Hydrocracking catalysts for vacuum gas oil & de-metalized oil blend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

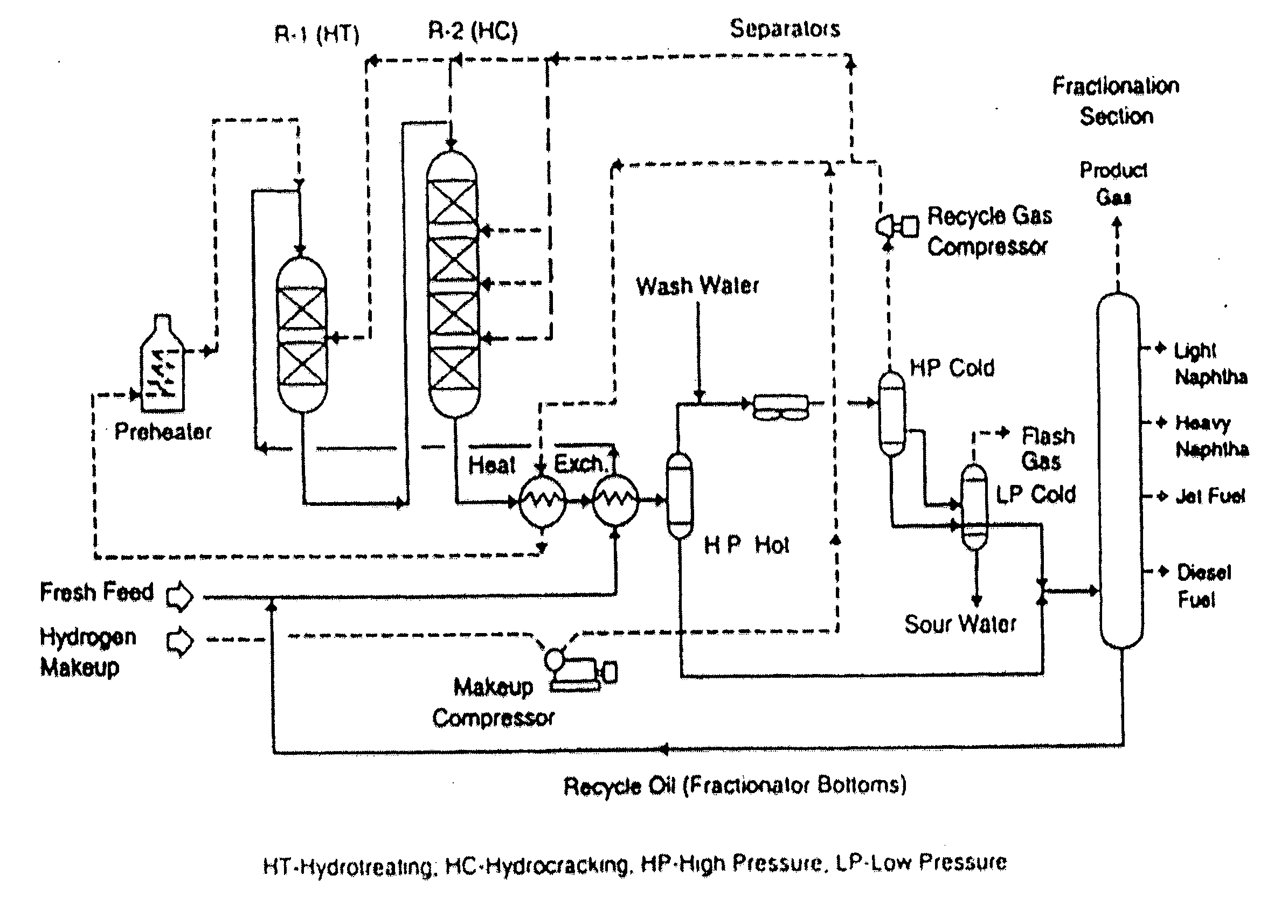

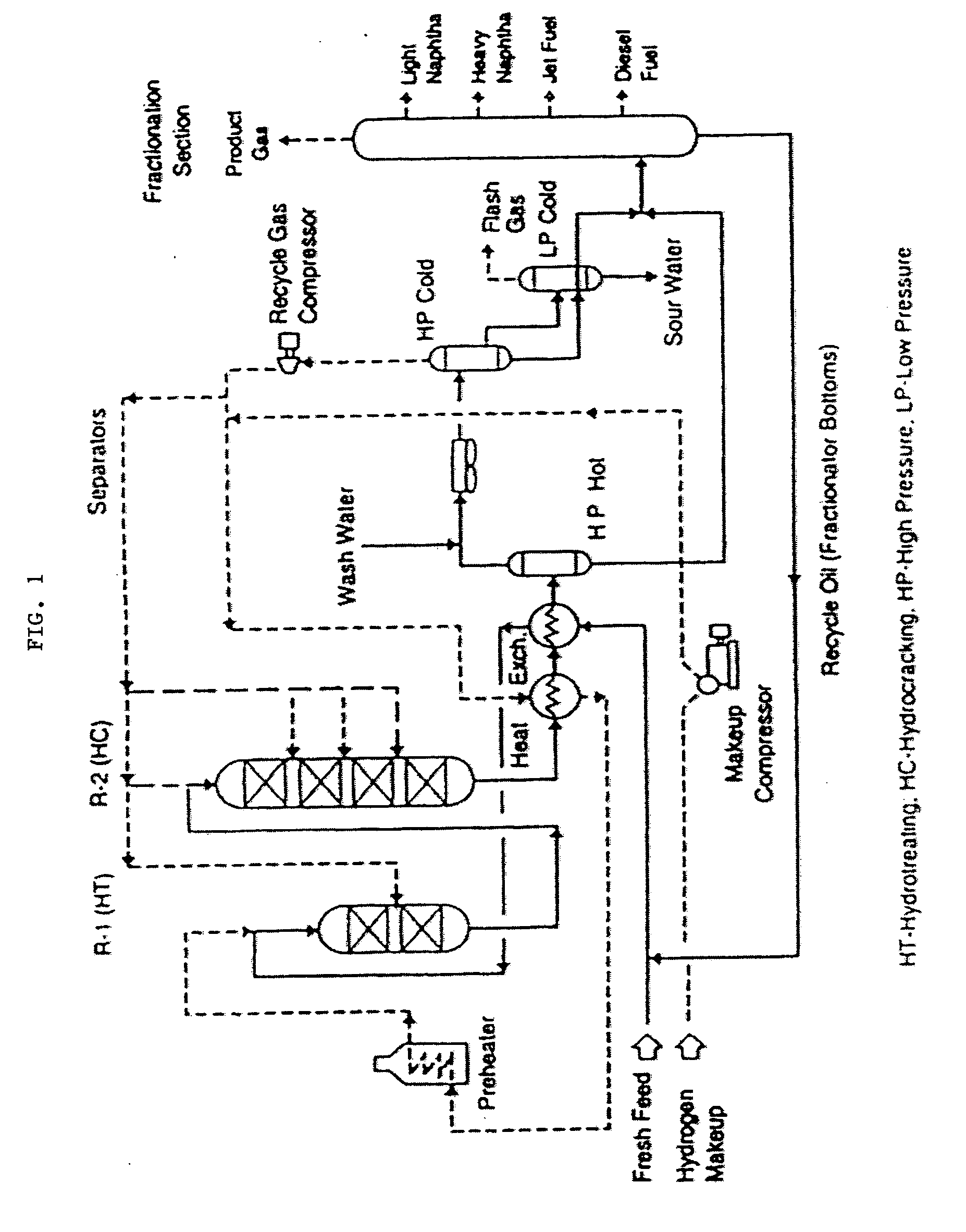

Image

Examples

Embodiment Construction

[0020] Several catalysts were prepared using nickel (Ni) / molybdenum (Mo) metals loadings along with the four different support materials identified above. The four catalyst formulations created in this manner were characterized using gas sorption analyzer, temperature programmed reduction (TPR) and temperature programmed de-sorption (TPD). Moreover, the catalyst formulations were tested in a batch reactor and compared against a commercial catalyst. The outcome of this work showed that the formulation including MCM-41 catalyst support, resulting in NiMo-MCM-41, has performed better than the commercial catalyst on heavy hydrocarbons, in particular, VGO / DMO blends. NiMo-MCM-41 showed higher hydrodesulfurization (HDS) and hydrogenation activities. In addition, it had higher conversion and higher diesel yield than commercial catalyst.

[0021] Most of the hydrocracking catalysts of commercial interest are dual functional in nature, consisting of both a hydrogenation-dehydrogenation compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com