Patents

Literature

271results about How to "Improve bending quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

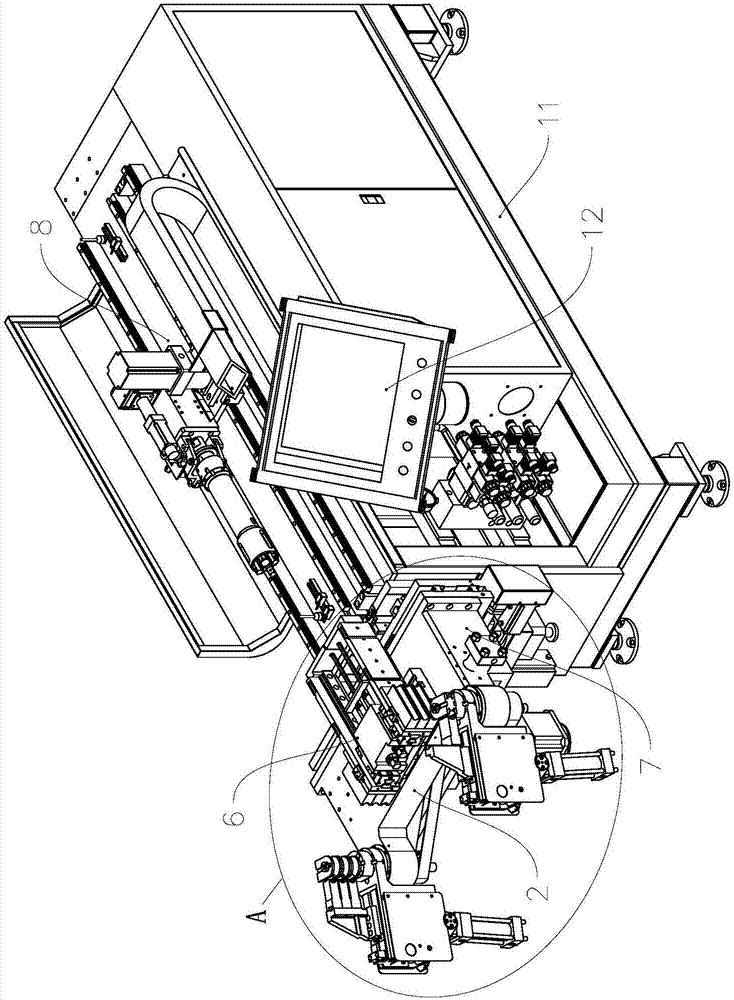

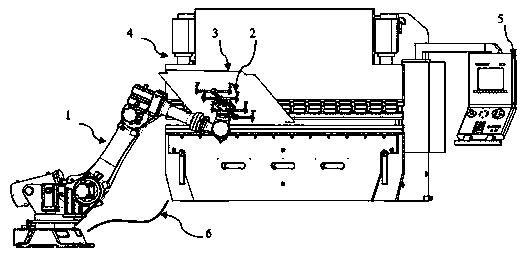

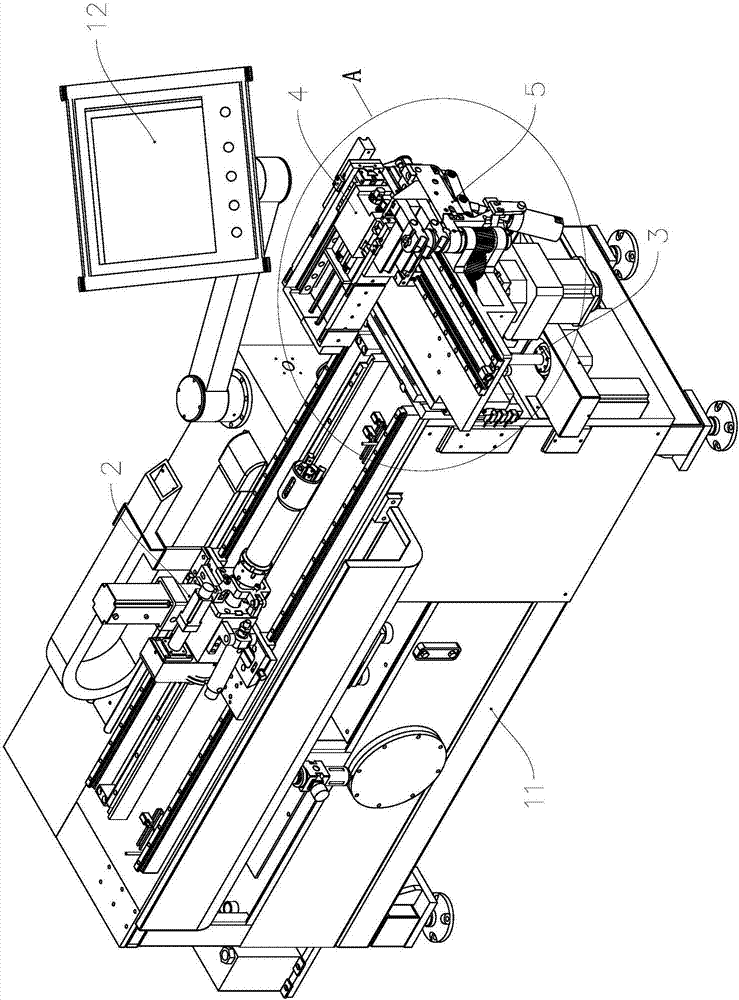

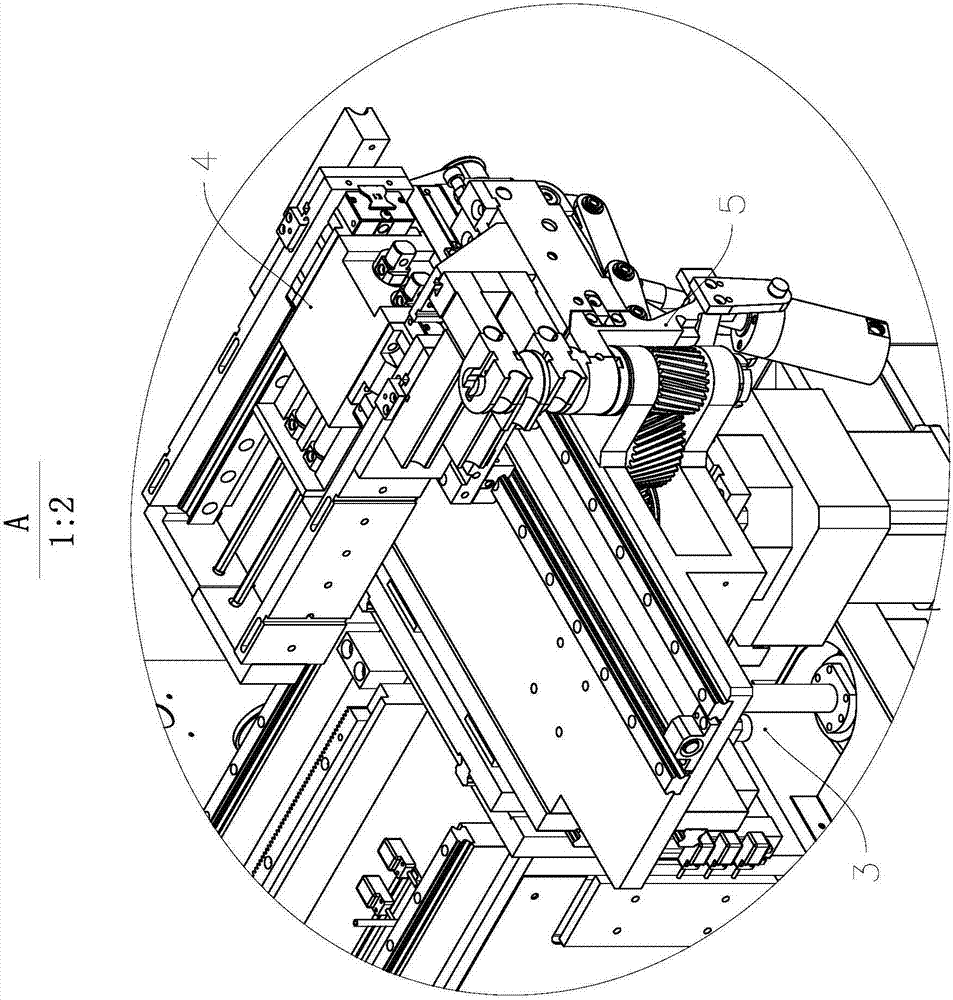

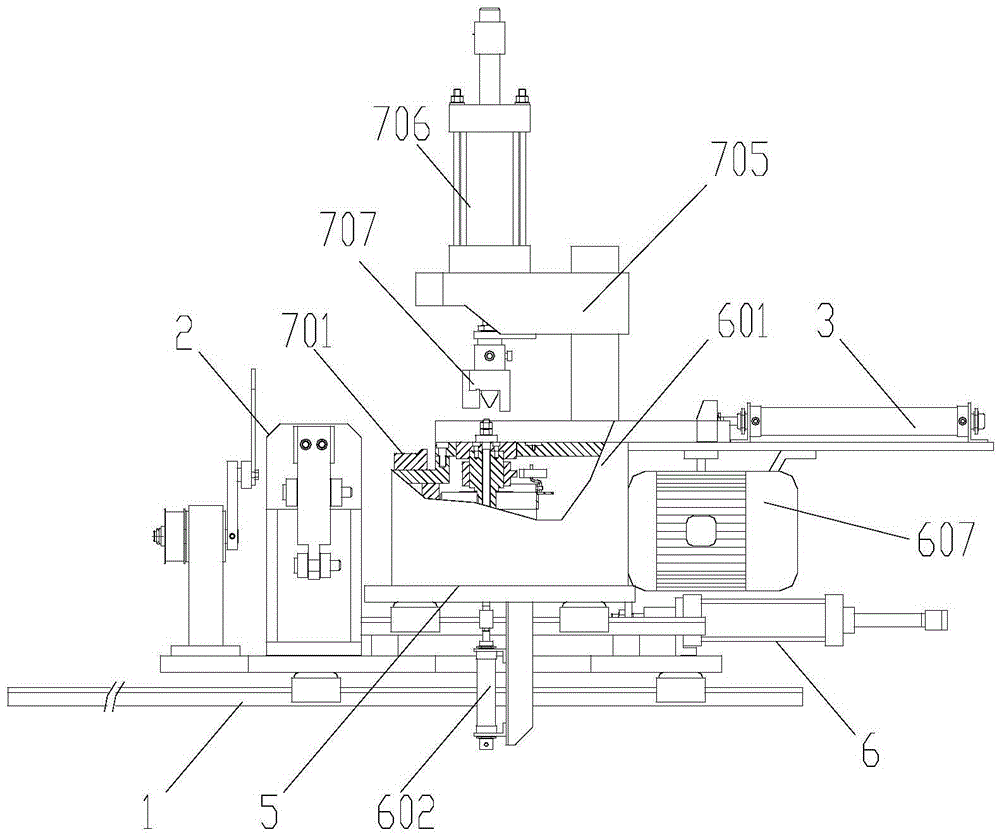

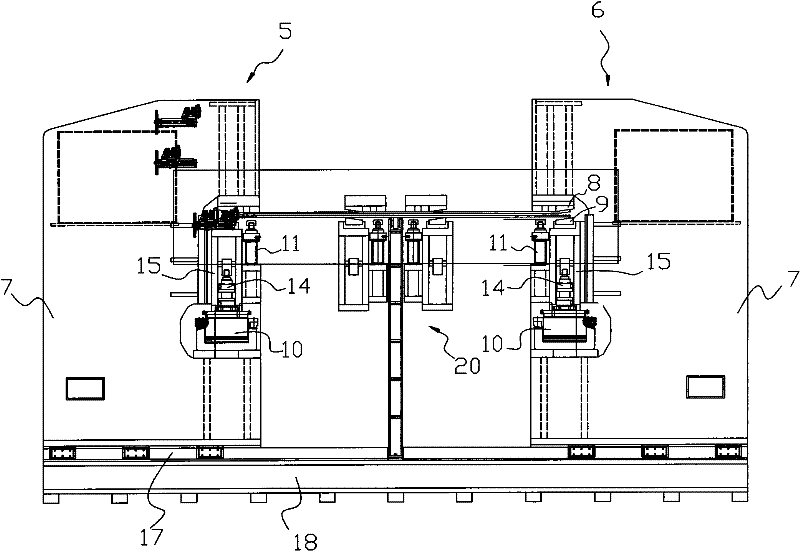

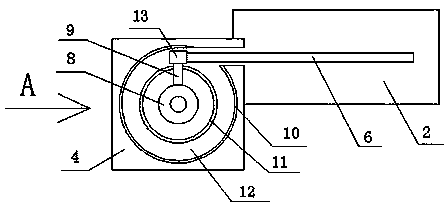

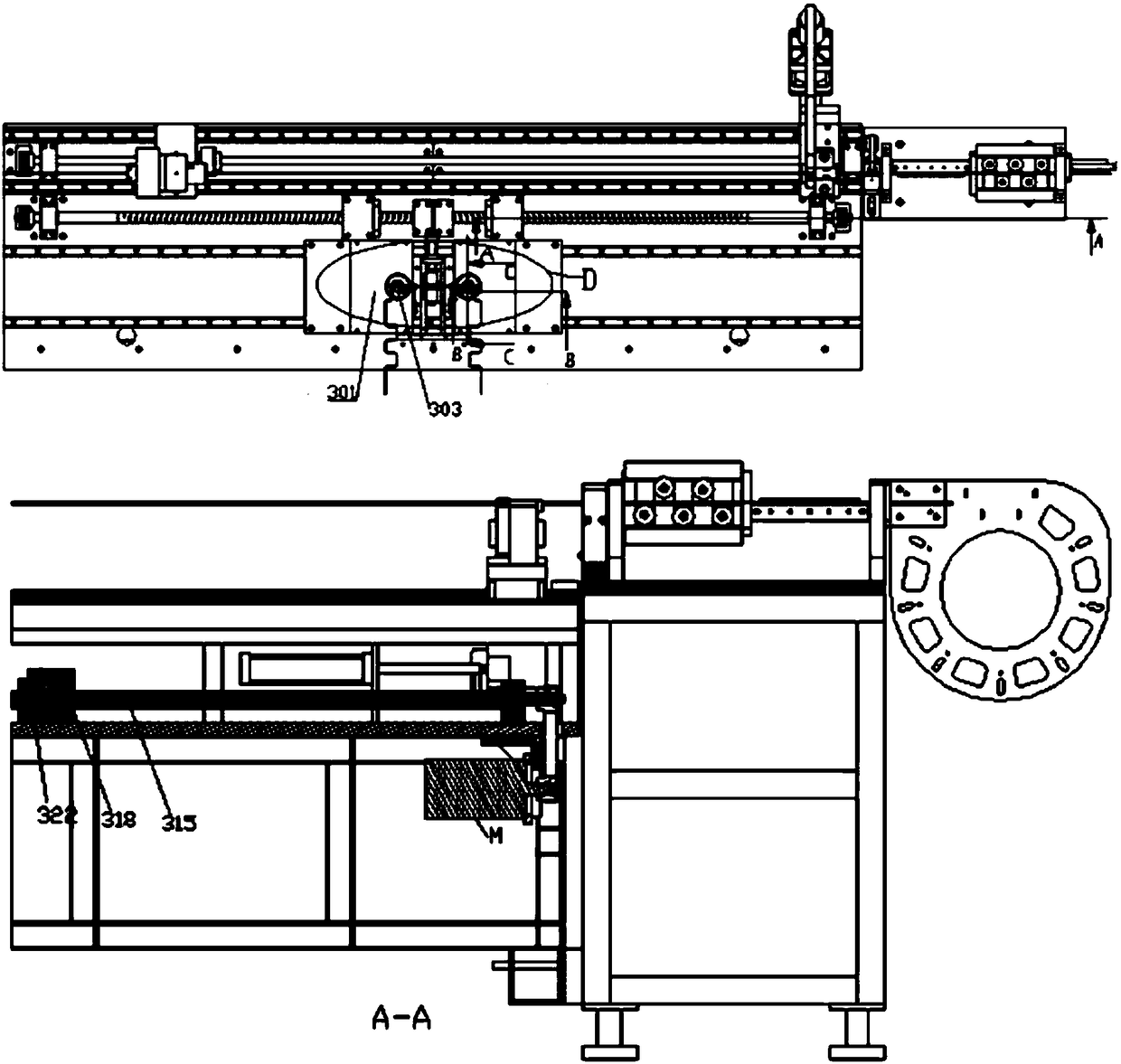

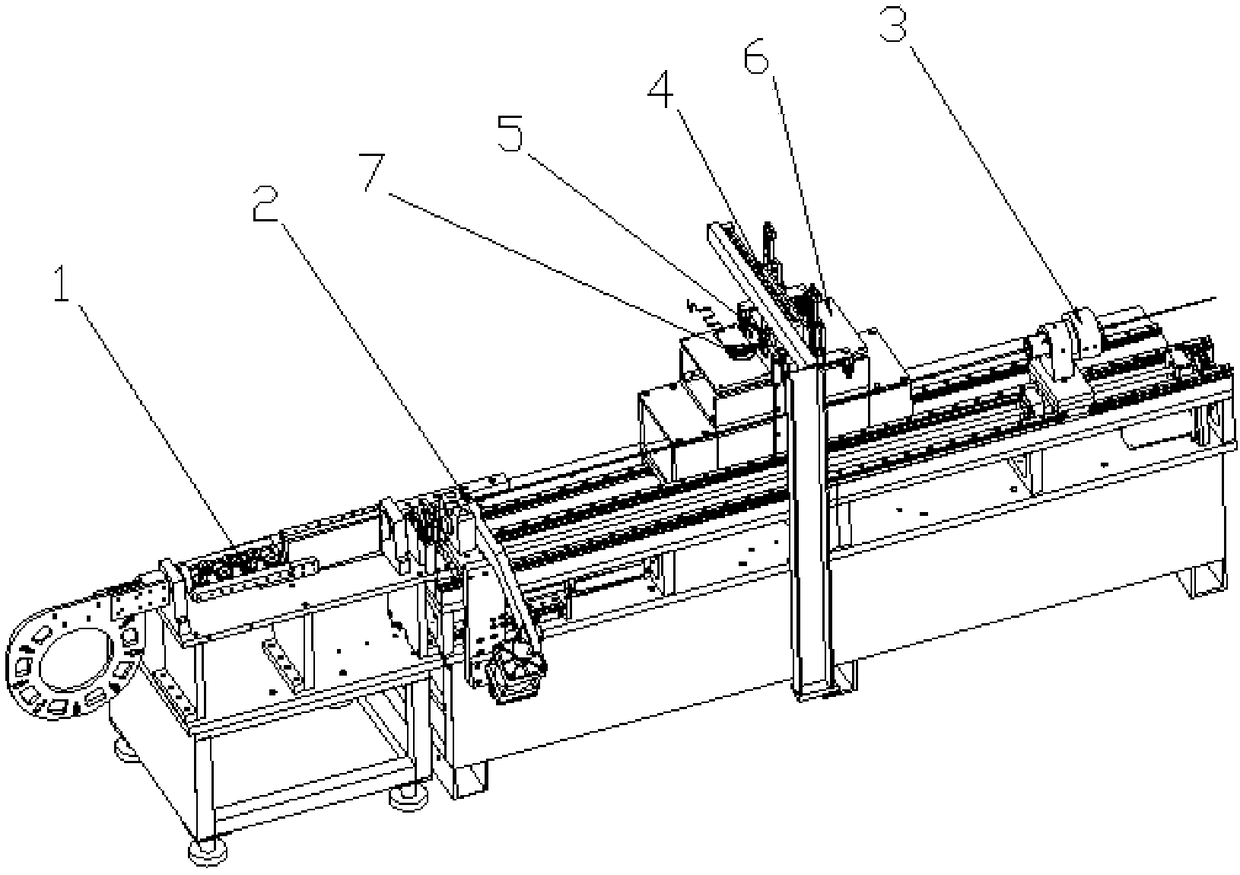

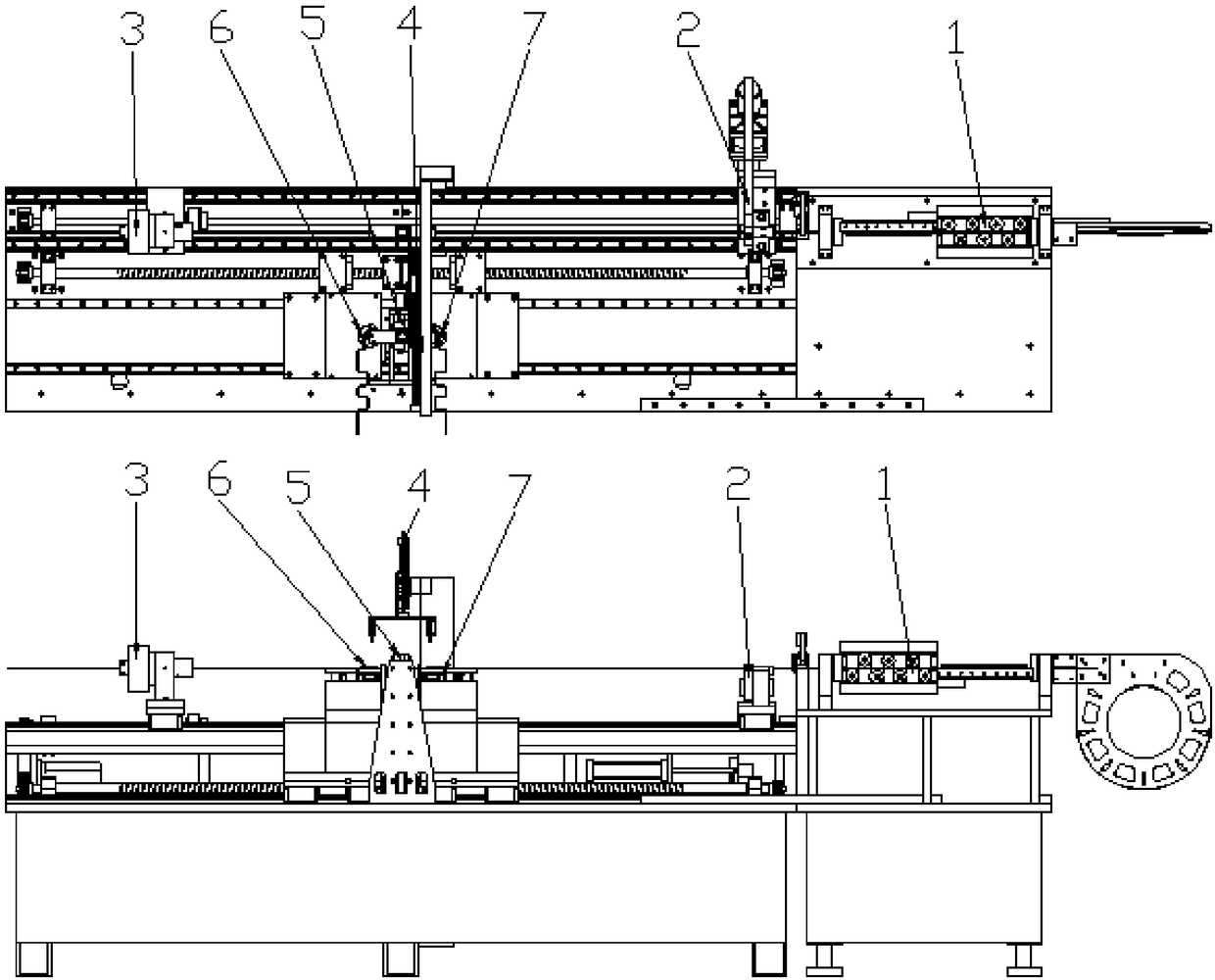

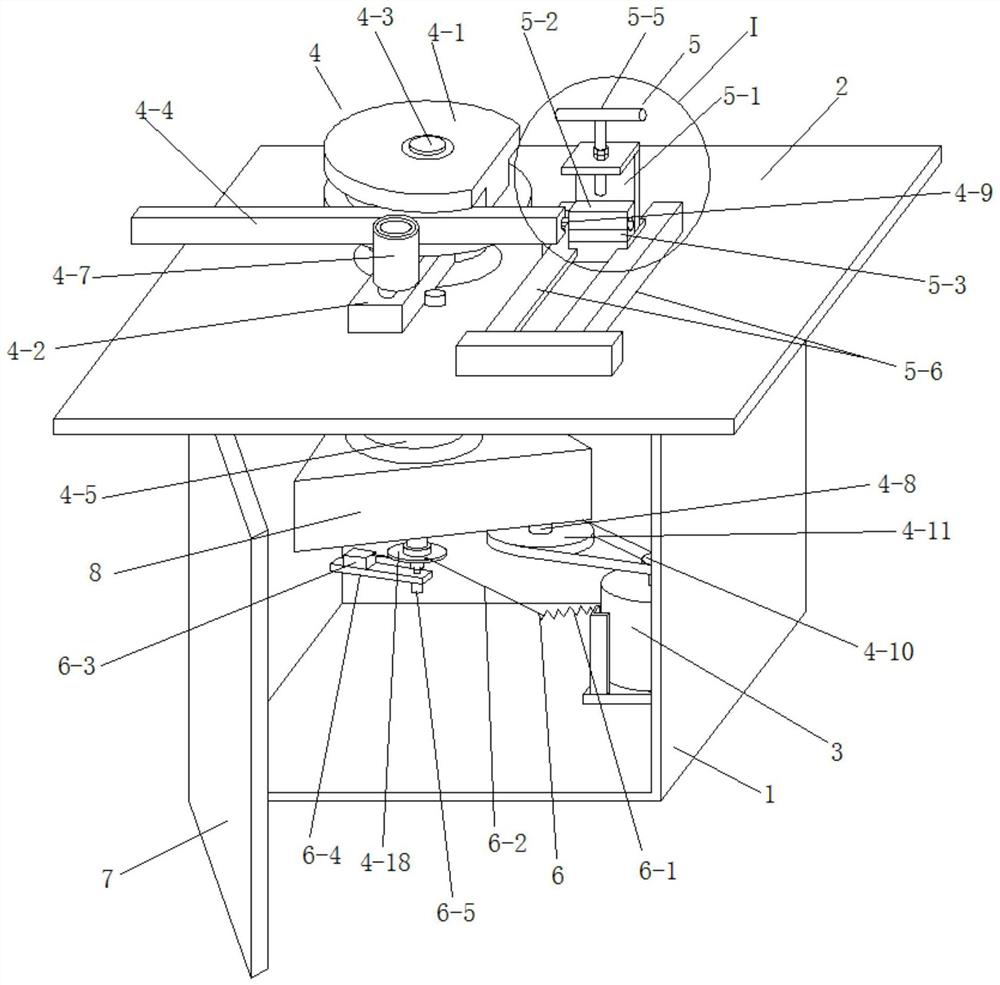

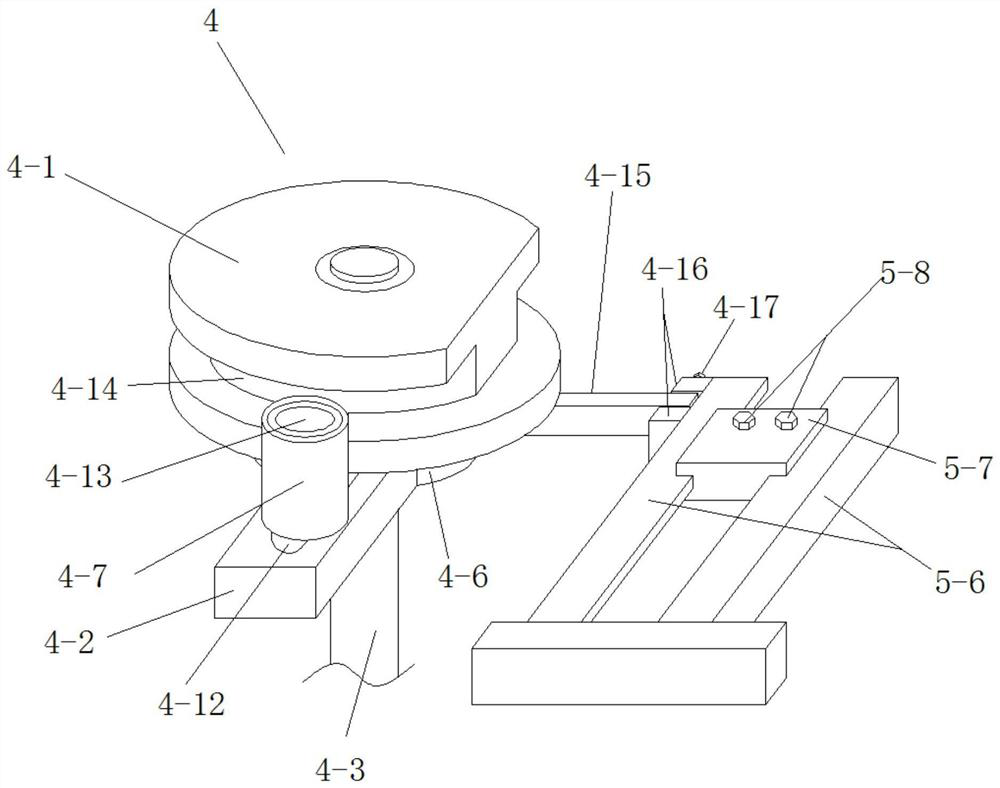

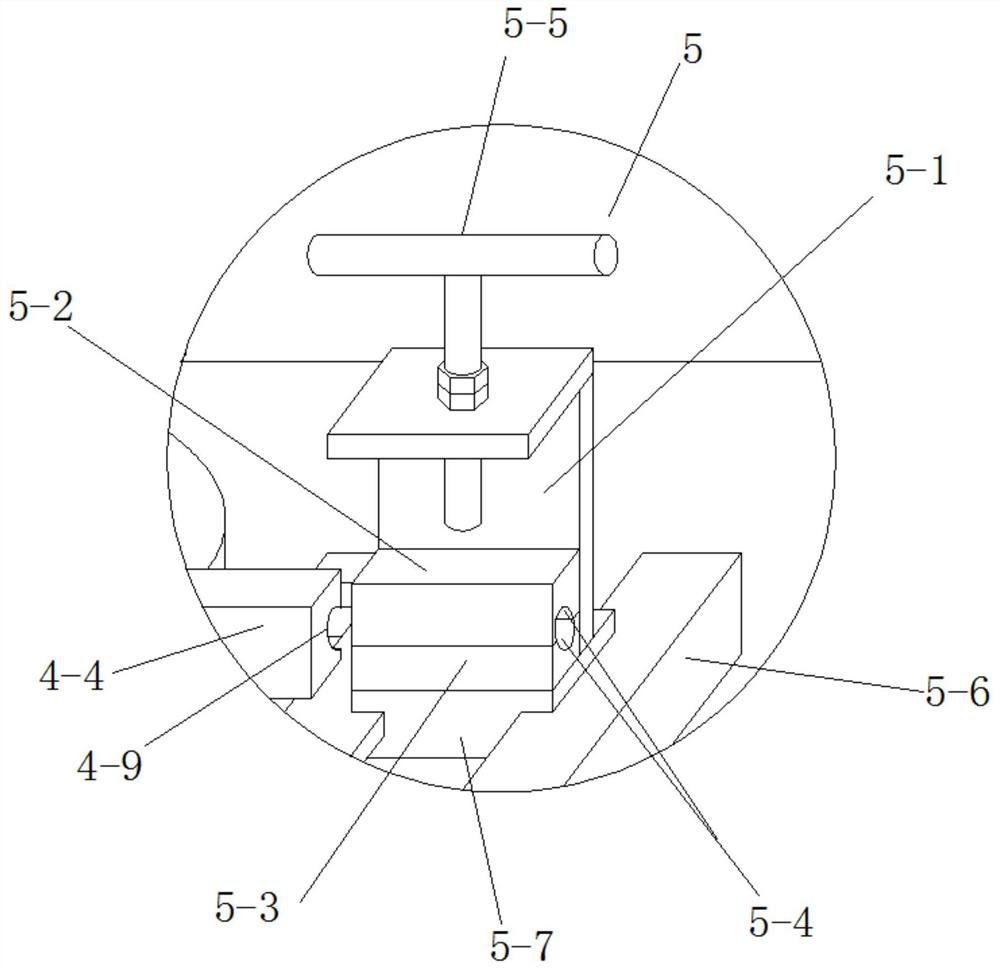

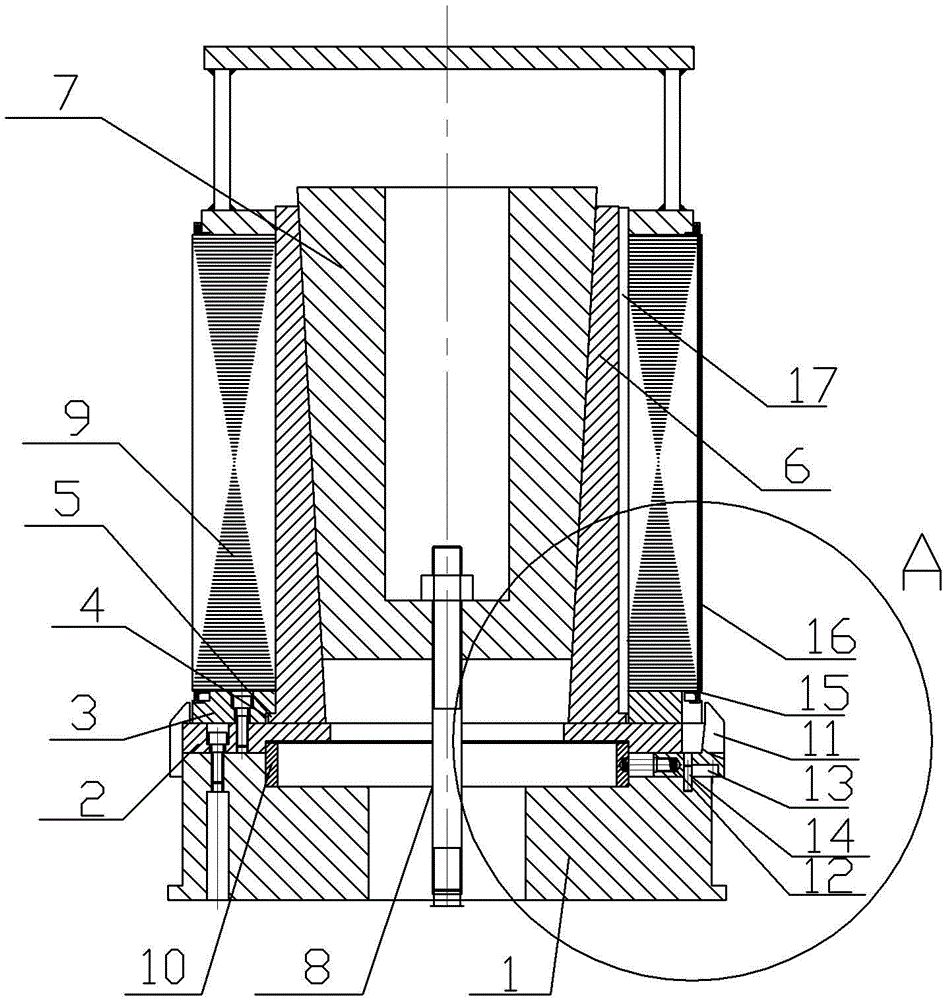

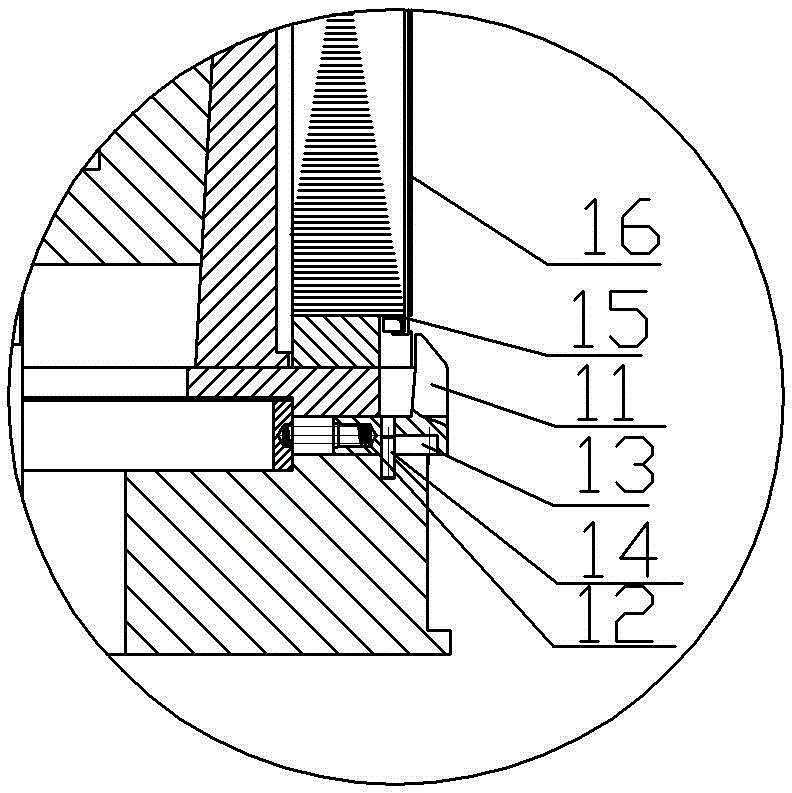

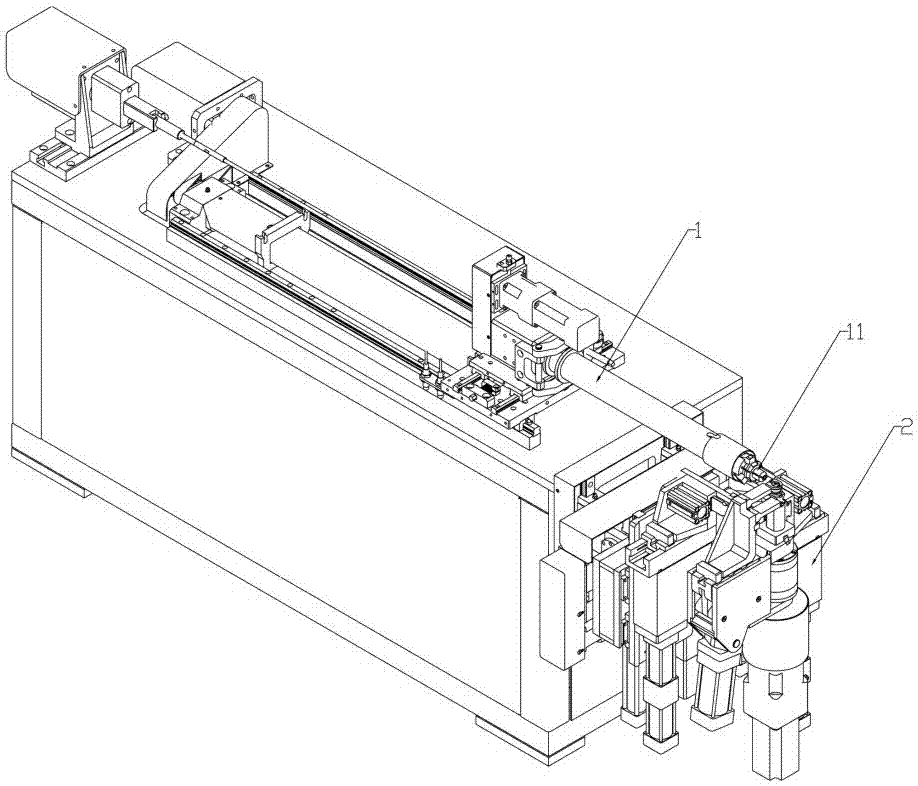

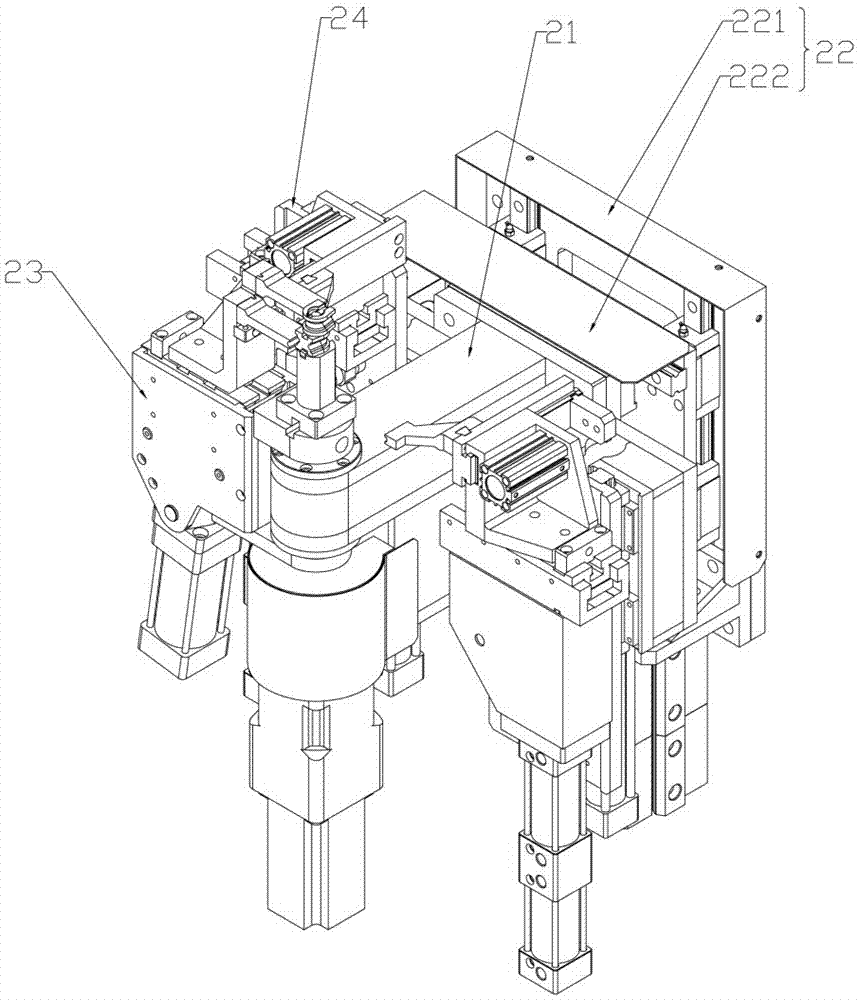

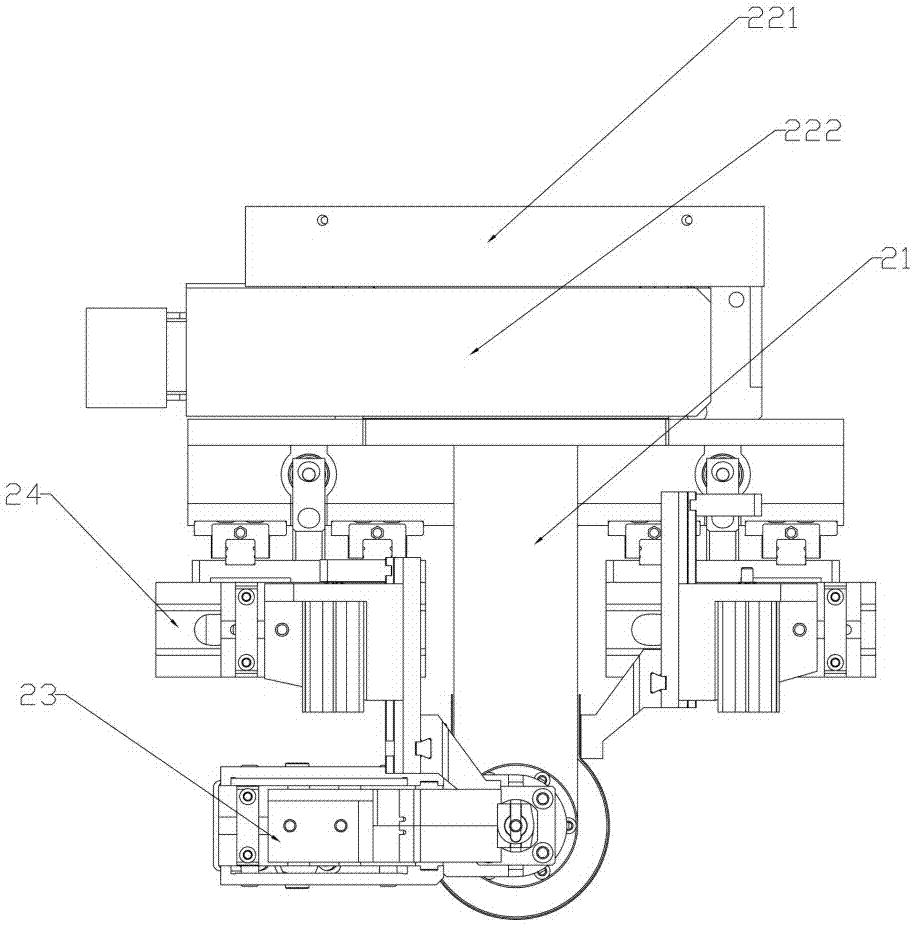

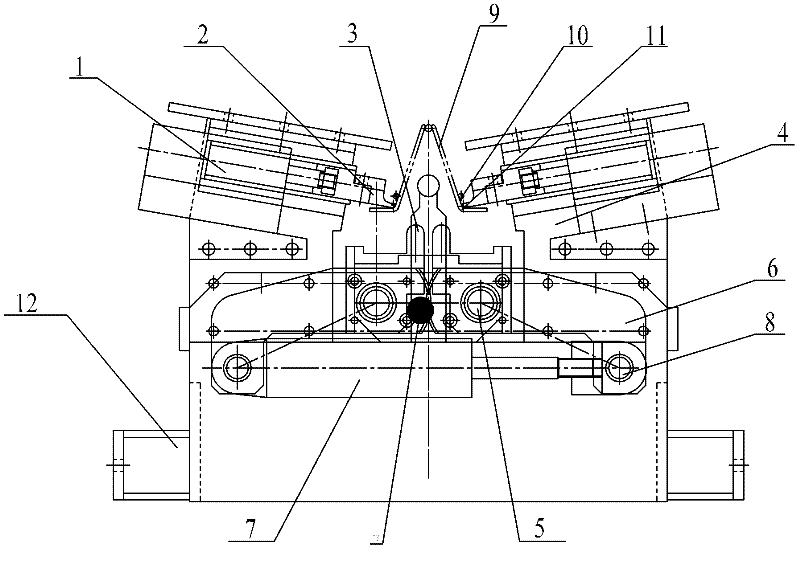

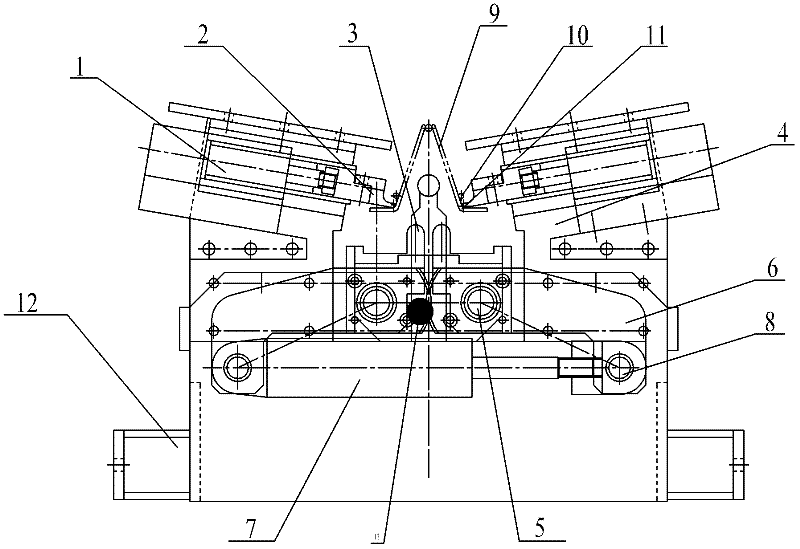

Leftward and rightward double-bending type numerical-controlled pipe bending machine

ActiveCN107282720AAvoid shakingQuality improvementMetal-working feeding devicesPositioning devicesAviationPipe fitting

The invention relates to a leftward and rightward double-bending type numerical-controlled pipe bending machine, and belongs to the technical field of pipe processing. The leftward and rightward double-bending type numerical-controlled pipe bending machine comprises a rack, a control unit, a pipe bending device and a feeding vehicle which are mounted on the rack and controlled by the control unit, wherein the pipe bending device comprises a machine head, a die guide unit and a die changing unit; the machine head comprises a mounting seat, a leftward pipe bending unit and a rightward pipe bending unit which are mounted on the mounting seat and driven by a same pipe bending motor; each of the leftward and rightward pipe bending units comprises a circular die, a swing arm and a clamping die mounted on the swing arm; the die changing unit is controlled by the control unit to drive the machine head to move in transverse and vertical directions being perpendicular to the axial direction of a pipe to be bent relative to the rack, so that the numerical-controlled pipe bending machine can switch between a leftward bending working mode and a rightward bending working mode. According to the leftward and rightward double-bending type numerical-controlled pipe bending machine, the same pipe bending motor drives the leftward pipe bending unit and the rightward pipe bending unit simultaneously, at the same time the switching between the leftward pipe bending unit and the rightward pipe bending unit is realized through the die changing unit, not only is the pipe bending quality effectively improved, but also the compactness of the integrated layout is improved, and therefore the leftward and rightward double-bending type numerical-controlled pipe bending machine can be extensively applied to fields such as air conditioning and aviation.

Owner:浙江和良智能装备有限公司

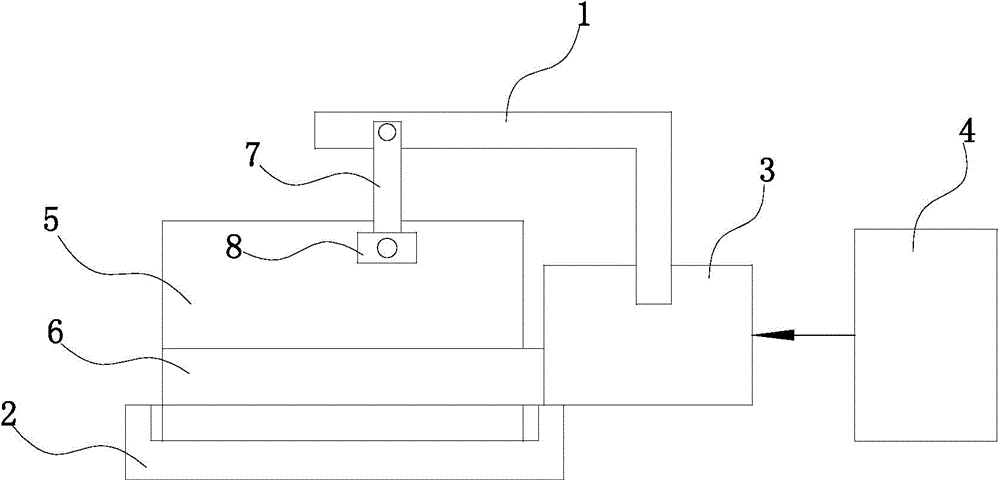

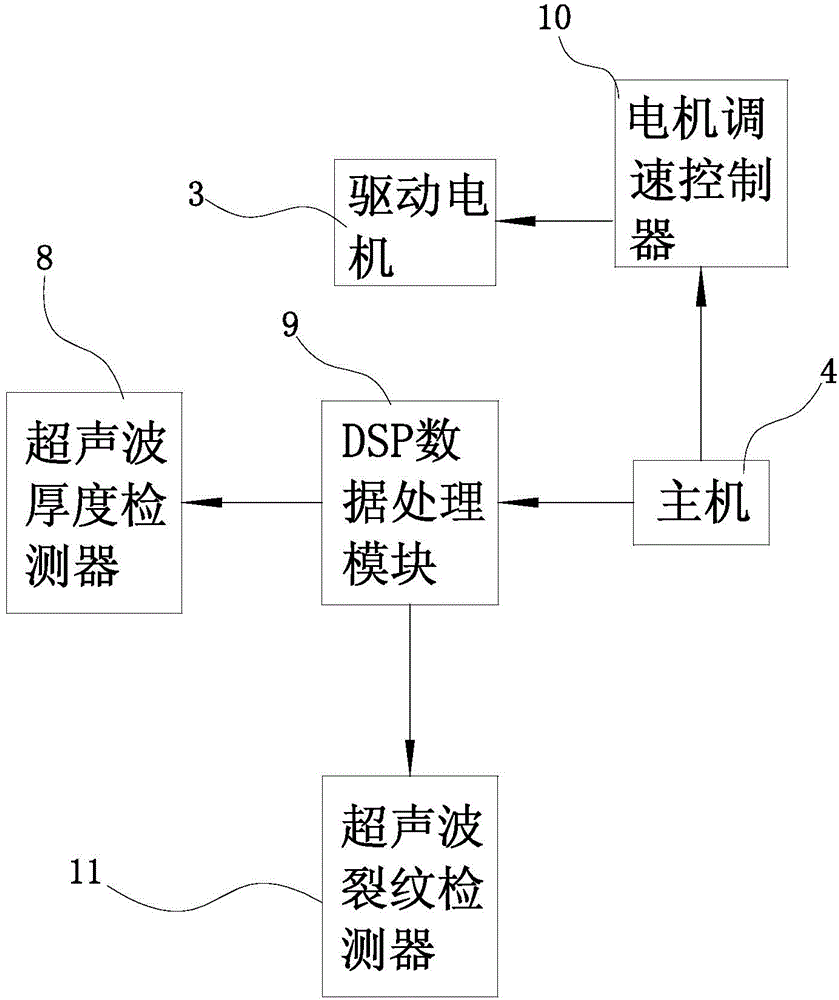

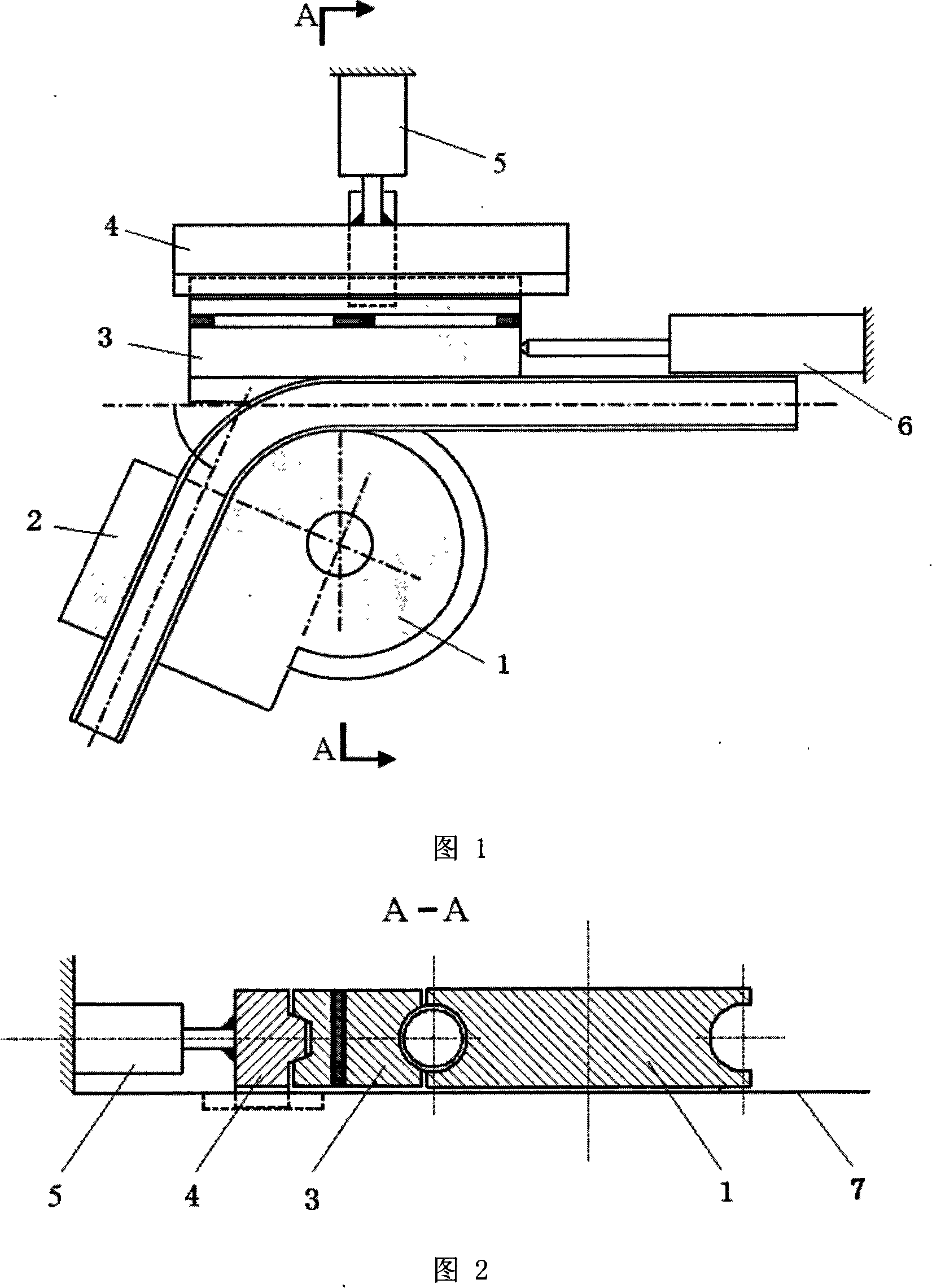

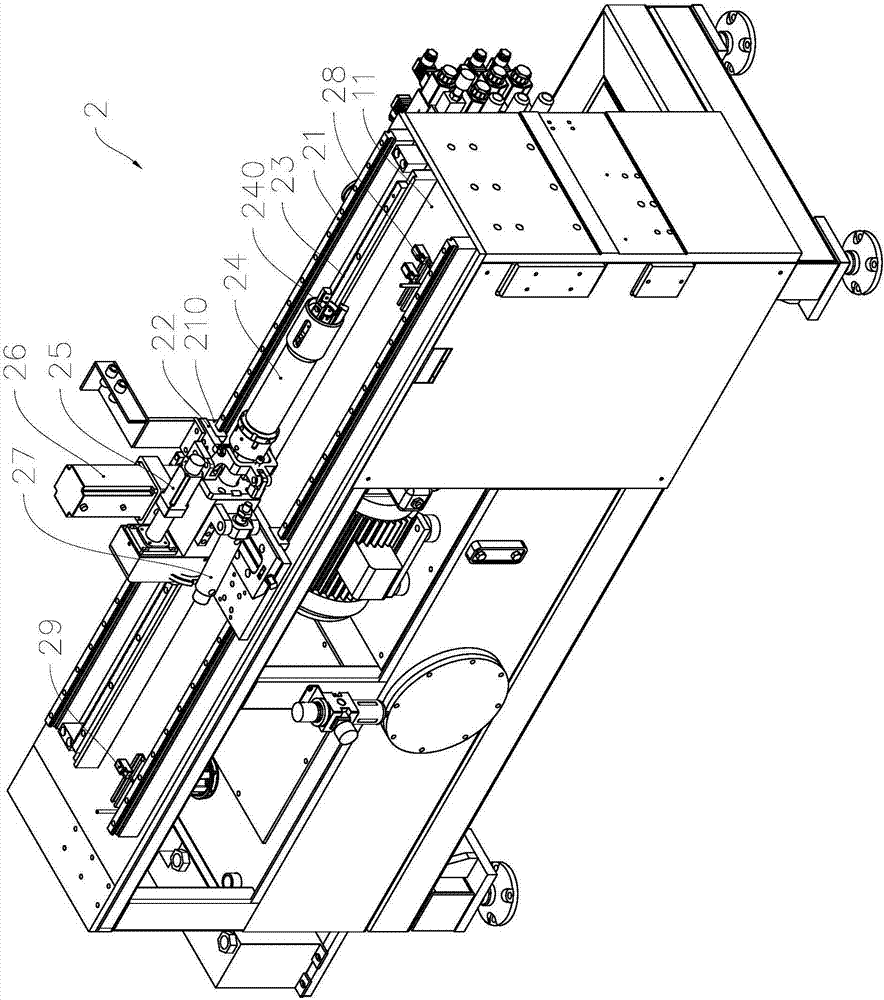

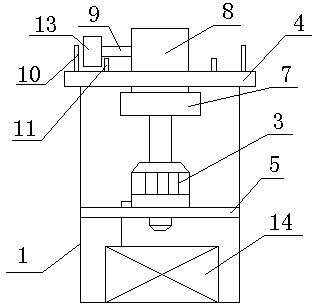

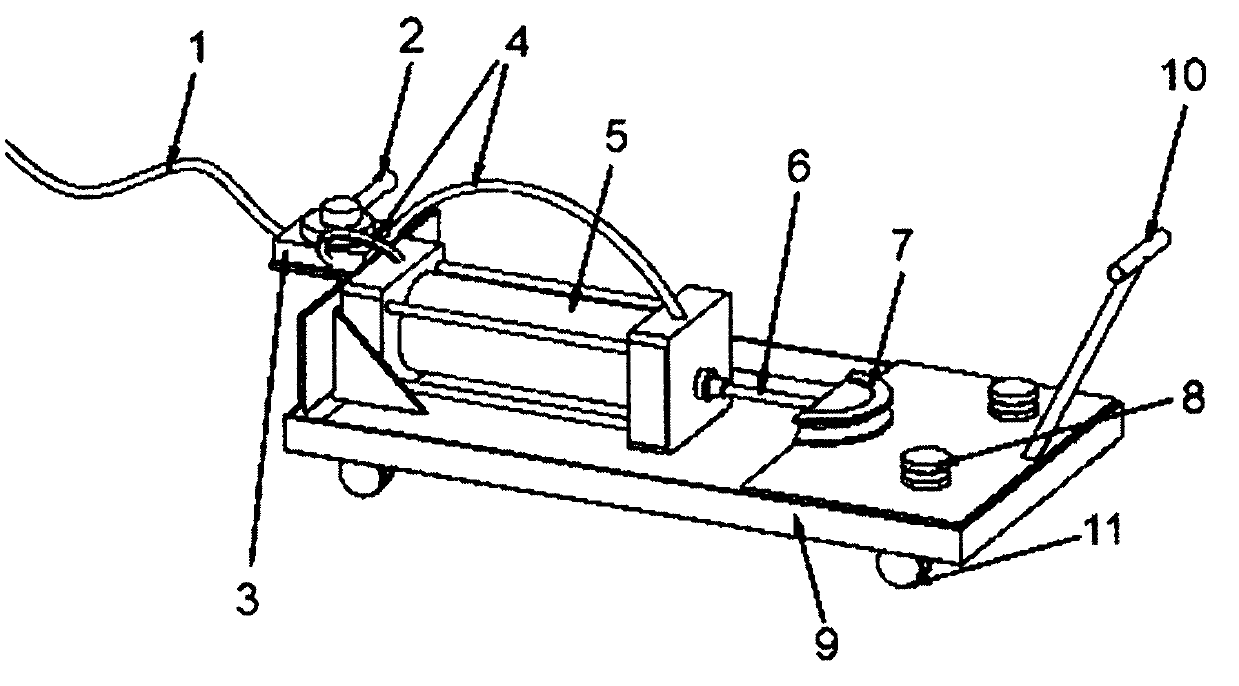

Bending machine based on PLC plate thickness detection and rotation speed control and bending machining method

ActiveCN104588439AReduce the amount of cracksImprove bending qualityMetal working apparatusDrive motorMotor shaft

The invention relates to a bending machine based on PLC plate thickness detection and rotation speed control. The bending machine comprises a drive motor arranged on a rack, a clamping fixed base and a PLC host used for controlling the drive motor, wherein a bending shaft is arranged on a motor shaft of the drive motor, and a to-be-machined member is arranged on the clamping fixed base. The bending machine further comprises an ultrasonic thickness detector arranged on the rack by virtue of a first bracket, a detection feedback device and a motor speed setting controller connected with the PLC host, wherein the detection feedback device comprises an ultrasonic crack detector mounted on the clamping fixed base by virtue of a second bracket; the ultrasonic thickness detector and the ultrasonic crack detector are respectively connected with the PLC host by virtue of a DSP data processing module. The invention further provides a bending machining method adopting the bending machine. The bending machine is used for bending the to-be-machined member at a most suitable rotating speed, thereby preventing the to-be-machined member from being overlow or overlarge rotating speed, reducing a number of cracks, and improving the bending machining quality.

Owner:NANJING CHEM CONSTR

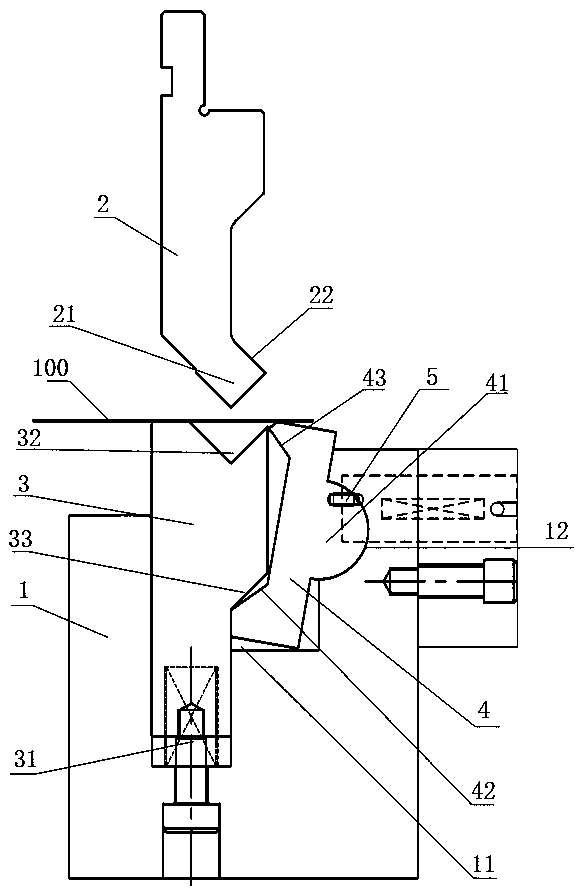

Tube bending forming processing device

InactiveCN101147934AImprove memory propertiesIncrease hydrostatic pressureShaping toolsHydraulic cylinderTangential force

The present invention discloses a bending forming processing equipment for pipe material. Said equipment includes the following several portions: bending die clamping die, pressing die, pressurizing plate, circumferential pressure-applying hydraulic cylinder, axial propulsion hydraulic cylinder and bending machine working table. The circumferential pressure-applying hydraulic cylinder pushing rod is rigidly connected with the pressurizing plate, the axial propulsion hydraulic cylinder pushing rod is flexibly connected with the pressing die end portion. The circumferential pressure-applying hydrautic cylinder can be used for driving said pressurizing plate to circumferentially apply pressure to the pipe material, and the axial propulsion hydraulic cylinder can be used for driving pressing die to apply tangential force to the pipe material, the bending die is fixed on the bending machine working table by means of bending centre, and bending die, pressing die and clamping die respectively have the groove fit with the outer diameter of said pipe material, the pressurizing plate is connected with the pressing die by means of dovelail groove, and the pressurizing plate also is connected with the bending machine working table by means of dovetail groove.

Owner:SHANGHAI JIAO TONG UNIV

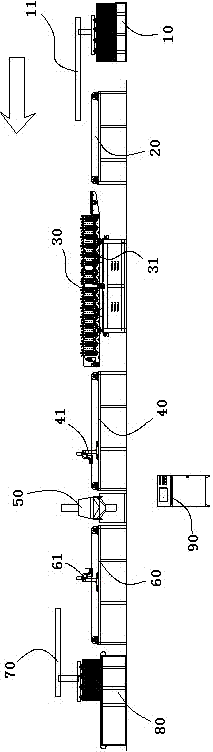

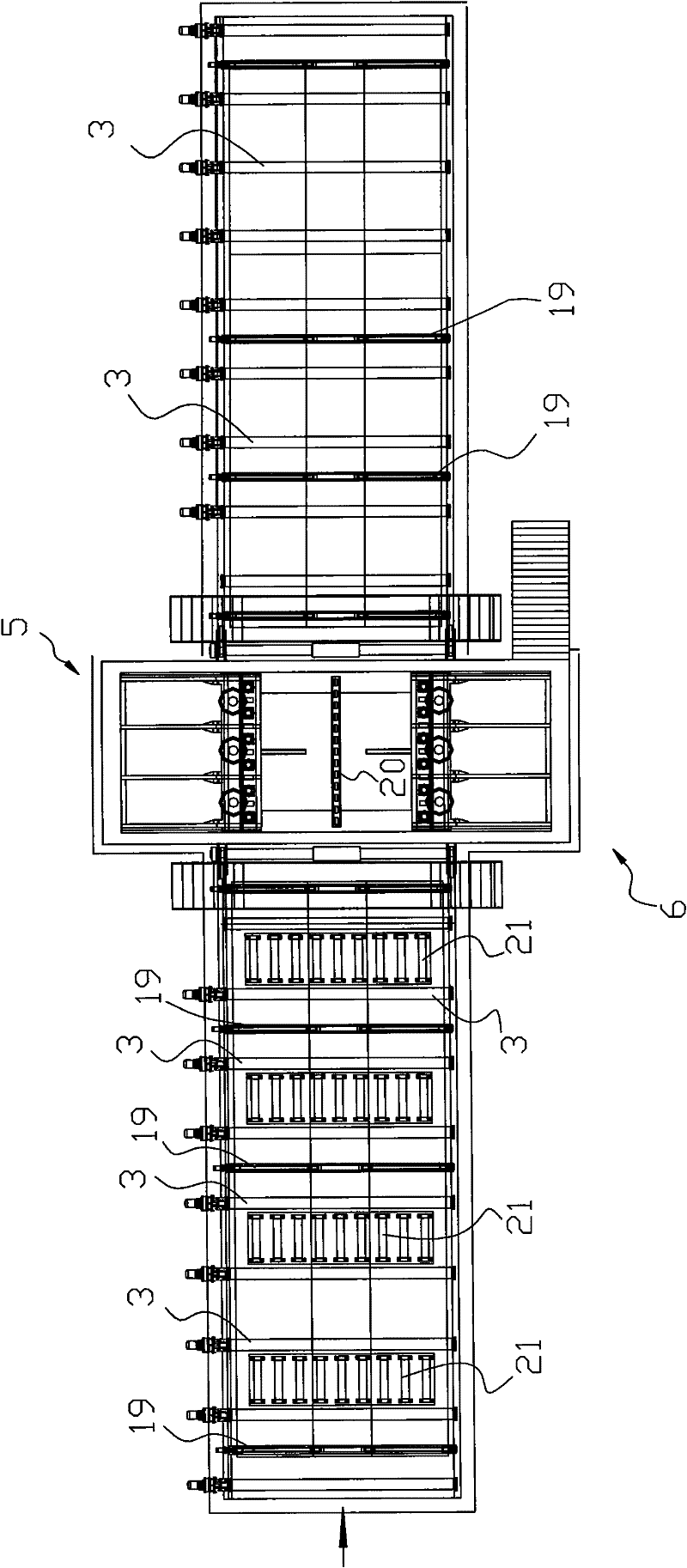

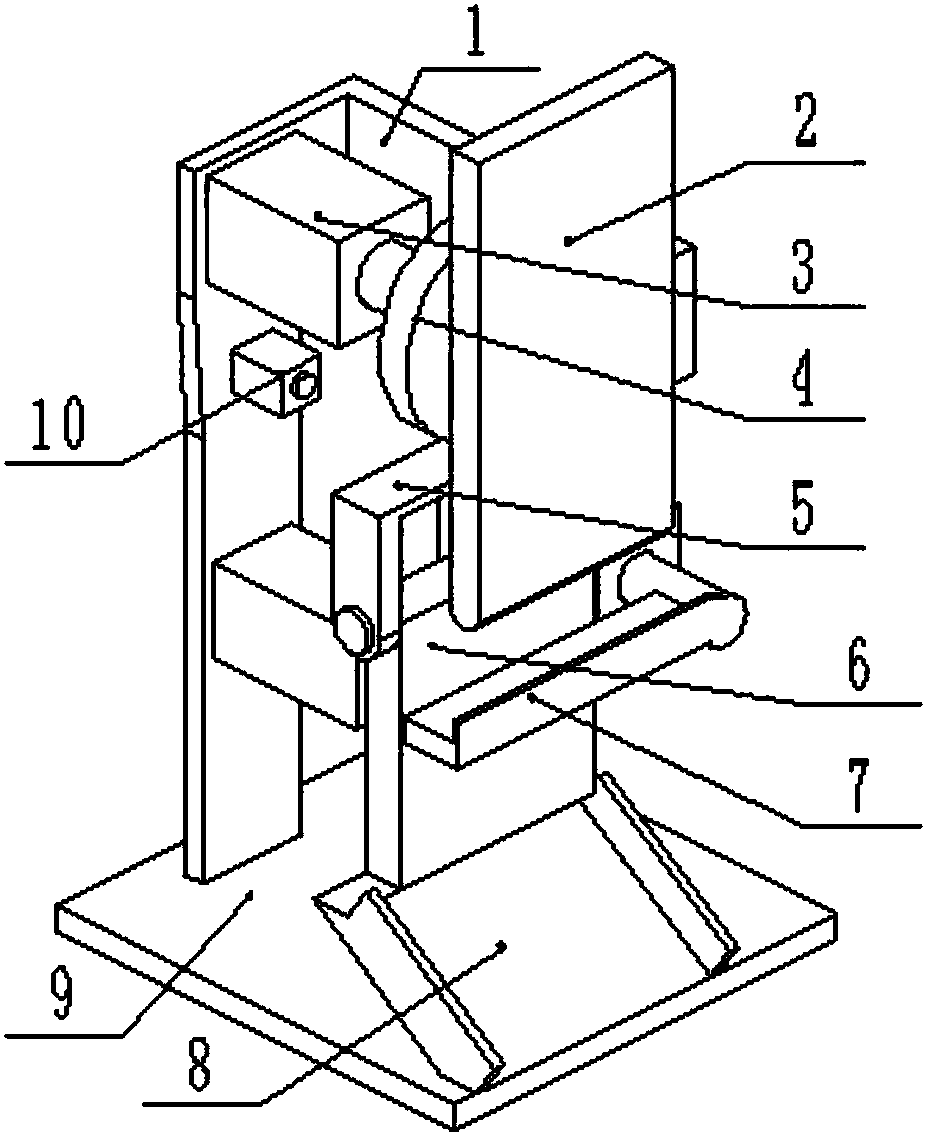

Panel bending automatic production line

ActiveCN104722610AFolding board is convenient and quickCompact structureMetal-working feeding devicesPositioning devicesProduction lineHydraulic cylinder

The invention discloses a panel bending automatic production line. The panel bending automatic production line comprises a feeding lifting table, a belt conveying platform, a cold bending molding machine, a first transition feeding table, a hydraulic panel bending machine, a second transition feeding table, a stacking mechanical arm, an output line and a control system which are sequentially arranged, wherein the control system is electrically connected the above mechanisms. The feeding lifting table is composed of four hydraulic cylinders, the first transition feeding table and the second transition feeding table are each composed of a conveying belt and a sensing positioning device, the stacking mechanical arm is composed of a sucker and a rotary arm, and the hydraulic panel bending machine is composed of a rack, a bending device, a panel pressing device and a hydraulic driving unit. By means of the panel bending automatic production line, panels in variable specifications and different modes can be bent so as to form a full-automatic production line, and can be bent in the modes such as a U type, a C type, a U type with turning edges and a C type with turning edges, mechanical automatic feeding and discharging devices and the accurate stacking device are arranged on the production line, and the aims of bending the panels in variable specifications and different modes and forming the full-automatic production line are achieved.

Owner:FOSHAN CITY NANHAI POPULA FAN

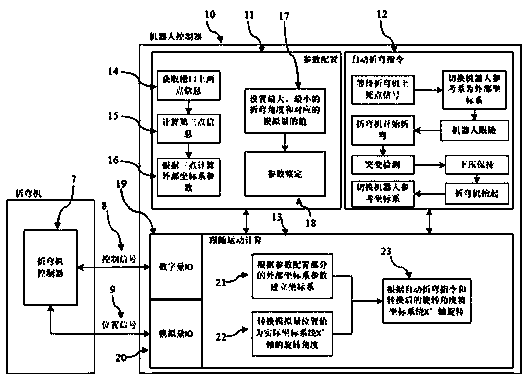

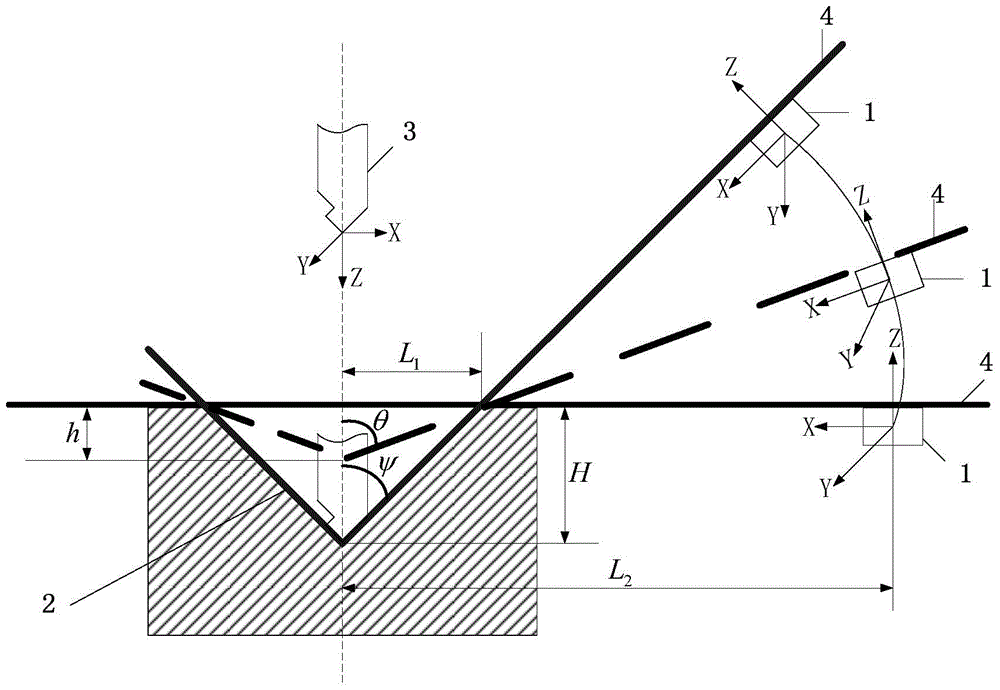

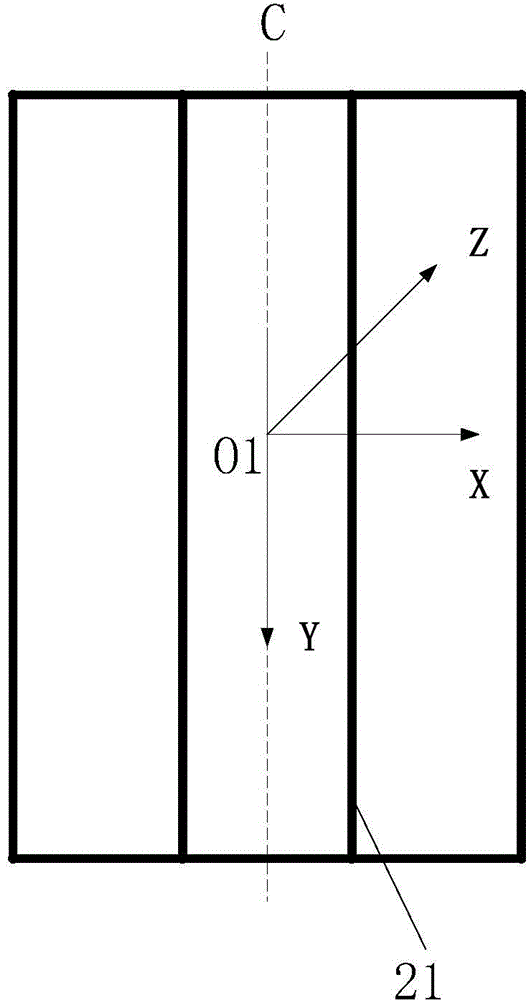

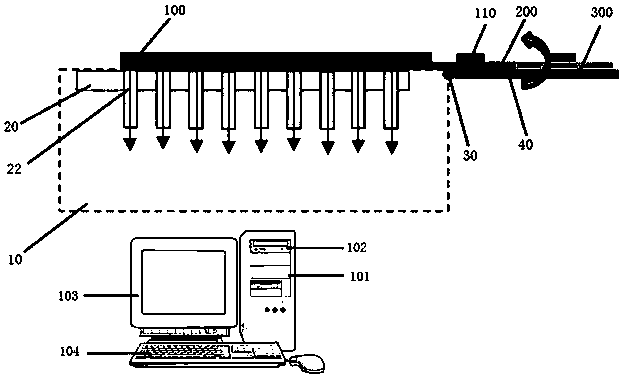

Method of implementing real-time bending follow of bending robot

ActiveCN103707299AShorten the timeImprove debugging efficiencyProgramme-controlled manipulatorEngineeringRobot

The invention provides a method of implementing real-time bending follow of a bending robot. According to the method, an external coordinate system is established using a groove edge of a bending machine as an axis; any two points of a groove of the bending machine are selected, a line of the points and the groove edge are overlapped; a third point is set, and coordinates of the third point are: x3=x2, y3=y2 and z3=z2+100; the third point is defined as a point in a plane of the external coordinate system, an axial vector x' of the external coordinate system is defined as the first point pointing to the second point, and the axial vector x' and an axial vector y' of the external coordinate system are calculated according to corresponding formulas; when the bending machine starts to bend, a robot coordinate system is switched to the external coordinate system, a bending angle is calculated in real time, and the axes of the external coordinate system are rotated according to the bending angle; the robot rotates with the axes in order to maintain unchanged self-position in the external coordinate system, and real-time bending follow is achieved. Through the application of the method, real-time following and automatic bending techniques for the robotic bending process are achieved, follow debugging takes a shorter time for a debugging operator, debugging efficiency is improved, and following precision and bending quality are improved.

Owner:NANJING ESTUN ROBOTICS CO LTD

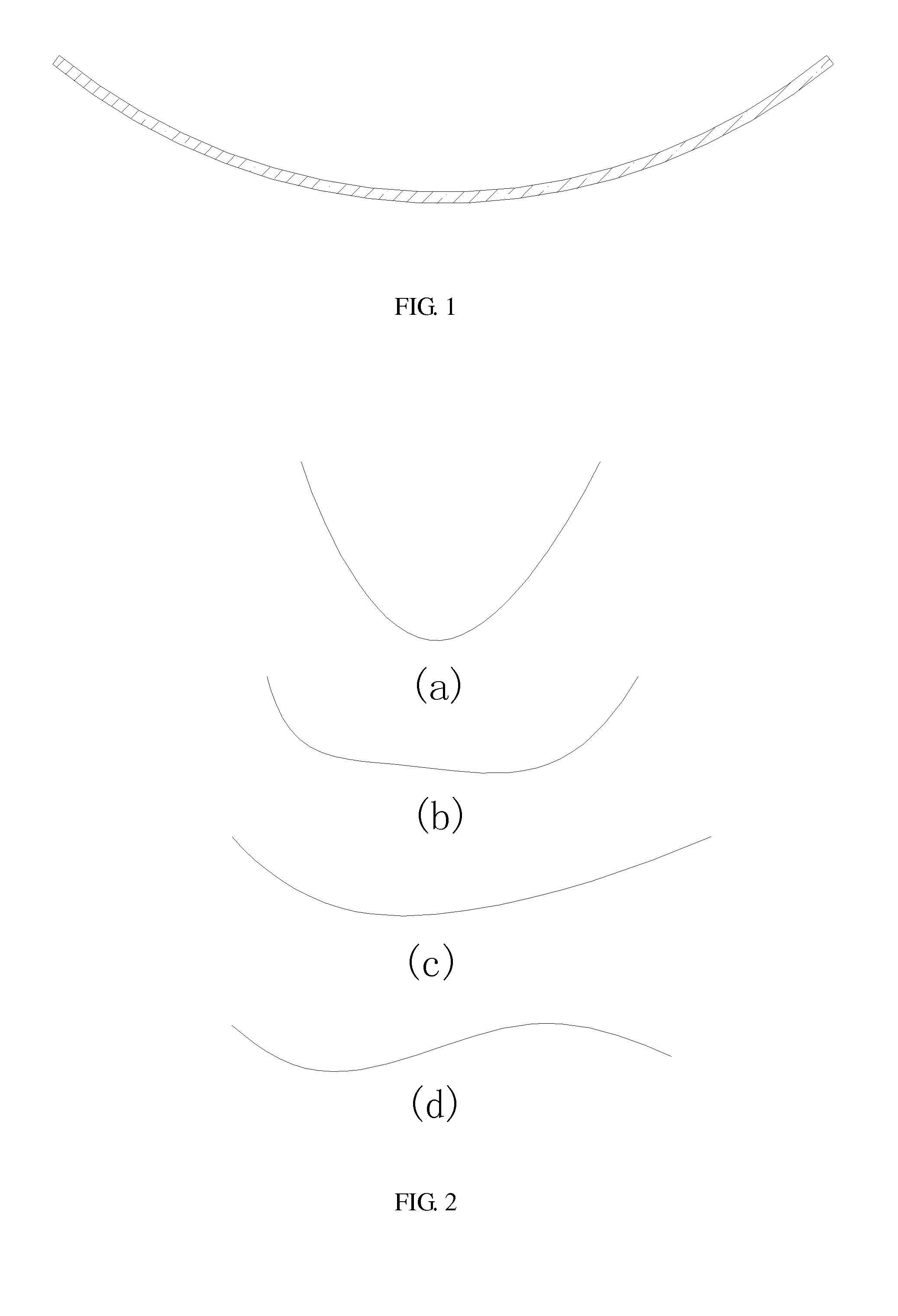

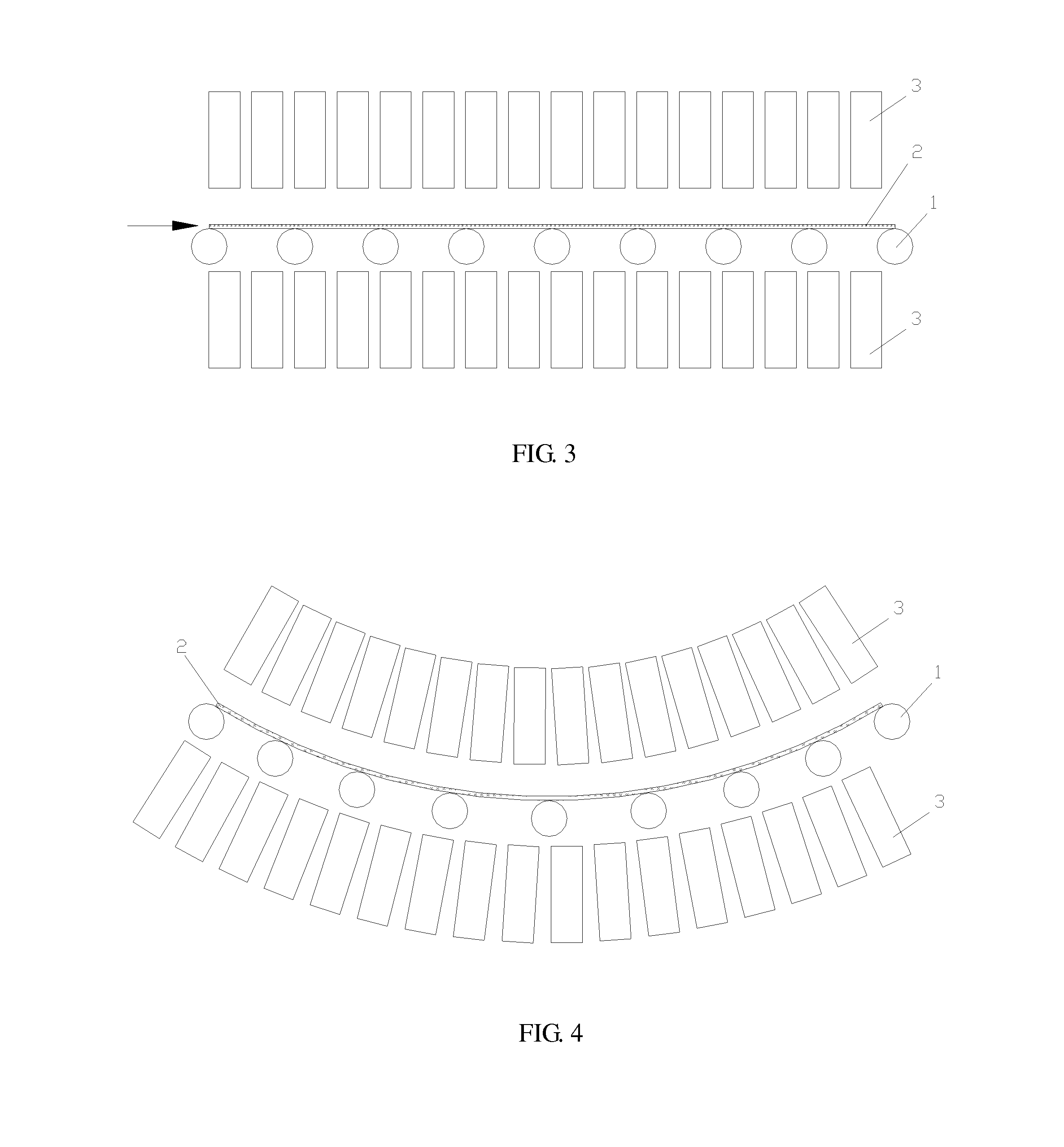

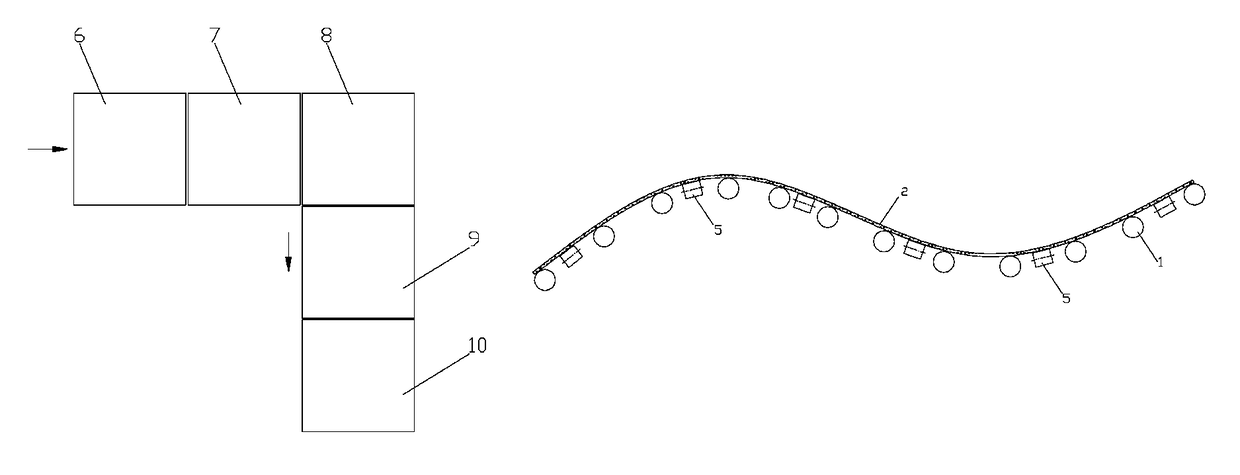

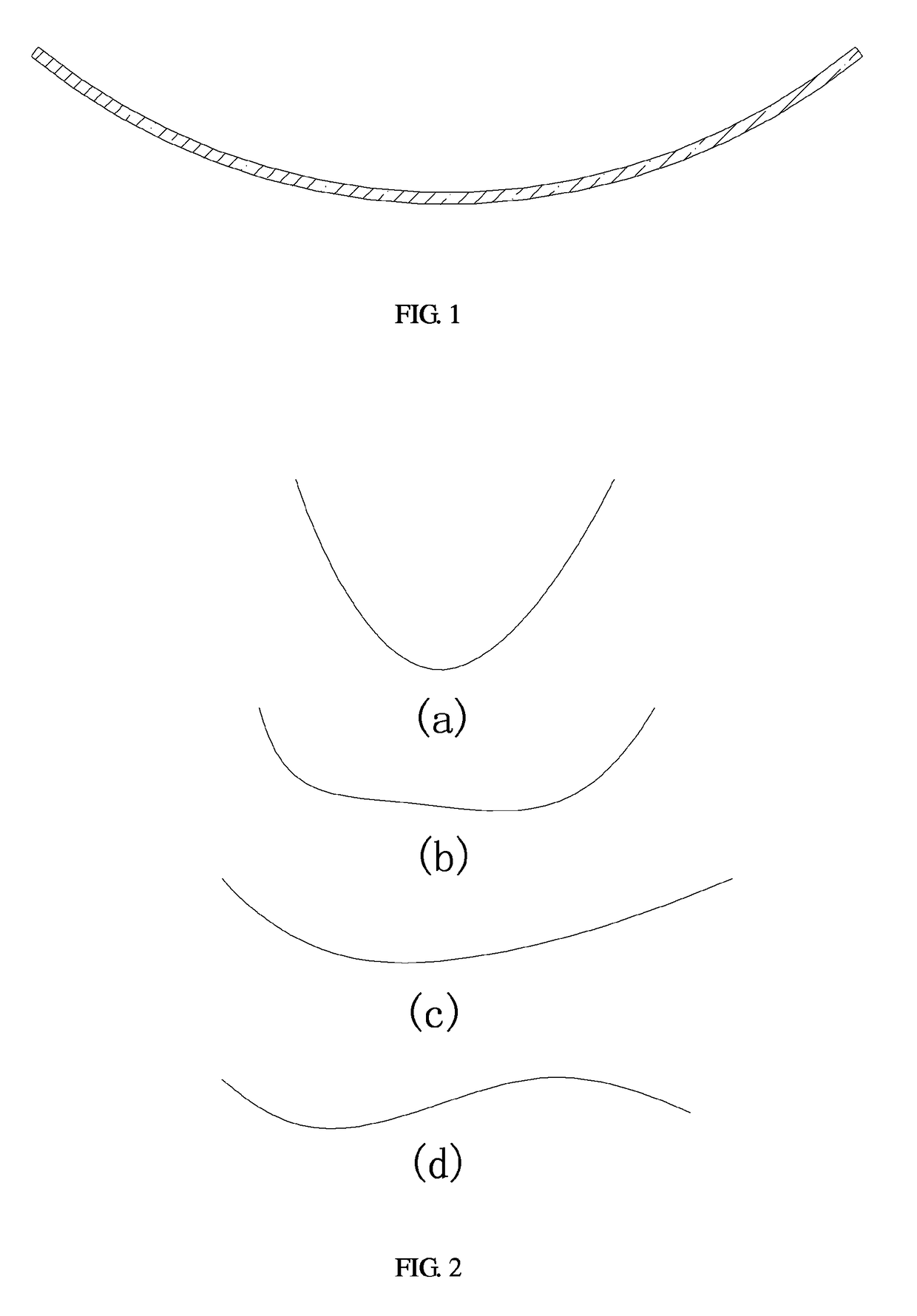

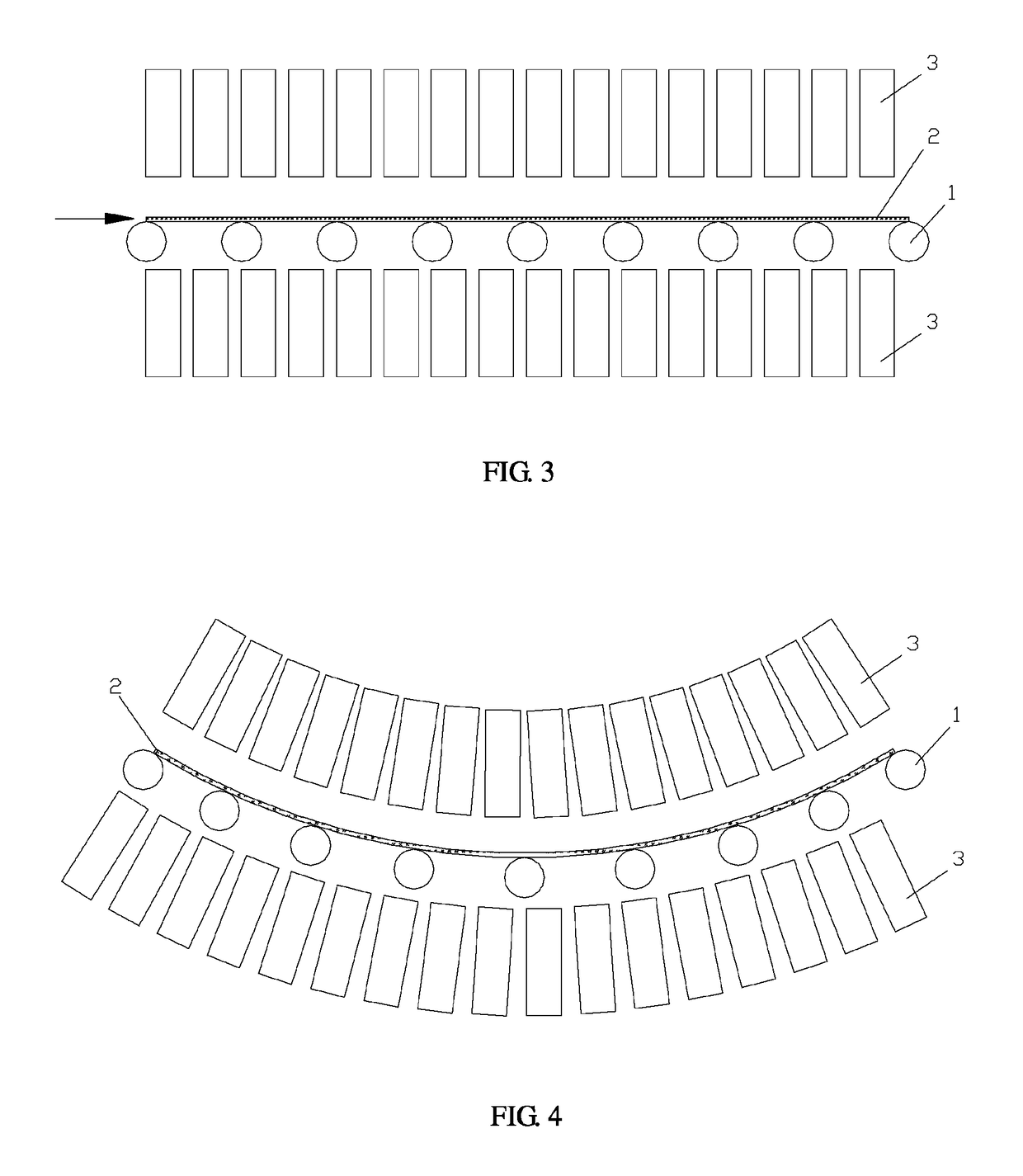

Method for manufacturing columnar curved tempered glass

ActiveUS20150121964A1Smooth transferImprove glass qualityGlass transportation apparatusGlass reforming apparatusFlat glassEngineering

The present invention discloses a device for processing columnar curved tempered glass. The device mainly comprises a glass heating furnace, a glass bending mechanism and a glass tempering mechanism connected sequentially, wherein the arrangement of each supporting roller in the rollers supporting the high temperature flat glass is changed from planar arrangement in space into curved arrangement corresponding to the shape of the glass to be formed, so that the glass bending mechanism enables the glass to suffer bending deformation. Transferring rollers for outputting the formed curved glass in the axial direction of the supporting roller are arranged at the clearance of the rollers of the bending mechanism. In the present invention, bending shaping and tempering of the high temperature flat glass are completed by two stations to break the normal procedure that bending shaping tempering are carried out by one bending appliance intensively, thereby providing a novel technological approach for processing columnar curved tempered glass.

Owner:LUOYANG LANDGLASS TECH CO LTD

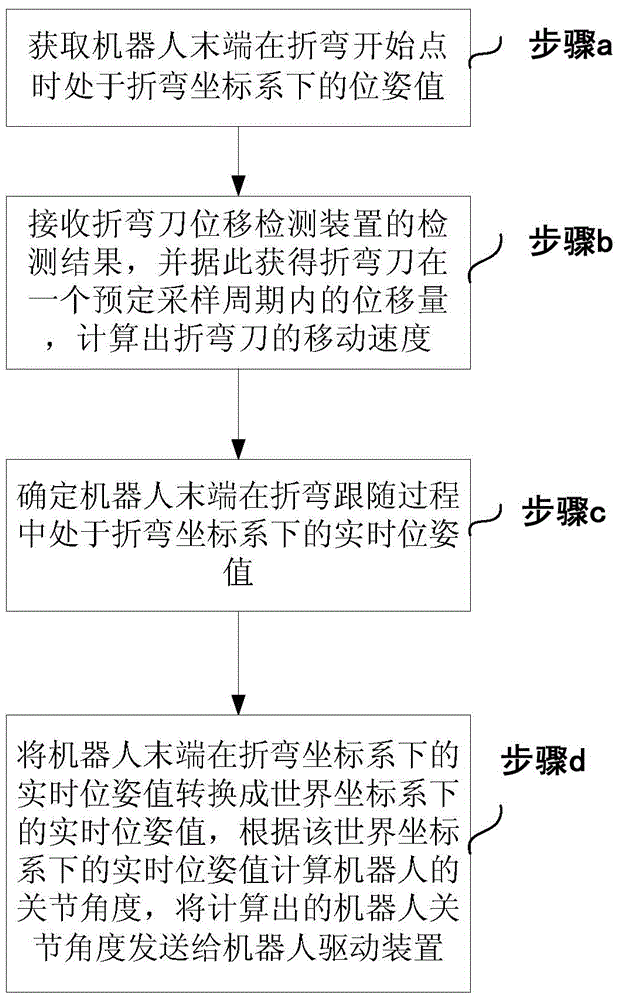

Real time following method for robot bend and device thereof

The invention discloses a real time following method for robot bend which comprises the following steps: step a, obtaining the position value of the end of the robot in the bend coordinate system at the bend start point; step b, receiving the detection result of a bend knife displacement detection device, obtaining the displacement of the bend knife in a preset sampling period according to the detection result, calculating the movement speed of the bend knife; step c, confirming the real time position value of the end of the robot in the bend coordinate system during the bend following process; step d, converting the real time position value of the end of the robot in the bend coordinate system into the real time position value in the world coordinate system, calculating the joint angle of the robot according to the real time position value in the world coordinate system, and sending the calculated joint angle of the robot to the robot driving device. A real time following device for robot bend is also disclosed. The high precision real time following operation for the robot during the bending process is achieved, the bending quality of the robot is raised and the work efficiency is improved.

Owner:SHANGHAI STEP ELECTRIC +1

Steel bar circular bending tool

The invention relates to steel bar bending equipment in the field of building engineering, in particular to a steel bar circular bending tool. The steel bar circular bending tool is characterized by comprising a pedestal, a rotating disk and a limiting device, wherein both the rotating disk and the limiting device are arranged on the pedestal; a driving device for driving the rotating disk to rotate is arranged inside the pedestal; a revolving drum is arranged on the rotating disk; a plurality of support plates are uniformly arranged on the outer side of the lower portion of the revolving drum along the circumferential direction; a fixing device for fixing a steel bar is arranged on one support plate; the limiting device is positioned on the side edge of the revolving drum, and is used for limiting the position of the steel bar. During use, the steel bar of which the position is limited is tangential to the outer wall of the revolving drum. By adopting the tool, the working efficiency during circular bending of the steel bar can be increased, and the bending quality can be improved.

Owner:CHINA FIRST METALLURGICAL GROUP

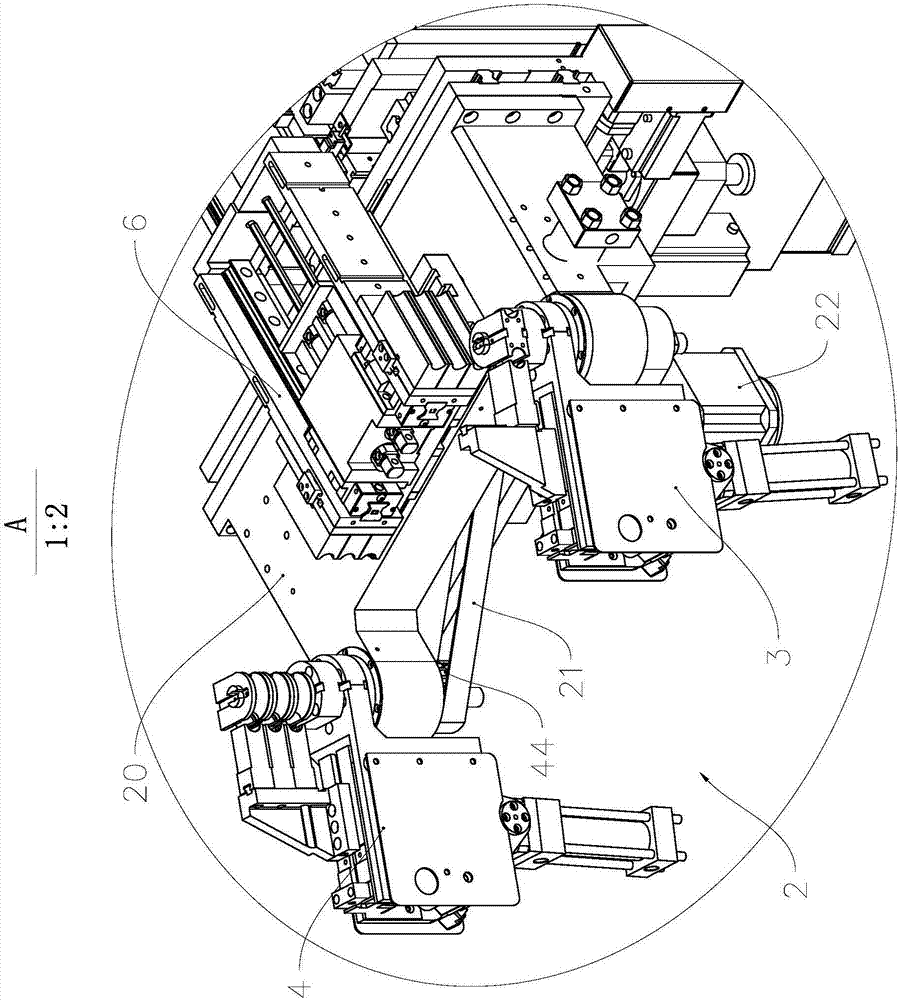

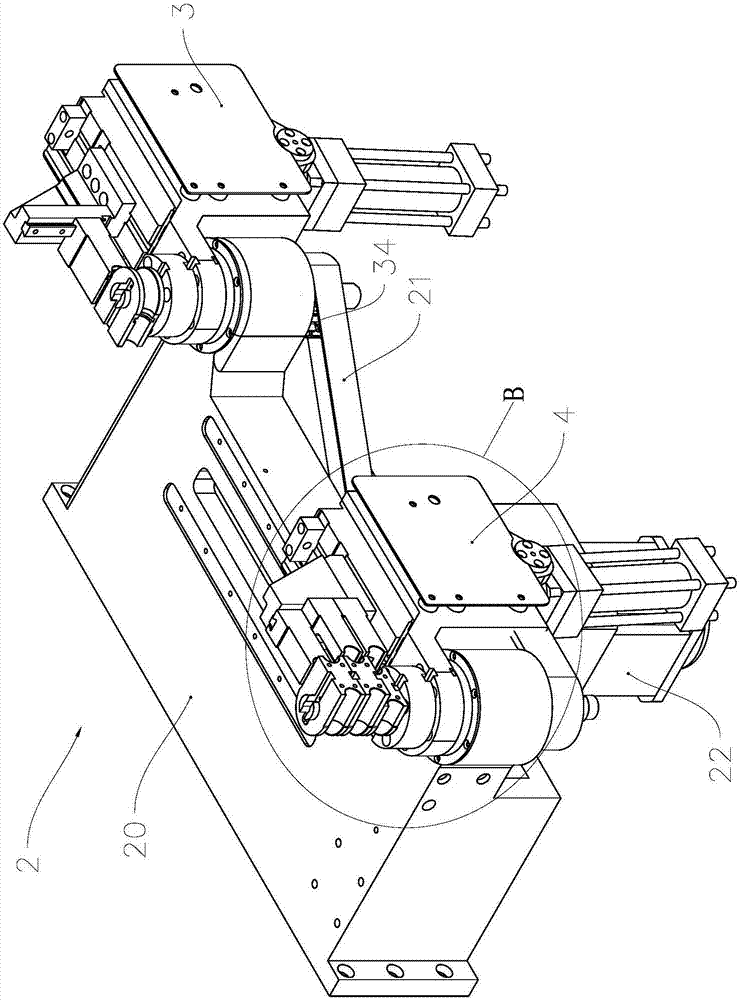

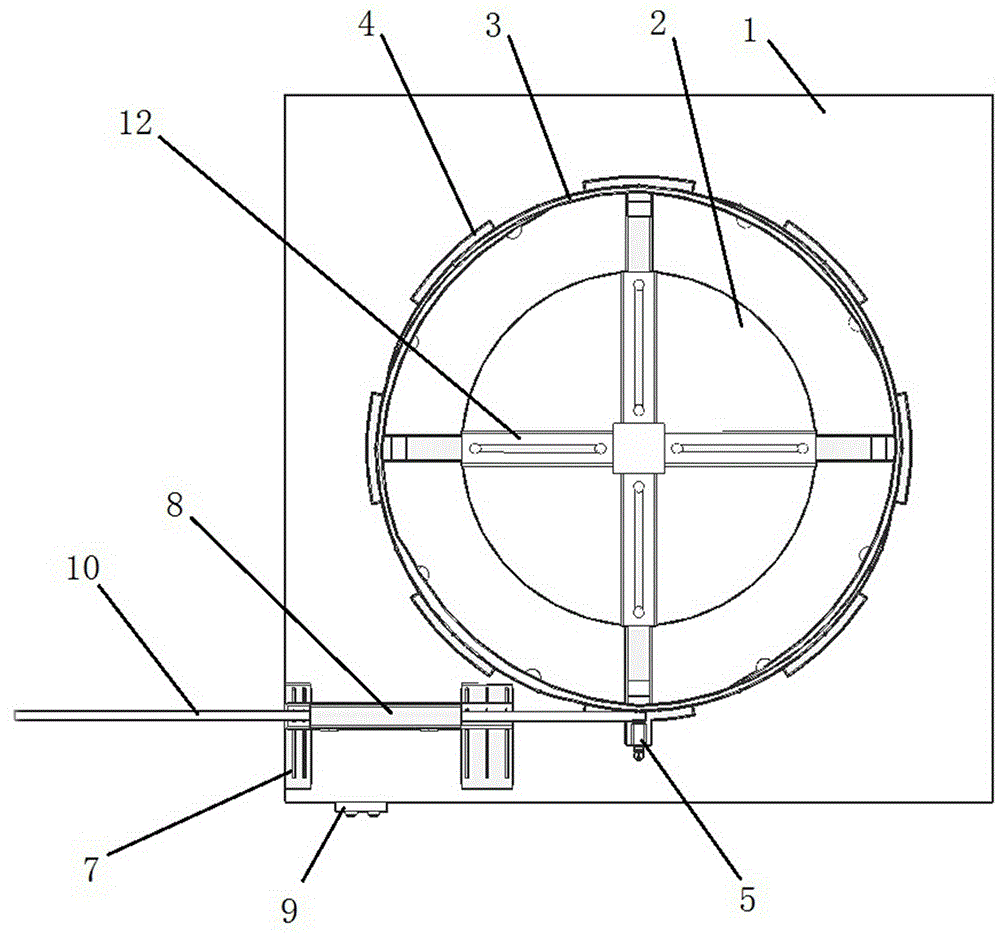

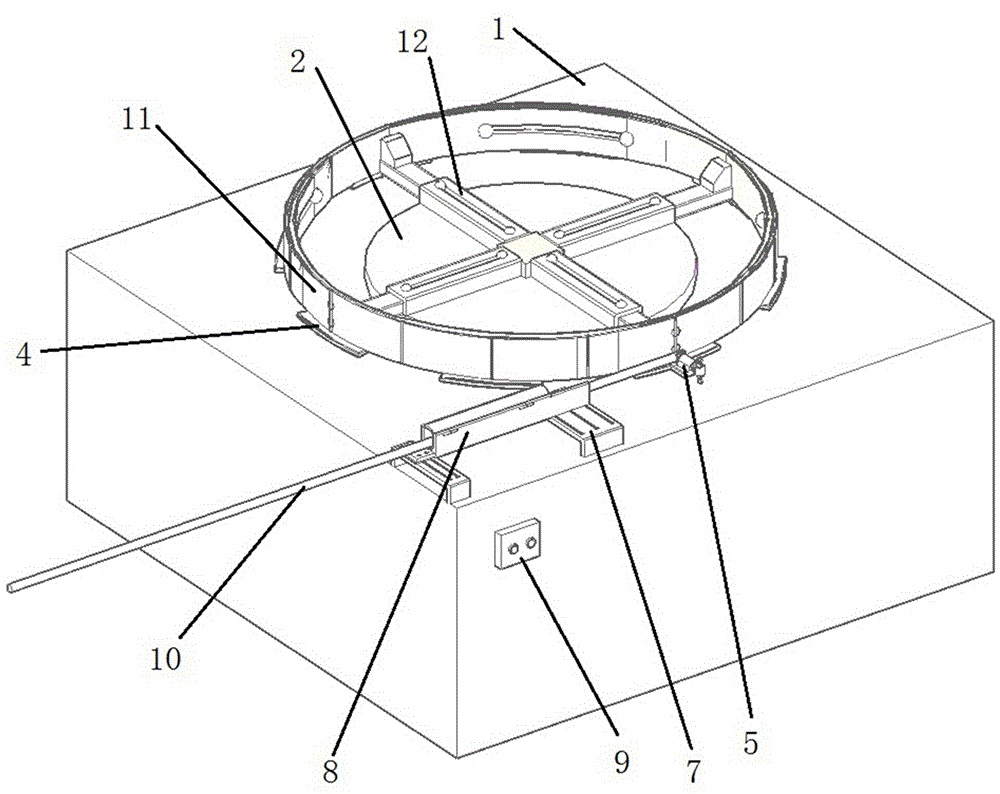

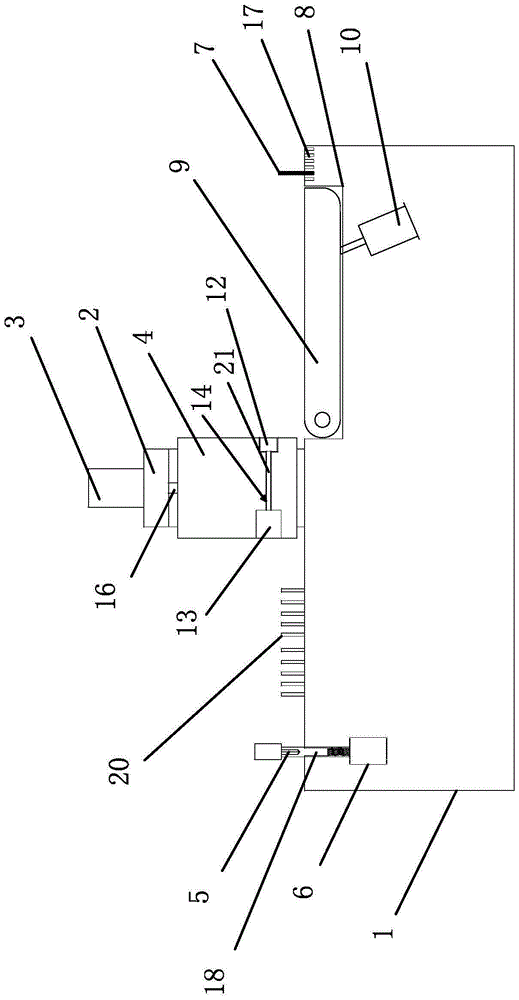

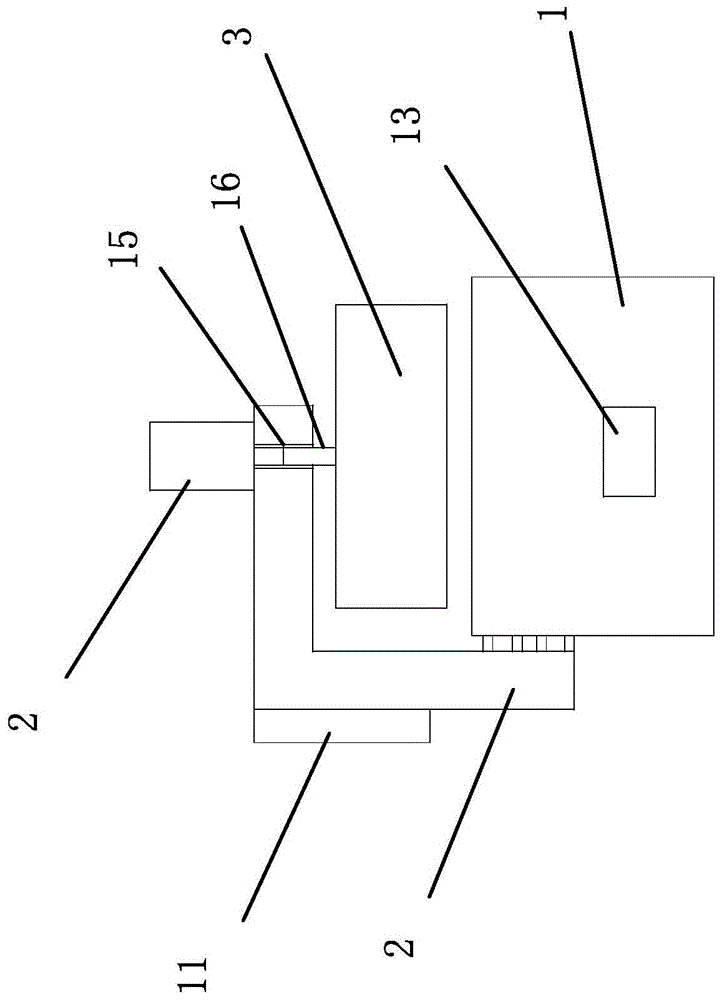

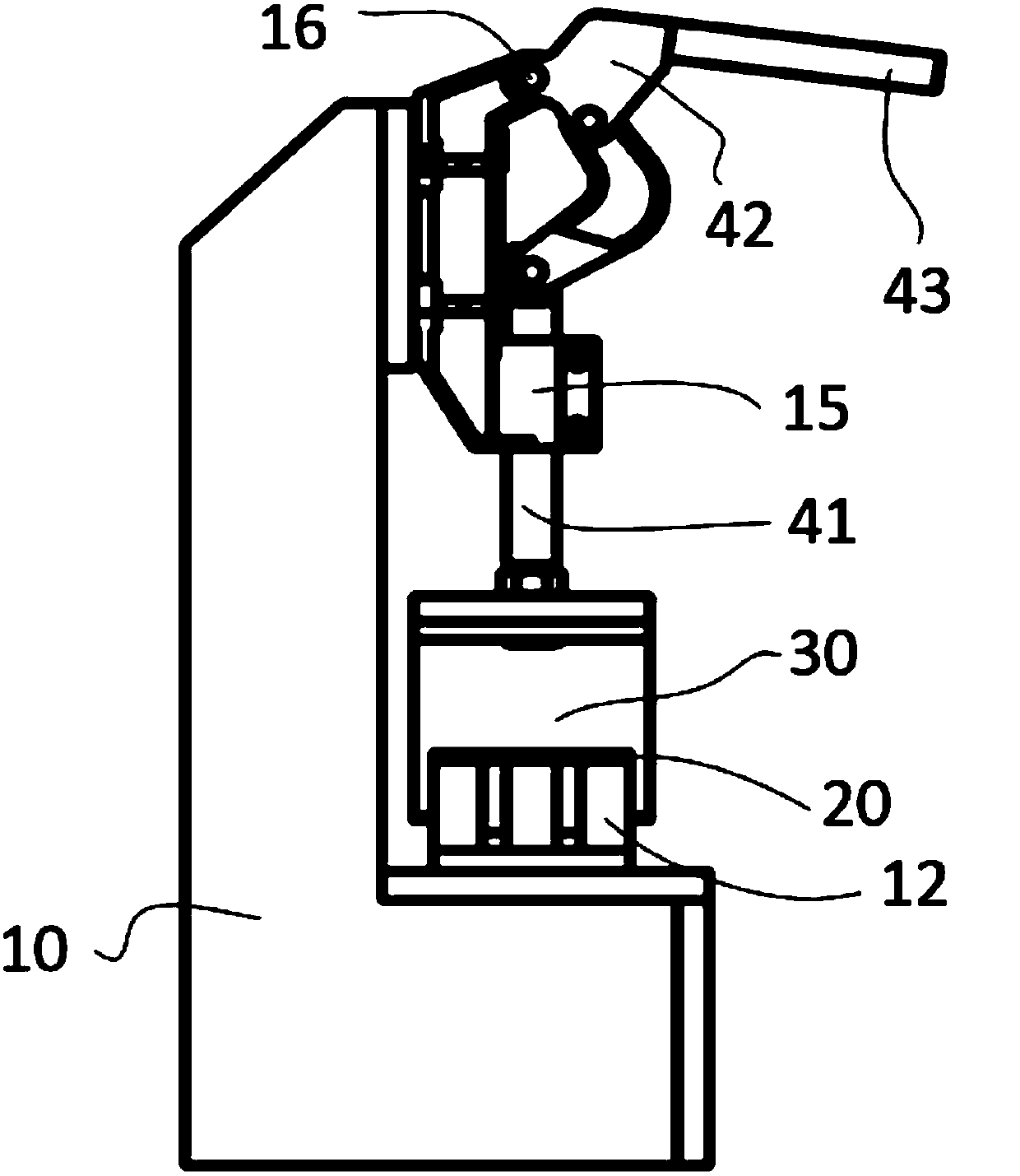

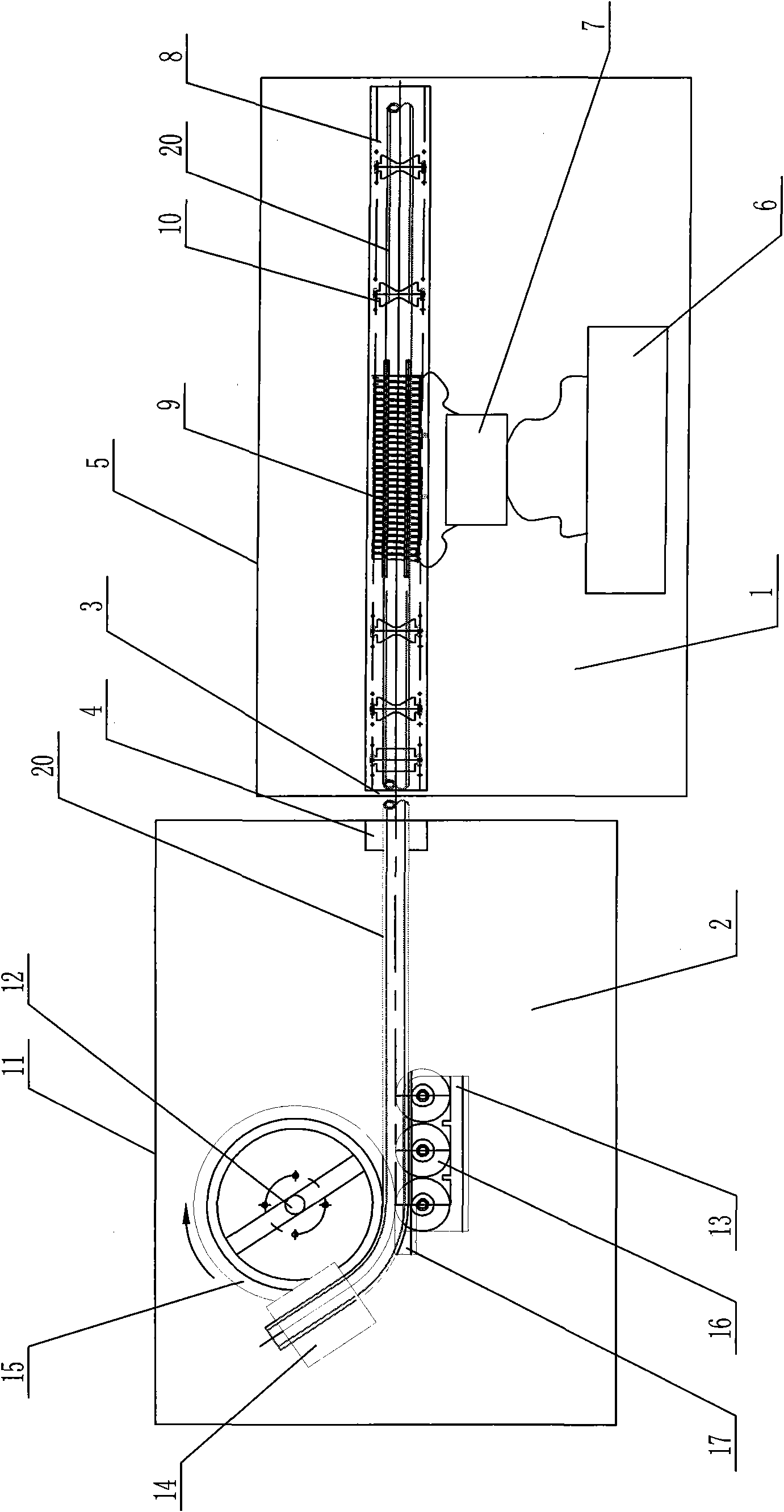

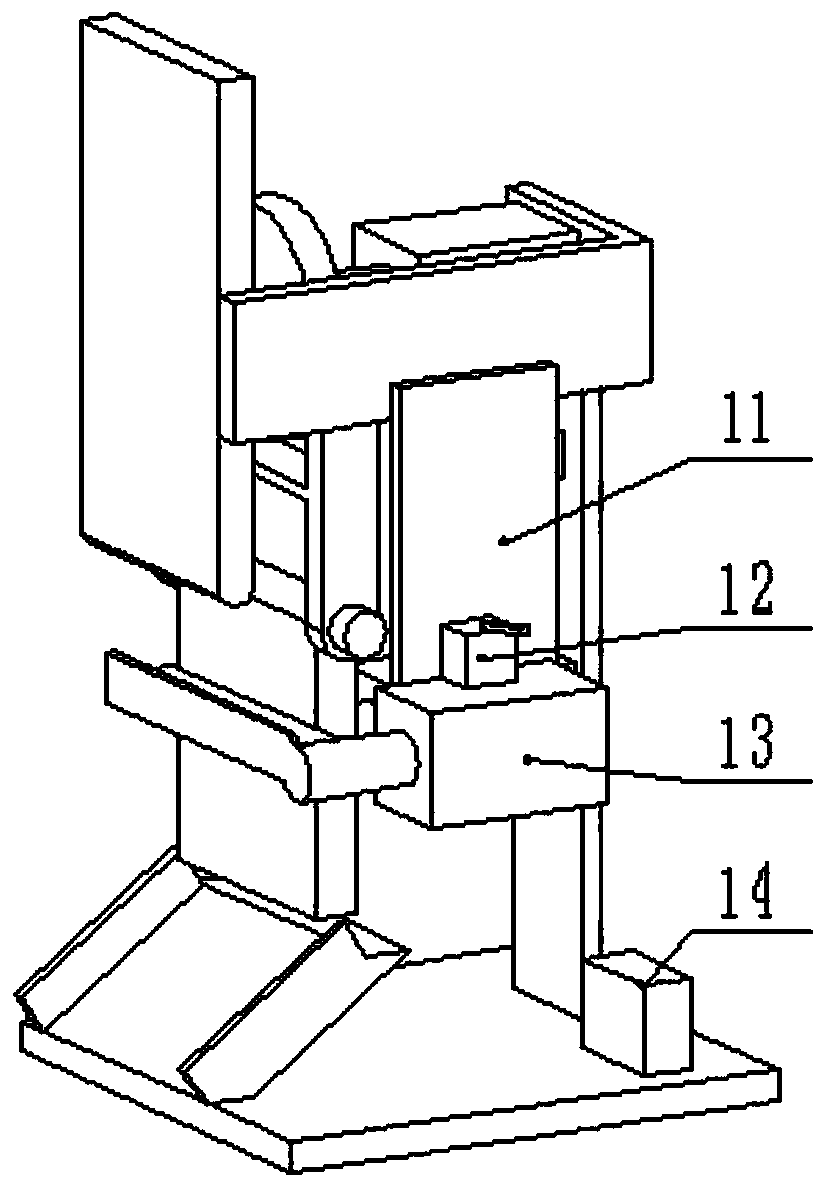

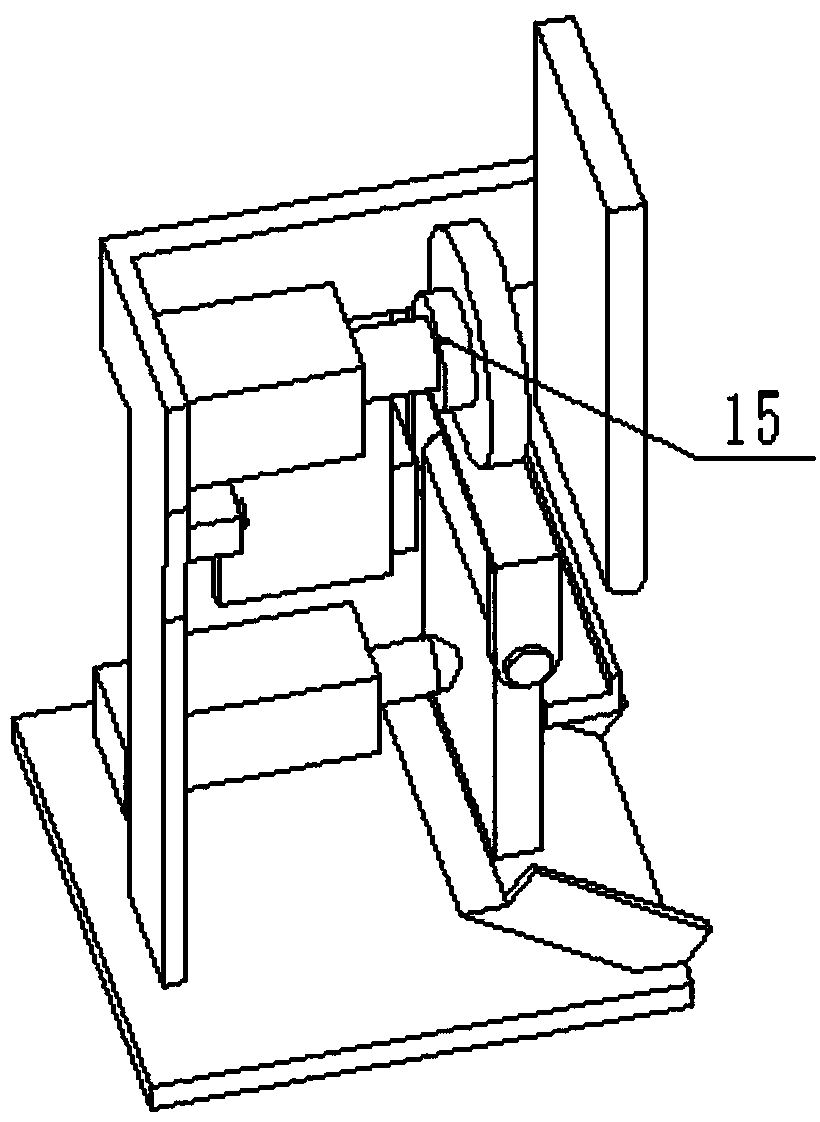

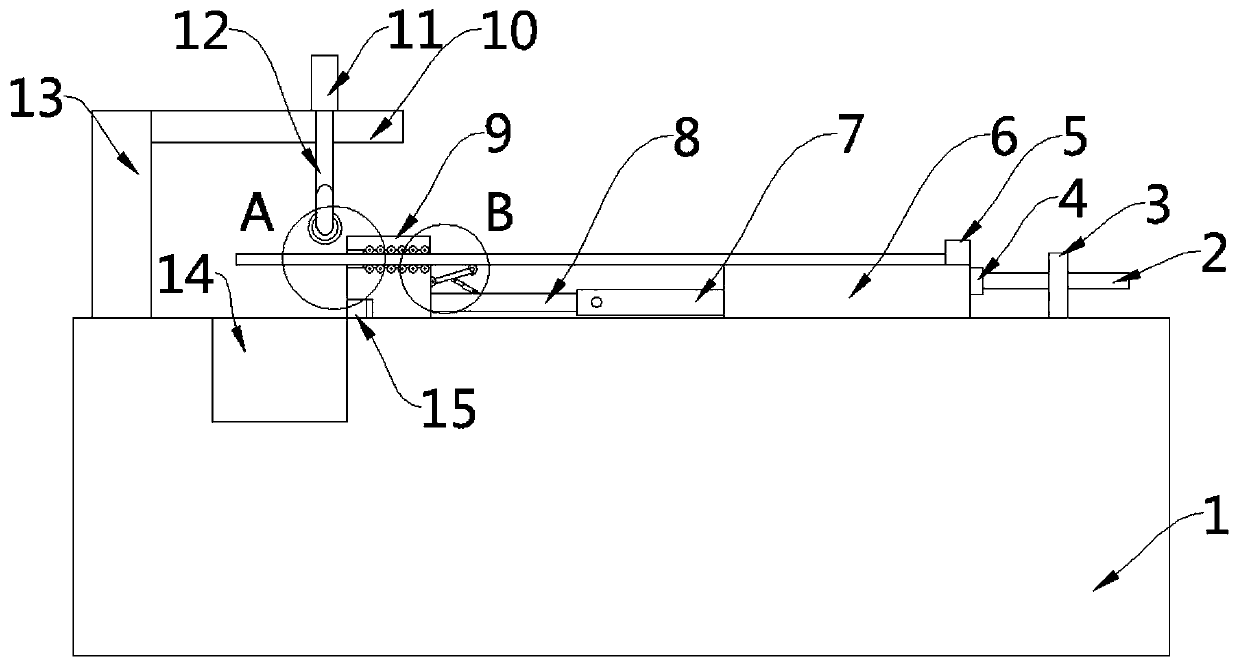

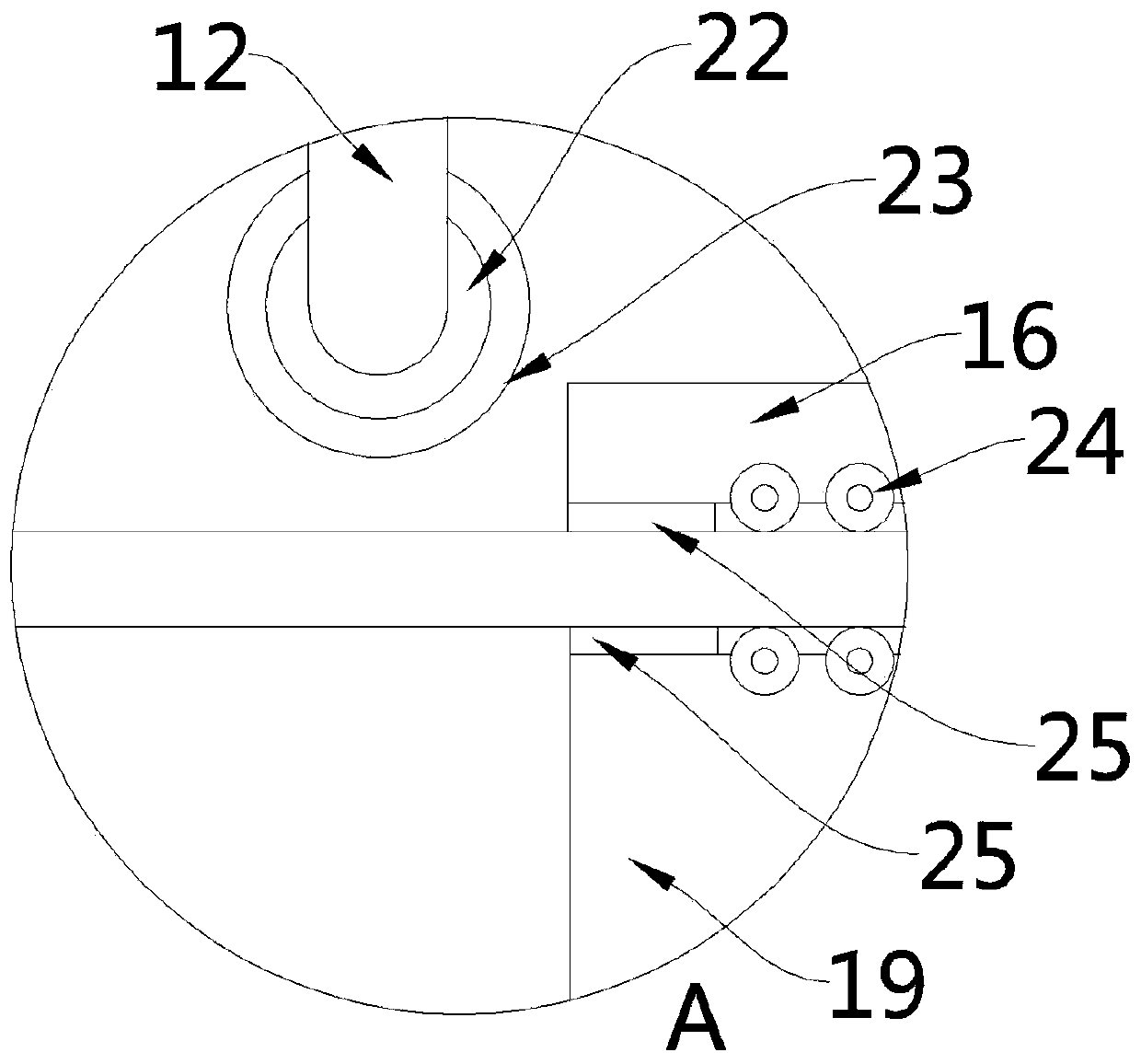

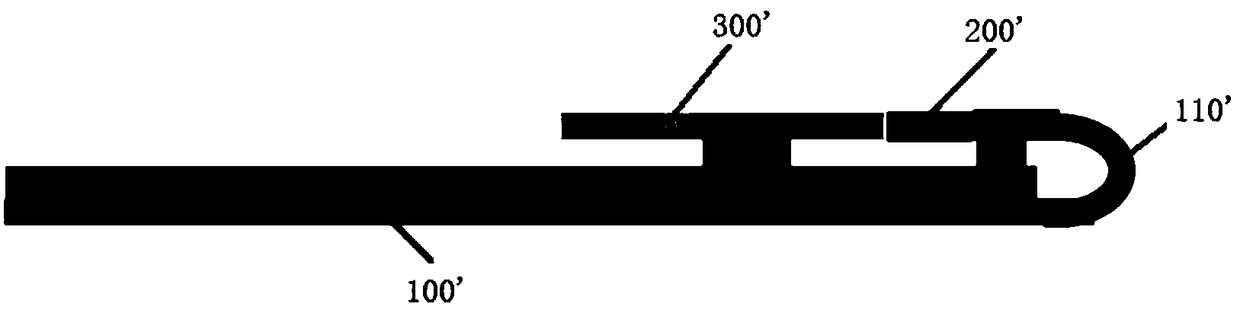

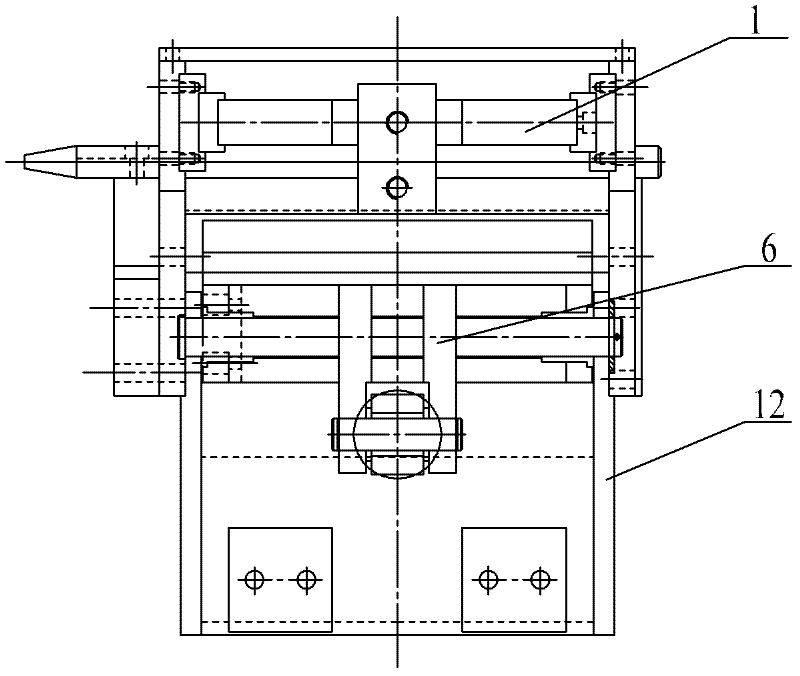

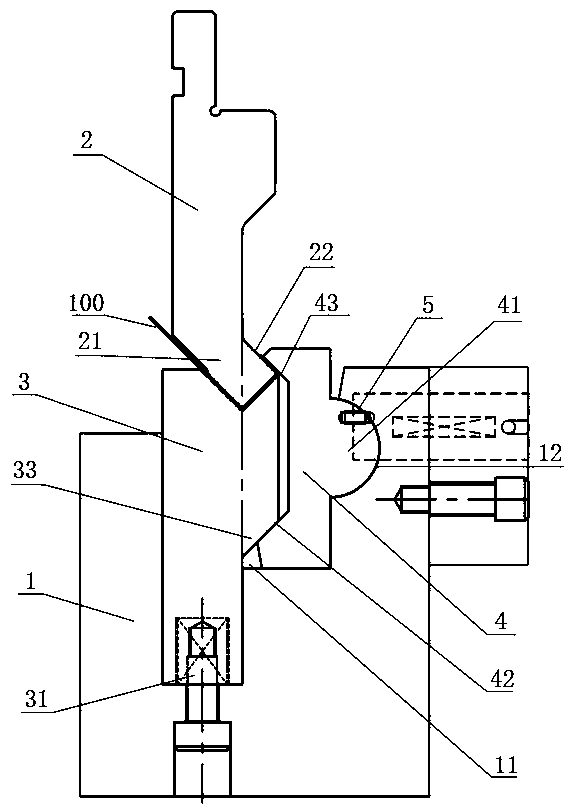

Single-oscillating-arm leftward and rightward co-bending type numerical control pipe bending machine

The invention relates to a single-oscillating-arm leftward and rightward co-bending type numerical control pipe bending machine and belongs to the technical field of pipe processing. The numerical control pipe bending machine comprises a machine frame, a control unit, a feeding trolley, a machine head, a mold guide unit and a switching unit, wherein the feeding trolley, the machine head, the mold guide unit and the switching unit are installed on the machine frame and controlled by the control unit; the machine head comprises a clamping mold, a round mold, an oscillating arm and a pipe bending motor, the oscillating arm shares the same drive spindle with the round mold, and the pipe bending motor is used for driving the round mold and the oscillating arm to rotate to bend a pipe and to rotate at the leftward pipe bending position or the rightward pipe bending position in a switching mode; and the switching unit is controlled by the control unit to drive the machine head to move transversely or vertically perpendicular to the axial direction of the pipe to be bent relative to the machine frame so that the machine head can be driven to switch between the leftward pipe bending position and the rightward pipe bending position. By means of the single-oscillating-arm leftward and rightward co-bending type numerical control pipe bending machine, leftward and rightward co-bending can be achieved based on the single oscillating arm, the pipe bending quality can be effectively improved, and the numerical control pipe bending machine can be widely applied to the fields of air conditioners, aviation and the like.

Owner:浙江和良智能装备有限公司

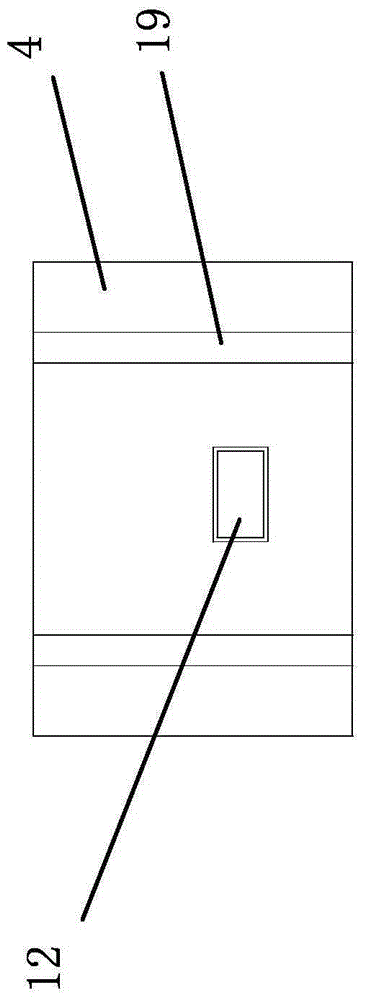

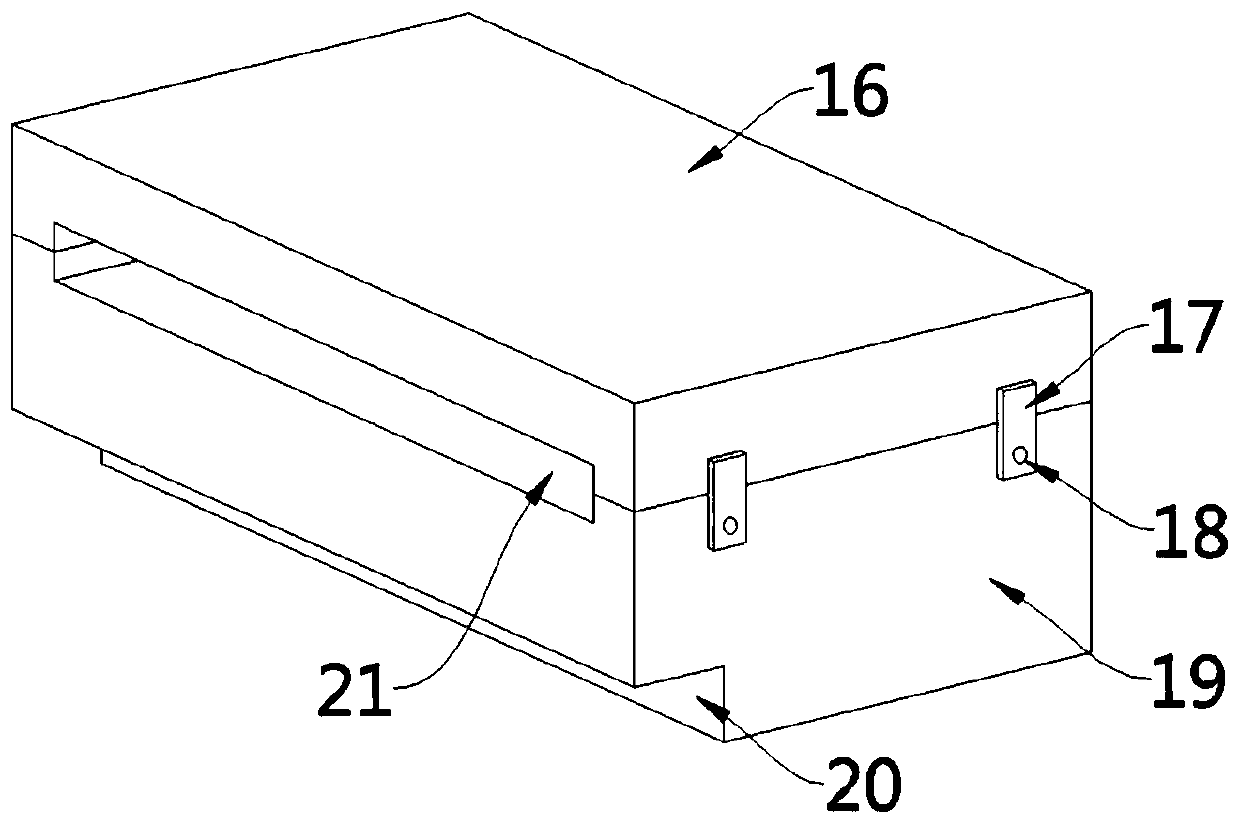

Automatic plate bending device of power distribution cabinet

InactiveCN105171428AAffect qualityAvoid compromising workpiece qualityMetal-working feeding devicesOther manufacturing equipments/toolsNumerical controlElectric machinery

The invention provides an automatic plate bending device of a power distribution cabinet, and belongs to the technical field of power distribution equipment. The automatic plate bending device of the power distribution cabinet comprises a rack with a workbench. The side of the workbench is connected with an L-shaped supporting arm. A first air cylinder and a press plate ascending and descending along the supporting arm are arranged on the supporting arm. The press plate is pushed by the first air cylinder to press workpieces on the workbench. A cutting wheel and a cutting motor are arranged at the feeding end of the workbench. A limiting rod is arranged at the discharging end of the workbench. A square groove is formed in the workbench. A bent plate is placed in the groove, one end of the bent plate is hinged to the workbench, and the other end of the bent plate is hinged to a push rod of a second air cylinder in the workbench. A numerical control table used for controlling the cutting motor, the first air cylinder and the second air cylinder to be started and stopped is fixed to the supporting arm. According to the automatic plate bending device of the power distribution cabinet, the plate can be automatically bent through the numerical control table on the supporting arm, manual labor intensity is lowered, and meanwhile the bending quality of the plate is improved.

Owner:浙江新跃电气有限公司

Method for manufacturing columnar curved tempered glass

ActiveUS9630870B2Smooth transferImprove glass qualityGlass transportation apparatusGlass reforming apparatusFlat glassEngineering

The present invention discloses a method for processing a columnar curved tempered glass. The method specifically comprises the following steps. Bending and tempering of the high temperature flat glass are divided into two stations. Bending is firstly carried out on the high temperature flat glass output by a heating furnace; the columnar extending direction of the curved glass is perpendicular to the direction the glass output from the heating furnace in the bending process, and then the formed curved glass is output to a tempering station in the columnar extending direction thereof to undergo tempering. In the present invention, bending and tempering of the high temperature flat glass are completed by two stations to break the normal procedure that bending and tempering are carried out by a single bending device intensively, thereby providing a novel technological approach for processing the columnar curved tempered glass.

Owner:LUOYANG LANDGLASS TECH CO LTD

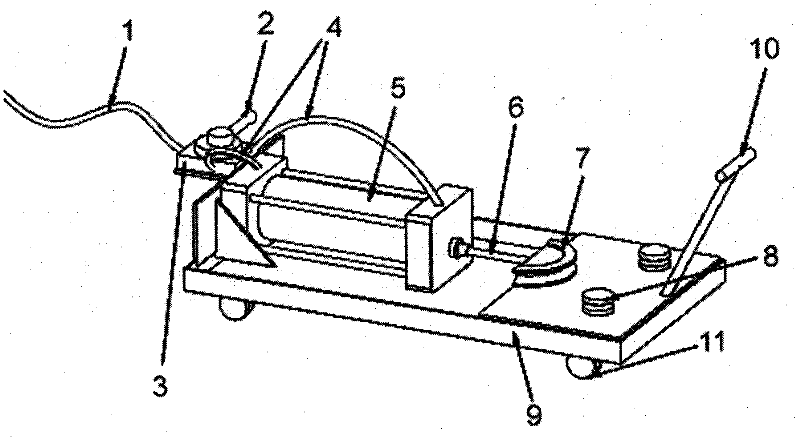

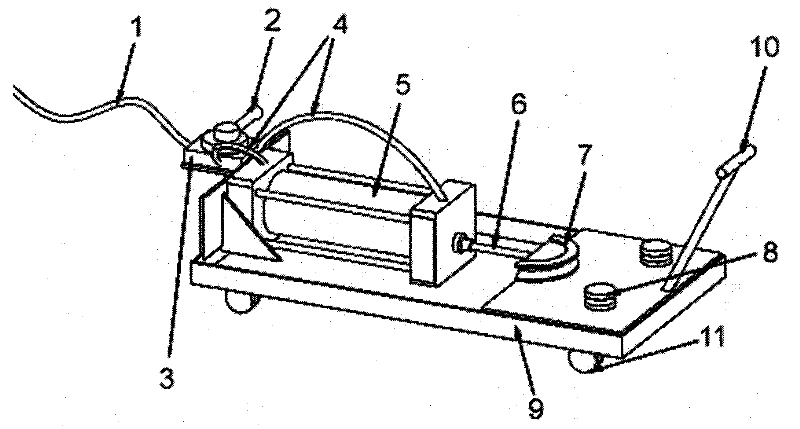

Air pressure pipe bending machine

The invention discloses an air pressure pipe bending machine. The machine comprises a worktable, a cylinder (5), a cylinder component, a pipe bending pressure tank (7) and rolling grooves (8), wherein a cylinder piston of the cylinder (5) is connected with the pipe bending pressure tank (7) through a telescopic shaft rod (6); the pipe bending pressure tank (7) is provided with a semi-circular notch of which the diameter is matched with that of a pipe; the worktable is provided with two rolling grooves (8) for positioning the two ends of the pipe and matching with the pipe bending pressure tank (7) to bend the pipe; each rolling groove (8) is provided with a semi-circular notch of which the diameter is matched with that of the pipe; and the cylinder piston moves forwards or backwards to push the telescopic shaft rod (6) and the pipe bending pressure tank (7) to move forwards or backwards along the direction of the worktable. The machine is high in pipe bending quality, ensures consistent and attractive bends, has high work efficiency, is not required to be operated by professional personnel, saves labor cost, is suitable for bending short pipes, can improve the utilization rate of the short pipes in a construction site, and reduces material loss.

Owner:GOLD MANTIS CONSTR DECORATION

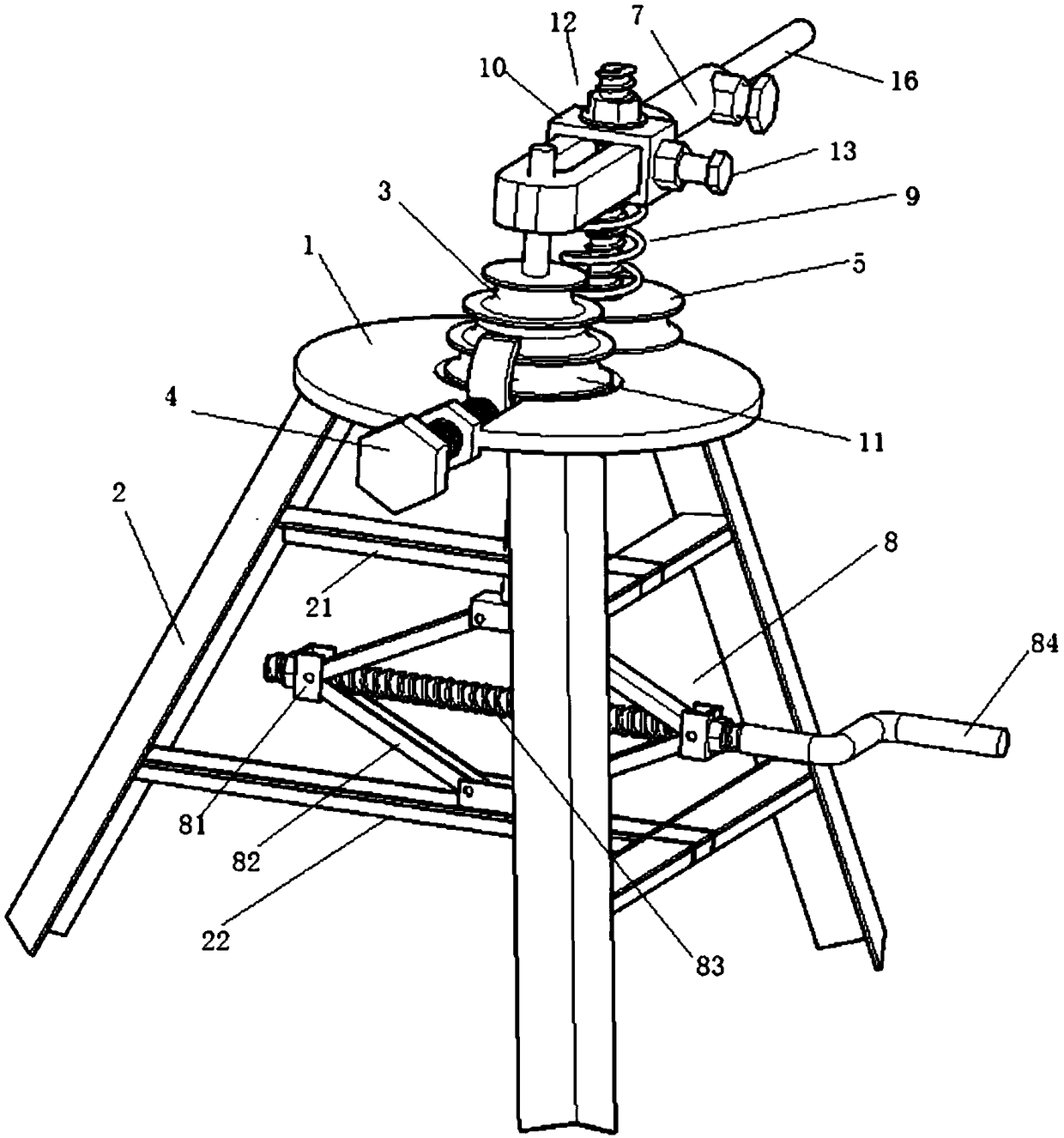

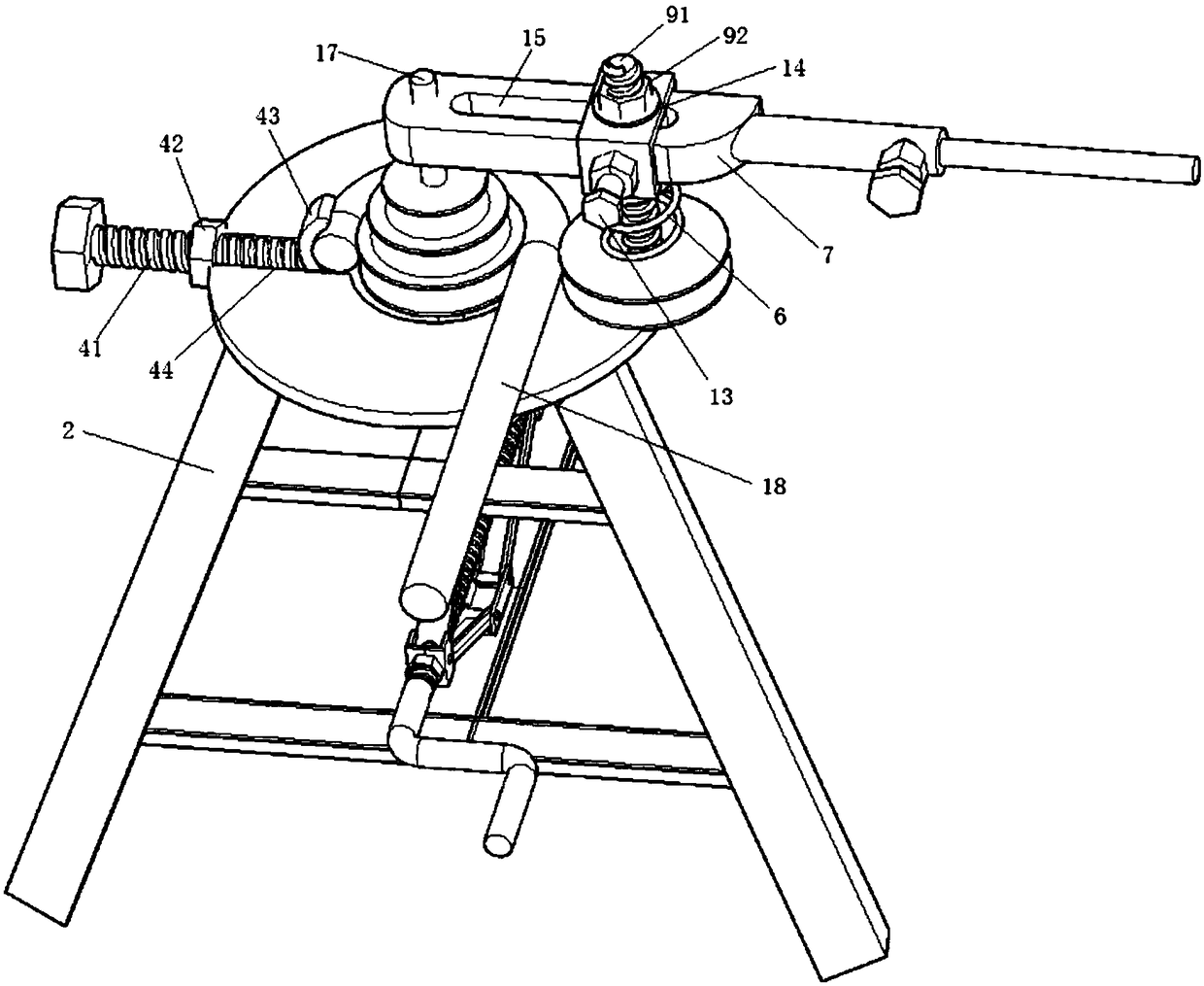

Pipe bending device with radius capable of being adjusted by 360 degrees

InactiveCN108746275APrecise control of bending angle and sizeGuaranteed metal propertiesEngineeringPressure pipe

The invention discloses a pipe bending device with a radius capable of being adjusted by 360 degrees. The pipe bending device comprises a supporting frame, a workbench, a multi-groove pipe bending plate, a torsional plate rod, a pressure pipe device, a pressure pipe adjusting block and a pipe bending locking device. A hole for mounting the multi-groove pipe bending plate is formed in the middle portion of the workbench, the multi-groove pipe bending plate is installed on the supporting frame through a first lifting device, and a plurality of pipe bending grooves with different elbow radii arearranged on the multi-groove pipe bending plate in the upper and lower directions. The pipe bending locking device is arranged on the workbench and is used for pressing and locking the end portion ofa pipe to be bent on the pipe bending grooves of the multi-groove pipe bending plate. The torsional plate rod is mounted on a central shaft of the multi-groove pipe bending plate by a rotating pair, the pressure pipe adjusting block is installed on the torsional plate rod by a transverse translation device, the pressure pipe device is installed at the bottom of the pressure pipe adjusting block through a second lifting device, and the relative position between the pressure pipe device and the multi-groove pipe bending plate is adjusted through the transverse translation device to match the bend radii of the bend grooves. The pipe bending device with the radius capable of being adjusted by 360 degrees is stable in structure, simple in operation and adjustable in pipe bending radius, and usecost is greatly reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

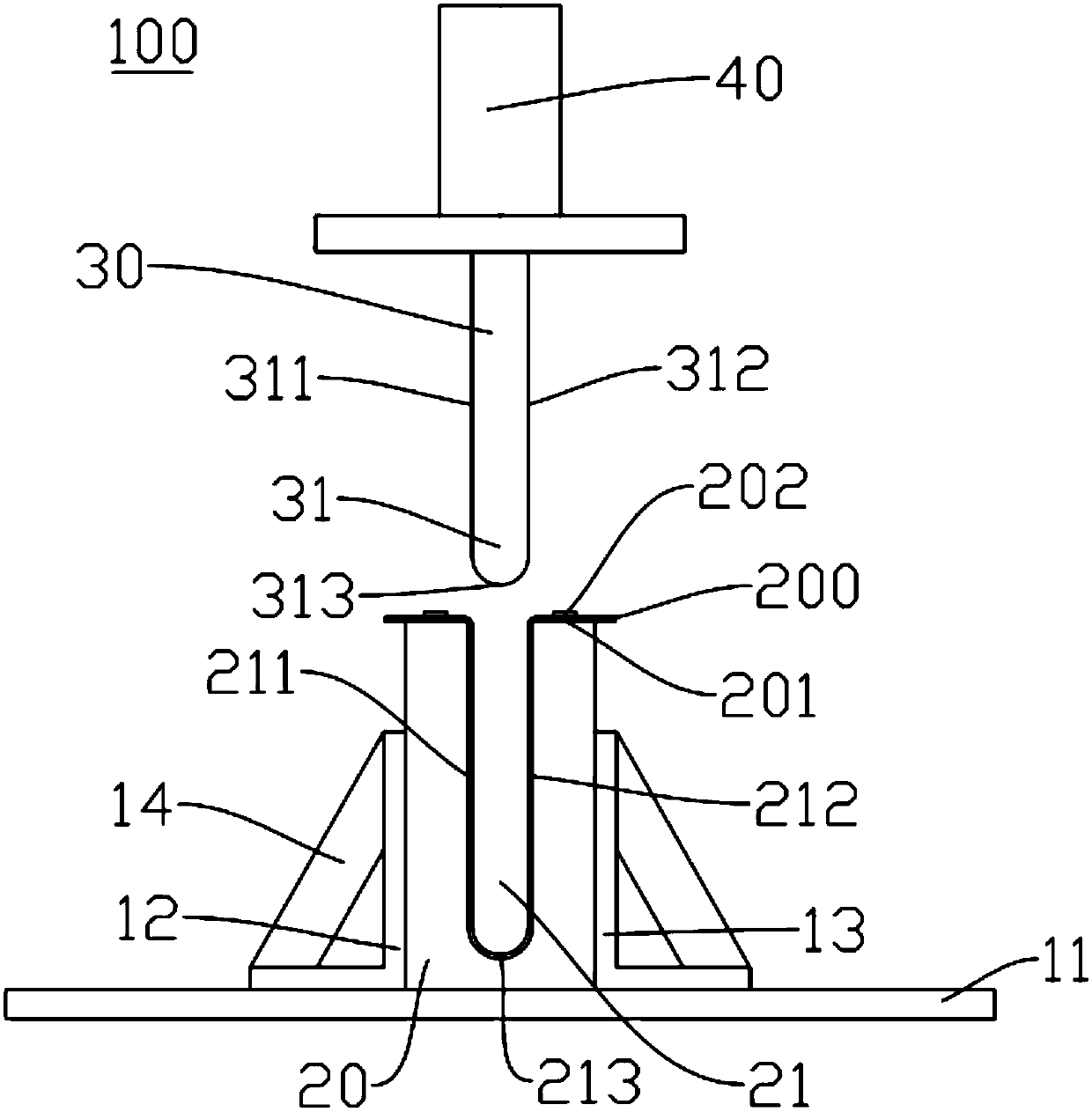

Bending fixture

InactiveCN107863005AEnsure consistency of applicationTightly supportedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLinear section

The invention relates to the field of display screen manufacturing, and discloses a bending fixture of a flexible OLED screen. The bending fixture comprises a bracket, concave dies, convex dies and apressing handle, and the bracket and the pressing handle are used for fixing the concave dies and the convex dies respectively so that the concave dies and the convex dies can be fitted to press the flexible OLED screen. Since grooves in the concave dies and protrusions on the convex dies are arranged opposite to each other, and particularly in an arrangement mode of linear sections every two of which are matched with each other, a bent area, a non-bent area and an overlapping area of the bent area and the non-bent area of the flexible OLED screen can be tightly supported in the bending process. While the bending operation is completed accurately, the fitting consistency of the flexible OLED screen is ensured, the bending quality of the bending process is improved, and the qualified product rate is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Steel wire winding and buckling molding device

The invention provides a steel wire winding and buckling molding device. The steel wire winding and buckling molding device comprises a base, a clamping mechanism, a wire pushing mechanism, an inversion mechanism, a rolling mechanism and a bending mechanism, wherein the clamping mechanism includes a clamping component and a clamping oil cylinder; the wire pushing mechanism includes a wire pushing baseplate, a wire pushing cylinder, a push head and an U-shaped groove; the inversion mechanism includes a rolling car, an inversion cylinder and a slide rail; the rolling mechanism includes a rolling machine body; the rolling machine body is provided with a hollow shaft; a slide column is arranged in the hollow shaft; a rolling turntable is arranged on the upper surface of the rolling machine body; a rolling bearing is arranged on one side of the rolling turntable; and the bending mechanism includes a bending fixing structure and a bending punching structure. The steel wire winding and buckling molding device has the advantages of simple structure, convenience for operation, good steel wire winding and buckling molding quality and high production efficiency.

Owner:TIANJIN YINHE METAL PROD

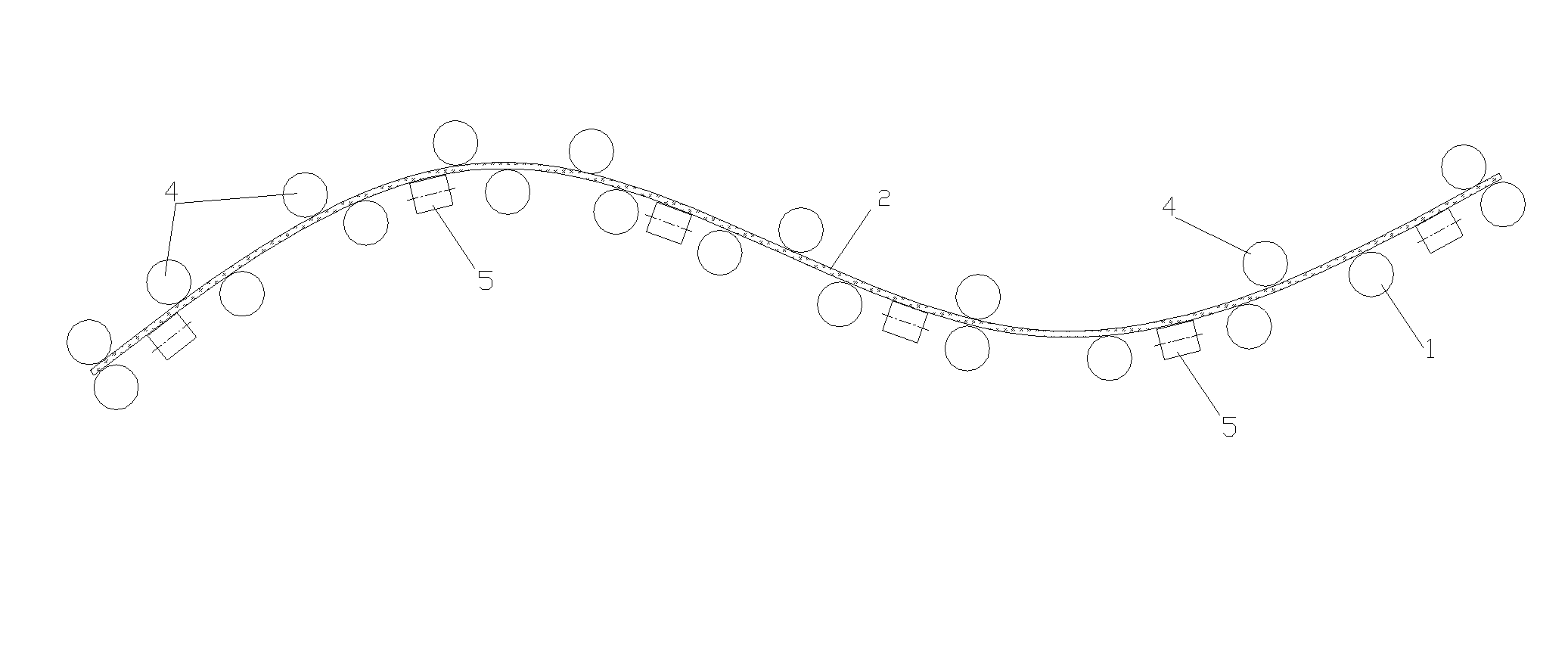

Pre-bending machine

The invention discloses a pre-bending machine comprising a material conveying mechanism, a main machine, a lubricating system and an electronic control system. The pre-bending machine is characterized in that the material conveying mechanism comprises a first material conveying unit and a second material conveying unit, the first material conveying unit and the second material conveying unit bothcomprise material conveying rollers, centring devices and clamping material conveying devices, wherein the material conveying rollers are sequentially arranged, and the clamping material conveying devices are close to one side of the main machine; the main machine comprises a first main machine unit and a second main machine unit which are separately erected at both sides of the main machine, thefirst main machine unit and the second main machine unit both comprise C-shaped stands, upper moulds, lower brackets and upper clamping rollers, wherein the lower brackets can carry lower moulds to move up and down; a main machine width adjusting device is arranged between the first main machine unit and the second main machine unit and comprises transmission screw rods and sliding rails, whereinthe transmission screw rods are respectively fixedly connected to the C-shaped stands through corresponding nuts, and the stands are connected with the sliding rails through slide blocks. The invention has the advantages of small resilience amount of preformed steel plate workpieces, high forming speed, high efficiency, undamaged workpieces, good bending quality, and the like.

Owner:QINGDAO WUXIAO GRP

Steel bar bender for building

The invention discloses a steel bar bender for building. The steel bar bender comprises a machine frame, a conveying mechanism, a drive device, a workbench board and a supporting board, wherein the workbench board is arranged on the machine frame and the supporting board is arranged on the machine frame. A steel bar is arranged on the conveying mechanism. The drive device is installed on the supporting board. An output shaft of the drive device is provided with a shaft sleeve. A rotary shaft is connected to the upper portion of the shaft sleeve. An operation transverse beam is arranged on the rotary shaft. A first bending operation board and a second bending operation board are arranged on the workbench board. A circular space is formed between the first bending operation board and the second bending operation board. One end of the operation transverse beam stretches into the circular space and the portion, stretching into the circular space, of the operation transverse beam is provided with a fixing device for fixing the steel bar. The steel bar bender for building is simple in structure, convenient to use and install, easy to operate, capable of saving labor, low in cost, capable of conveniently conducting bending, high in bending accuracy and bending quality, capable of being conveniently maintained in the later period, large in application range, long in service life, safe and reliable.

Owner:CHENGDU LYUDI TECH

Processing method for cold bending pipes by medium frequency heating

ActiveCN101623724AHeating evenlyHeating environmental protectionCoil arrangementsMetal-working feeding devicesMedium frequencyEngineering

The invention discloses a processing method for cold bending pipes by medium frequency heating, comprising the following steps: firstly, heating the part, which is required to be bent, of a pipeline to certain temperature by adopting the medium frequency heating mode, and then bending the pipeline. The method has the advantages that the design is reasonable, the heating effect is good, the work efficiency is high, the pipeline bending quality is good and the labor intensity of workers is reduced, and the method can provide good productivity benefits for the enterprises.

Owner:HENAN HUADIAN JINYUAN PIPING

Steel plate bending device

ActiveCN108393373AImprove bending efficiencyImprove bending qualityMetal-working feeding devicesPositioning devicesHydraulic cylinderSheet steel

The invention discloses a steel plate bending device and belongs to the field of constructional engineering equipment. A limiting plate is fixed to a supporting frame; a first hydraulic cylinder is perpendicularly fixed to the top of the supporting frame; a bending push plate is arranged below a first bracket; a supporting plate is pressed on a spindle of a stepping motor; a material discharging plate is fixed to a workbench; an ultrasonic sensor is arranged on the supporting frame; a magnet base is fixed to the upper surface of the stepping motor; the stepping motor is connected with the supporting plate; a controller is fixed to the workbench; a pressure sensor is arranged between the first hydraulic cylinder and a push plate; a thrust ball is arranged on a spindle of a second hydrauliccylinder; and the second hydraulic cylinder is fixed to the supporting frame. The first hydraulic cylinder is used for driving the push plate to fix a steel plate, and the second hydraulic cylinder isused for driving the thrust ball to allow the bending push plate to move forwards so as to bend the steel plate, so that the operation that the steel plate is manually bent is replaced, and the working efficiency and the quality are improved.

Owner:贝克曼沃玛金属技术(青岛)有限公司

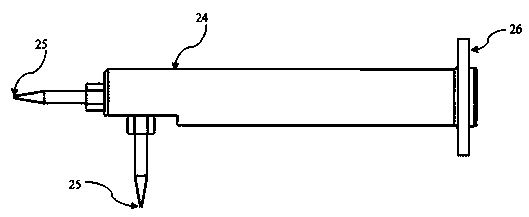

Airplane engine heat exchanger guiding-tube bend filling and technique

InactiveCN101058708AImprove bending qualityStable performance of filling processOther chemical processesHollow article cleaningSodium bicarbonateJet aeroplane

The invention discloses a bending filler and technique of heat exchanger conduit of airplane motor in the machine making domain, which comprises the following steps: allocating raw material proportionally; putting disodium phosphate and sodium bicarbonate in the autoclave; blending 2h; adding stablizier and reinforcer; packing the allocated fill; sealing to reserve. The filling technique of conduit product comprises the following steps: weighing the filler; controlling the temperature after the filler is fused; entering into the working condition; filling the conduit. The cleaning technique is characterized by the following: placing the moulded conduit into cleaning groove; injecting the tap water to heat and stir; controlling the water temperature between 80 and 90 deg. c for 20-30 min; fetching the conduit; draining the solution; repeating 5 times; fetching the conduit to dry; finishing the cleaning process.

Owner:沈阳华铁异型材有限公司 +1

Double-head seven-axis forming machine

The invention discloses a double-head seven-axis forming machine. The double-head seven-axis forming machine comprises a bottom frame and a rack platform arranged on the bottom frame and further comprises a material counting mechanism, a linear mechanism, a cutting-off mechanism, a feeding mechanism, a wire changing mechanism used for adjusting the angle of a wire, a left forming mechanism, a right forming mechanism, and a wire pulling mechanism which are all arranged on the rack platform, wherein the left forming mechanism and the right forming mechanism are used for bending the wire; the left forming mechanism and the right forming mechanism are arranged on the left side and the right side of the wire changing mechanism correspondingly; and the wire changing mechanism is fixed to the rack platform of the double-head seven-axis forming machine. According to the double-head seven-axis forming machine, the structure is integrally designed, the process steps are simplified, the bending forming time is shortened, the structures of front stations and rear stations are compact, cooperation is tight, machining debugging is easy, convenient and easy to operate, and one-time complex linearbending operation can be achieved; the bending efficiency is high, the manufacture process is good in stability, the bending quality is greatly improved, more convenience is realized, the manual handoperation error is reduced, manpower is saved, a computer is utilized to control multiple axes to conduct an action simultaneously, and debugging is easy; and the cost is reduced, the resources are saved, and the production efficiency is improved.

Owner:GUANGZHOU CAIHONG HARDWARE SPRING CO LTD

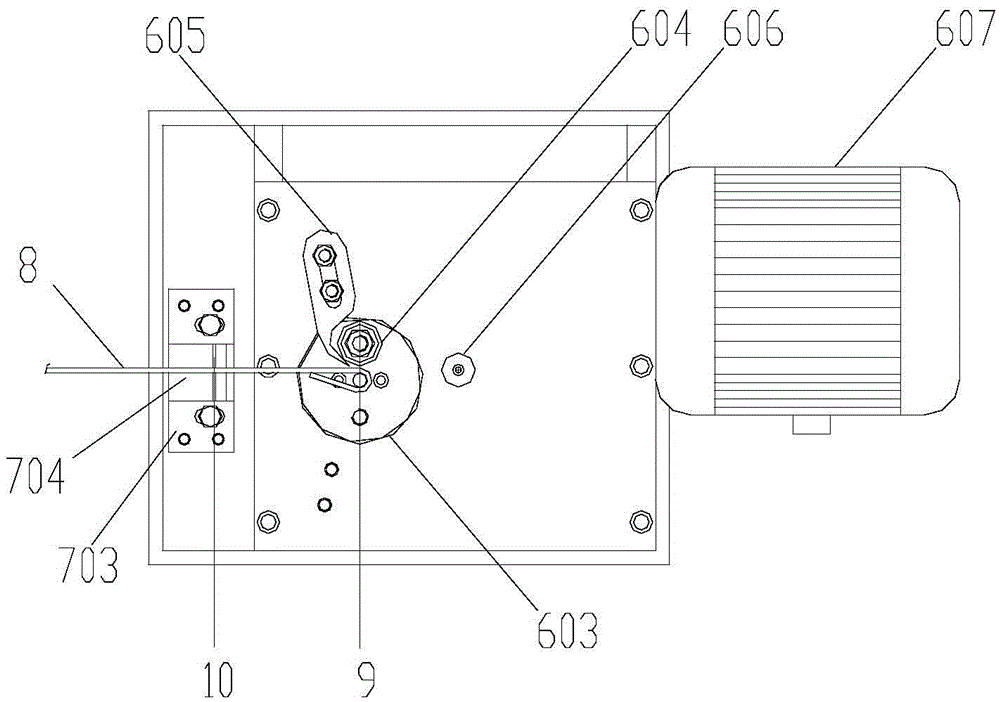

Bending device for thin-walled snake-shaped heat exchange tubes

Provided is a bending device for thin-walled snake-shaped heat exchange tubes. A box body is of an upper-end-open structure defined by a bottom plate, three side plates and a box door hinged to one side plate, and a bending platform is fixed to the upper end opening of the box body; a driving motor is installed in the box body, the driving motor is connected with a bending mechanism through a transmission piece, the lower half part of the bending mechanism is arranged in the box body, the upper half part of the bending mechanism is installed on the bending platform, and a feeding port positioning mechanism arranged on the surface of the bending platform is located on the right side of the bending mechanism; a resetting mechanism connected with the lower end of the bending mechanism is arranged in the box body; and after the driving motor drives the bending mechanism to rotate by a certain angle, bending of a to-be-bent rod piece which penetrates through the feeding port positioning mechanism and is inserted into the bending mechanism is achieved. The bending device overcomes quality defects caused by the deformation of the bending positions of the thin-walled snake-shaped heat exchange tubes, filling is not needed, the bending efficiency is improved, the uniformity of bent finished products is good, the bending process is mechanically completed, the labor intensity of staff isgreatly reduced, and the use value is high.

Owner:宝鸡特钢钛业股份有限公司

Overlaying buckling sheet tooling

ActiveCN105429386AAvoid offsetImprove bending qualityManufacturing stator/rotor bodiesStructural engineeringMechanical engineering

The invention belongs to the technical field of stator overlaying. The overlaying buckling sheet tooling comprises a base and a core tyre; an annular base plate is fixed on the surface of the base; the core tyre is placed on the base plate; an axle hole is formed in the center of the base; the core tyre is formed by multiple detachable split cores in a spliced manner; an inner hole is formed in the core tyre; the inner hole is a taper hole that is gradually reduced from upper to lower; an expansion tyre is glidingly matched in the taper hole; an annular lower pressing ring is fixed on the surface of the base plate; the lower pressing ring is positioned on the periphery of the core tyre; a matched limiting structure is arranged on the surface, opposite to the split cores, of the inner circle of the lower pressing ring; the expansion tyre, the core tyre and the lower pressing ring are all concentric with the axial ole of the base; two opposite sliding grooves are formed in the base in a radial direction of the axle hole; clamping jaws are glidingly matched in the sliding grooves; the inserting ends, in the sliding grooves, of the clamping jaws are connected with the end parts of the sliding grooves through springs; and stop pins fixed with the base are arranged on the clamping jaws. The scheme of the overlaying buckling sheet tooling is high in universality, high in alignment precision and good in bending quality of the buckling sheet.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

Plate bending device for computer mainframe box production

The invention provides a plate bending device for computer mainframe box production, and belongs to the technical field of computer mainframe box production. The plate bending device comprises a bottom box. A supporting table is slidably arranged on the upper portion of the bottom box. One side of the supporting table is connected with a pressing assembly through an adjusting assembly. A bending assembly is arranged above the pressing assembly, the pressing assembly comprises a base body and a cover body hinged to the upper portion of the base body, the cover body is connected with the side face of the base body through a locking assembly, and clamping grooves corresponding to each other are arranged in the side, facing the base body, of the cover body and the side, facing the cover body,of the base body. The plate bending device has the advantages of good bending quality, and the bending part of the plate can be heated to soften the plate by arranging the heating plate so that the bending treatment of the plate by the bending assembly is more convenient, the bending quality of the plate is improved, the bending difficulty of the plate is reduced and the problem that the plate isbroken during cold bending is effectively avoided.

Owner:广州市嘉翔电脑设备有限公司

Air pressure pipe bending machine

Owner:GOLD MANTIS CONSTR DECORATION

Flexible display screen bending jig

The invention provides a flexible display screen bending jig, comprising a base on which a stage, a rotating shaft arranged spaced apart from the stage, a rotating plate connected with one end of therotating shaft, and a monitoring lens arranged at a side part of the rotating shaft are arranged. The flexible display screen to be bent is placed on the stage, a bending region thereof is located atthe rotating shaft, and an FPC thereof is located on the rotating plate. When in use, the rotating shaft rotates so that the rotating plate rotates upward, thereby bending the bending region, and themonitoring lens continuously monitors the bending shape of the bending region so as to obtain the bending shape data of the bending region at a required bending angle. The invention provides a flexible display screen bending jig, which can comprehensively monitor the bending state of the flexible display screen bended in the flexible display screen, and ensure that the shape after bending is in accordance with the design, so as to improve the poor manufacturing process and the reliability abnormality caused by subsequent bending.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

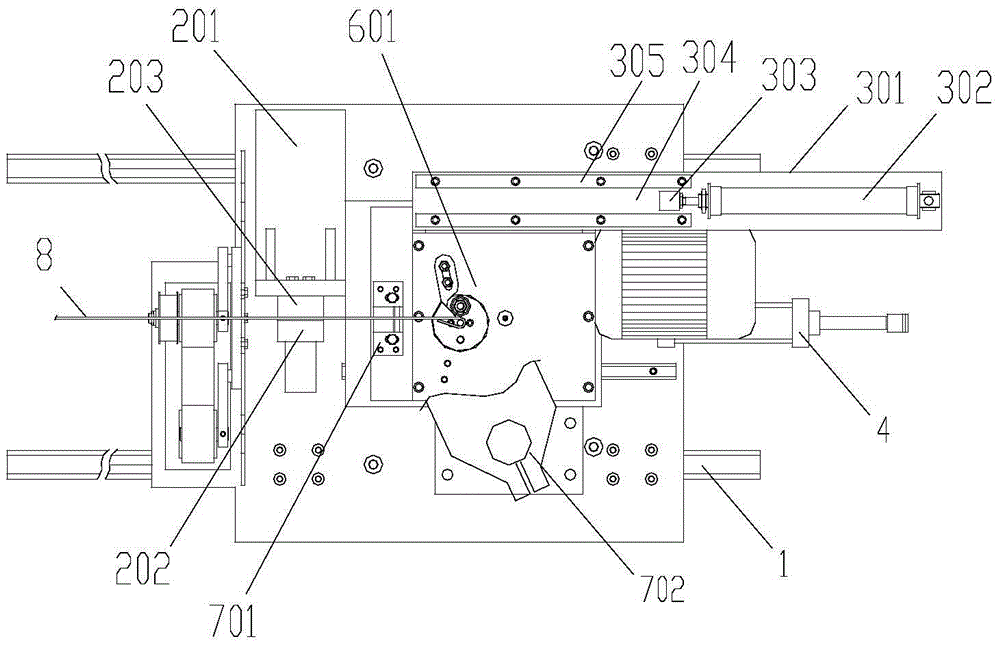

Numerical control pipe bend forming device

The invention provides a numerical control pipe bend forming device. The device comprises a feed rotating mechanism mounted on a frame for conveying pipes, and a pipe bending mechanism; the pipe bending mechanism is positioned in a pipe outlet of the feed rotating mechanism; the pipe bending mechanism comprises a connecting base, an adjusting module for driving the connecting base to move in the vertical direction and the horizontal direction, a bend clamping module, and two sets of profiling modules respectively arranged on two sides of the connecting base; the bend clamping module comprises a rotating arm rotationally connected with the connecting base, a rotating motor for driving the rotating arm to rotate along a vertical rotating shaft, a mold bending base and a mold clamping base; and the profiling modules comprise profiling bases, profiling cushion plates and profiling mounting plates. The numerical control pipe bend forming device realizes left-right bending formation, is not liable to generate deformation in the pipe bending process, is better in bending quality, and is high in production efficiency.

Owner:FOSHAN TIANJIAN MECHANICAL CO LTD

Bending mechanism for reinforcing steel bar truss web rib

The invention discloses a bending mechanism for a reinforcing steel bar truss web rib, in particular a bending mechanism for bending a wave trough of a reinforcing steel bar truss web rib, which is formed through welding, left and right. The bending mechanism for the reinforcing steel bar truss web rib comprises a rack, wherein supporting oil cylinder mounting brackets which are distributed symmetrically are arranged on the rack; supporting oil cylinders are arranged on the supporting oil cylinder mounting brackets; piston rods for supporting the oil cylinders are fixedly connected with supporting blocks; a rotary block mounting bracket is arranged below the supporting blocks; rotary blocks are arranged at ends, corresponding to the supporting blocks, of the rotary block mounting bracket;the rotary blocks are hinged with rotating shafts on the rack; a rotary driving mechanism is arranged at the other end, which is connected with the rotary blocks, of the rotary block mounting bracket; and the rotary driving mechanism drives the rotary blocks to rotate around revolving shafts through the rotary block mounting bracket. The bending mechanism for the reinforcing steel bar web rib is simple and compact in structure, convenient to mount and use, high in automation degree and bending speed, safe and reliable; moreover, the bending quality is improved.

Owner:WUXI WEIHUA ELECTRIC WELDING MFG

Airplane engine fuel oil total pipe bend filling and technique

InactiveCN101054506AStable performance of filling processImprove bending qualityOther chemical processesHollow article cleaningJet aeroplaneSodium bicarbonate

An airplane engine fuel manager bending filling and its craft in machinery manufacturing field are provided. The product preparing craft is correctly weighing material weight by proportion, adding the disodium hydrogen phosphate, trisodium phosphate, sodium bicarbonate by proportion into the material preparing vessel, fully mixing for two hours, adding stabiliser, seal preserving the prepared filling packing. The filling craft of the conduit product is weighing the fillings, enterring the working state after the filling melting achieves the controlling temperature, performing the conduit filling craft. The cleaning craft of the bending conduit product is putting the moulded conduit into the cleaning groove, emitting tap water, heating and stirring, controlling water temperature of 80-90 DEG C for 20-30 minutes, taking out conduit, discharging the water solution, repeating 5 times, taking out conduit and drying. The product and the craft is scientific and novel and has a low cost, a stability to the alloy conduit material non-erosion, alloy conduit bending filling easily being cleaned, and alloy conduit bending filling packing craft.

Owner:沈阳华铁异型材有限公司 +1

U-shaped double-right-angle bending device for plate

PendingCN110090878AReduce labor intensityImprove bending qualityShaping toolsEngineeringMechanical engineering

The invention provides a U-shaped double-right-angle bending device for a plate. The U-shaped double-right-angle bending device for the plate comprises a platform base, an upper die, a lower die and asecondary bending die. A die groove is formed in the platform base, the bottom of the lower die is mounted at the bottom of the die groove of the platform base through a lower die spring, the upper die is located above the lower die and is right opposite to the lower die, a first bending right-angle groove is formed in the upper end of the lower die, and a stamping head corresponding to the firstbending right-angle groove is arranged at the bottom of the upper die. The secondary bending die is located on the side portion of the lower die, the lower die drives the secondary bending die to rotate around a rotary boss, and secondary bending is completed. Two times of right-angle bending procedures of a U-shaped double-right bending plate are completed through onepressing stroke of the upperdie, the bending quality is improved, workers do not need to carry the plate back and forth, workbench conversion is not needed, the bending working efficiency is greatly improved, and the labor intensity of the workers is reduced.

Owner:HEBEI HUPAI GRP AODI CABINET IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com