Steel bar bender for building

A technology for steel bar bending and construction, applied in the field of steel bar bending machines for construction, can solve problems such as affecting the bending and bending accuracy of steel bars, reducing mechanical production efficiency, increasing labor intensity of workers, etc., achieving high bending accuracy and bending quality, and simple structure. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

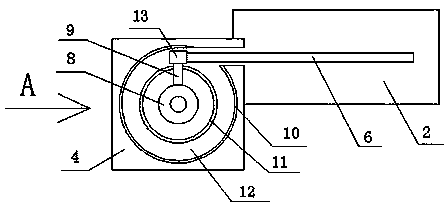

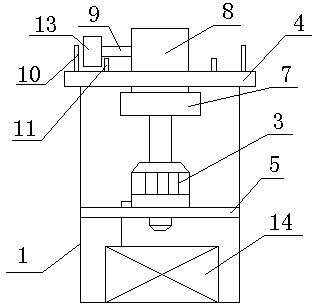

[0012] refer to figure 1 with figure 2 The shown a steel bar bending machine for construction includes a frame 1, a transmission mechanism 2 and a driving device 3, and a worktable 4 arranged on the frame 1, and a support plate 5 arranged on the frame 1, so that The transmission mechanism 2 is provided with steel bars 6, the driving device 3 is installed on the support plate 5, the output shaft of the driving device 3 is provided with a shaft sleeve 7, and a rotating shaft 8 is connected above the shaft sleeve 7. The rotating shaft 8 is provided with a working beam 9, and the worktable 4 is provided with a first curved working board 10 and a second curved working board 11, and a curved working board 10 and a second curved working board 11 are formed between them. A circular space 12, one end of the working beam 9 extends into the circular space 12, and a fixing device 13 for fixing the reinforcing bar 6 is provided on the working beam 9 extending into the circular space 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com