Plate incremental forming device and method based on overlaid double-layer auxiliary materials

A progressive forming and auxiliary material technology, applied in the field of material processing, can solve the problems of not being able to improve the surface quality of the target sheet metal, and achieve the effects of increasing the forming limit, improving processing efficiency, and increasing hydrostatic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

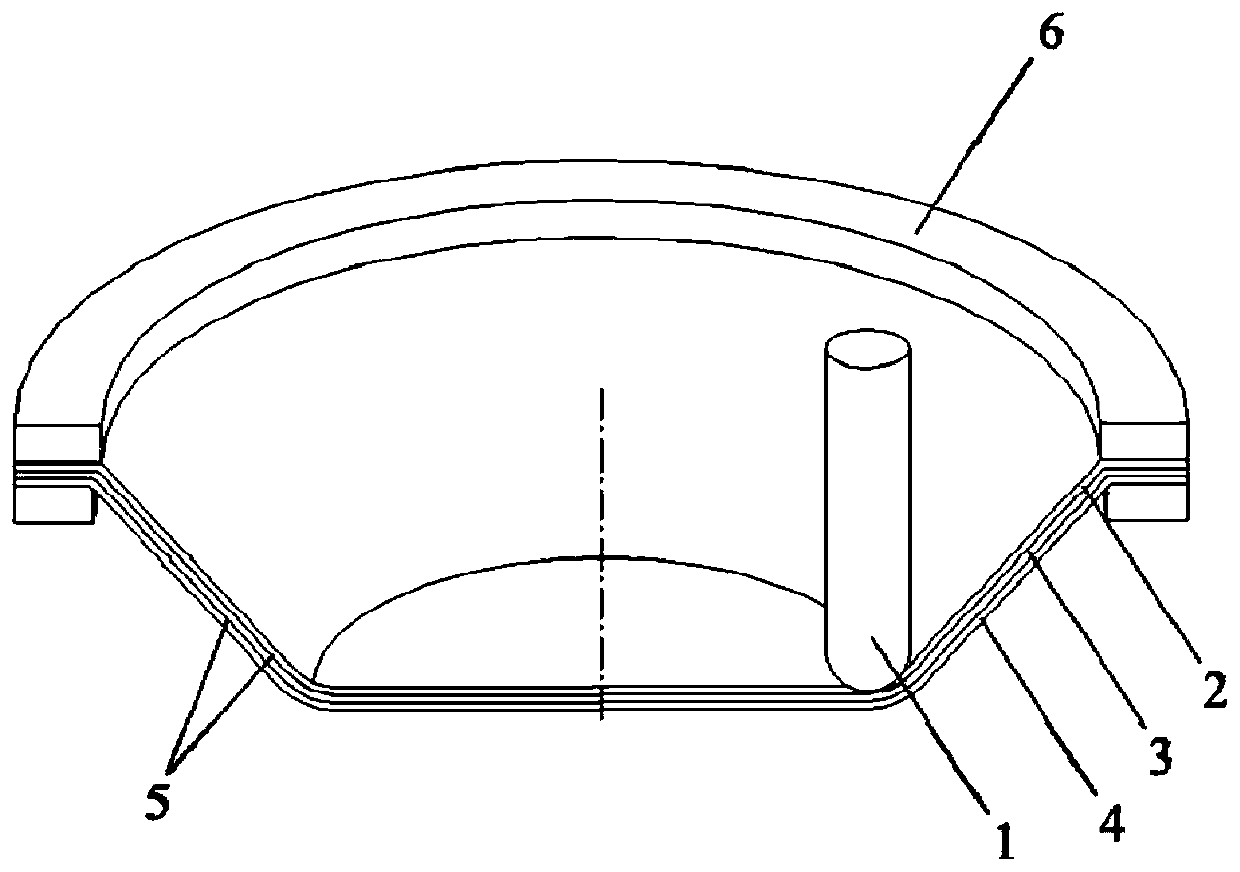

[0036] Such as figure 1 A sheet metal progressive forming device based on superimposed double-layer auxiliary materials is shown, including tool head 1, upper auxiliary material 2, base material 3, lower auxiliary material 4 and lubricating oil 5, upper auxiliary material 2 and lower auxiliary material 4 The shape is suitable for the base material 3 to be processed, and they are respectively laid on the upper and lower surfaces of the base material 3, and the lubricating oil 5 is filled between the base material 3 and the upper auxiliary material 2 and between the base material 3 and the lower auxiliary material 4. , the tool head 1 applies force to the base material 3 through the upper auxiliary material 2 to perform incremental forming processing, and the lubricating oil 5 is coated on the surface of the base material 3 to reduce the friction between it and the upper auxiliary material 2 and the lower auxiliary material 4, At the same time, it is guaranteed that the base mat...

Embodiment 2

[0043] Such as figure 1Shown is a sheet metal progressive forming device based on superimposed double-layer auxiliary materials. The device is used to process the base material 1, and mainly includes an upper auxiliary material 2 and a lower auxiliary material 4 respectively arranged on both sides of the base material 3 and The tool head 1 matching the upper auxiliary material 2, between the upper auxiliary material 2 and the base material 3, and between the lower auxiliary material 4 and the base material 3 are provided with a lubricating layer 5, and the tool head 1 passes through the upper auxiliary material 2 Pressure is applied to deform the upper auxiliary material 2 , the base material 3 and the lower auxiliary material 4 , so that the base material 3 can be progressively formed under the protection of the upper auxiliary material 2 and the lower auxiliary material 4 .

[0044] The upper auxiliary material 2 is used to protect the processed surface of the base material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com