Patents

Literature

403 results about "Natural resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural resin is a resin product which comes from a plant, in contrast with synthetic resin, which is made through chemical synthesis. Natural resins have been used in various human cultures for thousands of years; one notable example of an ancient use of resin can be seen in Egypt, where resin was used in the preparation of mummified bodies.

Natural resin formulations

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

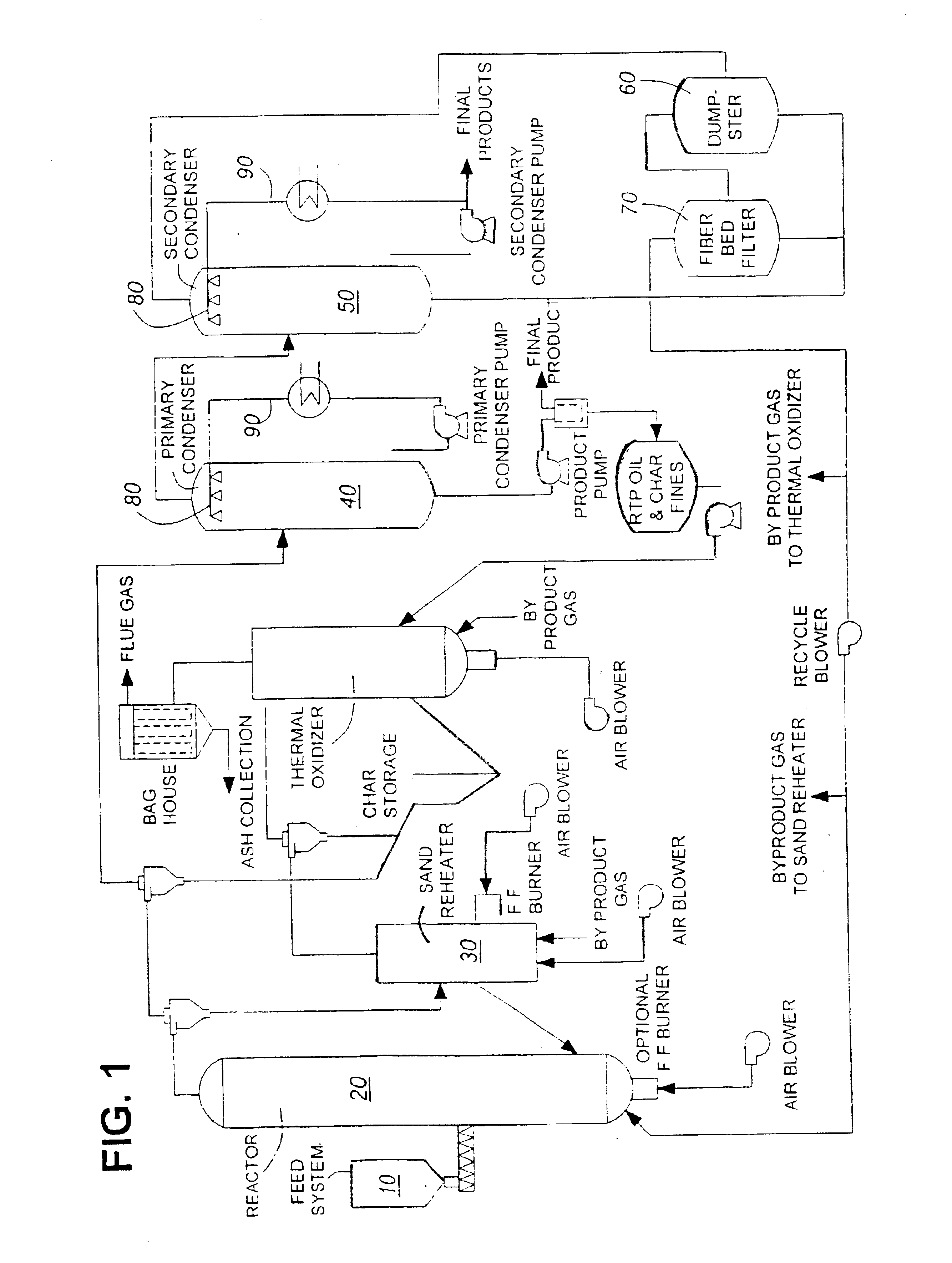

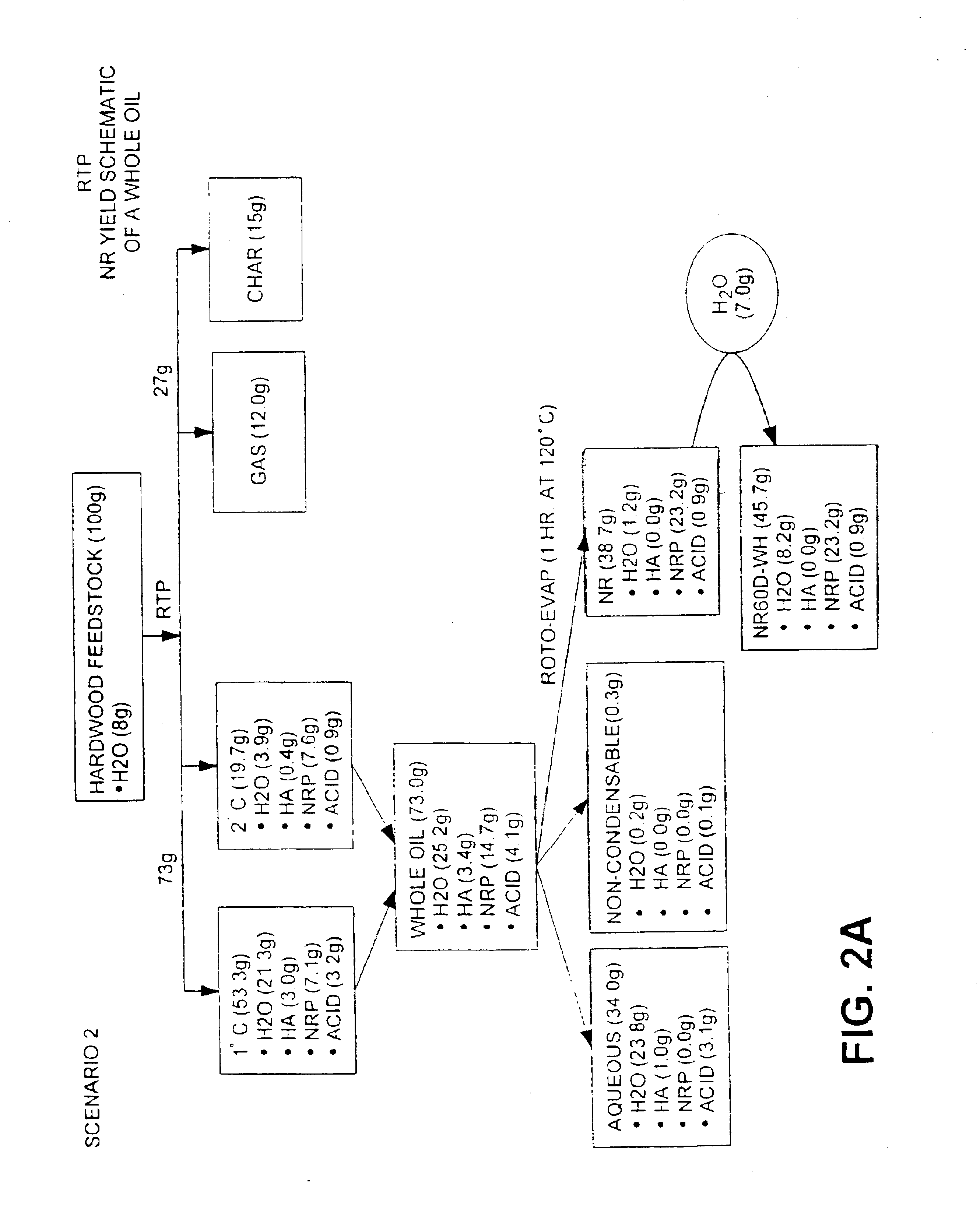

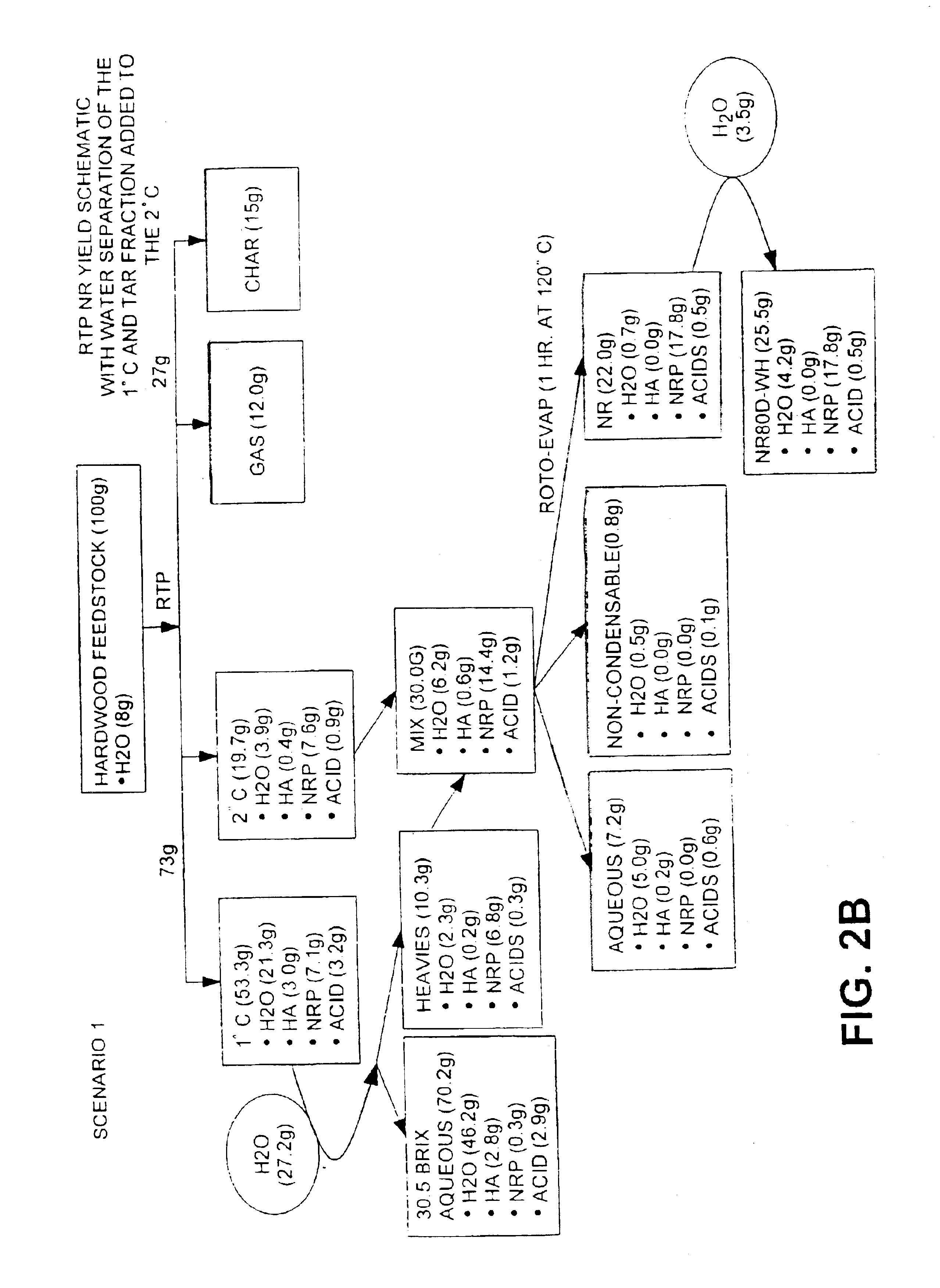

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

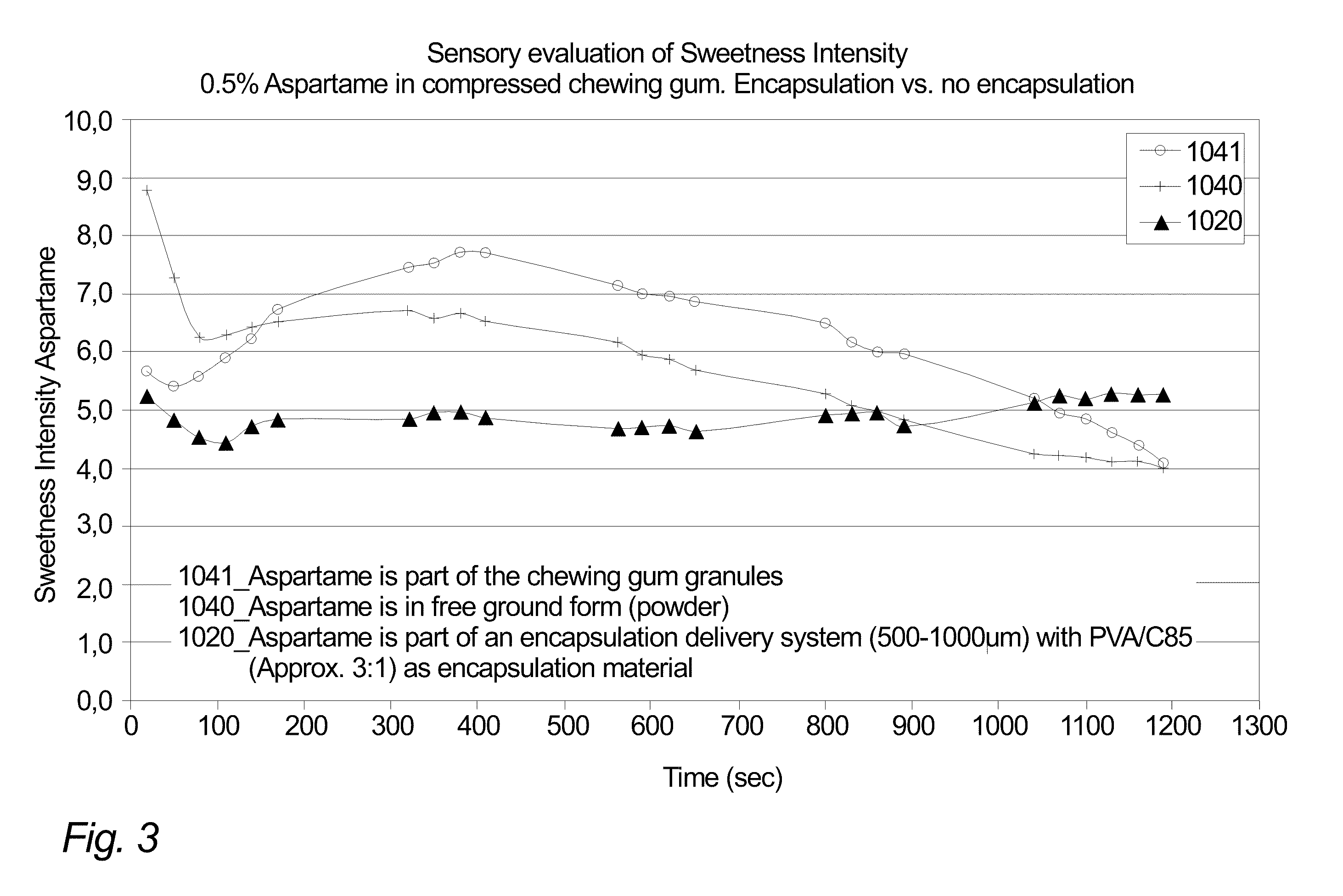

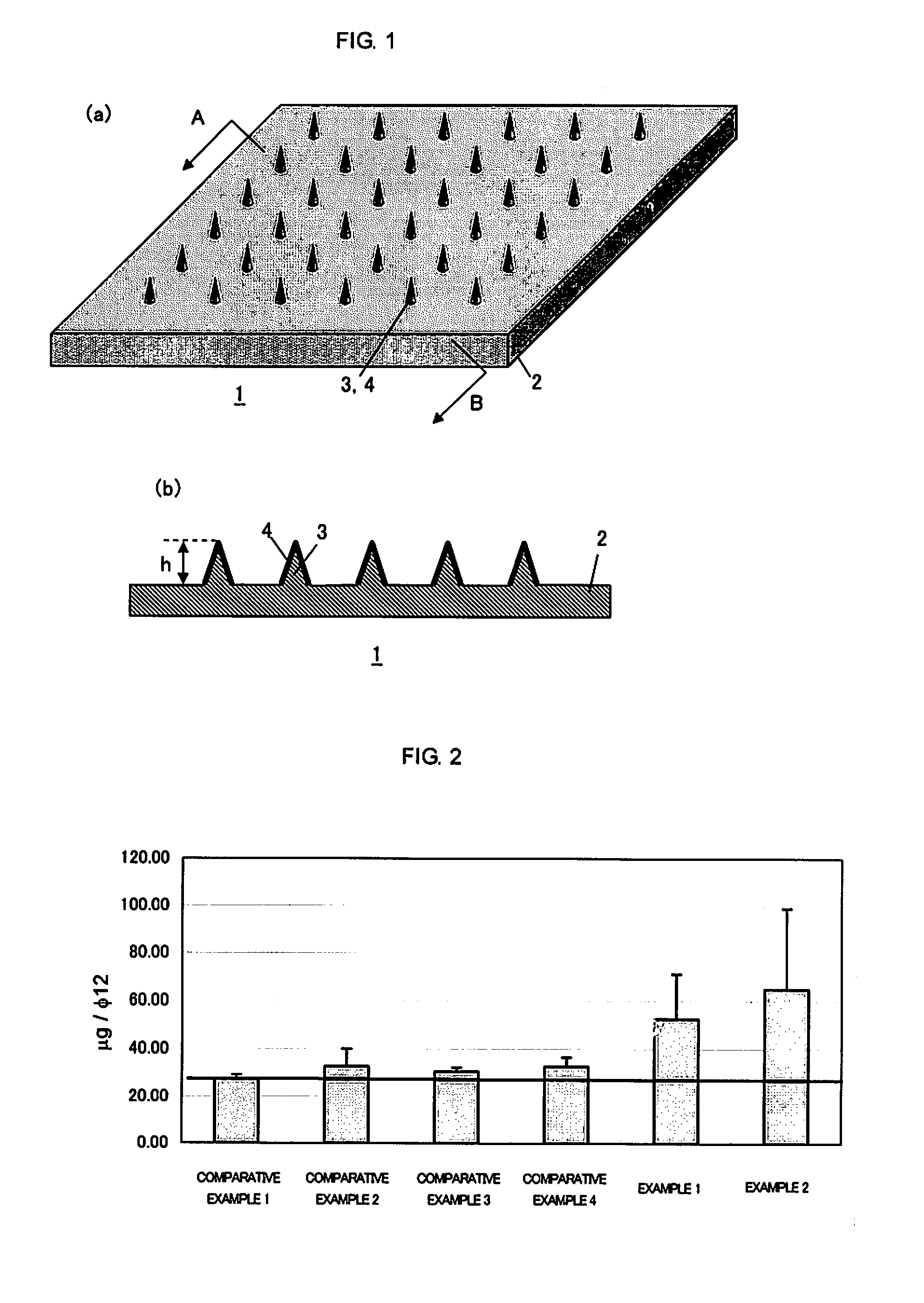

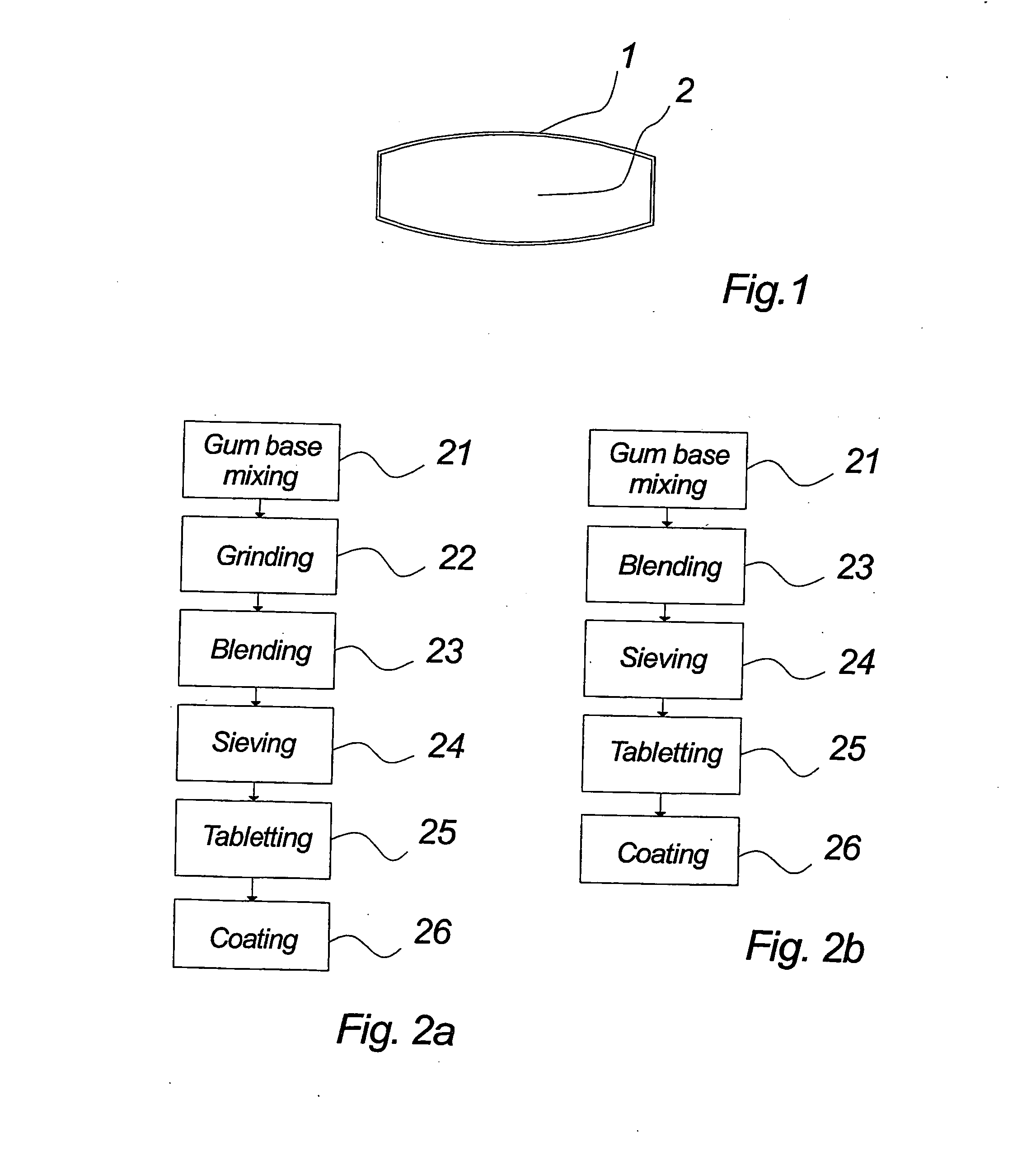

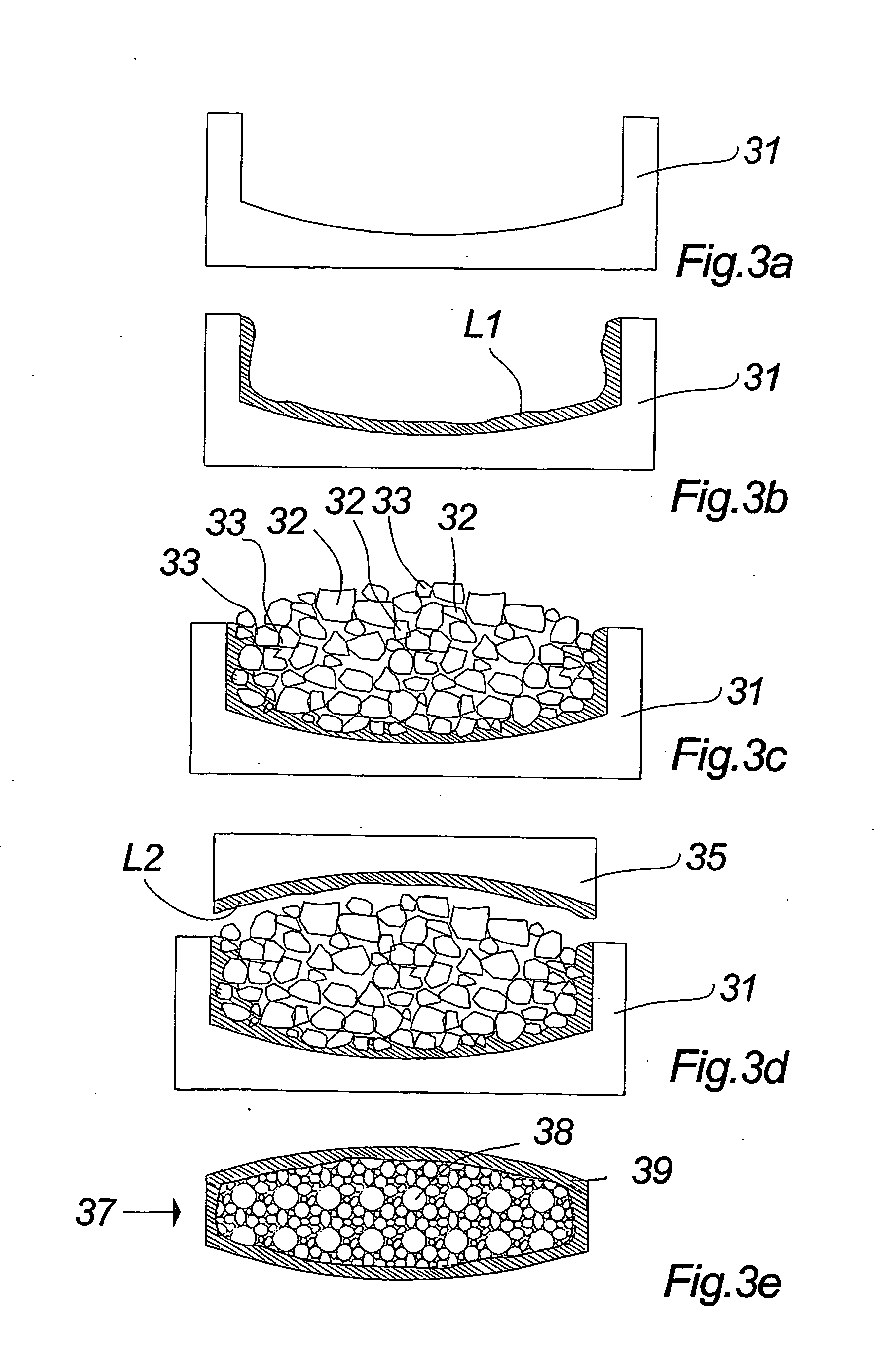

Compressed Chewing Gum Comprising An Encapsulation Delivery System Comprising Natural Resin

InactiveUS20100104689A1Avoid interactionWithout compromising texture propertyContainers for annular articlesChewing gumNatural resinAdditive ingredient

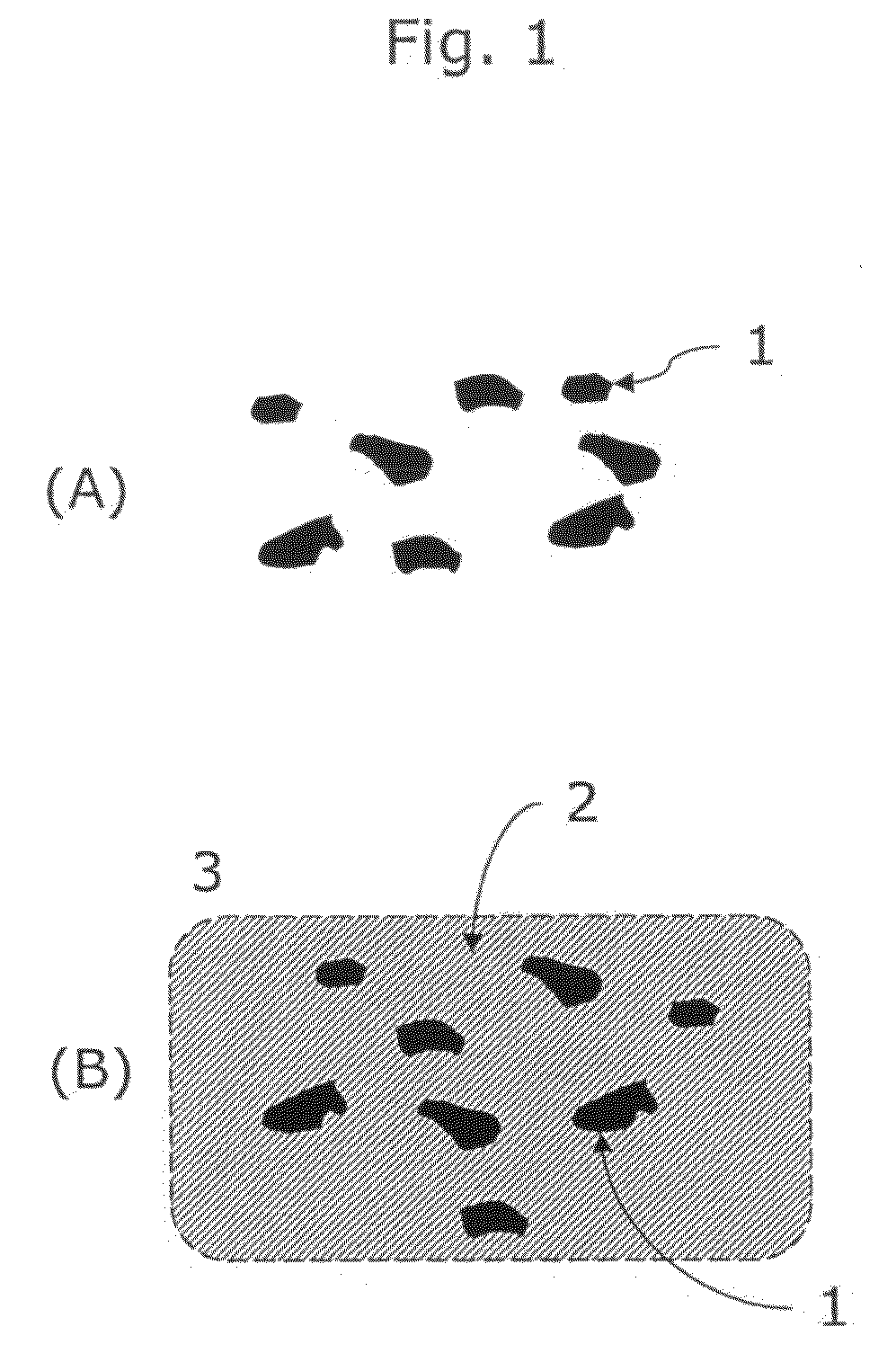

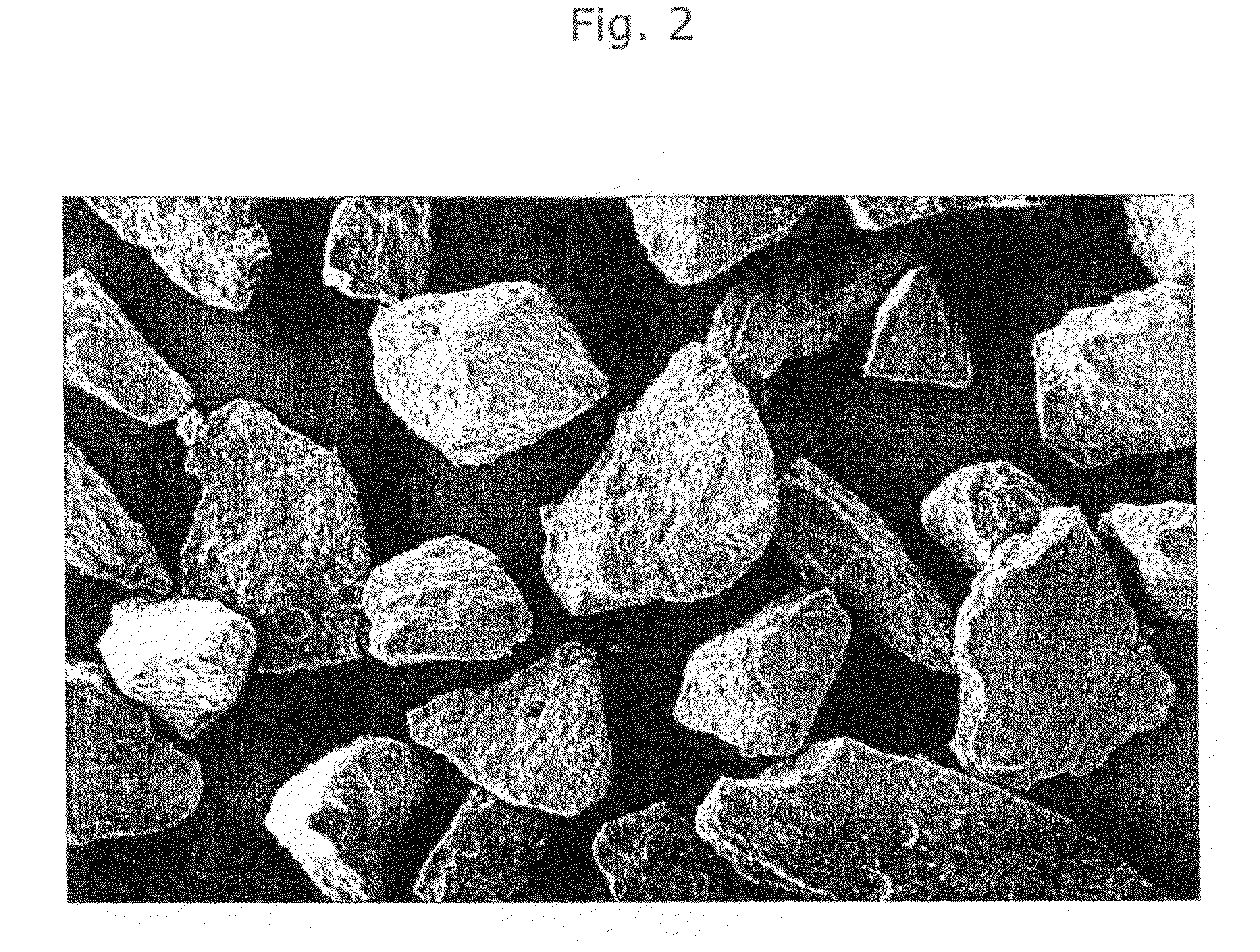

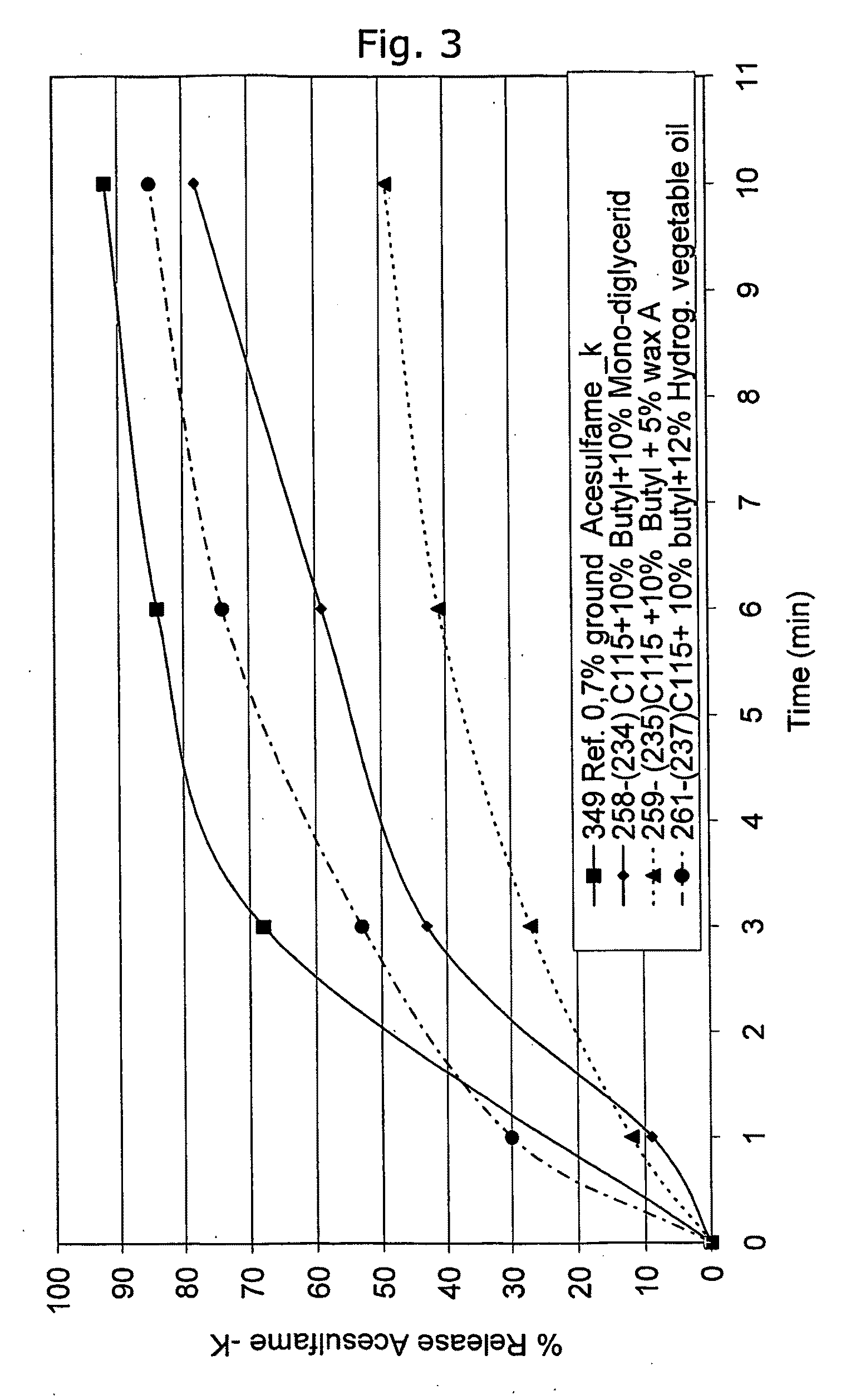

A compressible chewing gum composition includes i) chewing gum granules containing gum base and ii) particles of one or more encapsulation delivery systems including at least one encapsulation material and at least one active ingredient being encapsulated by the encapsulation material, wherein the encapsulation material includes at least one natural resin. The compressible chewing gum composition, which has been provided, is suitable for compression into compressed chewing gum tablets. Such compressed chewing gum tablets thus include a compression of a quantity of the compressible chewing gum composition and thus include chewing gum granules containing gum base and particles of one or more encapsulation delivery systems including an active ingredient encapsulated by an encapsulation material including natural resin.

Owner:GUMLINK AS

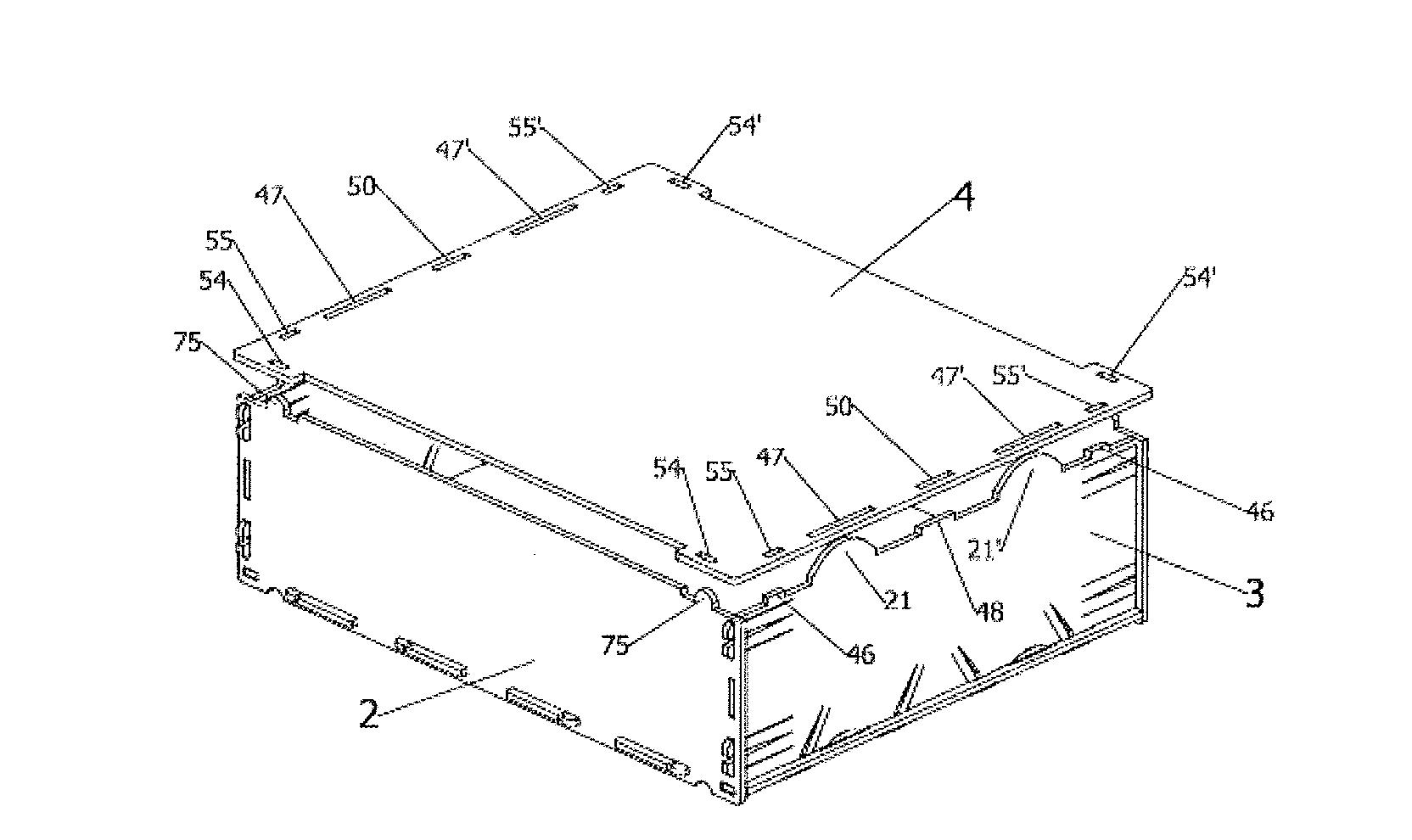

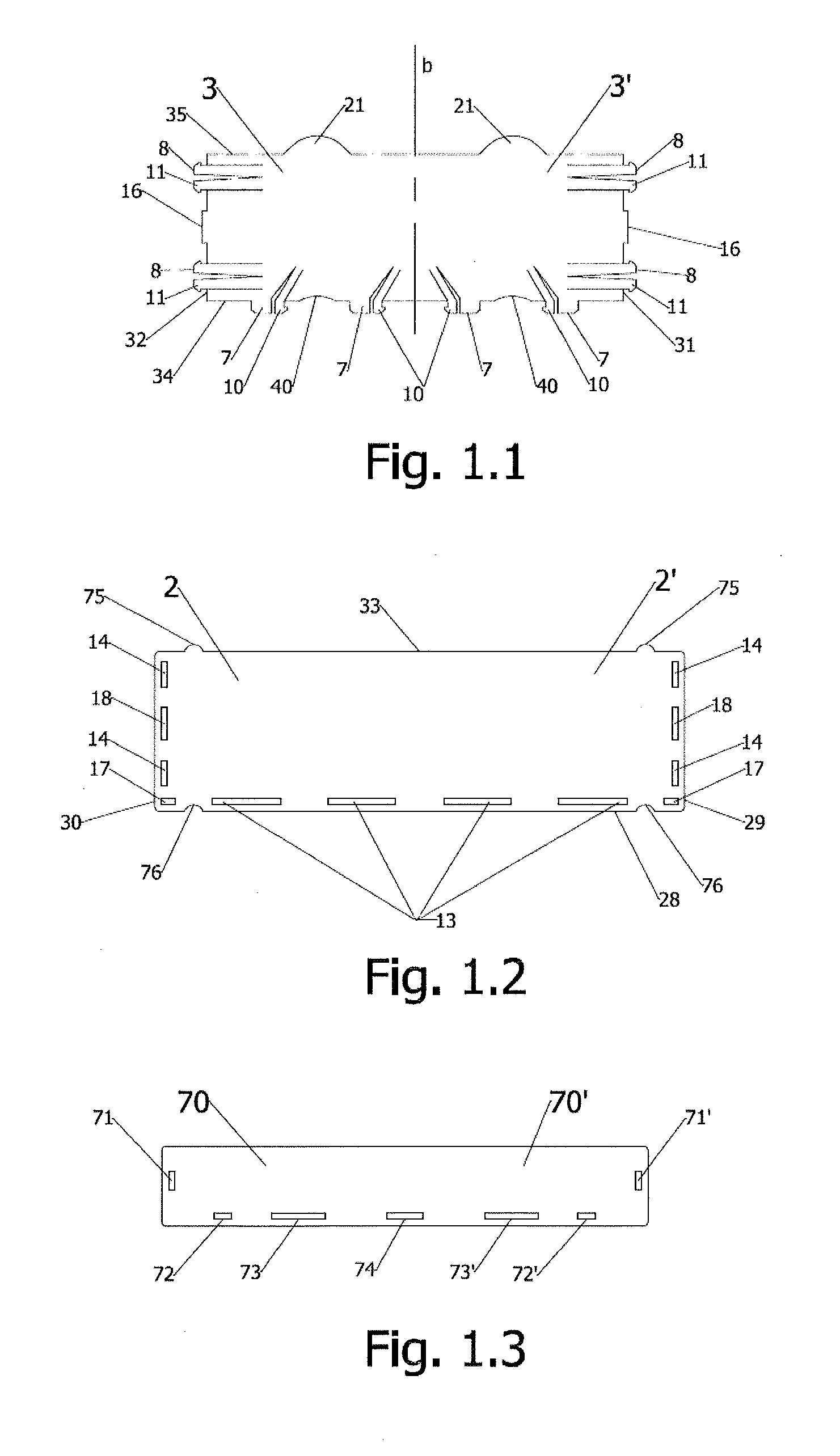

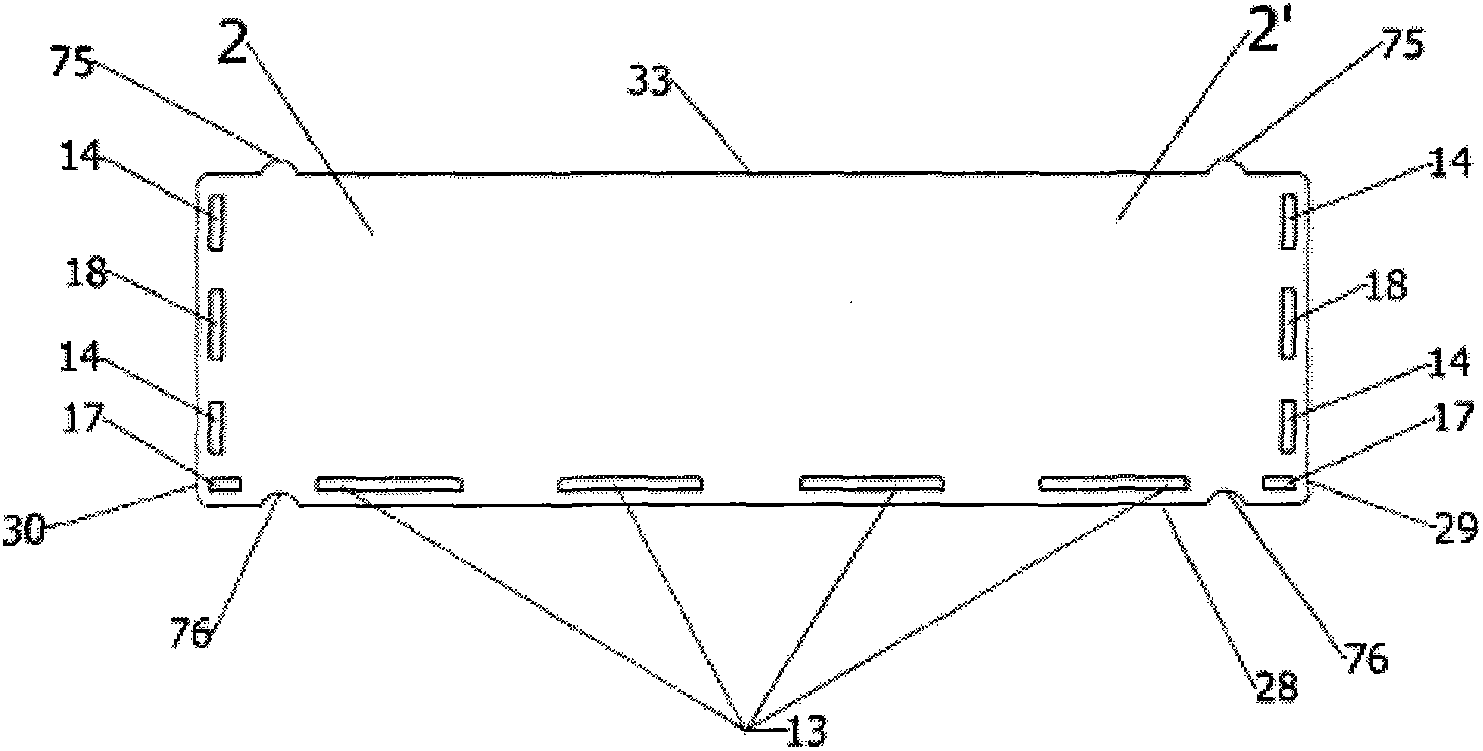

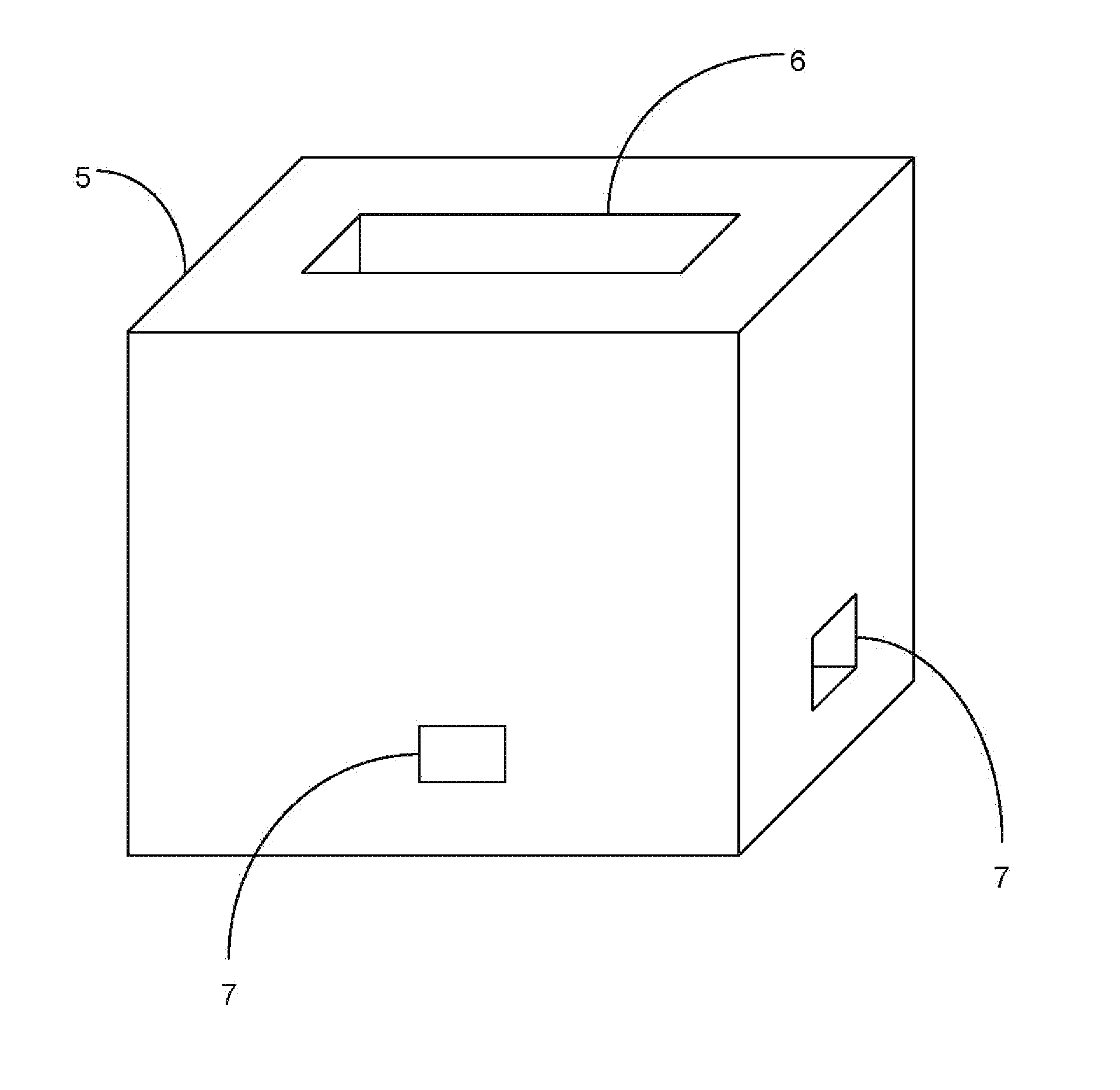

Self-assemblable container for generic use and manufacturing method thereof

ActiveUS20110309072A1Ensure structural stabilityAvoid disassemblyBoxes/cartons making machineryPaper-makingNatural resinMoisture penetration

The present invention refers to a self-assemblable container, preferably manufactured from ecologic materials such as standard fiberboard, comprising as its main structural elements a bottom, two longitudinal sides and two transverse sides of a basically rectangular shape having cauterized perimetrical faces to prevent moisture penetration into the structural elements that make up the container, thus providing long term structural stiffness to the perimetrical faces of the container's structural elements comparable to that of the fiberboard surface. Each of the main structural elements comprises in one side adjacent to another corresponding main structural element, tensile-resistant flexible tabs or receiving slots, the other corresponding main structural element in said side adjacent to the first main structural element respectively comprising slots or flexible tensile resistant tabs, said main structural elements being assembled together by the insertion of the flexible tabs into the receiving slots. In addition, the container may comprise an antisagging brace, a lid and / or two transverse laths. The invention also refers to a method of manufacturing the structural elements of a self-assemblable container by means of perimetrical laser cutting that by reason of the extremely high cutting temperature causes a reaction of the natural resins contained in the raw material and the resulting perimetrical cauterization.

Owner:COMPANIA DE PATENTES DEL PACIFICO

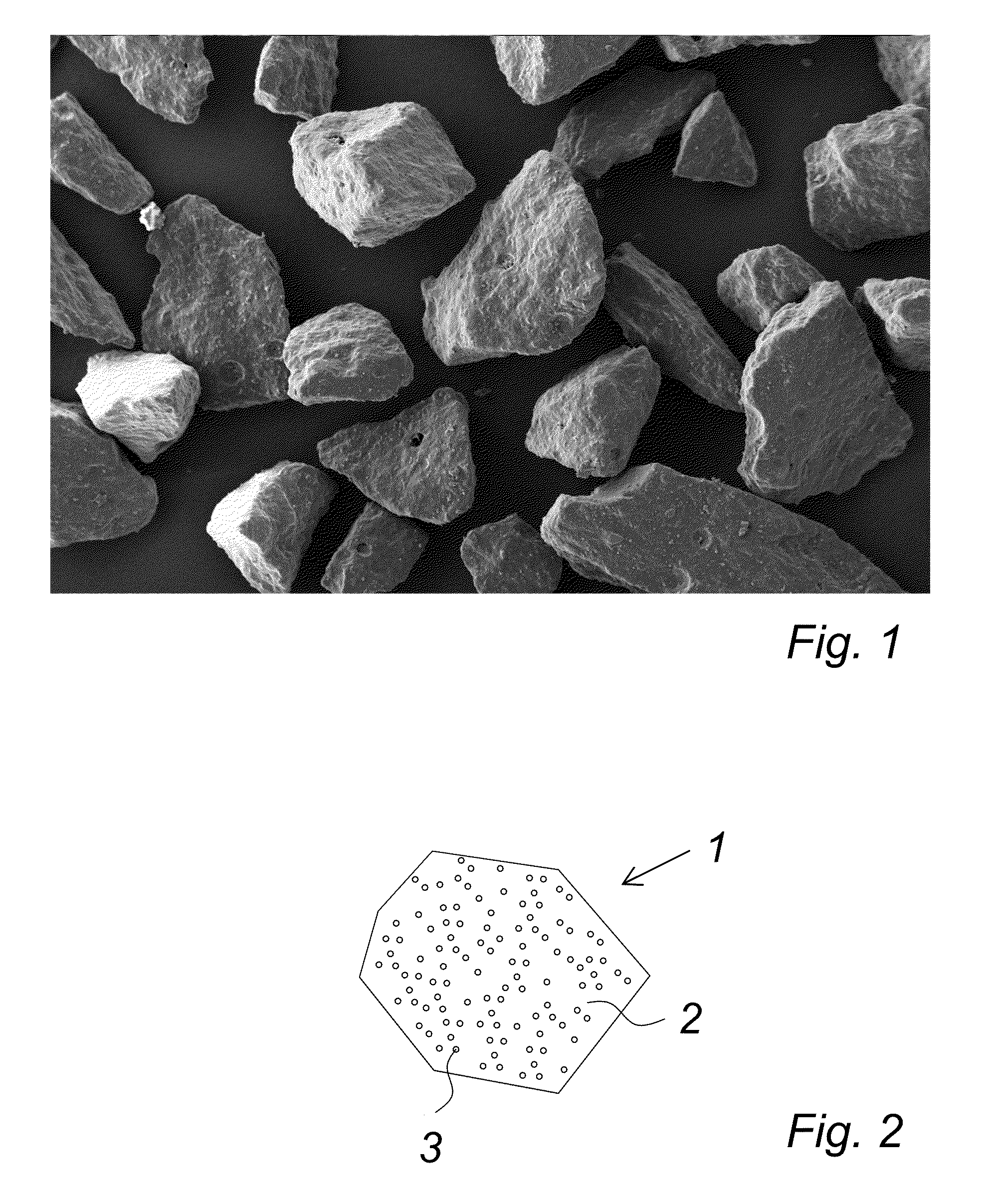

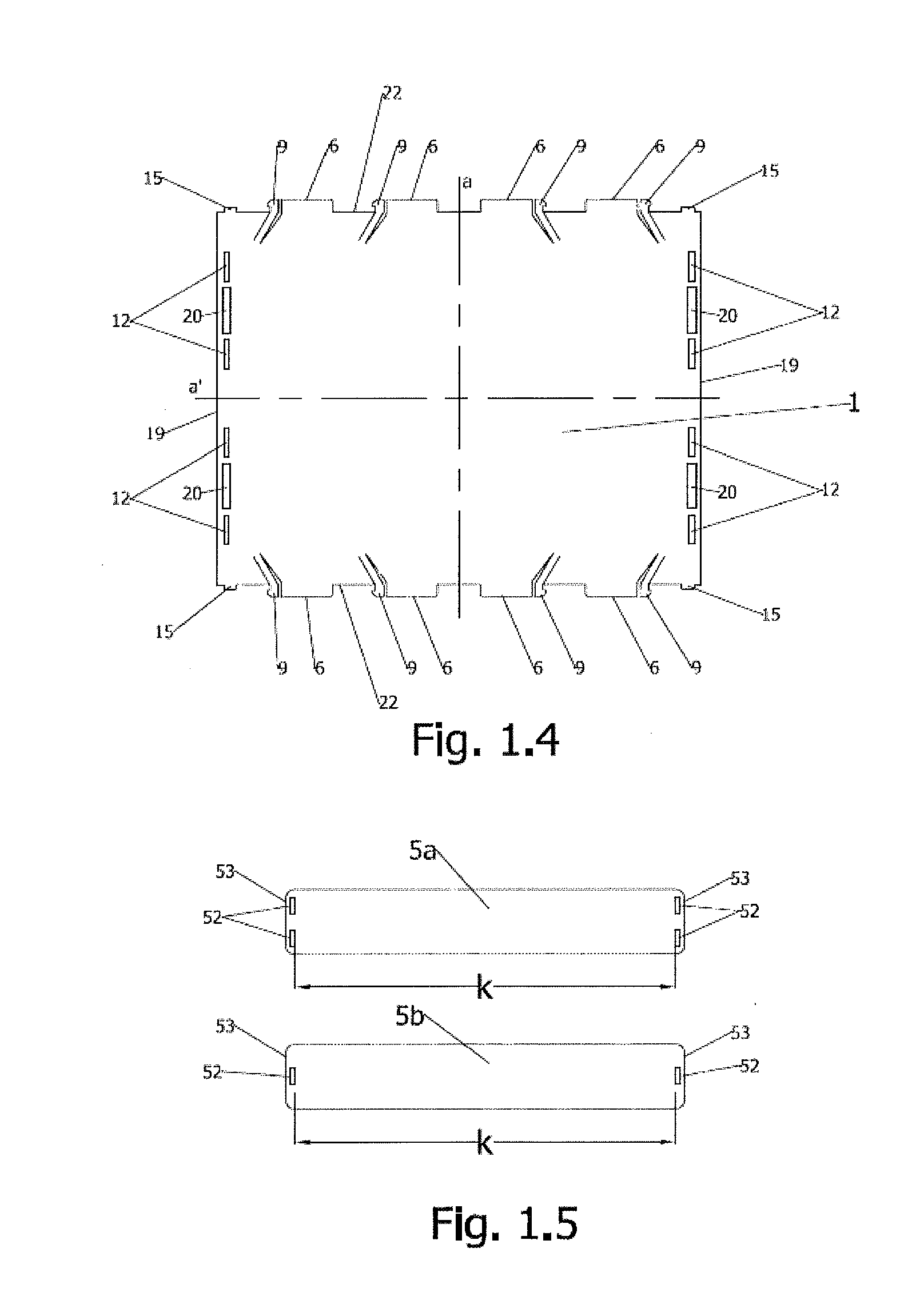

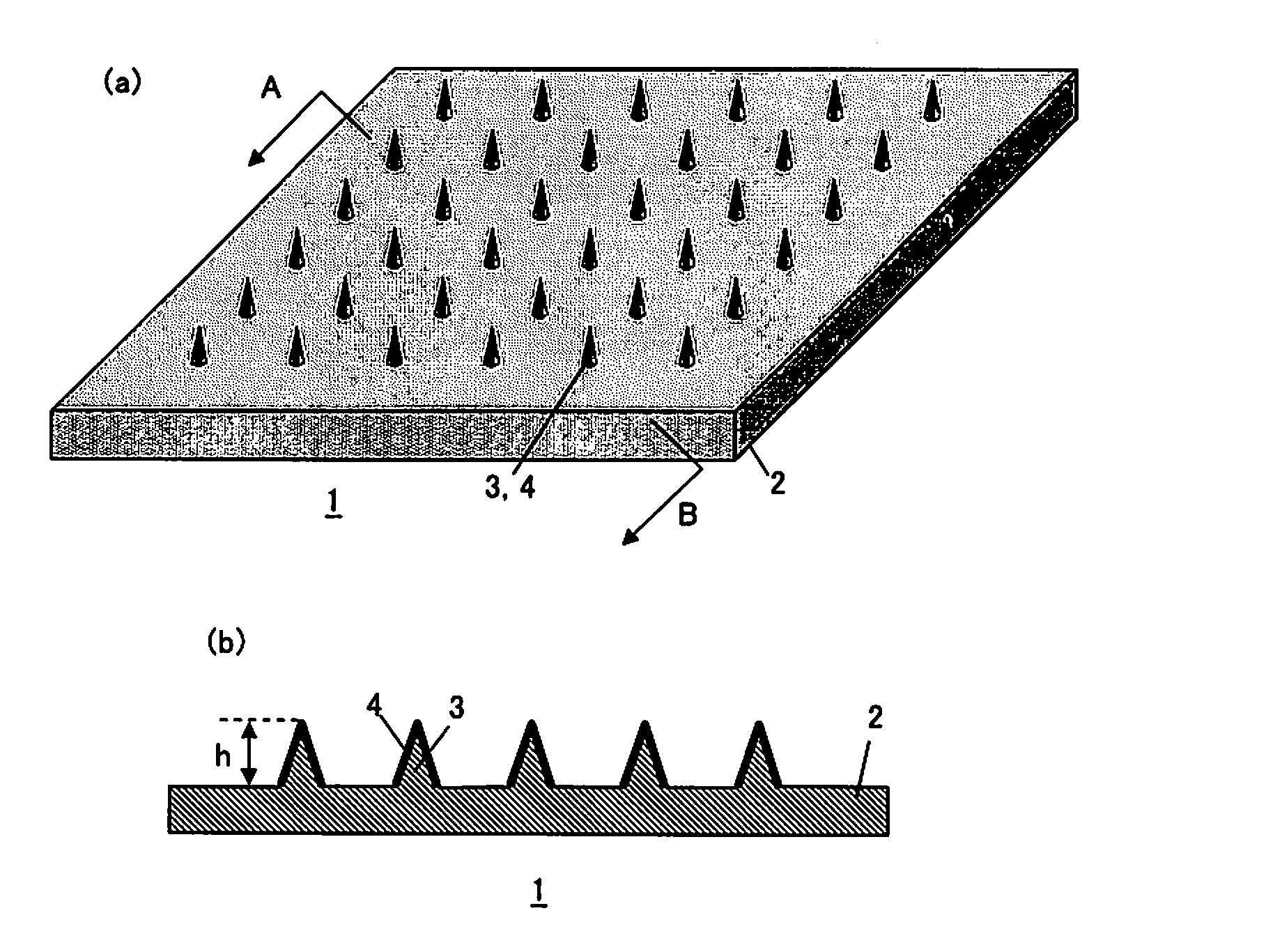

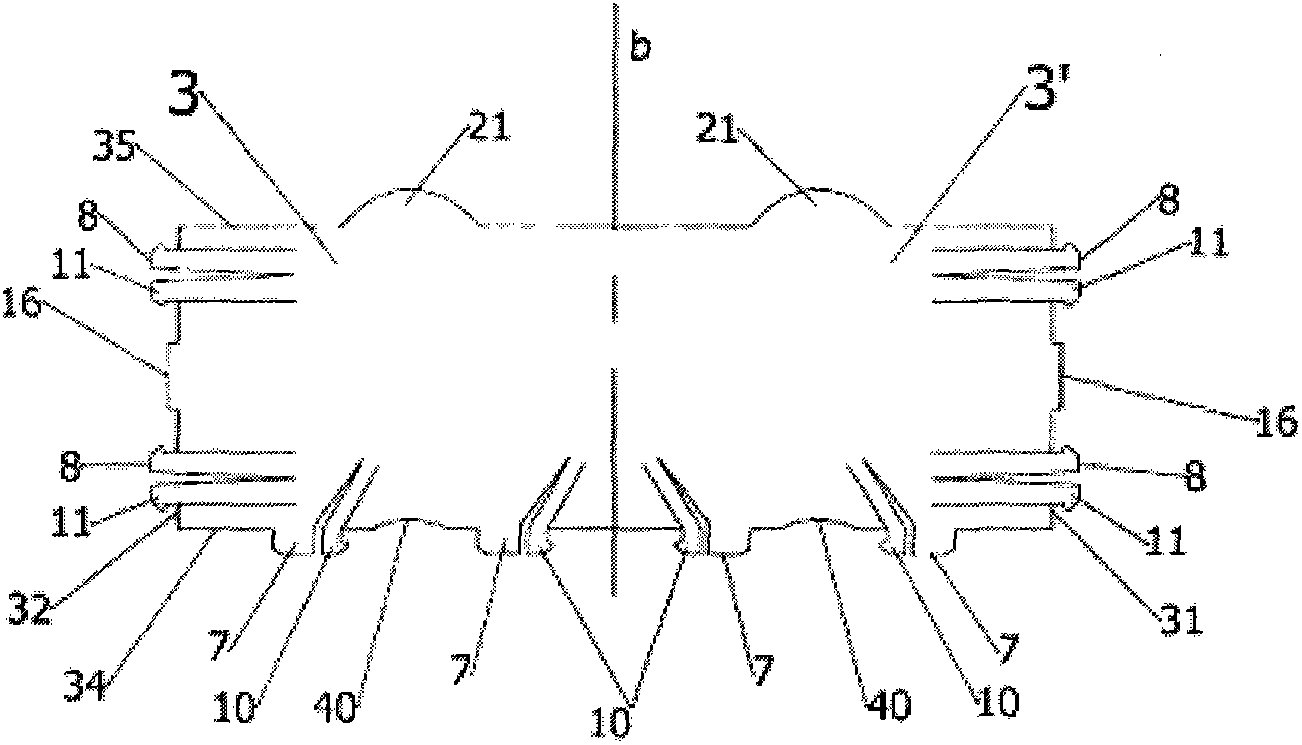

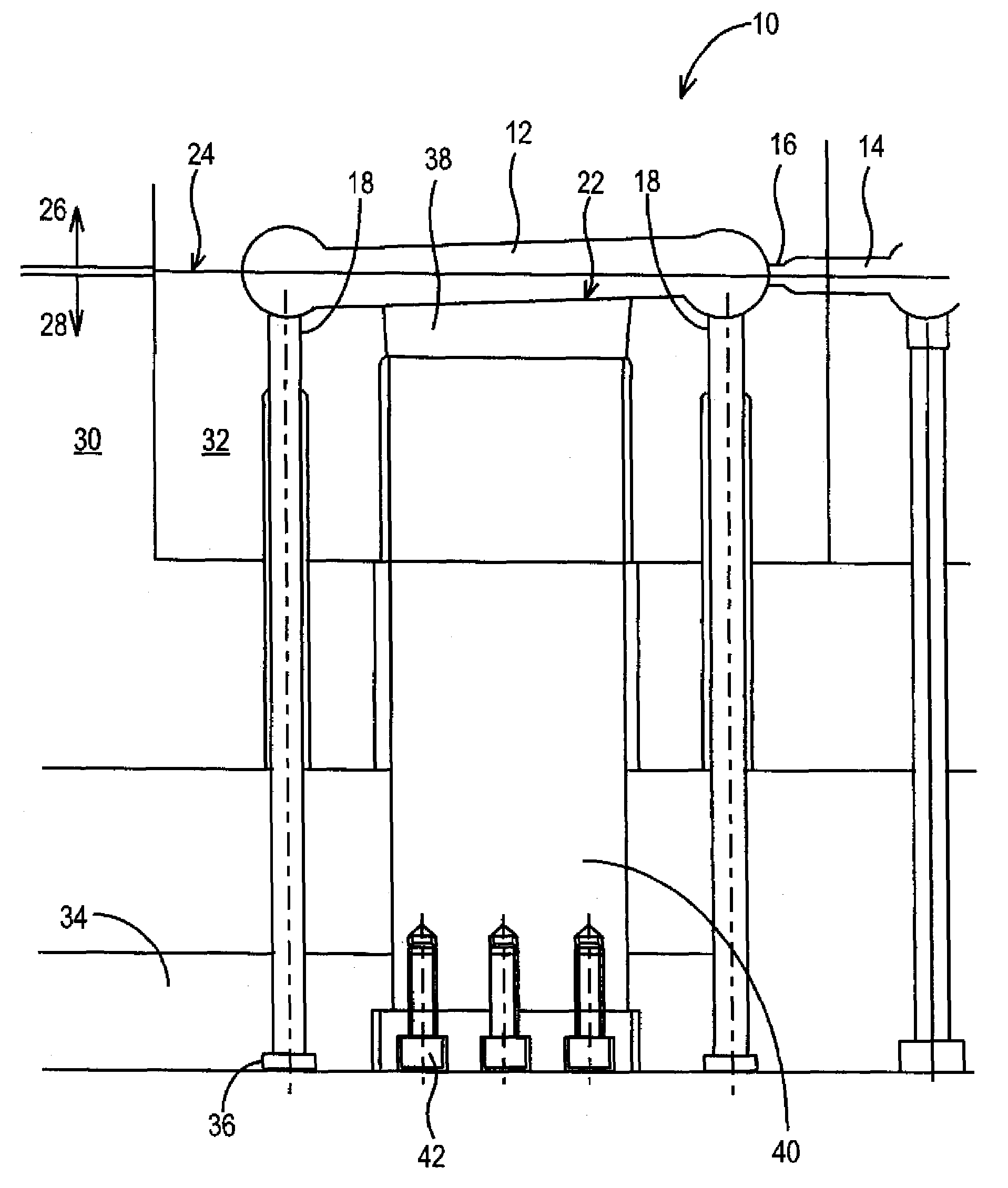

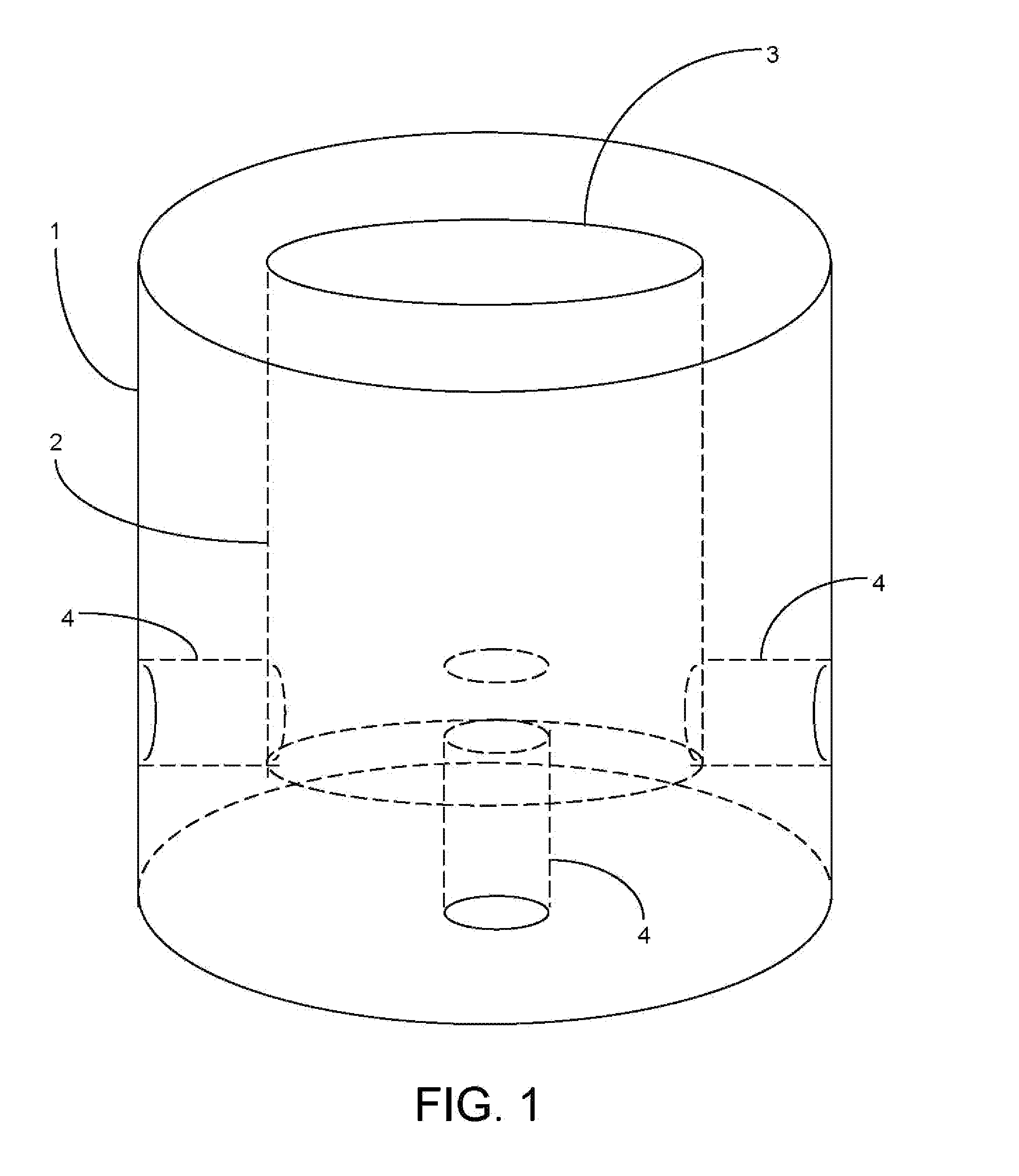

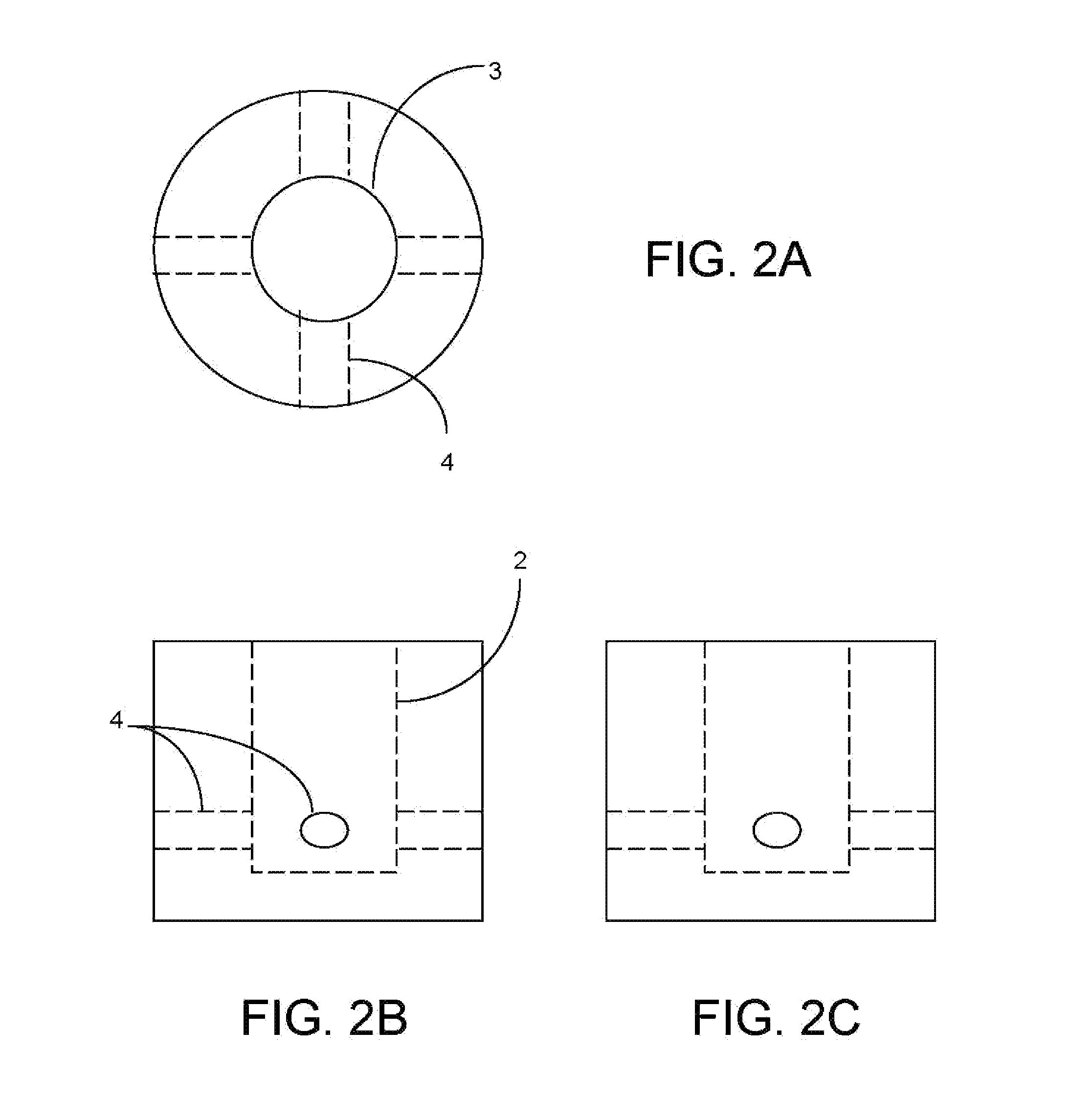

Microneedle Device For Diagnosis Of Allergy

InactiveUS20100030100A1Clearer skin testEasy to operateMicroneedlesVaccination/ovulation diagnosticsNatural resinSkin test

There is provided an inexpensive microneedle device for diagnosis of an allergy, enabling one to perform a clear skin test with simple operation for a short period of time in the diagnosis of allergies. The microneedle device (1) comprises: a microneedle substrate (2), microneedles (3) formed on the substrate at a density of 100 to 10000 needles per 1 cm2, being capable of piercing the skin 50 μm to 500 μm deep, and allergen-holding means (4) formed on the microneedles, holding at least one allergen. The microneedles (3) can be prepared by the use of a non-metallic synthetic or natural resin material.

Owner:HISAMITSU PHARM CO INC

Compressed resin moderated chewing gum

The invention relates to a compressed chewing gum tablet and gum base granule for such tablet including at least one elastomer in an amount of about 0% to about 35% by weight of the gum base, at least two resins in an amount of about 15% to about 60% by weight of the gum base, gum base ingredients and where the at least two resins include natural resin in an amount of about of about 5% to about 40% by weight of the gum base and synthetic resin in an amount of about 10% to about 40% by weight of the gum base.

Owner:GUMLINK AS

Method for production of preserved flower, and processing solution for use in the method

InactiveCN101861092AKeep natural colorReduce processDead plant preservationNatural resinVegetable oil

Disclosed is a method for producing a preserved flower, which enables to keep the original color of a real flower, particularly the subtle gradation in color of the real flower. Also disclosed is a processing solution for use in the method. Specifically disclosed is a method for producing a preserved flower, which comprises immersing a real flower in a processing solution and drying the flower, wherein the processing solution comprises a solution or dispersion containing at least one component selected from a natural oil material oil, a natural resin material, a siloxane, a synthetic resin, a water-addition-reaction-type urethane, a fatty acid ester and a surfactant, wherein the natural oil material is terpin oil, stand oil, whale oil, boiled oil, linseed oil, camellia oil, olive oil, rapeseed oil, a salad oil (a purified plant oil), sesame oil, camphor oil or the like, wherein the natural resin material is rosin, glue, wax, bees wax, rubber, rhus lacquer or the like, and wherein the fatty acid ester is an ester of a saturated or unsaturated fatty acid such as lauric acid, palmitic acid, stearic acid and myristic acid and a lower or polyhydric alcohol.

Owner:坂本好央

Rice hull fiber synthetic resin powder and manufacturing technology of rice hull fiber products

InactiveCN102690524AIncrease valueEnhanced value, the product of the present invention has super water resistanceFurniture waste recoveryCelluloseNatural resin

The invention relates to the field of chemical materials, in particular to a rice hull fiber synthetic resin powder and a manufacturing technology of rice hull fiber products; rice hulls are grinded to obtain rice hull powder; the hull powder is put into a mixer; cellulose, starch and water are added into the mixer to mix uniformly; then a mixture is taken out and cooled to obtain rice hull fiber powder; in addition, natural resin and lignin are put into a reactor; water is added into the reactor to stir uniformly and obtain slurry; then nano-silica is added into the slurry, continuously stirred uniformly and cooled; the rice hull fiber powder is added and continuously stirred; then the mixture is taken out after cooling to obtain paste materials; and then the paste materials are directly injected into a flash streaming drier to obtain the rice hull fiber synthetic resin powder; and the rice hull fiber synthetic resin powder can be used for manufacturing the rice hull fiber products such as tableware, toys, furniture, kitchen wares and so on, can be featured with hardness, high density, no toxicity, low cost and environmental protection, and also can be automatically degraded in the natural world to produce organic fertilizers; the products is featured with long service and wide market prospect.

Owner:HUSKS QUANZHOU GREEN TECH CO LTD

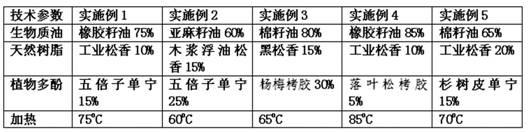

Environmentally-friendly biomass compound rubber regenerant and preparation method thereof

The invention provides an environmentally-friendly biomass compound rubber regenerant. The regenerant is prepared from the following raw materials in mass percentage: 60-85% of bio-oil, 10-20% of natural resin and 5-30% of plant polyphenol. The preparation method of the regenerant comprises the following steps: (1) heating the bio-oil to 60-85 DEG C; (2) respectively adding the natural resins andthe plant polyphenol to the bio-oil and evenly mixing; and (3) naturally cooling the evenly mixed product to room temperature to finally obtain the environmentally-friendly biomass compound rubber regenerant product. In the invention, the bio-oil, the natural resins and the plant polyphenol which are extracted from plants are taken as raw materials, and the raw materials are renewable materials, which realizes maximum resource utilization and reduces dependence on petrochemical resource so as to achieve the purpose of green production of reclaimed rubber. The regenerant has the advantages of good rubber regeneration effect, high product quality, low production cost and no pollution and nuisance during the production process. The environmentally-friendly reclaimed rubber produced by the regenerant can be widely applied to various rubber products and can replace rubber materials, thus saving rubber resources.

Owner:KUNMING PHOENIX RUBBERS

Paper pulp moulded sheet material and making method thereof

InactiveCN1433936AHigh compressive strengthImprove toughnessFlexible coversConstruction materialNatural resinAluminium sulfate

The present invention discloses a paper pulp moulding sheet material with high compression strength, good toughness and good moisture resistance. Its raw material composition includes waste paper, natural resin, starch and aluminium sulfate according to the mixing ratio of 100:5-10:5-20:1-2 and its production process inctudes the following steps: breaking pulp, mixing pulp, concentrating, moulding-forming, dampness-removing and drying and finishing. Said invented product is non-toxic, smellless, and has no irritation and can be naturally degraded, can be substituted for wood plate and artificial veneer, so that it has extensive application.

Owner:朱桂兴

Water-resistant putty powder

The invention discloses water-resistant putty powder and relates to the technical field of building materials. The water-resistant putty powder is prepared from, by weight, 18-35 parts of white cement, 2.5-3.5 parts of palygorskite clay, 3-8 parts of bagasse fibers, 0.5-1 part of hydroxypropyl methyl celluloses, 5-10 parts of natural resin and 2.5-3.5 parts of sodium alginate. The water-resistant putty powder is capable of solving the problem that existing water-resistant putty powder is not resistant to water.

Owner:LIUZHOU PUYA TRADE

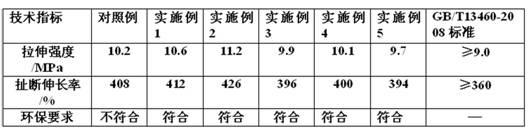

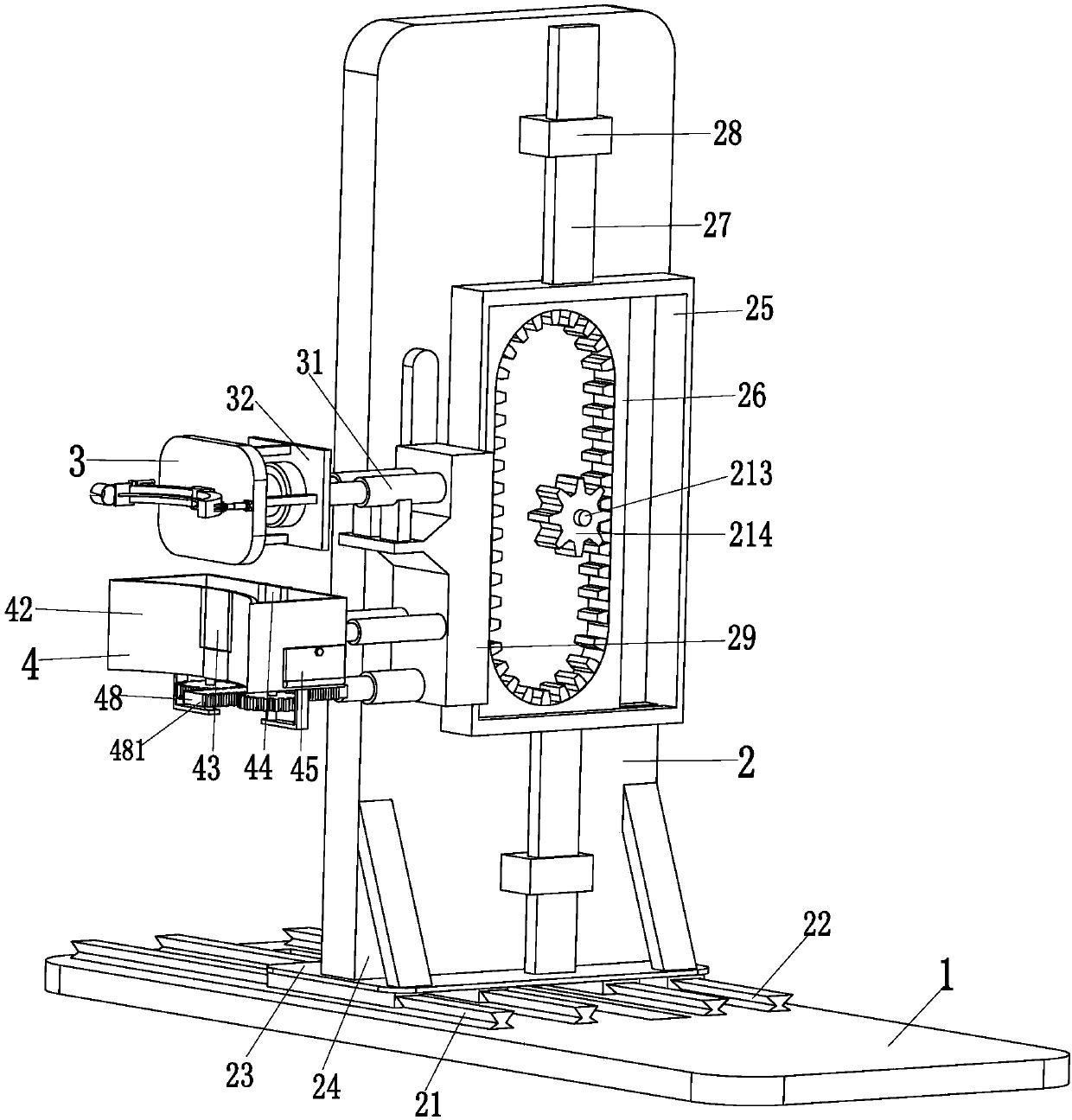

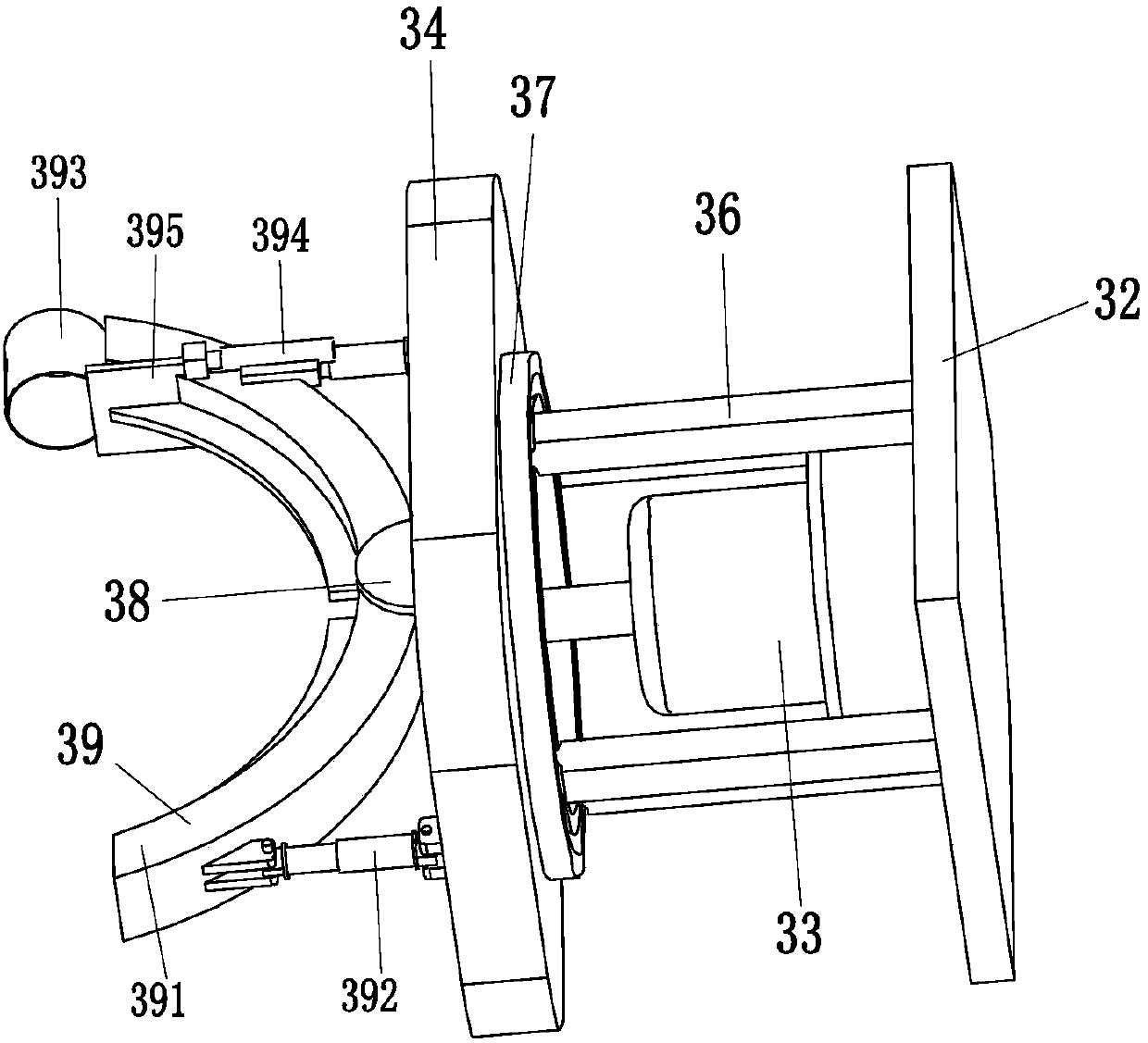

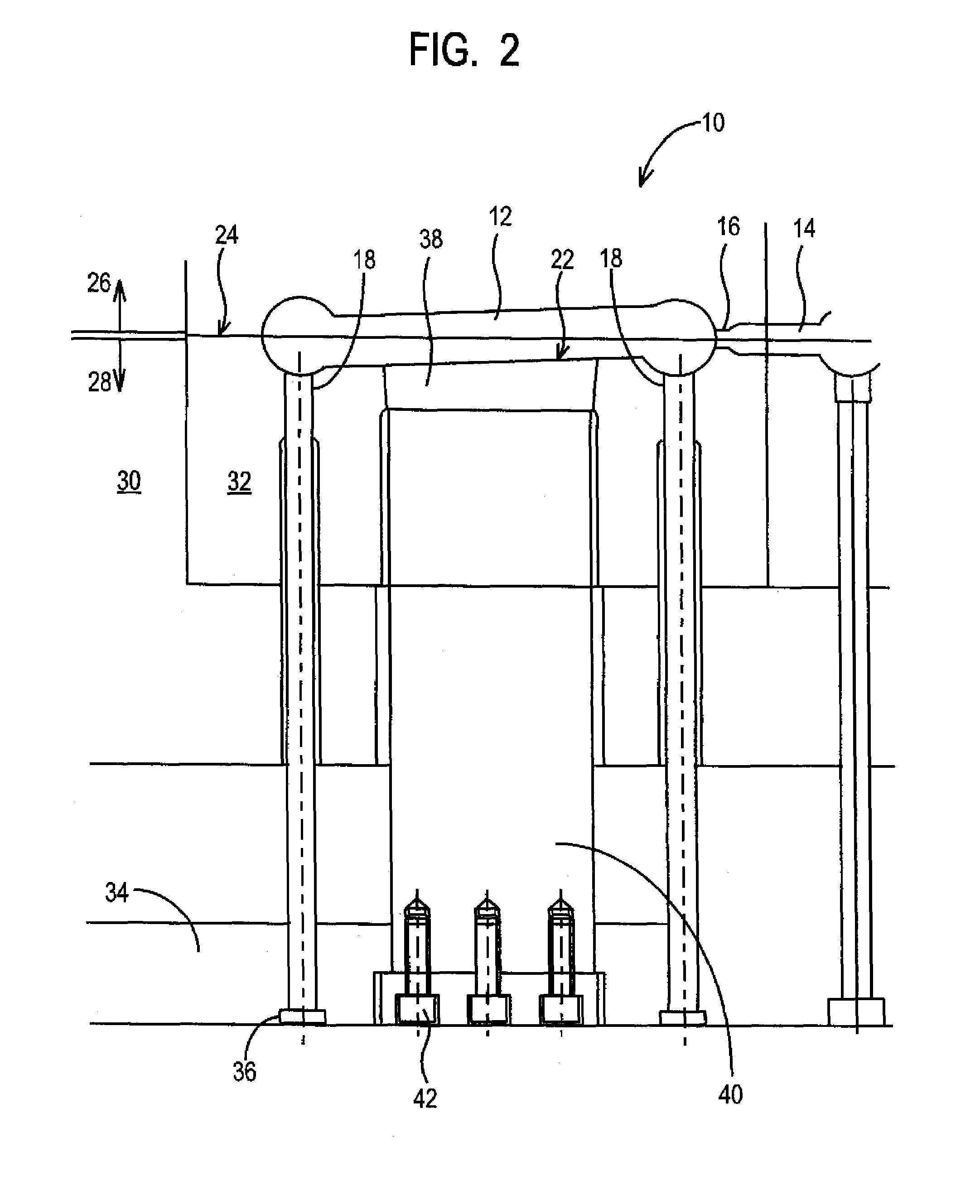

Pine bark treatment machine for acquiring rosin which mainly comprises natural resin and is raw material for preparing latex paint

The invention relates to a pine tree skin treatment machine for the collection of natural resin rosin, which is a raw material for latex paint preparation There are a rotating device and a lifting support device, the scraping device and the recovery device are installed on the rotating device, and the two slotting devices are symmetrically installed on the lifting support device. The invention can solve the problem that the existing manual scraping and grooving of pine trees have poor skin scraping effect and easily scratch the tree, the scraped pine bark cannot be recycled, two kinds of tools are required for scraping and straight grooving, and the inclined It is impossible to control the groove depth and other problems when grooving; it can automatically scrape the bark of pine trees, and automatically open straight grooves and oblique grooves for pine trees. Recycling, skin scraping and straight grooving require advantages such as a tool.

Owner:宋当建

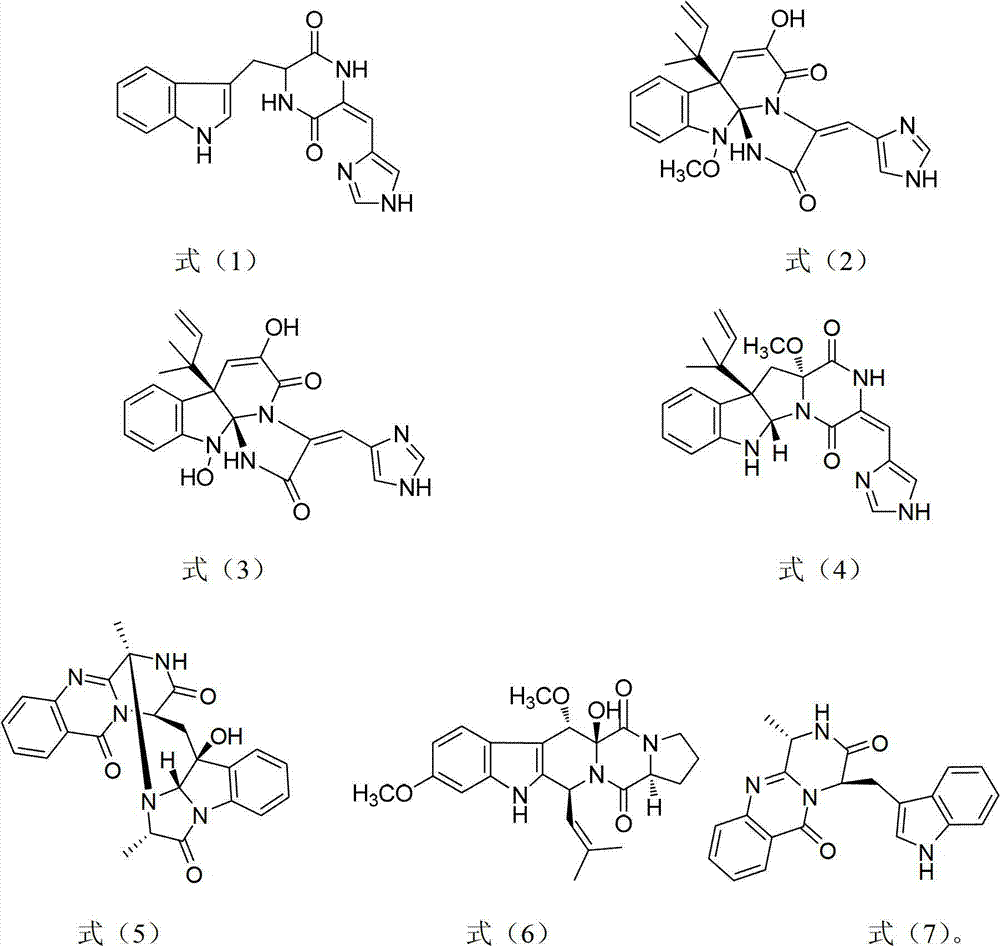

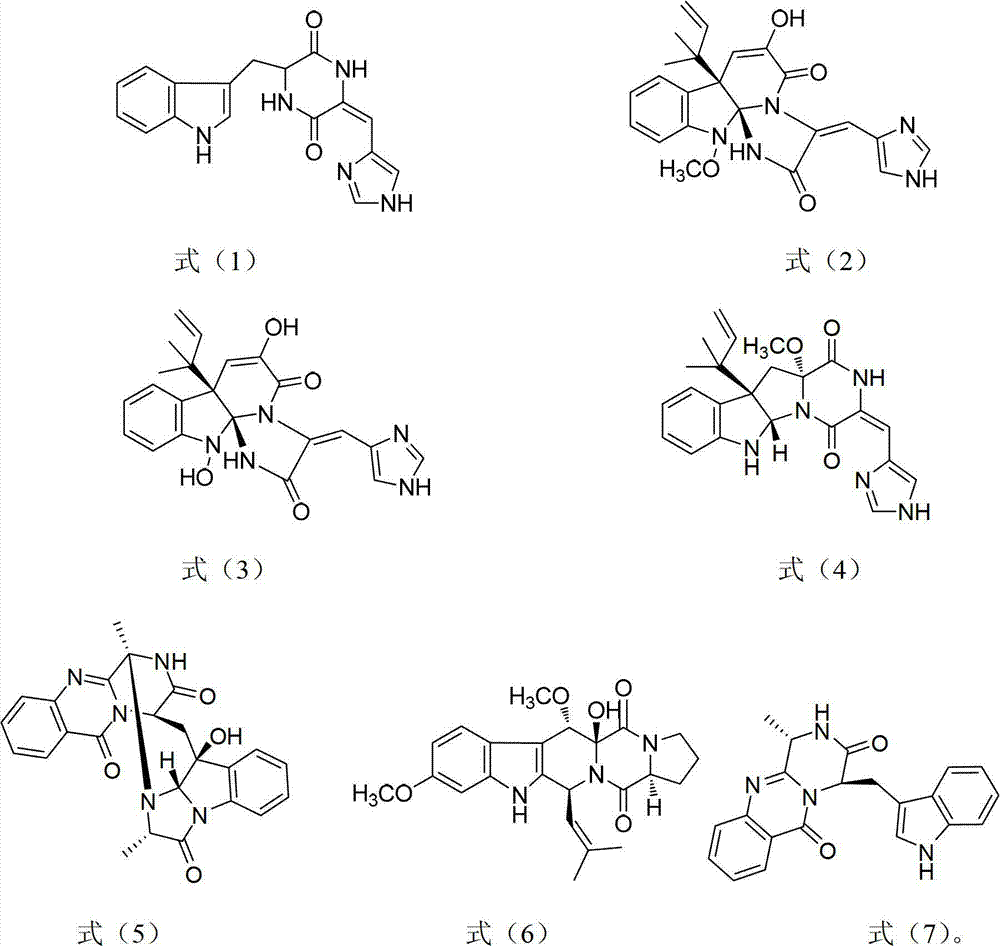

Application of class of indole alkaloids to preparation of marine biofouling prevention coating material

ActiveCN102757677AImprove lipophilicityAntifouling/underwater paintsPaints with biocidesNatural resinBiofouling

The invention discloses application of a class of indole alkaloids to preparation of a marine biofouling prevention coating material. The (E)-3-(1H-imidazole-4-yimethylene)-6-(1H-indl-3-ylmethyl)-2,5-piperazinediol (figured in formula 1), the meleagrin (figured in formula 2), the glandicoline B (figured in formula 3), the 11alpha-methoxyroquefortine C (figured in formula 4), the fumiquinazoline D (figured in formula 5), the cyclotryprostatins B (figured in formula 6) and the fumiquinozaline G (figured in formula 7), which are provided by the invention, have marine biofouling prevention activity and can be used for preparing the marine biofouling prevention coating material; if the compounds permeate or diffuse into film forming natural resin, polyethylene ethyl acetate copolymer and other polymers such as hydrolyzable, soluble or insoluble resin in an independent or combined way to prepare the marine biofouling prevention coating material, the marine biofouling prevention coating material can release sufficient effective components to a surface to achieve an antifouling function; and as the compounds are natural active ingredients, are hard to dissolve in water but easy to dissolve low-polarity organic solvents such as chloroform and ethyl acetate, and have favorable oleophilic properties, the components can be applied to preparing the marine antifouling agents in an independent or combined way and have a favorable application prospect.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Manufacturing technology of plant fiber synthetic resin powder and plant fiber product

The invention relates to the field of chemical materials, in particular to a manufacturing technology of plant fiber synthetic resin powder and a plant fiber product. The manufacturing technology comprises the following steps: grinding plant fiber into plant fiber powder with molecules, putting the plant fiber powder into a high-speed mixer, adding rice bran wax and starch, evenly mixing, putting into a reaction kettle, evenly stirring into pulp by added water, heating up by adding natural resin powder into pasty materials, and injecting into a flash streaming drier to prepare into the plant fiber synthetic resin powder. The manufacturing technology is the recycle derived from the plant fiber residue. The product of the manufacturing technology has the natural color and fragrance of the plant fiber per se, has super-strong water resisting property, further has the characteristics of being hard, high-density, smooth, non-toxic, low-cost, environment-friendly and the like, and can be automatically degraded into organic fertilizer in the natural world, and can return to nature, and the product produced by the manufacturing technology is freezing-resistant, high temperature-resistant, good in intensity, density and hardness, and long in service life, thereby being an environment-friendly material, and wide in market prospect.

Owner:XIAMEN HUSKS NEW MATERIAL TECH CO LTD

Preparing method for terahertz active functional water

InactiveCN106219837AIncrease the concentration of negative ionsPlay a role in health careWater/sewage treatment by irradiationTreatment involving filtrationNatural resinRubidium

The invention discloses a preparing method for terahertz active functional water. The terahertz active functional water is prepared from natural minerals, animal and plant materials, an additive and resin. The preparing method comprises the step that allophone, imogolite, tourmaline, attapulgite, oriental cherry roots, juniper roots, bamboo charcoal, coral tissue, lanthanum, rubidium and yttrium oxide, and natural resin or synthetic resin are adopted in preparation by weight. According to the preparing method, as rich OH-negative ions exit in water, the active functional water with rich negative ions is formed, actual measurement shows that the PH value of the water containing terahertz waves reaches 12.5 or above, the redox potential is -250 mV, the emission wavelength is 4-16 micrometers, and the normal emissivity reaches 88%; the active functional water has the health-care functions of promoting expansion of tip blood vessels of the human body, promoting recovery of tissue functions, improving blood microcirculation, removing fatigue substances such as lactic acid, improving the metabolism, and the like.

Owner:嘉兴中技科技服务有限公司

Biodegradable Chewing Gum Comprising Biodegradable Polymer with High Glass Transition Temperature

InactiveUS20080166448A1Good effectReduce amountContainers for annular articlesChewing gumNatural resinGlass transition

The invention relates to a chewing gum comprising at least one biodegradable polymer in an amount of from about 0.1% to about 95%, said biodegradable polymer having a glass transition temperature (Tg) above 37° C. and having a molecular weight (Mn) within the range of approximately 500 to 60000 g / mol and wherein said chewing gum comprises less than approximately 5% by weight of natural resins.

Owner:GUMLINK AS

Offset printing ink

An offset printing ink in which a modified pigment (D) is dispersed in a vehicle as a colorant, the modified pigment (D) contains a polymer (P) on the surface thereof, and the polymer (P) is obtained by polymerizing a resin or fat (B) which has a polymerizable unsaturated group, and is soluble in a nonaqueous solvent, and at least one of polymerizable unsaturated monomers (C) which are soluble in a nonaqueous solvent and insoluble or poorly-soluble after polymerization, and specifically, the resin or fat (B) is selected from the group consisting of acrylic resins having a polymerizable unsaturated group, alkyd resins which are soluble in the nonaqueous solvent, natural resin-modified phenol resins, and fats.

Owner:DAINIPPON INK & CHEM INC

Production of odorless reclaimed rubber at low-temperature by desulfurization rapidly from waste vulcanized rubber

A fast devulcanizing production of odorless reclaimed rubber at low temperature from waste vulcanized rubber is carried out by taking waste vulcanized rubber powder with 20-80 mesh as raw materials, adding into mixer in proportion by waste vulcanized rubber powder: polyethylene polyamine: dibasic metal halide: rubber accelerant: mineral oil: natural resin=100:0.1í½2:0.1í½0.5:0.5í½2:5í½15:5í½15, mixing, raising temperature to 50í½80íÒC, blowing off, piling and ageing for 2í½3hrs to obtain devulcanized reclaimed rubber powder, putting the mixed and aged devulcanized reclaimed rubber powder into mixing machine and tabletting to obtain odorless reclaimed rubber. It has simple process, no waste gas and liquid discharge and no pollution environmental pollution.

Owner:DONGGUAN FANGDA HUANYU ENVIRONMENTAL PROTECTION TECH CO LTD

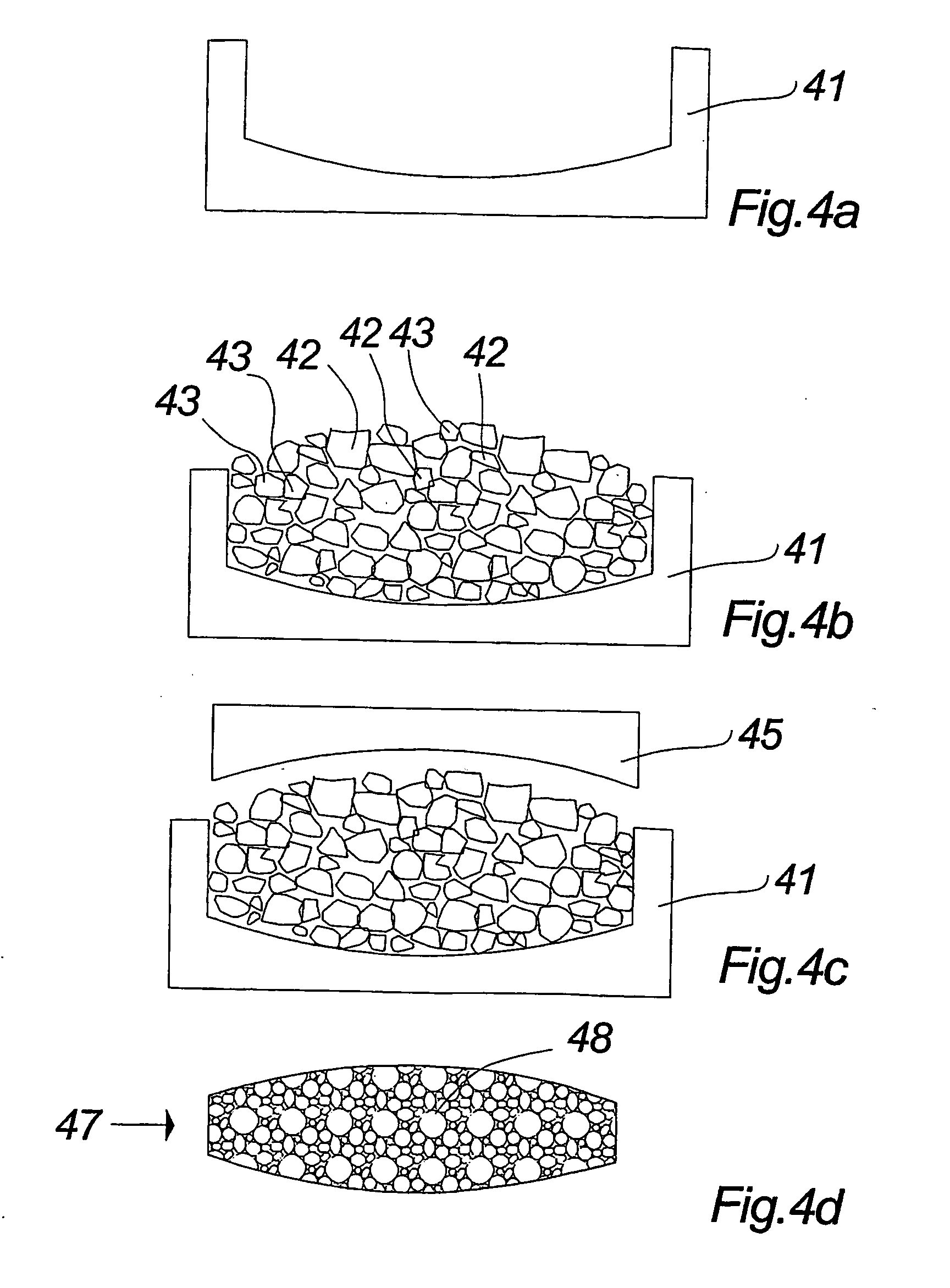

Method for preparing paper-pulp moulded board and mould there used

This invention involves a paper pulp mold pressing plate's preparation method and the mold. Its craft include:after scrap paper immersion beat the paper into pulp, the mold pressing to squeeze out the moisture content and formation, the drawing of patterns and dry. Its characteristic is the paper pulp density not bigger than 6%; And cancel in the existing craft to join the natural resin and the starch in the paper pulp, concentration dehydration the mixed pulp and so on. Its uses mold's characteristic is its frame and the lap can the move relativly; The briquetting is not smaller than obtained mold pressing plate thickness' 9 times in cavity effective work traveling schedule. The paper pulp mold pressing plate, is the entity plate or has the hole plate, its fiber structure is the level laminated structure. This invention simplify the craft, reduce the cost; The product has the better synthesis operational performance; And has a more ideal economic efficiency and the social efficiency. This product may widely apply in industry domains and packing storage and transport, building, repair and office equipment thing, has the enormous market potential.

Owner:郎旗

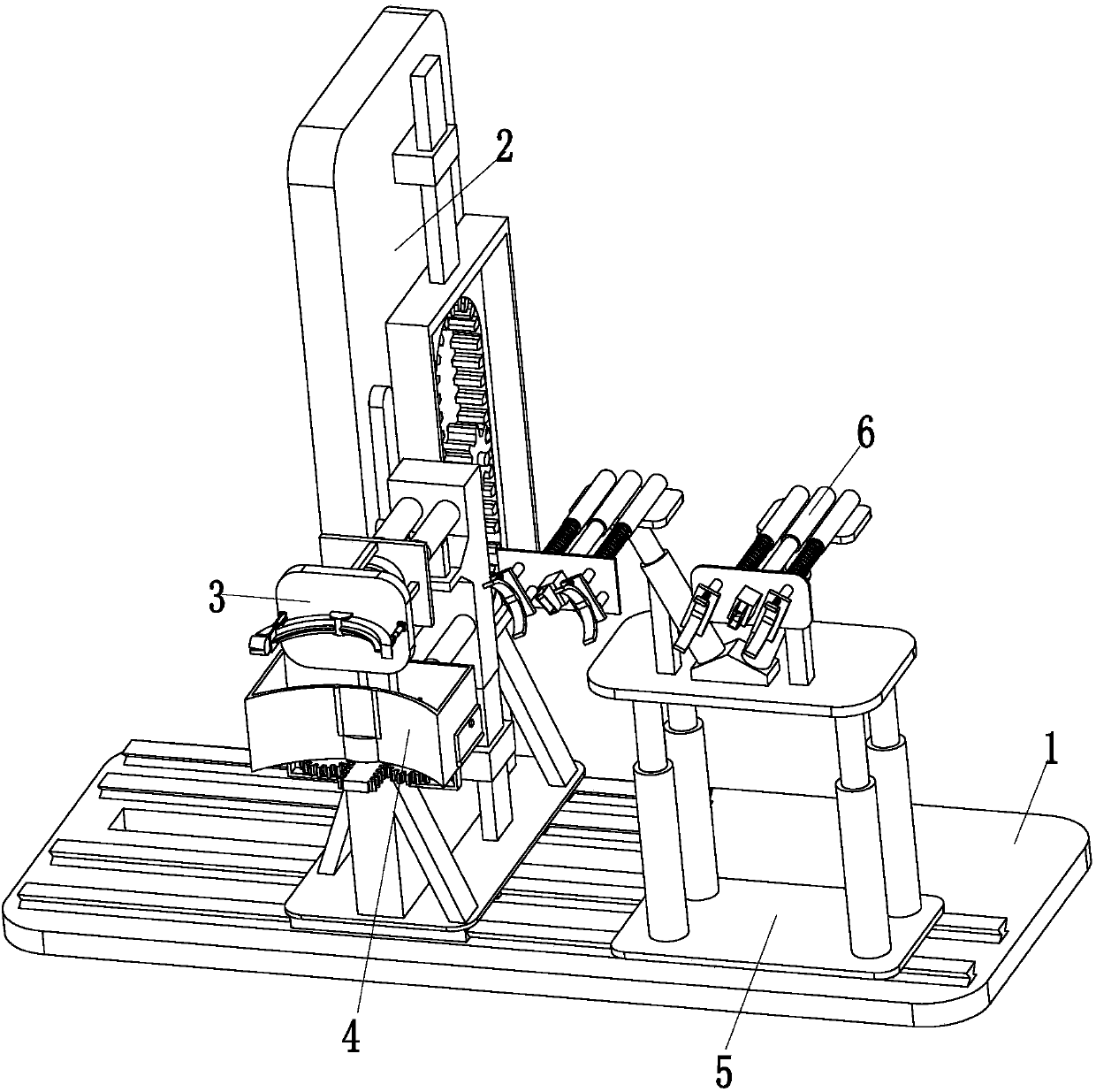

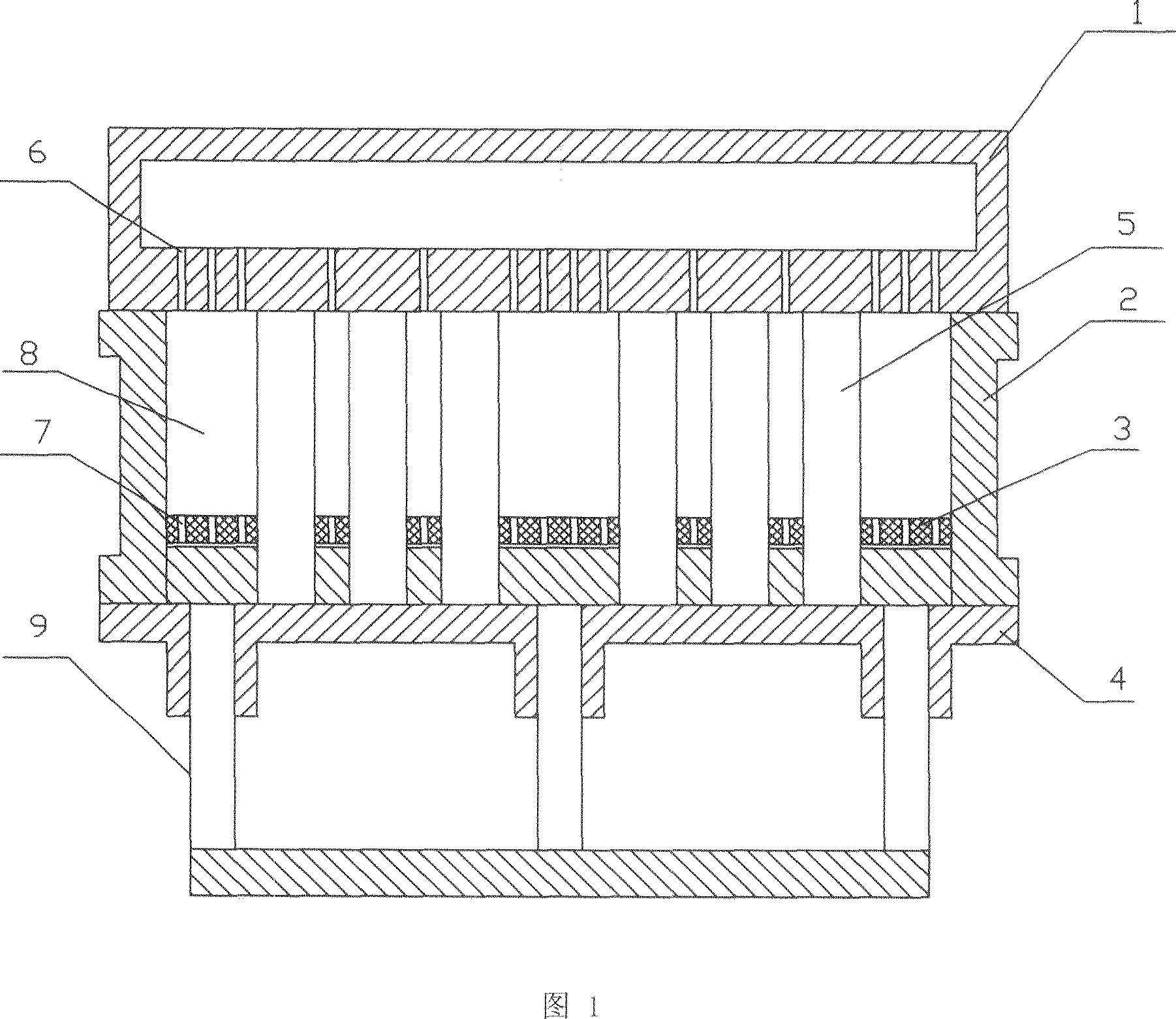

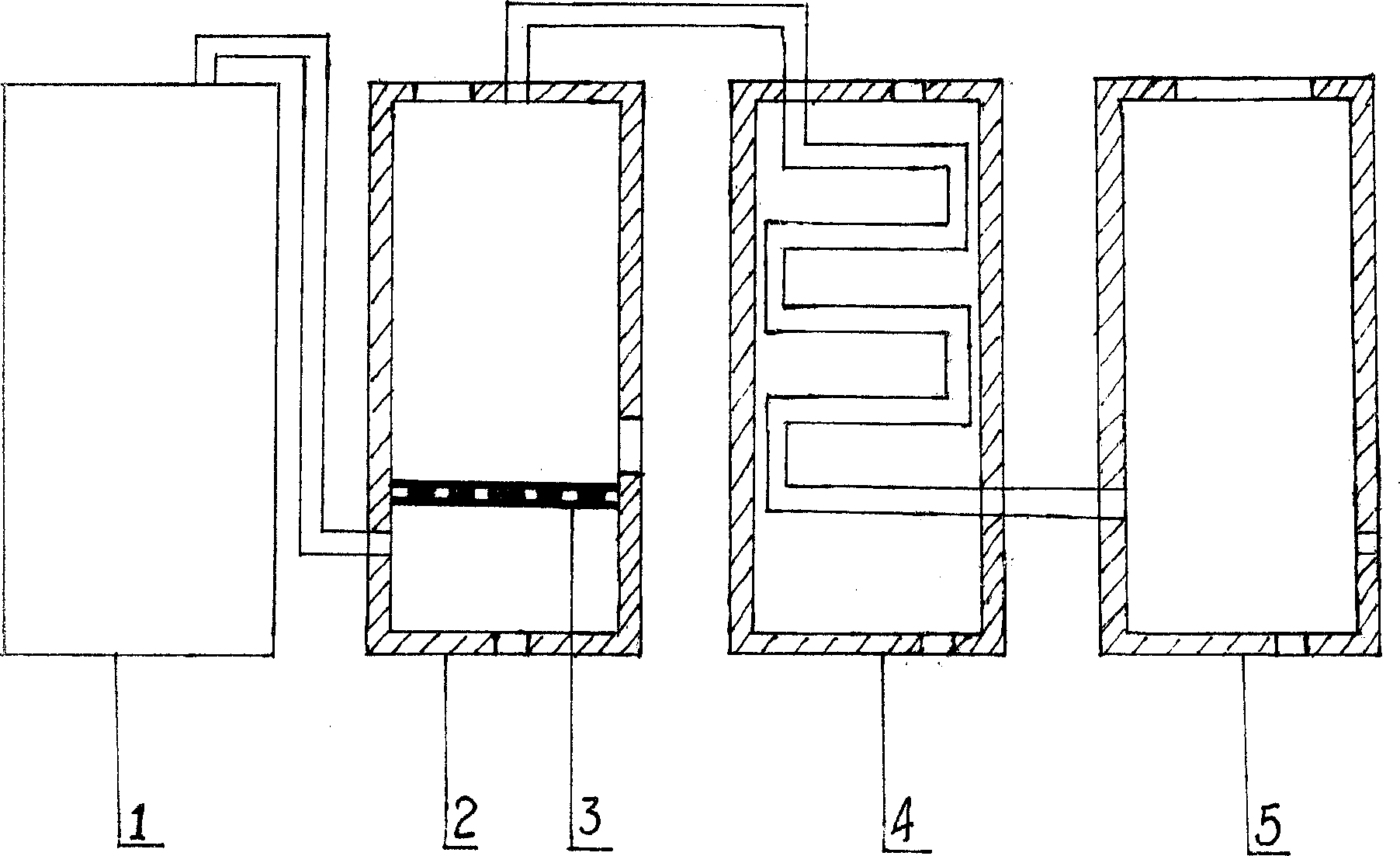

Natural resin extracting process and apparatus

InactiveCN101024754AHeated evenly and thoroughlyHigh purityNatural resin processNatural resinEngineering

The invention discloses a technology and device for distilled natural resin like san-mou oil and cedar oil. It includes the following steps: passing through steam into the barrel containing the slice of cunninghamia sinensis stump and coniferles vstump, taking oil-water separation to the natural resin, gathering natural resin. The device includes distilling barrel and steam boiler. The natural resin distilling technology and device could distil resin and have good quality. It has good economic and environment protection benefits.

Owner:粟国江

Manufacturing method of insect-resistant and moisture-proof composite wooden door

InactiveCN108858638ANon-perishableNot easy to stirWood treatment detailsWood veneer joiningNatural resinAdhesive

The invention discloses a manufacturing method of an insect-resistant and moisture-proof composite wooden door. The manufacturing method comprises the following steps: spraying insect powder onto straw and reed straw for dispelling insects for 3 days or above in order to kill internal worm eggs and dispel internal worms; then, drying the straw and reed straw, and smashing into granules; performingACQ preservative treatment on the granular raw material to prevent the raw material from decaying easily; uniformly mixing the raw material through natural resin in order to condense the granular material; repeatedly paving and pressing on a flat board with a fence; laminating and drying the middle part with an adhesive to form a multilayer solid regenerated board. When a door core is manufactured with the multilayer board, cracking is prevented compared with the conventional wooden door. The whole door core board is a solid regenerated board made of the straw and the reed straw, so that theregenerated board is low in density, is light in mass and is convenient to transport, waste utilization is realized, and meanwhile the problem of cracking of the conventional wooden door is solved.

Owner:CHENGDU TIANTIAN WOOD IND CO LTD

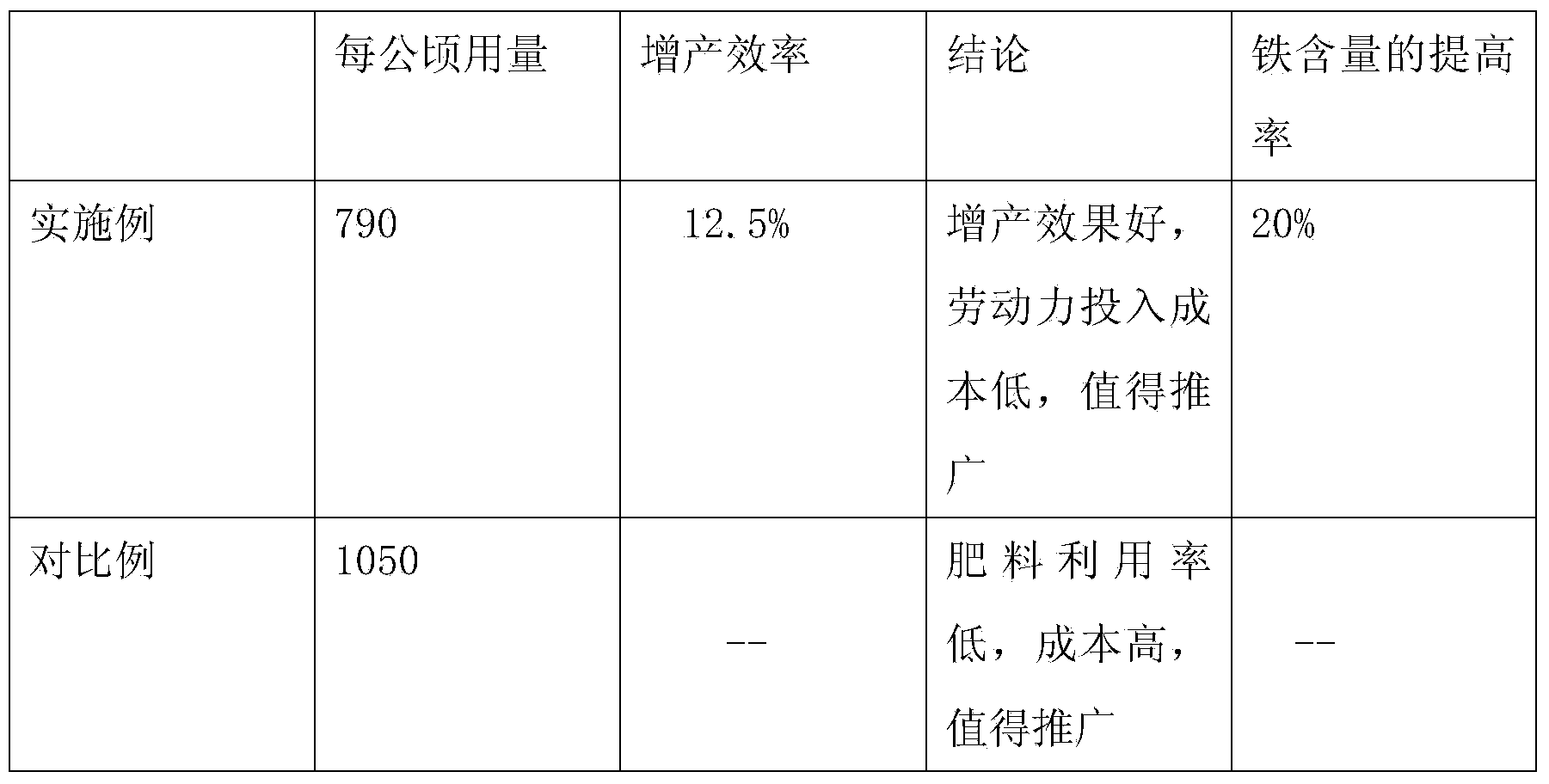

Special high-Fe slow release fertilizer for rice and preparation method thereof

InactiveCN104291972AEasy to useFull of nutritionSuperphosphatesOrganic fertilisersNatural resinPolyvinyl alcohol

The invention provides a special high-Fe slow release fertilizer for rice. The raw material components according to parts by weight are as follows: 20-25 parts of brown coal powder, 90-100 parts of calcium superphosphate, 20-30 parts of iron tailings powder, 10-20 parts of urea, 20-30 parts of monopotassium phosphate, 4-6 parts of potassium nitrate, 2-4 parts of polyaspartic acid, 0.1-0.3 part of dicyandiamide, 1-2 parts of zinc sulfate, 1-2 parts of magnesium sulfate, 0.2-0.4 part of ferrous sulfate, 0.2-0.4 part of manganese sulfate, 0.1-0.2 part of copper sulfate, 0.02-0.03 part of chlormequat chloride, 3-5 parts of emulsifier OP-10, 10-15 parts of polyvinyl alcohol, 90-100 parts of maifanite powder, 8-10 parts of xanthan gum, 4-6 parts of natural resin and 10-15 parts of fertilizer additives. The special high-Fe slow release fertilizer for rice, provided by the invention, is convenient to use, contains more nutrients, is scientific in nutrient proportion and high in utilization efficiency of nutrient resources, is capable of improving lodging resistance of rice, increasing the yield and is high in Fe content.

Owner:ANHUI HEQUAN SEED IND

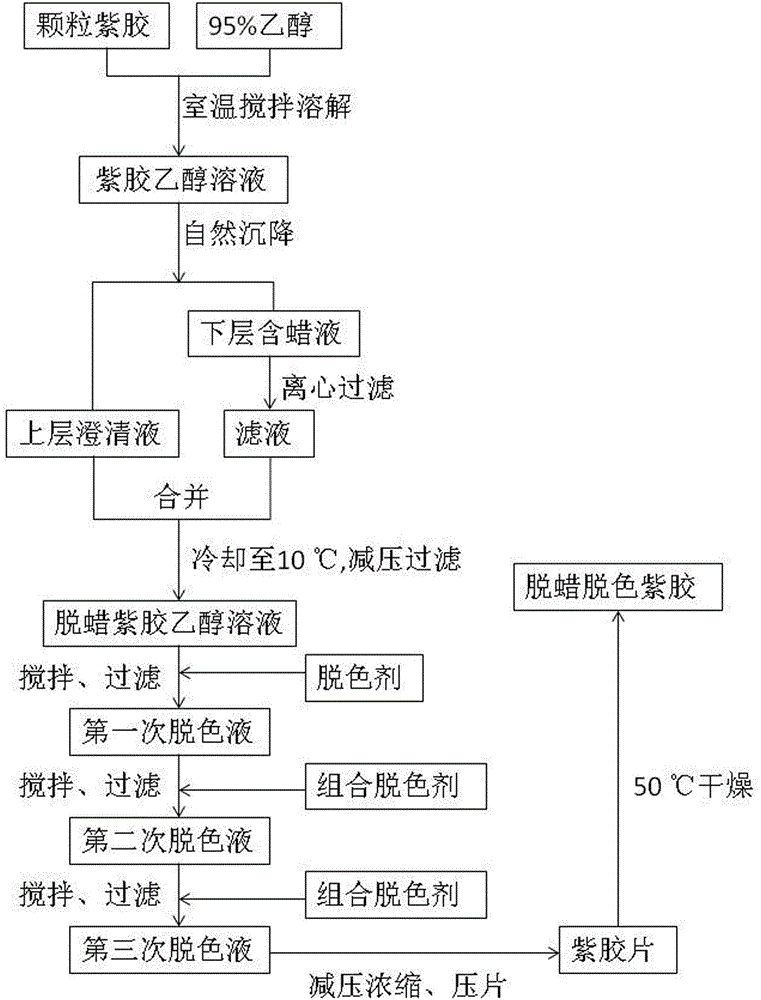

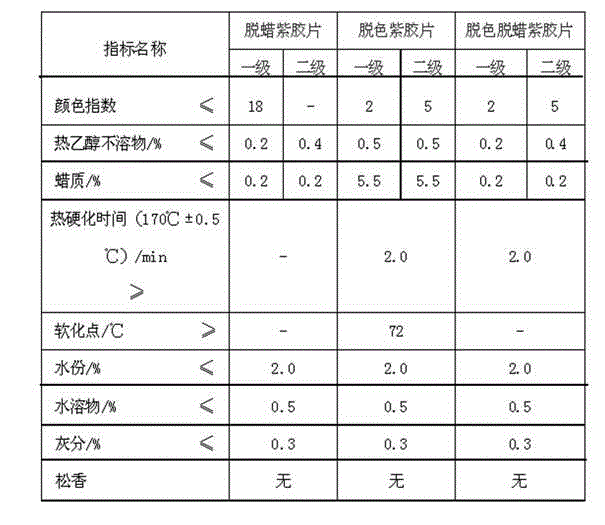

Preparation method of dewaxed and decolorized shellac

The invention relates to a production method of natural resin, and particularly relates to a preparation method of dewaxed and decolorized shellac. The preparation method comprises the following steps: by taking shellac particles as a raw material, adding a 95% ethanol solvent to the shellac particles to obtain a shellac ethanol solution; fully precipitating shellac wax and impurities in the shellac ethanol solution, separating supernatant which accounts for two thirds of the total volume of the solution, performing centrifugal filtration of sediment which accounts for one third of the total volume of the solution to obtain clear liquid, and mixing the clear liquid and the supernatant, wherein the wax content of shellac in the supernatant is less than 0.5%; cooling the shellac ethanol solution obtained by mixing the clear liquid and the supernatant to 10DEG C, performing filtration under reduced pressure to obtain a dewaxed shellac ethanol solution in which the shellac contains less than 0.2% of wax, and performing decolorization of the dewaxed shellac ethanol solution thrice to obtain a dewaxed and decolorized shellac sheet. The method provided by the invention is simple to operate, moderate in decolorization condition and high in product quality and can be used for large-scale production of dewaxed and decolorized shellac.

Owner:MOJIANG SENYUAN TECH

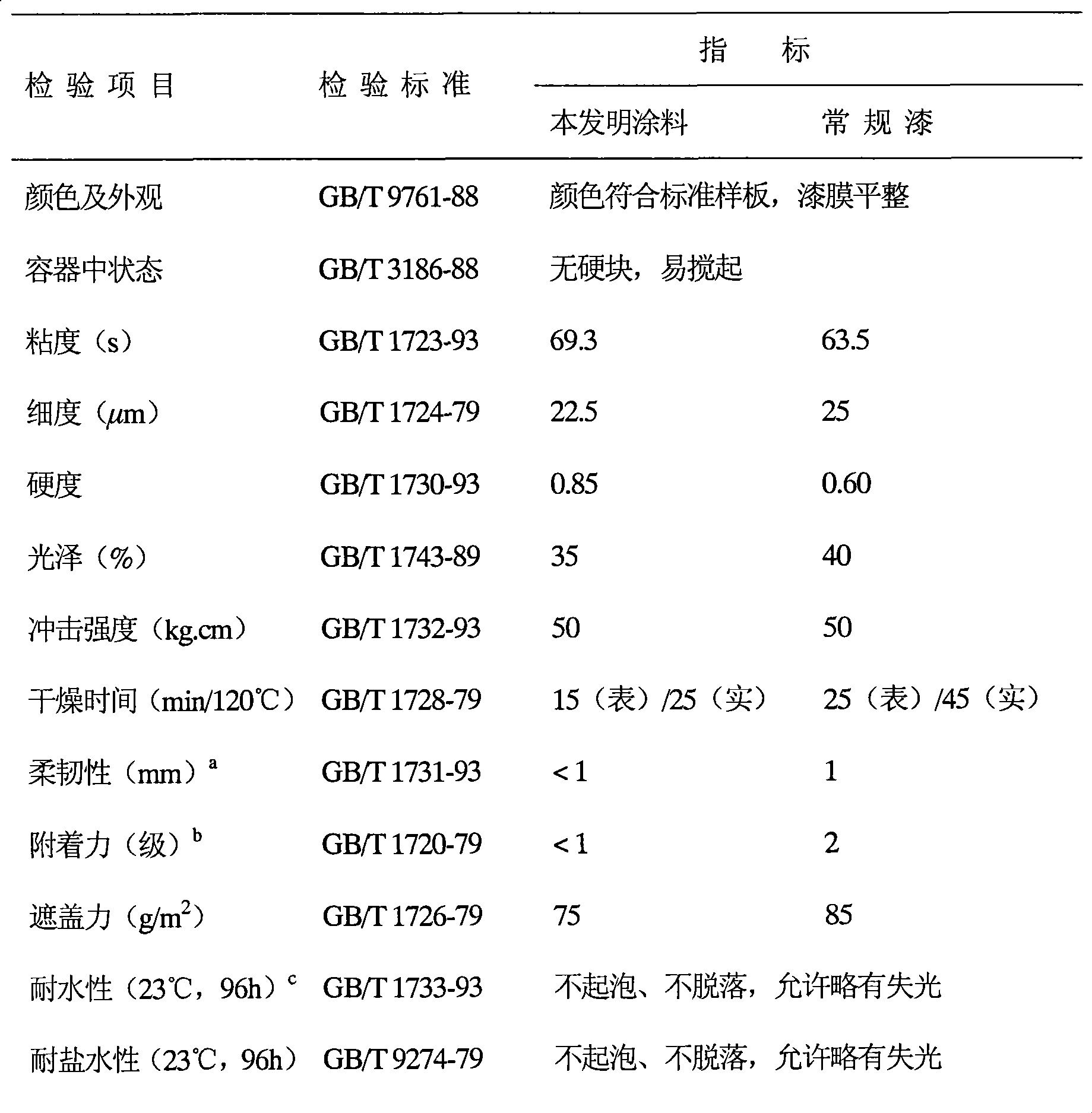

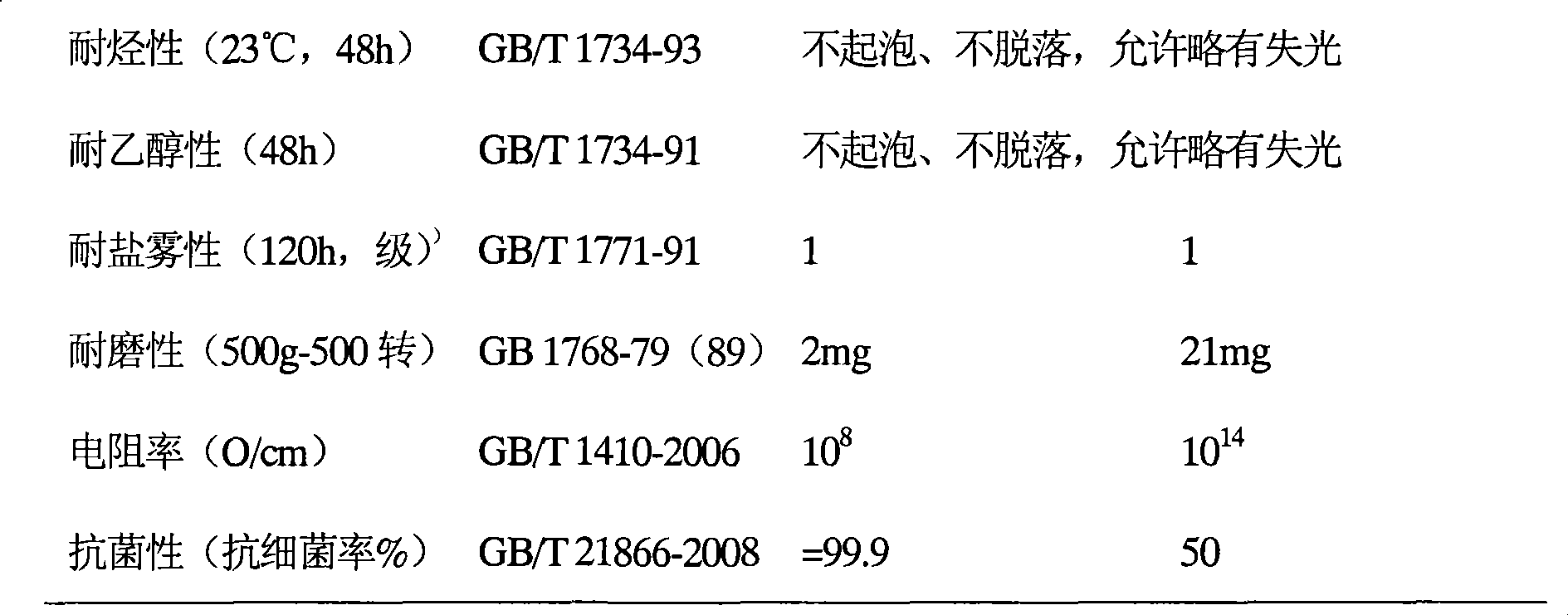

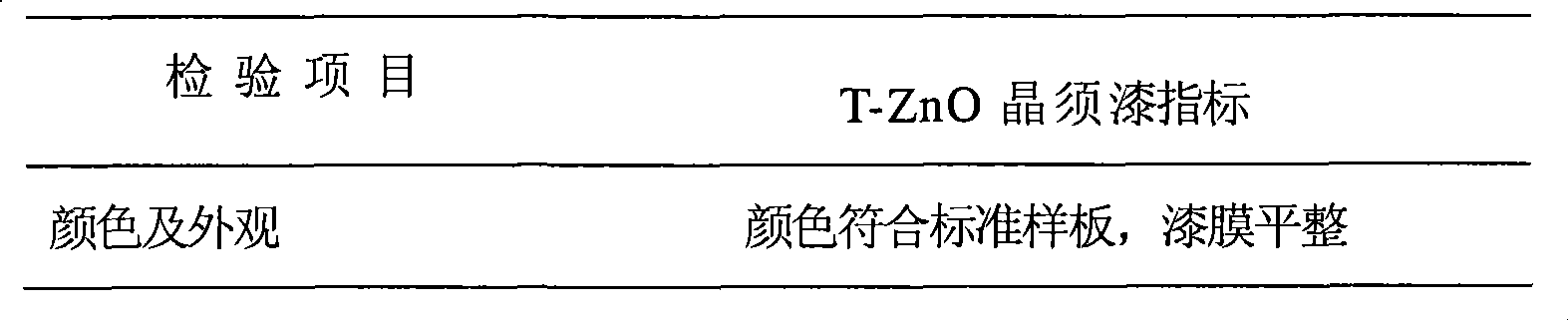

High abrasion-proof and anti static antibacterial coating

ActiveCN101397414AUnique preparation processSimple preparation processAntifouling/underwater paintsPaints with biocidesNatural resinSolvent

A high wear resistance and static-free antibiosis paint relates to an oil paint and takes natural resin or synthesis resin as the base; pigment, filler, four-footed zinc oxide T-ZnO crystal whisker treated with dispersion and coupling, charging material and addition agent and solvent are then added, finally the paint is manufactured by mechanical processing; the isotacticity of the crystal whisker is more than 90 percent, the foot length-diameter ratio of the T-ZnO crystal whisker is 16-20, the foot length is 40-50 Mum and the consumption of the T-ZnO crystal whisker accounts for 0.5-5 percent of the total weight of paint. Compared with corresponding similar paints, the paint has simple and unique preparation process, excellent quality, stronger adherence, outstanding anticorrosive performance and mechanical property and preparation cost not more than the corresponding paint.

Owner:SHENYANG HUADA R & D CENT OF POLYMER MATERIALS CO LTD

Polishing agent composition for wooden floor and furnitures maintenance

The invention discloses a brightener compound for wood floor and furniture nursing which comprises the following substance in the weight proportion of natural vegetable wax emulsion of 5-25%, polysiloxane emulsion of 0.5-10%, vegetable refined oil of 1.03-2.0%, natural resin emulsion of 0-5%, synthetic wax emulsion of 0.0-5%, colouring matter of 0.0-0.1% and water of 70-85%.The said brightener compound in the invention has a finite permeability and replenishes natural resin and vegetable refined oil into the inner of wood floor and furniture to stop the wood floor and furniture from drying crack and deforming by air drying, forms the protective film on the surface to cover and repair the lightness scratches and stop the scratches deep and blackening, and also has the characteristics of cleaning, electrostatic resistance, no dust and water resistance.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Environment-friendly bamboo charcoal plate capable of effectively adsorbing and automatically degrading formaldehyde and preparation process of bamboo charcoal plate

The invention discloses an environment-friendly bamboo charcoal plate capable of effectively adsorbing and automatically degrading formaldehyde. The environment-friendly bamboo charcoal plate comprises raw materials in percentage by mass as follows: 10%-50% of 200-mesh high-temperature bamboo particles, 15%-50% of 120-mesh low-temperature bamboo particles, 18%-19% of natural resin, 2%-3% of a composite stabilizer, 1%-2% of a density reduction agent, 2%-7% of bamboo fiber or reed fiber or carbonized bamboo powder, 1%-1.5% of nanoscale titanium dioxide powder, 1%-1.5% of a compatilizer, 0.5%-1% of light calcium carbonate, 0.5%-1% of calcium oxide, 1%-2% of PE (poly ethylene) wax serving as an outer lubricant, 1.5% of stearic acid serving as an inner lubricant, 0.5%-1% of CPE (chlorinated polyethylene), 0.5% of a dispersing agent, 0.5%-1% of a coupling agent and 0.5%-1% of a foaming agent. A preparation process comprises steps of material preparation, mixing, cooling, forming and cutting. With the adoption of the environment-friendly bamboo charcoal plate and the preparation process, the problem that bamboo charcoal cannot be automatically degraded after adsorbing formaldehyde is effectively solved, secondary pollution is avoided, and the charcoal plate has a high environmental protection property and is pollution-free, harmless and recyclable.

Owner:林文海

Self-assemblable container for generic use and manufacturing method thereof

InactiveCN102431694AGood for long distance transportationReduce shipping costsBoxes/cartons making machineryPaper-makingNatural resinMoisture penetration

The present invention refers to a self-assemblable container, preferably manufactured from ecologic materials such as standard fiberboard, comprising as its main structural elements a bottom, two longitudinal sides and two transverse sides of a basically rectangular shape having cauterized perimetrical faces to prevent moisture penetration into the structural elements that make up the container, thus providing long term structural stiffness to the perimetrical faces of the container's structural elements comparable to that of the fiberboard surface. Each of the main structural elements comprises in one side adjacent to another corresponding main structural element, tensile-resistant flexible tabs or receiving slots, the other corresponding main structural element in said side adjacent to the first main structural element respectively comprising slots or flexible tensile resistant tabs, said main structural elements being assembled together by the insertion of the flexible tabs into the receiving slots. In addition, the container may comprise an antisagging brace, a lid and / or two transverse laths. The invention also refers to a method of manufacturing the structural elements of a self-assemblable container by means of perimetrical laser cutting that by reason of the extremely high cutting temperature causes a reaction of the natural resins contained in the raw material and the resulting perimetrical cauterization.

Owner:PACIFIC PATENT CO LTD

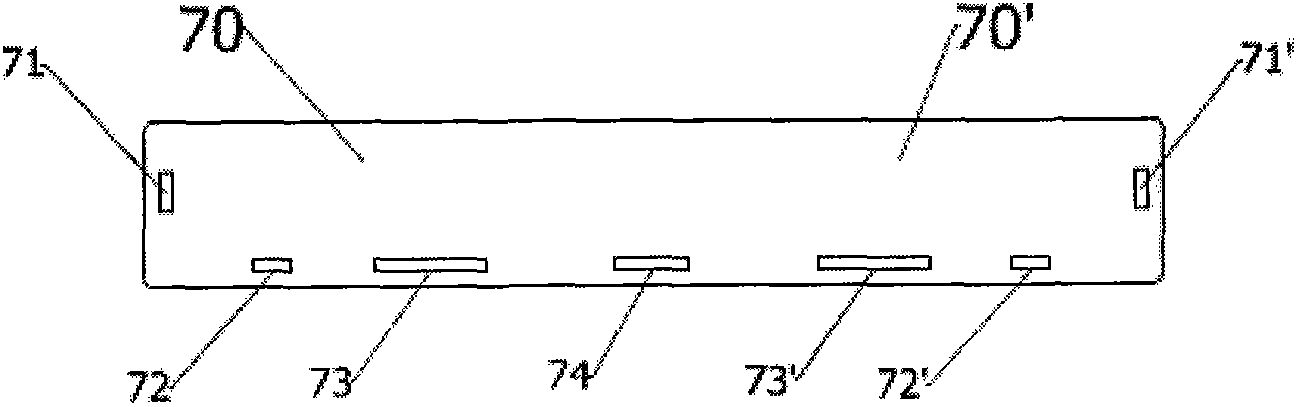

Method of removing molded natural resins from molds utilizing lifter bars

A process of injection molding a natural resin into a mold cavity including lifter bars as part of the ejection system for extracting the molded animal chew of the mold cavity. The lifter bars are provided with a contacting area having a relatively high surface area ratio relative to surface area of the molded part that remains in contact with the mold after injection and mold opening.

Owner:T F H PUBLICATIONS

Fire starter

The Present Invention is a fire starting device for use as kindling manufactured from pine straw, as the primary component, a vegetable oil, natural resins, and an herbal component. The composition of the device differs from prior art devices that burn petroleum hydrocarbons. The device is hollow, having at least one vertical channel and at least one horizontal channel drilled from the outer wall of the device to the inner vertical channel. The fire starter device is ignited from the top, and it burns to produce a high, intense flame that ignites other flammable materials having a much greater kindling temperature. The height of the flame and the burn duration are controlled by the overall size of the device and the sizes of the channels. The device burns clean with a minimum of smoke and harmful or noxious fumes. Burning the device minimally creates air pollution. It burns completely with a minimum of ash residue.

Owner:APPTEC

Resin encapsulated high intensity sweetener

The present invention relates to confectionery compositions comprising one or more encapsulation delivery systems containing high intensity sweeteners and natural resins. The invention furthermore relates to the encapsulation delivery system as such as well as to methods of preparing the encapsulation delivery system and the confectionery composition.

Owner:FERTIN PHARMA AS

High-imitation copying method for Chinese classical mural

InactiveCN102815163AStrong chemical and physical stabilityNever fadeSpecial artistic techniquesGraphicsDigital data

The invention relates to a high-imitation copying method for a Chinese classical mural and belongs to the technical field of decoration. The high-imitation copying method comprises the following steps: taking a sandy drawing material, utilizing a digital technology to collect an image digital data of a copied original mural; adding water and gelatin into clam meal, thereby preparing a clam meal base material; uniformly coating or brushing the clam meal base material on the surface of the sandy drawing material, naturally drying, and painting a pattern of the original mural by using a color spraying machine, thereby preparing a base image; repairing; and spraying a natural resin on the surface. A classical mural copied according to the method provided by the invention has the advantages: all details and figure sizes are accurate; the clam meal base material is adopted, so that the copied classical mural has ultrahigh chemical physical stability and is never faded; a traditional mineral pigment has a color developing function, so that the copied classical mural is more bright and colorful; the copied classical mural can be hung on a wall, rolled and stored in a box; the copied classical mural has quality, color, texture and unique frame effect of a sandy picture which are almost as same as those of the original mural; and the service life of the copied classical mural is far more than that of the classical mural.

Owner:姚智泉

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com