Metal foam catalytic purification silencer of automobile engine

An automotive engine, catalytic purification technology, applied in engine components, machines/engines, catalyst carriers, etc., can solve the problems of low exhaust gas conversion, poor noise reduction, low catalytic efficiency, etc., to achieve high exhaust gas conversion rate and reduce disassembly. Maintenance frequency, the effect of rapid catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

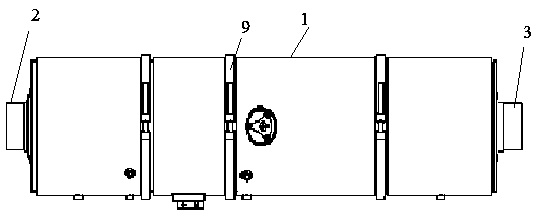

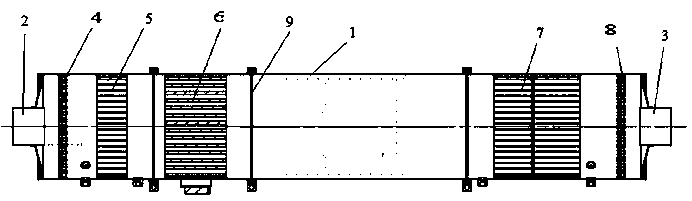

[0021] as attached figure 1 And attached figure 2 As shown, the present invention includes a cylinder body 1, an air inlet 2 at the front end of the cylinder body, and an exhaust port 3 at the rear end of the cylinder body, and a front metal foam catalytic muffler plate 4,750 is sequentially arranged in the cylinder body 1 from the front end to the rear end Mesh metal honeycomb front-end catalyst 5, CDPF 6, 750 mesh metal honeycomb rear-end catalyst 7, rear metal foam decatalysis sound board 8. The thickness of the pre-metal foam catalytic sound-absorbing plate 4 is 5-40 centimeters, which is formed by coating a small amount of cladding catalyst slurry on the metal-foam sound-absorbing plate. The main components of the composite catalyst are rare earth mixtures and precious metals. Although there are various proportions, its preparation and preparation methods are well-known techniques and are not limited in this embodiment. The water absorption rate of the carrier of the m...

Embodiment 2

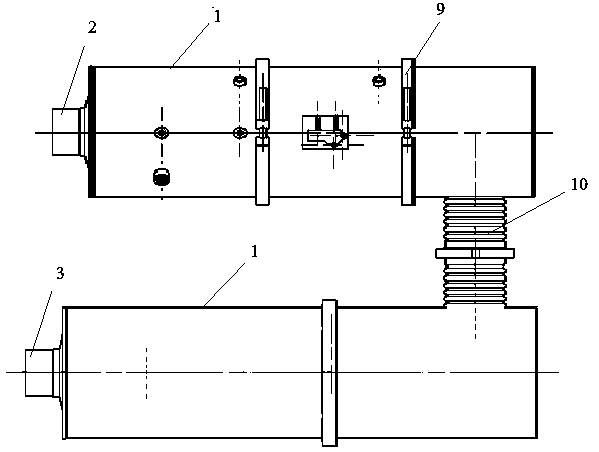

[0026] as attached image 3 shown, with image 3 It is another embodiment of the present invention. This embodiment is mainly set according to the specific structural arrangement of the automobile engine. In this embodiment, the cylinder body 1 of the catalytic purification muffler is divided into two independent cylinder bodies. The cylinder of the body is provided with a front metal foam catalytic muffler plate 4, a 750-mesh metal honeycomb front-end catalyst 5 and CDPF6, and a 750-mesh metal honeycomb rear-end catalyst 7 and a rear metal foam catalytic muffler plate 8 are arranged in the latter cylinder , the front and rear cylinders are connected by air pipe 10, and the connection method is welding, or fastened by hoop 9, and the front and rear cylinders are connected to form a "U"-shaped arrangement. Except for the arrangement of the two cylinders, the working principle and working state are the same as those in Embodiment 1.

Embodiment 3

[0028] as attached Figure 4 shown, with Figure 4 It is another embodiment of the present invention. This embodiment is mainly set according to the specific structural arrangement of the automobile engine. In this embodiment, the cylinder body 1 of the catalytic purification muffler is divided into two independent cylinder bodies. The cylinder of the body is provided with a pre-catalyzed metal foam anechoic plate 4, a 750-mesh metal honeycomb front-end catalyst 5 and CDPF6, and a 750-mesh metal honeycomb rear-end catalyst 7 and a rear metal foam catalytic anechoic plate 8 are arranged in the latter cylinder , the front and rear cylinders are connected by an air pipe 10, and the connection method is welding, or fastened by a hoop 9, and the front and rear cylinders are connected to form an "S"-shaped arrangement. Except for the arrangement of the two cylinders, the working principle and working state are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com