Patents

Literature

128results about How to "Good temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

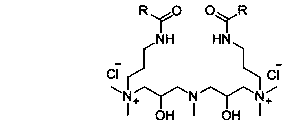

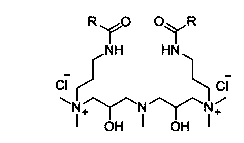

High temperature resistant Gemini cationic viscoelastic surfactant (VES) and synthetic method thereof

ActiveCN103965861ARapid flowbackGood temperature resistanceOrganic compound preparationCarboxylic acid amides preparationDiamineLong chain fatty acid

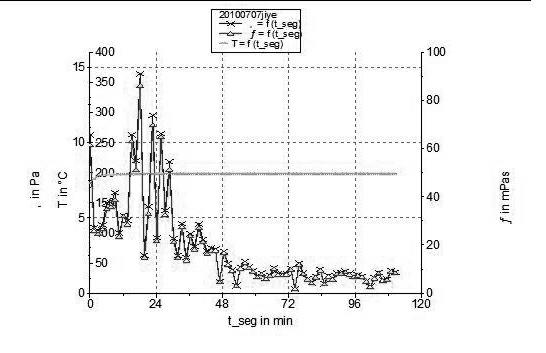

The invention provides a high temperature resistant Gemini cationic viscoelastic surfactant (VES) and a synthetic method thereof, relating to the field of oil recovery technology and engineering in the petroleum industry. The synthetic method is characterized by reacting unsaturated long-chain fatty acid with N,N-dimethyl propanediamine to synthesize a fatty acid amide intermediate; reacting methylamine with epichlorohydrin to synthesize a chloramine intermediate; reacting the intermediates synthesized in the two above steps respectively to synthesize the high temperature resistant Gemini cationic VES. The VES and the synthetic method have the beneficial effects that a high temperature surface active diverting acid system reacts with rocks at 160 DEG C, so that the liquid obviously diverts to become viscous and is subjected to automatic gel breaking under the condition that the hydrochloric acid concentration is below 5%, thus achieving rapid flowback; the VES has good temperature resistance, is relatively low in price and is beneficial for popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

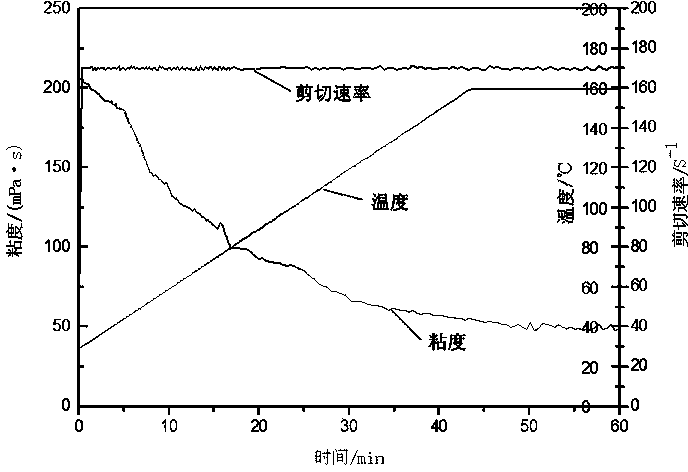

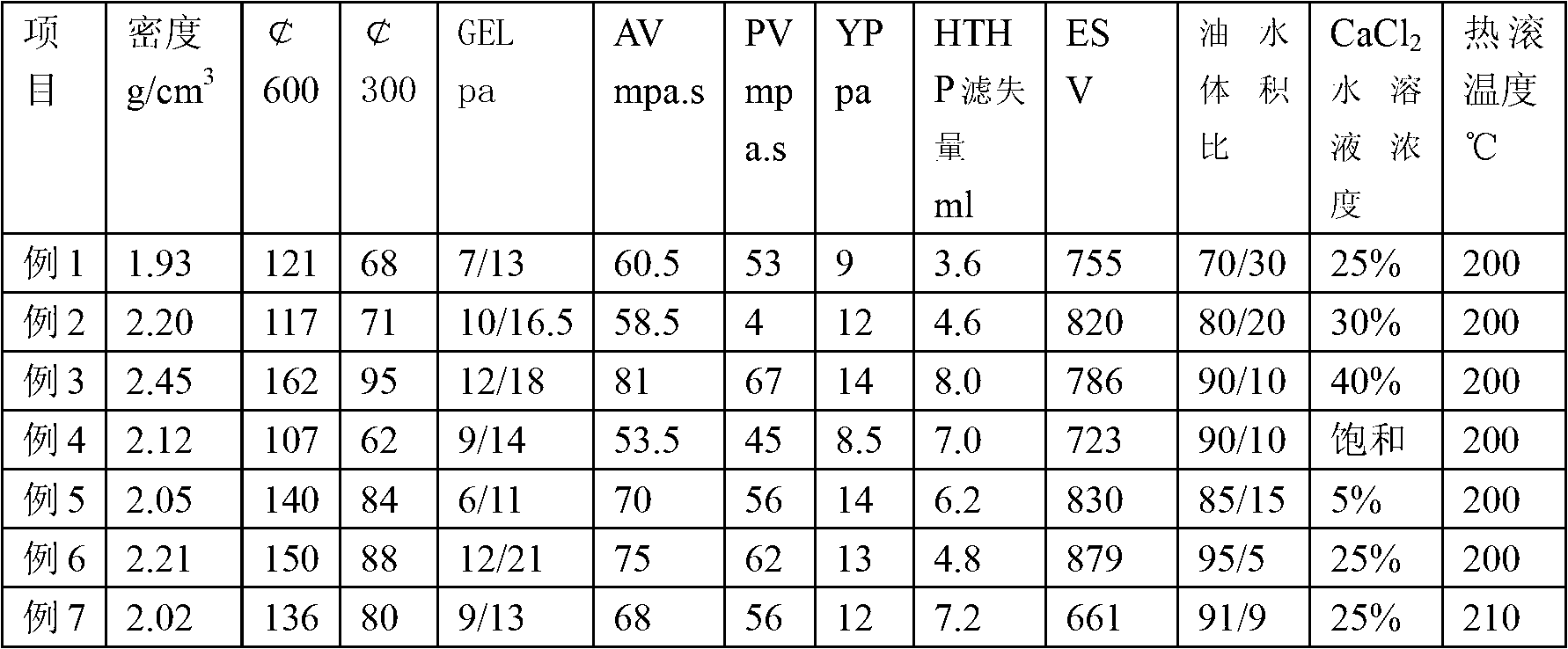

Gas oil base invert oil-emulsion drilling fluid and preparation method

InactiveCN102796497AStrong salt resistanceGood temperature resistanceDrilling compositionTemperature resistanceChemistry

The invention relates to a gas oil base invert oil-emulsion drilling fluid and a preparation method, wherein the total volume of gas oil and calcium chloride aqueous solution is 100 parts: the volume ratio of oil phase to water phase is between 95:5 and 70:30, and the concentration of calcium chloride aqueous solution is 5%-saturation; the required gas oil, primary emulsion, auxiliary emulsion and wetting agent are added into a high speed mixing beaker, and are mixed at high speed for 2-5 minutes; the calcium chloride aqueous solution is added and mixed at high speed for 15 minutes; organic soil, calcium oxide and a fluid loss agent are added and mixed at high speed for 10 minutes; and the required amount of barite is added according to density, and is mixed at high speed for 25 minutes. The gas oil base invert oil-emulsion drilling fluid is used for overcoming the defects of the existing gas oil base drilling fluid and solving the problems of the salt resistance and temperature resistance of the gas oil base drilling fluid, and can resist the temperature above 200 DEG C.

Owner:COSL CHEM TIANJIN +1

Superhard strong toughness and high-entropy alloy nitride nano-composite coating carbide blade and preparation method thereof

ActiveCN108642449AGood temperature resistanceImprove temperature resistanceVacuum evaporation coatingSputtering coatingHigh entropy alloysCemented carbide

The invention discloses a superhard strong toughness and high-entropy alloy nitride nano-composite coating cemented carbide blade. A superhard nano-composite coating is deposited on a cemented carbidesurface, wherein the superhard nano-composite coating is composed of a bonding layer, a transition layer, a support layer, a stiffening layer, a wear-resistant layer and a temperature-resistant layer; the bonding layer is a pure Cr layer, and the transition layer is a CrN layer; the support layer is a nano-multilayer film formed through alternate growth of the transition layer and the stiffeninglayer, and the stiffening layer is a TiVZrNbHfN high-entropy alloy nitride layer; and the wear-resistant layer is a nano-multilayer film formed through alternate growth of the stiffening layer and thetemperature-resistant layer material, and the temperature-resistant layer is an AlCrNbSiTi high-entropy alloy nitride layer. According to the nano-composite coating cemented carbide blade, by adopting deign of various high-entropy alloy coating materials and composition gradient, the internal stress of the coating can be reduced greatly, and the toughness of the coating is improved; the disadvantage of low temperature resistance of an existing blade coating is overcome effectively; and the service life of the cemented carbide blade is prolonged greatly, and the adaptability of the cemented carbide blade is improved.

Owner:WUHAN UNIV

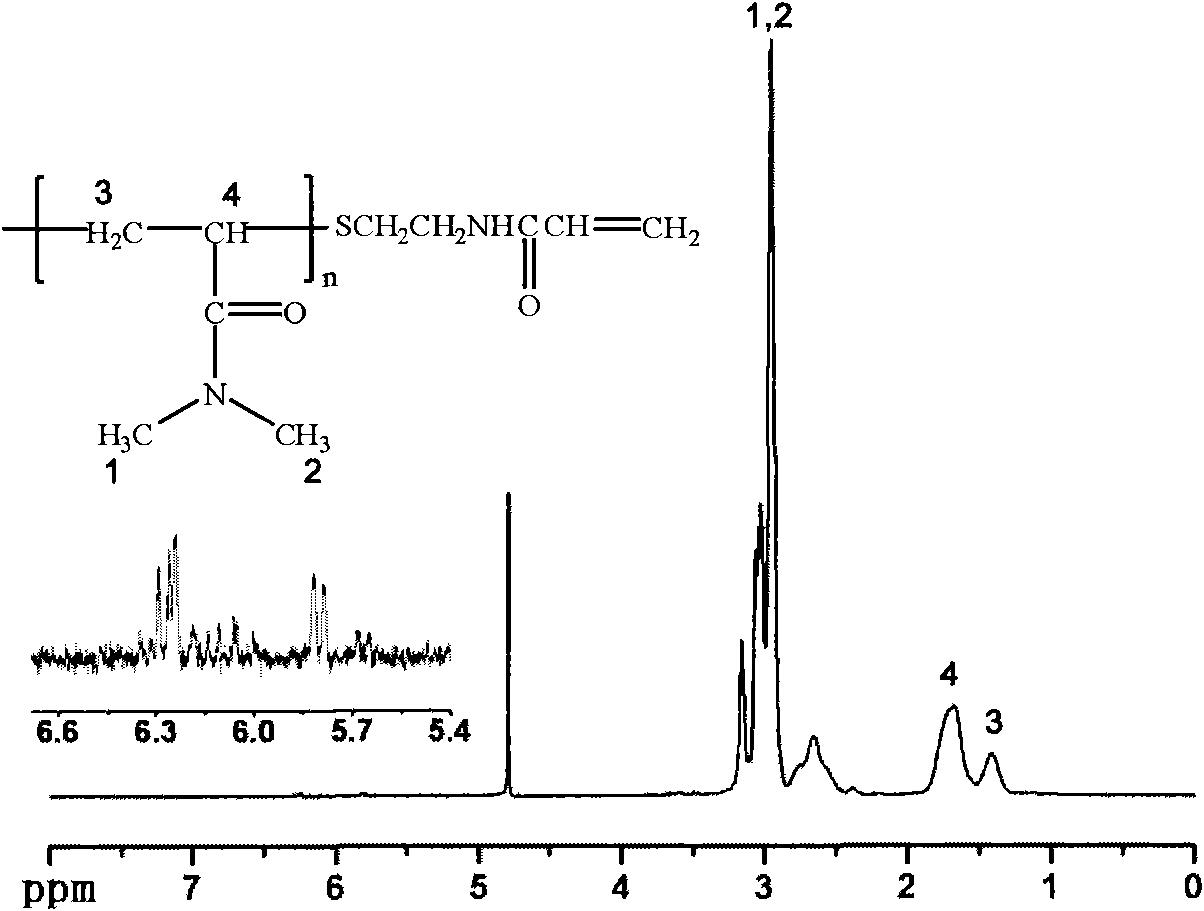

Temperature and salt resistant grafted polyacrylamide and preparation method thereof

ActiveCN102050913AHigh monomer conversion rateGood temperature resistanceDrilling compositionMethacrylamideWater soluble polymers

The invention relates to a temperature and salt resistant grafted polyacrylamide synthesized by a macromonomer route, belonging to the research field of water-soluble polymer used for displacement of reservoir oil. A method of chain transfer free radical polymerization and terminal group replacement is adopted to obtain a polyacrylamide (N,N-dimethylacrylamide) type macromonomer. Under an oxidation-reduction complex initiation system, temperature and salt resistant monomers, such as the macromonomer, acrylamide, N-polyvinyl pyrrolidone, N,N-dimethylacrylamide, 2-Acryloylamino-2-methyl propanesulfonic acid and the like, are copolymerized to obtain a target product. From molecular design, a functional long-grafted side chain can increase the viscoelasticity of the polymer molecule and lower solution surface tension. The product provided by the invention can be used for three-class oil deposit and provides a possible solution for improving the recovery ratio for chemical displacement of reservoir oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

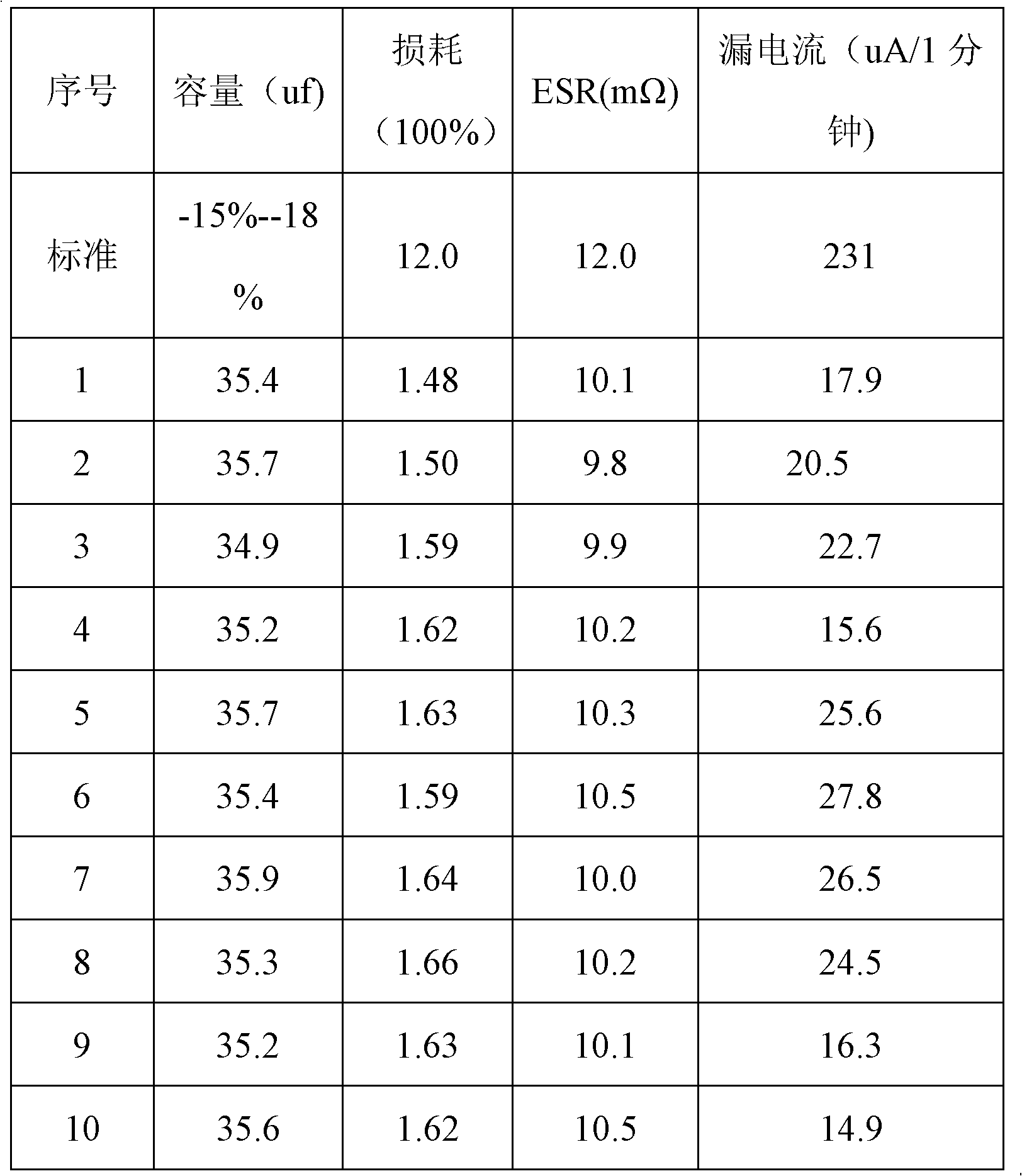

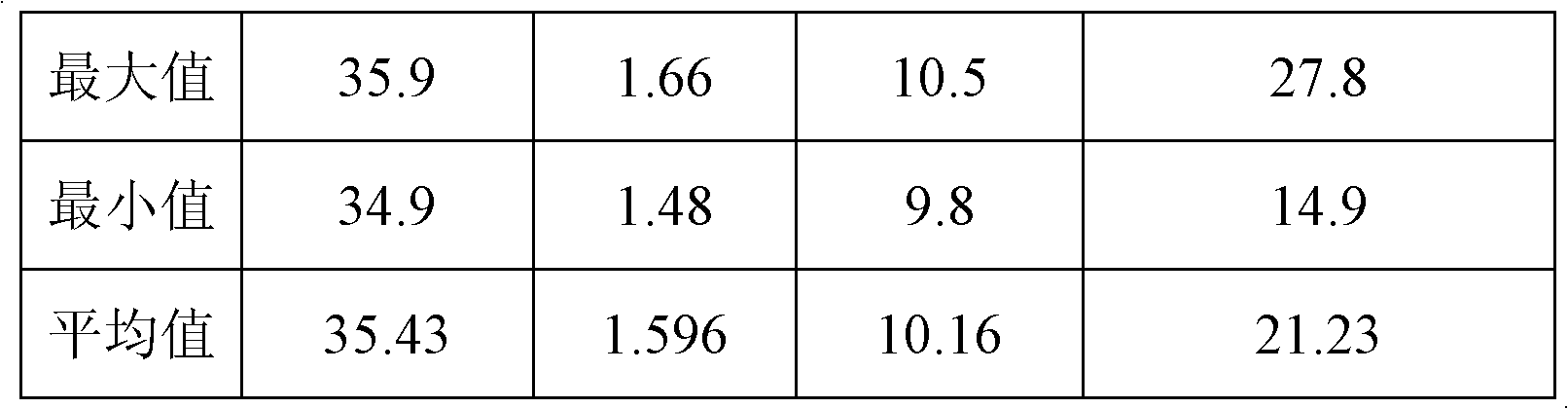

Improved method for manufacturing solid electrolyte/aluminum electrolytic capacitor

ActiveCN102592848AReduce dosageGood temperature resistanceSolid electrolytic capacitorsAluminium foilAluminium

The invention relates to an improved method for manufacturing a solid electrolyte / aluminum electrolytic capacitor. The method comprises the following steps: 1, electrolytic papers between an anode formation aluminium foil and a cathode foil are reeled to form core bags, wherein the cathode foil faces outwards and wraps the electrolytic papers, a high-temperature rubber belt is used for clinging and fixing both in a ring manner, and sealing rubber covers are mounted on the core bags; 2, the core bags are immersed into formation liquid to be subjected to repair processing, and the repaired core bags are subjected to carbonization processing, wherein the step 2 is repeated about 2-10 times; 3; the core bags are immersed into the formation liquid again to be subjected to formation and repair processing; 4, the carbonized core bags are immersed into an oxide-film protection liquid and then are dried at the temperature of 50-150 DEG C; and 5, firstly, the core bags are respectively placed into monomers and oxidant for immersion and heating convergence, then the processed core bags are mounted in an aluminum shell and a sealing procedure is performed, and lastly, the produced products are subjected to ageing processing.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Fracturing fluid which resists temperature of 200 DEG C

InactiveCN102367380AHigh crosslink density and crosslink strengthGood temperature resistanceDrilling compositionChemistryComposite material

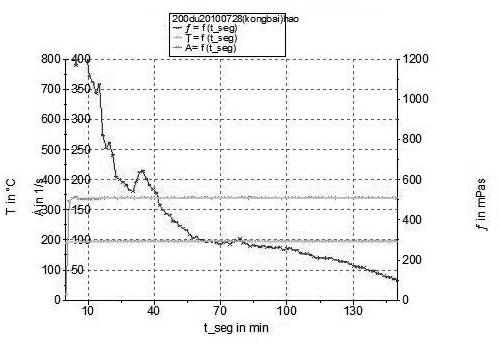

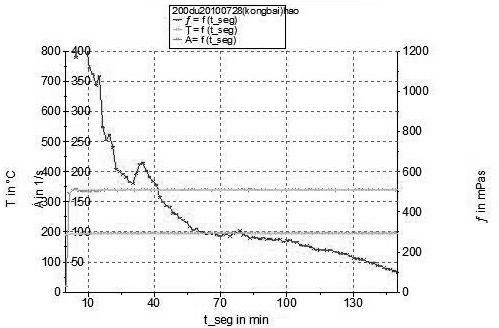

The invention relates to a fracturing fluid which resists temperature of 200 DEG C and solves the problem that present fracturing fluid systems can not adapt to the reservoir fracturing reconstruction technology over 160 DEG C. According to the fracturing fluid, self-made modified guar gum is used as a densifier which has good temperature toleration; and a self-made organic Ti-Zr composite cross-linking agent, which has good crosslinking density and strength, is adopted. Based on the above two components, a high-temperature stabilizing agent, a crosslinking promoter and other auxiliary agentsare added for the preparation of the fracturing fluid. With optimal combination of each component, the product still has good shearing resistance at the temperature of 200 DEG C through a test. The invention provides a high-temperature resistant fracturing fluid for the oil field development.

Owner:NORTHEAST GASOLINEEUM UNIV

Biodegradable temperature resistant material containing fiber base and polylactic acid and preparation method thereof

The invention relates to biodegradable temperature resistant material containing fiber base and polylactic acid and a preparation method thereof. The material prepared disclosed by the invention is obtained by mixing the following raw materials by weight: 30%-60% of polylactic acid, 30%-50% of fiber powder, 5%-20% of crosslinking modifier, 5%-10% of additive, 1%-10% of inducer. The preparation method comprises the following steps of drying and carrying out hydrophobic treatment to the fiber powder for 2-4 hours firstly; mixing the fiber powder, the crosslinking modifier, the additive and the inducer in a high-speed mixer uniformly and controlling the temperature below 110 DEG C; molding a mixer by an extruder and heating the molded product at the heating temperature of 105-150 DEG C for 10-30 seconds; and cooling the generated product to obtain the finished product. The material prepared by the method has the advantages of good temperature resistance property, wide range of application and low production cost, is fully biodegradable, and can beapplied to biodegradable lunch boxes, thereby solving the white pollution problem caused by the extensive use of petroleum-based plastic.

Owner:HUIZHOU JIAN SHENG PLASTIC MFG

Leaking stoppage slurry for fracture loss and preparation method

InactiveCN109810681AGood temperature resistanceAvoid repeated lossesDrilling compositionMicrofiberPolyester

The invention provides leaking stoppage slurry for fracture loss and a preparation method. The leaking stoppage slurry comprises base slurry, active clay, mica powder, ultrafine calcium carbonate, graphite, elastic rubber particles and microfiber, and is characterized by further comprising sponge, and the sponge is selected from one of polyester sponge and polyether sponge; the base slurry comprises bentonite slurry, diesel oil, white oil, gas to liquid or biological diesel oil. The preparation method comprises the following steps of adding the active clay, the mica powder, the ultrafine calcium carbonate, the graphite, the microfiber, the elastic rubber particles and the sponge successively into the base slurry and stirring continuously at a high speed until being uniform in the process of adding. The framework material of the leaking stoppage slurry has good elasticity, is easy to fracture inside to form a bridge, and can effectively improve the success rate of leaking stoppage; meanwhile, the leaking stoppage agent is wholly prepared from inert materials, can be simultaneously used in water-based drilling fluid and oil-based drilling fluid, and has high applicability.

Owner:SINOPEC SSC +2

Modified polyurethane asphalt corrosion-resistant coating

InactiveCN101906266AGood moisture permeabilityGood temperature resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSolventPolyphenyl isocyanate

The invention relates to a modified polyurethane asphalt corrosion-resistant coating. In the adopted technical scheme, the corrosion-resistant coating is prepared by mixing a component A and a component B in weight ratio of 1:0.5-1.5, wherein polymethylene polyphenyl isocyanate, isophorone diisocyanate, acrylate, polyether 3031K, polyether 450, dioctyl ester, epoxy resin, phosphate, solvent No.S1000 or industrial xylene are put into a reaction kettle, and react for 0.5 hour at the temperature of 40-42 DEG C, the temperature is raised to 80-82 DEG C, the heat is preserved for 2 hours, the temperature is decreased, and then the component A is prepared; and petroleum asphalt, coal tar asphalt, cyclohexanone, toluene, solvent No.S1000 or industrial xylene and epoxy rein are put into the reaction kettle, the heat is preserved for 2 hours at the temperature of 135-140 DEG C, and the temperature is decreased to room temperature; then, aluminum triphosphate, strontium chromate, mica powder and glass flake are added, grounded, and dispersed, and then the component B is prepared. The coating adopting the invention has the advantages of strong adhesive force, no moisture permeation, strong corrosion resistance, and long service life.

Owner:索慈利

Polyether-ether-ketone modified polytetrafluoroethylene composite material, bearing retainer and making method of bearing retainer

ActiveCN105061956AGood temperature resistanceReduce coefficient of frictionBearing componentsRolling resistance optimizationHeat deflection temperaturePoly ether ether ketone

The invention discloses a polyether-ether-ketone modified polytetrafluoroethylene composite material, a bearing retainer and a making method of the bearing retainer. The composite material comprises, by mass, 18-25% of polyether ether ketone, 5-8% of tungsten disulfide, and the balance of polytetrafluoroethylene. The composite material comprises polytetrafluoroethylene, polyether-ether-ketone and tungsten disulfide. Polyether-ether-ketone has good temperature resistance, hydrolysis resistance, compression strength and corrosion resistance, has a low friction coefficient and has wear fastness, tungsten disulfide has high compression strength and high oxidation resistance, and very low friction coefficient, and polyether-ether-ketone and tungsten disulfide are used to modify polytetrafluoroethylene as fillers, so the obtained composite material reserves the lubrication performance of polytetrafluoroethylene, improves the dimension stability, the compression strength and the wear resistance of polytetrafluoroethylene, and has a greatly higher thermal deformation temperature than a pure polytetrafluoroethylene material, thereby requirements of the material of the retainer by long life bearings are met.

Owner:LUOYANG BEARING RES INST CO LTD

Coloring master batch for RRP (polypropylene random) hot-water pipes and preparation method thereof

The invention relates to the technical field of plastic coloring master batches, particularly a coloring master batch for RRP (polypropylene random) hot-water pipes and a preparation method thereof. The invention discloses a coloring master batch for RRP hot-water pipes, which is prepared from the following raw materials in parts by weight: 40-60 parts of carrier resin, 35-55 parts of pigment, 0.5-5 parts of dispersing agent, 0.1-3 parts of antioxidant and 0.1-3 parts of antimicrobial agent. The pigment is a mixture of white, black and yellow pigments in a ratio of 5:2:1. The preparation method comprises the following steps: mixing, extruding, cooling, drying and granulating. The prepared master batch has the advantages of favorable workability, favorable weather resistance and favorable dispersity.

Owner:BLUESTAR CHENGDU NEW MATERIALS

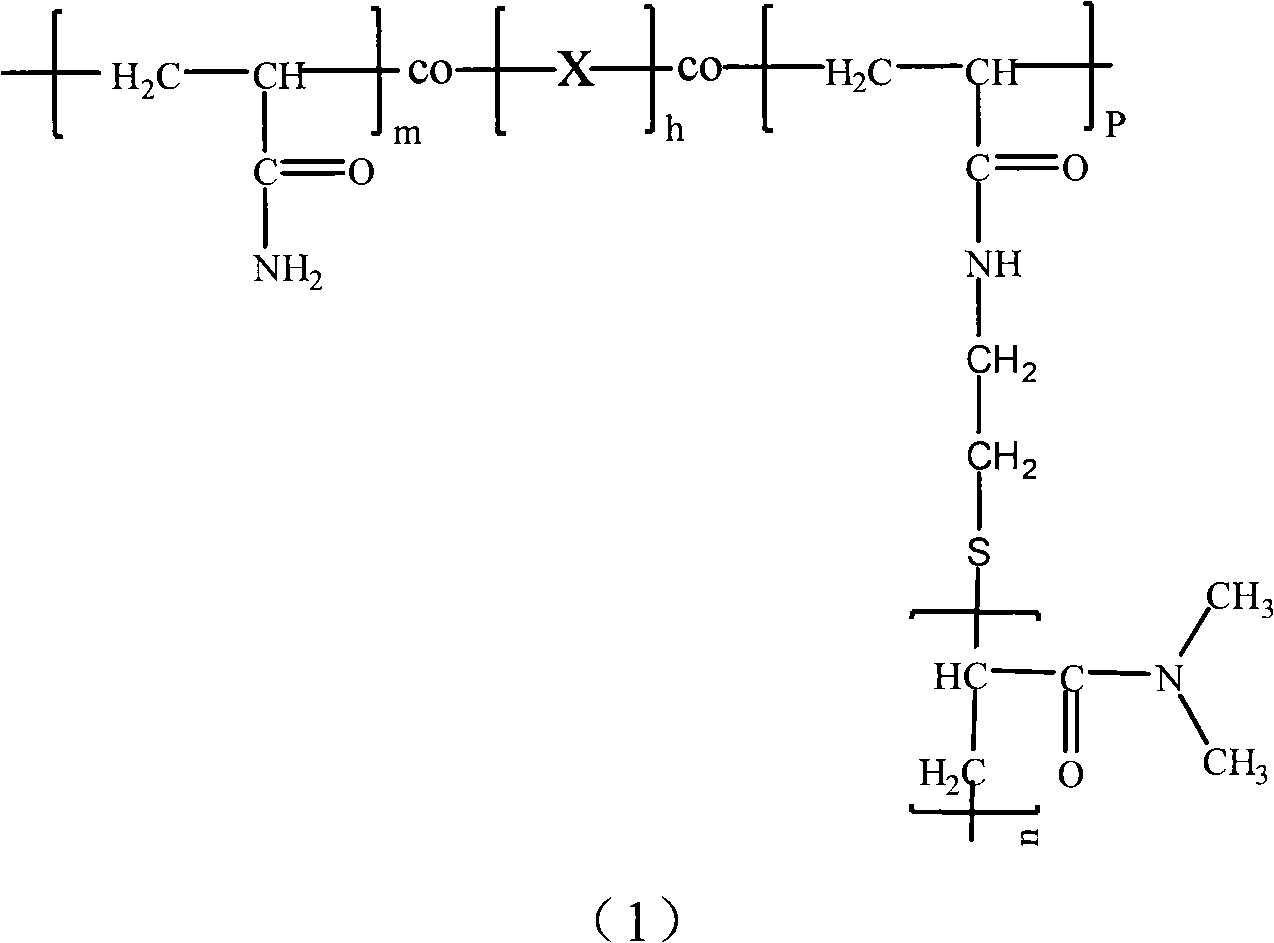

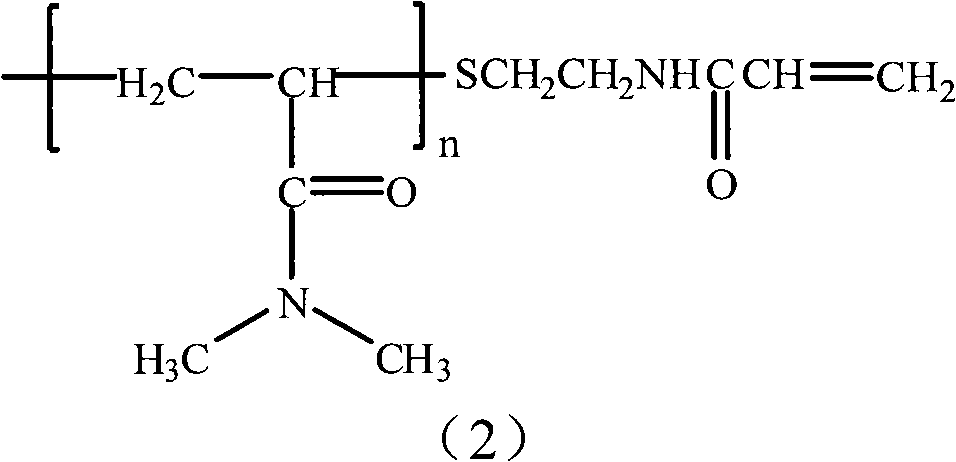

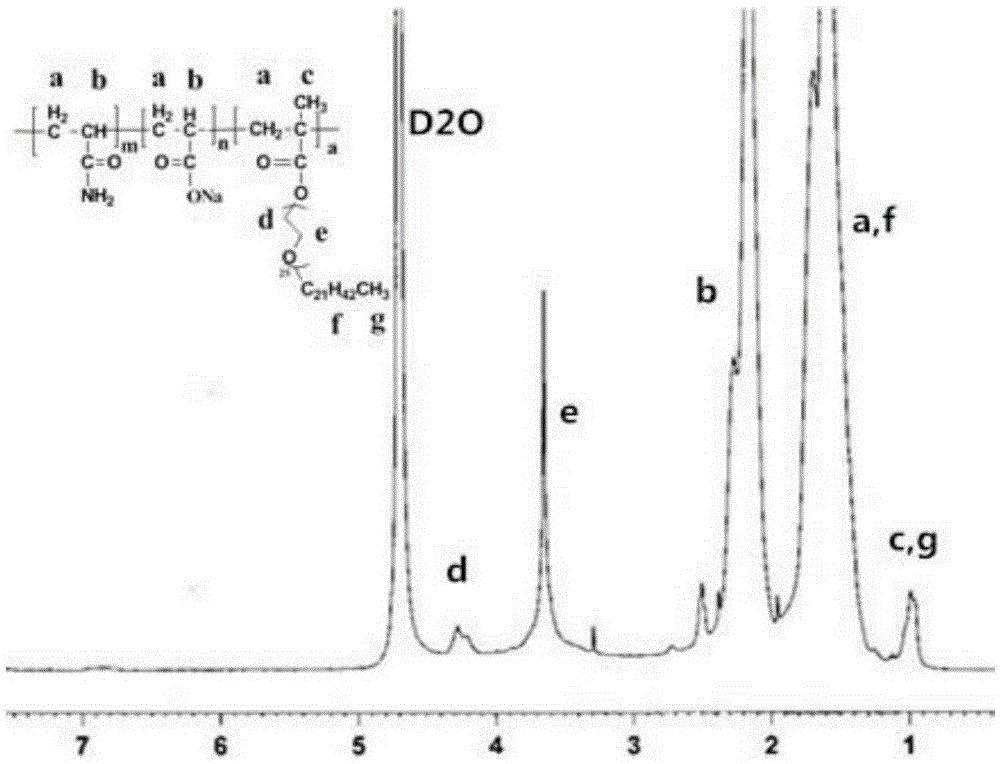

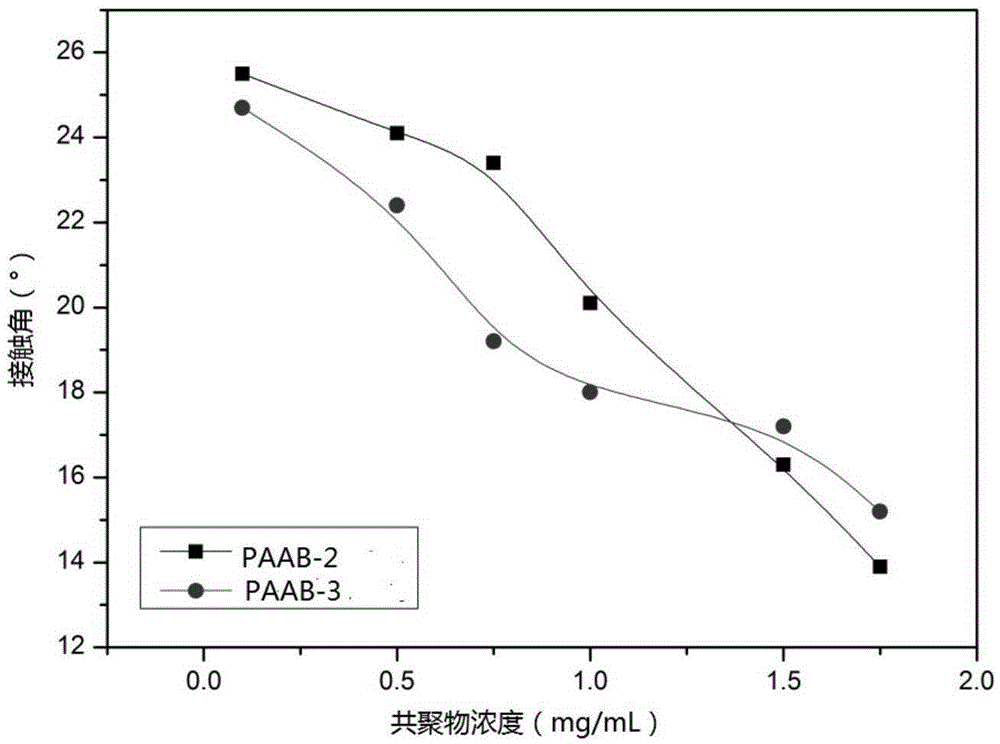

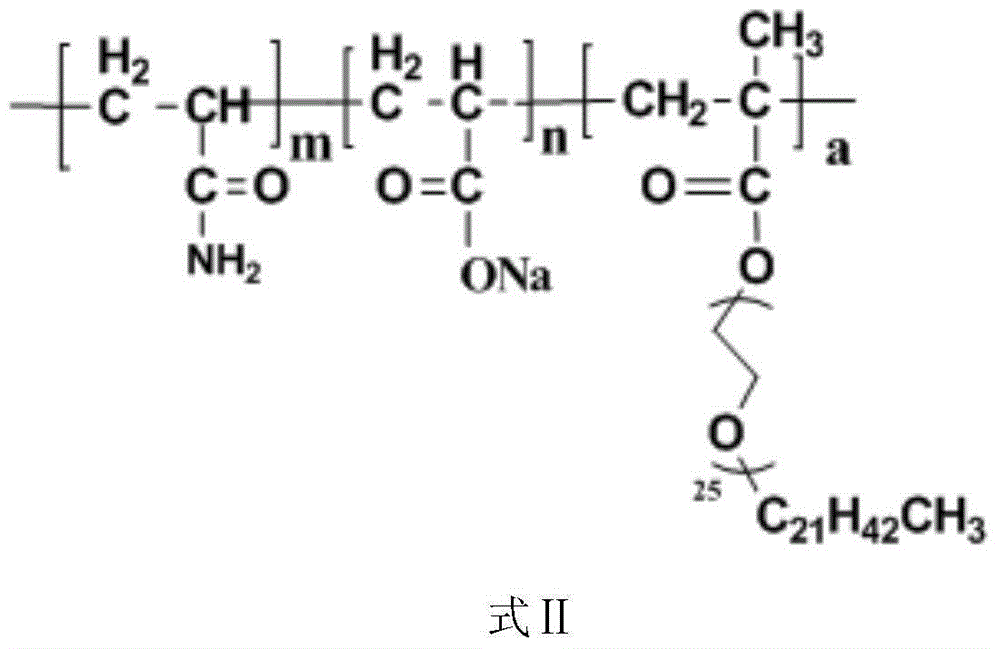

Partially hydrolyzed acrylamide water-soluble polymer with utlralong hydrophobic long chain, preparation method therefor and application thereof

The invention discloses a partially hydrolyzed acrylamide water-soluble polymer with an utlralong hydrophobic long chain, a preparation method therefor and an application thereof. A structural formula of the partially hydrolyzed acrylamide water-soluble polymer is as shown in formula II. The preparation method for the polymer as shown in formula II provided by the invention comprises the following steps: (1) under an inert atmosphere, dissolving acrylamide and docosyl polyoxyethylene ether methacrylate into water to obtain a solution I; (2) under the inert atmosphere, dissolving acrylic acid into water to obtain a solution II, and adding NaOH into the solution II to regulate the pH value of the system to 6-7; and (3) mixing solutions I and II obtained in the steps (1) and (2), and adding an initiator into the mixed solution to carry out a polymerization reaction, thereby obtaining the polymer. According to the preparation method provided by the invention, raw materials are easily available, preparation is simple, yield is relatively high, use is safe and storage is convenient. The partially hydrolyzed acrylamide water-soluble polymer with the utlralong hydrophobic long chain can be directly used, and has an extensive potential utilization value in the fields of oil exploitation, paint, medicines, daily use chemicals and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

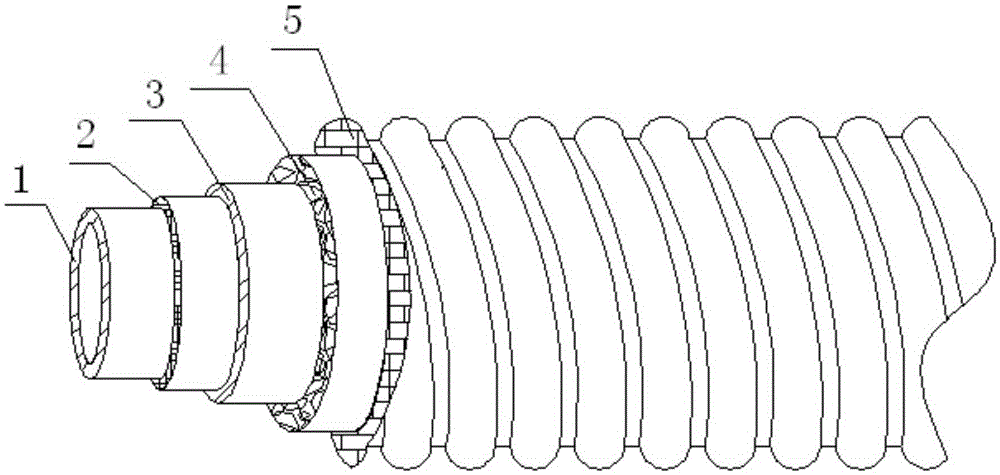

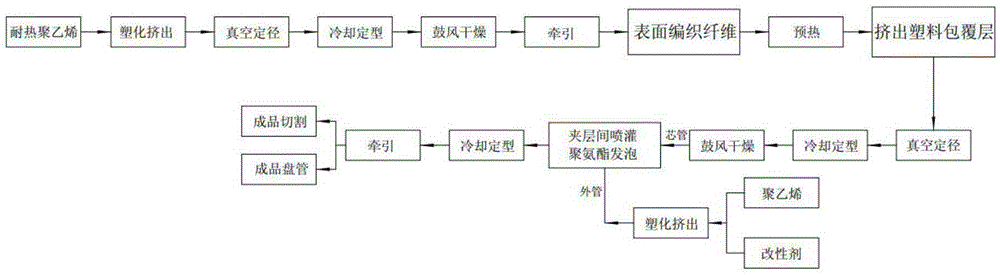

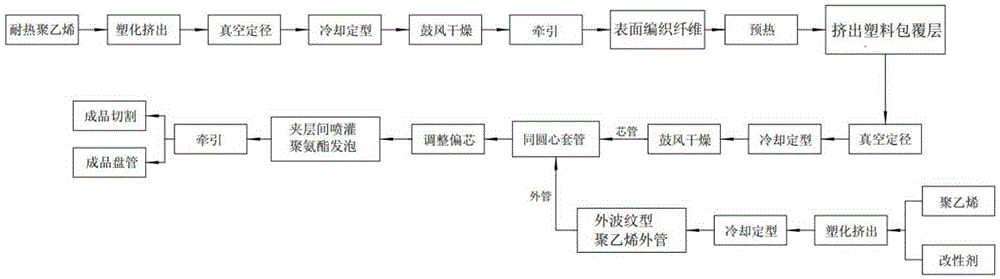

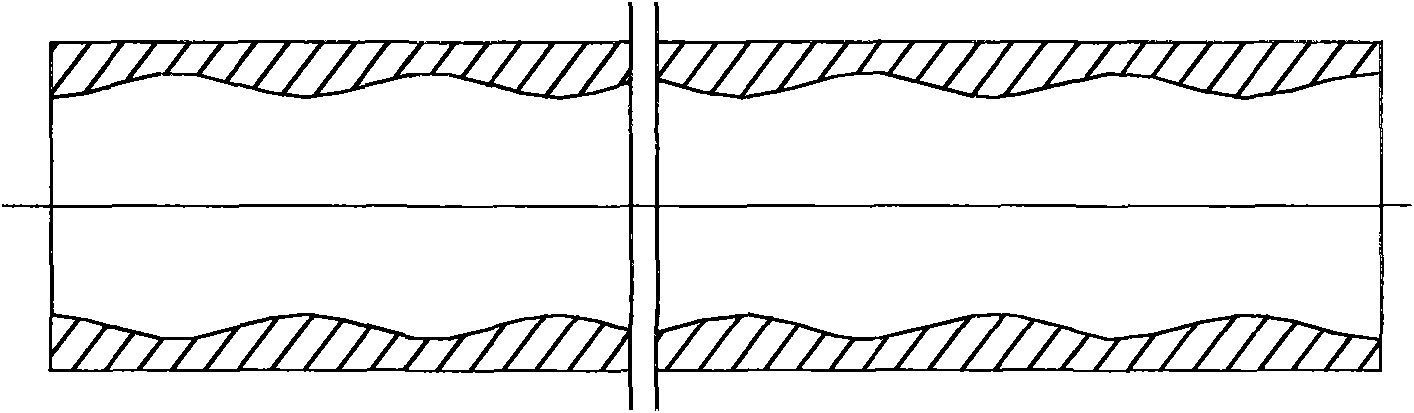

Production technique for external corrugated reinforced plastic heat-preservation heating/cooling pipe

ActiveCN105402502ALow thermal conductivityGood temperature resistanceThermal insulationFlexible pipesEngineeringMechanical engineering

The invention belongs to the technical field of building pipe materials and particularly relates to a production technique for an external corrugated reinforced plastic heat-preservation heating / cooling pipe. The production technique for the external corrugated reinforced plastic heat-preservation heating / cooling pipe comprises the steps that a heat-resistant polyethylene inner pipe body is prepared; a fiber reinforced layer is prepared; a plastic cladding layer is prepared; a foamed heat-preservation layer is prepared; and a polyethylene outer pipe body is prepared. The using temperature of the corrugated reinforced plastic heat-preservation heating / cooling pipe produced through the technique is -40-85 DEG C, the heating requirement of the plastic pipe can be met, and the pipe can also be used as a centralized cooling pipeline.

Owner:盘锦建硕管业有限公司

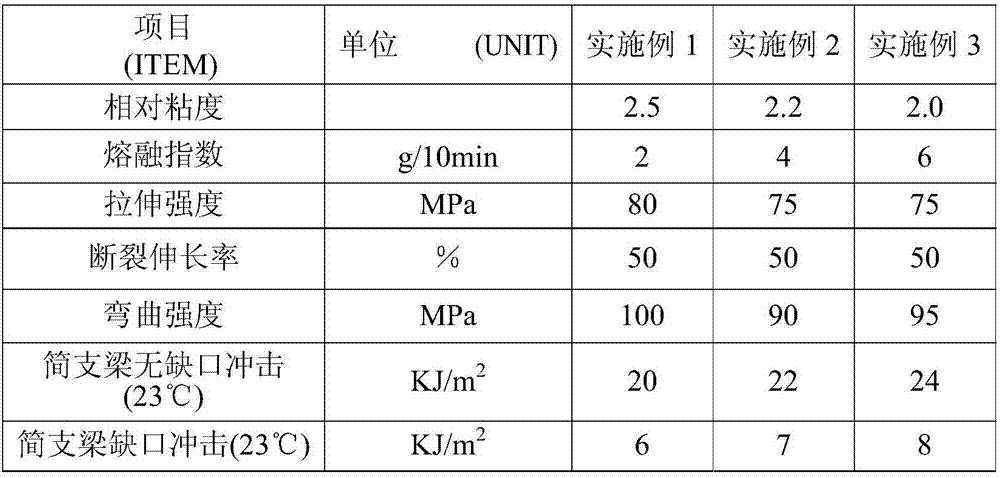

Semi-aromatic polyamide resin and preparation method thereof

The invention relates to semi-aromatic polyamide resin and a preparation method thereof, and belongs to the technical field of organic synthesis. The semi-aromatic polyamide resin comprises a p-xylylenediamine structural unit, a diacid unit of linear aliphatic diacid which has carbon atoms of 10 to 18, and a fatty acid unit with a carbon atom number which is greater than 18; the semi-aromatic polyamide resin is prepared by carrying out catalytic reaction on the linear aliphatic diacid and a raw material diamine under the condition of a polymerization catalyst. The polyamide resin provided by the invention has good flowability, good temperature resistance, low water absorption rate and good mechanical performance, and is especially suitable for various electronic parts and surface mounting parts, which have high heat resistance and low water absorptivity, small-sized thin-wall molded products which need a high crystallization speed, a high final crystallization degree and low water absorptivity, and automobile parts including automobile headlamp reflection plates, engine peripheral parts and the like, which need heat resistance and rigidity.

Owner:WUXI YINDA NYLON

Development of controllable cross-linking agent for methanol-based fracturing fluid

InactiveCN102492413AImprove crosslink strengthGood temperature resistanceDrilling compositionSolventSodium polyacrylate

The invention relates to a cross-linking agent for alcohol-based fracturing fluids, in particular to the development of a controllable cross-linking agent for methanol-based fracturing fluid, and the cross-linking time of the controllable cross-linking agent can be adjusted. For certain natural gas wells or oil wells with low formation pressure, low permeability and strong water-locking characteristic, the controllable cross-linking agent for methanol-based fracturing fluid can be used in the fracturing stimulation process. Inorganic zirconium or zirconate ester is adopted as a raw material, isopropanol or water or the mixture of isopropanol and water is adopted as solvent, suitable ligand is added, the materials react according to a certain material proportion under certain conditions for 4 hours, neutralizer is then added for neutralization, and finally, a moderate amount of diluent is added, so that the controllable cross-linking agent for methanol-based fracturing fluid is prepared. The cross-linking agent can be cross-linked with polymer with 60 to 100 percent of methanol content, the application range is wide, the dosage is little, and the controllable cross-linking agent cannot harm the environment. The biggest difference between the cross-linking agent disclosed by the invention and organic zirconium series cross-linking agents sold on the market is that mixed diluent formed by low-molecular weight sodium polyacrylate and low-molecular weight polyacrylic acid is adopted as the diluent of the controllable cross-linking agent.

Owner:北京希涛技术开发有限公司

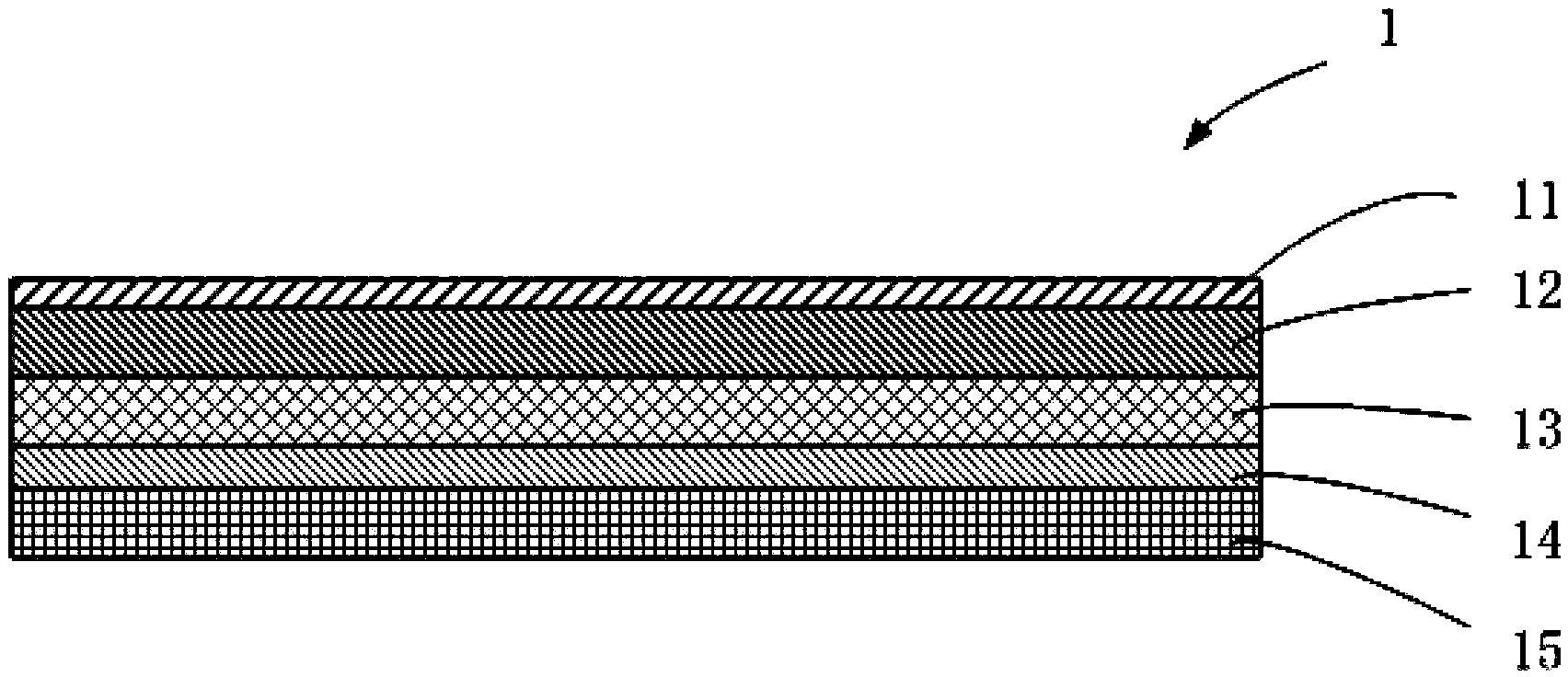

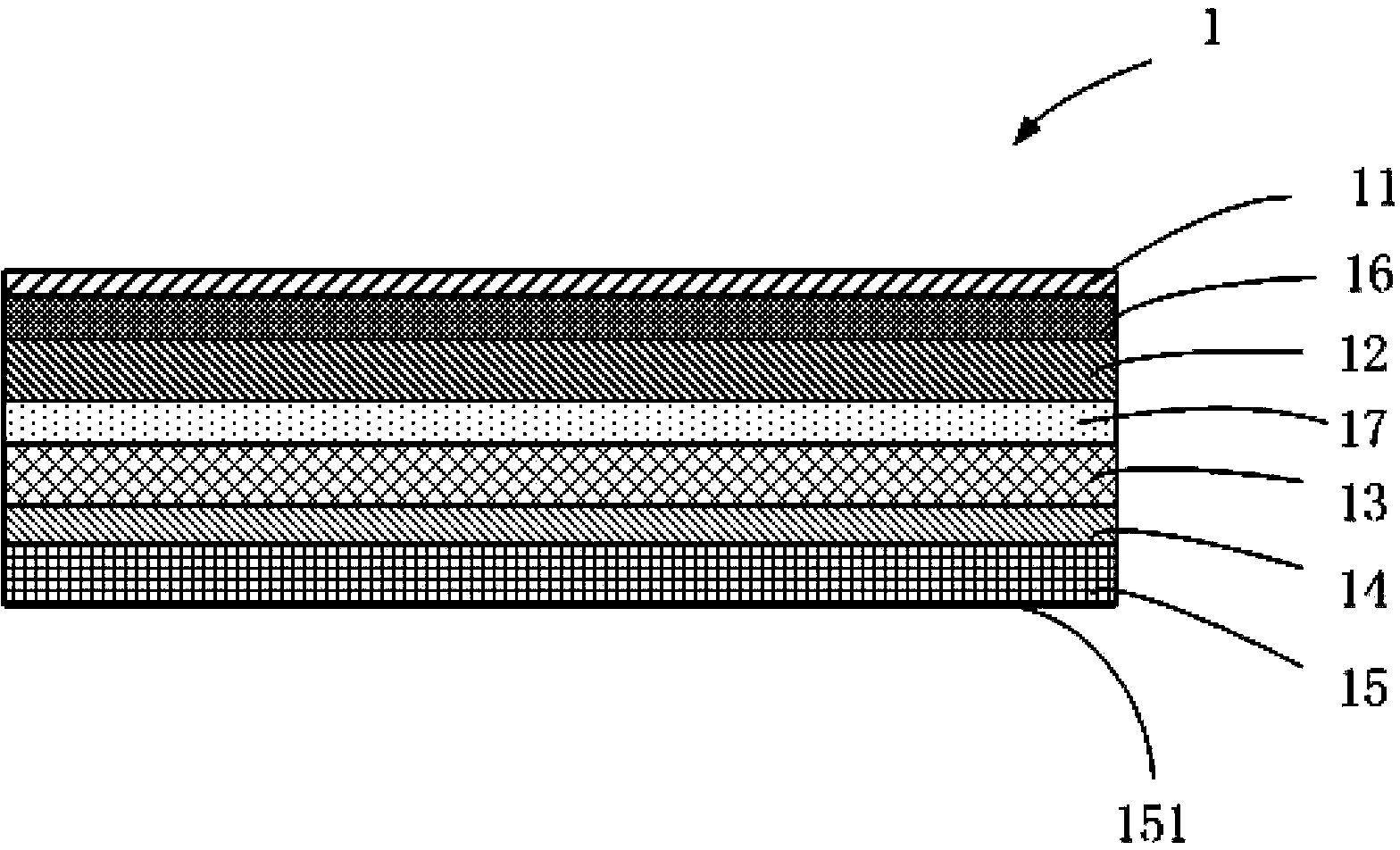

Self-adhesive label

InactiveCN103680303AGood temperature resistanceEco-friendly fitStampsPaper/cardboard layered productsSolvent freeSelf adhesive

The invention provides a self-adhesive label which comprises a surficial paper layer, a mucilage glue layer, a silicone oil layer and a base paper layer from top to bottom. The mucilage glue layer is made of solvent-free type acrylic PSA, and a thin film layer is further arranged on the surficial paper layer. The self-adhesive label is made of the solvent-free type acrylic PSA, has the advantages of being good in thermal endurance, environmentally friendly and firm in gluing, and due to the fact that the outermost thin film layer is arranged, the self-adhesive label further has the advantages of being durable and safe.

Owner:昆山亿达包装有限公司

Slush molding PVC (Poly Vinyl Chloride) material for instrument panel covering and preparation method of slush molding PVC material

The invention discloses a slush molding PVC (Poly Vinyl Chloride) material for an instrument panel covering and a preparation method of the slush molding PVC material. The slush molding PVC material consists of the following ingredients in parts by weight: 48-53 parts of polrvinyl chloride bulk polymerization resin, 23-27 parts of plasticizer, 3-8 parts of epoxy-ester compounds, 5-6 parts of heat stabilizer, 0.2-1.0 part of compound light stabilizer, 0.3-1.0 part of antioxidant, 3-5 parts of silicone oil, 0.2-0.3 parts of carbon black and 3-5 parts of dispersing agent. Antalkali is introduced in auxiliaries and used for neutralizing amino groups in polyurethane, the reaction of PVC with the amino groups is prevented and the light aging problem of the slush molding PVC surface cover is solved; meanwhile, the problem of poor temperature tolerance of the PVC is solved by virtue of the excellent temperature tolerance of silicone oil; and the dispersing agent is introduced into the formula of powder, so that fluffy powder material can be conveniently transformed to sand-shaped powder material and then the slush molding of powder is facilitated.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

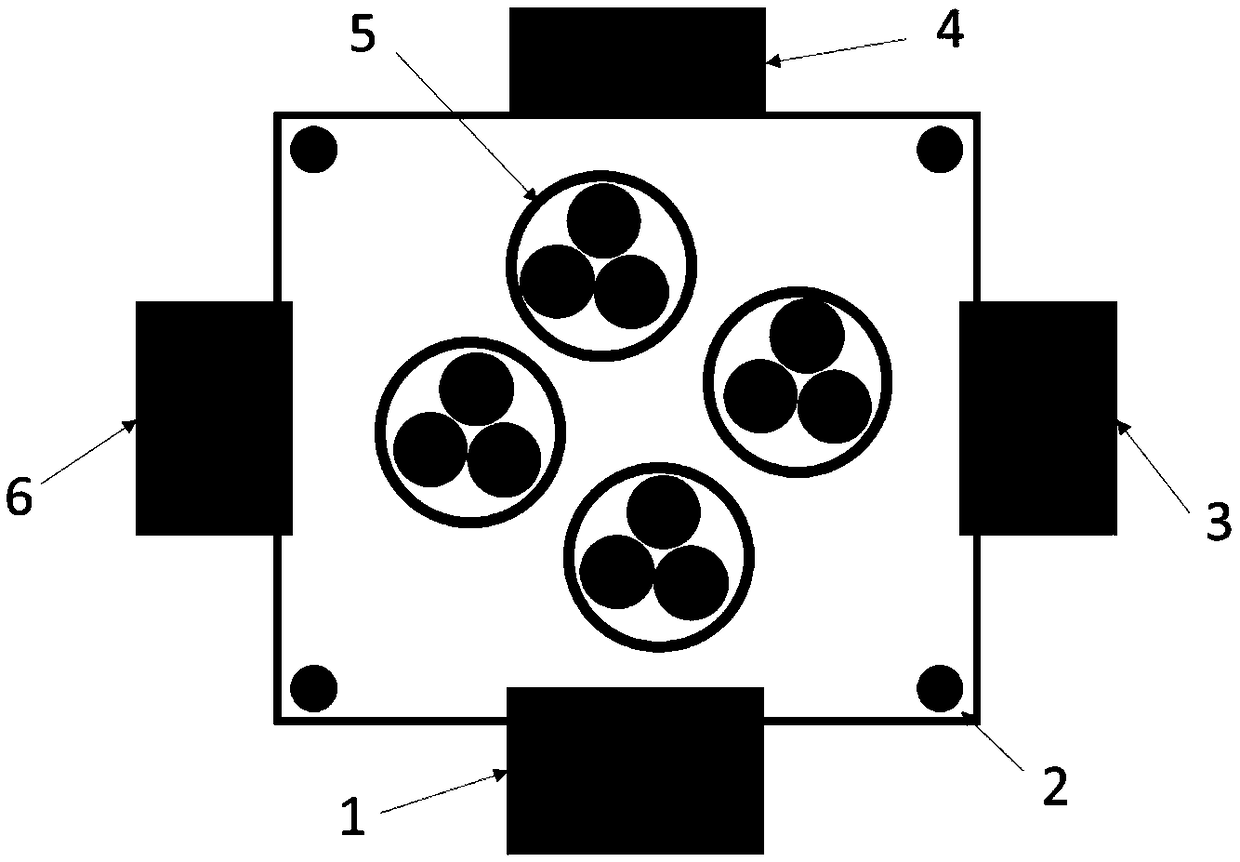

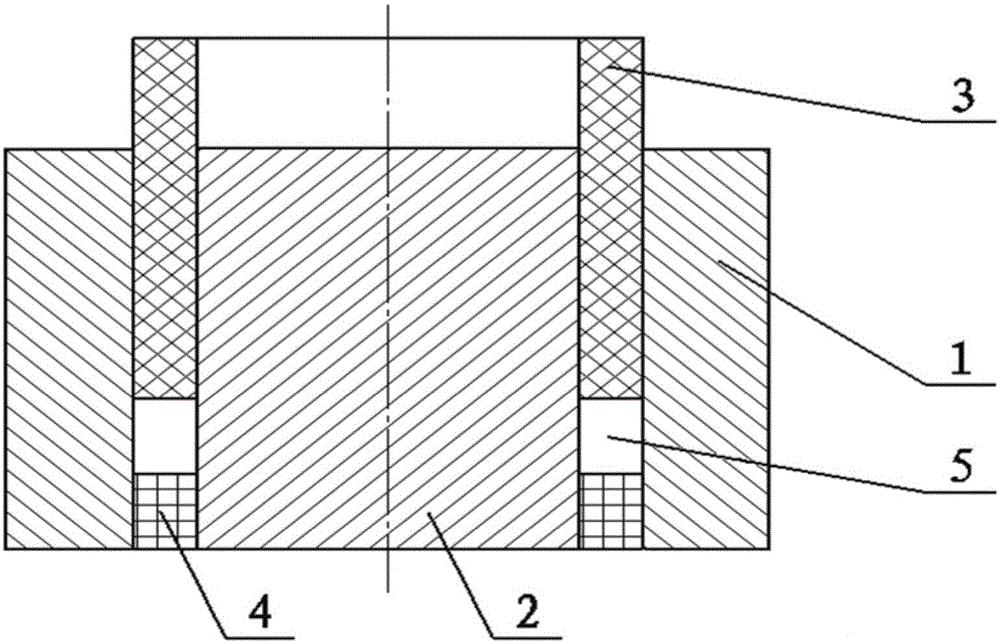

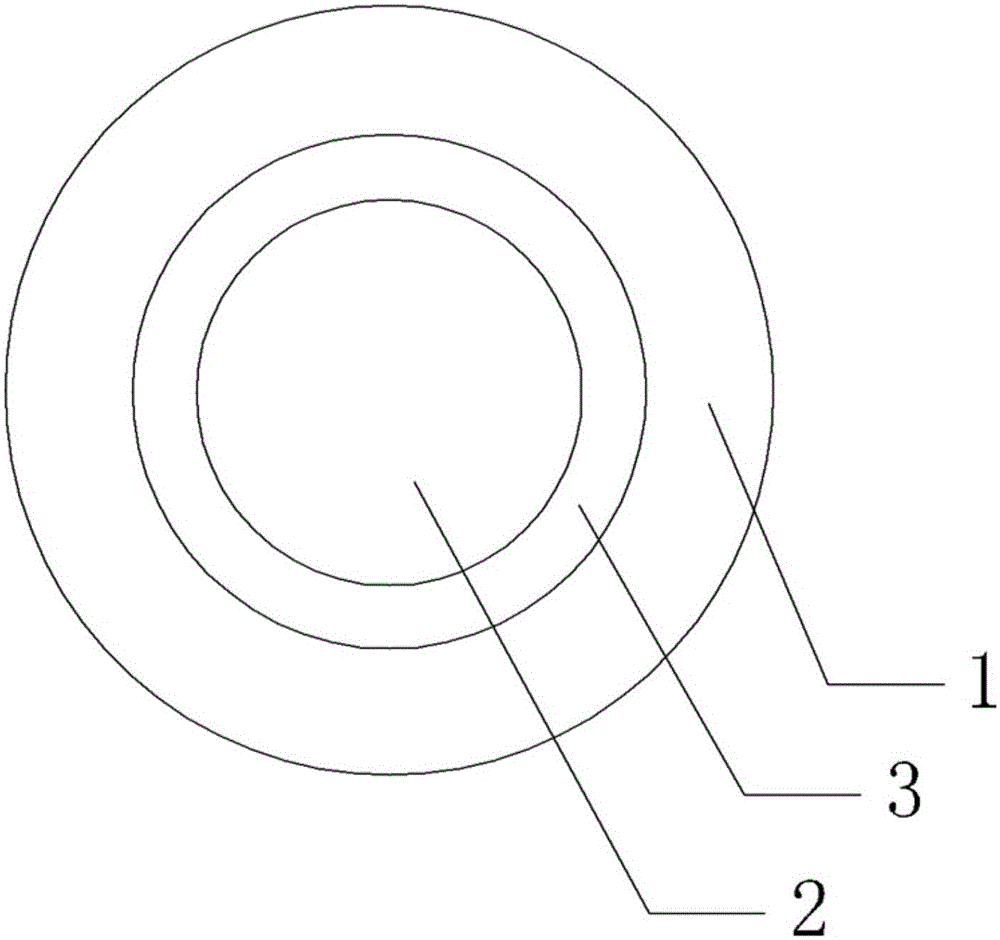

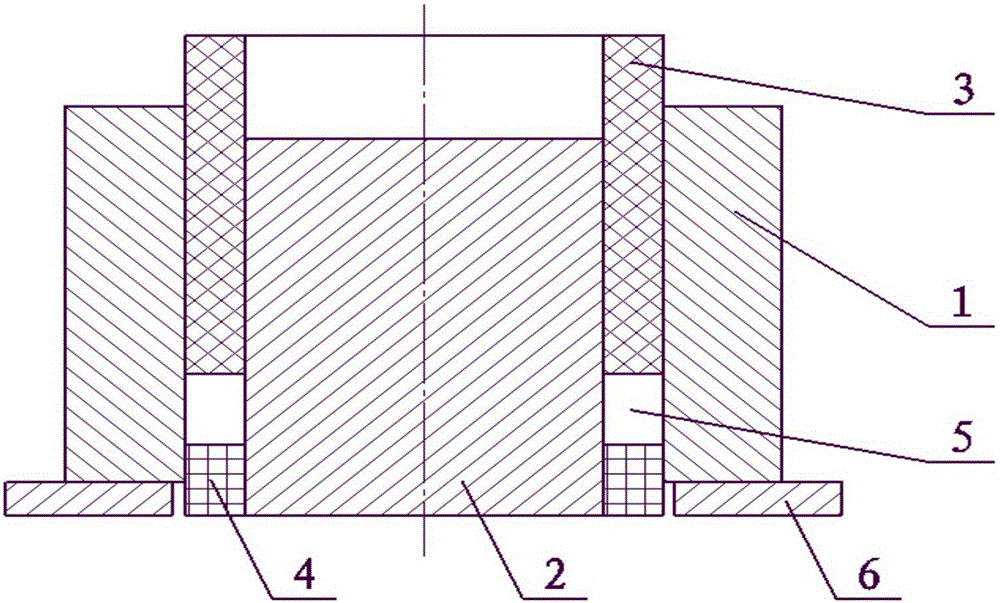

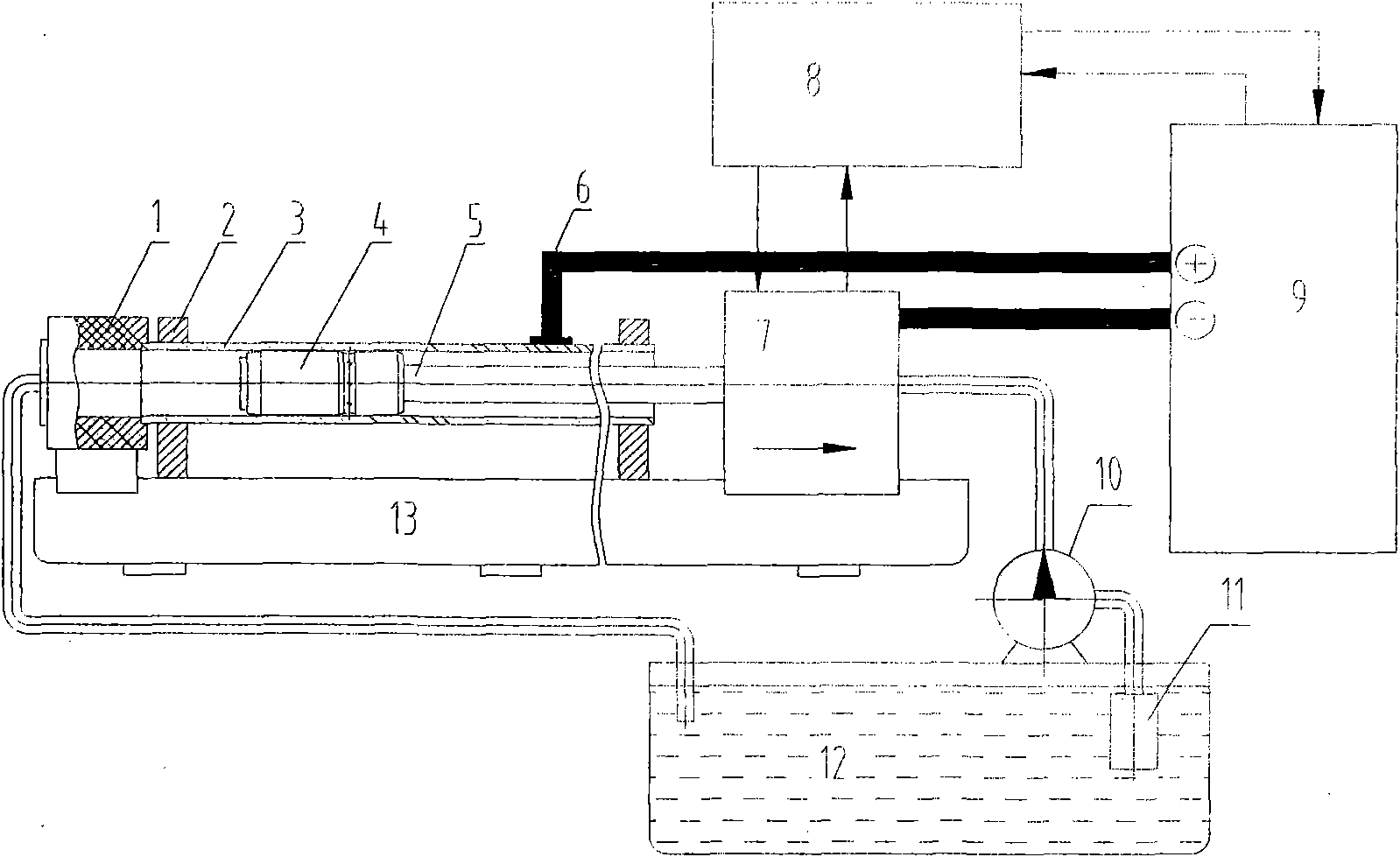

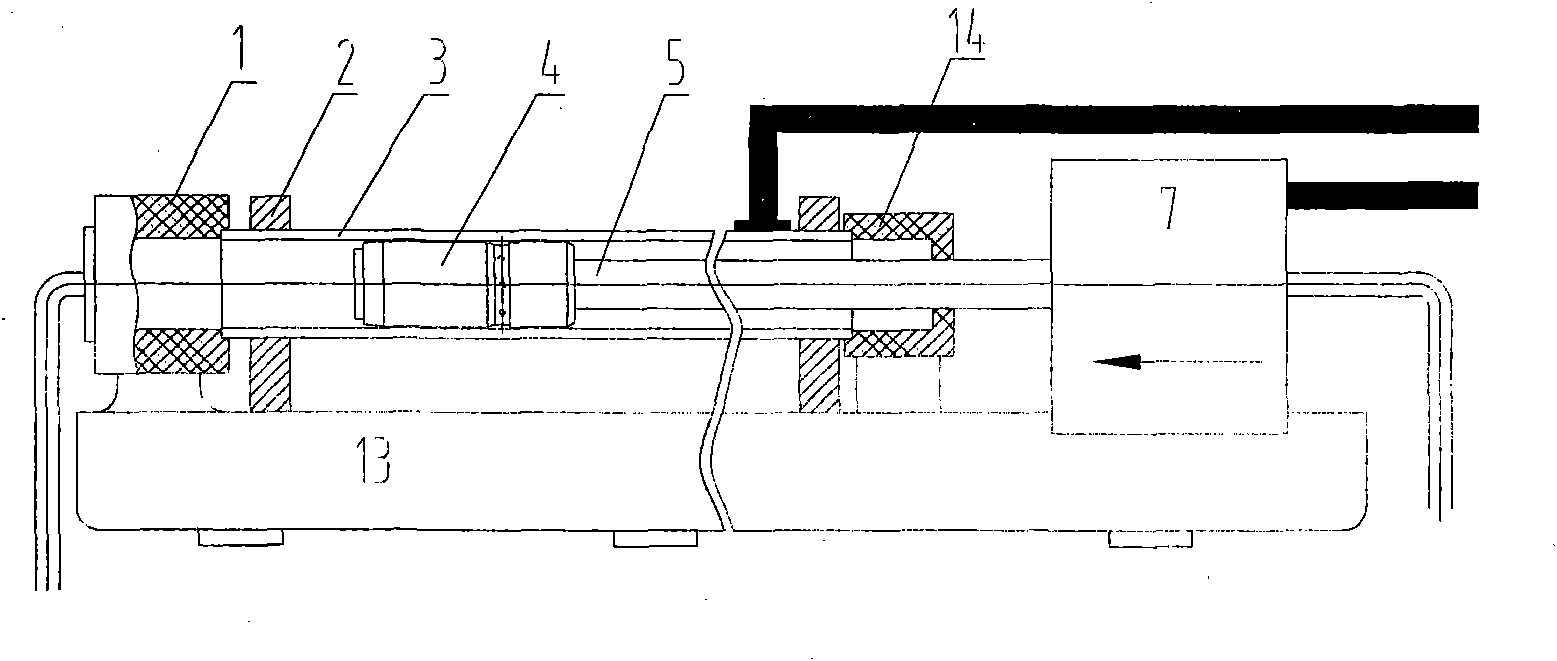

Preparation method and equipment of screw drill inside spin pre-outline stator

InactiveCN101850449AOutput highGood temperature resistanceElectrochemical machining apparatusElectrical-based auxillary apparatusPetroleumStator

The invention relates to a preparation method and equipment of a screw drill inside spin pre-outline stator, belonging to the technical field of the screw drill inside spin pre-outline stator for petroleum drilling. In the invention, rear seal is arranged on the tail bed of an electrolytic machine tool, a fixture is arranged on the electrolytic machine tool body between the rear seal and a spindle box, a prefabricated tube is clamped on the fixture before electrolytic machining, one end of a cathode rod is provided with a cathode, and the other end thereof is connected with the spindle box. The drill motor of the screw in the invention has high output torque, good thermal endurance, stable operation and long service life. The technology in the invention can promote the revolutionary development of the screw drill manufacture in our country and has an important significance on future oil exploitation in our country.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Polyurethane modified unsaturated polyester varnish

InactiveCN1821328AImprove scratch resistanceGood temperature resistancePolyurea/polyurethane coatingsPolyester coatingsDiluentHardness

The present invention discloses a kind of polyurethane modified unsaturated polyester varnish. The varnish is compounded with polyurethane and unsaturated polyester in the ratio of 1 to 0.3-5. The polyurethane consists of polyurethane paint, curing agent and diluent in the ratio of 1 to 1 to 0.6-1; and the polyurethane paint consists of alkyd resin 80-93 wt%, xylene 5-10 wt%, leveling agent 0.3-0.5 wt% and defoaming agent 0.1-0.3 wt%. The unsaturated polyester consists of unsaturated polyester paint, promoter and initiator in the ratio of 100 to 0.8-1.2 to 1-1.5, and the unsaturated polyester paint consists of unsaturated resin 80-90 wt%, styrene 9-18 wt%, leveling agent 0.3-0.5 wt% and defoaming agent 0.2-0.3 wt%. The present invention has the advantages of high hardness, good fullness, high adhesion, high flexibility, etc.

Owner:GUANGDONG LANYANG SCI & TECH

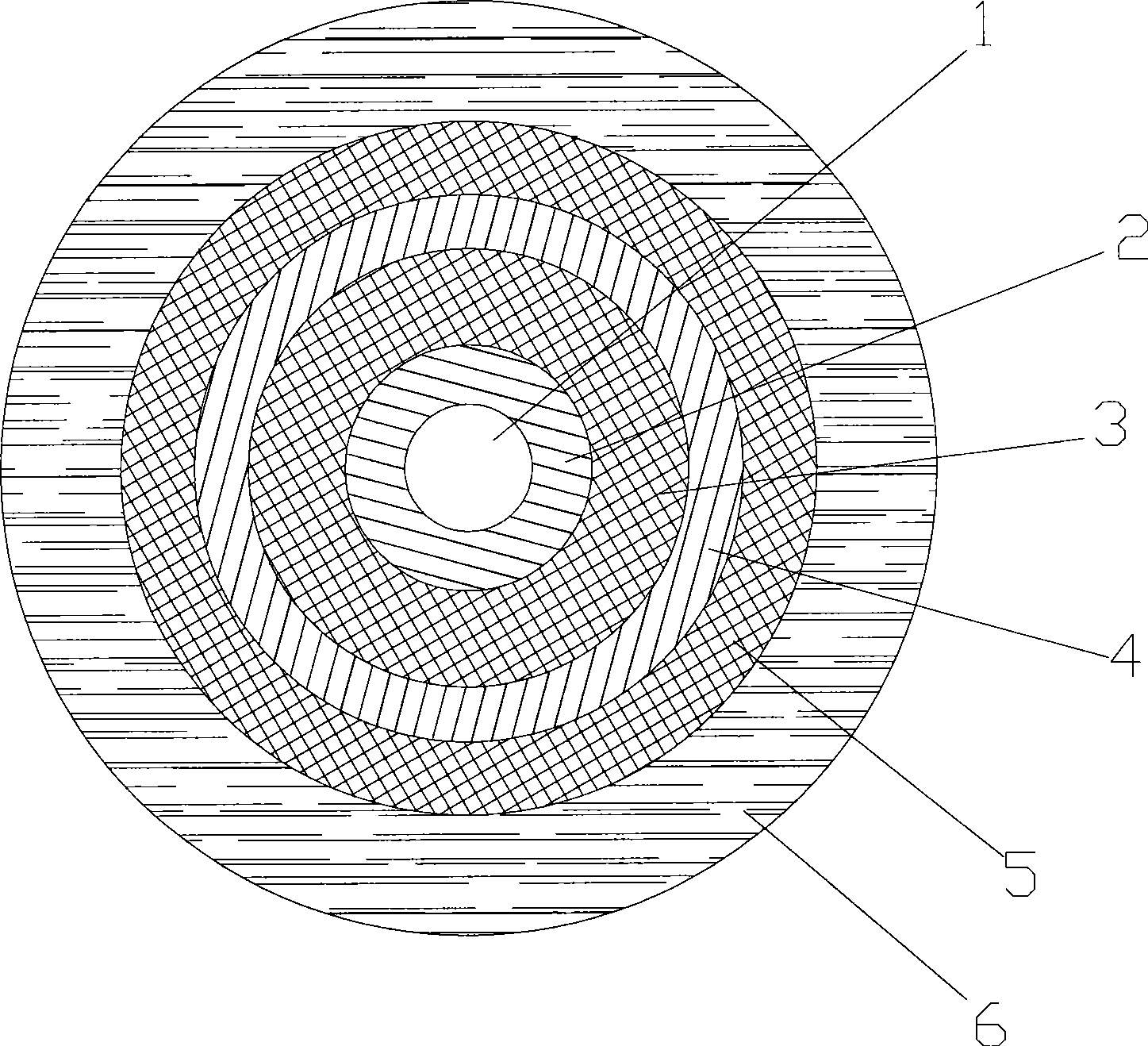

Distributed temperature sensing optic cable

InactiveCN101458375AStrong reliabilityExtended service lifeFibre mechanical structuresData informationTemperature monitoring

The invention discloses a distributed temperature sensing optical cable, comprising a fiber; a tight tube wraps the fiber, a flexible metallic tube wraps the tight tube, an aramid fiber reinforcing layer wraps the flexible metallic tube, wire sheathing wraps the aramid fiber reinforcing layer and a low-smoke halogen free flame retardant sheath wraps the wire sheathing. The optical cable can be applied to a distributed temperature monitoring system, which can be used as a temperature sensor and a channel for data information transmission.

Owner:JIANGSU ETERN

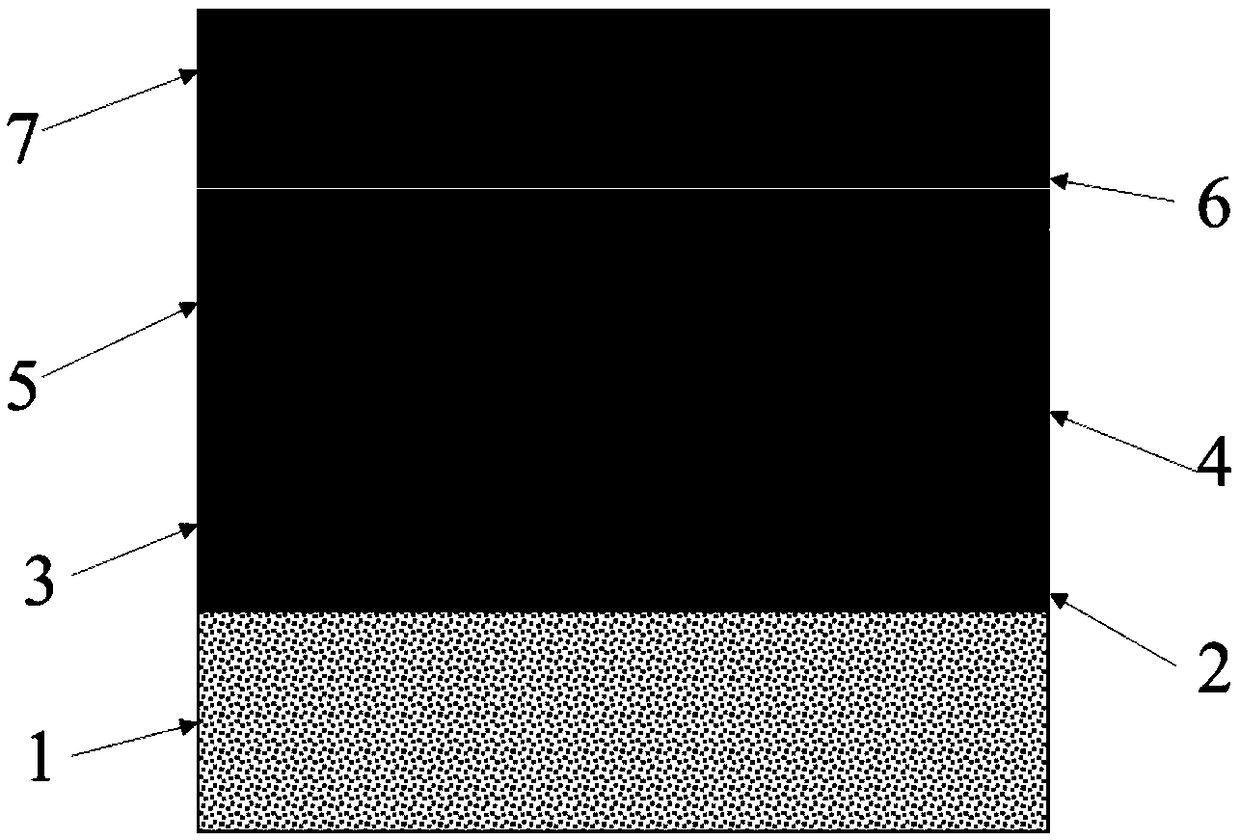

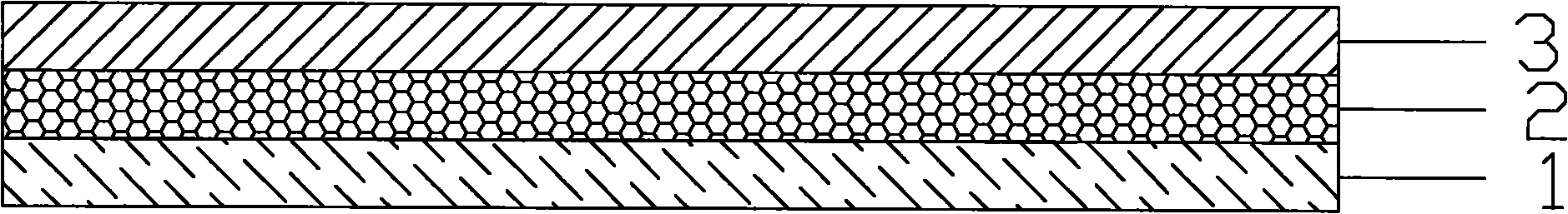

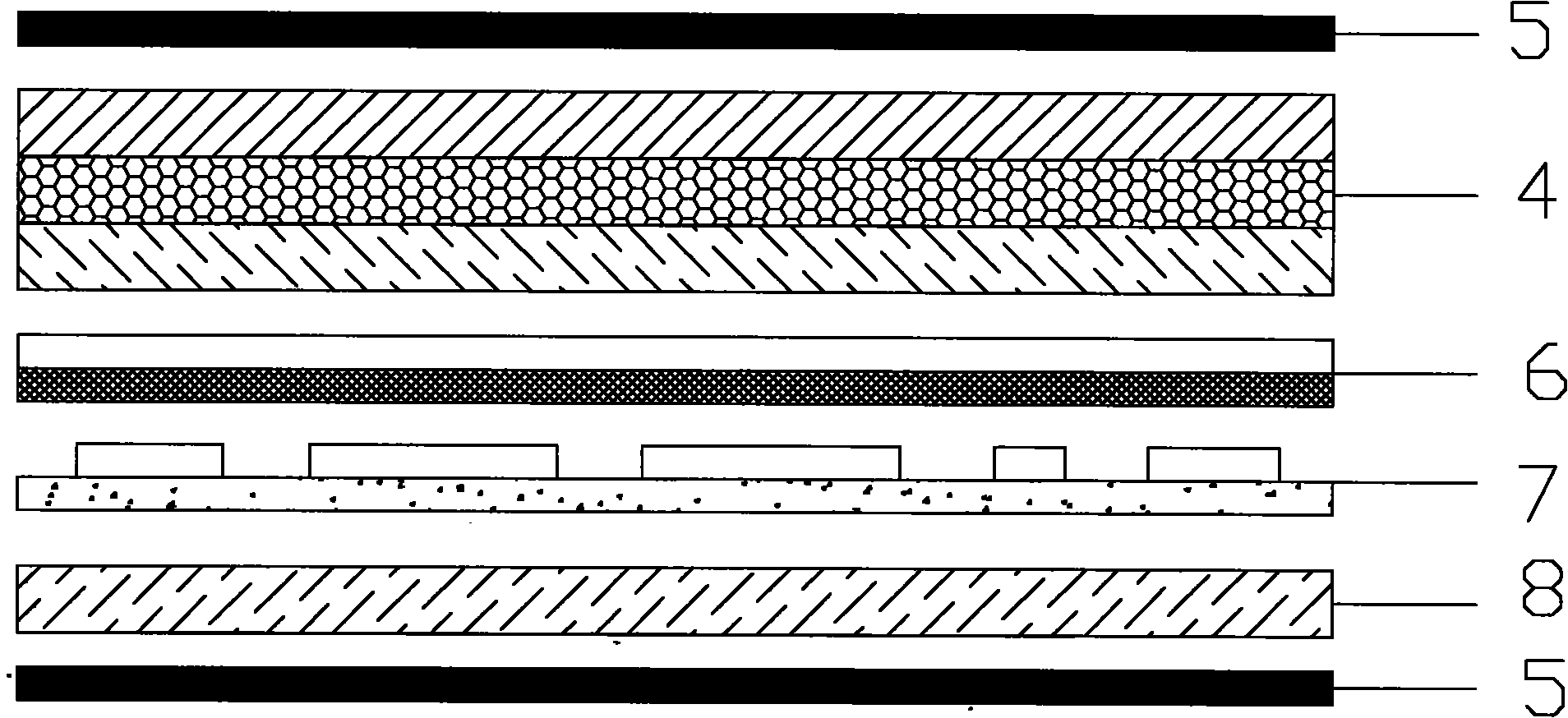

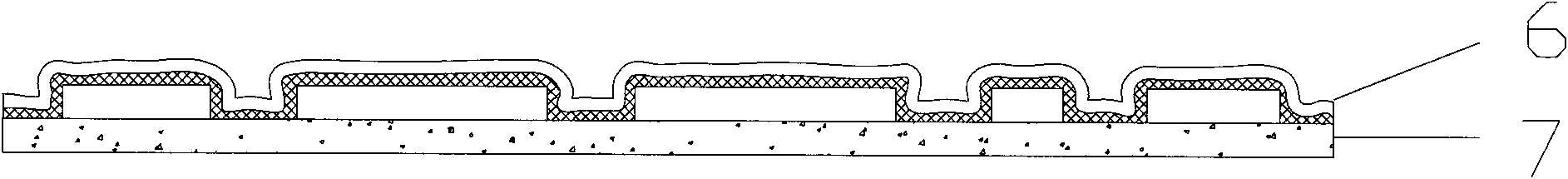

Auxiliary materials for lamination of flexibility circuit board and lamination process of same

InactiveCN101841971AGood temperature resistanceReduce thicknessPrinted circuit detailsSynthetic resin layered productsFluorinated ethylene propylenePolytetrafluoroethylene

The invention relates to an auxiliary material for lamination of a flexibility circuit board and lamination process of the same. The auxiliary material (4) for lamination of the flexibility circuit board comprises the following layers: heat-resistant release film (1), a filling and coating material (2) and a deformation control material (3), wherein the heat-resistant release film (1) is fluorinated ethylene propylene or polytetrafluoroethylene film; the filling and coating material (2) comprises the following components: crylic acid alkyl ester polymer, polysiloxane and polyethylene; the deformation control material (3) comprises PET, PBT or PA film; and at least two adjacent layers of the heat-resistant release film (1), the filling and coating material (2), the deformation control material (3) are composited into a whole or three layers are composited into a whole. The invention solves the problem that foreign body plug the hole; and the special filling and coating material can not escape in cross flow in the process of the lamination. The invention also provides a lamination process with excellent glue resistance capability.

Owner:周伟

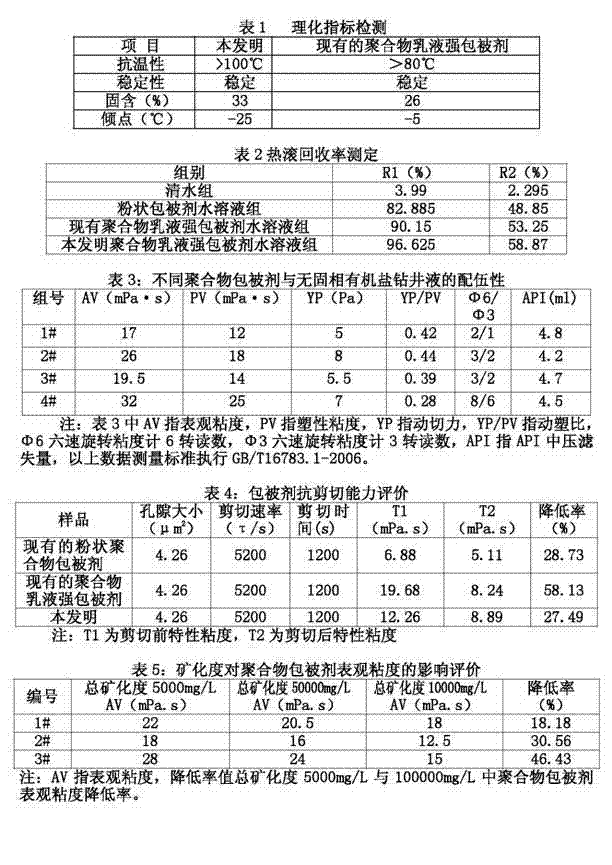

AM/AAK/AMPS terpolymer and polymer emulsion strong coating agent as well as preparation methods thereof

ActiveCN103755869AGood temperature resistanceGood resistance to saltDrilling compositionPetrochemicalPolymer chemistry

The invention relates to the technical field of coating agents in petrochemical industry and provides a polymer emulsion strong coating agent. An AM / AAK / AMPS terpolymer comprises acrylamide, potassium acrylate, 2-acryloylamino-2-sodium methylacrylsulfonate, an emulsifying agent, an initiator, an oil phase and water. The polymer emulsion strong coating agent comprises the following raw materials in parts by weight: 90-94.5 parts of the AM / AAK / AMPS terpolymer, 5-9.9 parts of small positive ion quaternary ammonium salt and 0.1-0.5 part of an anti-gelling agent. The polymer emulsion strong coating agent is good in temperature resistance, salt resistance and shearing resistance, has strong coating inhibition performance and excellent working performance, can meet the requirements of construction in low-temperature regions and has a wide application range and when the polymer emulsion strong coating agent is applied to an HRD non-clay-phase drilling fluid system, the cost can be effectively reduced.

Owner:克拉玛依市金鑫科技有限公司

Oil-permeation polishing treatment agent for synthetic leather and preparation method of polishing treatment agent

ActiveCN104032577AGood temperature resistanceOil wax effect is goodFibre treatmentErucyl amideChemistry

The invention relates to an oil-permeation polishing treatment agent for synthetic leather and a preparation method of the polishing treatment agent. The treatment agent is prepared from the following components: alkyd resin, nitrocotton, cyclohexanone, butyl ether, ethyl ester, silicon dioxide extinction powder, oleamide, erucyl amide, cellulose acetate, an antibacterial and anti-mildew agent, methyl phenyl silicone oil and a dispersing agent. The oil-permeation polishing treatment agent is a novel material for later printing of the synthetic leather; the treatment agent can enable the synthetic leather to have remarkable temperature tolerance, to be embossed, have excellent glossy and oil waxy effects after being polished, and have special hand feeling, and the leather surface treated by the treatment agent is glossy and natural, and has clear color, excellent permeation feeling, strong leather effect and good general effect.

Owner:浙江宝泽高分子材料有限公司

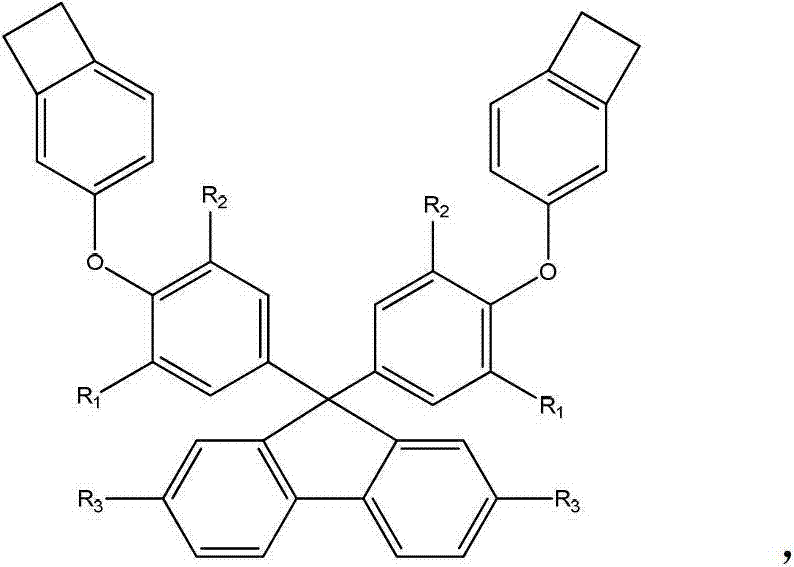

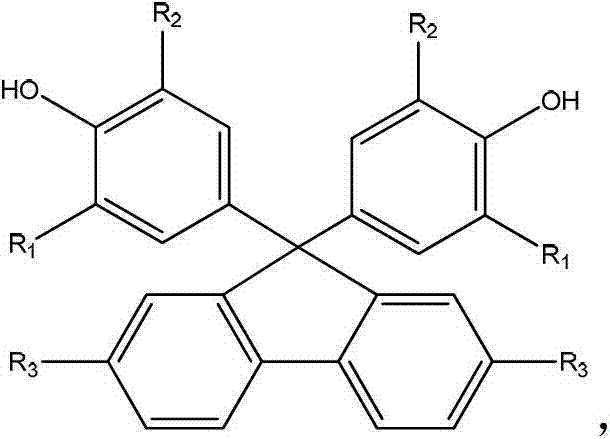

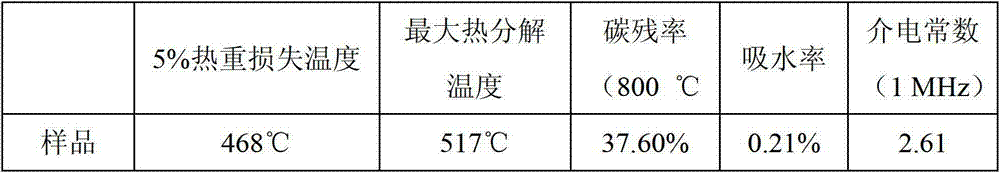

Thermosetting resin monomer containing fluorene and benzocyclobutene construction unit as well as preparation method and application thereof

InactiveCN103086851AGood temperature resistanceExcellent dielectric propertiesEther preparation by ester reactionsSolventHigh performance polymer

The invention belongs to the filed of high-performance polymer preparation, and particularly relates to a thermosetting resin monomer containing fluorene and benzocyclobutene construction unit as well as a preparation method and application thereof. The constitutional formula of the monomer is shown in the description; and the monomer is obtained through etherification reaction between bisphenol fluorine and 4-bromobenzocyclobutene in a solvent in the presence of cuprous salt, imidazole ligand and inorganic base. The monomer has very good film formation property, and a solid film with high heat resistance, low water absorbing capacity, low specific inductive capacity and high flatness can be obtained through thermal curing of the obtained organic film. In the atmosphere of nitrogen, 5% weight loss temperature (Td 5%) of the film is 468.5 DEG C, and the carbon yield at 1000 DEG C is up to 37.6%. The monomer is suitable for serving as a high-temperature resistant bonding agent in the fields of aerospace, national defense and the like and an encapsulating material of electronic devices and components in an electric industry.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

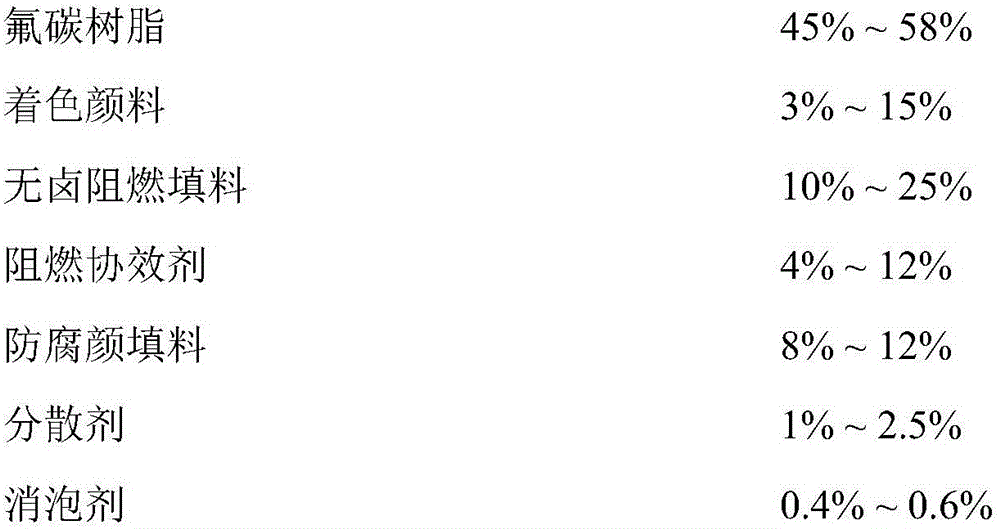

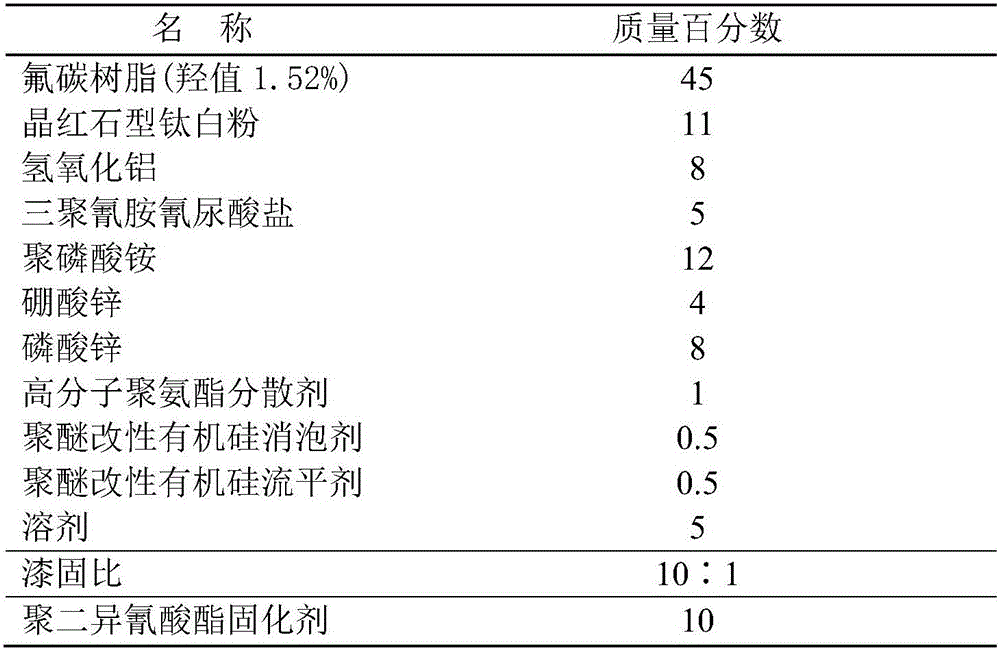

Weather-proof, halogen-free, flame-retardant, anti-corrosion and insulating fluorine-carbon coating

ActiveCN105733376AStrong adhesionGood temperature resistanceFireproof paintsAnti-corrosive paintsCarbon coatingFluorocarbon Resins

The invention provides a weather-proof, halogen-free, flame-retardant, anti-corrosion and insulating fluorine-carbon coating. Fluorine-carbon resin is compounded with a halogen-free flame retardant, wherein the fluorine-carbon resin accounts for 45% to 58%, and the halogen-free flame-retardant filler accounts for 10% to 25%. The weather-proof, halogen-free, flame-retardant, anti-corrosion and insulating fluorine-carbon coating is high in adhesive force, good in temperature resistance, high in low-temperature drying speed and the like, has excellent flame-retardant performance, electrical insulating performance, anti-corrosion and damp-proof performance and excellent ultraviolet light resistance, has high applicability, and is especially suitable for the field of flame-retardant, anti-corrosion and insulating operation on the surface of electrical equipment.

Owner:广东四方威凯新材料有限公司

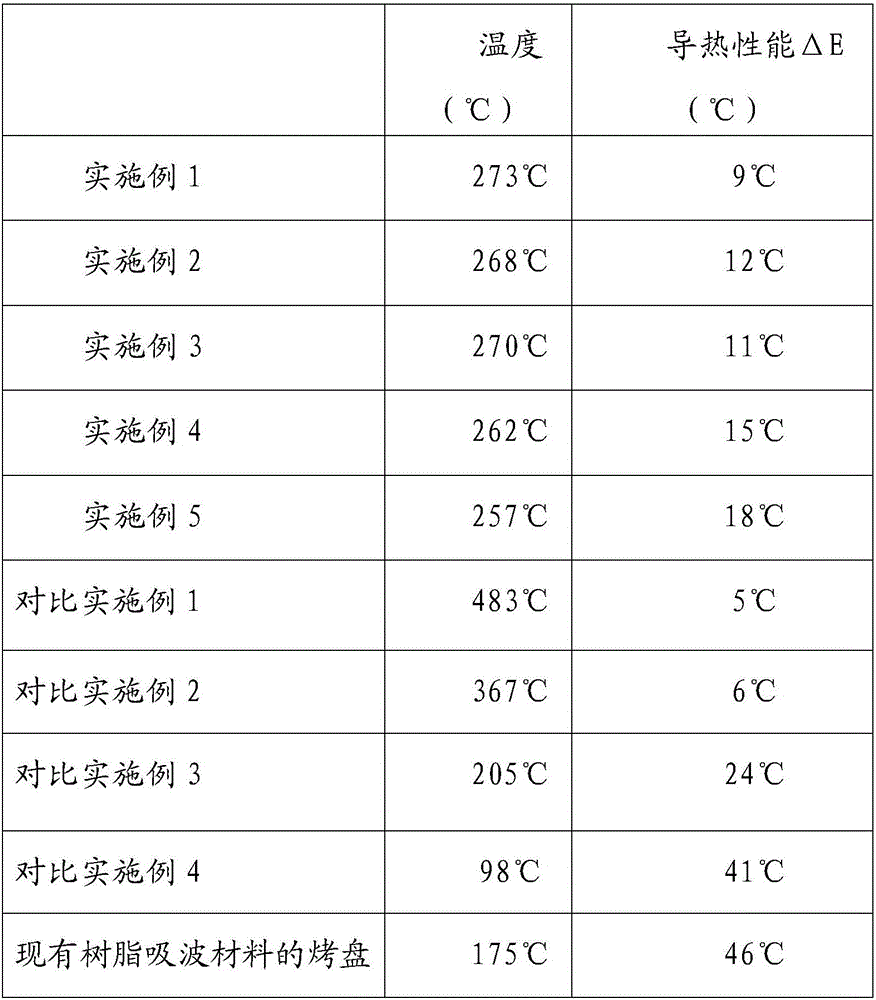

Heat conduction type wave-absorbing material and preparing method thereof

ActiveCN106118144AGood temperature resistanceGood thermal conductivityCoatingsGrapheneConduction type

The invention relates to a heat conduction type wave-absorbing material and a preparing method thereof. The heat conduction type wave-absorbing material comprises, by mass, 99.2-99.7% of wave-absorbing material binder, 0.2-0.5% of wave-absorbing material and 0.1-0.3% of auxiliary. The wave-absorbing material is a graphene material. During preparation, the components are mixed in proportion. The heat conduction type wave-absorbing material has the advantages that heat conduction property is good, temperature distribution is uniform, and wave-absorbing performance is good.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Black temperature change paint

InactiveCN106118276ABright colorsGood temperature resistanceAnti-corrosive paintsThermosensitive paintsLacquerMethyl isobutyl ketone

The invention discloses a black temperature-changing paint, which includes resin, pigment, solvent and auxiliary agent. According to the weight percentage, each component is composed as follows: resin: (1) polyurethane resin 24±1%; (2) thermoplastic acrylic resin 10±2%; (3) fully etherified amino resin 5±2%; pigment: (1) thermochromic pigment 25±5%; solvent: (1) cyclohexanone 5±0.5%; (2) xylene 8 ±0.5%; (3) butyl ester 12±0.5%; (4) methyl isobutyl ketone (MIBK) 9±0.5%; additives: (1) fluorine modified leveling agent 1±0.2%; (2 ) Silicon defoamer 2±0.3%; (3) Polymer copolymer alkyl ammonium salt dispersion 1±0.3%.

Owner:深圳市鑫太庆科技有限公司

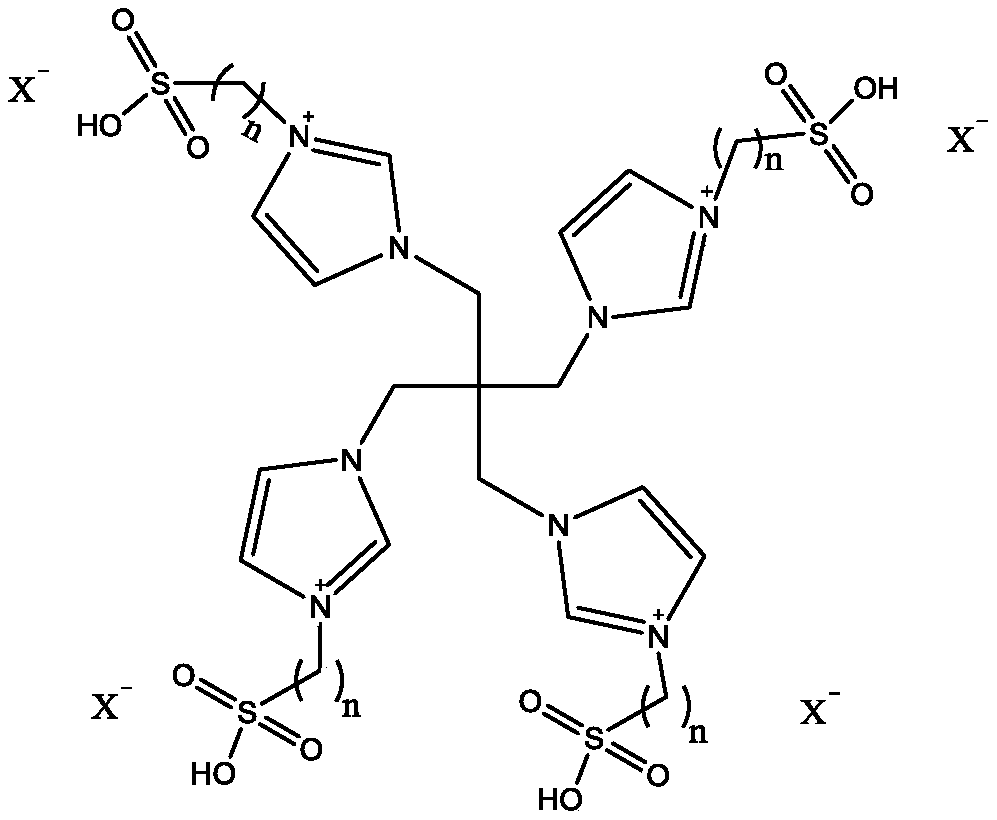

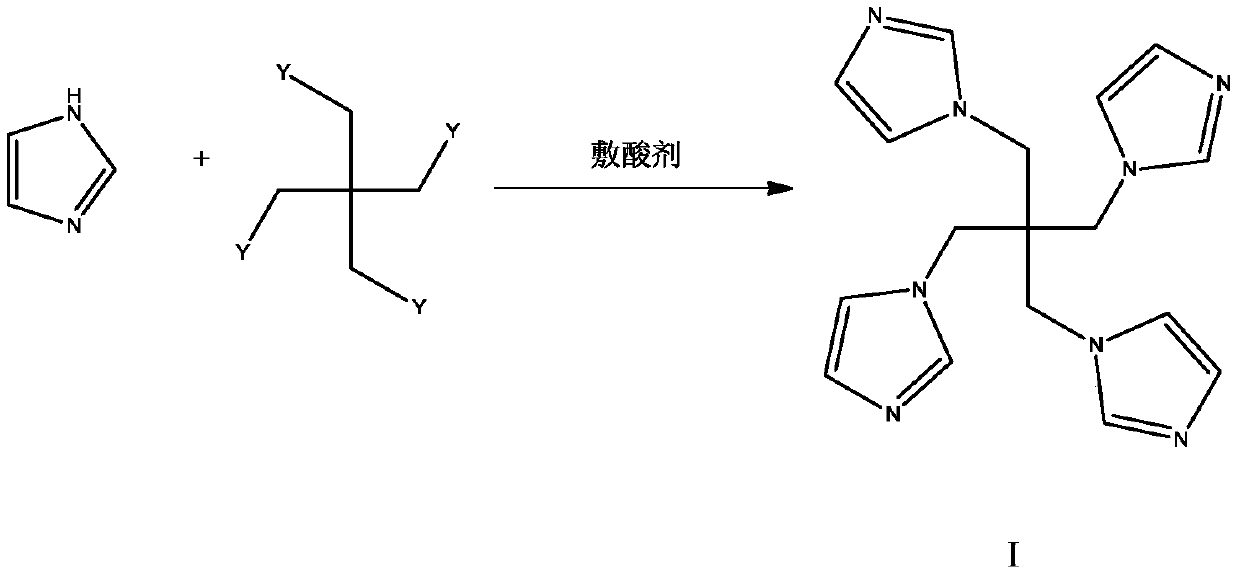

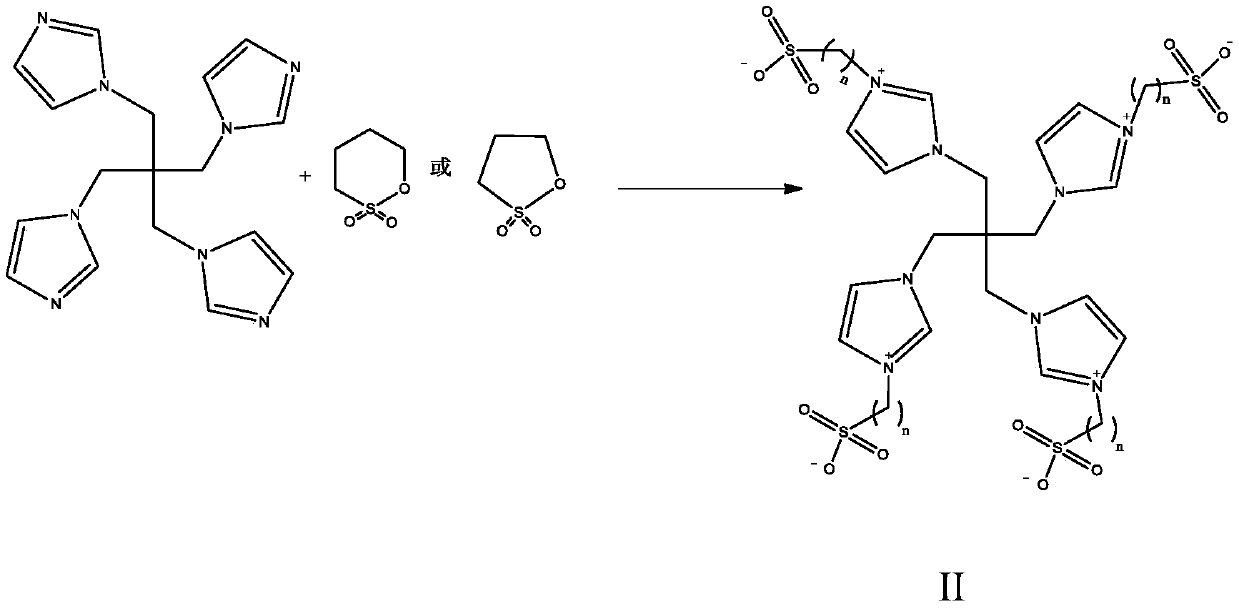

Ionic liquid supported transition metal catalyst and preparation thereof, and application of ionic liquid supported transition metal catalyst to olefin oligomerization

ActiveCN110227543AReduce acidityReduce corrosionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsTemperature resistanceIonic liquid

The invention relates to the preparation of a novel ionic liquid supported transition metal catalyst and application of the catalyst in the field of olefin oligomerization. According to the invention,a sulfonic acid functionalized tetranuclear ionic liquid supported transition metal is used as a catalyst, and propylene, butene-1, butene-2, isobutylene, 1-pentene and the like are used as raw materials to synthesize olefin oligomers under certain temperature and pressure conditions. The method uses the novel ionic liquid supported transition metal as the catalyst to prepare olefin oligomers, and the catalyst has low corrosivity, good temperature resistance, stable activity, and no reduction in activity after being used indiscriminately a plurality of times.

Owner:WANHUA CHEM GRP CO LTD

Tire stock of IPN (Interpenetrating Polymer Network) crosslinked structure and mixing method as well as application thereof

InactiveCN102250394AEasy to useGood temperature resistanceSpecial tyresInterpenetrating polymer networkCarbon black

The invention relates to the field of rubber tires, in particular to a tire stock and a mixing method as well as application thereof. The tire stock of an IPN (Interpenetrating Polymer Network) crosslinked structure is prepared by mixing the following raw material components in part by weight: 100 parts of first network material, 0.1-30 parts of second network material, 0.8-20 parts of co-meltingassistant, 20-150 parts of carbon black, 1-30 parts of activating agent, 0-50 parts of softening agent, 0-20 parts of anti-aging agent, 0.1-10 parts of vulcanizing agent and 0.1-20 parts of vulcanization accelerator, wherein the first network material is one or the combination of more selected from diene rubbers; and the second network material is selected from natural resin or synthetic resin providing a crosslink bond and monomer of the synthetic resin. In the invention, the advantages of superior temperature resistance, high shear strength resistance and high torsion deformation resistanceof an IPN vulcanization network bond are integrated while each item of physical performance and processing performance of the conventional single sulfur crosslink bond are kept; and the service performance of a tire formula is improved to the greatest extent.

Owner:ZHONGCE RUBBER GRP CO LTD

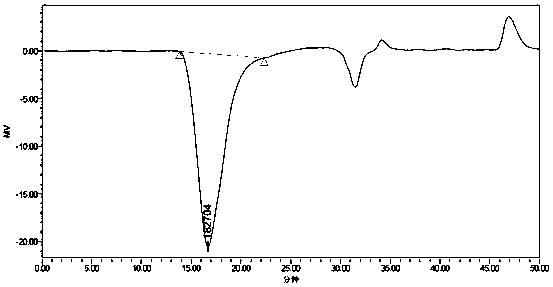

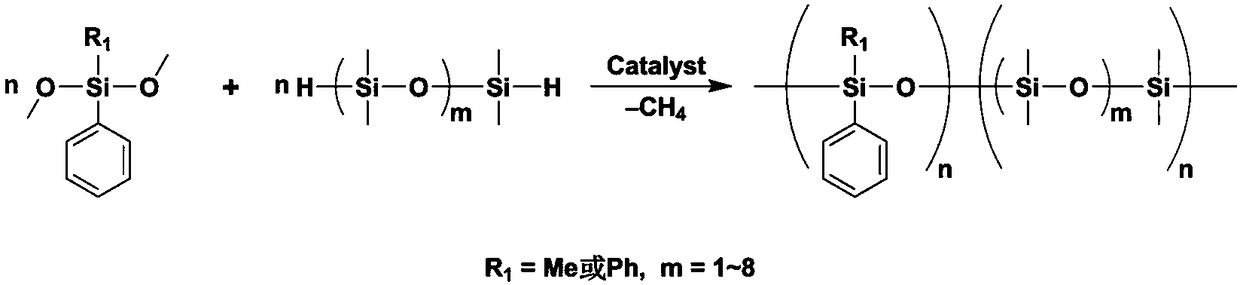

Preparation method of methylphenyl silicone oil with phenyl groups of medium and high content

The invention relates to the technical field of silicone industry. In order to overcome the deficiencies in the prior art, the invention provides a preparation method of methylphenyl silicone oil withphenyl groups of a medium and high content, wherein raw materials and intermediates with steric hindrance and electronic effects are selected, and preparation is achieved by utilizing a catalytic dealkylation polycondensation reaction between Si-H and Si-OR. In the molecular chain of the prepared methylphenyl silicone oil with phenyl groups of a medium and high content, PhSiO and Me2SiO chain segments are evenly distributed, and the prepared methylphenyl silicone oil has a structure close to the structure of an alternating copolymer, so that the silicone oil has excellent transparency and temperature resistance, and the content of a by-product cyclic siloxane is extremely low.

Owner:HANGZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com