Biological degradable gas-permeable membrane for paper diaper and preparation method of biological degradable gas-permeable membrane

A technology for diapers and breathable films, applied in the field of organic polymer films, can solve the problems of air and water pollution, waste of land resources, etc., and achieve the effects of high degree of spheroidization, good flatness and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

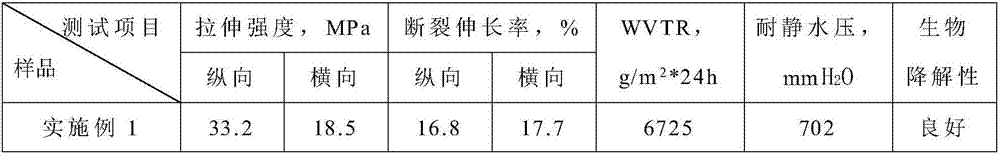

Examples

Embodiment 1

[0027] A biodegradable breathable film for paper diapers, comprising a spunbonded non-woven fabric layer made of corn fiber and a film layer made of polylactic acid PLA as a base material, and the two layers are laminated by hot pressing. The film layer of lactic acid PLA as the base material includes the following components in parts by mass: 50 parts of polylactic acid, 40 parts of cross-linked polystyrene, 0.5 part of lubricant, 0.1 part of antioxidant and 0.1 part of color masterbatch, the The particle size of the cross-linked polystyrene is 1 μm.

[0028] The above-mentioned preparation method of the biodegradable breathable film for paper diapers comprises the following steps:

[0029] 1) Spinning the corn fiber, laying it into a net shape, and bonding by hot pressing to obtain a spunbonded non-woven fabric layer;

[0030] 2) Mix and stir the components of the film layer evenly according to the mass ratio, extrude and granulate through a twin-screw machine to obtain fil...

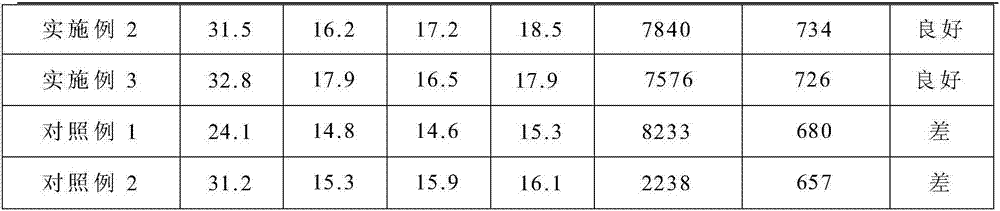

Embodiment 2

[0036] A biodegradable breathable film for diapers, comprising a spun-bonded non-woven fabric layer made of flax and a film layer based on polylactic acid PLA, the two layers are laminated by hot pressing, and the polylactic acid The film layer with PLA as the base material includes the following components in parts by mass: 54 parts of polylactic acid, 42 parts of cross-linked polystyrene, 0.8 part of lubricant, 0.2 part of antioxidant and 0.3 part of color masterbatch. The particle size of polystyrene is 3 μm.

[0037] The above-mentioned preparation method of the biodegradable breathable film for paper diapers comprises the following steps:

[0038] 1) flax fibers are spun, spread into a net shape, and bonded by hot pressing to obtain a spun-bonded non-woven fabric layer;

[0039] 2) Mix and stir the components of the film layer evenly according to the mass ratio, extrude and granulate through a twin-screw machine to obtain film layer masterbatch particles, wherein the ext...

Embodiment 3

[0045] A biodegradable breathable film for diapers, comprising a spun-bonded non-woven fabric layer made of bamboo fiber and a film layer made of polylactic acid PLA as a base material, and the two layers are laminated by hot pressing. Lactic acid PLA is the film layer of base material and comprises the following components in parts by mass: 60 parts of polylactic acid, 45 parts of cross-linked polystyrene, 1.2 parts of lubricant, 0.3 part of antioxidant and 0.5 part of color masterbatch, said The particle size of the cross-linked polystyrene is 5 μm.

[0046] The above-mentioned preparation method of the biodegradable breathable film for paper diapers comprises the following steps:

[0047] 1) Bamboo fiber is spun, spread into a net shape, and bonded by hot pressing to obtain a spun-bonded non-woven fabric layer;

[0048] 2) Mix and stir the components of the film layer evenly according to the mass ratio, extrude and granulate through a twin-screw machine to obtain film laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com