Three-way catalyst for preparing glyceric acid by oxidizing glycerol and preparing method thereof

A technology of glyceric acid and supported catalysts, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor selectivity and low catalytic activity, and achieve Easy operation, high catalytic conversion rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

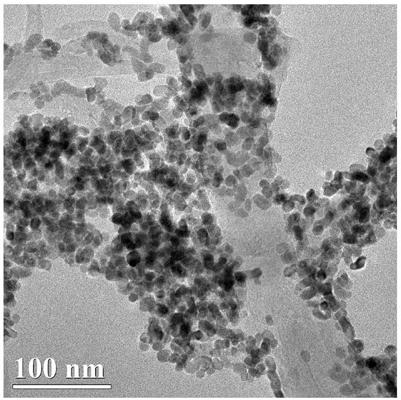

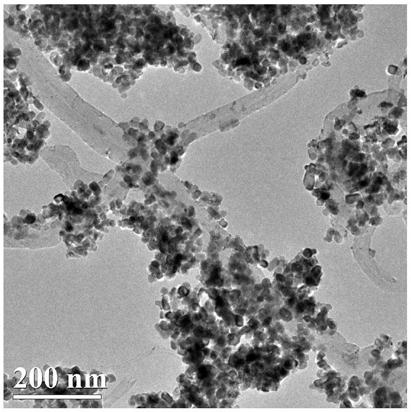

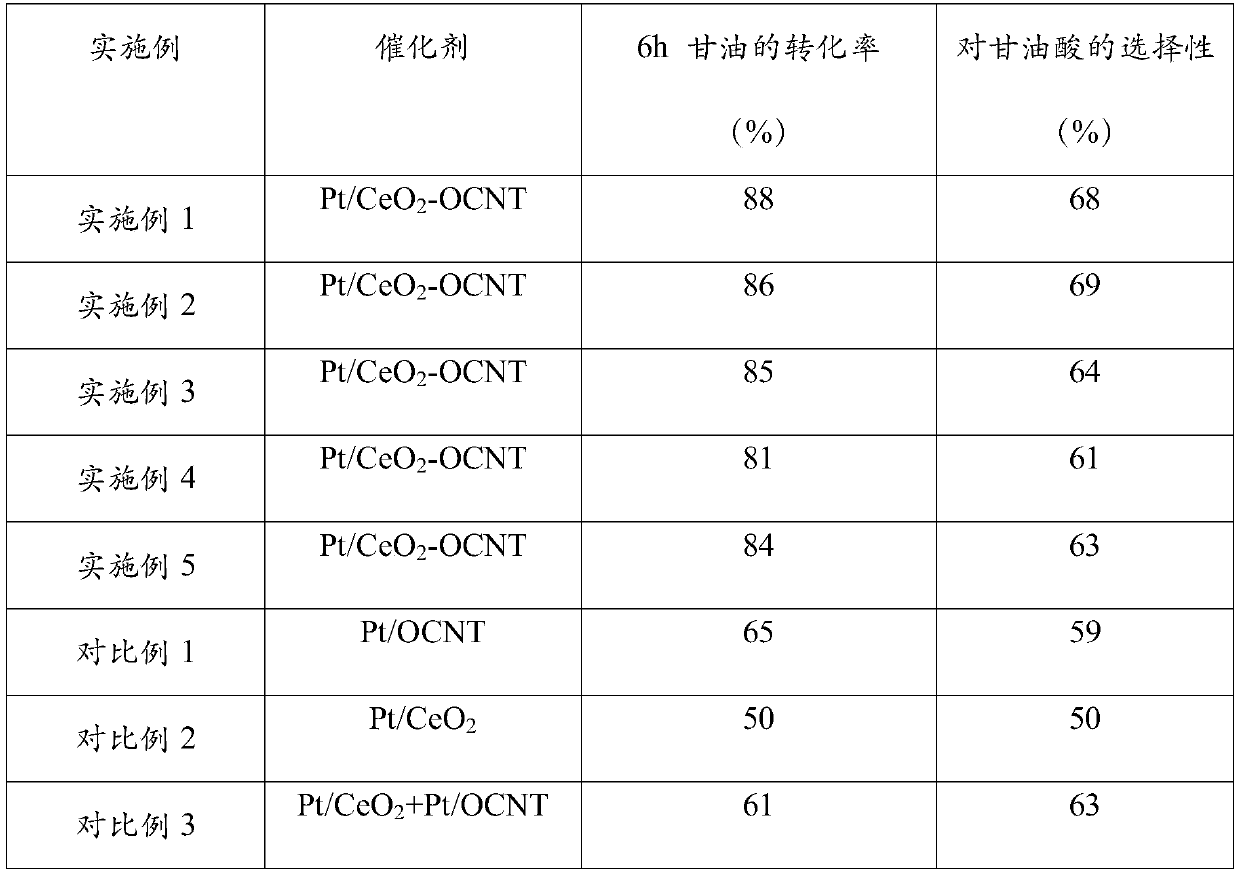

[0025] Example 1: Pt / CeO 2 -OCNT

[0026] S01: Weigh multi-walled carbon nanotubes (MWCNTs, diameter 40-60nm), oxidize with concentrated nitric acid, control the mass ratio of multi-walled carbon nanotubes and nitric acid to 1:98, the temperature is 75°C, and the stirring time is 12h After the reaction, wash with distilled water for several times until the washing supernatant is neutral, and dry the sample at 80°C to obtain OCNT oxidized by nitric acid.

[0027] S02: Disperse 100mg of carbon nanotubes OCNT oxidized by nitric acid in 30mL of absolute ethanol, ultrasonicate for 5 minutes to form a uniform solution, and continue stirring for 10 minutes; then add 0.478g of cerium ammonium nitrate (according to CeO 2 The mass ratio of OCNT to OCNT is 1.5:1 (calculated) powder, and the powder is completely dispersed into the solution by ultrasound, and the stirring is continued for 10 minutes; a sodium hydroxide aqueous solution with a concentration of 0.09g / mL is added dropwise, a...

Embodiment 2

[0030] Example 2: Pt / CeO2 -OCNT

[0031] S01: Weigh MWCNTs, and the processing method is the same as that in Example 1.

[0032] S02: Preparation of CeO 2 When / OCNT carrier, method is the same as embodiment 1, and the results are shown in summary table 1.

[0033] S03: Weigh 0.1425g of CeO 2 / OCNT (1.5:1) carrier was dispersed in absolute ethanol, dispersed to form a uniform solution, kept stirring for 30min, added 3.79mL K 2 PtCl 4 aqueous solution, and the subsequent loading process is the same as in Example 1.

[0034] S04: The reaction conditions for glycerol oxidation are the same as in Example 1, and the results are shown in summary table 1.

Embodiment 3

[0035] Example 3: Pt / CeO 2 -OCNT

[0036] S01: Weigh MWCNTs, and the processing method is the same as that in Example 1.

[0037] S02: Preparation of CeO 2 When / OCNT carrier, method is the same as embodiment 1, and the results are shown in summary table 1.

[0038] S03: Weigh 0.1425g of CeO 2 / OCNT (1.5:1) carrier was dispersed in absolute ethanol, dispersed to form a uniform solution, kept stirring for 30min, and added 3.59mL Pt(acac) 2 aqueous solution, and the subsequent loading process is the same as in Example 1.

[0039] S04: The reaction conditions for glycerol oxidation are the same as in Example 1, and the results are shown in summary table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com