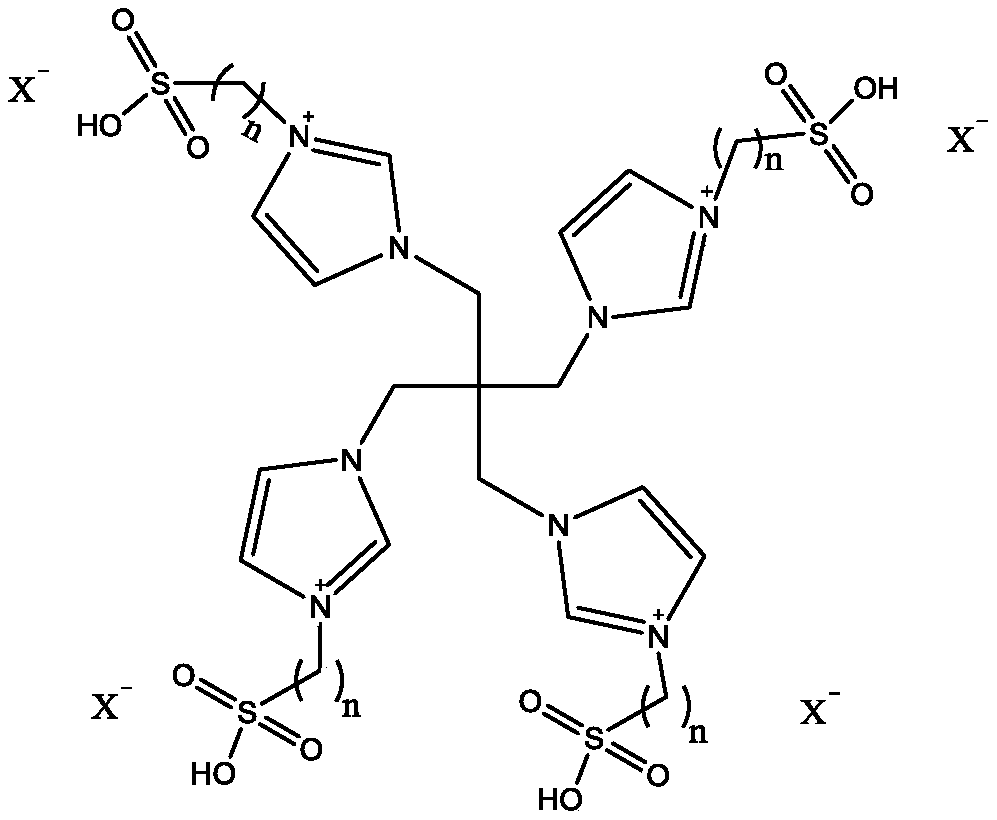

Ionic liquid supported transition metal catalyst and preparation thereof, and application of ionic liquid supported transition metal catalyst to olefin oligomerization

A transition metal, ionic liquid technology, used in catalytic reactions, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. , the catalyst cannot be reused, etc., to achieve the effect of long-term operation, good stability and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

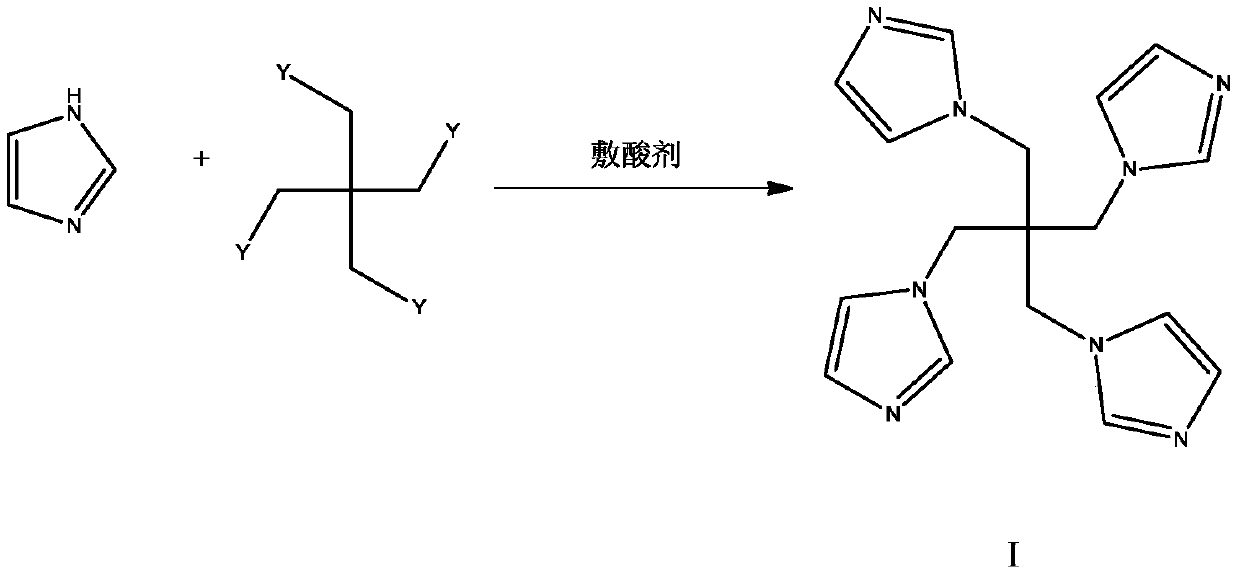

[0040] (1) Catalyst preparation

[0041] Use pentaerythritol bromide as the raw material to react with imidazole, the molar ratio of the feed is 1:10, add sodium hydroxide as the acid coating agent, the molar ratio of the amount added to imidazole is 1:1, use DMSO as the solvent, and the amount of solvent added as the raw material 50% of the total mass, reaction temperature -20 ° C, reaction time 1h, after the reaction, remove the solvent, wash with water to obtain the intermediate product I, the yield is 90%, the reaction equation is as follows:

[0042]

[0043]Qualitative Analysis: NMR: 1 H NMR (500MHz, D 2 O, TMS), δ (ppm): 3.65, (8H, s), 6.78, (4H, m), 7.22 (4H, m), 7.92 (4H, m)

[0044] 13 C NMR (150MHz, D 2 O, TMS), δ (ppm): 137.8, 128, 120.6, 43.9, 29.3.

[0045] Mass spectrum: 336.2, 337.2, 338.2

[0046] Elemental analysis: C, 60.70; H, 5.99; N, 33.31

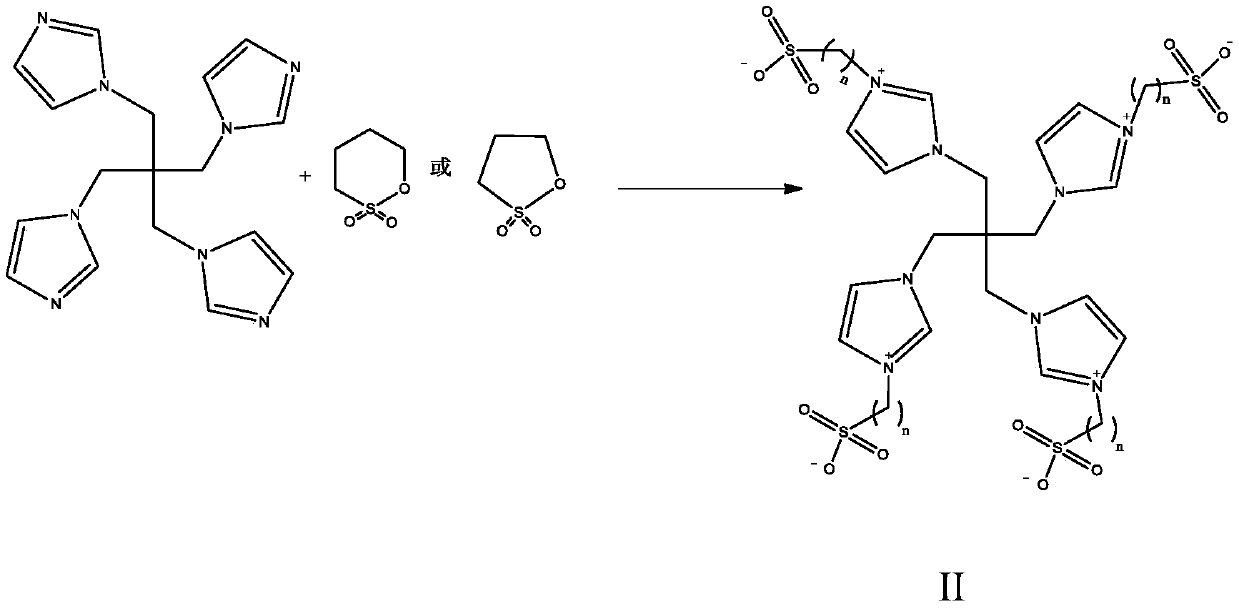

[0047] Intermediate I reacts with 1,3-propane sultone, the molar ratio is 1:10, toluene is used as the so...

Embodiment 2

[0078] (1) Catalyst preparation

[0079] Adopting pentaerythroxychloride as raw material to react with imidazole, the molar ratio of feeding and feeding is 1:4, adding potassium hydroxide as acid coating agent, the molar ratio of the addition amount to imidazole is 1:2, using hexane as solvent, the solvent addition amount is 200% of the total mass of raw materials, 80°C of reaction temperature, 4h of reaction time, after the reaction finishes, remove solvent, wash with water to obtain intermediate product I, yield 86%, reaction equation is as follows:

[0080]

[0081] Qualitative Analysis: NMR: 1 H NMR (500MHz, D2O, TMS), δ (ppm): 3.65, (8H, s), 6.78, (4H, m), 7.22 (4H, m), 7.92 (4H, m)

[0082] 13 C NMR (150MHz, D2O, TMS), δ (ppm): 137.8, 128, 120.6, 43.9, 29.3.

[0083] Mass spectrum: 336.2, 337.2, 338.2

[0084] Elemental analysis: C, 60.70; H, 5.99; N, 33.31

[0085] Intermediate I reacts with 1,4-butane sultone, the molar ratio is 1:4, hexane is used as the solve...

Embodiment 3

[0114] (1) Catalyst preparation

[0115] Use pentaerythroxytetraiodide as raw material to react with imidazole, the molar ratio of feed is 1:5, cesium hydroxide is added as an acid agent, the molar ratio of the amount added to imidazole is 1:1.5, and toluene is used as solvent, and the amount of toluene is the total amount of raw materials. 100% of the mass, the reaction temperature is 50°C, the reaction time is 2h, after the reaction is finished, the solvent is removed, and the intermediate product I is obtained by washing with water, the yield is 95%, and the reaction is as follows:

[0116]

[0117] Qualitative Analysis: NMR: 1 H NMR (500MHz, D2O, TMS), δ (ppm): 3.65, (8H, s), 6.78, (4H, m), 7.22 (4H, m), 7.92 (4H, m)

[0118] 13 C NMR (150MHz, D2O, TMS), δ (ppm): 137.8, 128, 120.6, 43.9, 29.3.

[0119] Mass spectrum: 336.2, 337.2, 338.2

[0120] Elemental analysis: C, 60.70; H, 5.99; N, 33.31

[0121] Intermediate I reacts with 1,3-propane sultone, the molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com