE +2

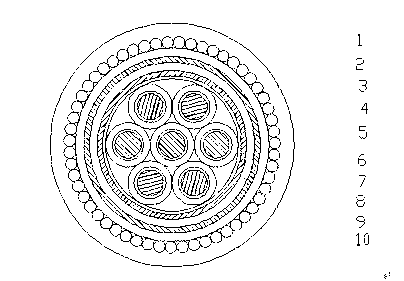

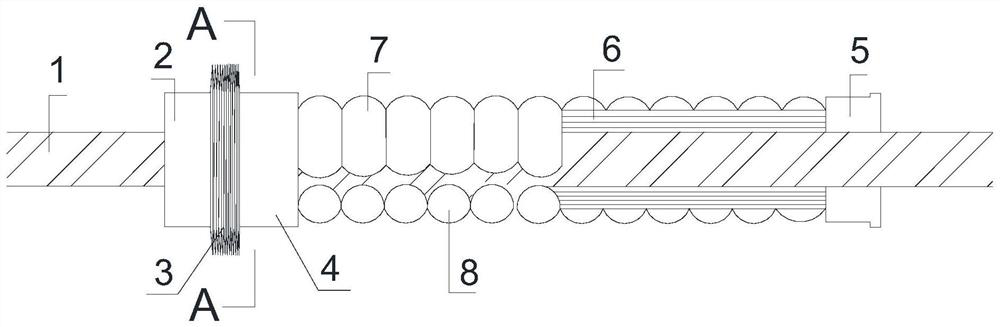

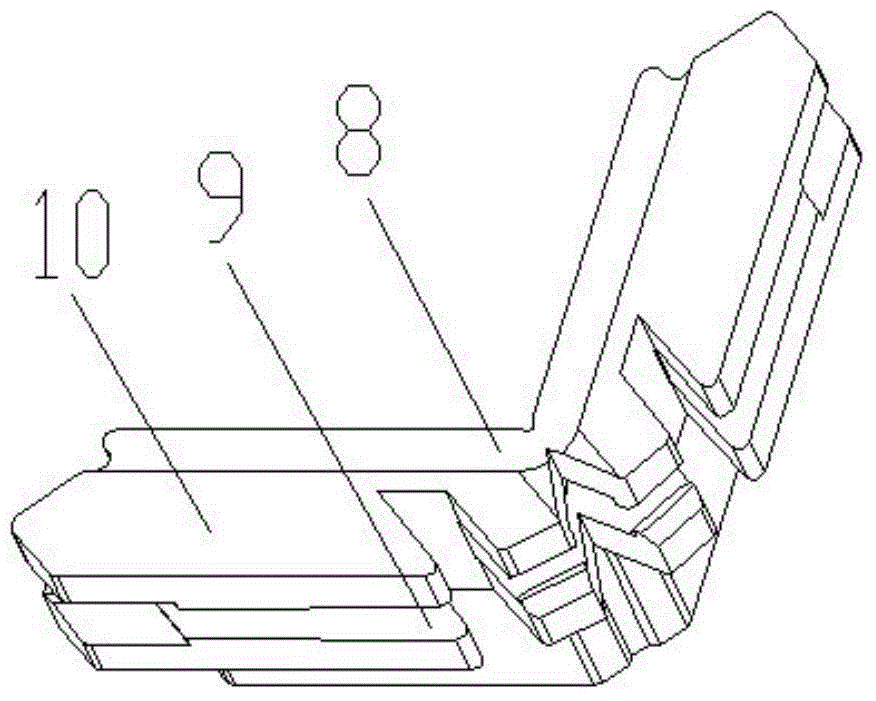

Multilayer protective low-smoke zero-halogen flame retardant fireproof control cable and manufacture method thereof

ActiveCN103123818AImprove shielding effectImprove sealingClimate change adaptationInsulated cablesCopper conductorPolyester

The invention relates to a multilayer protective low-smoke zero-halogen flame retardant fireproof control cable and a manufacture method thereof and belongs to the technical field of control cable manufacture. The technical scheme is that a fireproof mica layer (2) and a crosslinked polyethylene insulating layer (3) are sequentially arranged outside a copper conductor (1), and a polyester film wrapping belt (4), a metal shielding layer (5), an inner protective layer I (6), an inner protective layer II (7), an inner protective layer III (8), a metal armor layer (9) and an outer protective layer (10) are sequentially arranged outside the cable. The method adopts an aluminum belt embossing and double layer coextrusion mode, improves working efficiency and improves the quality of longitudinal wrapped aluminum tapes and extruded nylon. The cable adopts the 105 DEG C irradiation crosslinked polyethylene insulating layer, the temperature resisting level of the cable is improved, the mechanical performance of the cable is good, the tangent value of dielectric constant and dielectric loss angle is small, and the insulating electrical performance is excellent. Water or moist can be effectively prevented from entering the cable by adopting the embossing longitudinal wrapped aluminum tapes, simultaneously the cable has good shielding effect, the bending performance of the cable is ensured, and installation and using of the cable are facilitated.

Owner:HEBEI HUATONG WIRES & CABLES GRP CO LTD

High temperature resistance extrasoft fluoroplastic insulation branch cable component

InactiveCN101593575AEasy to useWide range of usesInsulated cablesCable junctionsTemperature resistanceCopper wire

The invention provides a high temperature resistance extrasoft fluoroplastic insulation branch cable component. The component is characterized in that the component adopts a structure mode of a master control cable and a plurality of branch cables, wherein conductor wire cores among the master control cable and each branch cable are connected by silver-plated connectors; a high temperature resistance heat shrinkage bushing arranged outside the silver-plated connector is taken as an envelope; a tinned copper wire woven shield, an F4 tape wrapping layer and a restrictive coating made of aramid fiber are formed on the outer layer of the envelope in sequence; the cable structure of the master control cable and each branch cable uses a shield signal wire as an inner ring and an operating line as an outer ring. The component can greatly reduce the consumption of wire bundles, is convenient for construction, can meet special performance requirement, such as high and low temperature resistance, fire retardation, climate resistance, corrosion resistance, aging resistance, mold resistance, reliability, flexibility, small volume, light weight and the like.

Owner:HUAINAN XINGUANGSHEN OPTICAL FIBER CABLE

Strip-casting 700-MPa-level weathering resistant steel and production method thereof

The invention discloses strip-casting 700-MPa-level weathering resistant steel and a production method thereof. The method comprises the steps of 1), smelting: the chemical components of molten steelcomprises C lower than 0.03%, 0.20-0.80% of Si, Mn lower than 1.0%, 0.03-1.50% of P, S lower than or equal to 0.008%, N lower than or equal to 0.008%, 0.40-1.50% of Cu, 0.80-1.50% of Cr, Ni lower than0.10%, 0.05-0.20% of Nb, 0.05-0.20% of V and the balanced Fe and unavoidable impurities; 2), strip casting: continuous casting is conducted on molten steel on which qualified smelting is conducted bya pair of copper casting rolls which are rotated in the same directions to produce a casting strip with the thickness of 1.4-2.5 mm, and the superheating of the molten steel is controlled to be lowerthan 80 DEG C; 3), casting strip online hot rolling: the hot rolling pressing amount is 15-65%, the temperature of pressed strip steel is 950-1050 DEG C; 4), cooling and winding: the temperature of strip steel on which hot rolling is conducted is cooled down to 300-450 DEG C through atomizing cooling to obtain fine and uniform ferrite and less amount of pearlite tissues. The 700-MPa-level weathering resistant steel has the advantages of short production procedure, low production cost, good strip steel shape and easy welding.

Owner:SHAGANG GROUP +2

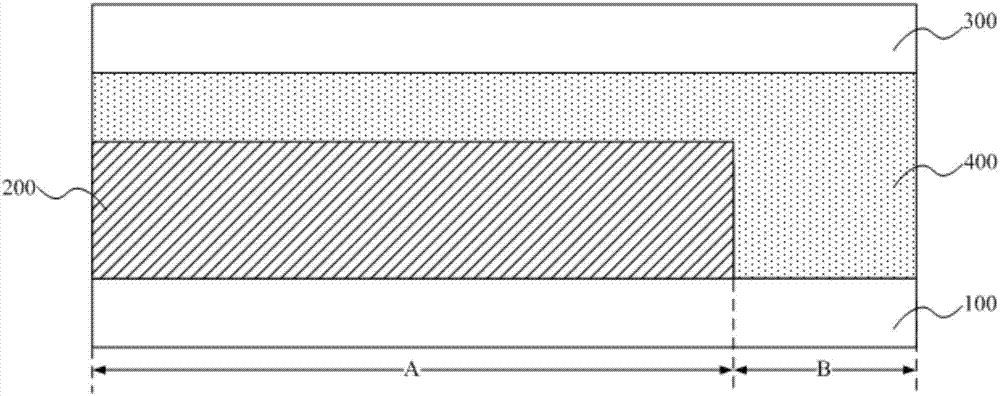

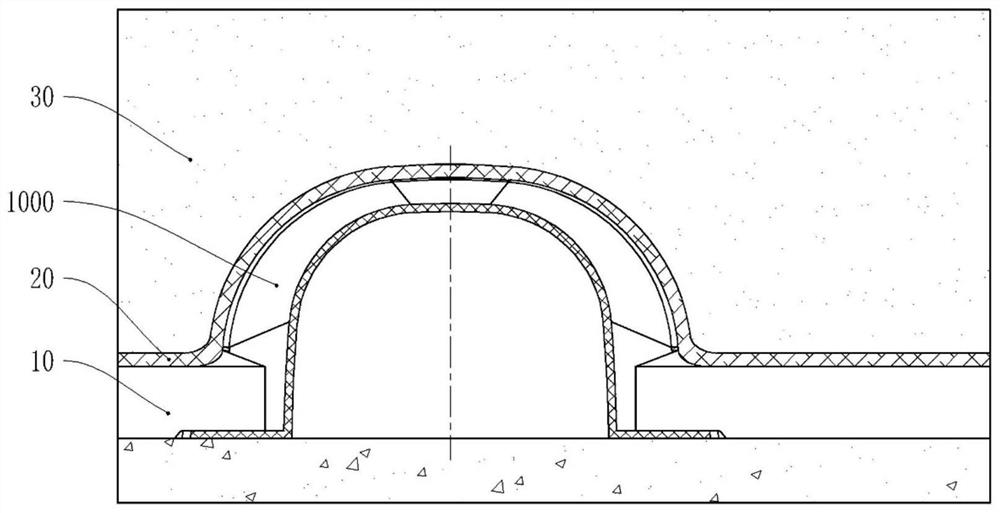

Display screen and electronic equipment

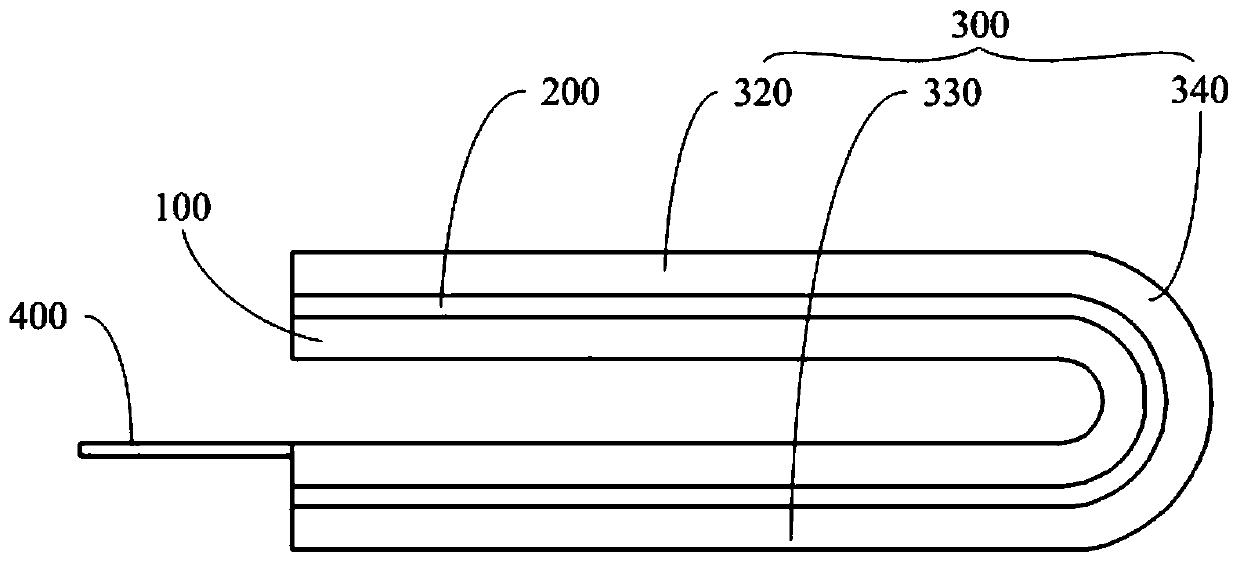

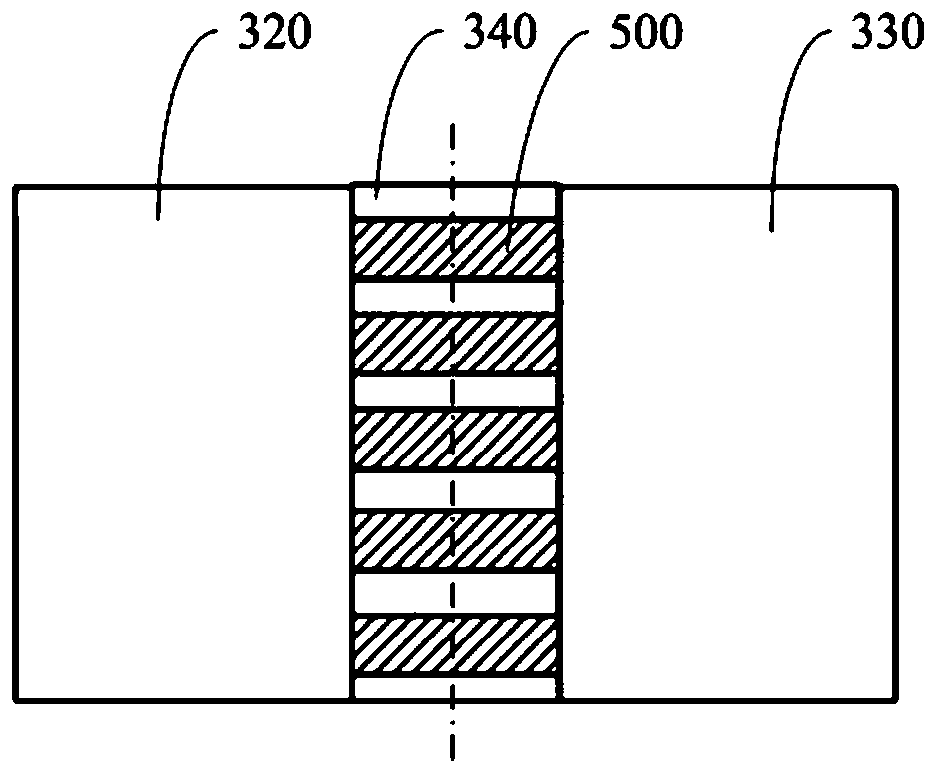

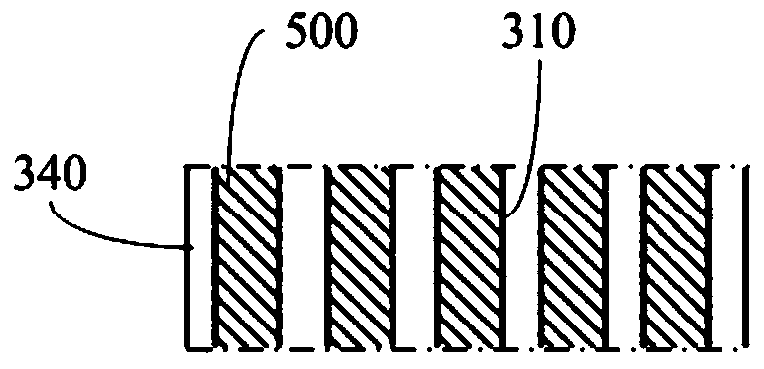

PendingCN111443768AGuaranteed bending performanceBend limitDigital data processing detailsIdentification meansEngineeringFlexible display

The invention discloses a display screen and electronic equipment, the display screen comprises a flexible display screen body (100), connecting glue (200) and a protective layer (300), the flexible display screen body (100) is connected with the protective layer (300) through the connecting glue (200), and the protective layer (300) covers the connecting glue (200); the flexible display screen body (100) comprises a first area, a second area and a third area. The third area is located between the first area and the second area, the protective layer (300) is provided with at least two concaveparts (310) corresponding to the third area, and the concave parts (310) are arranged at intervals in the extending direction of the bending axis of the flexible display screen body (100). The schemecan solve the problem that the display screen is easy to damage.

Owner:VIVO MOBILE COMM CO LTD

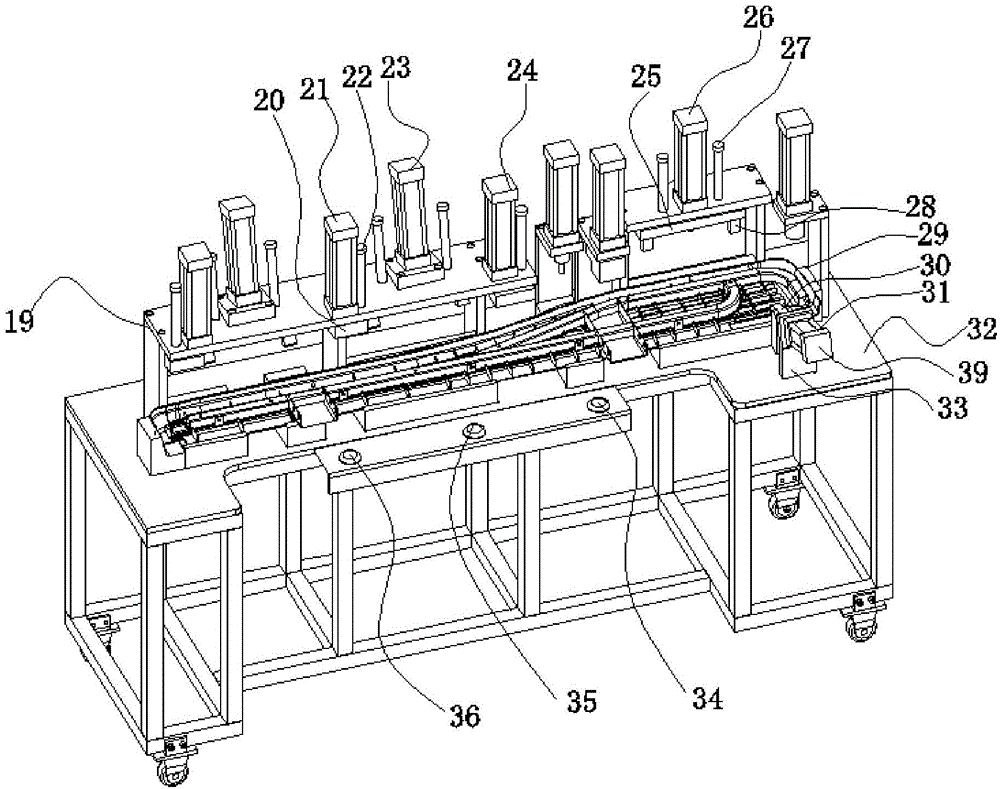

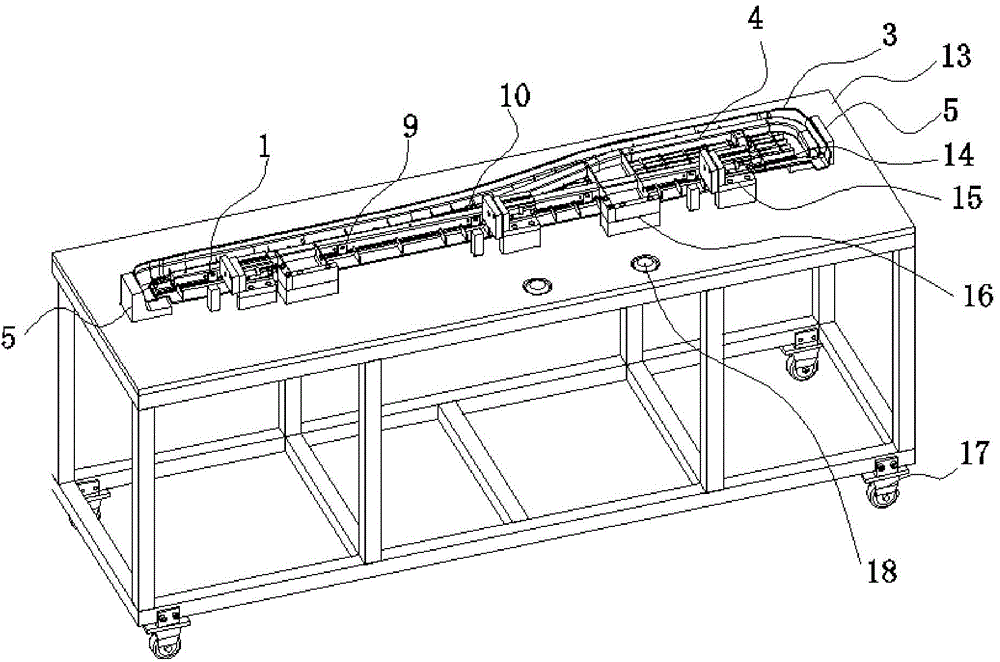

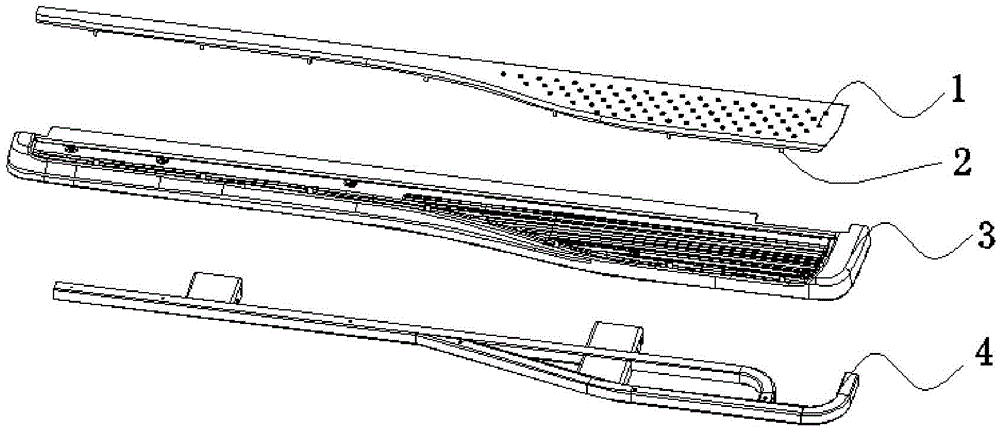

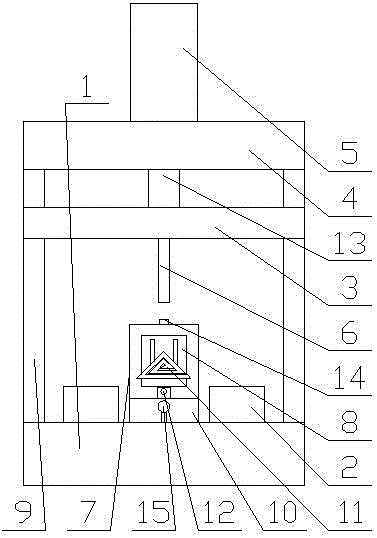

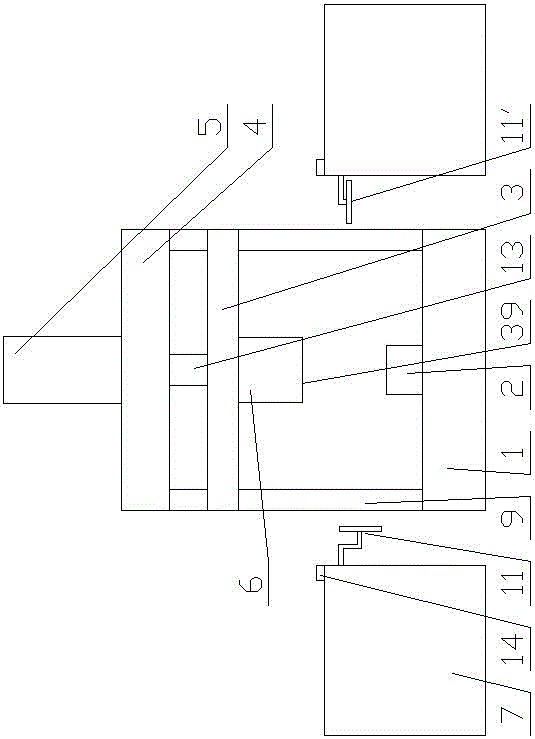

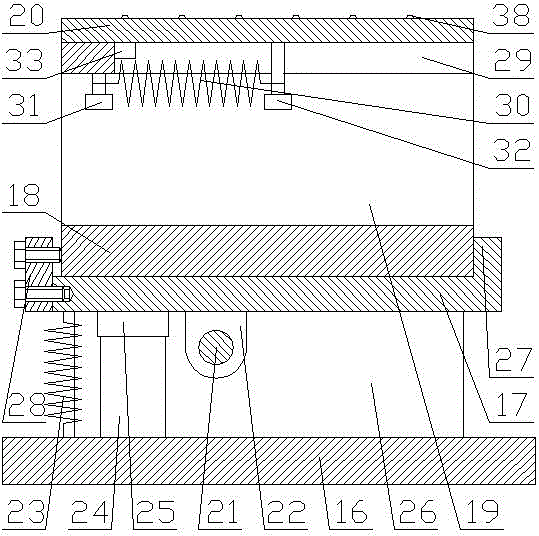

Assembling equipment and assembling process for automobile pedal assembly

ActiveCN104589035AAvoid misalignmentFacilitate the oblique downward forceMetal working apparatusControl switchRivet

The invention discloses assembling equipment and an assembling process for an automobile pedal assembly, which are applied to the assembling of an automobile pedal. The assembling equipment for the automobile pedal assembly comprises an initial assembling device and a pressing fixing device; the initial assembling device comprises an operating floor, cylinder push-on assemblies, plastic part locating pieces, push-on switches and metal part support locating pieces, wherein the cylinder push-on assemblies, the plastic part locating pieces, the push-on switches and the metal part support locating pieces are arranged on the operating floor; the pressing fixing device comprises a worktable, a product locating seat, cylinder fixing assemblies, first cylinder bending assemblies, a second cylinder bending assembly and a control switch, wherein the product locating seat, the cylinder fixing assemblies, the first cylinder bending assemblies, the second cylinder bending assembly and the control switch are arranged on the worktable; initial assembling and locating are performed on all components of the automobile pedal through the initial assembling device; metal feet of the automobile pedal are bent and fixed through the pressing fixing device, and finally, rivet installation is performed. The invention aims at solving the problems of difficult assembling, low assembling precision and low efficiency of the existing automobile pedal assembling technology.

Owner:GUANGZHOU ZHONGXIN PLASTIC

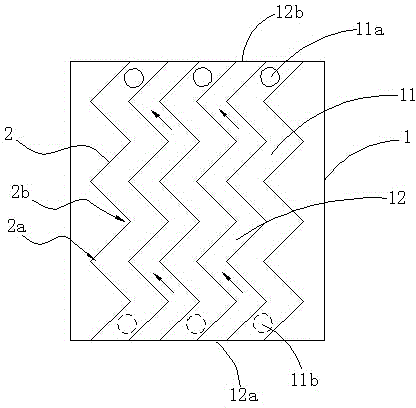

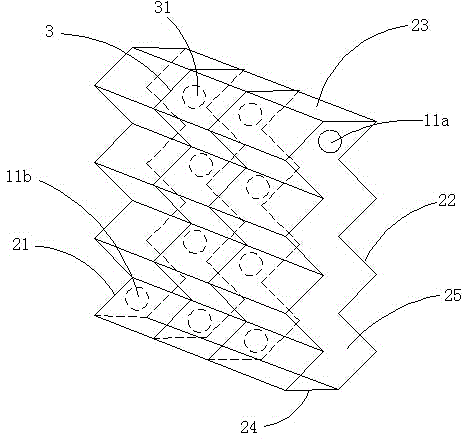

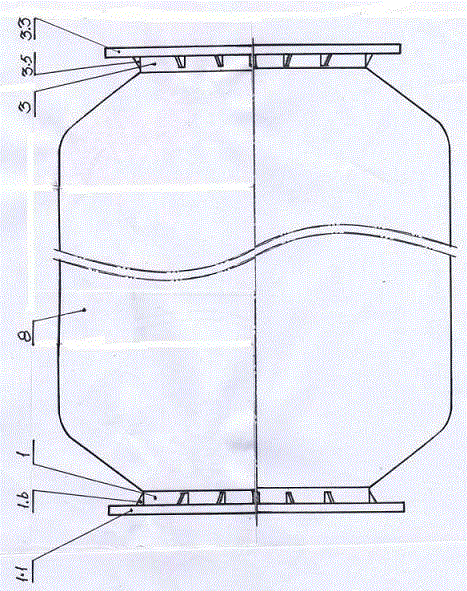

Pressure resistant heat exchanger

ActiveCN104567492AEasy to useReduce volumeHeat exchanger casingsStationary plate conduit assembliesEngineeringHeat exchanger

The invention discloses a pressure resistant heat exchanger comprising a housing. Bent units are arranged in the housing at intervals, are provided with liquid accommodating cavities inside and are provided with liquid inlets and liquid outlets; partitions matching with the bent units in shapes are arranged in the bent units at internals, two sides of the partitions are fixedly connected to first bent plates and second bent plates of the bent units, the partitions are provided with through holes, smoke channels are formed between the adjacent bent units, one ends of the smoke channels are provided with smoke inlets, the other ends are provided with smoke outlets, and the sections of the liquid cavities and smoke channels are in continuous bent structures. The pressure resistant heat exchanger is simple in structure, the bent units are adopted and the liquid cavities and smoke channels in the continuous bent structures are arranged in the housing, structure is compact, and size is small; the pressure resistance of the bent units is improved by arranging the partitions in the bent units.

Owner:宁波锦心节能环保科技有限公司

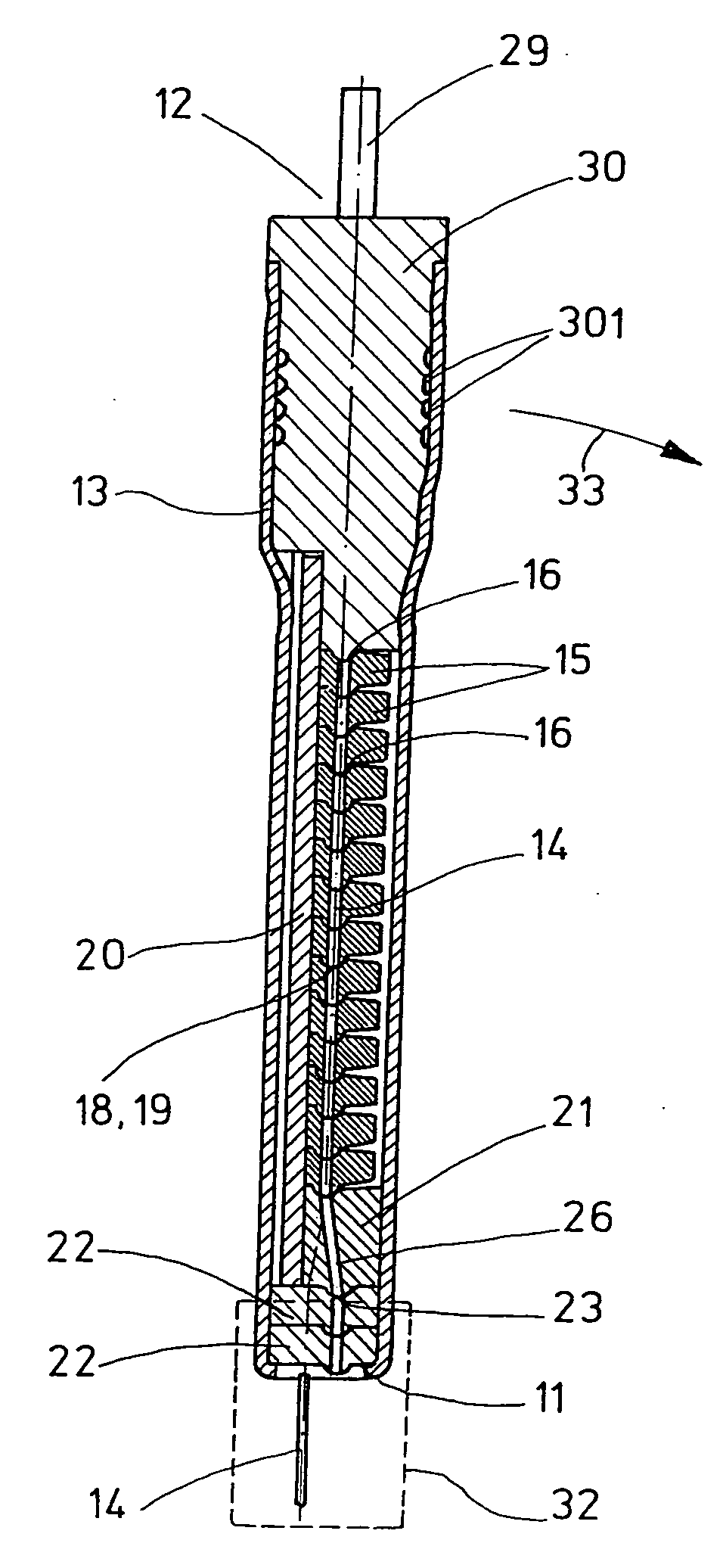

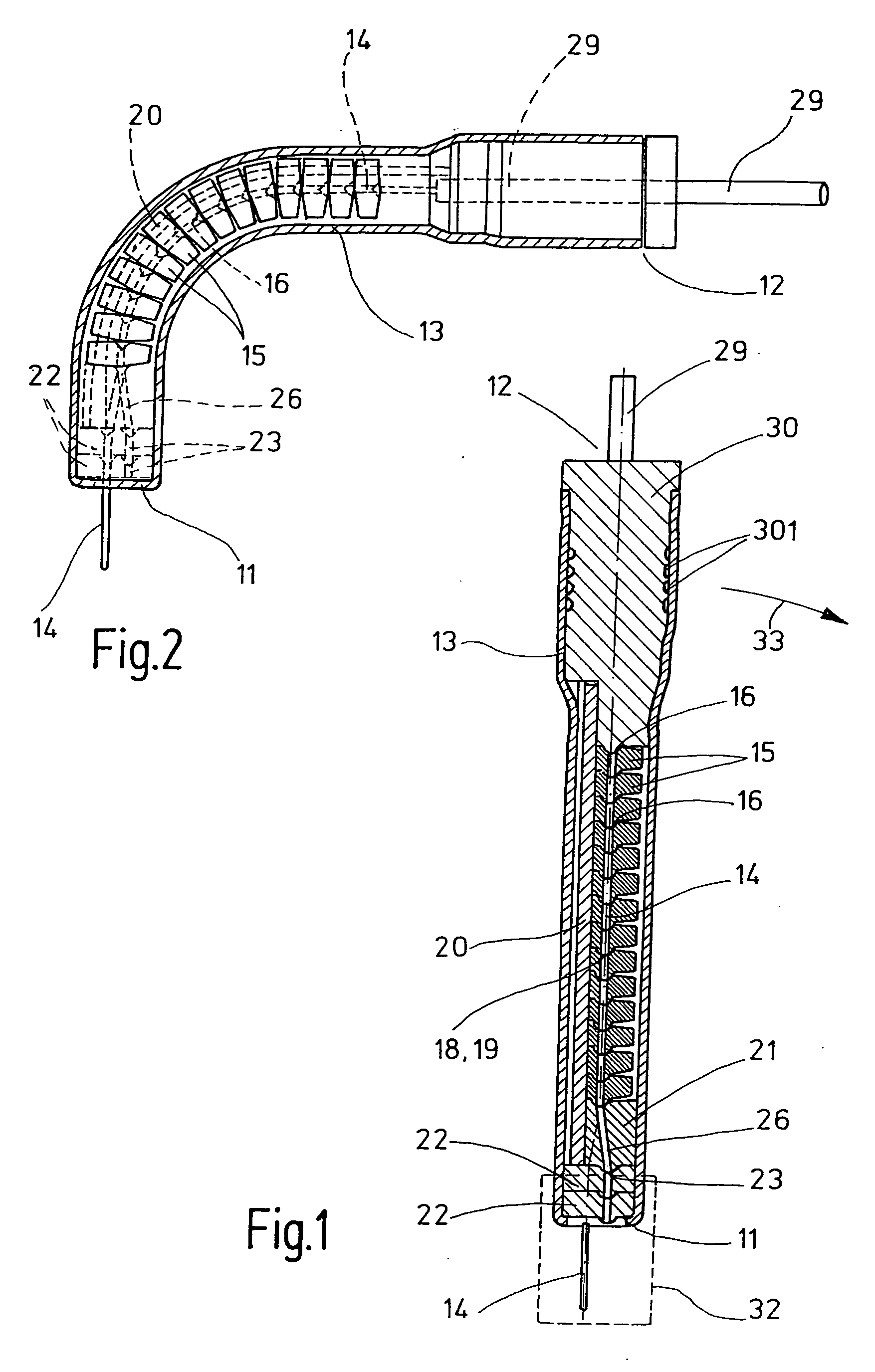

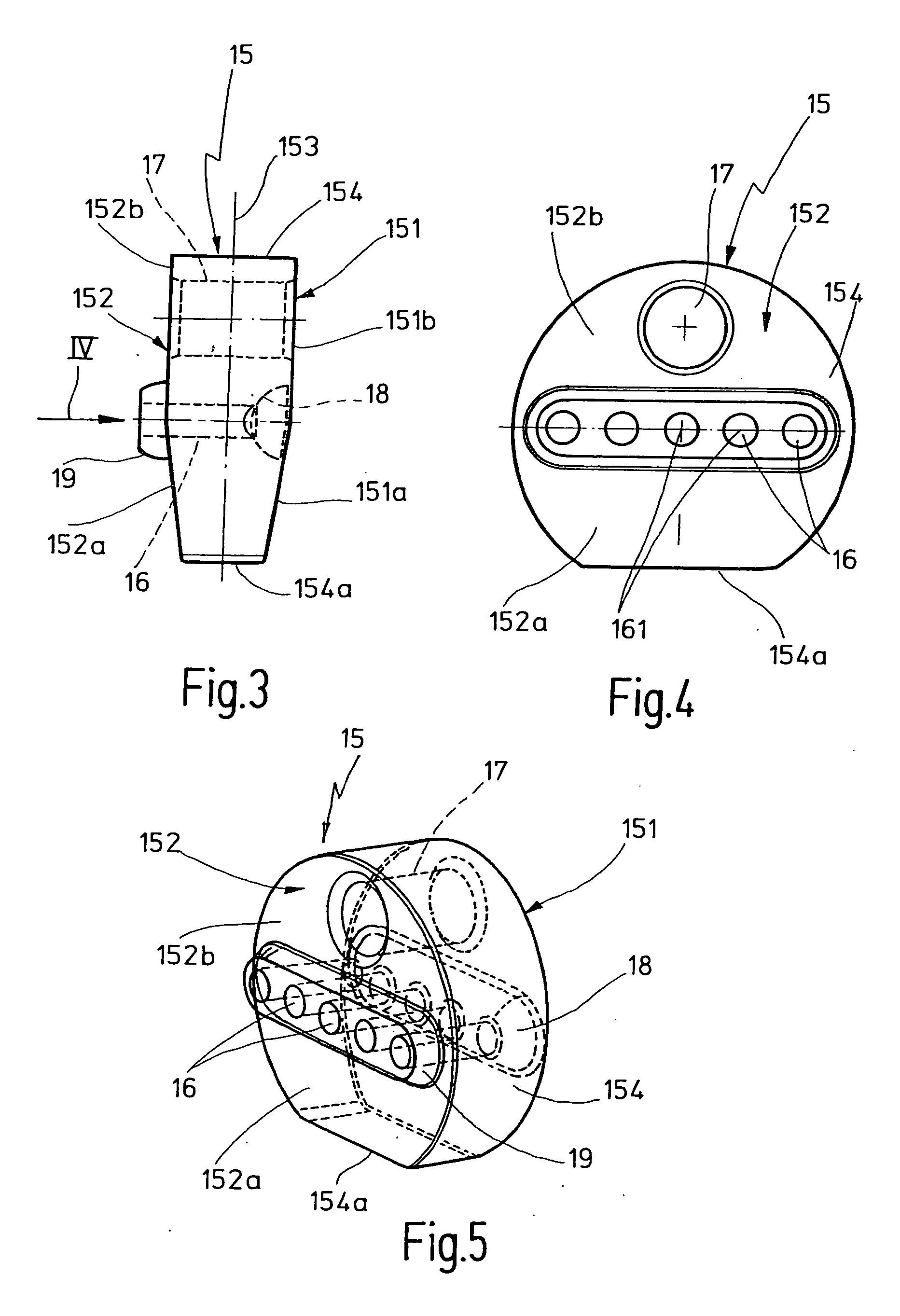

Connecting lead for a sensor

InactiveUS20060121800A1Expensive to manufactureSimple and inexpensive fashionRigid-tube cablesSoldered/welded conductive connectionsCombustionElectrical conductor

A connecting lead for a sensor, in particular for a sensor for determining a physical property of a measured gas, e.g. for determining the temperature or oxygen content in the exhaust gas of internal combustion engines, is described, said sensor comprising a sheathing tube, at least two electrical conductors extending in the sheathing tube, and an insulating arrangement that insulates the electrical conductors from one another and from the sheathing tube. To allow the use of unsheathed bare metal wires as electrical conductors, and avoid short circuits on the one hand between the metal wires and on the other hand between the metal wires and the sheathing tube, especially upon bending of the metal tube during installation, the insulating arrangement has a plurality of insulating elements, braced against one another, that have at least two through holes through each of which one electrical conductor is guided.

Owner:ROBERT BOSCH GMBH

Prefabricated on-site bending forming connecting device, FRP rib bending forming method and FRP rib material

ActiveCN111877643AExert strengthSolve the durability problemBuilding reinforcementsFirming agentStructural engineering

The invention discloses a prefabricated on-site bending forming connecting device, an FRP rib bending forming method and an FRP rib material. The connecting device comprises a connecting piece, the two ends of the connecting piece are provided with a first end and a second sleeve respectively, and the first end comprises a casing pipe, a telescopic pipe and a first sleeve which are fixedly connected in sequence. A curing agent capsule and an epoxy resin capsule body are arranged outside the connecting piece, after a telescopic pipe is stretched, the tail end of the first sleeve is arranged onthe second sleeve in a sleeving mode, the telescopic pipe wraps the connecting piece, the curing agent capsule and the epoxy resin capsule body, and a blade is fixed in the first sleeve. By utilizingthe property that a curing agent and epoxy resin glue are cured after being mixed, the curing agent and the epoxy resin glue are separated firstly, and when bending is needed, the blade is driven to move by means of the telescopic performance of the telescopic pipe, so that the curing agent and the epoxy resin glue are mixed to connect and fix FRP ribs broken due to bending.

Owner:CHANGAN UNIV

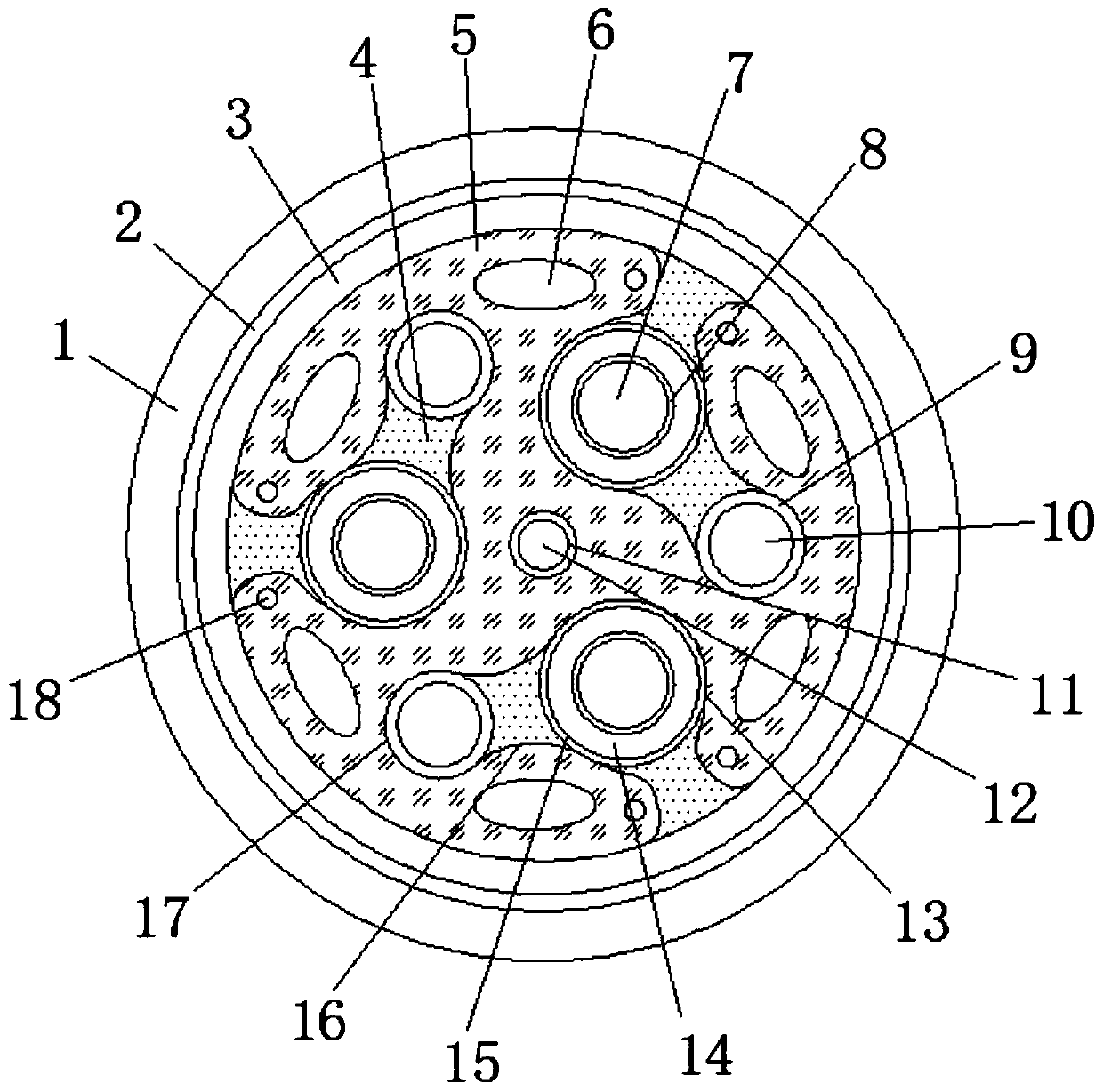

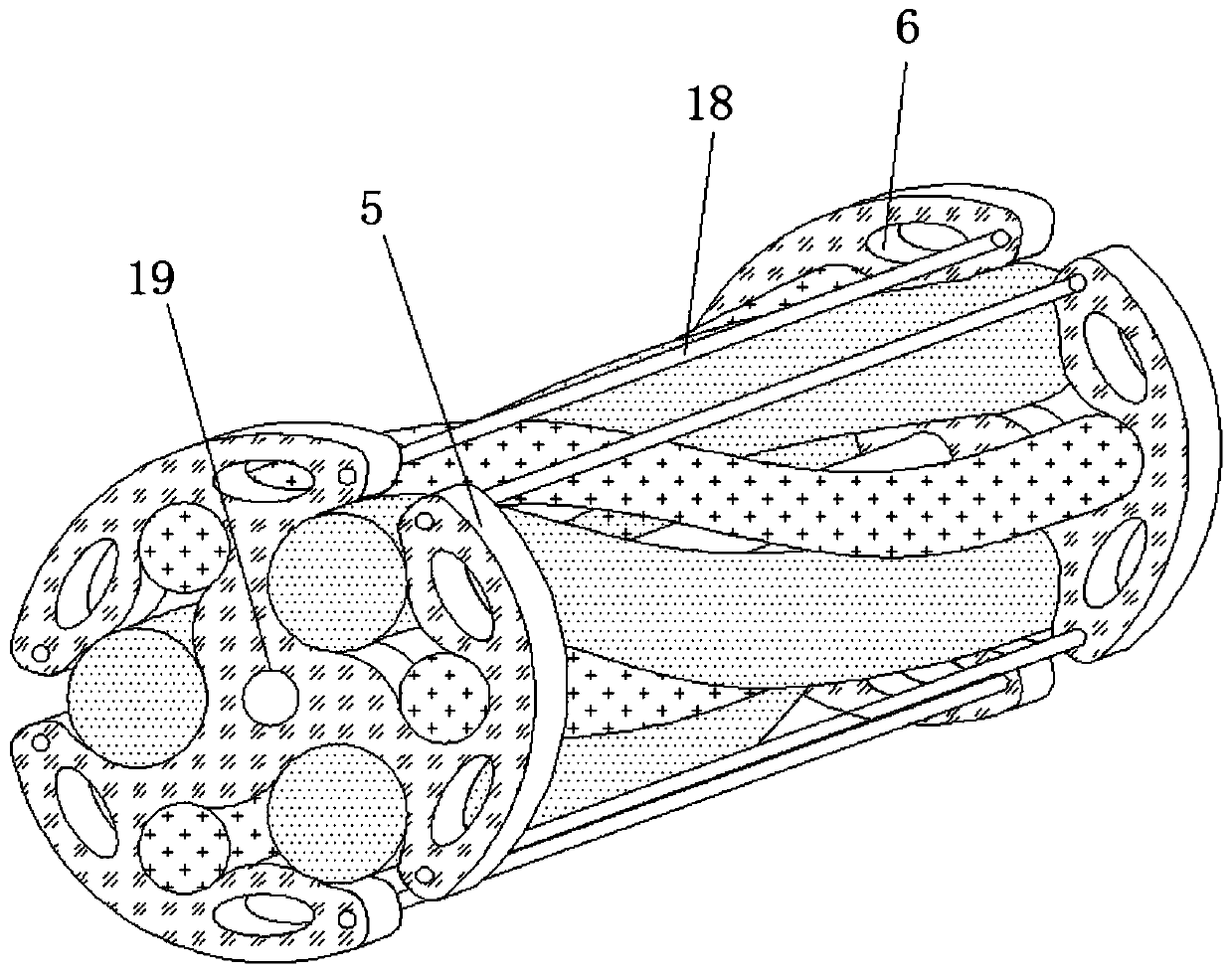

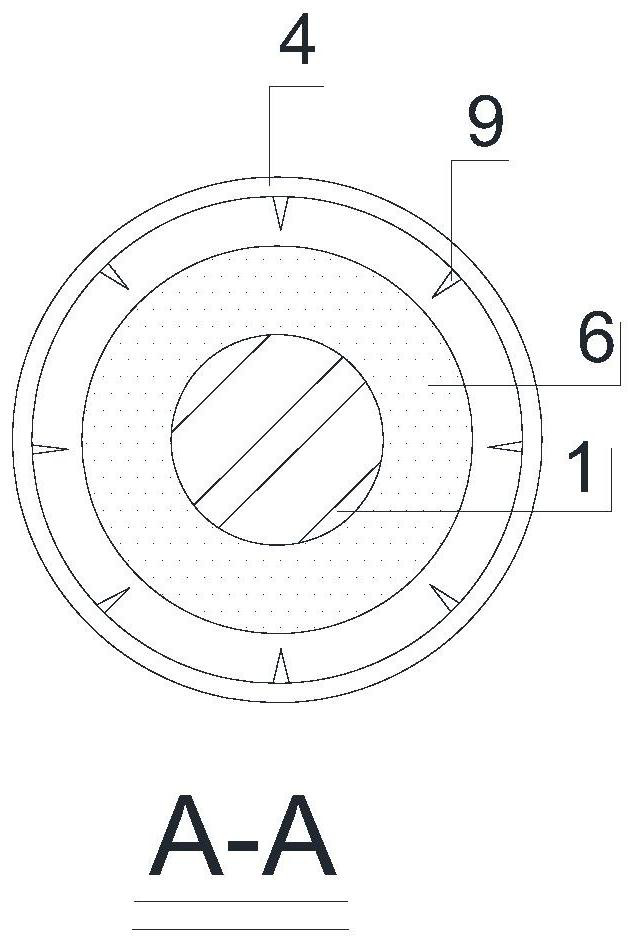

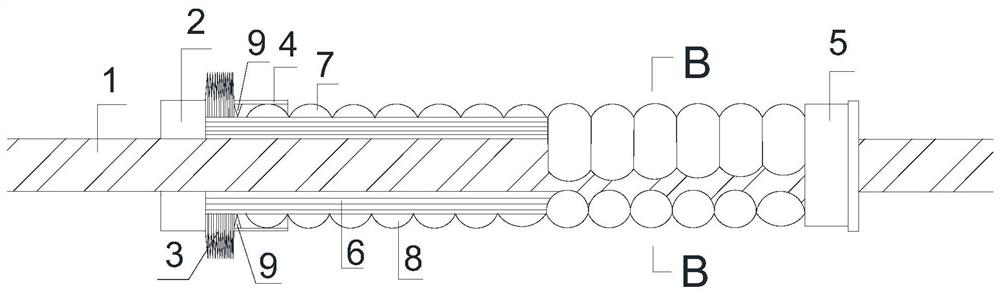

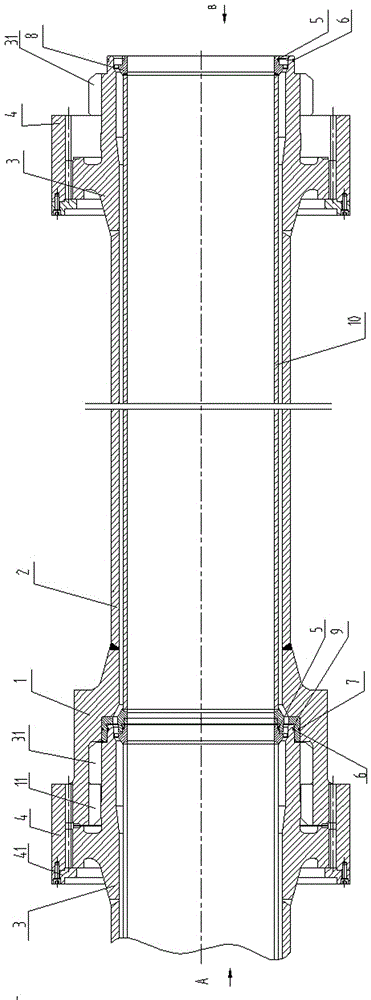

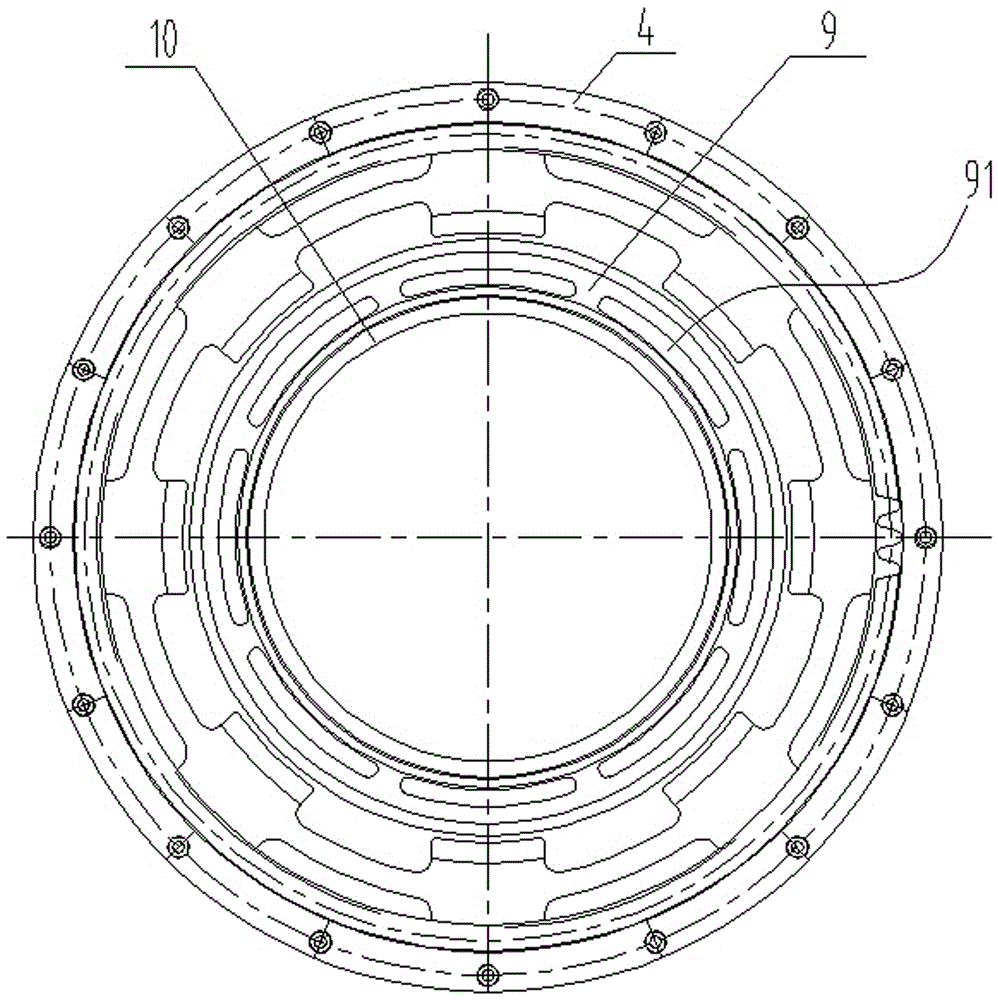

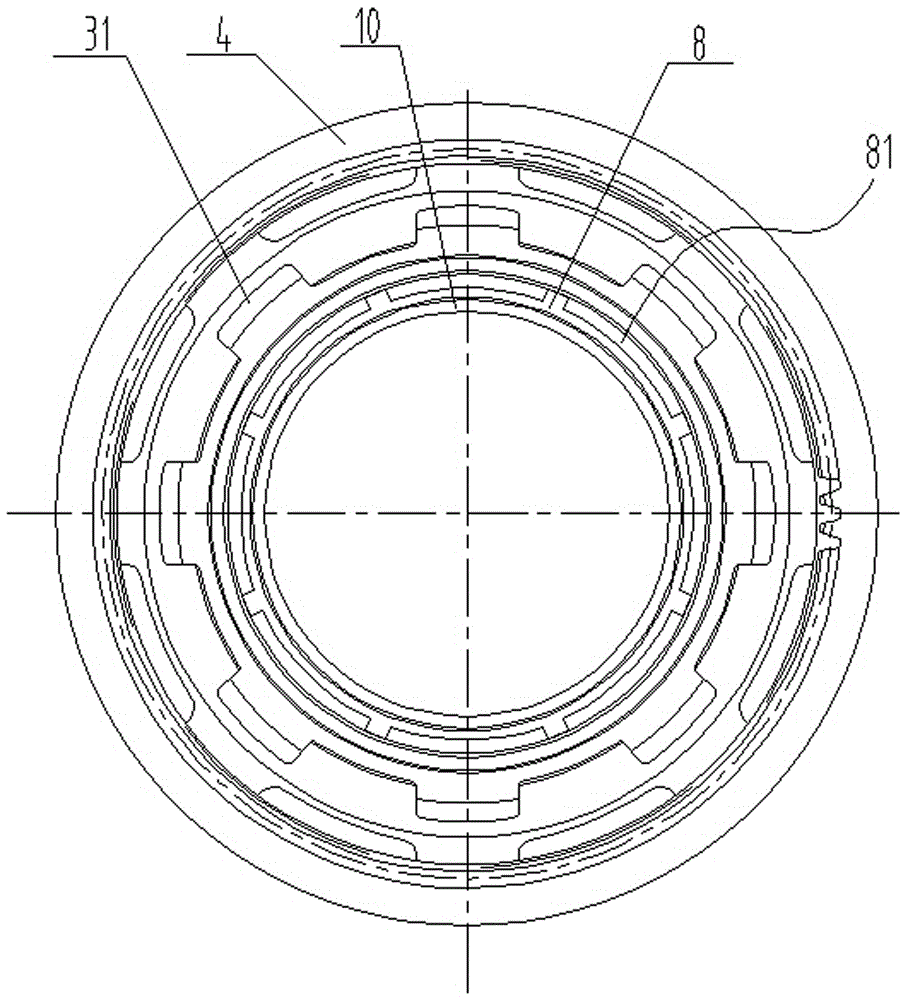

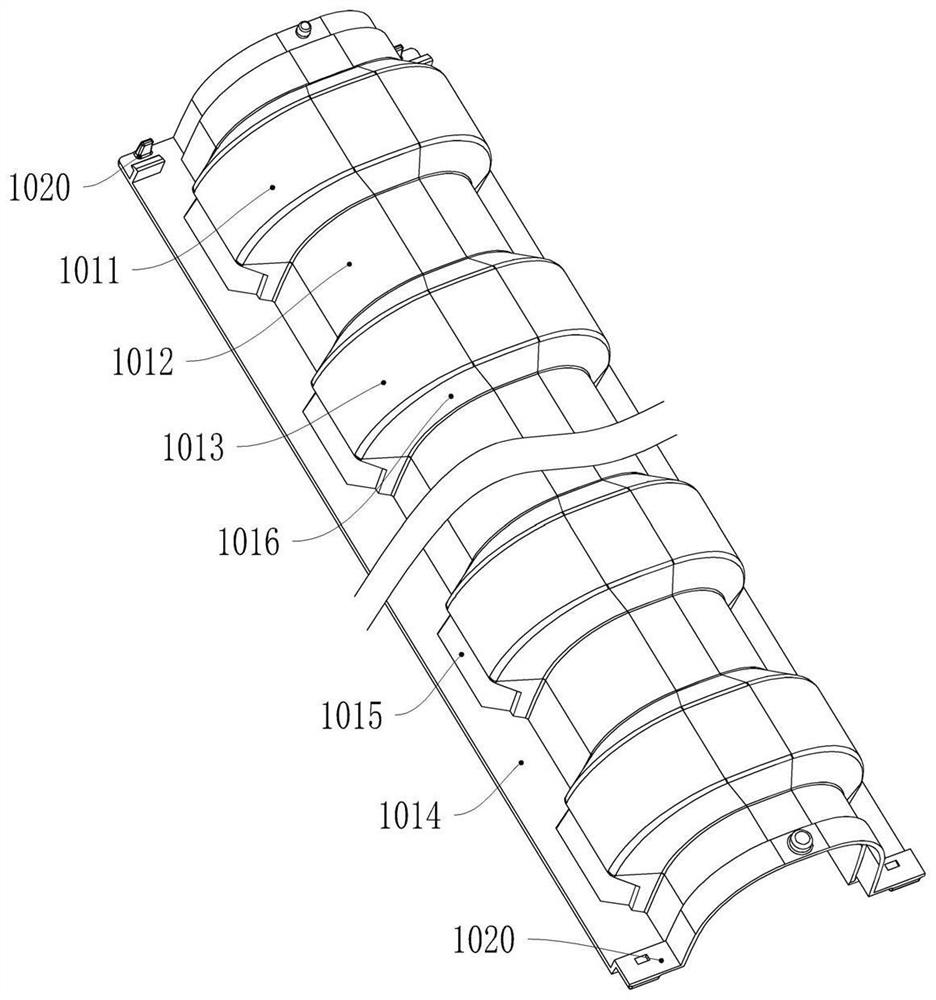

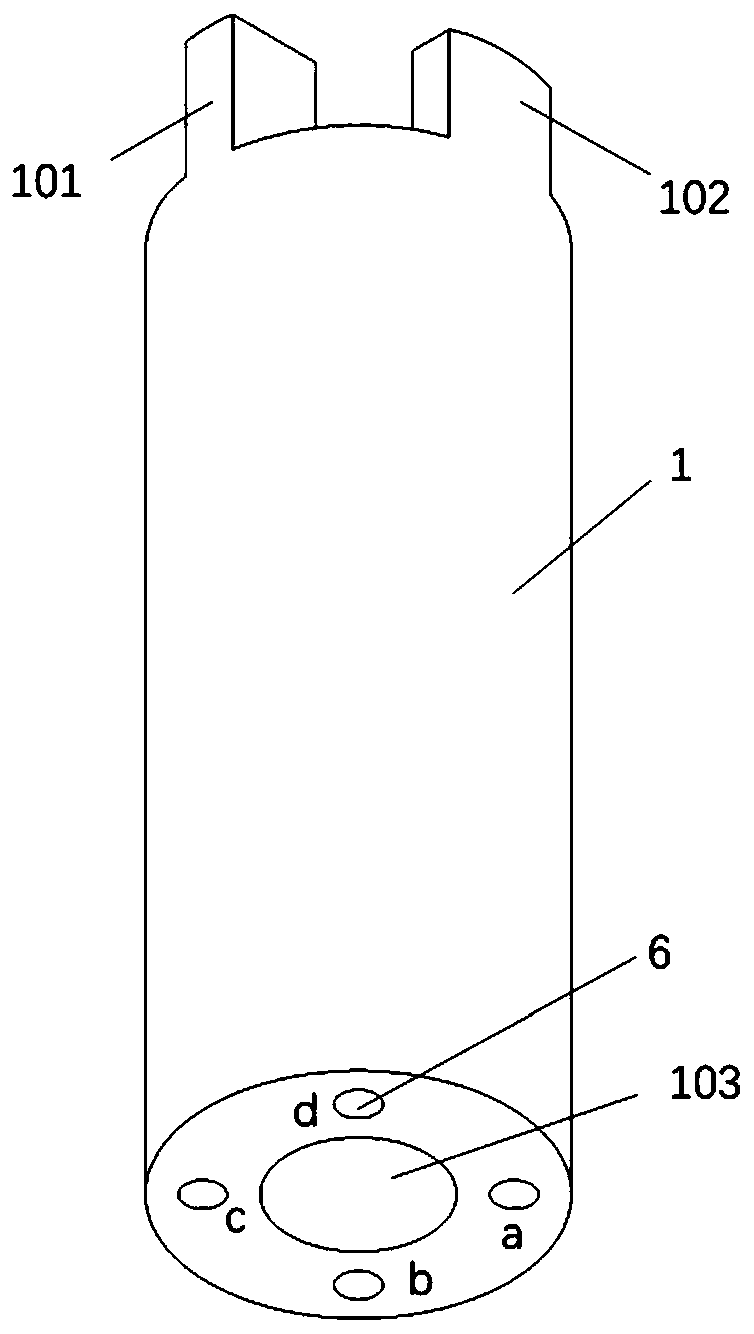

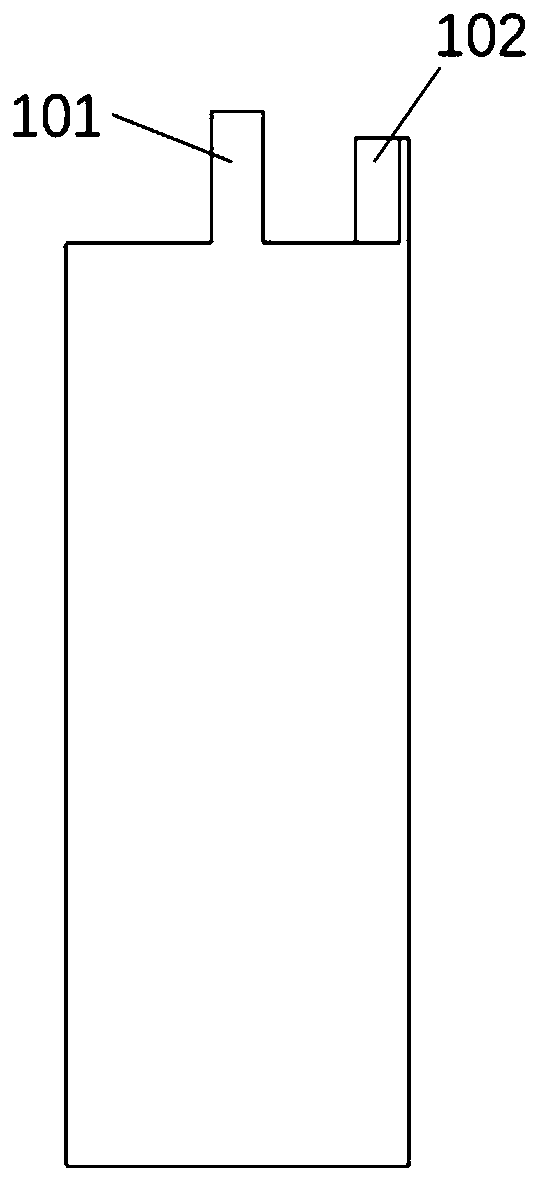

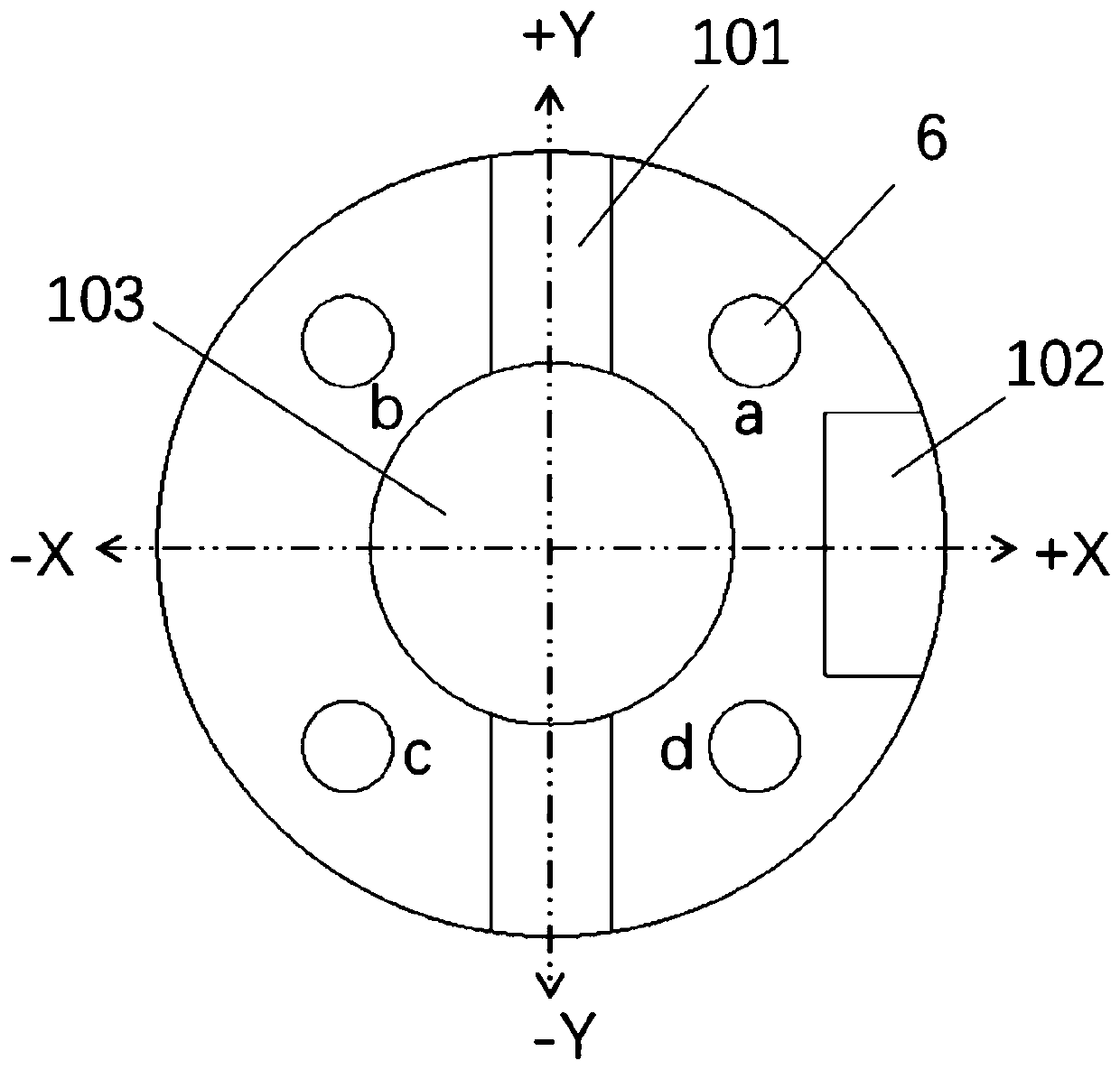

Inner embedding tooth and outer gear coupler type double-layer drill rod

ActiveCN105756574ARealize twistGuaranteed bending performanceDrilling rodsDrilling casingsUpper jointEmbedded tooth

The invention discloses an inner embedding tooth and outer gear coupler type double-layer drill rod, which comprises a double-layer drill rod body, wherein the double-layer drill rod body comprises an outer pipe, an inner pipe, an upper joint, a lower joint, an upper sealing ring and a lower sealing ring; the inner pipe and the outer pipe are arranged in the same axial direction; a gap is formed between the inner pipe and the outer pipe; the upper joint is arranged at the upper end of the outer pipe; the lower joint is arranged at the lower end of the outer pipe; the upper joint and the lower joint are respectively and fixedly connected with the outer pipe to form a bearing structure of the drill rod; the upper sealing ring and the lower sealing ring are respectively positioned in the upper joint and the lower joint of the drill rod and are connected with the inner pipe to form an inner layer structure of the drill rod; inner embedding teeth are arranged inside the upper joint along the circumferential direction; outer embedding teeth are arranged outside the lower joint along the circumferential direction; the outer periphery of the upper joint and the outer periphery of the lower joint are provided with outer gears in the same structures; an inner gear sleeve sleeves the outside of the outer gear of the lower joint. The drill rod provided by the invention is used as an engineering drilling machine drill rod, is used for power transmission and airlifting reverse circulation fluid transmission, and has the advantages that the bearing is safe, the fast dismounting can be realized, and the double-layer sealing is reliable.

Owner:PINGMEI JIANGONG GRP SPECIAL DRILLING ENG CO LTD +1

Super-flexible intelligent-control photoelectric composite cable for high-speed video transmission

InactiveCN108847305ASimple structureMeet video signal transmissionFibre mechanical structuresFlexible cablesYarnElectrical conductor

The invention discloses a super-flexible intelligent-control photoelectric composite cable for high-speed video transmission. The super-flexible intelligent-control photoelectric composite cable for high-speed video transmission can simultaneously meet the requirements of video signal transmission, control signal transmission and electricity energy supplying; the composite cable comprises opticalunits, electric units, data lines, a reinforcing core, and a cable core; a bending loss insensitive tight-buffered optical fiber serves as an optical fiber, the surface of the optical fiber is wrappedwith a nylon tight-buffered layer in an extruded mode, the exterior of the nylon tight-buffered layer is reinforced through water blocking aramid, and the exterior of the water blocking aramid is wrapped with an optical fiber protecting bush in an extruded mode; tinned copper stranded conductors serve as conductors, and the surfaces of the electric unit conductors are wrapped with crosslinked polyethylene insulation materials in an extruded mode; the data lines adopt bare copper stranded conductors, and the surfaces of the data line conductors are wrapped with high-density polyethylene insulating materials in an extruded mode; the reinforcing core adopts vertically-placed aramid yarn, and the surface of the aramid yarn is wrapped with a reinforcing core protecting sleeve in an extruded mode; the cable core comprises the two optical units, the four electric units, the two data lines and the reinforcing core, the center of the reinforcing core is vertically placed, and the two optical units, the four electric units and the two data lines surround the reinforcing core; and the cable core is externally provided with a wrapping tape, a shielding part and an outer protecting sleeve in sequence.

Owner:JIANGSU ZHONGLI GRP CO LTD

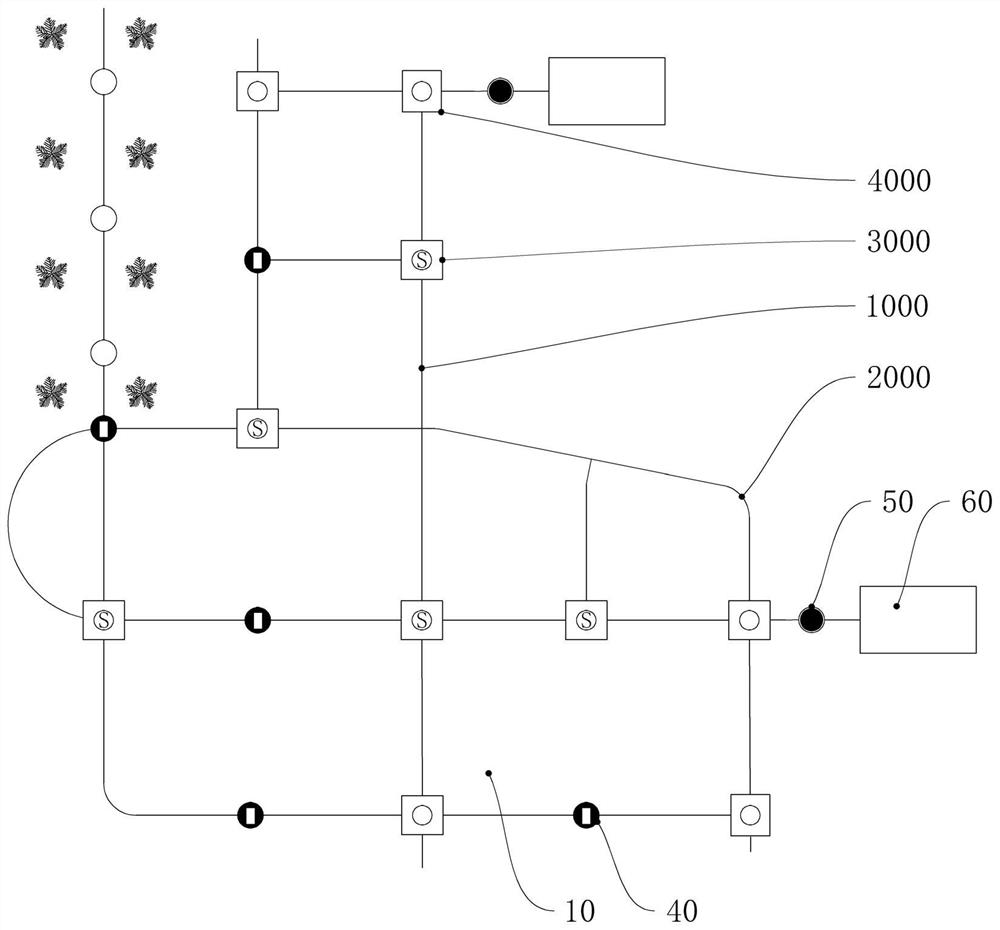

Rainwater management system

ActiveCN113775020AReduce hedgingReduce deliverySewerage structuresGeneral water supply conservationSiphonWater management system

The invention relates to the field of drainage, in particular to a rainwater management system capable of quickly draining rainwater. The rainwater management system comprises a drainage plate, a drainage network and a permeable layer, wherein the permeable layer covers the drainage network, and the drainage network at least comprises a unit area, a plurality of siphon variable-flow devices which are distributed on the periphery of the unit area and are connected through drainage grooves and are used for discharging water out of the unit area, a plurality of variable-flow drainage devices which are distributed on nodes of the drainage network in the unit area and are connected with one or more siphon variable-flow devices through drainage grooves so as to directionally guide water in different positions in the unit area to the siphon variable-flow devices and drainage plates which are distributed among the drainage grooves and are used for receiving water permeated from the permeable layer in the unit area and guiding the water into the drainage grooves. The relation among the drainage plates, the drainage grooves, the variable-flow drainage devices and the siphon variable-flow devices are reasonably arranged, so that the drainage efficiency is improved step by step, and an efficient drainage system is formed.

Owner:KESHUN WATERPROOF TECH CO LTD

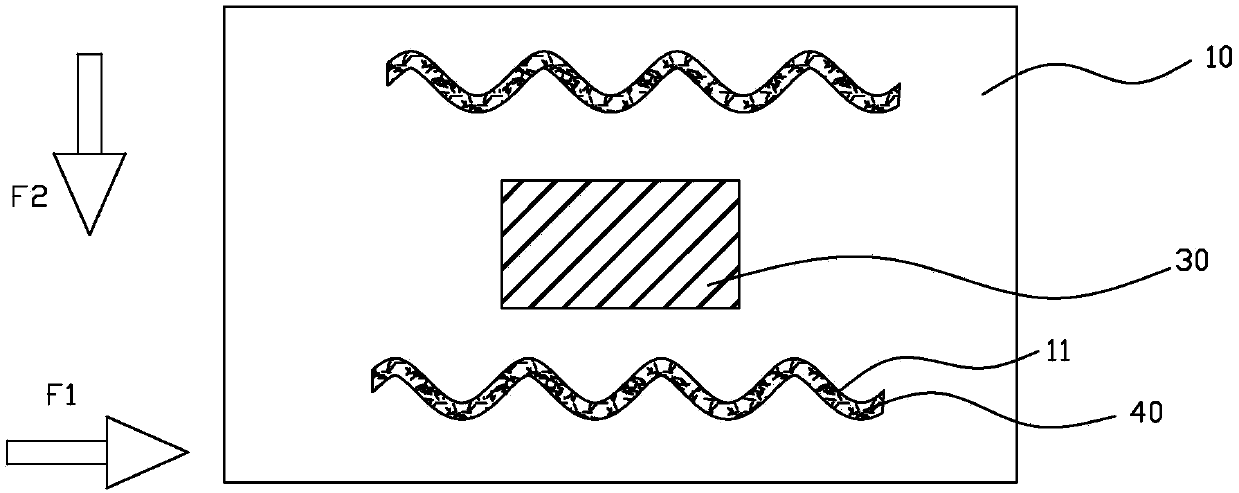

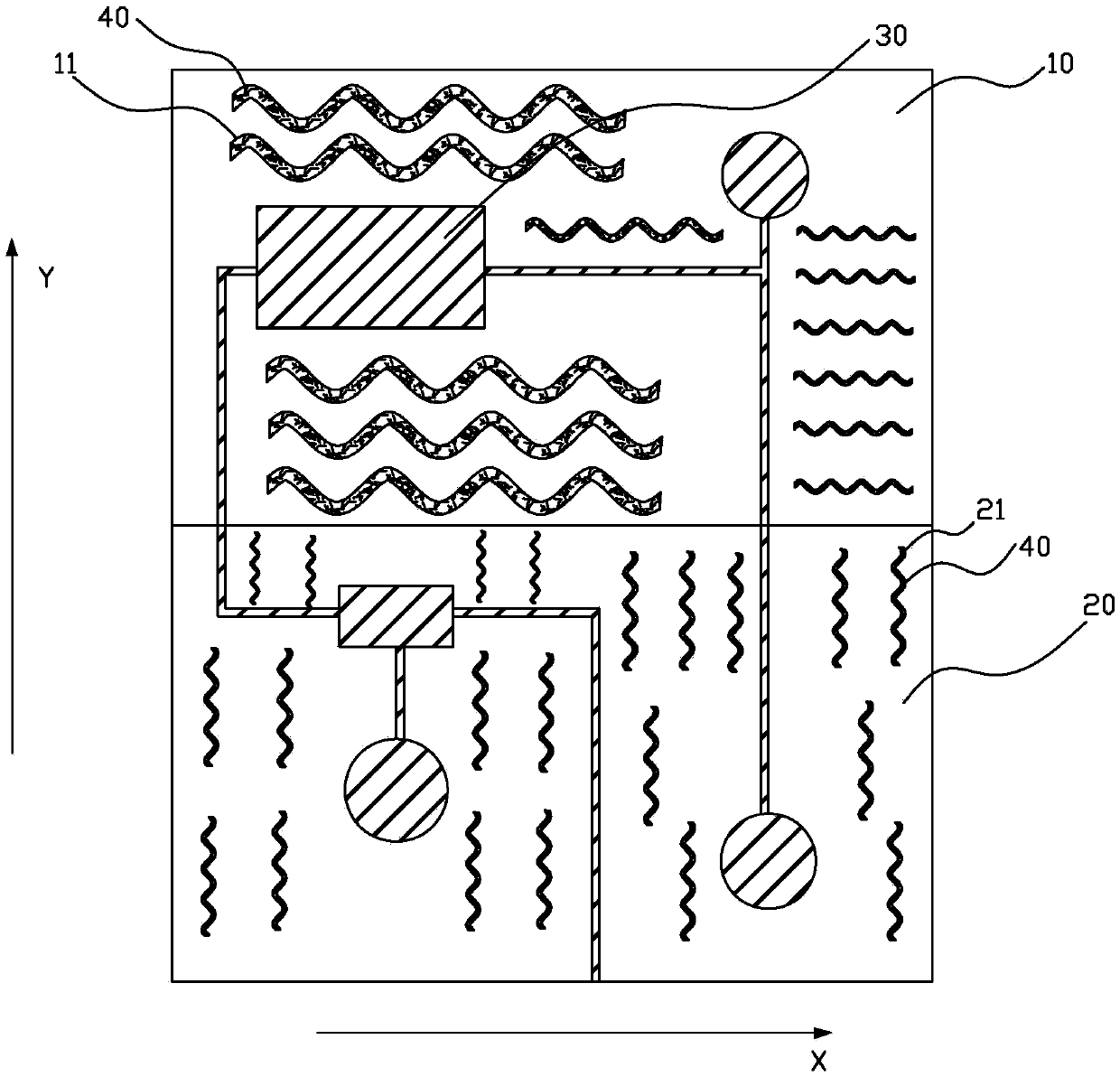

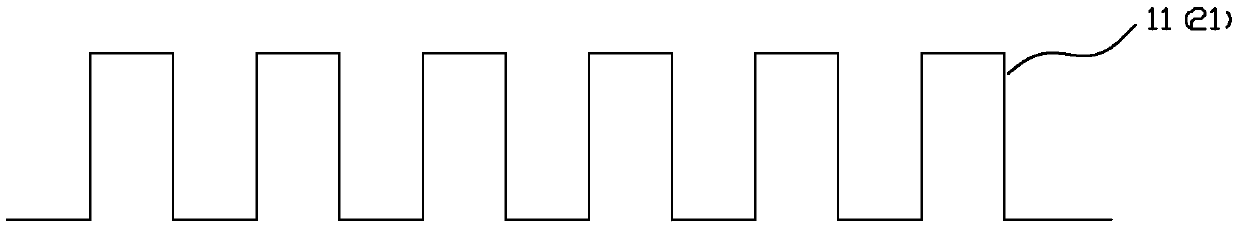

Flexible electronic device and fabrication method thereof

ActiveCN109616449ASave spaceGuaranteed bending performanceSemiconductor/solid-state device detailsSolid-state devicesFlexible electronicsNon-Newtonian fluid

The invention provides a flexible electronic device and a fabrication method thereof. The flexible electronic device comprises a first flexible substrate, wherein a circuit and a first runner are arranged on the first flexible substrate, the first runner extends along a wriggling shape, and the first runner is filled with a non-Newtonian fluid. By the flexible electronic device, the bending performance is ensured, and relatively good impact-resistant capability can be provided for the circuit.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

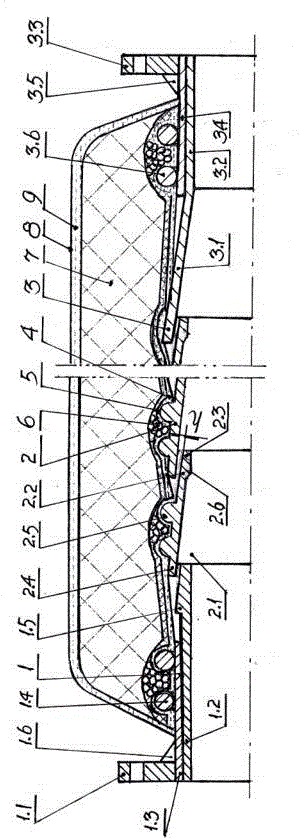

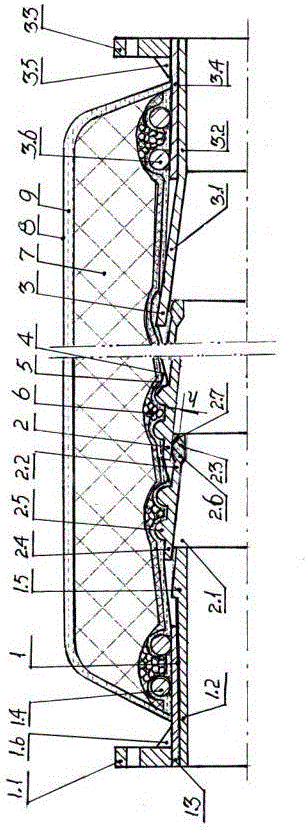

Mud pipe and design method for self-floating armored mud pipe

ActiveCN105135089AHighlight substantiveSignificant progressSoil-shifting machines/dredgersFlexible pipesProtection layerDesign methods

The invention discloses a mud pipe and a design method for the self-floating armored mud pipe, and belongs to the technical field of dredging engineering equipment. The design method for the self-floating armored mud pipe comprises overall design of the mud pipe and a floating body layer on the mud pipe and specific design of all parts; and the mud pipe is composed of an inlet end connecting pipe, an armored pipe body and an outlet end connecting pipe. The outer lateral face of the mud pipe is wrapped with a cord fabric powerful elastic material layer, an elastic material layer and a steel wire fastening layer which are bonded with the outer lateral face of the mud pipe; and the floating body layer is characterized in that a light body layer and a protection layer which are integrally connected with the elastic material layer of the mud pipe and are sequentially arranged on the outer side of the elastic material layer of the mud pipe. Compared with the prior art, the design method has the outstanding substantive features and prominent beneficial effects that the technical scheme is reliable, the bending requirement for adjusting the direction of the mud pipe is met, and the wear-resisting property of the mud pipe can be close to that of a metal composite mud pipe.

Owner:姜考成

Large-size angle steel high-frequency heating single-face bending machine used for extra-high voltage iron tower

The invention discloses a large-size angle steel high-frequency heating single-face bending machine used for an extra-high voltage iron tower. The large-size angle steel high-frequency heating single-face bending machine comprises a base. Workpiece placing racks are symmetrically fixed to the front end and the back end of the top surface of the base. A pressing block is connected to the position above the workpiece placing racks in an up-down movement mode. A bending pressing die is fixed to the bottom surface of the pressing block and located between the workpiece placing racks. The pressing block provides the driving force through a hydraulic piston which is fixed to a top plate. The top plate is fixed to the base through vertical posts. High-frequency heating machines are arranged on the left side and the right side of the base correspondingly. The shape defined by heating coils of the high-frequency heating machines is the same as that of a bent and deformed region of a workpiece. By means of the structure of the large-size angle steel high-frequency heating single-face bending machine, the high-frequency heating machines and the bending mechanism are combined together, and after being heated, the workpiece can be bent immediately without turnover, so that the heat loss is avoided, and energy consumption is reduced; and meanwhile workpiece turnover is omitted, the production efficiency is improved, and the hidden danger that an operator is scalded by the workpiece in the workpiece turnover process is also avoided.

Owner:JIANGSU FLIGHT ELECTRIC EQUIP MFG

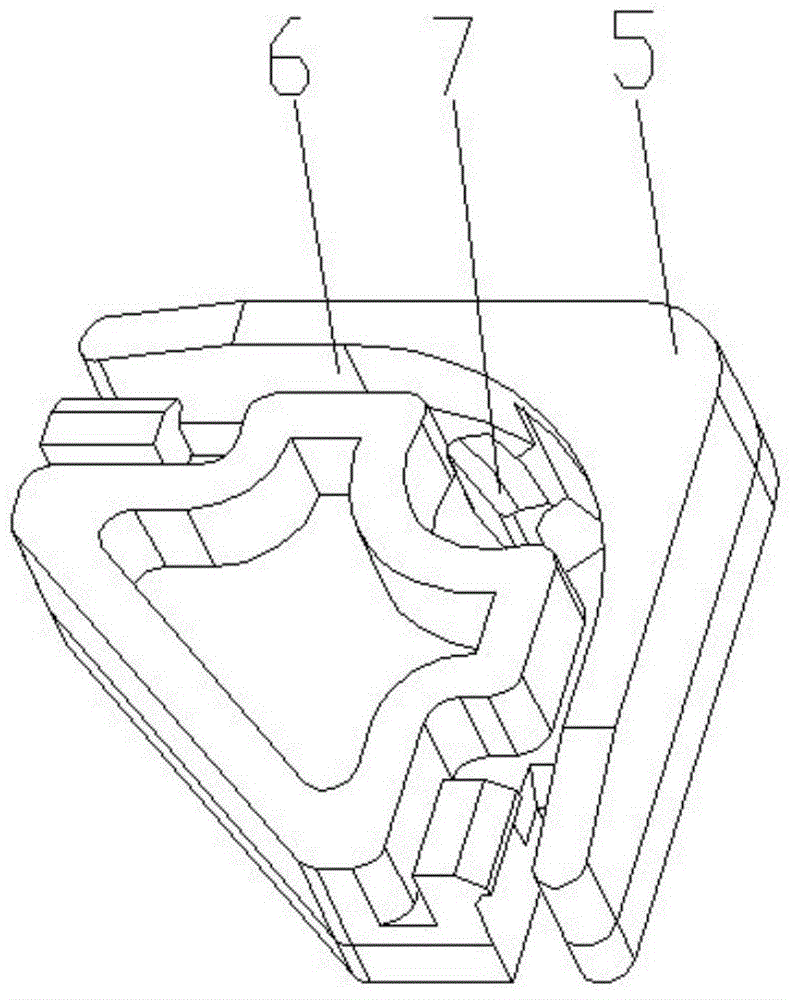

Omnidirectional special-shaped bent continuum flexible mechanical arm for intracavity interventional diagnosis and treatment

ActiveCN111588470AAdjust the bending curvature step by stepBending curvature changeSurgical manipulatorsSurgical robotsModular unitMedicine

The invention provides an omnidirectional special-shaped bent continuum flexible mechanical arm for intracavity interventional diagnosis and treatment. The mechanical arm comprises a base and a plurality of modular units, and the plurality of modular units are arranged on the base from bottom to top in a layering mode; a plurality of contact blocks and a plurality of frameworks are arranged on theupper end faces of the base and the modular units; the height of the contact block is lower than or equal to the height of the framework, through holes are formed in the centers of the base and the modular units, a plurality of wire holes are formed in the peripheries of the through holes, and the wire holes in the plurality of modular units and at least one wire hole in the base are through topand bottom and used for allowing driving wires to penetrate through; and the through hole of the base and the through holes of the plurality of modular units are through top and bottom to form a middle cavity channel. According to the continuum mechanical arm, the bending curvature of the mechanical arm can be adjusted section by section, the shape of the whole mechanical arm can be changed to a large extent through few degrees of freedom, then the position and posture of the top end of the mechanical arm are adjusted, and therefore the continuum mechanical arm has good direction positioning capacity.

Owner:SHANGHAI JIAO TONG UNIV

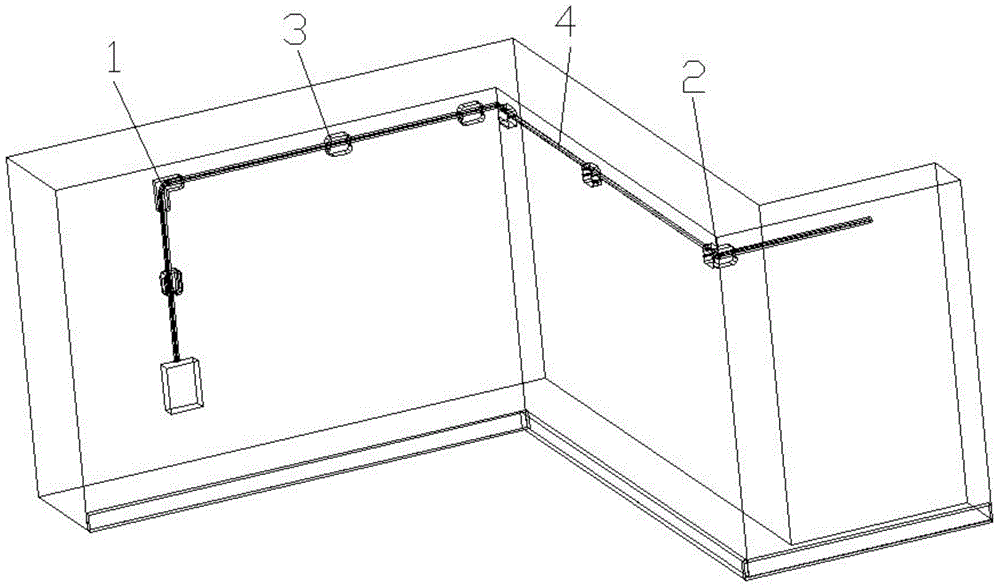

Optical cable mounting method and mounting fixture

ActiveCN104698563AGuaranteed bending performanceAvoid influenceOptical fibre/cable installationEngineeringOptical fiber cable

The invention discloses an optical cable mounting method and mounting fixture. The optical cable mounting method includes that confirming a mounting route, the mounting fixture and laying optical cable, wherein the fixture is made of transparent material and arranged along the mounting route, the fixture comprises a plane turning fixture and an external corner turning fixture, the external corner turning fixture can be divided into two straight fixtures along the central line, the plane turning fixture can make the optical cable turn on the same plane, the external corner turning fixture can make the optical cable perform right-angle turning at the external corner, and the two straight fixtures are correspondingly arranged at internal corners and capable of making the optical cable perform right-angle turning at the internal corners. The optical cable mounting method does not depend on tools, the operation is easy and convenient to perform, the mounting is quick and flexible, and the concealment is strong.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com