Patents

Literature

107results about How to "Avoid stress shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

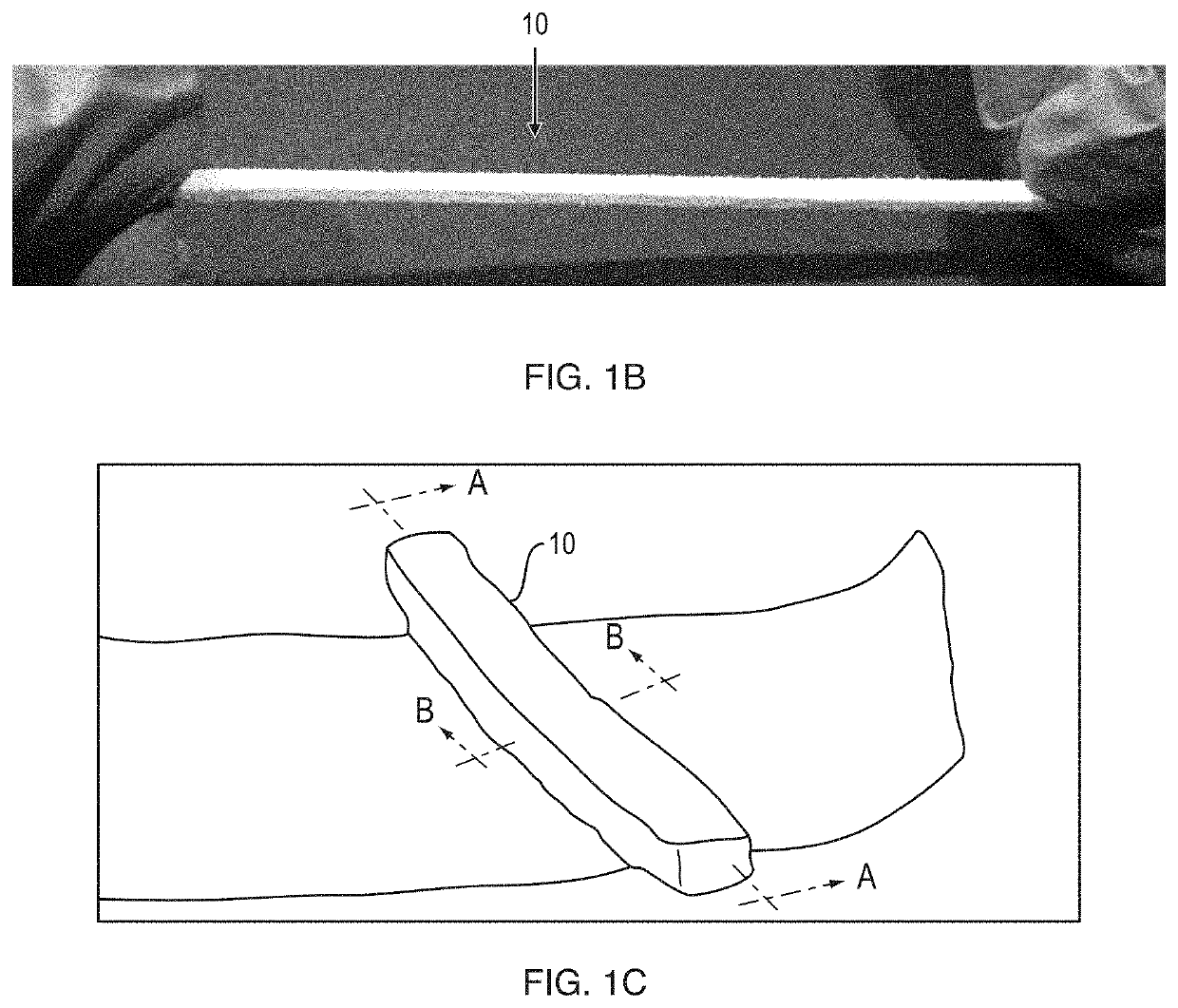

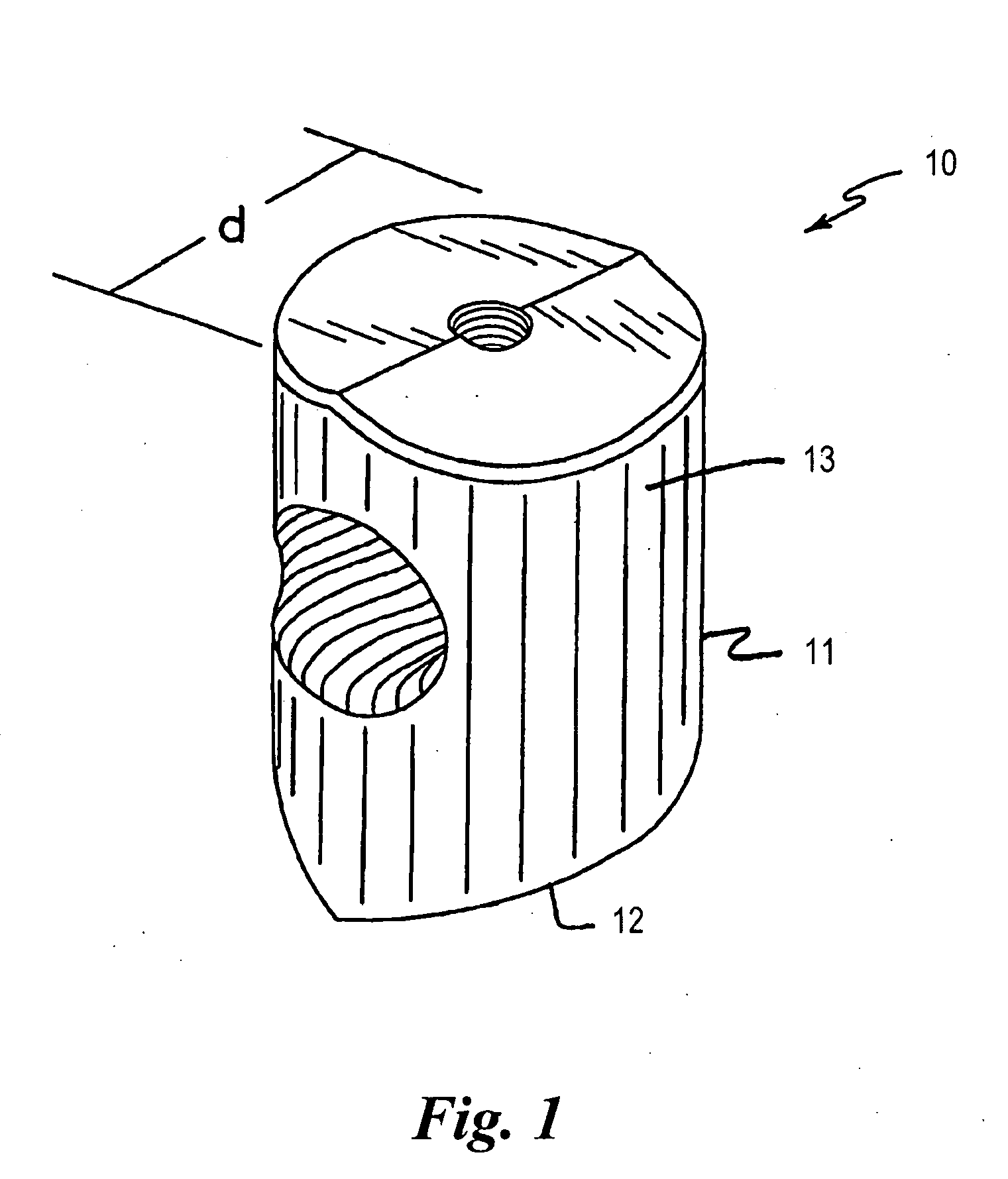

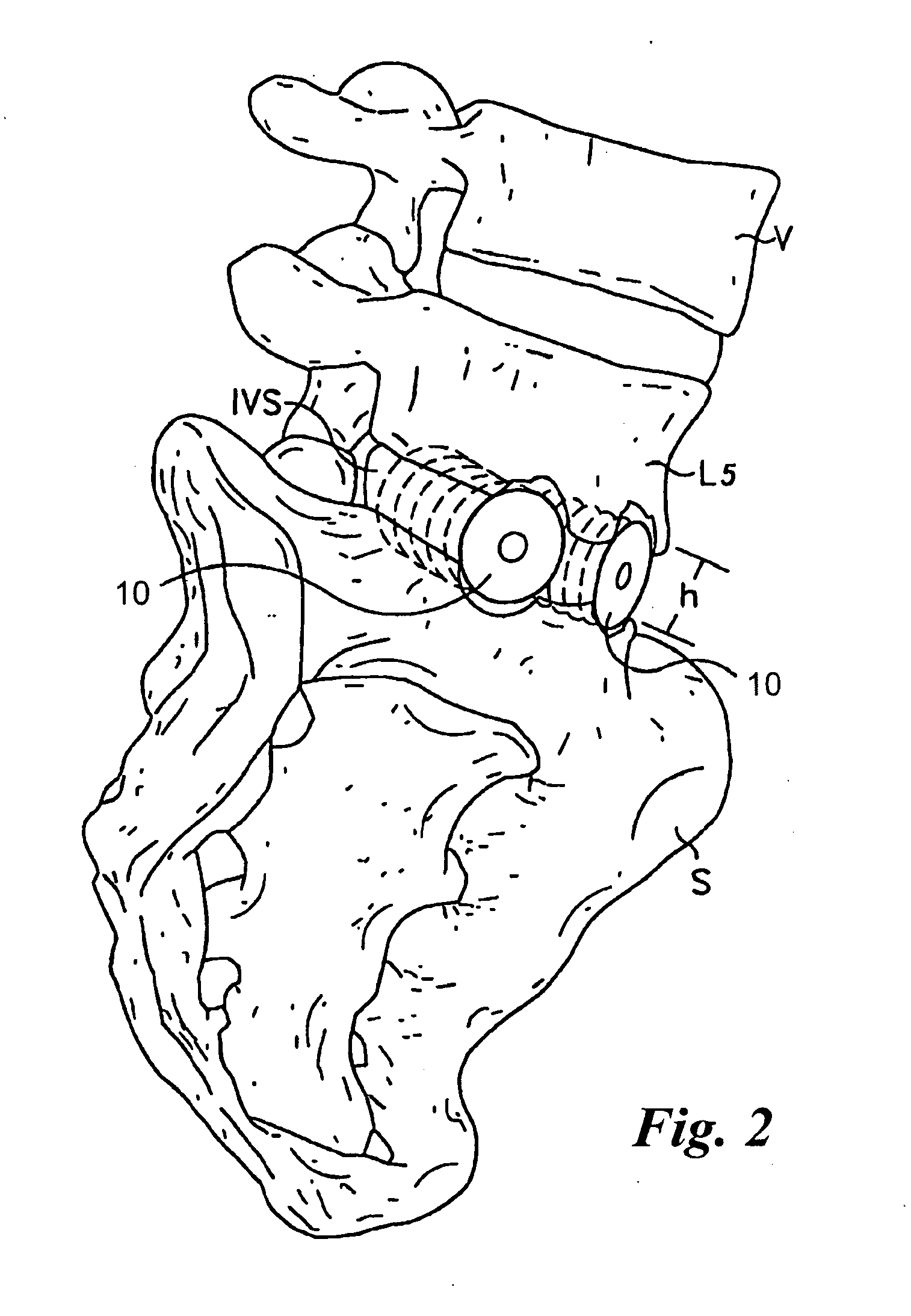

Apparatus and method for providing dynamizable translations to orthopedic implants

InactiveUS20050085812A1Avoid stress shieldingLimited supportSuture equipmentsInternal osteosythesisBone structureJoint arthrodesis

The present invention generally relates to orthopedic devices and methods for treating bone defects. The orthopedic devices can provide sufficient support to the bone defect while allowing bone ingrowth and minimizing the risk to stress shield and / or pseudo-arthrodesis. The bone fixation devices include a biodegradable material or component that further resists relative motion of attached bones and allows the device to gradually transfer at least some load from the device to the growing bone structure in vivo and permitting an increase in the relative motion of bones attached to the device.

Owner:WARSAW ORTHOPEDIC INC

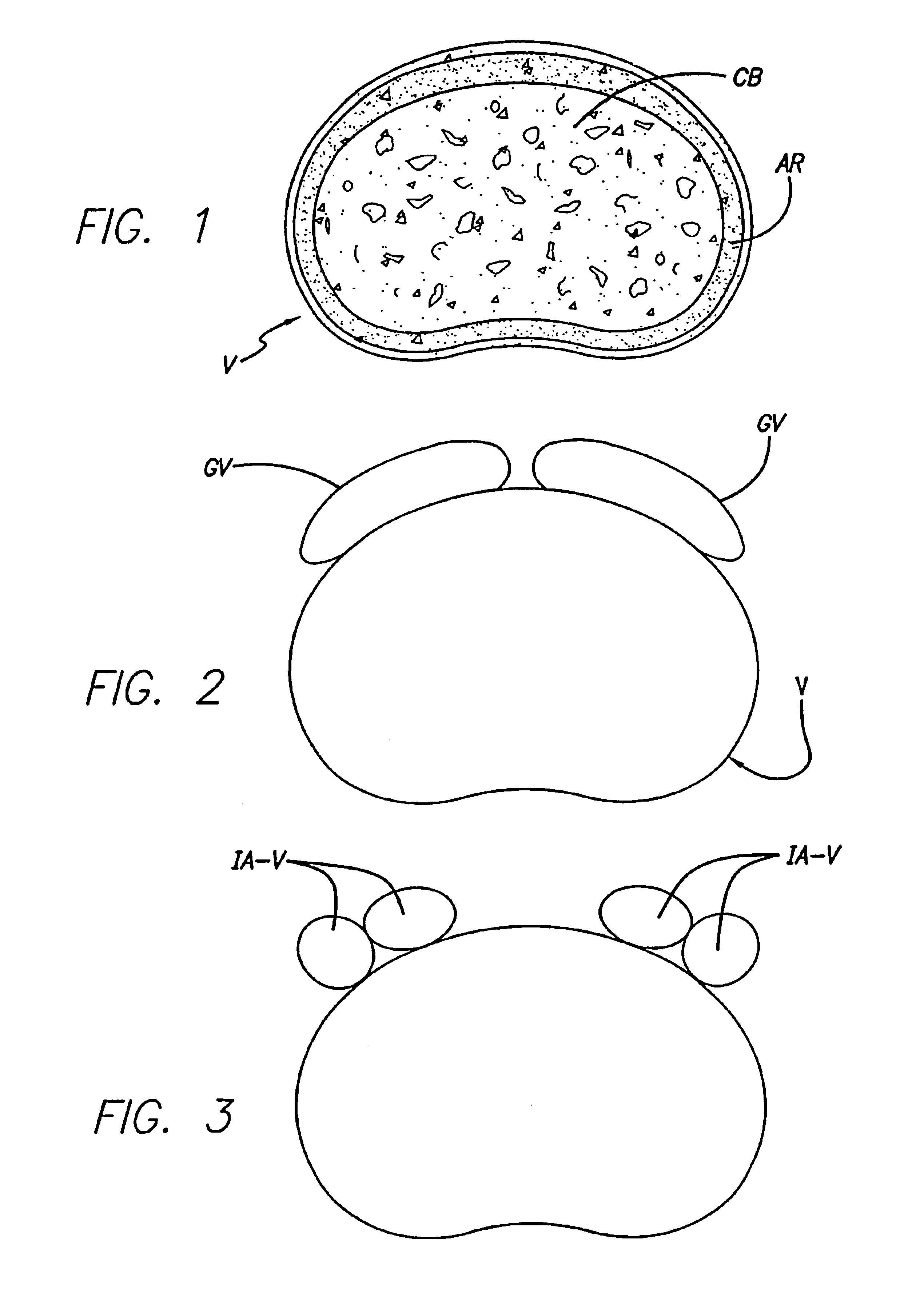

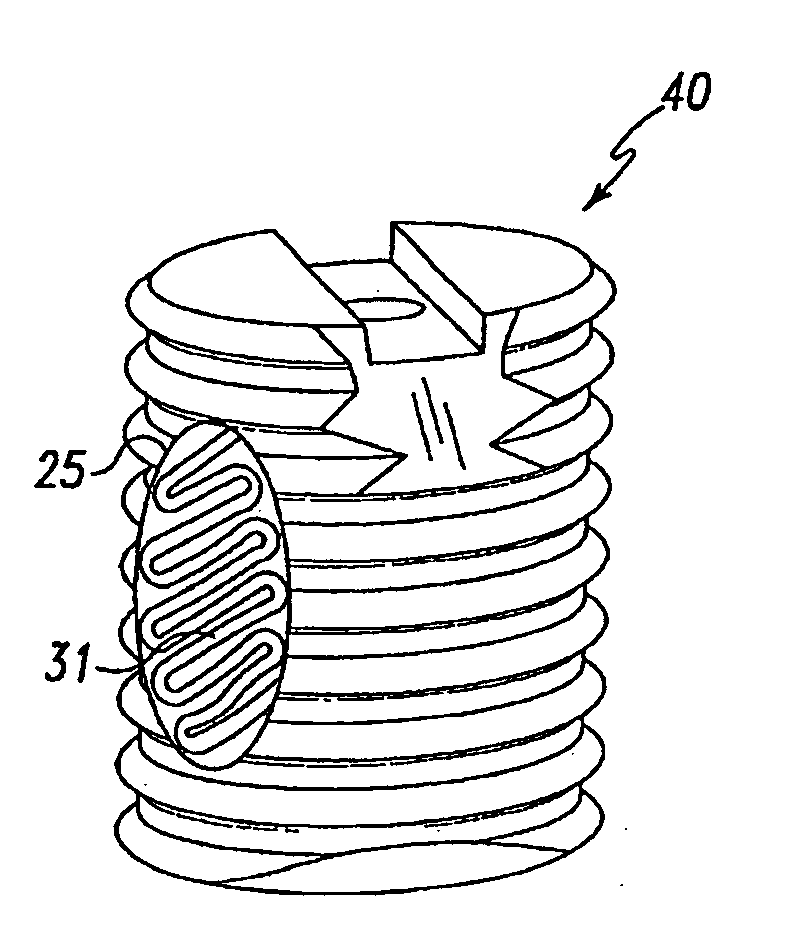

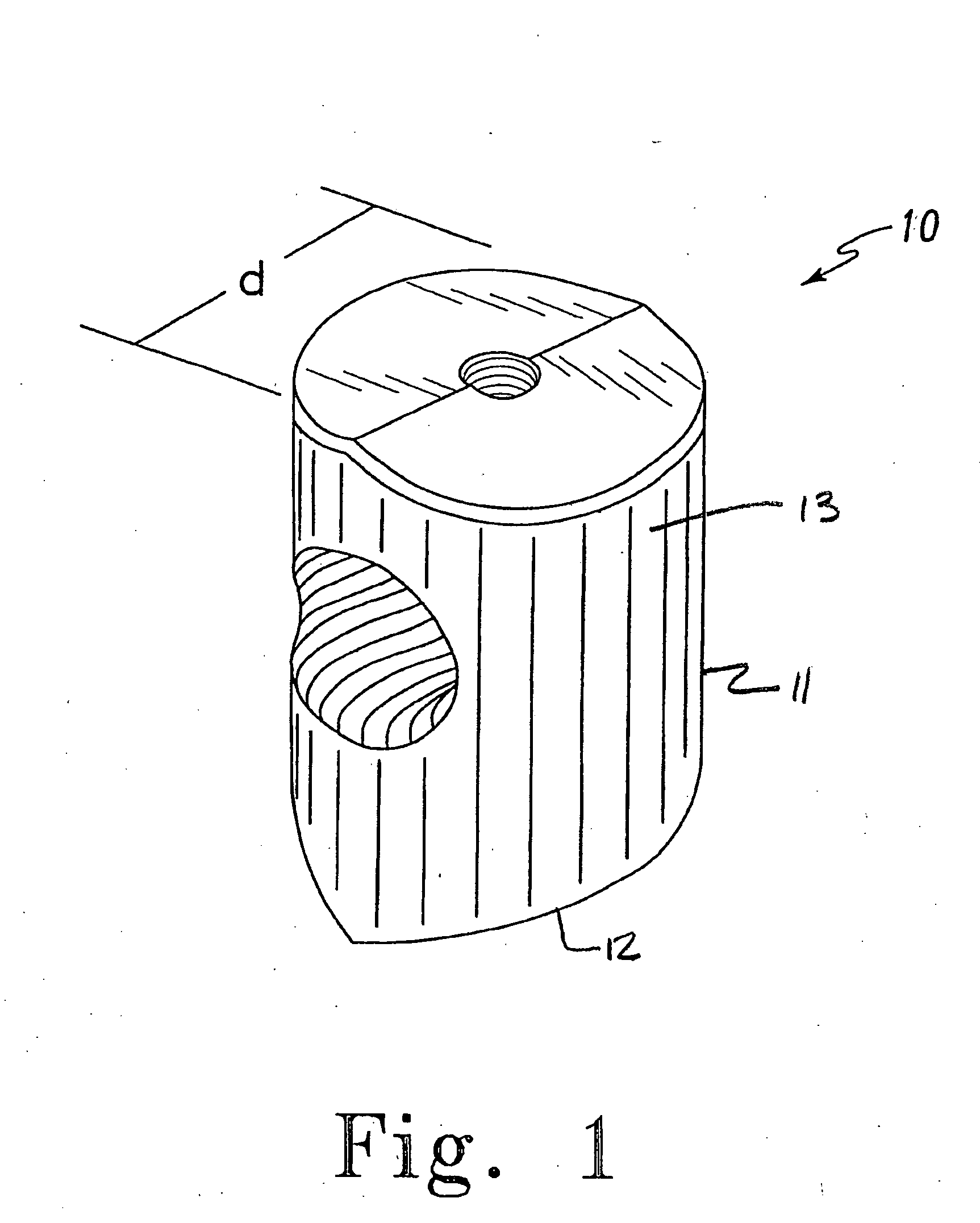

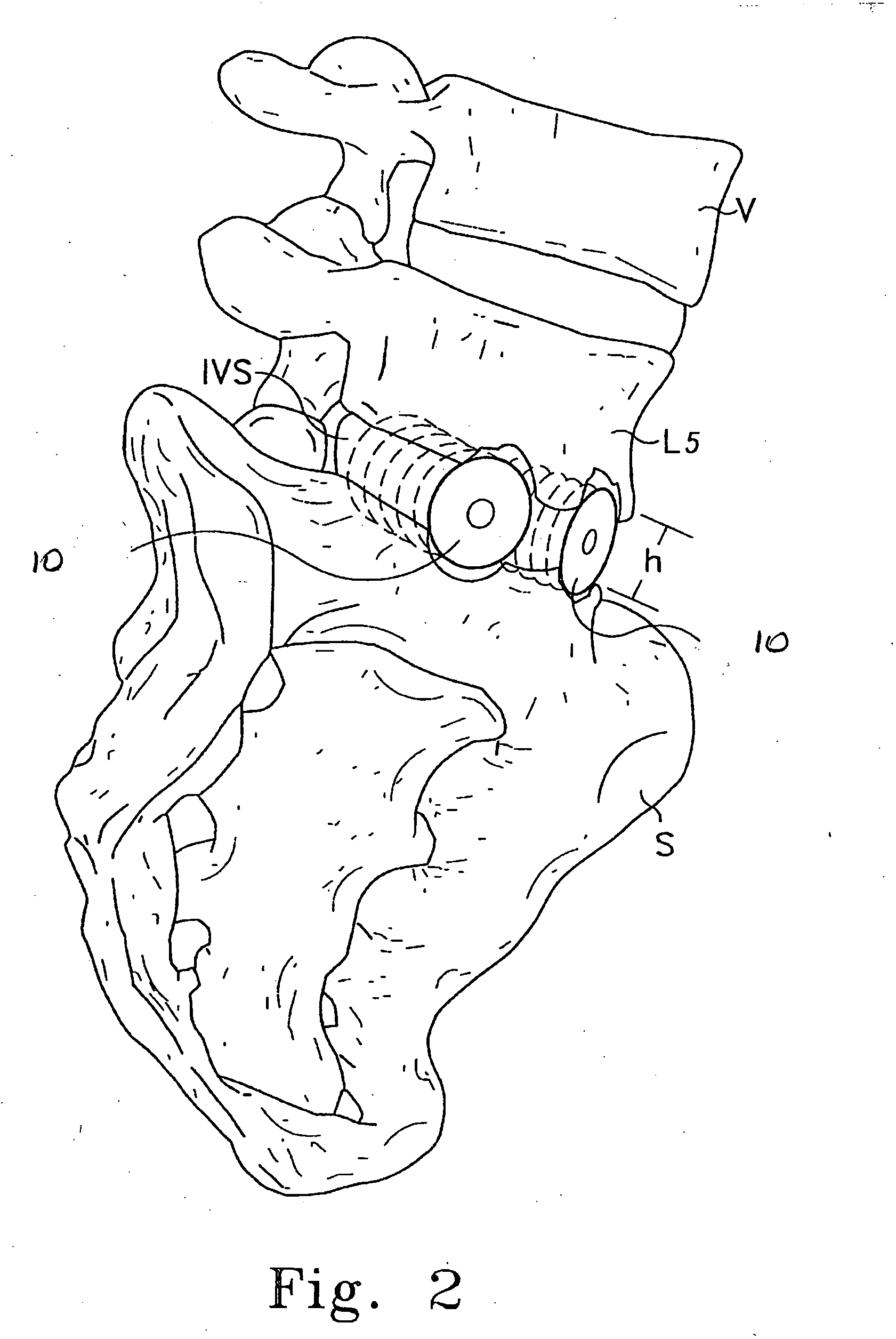

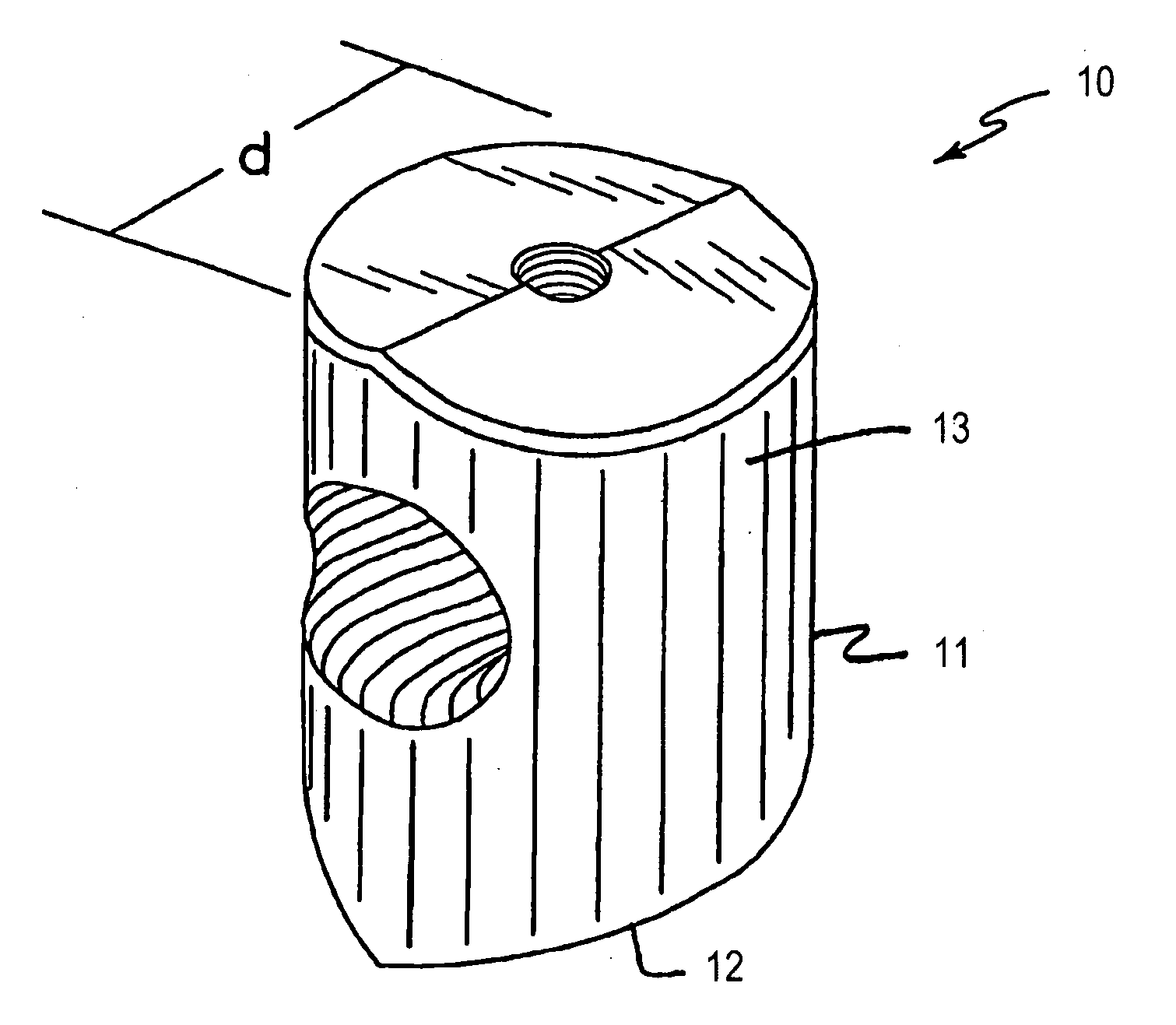

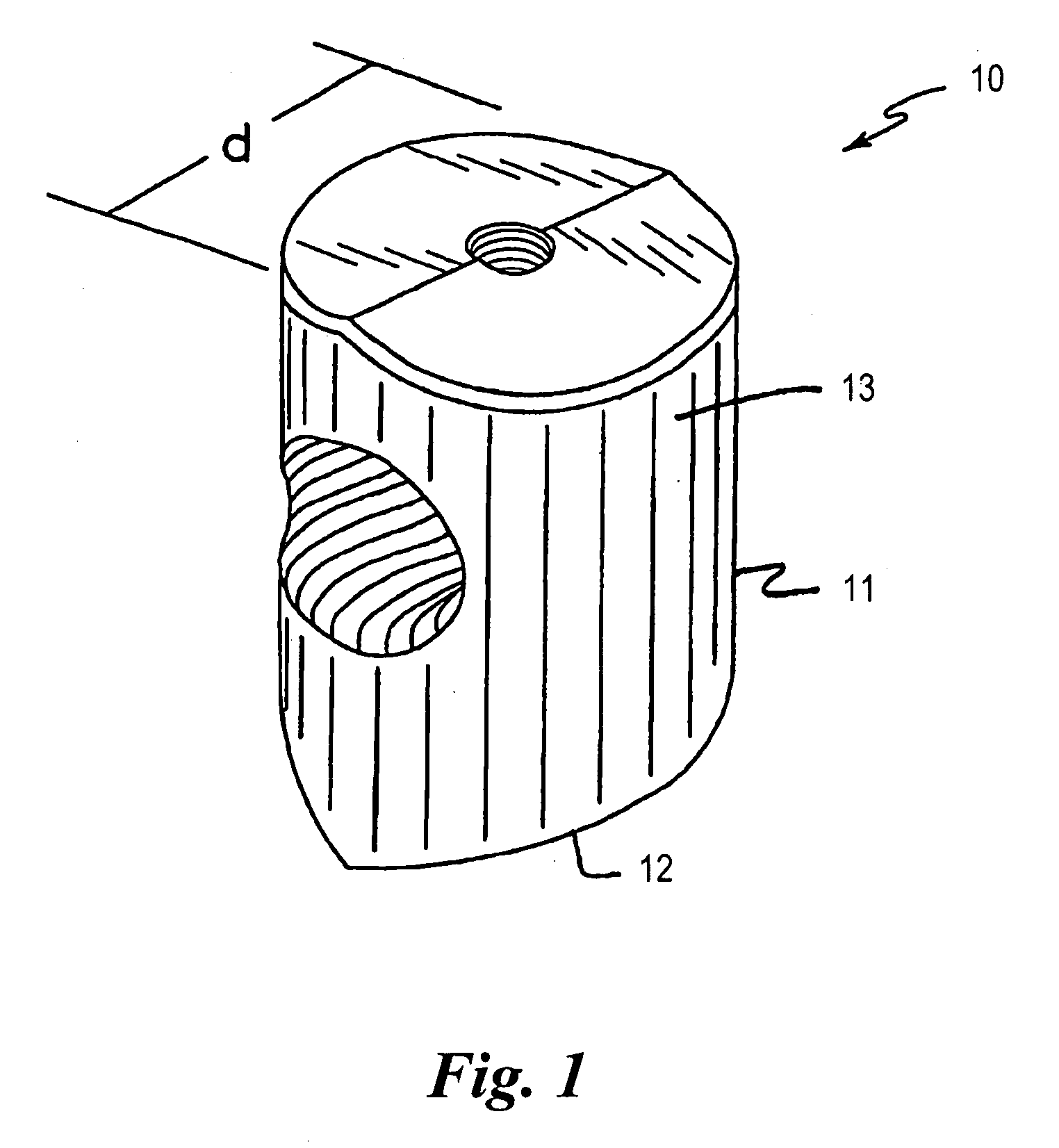

Bone grafts

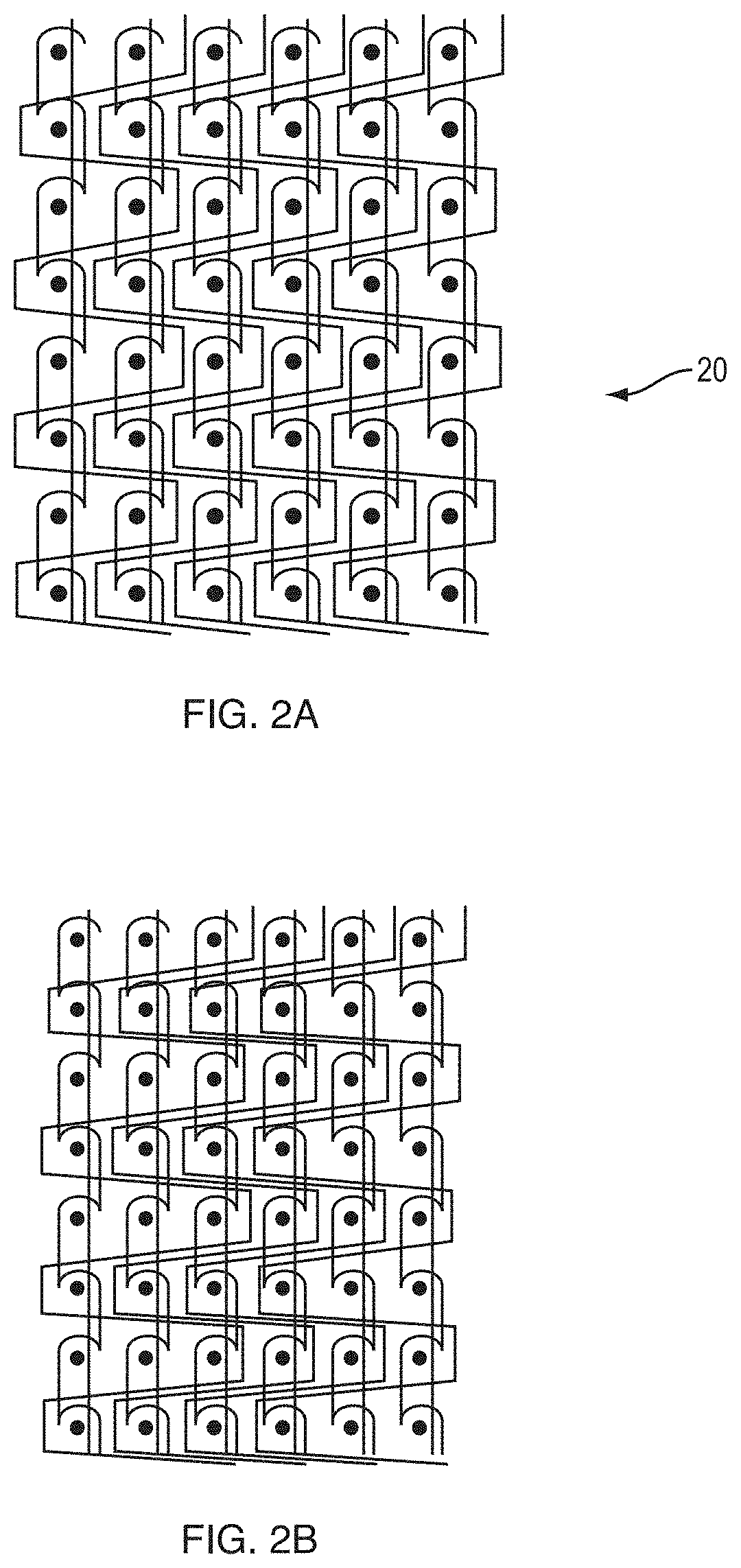

InactiveUS20050004672A1Encourages bone ingrowthAvoid stress shieldingDiagnosticsBone implantBiomedical engineeringVertebra

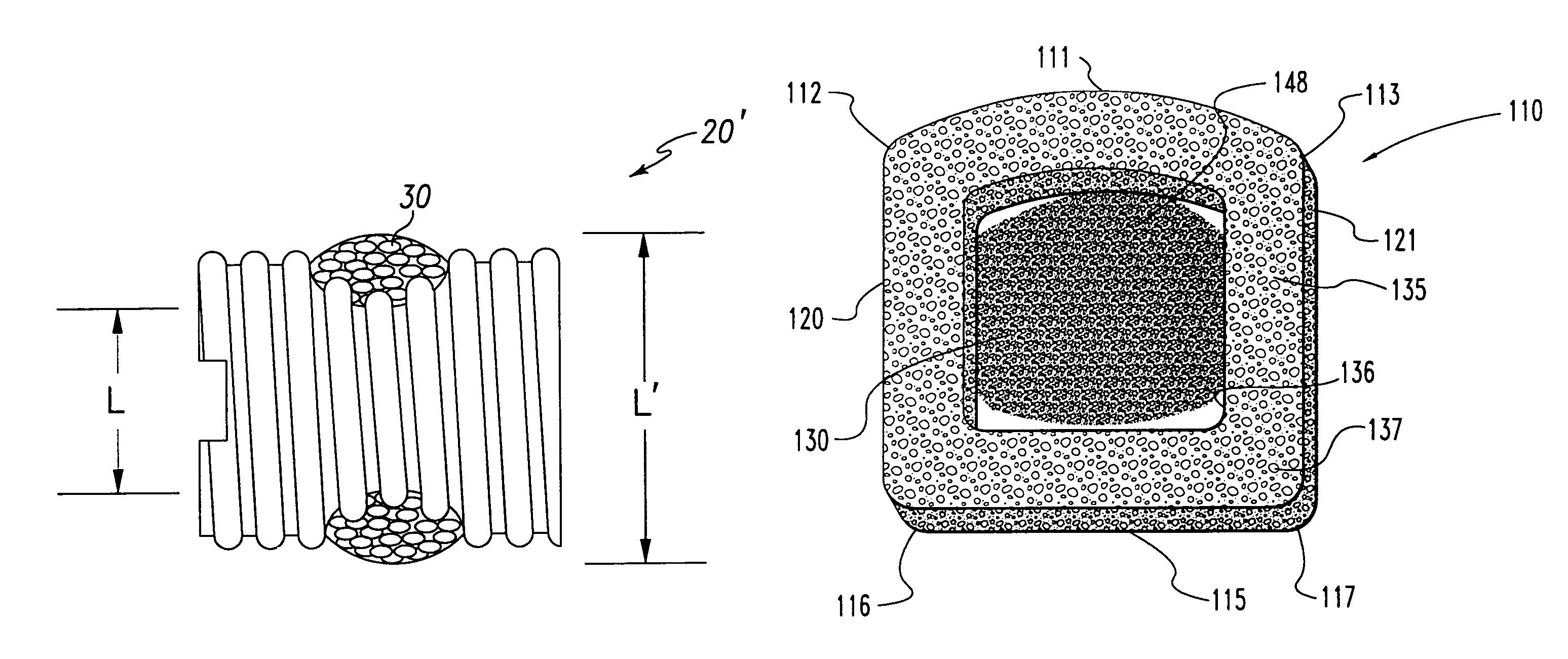

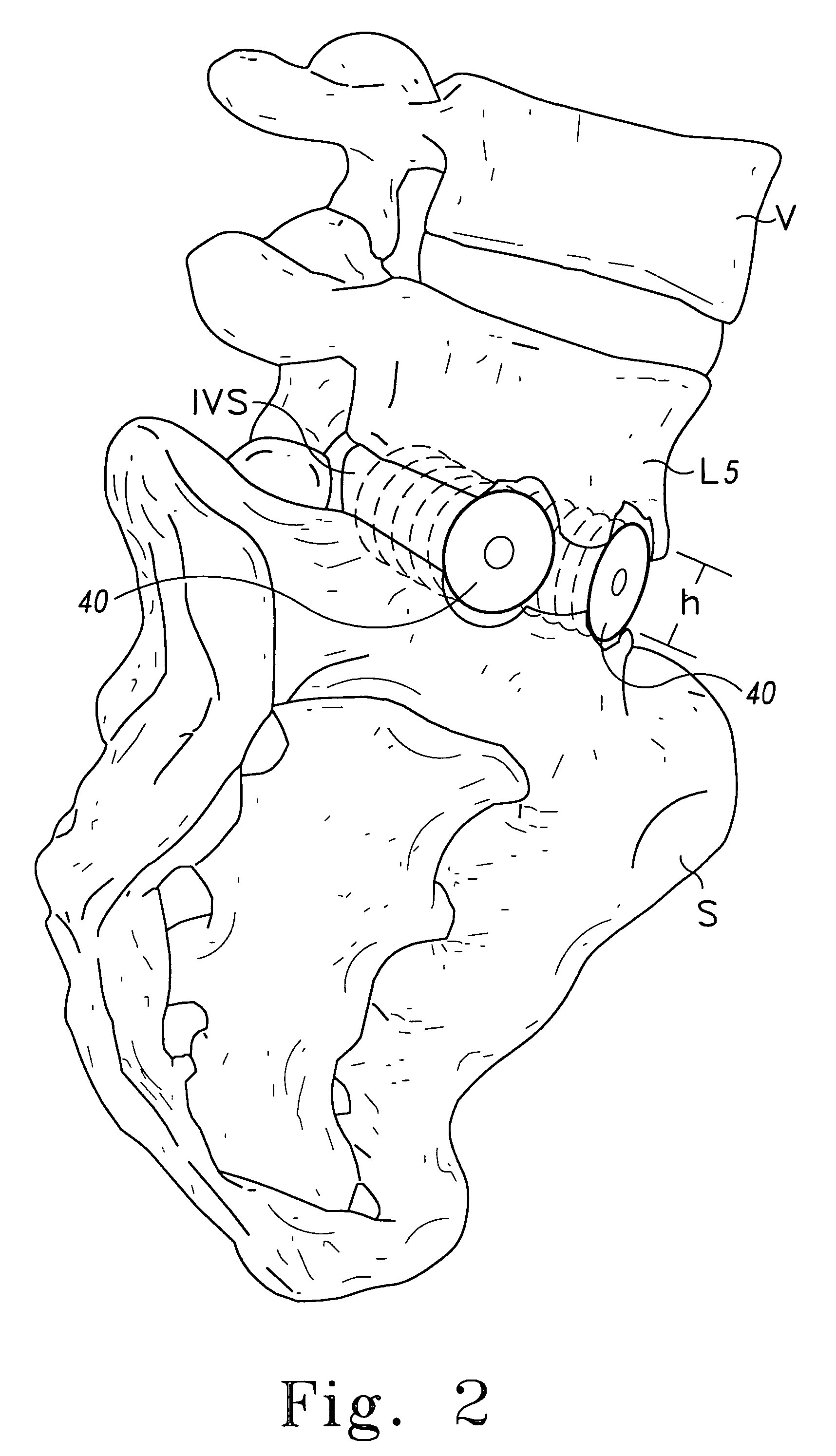

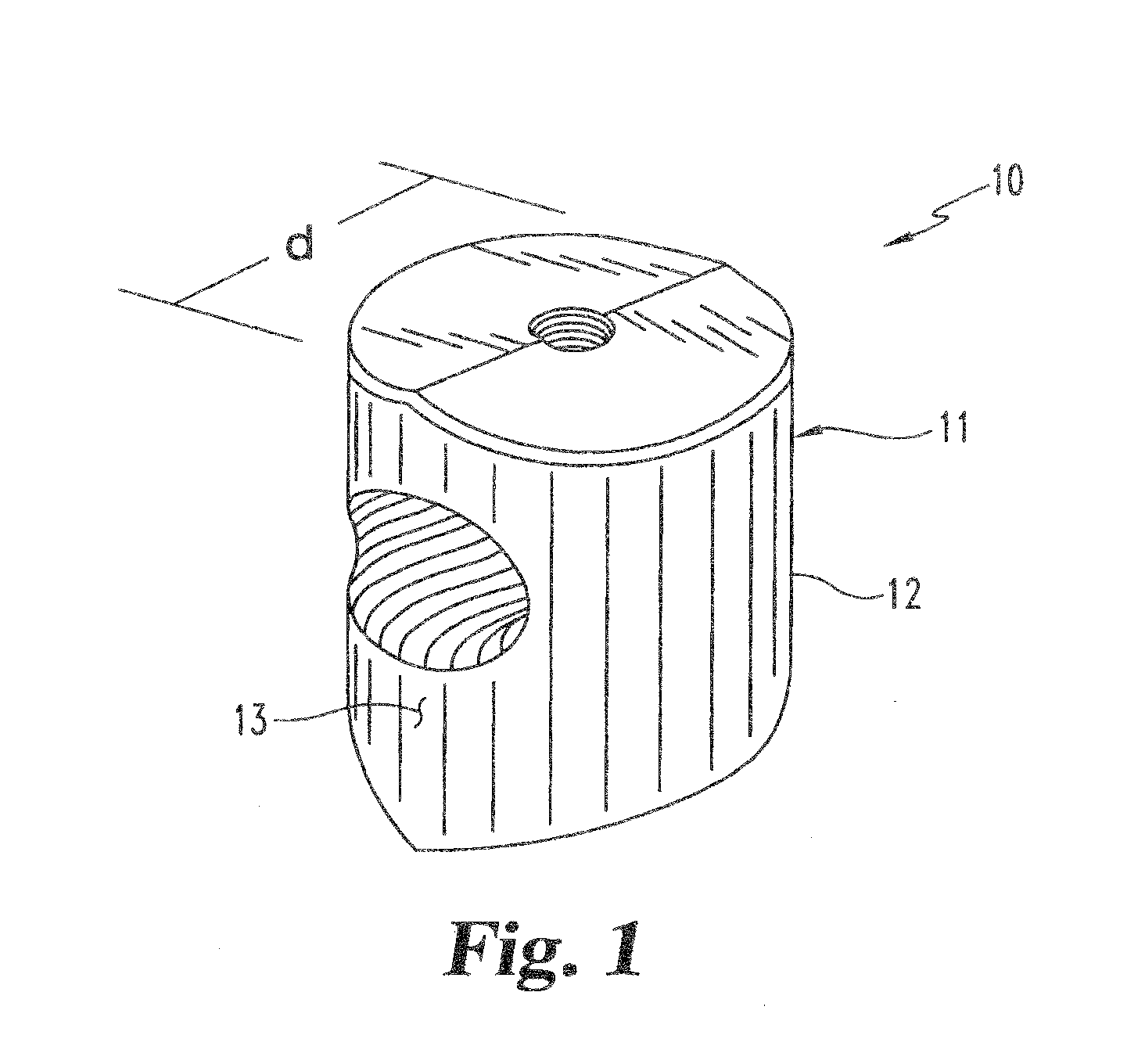

Spinal spacers 20 are provided for fusion of a motion segment. The spacers include a load bearing member 21 having a wall 22 sized for engagement within a space between adjacent vertebrae to maintain the space and an effective amount of an osteogenic composition to stimulate osteoinduction. The osteogenic composition includes a substantially pure osteogenic factor in a pharmaceutically acceptable carrier. In one embodiment the load bearing member includes a bone graft impregnated in an osteogenic composition. In another embodiment, the osteogenic composition 30 is packed within a chamber 25 defined in the graft. Any suitable configuration of a bone graft is contemplated, including bone dowels, D-shaped spacers and cortical rings.

Owner:DANEK MEDICAL

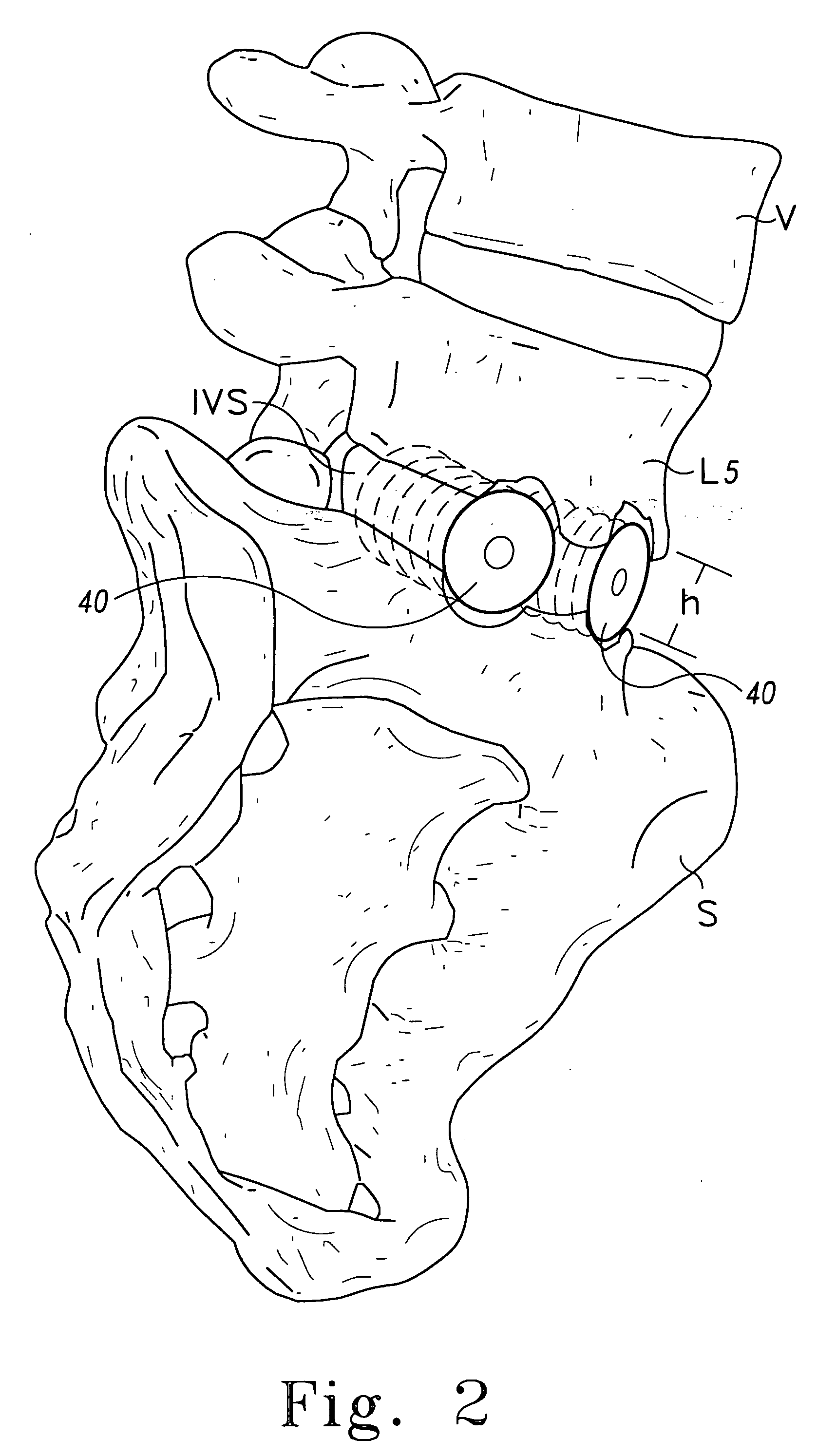

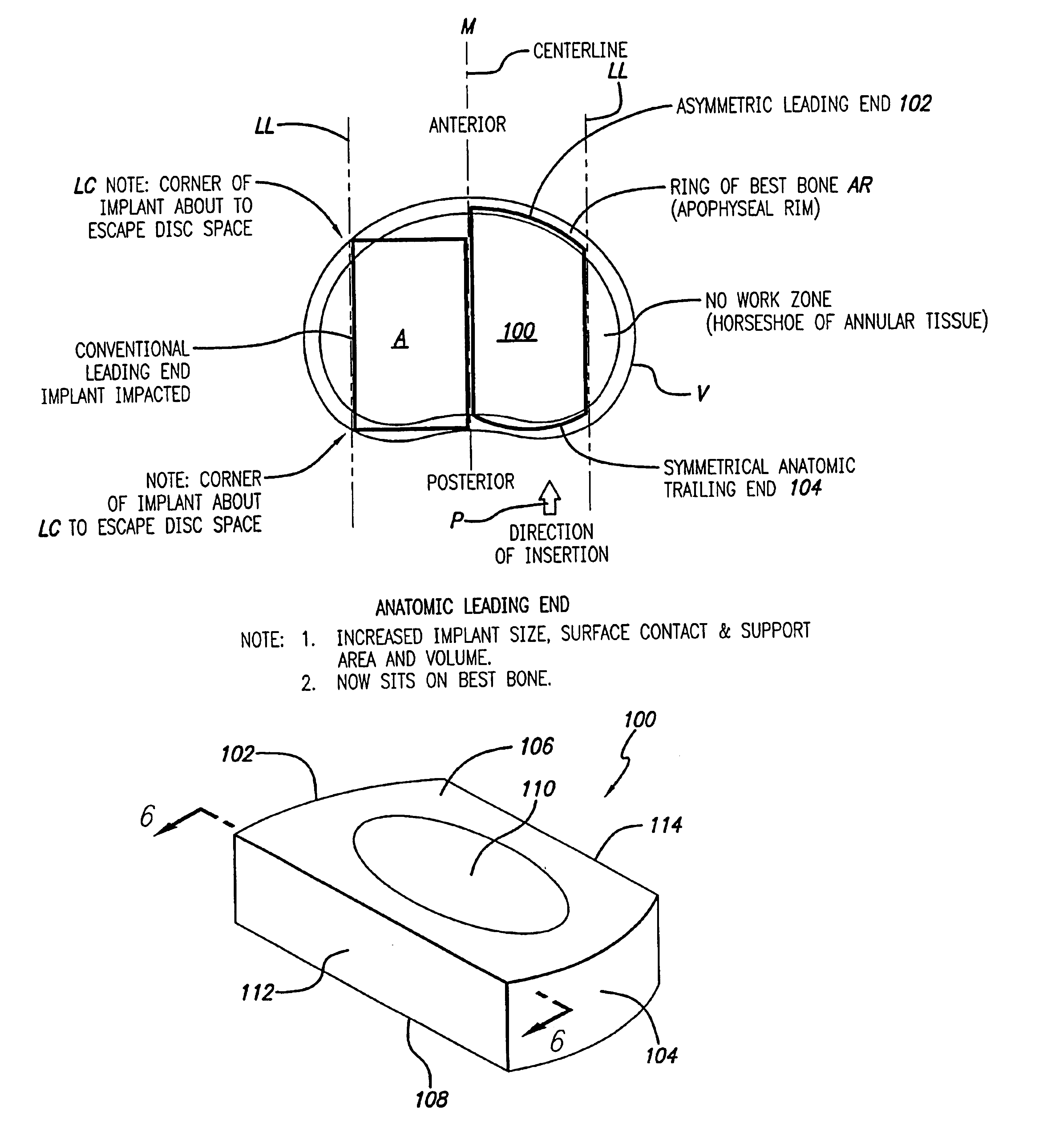

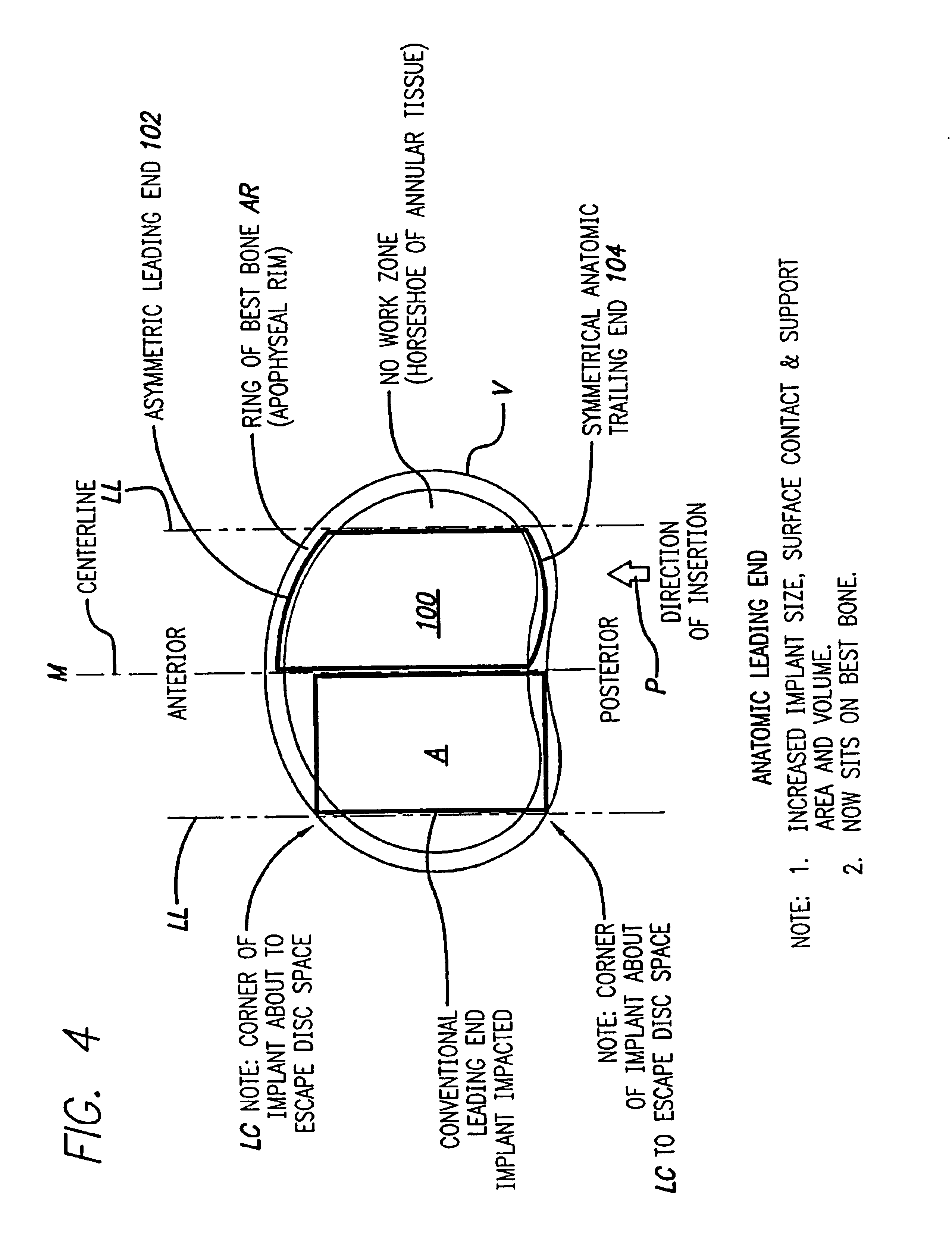

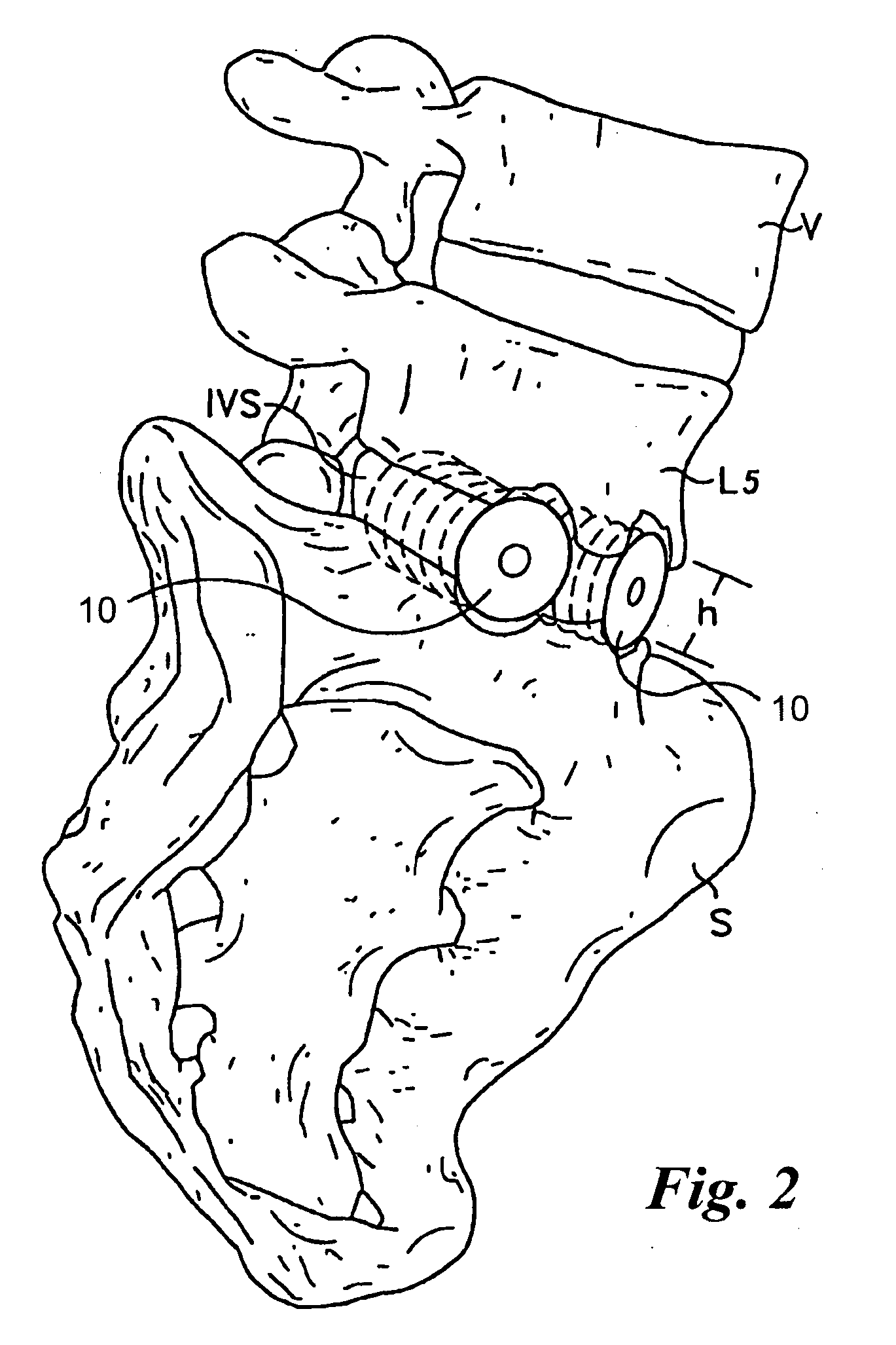

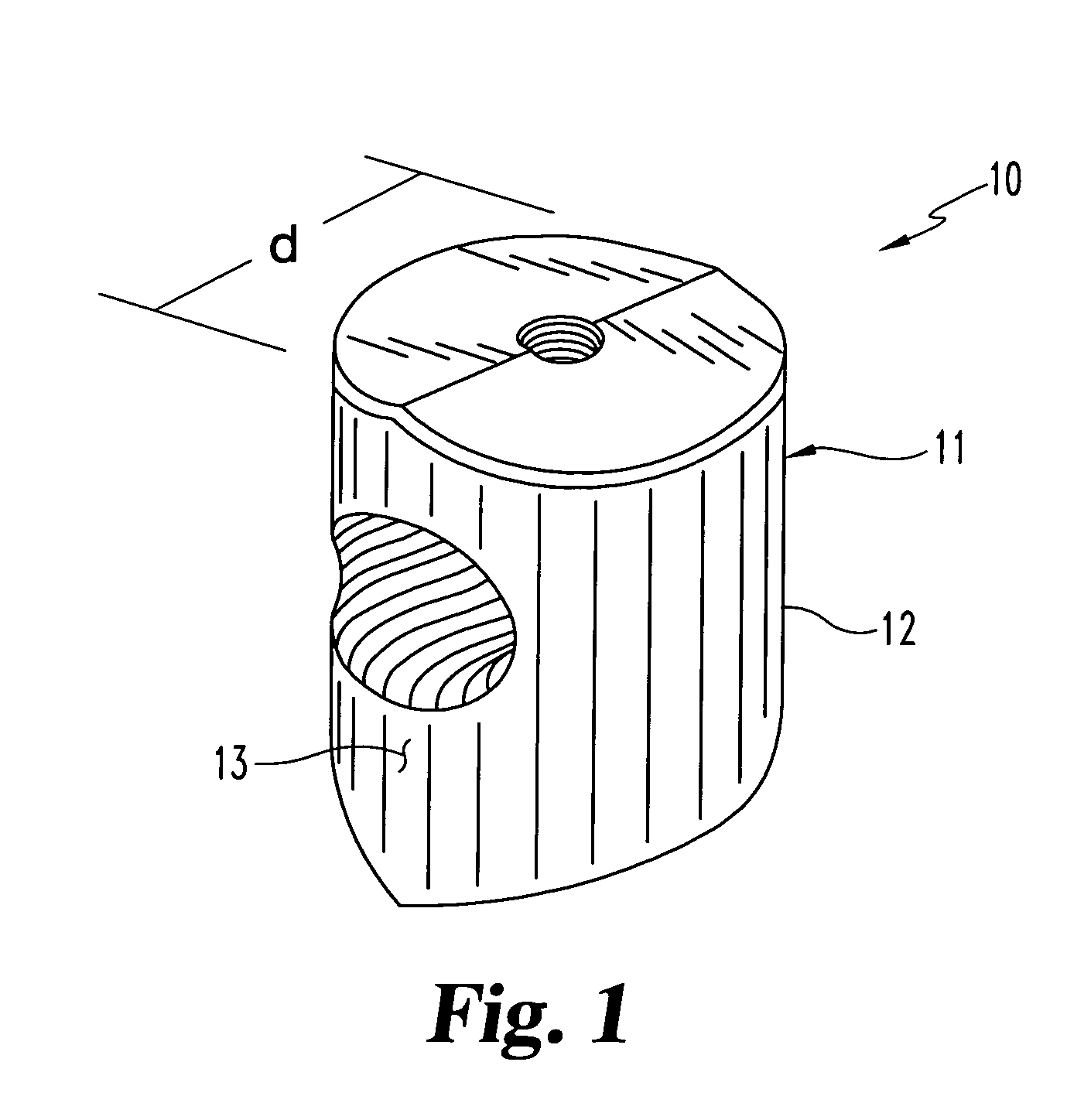

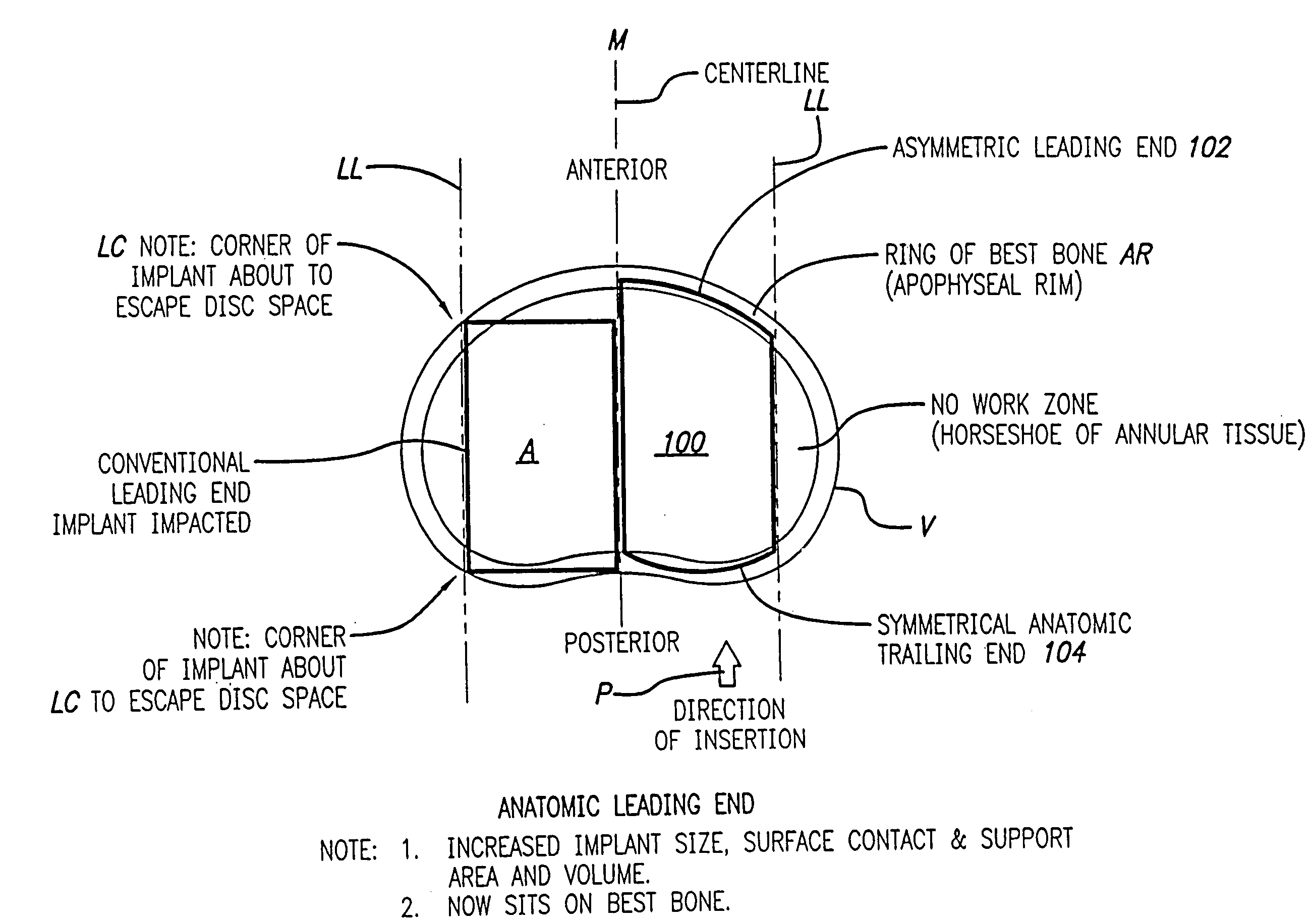

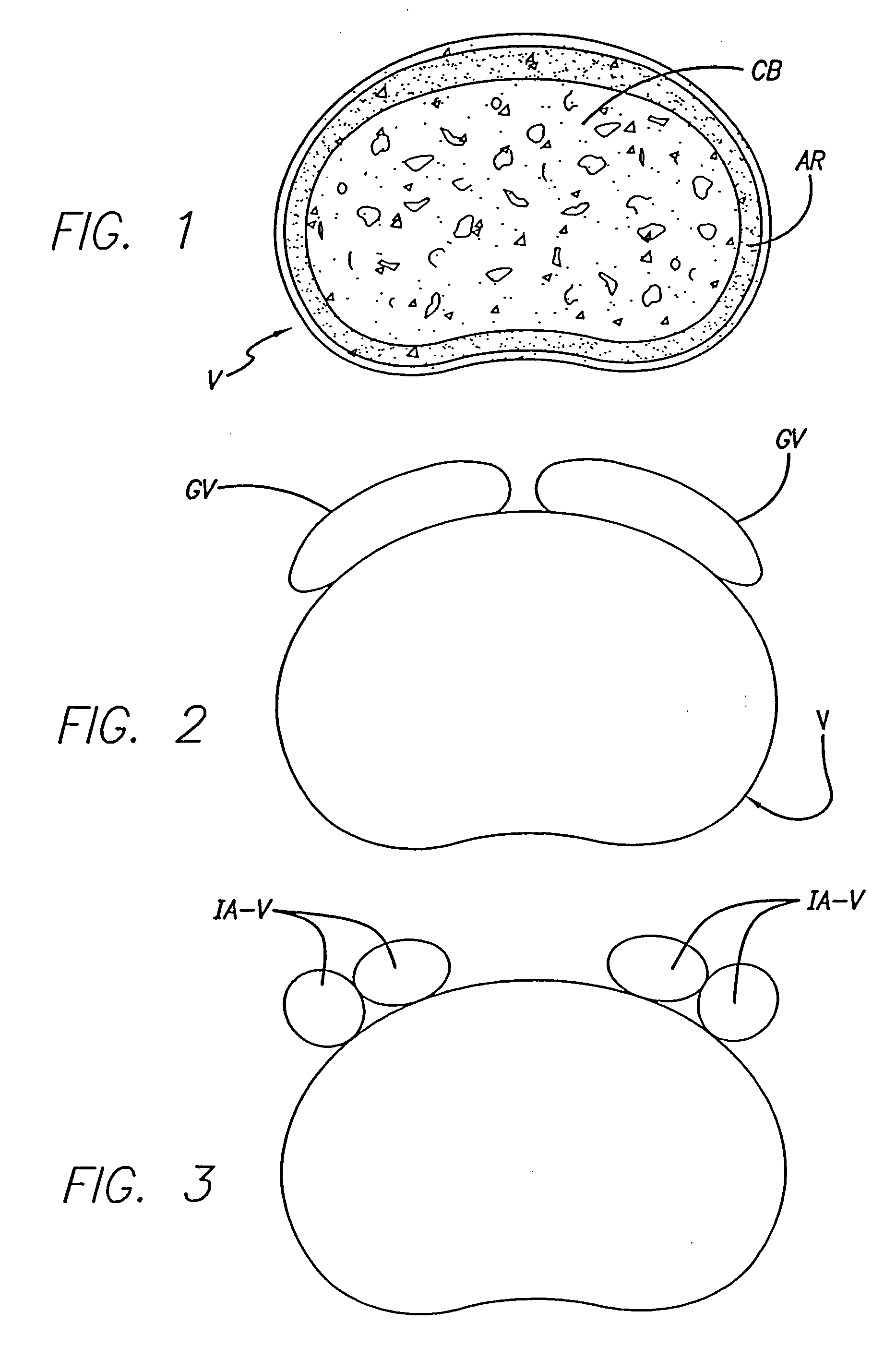

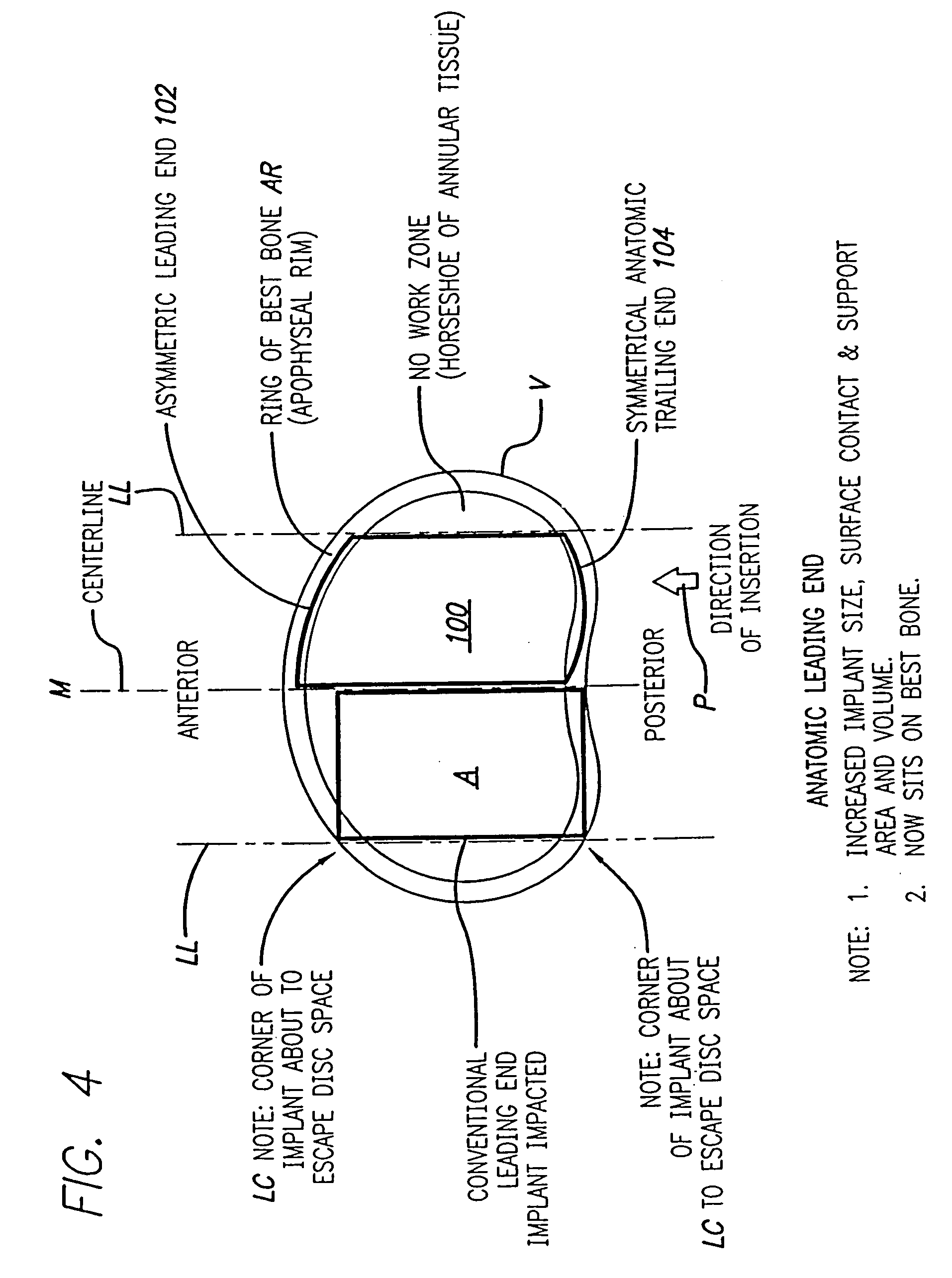

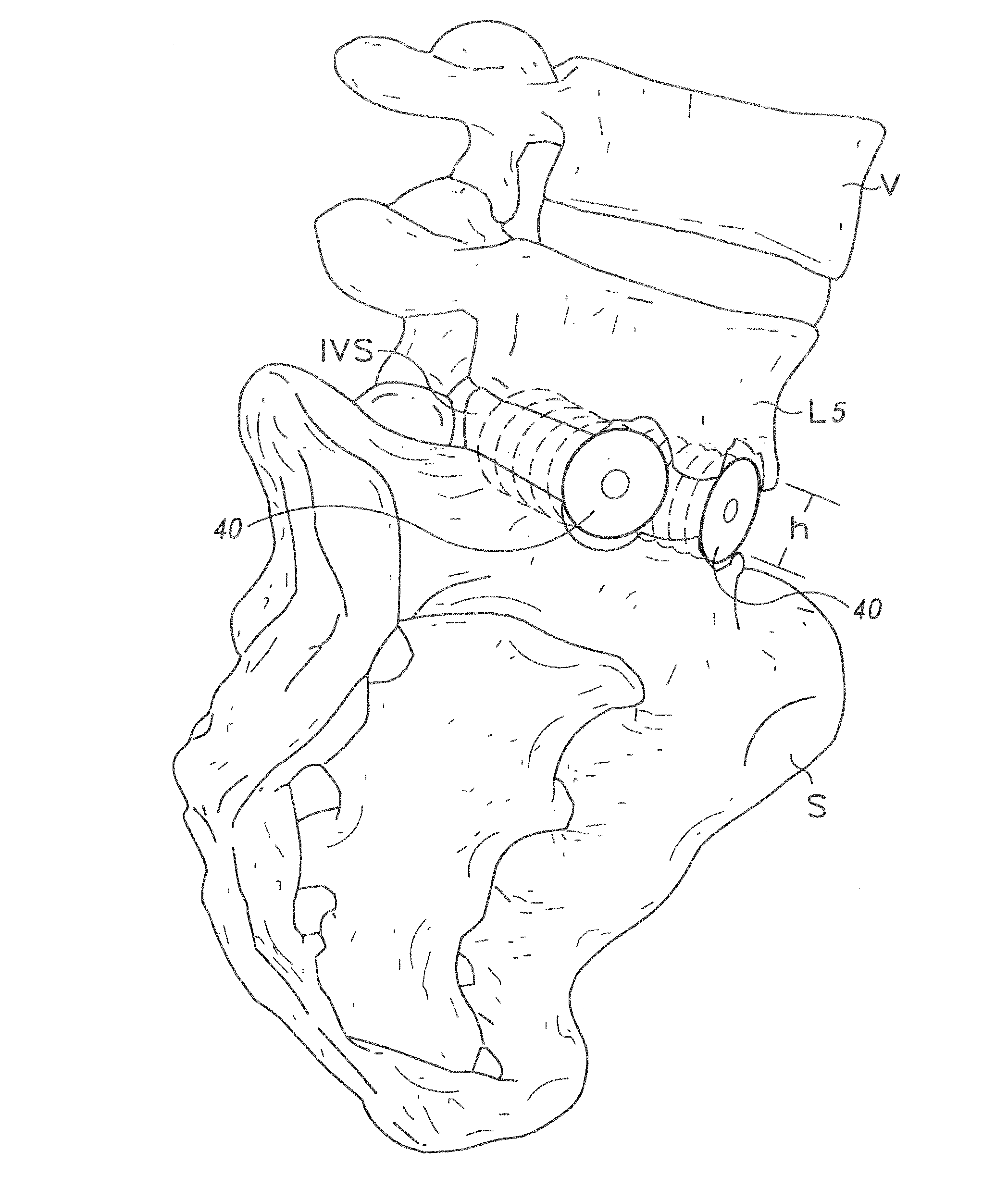

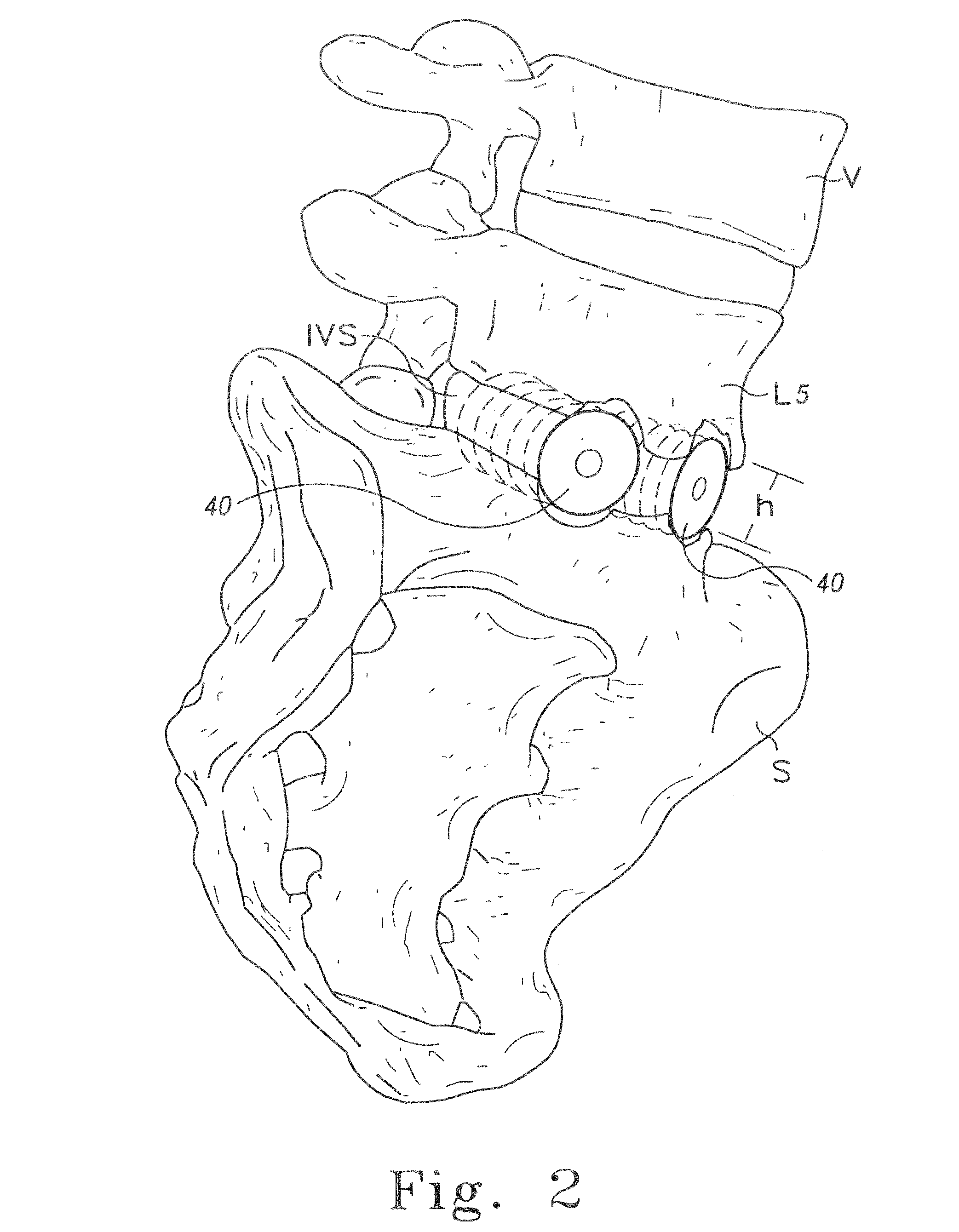

Bone hemi-lumbar interbody spinal fusion implant having an asymmetrical leading end and method of installation thereof

InactiveUS7022137B2Maximize contact areaIncrease implant lengthBone implantJoint implantsSpinal columnIntervertebral space

Owner:WARSAW ORTHOPEDIC INC

Bone grafts

InactiveUS20050165483A1Encourage bone ingrowthAvoid stress shieldingBone implantSpinal implantsVertebral boneBiomedical engineering

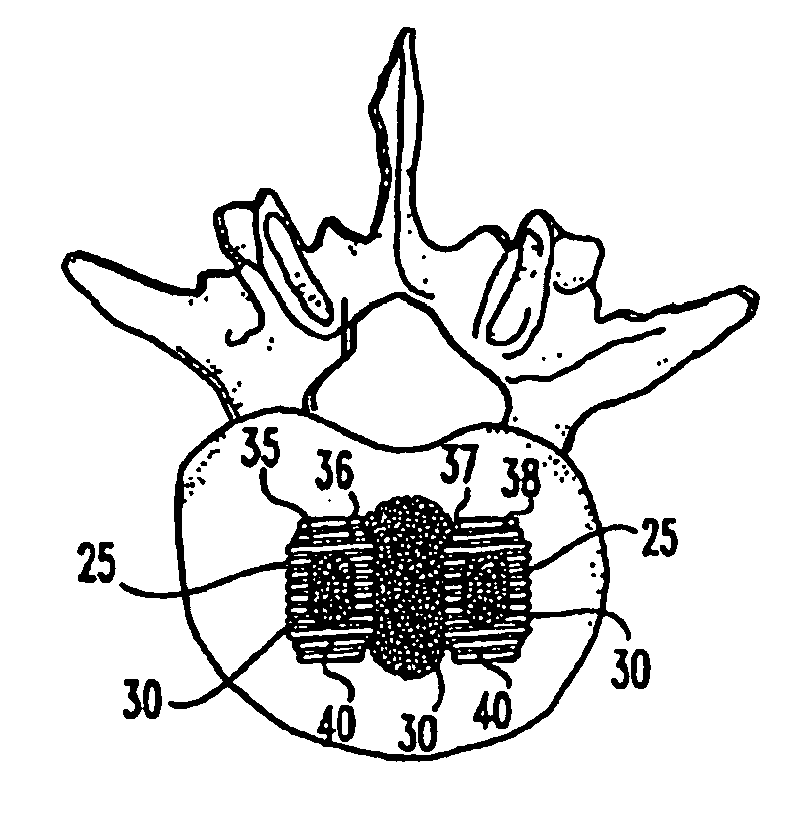

Spinal spacers 20 are provided for fusion of a motion segment. The spacers include a load bearing member 21 having a wall 22 sized for engagement within a space between adjacent vertebrae to maintain the space and an effective amount of an osteogenic composition to stimulate osteoinduction. The osteogenic composition includes a substantially pure osteogenic factor in, a pharmaceutically acceptable carrier. In one embodiment the load bearing member includes a bone graft impregnated in an osteogenic composition. In another embodiment, the osteogenic composition 30 is packed within a chamber 25 defined in the graft. Any suitable configuration of a bone graft is contemplated, including bone dowels, D-shaped spacers and cortical rings. A spinal spacer 300 for engagement between vertebrae is also provided which includes a body 301 formed of a bone composition. The body 301 includes a first end 311, an opposite second 315 end, a superior face 335 defining a superior vertebral engaging surface 337 and an inferior face 338 defining an inferior vertebral engaging surface 340. At least one of the vertebral engaging surfaces defines a set of migration resistance grooves 350. Each of the grooves 350 includes a first face 355 defining an angle of no more than about 90 degrees relative to the engaging surface 340 and a second opposing sloped face 360. The first and second faces 355, 360 define an arcuate pocket 370 therebetween for trapping vertebral bone to resist migration of the spacer 300. In one embodiment, the grooves 350 are arranged in series in that all of the second faces 360 slope in the same direction.

Owner:MEDTRONIC SOFAMOR DANEK

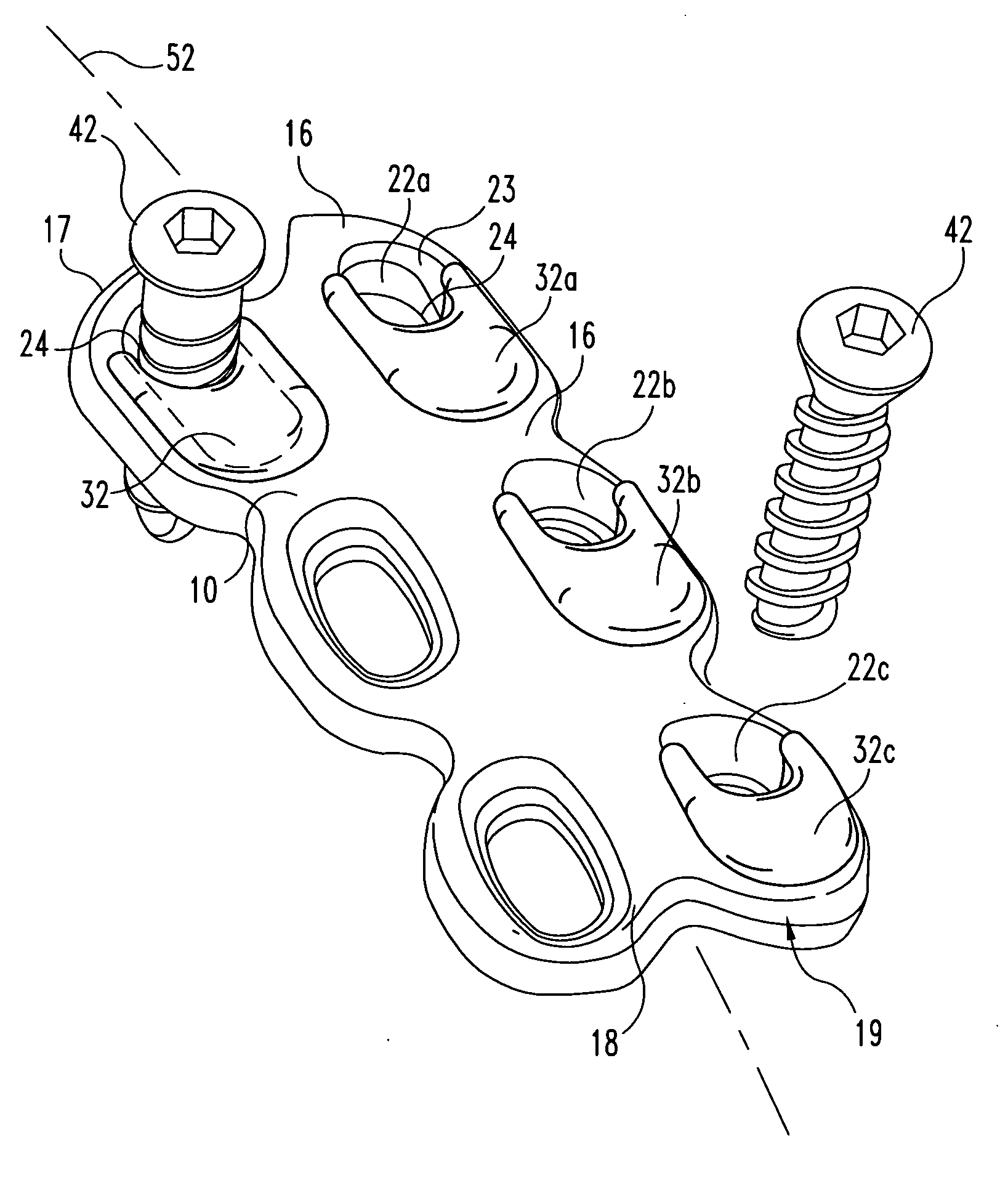

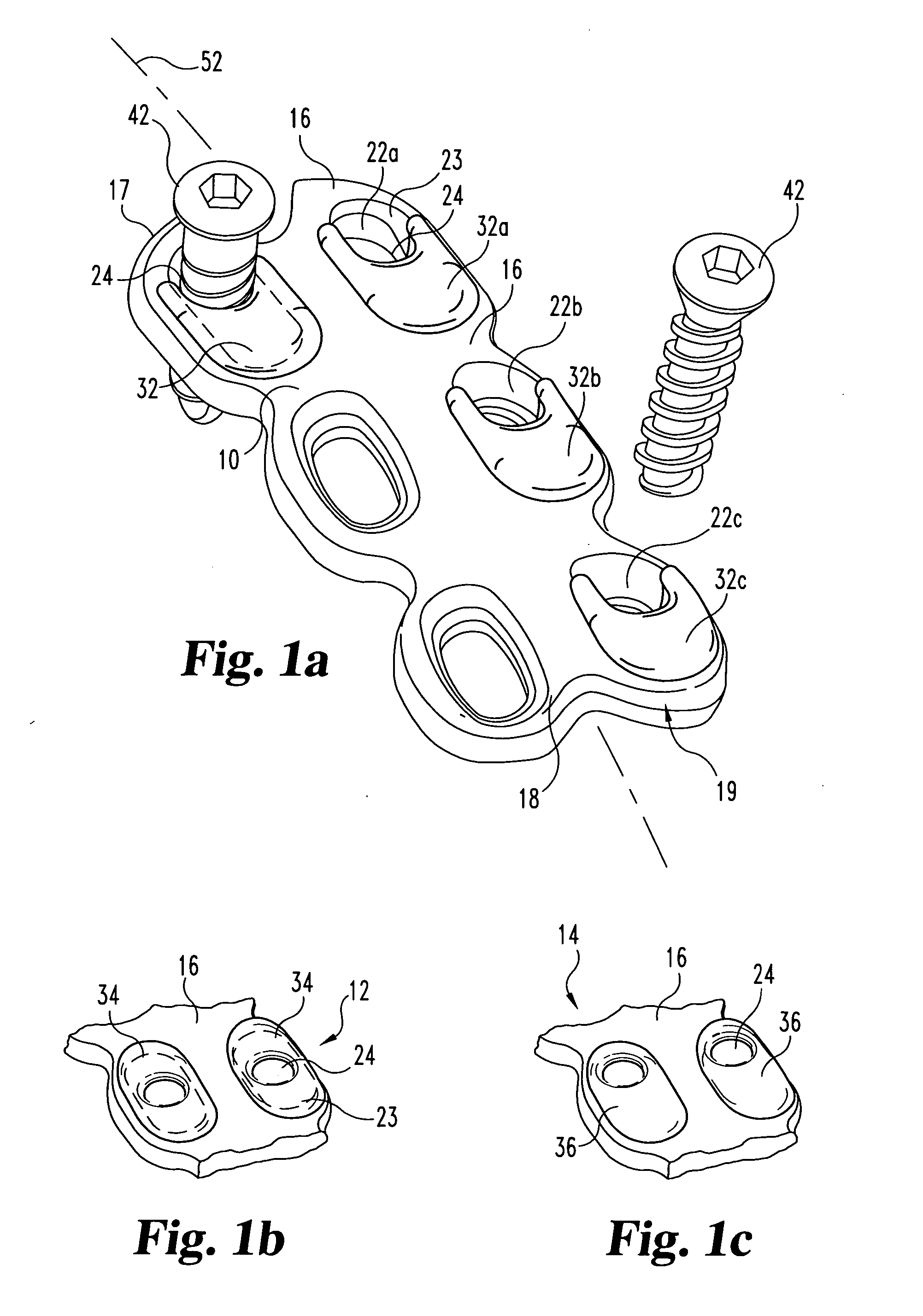

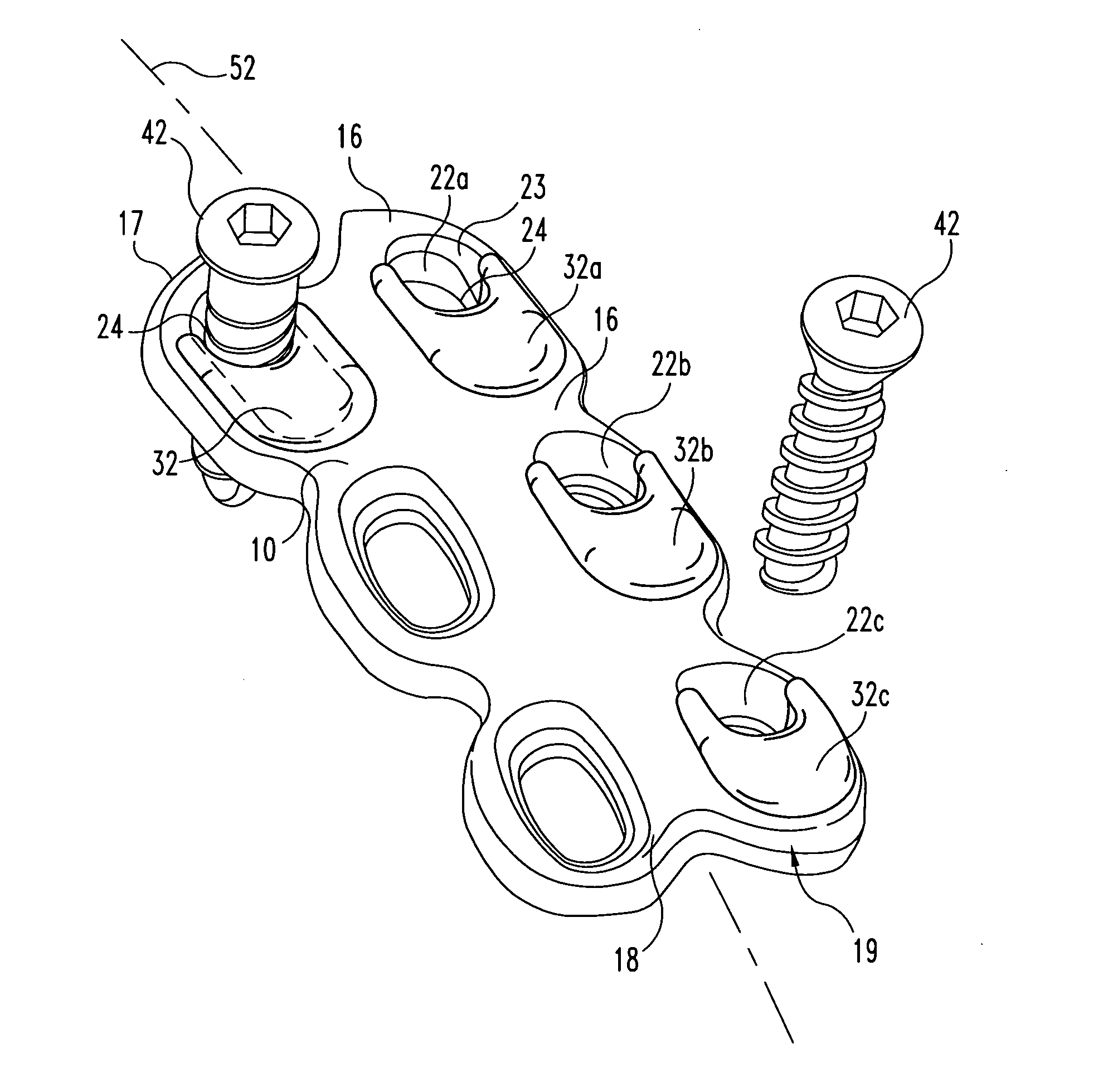

Anterior cervical plating system and method

InactiveUS20070203492A1Easy to fuseEasy to incorporateInternal osteosythesisBone platesSpinal columnAnterior approach

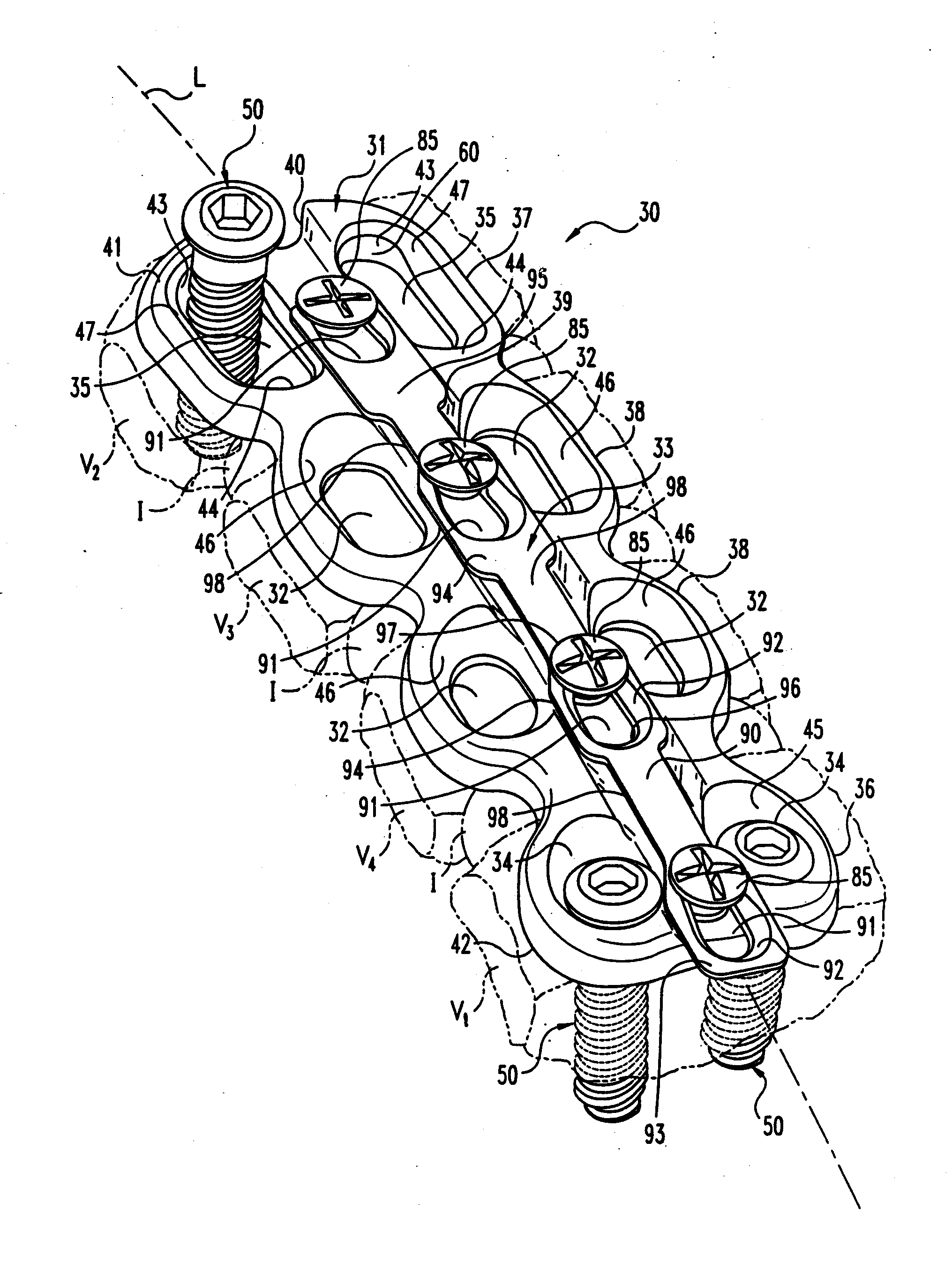

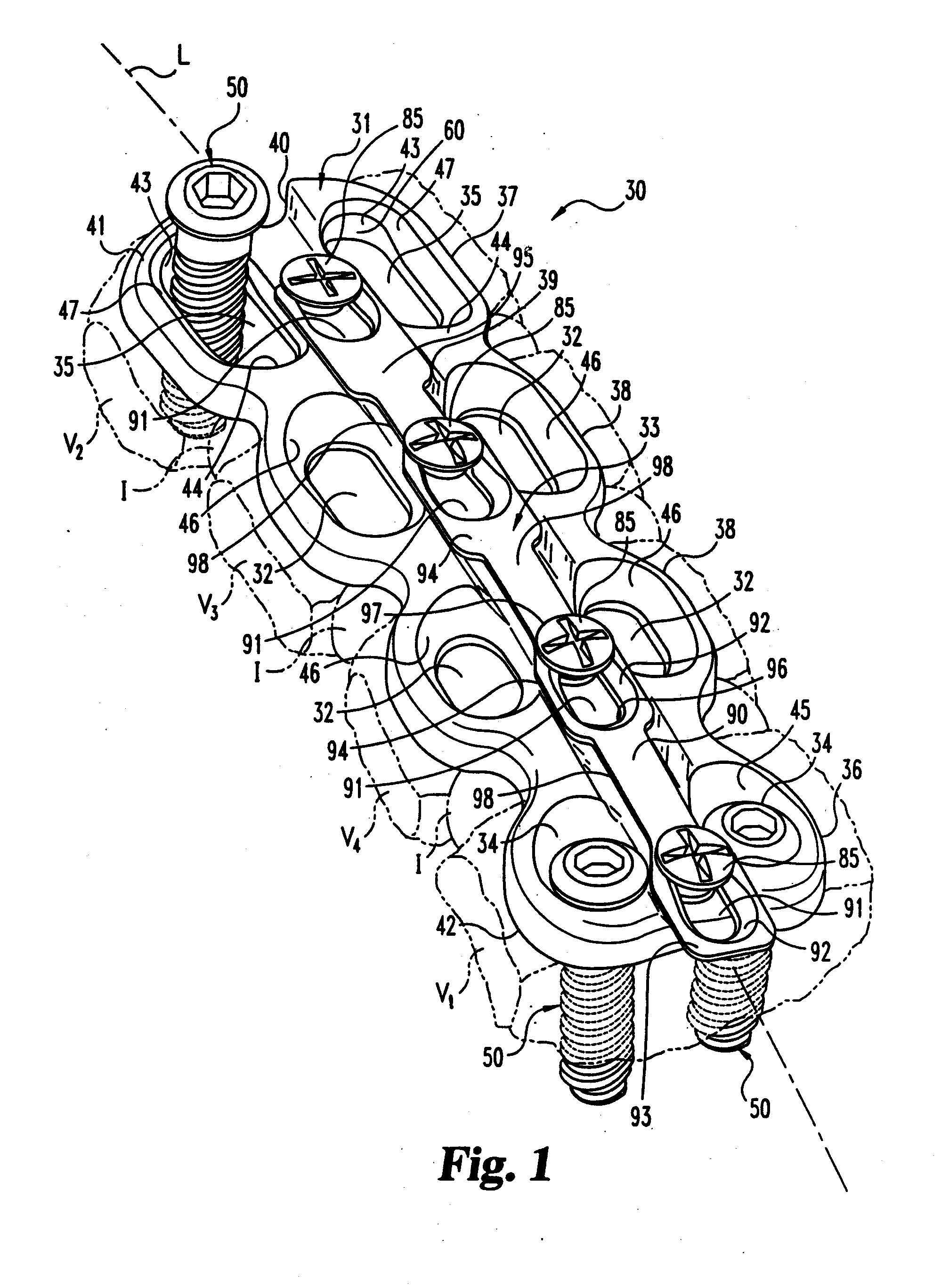

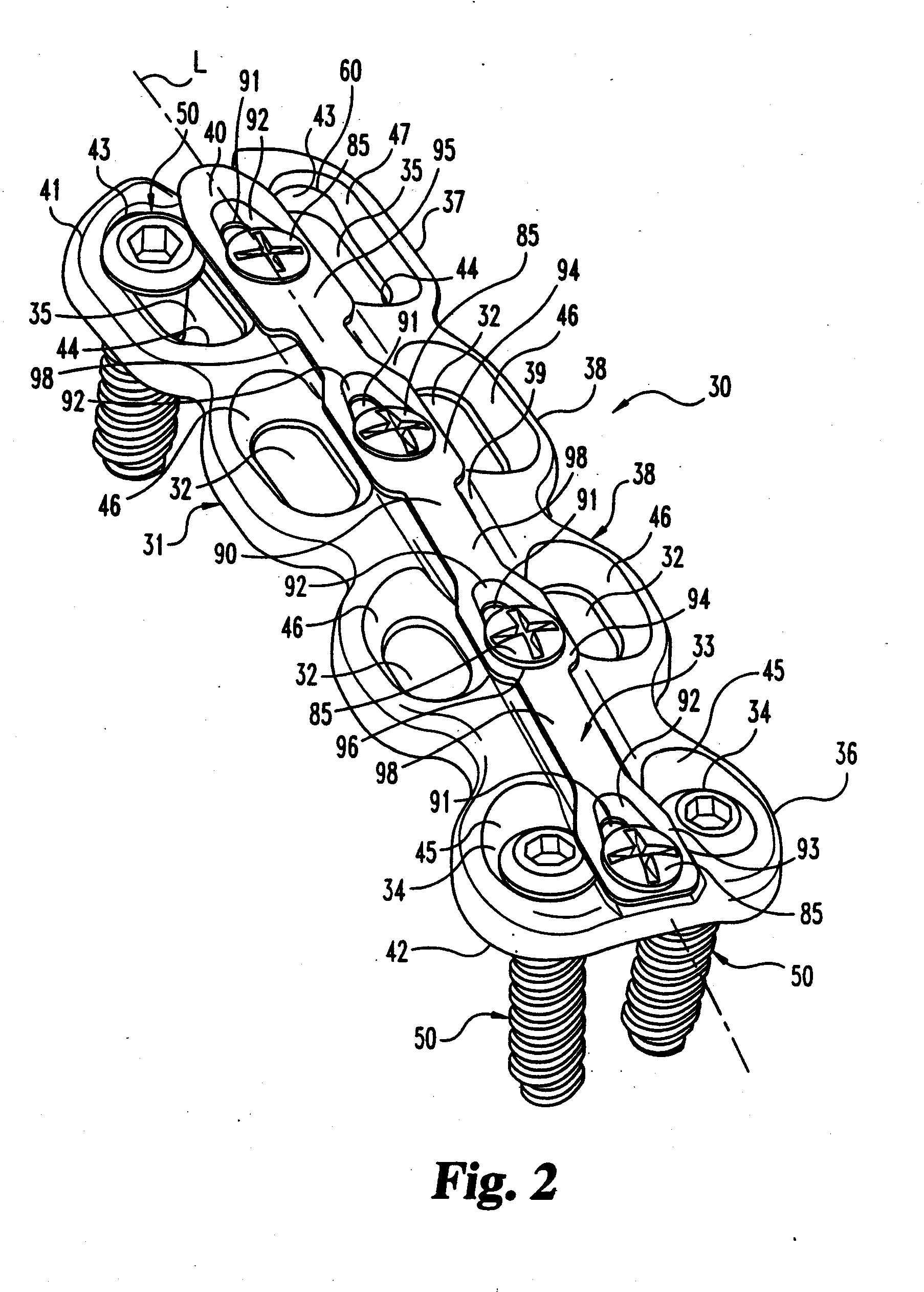

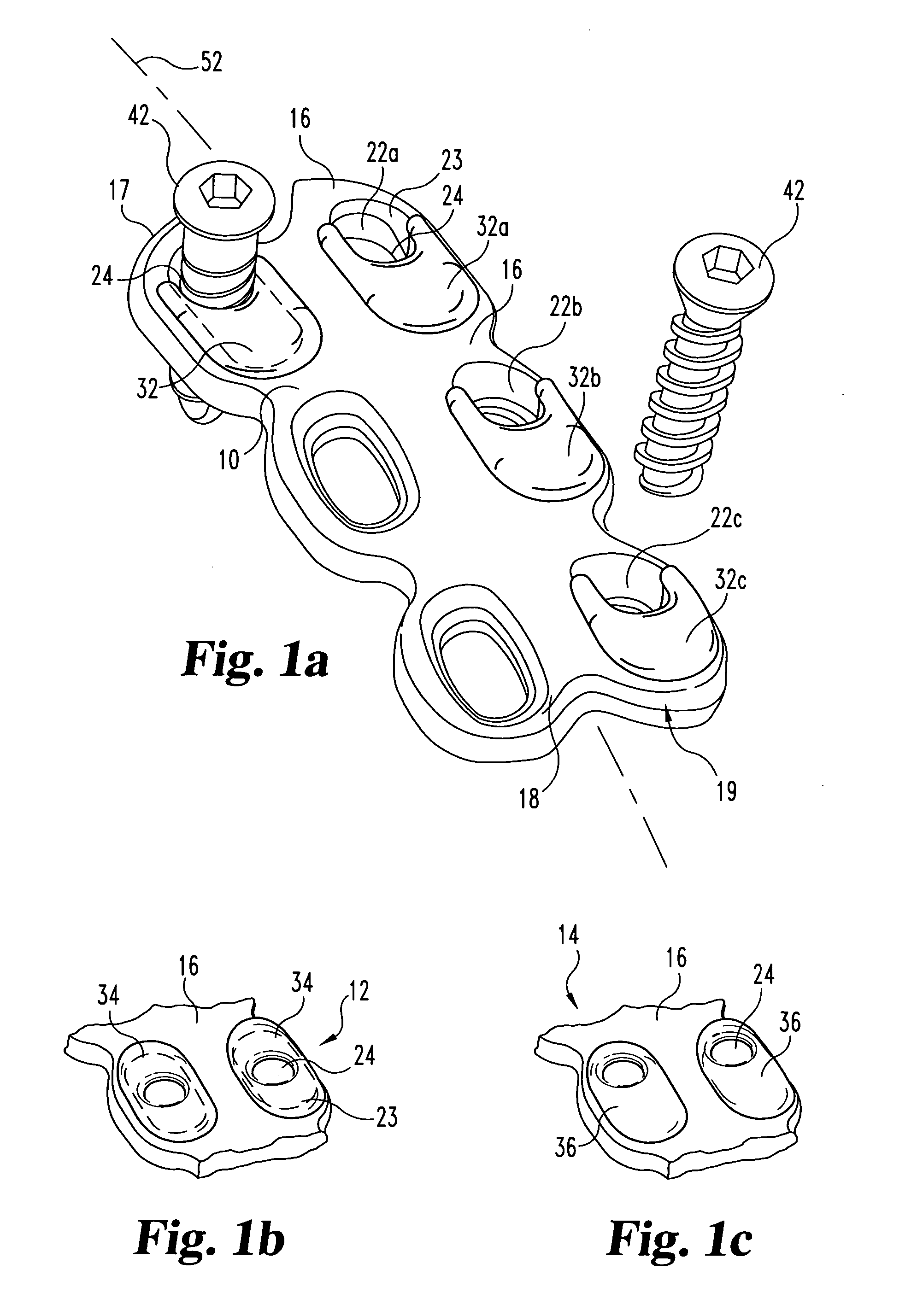

The present invention is directed to a system for anterior fixation of the spine that utilizes an elongated fixation plate. The plating system stabilizes the spine and promotes fusion and incorporation of a graft or implant in a portion of the spinal column. In one aspect of the invention, the fixation plate has a first end with a pair of holes. Bone screws extend through the holes to rigidly secure the plate to a first vertebra. The second end of the plate is provided with a pair of slots through which bone screws extend for engagement with a second vertebra. The screws extending through the slots are translatable in the slot to maintain compression of the spinal column portion. The plating system includes a retainer assembly that prevents screw back out. Methods and instruments relating to the plating system are also described.

Owner:WARSAW ORTHOPEDIC INC

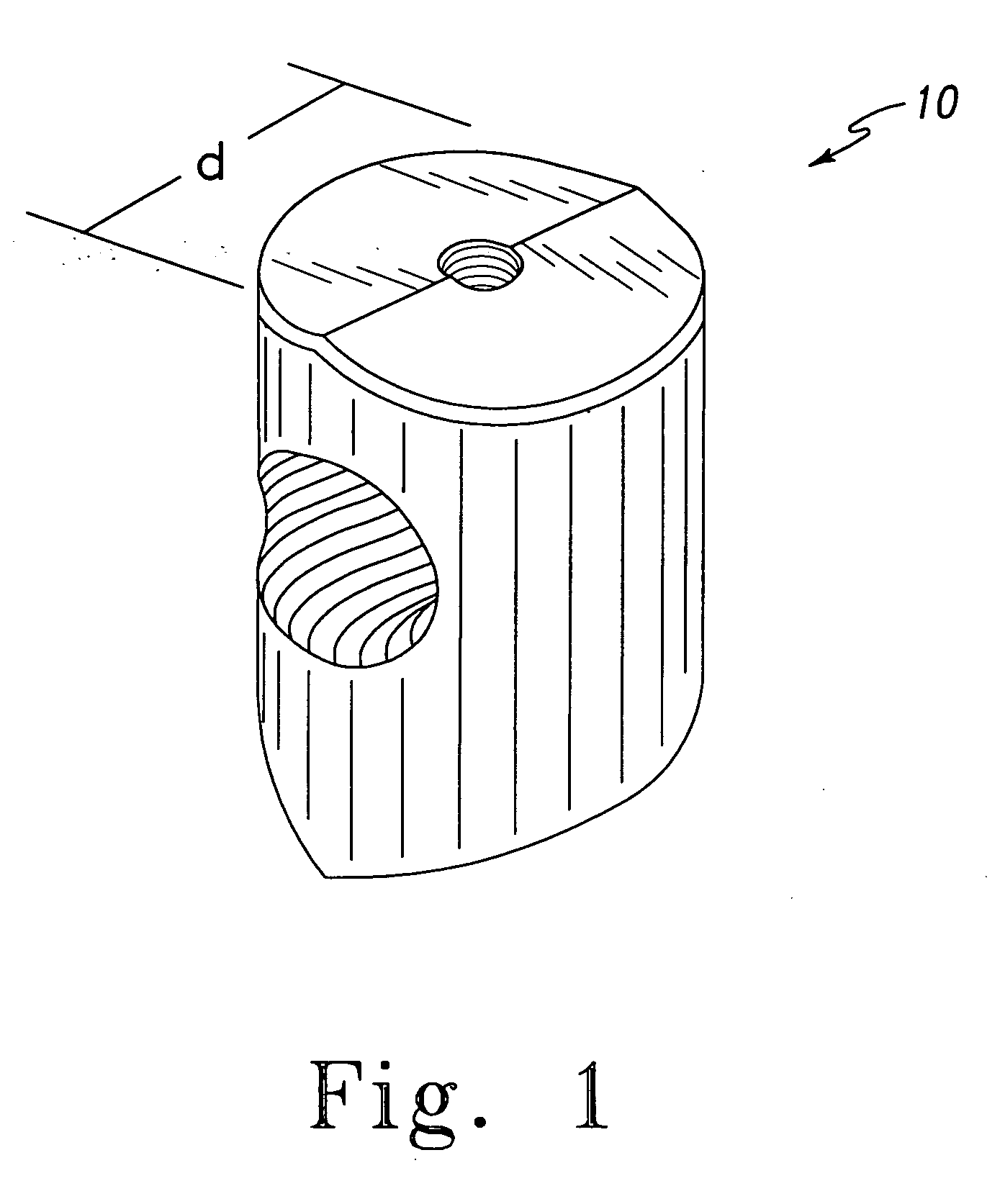

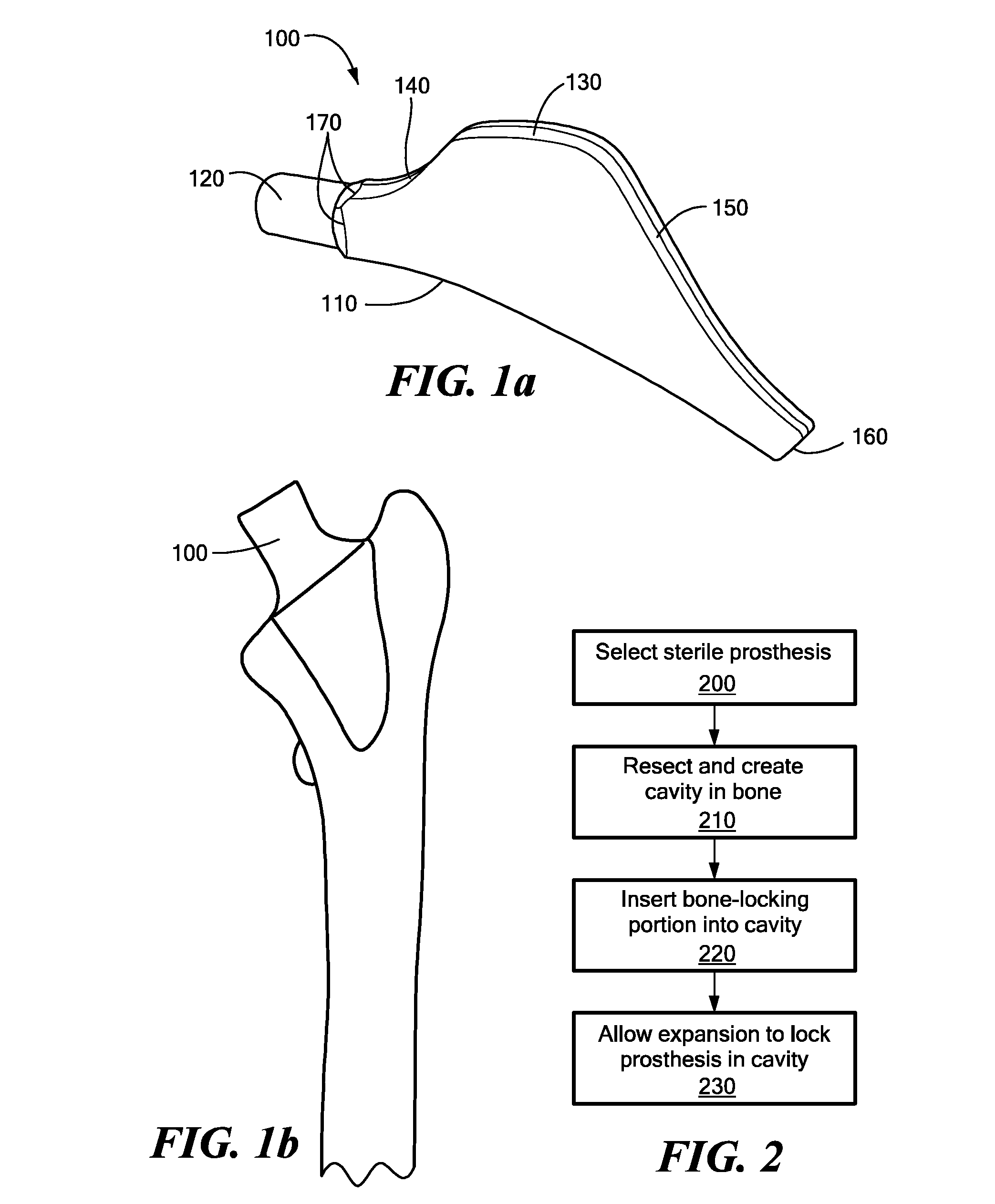

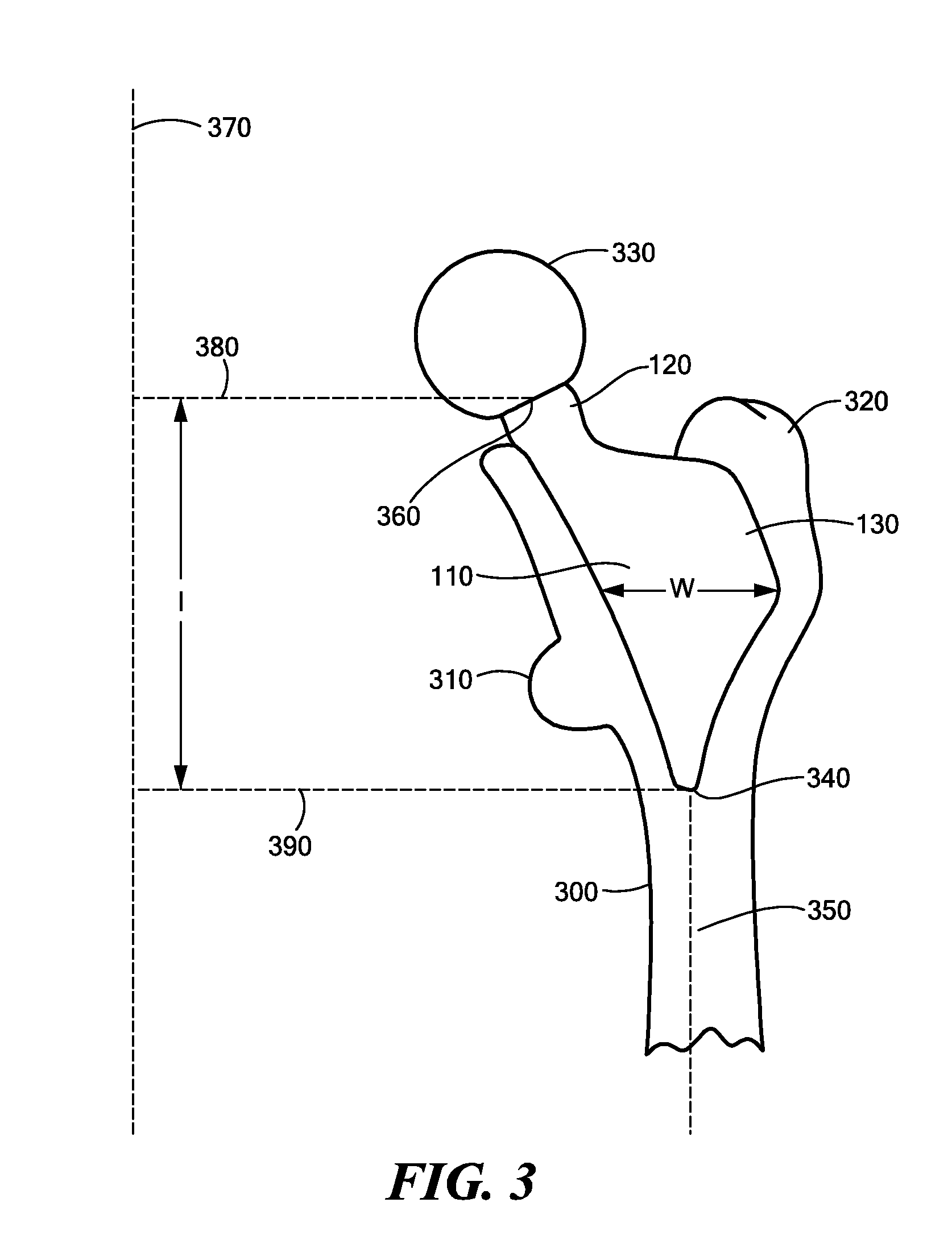

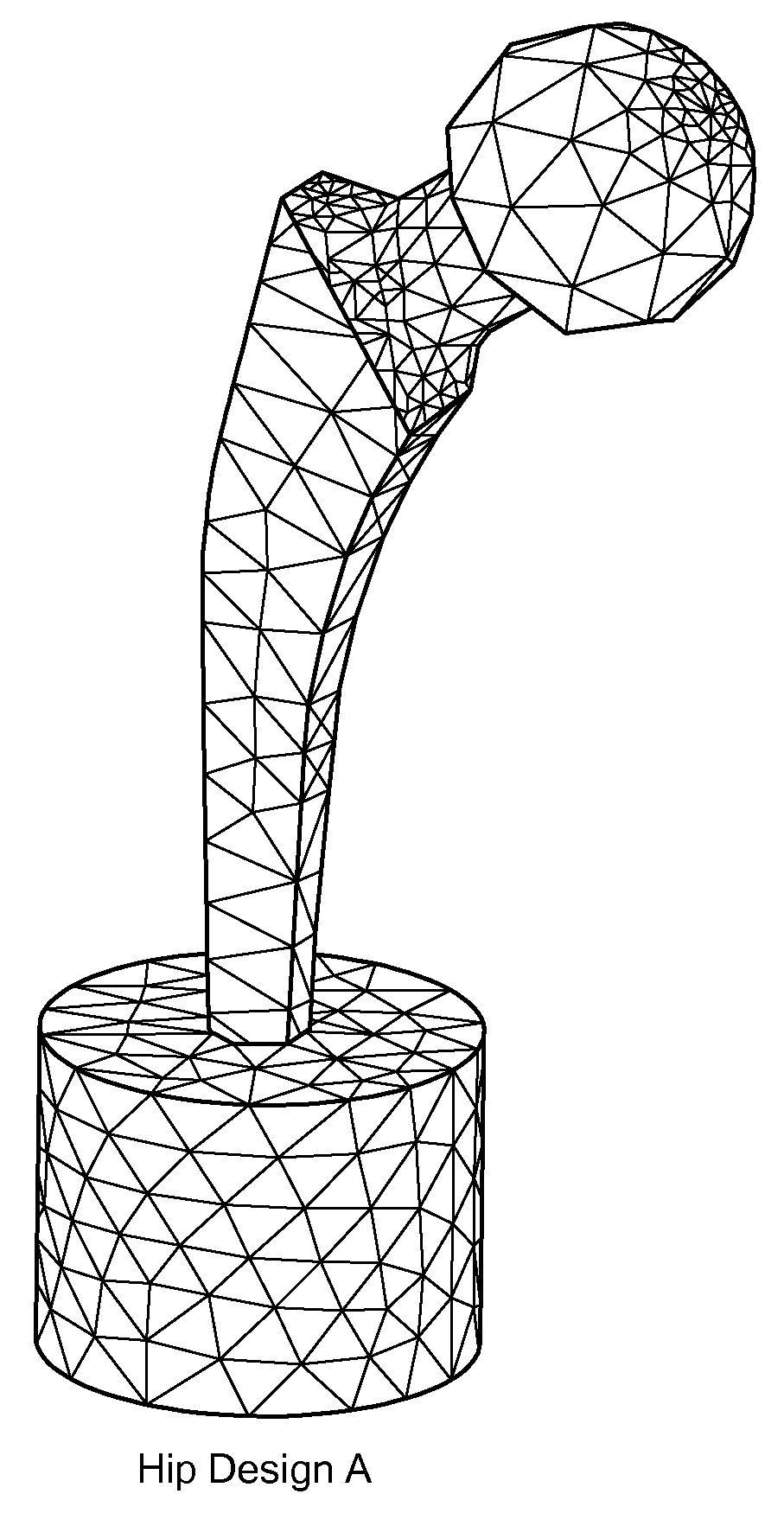

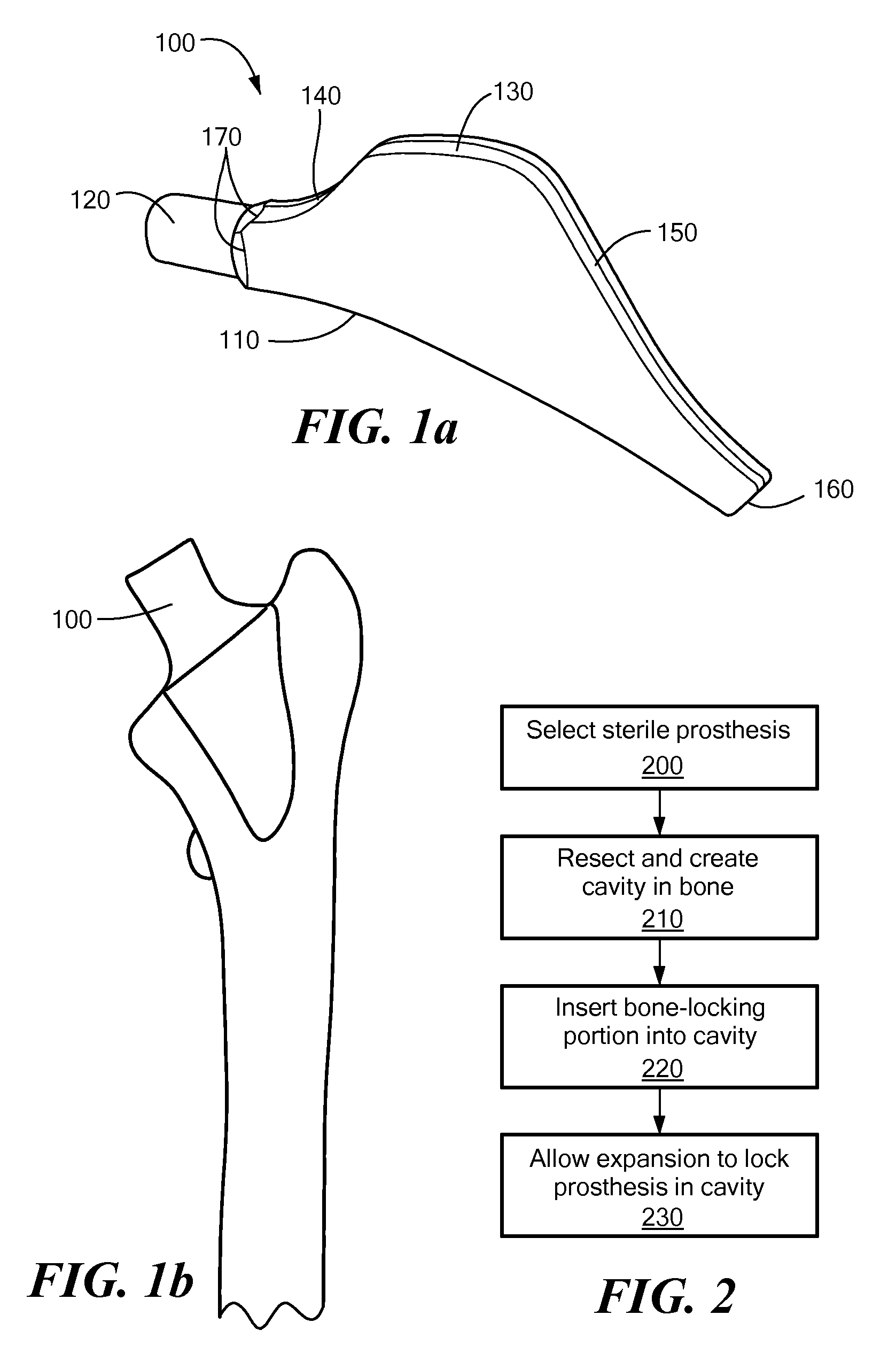

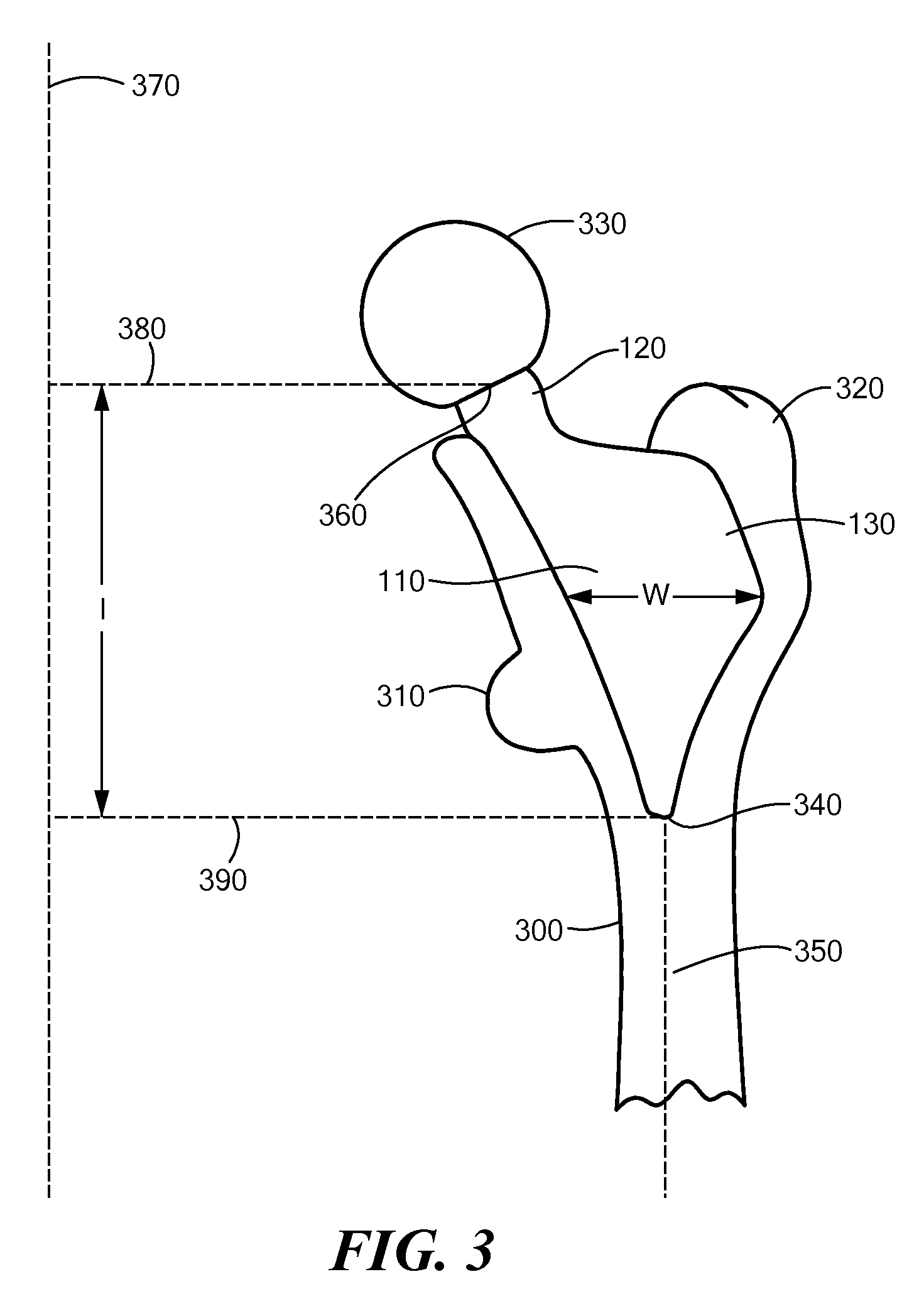

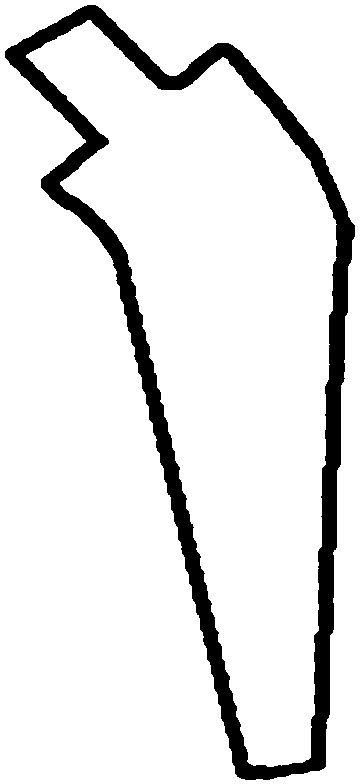

Proximally Self-Locking Long Bone Prosthesis

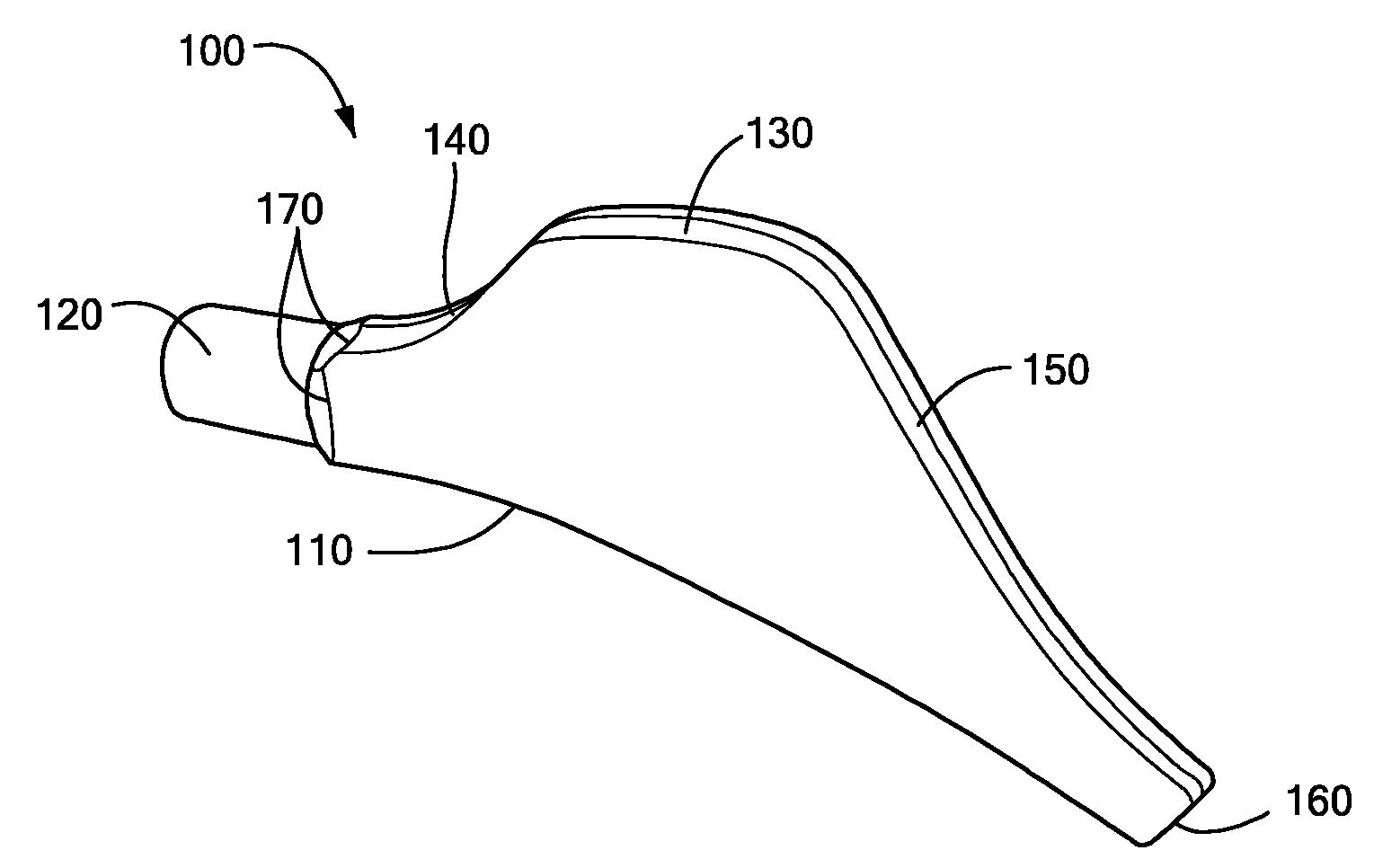

A method for arthroplasty includes using a self-locking prosthesis that has a member structured to transfer a load produced by the weight of a patient to a bone. An expandable bone-locking portion that is integral to the member includes a shape-memory material and expands to produce a locking force. A portion of the bone is removed to form an aperture in the bone. The bone-locking portion is inserted into the aperture, and a temperature increase causes a change from a contracted state to an expanded state resulting in expansion of the bone-locking portion so as to contact the inner surface. The expanding is sufficient to create a locking force at the junction between the inner surface and the bone-locking portion of the prosthesis and the majority of the locking force is applied at or above the metaphysis. The length / width ration of the prosthesis may be less than or equal to 5. The resulting reconstructed long-bone may have improved primary and long-term stability.

Owner:ARTHREX +1

Bone grafts

InactiveUS20100057207A1Encourage bone ingrowthAvoid stress shieldingSpinal implantsVertebral boneBiomedical engineering

Spinal spacers 20 are provided for fusion of a motion segment. The spacers include a load bearing member 21 having a wall 22 sized for engagement within a space between adjacent vertebrae to maintain the space and an effective amount of an osteogenic composition to stimulate osteoinduction. The osteogenic composition includes a substantially pure osteogenic factor in, a pharmaceutically acceptable carrier. In one embodiment the load bearing member includes a bone graft impregnated in an osteogenic composition. In another embodiment, the osteogenic composition 30 is packed within a chamber 25 defined in the graft. Any suitable configuration of a bone graft is contemplated, including bone dowels, D-shaped spacers and cortical rings. A spinal spacer 300 for engagement between vertebrae is also provided which includes a body 301 formed of a bone composition. The body 301 includes a first end 311, an opposite second 315 end, a superior face 335 defining a superior vertebral engaging surface 337 and an inferior face 338 defining an inferior vertebral engaging surface 340. At least one of the vertebral engaging surfaces defines a set of migration resistance grooves 350. Each of the grooves 350 includes a first face 355 defining an angle of no more than about 90 degrees relative to the engaging surface 340 and a second opposing sloped face 360. The first and second faces 355, 360 define an arcuate pocket 370 therebetween for trapping vertebral bone to resist migration of the spacer 300. In one embodiment, the grooves 350 are arranged in series in that all of the second faces 360 slope in the same direction.

Owner:RAY III EDDIE F +4

Bone grafts

InactiveUS7981156B2Encourages bone ingrowthAvoid stress shieldingBone implantDiagnosticsBone stapleVertebra

Spinal spacers 20 are provided for fusion of a motion segment. The spacers include a load bearing member 21 having a wall 22 sized for engagement within a space between adjacent vertebrae to maintain the space and an effective amount of an osteogenic composition to stimulate osteoinduction. The osteogenic composition includes a substantially pure osteogenic factor in a pharmaceutically acceptable carrier. In one embodiment the load bearing member includes a bone graft impregnated in an osteogenic composition. In another embodiment, the osteogenic composition 30 is packed within a chamber 25 defined in the graft. Any suitable configuration of a bone graft is contemplated, including bone dowels, D-shaped spacers and cortical rings.

Owner:DANEK MEDICAL

Bone hemi-lumbar arcuate interbody spinal fusion implant having an asymmetrical leading end

InactiveUS20060235519A1Maximize contact areaIncrease the lengthBone implantJoint implantsSpinal columnIntervertebral space

An interbody spinal implant is formed of cortical bone adapted for placement across an intervertebral space formed across the height of a disc space between two adjacent vertebral bodies. An asymmetrical leading end on the implant is adapted to sit upon the peripheral areas, such as the apophyseal rim and the apophyseal rim area, of the vertebral end plate region of the vertebral bodies without protruding therefrom. The asymmetrical leading end allows for the safe use of an implant of maximum length for the implantation space into which it is installed. The implant can also include an asymmetric trailing end adapted to sit upon the more peripheral areas of the vertebral end plate region of the vertebral bodies.

Owner:WARSAW ORTHOPEDIC INC

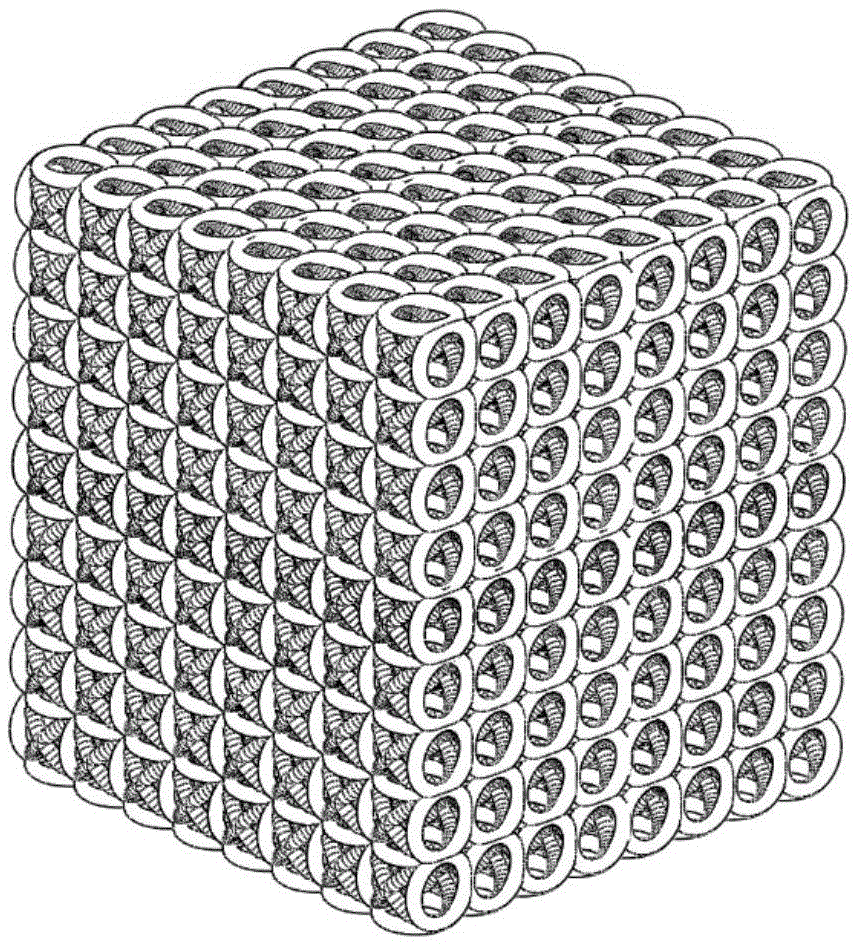

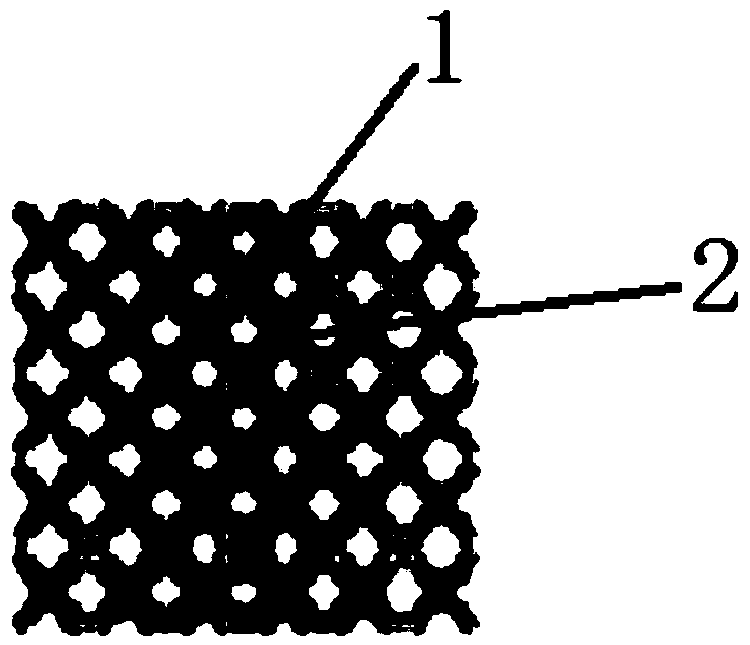

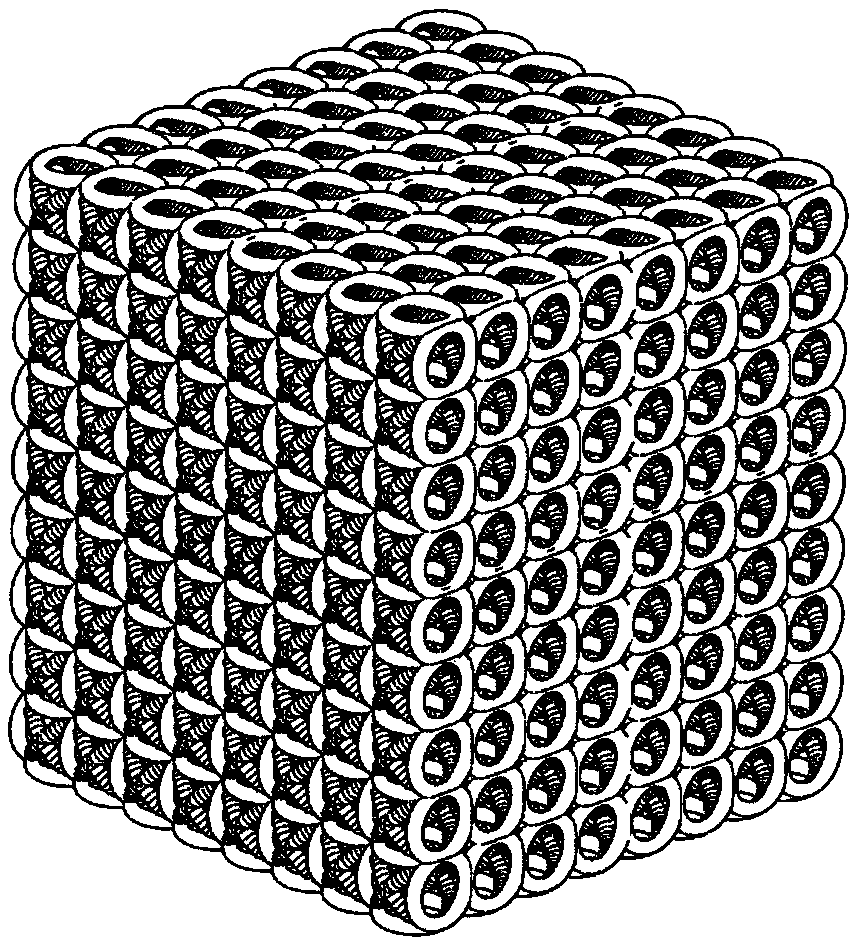

Composite implant having porous structure filled with biodegradable alloy and method of magnesium-based manufacturing the same

InactiveCN102014798AIncrease spawn ratePromote generationDental implantsBone implantAlloyMechanical property

The present invention provides a composite implant comprising pores of a porous structure filled with a biodegradable magnesium-based alloy. Further, the present invention provides a composite implant which filles pores of the porous structure prepared by a metal, a ceramic or a polymer with a biodegradable magnesium-based alloy. Mechanical properties of the composite implant of the present invention are improved because a magnesium-based alloy filled in its pores increases the strength of a porous structure comprised of a metal, a ceramic or a polymer. Futher, it can be expected that the magnesium-based alloy filled in the porous structure is decomposed in a living body, thus increasing bone formation rate. Accordingly bone tissue can be rapidly formed because the composite implant of the present invention has high strength and excellent interfacial force between the composite implant and bone tissue, compared to conventional porous materials.

Owner:U & I INC

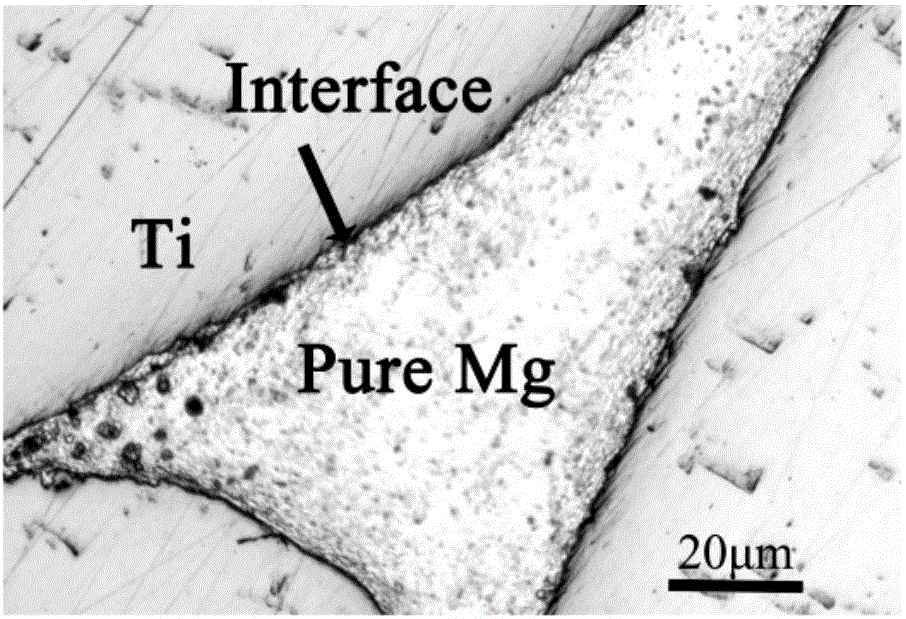

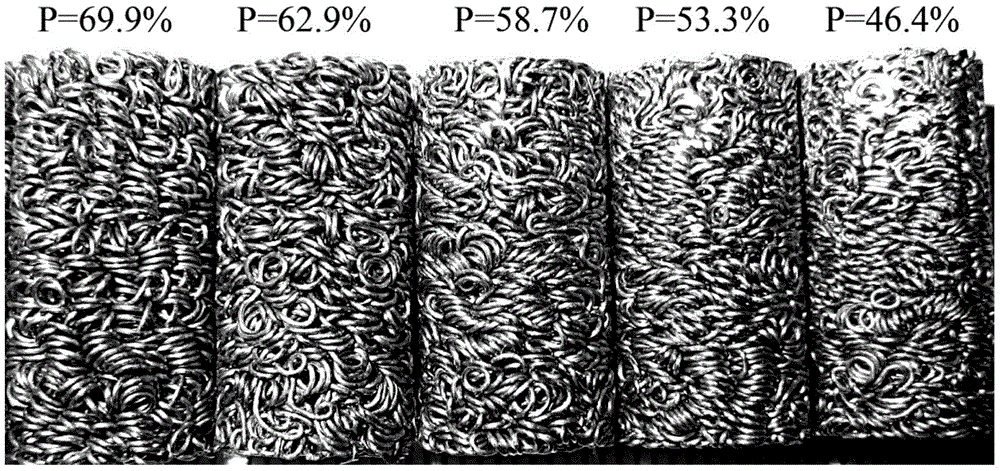

Medical titanium/magnesium composite material and preparation method thereof

InactiveCN103599560AAvoid stress shieldingGood for bone conductionSurgeryProsthesisPorosityTitanium alloy

The invention discloses a medical titanium / magnesium composite material which comprises a porous skeleton, wherein the porous skeleton is prepared from medical-grade titanium wires or titanium alloy wires and prepared into a preset shape and a preset porosity by using a conventional winding or knitting machine, the porous skeleton is filled with three-dimensional through pores with different porosities capable of meeting various bone implantation requirements, then a medical magnesium or magnesium alloy melt is infiltrated in the pores of the porous skeleton by pressureless infiltration or negative-pressure suction casting, and after the porous skeleton is cooled, a medical titanium / magnesium composite material is formed. The composite material disclosed by the invention is reasonable in structure and excellent in mechanical properties; in the early stage of body implantation, the mechanical properties of the composite material can be matched with bones well, thereby avoiding stress shielding; after the composite material is implanted, with the degradation of magnesium, a porous structure of an implant is constantly restored, so that bone conduction is facilitated, and the requirements of most of bone filling, bone repair and bone transplantation applications can be met, therefore, the composite material is applicable to bone implanting operations with relatively high strength requirements.

Owner:SHANGHAI JIAO TONG UNIV

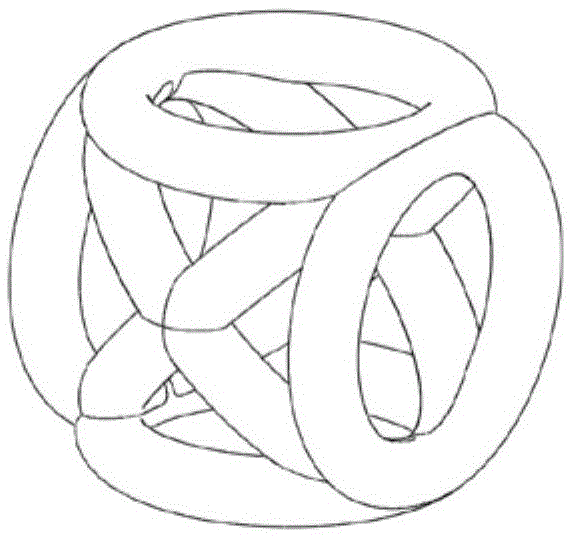

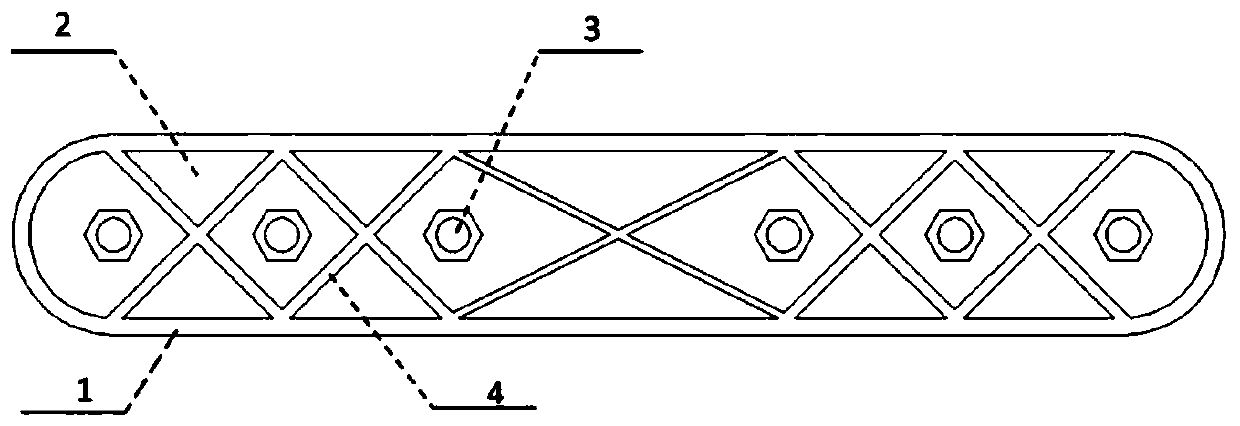

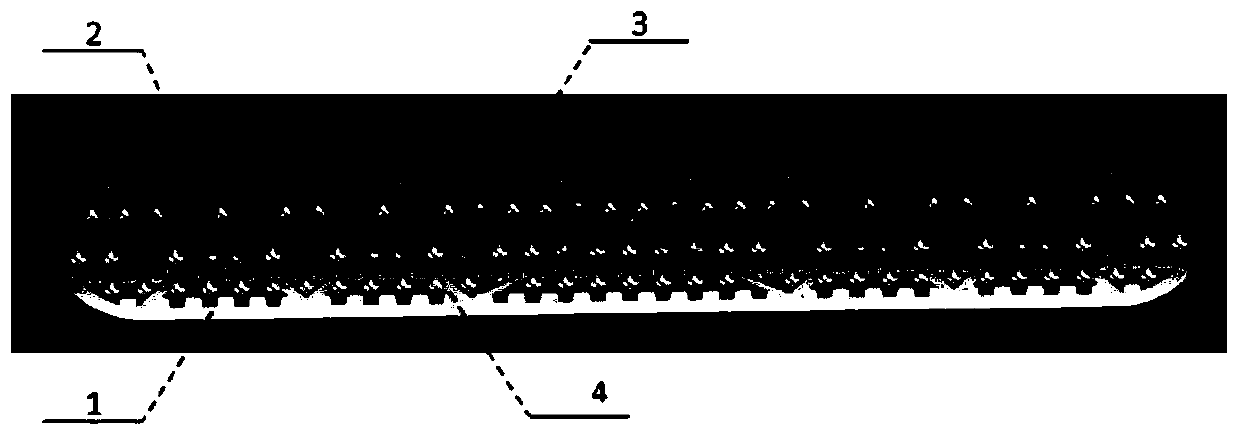

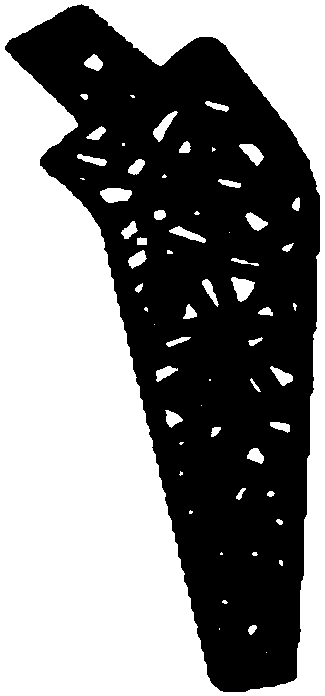

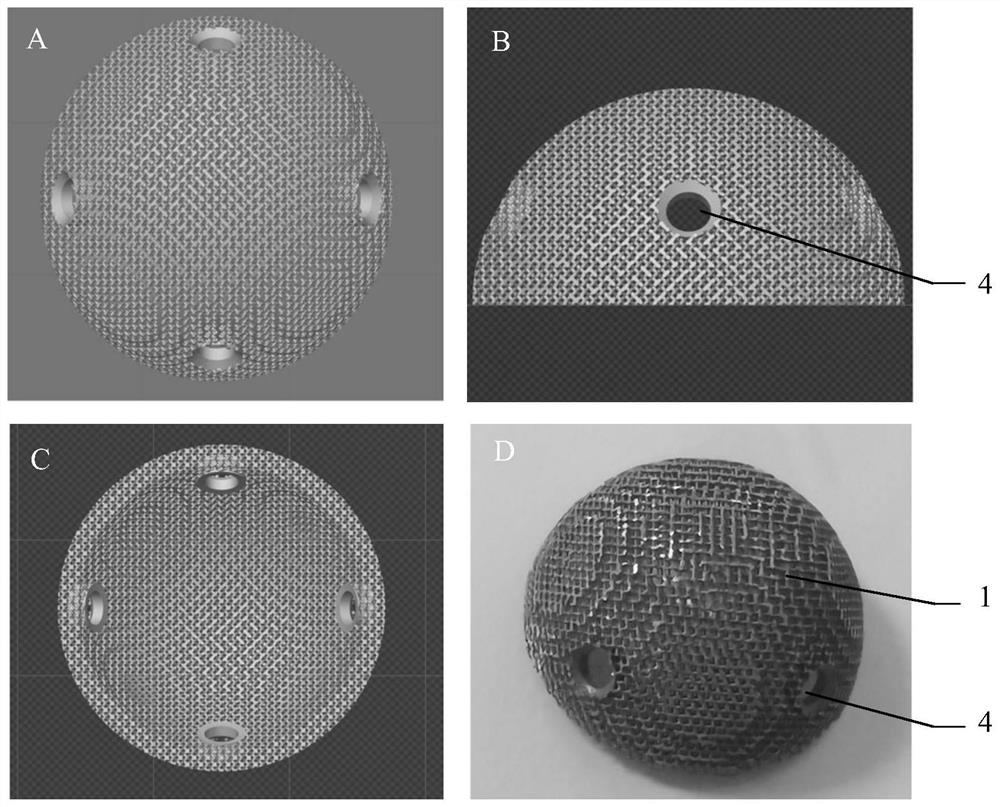

Preparation method of porous implant filled with O-intersecting lines units

InactiveCN105559947AThe preparation method is reliable and feasibleGreat potentialJoint implantsFemoral headsSand blastingPorous implant

The invention provides a preparation method of a porous implant filled with O-intersecting lines units. The preparation method comprises the following steps: drawing a three-dimensional model of the O-intersecting lines units, controlling the bore diameter, wall thickness and porosity of the three-dimensional model according to the given specific dimension so as to generate a unit structure cell body, carrying out array copying operation on the unit structure cell body, thus obtaining a space porous network body, introducing in a femoral three-dimensional surface model, scaling the model to reach the proportion actually needed, carrying out cutting and Boolean operation on the porous network body and the femoral three-dimensional surface, thus obtaining a porous main body part, drawing the femoral steam end and a bolt positioning hole part by utilizing three-dimensional modeling, combing the porous main body part to enable the porous main body part to form a single-output porous implant body, saving the single-output porous implant body into an output format file and transmitting the file to layering software, adding with a bottom surface support, printing the porous implant body by adopting a 3D printer, clearing a substrate plate, taking out the porous implant, carrying out sand blasting treatment on the porous implant, and packaging the porous implant. With the adoption of the preparation method, units which are regular and uniform and having no closure can be generated, and the stressing uniformity is guaranteed.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Proximally Self-Locking Long Bone Prosthesis

A method for arthroplasty includes using a self-locking prosthesis that has a member structured to transfer a load produced by the weight of a patient to a bone. An expandable bone-locking portion that is integral to the member includes a shape-memory material and expands to produce a locking force. A portion of the bone is removed to form an aperture in the bone. The bone-locking portion is inserted into the aperture, and a temperature increase causes a change from a contracted state to an expanded state resulting in expansion of the bone-locking portion so as to contact the inner surface. The expanding is sufficient to create a locking force at the junction between the inner surface and the bone-locking portion of the prosthesis and the majority of the locking force is applied at or above the metaphysis. The length / width ration of the prosthesis may be less than or equal to 5. The resulting reconstructed long-bone may have improved primary and long-term stability.

Owner:ARTHREX INC

3D-printed porous tantalum metal bone plate

ActiveCN109793565AAids in healingAvoid stress shieldingAdditive manufacturing apparatusBone platesOsseointegrationBone growth

The invention relates to a 3D-printed porous tantalum metal bone plate. The 3D-printed porous tantalum metal bone plate is characterized in that tantalum metal powder is taken as a base material, andthe bone-imitating trabecular bone plate having bone induction property and produced by 3D printing has an interconnecting-pore structure fit for bone growth. The production method includes: under argon production, using medical grade spherical tantalum powder as a raw material to produce the porous bone plate by 3D printing; removing excess metal powder adhering to the surface of the bone plate through sandblasting; removing residual stress through heat treatment to make the surface of the bone plate smooth. By the arrangement, the porous bone plate with the bone induction property can form excellent bone integration with bone tissue so as to achieve permanent fixation in biology.

Owner:赵德伟 +2

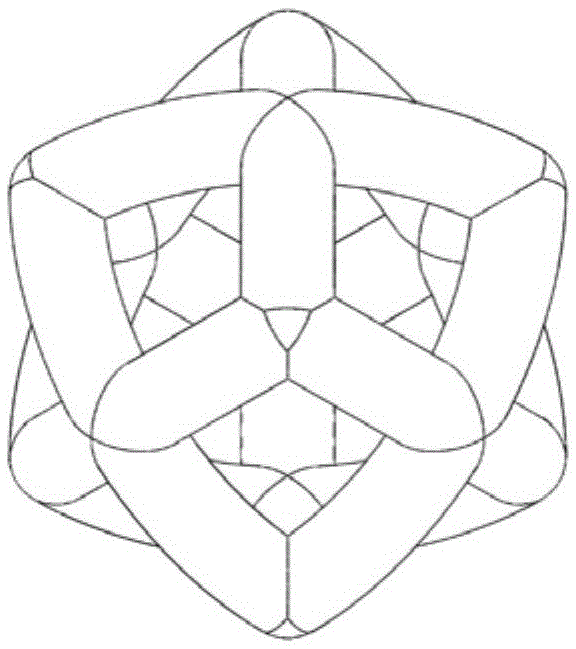

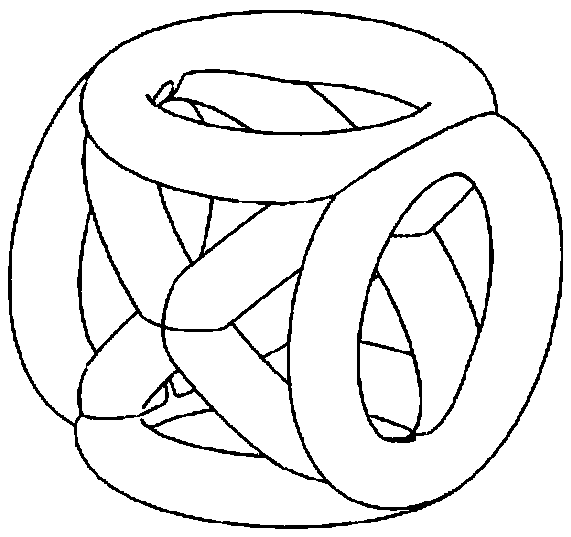

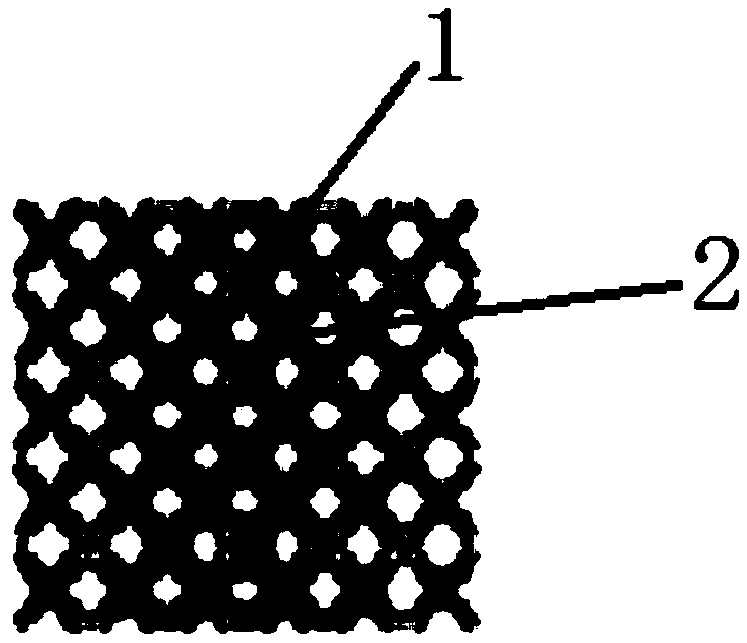

Metal bone trabecula and bone implant comprising metal bone trabecula

PendingCN107647941AMeet the stiffnessMeet the intensityBone implantJoint implantsHuman bodyBone Trabeculae

The invention discloses a metal bone trabecula. The metal bone trabecula comprises at least three crossed metal bone trabecula supports, a micro-topological grid structure is embedded into the metal bone trabecula, and at least three intersection points are formed between the micro-topological grid structure and the metal bone trabecula supports. The bone trabecula is formed by regularly or irregularly arranging hollowed-out unit structure bodies in a three-dimensional space, the weight reducing effect is obvious, meanwhile, the requirement of rigidity and strength of different areas of partscan be met at the same time, stress shielding is avoided, and good matching of high strength and high weight reduction ratio can be achieved; in addition, after growing into the bone trabecula structure comprising a micro-topological grid, human body sclerotin can be fused with bone, bone ingrow can be induced to the largest extent, and accordingly long-term biological fixation of a prosthesis canbe achieved. Meanwhile, the invention further discloses a bone implant comprising the metal bone trabecula. The bone implant can achieve personalized customization through 3D printing, the process issimplified, and the economic cost is greatly reduced.

Owner:GUANGZHOU HUATAI 3D MATERIAL MFG TECH CO LTD

Porous implant filled with O-intersecting lines units

InactiveCN105496611AThe preparation method is reliable and feasibleGreat potentialJoint implantsTissue regenerationBone structureTissue fluid

A porous implant filled with O-intersecting lines units is mainly oriented to femoral stems and comprises a femoral stem end, a porous main body part and a screw positioning hole part, wherein the femoral stem end is used for positioning the porous implant, the screw positioning hole part is used for fixing the implant and a host, the porous main body part is a three-dimensional through porous network entity mainly formed by being filled with the O-intersecting lines units, the porous network entity comprises hollowed-out entities formed by scanning of O-intersecting lines unit cylinders penetrating through and crossing with one another in space, the hollowed-out entities are formed by pairwise perpendicular and linearly stacked O-intersecting lines unit cylinder surfaces, and the porous network entity has the pore diameter ranging from 400 mu m to 1,000 mu m, the unit wall thickness ranging from 80 mu m to 120 mu m and the porosity ranging from 55% to 85%. Thus, a porous network structure formed by stacking of the hollowed-out entities is close to a bone structure, has the high porosity, the high communication ratio and the larger surface contact area, is suitable for new bone ingrowth and circulation of nutrition tissue liquids and has the considerable clinical medical prospect.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

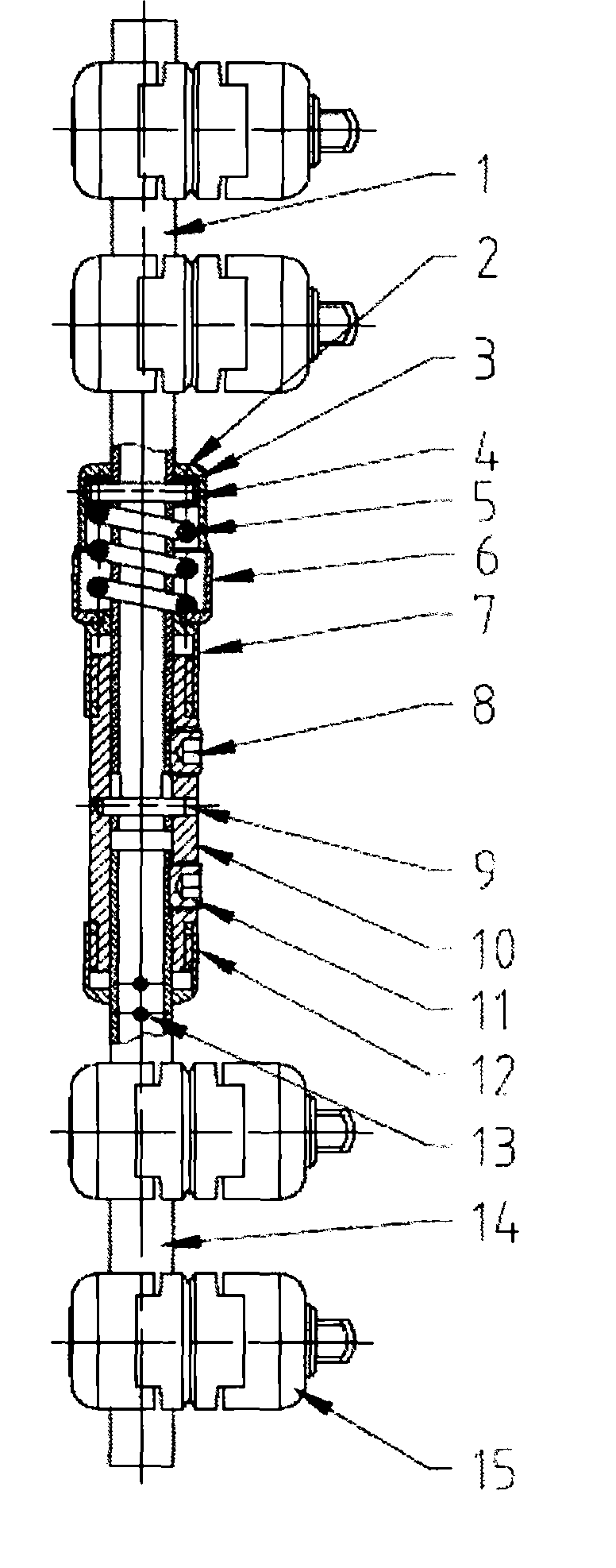

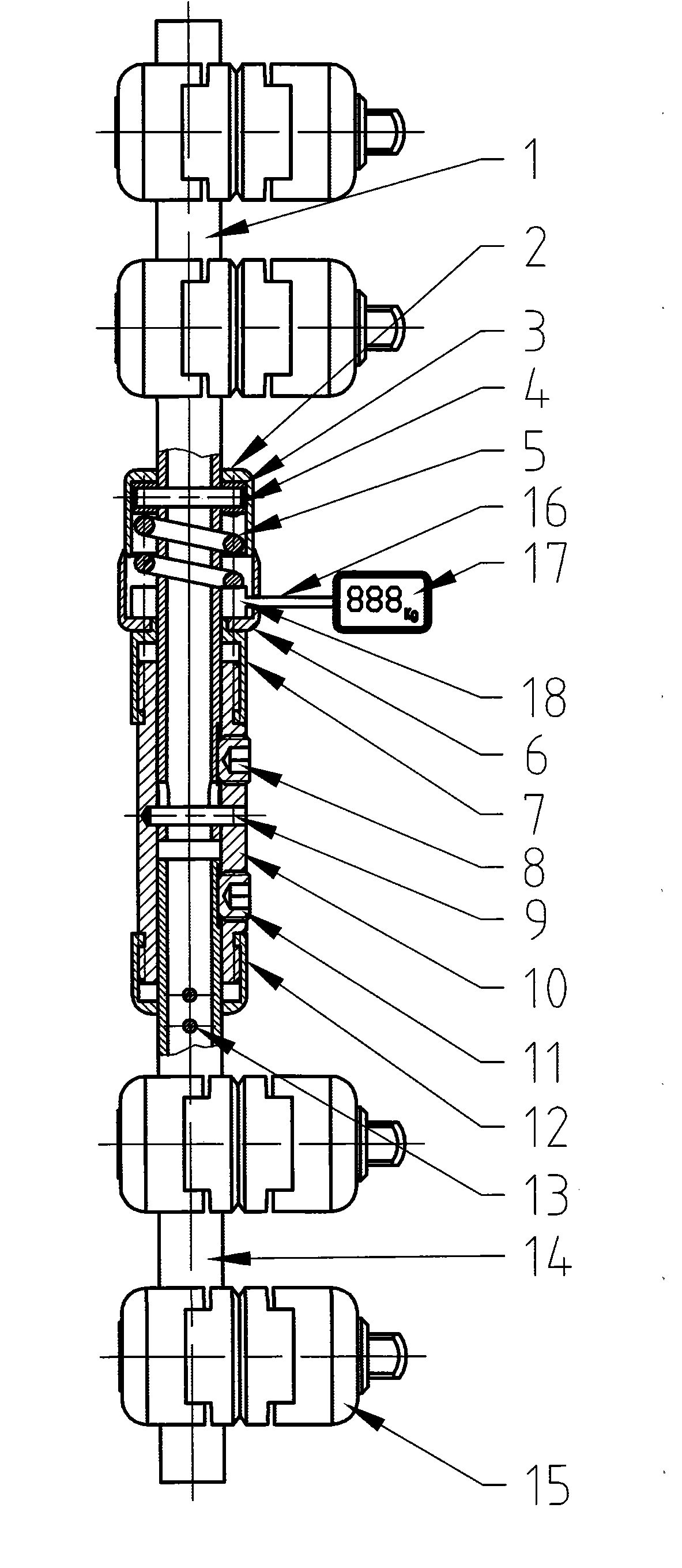

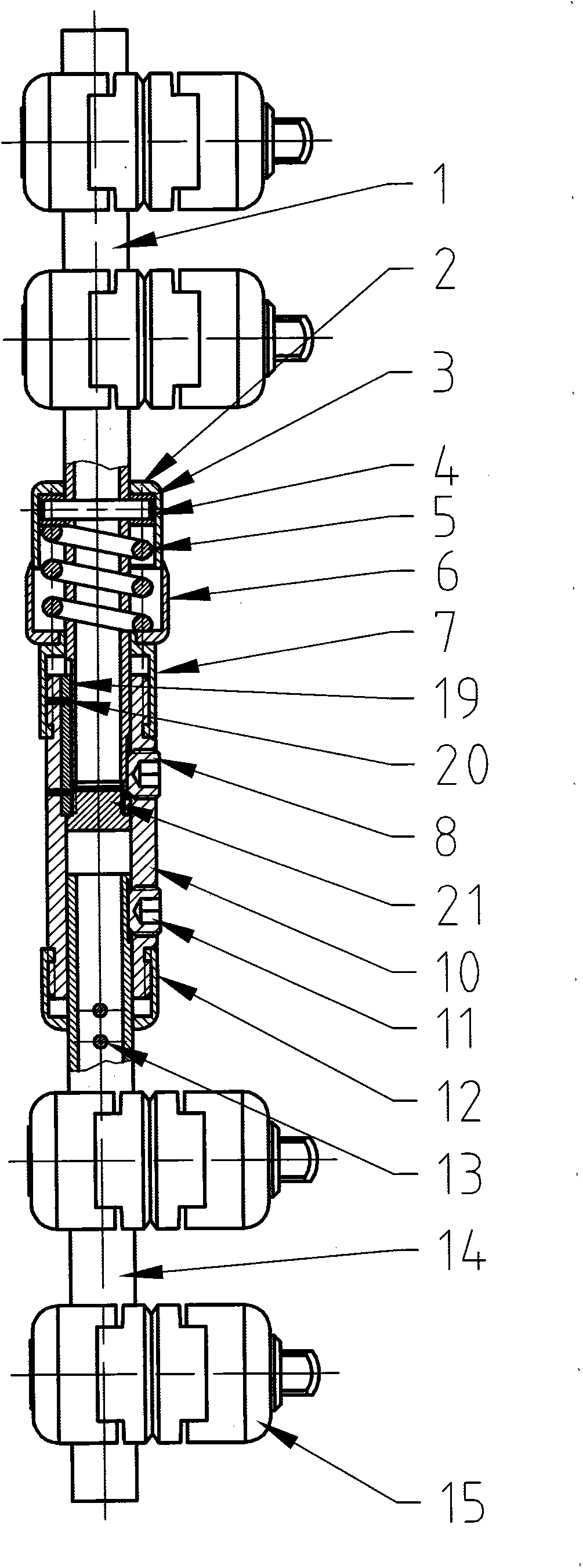

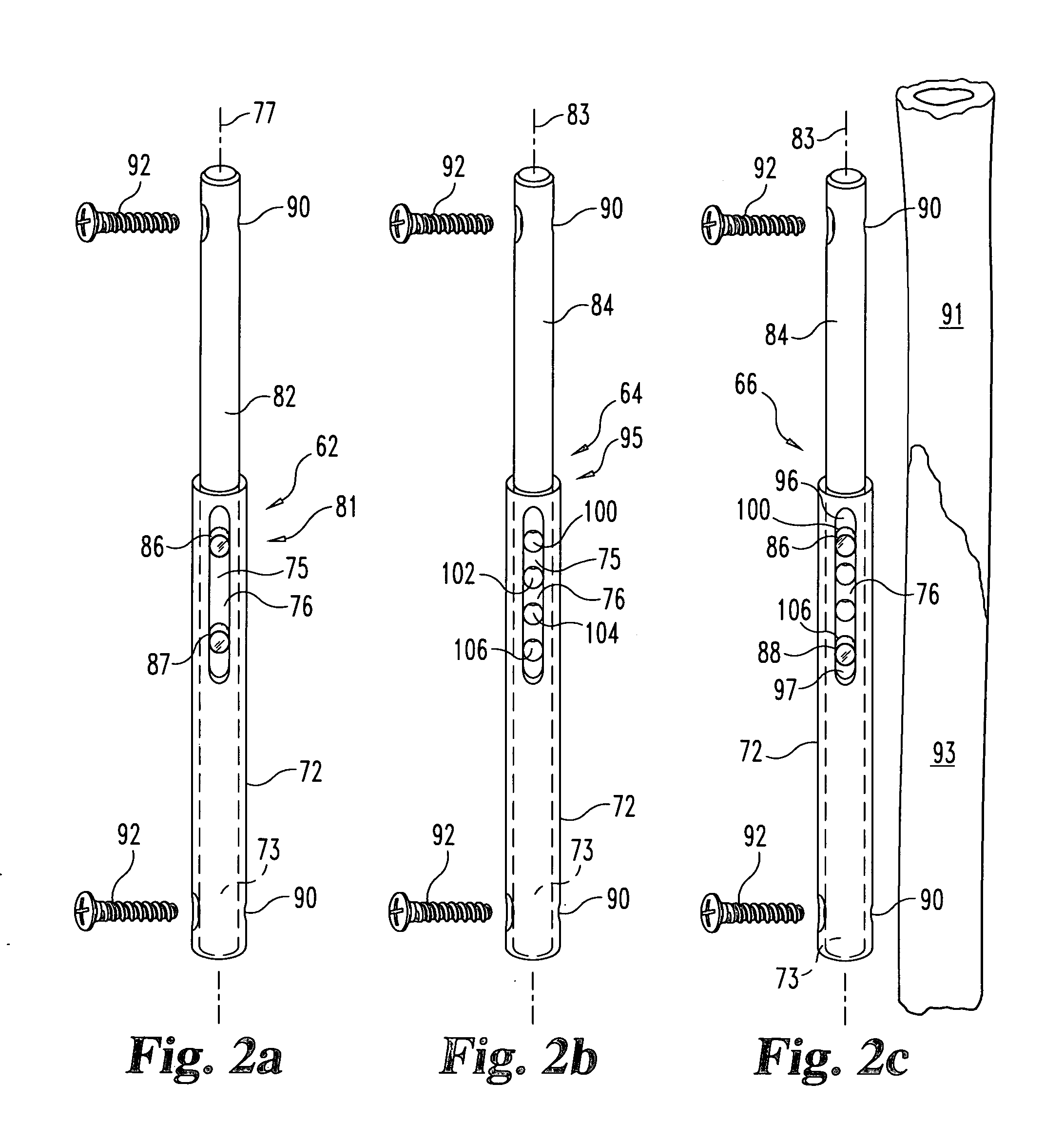

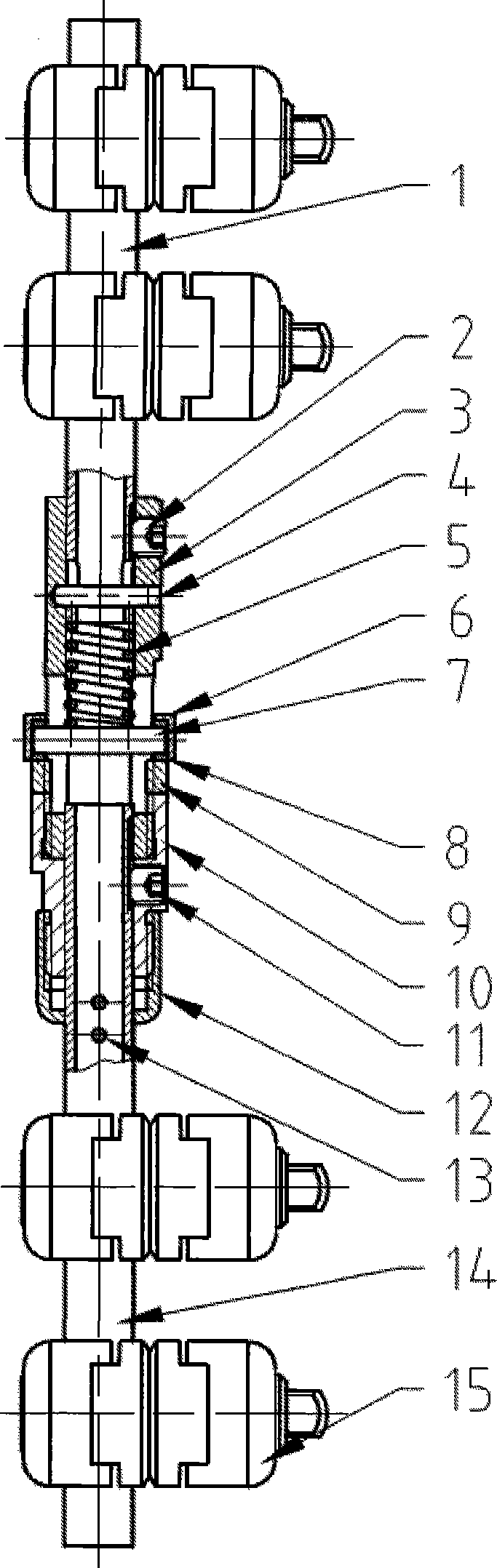

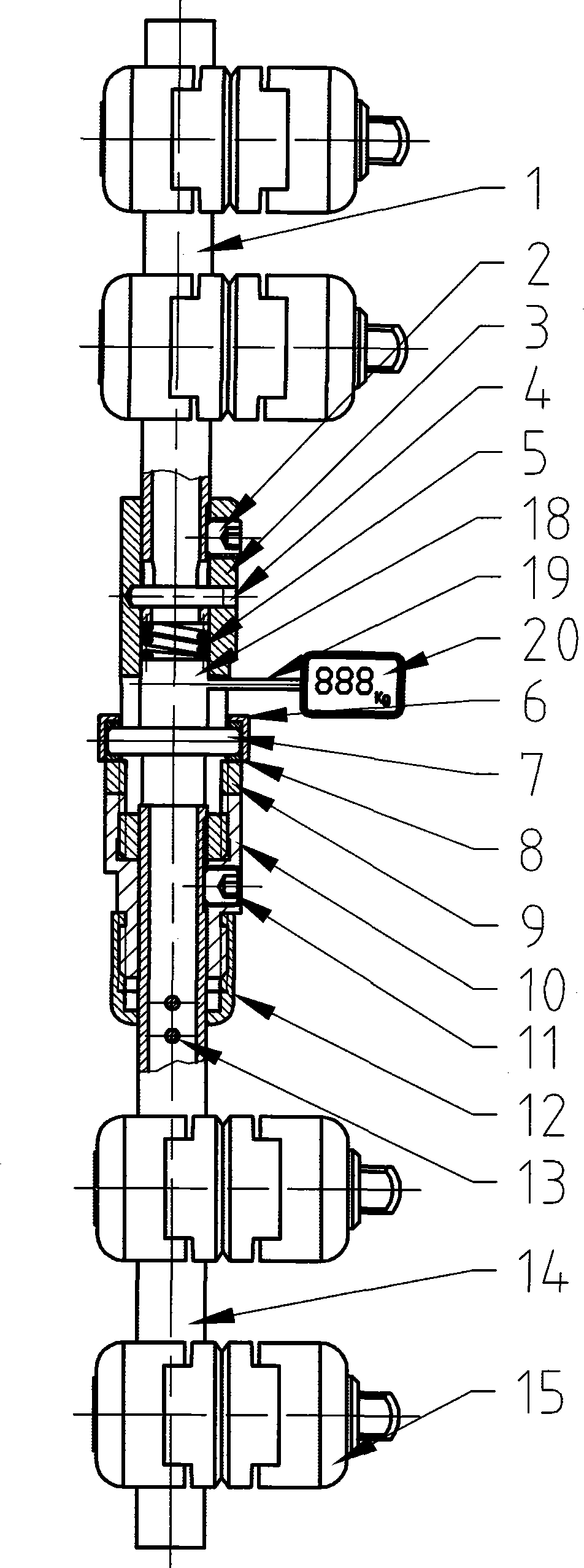

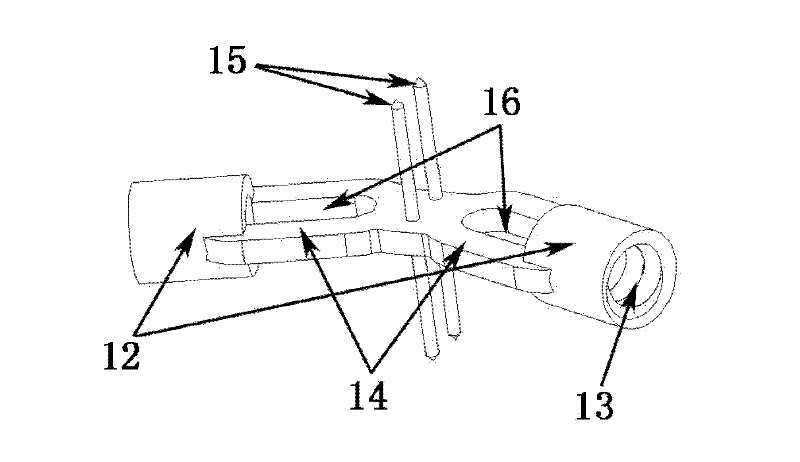

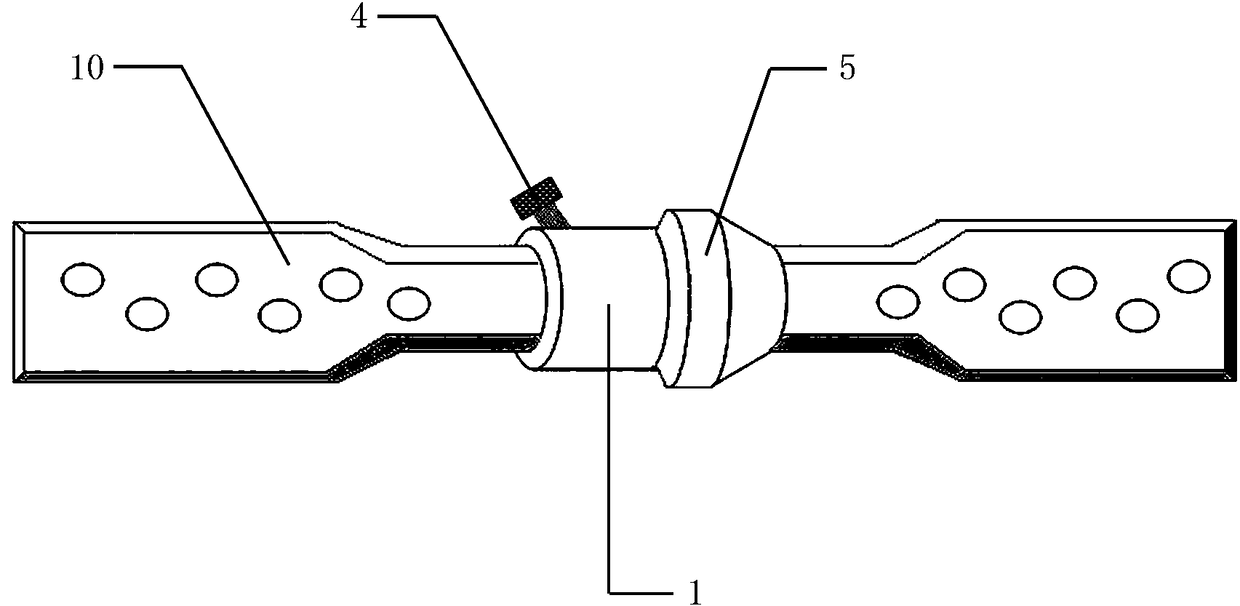

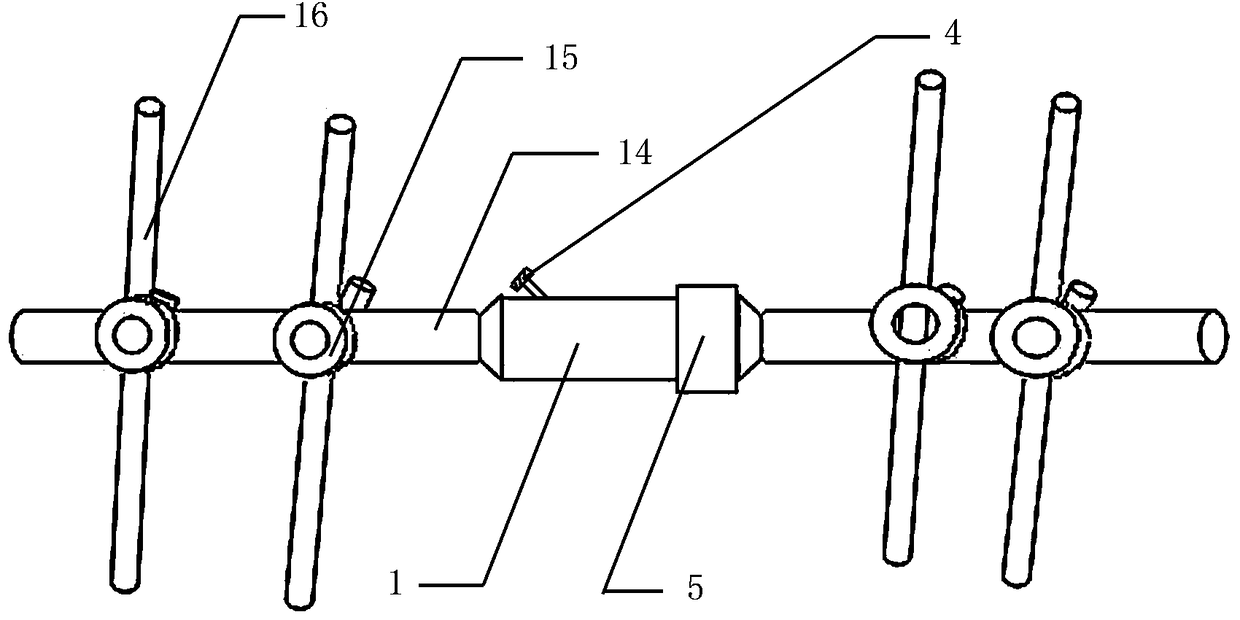

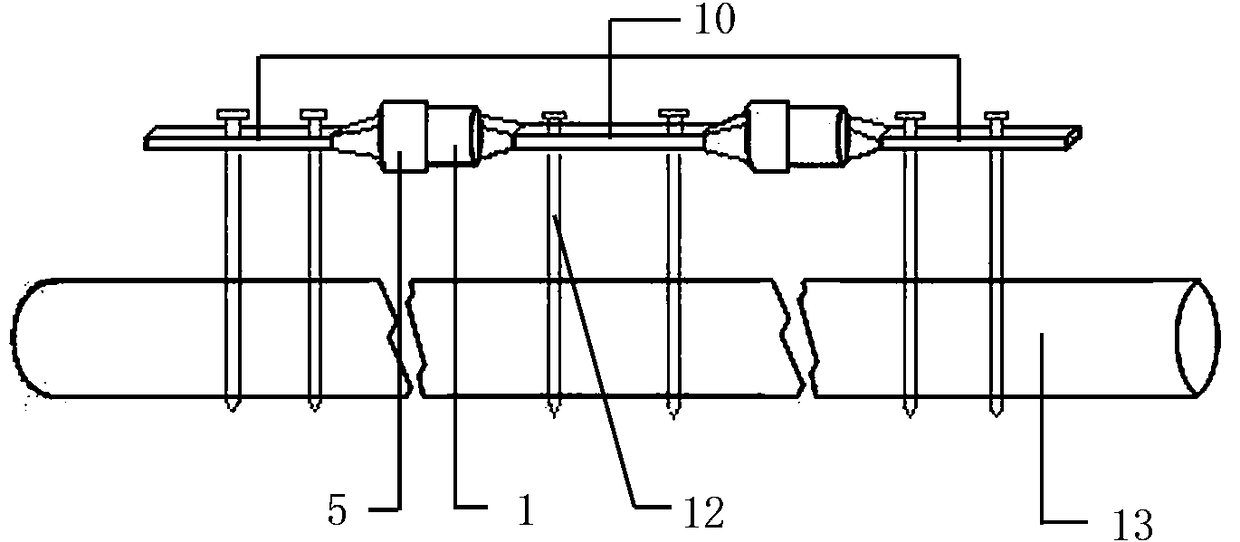

Pressure-adjustable combined-type outer fixing support and pressure-adjustable fixing arm

ActiveCN103876812AEasy to combineFacilitate accurate resetExternal osteosynthesisDisplay deviceEngineering

The invention relates to a pressure-adjustable combined-type outer fixing support for clinical orthopedic application. Combining forms of the pressure-adjustable combined-type outer fixing support include a single arm type, a semi-ring type and a ring type, fixing clamping blocks include knitting needle clamping blocks and knitting rod clamping blocks, a pressure-adjustable fixing arm is composed of an adjusting shaft, an adjusting nut, a sliding fit thread sleeve, an elastic device, a fastening nut and a fixing rod, the adjusting shaft is radially provided with a retaining spring pin, a fixing ferrule, a graduated sleeve and a sliding sleeve, the sliding fit thread sleeve is radially provided with a limiting pin, a limiting jack screw and a fastening jack screw, and the elastic device is composed of a spring, a pressure sensor, a connecting pipe and a pressure displayer and can be provided with a piezometer or not. The pressure-adjustable combined-type outer fixing support can transmit stress to enable stress to be generated at a fracture end, stress shielding can be avoided, and delayed fracture healing and fracture disunion are prevented.

Owner:宋若怡

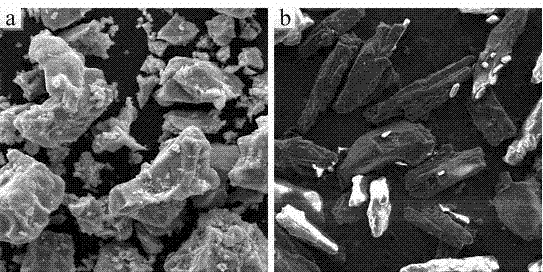

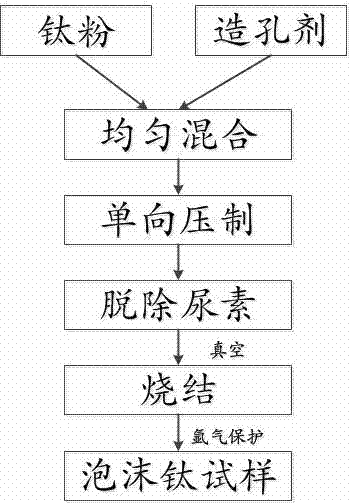

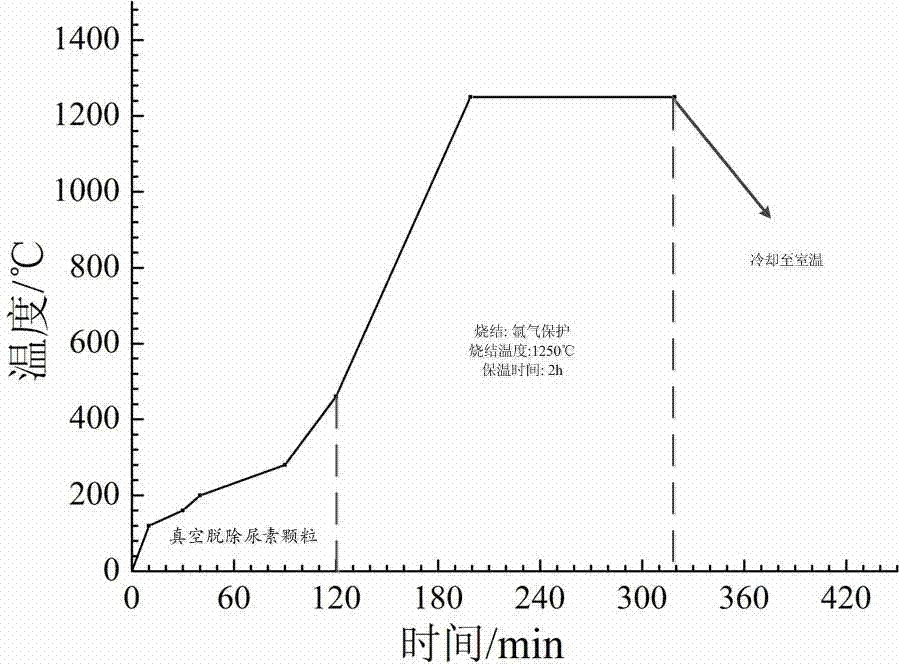

Preparation method of titanium foams for cancellous bone

The invention relates to a preparation method of titanium foams for cancellous bone. The preparation method comprises the following steps of: (1) mixing raw materials, namely selecting a primary mixture which is obtained by uniformly mixing titanium powder and a pore forming agent in a grinding body, wherein the mass part ratio of the titanium powder to the pore forming agent is (42.8-48.2):(52.8-58.2); (2) carrying out one-direction pressing on the primary mixture by adopting a universal material testing machine to prepare a green pressing body, wherein the one-direction pressure is 200-250MPa, and the pressure holding time is 1 minute; and (3) putting the green pressing body into a vacuum carbon tube furnace, sintering the green pressing body for 2 hours at 1200-1300 DEG C in an argon protective atmosphere to ensure that the pore forming agent is removed, and finally cooling along with the furnace to obtain the titanium foams. According to the titanium foams prepared by using the preparation method, the Young modulus is matched with that of the cancellous bone of the human body, therefore the stress shielding phenomenon is effectively avoided, and an implant can be permanently fixed; and meanwhile, the titanium foams can be prevented from being oxidized as far as possible by adopting the argon protective atmosphere.

Owner:CHONGQING UNIV

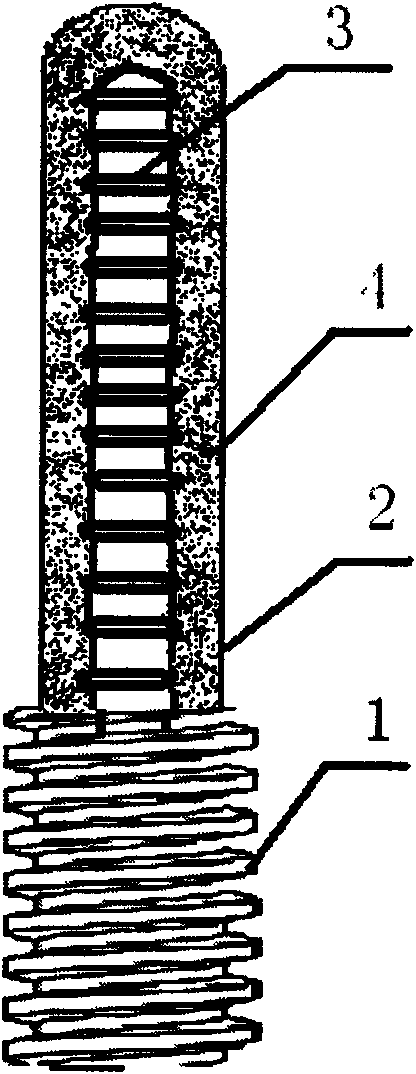

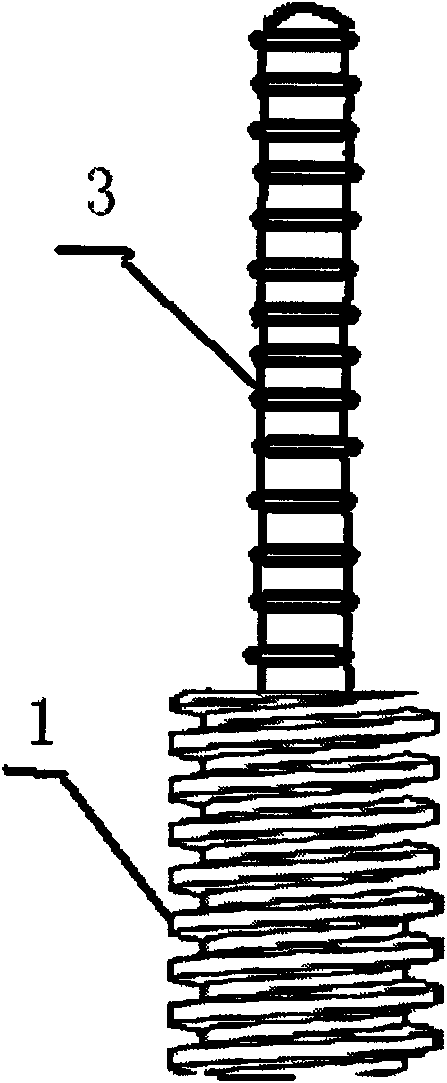

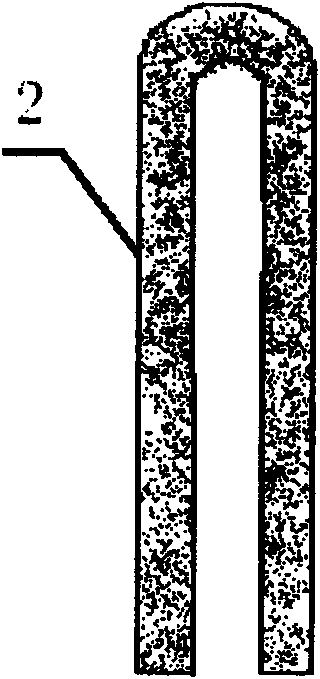

Femoral head support frame and manufacturing method thereof

The invention relates to a femoral head support frame and a manufacturing method thereof. The femoral head support frame is characterized in that the whole femoral head support frame is cylindrical; the front end of a body part is hemispherical; a tail part is a cylinder provided with an external thread; core columns of the body part and the tail part of the support frame are manufactured by mechanically processing solid metals; a hemispherical cylindrical shell on the outer layer of the body part of the support frame is formed by porous metals manufactured by powder metallurgy technology; and the porous metals are metal materials with pore diameter being 20-800mu m and porosity being 20-70%. The femoral head support frame has large pore diameter, high porosity and high strength and avoids stress shielding caused by high elastic modulus after being implanted in the human body, and the porous metal structure is beneficial to adhesion and ingrowth of the bone tissues toward the support frame.

Owner:北京畅想天行医疗技术有限公司

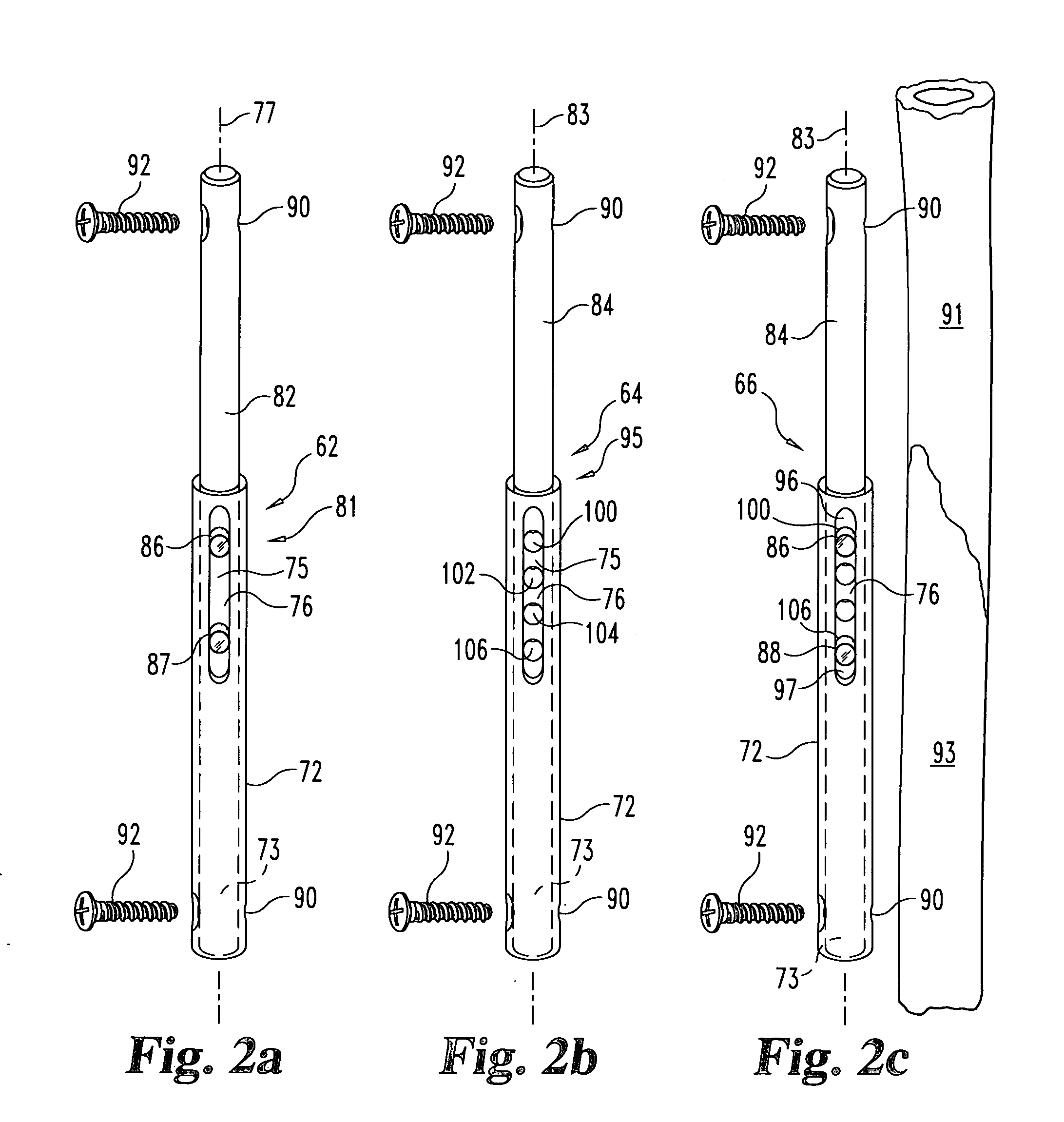

Apparatus and method for providing dynamizable translations to orthopedic implants

InactiveUS7699879B2Avoid stress shieldingLimited supportSuture equipmentsInternal osteosythesisBone structureJoint arthrodesis

The present invention generally relates to orthopedic devices and methods for treating bone defects. The orthopedic devices can provide sufficient support to the bone defect while allowing bone ingrowth and minimizing the risk to stress shield and / or pseudo-arthrodesis. The bone fixation devices include a biodegradable material or component that further resists relative motion of attached bones and allows the device to gradually transfer at least some load from the device to the growing bone structure in vivo and permitting an increase in the relative motion of bones attached to the device.

Owner:WARSAW ORTHOPEDIC INC

Cap type cervical vertebra pyramid fusion apparatus

InactiveCN1555771ANo mobility issuesReduce chance of sinkingInternal osteosythesisSpinal implantsLamina terminalisBiomechanics

A cap-type fusion device used between two cervical pyramids is a hollow truncated conic body, which has a holes, inclined top surface and flat bottom surface, which are matched with the top and bottom end-plate of cervical pyramid, and the projected edges. Its advantages are high effect and biologic compatibility, low cost and high safety.

Owner:贾连顺 +2

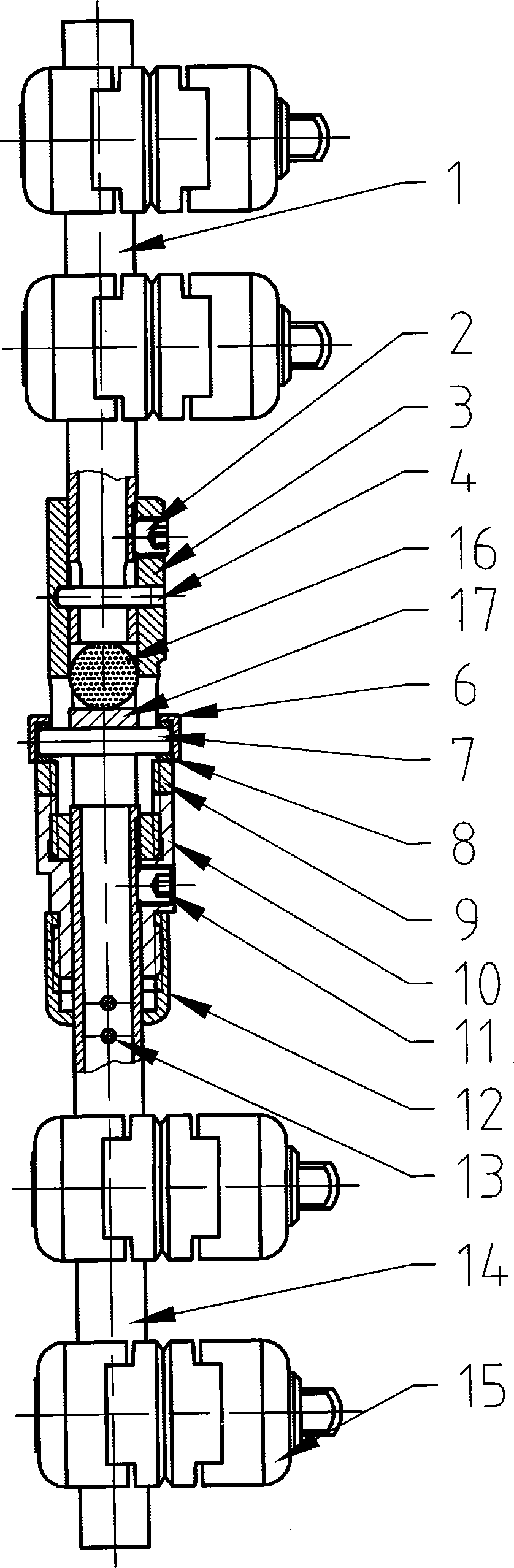

Pressure-adjustable combined-type outer fixing support and pressure-adjustable fixing arm

ActiveCN103876813AThe connection is tight and firmEasy to assembleExternal osteosynthesisDisplay deviceEngineering

The invention relates to a pressure-adjustable combined-type outer fixing support for clinical orthopedic application. Combining forms of the pressure-adjustable combined-type outer fixing support include a single arm type, a semi-ring type and a ring type, fixing clamping blocks include knitting needle clamping blocks and knitting rod clamping blocks, a pressure-adjustable fixing arm is composed of an adjusting shaft, a sliding fit thread sleeve, an elastic device, a connecting nut, a fastening nut and a fixing rod, the sliding fit thread sleeve is radially provided with a limiting pin, a limiting jack screw, a pressure adjusting pin, an outer ferrule, an inner ferrule, a pressure adjusting nut and a pressure adjusting pin hole, the adjusting shaft is in sliding fit with the sliding fit thread sleeve, the connecting nut is in threaded connection with the sliding fit thread sleeve and the fastening nut, the fastening nut and a pipe clamping pin are in relatively fixed fit, the elastic device is composed of a spring or an elastic capsule, a pressure sensor, a sliding base, a pressure sensor connecting device and a pressure displayer and can be provided with a piezometer or not. The pressure-adjustable combined-type outer fixing support can transmit stress to enable stress to be generated at a fracture end, stress shielding can be avoided, and delayed fracture healing and fracture disunion are prevented.

Owner:河南科科生物科技有限公司

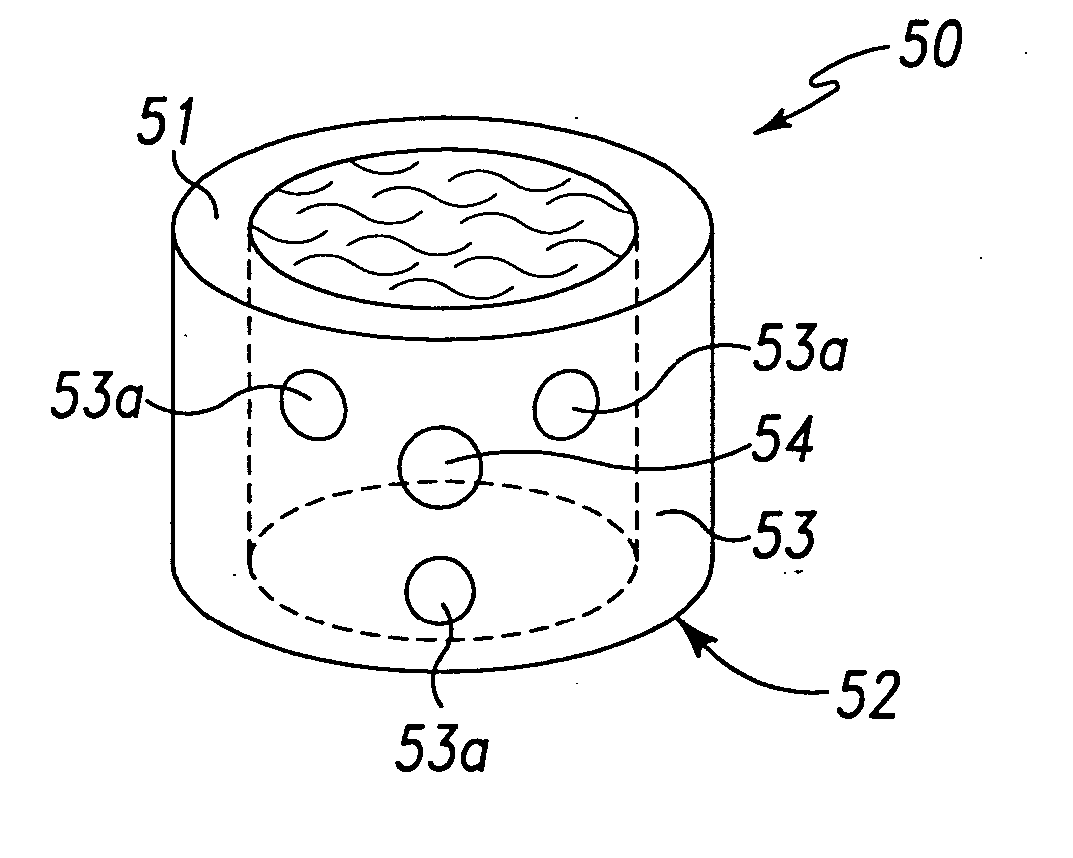

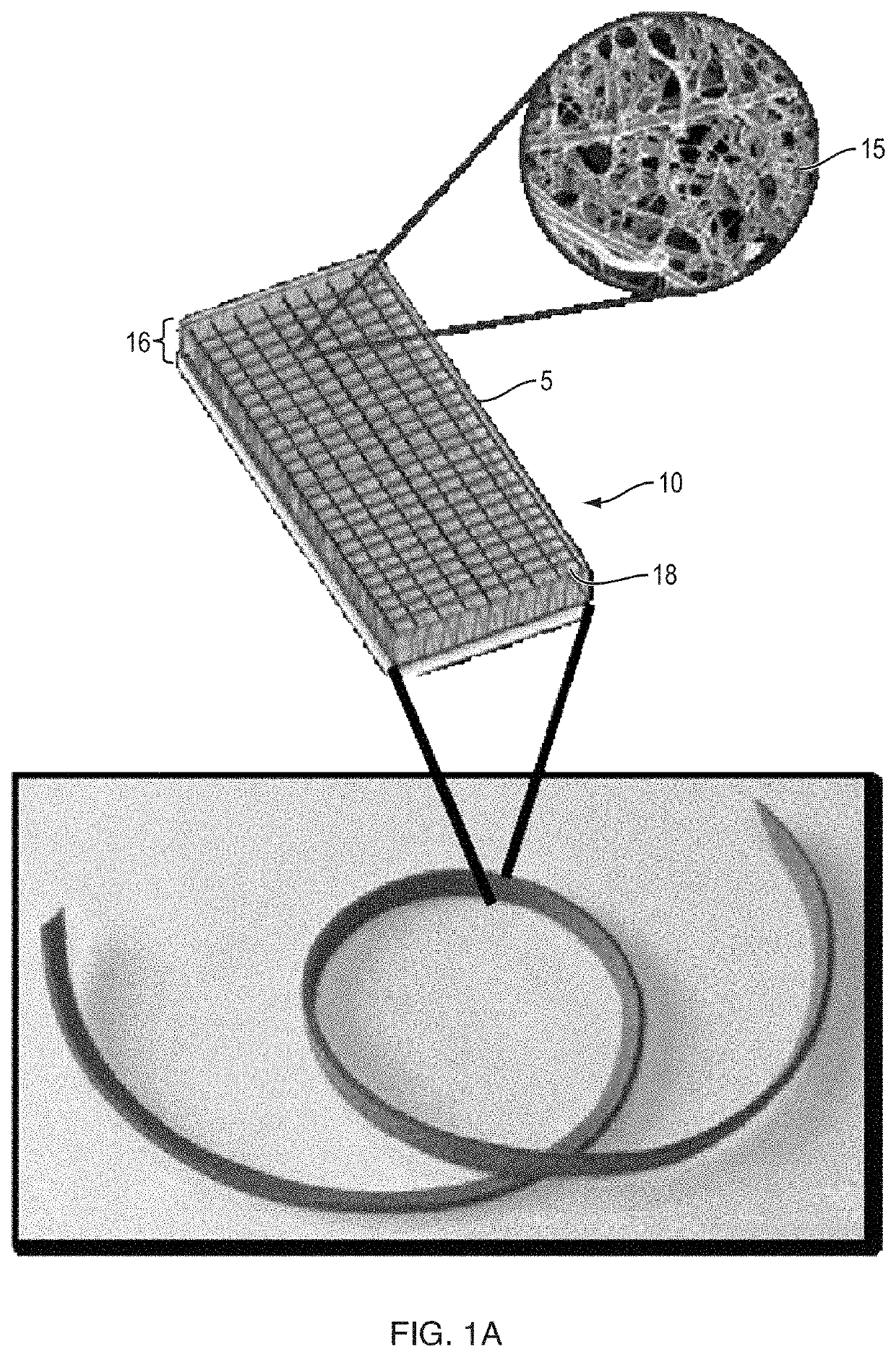

Composite scaffold for the repair, reconstruction, and regeneration of soft tissues

PendingUS20210161645A1High tensile strengthFacilitate and accelerate healingSuture equipmentsOrnamental textile articlesMedicineEngineering

The disclosed composite scaffold provides a highly porous and flexible structure that substantially maintains its three-dimensional shape under tension and provides mechanical reinforcement of the repair or reconstruction-first via scaffold mechanical properties, and subsequently, through newly regenerated functional tissue as the scaffold is resorbed.

Owner:BIOREZ INC

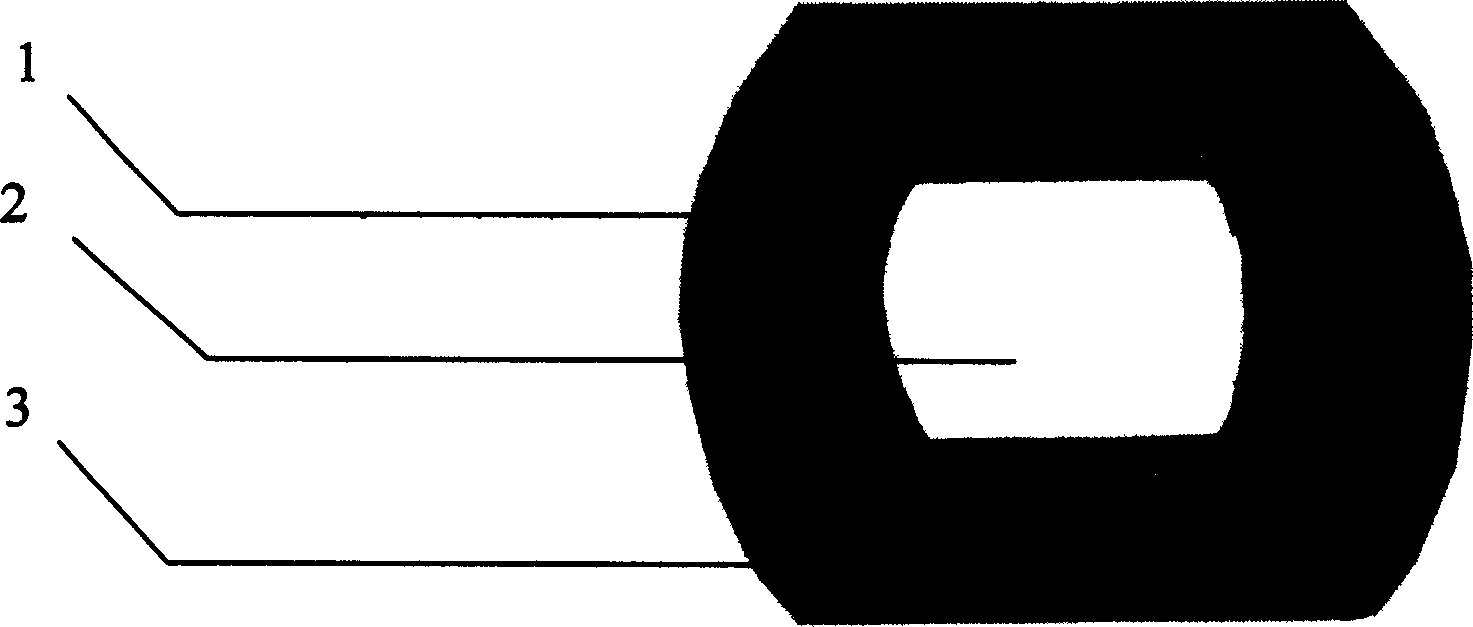

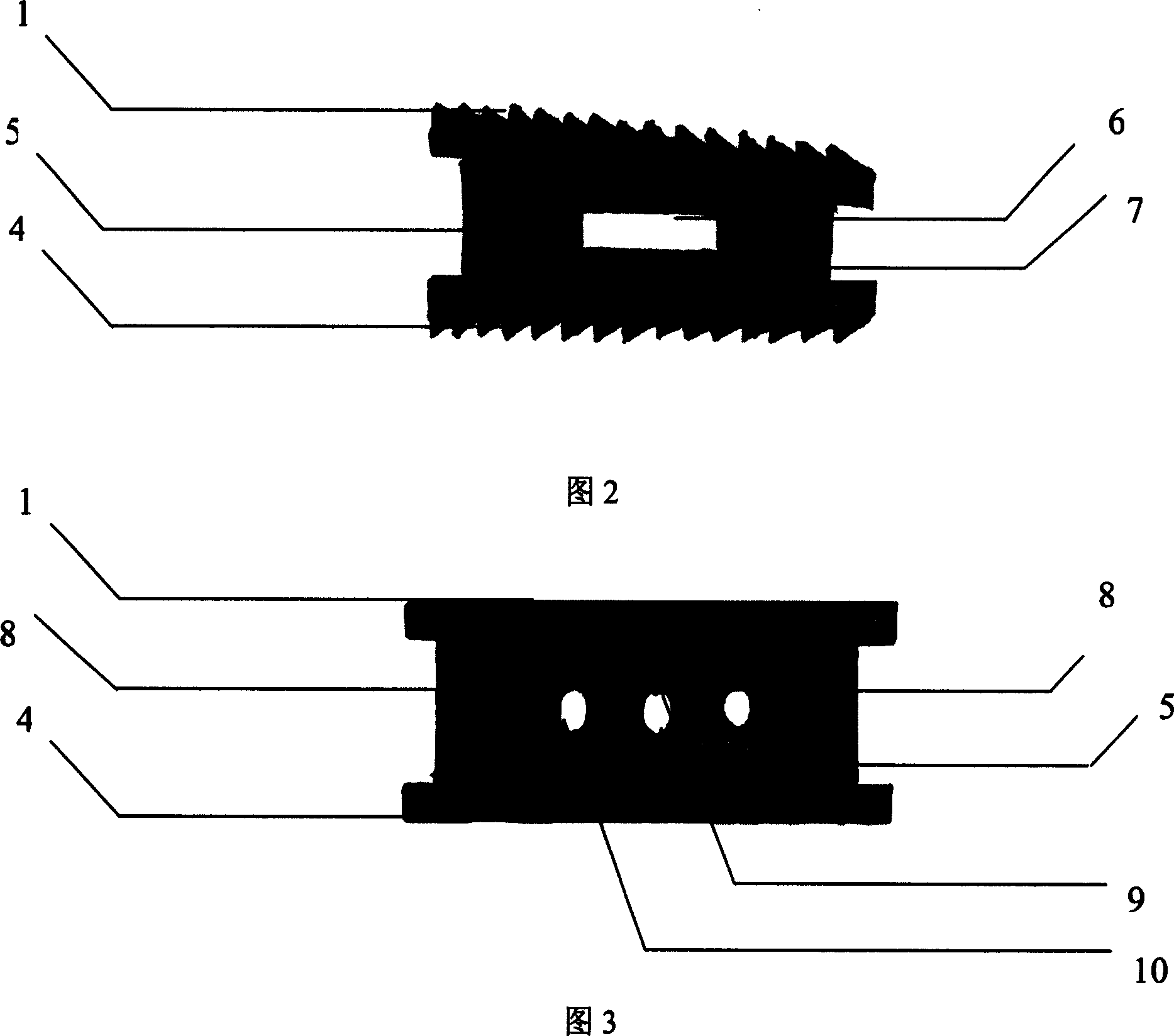

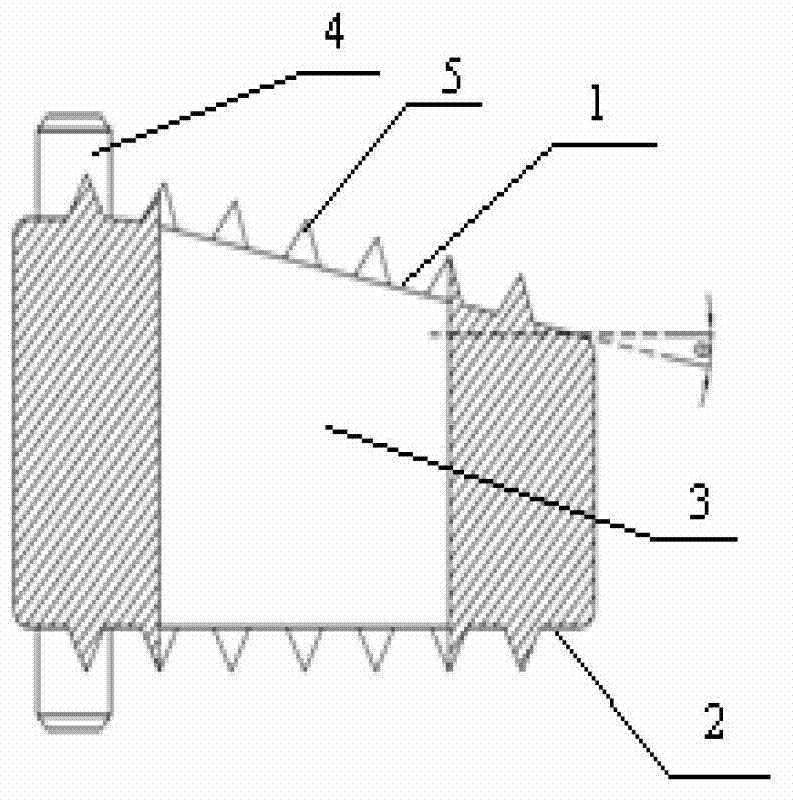

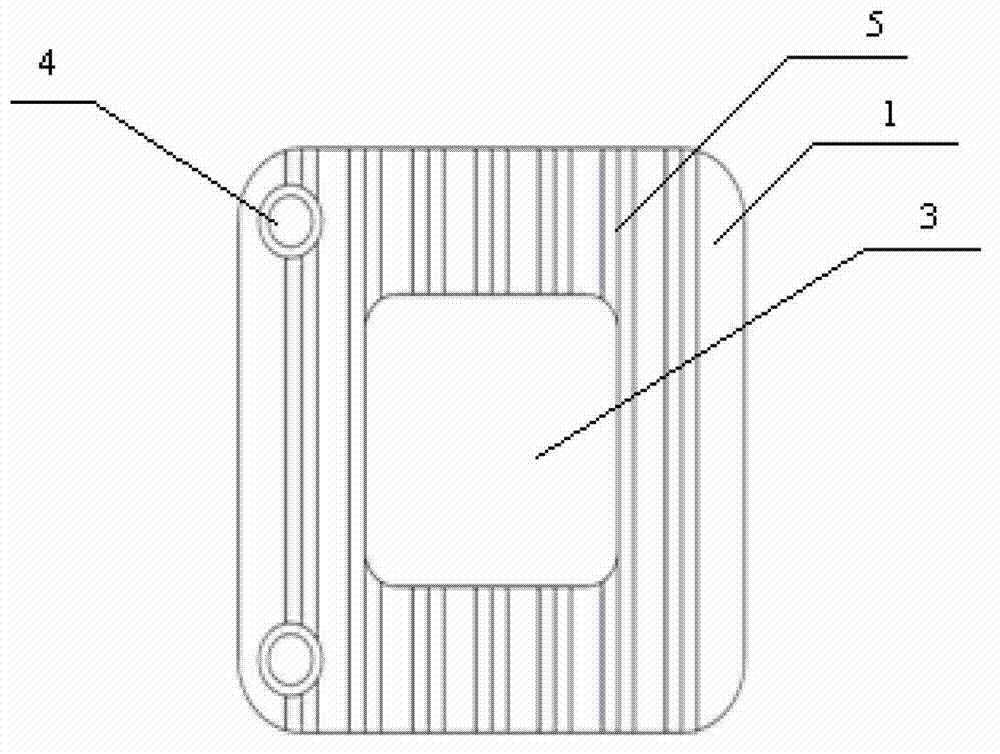

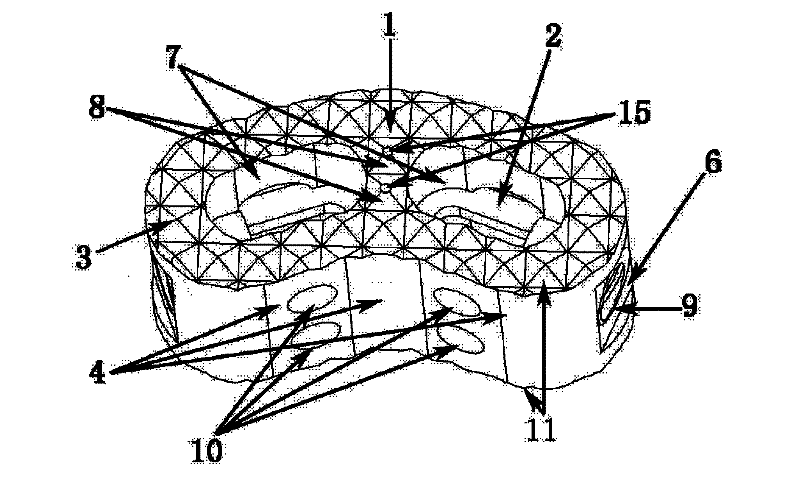

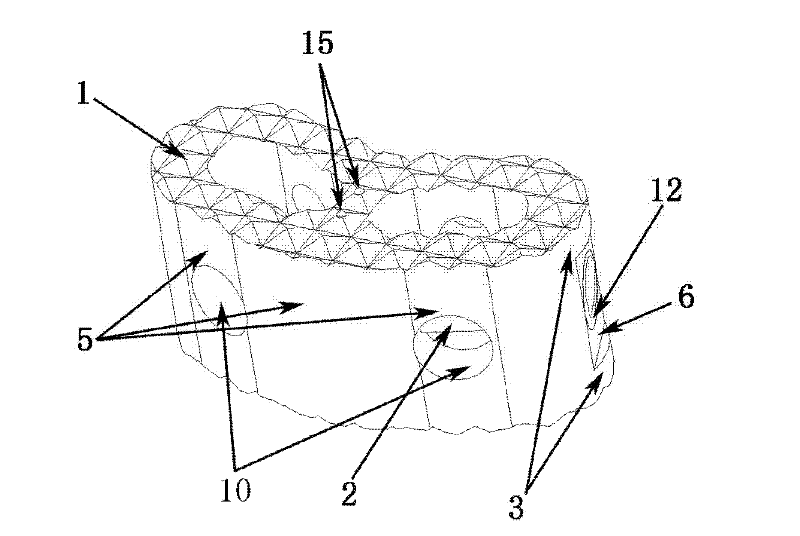

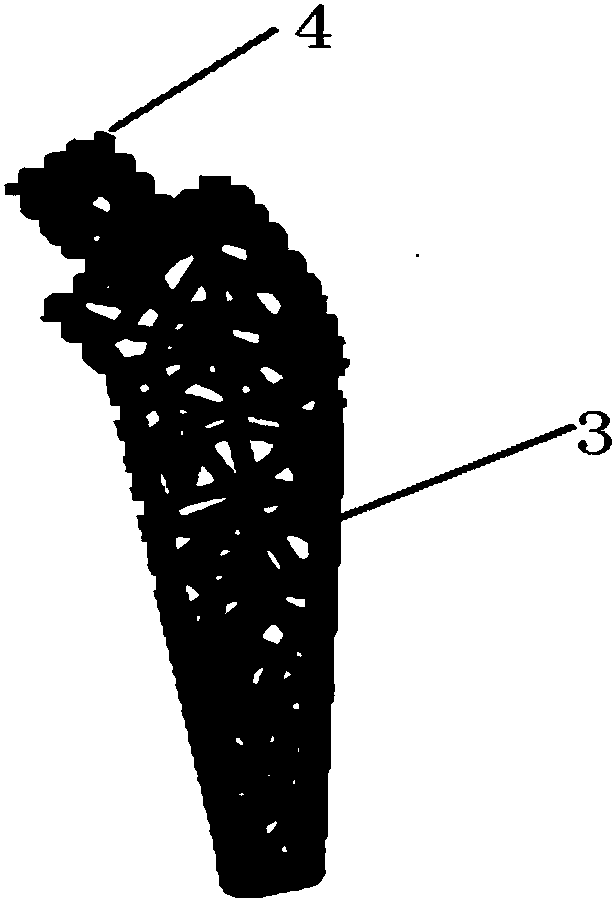

Medical degradable magnesium alloy interbody fusion cage

InactiveCN102784415AAvoid non-specific inflammationImprove stabilityInternal osteosythesisSpinal implantsSpinal cageStress shielding

The invention discloses a medical degradable magnesium alloy interbody fusion cage, relates to an interbody fusion cage and aims at solving problems that inflammation is caused due to acidic materials which are produced by existing interbody fusion cages during degradation and stress shielding can occur due to inappropriate selection of elasticity modulus. The medical degradable magnesium alloy interbody fusion cage is made of Mg-Sn-Mn series alloy or Mg-Sn-Mn-Zn series alloy; the medical degradable magnesium alloy interbody fusion cage comprises an upper end plate contact surface (1) and a lower end plate contact surface (2), a through hole (3) is opened at the center of the fusion cage, the upper end plate contact surface (1), the lower end plate contact surface (2) and the through hole (3) are polygons which are of the same shape, two protuberant studs (4) are respectively arranged on the upper end plate contact surface (1) and the lower end plate contact surface (2), and the upper end plate contact surface (1) can be an inclined surface to form an angle theta with the lower end plate contact surface (2). The medical degradable magnesium alloy interbody fusion cage can be applied to the field of degradable and absorptive medical instrument manufacturing.

Owner:HARBIN ENG UNIV

Bone grafts

InactiveUS20120310348A1Encourages bone ingrowthAvoid stress shieldingBone implantDiagnosticsVertebraLoad bearing

Spinal spacers 20 are provided for fusion of a motion segment. The spacers include a load bearing member 21 having a wall 22 sized for engagement within a space between adjacent vertebrae to maintain the space and an effective amount of an osteogenic composition to stimulate osteoinduction. The osteogenic composition includes a substantially pure osteogenic factor in a pharmaceutically acceptable carrier. In one embodiment the load bearing member includes a hone graft impregnated in an osteogenic composition. In another embodiment, the osteogenic composition 30 is packed within a chamber 25 defined in the graft. Any suitable configuration of a bone graft is contemplated, including bone dowels, D-shaped spacers and cortical rings.

Owner:PAFFORD JOHN +4

Bone grafts

Owner:RAY III EDDIE F +4

Spinal column fusion device internally lined with reinforced ribs

ActiveCN102512230AHigh strengthImprove toughnessInternal osteosythesisSpinal implantsSpinal columnAnatomical structures

A spinal column fusion device internally lined with reinforced ribs comprises a main body structure and two internally-lined metal reinforced rib structure bodies embedded in the main body structure, wherein the main body structure is of a tubular structure with two hollow holes, each internally-lined metal reinforced rib structure body comprises a metal connecting bridge and two cylinders with internal thread structures, the two cylinders are connected by the metal connecting bridge, and the connecting bridge is embedded in a tube wall of the tubular structure. The horizontal section of the fusion device imitates a spinal column anatomical structure, the whole strength and toughness of the fusion device are improved by a form of internally-lined reinforced ribs, and the selecting range of novel biological materials is enlarged. In the process of an implantation operation, the main body part borne by the internally-lined metal reinforced rib structure is implanted into a body, so thatthe situation that the fusion device can be damaged due to a bad mechanics environment during the operation to influence an operation success can be avoided.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

Fracture external fixing frame with adjustable axial pressure among bone blocks

The invention relates to a fracture external fixing frame and particularly relates to a fracture external fixing frame with an adjustable axial pressure among bone blocks, belonging to external fixation instruments for fracture treatment. According to the fracture external fixing frame, the problem that the space among fractured blocks usually cannot be properly pressurized when fracture is steadily fixed by virtue of an existing fixing instrument is solved. The fracture external fixing frame is characterized in that a frame rod is segmented, and one or two ends of each segment is / are providedwith plugs or interfaces; spring devices (including one or more of metal springs, gas springs and elastic matter pads) are arranged in the plugs or the interfaces and are spliced to form connecting devices for adjusting the axial pressure among the bone blocks, and the frame rod segments can form an integrated combined frame rod by the connecting devices. By adjusting the elastic forces of the whole spring devices, the action forces of the connecting devices on two frame rod segments on two sides in the long-axis direction are changed, and therefore, the axial pressure among the bone blocks is adjusted. The fracture external fixing frame is applied to fracture fixation, and when the fracture is steadily fixed, excessive stress shielding can be avoided, and the axial pressure among the bone blocks can be flexibly quantized, adjusted and controlled into a proper level required by fracture healing, so that fracture healing is promoted.

Owner:王培林

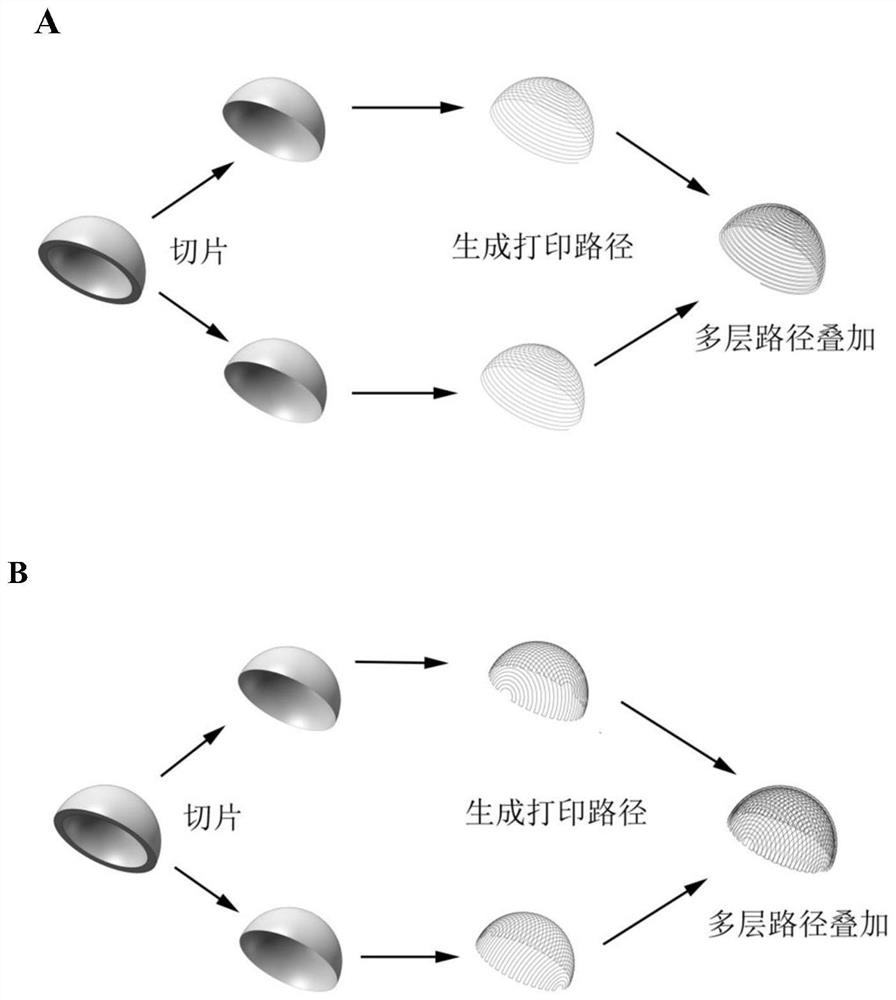

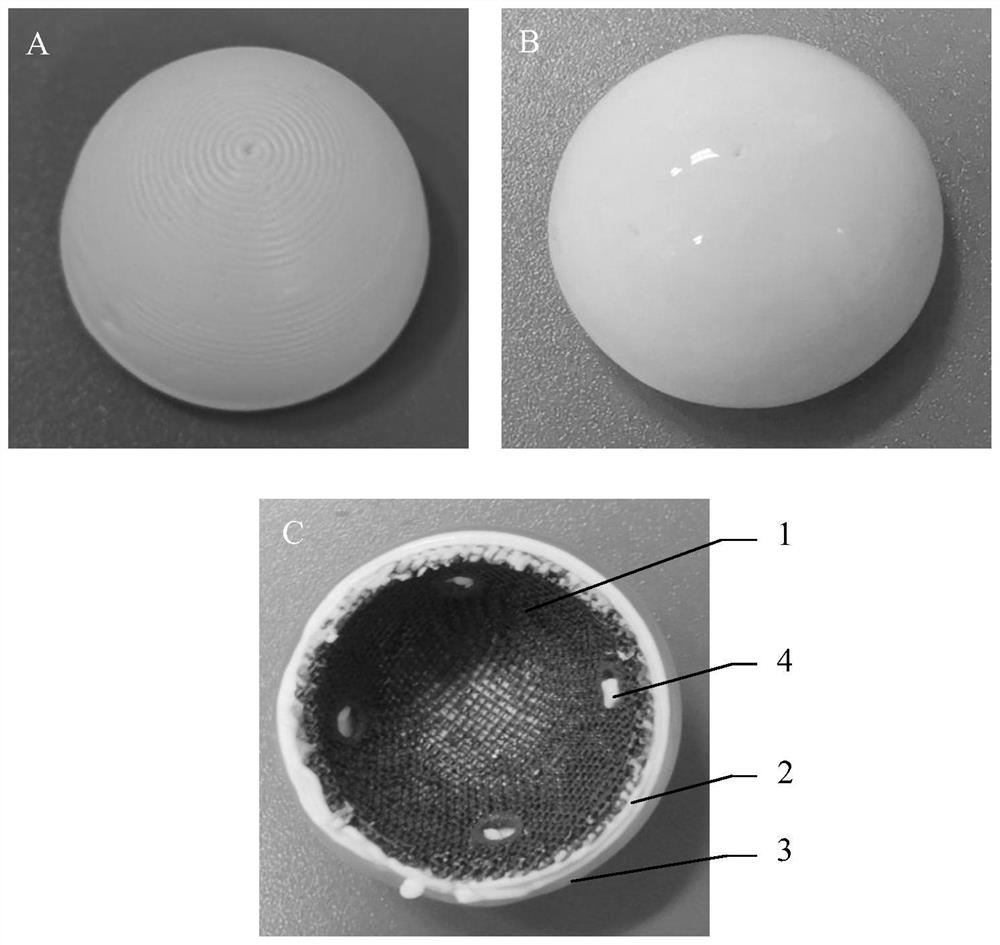

Multilayer bionic joint based on curved surface 3D printing and preparation method thereof

PendingCN112076009ATo achieve the effect of integrationAids in healingJoint implantsTomographyPorous tantalumBones joints

The invention discloses a bionic bone joint based on curved surface 3D printing and a preparation method thereof. The multilayer bionic joint is formed by an inner layer, a middle layer and an outer layer which are in close contact in sequence, wherein the inner layer is a porous tantalum metal support, the middle layer is a solid biological ceramic support, the outer layer is a solid gelatin / sodium alginate composite hydrogel support, the inner layer, the middle layer and the outer layer are all of an arc-shaped shell structure, the radian of the arc-shaped shell is 120-240 degrees, and a cell loading cavity formed by continuous or discontinuous edges formed by protruding outwards from the surface of the outer layer and grooves formed between the edges is formed in the surface of the outer layer. The multilayer bionic joint is large in arc surface radian and suitable for repairing large-area osteochondral joint defects, and the repairing area can be larger than 1 / 2 of the area of thewhole joint. Cells are inoculated into the cell loading cavity, so that the adhesion rate of the cells is increased, and the problem that the surface of the outer layer of the bionic joint is smooth,so that the inoculated cells are not prone to adhesion is solved.

Owner:AFFILIATED ZHONGSHAN HOSPITAL OF DALIAN UNIV +1

Metal bone trabecula and bone implant comprising metal bone trabecula

InactiveCN107647942AAvoid stress shieldingMeet strength and stiffnessBone implantJoint implantsBone ingrowthHigh weight

The invention discloses a metal trabecular bone, which comprises at least three intersecting metal trabecular supports, and a micro-topological grid structure is embedded in the metal trabecular bone, and the micro-topological grid structure is connected with the metal bone trabecular The trabecular support has at least three intersections, and part of the outer surface of the metal trabecular is provided with a bone trabecular coating. The trabecular bone of the present invention is formed by regular or irregular arrays of hollowed-out unit structures in three-dimensional space, which not only has an obvious weight-reducing effect, but also satisfies the stiffness and strength of different parts of the parts at the same time, avoiding stress shielding, Achieve a good match of high strength and high weight loss ratio; in addition, human bone grows into the trabecular bone structure and can be integrated with the bone, so that the trabecular bone prosthesis can be firmly combined with the bone bed, and can Induce bone ingrowth to the greatest extent so as to achieve long-term biological fixation of the prosthesis. At the same time, the invention also discloses a bone implant comprising the metal bone trabecular.

Owner:GUANGZHOU HUATAI 3D MATERIAL MFG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com