Electrode bending punch head with inclined plane structure and inclined plane type electrode bending method

A stamping head and electrode technology, which is applied in the semiconductor field, can solve the problems that the electrode bending of the IGBT module is difficult to be carried out accurately and quickly, and the size and height of the electrodes are different, so as to improve the quality of electrode bending, reduce electrode surface damage, and reduce scratches. rubbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

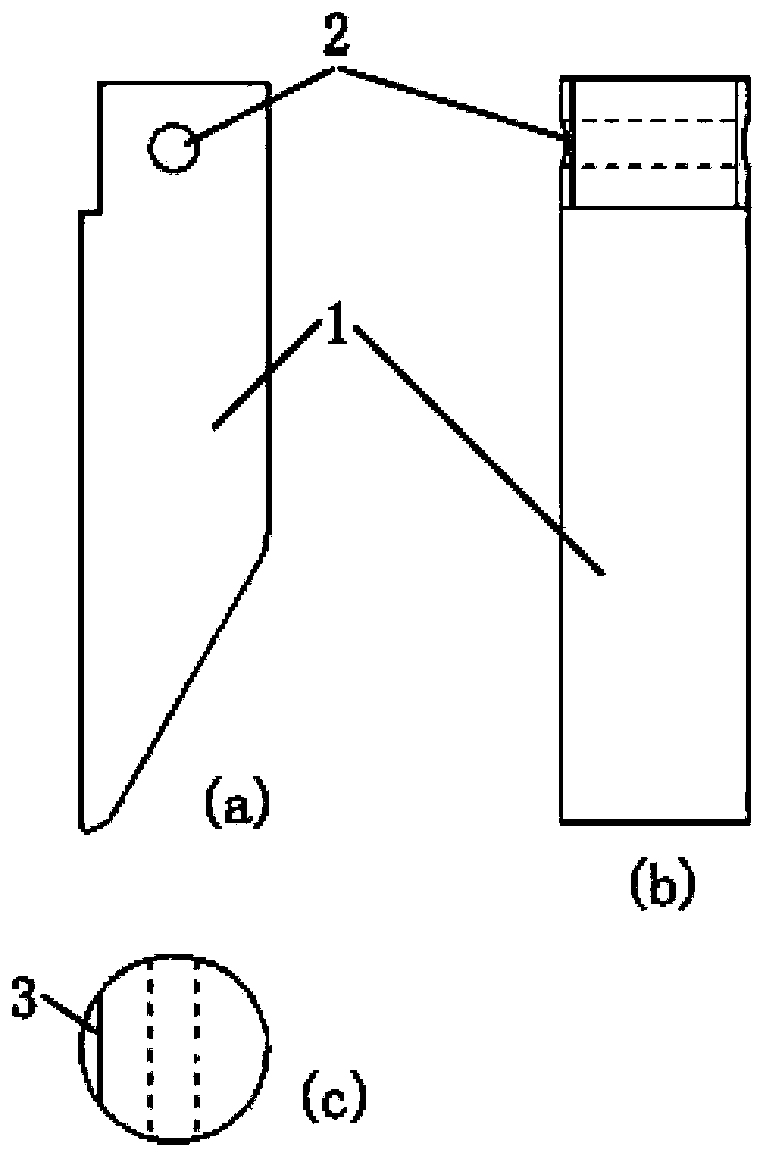

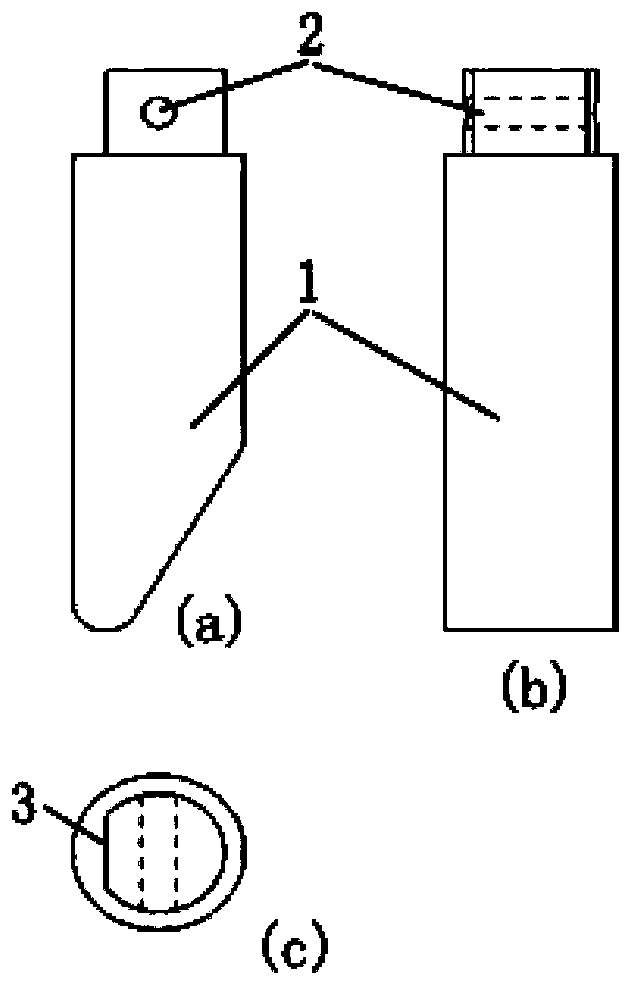

[0022] The upper part of the electrode bending punching head with inclined plane structure of the present invention is the connecting part, and the lower part is the electrode bending inclined surface, and the electrode pressing inclined surface is made of high hardness material, and its surface is covered with an electroplating layer.

[0023] Further, the edge of the electrode crimping bevel is in the form of a curved chamfer.

[0024] Preferably, the connecting part is a connecting cylindrical head with an orientation plane, and a positioning pin hole is arranged on it.

[0025] Further, the positioning pin hole is parallel to the orientation plane.

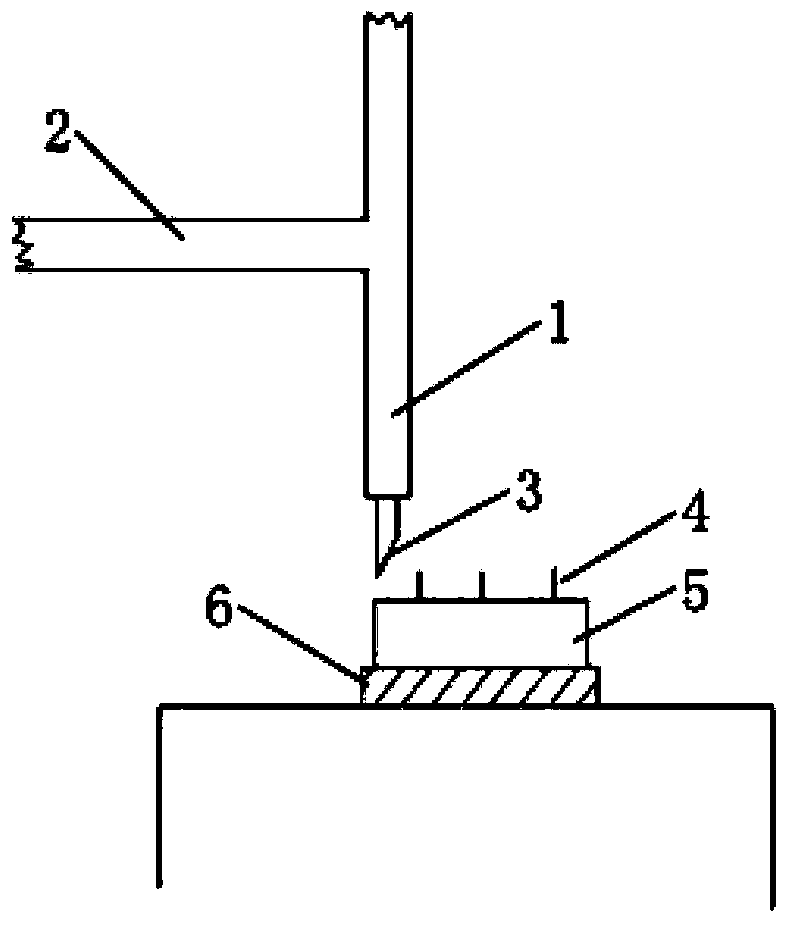

[0026] The present invention also provides an electrode bending method for an electrode bending punch head based on the above inclined plane structure, comprising the following steps:

[0027] Step 1: The longitudinal hydraulic rod column first drives the electrode bending slope to move downward. After reaching the predetermi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com