Patents

Literature

59results about How to "Improve catalytic conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

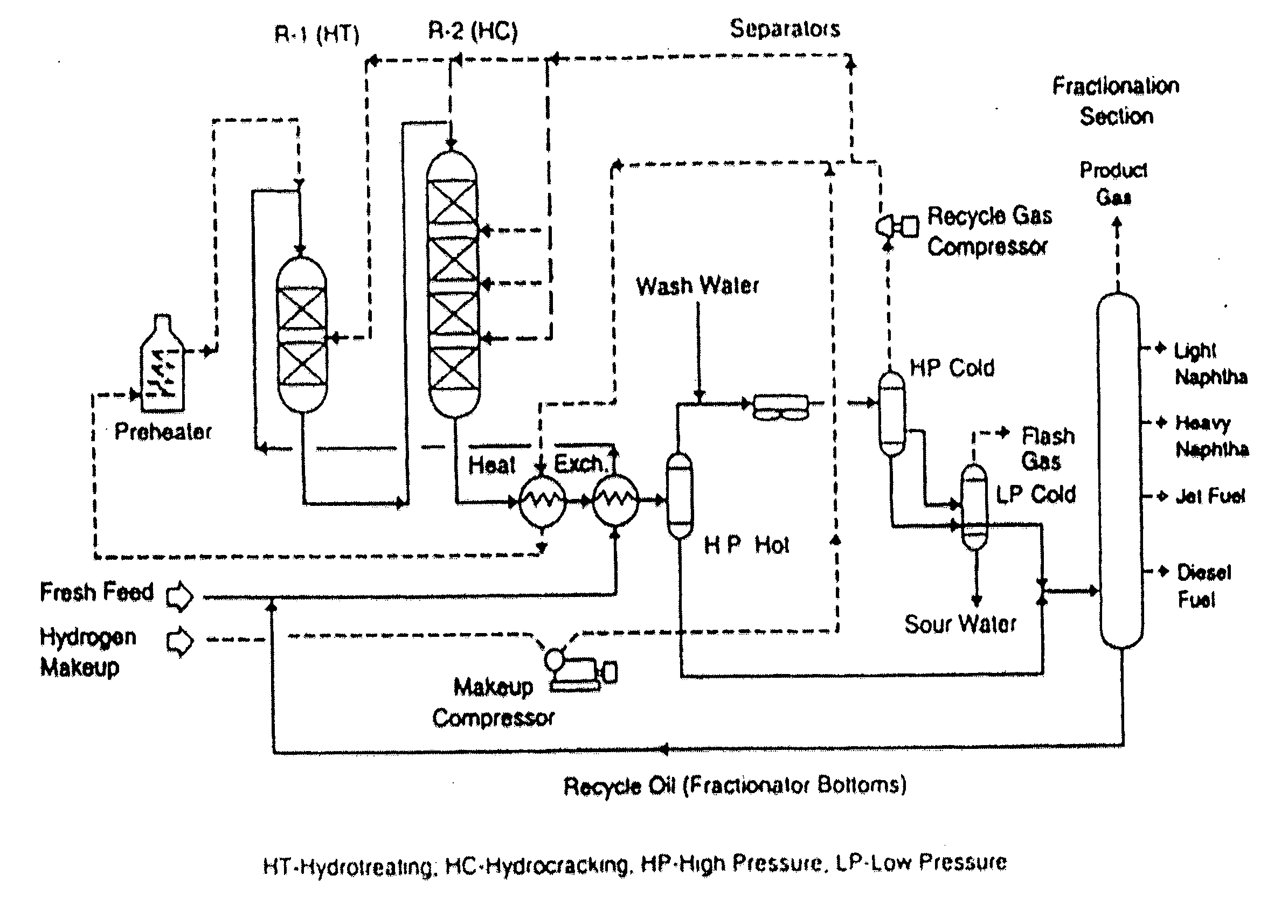

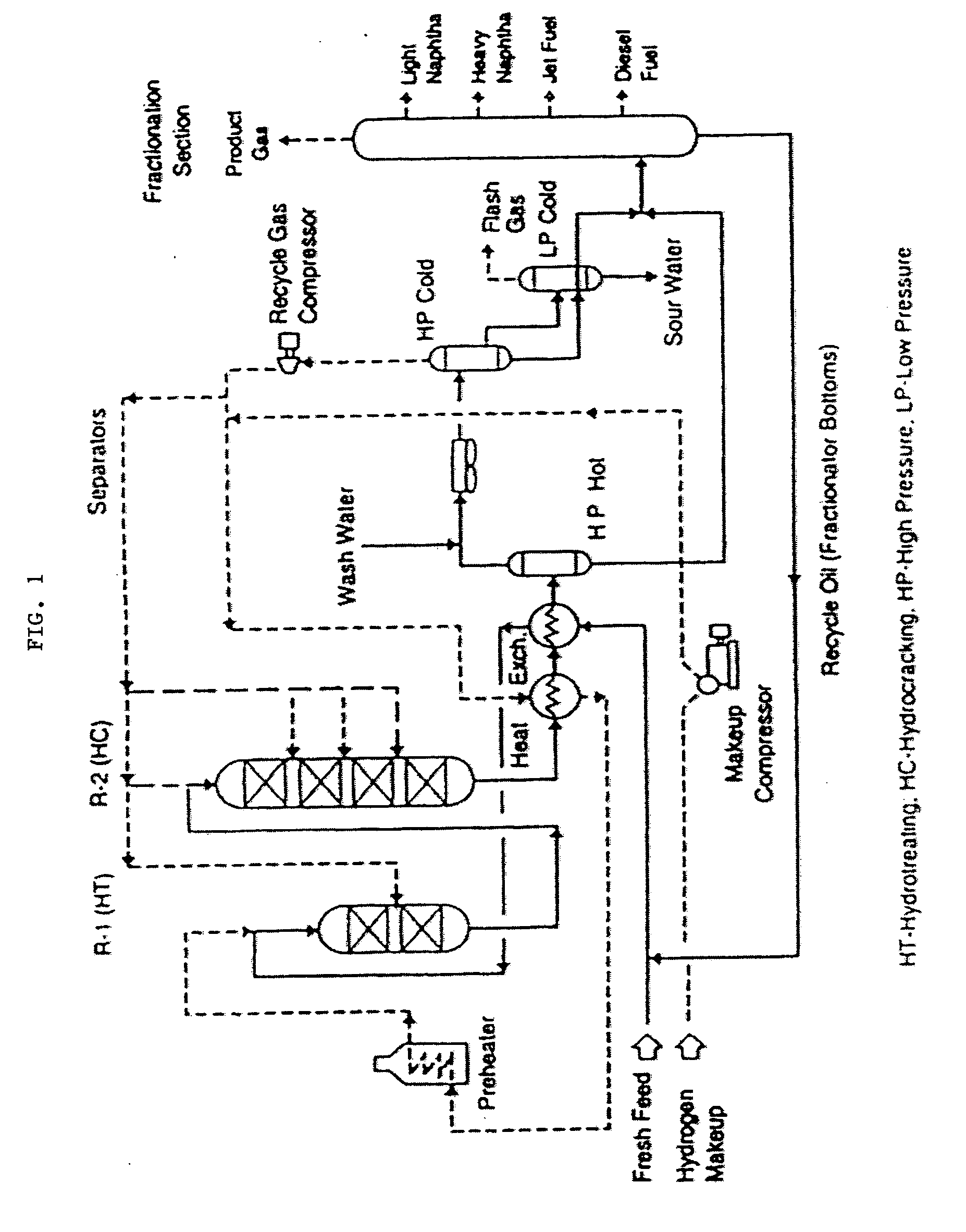

Hydrocracking catalysts for vacuum gas oil & de-metalized oil blend

InactiveUS20060157386A1Improve catalytic conversionSpeed up the conversion processCatalytic crackingMolecular sieve catalystsChemistryCarbon chain

This invention relates to a catalyst and a process for treating heavy hydrocarbons using the catalyst. The catalyst is useful for treating heavy hydrocarbons, de-metallize oil (DMO) and is particularly useful in VGO / DMO hydrocarbon blend. It is also useful for DAO. The catalyst acts to catalytically convert the VGO / DMO blend to shorter-chain valuable hydrocarbon products. The catalyst includes a catalytic support material, a catalytic metal impregnated upon the catalytic support material, and a promoter metal on the catalytic support material to enhance catalytic conversion. The combination of the catalytic support material with catalytic metal and promoter metal is operable to catalytically convert VGO / DMO into hydrocarbon products having shorter carbon chains.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

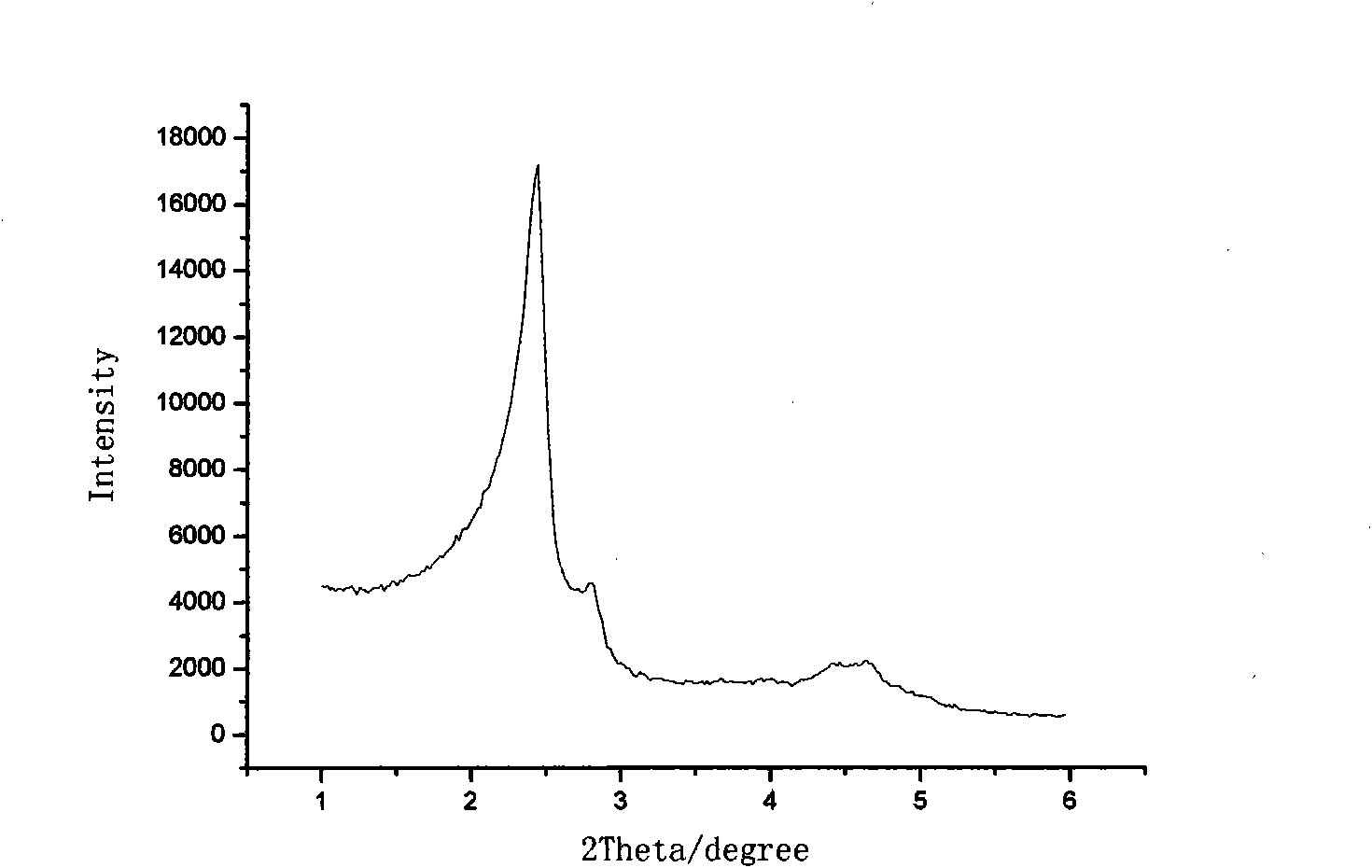

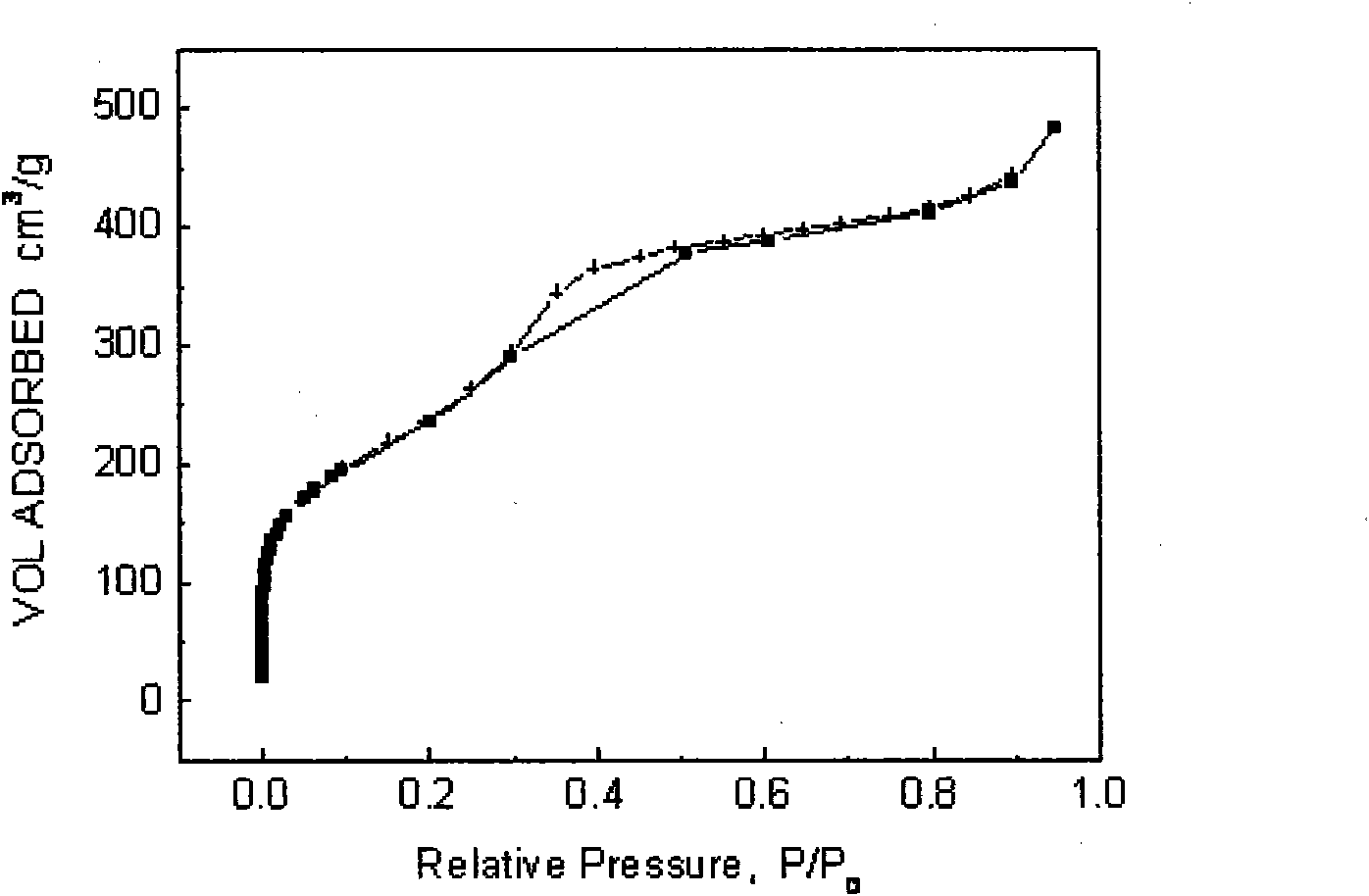

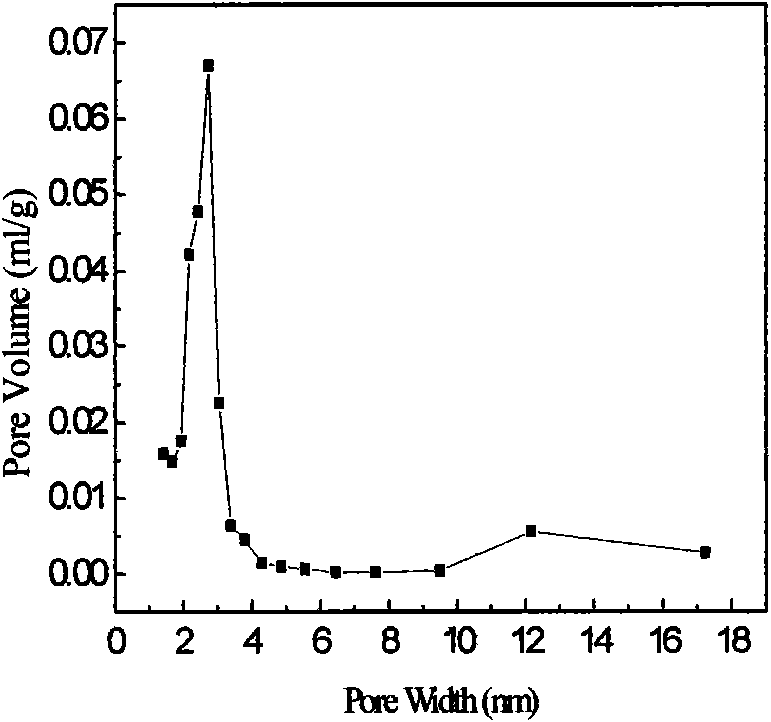

Cubic mesoporous molecular sieve catalyst with micropore canals, preparation method and use thereof

InactiveCN101683620AHigh catalytic activityGood choiceMolecular sieve catalystsHydrocarbonsMicrowaveSynthesis methods

The invention relates to a cubic mesoporous molecular sieve catalyst with micropore canals, a preparation method and use thereof. The catalyst comprises the raw materials of an aluminium source, a silicon source, sodium hydroxide, a template, surfactant and de-ionized water, and is prepared through the following steps: firstly preparing a silicon-aluminium precursor; and then utilizing a self-assembly function between the precursor and the surfactant to obtain stable molecular sieve materials. The preparation method comprises two methods of hydro-thermal synthesis and microwave synthesis. Dueto the adoption of the microwave synthesis method, the cubic mesoporous molecular sieve catalyst in the invention has the advantages of shortening the crystallization time, obtaining a synthesized molecular sieve with a cubic mesoporous structure, having micropore canals, having acid strength similar to that of a ZSM-5 molecular sieve, and having relatively higher catalytic activity when used forthe catalytic cracking reaction of 1,3,5-tri-isopropyl benzene.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

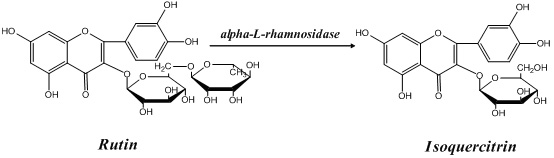

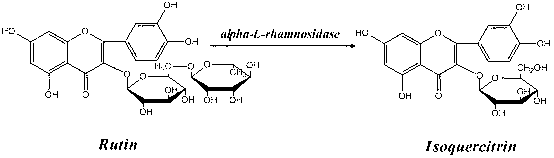

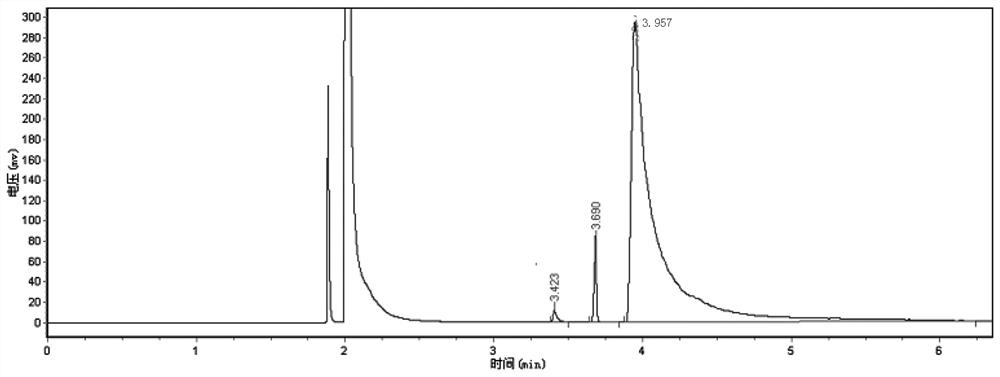

Application of alpha-L-rhamnoside enzyme in directional synthesis of isoquercitrin by biological conversion of rutin

ActiveCN101985639AImprove catalytic conversionLow costOn/in organic carrierFermentationPtru catalystEnzyme catalysis

The invention relates to application of an alpha-L-rhamnoside enzyme in the directional synthesis of isoquercitrin by the biological conversion of rutin. Because the crude enzyme preparation or the immobilized enzyme preparation of the alpha-L-rhamnoside enzyme is used for catalyzing and hydrolyzing the rutin and directionally and biologically synthesizing the isoquercitrin, the application has the advantages of wide source, easy preparation and low cost of catalysts, high stability, and high catalysis efficiency and specificity of the enzyme preparation, and is easy to store. Thus, the alpha-L-rhamnoside enzyme can greatly reduce the production cost of quercetin, the catalysis and conversion rate of the enzymes is high, and the products are single.

Owner:JIANGSU UNIV OF SCI & TECH

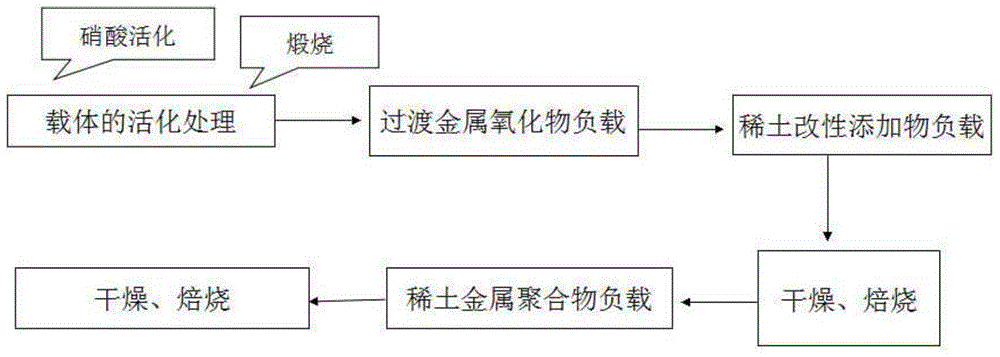

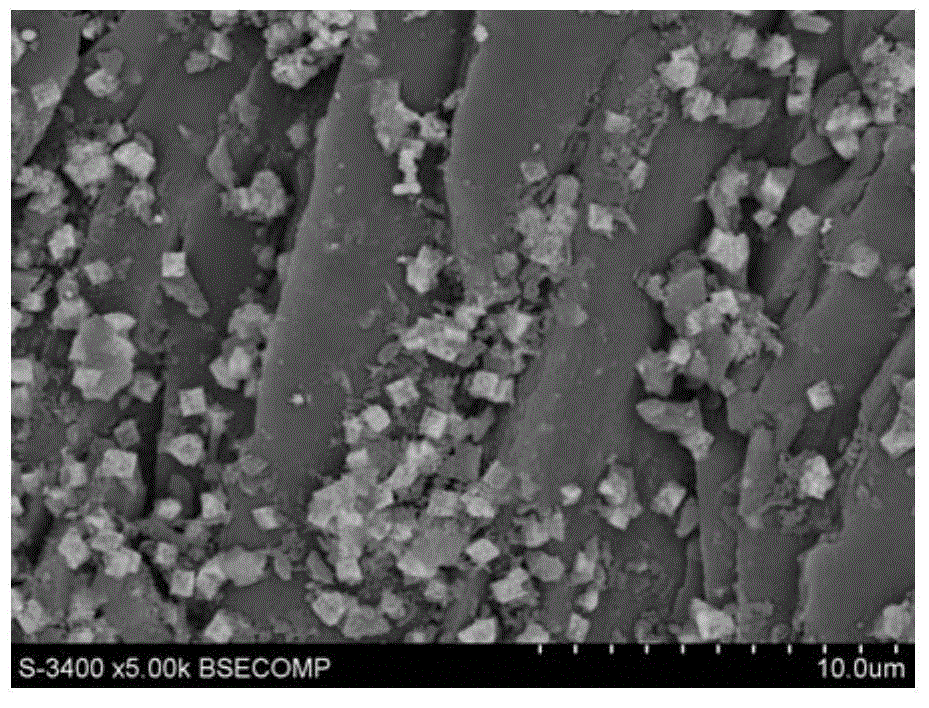

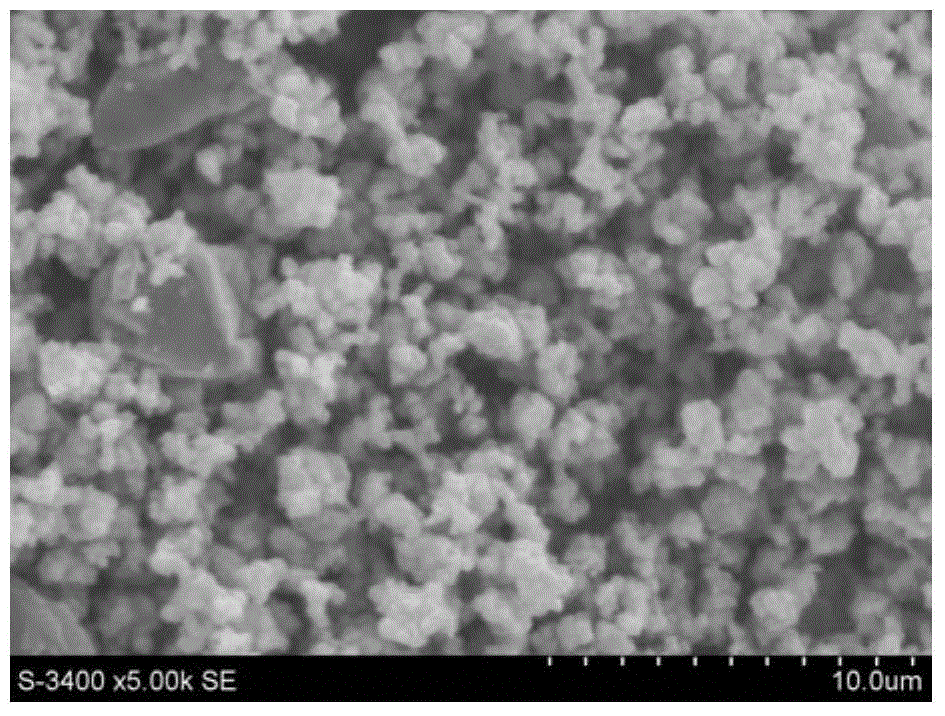

Selective catalytic reduction denitration catalyst, preparation method and application thereof

InactiveCN104785302AHigh catalytic activityImprove anti-sintering performanceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationMetal frameworkSulfur

The invention relates to the technical field of denitration, in particular to a selective catalytic reduction denitration catalyst, a preparation method and application thereof. The catalyst is prepared from a carrier, transition metal oxide loaded on the carrier, and a rare earth modification additive, as well as a rare earth metal polymer distributed on the carrier as a porous mesh metal frame structure, wherein the total load capacity of the transition metal oxide, the rare earth modification additive and the rare earth polymer on the carrier is 25-35%. The catalyst disclosed by the invention is excellent in catalytic activity at a temperature interval from 200 DEG C to 400 DEG C; the denitration conversion ratio can be up to 90% above; meanwhile, the trace of rare earth modification additive is added to the catalytic system to effectively improve the sintering resistance of the catalyst; the catalyst can effectively improve the lead and sulfur toxic resistance of the catalyst, widens the low temperature reaction window, and prolongs the service life of the catalyst.

Owner:北京大学包头创新研究院

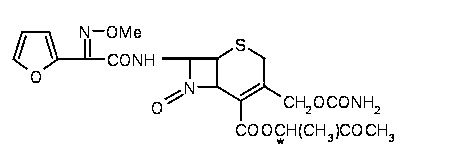

Preparation method of cefuroxime axetil

The invention discloses a preparation method of cefuroxime axetil. The method comprises the following steps: completely dissolving cefuroxime acid in dimethylformamide, and carrying out esterification reaction with 1-bromethylacetate under the catalytic action of cupric chloride; and hydrolyzing with ethyl acetate and sodium chloride solution, extracting, carrying out vacuum distillation, crystallizing with cyclohexane, carrying out vacuum filtration, and drying to obtain high-purity cefuroxime axetil. The cupric chloride, which has the advantages of no toxicity, no harm and high catalytic efficiency, is preferably used as the catalyst; the cyclohexane for crystallization is easy to recover and reutilize, thereby lowering the production cost; and meanwhile, the method has the advantages of mild and controllable reaction conditions, short production cycle and lower energy consumption, and is suitable for industrial production.

Owner:GUANGDONG LIGUO PHARMACY

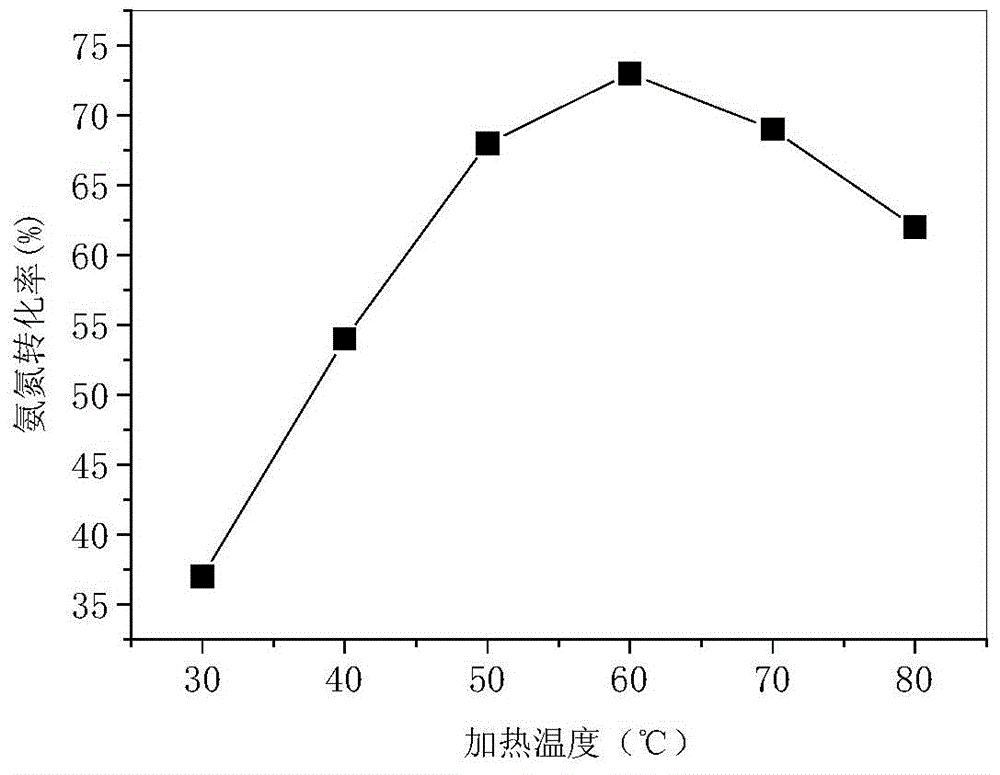

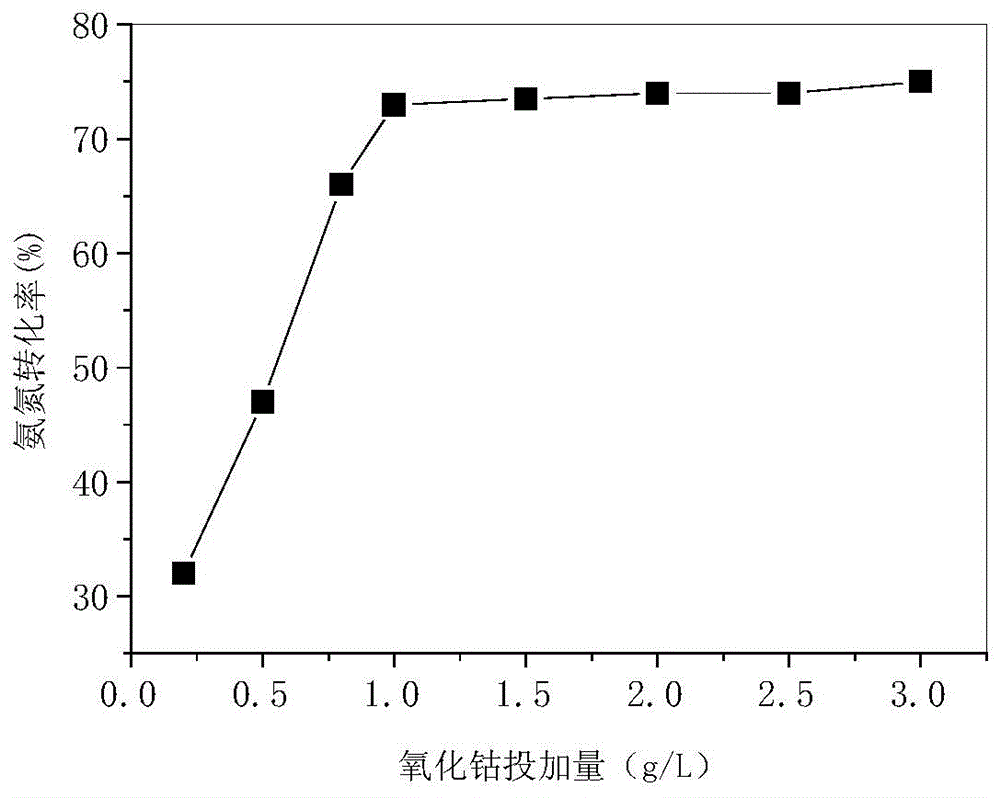

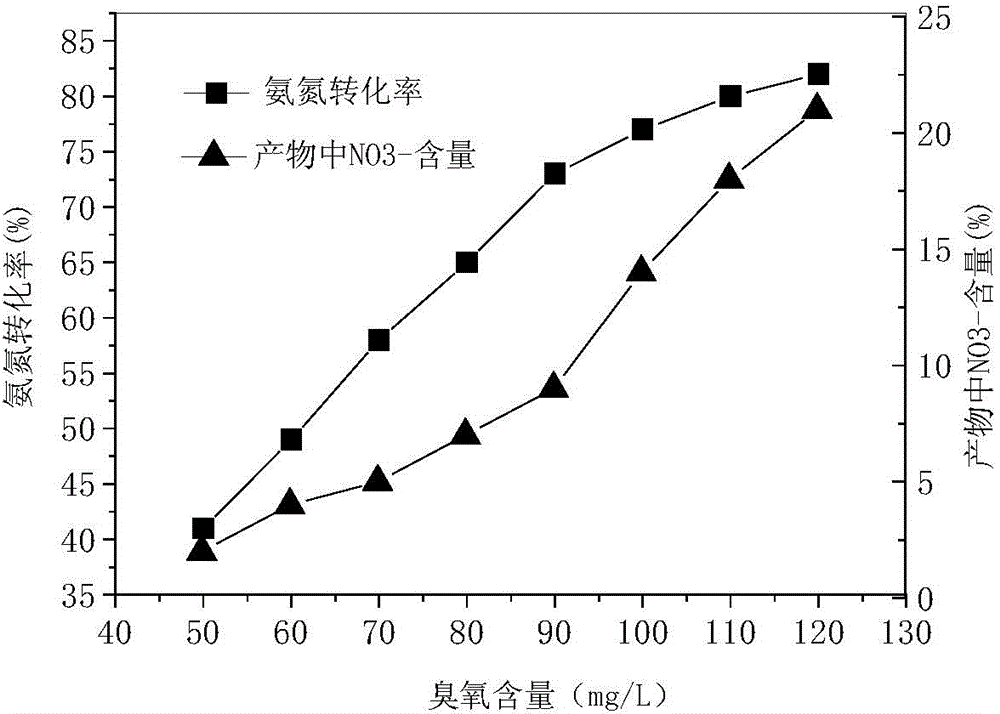

Process for treating ammonia-nitrogen wastewater with medium and low concentration through catalytic ozonation of metallic oxides

InactiveCN104445577AImprove catalytic conversionWater treatment compoundsWater contaminantsCatalytic oxidationNitrogen

The invention relates to the technique of ammonia-nitrogen wastewater treatment, particularly relates to a process for treating ammonia-nitrogen wastewater with medium and low concentration through catalytic ozonation of metallic oxides. The process comprises the following steps: introducing O2 into ammonia-nitrogen wastewater with medium and low concentration at a flow rate of 100mL / min and heating to 30-80 DEG C; at the temperature of 30-80 DEG C, adding a catalyst cobaltous oxide (Co3O4) powder into the ammonia-nitrogen wastewater, introducing O3 / O2 mixed gas at a total flow rate of 100mL / min and carrying out catalytic oxidation on ammonia and nitrogen in water for 2-8h continuously, wherein the addition amount of the catalyst cobaltous oxide is 0.2-3.0g / L and the addition amount of O3 is 50-120mg / L, the percent conversion of NH4<+>-N is 37-73%, and the NO3- content of products is 2-21%. The process is high in purification efficiency, simple in flow and free of secondary pollution.

Owner:JIANGXI UNIV OF SCI & TECH

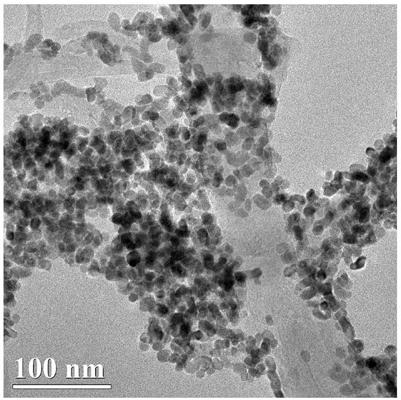

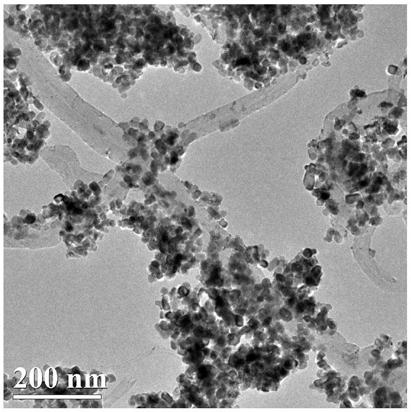

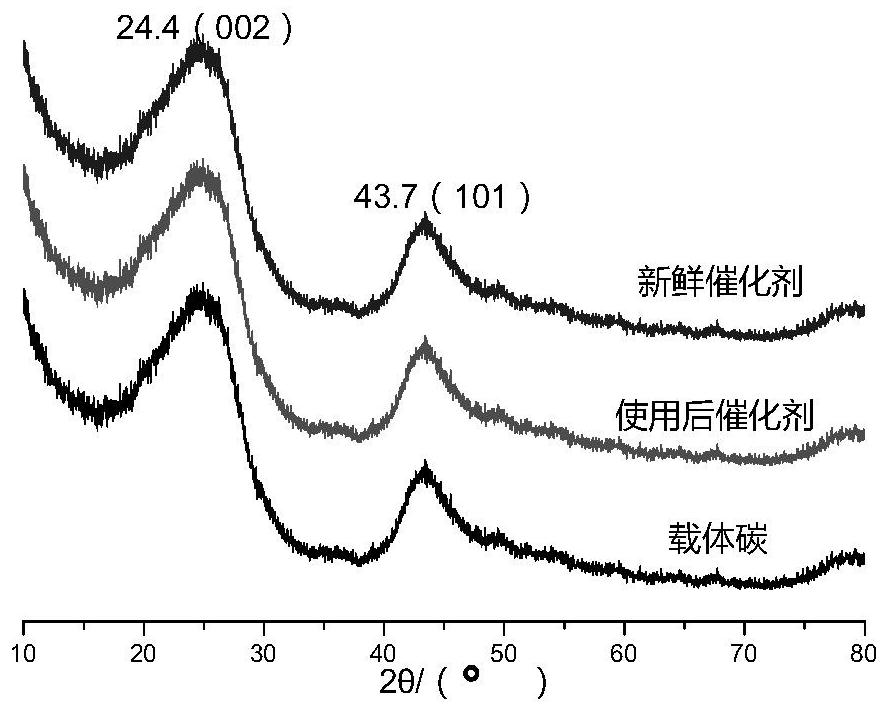

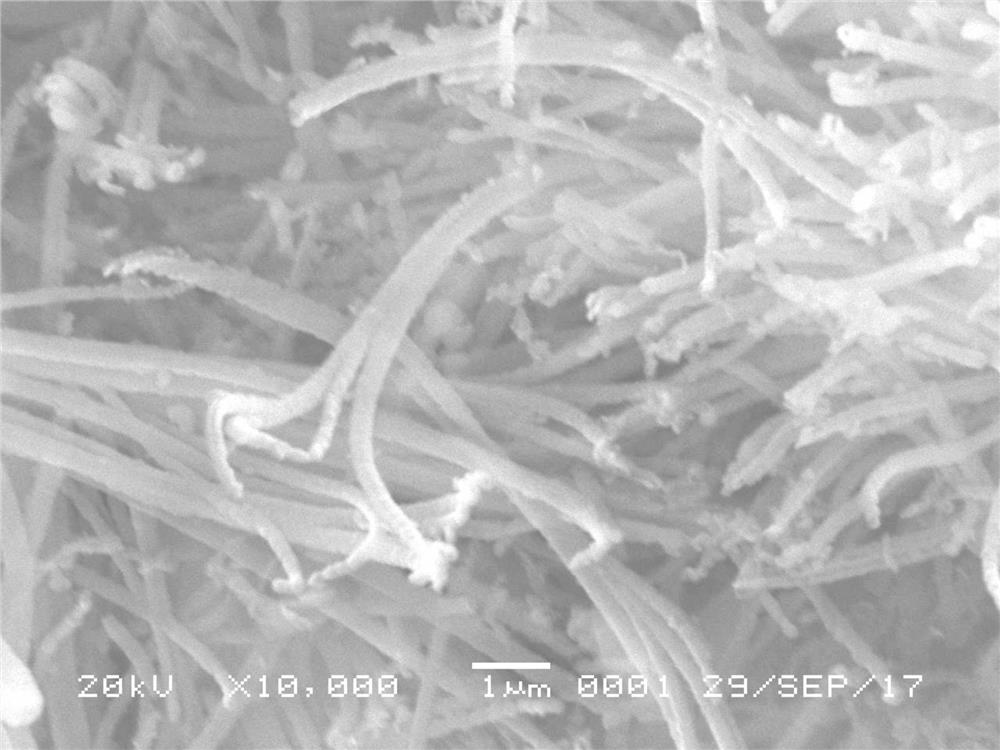

Fe-CNx nano composite catalyst as well as preparation method and application thereof

InactiveCN104069885AEvenly heatedNo hysteresisMolecular sieve catalystsLiquid hydrocarbon mixture productionPtru catalystIron salts

The invention belongs to the technical field of energy material, and particularly relates to a Fe-CNx nano composite catalyst as well as a preparation method and the application of the catalyst. The preparation method comprises the steps of firstly dipping soluble iron salt onto a molecular sieve; after that, feeding organic amine into a tube furnace, and treating by microwave heating to obtain a nitrogen-doped carbon nanotube CNx; loading iron salt onto the carbon nanotube CNx to obtain the final Fe-CNx nano composite catalyst. The preparation method is simple in technology, easy to control, wide in raw material source and low in price of raw material; the obtained Fe-CNx nano composite catalyst is good in repeatability, can be used for coal direct liquefaction hydrogenation catalytic reaction, and is capable of effectively improving the hydrogenation effect of the coal liquefaction reaction, so that the oil yield and the conversion rate of coal liquefaction are improved. Furthermore, when the catalyst is applied to the coal direct liquefaction hydrogenation catalytic reaction, microwave heating is adopted, so that the temperature of a reaction system rapidly rises, a sample is more evenly heated, the reaction time is shortened, and the reaction energy consumption is reduced.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Production art of cellular catalyst carrier using natural zeolite as principal raw material

InactiveCN100563828CImprove adsorption capacityGood dispersionMolecular sieve catalystsCatalytic transformationPtru catalyst

A high-efficiency honeycomb-shaped catalyst carrier production process, characterized in that the natural zeolite is crushed into powder, injected with dilute hydrochloric acid and stirred evenly, after standing still, the zeolite powder is rinsed with water to neutrality; clay, mixed rare earth oxidation are added to the zeolite powder After mixing evenly, put it into a vacuum kneader to fully bond and extrude it into a honeycomb semi-finished product through a mold. Put the honeycomb (made) semi-finished product into the activation furnace, dry it at low temperature, then raise the temperature to 500°C-600°C, and wait for it to cool to become the finished honeycomb catalyst carrier. The invention has the advantages of simple preparation process, low cost and energy consumption, and the finished carrier product has good adsorption performance and metal cation exchange performance, which can greatly reduce the usage of rare and precious metals in the active components of the catalyst and improve the catalytic conversion rate.

Owner:胡琳

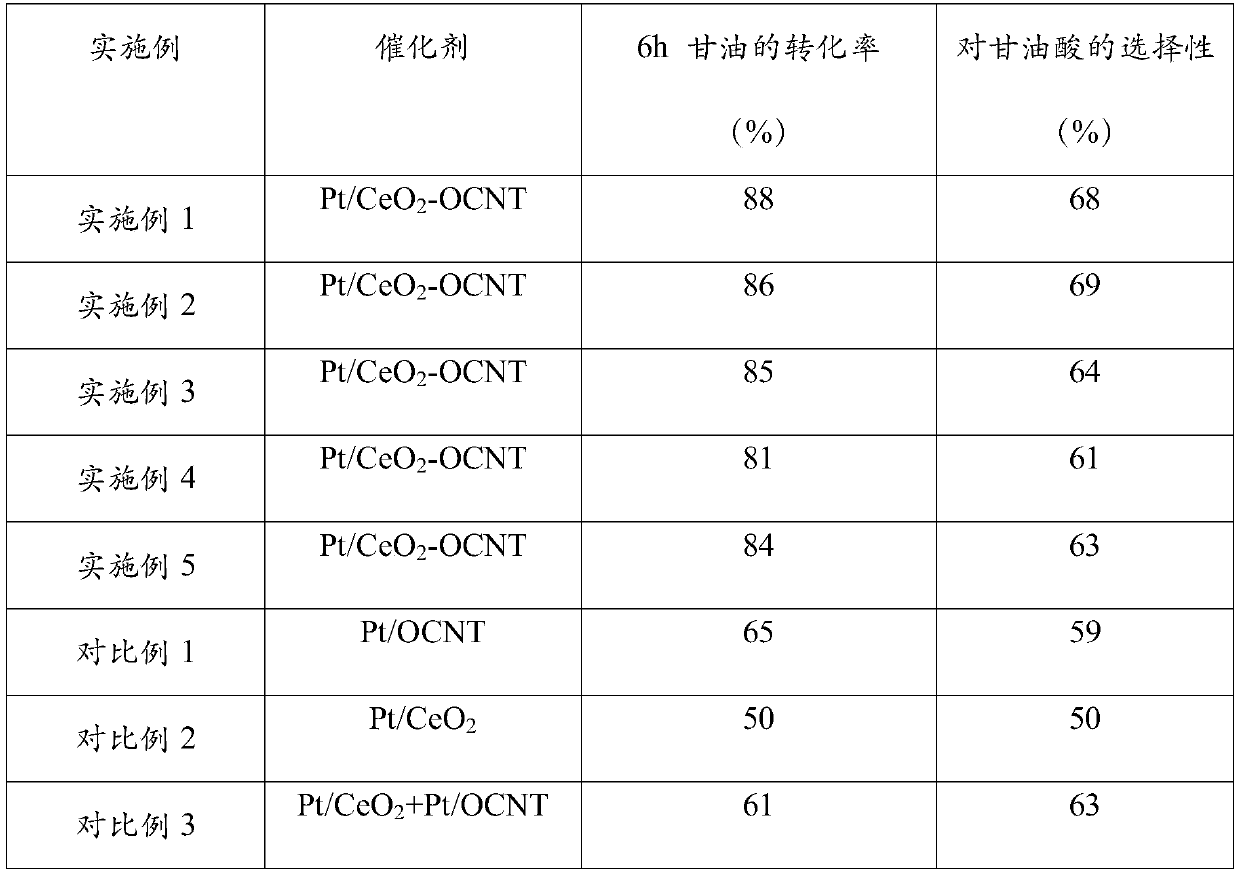

Three-way catalyst for preparing glyceric acid by oxidizing glycerol and preparing method thereof

InactiveCN109621951AReduce consumptionImprove catalytic conversionOrganic compound preparationCarboxylic compound preparationGlyceric acidCarbon nanotube

The invention relates to a three-way catalyst for preparing glyceric acid by oxidizing glycerol and a preparing method thereof. In the three-way catalyst, precious metal serves as an active component,rare earth oxide and carbon nanotubes serve as a carrier, and the mass ratio of the precious metal, the rare earth oxide and the carbon nanotubes is (0.02-0.05):(1.0-3.0):1.0; the carbon nanotubes are selected from at least one kind of unprocessed carbon nanotubes, carbon nanotubes oxidized with concentrated nitric acid, carbon nanotubes oxidized with concentrated sulfuric acid, carbon nanotubesprocessed with KON and carbon nanotubes processed with PEG. Compared with a metal / carbon-carrier binary catalyst, the three-way catalyst has higher catalytic activity and higher glyceric acid selectivity in the process of a glycerol selective oxidation reaction conducted under the neutral condition. The preparing method is easy and convenient to operate, instrument equipment is simple, and energyconsumption is low.

Owner:INNER MONGOLIA UNIVERSITY

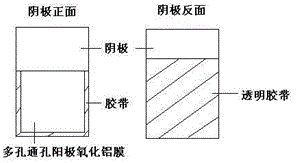

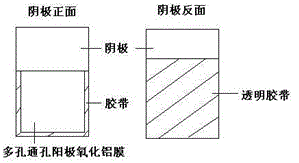

Nickel-copper-rare earth-aluminum oxide catalysis separation composite film and preparation method and application thereof

InactiveCN102908909AImprove catalytic conversionHas the ability to resist hydrogen embrittlementSemi-permeable membranesHydrogen separation using solid contactMixed gasAluminium oxides

The invention discloses a nickel-copper-rare earth-aluminum oxide catalysis separation composite film and a preparation method and the application thereof. The method includes adopting an electroplating method to plate a nickel-copper-rare earth film on the surface of a porous through hole anode alumina film. In the preparation process, the nickel-copper-rare earth film bonded to a cathode and plated on the face is compact in structure, and the thickness of the nickel-copper-rare earth film is 0.1-0.5mum. Finally, the nickel-copper-rare earth-aluminum oxide catalysis separation composite film with multiple nanometer holes on one face and the nickel-copper-rare earth film on the other face is formed. The nickel-copper-rare earth-aluminum oxide catalysis separation composite film is applied to reproduction of hydrogen by catalyzing methane and water vapor and separation of hydrogen in mixed gas. Finally, the methane catalysis and conversion rate is 100%, the hydrogen transmission rate is 7.52-8.02*10-6mol*m-2*s-1Pa-1, the separation coefficient of the hydrogen obtained in reproduction of hydrogen by catalyzing methane and water vapor is 996-1002, and the separation coefficient of the hydrogen in the mixed gas is 1000-1008.

Owner:SHANGHAI INST OF TECH

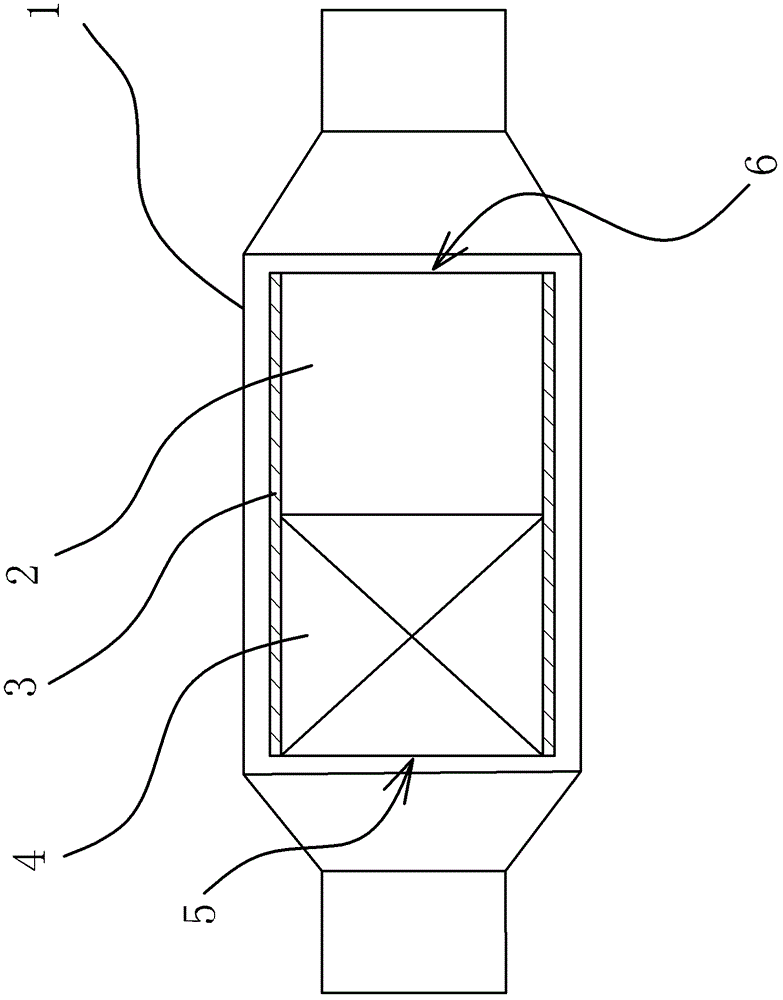

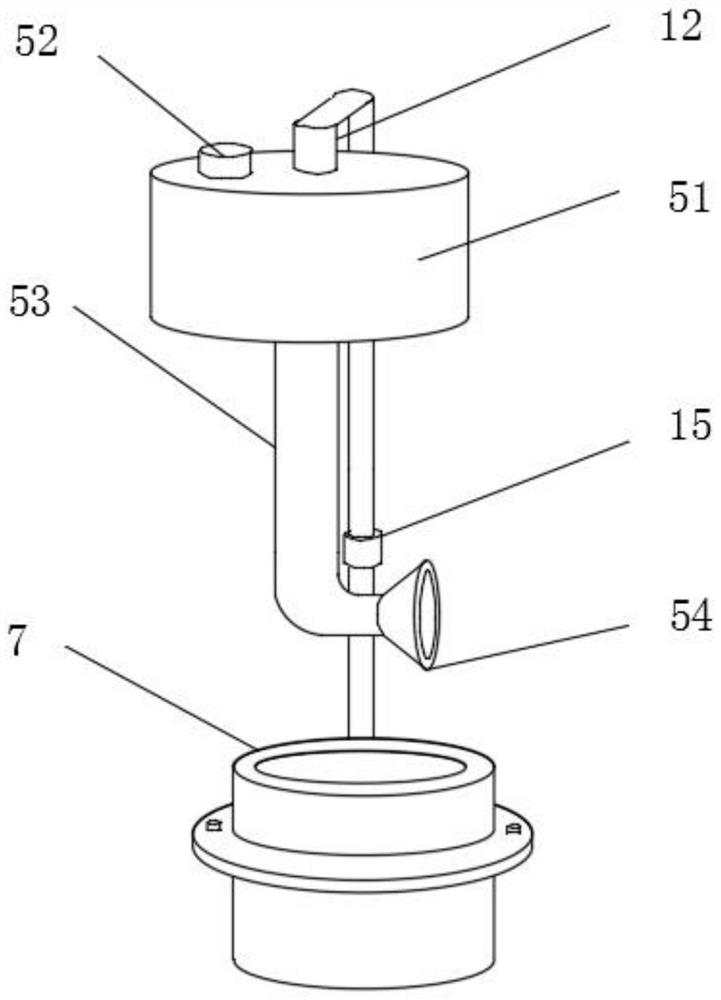

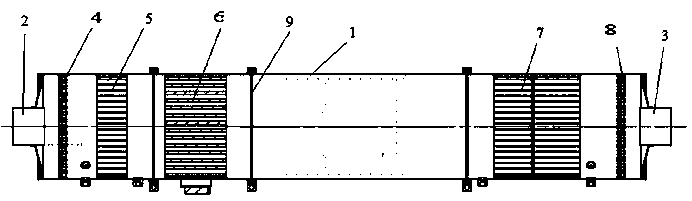

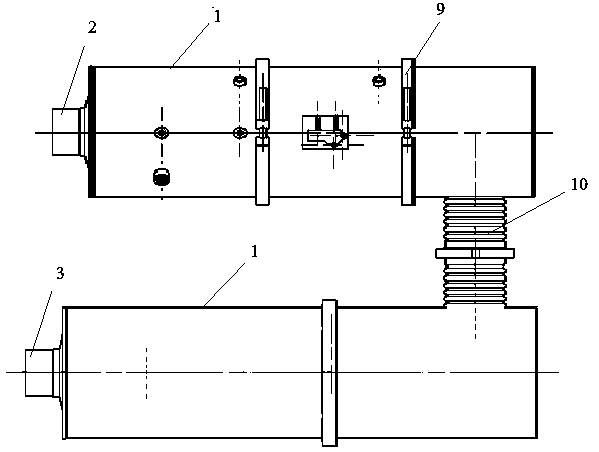

Ternary catalytic converter and method for coating catalytic layers thereof

ActiveCN102400745BImprove catalytic performanceImprove catalytic conversionLiquid surface applicatorsInternal combustion piston enginesTernary catalystChemistry

The invention relates to a ternary catalytic converter and a method for coating catalytic layers thereof. The ternary catalytic converter comprises a shell and a carrier arranged in the shell, wherein a catalytic layer I prepared by adopting a ternary catalyst I and a catalytic layer II prepared by adopting a ternary catalyst II are sequentially coated on the inner surface of the carrier from an air inlet to an air outlet; and the ternary catalyst II has the precious metal content being lower than that in the ternary catalyst I. Compared with the prior art, the ternary catalytic converter has the advantages that because the catalysts are coated in a partitioning manner, the structure is novel, the integral catalytic performance of the catalytic converter is increased, the catalytic conversion rate of the ternary catalytic converter during cold start is increased, the integral catalytic conversion rate of the ternary catalytic converter is increased, and the pertinence and the catalytic performance are strong; in addition, the method for coating the catalytic layers of the ternary catalyst is simple in process, can be used for ensuring the coating uniformity of the catalysts and is suitable for actual industrial production.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

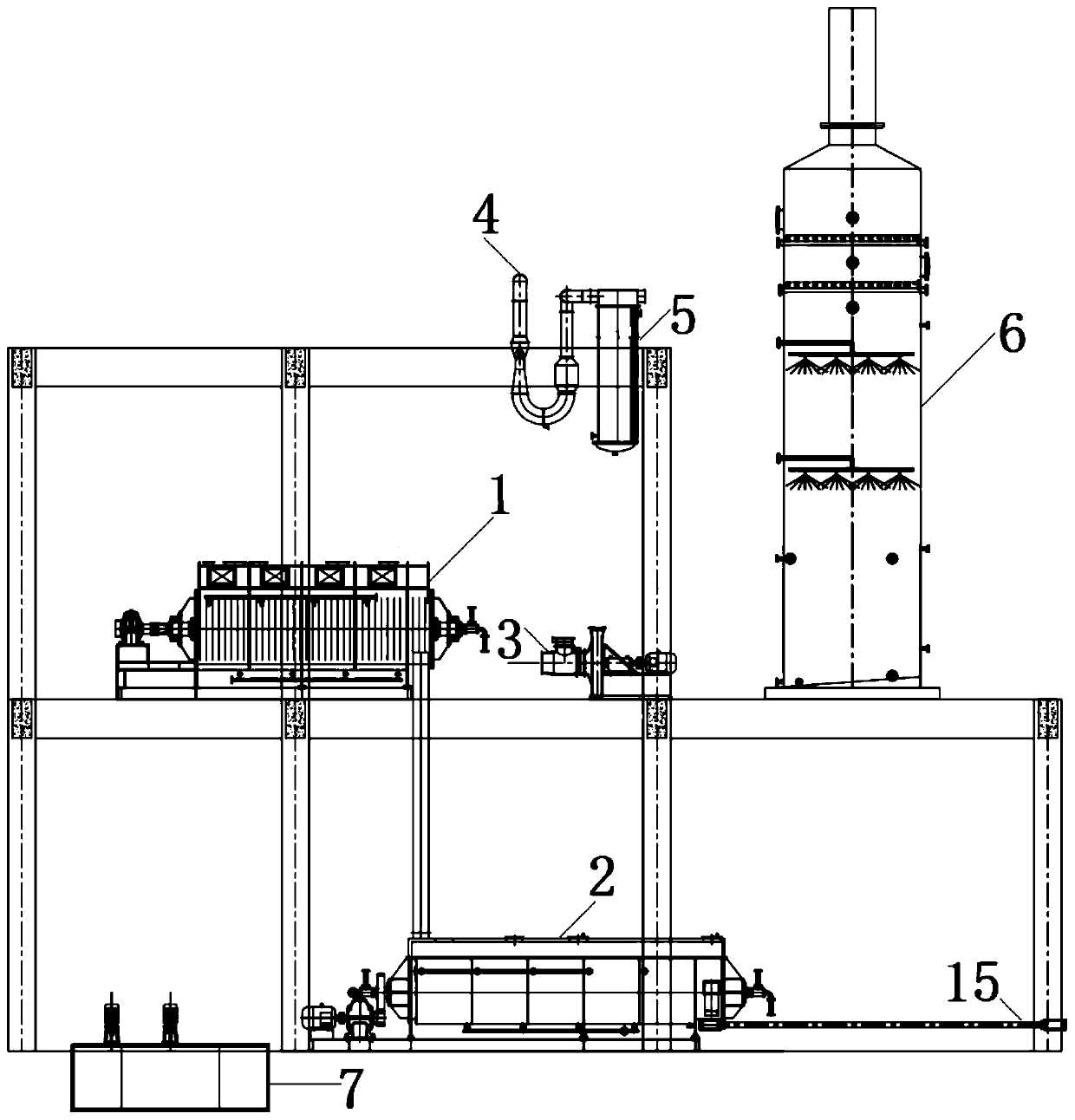

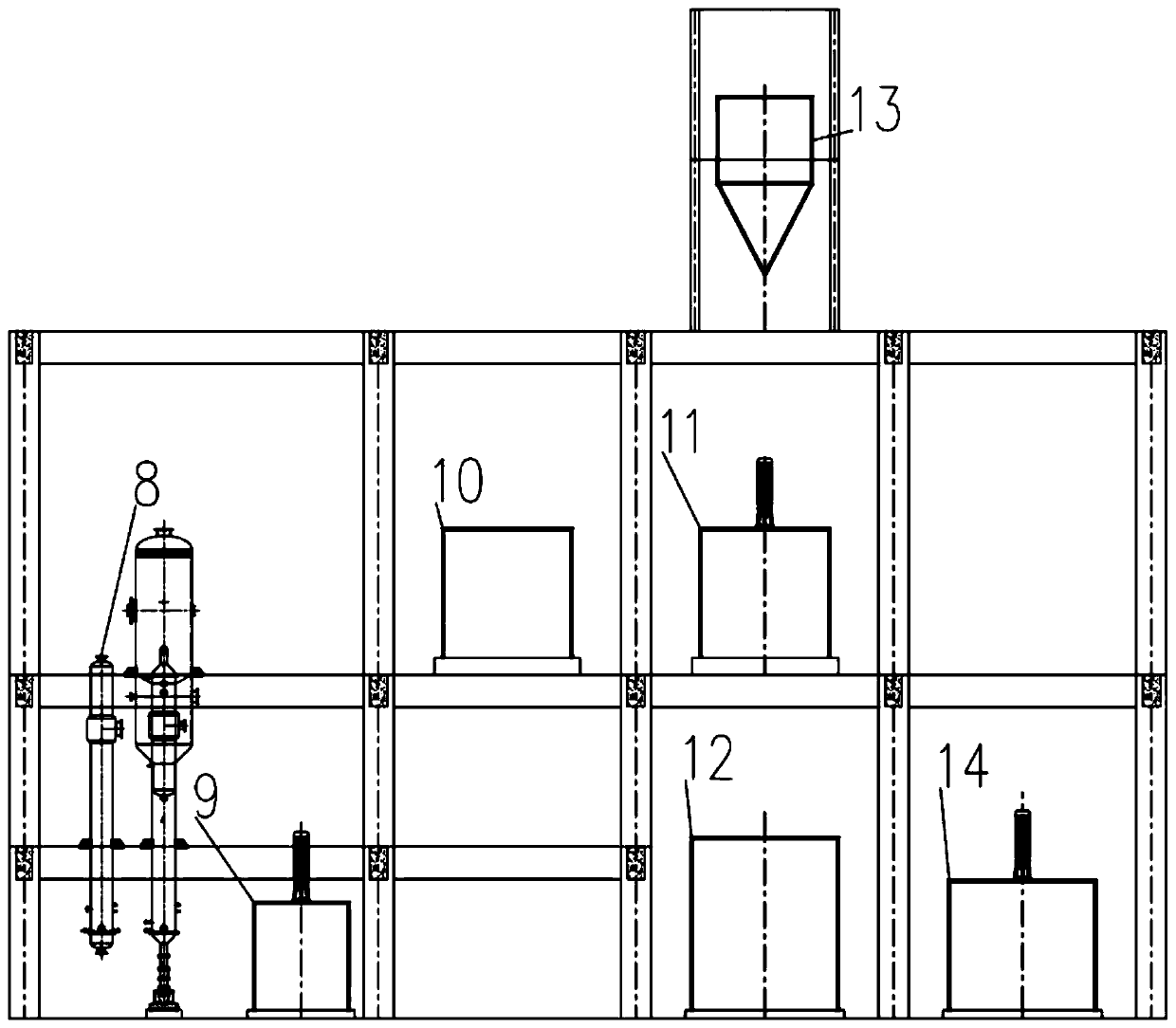

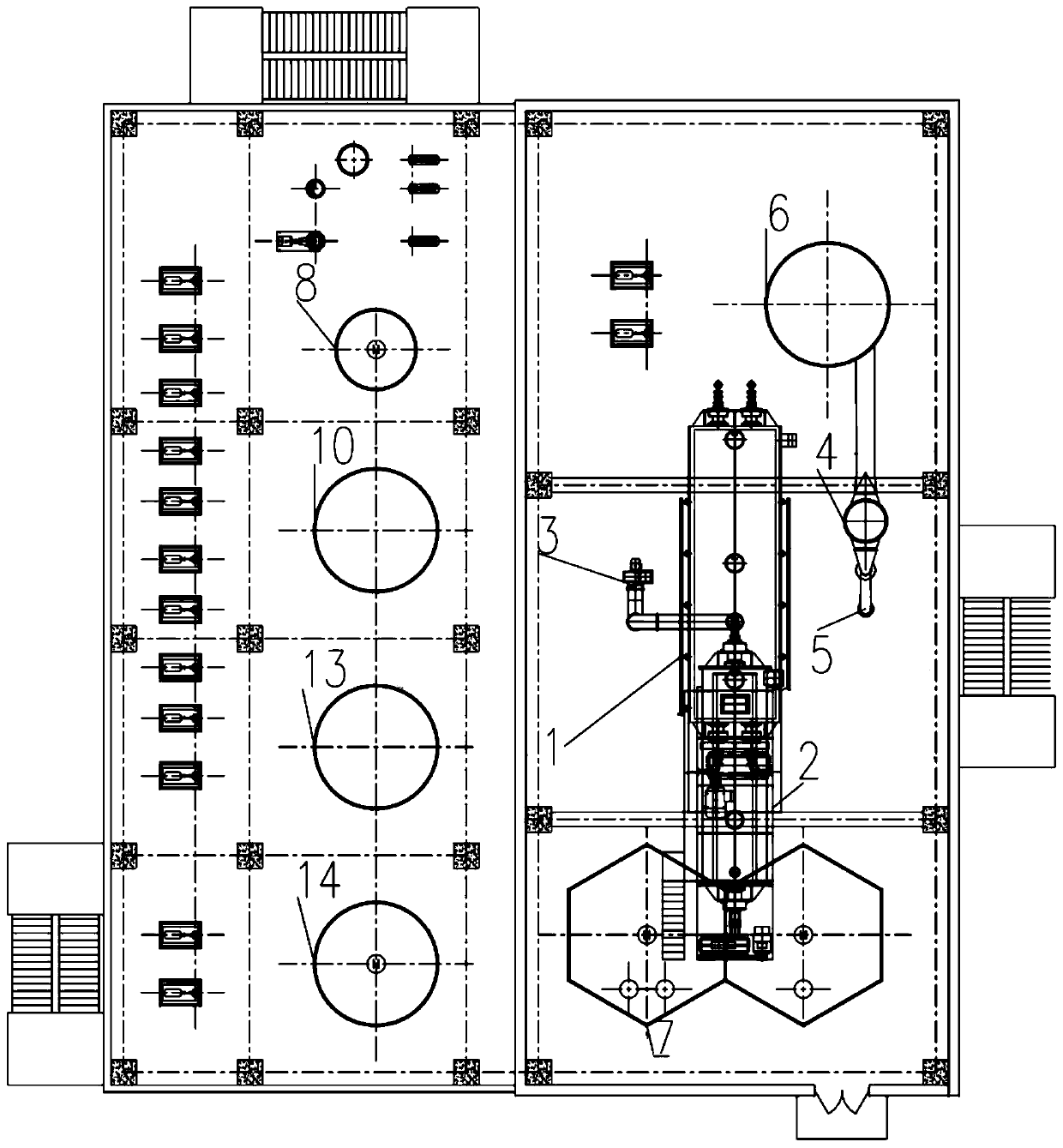

Device for utilizing desulfurization waste liquid and operation method thereof

PendingCN111232934AAvoid secondary pollutionAvoid saturationSteam generation heating methodsSulfur compoundsPtru catalystAdhesive

The invention discloses a device for utilizing desulfurization waste liquid and an operation method thereof. The device comprises a pretreatment adjusting section, a drying curing and tail gas section, a sulfur burning section, a cooling section, a washing section, a conversion absorption section and a tail gas treatment section. The invention further provides an operation method of the device forutilizing the desulfurization waste liquid, wherein comprehensive treatment is conducted on the desulfurization liquid and sulfur foam generated in the coking HPF wet desulfurization process, so thatthe waste is turned into resources, internal circulation is achieved, secondary pollution is eradicated, the production cost is saved, automatic control is achieved, and energy consumption is reduced. Sulfuric acid is prepared through the two-conversion and two-absorption process, a vanadium catalyst is used, a converter uses a refractory fiber adhesive, a ceramic fiber plate and a refractory fiber reinforced coating, the catalytic conversion rate of sulfur dioxide is increased, and the conversion rate is larger than or equal to 99.75%.

Owner:禹勤工程设计咨询有限公司

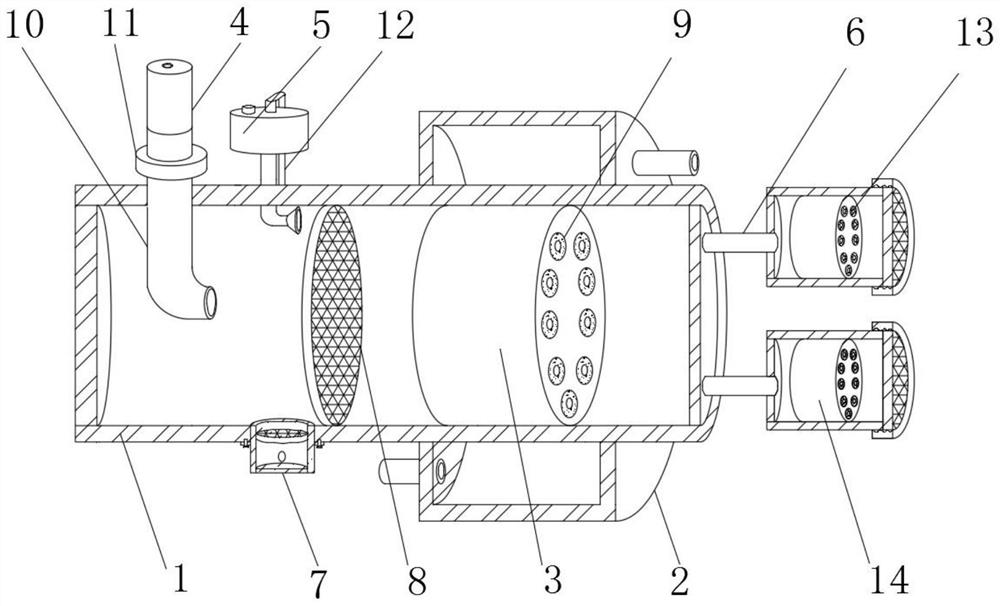

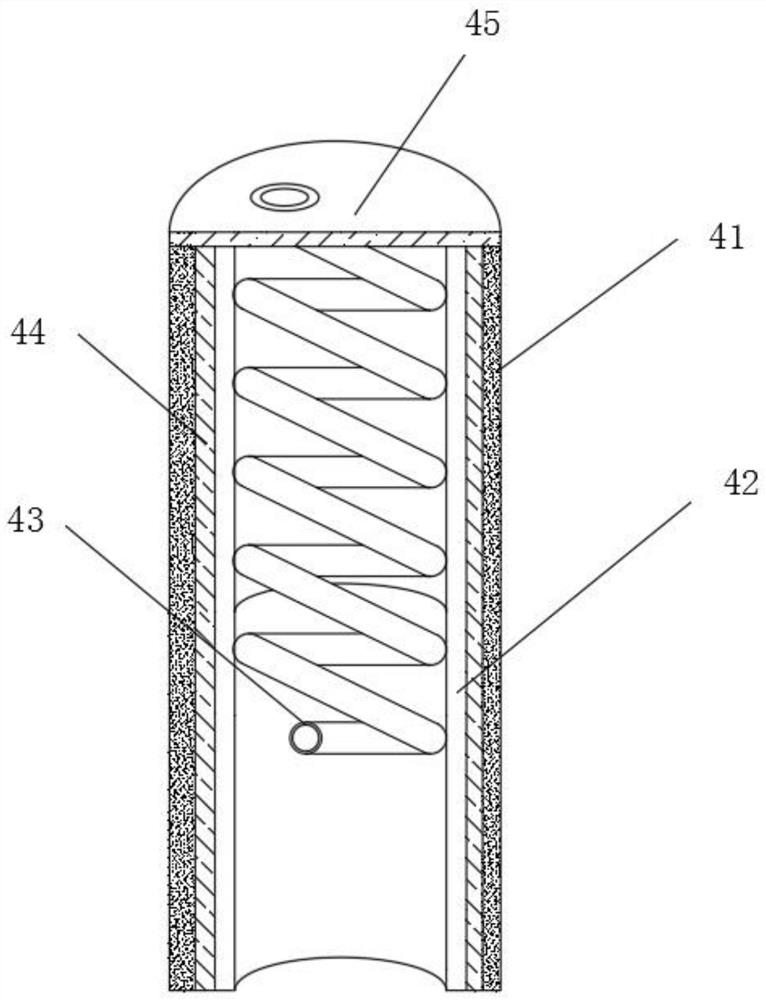

Vehicle exhaust catalytic purifying device

InactiveCN111663987AExtended reaction timeIncrease contact areaExhaust apparatusSilencing apparatusPtru catalystProcess engineering

The invention discloses a vehicle exhaust catalytic purifying device including a purifying drum. An exhaust pipe penetrates through the left part of the upper end in the purifying drum, a noise reduction device is fixedly connected with the upper end of the exhaust pipe, a first filter net and a reduction catalyst core are fixedly arranged in the purifying drum separately, a cleaning device is fixedly arranged at the upper end of the purifying drum, a cycling pipe is fixedly connected with the upper end of the cleaning device, a collection device is fixedly connected with the lower end of thecycling pipe, and two oxidation drums are fixedly connected with the right end of the purifying drum. According to the vehicle exhaust catalytic purifying device, a catalyst layer of a spiral structure and a groove are arranged to prolong the responding time of a catalyst and exhaust and meanwhile enlarge the contact area to improve the purifying effect, and a noise reduction sponge and a ring-shaped ventilation pipe can achieve noise reduction of exhaust so that the service life of the device is prolonged. In addition, the cleaning device can guarantee that the exhaust purifying work can carry out stably and efficiently, and a collection groove and a second filter net can be cleaned regularly so that the maintenance cost is reduced.

Owner:HEFEI SHENZHOU CATALSIS PURIFIER CO LTD

Preparation method of 1-bromoethyl acetate

InactiveCN103012143ALow Feed QuantityLow costPreparation from carboxylic acid halidesParacetaldehydeCombinatorial chemistry

The invention discloses a preparation method of 1-bromoethyl acetate, which comprises the following steps: under the catalysis of aluminum oxide, reacting acetyl bromide with paracetaldehyde; and then, extracting with dichloromethane / water to obtain the high-purity 1-bromoethyl acetate. According to the method, the paracetaldehyde is used instead of acetaldehyde in the traditional process, and the aluminum oxide is used for catalysis preferably, so that the method is environment-friendly, is easy to realize quantification and ensures high yield and purity of the product; and meanwhile, the process conditions of the method are mild and easy to control, thereby being suitable for industrial production.

Owner:GUANGDONG LIGUO PHARMACY

Catalyst, as well as preparation method and application thereof

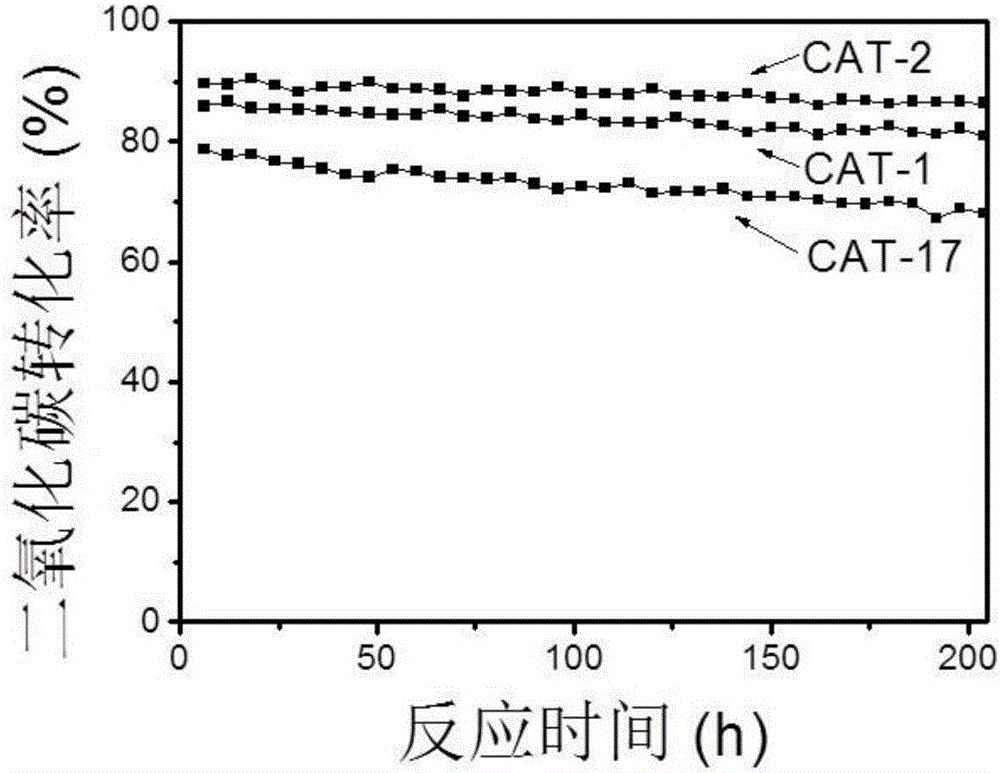

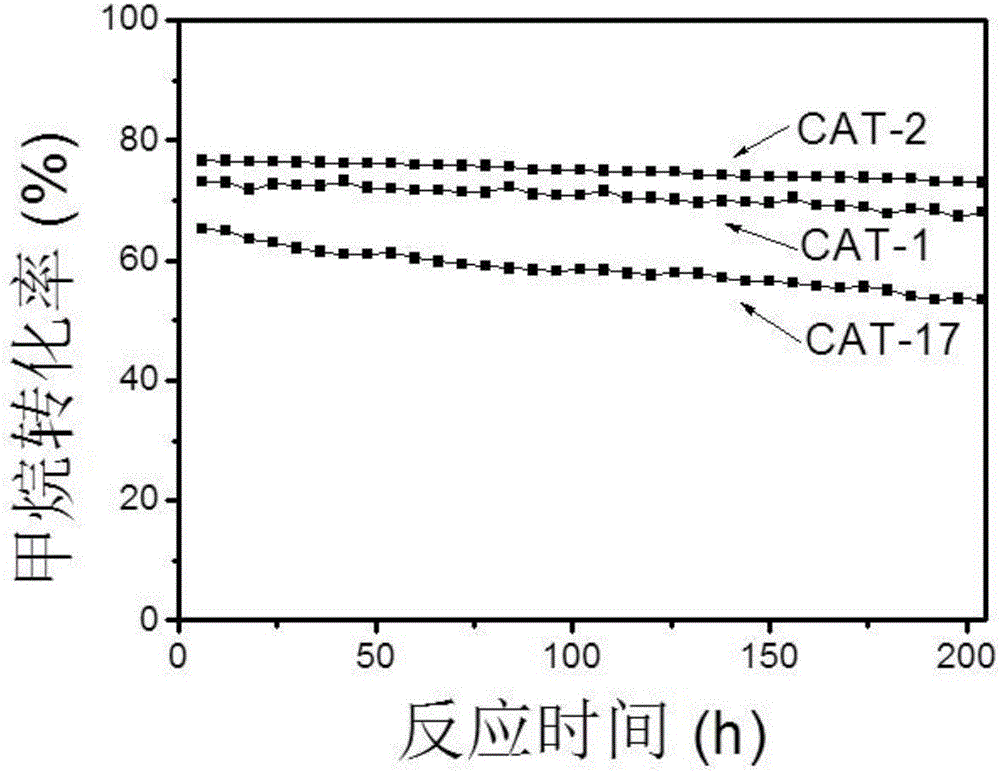

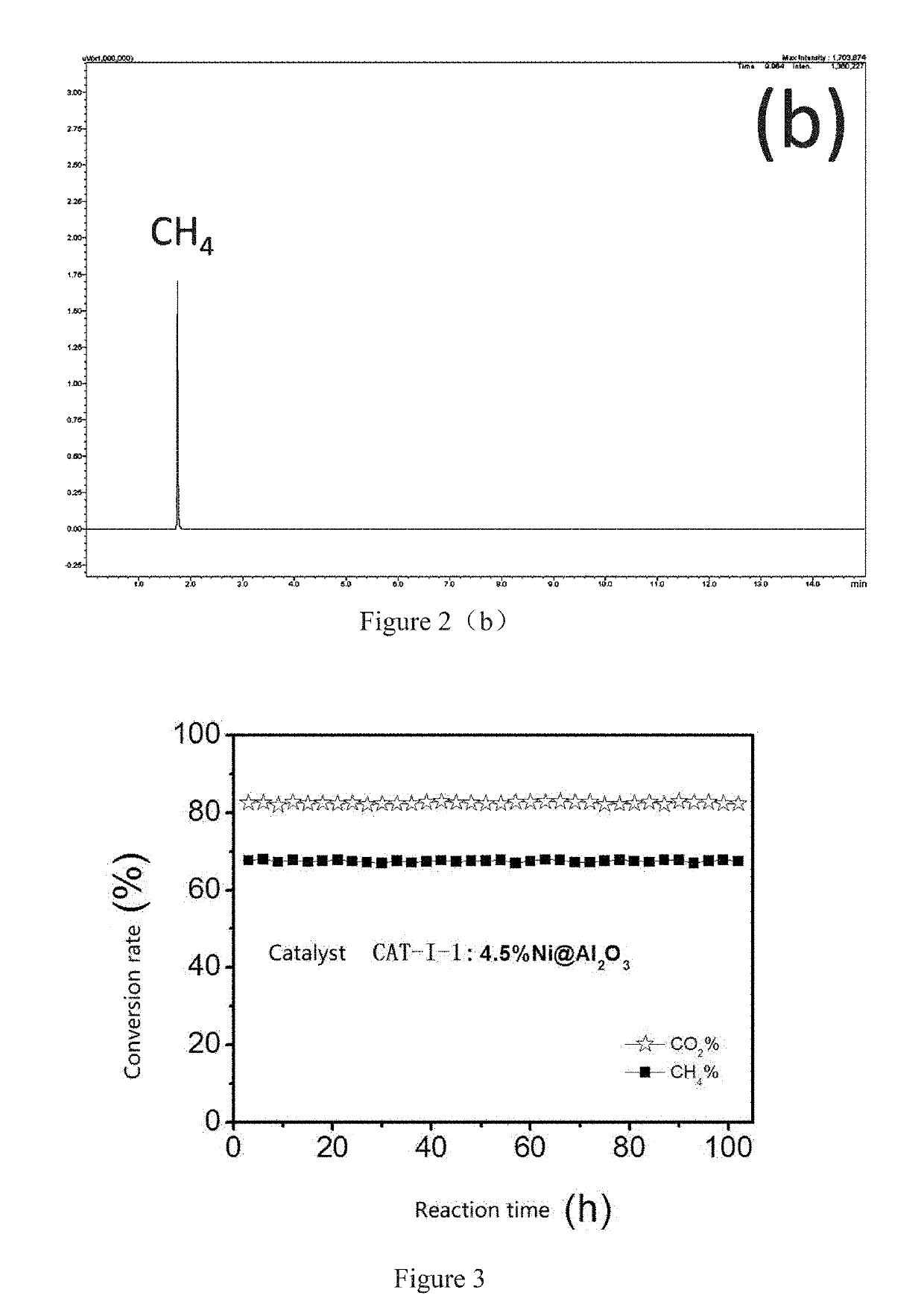

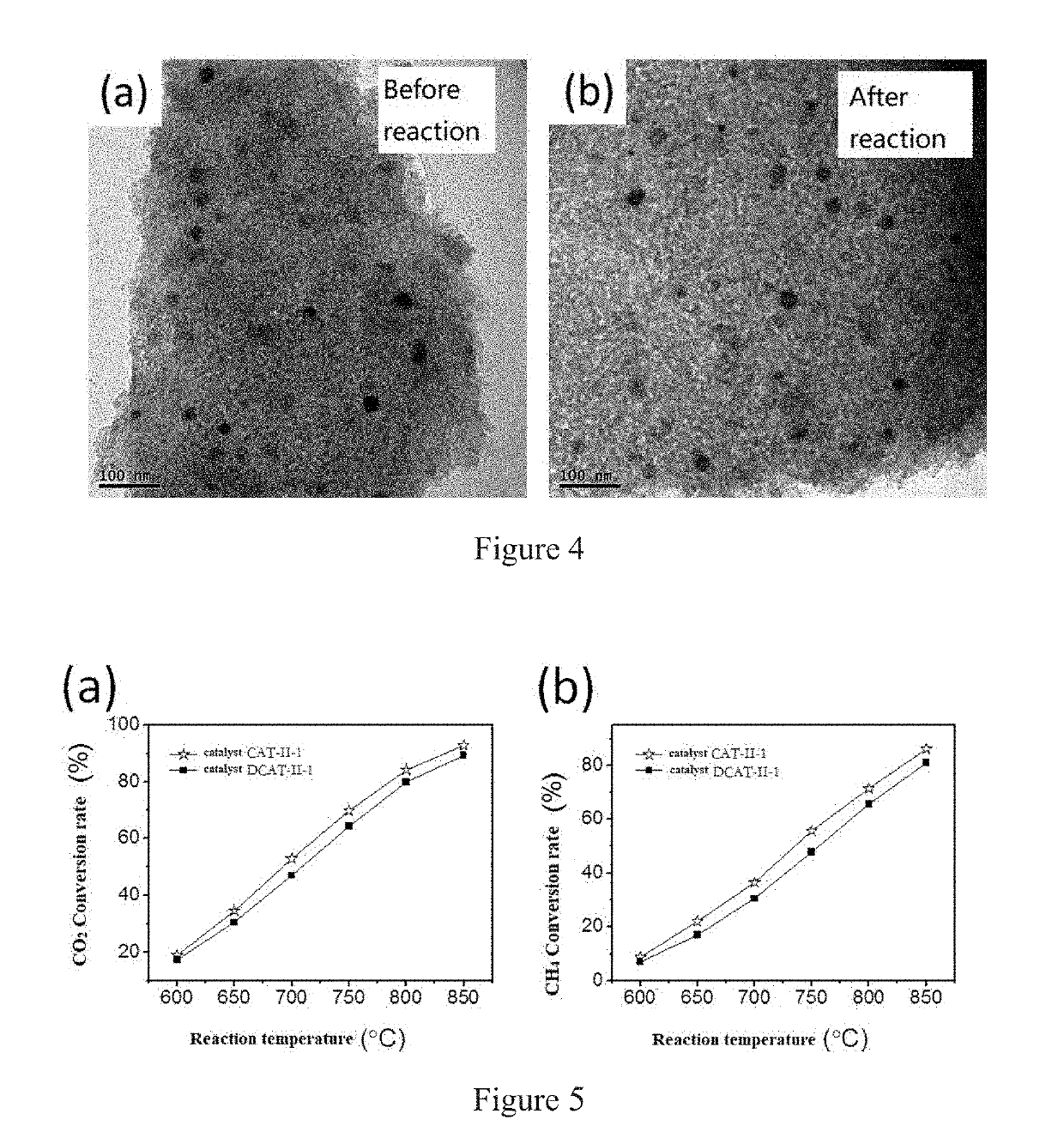

InactiveCN106807375AAchieve emission reduction and recyclingExcellent comprehensive catalytic performanceHydrogenHydrogen/synthetic gas productionCarbon dioxideMacropore

The invention discloses a catalyst which comprises a carrier and an active component dispersed over the carrier and is characterized in that the carrier is selected from at least one of inorganic oxides; the carrier comprises macropores and mesoporouses; the active component comprises an active element; the active element comprises a ferrum element; the ferrum element is ferrum and / or cobalt. The catalyst, as a high-temperature stable catalyst of a carbon dioxide reforming methane reaction, can produce synthetic gas and achieves emission reduction and recycling of carbon dioxide. Under a reaction condition of normal atmosphere and 800 DEG C, the multilevel pore loading metal catalyst shows excellent comprehensive catalytical performance and has very good stability, sintering resistance and carbon deposit resistance in addition to high activity and good selectivity.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

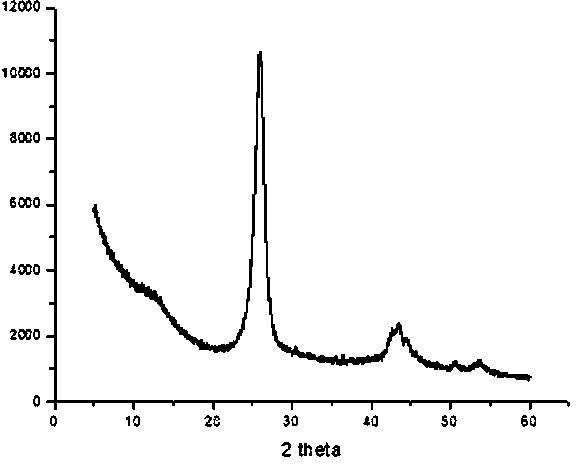

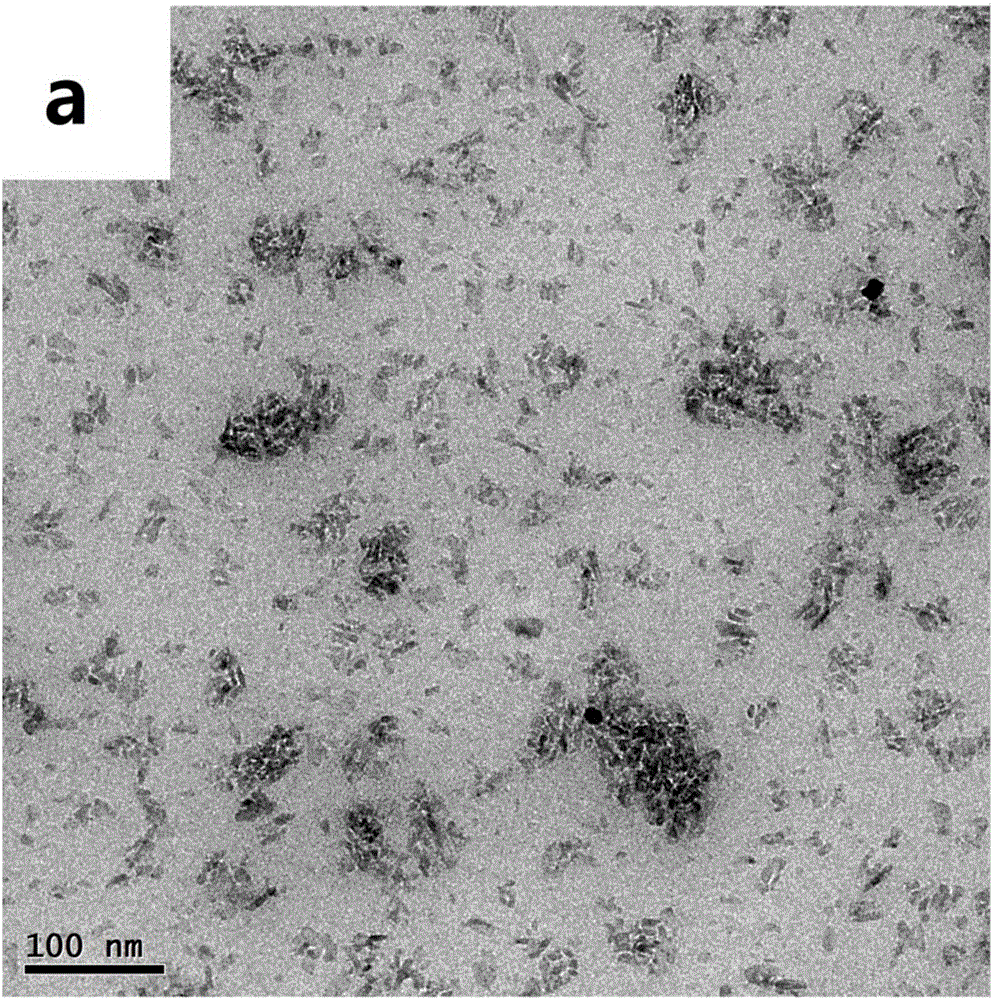

Nanocatalysts, preparation methods and applications for reforming carbon dioxide and methane to syngas

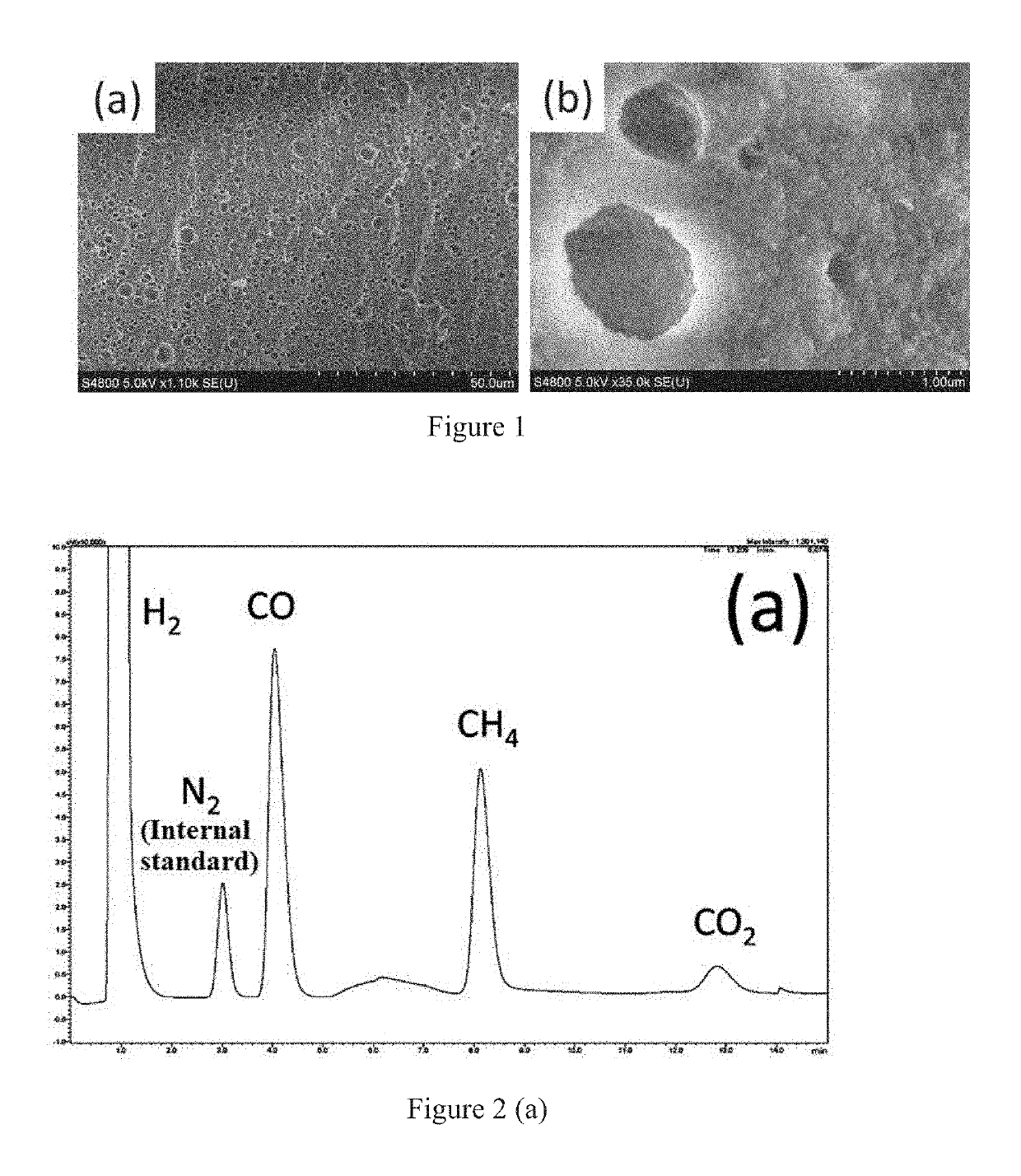

ActiveUS20190144275A1Increased diffusion rateIncrease mass transfer rateHydrogenHeterogenous catalyst chemical elementsNano catalystHigh resistance

The catalyst in this present application includes a support and an active component dispersed on / in the support; wherein the support is at least one selected from inorganic oxides and the support contains macropores and mesopores; and the active component includes an active element, and the active element contains an iron group element. As a high temperature stable catalyst for methane reforming with carbon dioxide, the catalyst can be used to produce syngas, realizing the emission reduction and recycling utilization of carbon dioxide. Under atmospheric pressure and at 800° C., the supported metal catalyst with hierarchical pores shows excellent catalytic performance. In addition to high activity and good selectivity, the catalyst has high stability, high resistance to sintering and carbon deposition.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Acetylene hydrochloride high-dispersity nanometer mercury-free catalyst and preparation method thereof

InactiveCN107456989ANarrow particle size distributionGood dispersionPhysical/chemical process catalystsPreparation by halogen halide additionDispersityMicrowave

The invention discloses an acetylene hydrochloride high-dispersity nanometer mercury-free catalyst and a preparation method thereof. The catalyst is prepared from PtCl2 serving as a main catalyzing component, KCl and InCl3 serving as catalyzing assistants, TiO2 which is less than 5nm in particle diameter serving as a dispersing agent and nitrogen-doped active carbon serving as a carrier by an ultrasonic stepwise impregnation-microwave drying method. The catalyst has the advantages of high dispersity, small active site, narrow particle size distribution, good carbon deposition resisting effect, high catalytic conversion rate, short induction period and long service life.

Owner:贵州重力科技环保股份有限公司

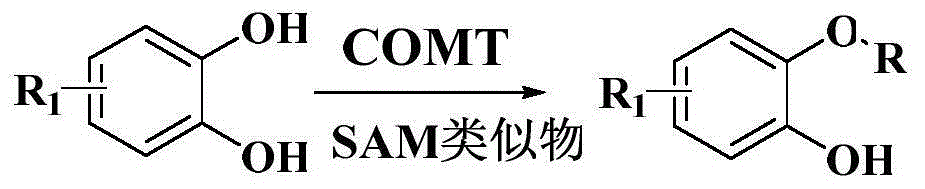

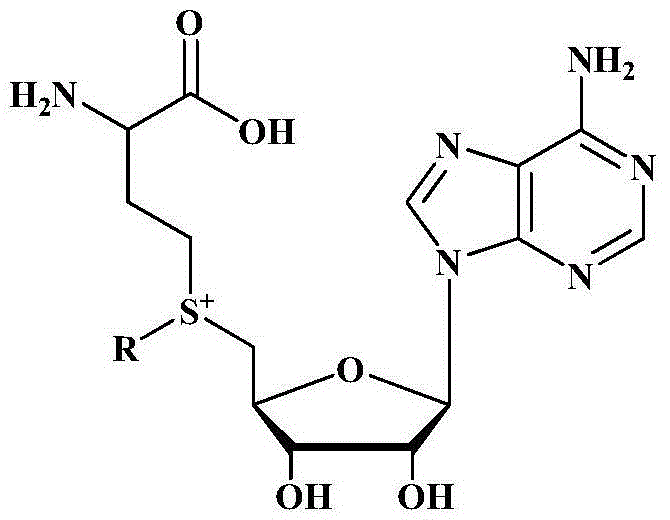

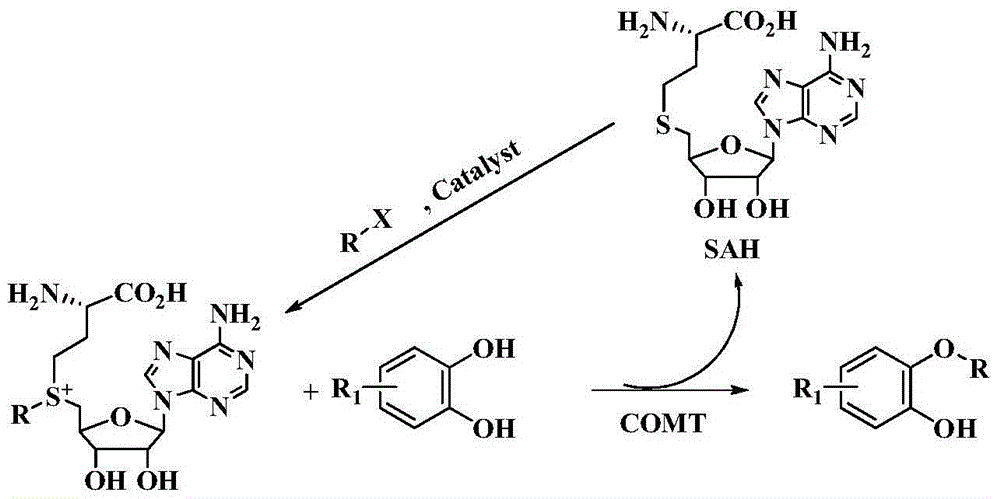

Method for biologically catalyzing hydrocarbylation of catechols

ActiveCN106148430AImprove catalytic conversionExtended reaction timeFermentationS-Adenosyl methionineS-Adenosyl-l-methionine

The invention discloses a method for biologically catalyzing hydrocarbylation of catechols. The method comprises the steps that catechol-O-methyltransferase serves as a catalyst, an S-adenosyl methionine analogue serves as a hydrocarbyl donor, hydrocarbylation of the catechols is achieved through enzymatic catalysis, and corresponding products are obtained. The method has the advantages of being mild in reaction condition, environmentally friendly, easy to operate, wide in applicable range of raw materials, high in catalytic conversion rate and good in chemical and regional selectivity; in addition, cyclic regeneration of the hydrocarbyl donor can be achieved by adding a solid acid catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

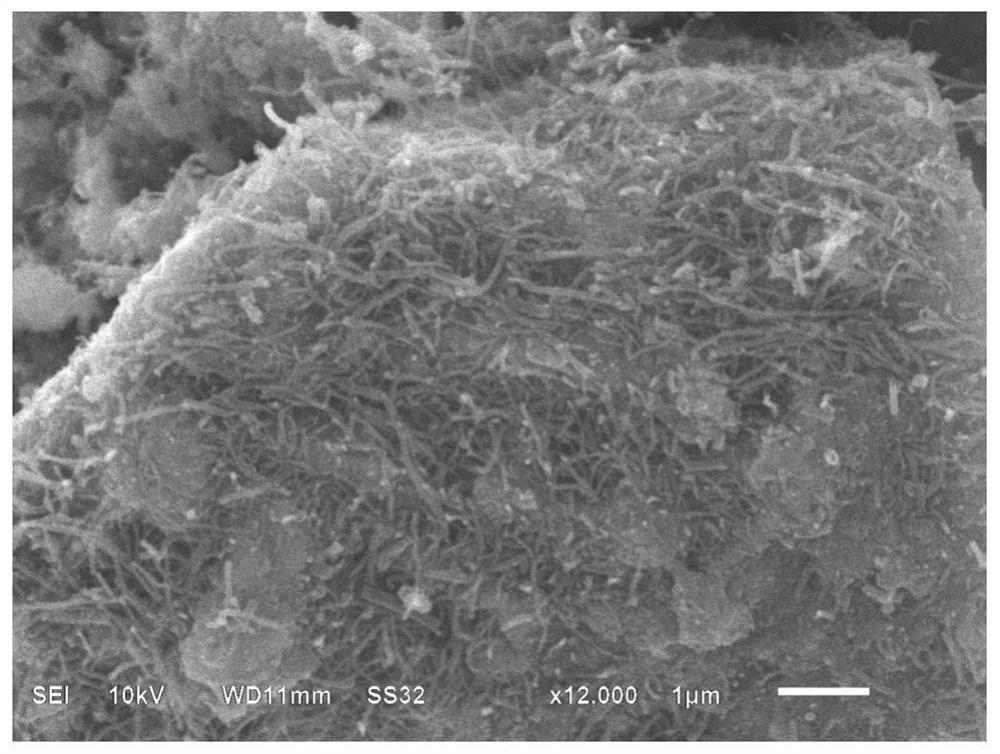

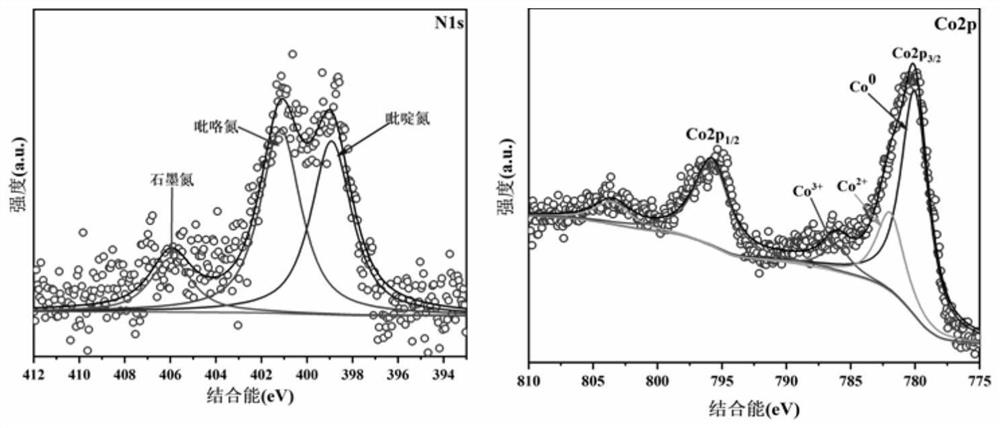

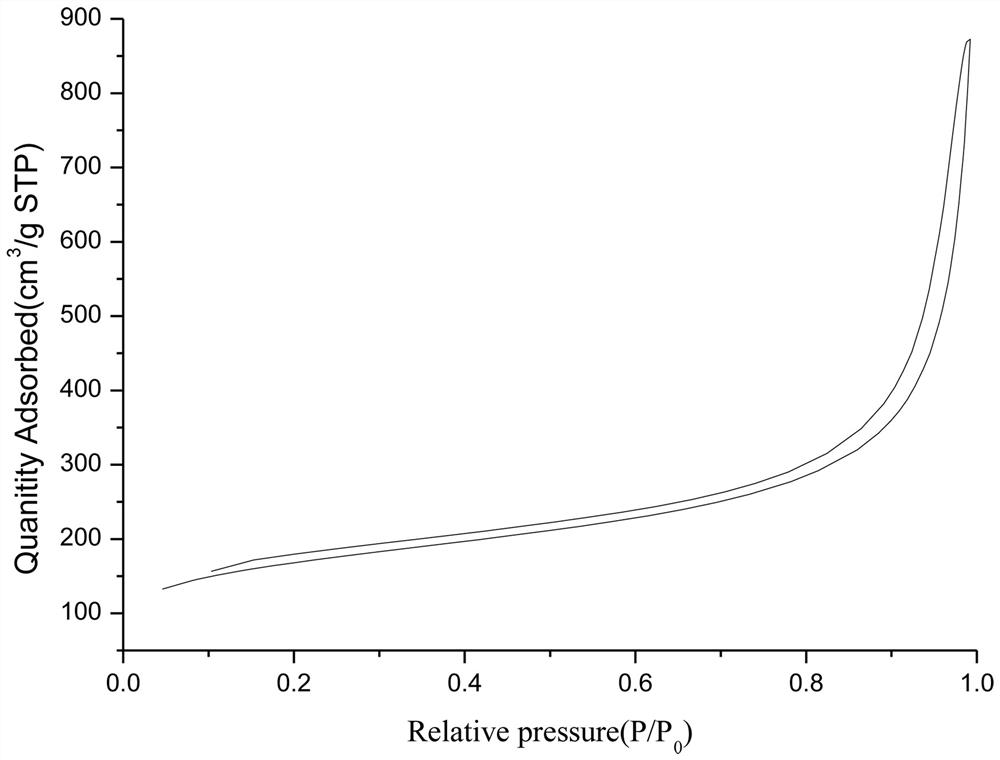

A kind of cobalt nitrogen co-doped fish scale biochar catalyst and its preparation method and application

ActiveCN113546664BLarge amount of reliefRealize resource utilizationOrganic chemistryCatalyst activation/preparationPtru catalystHydrothermal carbonization

The invention discloses a cobalt nitrogen co-doped fish scale biochar catalyst, a preparation method and application thereof. Cobalt nitrogen co-doped fish scale biochar was obtained by pretreatment and hydrothermal carbonization reaction of fish scale waste as the starting material to obtain carbon precursors, chelating agent with ethylenediamine as metal cobalt source combined with melamine at high temperature for the next step pyrolysis catalyst. The obtained catalyst has a large number of tubular structures, rich in mesopores and macropores, and a specific surface area of 240-400m 2 / g, the doping amount of nitrogen is 3-8wt.%, and the doping amount of cobalt is 1-5wt.%. The cobalt-nitrogen co-doped carbon catalyst prepared from fish scales in the present invention is applied in the reaction of preparing γ-valerolactone by catalytic hydrogenation of levulinic acid, and has high efficiency, high yield and good cycle stability, and the present invention The preparation method is simple, and the environmentally unfriendly process without any acid-base post-treatment provides a new way for high-value recycling of fish scale waste.

Owner:XIANGTAN UNIV

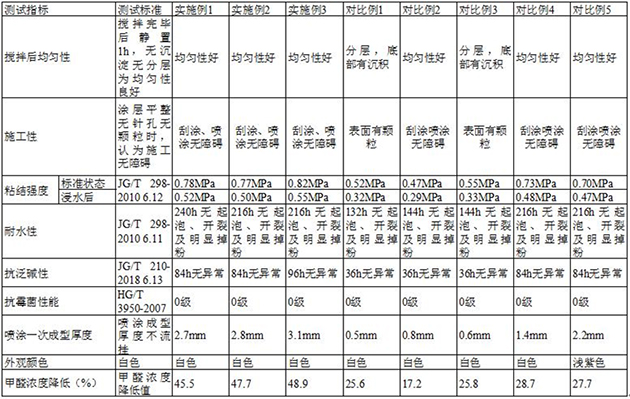

Putty surface decorative material, and preparation method and use method thereof

ActiveCN112011208ALoose inner structurePromote respirationFilling pastesAnti bacteriaAluminium oxides

The invention relates to a putty surface decorative material, and a preparation method and a use method thereof. The putty surface decorative material is prepared from, by weight, 10-30 parts of a base material, 20-40 parts of manganese dioxide loaded diatomite, 1-5 parts of calcium carbonate whiskers, 5-10 parts of nanometer titanium dioxide, 5-10 parts of aluminum oxide, 15-50 parts of heavy calcium carbonate and 5-35 parts of spherical silica powder. The putty surface decorative material can improve the antibacterial, mildew-proof, odor-removing and formaldehyde-removing effects.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

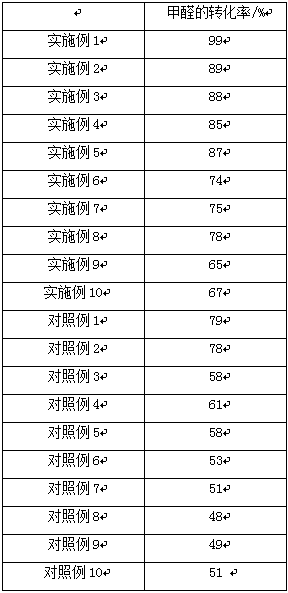

Preparation method of carbon nanotube air purifying agent for removing formaldehyde

InactiveCN109465033AImprove catalytic conversionEliminate freeGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsCarbon nanotubeRare earth

The invention discloses a preparation method of a carbon nanotube air purifying agent for removing formaldehyde. The preparation method comprises the following steps: taking carbon nanotubes, potassium permanganate, hydrogen peroxide, silica microspheres, PDDA, PSS, rare-earth nitrate, sodium tungstate, nickel nitrate and ferric nitrate as raw materials, carrying out double modification on silicaand then performing coprecipitation modification with metal salt to prepare the formaldehyde purifying agent, the carbon nanotube air purifying agent comprises the following main raw materials in ratios: the mass ratio of carbon nanotube solid to potassium permanganate solid is 1: 4, the molar ratio of PDDA to PSS is 1: 2, the molar ratio of rare-earth nitrate to sodium tungstate is 3: 1, and themass ratio of nickel nitrate to ferric nitrate is 1: 1. According to the invention, the double modification and modification are carried out on the carbon nanotubes, to obtain the formaldehyde purifying agent, and the formaldehyde purifying agent is high in catalytic activity, long in catalyst life, good in stability, easy to obtain the preparation materials, low in cost and easy to recycle and further can be reused.

Owner:梅玉杰

Nickel-modified molecular sieve SCR catalyst and preparation method thereof

InactiveCN105536859AImprove adsorption capacityIncrease flexibilityMolecular sieve catalystsDispersed particle separationFree coolingRoom temperature

The invention discloses a nickel-modified molecular sieve SCR catalyst and a preparation method thereof, and relates to the technical field of catalyst preparation. The molecular sieve SCR catalyst comprises a ZSM-5 zeolite molecular sieve and a nickel element. The preparation method comprises the following steps: first, dipping nickel nitrate solution in the ZSM-5, and stirring for 24 hours at 75 to 85 DEG C; then, drying for 3.5 to 4.5 hours at 115 to 125 DEG C; next, roasting for 3.5 to 4.5 hours at the high temperature of 540 to 560 DEG C; finally, naturally cooling to room temperature to obtain the molecular sieve SCR catalyst. According to the nickel-modified molecular sieve SCR catalyst and the preparation method thereof, the problem of reducing NOx to N2 with catalysis in a low-temperature environment is solved; the conversion rate of the NOx reaches 98 percent or above; the reaction speed is faster than that at a high temperature; the catalyst is safe and has no biotoxicity.

Owner:LIUZHOU HAIDA NEW MATERIAL TECH

Palladium-copper-rare earth-aluminum oxide catalytic separation composite membrane and preparation method and application thereof

InactiveCN102935335BImprove catalytic conversionReduce resistanceSemi-permeable membranesHydrogen separationAluminium oxidesHydrogen production

Owner:SHANGHAI INST OF TECH

Application of alpha-L-rhamnoside enzyme in directional synthesis of isoquercitrin by biological conversion of rutin

ActiveCN101985639BImprove catalytic conversionLow costOn/in organic carrierFermentationPtru catalystEnzyme catalysis

The invention relates to application of an alpha-L-rhamnoside enzyme in the directional synthesis of isoquercitrin by the biological conversion of rutin. Because the crude enzyme preparation or the immobilized enzyme preparation of the alpha-L-rhamnoside enzyme is used for catalyzing and hydrolyzing the rutin and directionally and biologically synthesizing the isoquercitrin, the application has the advantages of wide source, easy preparation and low cost of catalysts, high stability, and high catalysis efficiency and specificity of the enzyme preparation, and is easy to store. Thus, the alpha-L-rhamnoside enzyme can greatly reduce the production cost of quercetin, the catalysis and conversion rate of the enzymes is high, and the products are single.

Owner:JIANGSU UNIV OF SCI & TECH

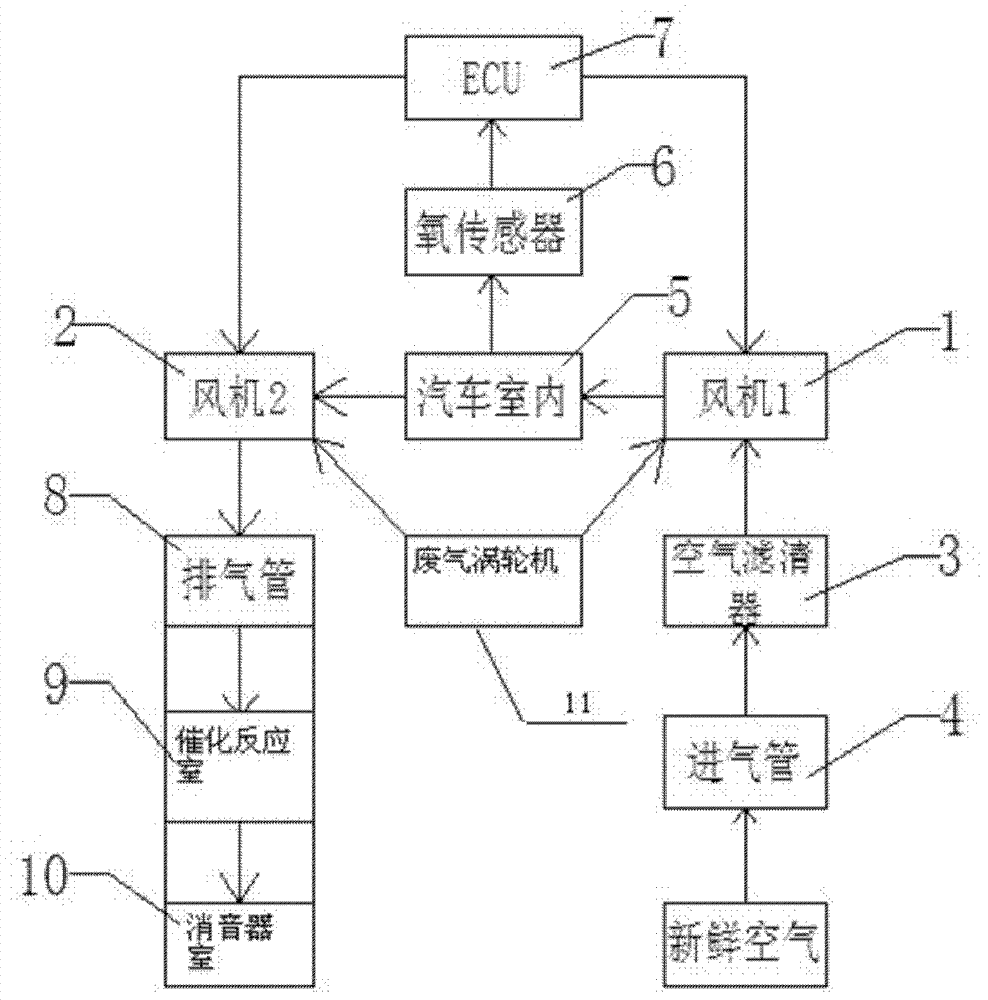

Automobile room air purifying device for providing supplementary air for exhausting system

InactiveCN102310747BEfficient use ofEmission reductionAir-treating devicesExhaust apparatusIndoor air qualityElectronic controller

The invention discloses an automobile room air purifying device, belonging to the field of air quality in automobile rooms. The automobile room air purifying device comprises an electronic controller (7), an oxygen sensor (6), a fan (1), a fan (2), an air inlet pipe (4) with an air damper, a waste gas exhaust pipe (8) of an engine, a waste gas turbine (11) of the engine, a catalytic reaction room (9), an air purifying device filter (3), an automobile room (5), a muffler room (10) and electromagnetic clutches, wherein the electromagnetic clutches are positioned between the waste gas turbine (11) and the fan (1) as well as between the waste gas turbine (11) and the fan (2) respectively; both the catalytic reaction room (9) and the muffler room (10) are positioned in the waste gas exhaust pipe (8) of the engine; and the fan (2) is connected with the waste gas exhaust pipe (8) of the engine through an air supply duct.

Owner:SHANDONG UNIV OF TECH

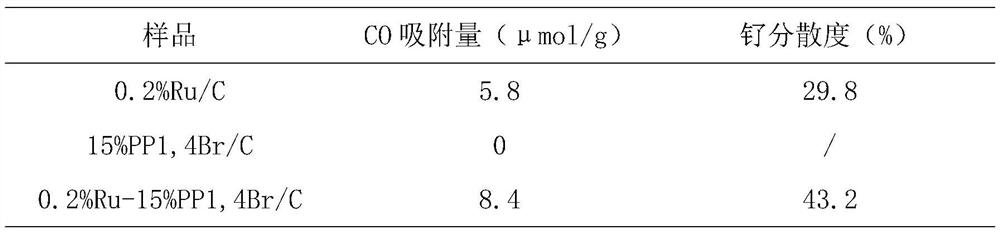

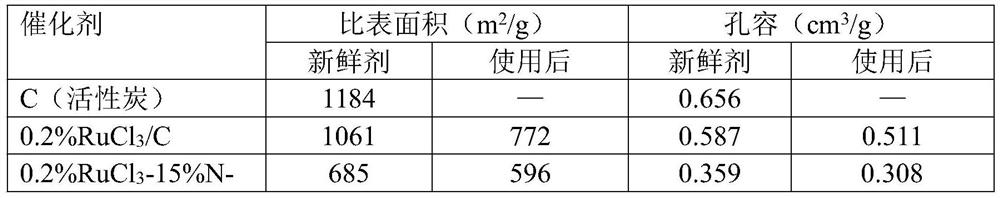

A kind of highly dispersed ruthenium-based catalyst for acetylene hydrochlorination and preparation method thereof

ActiveCN107456990BGood dispersionHas an anchoring effectPhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonCatalytic transformation

The invention discloses a high-dispersion ruthenium-based catalyst for acetylene hydrochlorination and a preparation method thereof. The catalyst uses PtCl 2 Main catalytic components, KCl and InCl 3 As a catalytic promoter, nano-TiO with particle diameter less than 5nm 2 It is a dispersant, hydrochloric acid is a competitive adsorbent, and nitrogen-doped activated carbon is a carrier. It is prepared by ultrasonic dispersion step-by-step impregnation-microwave drying method. The catalyst has the advantages of high dispersion, small active sites and narrow particle size distribution, good anti-coking effect, high catalytic conversion rate, short induction period and long service life.

Owner:贵州重力科技环保股份有限公司

Supported ruthenium-pyrrolidine ionic liquid catalyst as well as preparation method and application thereof

PendingCN114308119AGood dispersionEvenly dispersedPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic transformationPtru catalyst

The invention discloses a supported ruthenium-pyrrolidine ionic liquid catalyst, the catalyst is composed of RuCl3 and pyrrolidine ionic liquid, the catalyst is prepared by adopting a dipping-drying mode, and the catalyst has the advantages of multiple active sites, high dispersity, high catalytic conversion rate, high selectivity and good anti-carbon deposition effect.

Owner:贵州重力科技环保股份有限公司

Catalytic purifier selective reduction ultrasonic vaporization method acting on tail gas purification

InactiveCN108843430ASolve the long-standing problem of crystallizationImprove mixing uniformityInternal combustion piston enginesExhaust apparatusEngineeringElectric control

The invention discloses a catalytic purifier selective reduction ultrasonic vaporization method acting on tail gas purification. An external power source is connected into an electric control PLC, theelectric control PLC supplies power to a PID, and the PID controls an entire post-processing circulation system. Compressed air is led into an AdBlue tank to form micro-pressure, urea liquid is fed into an ultrasonic atomization working chamber, and the urea liquid is ultrasonically atomized and then enters a catalytic muffler purifier through a pipeline. Urea is detected by a nitrogen oxygen sensor so as to obtain the conversion rate of converting to the nitrogen oxide PPM value, the conversion rate is transmitted to the PID through a CAN signal, the PID calculates the amount of atomized urea required to obtain the nitrogen oxide PPM value, the current voltage value of MOS is obtained, the MOS controls an ultrasonic atomization generator to convert the urea liquid into atomized urea, theatomized urea is fed into the catalytic muffler purifier, and the whole process forms a CAN signal cycle. According to the catalytic purifier selective reduction ultrasonic vaporization method actingon the tail gas purification, the urea liquid is converted into the atomized urea through ultrasonic waves, the use of a high-precision nozzle is abandoned, and the problem of urea crystallization isfurther solved.

Owner:刘光文 +1

Metal foam catalytic purification silencer of automobile engine

PendingCN111022166ASingle functionEven air distributionSilencing apparatusMachines/enginesCatalytic transformationPtru catalyst

The invention discloses a metal foam catalytic purification silencer of an automobile engine. The metal foam catalytic purification silencer comprises a front metal foam catalytic silencing plate, a 750-mesh metal honeycomb front-end catalyst, CDPF, a 750-mesh metal honeycomb rear-end catalyst and a rear metal foam catalytic silencing plate which are sequentially arranged in a cylinder from the front end to the rear end. According to the invention, the front metal foam catalytic silencing plate, the 750-mesh metal honeycomb front-end catalyst, the CDPF, the 750-mesh metal honeycomb rear-end catalyst and the rear metal foam catalytic silencing plate are scientifically and reasonably arranged and combined, so that waste gas and harmful particles exhausted by the gasoline engine from low-speed starting to high-speed running and even high-speed running of a cold vehicle are effectively converted and intercepted, meanwhile, noise is also eliminated, and the decibel of the noise is superiorto the national standard. Through detection of a waste gas detection test bed, when 15 g of aprecious metal is adopted per cubic foot, the catalytic conversion rate of waste gas is 97% or above, and the catalytic conversion rate of waste gas adopted per cubic foot in a traditional structure is 70% or below.

Owner:BEIHAI HUIHUANG LANGJIE ENVIRONMENTAL & TECH

A kind of preparation method and application of quaternary ammonium salt template agent

ActiveCN110592610BHigh activityNo decrease in activityElectrolysis componentsOrganic-compounds/hydrides/coordination-complexes catalystsHigh concentrationSolid-phase synthesis

The application provides a preparation method and application of a quaternary ammonium salt template, which belongs to the technical field of compounds with molecular sieve and base exchange properties. Using dialkylpyridine as raw material, through the synthesis of dialkylpiperidine, tertiary amination of dialkylpiperidine, quaternization of dialkylpiperidine, hydrogenation of N,N-dialkylated dioxane The synthesis of base piperidine quaternary ammonium base obtains high-concentration template agent, which is used for solid-phase synthesis of SSZ-39 zeolite to synthesize SSZ-39 zeolite molecular sieve. Applying the present application to template agent and SSZ‑39 zeolite synthesis has the advantages of good safety, low reaction pressure, high yield and good selectivity.

Owner:KENTE CATALYSTS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com