Preparation method of carbon nanotube air purifying agent for removing formaldehyde

A carbon nanotube and purifying agent technology, applied in the field of carbon nanotube air purifying agent preparation, can solve the problems of inability to eliminate odorous substances, high price, unsatisfactory effect, etc., and achieve full exposure, eliminate free formaldehyde, The effect of improving the catalytic conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

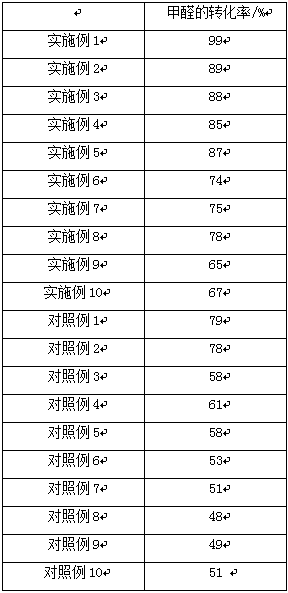

Examples

Embodiment 1

[0020] Step 1 Add 0.05 kg of single-walled carbon nanotube solids and potassium permanganate solids in a ratio of 1:4 to excess concentrated sulfuric acid solution, and place the resulting reaction mixture in a water bath at 50°C under constant temperature magnetic Stir with a stirrer for 1h;

[0021] Step 2 After diluting the above-mentioned reacted mixed solution with deionized water, add excess hydrogen peroxide solution and stir for 20 minutes;

[0022] Step 3 After the above-mentioned reacted mixed solution is filtered with a microporous membrane and washed with dilute hydrochloric acid solution, the obtained solid is then washed with deionized water by high-speed centrifugation until the supernatant is neutral (PH=7);

[0023] Step 4 Then take the solid in the lower layer and add deionized water to fully stir, and after further centrifugation and washing, take the uniform and stable solution in the upper layer to obtain solution A;

[0024] Step 5 Ultrasonically dispers...

Embodiment 2

[0034] Step 1 Add 0.05 kg of single-walled carbon nanotube solids and potassium permanganate solids in a ratio of 1:2 to excess concentrated sulfuric acid solution, and place the resulting reaction mixture in a water bath at 50°C under constant temperature magnetic Stir with a stirrer for 1h;

[0035] Step 2 After diluting the above-mentioned reacted mixed solution with deionized water, add excess hydrogen peroxide solution and stir for 20 minutes;

[0036] Step 3 After the above-mentioned reacted mixed solution is filtered with a microporous membrane and washed with dilute hydrochloric acid solution, the obtained solid is then washed with deionized water by high-speed centrifugation until the supernatant is neutral (PH=7);

[0037] Step 4 Then take the solid in the lower layer and add deionized water to fully stir, and after further centrifugation and washing, take the uniform and stable solution in the upper layer to obtain solution A;

[0038] Step 5 Ultrasonically dispers...

Embodiment 3

[0048] Step 1 Add 0.05 kg of single-walled carbon nanotube solids and potassium permanganate solids in a ratio of 1:1 to excess concentrated sulfuric acid solution, and place the resulting reaction mixture in a water bath at 50°C under constant temperature magnetic Stir with a stirrer for 1h;

[0049] Step 2 After diluting the above-mentioned reacted mixed solution with deionized water, add excess hydrogen peroxide solution and stir for 20 minutes;

[0050] Step 3 After the above-mentioned reacted mixed solution is filtered with a microporous membrane and washed with dilute hydrochloric acid solution, the obtained solid is then washed with deionized water by high-speed centrifugation until the supernatant is neutral (PH=7);

[0051] Step 4 Then take the solid in the lower layer and add deionized water to fully stir, and after further centrifugation and washing, take the uniform and stable solution in the upper layer to obtain solution A;

[0052] Step 5 Ultrasonically dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com