Tire stock of IPN (Interpenetrating Polymer Network) crosslinked structure and mixing method as well as application thereof

A cross-linked structure and tire technology, applied in the field of rubber tires, can solve problems such as impossible to achieve, and achieve the effects of improving performance, high shear strength, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

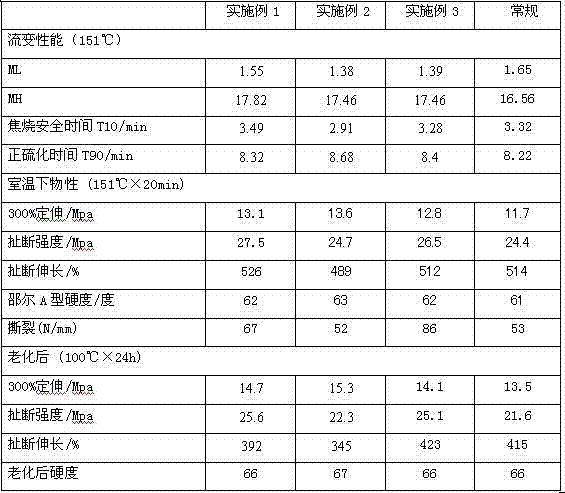

Embodiment 1

[0045] The tire cushion compound of IPN cross-linked structure, this compound is made up of following composition by weight:

[0046] natural rubber 100 Enyl ether 1 Terpene resin 2 carbon black 35.0 Silica 15 Zinc oxide 7.5 9010 1.2 Antiaging agent RD 1 stearic acid 1.0 softener 2 Antiaging agent 4020 3 Accelerator DTDM 0.8 sulfur 3.8 Accelerator NS 1.2 DCP 0.1 Accelerator D 0.2

[0047] The mixing method of above-mentioned sizing material, this method comprises the following steps:

[0048] a) Mastication: Add natural rubber to the internal mixer, rotate at 50 rpm, pressurize for 40 seconds to lift the mound, then pressurize for 35 seconds to lift the mound, and remove the rubber;

[0049] b) One-stage mixing: add masticated natural rubber, vinyl ether, and terpene resin into the internal mixer, the internal mixer speed is 50 rpm, and the pressure is lifted for 60 seconds. At this time, the polym...

Embodiment 2

[0053] The tire cushion compound of IPN cross-linked structure, this compound is made up of following composition by weight:

[0054] natural rubber 100 Cross-linked phenolic resin 1 Modified Rosin Resin 2 carbon black 35.0 Silica 15 Zinc oxide 7.5 9010 1.2 Antiaging agent RD 1 stearic acid 1.0 softener 2 Antiaging agent 4020 3 Accelerator DTDM 0.8 sulfur 3.8 Accelerator NS 1.2 Accelerator H 0.1 Accelerator D 0.2

[0055] The mixing method of above-mentioned sizing material, this method comprises the following steps:

[0056] a) Mastication: Add natural rubber to the internal mixer, rotate at 50 rpm, pressurize for 40 seconds to lift the mound, then pressurize for 35 seconds to lift the mound, and remove the rubber;

[0057] b) One-stage mixing: add masticated natural rubber, cross-linked phenolic resin, and modified rosin resin to the internal mixer, and the internal mixer speed is 50 rpm; The po...

Embodiment 3

[0061] IPN cross-linked tire tire pad rubber compound, the rubber compound is composed of the following ingredients in parts by weight:

[0062] natural rubber 100 Bismaleimide 1 Terpene resin 2 carbon black 35.0 Silica 15 Zinc oxide 7.5 9010 1.2 Antiaging agent RD 1 stearic acid 1.0 softener 2 Antiaging agent 4020 3 Accelerator DTDM 0.8 sulfur 3.8 Accelerator NS 1.2 DCP 0.1 Accelerator D 0.2

[0063] The mixing method of above-mentioned sizing material, this method comprises the following steps:

[0064] a) Mastication: Add natural rubber to the internal mixer, rotate at 50 rpm, pressurize for 40 seconds to lift the mound, then pressurize for 35 seconds to lift the mound, and remove the rubber;

[0065] b) One-stage mixing: add masticated natural rubber, terpene resin, and bismaleic imide into the internal mixer, and the internal mixer speed is 50 rpm; The polymer materials are all in a viscous f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com