Selective catalytic reduction denitration catalyst, preparation method and application thereof

A denitrification catalyst and catalyst technology, applied in the field of denitrification, can solve the problems of complex flue gas composition, high optimal operating temperature, high investment and operating costs, achieve good electron transfer ability, widen the low temperature reaction window, and improve the catalytic conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

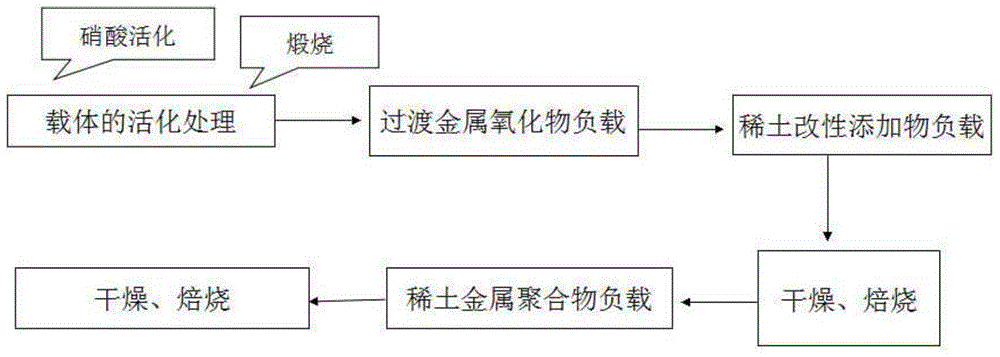

[0113] In another preferred embodiment, the present invention provides a kind of synthetic method that is the SCR flue gas denitration catalyst of active component with transition metal, rare earth modification additive, rare earth metal polymer, comprises the following steps: a1 step: Activation of semi-coke or silicon-aluminum honeycomb ceramics: semi-coke or silicon-alumina honeycomb ceramics are activated by immersing them in nitric acid with a mass concentration of 20% for 6 hours, drying, and annealing in a muffle furnace at 500°C; step a2: dip-coating transition metals, rare earth modified Additives: Immerse the carrier obtained in step a1 into a solution with a mass concentration of 10% transition metal manganese and a rare earth modification additive with a mass concentration of 0.1% lanthanum. After fully soaking, blow it with a fan and dry it in an oven. Repeat the above dipping, purging, and drying processes until the solution is completely coated on the active semi...

Embodiment 1

[0129] Preparation of selective catalytic reduction denitration catalyst, the specific steps are:

[0130] a. Forming a carrier containing transition metal oxides and rare earth modification additives

[0131] a1. Preparation of carrier

[0132] The required carrier was obtained through the following activation process: immerse 26g of semi-coke (passed through a 40-mesh Taylor sieve standard) in 200mL of nitric acid with a mass concentration of 20%, activate it at 80°C for 6 hours, dry it, and place it in a muffle In the furnace, it was annealed at 500°C for 6 hours, and after cooling with the furnace, activated semi-coke was obtained as a carrier.

[0133] a2. Form transition metal-containing support

[0134] Immerse 26.4g of the a1-treated carrier in 138mL of 10% manganese nitrate solution, treat for 2 hours, dry at constant temperature, and repeat the immersion and drying 3 times, so that the carrier can be loaded with soluble manganese salt as much as possible.

[0135]...

Embodiment 2

[0159] Preparation of selective catalytic reduction denitration catalyst, the specific steps are:

[0160] a. Forming a carrier containing transition metal oxides and rare earth modification additives

[0161] a1. Preparation of carrier

[0162] Immerse 12.8g of silicon-aluminum honeycomb ceramics in 120mL of nitric acid with a mass concentration of 5%, activate at 80°C for 3 hours, dry, place in a muffle furnace and anneal at 300°C for 6 hours, and after cooling in the furnace, the active Semi-focus, as a carrier.

[0163] a2. Form transition metal-containing support

[0164] Immerse 5.6 g of the a1-treated carrier in 80 mL of manganese acetate solution with a mass concentration of 25%, treat for 2 hours, dry at a constant temperature, and repeat the dipping and drying 3 times, so that the carrier can be loaded with soluble manganese salt as much as possible.

[0165] a3. Form a carrier containing transition metal oxides and rare earth modified additives

[0166] Immerse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com