A kind of preparation method and application of quaternary ammonium salt template agent

A technology of template agent and quaternary ammonium salt, which is applied in the field of compounds with molecular sieve and base exchange properties, can solve problems such as limitations, and achieve the effects of reducing synthesis costs, high safety, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

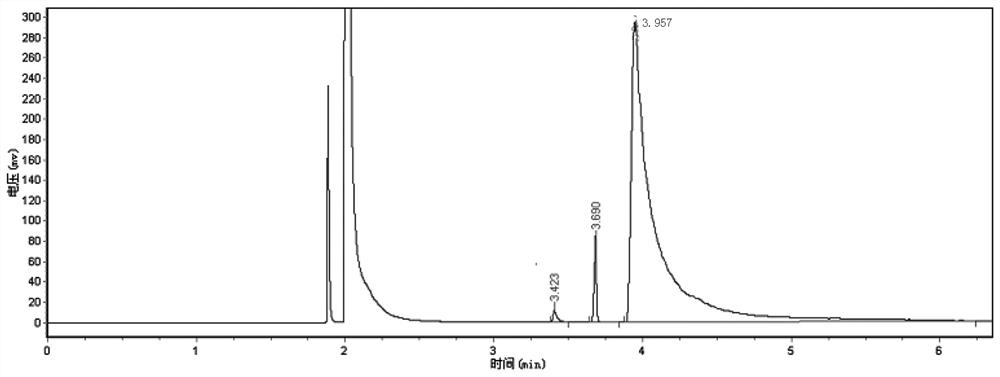

[0041] Embodiment 1: the preparation of 2,6-dimethylpiperidine

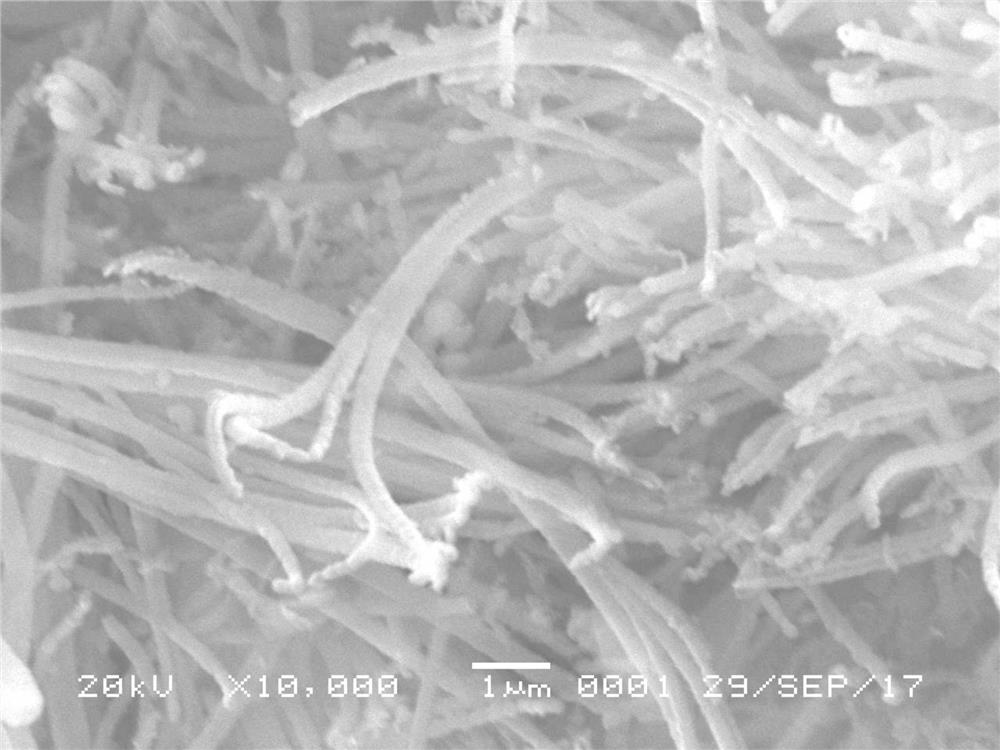

[0042] The first step supports rhodium catalyst preparation

[0043] After mixing 11.2 g (0.1 mol) of triethylenediamine and propylene chloride at a molar ratio of 1:2, and stirring and reacting at room temperature for 72 hours, a white solid was obtained, which was filtered, washed with ethyl acetate and dried to obtain an ionic liquid mono Dissolve it in DMF, add an azobisisobutyronitrile initiator, stir evenly, transfer to an autoclave, and place in an oven for 12 hours of heating solvent thermal polymerization at 120°C to obtain a super-crosslinked porous polyionic liquid. Dissolve ammonium chlororhodate in ethanol to make a 2% solution, add the above-mentioned hypercrosslinked porous polyionic liquid, control the molar ratio of ammonium chlororhodate to the ionic liquid center to be 1:8, and carry out stirring and exchange at room temperature for 12 hours After filtering, washing and drying with ethanol, a ...

Embodiment 2

[0048] Embodiment 2: Preparation of 3,5-dimethylpiperidine

[0049] Step 1: Preparation of supported rhodium catalyst

[0050] After mixing 11.2 g (0.1 mol) of triethylenediamine and propylene chloride at a molar ratio of 1:2, and stirring and reacting at room temperature for 72 hours, a white solid was obtained, which was filtered, washed with ethyl acetate and dried to obtain an ionic liquid mono Dissolve it in DMF, add an azobisisobutyronitrile initiator, stir evenly, transfer to an autoclave, and place in an oven for 16 hours of heating solvent thermal polymerization at 110°C to obtain a super-crosslinked porous polyionic liquid. Dissolve ammonium chlororhodate in ethanol to make a 2% solution, add the above-mentioned hypercrosslinked porous polyionic liquid, control the molar ratio of ammonium chlororhodate to the ionic liquid center to be 1:4, and carry out stirring and exchange at room temperature for 12 hours After filtering, washing and drying with ethanol, a loaded ...

Embodiment 3-8

[0055] Embodiment 3-8: Catalyst recycling

[0056] The catalyst in Example 1 was recovered and reused. The basic process was the same as that in Example 1. Table 1 shows the results of the impact of the repeated use of the catalyst on the reaction.

[0057] Table 1 The impact of catalyst recycling times on the reaction

[0058] Example Reuse times Yield / % Proportion of trans product / % 3 1 99 87 4 2 98 88 5 3 99 87 6 4 98 87 7 5 99 87 8 6 98 88

[0059] As can be seen from Table 1, the supported rhodium catalyst prepared by the method of the present application has high activity, and when applied to the hydrogenation reaction of dialkylpyridine, the catalytic hydrogenation of dialkylpyridine can be converted into dioxane with high efficiency and high selectivity. Even if the base piperidine is reused six times, the activity is basically not reduced, and its catalytic conversion rate is still as high as 98%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

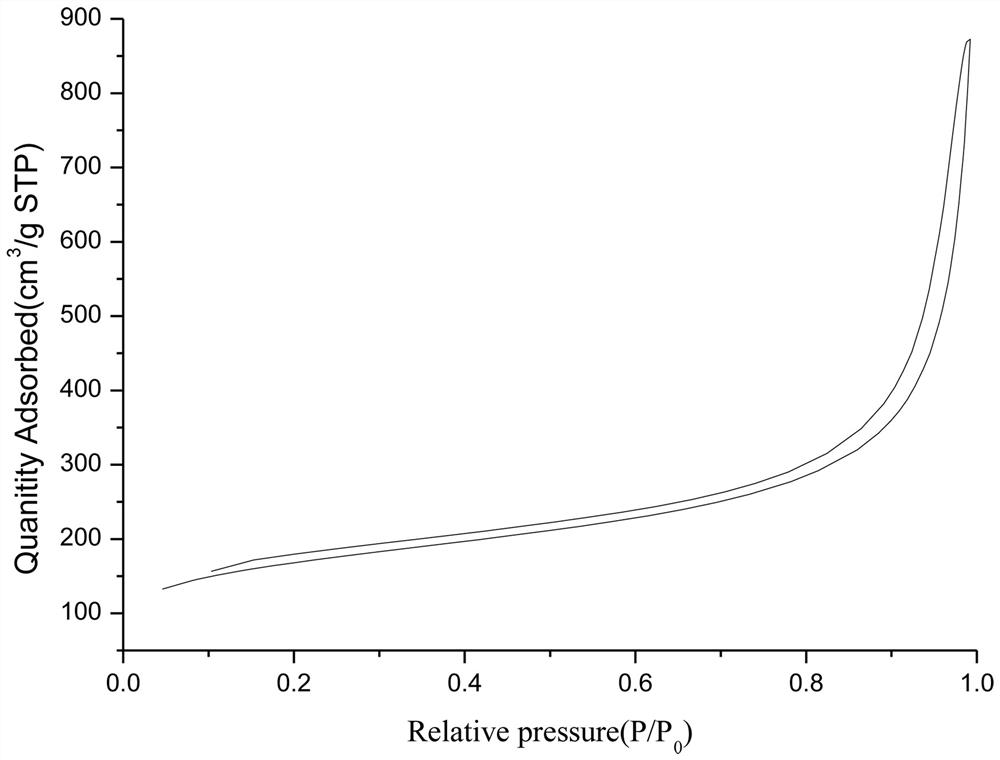

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com