Patents

Literature

91results about How to "Increase hydrostatic pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

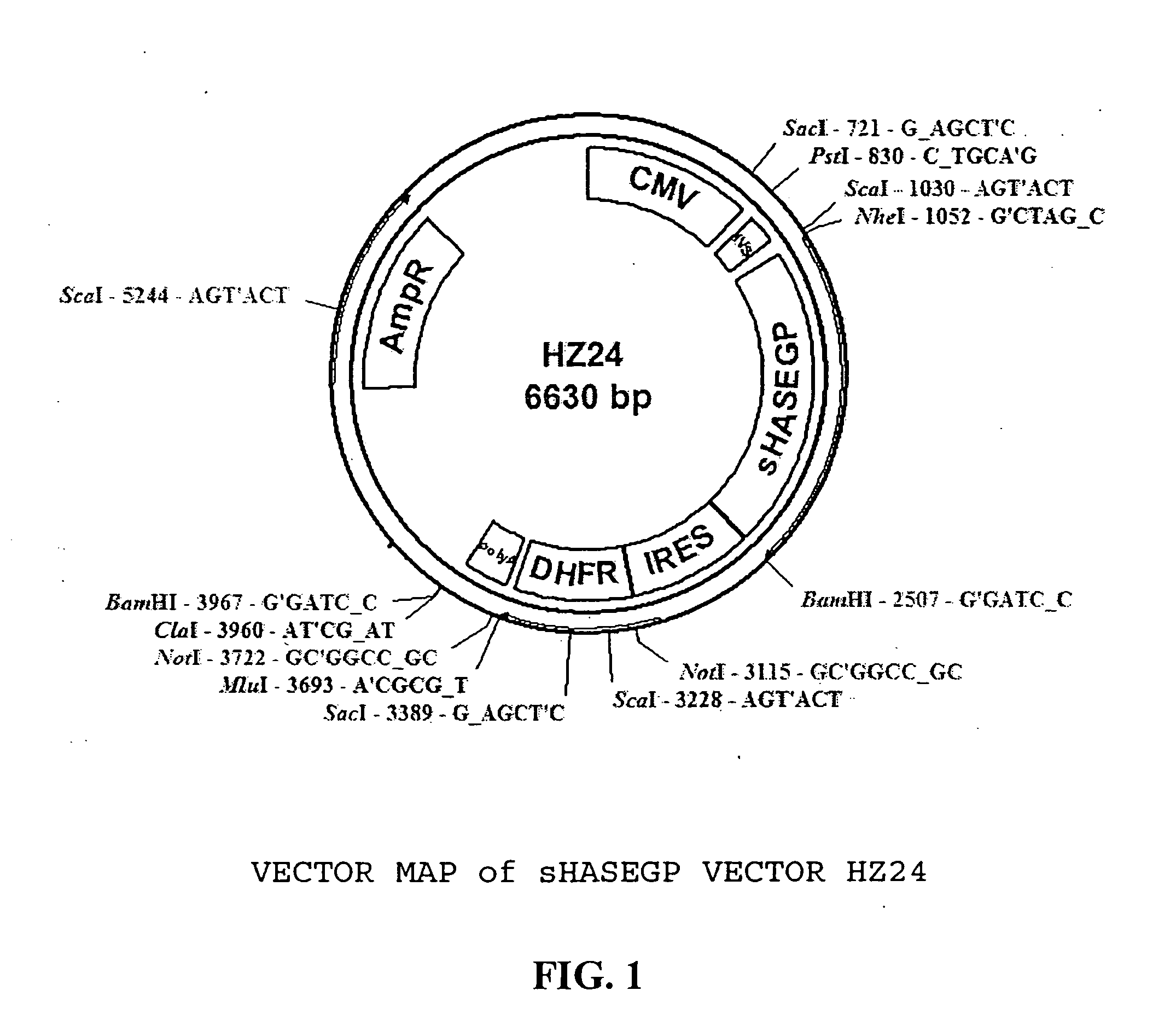

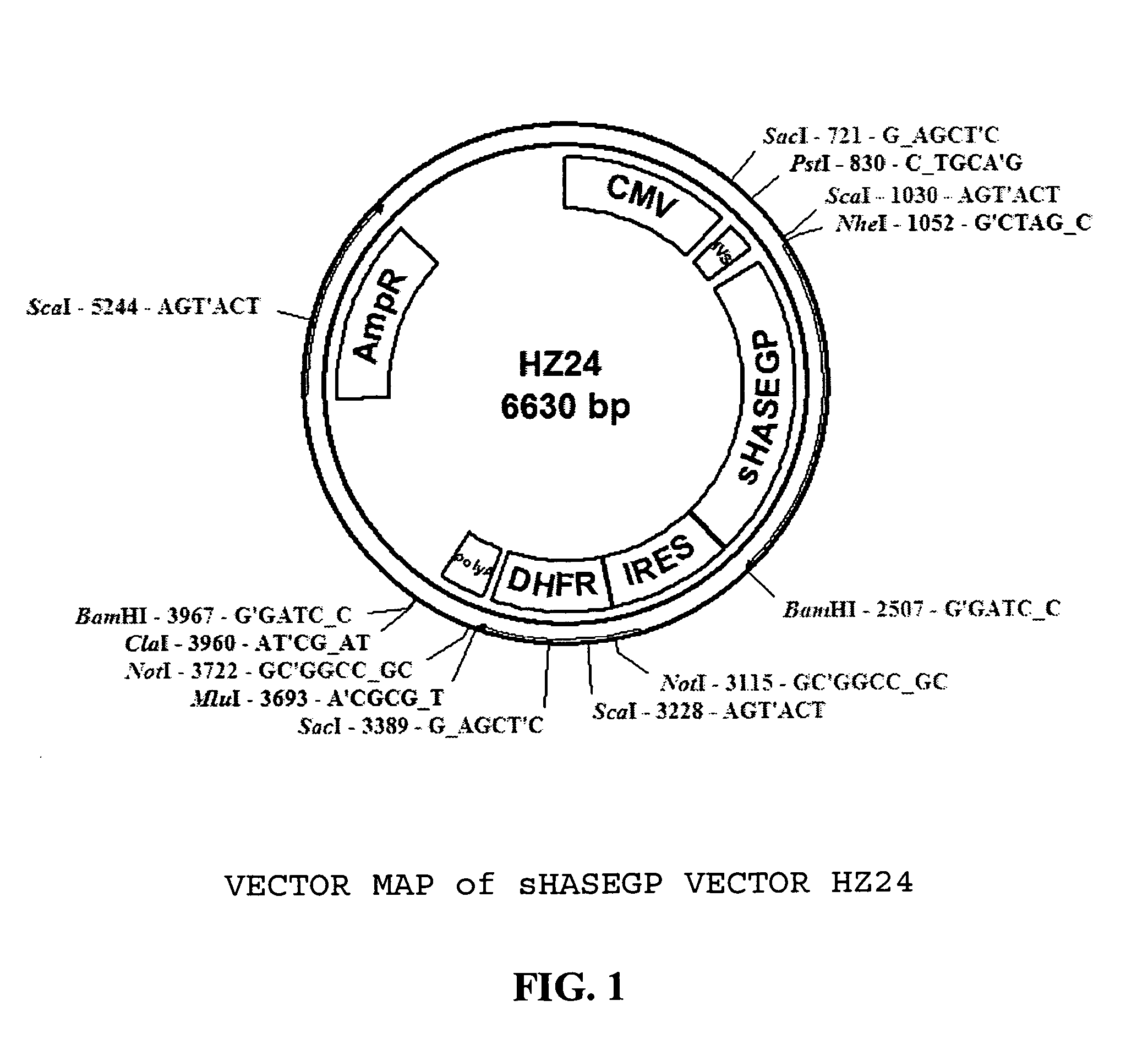

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminogly ycanases

PendingUS20060104968A1Improve extentIncrease ratingsSenses disorderNervous disorderHyaluronidaseRecombinant glycoprotein

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminoglycanases

ActiveUS20050260186A1Improve extentIncrease ratingsAntibacterial agentsSenses disorderHyaluronidasePathology diagnosis

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

Method For Completing Injection Wells

InactiveUS20040014606A1Reducing surface storage capacity requirementEliminate needCleaning apparatusFluid removalEngineeringWater well

This invention proposes a method for completing an interval of an open-hole injection wellbore penetrating a subterranean formation, said wellbore being communicating with the formation by way of an interface that comprises at least a filter cake invaded zone comprising bridging materials and other embedded solid materials, said method comprising the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loose some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid comprising suspending additives; and then injecting a dissolving fluid comprising a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

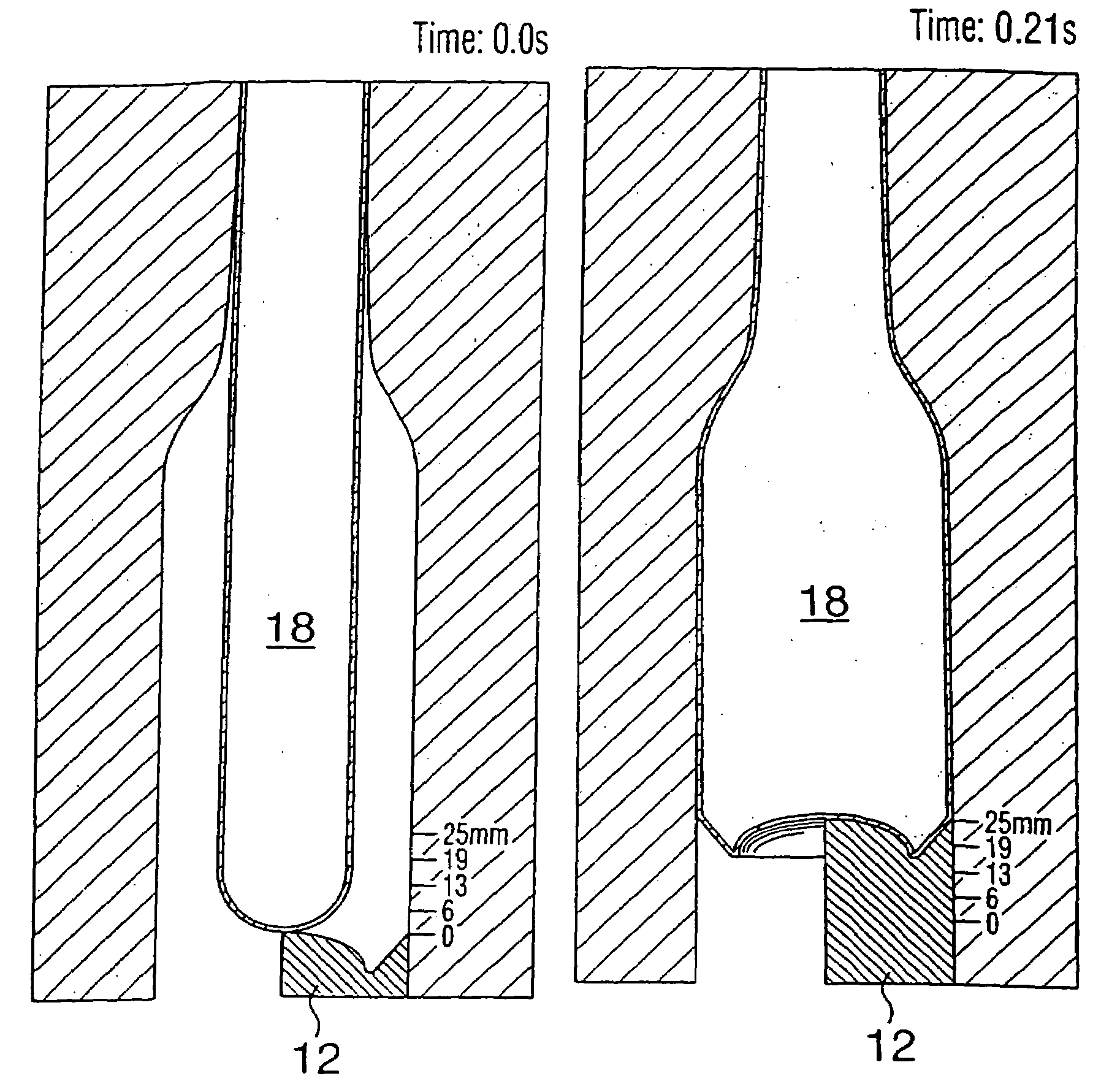

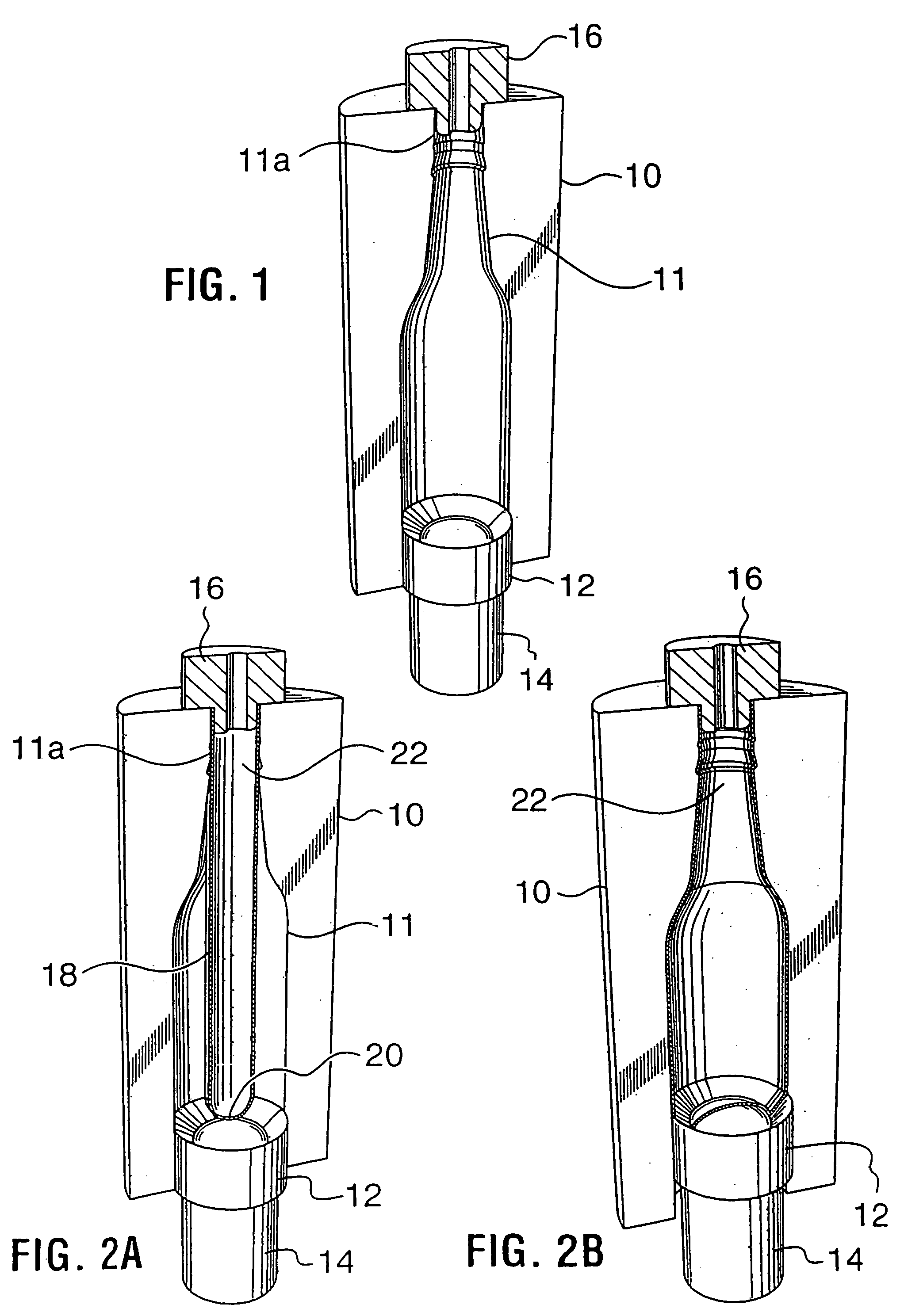

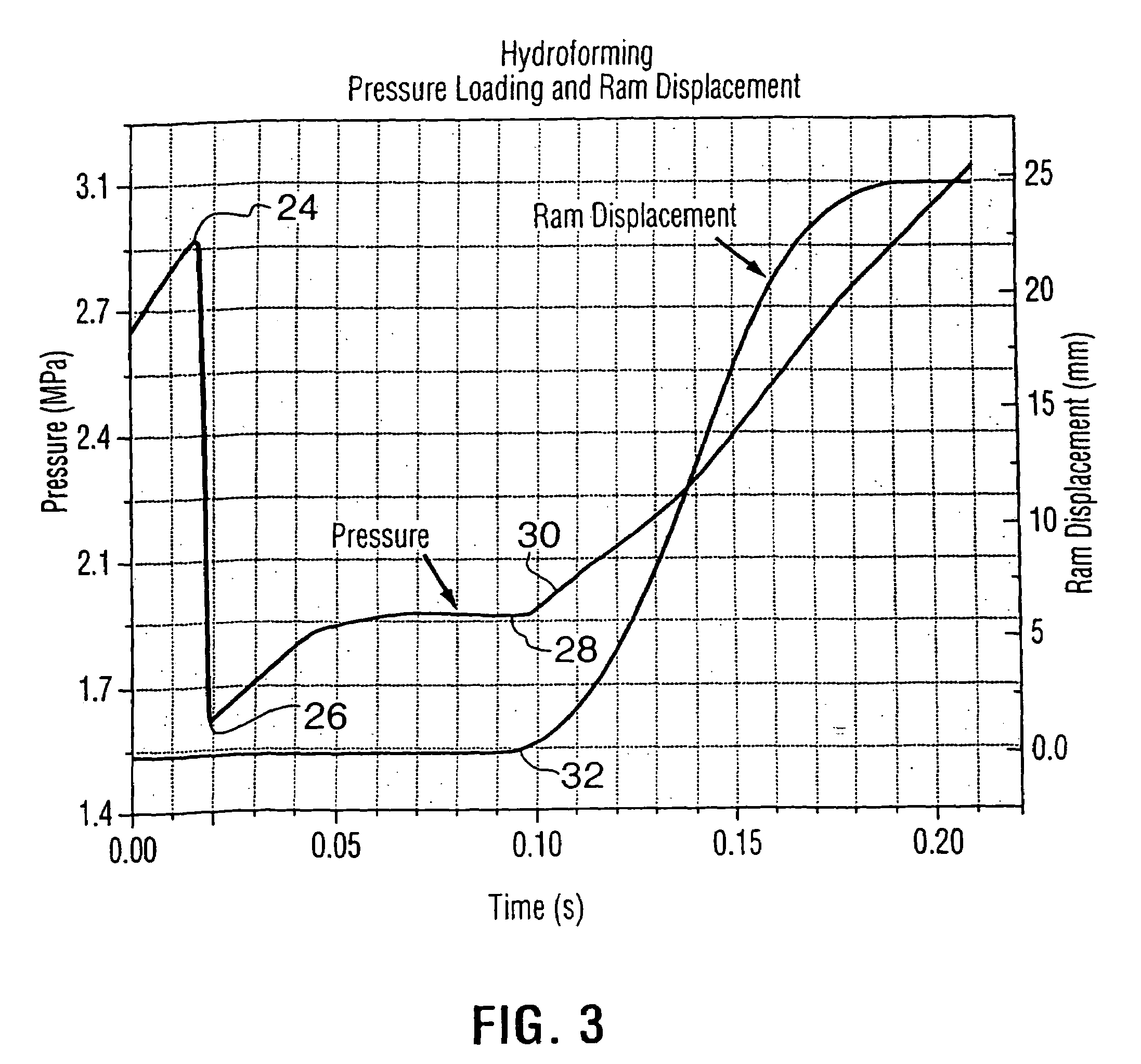

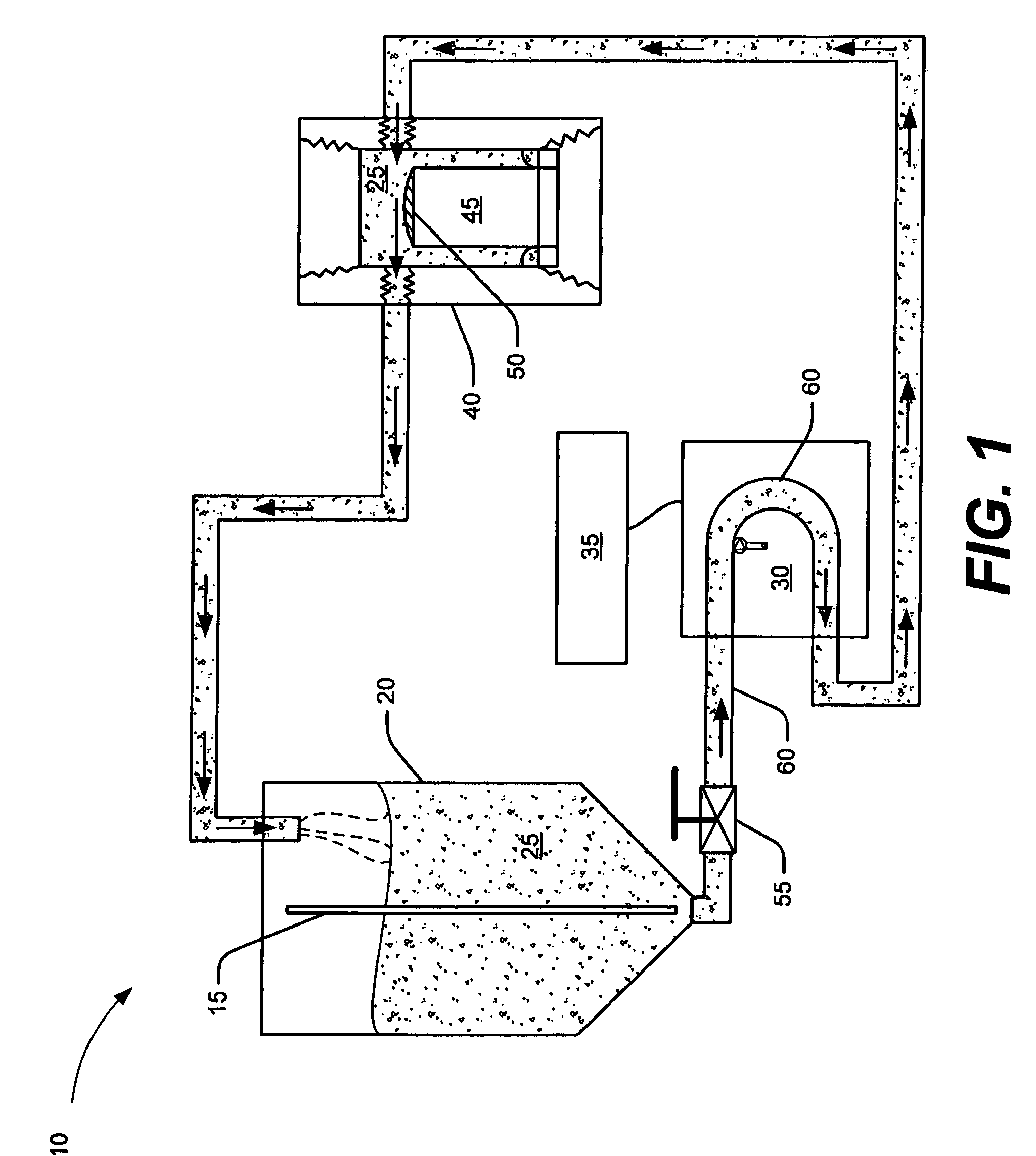

Methods of and apparatus for pressure-ram-forming metal containers and the like

A method of forming a bottle-shaped or other contoured metal container by subjecting a hollow metal preform having a closed end to internal fluid pressure to cause the preform to expand against the wall of a die cavity defining the desired shape, and advancing a punch by means of a backing ram into the die cavity to displace and deform the closed end of the preform either before or after expansion begins but before it is complete. The pressure-subjecting step is performed by simultaneously subjecting the preform in the die cavity to independently controllable internal and external positive fluid pressures and varying the difference between them to control strain rate. Apparatus for performing the method includes a split die with plural split inserts disposed in tandem to define the die cavity wall and heaters respectively inserted within the preform and arranged to heat the backing ram.

Owner:MONTEBLLO PACKAGING A DIV OF GREAT PACIFIC ENTERPRISE INC

Well completion spacer fluids containing fibers and methods

Owner:HALLIBURTON ENERGY SERVICES INC

Well completion foamed spacer fluids and methods

InactiveUS6852676B1Drilling fluidEfficient removalOther chemical processesFlushingWellboreEnvironmental geology

Owner:HALLIBURTON ENERGY SERVICES INC

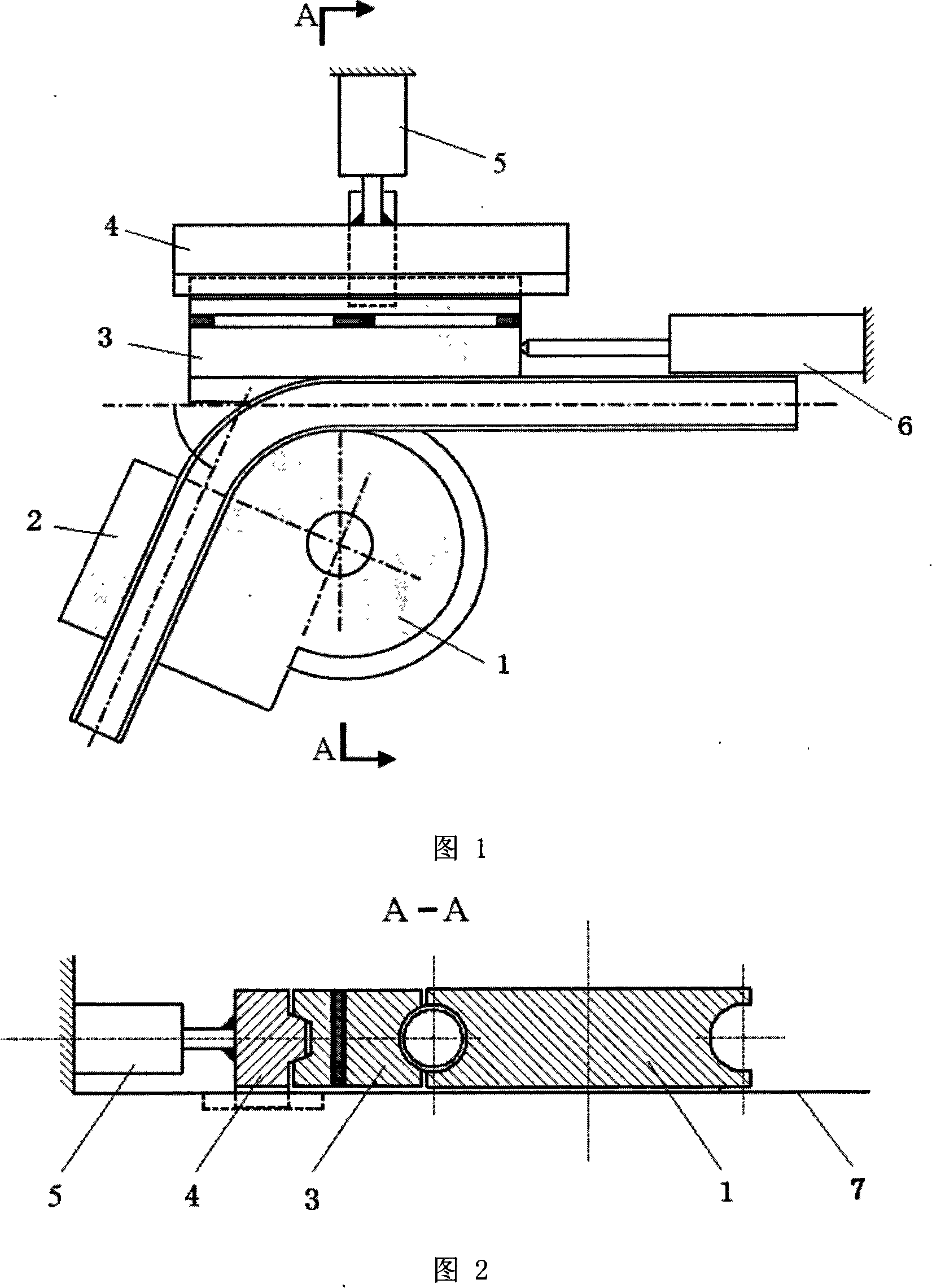

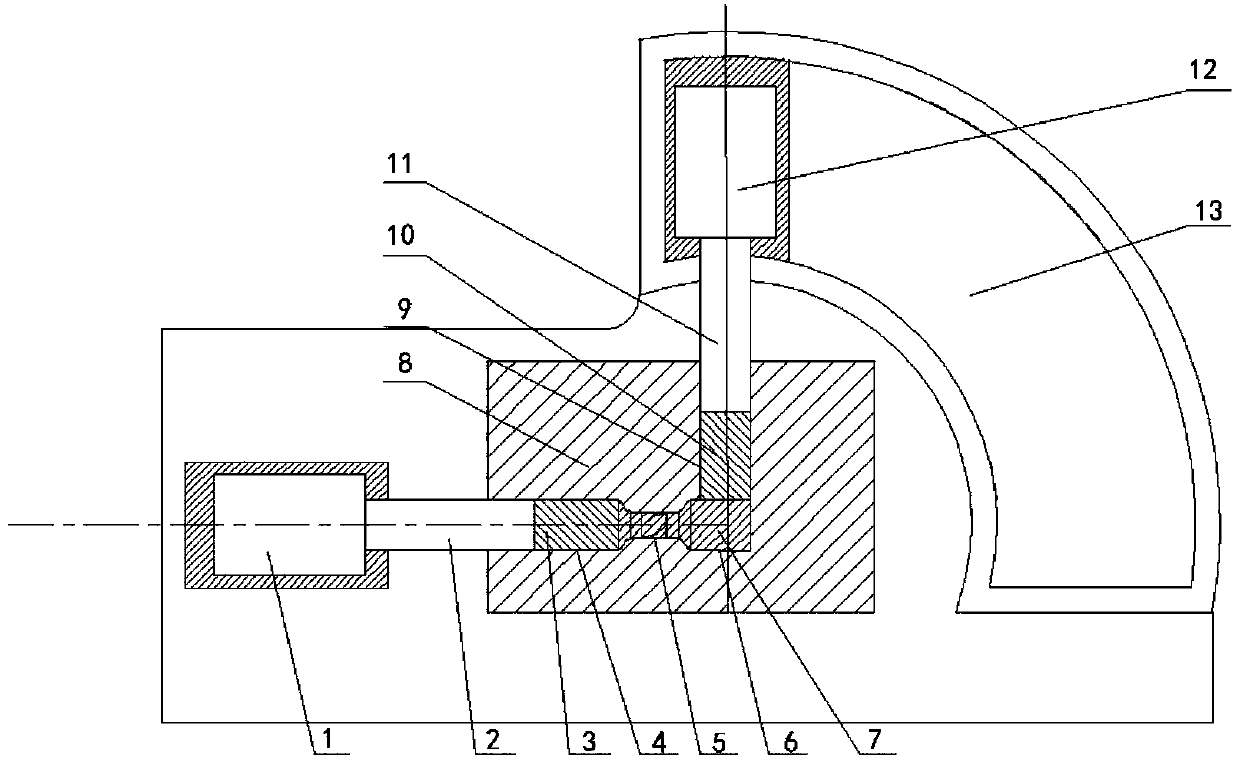

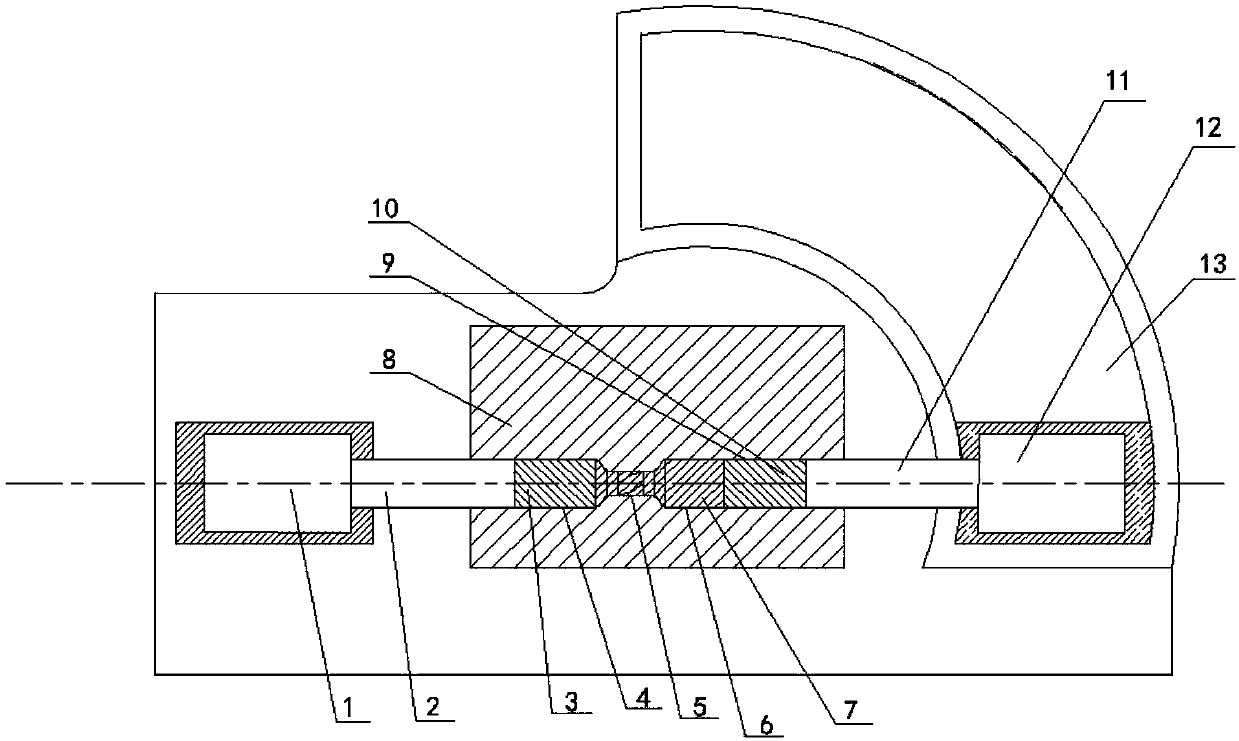

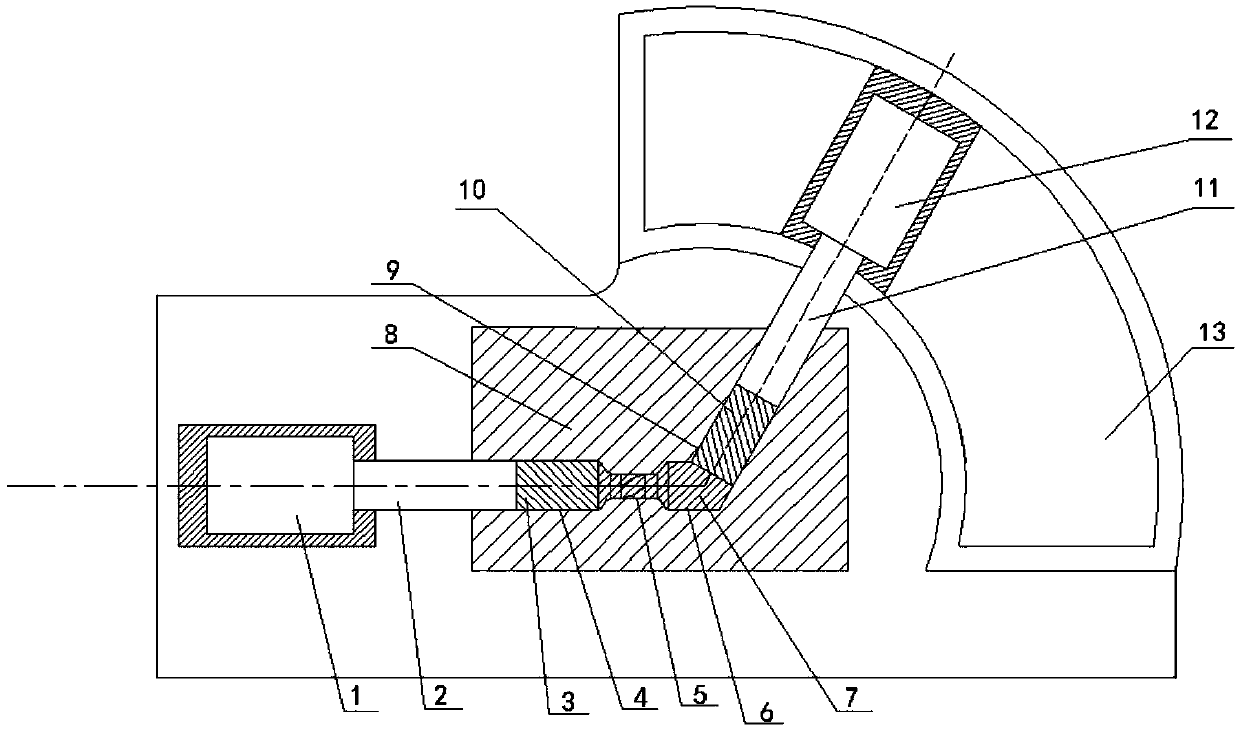

Tube bending forming processing device

InactiveCN101147934AImprove memory propertiesIncrease hydrostatic pressureShaping toolsHydraulic cylinderTangential force

The present invention discloses a bending forming processing equipment for pipe material. Said equipment includes the following several portions: bending die clamping die, pressing die, pressurizing plate, circumferential pressure-applying hydraulic cylinder, axial propulsion hydraulic cylinder and bending machine working table. The circumferential pressure-applying hydraulic cylinder pushing rod is rigidly connected with the pressurizing plate, the axial propulsion hydraulic cylinder pushing rod is flexibly connected with the pressing die end portion. The circumferential pressure-applying hydrautic cylinder can be used for driving said pressurizing plate to circumferentially apply pressure to the pipe material, and the axial propulsion hydraulic cylinder can be used for driving pressing die to apply tangential force to the pipe material, the bending die is fixed on the bending machine working table by means of bending centre, and bending die, pressing die and clamping die respectively have the groove fit with the outer diameter of said pipe material, the pressurizing plate is connected with the pressing die by means of dovelail groove, and the pressurizing plate also is connected with the bending machine working table by means of dovetail groove.

Owner:SHANGHAI JIAO TONG UNIV

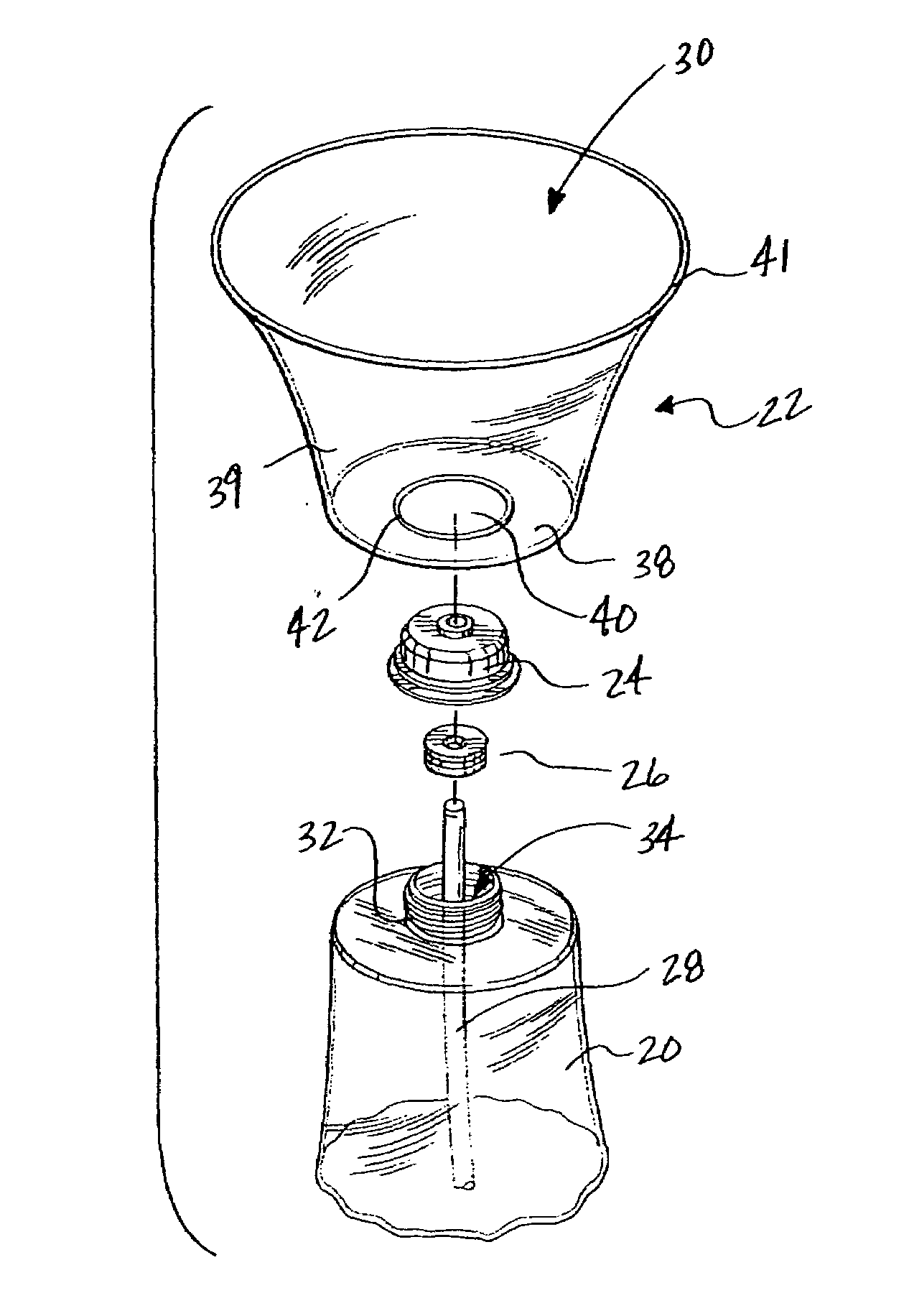

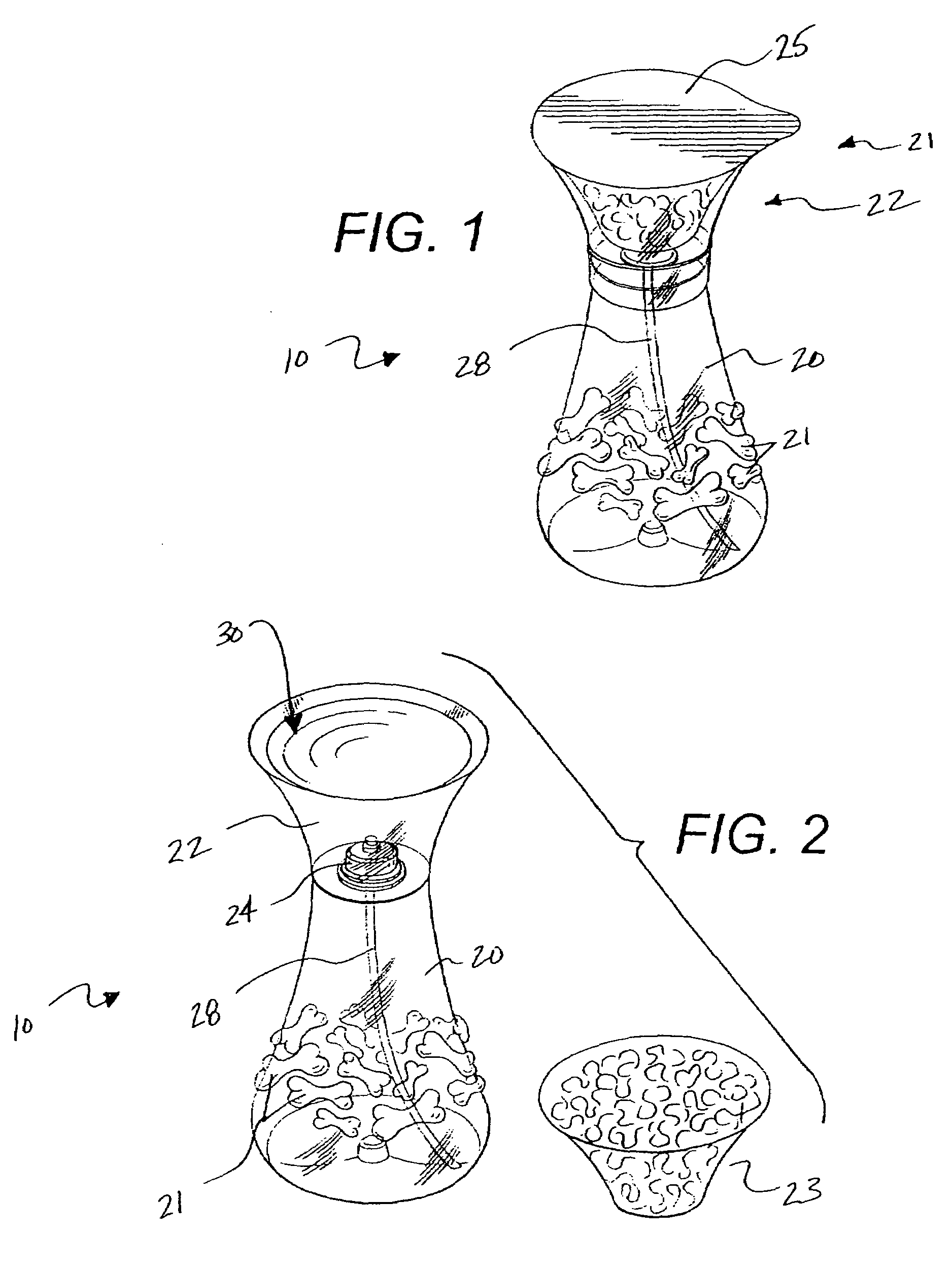

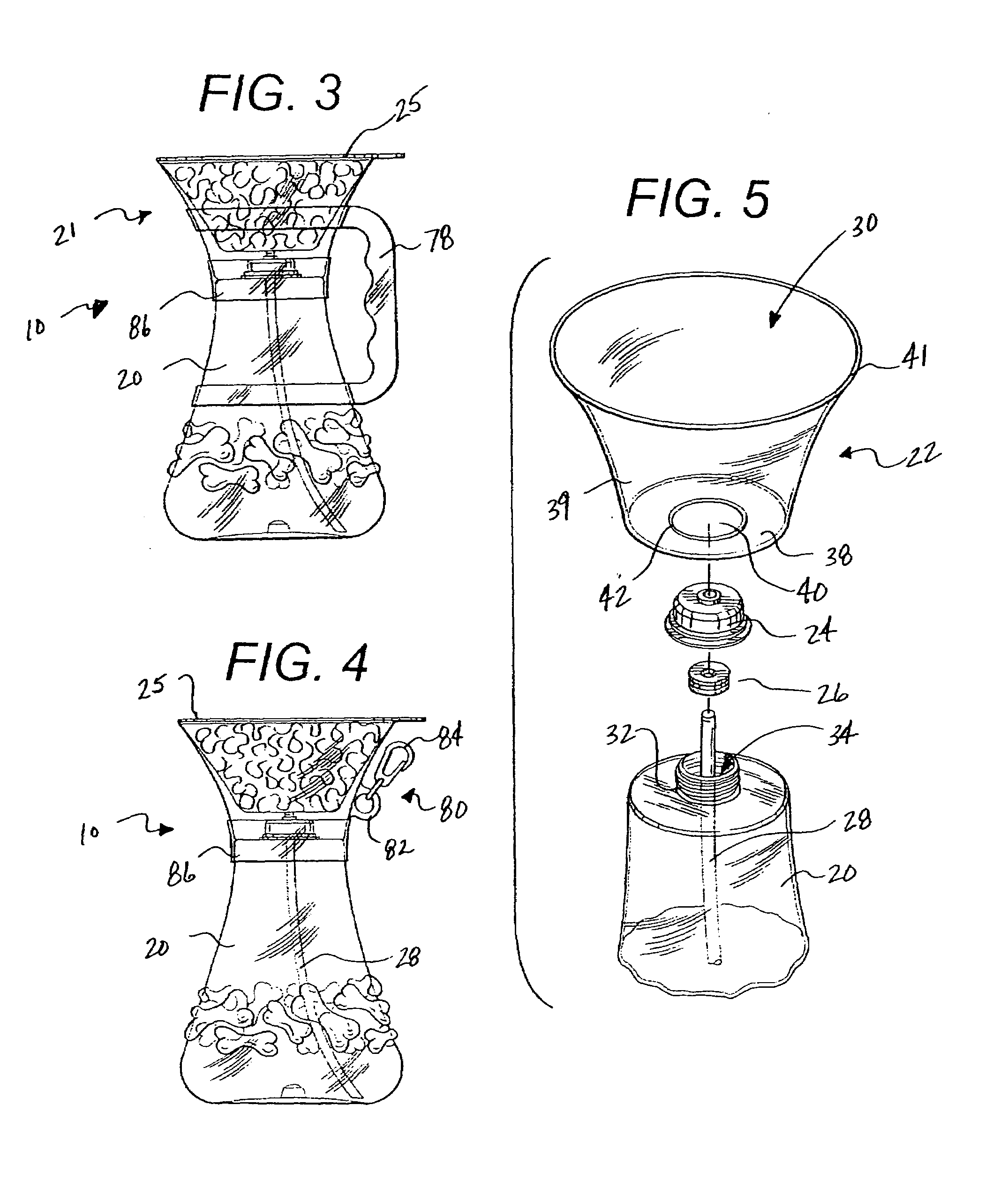

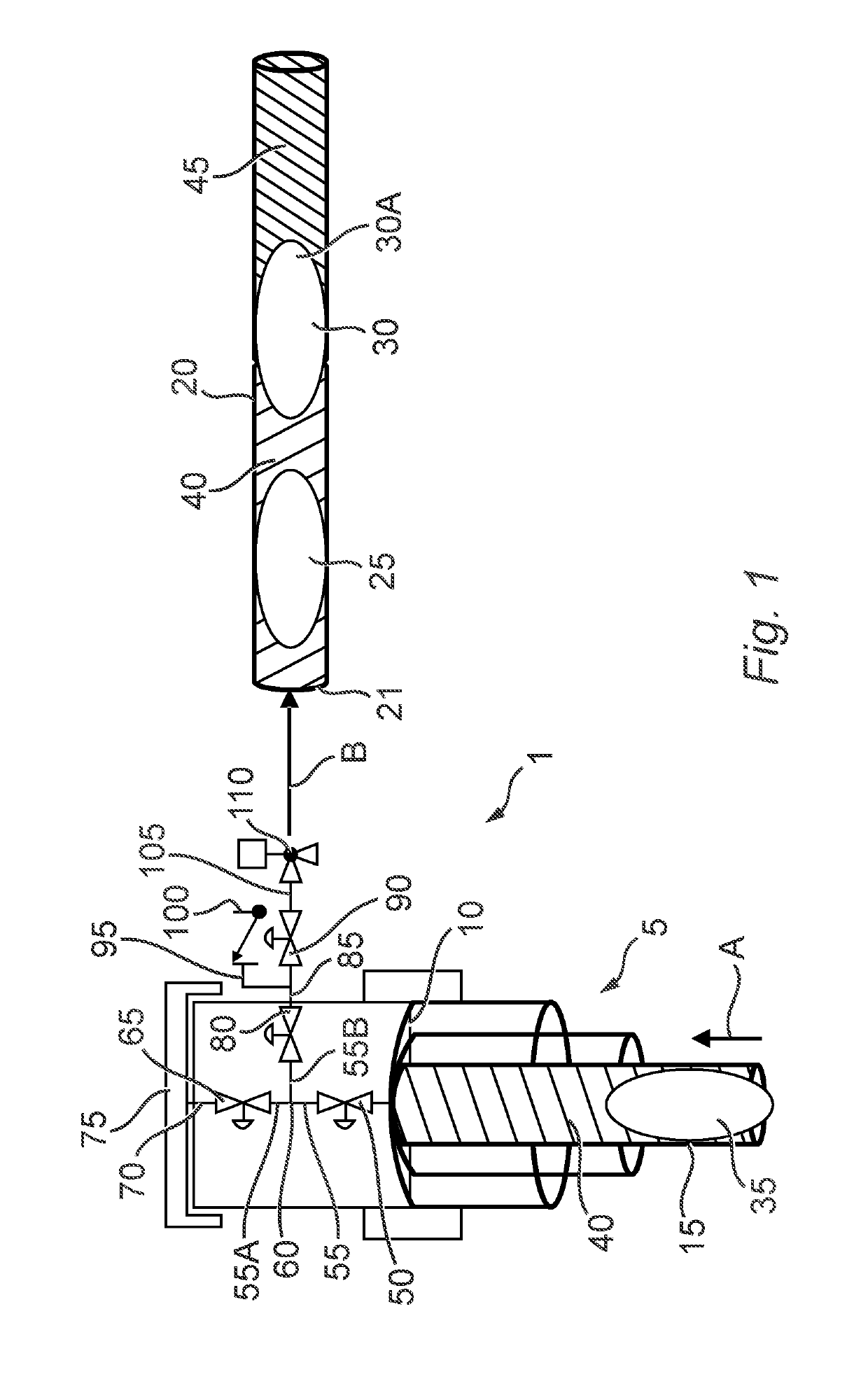

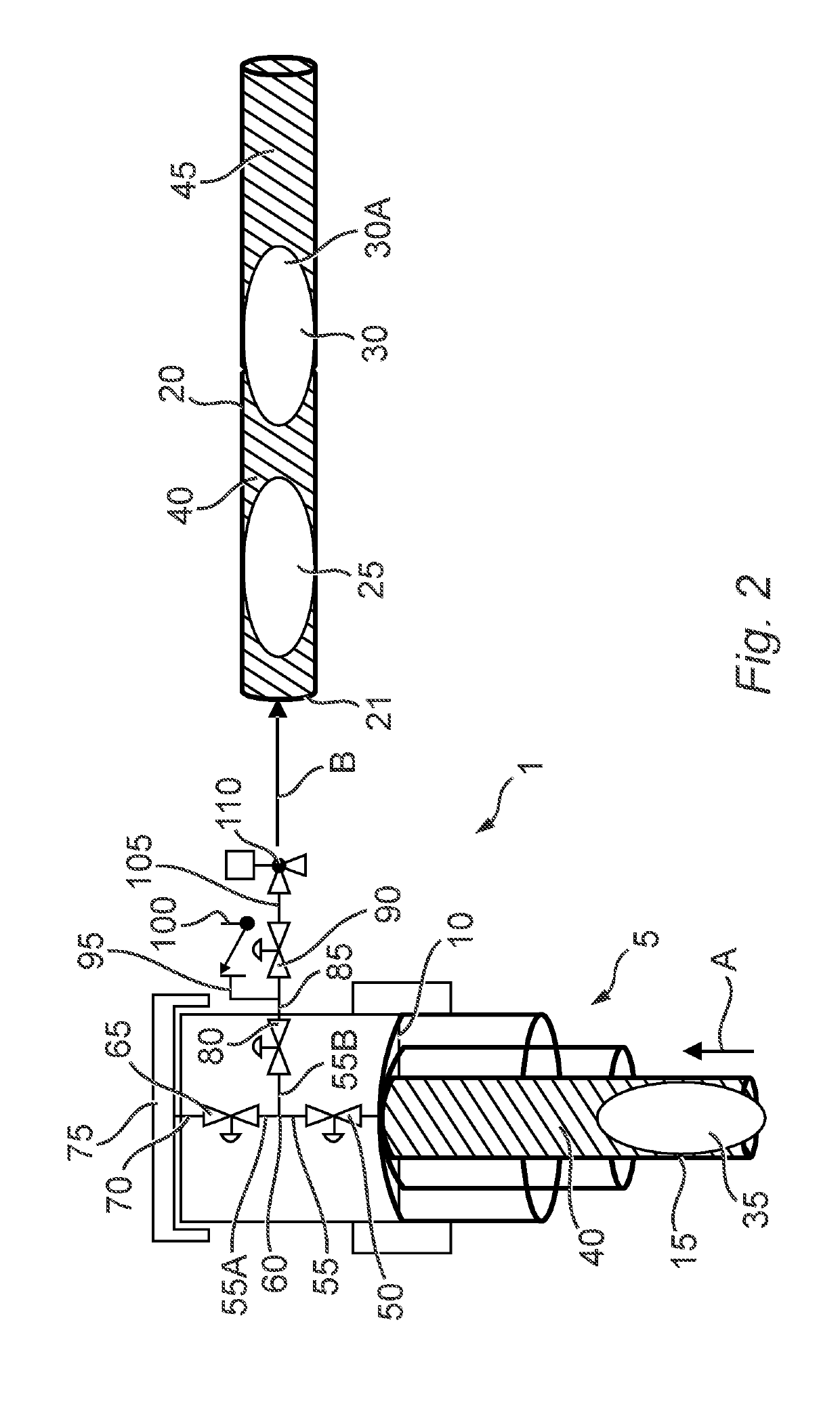

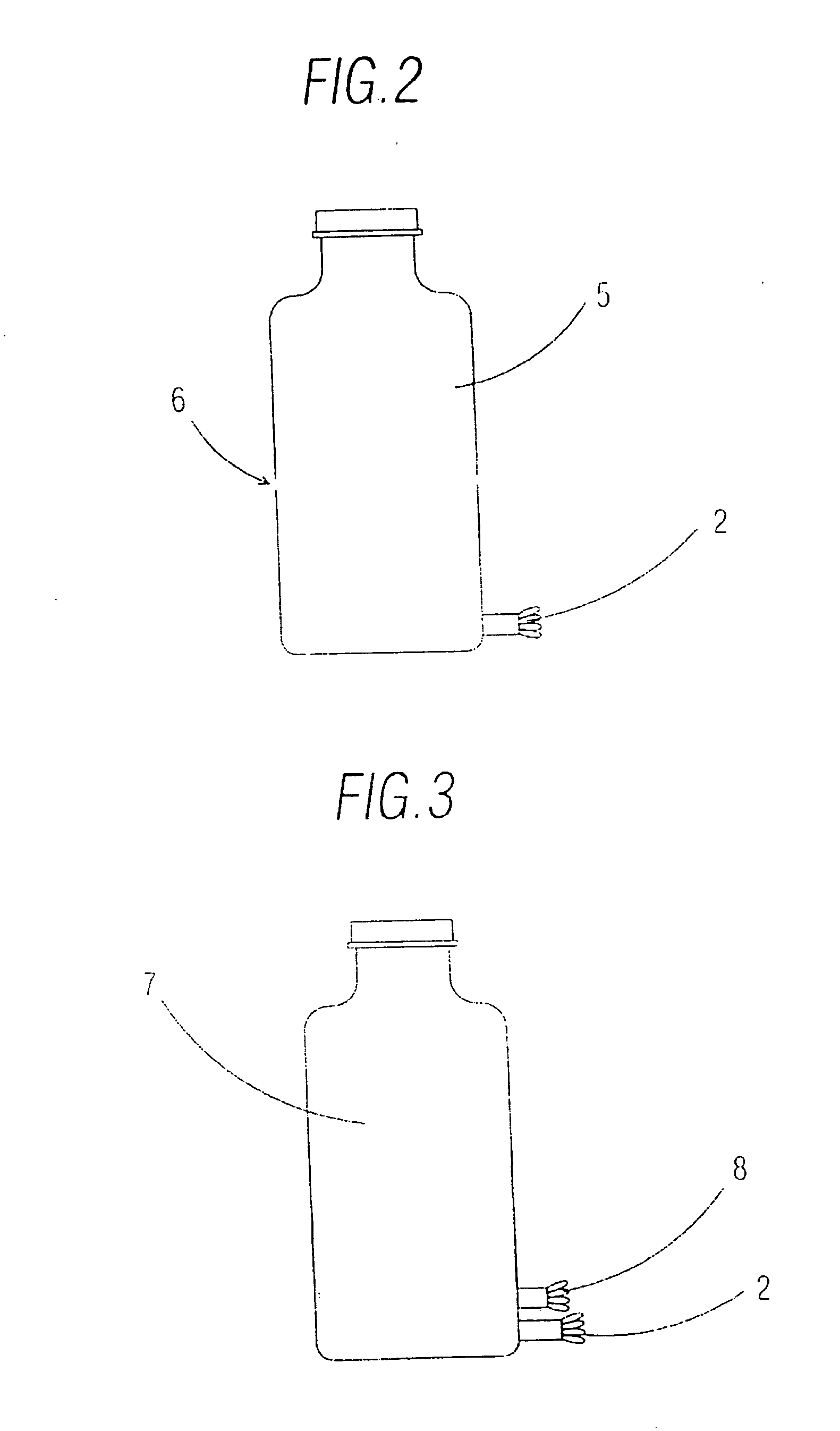

Portable drink container for pets

InactiveUS7549395B2Improve versatilityIncrease hydrostatic pressureAnimal watering devicesLiquid transferring devicesHydrostatic pressureEngineering

A portable drink container includes a fluid vessel having an upwardly extending neck with an outlet opening. A removable cap has a central aperture and a cavity that engages the vessel neck. A drinking bowl includes a bottom wall with a central opening defined by an internal edge of the bottom wall. A lower peripheral channel of the cap slidingly receives the bottom wall edge to connect the cap and the drink bowl, whereby the cap extends through the central opening of the bowl. A flexible conduit is positioned within the vessel and extends the cap and the central opening of the drink bowl. The conduit defines a passageway for fluid to travel from the vessel into the drink bowl. An elastomeric plug may be secured within the cap to stabilize the conduit. The pet owner applies a compressive force on the vessel to increase the hydrostatic pressure thereby forcing liquid through the conduit and into the drink bowl.

Owner:STENBERG MARK

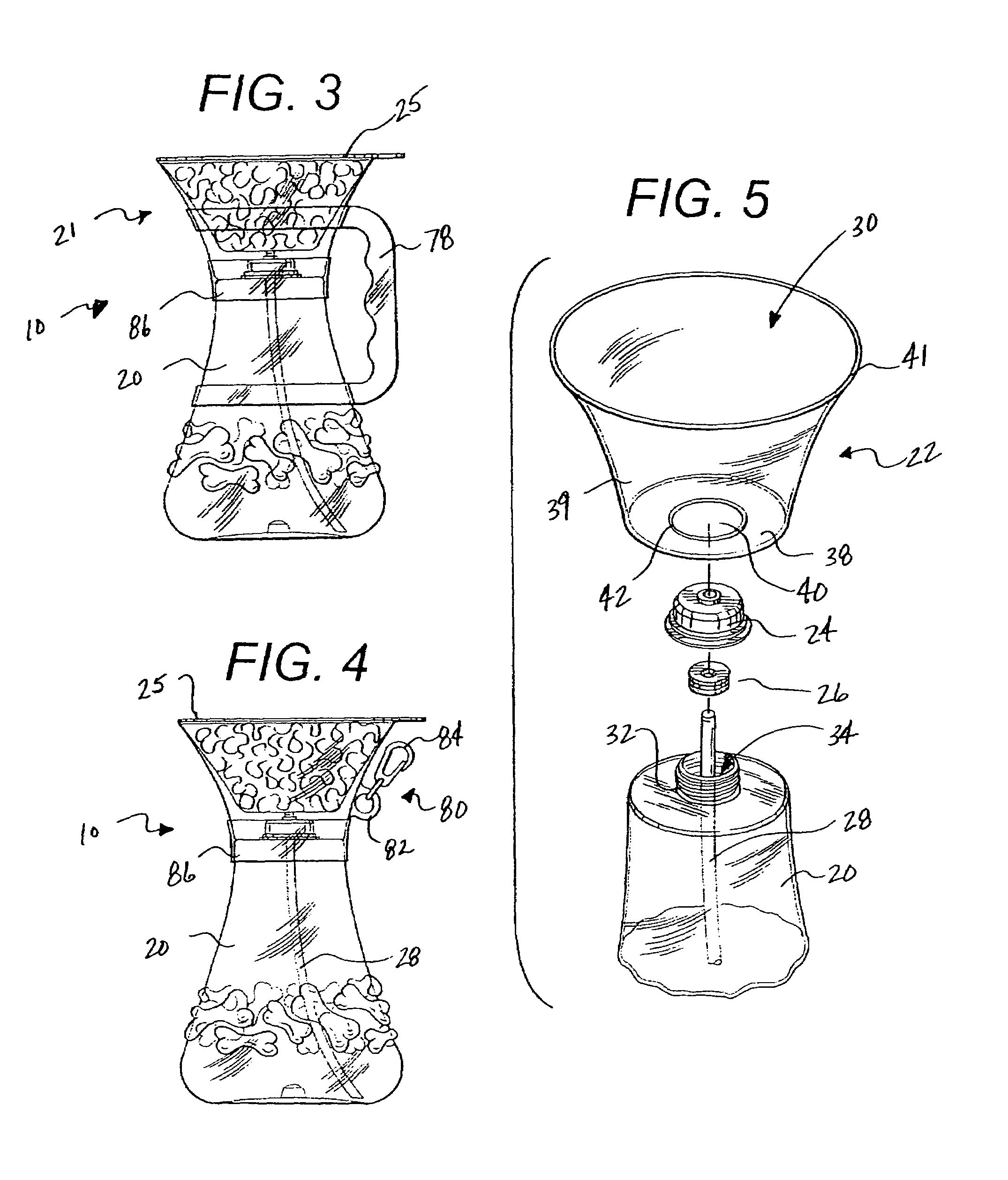

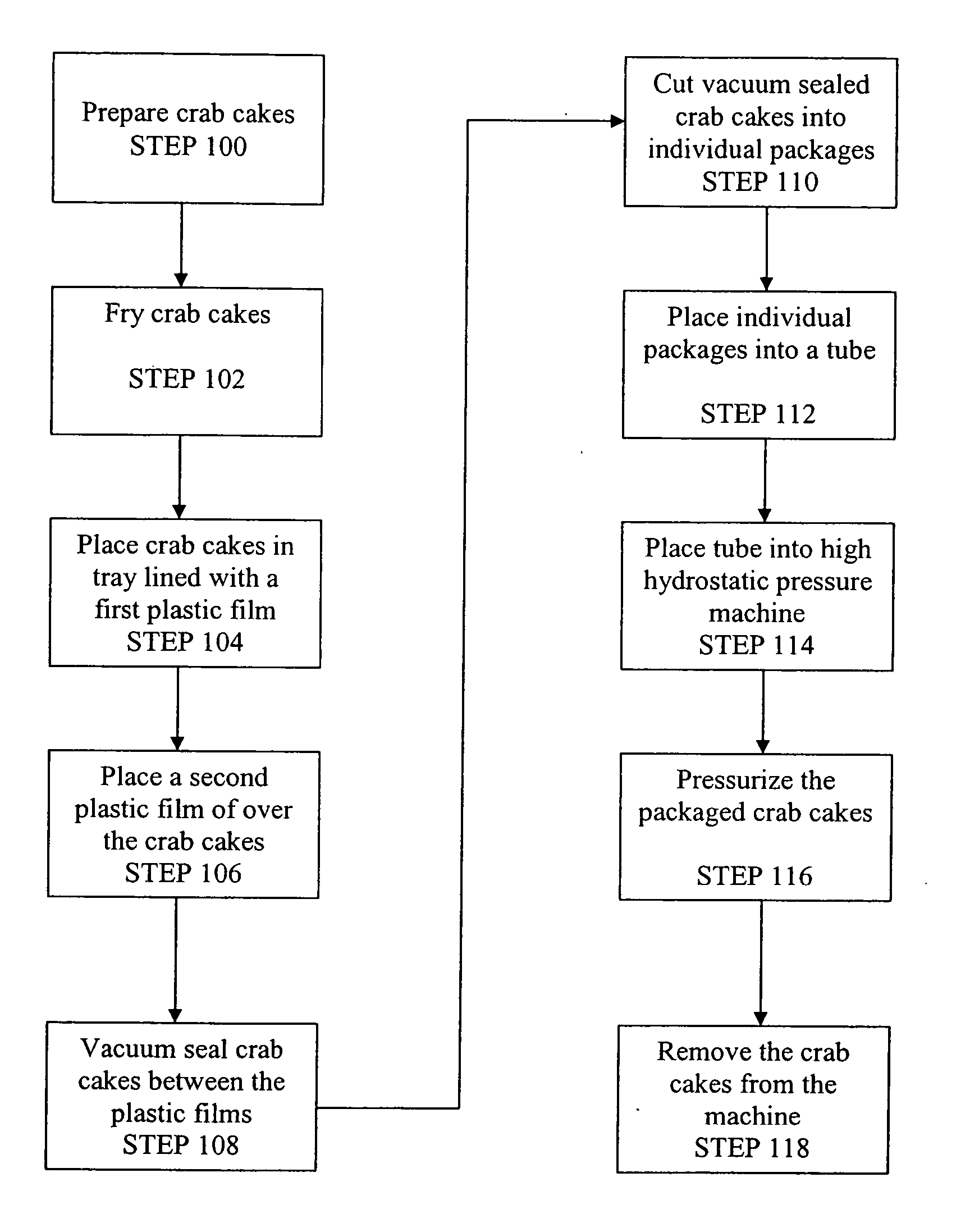

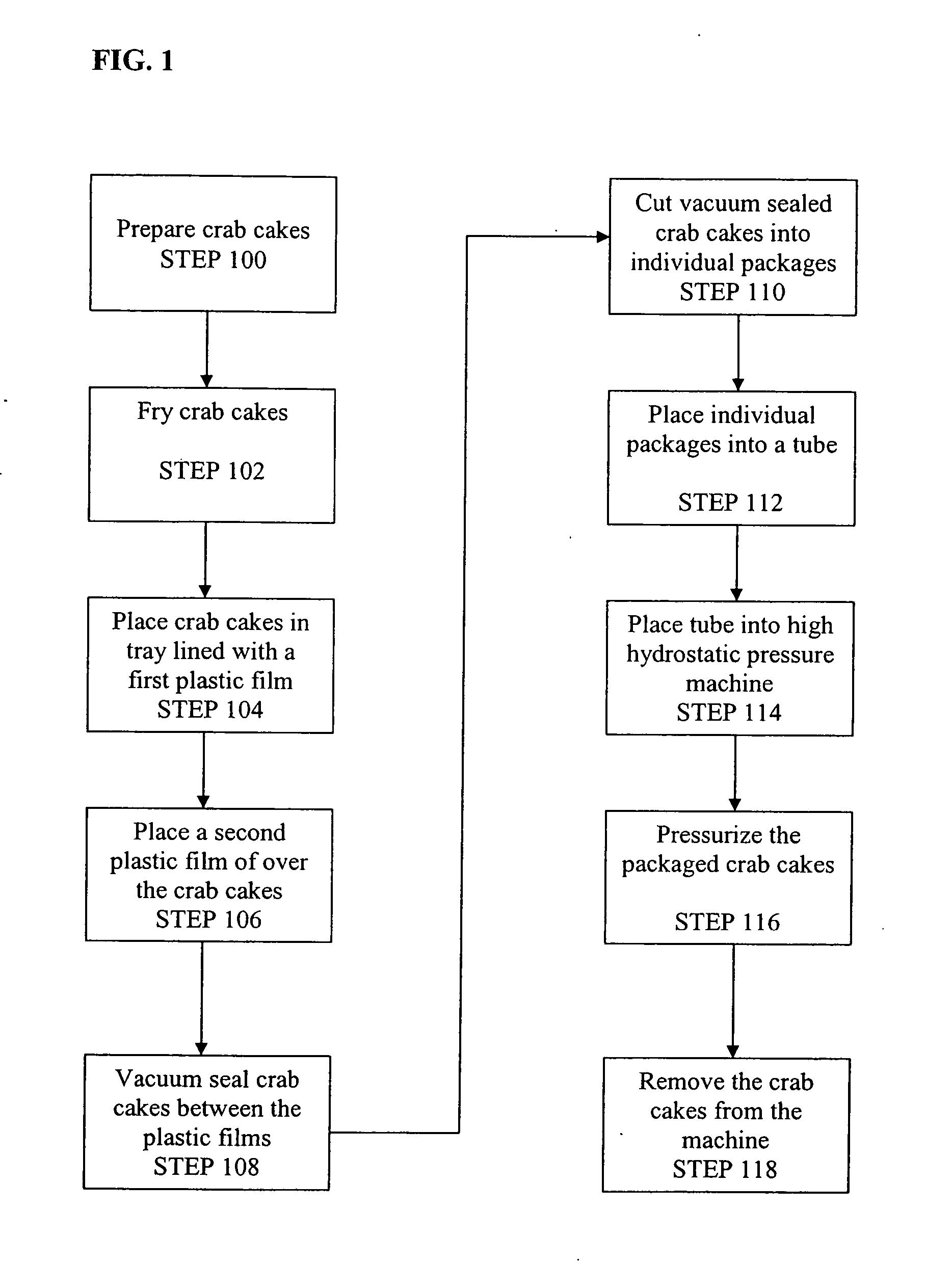

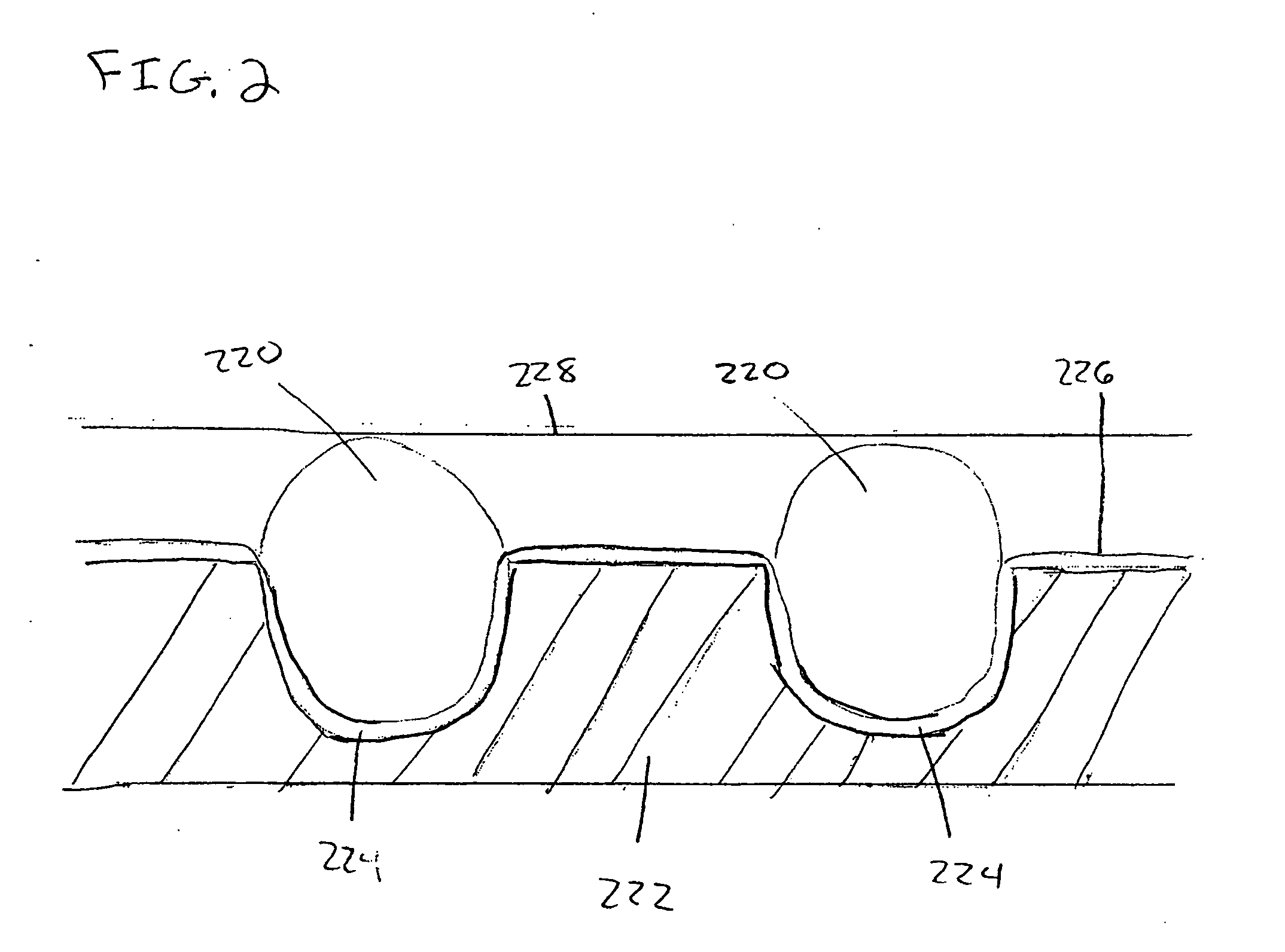

Method for manufacturing high pressure processed food products

InactiveUS20070237865A1Extended shelf lifeIncrease hydrostatic pressureReady-for-oven doughsMeat/fish preservationHydrostatic pressureFresh food

The present invention is directed to the high pressure processing of food products after packaging in order to extend the shelf life and eliminate bacteria and microorganisms. Fresh food products that can be processed according to the present invention include, for example, beef, chicken, pork, lamb, seafood, vegetables, sauces and starches. The method for processing food products involves vacuum sealing a food product within plastic film to form a vacuum sealed package. The vacuum sealed package is then placed in a pressurizing apparatus and the pressurizing apparatus is then loaded with water. The water is then pressurized inside the pressurizing apparatus to exert hydrostatic pressure on the vacuum sealed package.

Owner:PHILLIPS FOODS

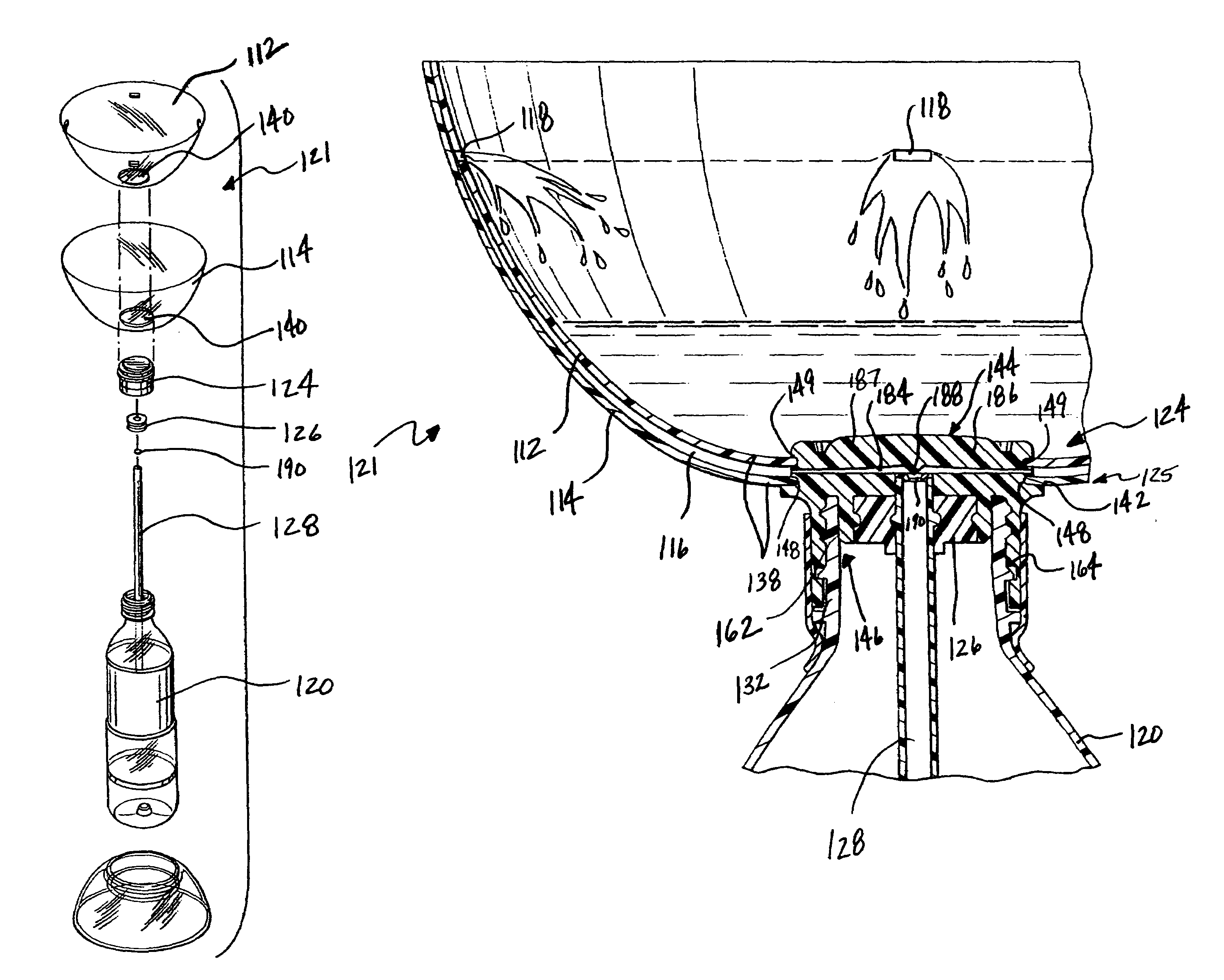

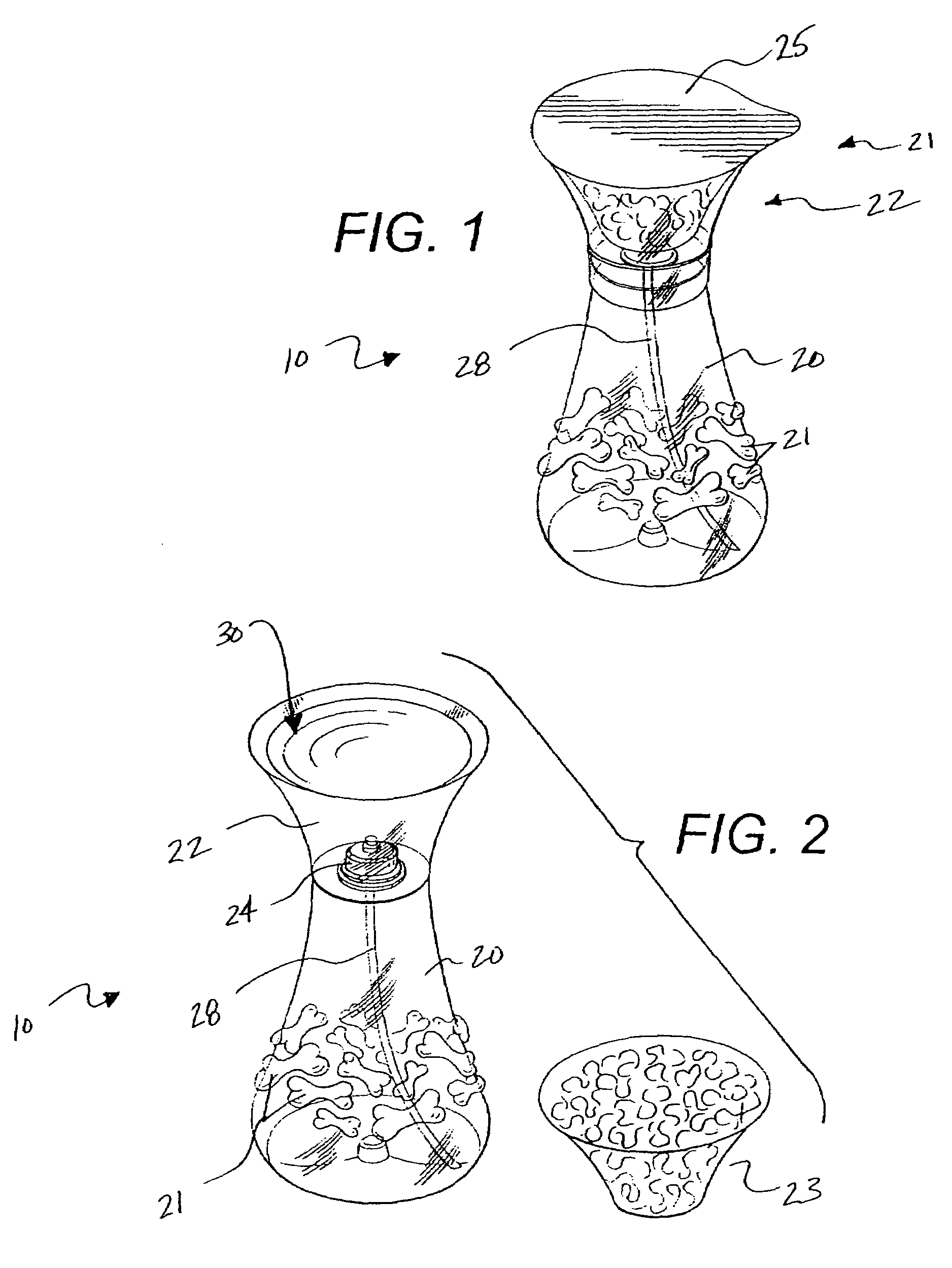

Portable drink container for pets

InactiveUS20080115732A1Improve versatilityIncrease hydrostatic pressureAnimal watering devicesLiquid transferring devicesHydrostatic pressureEngineering

The present invention is directed to a portable drink container for pets that the pet owner can carry while walking the pet or engaging in activities that result in the pet being thirsty. The portable drink container includes a fluid vessel having an upwardly extending neck with an outlet opening. A removable cap has a central aperture and a cavity that engages the vessel neck. A drinking bowl includes a bottom wall with a central opening defined by an internal edge of the bottom wall. A lower peripheral channel of the cap slidingly receives the bottom wall edge to connect the cap and the drink bowl, whereby the cap extends through the central opening of the bowl. A flexible conduit is positioned within the vessel and extends the cap and the central opening of the drink bowl. The conduit defines a passageway for fluid to travel from the vessel into the drink bowl. An elastomeric plug may be secured within the cap to stabilize the conduit. The pet owner applies a compressive force on the vessel to increase the hydrostatic pressure thereby forcing liquid through the conduit and into the drink bowl for consumption by the pet.

Owner:STENBERG MARK

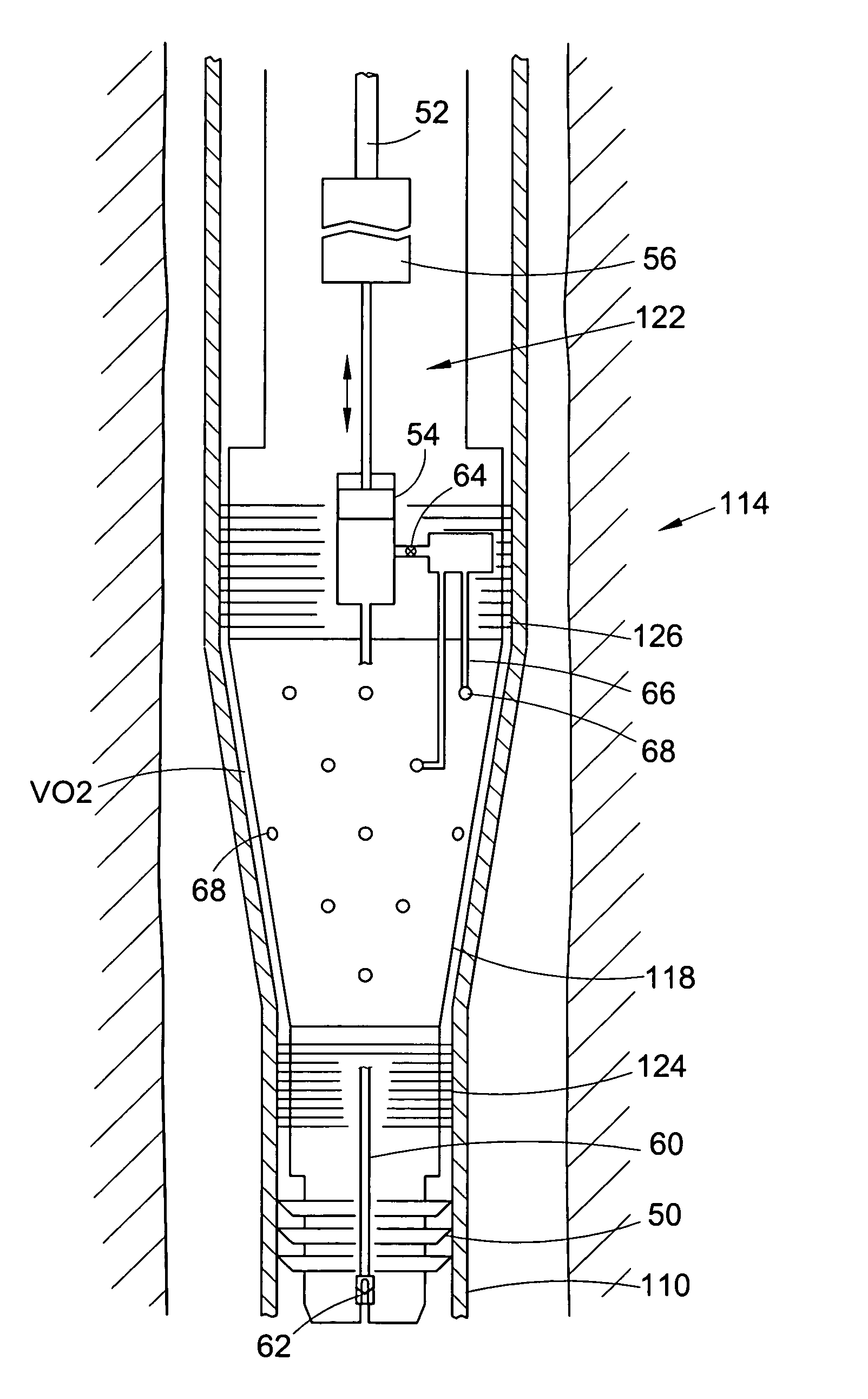

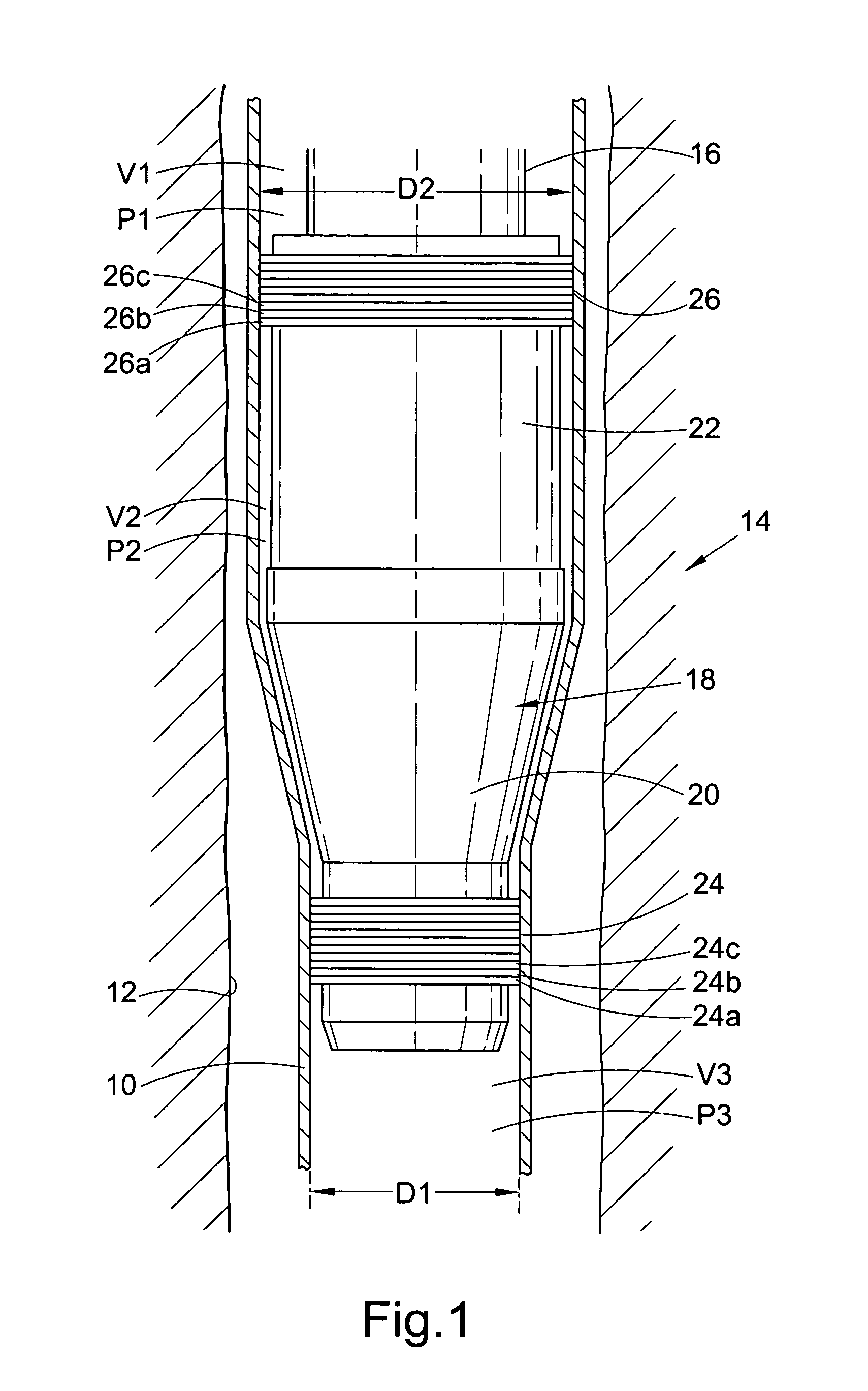

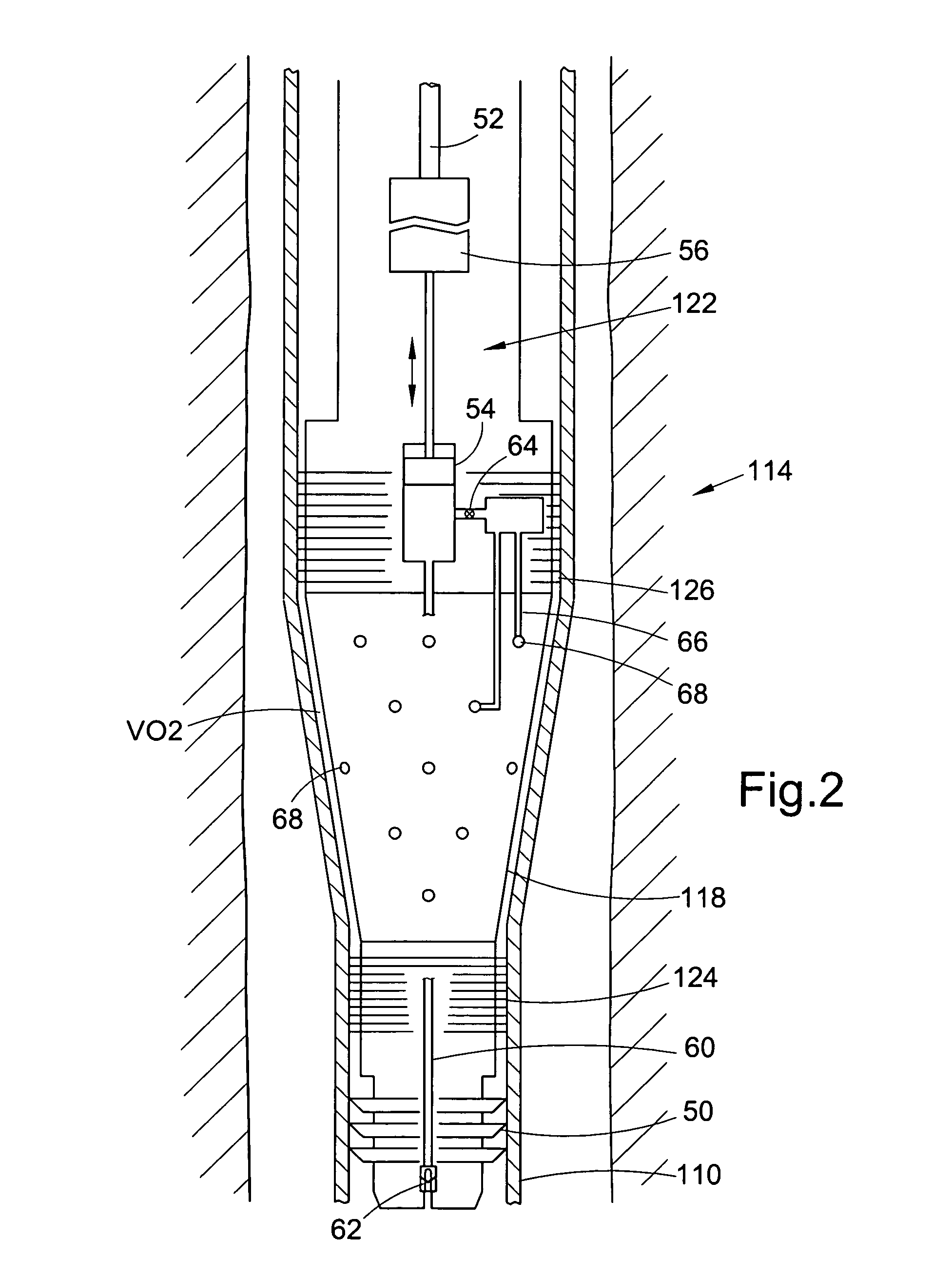

Hydraulically assisted tubing expansion

InactiveUS7350585B2Reducing or even eliminating the need to utilise pumpsImprove the level ofDrilling rodsFluid removalEngineeringBiomedical engineering

A method of expanding tubing comprises applying a varying fluid pressure across the wall of the tubing. The variation in pressure may be achieved by varying one or both of the fluid pressure within the tubing and the fluid pressure externally of the tubing. A body of varying volume may be located in a volume of fluid associated with the tubing. Alternatively, the volume of a body of fluid associated with the tubing may be varied by movement of a wall portion defining a boundary of the volume, which wall portion may be associated with an oscillator or a percussive or hammer device. In other embodiments a pressurised fluid source may be provided, and the fluid may be supplied at varying pressure from the source. An increase in pressure within the tubing may be accompanied by a reduction in pressure externally of the tubing.

Owner:WEATHERFORD TECH HLDG LLC

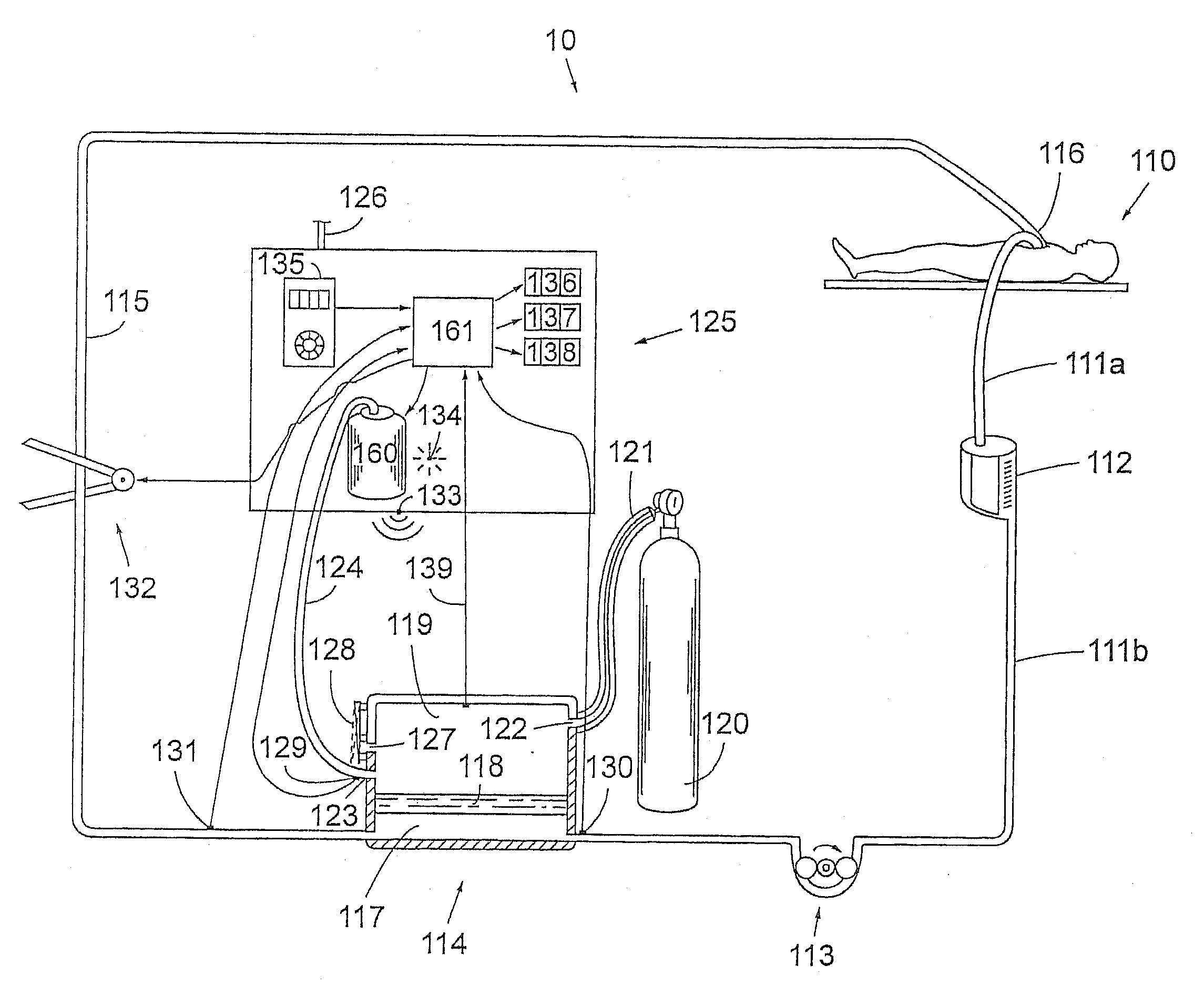

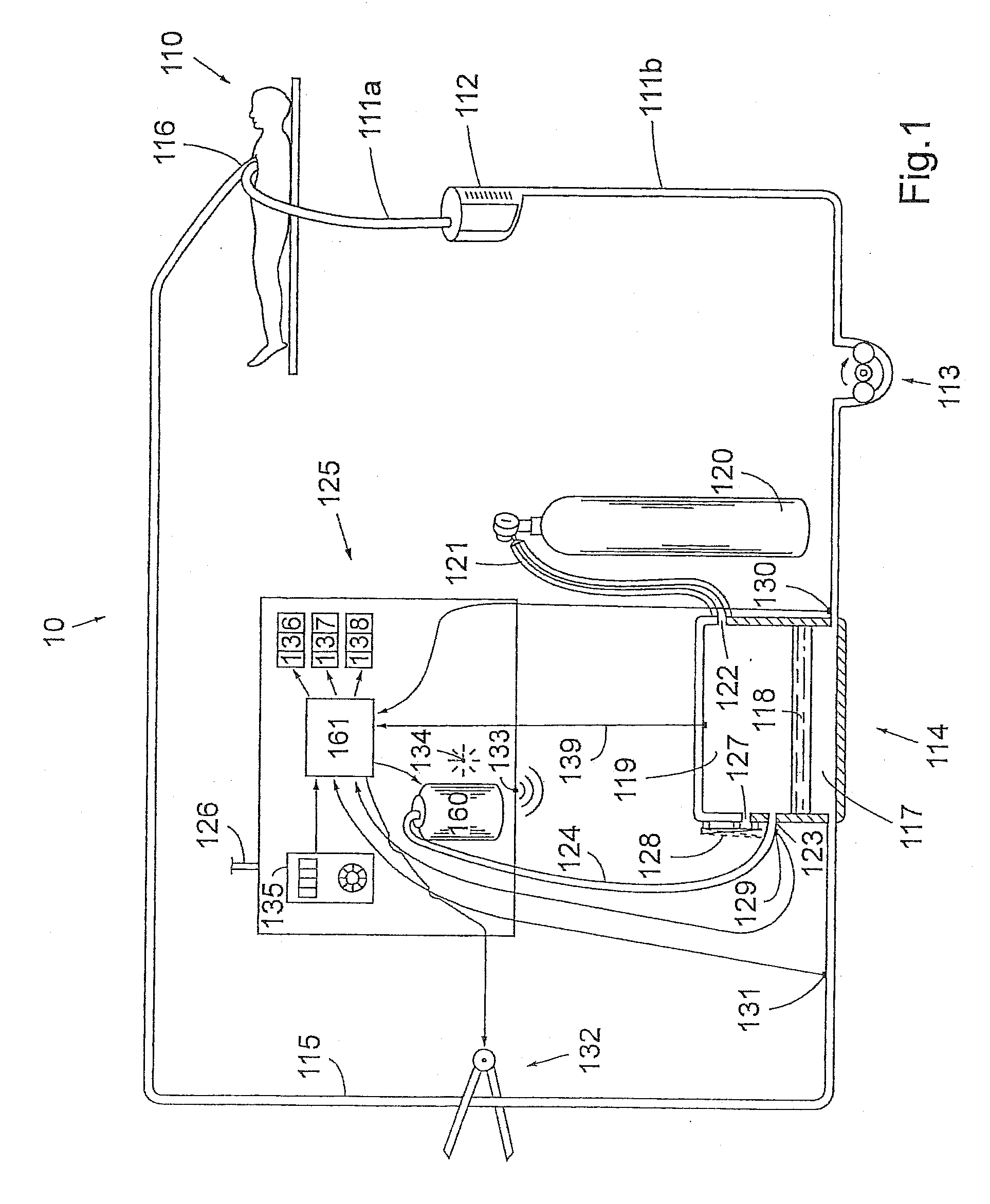

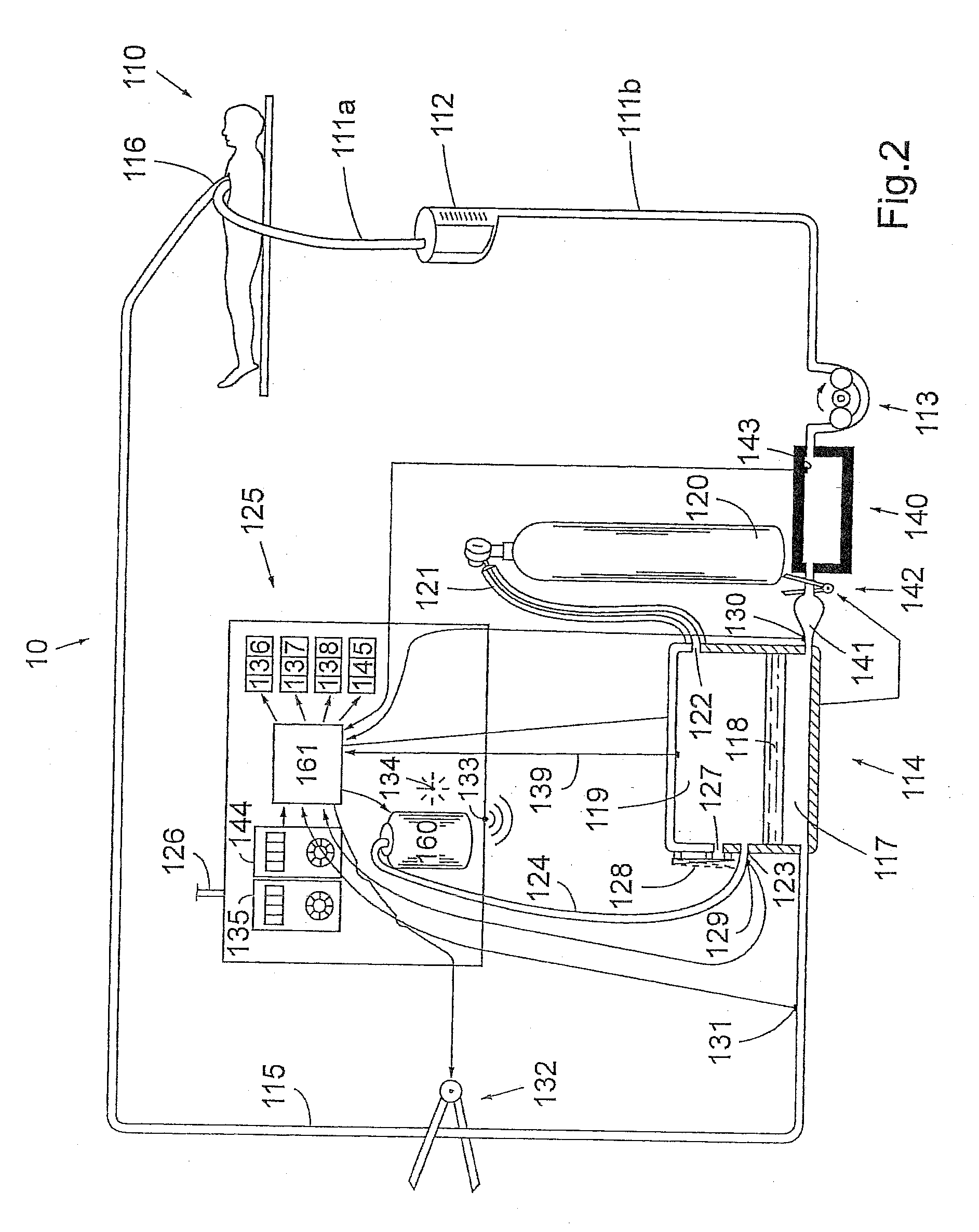

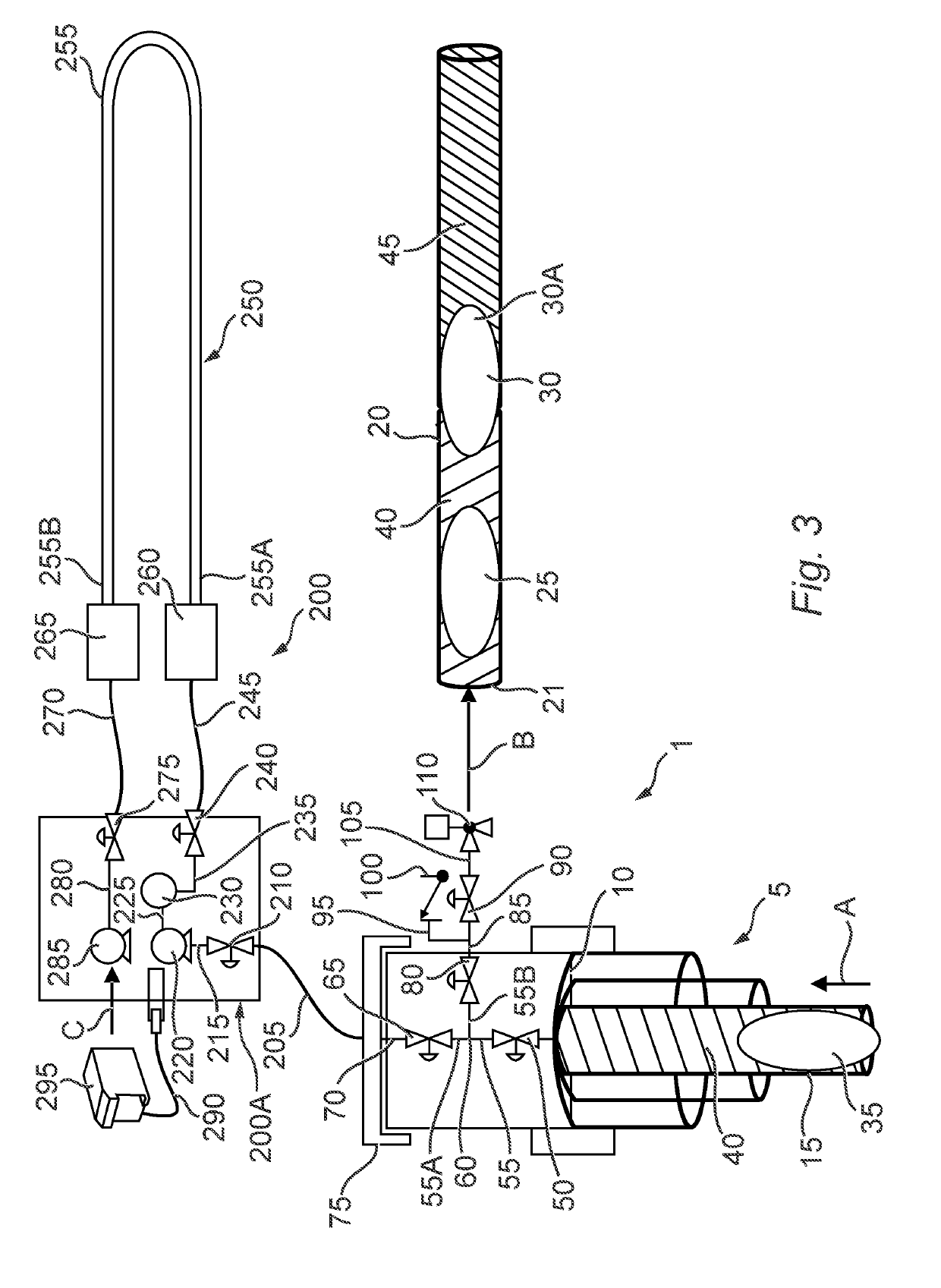

Control of bubble formation in extracorporeal circulation

InactiveUS20090230058A1Increase volumeIncrease pressureSolvent extractionHaemofiltrationExtracorporeal circulationGas exchange

The invention relates to control of bubble formation in a fluid during extracorporeal circulation. A fluid supply means (111a) is configured to supply fluid to the extracorporeal circuit (111a, 111b, 113, 114, 115, 116), a flow control means (113) is connectable to the extracorporeal circuit and configured to control the flow of the fluid in the circuit; a gas exchange means (114) is connectable to the circuit and configured to gas exchange of the circulated fluid; an antibubble control unit (125) is connectable to an outlet (123) of the gas exchange means and configured to control the total gas pressure over a gas-exchange membrane (118) of the gas exchange means, whereby the amount of gas in the fluid leaving the gas exchange means can be controlled; and fluid return means (115, 116) is connected to the gas exchange means and configured to reintroduce the fluid into the patient.

Owner:SIFR2000

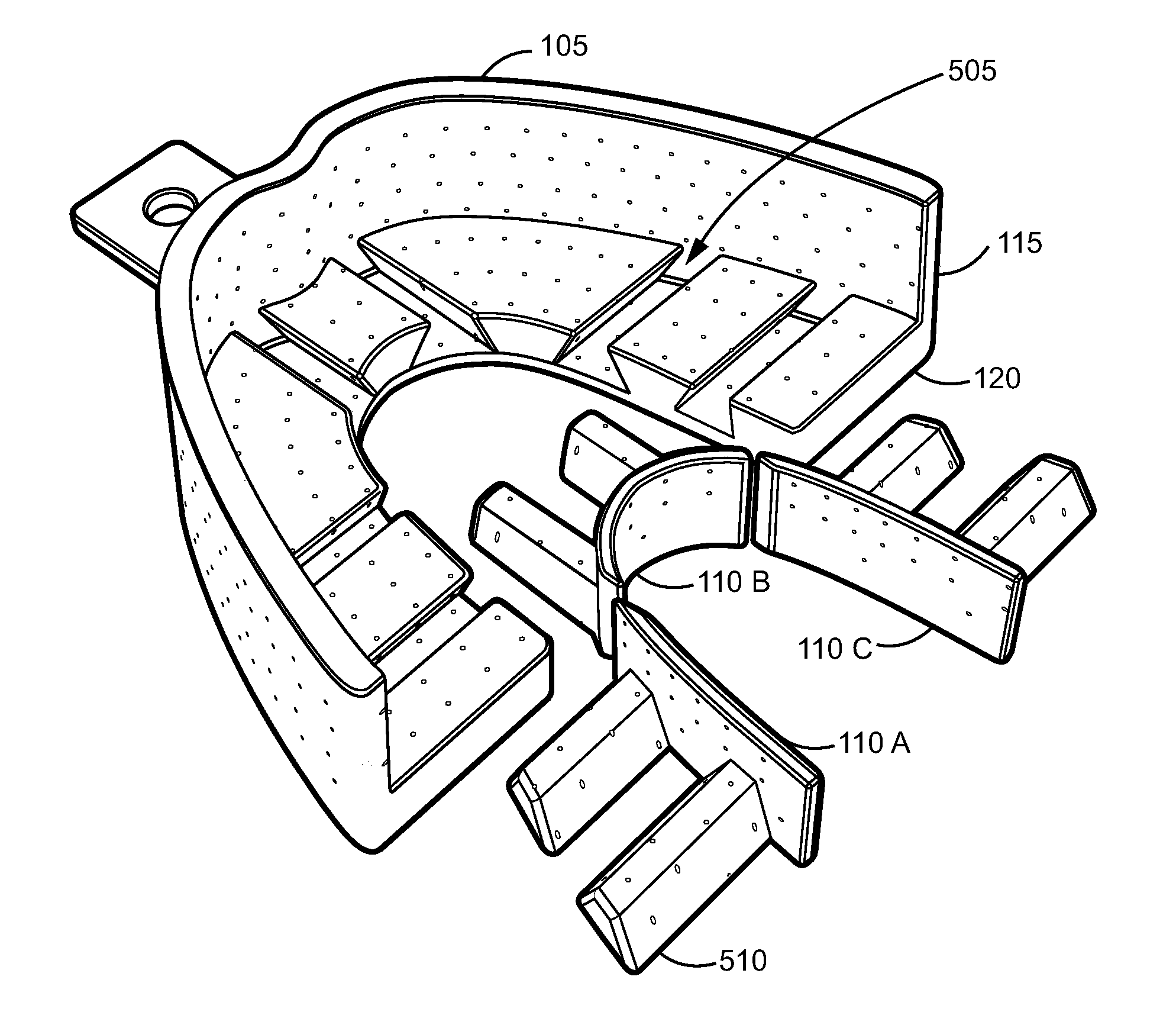

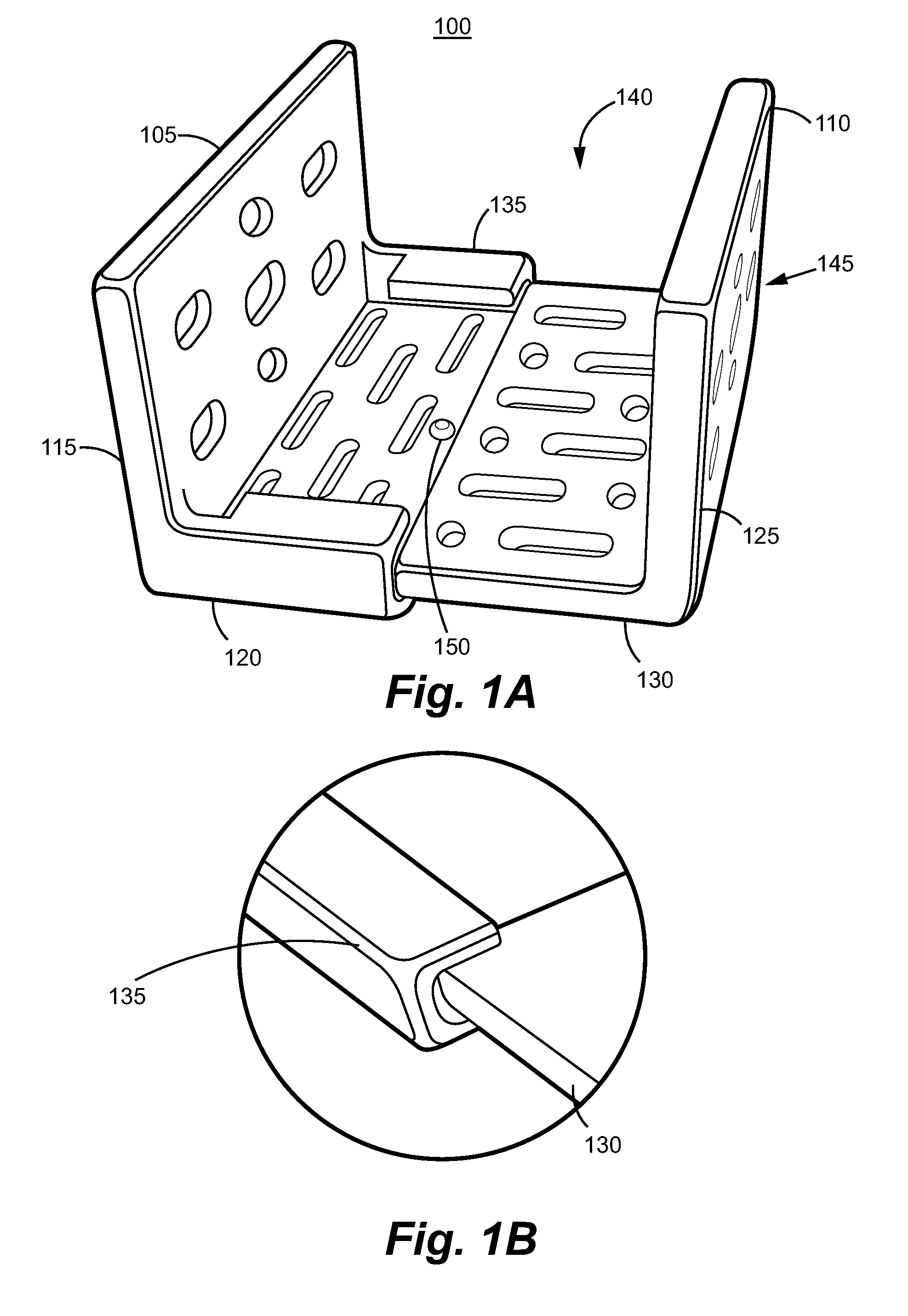

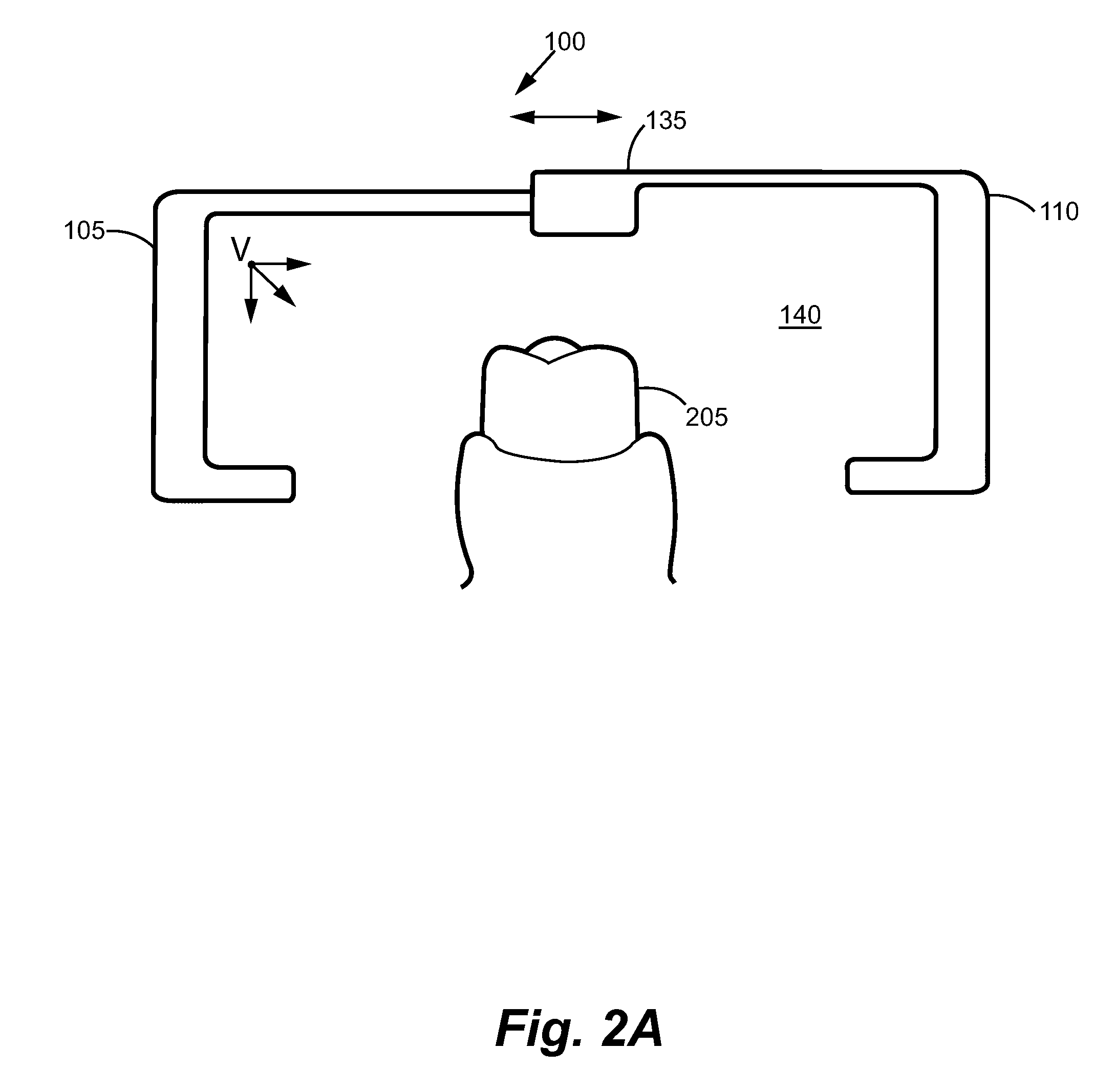

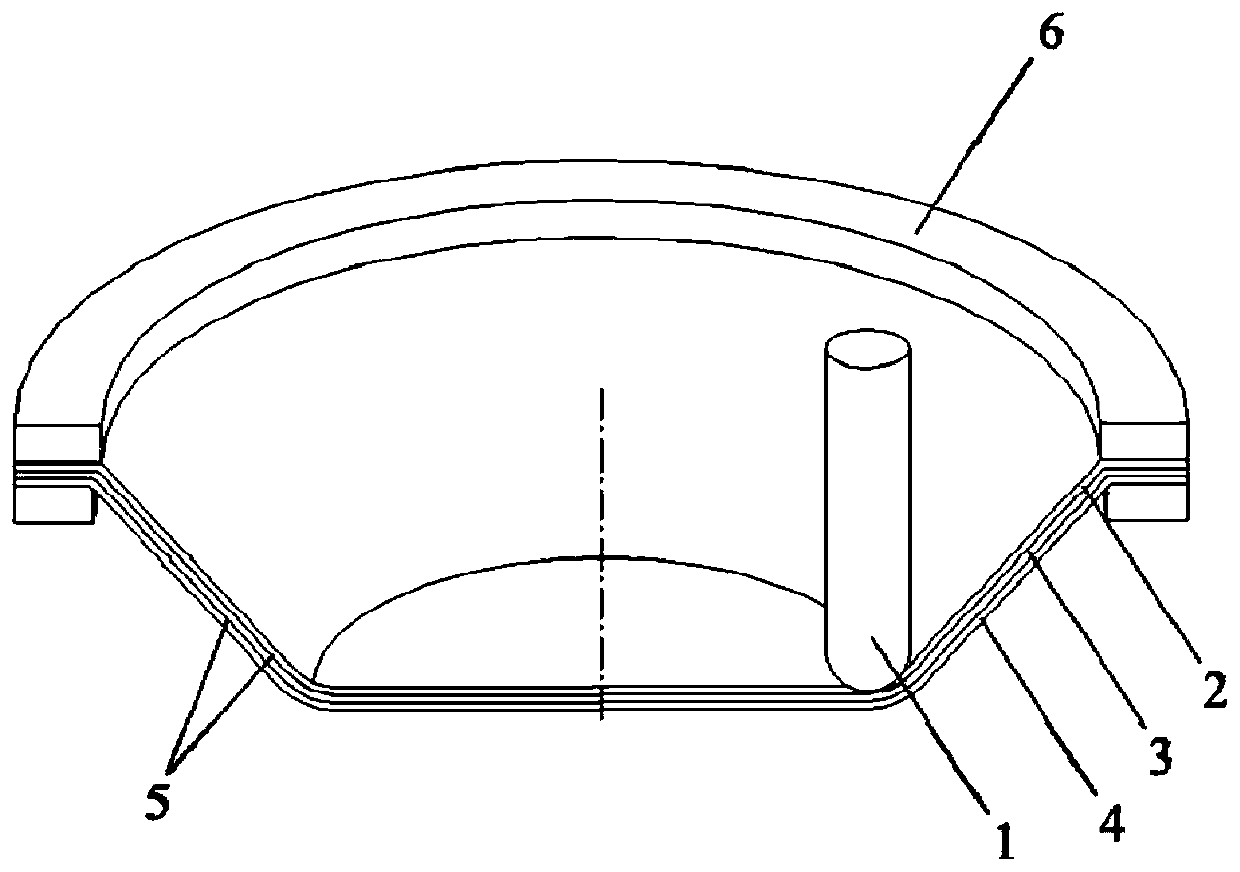

Dynamically adjustable dental impression devices and methods for using the same

InactiveUS20110171593A1Small sizeIncrease hydrostatic pressureImpression capsHydrostatic pressureEngineering

The present invention describes systems and methods to provide dynamically adjustable dental impression devices. In an exemplary embodiment, the present invention provides a dynamically adjustable dental impression device including a facial portion having at least a first wall and a lingual portion having at least a first wall. The facial portion is movably connected to the lingual portion to form an internal cavity enabled to receive a quantity of impression material. Furthermore, the size of the internal cavity can be reduced during the formation of an impression of a dental structure. In some embodiments, the facial portion can be contracted with the lingual portion during the formation on the impression of the dental structure, resulting in the reduction in the size of the internal cavity. Additionally, in some embodiments, the reduction in the size of the internal cavity during the formation on the impression of the dental structure can increase the hydrostatic pressure within the quantity of impression material. Furthermore, the dynamically adjustable dental impression device can simultaneously apply forces substantially nonparallel and substantially parallel to the long axis of the tooth in the dental structure.

Owner:ROSS DONALD H

Depressurisation method and apparatus for subsea equipment

ActiveUS20190136671A1Avoiding high hydrostatic pressureReduce pressureCleaning apparatusFluid removalBiomedical engineering

A method for reducing the pressure of fluid within subsea equipment. The method includes the steps of: (a) providing a pipe, (b) laying the pipe on the sea floor, (c) providing a connector, (d) connecting the pipe to the subsea equipment via the connector, and (e) extracting fluid from the subsea equipment through the connector and into the pipe. Apparatus for reducing the pressure of fluid within subsea equipment by extracting fluid from the subsea equipment.

Owner:TECHNIP UK

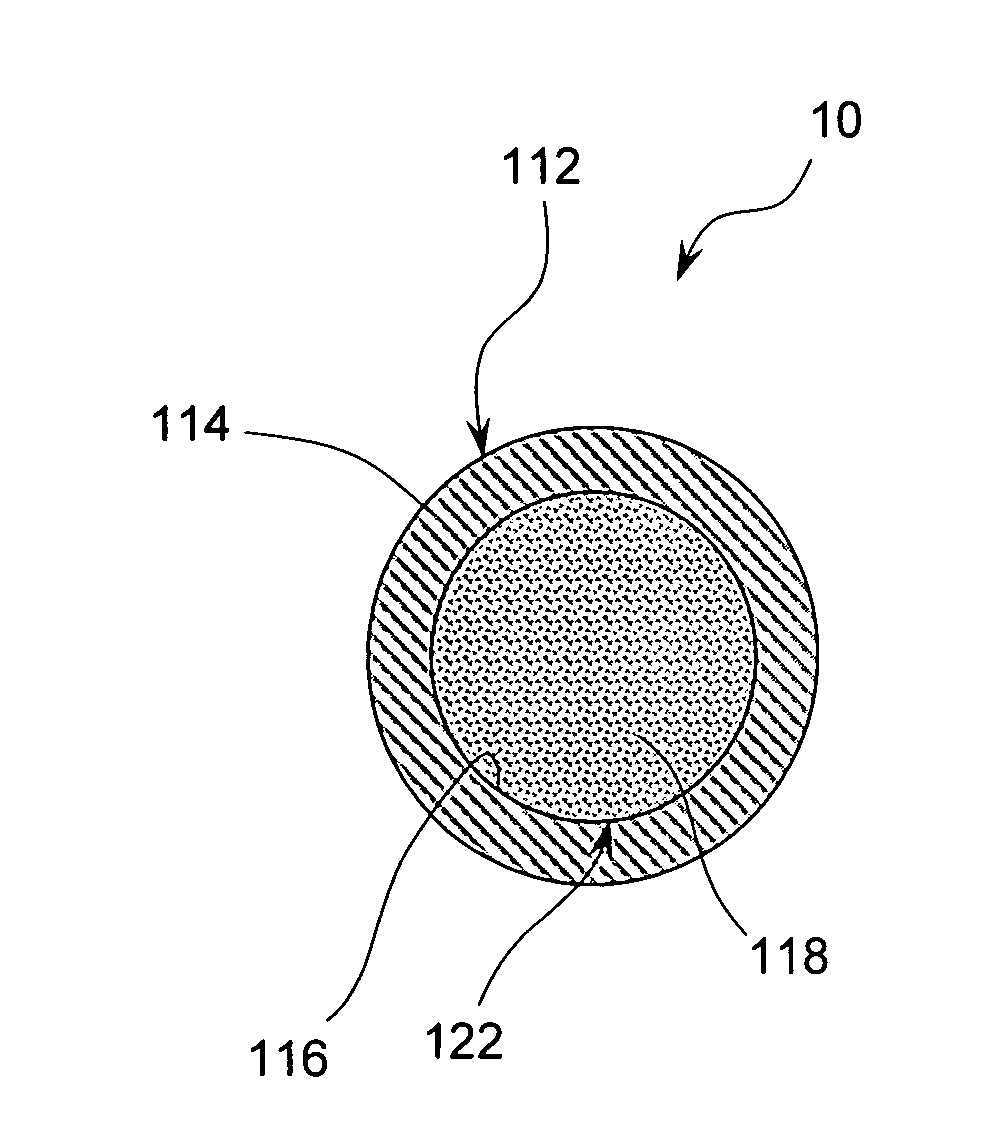

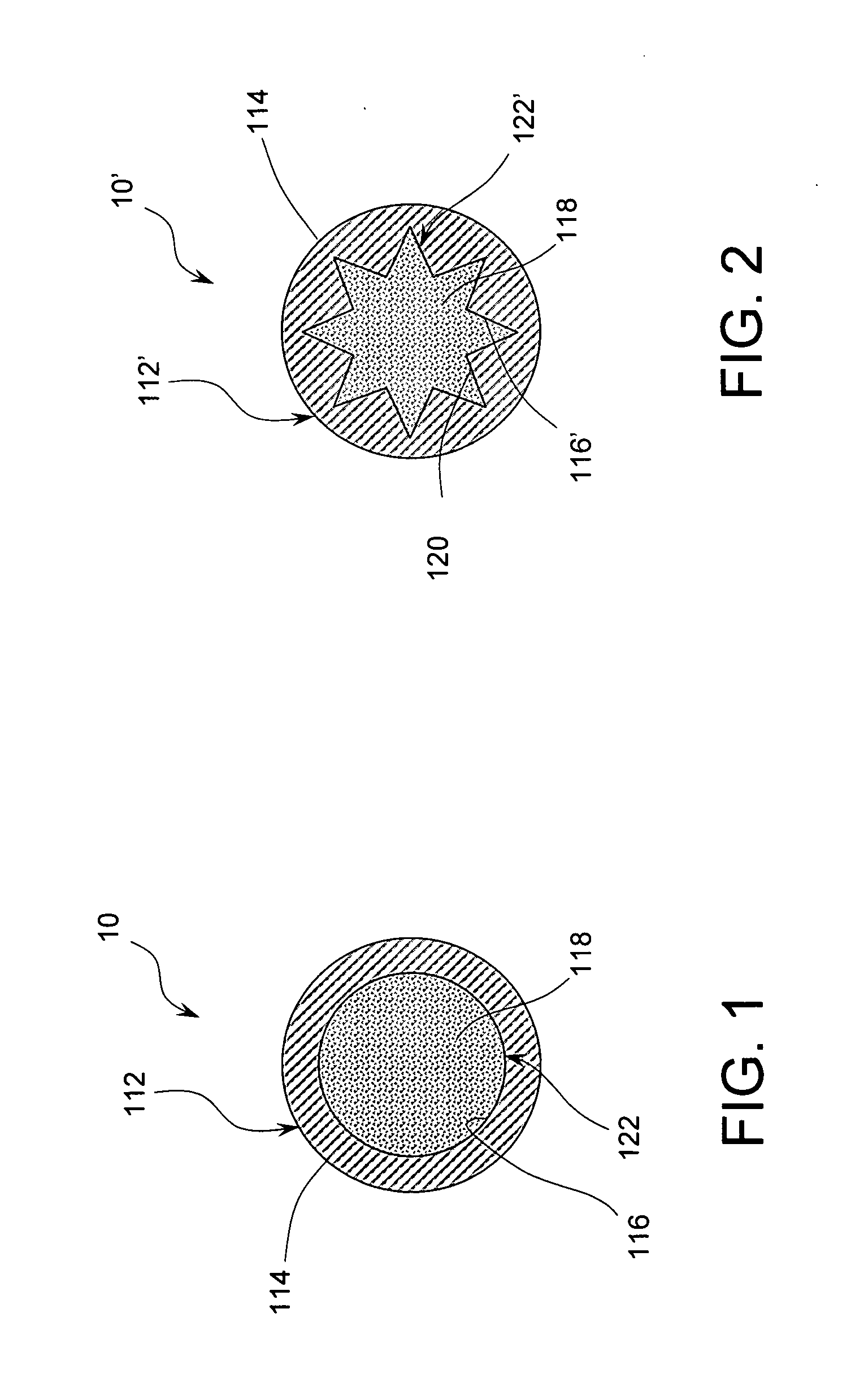

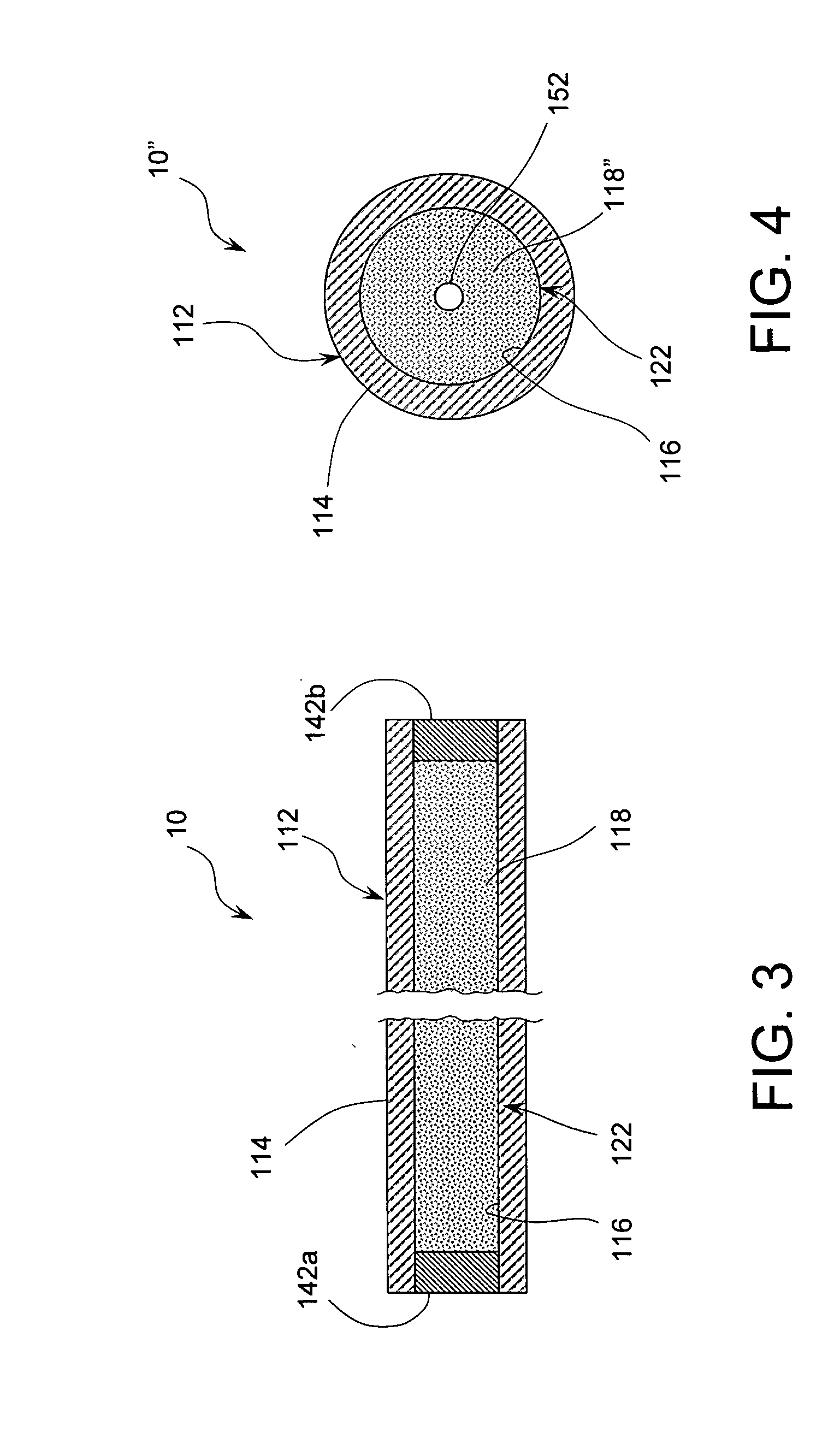

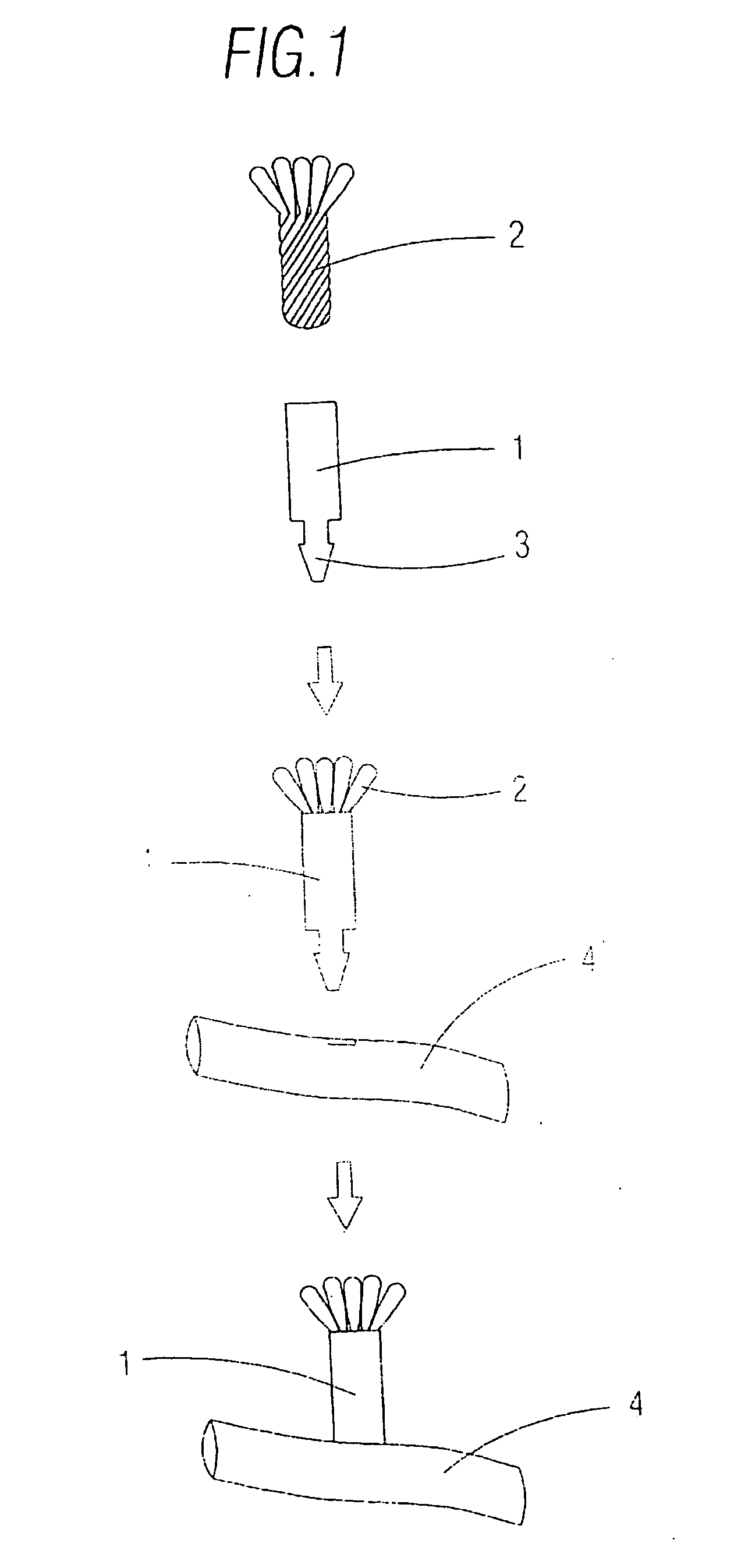

Lightweight electric conductor assembly

InactiveUS20090242271A1High electrical conductivityThermal contactConductive materialMetal/alloy conductorsLatent heat storageElectric vehicle

The invention provides a lightweight electric conductor capable of storing waste heat induced by intermittent high currents. The conductor comprises a high electric conductivity (HEC) element and a phase change material (PCM) arranged in a thermal contact therewith. In one preferred embodiment, the HEC element is formed as a tubular member having longitudinal cavity substantially filled with PCM. In another embodiment of the subject invention, the HEC element may be formed as a long rod, bar, or a wire having PCM applied to, and in thermal communications with its exterior surface. Waste heat generated by passage of intermittent high electric through the HEC element generates waste heat that is conducted into the PCM and temporarily stored therein as latent heat. The invention allows reducing the cross-section of electrically conducting parts of electric conductors used for intermittent high currents. As a result, the conductor weight is reduced. The innovative lightweight conductor may be used in hybrid electric vehicles and certain electric weapons systems.

Owner:VETROVEC JAN

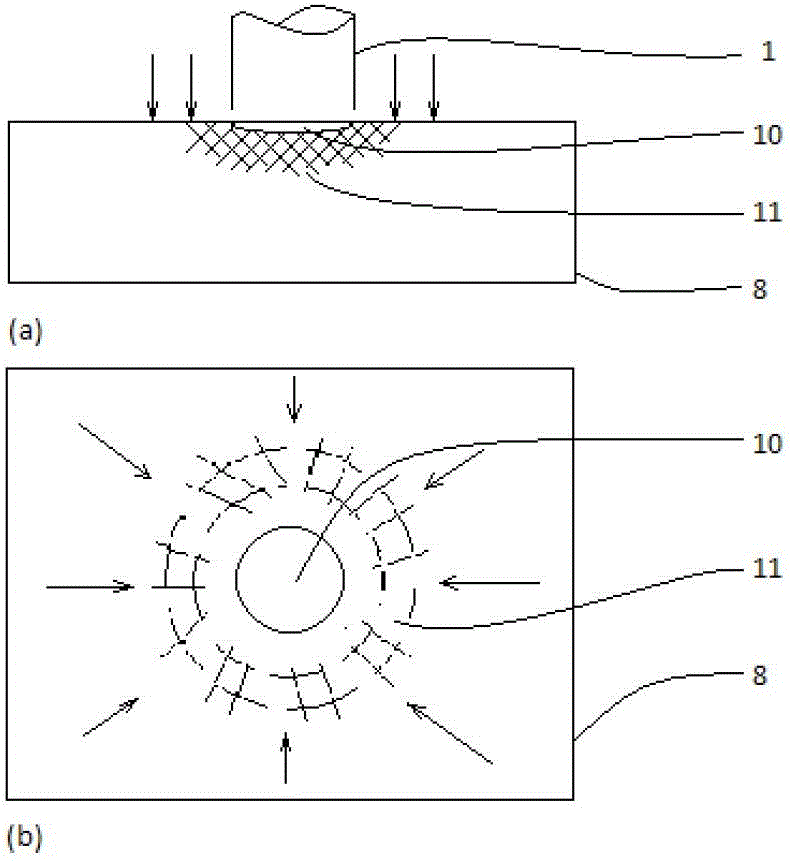

Method and device for improving room temperature plasticity of block amorphous alloy and structural member of block amorphous alloy

The invention relates to a method and a device for improving room temperature plasticity of block amorphous alloy and the structural member of the block amorphous alloy. The method comprises the following steps of: polishing and smoothening the surface of an amorphous alloy body and placing the polished amorphous alloy body on a rigid cushioning plate; introducing short-pulse laser beams to the surface of the polished amorphous alloy body through a boss with a center hole to generate explosion plasma impact waves which act on the amorphous alloy body so that an irradiated region generates trace high-strain-rate plastic deformation and compact shearing zone and residual compressive stress are formed. According to the invention, multiple mechanical and materialogical mechanisms for improving the room temperature plasticity of the amorphous alloy are compressively utilized, thus the plasticizing effect is obvious, and the method and the device are suitable for various amorphous alloy materials.

Owner:SHANDONG UNIV

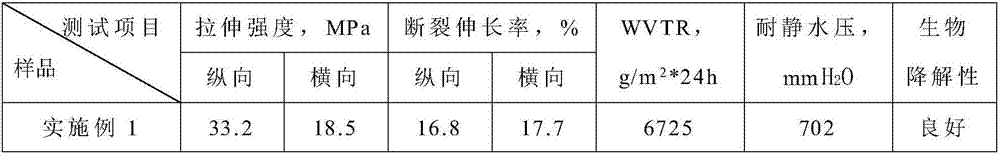

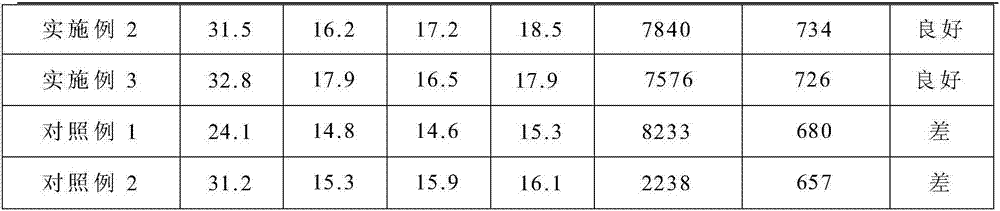

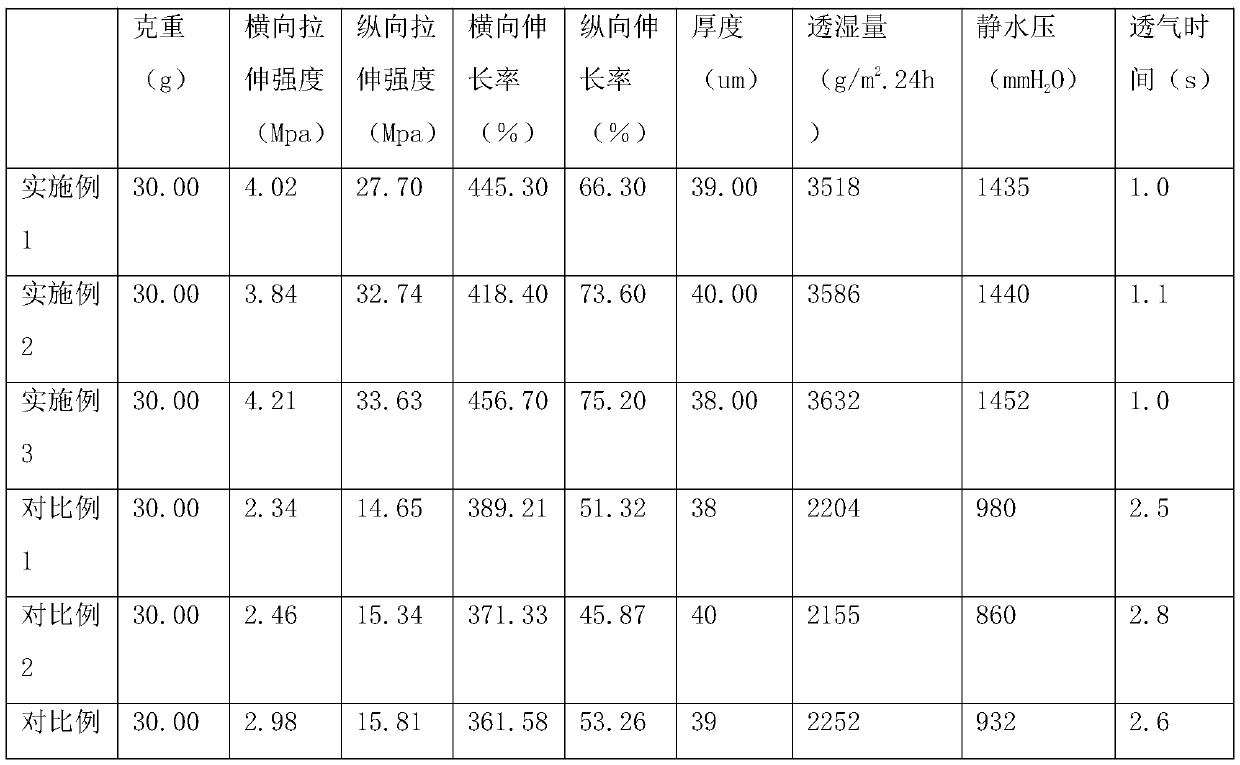

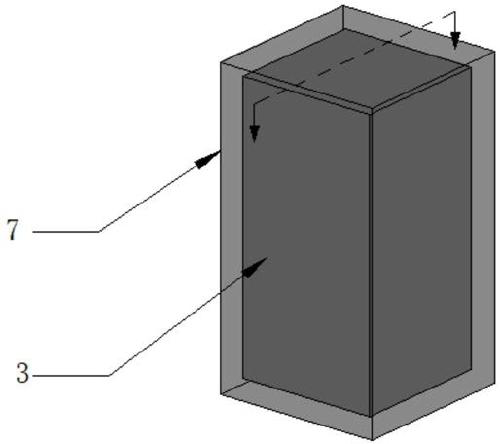

Biological degradable gas-permeable membrane for paper diaper and preparation method of biological degradable gas-permeable membrane

ActiveCN107083033AHigh degree of spherificationEven by forcePersonal careSynthetic resin layered productsPolylactic acidPolystyrene

The invention relates to a biological degradable gas-permeable membrane for paper diaper and a preparation method of the biological degradable gas-permeable membrane, and belongs to the technical field of organic macromolecule film. The biological degradable gas-permeable membrane for paper diaper comprises a spunbond nonwoven fabric which is made of natural plant fibers as a raw material, and a membrane layer with polylactic acid PLA as a substrate, wherein the two layers are compounded through thermal pressing; the membrane layer with the polylactic acid PLA as the substrate contains the following components in parts by mass: 50-60 parts of polylactic acid, 40-45 parts of crosslinked polystyrene, 0.5-1.2 parts of a lubricant, 0.01-0.3 part of an antioxidant and 0.1-0.5 parts of color master batch. The biological degradable gas-permeable membrane provided by the invention has certain tensile strength, anti-leakage properties and good air permeability, can be biologically degraded, and is environment-friendly.

Owner:怡佳(福建)卫生用品股份有限公司

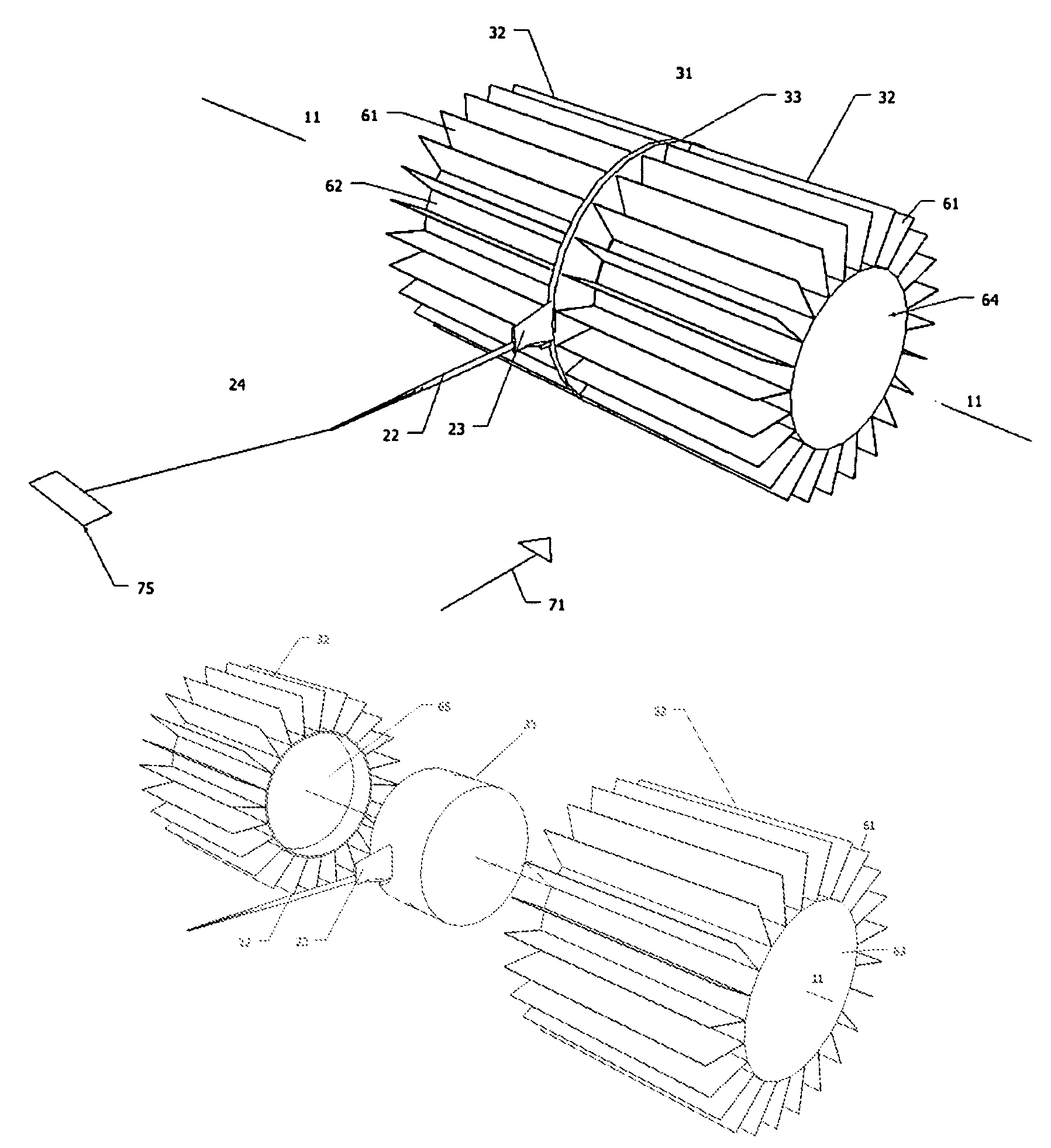

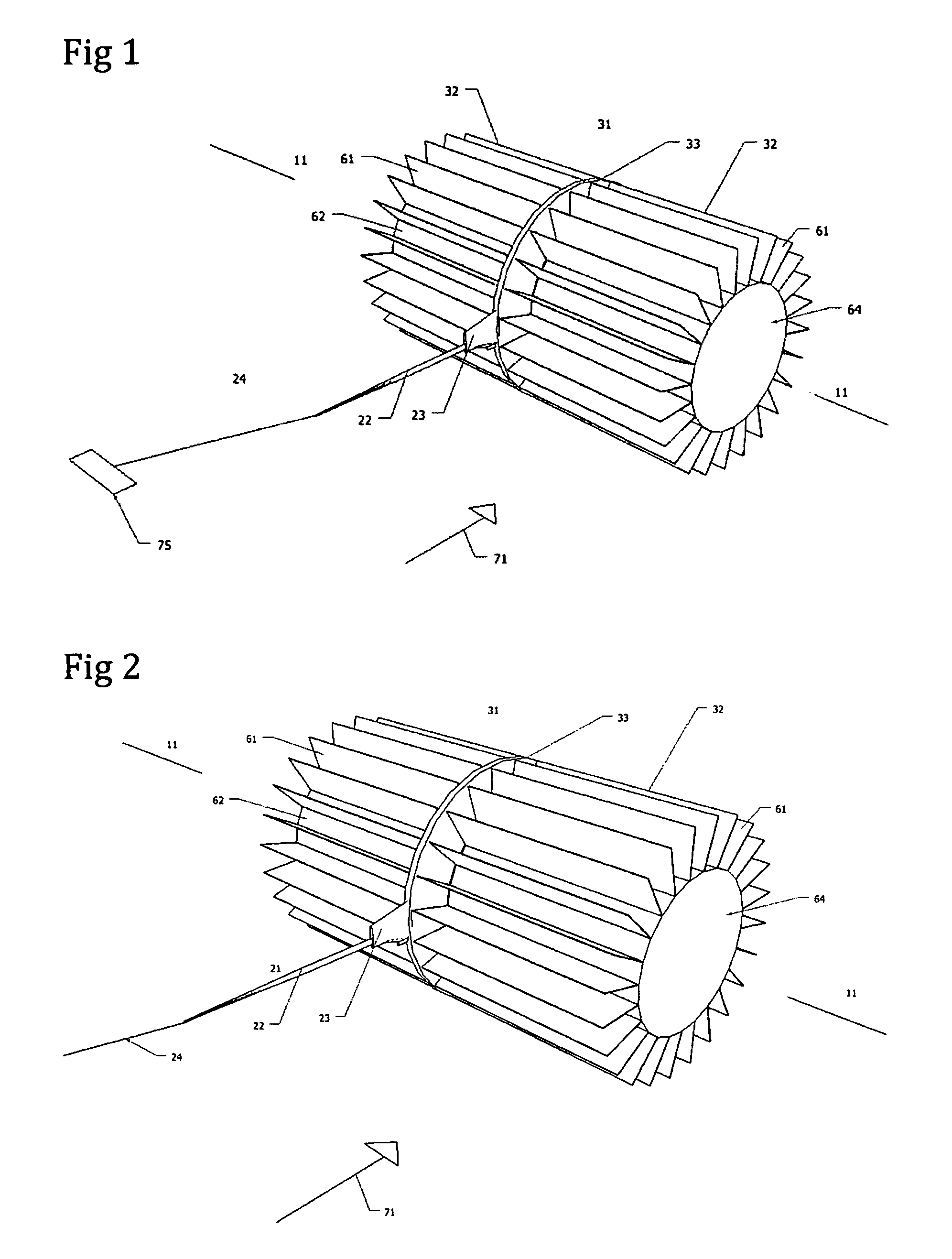

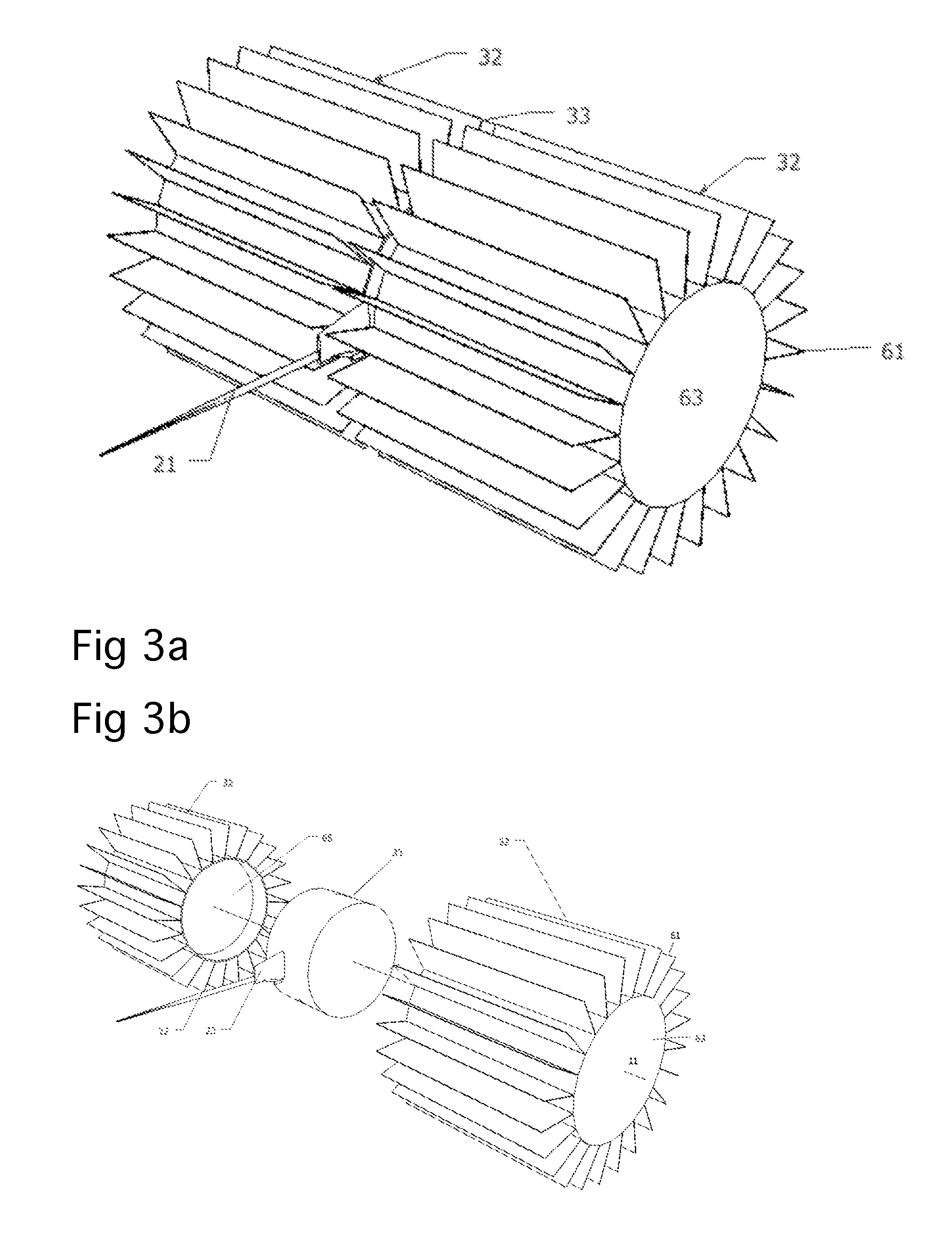

Buoyant in-stream hydro turbine

ActiveUS8102068B1Reduce riskIncrease hydrostatic pressurePropellersWind motor controlElectricityEnergy coupling

A buoyant hydro turbine(31) for capturing and utilizing energy in the currents of flowing water. A driven component(33) produces electricity or other energy is coupled to and supported by a buoyant rotor(64), increasing efficiency and eliminating the need for an independent supporting structure. Tethered in flowing water, the current(71) rotates the rotors(32) and transfers rotatable energy to the central driven component(33) where electricity or other mechanical work is produced. A number of embodiments are adapted for optimizing and maintaining positioning in a stream of moving water. Additional embodiments optimizing the efficiency and effectiveness of the turbine in capturing and utilizing the current's kinetic energy as well as hydrostatic pressure.

Owner:GUTEKUNST BRENT LEE

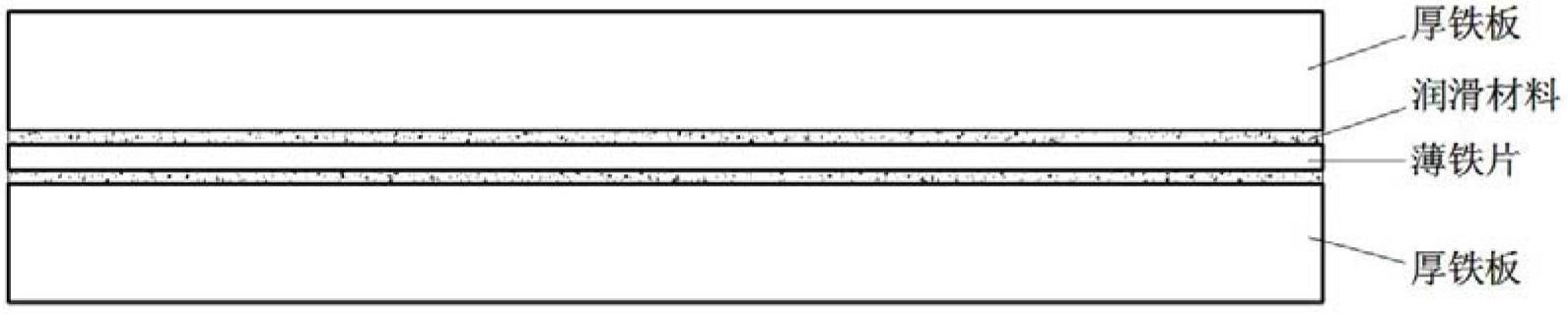

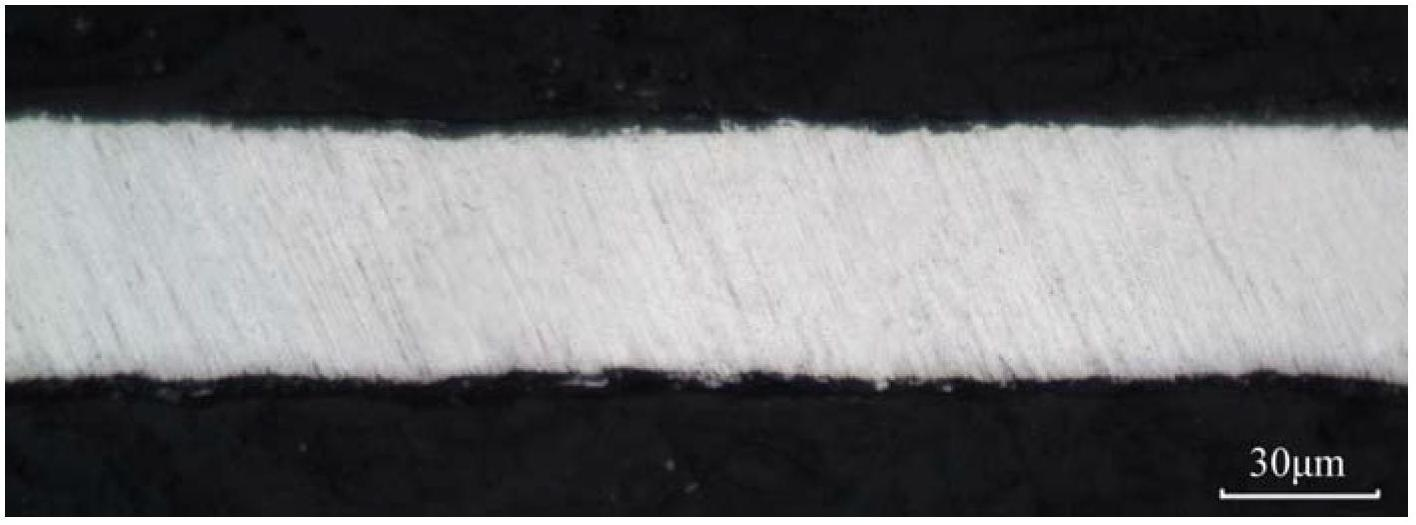

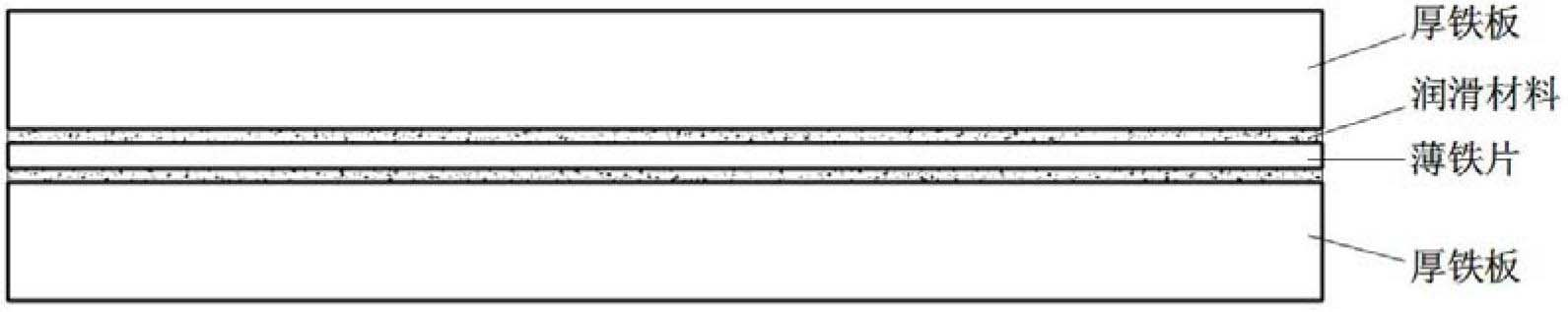

Preparation method for synchronously cold-rolling iron foil by using laminated method

InactiveCN102688885AConducive to relative deformation movementImprove efficiencyMetal rolling arrangementsReduction ratioThinning

The invention relates to a preparation method for synchronously cold-rolling iron foil by using a laminated method. The method belongs to the technical field of rolling. The method comprises the following steps of: selecting a plurality of thick iron pieces and a plurality of thin iron pieces, wherein the thin iron pieces are clamped by the thick iron pieces to form a laminated structure; respectively carrying out heat treatment on each laminated layer of materials before rolling, and coating a lubricating material among laminations; and delivering the combination laminated structure to a common two-roller or four-roller rolling machine for cold-rolling and thinning, and thinning the thin iron pieces to iron foil with required thicknesses by selecting an appropriate reduction ratio and rolling passes. With the adoption of the preparation method for synchronously cold-rolling the iron foil by using the laminated method, the defects of low efficiency, large environment pollution, complex equipment, high cost, and the like of other preparation method are overcome, and the preparation method is suitable for preparing an extremely thin material of materials of pure iron, iron alloy and the like. The preparation method has the characteristics of being simple in process and convenient for operation. The prepared iron foil has high dimensional precision, good shape, and good flatness and surface quality. The preparation method has the characteristics of being high in efficiency, convenient, energy-saving, low in cost and the like and is suitable for industrial application.

Owner:CENT SOUTH UNIV

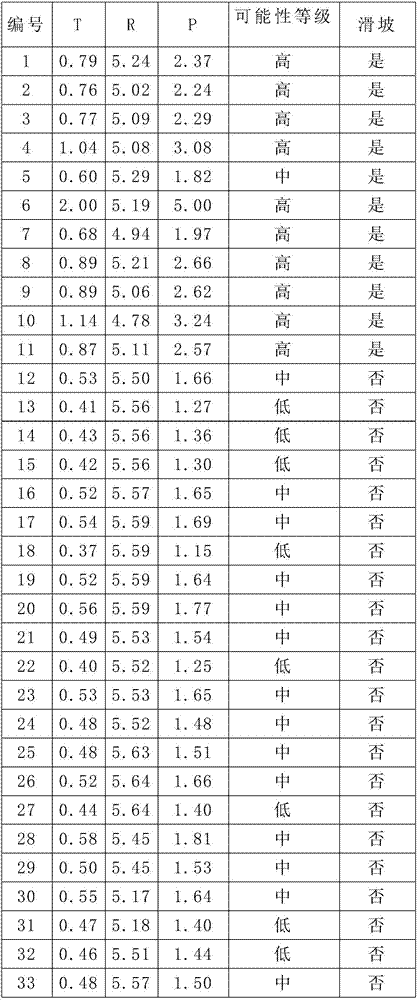

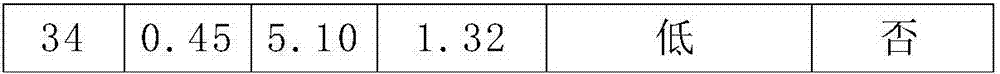

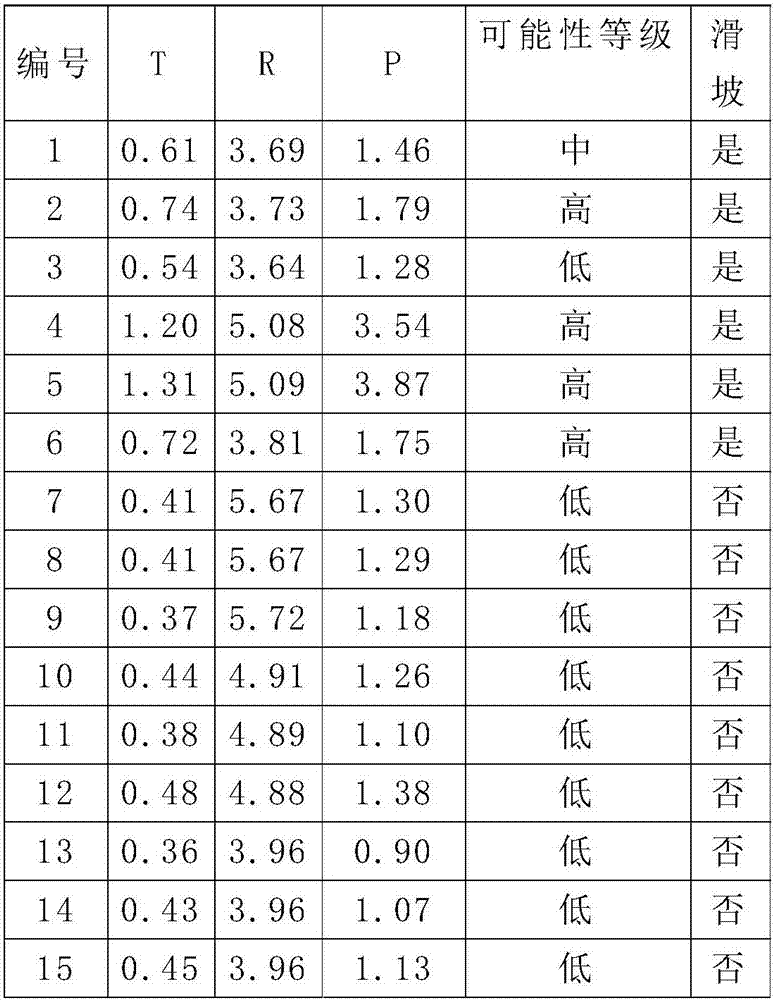

Red-bed region rock landslide prewarning method and application thereof

ActiveCN107476275AImprove the accuracy of early warningImprove accuracyIn situ soil foundationTerrainLandslide

The invention discloses a red-bed region rock landslide prewarning method and application thereof, and belongs to the technical field of landslide prevention engineering. The prewarning method comprises the following steps: (a) a slope alpha of a landslide mass, an area A of the landslide mass, an upper side area Au of the landslide mass and an upper side surface slope beta of the landslide mass are determined through field surveying and mapping; (b) the rainfall is monitored to obtain the rainfall time and the average rainfall intensity; (c) landslide prewarning judging factors P are calculated according to a formula 1 by terrain factors and rainfall factors; and (d) the rock landslide prewarning grades are divided by the landslide prewarning judging factors P; when P is not lower than 1.85, the possibility is high; when P is not lower than 1.45 and lower than 1.85, the possibility is medium; and when P is lower than 1.45, the possibility is low. The prewarning method deeply researches the terrain conditions and the rainfall conditions formed by the rock landslide, builds precise prewarning calculation models of the rock landslide, determines the prewarning grade of the rock landslide, and greatly improves the prewarning accuracy and applicability.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

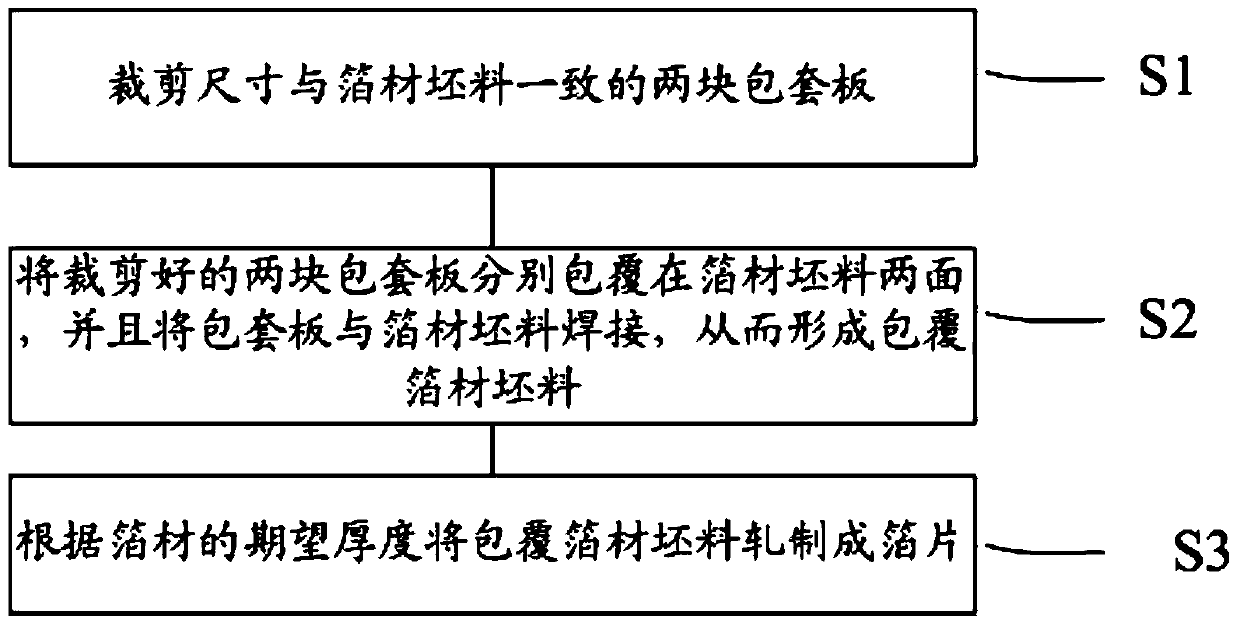

Preparation method by employing double-face coated jacketing plates to roll foil

InactiveCN105499270AImprove machinabilityIncrease hydrostatic pressureMetal rolling arrangementsMaterials science

The invention provides a preparation method by employing double-face coated jacketing plates to roll a foil. The preparation method comprises the steps that Step one, two jacketing plates of which the sizes are consistent with that of a coil blank are cut; Step two, the two faces of the coil blank are coated with and welded to the cut two jacketing plates respectively, so as to form a coated coil blank; and Step three, according to the expected thickness of the foil, the coated coil blank is rolled to form a coil sheet. In the step two, the peripheries of the jacketing plates are welded to the periphery of the foil blank, so that the edges of the jacketing plates are welded to the corresponding edge of the foil blank together. In the third step, during rolling, according to the volume constant principle, by measuring the real-time length of the coated foil blank, the coated foil blank is rolled till the foil sheet reaches the required thickness.

Owner:上海六晶科技股份有限公司

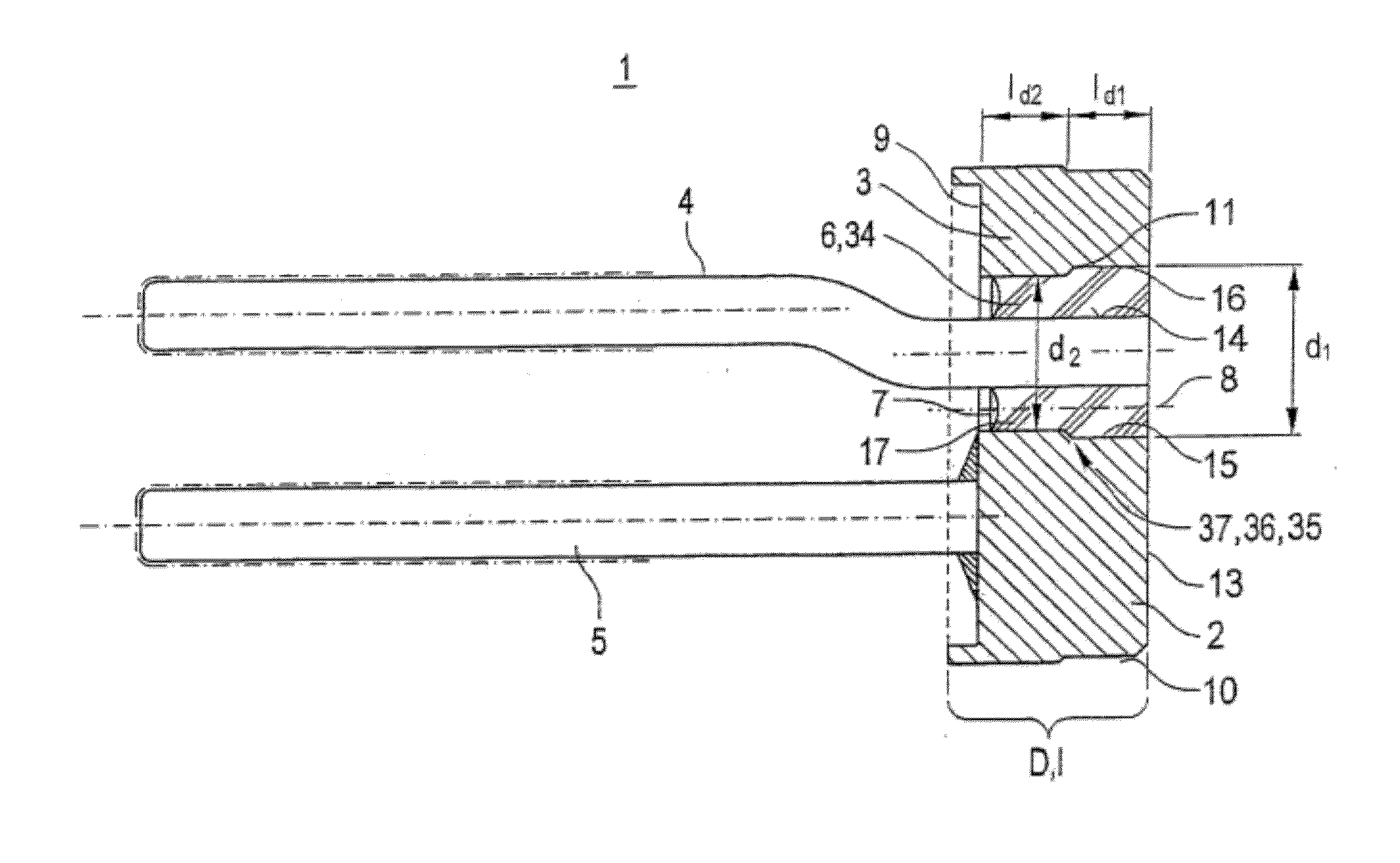

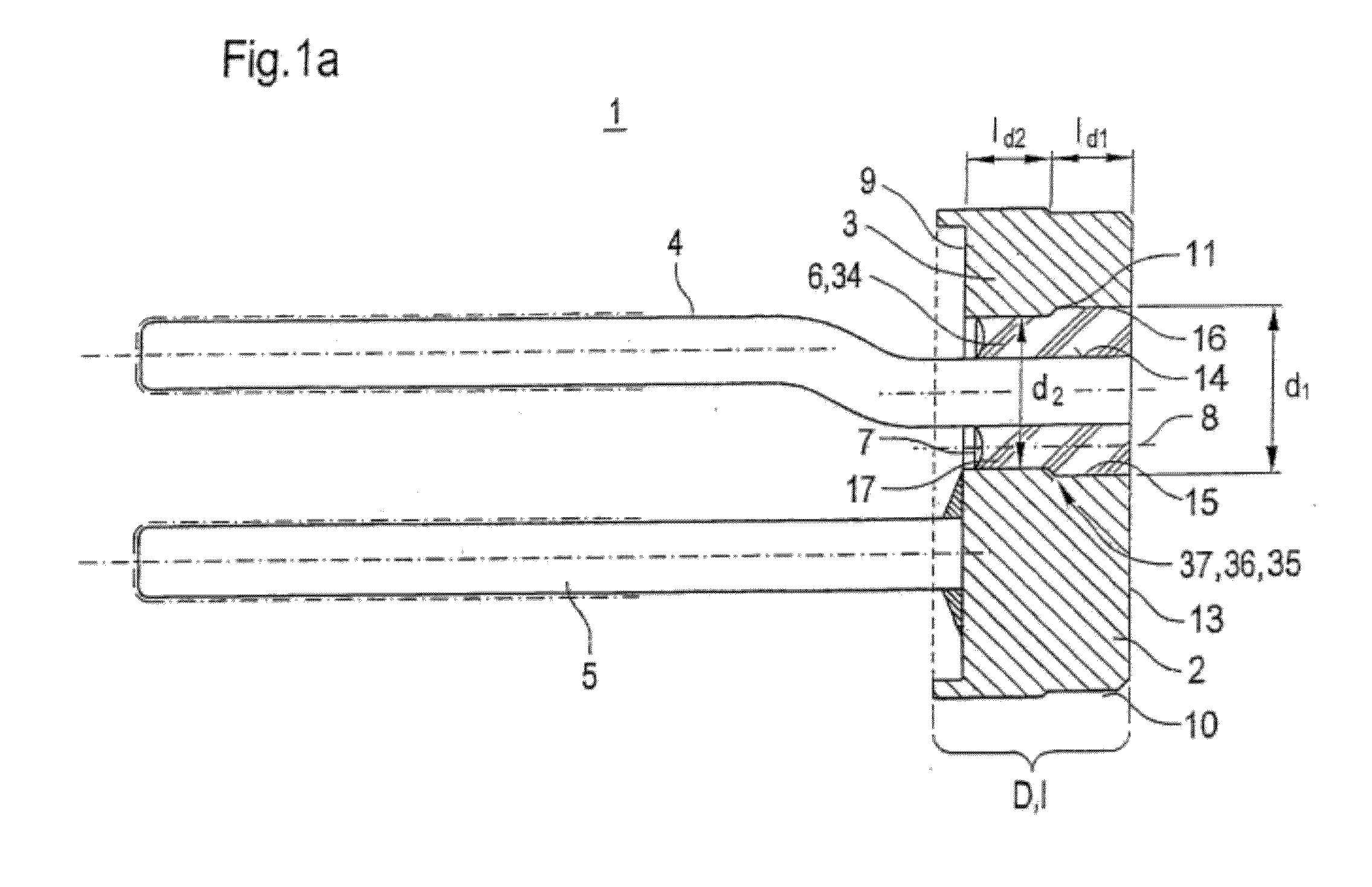

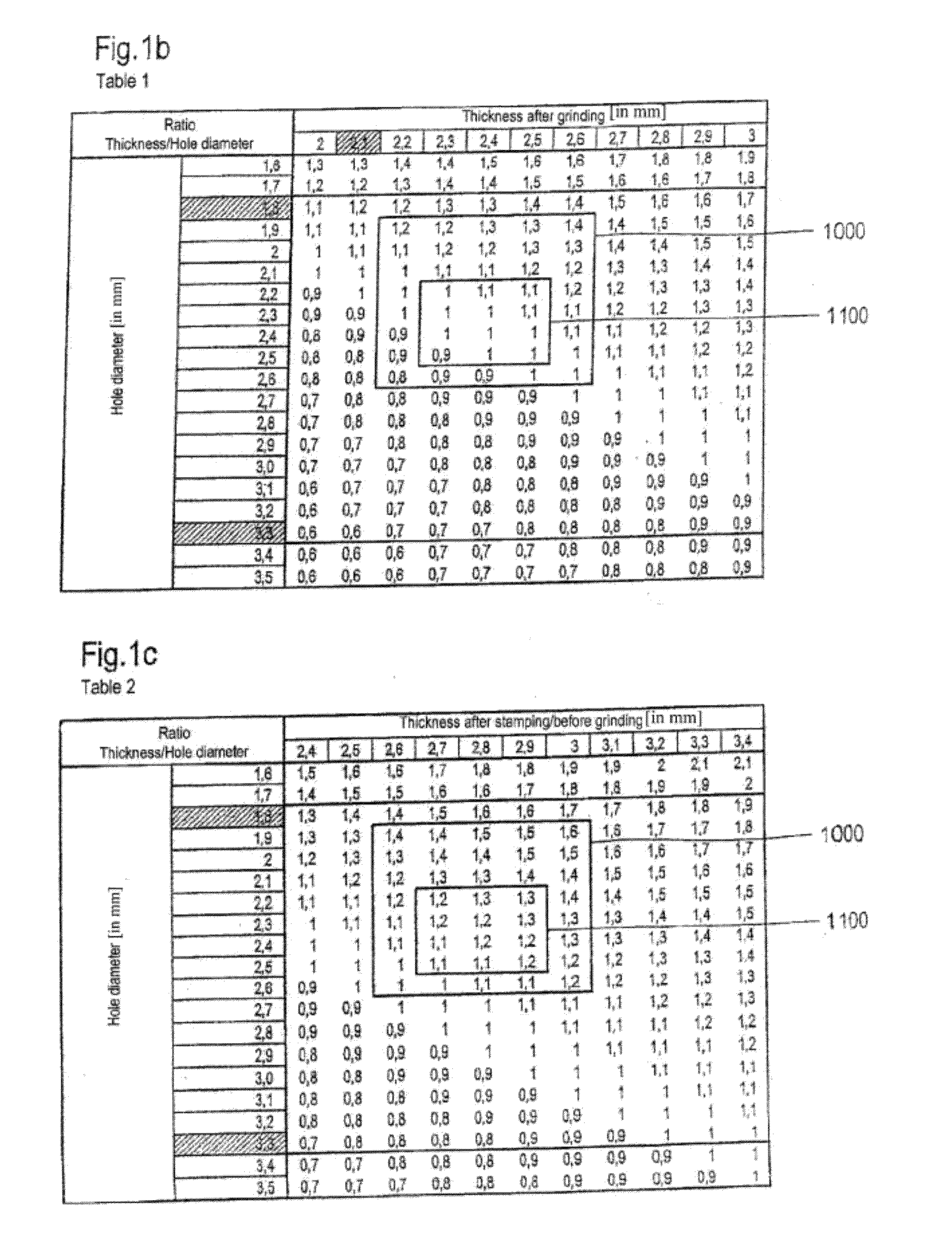

Metal-sealing material-feedthrough and utilization of the metal-sealing material feedthrough with an airbag, a belt tensioning device, and an ignition device

ActiveUS20120199036A1Save materialReduce supportEngine sealsBlasting cartridgesMaximum dimensionEngineering

A metal-sealing material-feedthrough for igniters includes: a base body including a feedthrough opening, a front side, and a back side, the base body configured such that a ratio of a thickness of the base body to a maximum dimension of the feedthrough opening vertical to an axis direction of the feedthrough opening is in a range of approximately 0.5 to 2.5, the base body having a thickness between 1.5 mm and 3.5 mm; a sealing material; and a metal pin which is located in the feedthrough opening, the thickness being such that the base body is deformed under compression, the deformation adding an additional force to the sealing material such that the metal-sealing material-feedthrough is configured for avoiding a relative movement of the sealing material between the front side and the back side in a direction toward the back side relative to an inside circumference of the feedthrough opening.

Owner:SCHOTT AG

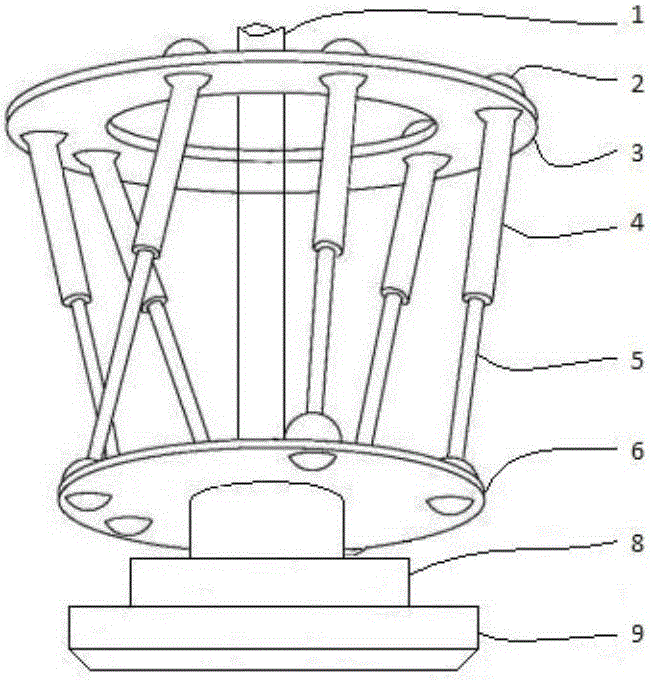

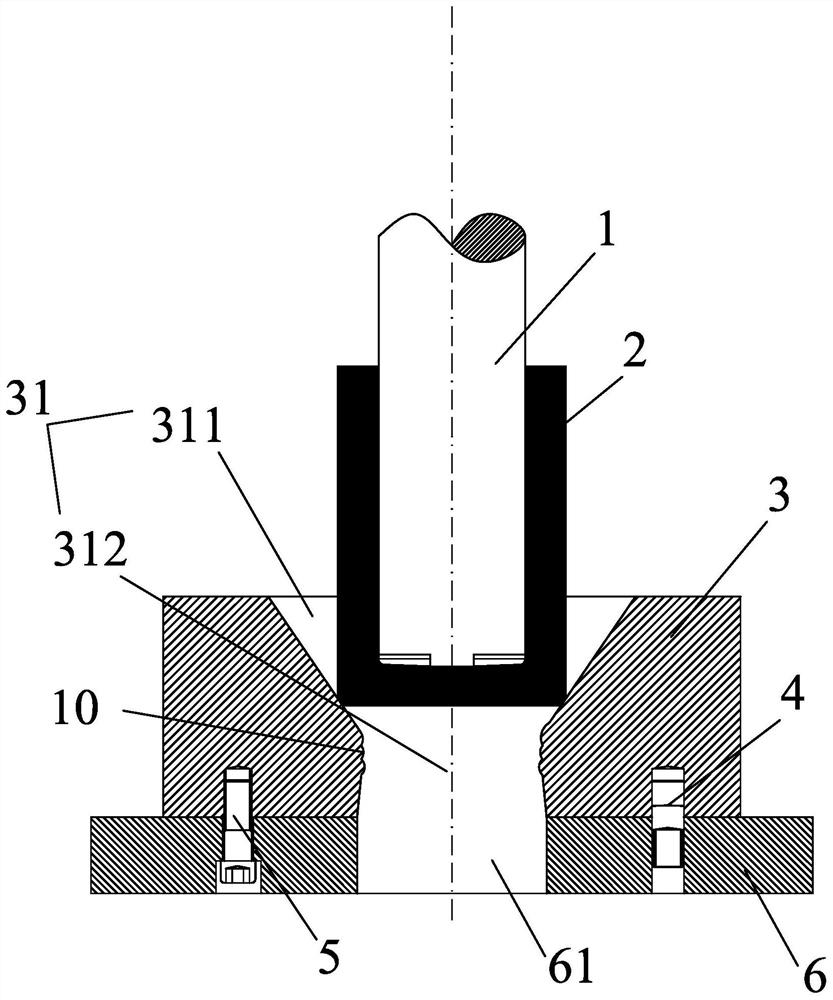

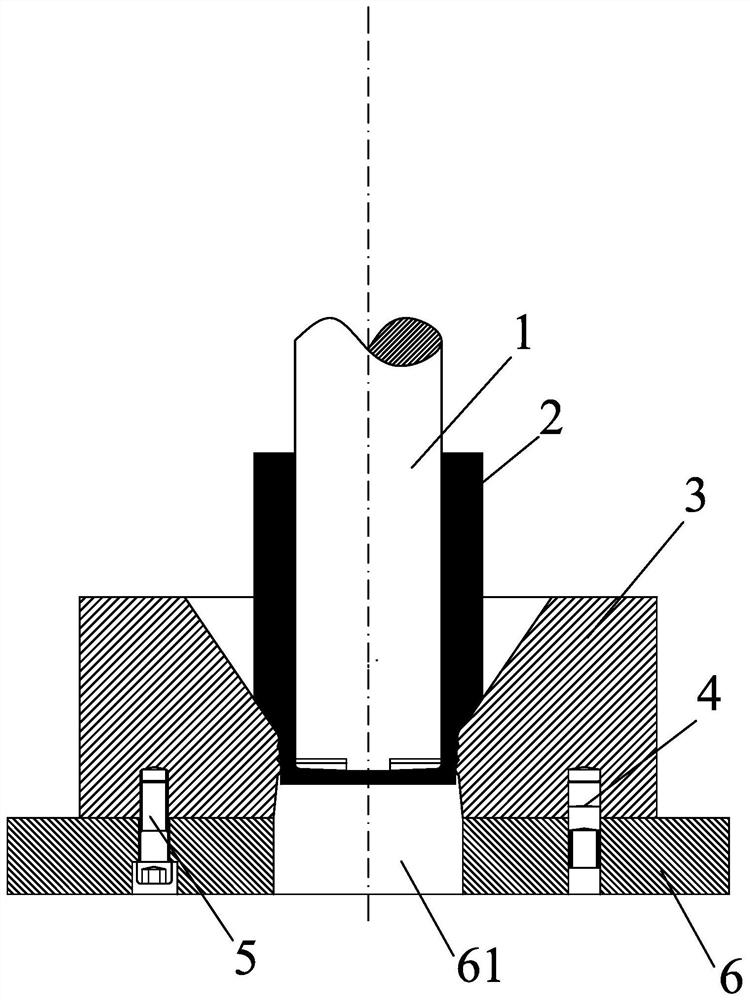

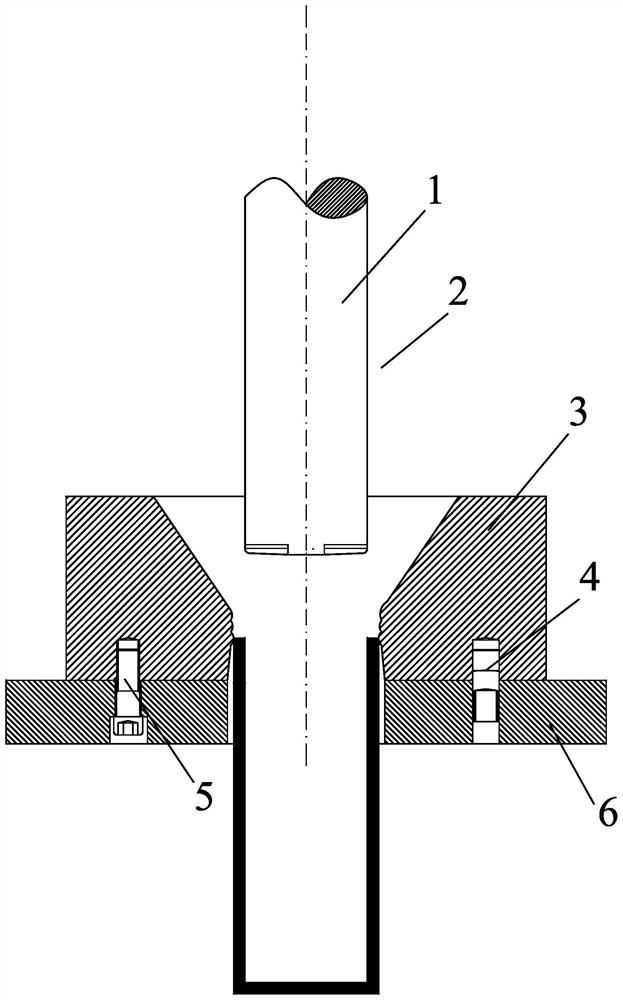

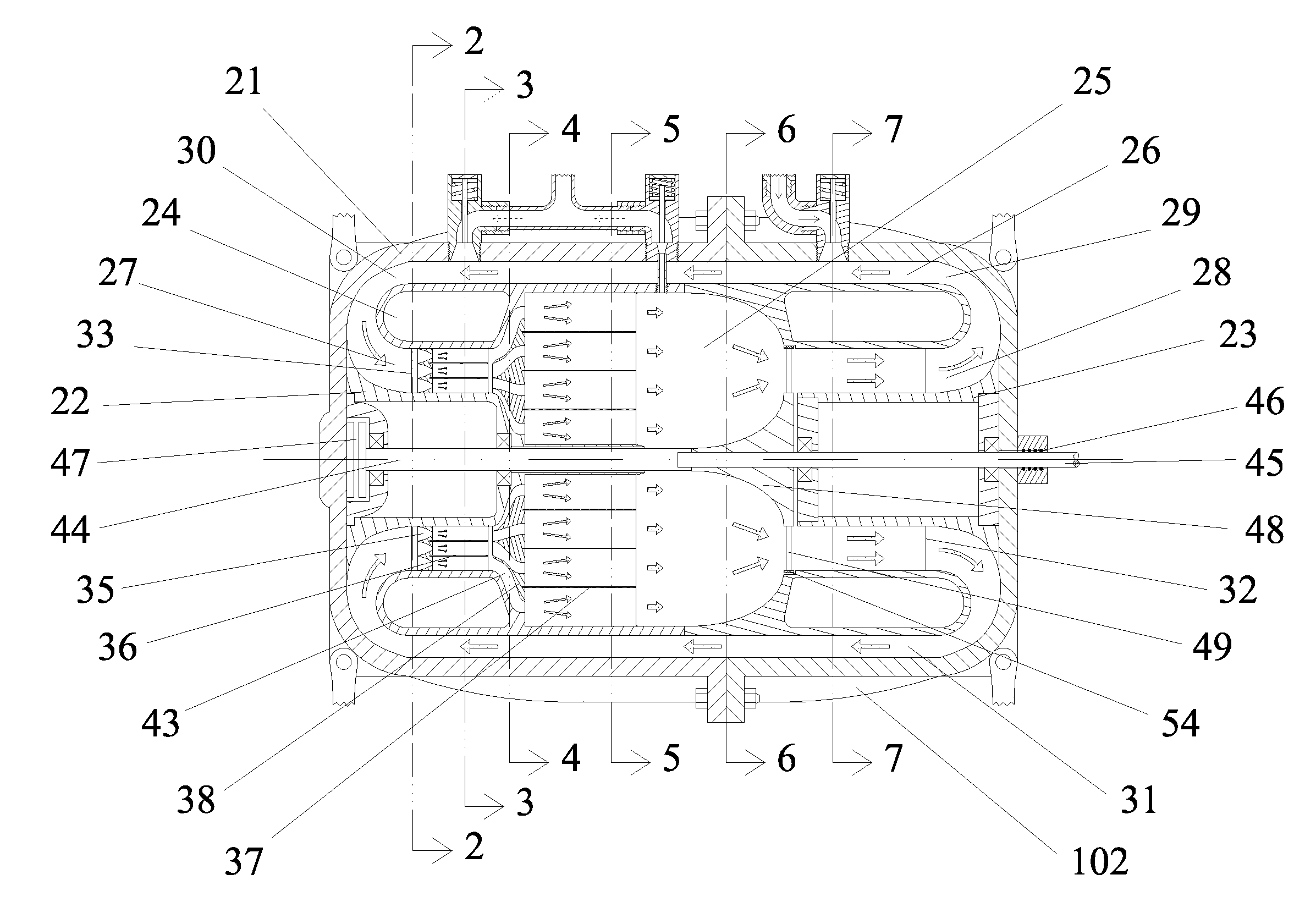

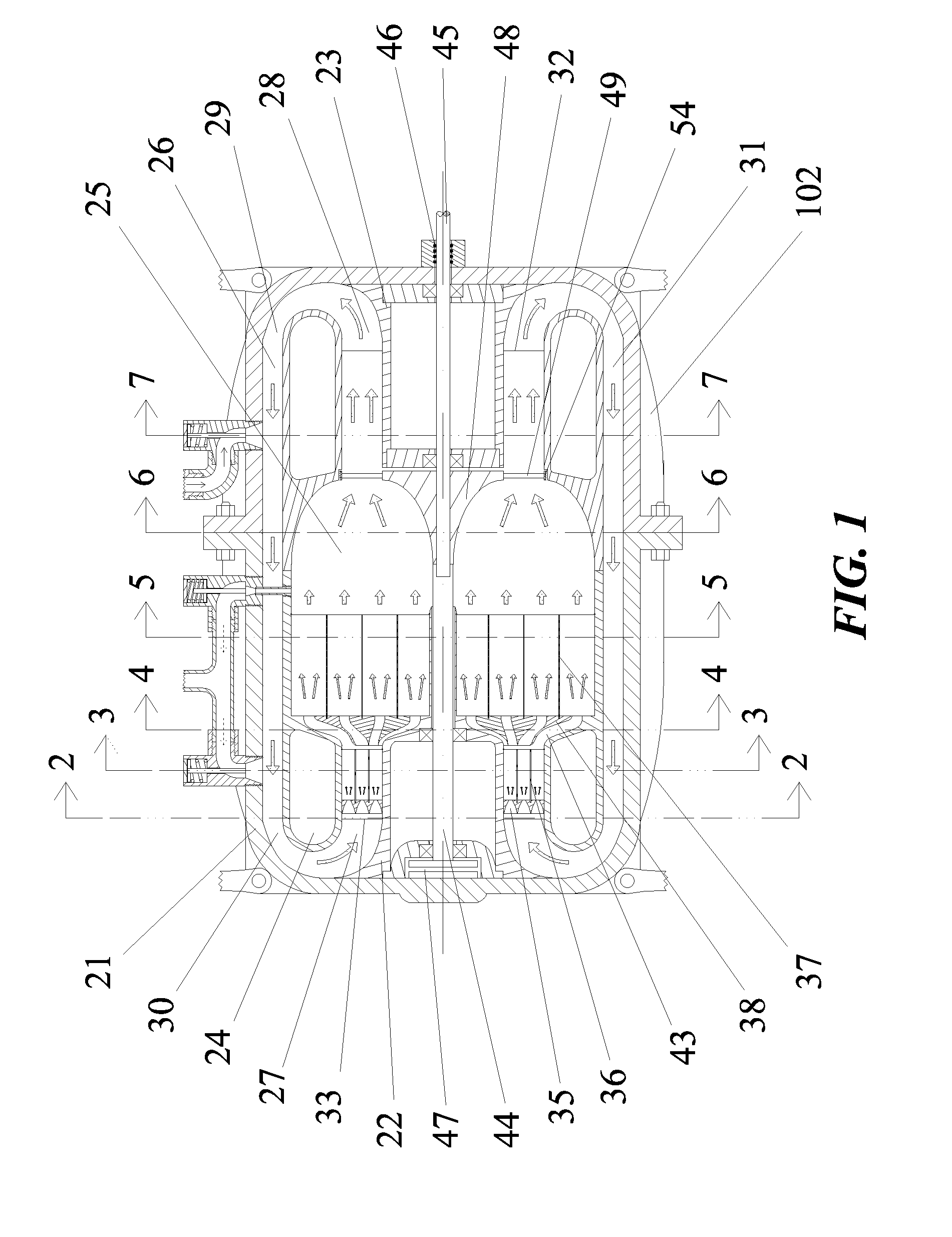

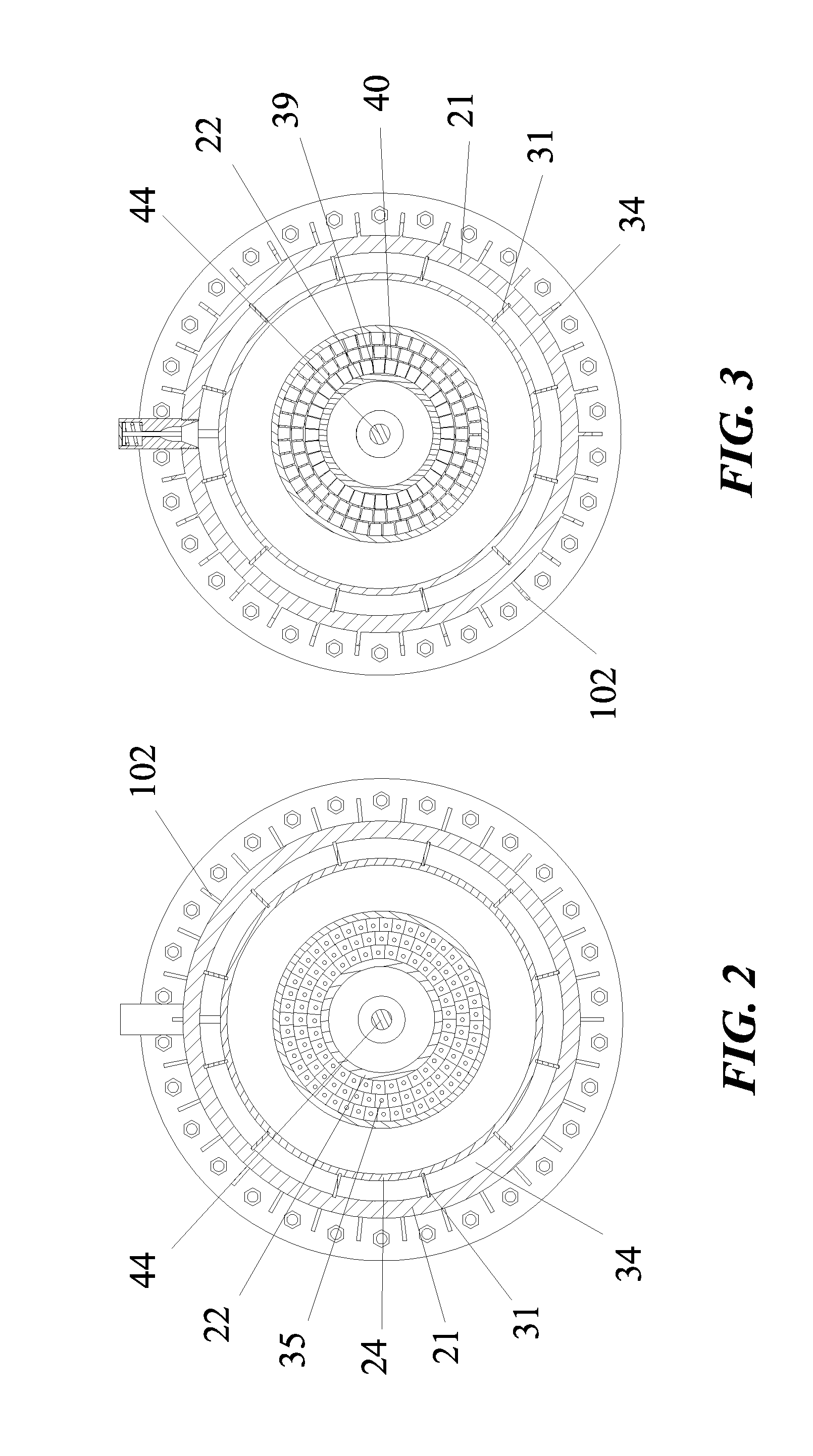

Rotary deep drawing forming mold of thin-wall cup-shaped part

ActiveCN111715793AReduce hydrostatic pressureIncrease hydrostatic pressureShaping toolsEngineeringUltimate tensile strength

The invention discloses a rotary deep drawing forming mold of a thin-wall cup-shaped part. The mold comprises a punch, a forming female mold and a lower mold plate, the forming female mold is coaxially provided with a composite mold cavity allowing a blank to be placed in, the end face of the contact of the punch and the blank is a conical boss mold face, the composite mold cavity is formed through compositing of a V mold cavity in the upper portion and a rectangular mold cavity in the lower portion, the two sides of the connecting position of the V mold cavity and the rectangular mold cavityare each provided with multi-pass arc convex face tables making contact with the blank, the multi-pass arc convex face tables are sequentially mounted from top to bottom, the arc radii of the convex face tables are sequentially increased, the number of the arc convex face tables on one side is larger than that of the arc convex face tables on the other side by one, the forming die mold is an asymmetric annular rotation body, the additional arc convex face table is mounted on the highest position on the side, according to the mold, the steel forming property can be improved, the forming component comprehensive mechanical property can be improved, and the defect that strength differences of all directions of a traditional thin drawing forming thin-wall cup-shaped part are large can be overcome.

Owner:ZHONGBEI UNIV

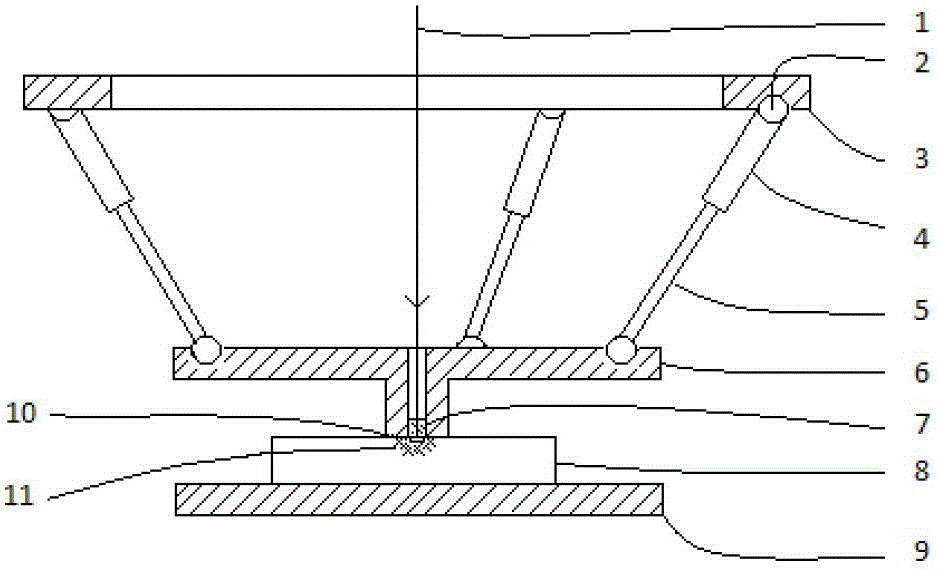

Plate incremental forming device and method based on overlaid double-layer auxiliary materials

The invention relates to a plate incremental forming device based on overlaid double-layer auxiliary materials. The plate incremental forming device comprises an upper auxiliary material, a lower auxiliary material and a tool head matched with the upper auxiliary material, and the upper auxiliary material and the lower auxiliary material are arranged on the two sides of a base material. Lubricating layers are arranged between the base material and the upper auxiliary material and between the base material and the lower auxiliary material. The tool head exerts pressure to the upper auxiliary material, so that the upper auxiliary material, the base material and the lower auxiliary material deform. A plate incremental forming method based on the device comprises the steps that 1) the lubricating layers are arranged on the upper surface and the lower surface of the base material and are attached to the upper auxiliary material and the lower auxiliary material, and a piled material is obtained; 2) the edge of the piled material is clamped and fixed, and processing is carried through the tool head; and 3) and the piled material is taken down, all the layers are separated, and the processed material is obtained. Compared with the prior art, it can be guaranteed that no residual height or processing mark exists on the surface of the base material, and high surface quality is achieved;and according to the plate incremental forming device based on the overlaid double-layer auxiliary materials and the plate incremental forming method, the stress state of base material forming can bechanged, friction force is reduced, and the forming limit of the base material is improved.

Owner:SHANGHAI JIAO TONG UNIV

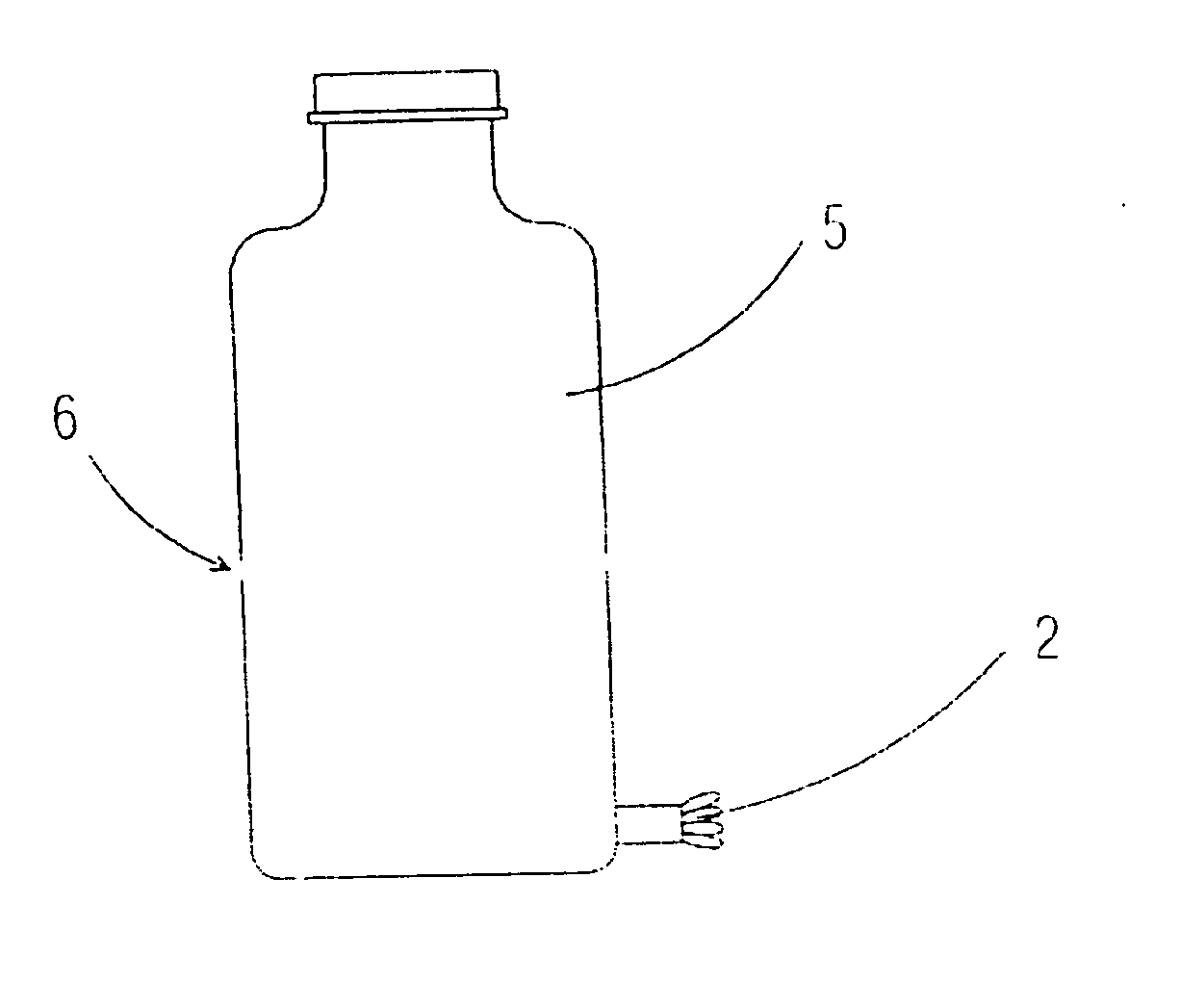

Device and container for irrigation by capillarity

InactiveUS20050204624A1Increase hydrostatic pressureReduce manufacturing costSelf-acting watering devicesWatering devicesFiberSoil science

It comprises a synthetic tissue provided inside a support (1) connected to the container (5, 7, 9, 12) for providing irrigation liquid to the soil, and means for controlling the vacuum degree of the upper part of the container (5, 7, 9, 12). The container (5, 7, 9, 12) is a bottle independent from the flowerpot or similar containing the soil and its lower part is placed onto the soil. The irrigation tissue is a set of fibres.

Owner:RIEGO DOMESTIKO SL

Reciprocating twisting and upsetting isometric angle forming method for preparing ultra-fine grain material

ActiveCN107893201ASolve the problem of uneven strainSolve the problem of limited sample sizeHydraulic cylinderUltra fine

The invention discloses a reciprocating twisting and upsetting isometric angle forming method for preparing an ultra-fine grain material. Based on a multi-station forming hydraulic machine, a combinedfemale die is adopted as the die, wherein an upper die and a lower die of the combined female die are split. An upper sliding block in the multi-station forming hydraulic machine is used for providing die combining force needed by the combined female die, and a die inner cavity of the combined female die is formed by sequentially connecting a left-side extruding channel, a twisting channel, a right-side extruding channel and an isometric angle extruding channel. Due to the fact that a left-side hydraulic cylinder located at the inlet end of the left-side extruding channel and a right-side hydraulic cylinder located at the inlet end of the isometric angle extruding channel are used for providing extruding force and back pressure force in turns. The right-side hydraulic cylinder is arrangedon an arc sliding rail, the position of the right-side hydraulic cylinder in the arc sliding rail is adjusted so that the set angle of the isometric angle extruding channel can be obtained. By meansof the reciprocating twisting and upsetting isometric angle forming method, the grain structure of the material can be refined to the ultra-fine grain level, the material strength and plasticity are obviously improved, the application range is wide, operation is easy and convenient, and industrial application is easy to achieve.

Owner:HEFEI UNIV OF TECH

Moisture permeation, ventilation and high hydrostatic pressure breathable film and preparation method thereof

InactiveCN110712350AExtended pathImprove breathabilityFlat articlesLinear low-density polyethyleneLow-density polyethylene

The invention discloses a preparation method of a moisture permeation, ventilation and high hydrostatic pressure breathable film. The preparation method of the moisture permeation, ventilation and high hydrostatic pressure breathable film includes following steps: (1) mixing raw materials to obtain a mixed material, wherein the raw materials are mixed according to the following weight percentage:5-20% of metallocene linear low density polyethylene, 10-20% of linear low density polyethylene and 60-85% of breathable material; (2) after extruding and fusing the mixed material through three-layerco-extrusion, extruding the mixed material from a mold head, wherein temperature of a screw is 180-200 DEG C, and temperature of the mold head is 190-200 DEG C; (3) after forming film buckles throughfilm blowing, performing cooling; (4) performing upward traction on the film buckles, wherein traction speed is 20m / min; (5) performing MDO (machine direction orientation) stretching on a film, setting heating temperature of the MDO stretching at 95 DEG C, completing 4-5 times of stretching through a stretching roller, and forming the breathable film; and (6) preforming corona treatment. The preparation method of the moisture permeation, ventilation and high hydrostatic pressure breathable film solves the puzzle that high moisture permeability, high breathability and high hydrostatic pressurecannot coexist in an existing breathable film.

Owner:山东恒鹏卫生用品有限公司

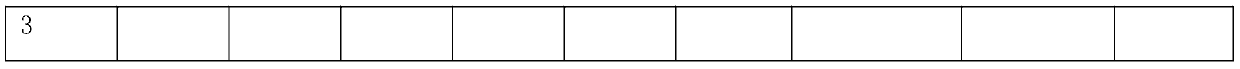

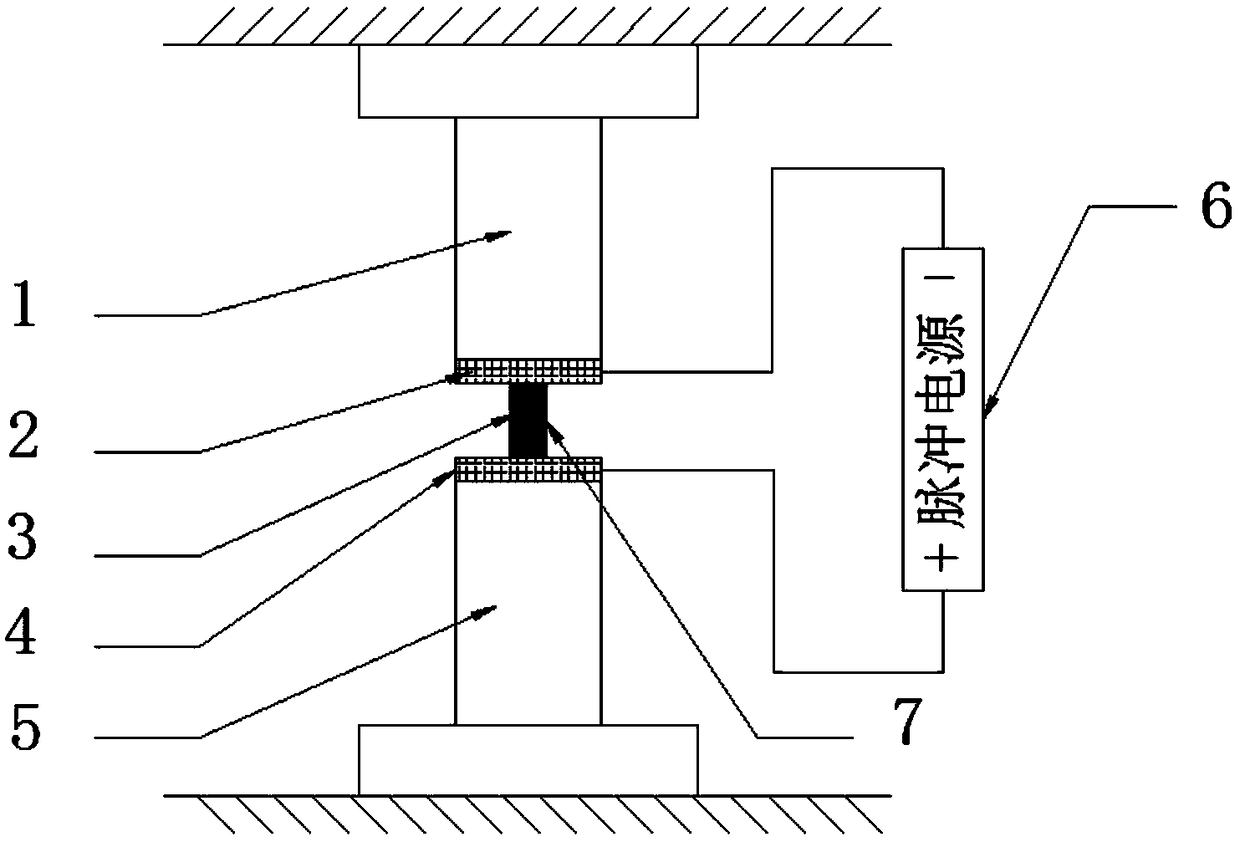

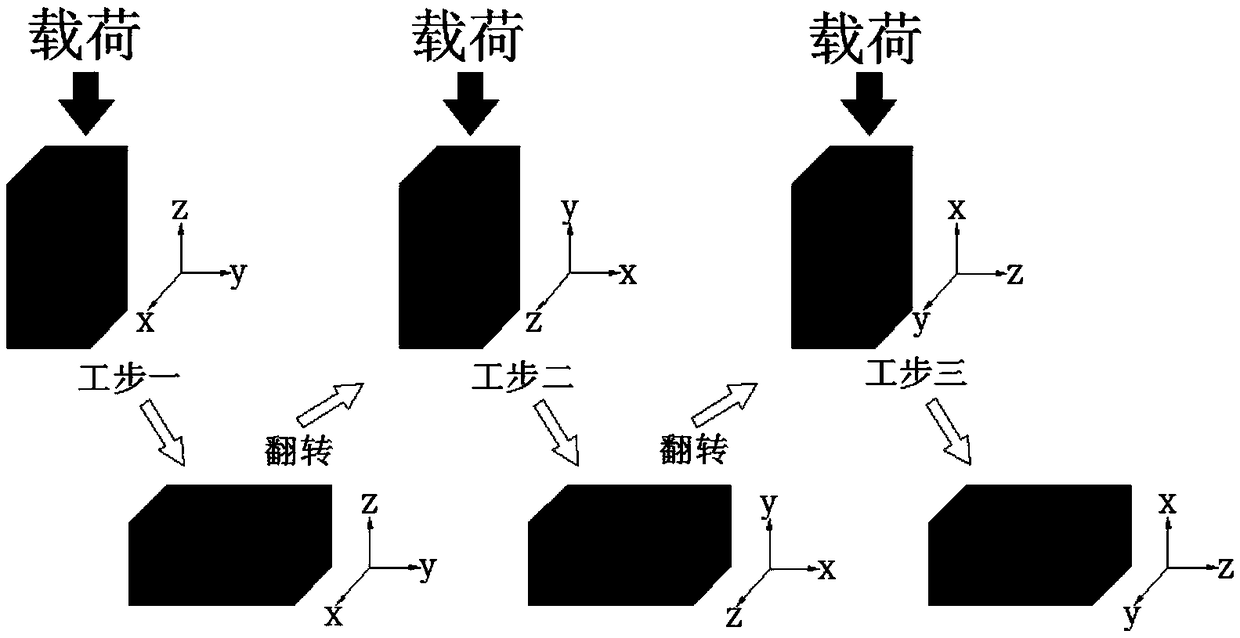

Electro-plastic multi-directional forging method and device for spray-formed aluminum alloy

InactiveCN109201983AHigh degree of densificationImprove mechanical propertiesForging hammersForging/hammering/pressing machinesIngotSpray forming

The invention discloses an electro-plastic multi-directional forging method and device for a spray-formed aluminum alloy. The electro-plastic multi-directional forging method comprises the steps thata spray-formed aluminum alloy blank is cut into an aluminum alloy ingot blank which is in a cuboid shape; sleeving processing is performed on the cut aluminum alloy ingot blank, and the whole aluminumalloy ingot blank is tightly wrapped with a steel plate; the sleeved aluminum alloy ingot blank is forged in the Z direction of the height of the cuboid, and an impulse current is applied to the aluminum alloy ingot blank at the same time; the aluminum alloy ingot blank is turned over, and forging is performed on the aluminum alloy ingot blank in the Y direction and is supplemented by the impulsecurrent; the aluminum alloy ingot blank is continuously turned over, and forging is performed on the aluminum alloy ingot blank in the X direction and is supplemented by the impulse current to complete one-pass electro-plastic multi-directional forging; the step (3) is repeated to complete multiple-pass electro-plastic multi-directional forging; and a spray-formed aluminum alloy blank is obtainedafter a sleeve is removed. The electro-plastic multi-directional forging method and device for the spray-formed aluminum alloy are suitable for densification of the spray-formed aluminum alloy ingotblank, and the spray-formed aluminum alloy blank with fine grain structures, uniform dispersion distribution of a second phase, a high degree of densification and good mechanical properties can be obtained.

Owner:HEFEI UNIV OF TECH

Soft high-strength terylene SMS composite non-woven material and manufacturing method thereof

ActiveCN105586719AImprove toughnessFiber thinningNon-woven fabricsHydrostatic pressureMechanical property

The invention relates to a soft high-strength terylene SMS composite non-woven material. The soft high-strength terylene SMS composite non-woven material is in a three-layer structure. The structure comprises a modified terylene spun-bonded non-woven material on an upper layer and on a lower layer, and a modified terylene meltblown non-woven material on a middle layer. The surface density of the soft high-strength terylene SMS composite non-woven material is 20-100 g / m<2>, longitudinal strength is 40-200 N / 5cm, longitudinal bending rigidity is 0.1-1 cN.cm, horizontal strength is 60-300 N / 5cm, and horizontal bending rigidity is 0.2-1.5 cN.cm. The soft high-strength terylene SMS composite non-woven material has excellent mechanical property and relatively high hydrostatic pressure. In addition, the invention also provides a manufacturing method for the soft high-strength terylene SMS composite non-woven material.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

Closed-cycle hydro-jet thruster

InactiveUS20130298540A1Raise the ratioIncrease hydrostatic pressureRotary clutchesTransmission with non-mechanical gearingJet propulsionWorking fluid

The present invention provides closed-cycle hydro jet thruster (CCHJT) used for the direct conversion of torque into thrust and / or lift force. In a preferred embodiment, the CCHJT includes an outer casing; two inner-members; an intermediate body; a plurality of convergent nozzles; a set of intersecting members; a drive shaft; a rotor assembly having a plurality of blades; a hydraulic fluid completely filling the space within the casing; and a fluid pressure regulating system. In operation, the rotating blades accelerate and compress the hydraulic fluid leading to generation of thrust / lift force on the blades, which is transmitted to the CCHJT's casing through thrust bearings. This is followed by acceleration of the working fluid within the nozzles, suddenly expanding the accelerated working fluid within sub-passages defined in-between the intersecting members, and then directing the flow of the working fluid towards the upstream suction surfaces of the blades for re-acceleration.

Owner:MARCUS ESSAM TAWFIK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com