Complex rubber pad board, preparation method thereof and combined mold machine of pad board blank

A composite rubber and forming machine technology, which is applied to building components, mechanical equipment, flat products, etc., can solve the problems of high difficulty, large cutting volume, and high process cost, so as to ensure reliability and uniformity, prolong service life, and expand Effect of Ambient Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

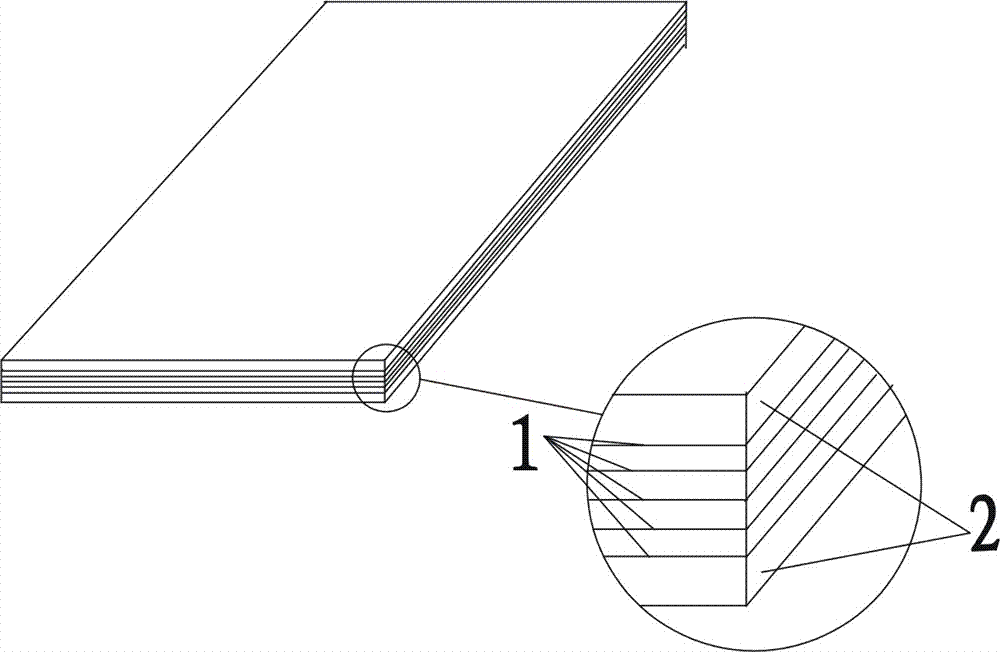

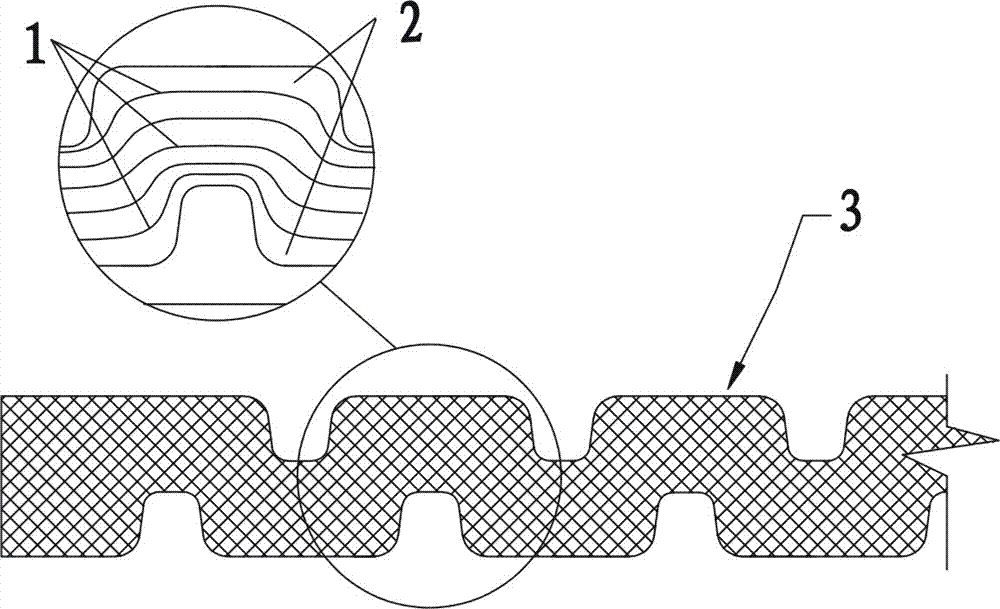

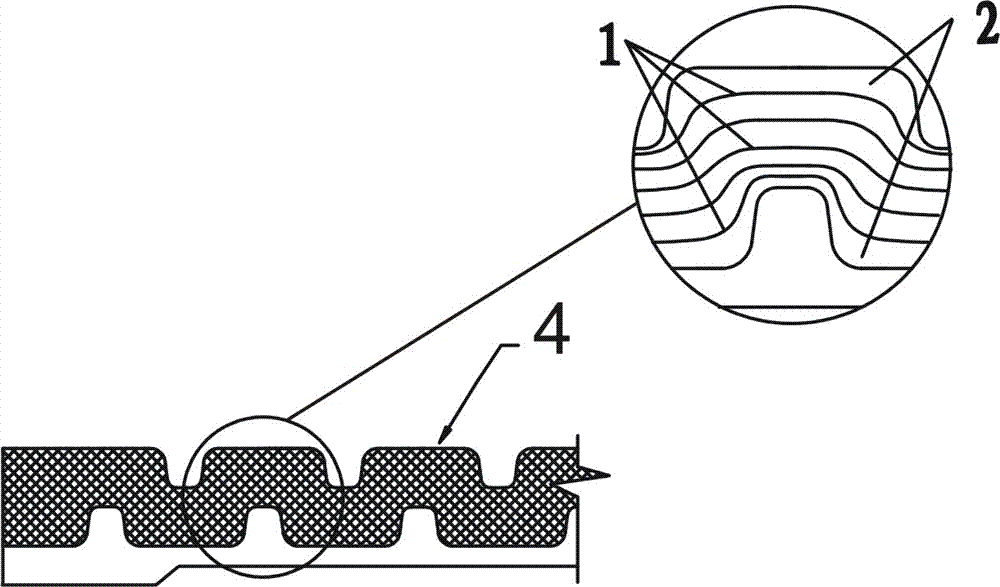

[0033] Such as figure 1 , 2 , 3, the composite rubber backing plate 3 includes two surface rubber layers 2 and a core layer for enhancing the compressive strength and expanding the use environment temperature range of the backing plate and its application field; the core layer is composed of 2 to 5 A composite layer formed by laminating layers of laminated fabric, wherein the laminated fabric is made of cord fabric or slit fabric 1 woven from high-strength fibers and laminated with rubber compound. The number of layers of laminated cloth can be increased or decreased according to the performance requirements of the product in actual production. And the above-mentioned high-strength fibers can adopt tough fibers such as nylon fibers or polyester fibers. The surface rubber layer 2 is made of rubber compound with better abrasion resistance than the rubber co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com