Tissue engineering interbody fusion cage for cervical vertebra and using method

An intervertebral fusion device and tissue engineering technology, which is applied in the field of tissue engineering cervical intervertebral fusion device, can solve problems affecting fusion quality and long-term effect, affecting radiological examination, and bone fusion cannot be judged, etc., to achieve good fusion Quality and long-term effect, facilitate bone healing, achieve bone healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of tissue engineering cervical intervertebral fusion device

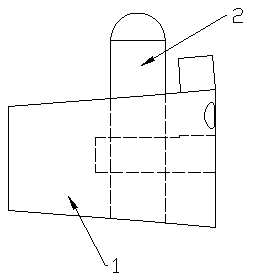

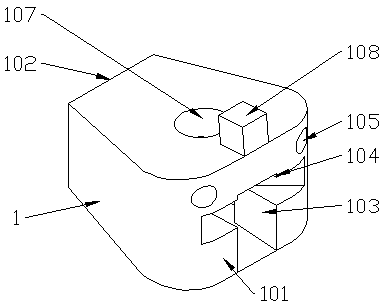

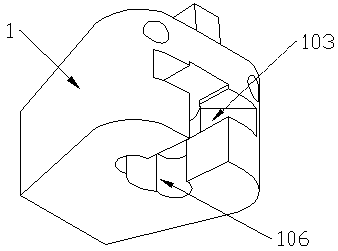

[0041] Such as Figure 1-8 Commonly shown, the present invention provides a tissue engineering cervical intervertebral fusion device, including a fusion device body 1, the inside of the fusion device body 1 is pierced with a stud 2 for insertion into the vertebral body for fixation, and the stud 2 is self-locking Inside the fusion device body 1; the fusion device body 1 and the stud 2 are porous scaffolds formed by 3D printing of absorbable medical polymer materials.

[0042]The shape of the fusion device body 1 is a wedge-shaped structure suitable for the angle of the cervical spine. The fusion device body 1 includes a front end surface 101 and a rear end surface 102. The height of the front end surface 101 is greater than the height of the rear end surface 102; Hole 103, the adjustment hole 103 extends horizontally from the front end surface 101 to the inside of the fusion device body 1...

Embodiment 2

[0044] Embodiment 2 A method of using tissue engineering cervical intervertebral fusion device

[0045] Include the following steps:

[0046] Step 1: Use absorbable medical polymer materials to 3D print the porous scaffold of fusion cage body 1 and post plug 2 according to the pre-set specifications and models, and load matrix materials that induce bone regeneration or cartilage regeneration into the scaffold; Make the scaffold produce micropores suitable for bone cells to grow into; take the patient's bone marrow stromal stem cells and load them into the scaffold for stem cell induction culture; no matter whether the cage for osteoinduction or cartilage induction culture is placed in the intervertebral space, it will grow towards the bone.

[0047] Step 2: Process a groove and a hole on the vertebral body on the adjacent side where the intervertebral fusion device is pre-installed with an instrument. The position and shape of the groove match the positioning protrusion 108, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com