AM/AAK/AMPS terpolymer and polymer emulsion strong coating agent as well as preparation methods thereof

A technology of terpolymer and coating agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low temperature resistance, salt resistance and shear resistance, and achieve excellent working performance , cost reduction, good salt resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

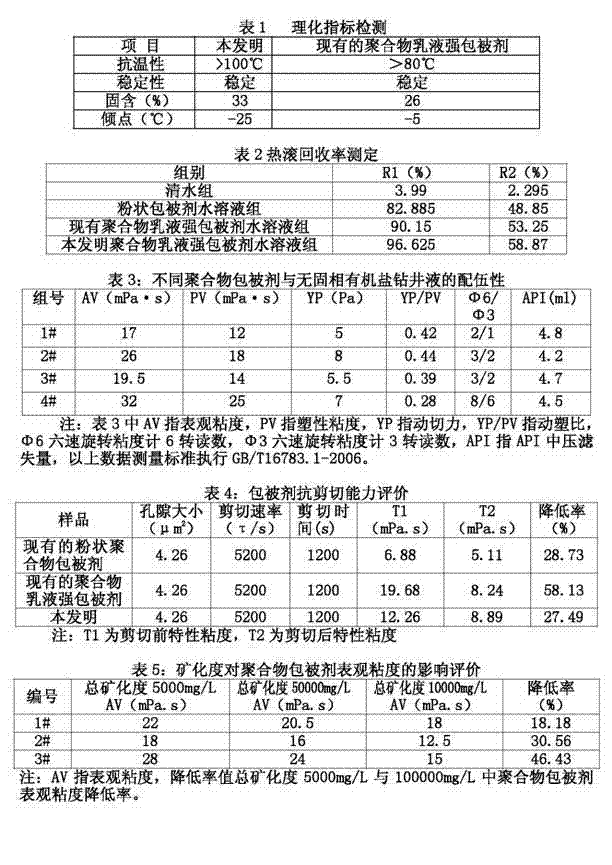

Image

Examples

Embodiment 1

[0023] Example 1, the raw materials of the AM / AAK / AMPS terpolymer include 20 to 25 parts by weight of acrylamide, 10 to 15 parts of potassium acrylate, 2-acrylamido-2-methylpropanesulfonic acid 5-10 parts of sodium, 5-10 parts of emulsifier, 0.5-1 part of initiator, 25-30 parts of oil phase and 9-34.5 parts of water.

Embodiment 2

[0024] Example 2, the raw materials of the AM / AAK / AMPS terpolymer include 20 or 25 parts by weight of acrylamide, 10 or 15 parts of potassium acrylate, 2-acrylamide-2-methylpropanesulfonic acid 5 or 10 parts of sodium, 5 or 10 parts of emulsifier, 0.5 or 1 part of initiator, 25 or 30 parts of oil phase and 9 or 34.5 parts of water.

Embodiment 3

[0025] Embodiment 3, as the preference of embodiment 1 and embodiment 2, the oil phase is more than one in 3# white oil, 4# white oil, 5# white oil, 10# white oil and 15# white oil; or / And, the emulsifier is obtained by mixing SP-80 and OP-10 in a mass ratio of 1:0.05 to 1:0.1; or / and, the initiator is one of ammonium persulfate, sodium bisulfite and potassium persulfate above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com