Metal bone trabecula and bone implant comprising metal bone trabecula

A metal bone and implant technology, used in bone implants, joint implants, joint implants and other directions, can solve the problems of lack of, unfavorable prosthesis service, affecting bone growth, etc., to avoid stress shielding, High strength and high weight loss ratio, well matched effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

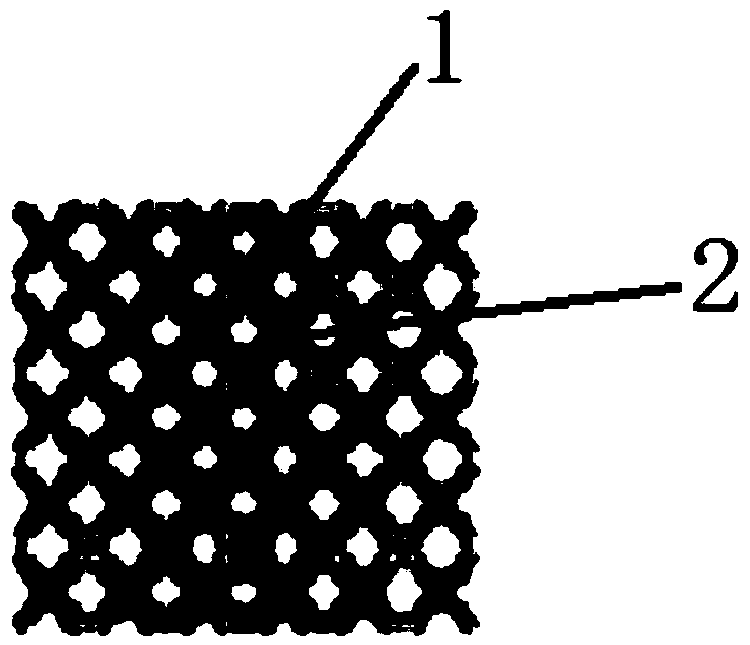

[0035] An embodiment of the metal trabecular bone described in the present invention, the structure of the metal trabecular bone described in this embodiment is as attached figure 1 Shown:

[0036] The metal trabecular bone is a three-dimensional structure composed of hollow grid units, and the hollow grid unit is composed of a metal trabecular bone support 1 and a gradually changing diameter micro-topological grid structure 2, and each metal trabecular bone support 1 The length is 200-2000 microns, and the diameter of the micro-topological grid structure 2 is 30-120 microns; the metal trabecular bone scaffold 1 and the micro-topological grid structure 2 have at least three intersection points, and the metal trabecular bone scaffold 1 and the micro-topological network At the intersection of the lattice grid structure 2, the diameter of the metal trabecular bone scaffold 1 is the same as that of the micro-topological grid structure 2; The diameter of the scaffold 1 is smaller ...

Embodiment 2

[0047] An embodiment of the metal trabecular bone described in the present invention, the structure of the metal trabecular bone described in this embodiment is as attached figure 1 Shown:

[0048] The metal trabecular bone is a three-dimensional structure composed of hollow grid units, and the hollow grid unit is composed of a metal trabecular bone support 1 and a gradually changing diameter micro-topological grid structure 2, and each metal trabecular bone support 1 The length is 200-2000 microns, and the diameter of the micro-topological grid structure 2 is 30-120 microns; the metal trabecular bone scaffold 1 and the micro-topological grid structure 2 have at least three intersection points, and the metal trabecular bone scaffold 1 and the micro-topological network At the intersection of the lattice structure 2, the diameter of the metal trabecular bone scaffold 1 is the same as that of the micro-topological grid structure 2; The diameter of is smaller than the diameter of...

Embodiment 3

[0059] An embodiment of the metal trabecular bone described in the present invention, the structure of the metal trabecular bone described in this embodiment is as attached figure 1 Shown:

[0060] The metal trabecular bone is a three-dimensional structure composed of hollow grid units, and the hollow grid unit is composed of a metal trabecular bone support 1 and a gradually changing diameter micro-topological grid structure 2, and each metal trabecular bone support 1 The length is 200-2000 microns, and the diameter of the micro-topological grid structure 2 is 30-120 microns; the metal trabecular bone scaffold 1 and the micro-topological grid structure 2 have at least three intersection points, and the metal trabecular bone scaffold 1 and the micro-topological network At the intersection of the lattice structure 2, the diameter of the metal trabecular bone scaffold 1 is the same as that of the micro-topological grid structure 2; The diameter of is smaller than the diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com