Heat conduction type wave-absorbing material and preparing method thereof

A technology of wave-absorbing materials and substrates, applied in the field of heat-conducting wave-absorbing materials and their preparation, can solve problems such as poor thermal conductivity, failure to meet temperature rise requirements, poor uniformity, etc., and achieve good temperature resistance, good thermal conductivity, The effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

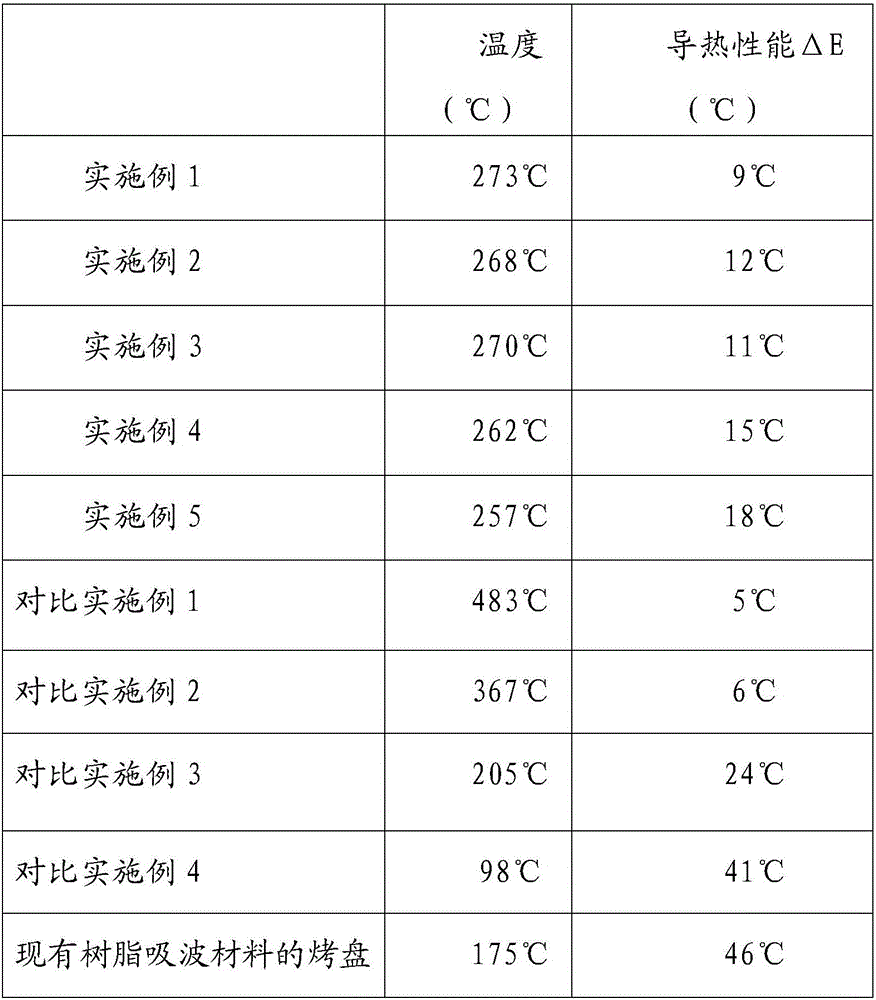

Examples

Embodiment 1

[0063] A heat-conducting wave-absorbing material, each component of the heat-conducting wave-absorbing material is calculated by mass percentage, the wave-absorbing material binder is 99.2%, the wave-absorbing material is 0.5%, and the additive is 0.3%.

[0064] The preparation method is as follows:

[0065] 1) Preparation of additives and binder mixing components:

[0066] Mix 99.2kg of liquid ceramic material with 0.3kg of additives; additives include 0.1kg of wetting and dispersing agent Disperbyk-161, 0.05kg of defoamer AMAFCA, 0.1kg of suspension thickener and 0.05kg of 1121 adhesion promoter; among them, The suspension thickener is a mixture of 0.05kg polyacrylamide and 0.05kg guar gum; mechanically stir at a speed of 300r / min for 5min to obtain a mixed solution;

[0067] 2) Preparation of heat-conducting and wave-absorbing materials:

[0068] Add 0.5 kg of graphene oxide wave-absorbing powder to the mixed liquid prepared in step 1), and mechanically stir at a speed of...

Embodiment 2

[0070] A heat-conducting wave-absorbing material, each component of the heat-conducting wave-absorbing material is calculated by mass percentage, the wave-absorbing material binder is 99.4%, the wave-absorbing material is 0.4%, and the auxiliary agent is 0.2%.

[0071] The preparation method is as follows:

[0072] 1) Preparation of additives and binder mixing components:

[0073] Mix 99.4kg of liquid ceramic material with 0.2kg of additives; additives include 0.06kg of wetting and dispersing agent Disperbyk-161, 0.04kg of defoamer AMAFCA, 0.07kg of suspension thickener and 0.03kg of 1121 adhesion promoter; among them, The suspension thickener is a mixture of 0.04kg polyacrylamide and 0.03kg guar gum; mechanical stirring at a speed of 300r / min for 5min to obtain a mixed solution;

[0074] 2) Preparation of heat-conducting and wave-absorbing materials:

[0075] Add 0.4 kg of graphene oxide wave-absorbing powder to the mixed solution prepared in step 1), and mechanically stir ...

Embodiment 3

[0077] A heat-conducting wave-absorbing material, each component of the heat-conducting wave-absorbing material is calculated by mass percentage, the wave-absorbing material binder is 99.3%, the wave-absorbing material is 0.4%, and the auxiliary agent is 0.3%.

[0078] The preparation method is as follows:

[0079] 1) Preparation of additives and binder mixing components:

[0080] Mix 99.3kg of liquid ceramic material with 0.3kg of additives; additives include 0.12kg of wetting and dispersing agent Disperbyk-161, 0.06kg of defoamer AMAFCA, 0.08kg of suspension thickener and 0.04kg of 1121 adhesion promoter; among them, The suspension thickener is a mixture of 0.05kg polyacrylamide and 0.03kg guar gum; mechanically stirred at a speed of 300r / min for 5min to obtain a mixed solution;

[0081] 2) Preparation of heat-conducting and wave-absorbing materials:

[0082] Add 0.4 kg of graphene oxide wave-absorbing powder to the mixed liquid prepared in step 1), and mechanically stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com