Patents

Literature

47results about How to "Meet bending requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

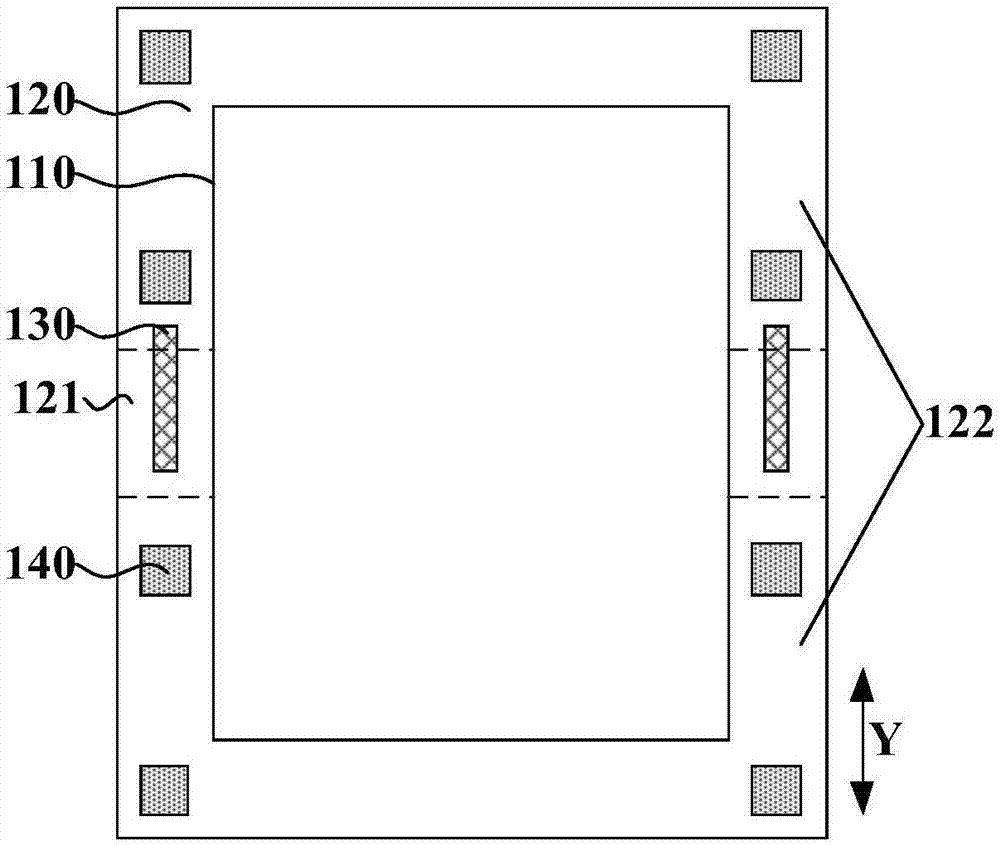

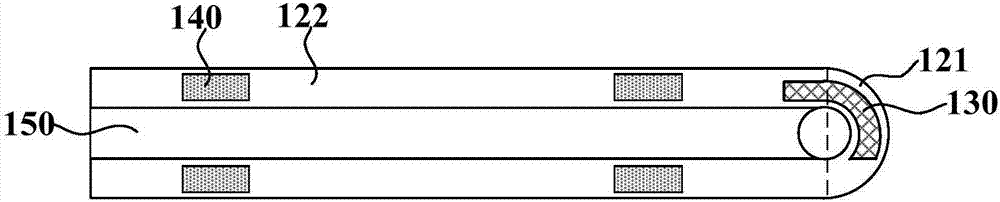

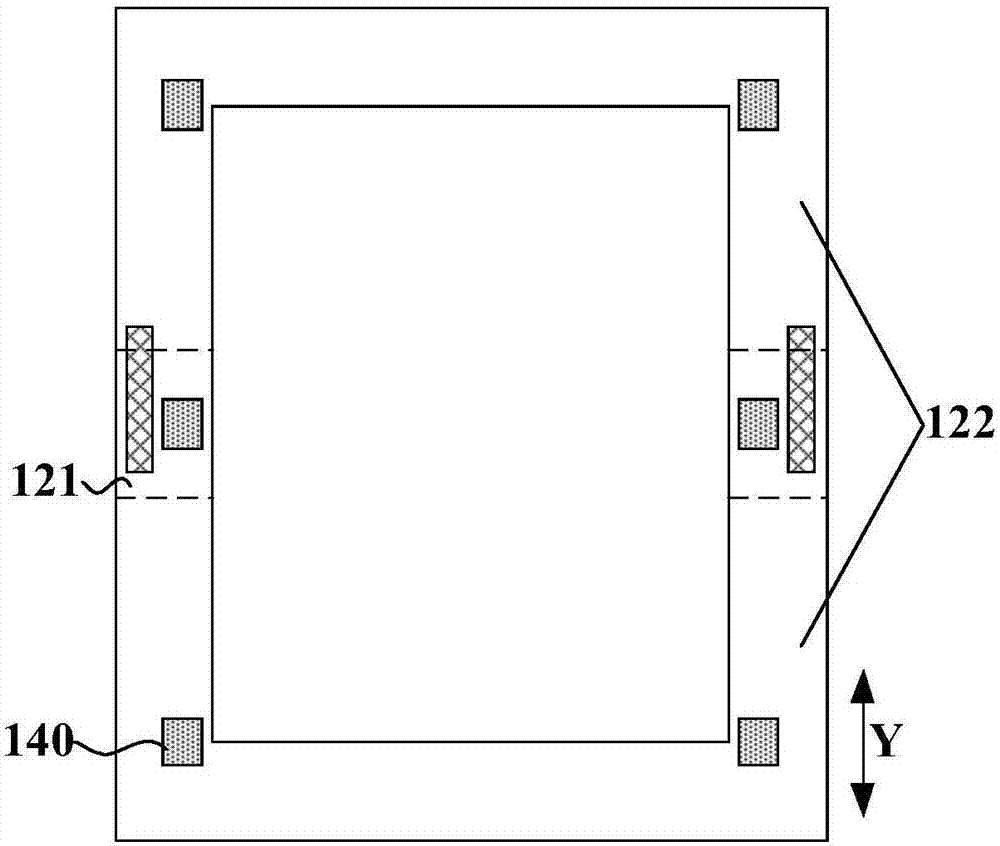

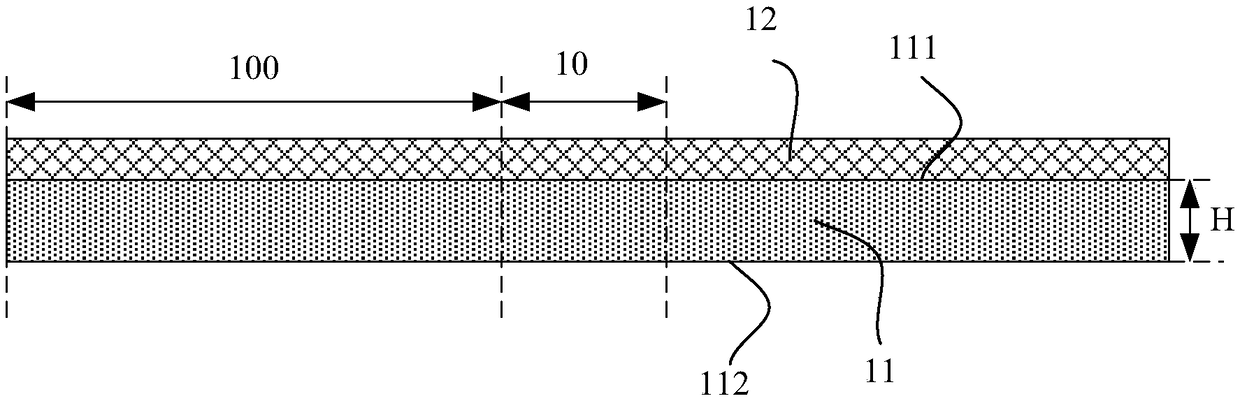

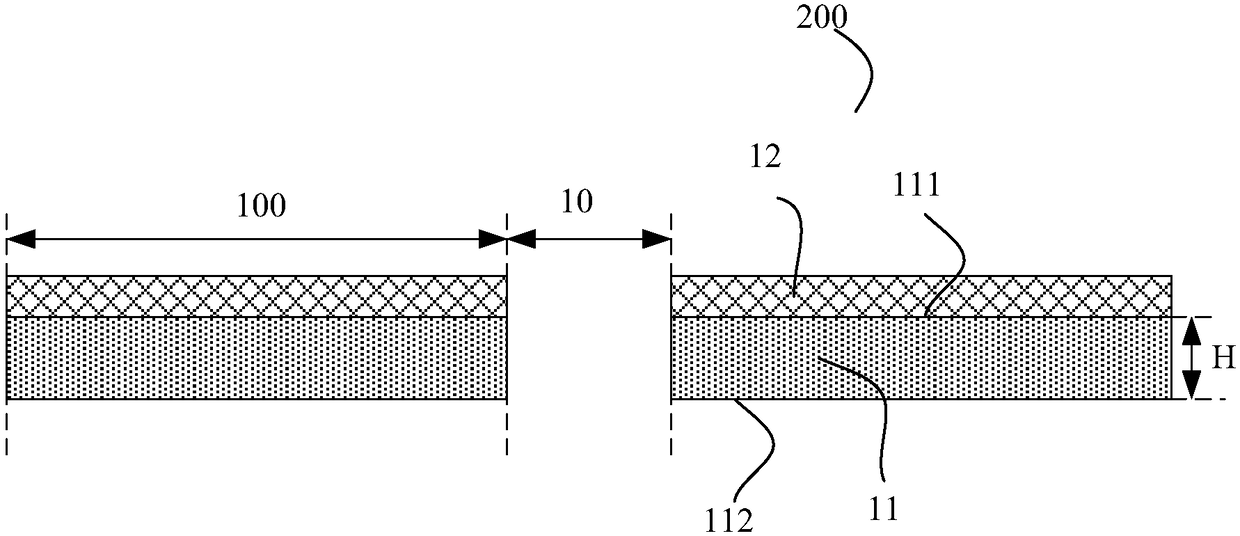

Flexible organic light-emitting display panel and electronic equipment

ActiveCN107195667AMeet bending requirementsEnables bend detectionSolid-state devicesForce measurementEngineeringSemiconductor

The embodiment of the invention discloses a flexible organic light-emitting display panel and electronic equipment. The flexible organic light-emitting display panel comprises a display area and a non-display area surrounding the display area, at least one metal bridge pressure detection unit and a plurality of semiconductor pressure detection units, wherein the non-display area comprises a bendable area and a non-bending area; the metal bridge pressure detection unit is at least partially arranged in the bendable area and extends along the bending direction of the flexible organic light-emitting display panel; and the semiconductor pressure detection units are at least arranged in the non-bending area. In the embodiment of the invention, the bridge pressure detection unit is at least partially arranged in the bendable area, bending detection can be carried out on the flexible organic light-emitting display panel and electronic equipment, and the product reliability is improved; and the semiconductor pressure detection units are at least arranged in the non-bending area, pressure detection can be carried out on the flexible organic light-emitting display panel and electronic equipment, and the product sensitivity is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

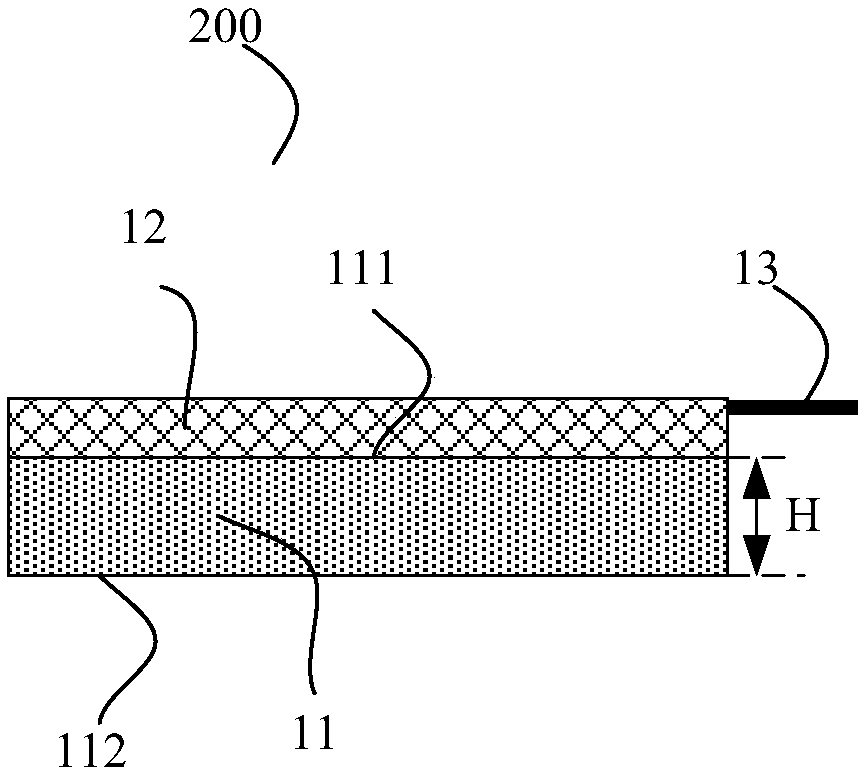

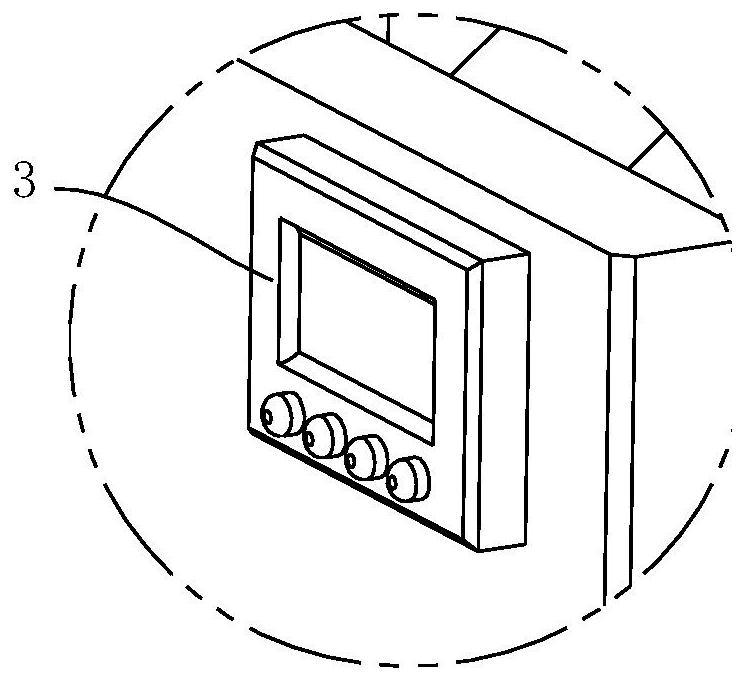

Curved surface touch screen and manufacturing method thereof

InactiveCN108153448AMeet bending requirementsGood optical reliabilityInput/output processes for data processingThin membraneTouchscreen

The invention discloses a curved surface touch screen and a manufacturing method thereof. According to the technical scheme, a glass substrate is adopted as a base material of a touch control electrode, when the thickness of the thinned glass substrate is smaller than a preset threshold value, the bending requirement can be met, and then the glass substrate can be fixedly fitted with a curved surface cover plate. Compared with an existing mode of adopting flexible thin film, a glass material has the advantages that the glass substrate is fixedly fitted with the curved surface cover plate, theoptical reliability is good, and the problem of rainbow stripes can be avoided.

Owner:TRULY OPTO ELECTRONICS

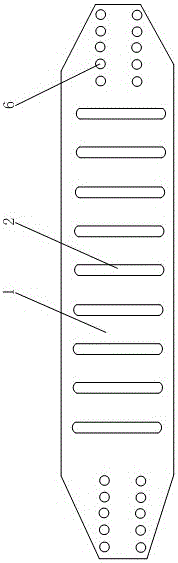

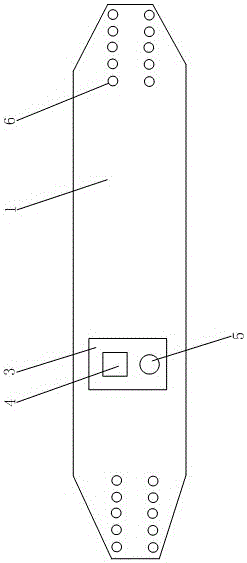

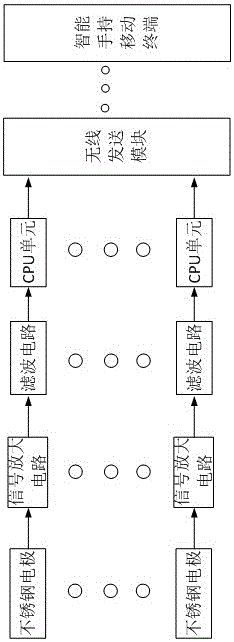

Abdominal belt type fetal cardiogram monitor and use method thereof

InactiveCN105997059AEasy to useEasily meet needsDiagnostic recording/measuringSensorsSilica gelMental stress

The invention discloses an abdominal belt type fetal cardiogram monitor. The abdominal belt type fetal cardiogram monitor includes an abdominal belt main body which is formed by connecting an abdominal belt and a brace through fasteners, a flexible foldable fetal cardiogram acquisition device, and an intelligent handheld mobile terminal which is in wireless connection with the flexible foldable fetal cardiogram acquisition device; and the abdominal belt main body is made of medical silica gel, two ends of the abdominal belt are provided with row holes, and the fasteners are arranged at two end of the brace. The abdominal belt type fetal cardiogram monitor can automatically acquire, process and display fetal cardiogram data, can improve the accuracy and the timeliness of fetal cardiogram detection, can relieve the mental stress of a pregnant woman due to hand feeling, and has a high practical value.

Owner:CHENGDU HEXU MEDICAL TECH CO LTD

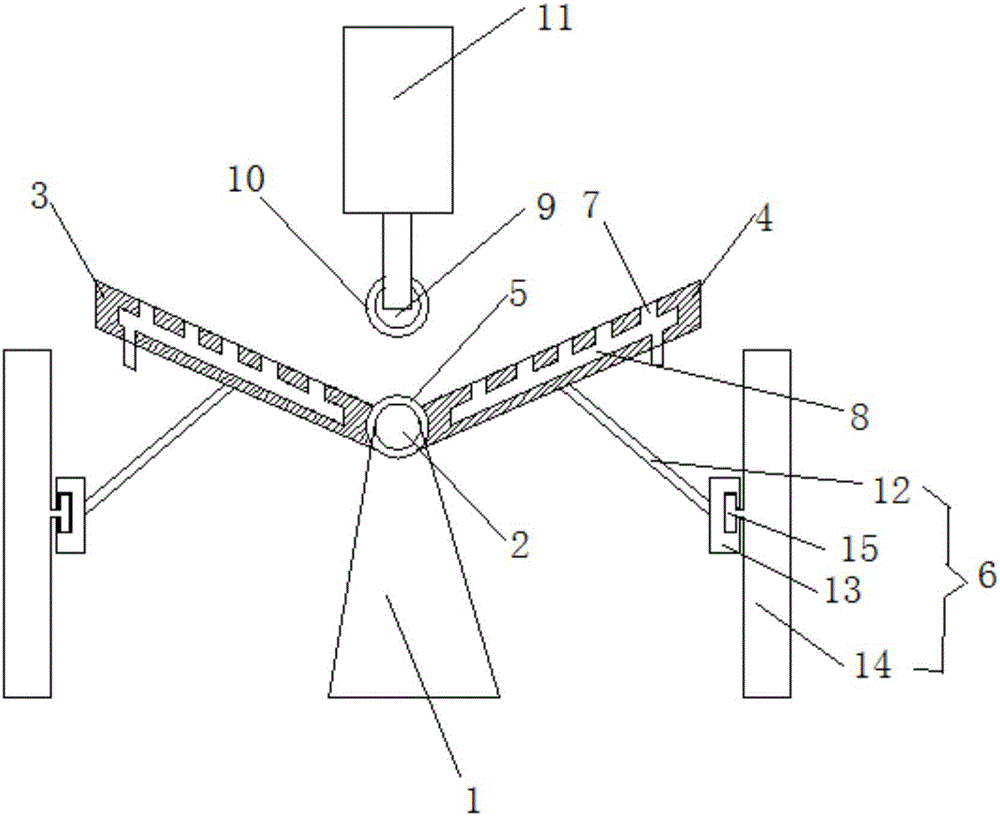

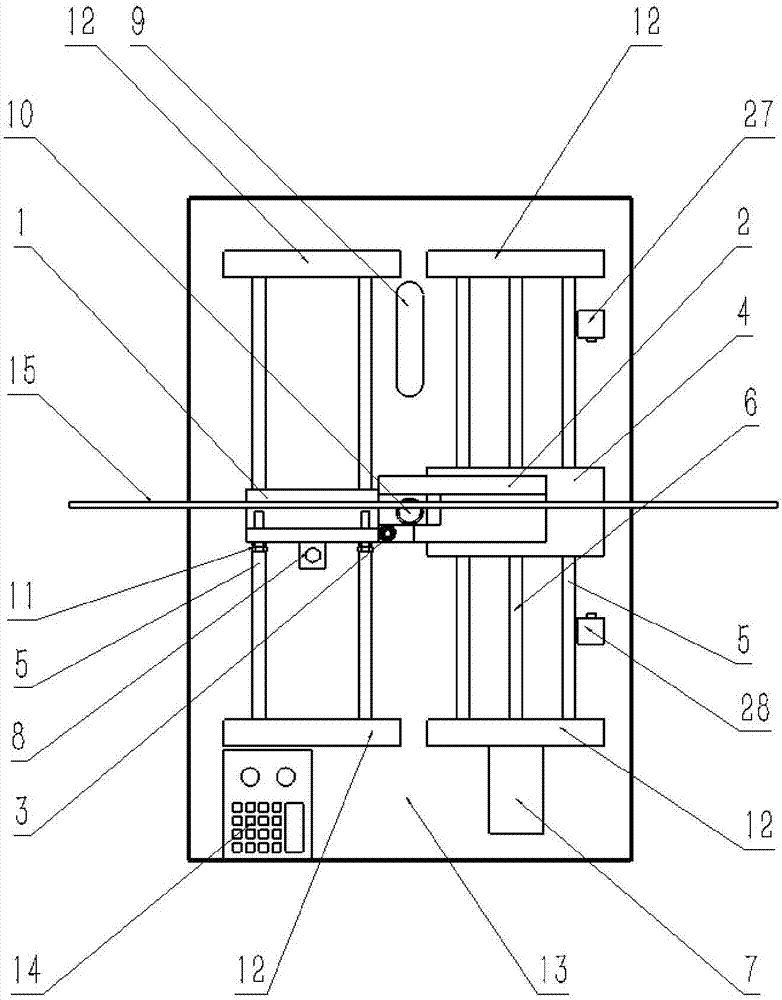

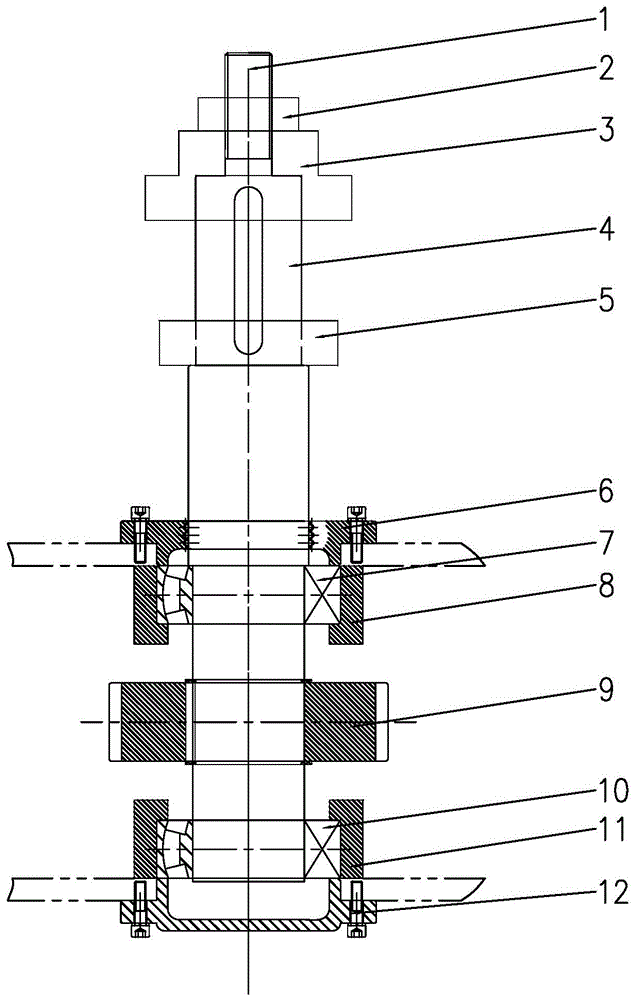

Sheet bending device

The invention discloses a sheet bending device which comprises a base. A fixing shaft is installed at the middle portion of the base. Overturning plates rotating around the fixing shaft are installed on the two sides of the fixing shaft. The inner side of each overturning plate is provided with a shaft sleeve matched with the fixing shaft. The shaft sleeves of the two overturning plates are arranged in a spaced and staggered manner. Overturning of the overturning plates is driven by guide rod sliding block mechanisms on the outer sides of the overturning plates. Multiple air outlet holes are distributed in the overturning plates. The air outlet holes stretch in the overturning plates and communicate with ventilation cavities in the overturning plates. Air inlets of the ventilation cavities communicate with air inlet pipes correspondingly. A pressing shaft is erected over the fixing shaft and is sleeved with a shaft sleeve, and the pressing shaft is driven by an air cylinder at the upper end of the pressing shaft. According to the sheet bending device, the overturning plates on the two sides are used for overturning sheets, the stress position and the stress direction of the sheets are changed, the performance at bend positions of the sheets is ensured, the bending requirements are met, the manual labor intensity in the process is low, time and labor are saved, the work efficiency is high, and the requirement for large-batched machining and production is met.

Owner:讯龙型材折弯(合肥)有限公司

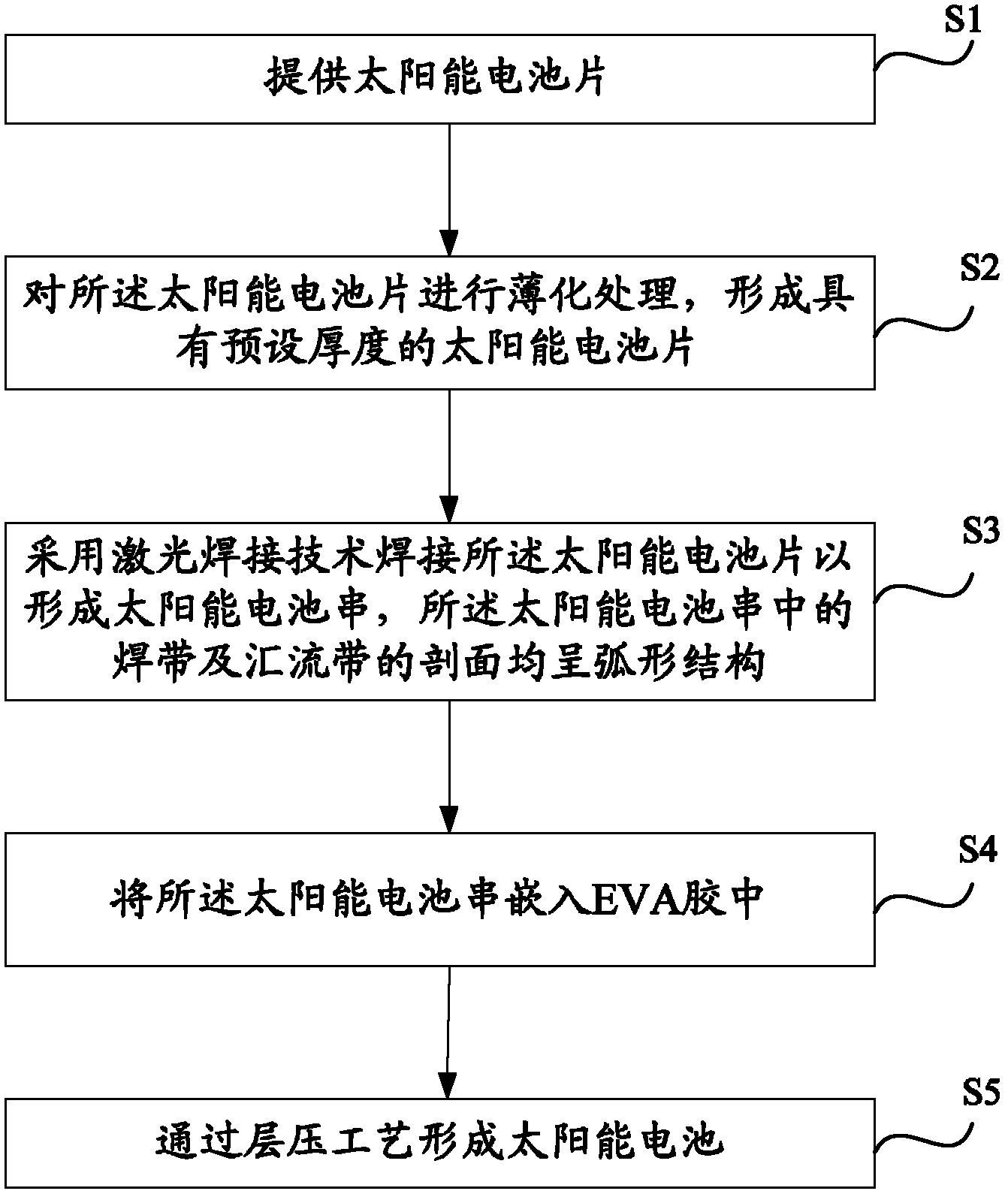

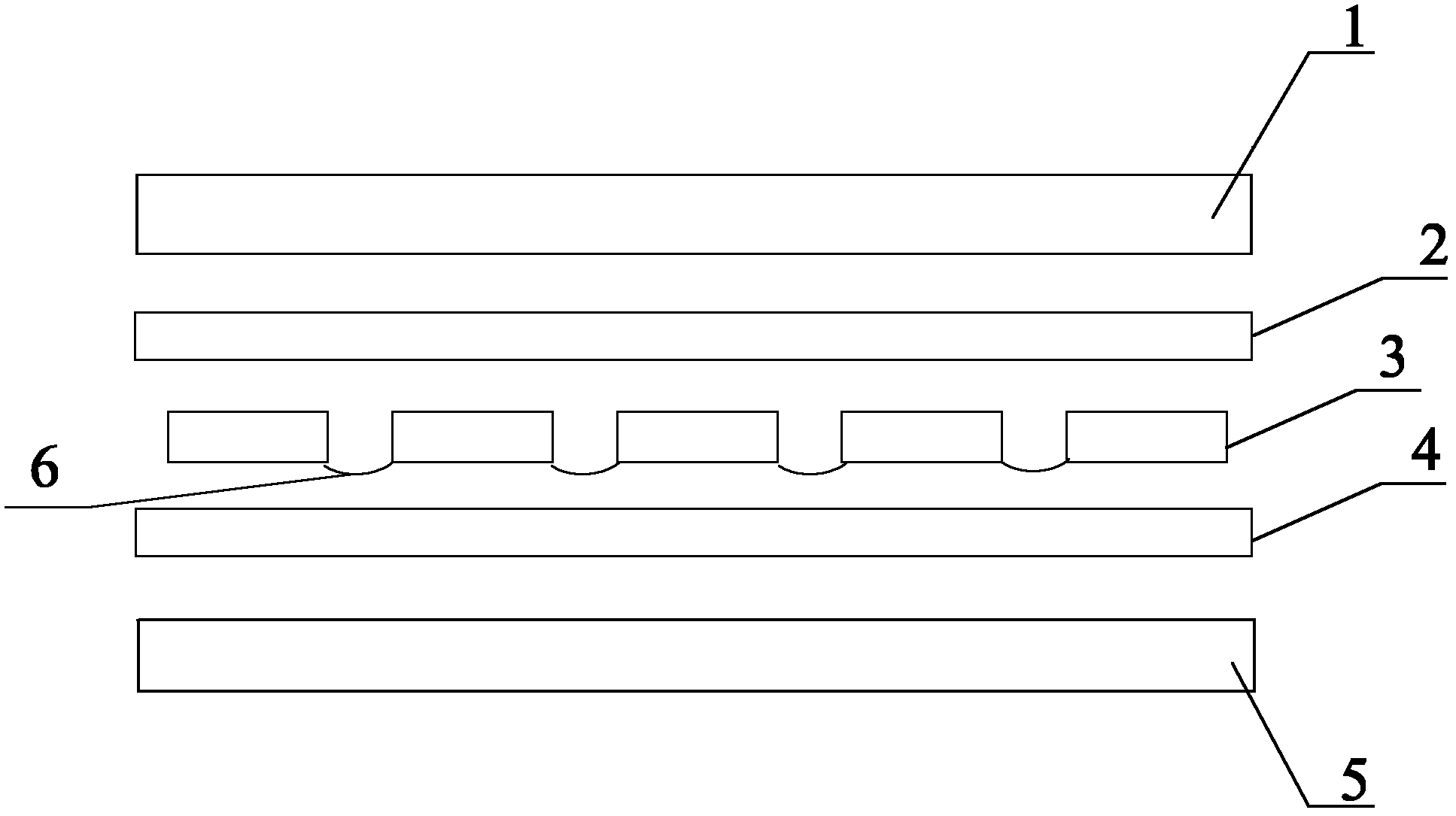

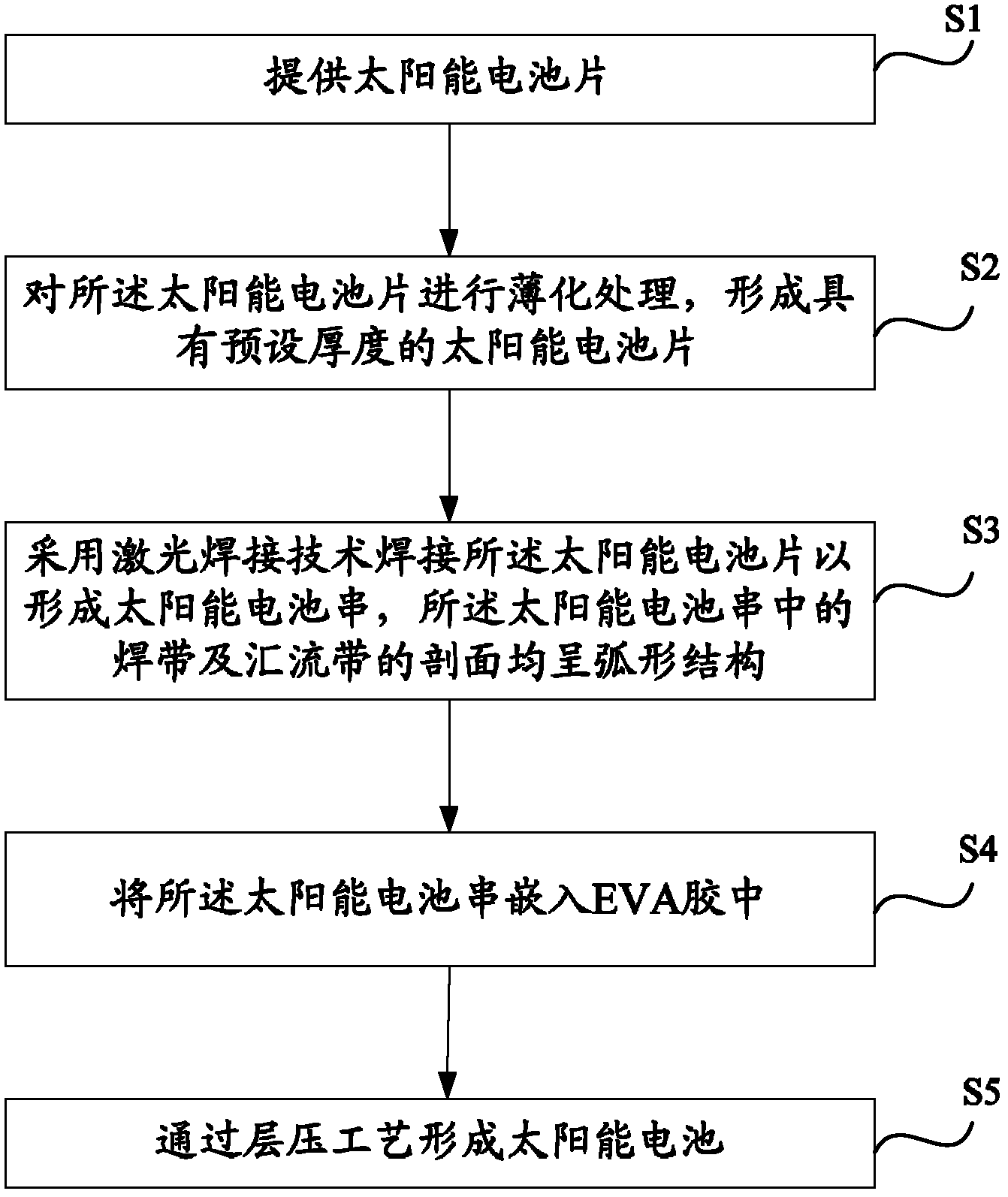

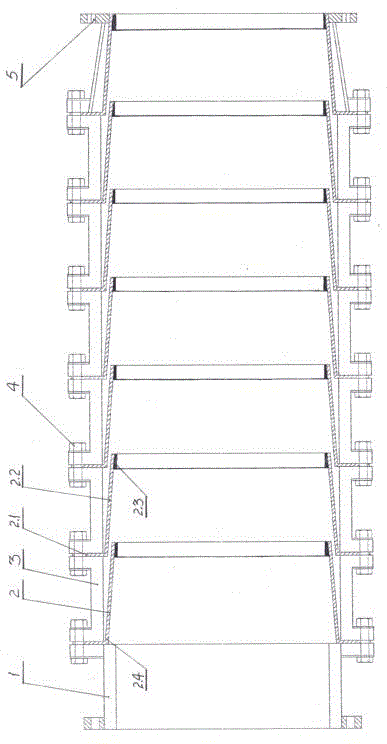

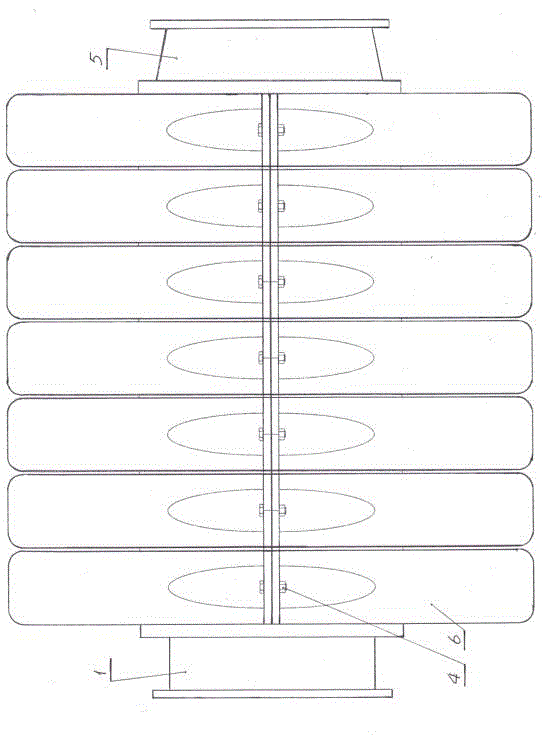

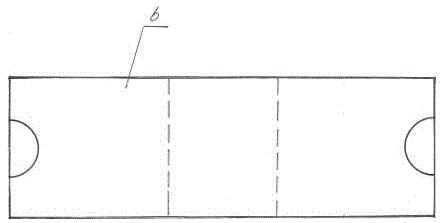

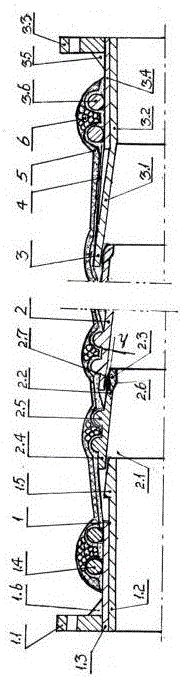

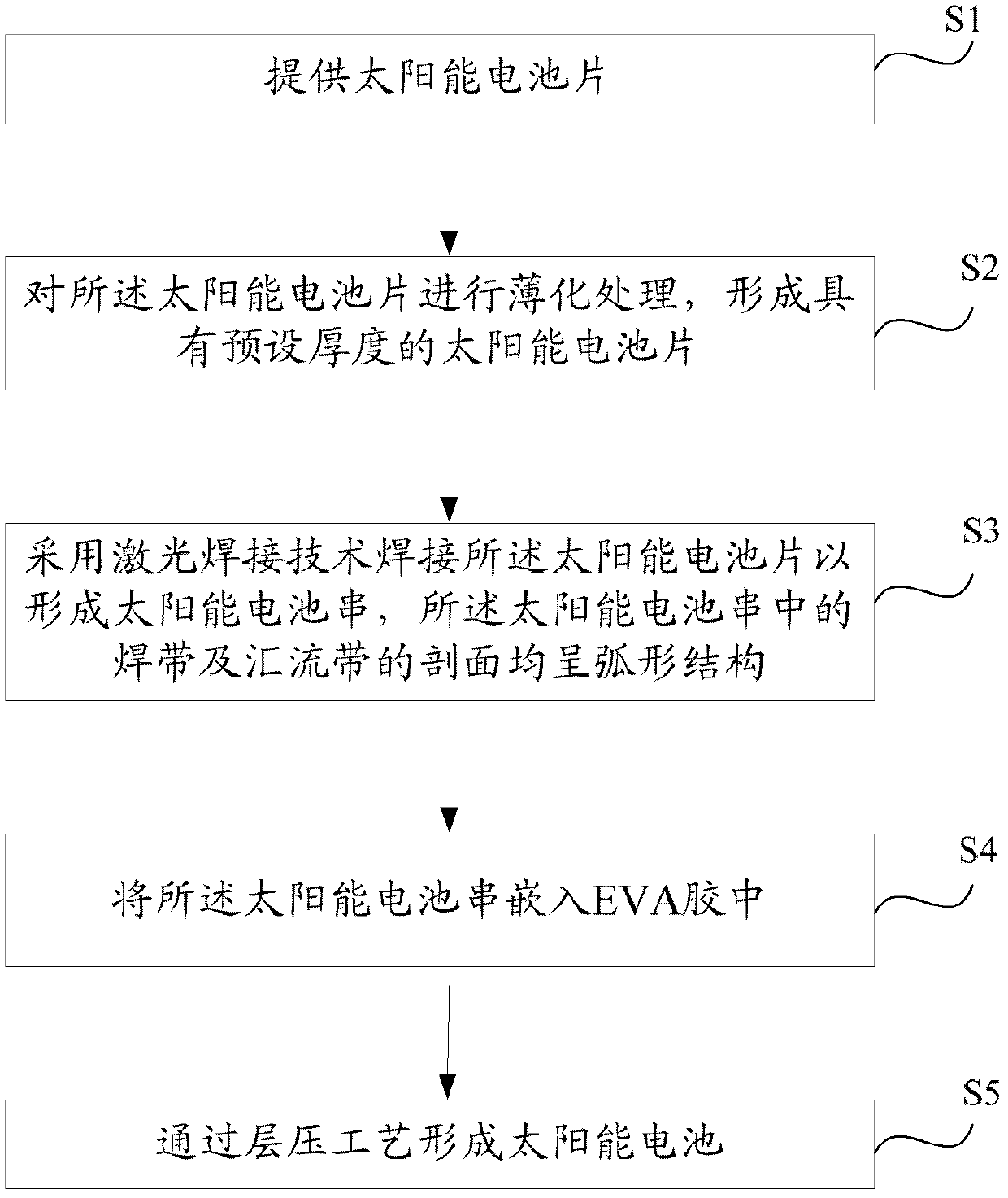

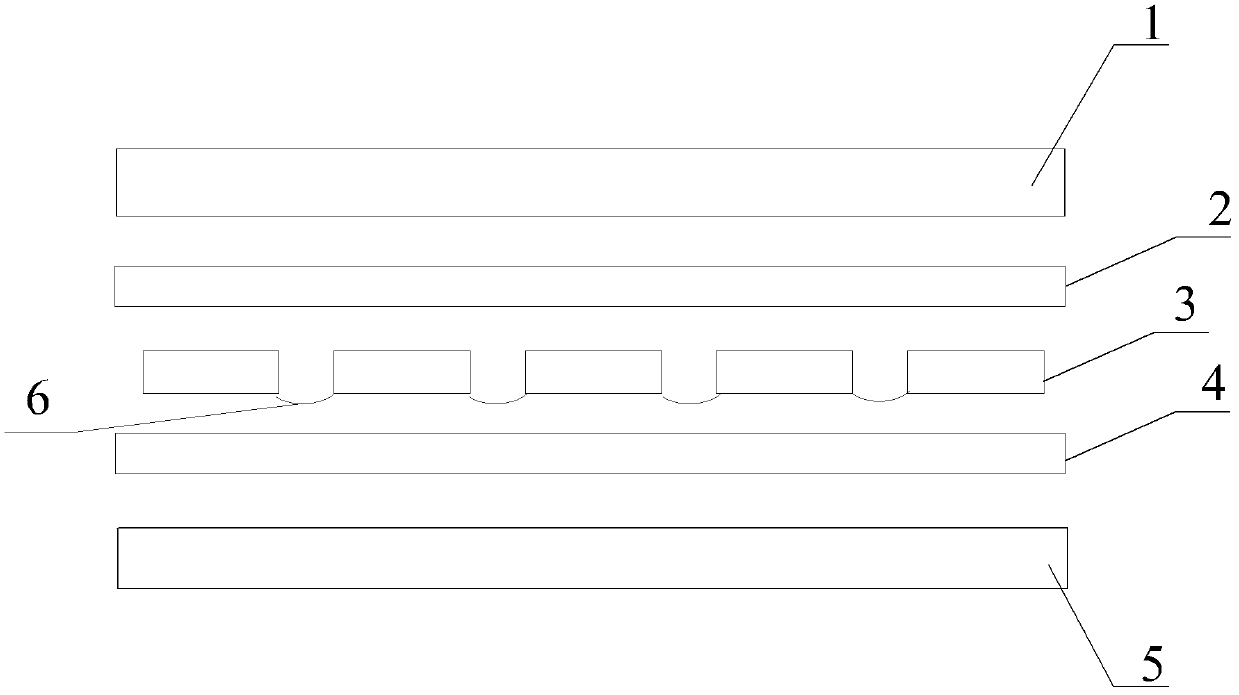

Solar cell, packaging method of solar cell, and unmanned aerial vehicle employing solar cell

ActiveCN102569520AReduce weightIncrease the curvatureFinal product manufactureWeight reductionEngineeringEthyl vinyl acetate

The embodiment of the invention discloses a solar cell, a packaging method of the solar cell, and an unmanned aerial vehicle employing the solar cell. The packaging method of the solar cell comprises the following steps of: providing solar cell plates; thinning the solar cell plates to form solar cell plates with preset thickness; welding the solar cell plates to form a solar cell string by a laser welding technology, wherein sections of solder strips and convergence strips in the solar cell string have an arc structure; embedding the solar cell string into ethyl vinyl acetate (EVA) adhesives; and forming the solar cell by a laminating process. The solar cell formed by the packaging method has light weight and high bending property, and the requirements of the unmanned aerial vehicle are met.

Owner:YINGLI ENERGY CHINA

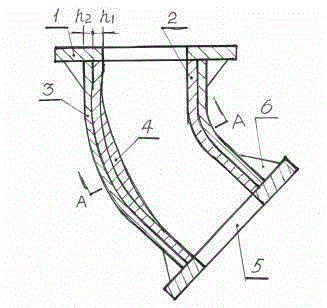

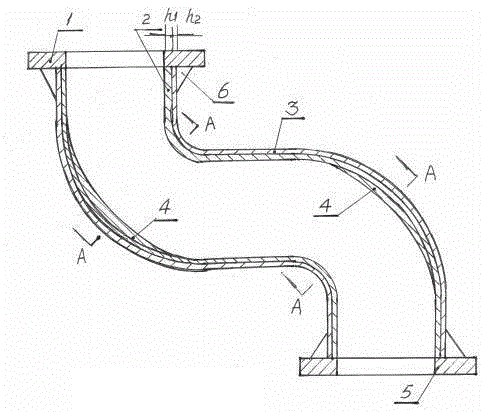

Armored sludge pipe design method and sludge pipe thereof

The invention discloses an armored sludge pipe design method and a sludge pipe thereof, and belongs to the technical field of dredging engineering equipment. The technical scheme includes that the armored sludge pipe design method includes overall design for an armored pipe body and flange plates at two ends of the pipe body and specific design for parts. The armored sludge pipe design method is characterized in that the technical requirement that the curvature of the armored sludge pipe is larger than or equal to 35 degrees is met, a plurality of armored pipe body conical inner pipes and armored pipe body outer pipes are connected in a bolt-on manner to form an armored pipe body unit, and the armored sludge pipe comprises the armored pipe body unit and the flange plates at the two ends. Compared with the prior art, the armored sludge pipe design method has the outstanding substantial advantages and the remarkable progress that the technical scheme is reliable, the bending requirement for adjusting the direction of the sludge pipe is met, the abrasion resistance of the sludge pipe can be closer to that of a metal composite sludge pipe, and the service performance of the metal sludge pipe is comprehensively improved.

Owner:姜考成

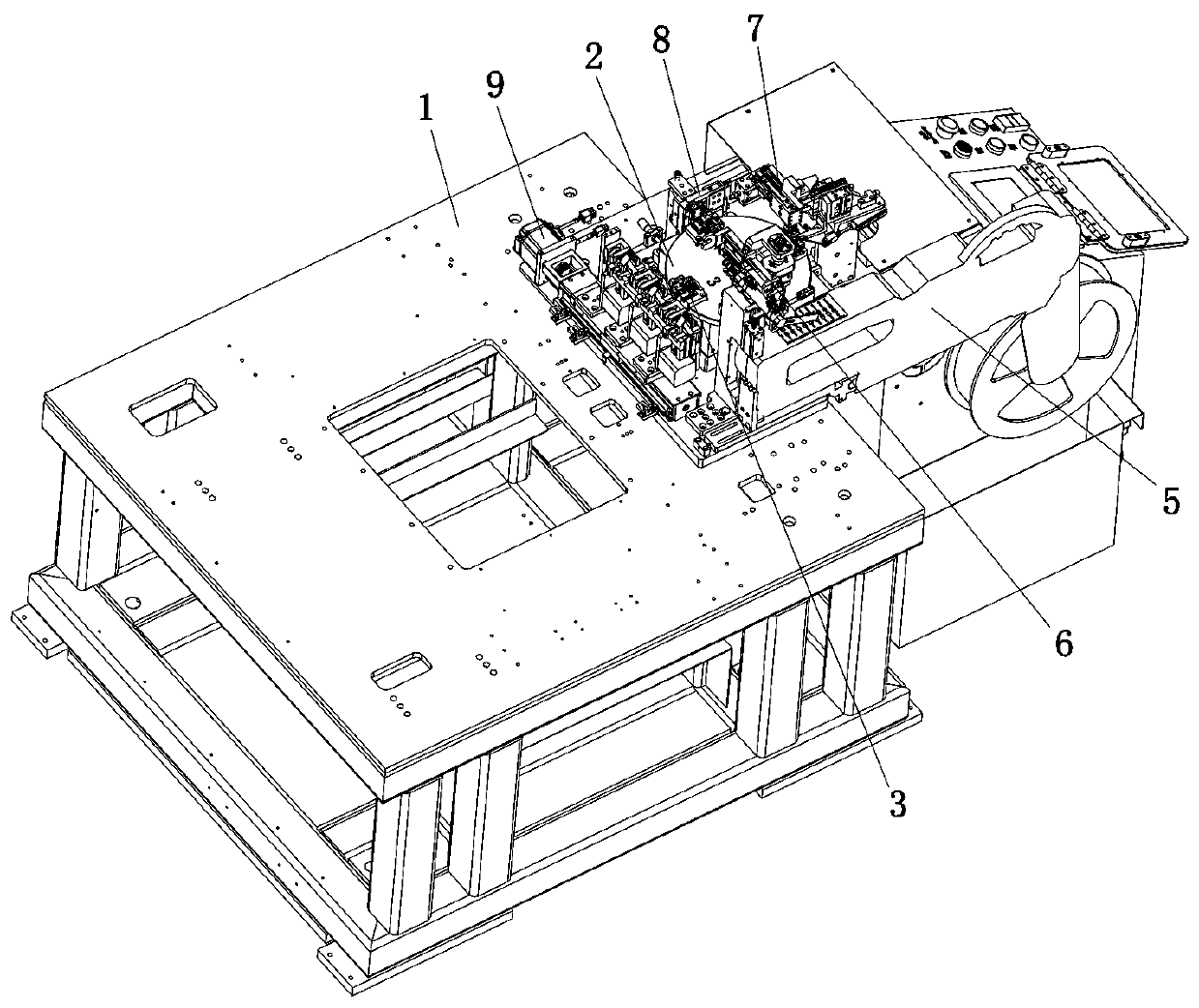

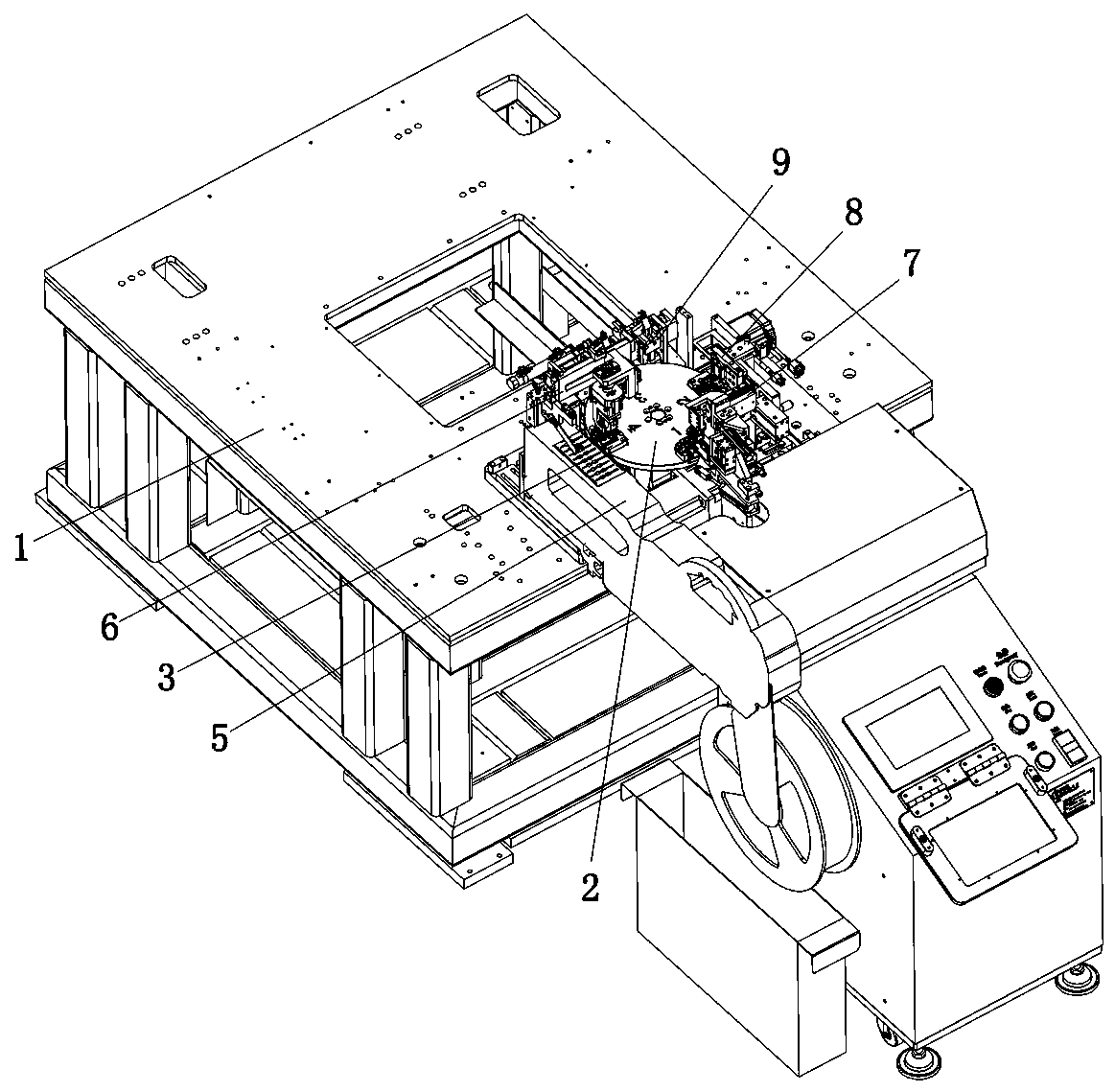

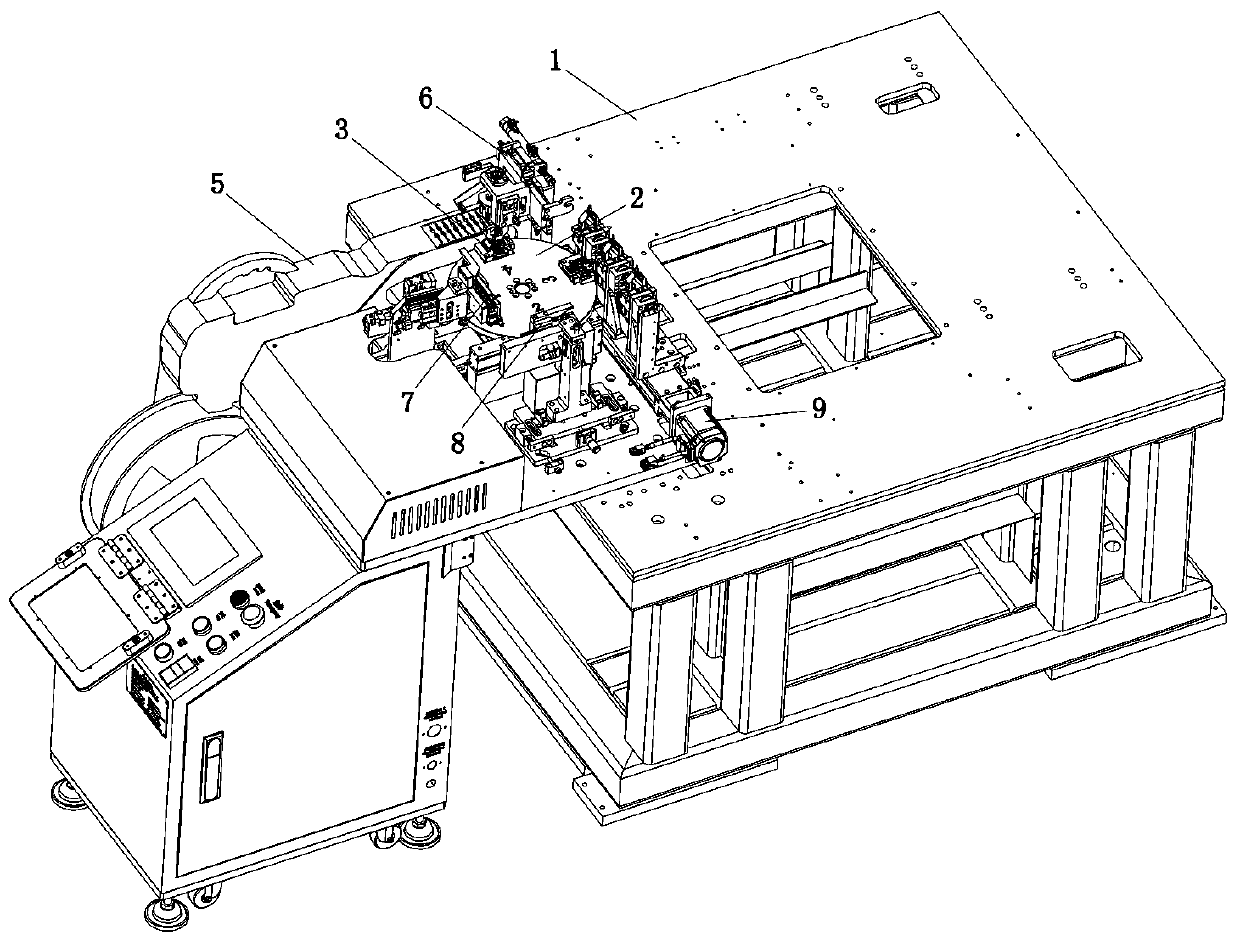

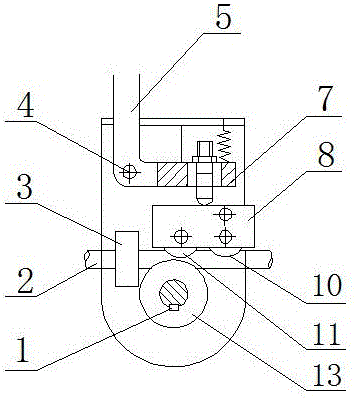

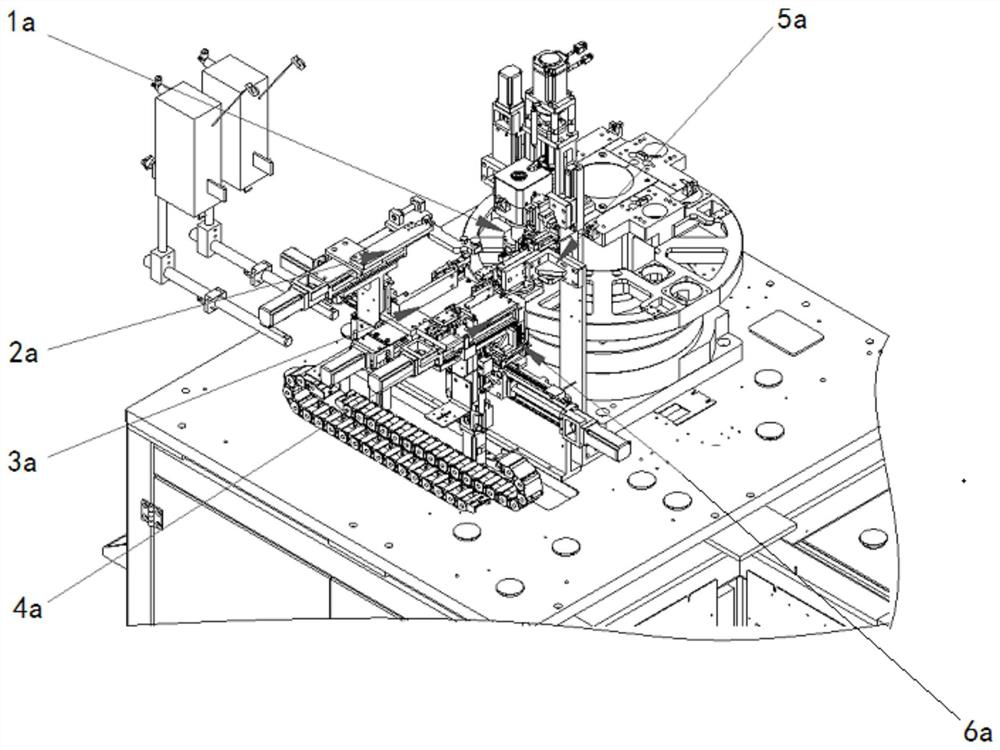

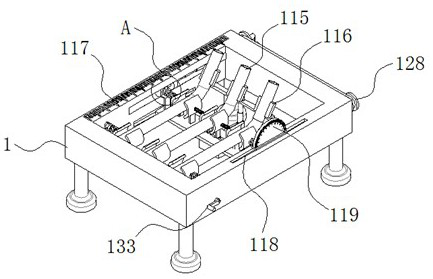

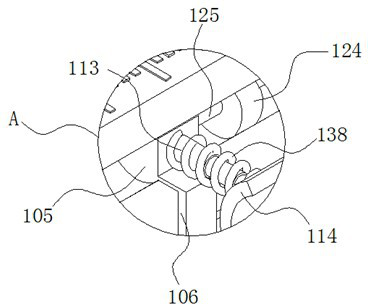

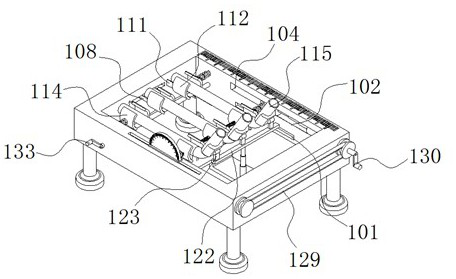

Automatic forming shear pin device for electronic parts and components and process of automatic forming shear pin device

The invention discloses an automatic forming shear pin device for electronic parts and components and a process of the automatic forming shear pin device. The automatic forming shear pin device comprises a rotary disc, at least two sets of jigs, an opening-closing mechanism, a supply mechanism, a loading mechanism, a forming mechanism, a shear pin mechanism and an unloading mechanism, wherein therotary disc is rotatably arranged on a machine table; the jigs are arranged on processing stations of the rotary disc; to-be-processed components and parts are placed in the jigs, and forming blocks are arranged at sides of the components and parts; the opening-closing mechanism is separately arranged below the jigs; the supply material is arranged on the machine table, and extends to one side ofthe rotary disc; the loading mechanism is arranged at one side of the supply mechanism; and the forming mechanism, the shear pin mechanism and the unloading mechanism are arranged on the machine table, and are sequentially arranged on the side part of the rotary disc in a spaced mode in a peripheral direction. The automatic forming shear pin device realizes transmission turning through an inclinedpushing block, utilizes a roller and a guide arc surface to realize linked opening-closing of a pin clamping assembly and an component and part clamping assembly, and effectively improves automationdegree of the forming shear pin for the components and parts, forming shear pin quality and efficiency.

Owner:SHENZHEN TUPURUI TECH CO LTD

Wear-resisting antioxidant alloy spring steel and heat treatment process thereof

The invention discloses wear-resisting antioxidant alloy spring steel and a heat treatment process thereof. The spring steel comprises 0.360-0.550% of C, 0.260-0.450 % of Cu, 0.150-2.20% of Mn, 0.800-5.420% of Si, 0.700-3.800% of Cr, 0.030-0.080% of P, 0.030-0.050% of S, 0.300-0.500% of Ni, 0.008-0.050% of Al, 0.020-0.100% of V, and the balance Fe and inevitable impurities. According to the heat treatment process, the tempering temperature is 750+ / -10 DEG C, the temperature holding time is 6-8 h, and then air cooling is carried out; and the quenching temperature is 800-830 DEG C, the temperature holding time is 80-150 min, and then water cooling is carried out. Through the heat treatment process, the excellent wear-resisting antioxidant properties of the wear-resisting antioxidant alloy spring steel are realized, consumption of materials is reduced, and the production efficiency is improved.

Owner:ANHUI HONGQIAO METAL MFG

Corner folding equipment for industrial steel plate corner machining and working method

PendingCN112872141AReduce labor intensityImprove bending efficiencyMetal-working feeding devicesMetal working apparatusRotational axisAuto regulation

The invention relates to the field of bending devices, in particular to corner folding equipment for industrial steel plate corner machining and a working method. The corner bending equipment comprises a base and a supporting frame and further comprises a controller, a sliding mechanism, a rotating mechanism, a pressing mechanism and a bending mechanism; the sliding mechanism comprises a sliding base and a pushing assembly, and the rotating mechanism comprises a machining table, a rotating shaft and a driving assembly; and the pressing mechanism comprises a pressing plate and a lifting assembly, the bending mechanism comprises an arc-shaped pressing plate, a rotating assembly and a traction assembly, the arc-shaped pressing plate is fixedly arranged on the traction assembly, and the pushing assembly, the driving assembly, the lifting assembly and the rotating assembly are all electrically connected with the controller. According to the corner folding equipment for industrial steel plate corner machining and the working method, manual work is replaced by an automatic mode, the labor intensity is low, meanwhile, bending is uniform, the bending efficiency is high, the position of a steel plate can be automatically adjusted, and it is guaranteed that multiple edges of the steel plate can be automatically bent.

Owner:周俊玉

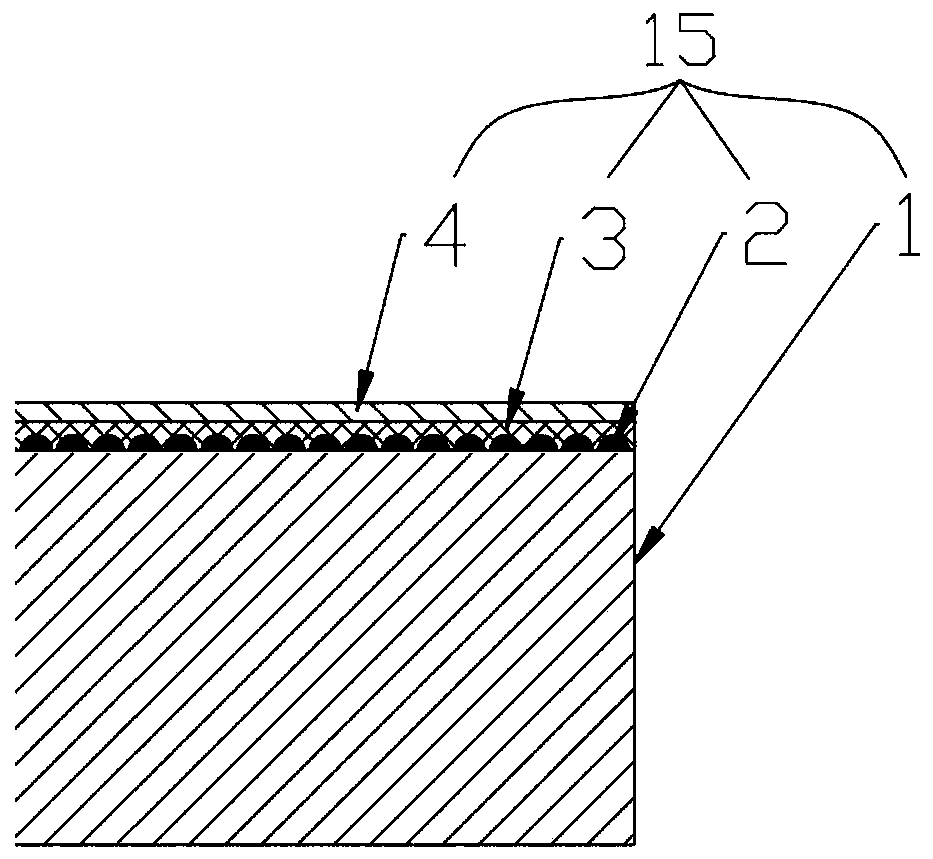

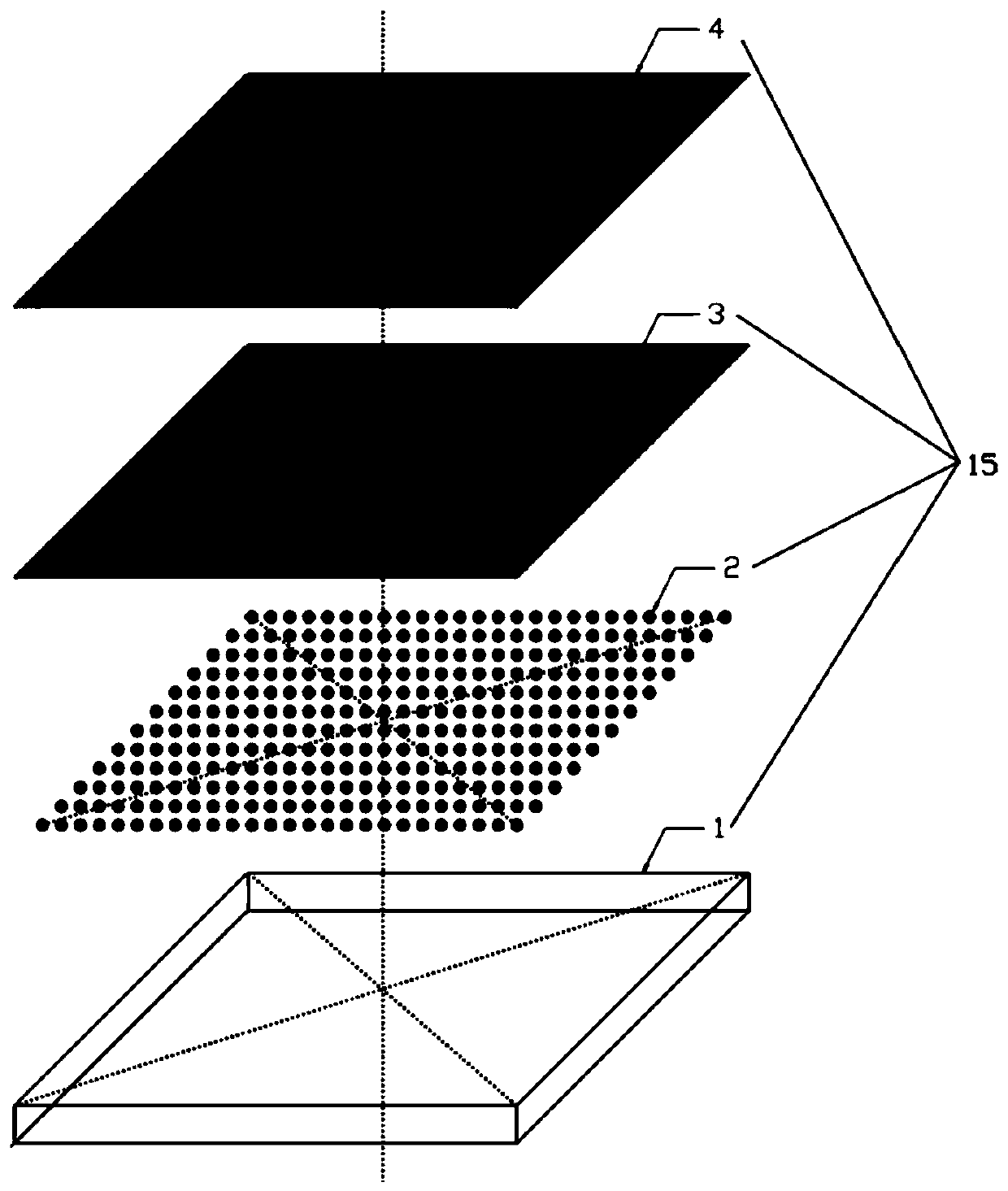

Glass light guide plate and production process thereof, and display device

ActiveCN111522091ASaving processabilitySave assemblyOptical light guidesNon-linear opticsUv laserLight spot

Owner:冯宪轮

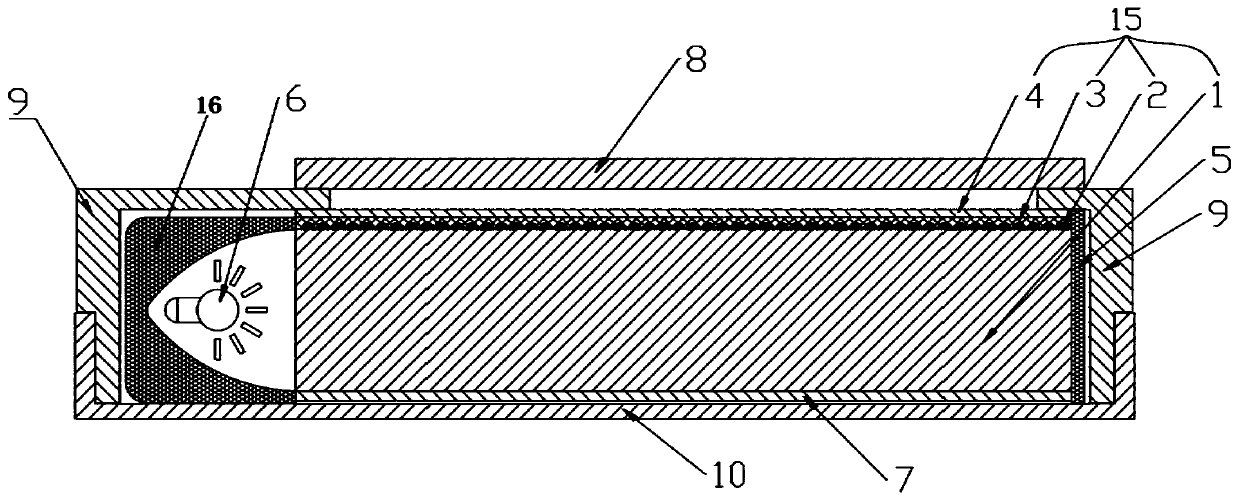

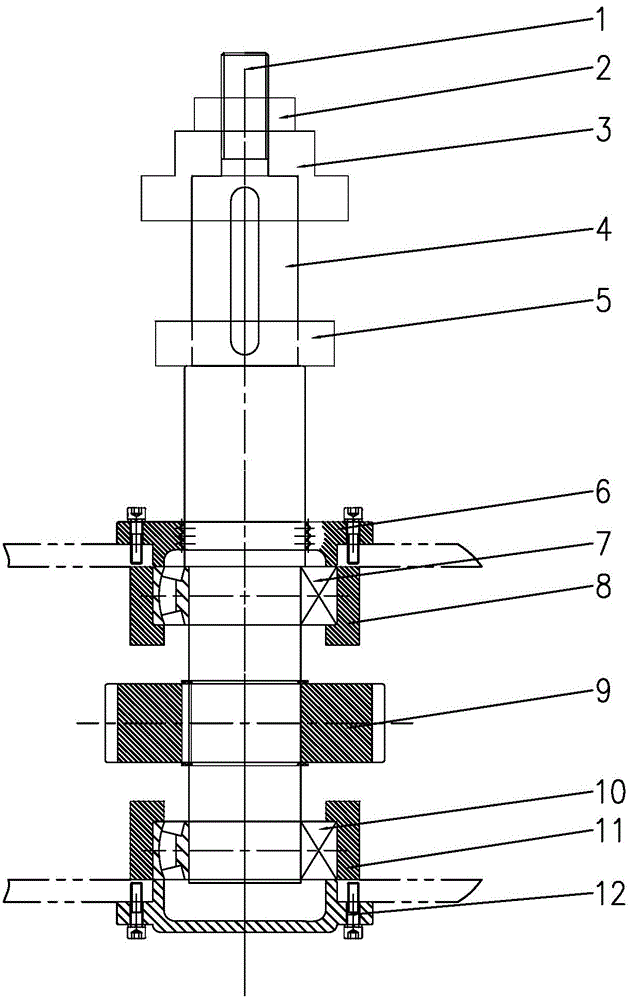

Thin-wall steel tube bending machine

The invention discloses a thin-wall steel tube bending machine which comprises a fixing key, a steel tube, a steel tube clamp, a hinge pin, a handle, a spring, an adjusting screw, a wheel seat, a spindle, a guide wheel, a rolling press wheel, a rotating disc and a tube bending module. The fixing key is embedded in the tube bending module, and the outer portion of the tube bending module is tightly connected with the steel tube. The steel tube penetrates through the steel tube clamp. One end of the steel tube is provided with a wheel seat, and the guide wheel and the rolling press wheel are fixedly mounted in the wheel seat. The adjusting screw is arranged at the top end of the wheel seat and fixedly mounted at the tail end of the handle. The handle is fixed through the hinge pin. The thin-wall steel tube bending machine can stably bend tubes, the cost is low, the bending requirements of workpieces of different sizes can be met, the application range is expanded, and tube forming consistency in the batched tube bending process can be guaranteed; and time and labor are saved, the bending angle of the tube can be conveniently adjusted, the production procedure is shortened, the production cost is lowered, and work efficiency is improved.

Owner:YUZHOU SHENYUN MACHINERY CO LTD

Wear-resistant alloy spring steel and thermal treatment process thereof

InactiveCN106048451AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesWear resistantAlloy

The invention discloses wear-resistant alloy spring steel and a thermal treatment process thereof. The thermal treatment process comprises the following steps: performing air cooling, wherein the tempering temperature is 600+ / -10 DEG C and the insulating time is 6-8h; and performing water cooling, wherein the quenching temperature is 800-830 DEG C and the insulating time is 50-100min. The spring steel comprises the following components in percentages: 0.3600-0.5500% of C, 0.2600-0.4500% of Cu, 0.1500-2.200% of Mn, 0.8000-5.4200% of Si, 0.7000-3.8000% of Cr, 0.030-0.0800% of P, 0.0030-0.0500% of S, 0.3000-0.5000% of Ni, 0.0008-0.0500% of Al, 0.0020-0.0100% of V and the balance of Fe and inevitable impurities. The wear-resistant alloy spring steel disclosed by the invention has an excellent wear-resisting performance, the consumption of materials is reduced, and the production efficiency is enhanced.

Owner:ANHUI HONGQIAO METAL MFG

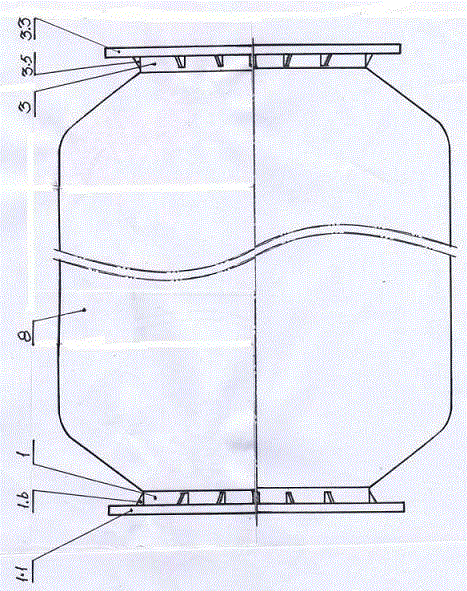

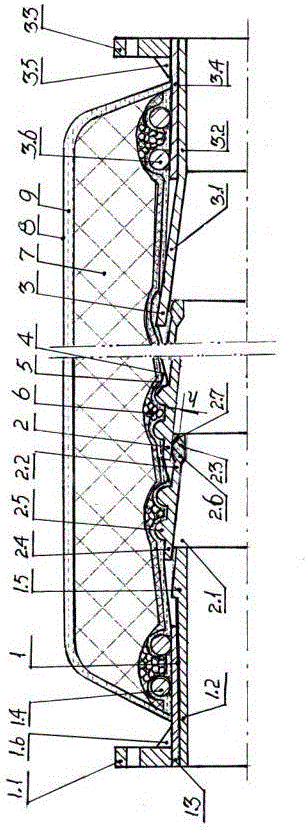

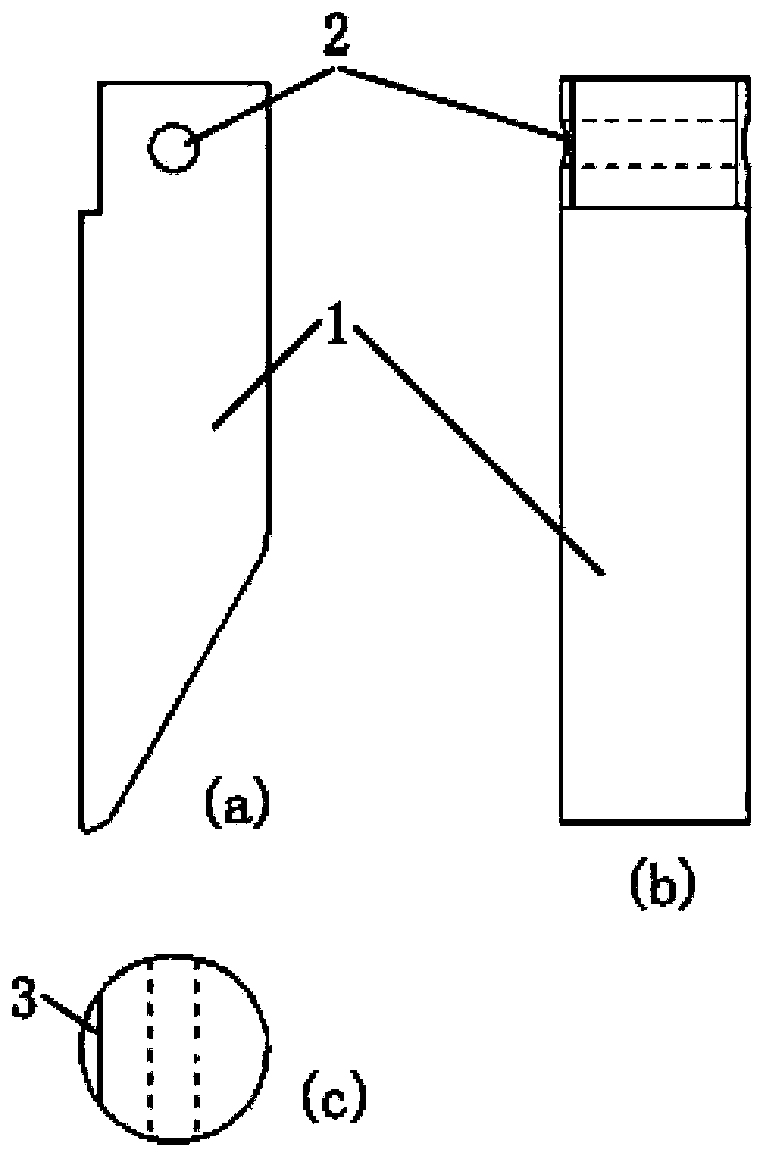

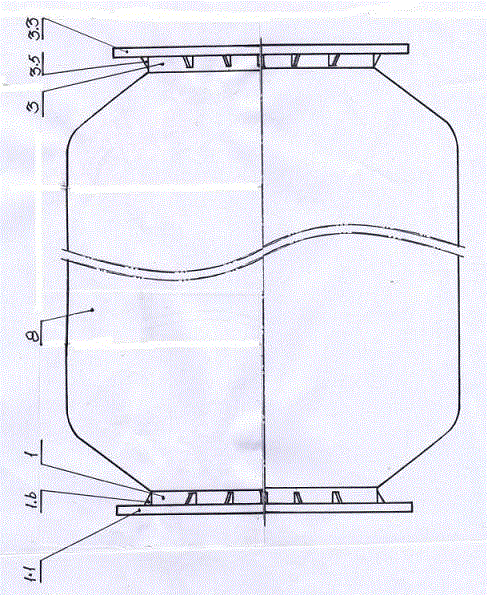

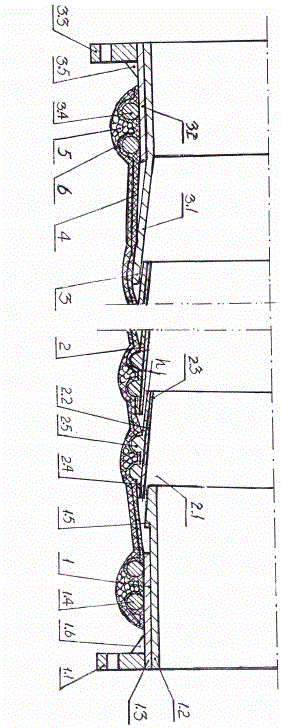

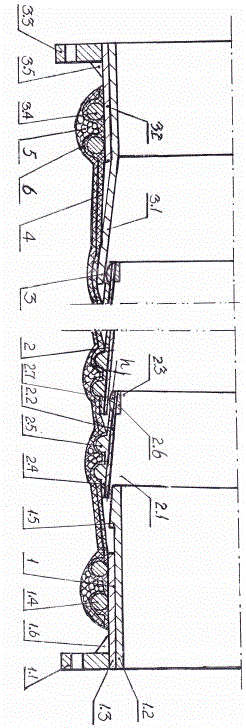

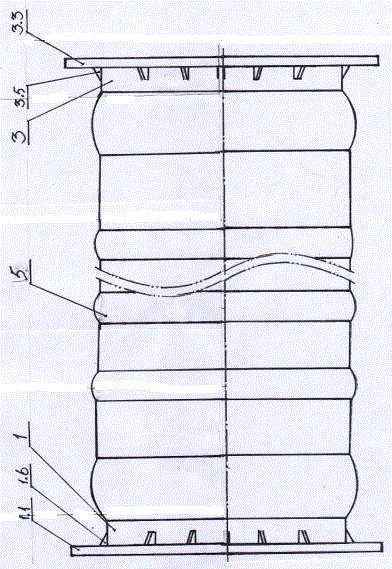

Mud pipe and design method for self-floating armored mud pipe

ActiveCN105135089AHighlight substantiveSignificant progressSoil-shifting machines/dredgersFlexible pipesProtection layerDesign methods

The invention discloses a mud pipe and a design method for the self-floating armored mud pipe, and belongs to the technical field of dredging engineering equipment. The design method for the self-floating armored mud pipe comprises overall design of the mud pipe and a floating body layer on the mud pipe and specific design of all parts; and the mud pipe is composed of an inlet end connecting pipe, an armored pipe body and an outlet end connecting pipe. The outer lateral face of the mud pipe is wrapped with a cord fabric powerful elastic material layer, an elastic material layer and a steel wire fastening layer which are bonded with the outer lateral face of the mud pipe; and the floating body layer is characterized in that a light body layer and a protection layer which are integrally connected with the elastic material layer of the mud pipe and are sequentially arranged on the outer side of the elastic material layer of the mud pipe. Compared with the prior art, the design method has the outstanding substantive features and prominent beneficial effects that the technical scheme is reliable, the bending requirement for adjusting the direction of the mud pipe is met, and the wear-resisting property of the mud pipe can be close to that of a metal composite mud pipe.

Owner:姜考成

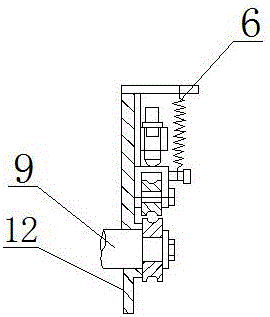

Thermoplastic FRP rib bending device

The invention provides a thermoplastic FRP rib bending device. The device comprises a fixing mechanism, a rotating mechanism, a slide block, a heater and a cooler. A spring is arranged between the fixing mechanism and the rotating mechanism; a guide rail penetrates through the fixing mechanism and the slide block; two ends of the guide rail are fixed on a working platform by a base; a stepper motor drives and controls the slide block through a lead screw; under the effect of the slide block, the rotating mechanism and the fixing mechanism can perform translation and rotation; through translation, FRP ribs move between the heater and the cooler; through rotation, the FRP ribs are bent; and the bending angles are 0-90 degrees. The device has such advantages as high automation degree, high machining precision, simple operation and low requirements on constructors and places.

Owner:HARBIN ENG UNIV

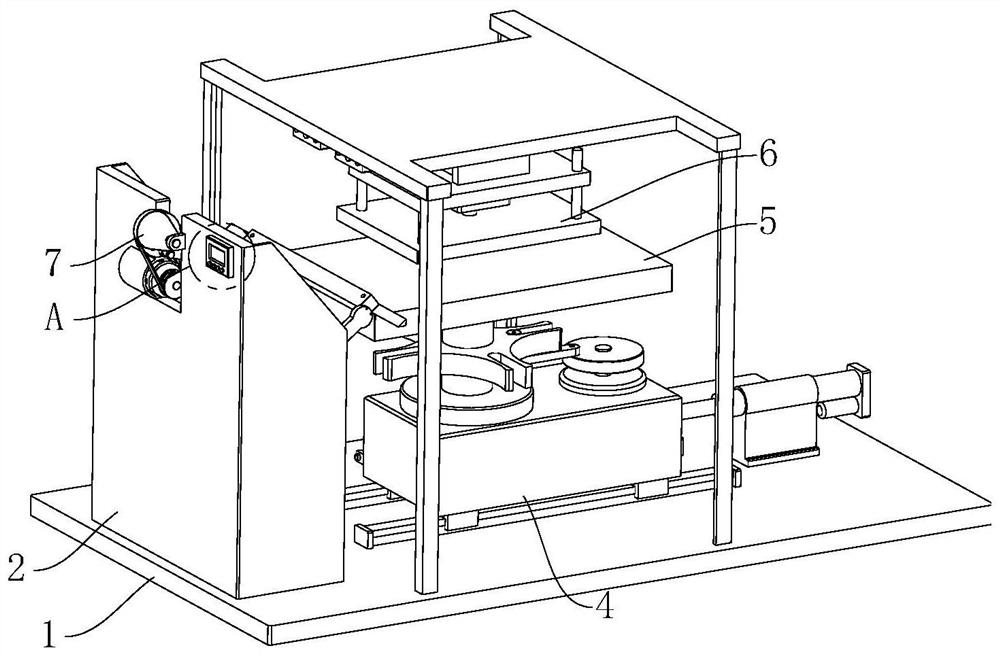

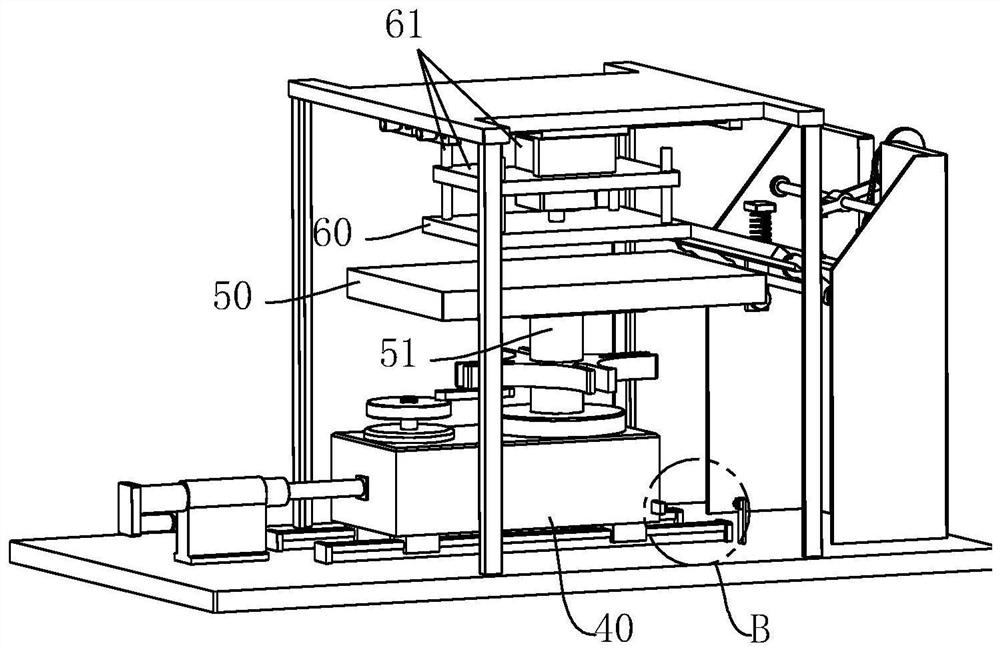

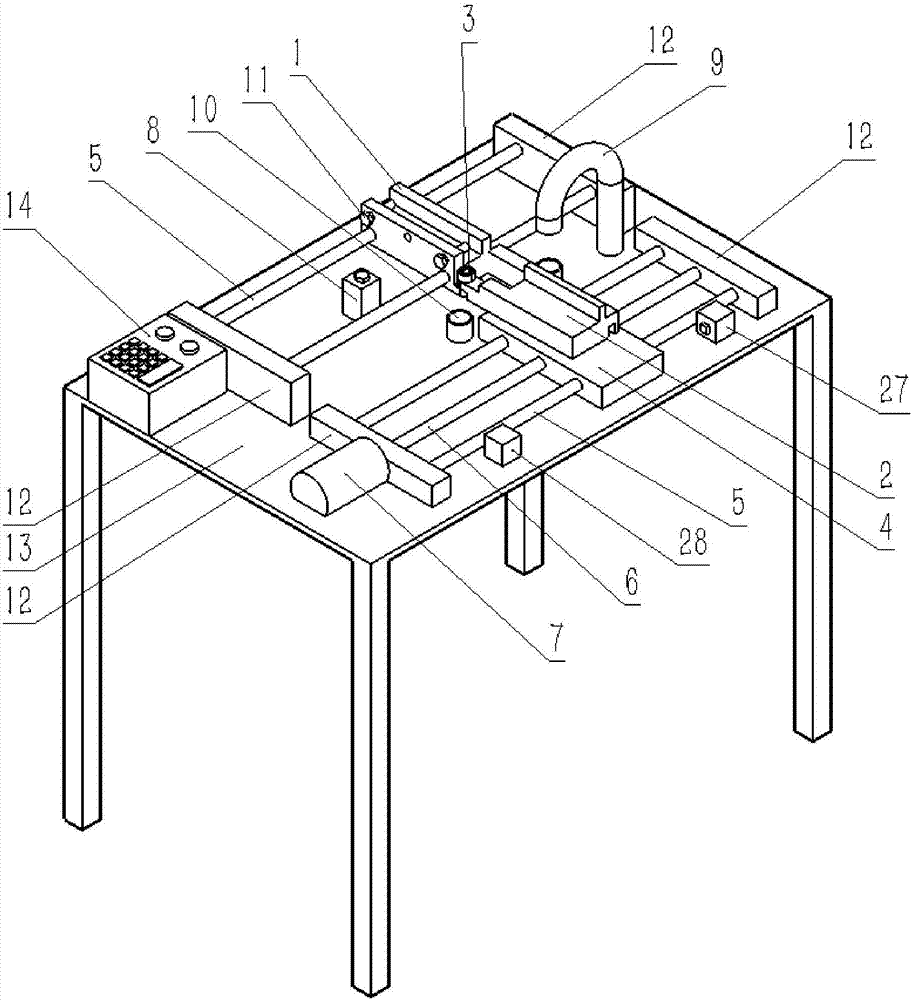

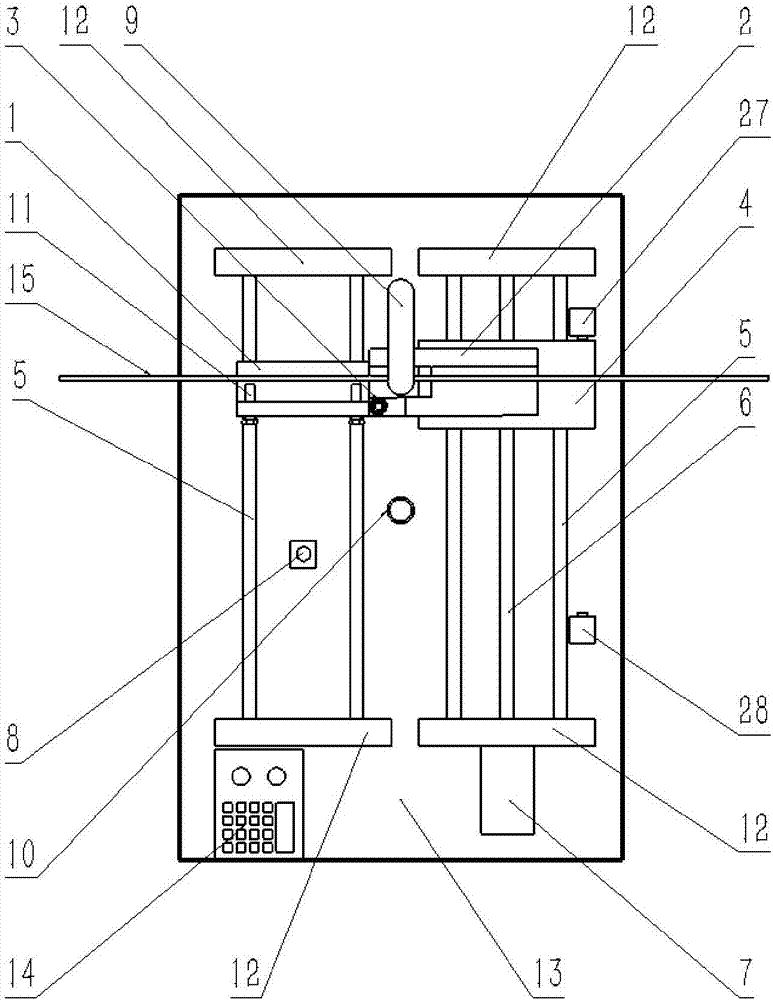

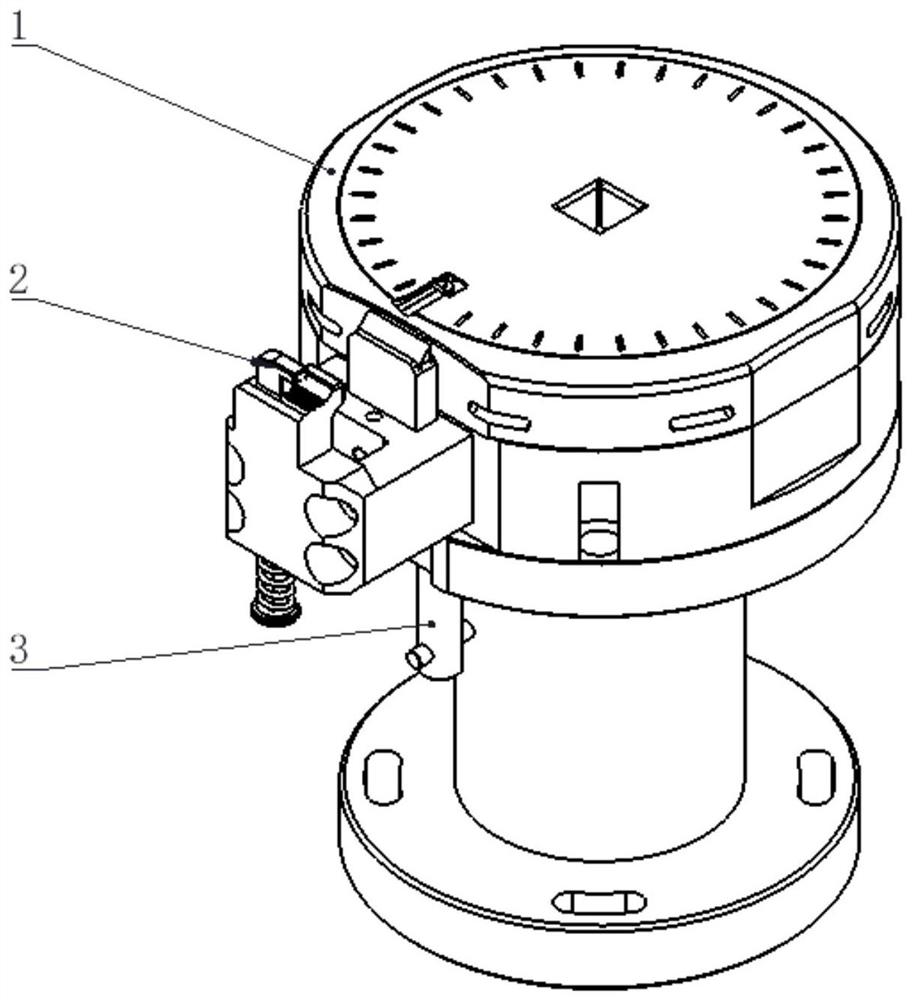

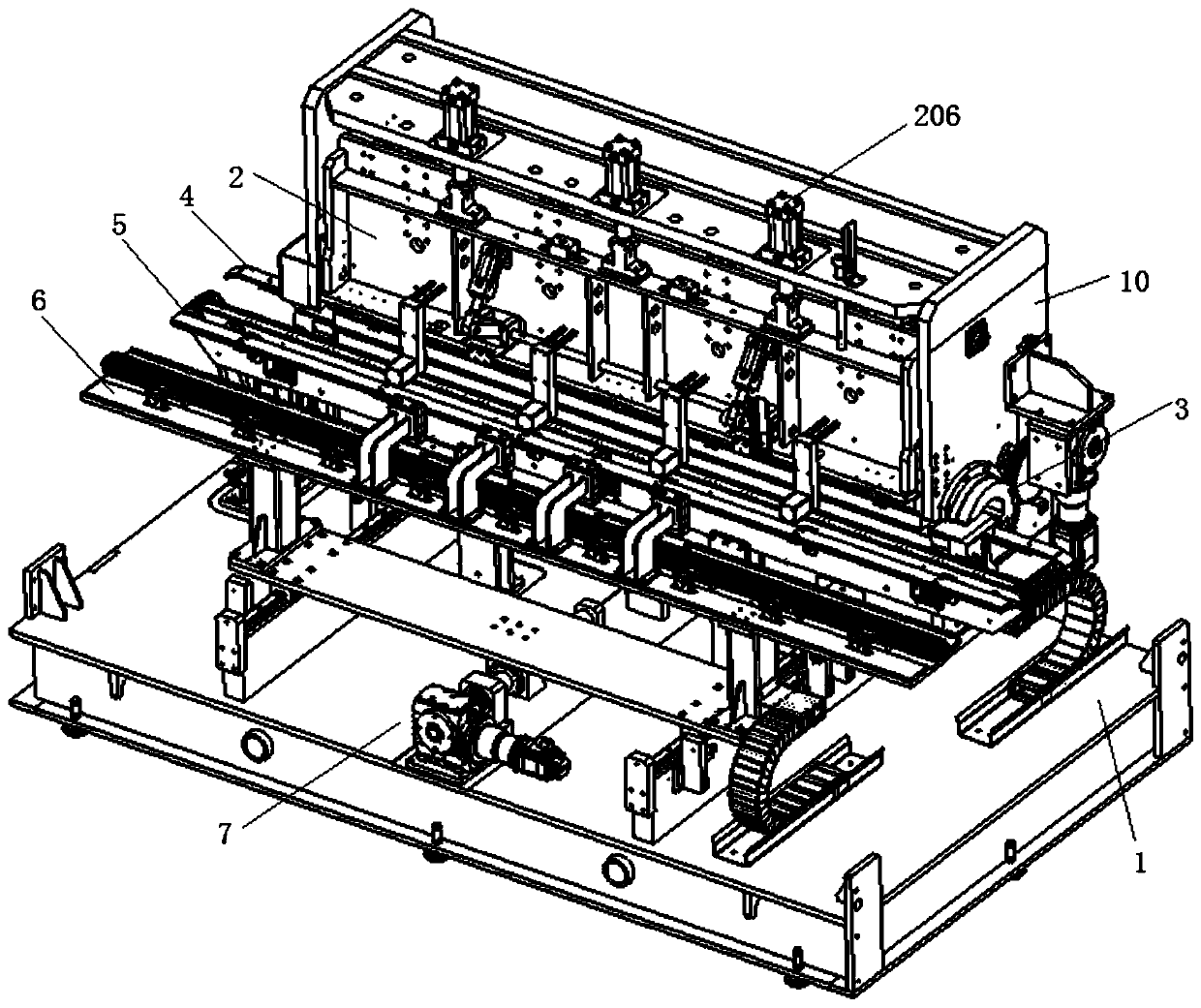

Winding forming equipment and process based on mixed alpha winding technology

ActiveCN112951588AHigh precisionMeet bending requirementsCoils manufactureWire wrapInductive charging

The invention is applicable to the technical field of wireless charging coil manufacturing, and particularly relates to winding forming equipment based on a hybrid alpha winding technology, which comprises an operation table, an upper and lower die group is mounted on the operation table; bending pins, wire clamps and die cores are arranged on the upper and lower die group, and the bending pins, the wire clamps and the die cores are matched to wind one or more enameled wires into a specified shape, including cable bending; a wire passing mechanism and a lead clamping mechanism are mounted on the operation table on the side edge of the upper and lower die group; a straightening wire inlet module, an upper wire clamp opening mechanism, a lower die wire clamp opening mechanism and a bending pin top block mechanism are installed on the side edge of the upper and lower die group. According to the invention, automatic linkage is achieved, large-batch and high-quality coil production is completed, cables can be wound more comprehensively and completely, layering is avoided, the yield of wound wireless charging coil products is high, and the requirement for a large-batch and stable-quality production mode can be met.

Owner:深圳市星特科技有限公司

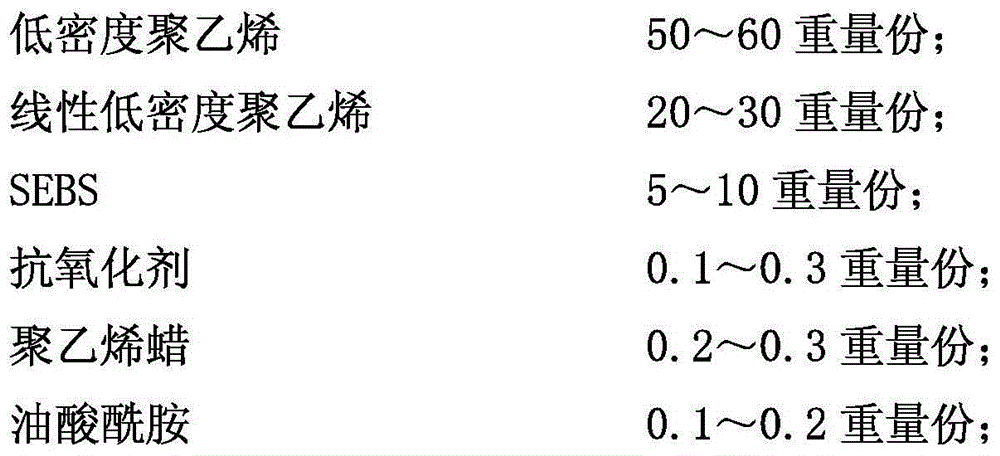

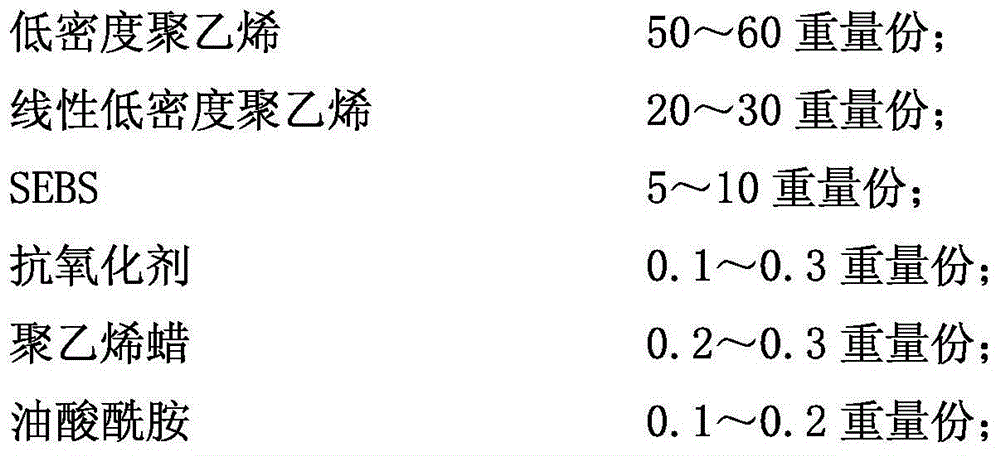

Formula for special protective film of brushed aluminum plate

ActiveCN104788774AReduce risk of precipitationSolve indentationLow-density polyethyleneTectorial membrane

The invention discloses a formula for a special protective film of a brushed aluminum plate. The formula comprises the following materials in parts by weight: 50-60 parts of low-density polyethylene, 20-30 parts of linear low-density polyethylene, 5-10 parts of SEBS, 0.1-0.3 part of an antioxidant, 0.2-0.3 part of polyethylene wax, and 0.1-0.2 part of oleamide. Through the adoption of the elasticity and self adhesive force of SEBS, the problem of glue residues on a glue coating film is effectively solved, and the problems of indentation, scratch, pollution and the like appearing in a stamping process of the brushed aluminum plate are solved; through the addition of the polyethylene wax, the protective film can be quicker and more convenient to form and easy to peel off, so that the sticky phenomenon after stamping of the brushed aluminum sheet is prevented, that is, not only can the stickiness be kept, but also the protective film can be conveniently tore down; through the introduction of a composite antioxidant in the formula, the ageing-resistant performance of the protective film is greatly improved, and the weathering-resistant performance of the brushed aluminum plate is improved. Therefore, the protective film is more durable.

Owner:昆山金华安电子科技有限公司

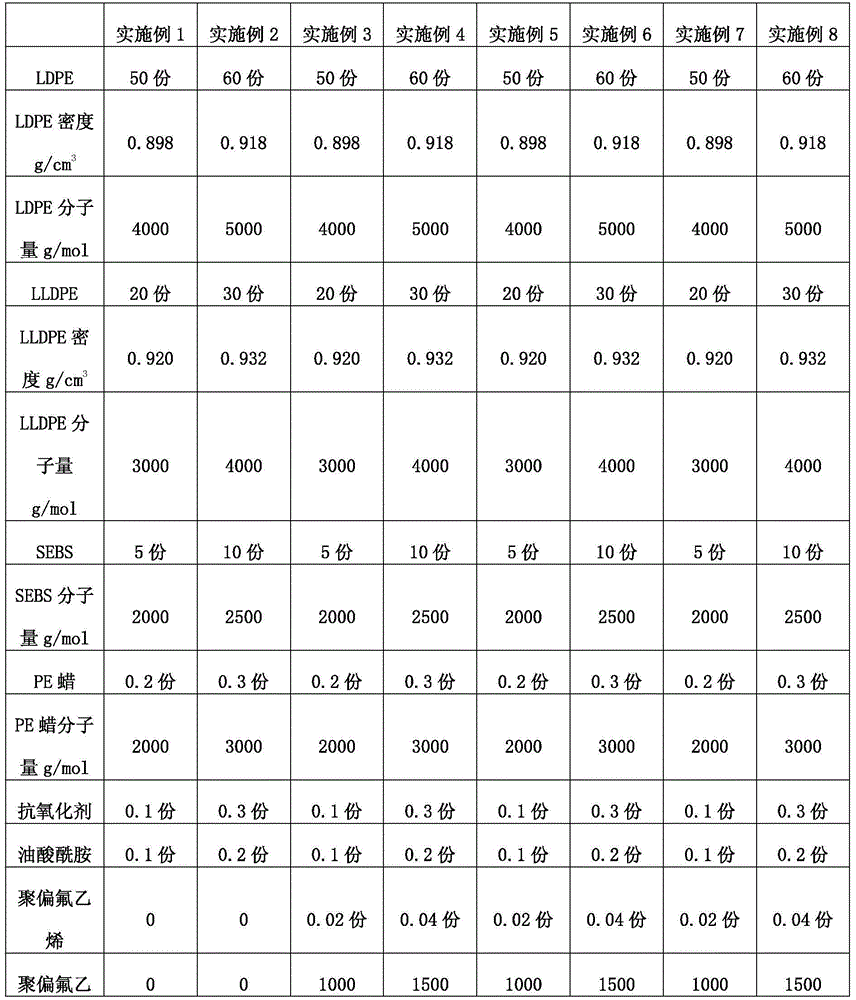

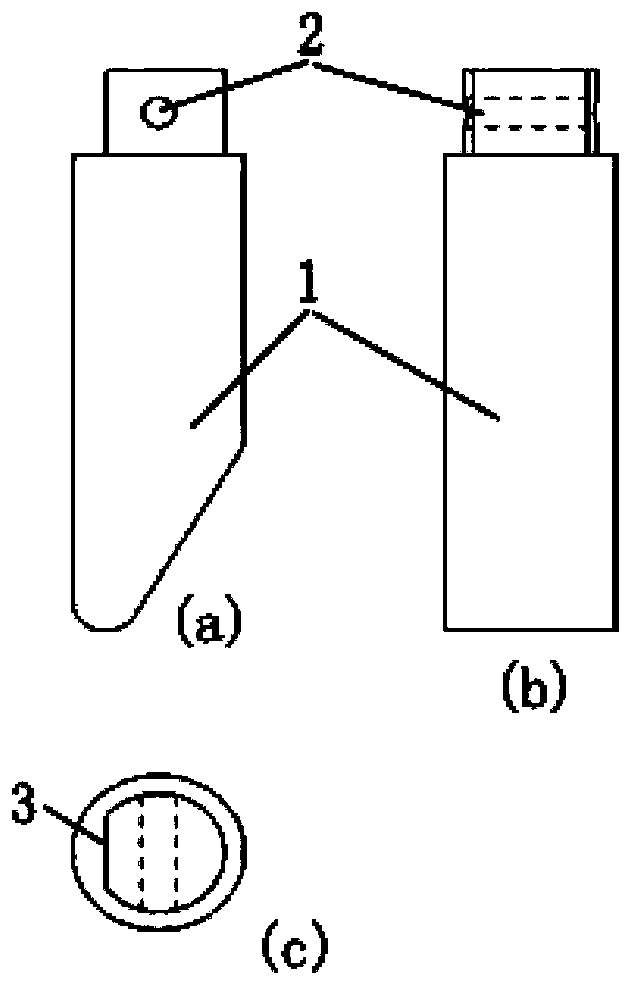

Design method for elbow used for dredging engineering conveying pipeline and elbow designed by design method

ActiveCN105221883AHighlight substantiveSignificant progressRigid pipesPipe protection against damage/wearRare earthSteel tube

The invention discloses a design method for an elbow used for a dredging engineering conveying pipeline and an elbow designed by design method, and belongs to the technical field of dredging engineering equipment. According to the technical scheme adopted by the invention, a cast-steel tube, which is formed by casting a wear-resisting high-chromium cast iron material added with rear-earth elements through a mould, is taken as an elbow inner-layer steel tube, and an elbow tube body, which is of an outer-layer steel tube formed by carrying out processes of dosing, profiling and welding processes on a low-carbon steel plate, coats the outside of the inner-layer steel tube; a wear-resisting high-chromium cast iron reinforcing layer which is integrated with the inner-layer steel tube is arranged on a bending stress part of the inner-layer steel tube; and the reinforcing layer is a curved surface structure which is formed by connecting double curved surfaces. Compared with the prior art, the technical scheme is reliable, thereby meeting the bending requirements of regulating a mud delivery pipeline, and achieving the substantial characteristics and remarkable progress that wear resistance of a metal composite mud delivery pipeline are similar with those of the mud delivery pipeline for ancillary use.

Owner:南通嘉奇钣金科技有限公司

Tool with bent angle

Owner:陈财庆

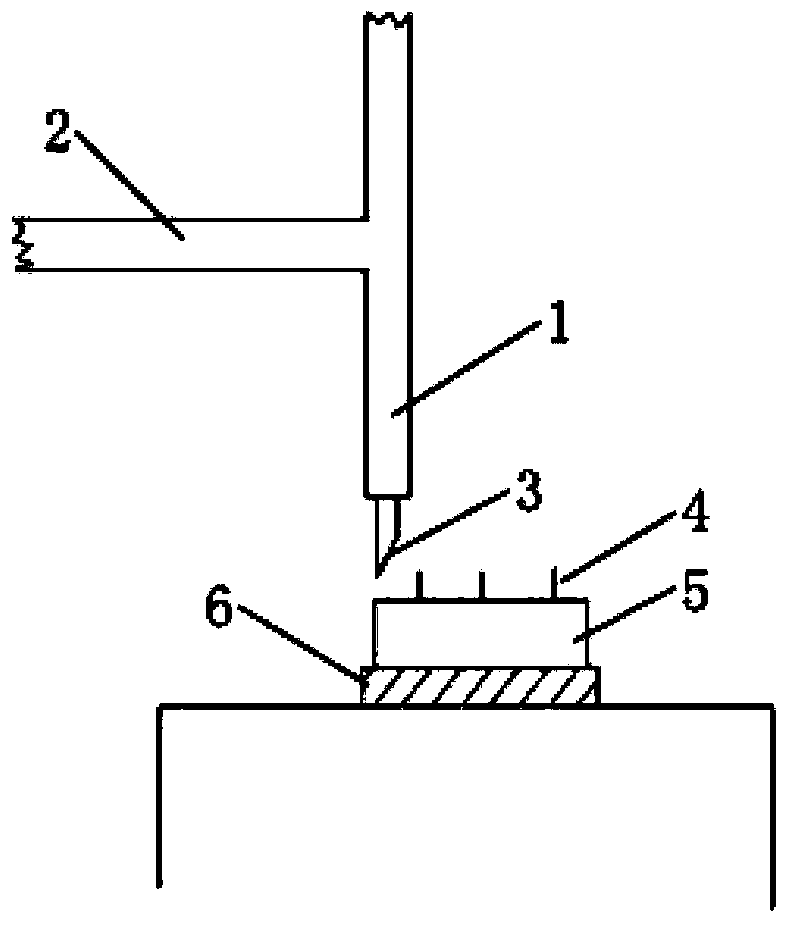

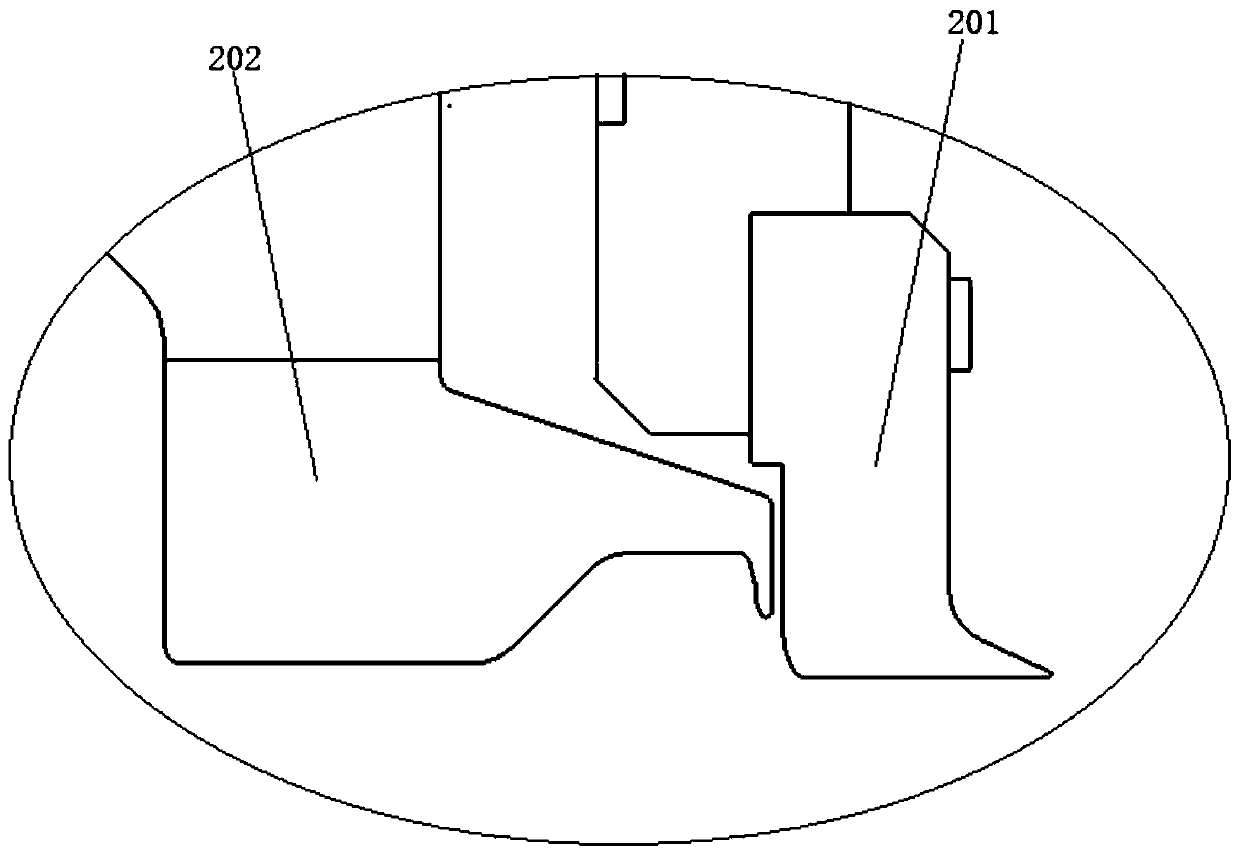

Electrode bending punch head with inclined plane structure and inclined plane type electrode bending method

Disclosed is an electrode bending punch head with an inclined plane structure. An upper portion of the electrode bending punch head is a connection portion, the lower portion of the electrode bending punch head is an electrode backfin inclined plane which is made of high-hardness materials, and the surface of the electrode backfin inclined plane is covered by an electroplated layer. According to an electrode bending method based on the electrode bending punch head, during the whole bending process, the electrode backfin inclined plane directly contacts with electrodes of an insulated gate bipolar translator (IGBT) module and bends and flattens the electrodes, so that heights of the bent electrodes can be conveniently controlled, heights of groups of the bent electrodes are identical, cladding layers on the surfaces of the electrodes are intact and free of scratches, various electrode bending requirements of the IGBT module are well met, and electrode bending qualities are improved.

Owner:XIAN YONGDIAN ELECTRIC

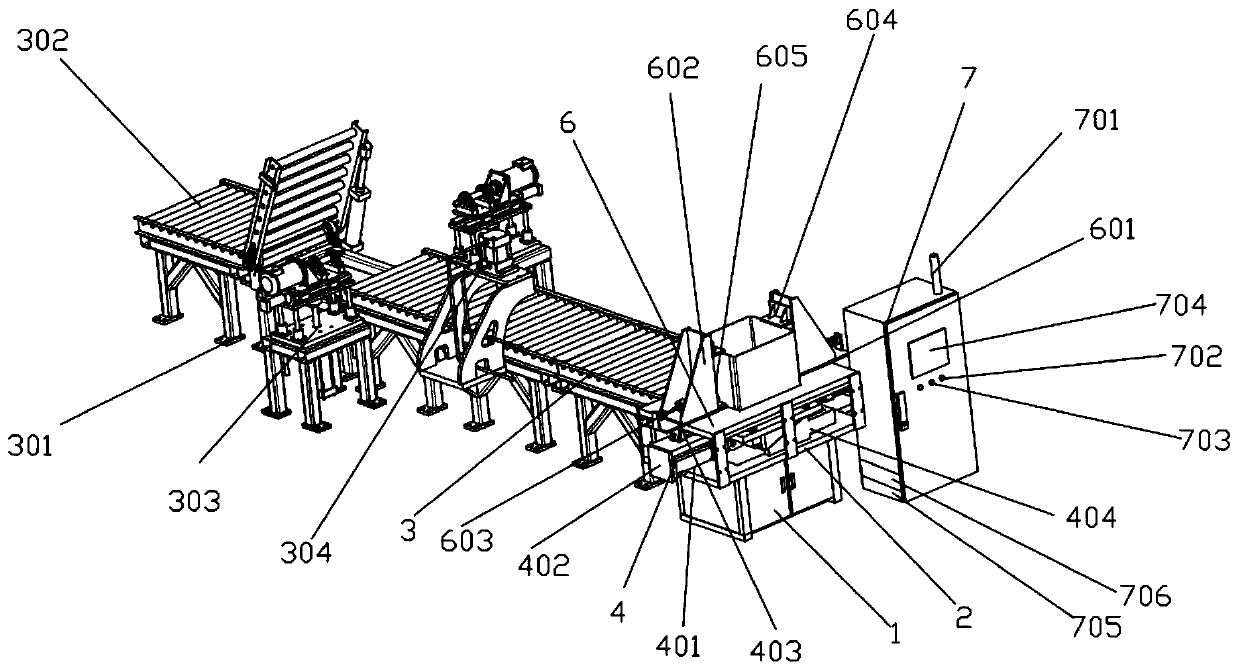

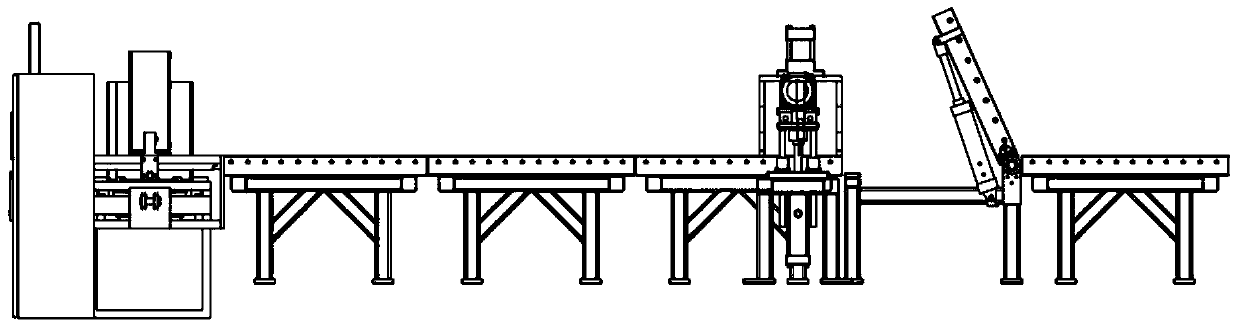

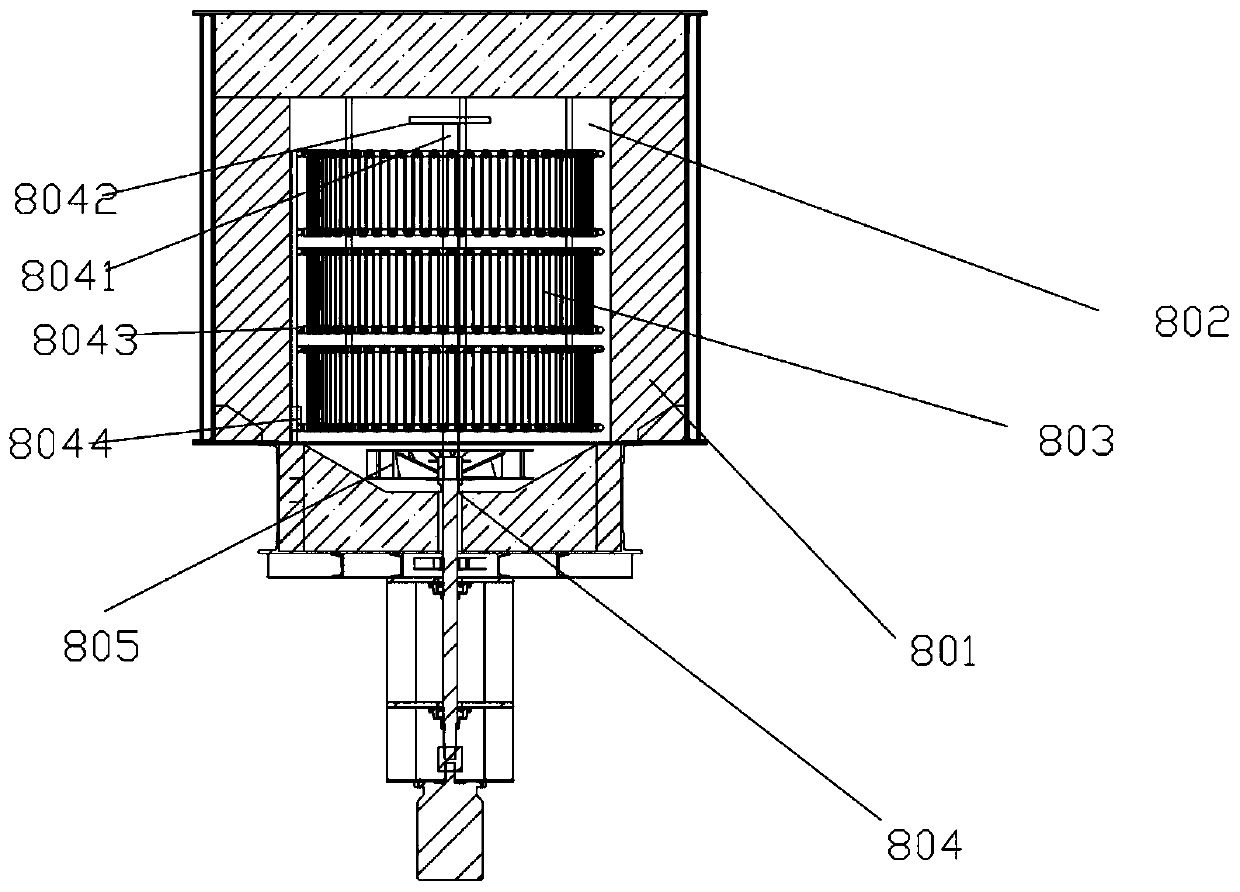

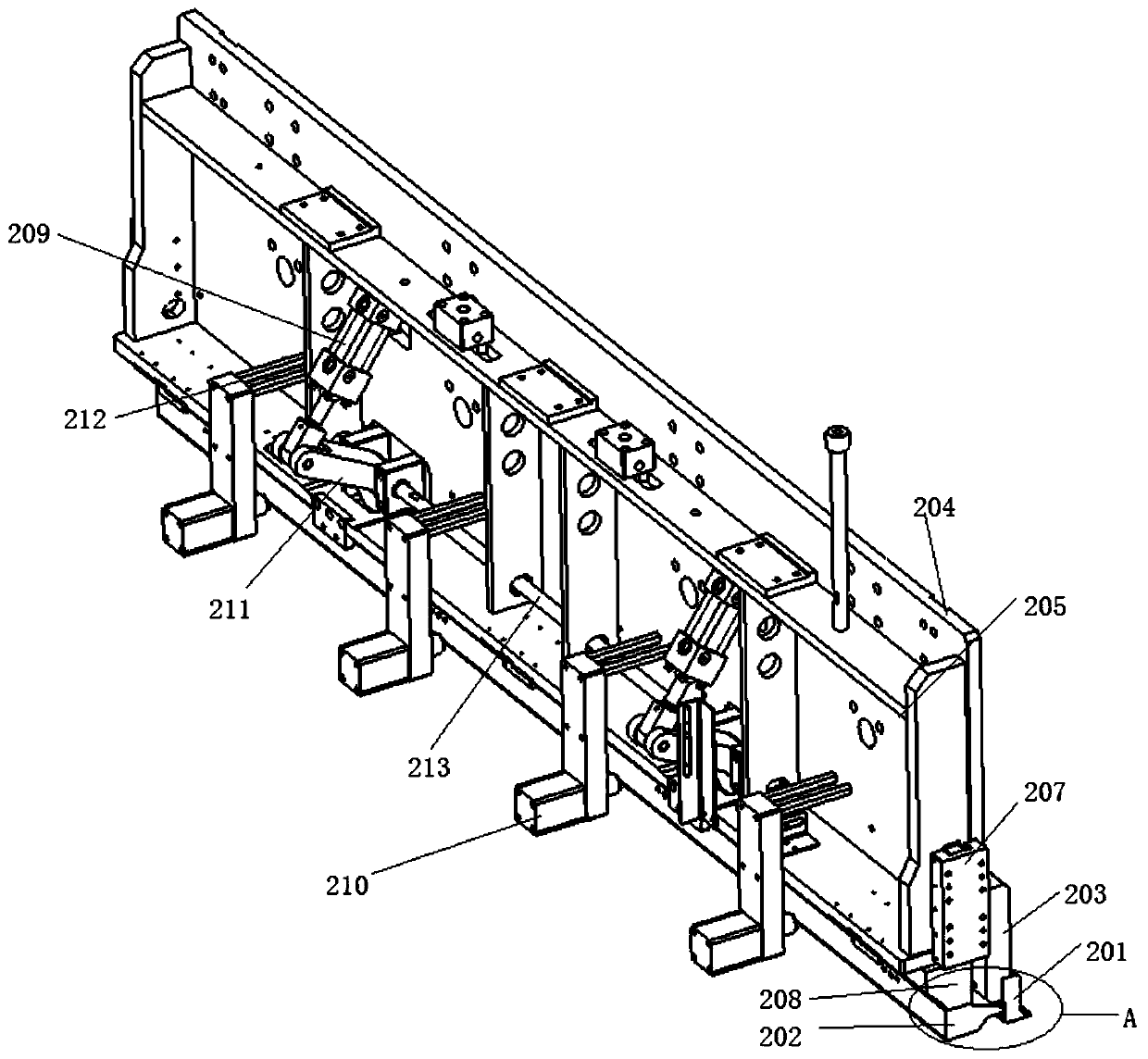

Automatic flanging equipment and working method thereof

The invention discloses automatic flanging equipment and a working method thereof and belongs to the field of novel bending. The automatic flanging equipment is provided with a base and a fixed tableboard arranged on a base body. For the automatic flanging equipment, by arranging an automatic conveying device on the side surface of the fixed table board, labor force conservation is facilitated; in automatic workpiece conveying work, in order to improve the working efficiency, the procedures are integrated, the two ends of the automatic conveying device are provided marking devices respectively, mechanical automatic marking is performed, and the working efficiency is improved while the labor force is liberated; by arranging a heat treatment device in the base body, a workpiece can be automatically lifted into a hearth and is subjected to normalizing treatment at 900 DEG C; with normalizing, grains can be refined, tissues are uniform, the comprehensive mechanical properties of a steel plate are improved, and the plasticity and the toughness of the steel plate are improved under the condition without lowering the strength; and when a part is bent or flanged, the bending requirementsare met, the material utilization rate is increased, and the cost is lowered.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

Upward-90-degree bending double-bending die strip and bending machine

PendingCN111229942ASimple structureReduce movementShaping toolsMetal-working feeding devicesAcute angleMachine

The invention discloses an upward-90-degree bending double-bending die strip and a bending machine. The double-bending die strip comprises a first bending die strip and a second bending die strip. Thesecond bending die strip is horizontally and movably arranged on one side of the first bending die strip through a second bending die strip horizontal moving mechanism. The first bending die strip atleast comprises a pressing face, a bending angle is formed at the front end of the pressing face, and the bending angle is inwards bent by the acute angle. The side, close to the first bending die strip, of the second bending die strip is provided with a bending face, and the lower end of the bending face downwards extends in a hook shape. The bending machine comprises a bending swinging mechanism, a bending overturning mechanism, a lower die mechanism, a conveying mechanism and a side positioning mechanism. A die head of the first bending die strip is horizontally arranged, the second bending die strip is vertically arranged, 90-degree bending or clamping bending of a plate in the small gap can be achieved, and the bending efficiency is improved.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Design method of a self-floating armored mud discharge pipe and its mud discharge pipe

ActiveCN105135089BHighlight substantiveSignificant progressSoil-shifting machines/dredgersFlexible pipesProtection layerDesign methods

Owner:姜考成

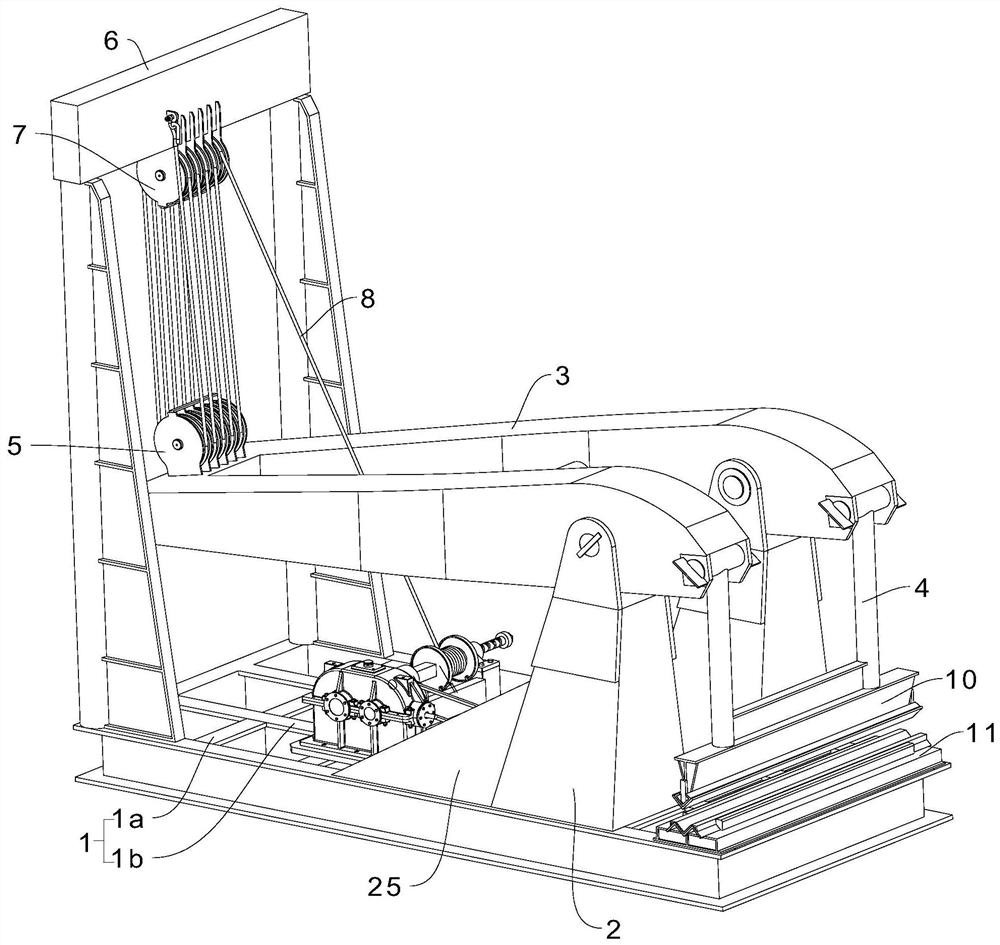

Bending machine for ship manufacturing

The invention relates to the technical field of ship manufacturing, and discloses a bending machine for ship manufacturing. The bending machine comprises a bottom frame, two support piers and two rotating parts, a pressure applying rod is arranged at one end of each rotating part, a lower pulley block is arranged at the other end of each rotating part, a door-shaped frame is arranged on the bottom frame, and an upper pulley block is arranged at the bottom of a top frame of the door-shaped frame. the bending machine further comprises a tension rope and a traction assembly, one end of the tension rope is connected with the door-shaped frame, the middle of the tension rope is wound around the upper pulley block and the lower pulley block, the other end of the tension rope is wound around the traction assembly, pressure applying pieces are arranged at the bottoms of the two pressure applying rods, and a piece placing table is arranged below the pressure applying pieces. According to the bending machine, the rotating parts, the pressure applying rod, the pressure applying pieces, the upper pulley block, the lower pulley block, the tension rope and the like are arranged, the lever principle and the pulley blocks are comprehensively applied, large bending force can be obtained with small applied force, the bending requirement of steel plates used in ship manufacturing is met, the cost is far lower than that of the bending machine for applying the same bending force in the market, and the equipment investment is greatly reduced.

Owner:湖北誉江船舶制造股份有限公司

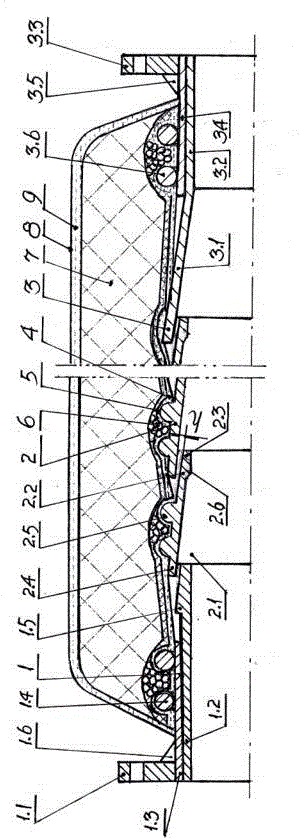

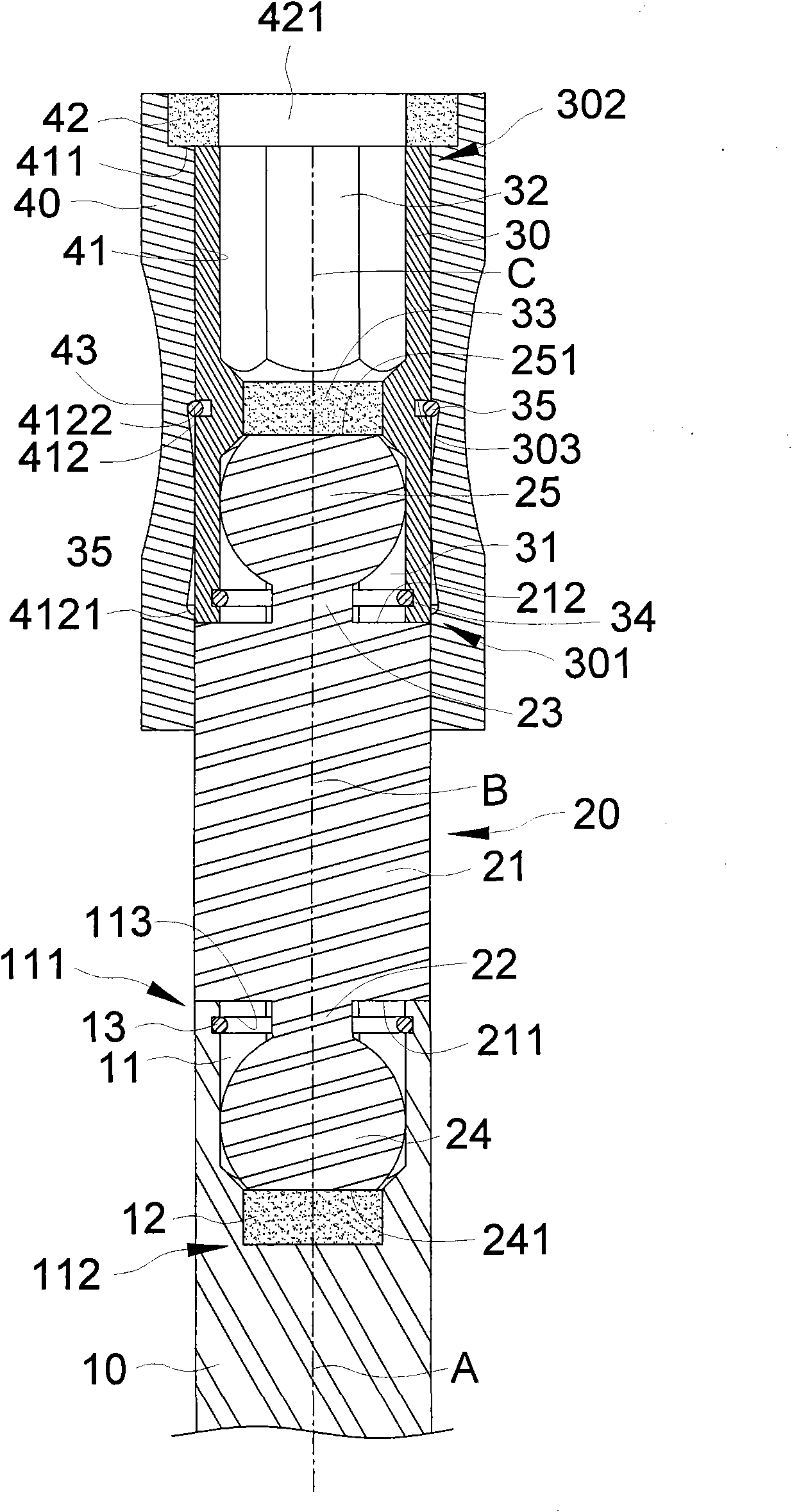

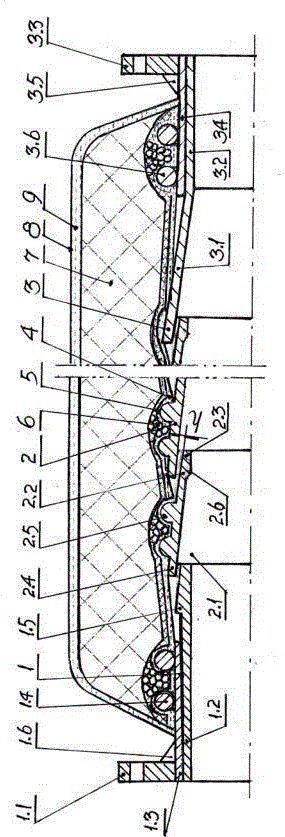

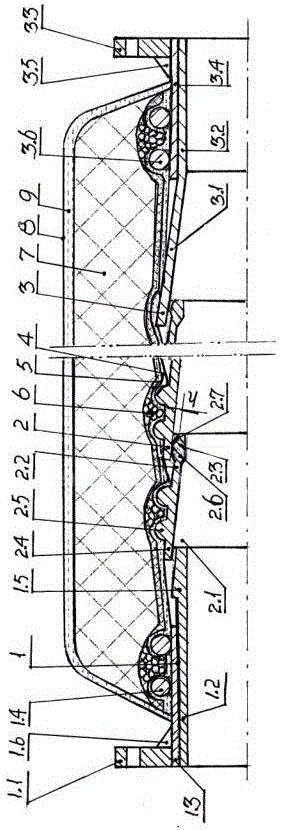

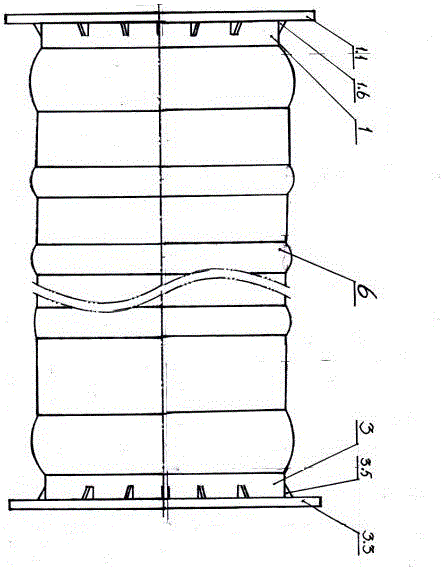

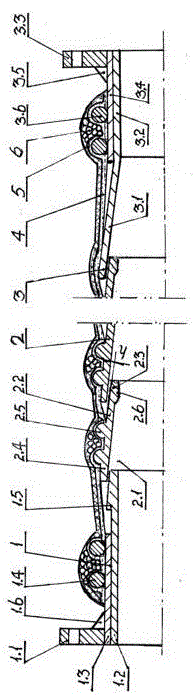

Full-armor mud discharging pipe, production method and special device of full-armor mud discharging pipe

The invention discloses a full-armor mud discharging pipe, a production method and a special device of the full-armor mud discharging pipe and belongs to the technical field of dredging engineering equipment. According to the technical scheme, the full-armor mud discharging pipe comprises a pipe body and a connecting and fastening layer combined to the outer side of the pipe body; the full-armor mud discharging pipe is characterized in that an inlet end joint pipe, tapered pipes and an outlet end joint pipe are sequentially assembled into a whole in an armored manner to form the pipe body and are each at least formed by combing an inner steel pipe layer and an outer steel pipe layer, and at least two annular locating and fastening rings are arranged on the outer side wall of each outer steel pipe layer; and each connecting and fastening layer is sequentially wrapped with a strengthened elastic material layer, a multi-layer steel fastening layer and an elastic material layer. Compared with the prior art, the full-armor mud discharging pipe, the production method and the special device have remarkable improvements and the prominent substantive distinguishing features that the technical scheme is reliable, the bending requirement for adjusting the direction of the mud discharging pipe is met, and the wear resistance of the full-armor mud discharging pipe can be close to that of a metal composite mud discharging pipe, and the use performance of the metal mud discharging pipe is improved comprehensively.

Owner:姜考成

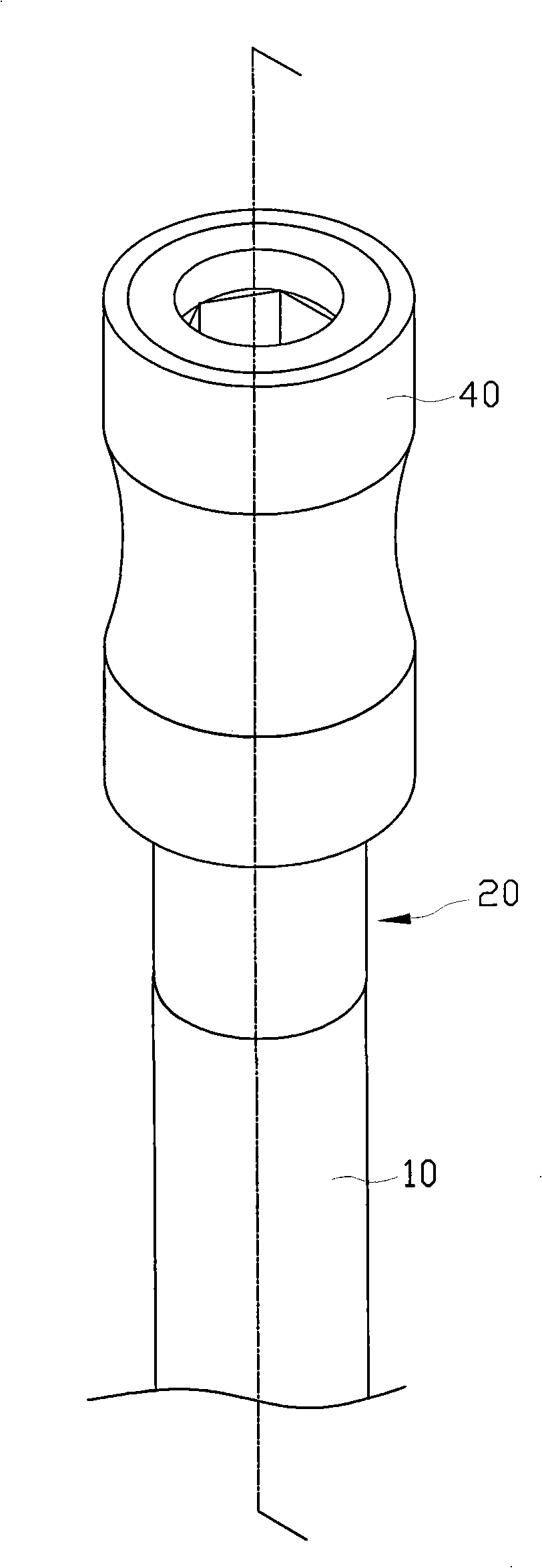

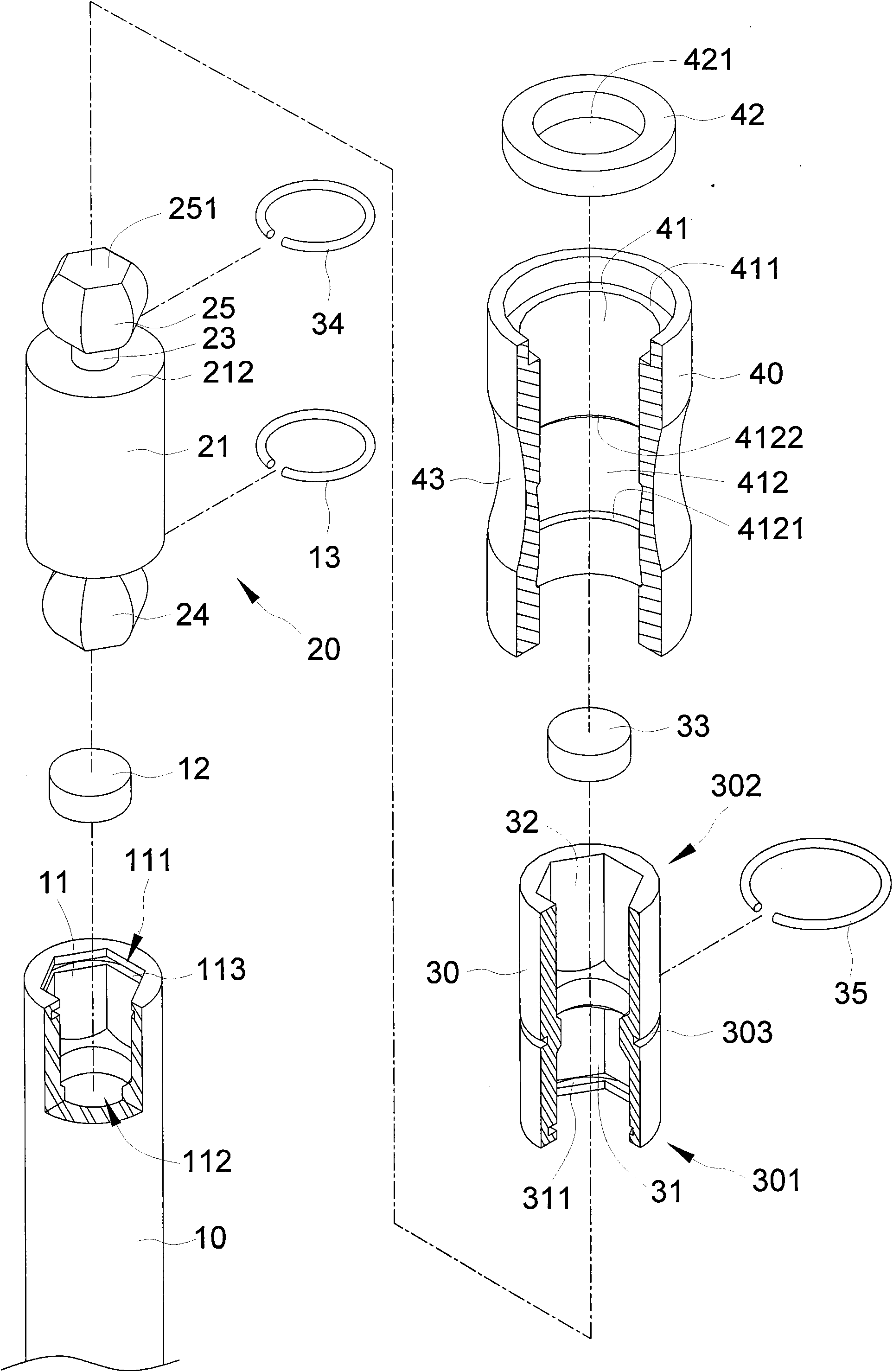

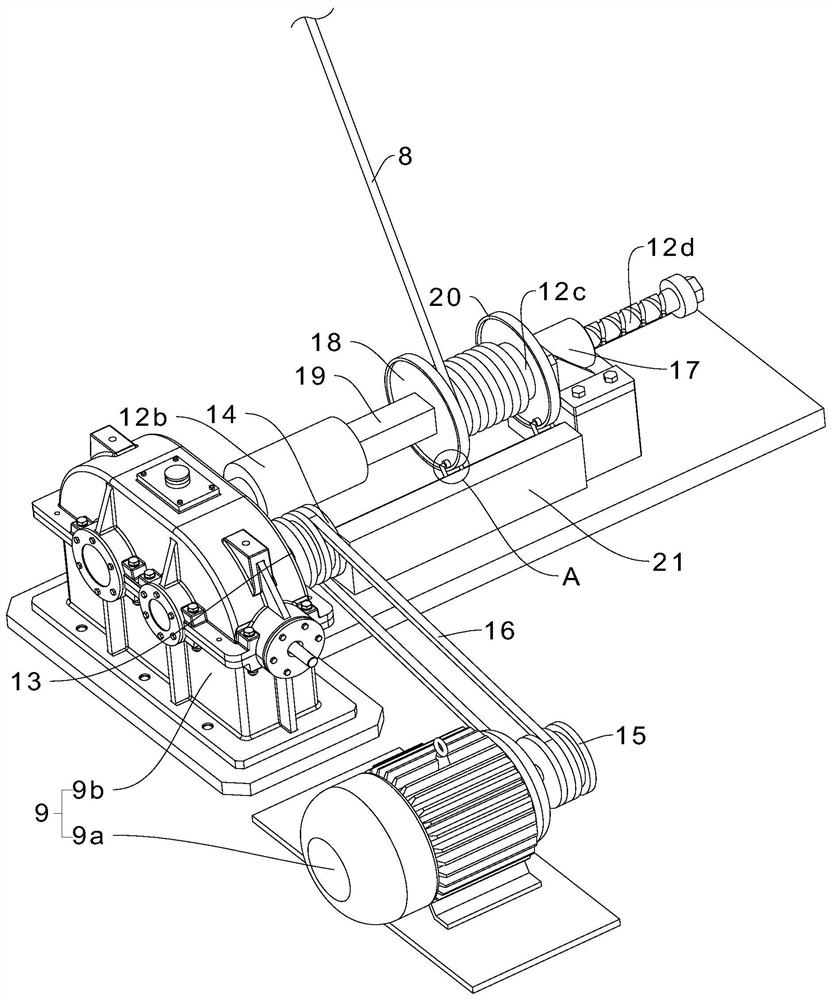

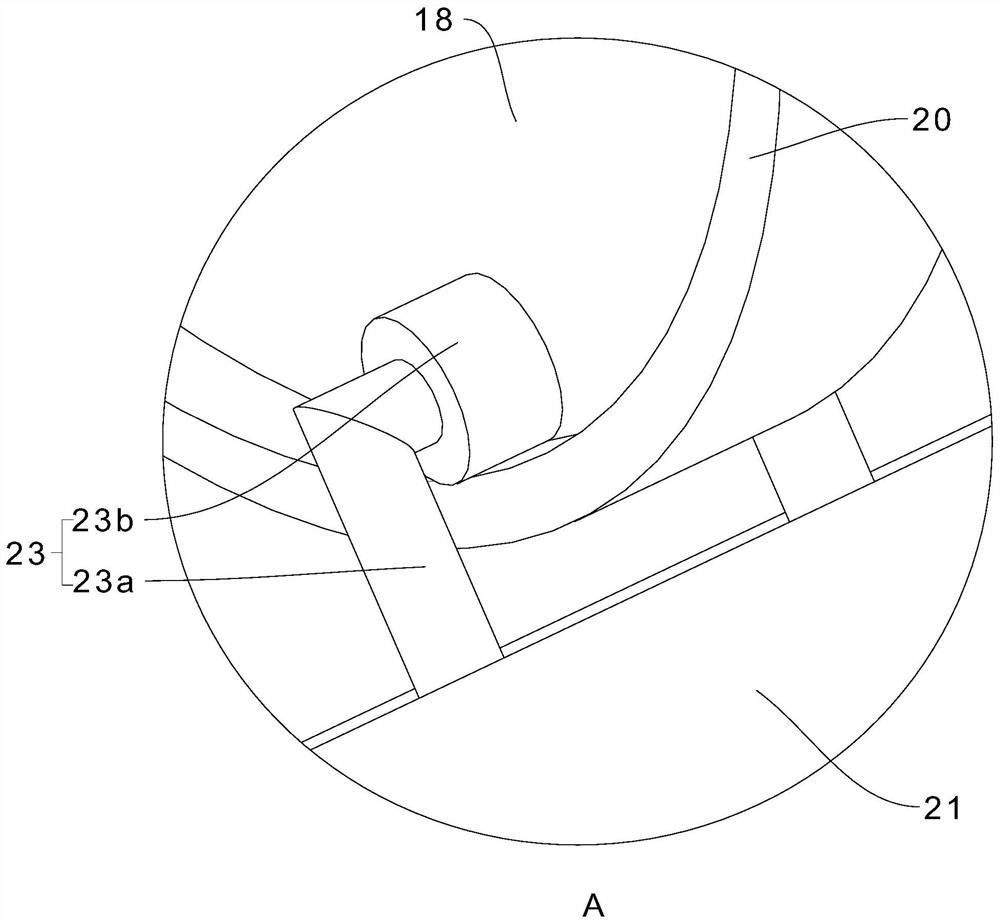

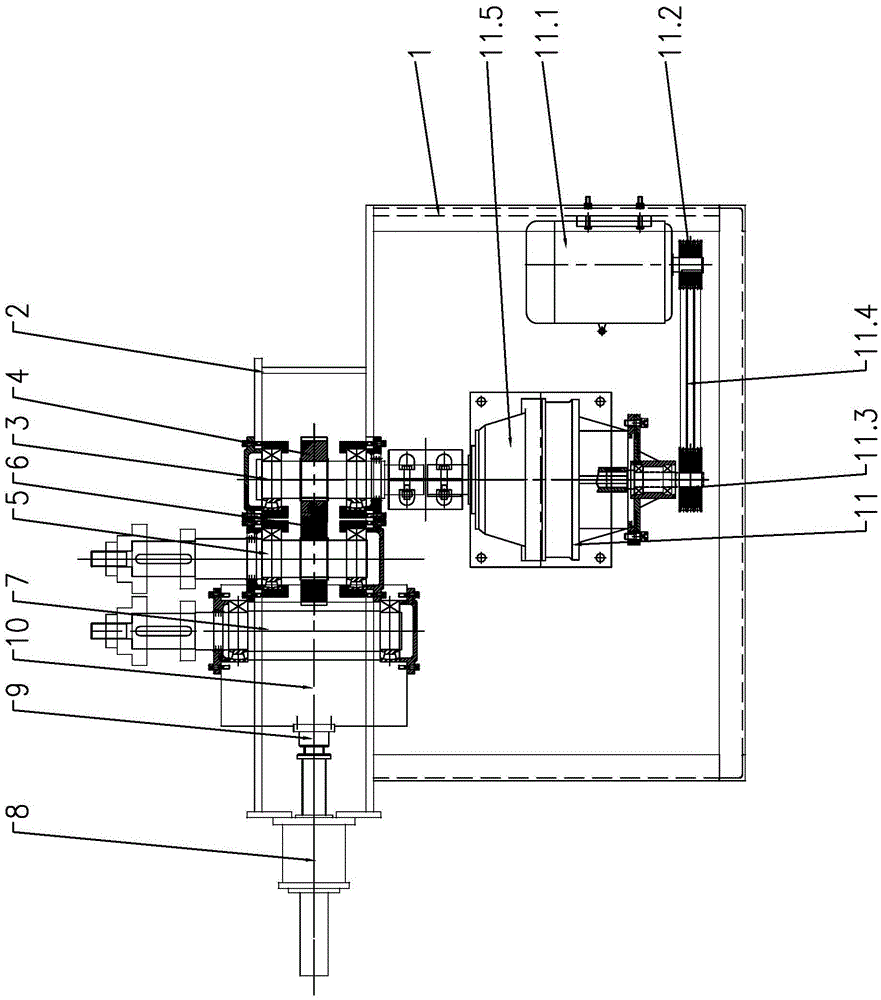

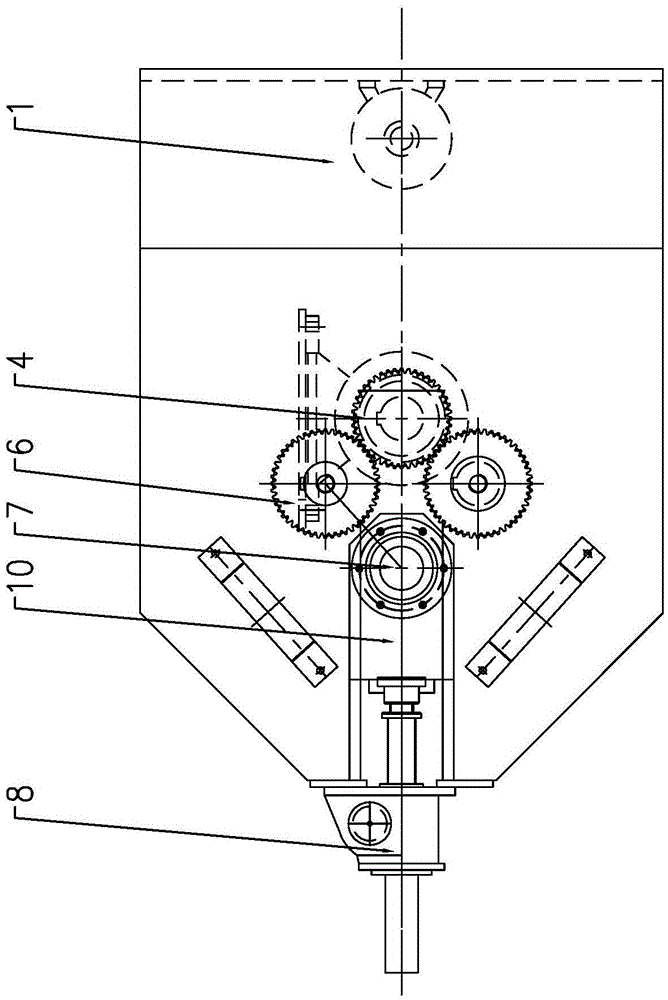

Bender

InactiveCN104525651BImprove stabilityMeet bending requirementsMetal-working feeding devicesPositioning devicesGear wheelDrive shaft

The invention relates to a pipe bending machine, specifically relates to a rolling type pipe bending machine, and belongs to the technical field of pipe bending machines. The pipe bending machine comprises a main bracket, a driving shaft bracket, a driving shaft assembly, a driving gear, fixed wheel assemblies, fixed wheel shaft gears, a movable wheel assembly, a worm gear screw lifting machine, a movable wheel bracket and a driving mechanism; the driving shaft bracket and the driving mechanism are fixed on the main bracket; the driving shaft assembly is arranged on the driving shaft bracket; the fixed wheel assemblies are respectively arranged at the left side and the right side of the driving shaft assembly; the driving gear is arranged on the driving shaft assembly; the fixed wheel shaft gears are arranged on the fixed wheel assemblies; the driving gear of the driving shaft assembly are respectively connected with the fixed wheel shaft gears on the fixed wheel assemblies at two sides by an engaging manner. According to the pipe bending machine, a workpiece can be clamped through an upper pressing plate and a lower supporting plate during working, so that the pipe bending machine can stably work for bending, the working efficiency is increased, and the cost is relatively low; the distance from the upper pressing plate to the lower supporting plate can be adjusted to meet the requirement on bending the workpiece of different size, and therefore, the applicable scope is expanded.

Owner:无锡晶瑜智能机械有限公司

Metal pipe bending machining device based on measuring assembly

ActiveCN112091023AFor a stable gripSimple structureMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention discloses a metal pipe bending machining device based on a measuring assembly, and relates to the technical field of metal pipe bending devices. The device comprises a mounting table; one end of one of first supporting rods is fixedly connected with a first electromagnet; one end of the other first supporting rod is fixedly connected with a second electromagnet; one end of a second supporting rod is fixedly connected with a first arc-shaped clamping plate; one end of a first telescopic part is fixedly connected with a second arc-shaped clamping plate; a bending driving plate is attached to the outer wall of a metal pipe; the upper surface of the mounting table is fixedly connected with linear scale lines; and an angle measuring disc is fixedly connected into a second slidinggroove through a sliding block. Through the design of a sliding clamping groove, the first electromagnet, the second electromagnet, the second supporting rod, the first arc-shaped clamping plate, thefirst telescopic part, the second arc-shaped clamping plate, a fourth telescopic part, a first spring and a two-way threaded rod, stable clamping of metal pipes with different pipe diameters can be achieved, and the application range of the metal pipe bending device is greatly widened.

Owner:安徽鳌鸟信息科技有限公司

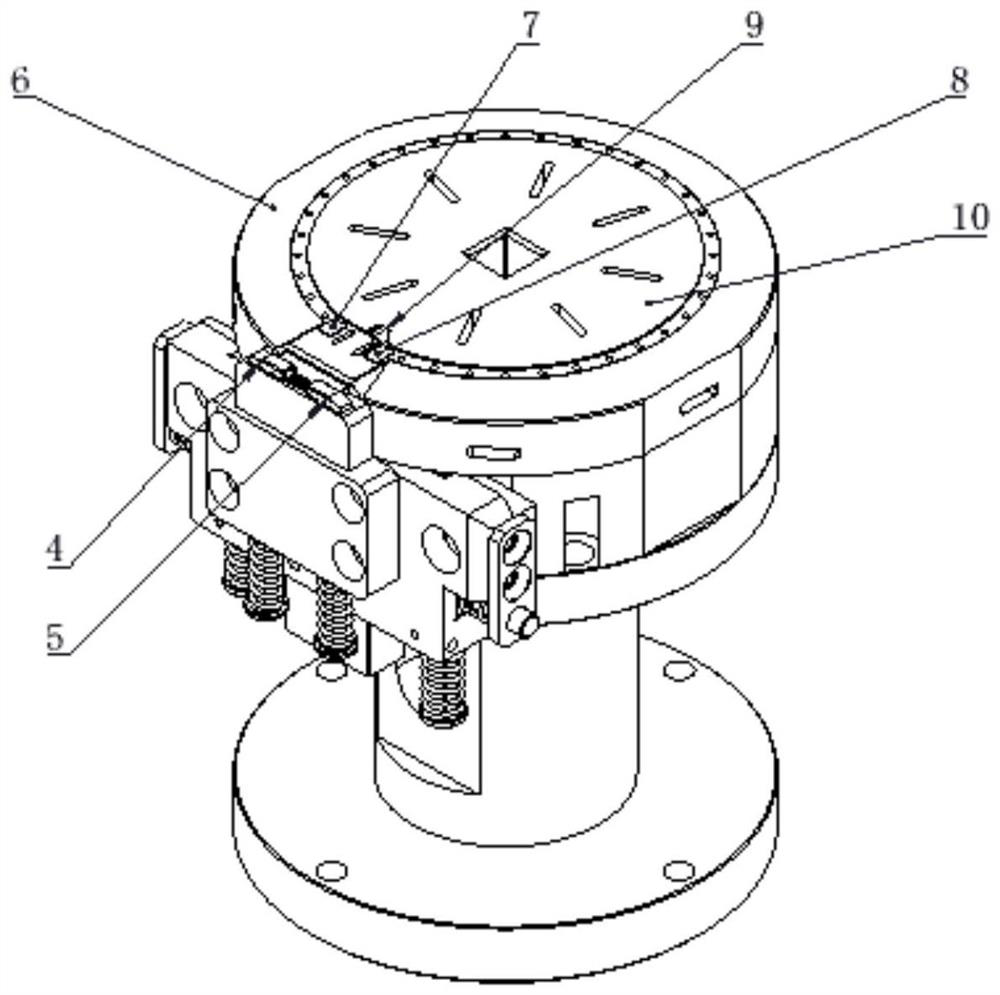

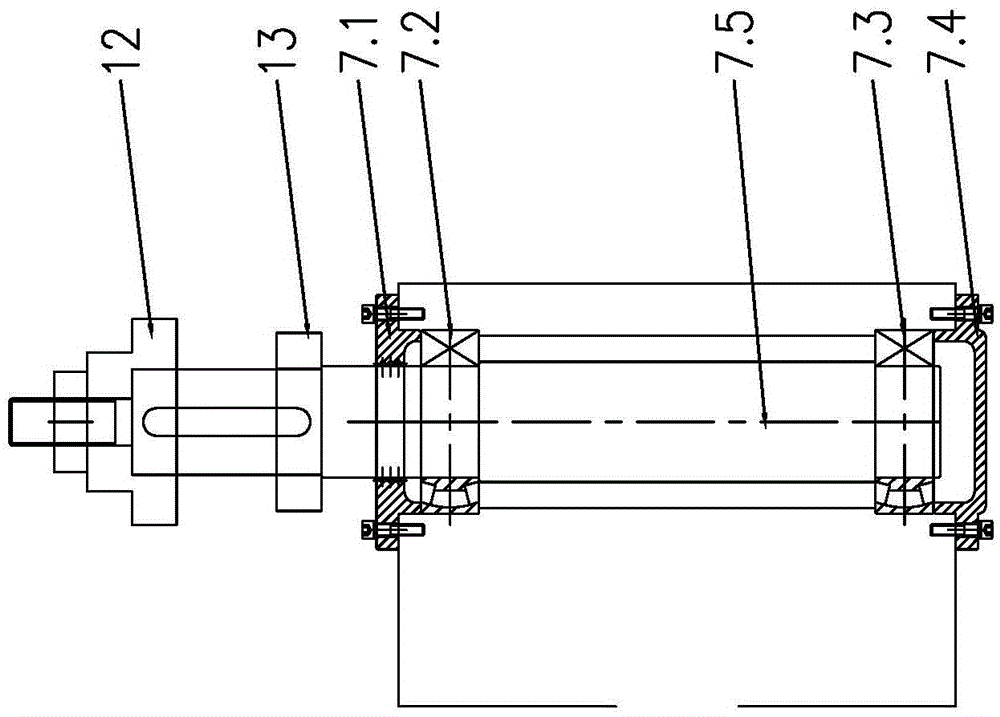

Fixed wheel assembly of pipe bending machine

ActiveCN104525767AStable bending workMeet bending requirementsMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates a fixed wheel assembly, specifically relates to a fixed wheel assembly of a pipe bending machine, and belongs to the technical field of pipe bending machines. The fixed wheel assembly of the pipe bending machine comprises a fixed wheel shaft; a fixed gear is arranged at the lower part of the fixed wheel shaft; an upper pressing plate and a lower supporting plate are connected to the upper part of the fixed wheel shaft from top to bottom in a sequence; the fixed wheel is respectively connected with an upper bearing block and a lower bearing block through an upper bearing and a lower bearing; the upper bearing block and the lower bearing block are respectively positioned at the upper end and the lower end of the fixed gear. The fixed wheel assembly of the pipe bending machine is simple, compact and reasonable in structure; when in working, a workpiece is clamped through the upper pressing plate and the lower supporting plate, so that the pipe bending machine can stably work for bending, the working efficiency is increased, and the cost is relatively low; the distance from the upper pressing plate to the lower supporting plate can be adjusted to meet the requirement on bending the workpiece of different size, and therefore, the applicable scope is expanded.

Owner:无锡晶瑜智能机械有限公司

A design method of armored mud discharge pipe and its mud discharge pipe

ActiveCN105135088BHighlight substantiveSignificant progressSoil-shifting machines/dredgersFlexible pipesLine tubingPipe

Owner:姜考成

Solar cell, packaging method of solar cell, and unmanned aerial vehicle employing solar cell

ActiveCN102569520BReduce weightIncrease the curvatureFinal product manufactureWeight reductionEngineeringEthyl vinyl acetate

The embodiment of the invention discloses a solar cell, a packaging method of the solar cell, and an unmanned aerial vehicle employing the solar cell. The packaging method of the solar cell comprises the following steps of: providing solar cell plates; thinning the solar cell plates to form solar cell plates with preset thickness; welding the solar cell plates to form a solar cell string by a laser welding technology, wherein sections of solder strips and convergence strips in the solar cell string have an arc structure; embedding the solar cell string into ethyl vinyl acetate (EVA) adhesives; and forming the solar cell by a laminating process. The solar cell formed by the packaging method has light weight and high bending property, and the requirements of the unmanned aerial vehicle are met.

Owner:YINGLI ENERGY CHINA

Pipe bender fixed wheel assembly

ActiveCN104525767BStable bending workMeet bending requirementsMetal-working feeding devicesPositioning devicesGear wheelWheel and axle

The invention relates a fixed wheel assembly, specifically relates to a fixed wheel assembly of a pipe bending machine, and belongs to the technical field of pipe bending machines. The fixed wheel assembly of the pipe bending machine comprises a fixed wheel shaft; a fixed gear is arranged at the lower part of the fixed wheel shaft; an upper pressing plate and a lower supporting plate are connected to the upper part of the fixed wheel shaft from top to bottom in a sequence; the fixed wheel is respectively connected with an upper bearing block and a lower bearing block through an upper bearing and a lower bearing; the upper bearing block and the lower bearing block are respectively positioned at the upper end and the lower end of the fixed gear. The fixed wheel assembly of the pipe bending machine is simple, compact and reasonable in structure; when in working, a workpiece is clamped through the upper pressing plate and the lower supporting plate, so that the pipe bending machine can stably work for bending, the working efficiency is increased, and the cost is relatively low; the distance from the upper pressing plate to the lower supporting plate can be adjusted to meet the requirement on bending the workpiece of different size, and therefore, the applicable scope is expanded.

Owner:无锡晶瑜智能机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com