Mud pipe and design method for self-floating armored mud pipe

A design method and technology for sludge discharge pipes, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve problems such as service life, product transportation cost gap, mismatch, etc., to achieve outstanding substantive characteristics and improve buoyancy. , the effect of ensuring the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

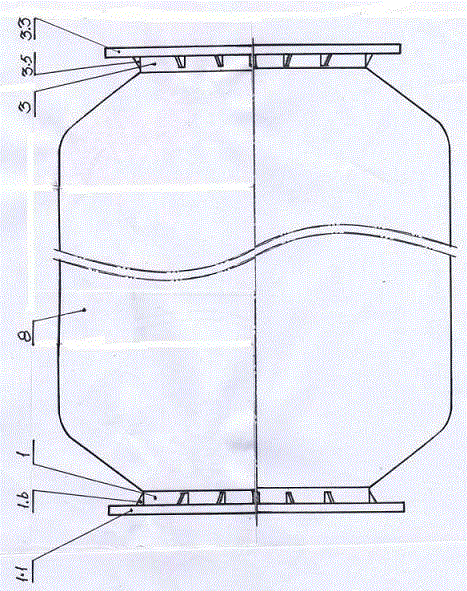

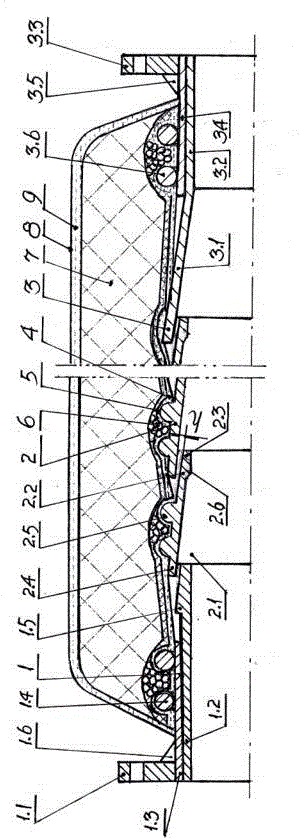

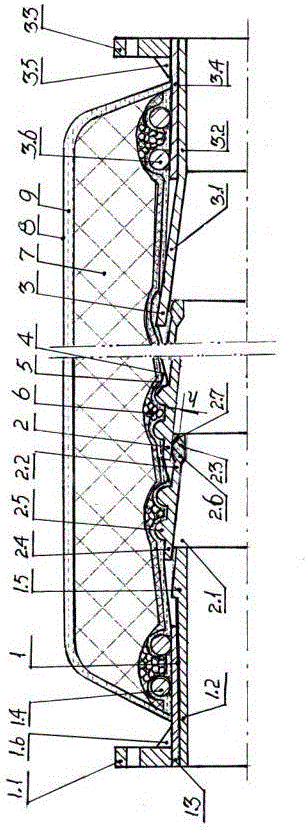

[0030] The design method of a kind of self-floating armored mud discharge pipe of the embodiment 1 of the present invention comprises the overall design of the floating body layer on the mud discharge pipe and the mud discharge pipe and the specific design of each component, and is characterized in that described self-floating The design method of the floating armored pipe body is to meet the technical requirements of the armored mud discharge pipe with a curvature ≥ 35°. The mud discharge pipe is composed of an inlet end pipe, an armored pipe body and an outlet end pipe. The inlet end connection pipe is a casing with inner and outer pipes combined, and a flange is provided at the inlet end, and two ring-shaped positioning fastening rings are arranged on the outside, and the outlet end is inserted into the inlet of the armored pipe body. The inner chamber of the end; the armored pipe body is connected by a plurality of conical pipes, the tapered pipe is an inverted tapered stru...

Embodiment 2

[0049]A design method of an armored mud discharge pipe according to Embodiment 2 of the present invention, a design method of a self-floating armored mud discharge pipe, including the overall design of the mud discharge pipe and the floating body layer on the mud discharge pipe and the components The specific design, the design method of the self-floating armored pipe body described in Embodiment 2 of the present invention is to meet the technical requirements of the bending degree of the armored mud discharge pipe ≥ 35 °, and the described mud discharge pipe is made of It is composed of an inlet end pipe, an armored pipe body and an outlet end pipe. The inlet end pipe is a casing in which the inner and outer pipes are combined and a flange is provided at the inlet end, and two ring-shaped positioning The fastening ring, the outlet end is inserted in the inner cavity of the inlet end of the armored pipe body; the armored pipe body is connected by a plurality of tapered pipes, t...

Embodiment 3

[0068] A design method of a self-floating armored mud discharge pipe according to Embodiment 3 of the present invention, including the overall design of the mud discharge pipe and the floating body layer on the mud discharge pipe and the specific design of each component, the self-floating type The design method of the armored pipe body is to meet the technical requirements of the armored mud discharge pipe with a curvature ≥ 35°. The mud discharge pipe is composed of an inlet end pipe, an armored pipe body and an outlet end pipe. The inlet end connection pipe is a casing with inner and outer pipes combined, and a flange is provided at the inlet end, and two annular positioning fastening rings are arranged on the outside, and the outlet end is inserted into the inlet end of the armored pipe body. Cavity; the armored pipe body is connected by a plurality of conical pipes, the tapered pipe is an inverted tapered structure, and its inlet end shrinks inward along the centerline of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com