Medical degradable magnesium alloy interbody fusion cage

A technology of intervertebral fusion and magnesium alloy, which is applied in the field of intervertebral fusion, can solve problems such as stress shielding and improper selection of elastic modulus of inflammation, and achieve the effect of avoiding stress shielding, avoiding stress shielding effects, and avoiding non-specific inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

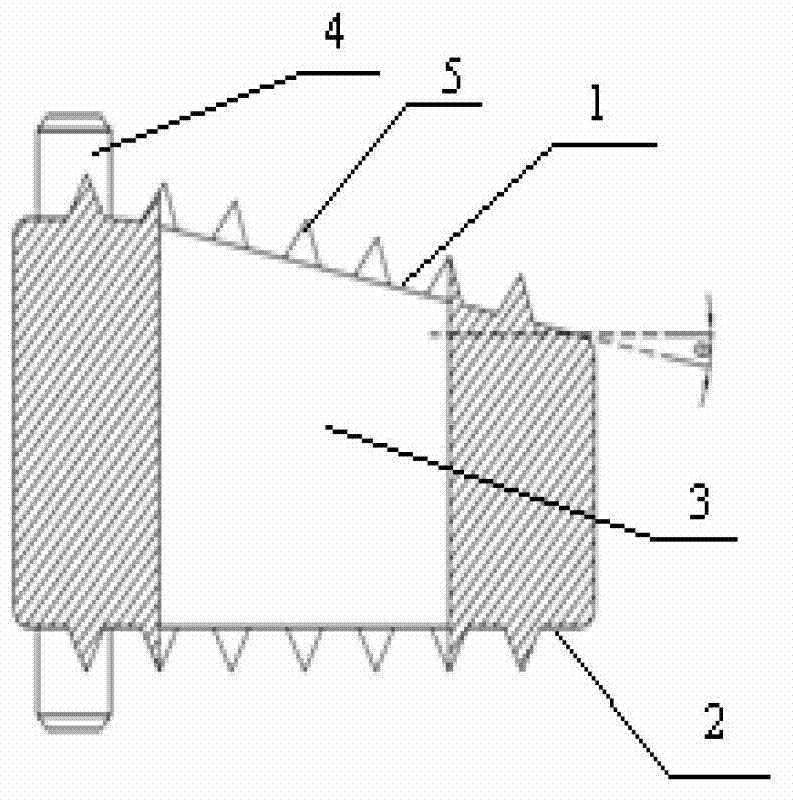

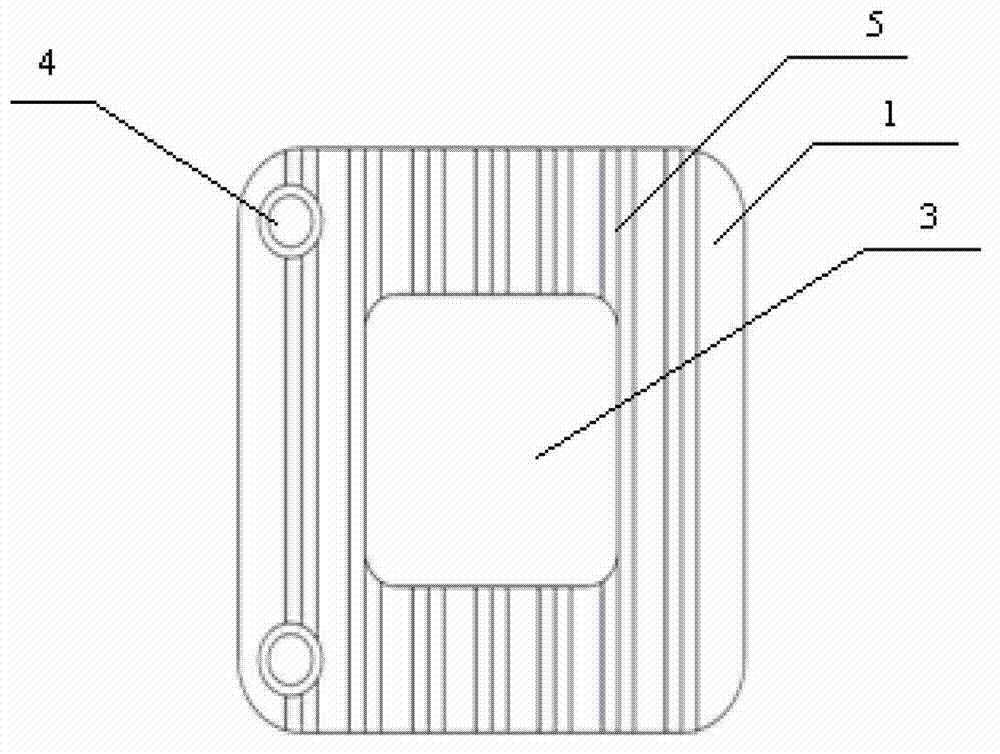

[0021] Embodiment 1: The medical degradable magnesium alloy intervertebral fusion device in this embodiment is a polygonal column with a through hole (3) along its axis, and its upper endplate contact surface (1) and lower endplate The surface of the contact surface (2) has occlusal teeth (5), which is characterized in that the surfaces of the upper endplate contact surface (1) and the lower endplate contact surface (2) have protruding studs (4), which consist of Made of Mg-Sn-Mn alloy, the mass percentage content of Sn is 1%~3%, the mass percentage content of Mn is 0.15%~1%, and the mass percentage content of impurity elements Fe, Cu and Ni is 0~0.006 %, the balance is Mg.

[0022] The material selection basis of the present invention is: magnesium is one of the metal elements with the most abundant reserves on the earth, and is also one of the most abundant cations in the human body. It is an indispensable and important nutritional element for the human body. Medical materi...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass percentage content of the described Sn is 2%, the mass percentage content of Mn is 0.5%, and the mass percentage content of the impurity elements Fe, Cu and Ni is 0.005%, the mass percentage content of Mg is 97.495%. Other structures and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: The medical degradable magnesium alloy intervertebral fusion device in this embodiment is a polygonal column with a through hole (3) along its axis, and its upper endplate contact surface (1) and lower endplate The surface of the contact surface (2) has occlusal teeth (5), which is characterized in that the surfaces of the upper endplate contact surface (1) and the lower endplate contact surface (2) have protruding studs (4), which consist of Made of Mg-Sn-Mn-Zn alloy, wherein the mass percentage content of Sn is 1%~5%, the mass percentage content of Mn is 0.15%~1.5%, the mass percentage content of Zn is 0.5%~3%, and the impurity The mass percentage content of elements Fe, Cu and Ni is 0~0.006%, and the balance is Mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com