Patents

Literature

85results about How to "Never fade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light and color glazed tile for building

The invention discloses a light and color glazed tile for a building, which is obtained by the following steps: adding 0.4 to 0.6 kg of magnesium oxide to each kilo of a magnesium chloride solution; agitating the mixture for 6 to 8 minutes; successively adding 0.05 to 0.1 kg of magnesium silicate, 0.02 to 0.03 kg of urea-formaldehyde resin, 0.06 to 0.1 g of ammonium carbonate, 2 to 3 g of trisodium phosphate and 2 to 3 g of pigment; agitating the obtained mixture for 20 to 30 minutes; pouring the agitated mixture to a glass fiber cloth; scraping and compacting the poured mixture; and performing natural cure and drying to obtain the light and color glazed tile for the building. In the way above, the light and color glazed tile for the building has the advantages of smooth and clean surface, bright color, color retention, fracture resistance, compression resistance, thermal and cooling shock resistance, acid and alkali resistance, freezing resistance, light weight, low water absorption, good thermal insulation, good sound insulation and low cost.

Owner:CHINA CHANGSHU CONSTR GRP

Matte brick and preparation method

The invention discloses a preparation method of a matte brick. The preparation method comprises the steps: preparing ground glaze, decorative patterns and surface glaze on the surface of a green bodysequentially, then performing drying and firing, performing polishing by using a matte grinding block and a fiber grinding block sequentially, and performing wax so as to obtain the matte brick finished product. The matte brick with a glossiness of 28-36 degrees is prepared through adoption of a reasonable surface glaze formula and a polishing technology, and the decorative patterns have good color and clear patterns, so that the brick is more similar to natural marble; and light reflection and light pollution are reduced through the brick, and broad application prospects are achieved.

Owner:肇庆乐华陶瓷洁具有限公司

Wear-resistant anti-skid tile and preparation method thereof

InactiveCN109279920AIncrease the amount of glaze appliedImprove wear resistanceCeramic glazeWear resistant

The invention discloses a preparation method of a wear-resistant anti-skid tile. The preparation method comprises the following steps: sequentially preparing bottom glaze, protecting glaze, decorationpatterns and surface glaze on the surface of a green body, and then carrying out drying and firing to obtain a wear-resistant anti-skid tile finished product. According to the invention, surface glaze application is carried out at least twice, and the glaze applying amount on the surface of the ceramic tile green body is effectively improved through a mode of applying the protecting glaze, so that wear resistance of the surface of the ceramic tile is improved, and the Moh's hardness of the surface of the ceramic tile provided by the invention is larger than or equal to 7; on the other hand, an anti-skid effect of the ceramic tile is achieved through the special glaze, and the friction coefficient of the ceramic tile provided by the invention is larger than or equal to 0.8.

Owner:肇庆乐华陶瓷洁具有限公司

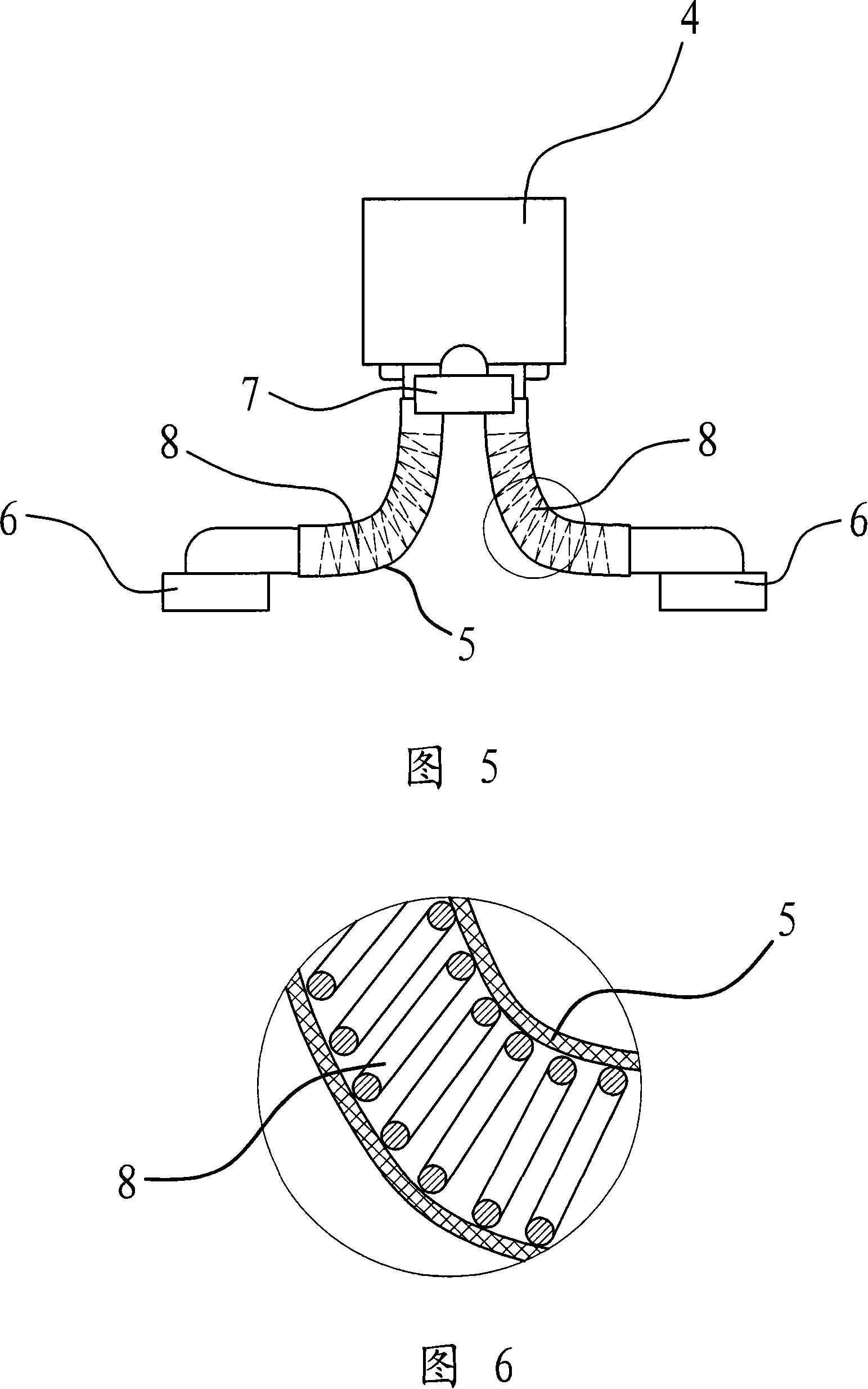

Fabric structure color preparation method

ActiveCN105603715AWide adaptabilityNo dischargeMaterial nanotechnologyVacuum evaporation coatingSputteringHigh energy

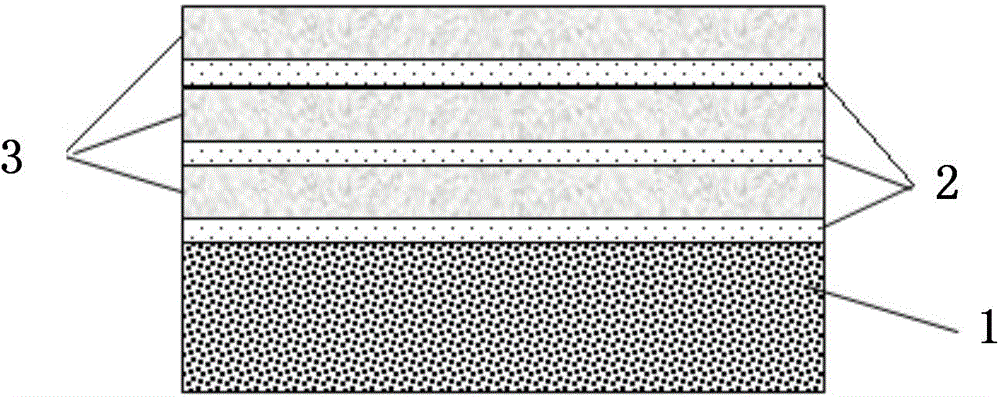

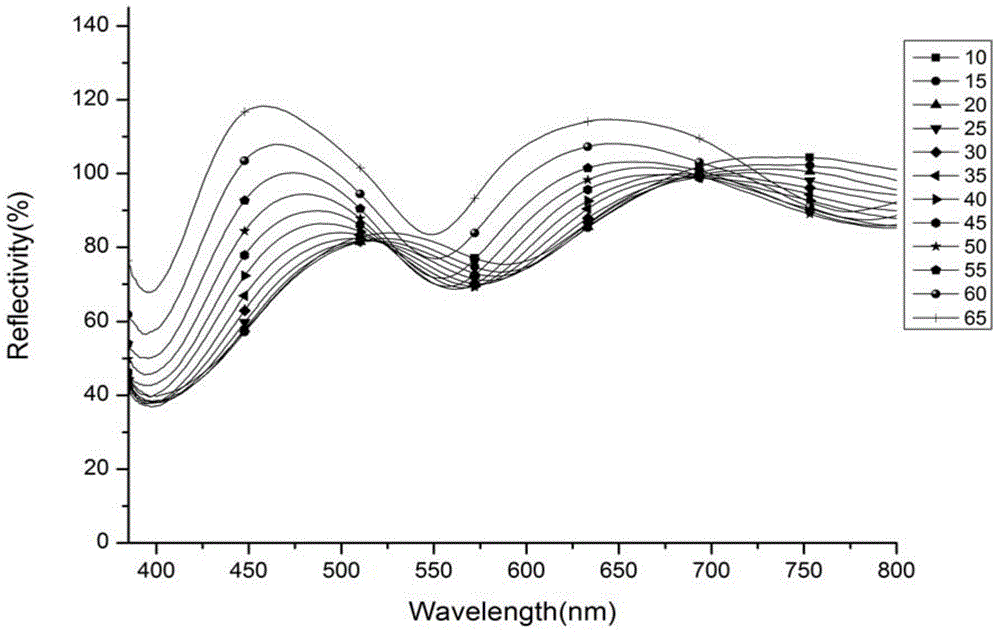

The present invention relates to a fabric structure color preparation method. According to the present invention, a magnetron sputtering radio frequency method is used, TiO2, SiO2 and the like are adopted as targets, sputtering is performed on a base cloth, the TiO2 and SiO2 (or other materials) targets are subjected to alternate sputtering on the surface of a fabric to form a nanometer period film on the fabric surface, the fabric presents a bright structure color due to light interference and other optical principles, the fabric surface color is determined by the sputtering material, the number of the sputtering layers and the thickness of each sputtering layer, the fabric color is changed along with the change of the observation angle, and the fabric does not fade if the film structure is not damaged; and the structure color fabric researched and developed through the preparation method has characteristics of uniform film, controllable film thickness and no requirement of any dye auxiliary agents, the method is the environmentally friendly dyeing method, and the defects of high pollution and high energy consumption in the traditional dyeing and finishing industry are expected to be solved.

Owner:GUANGDONG XINFENG TECH

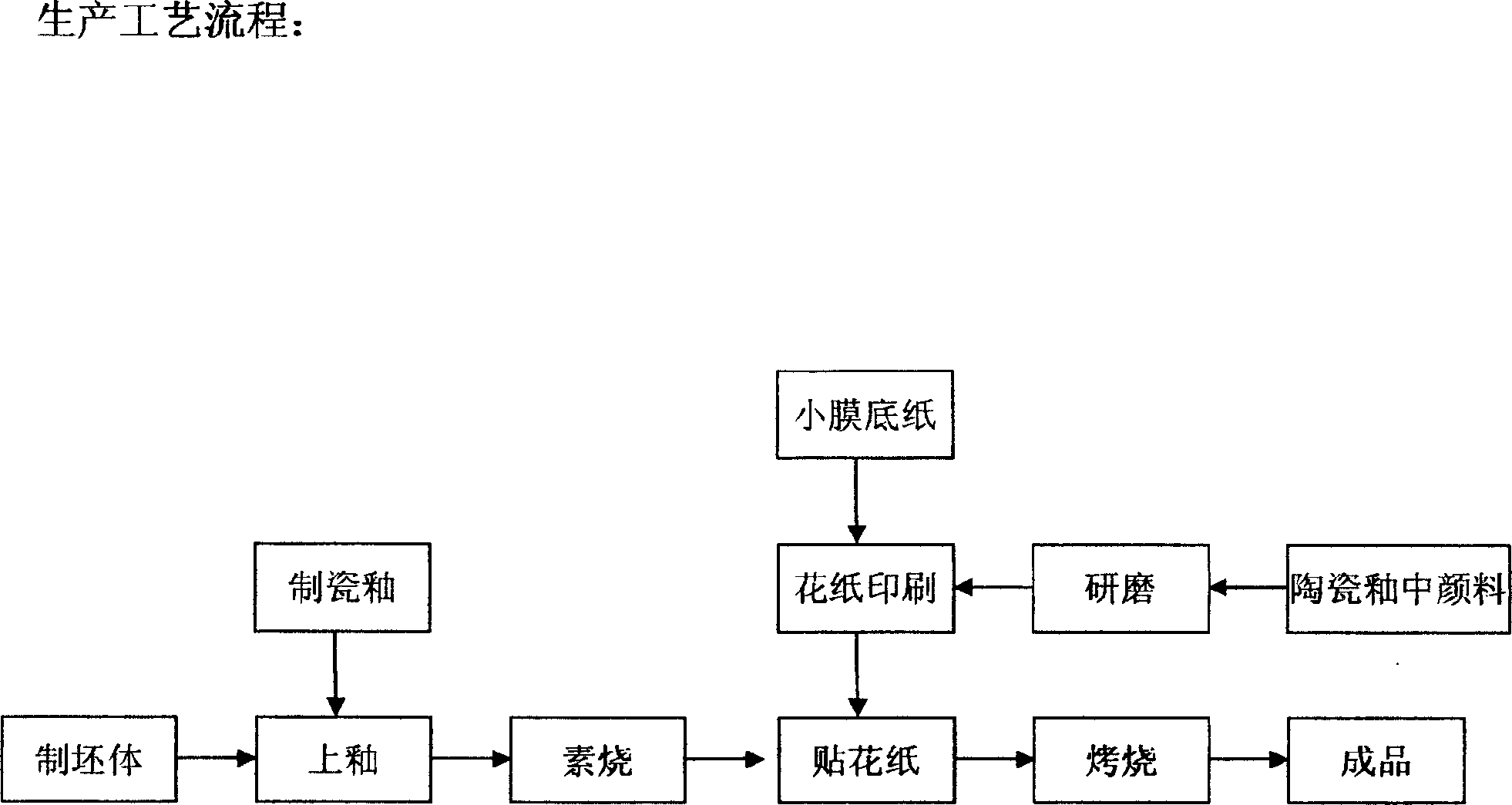

Glaze coloured decoration daily use poocelain and its production method

InactiveCN1911855AMeet technical requirementsMeet the process requirementsHigh volume manufacturingThermal stability

The present invention relates to ceramic product, and is especially one kind of in-glaze color decorated daily use porcelain product and its production process. The materials for the in-glaze color decorated daily use porcelain include Longyan clay, weathered potash feldspar, Jiepai clay, potash feldspar, calcined alumina, Guizhou clay and quarztz. The production process of the in-glaze color decorated daily use porcelain product includes the steps of making biscuit, preparing glaze and in-glaze color paper, glazing the biscuit, firing biscuit, adhering the in-glaze color paper, and baking to obtain the product. The in-glaze color decorated daily use porcelain has rich bright colors, smooth and fine glaze surface, low Pb and Cd leaching out amount, high strength, and other advantages.

Owner:林伟河

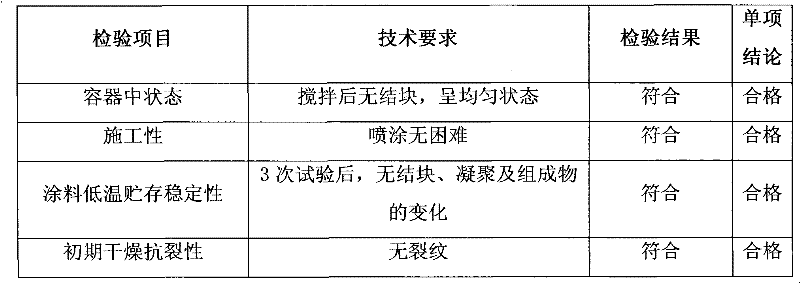

Natural color sand decorative mortar

The invention relates to a wall decorative material, and concretely relates to a natural color sand decorative mortar for decorating inner walls and outer walls. The natural color sand decorative mortar comprises 15 to 30 wt% of a synthetic resin emulsion, 10 to 60 wt% of natural color sand grains, 1 to 4 wt% of a film forming assistant, 0.1 to 1 wt% of a thickening agent, 11 to 73 wt% of ceramic grains, 0.1 to 0.2 wt% of an antifoaming agent, 0.1 to 0.2 wt% of an anti-mildew bactericide, and 0.5 to 18 wt% of a pH additive. The natural color sand decorative mortar has the advantages that: various artistic effects can be generated through combination of various natural color sand grains because of strong decoration; the color of the mortar lasts longer than methods of adding toner or other pigments and never fades because of good weatherability and UV- resistance; and pollution resistance, good waterproof effect, and convenient construction are achieved because the mortar can be used with priming paints and finishing varnishes, and has good bonding force with substrates of various materials.

Owner:陈轶 +2

Green environment-protecting co-squeezing core layer foaming special-shaped material and its production process

InactiveCN1908338AHigh hardnessStrong corrosion resistanceConstruction materialLayered productsCalcium carbonatePolymer chemistry

The invention relates to an environment-friend extrusion corn foaming section bar and relative production, wherein the inner layer is foaming layer, the outer layer is extrusion rigid layer; said foaming layer contains: polyvinyl chloride resin at 63-67%; calcium carbonate at 11-15%; chlorinated polyvinyl chloride at 3-7%; and chemical agent at 12-19%; the extrusion rigid layer contains: polyvinyl chloride resin at 42-46%; calcium carbonate at 42-46%; chlorinated polyvinyl chloride at 3.5-5%; and chemical agent at 7-9%. The invention can avoid deformation and color fade, with high rigidity and lower cost, while its smoothness can reach 95%.

Owner:金木根

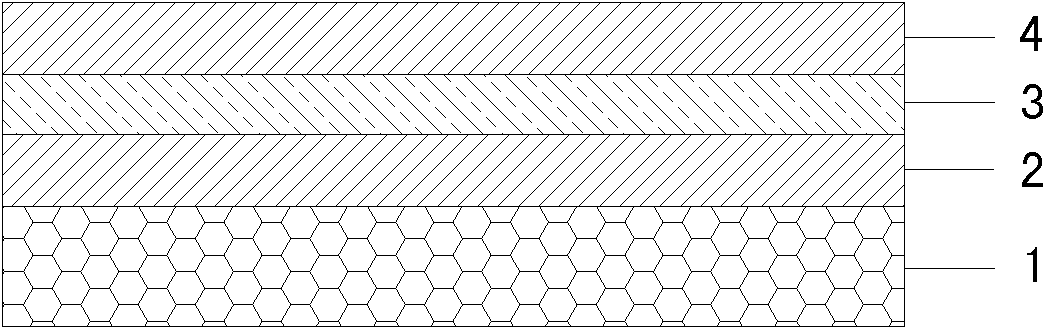

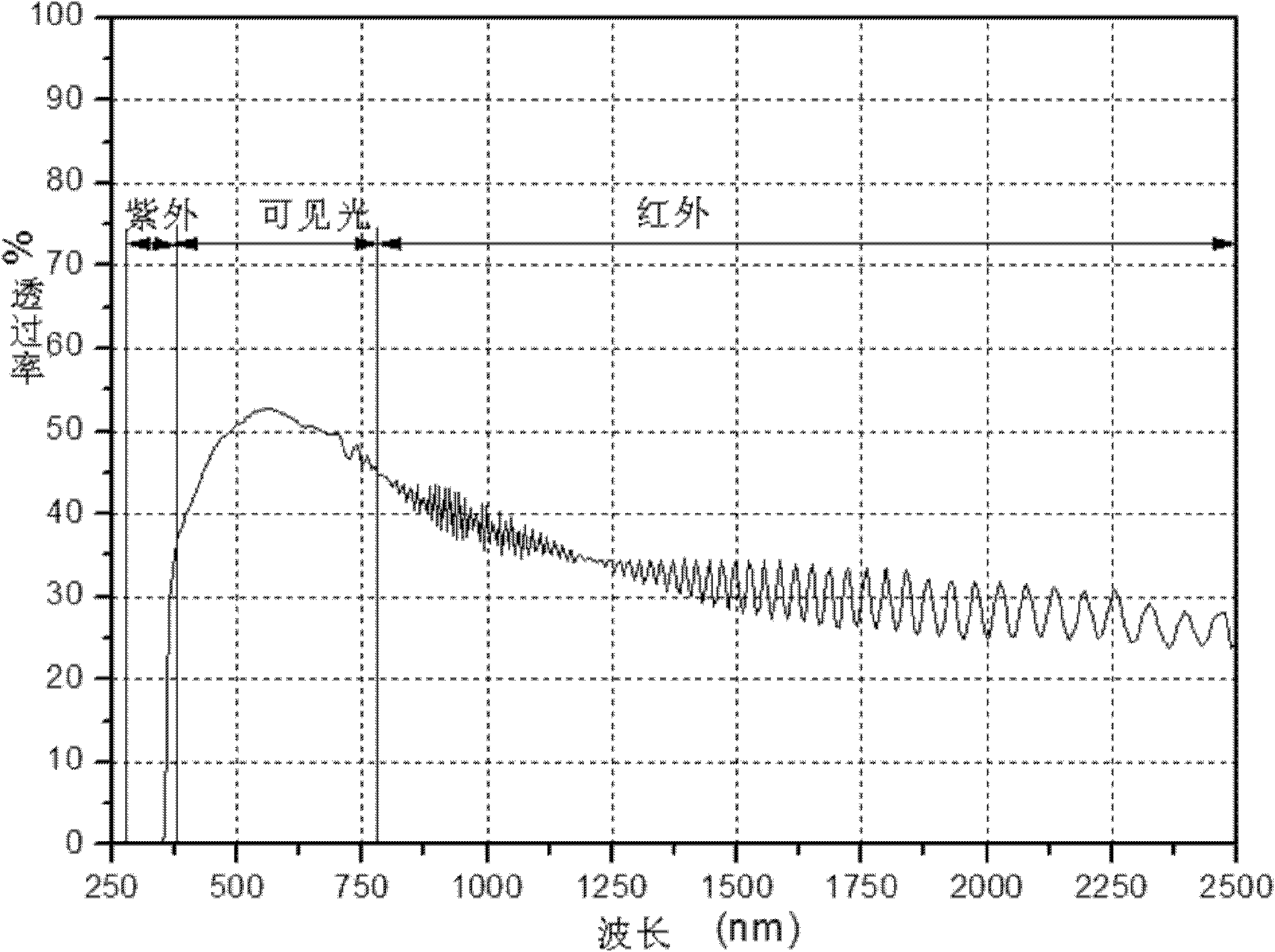

Nanometer ceramic solar film

InactiveCN102837460AGood spectral selectivityImprove transmittanceSynthetic resin layered productsVacuum evaporation coatingInfraredThermal insulation

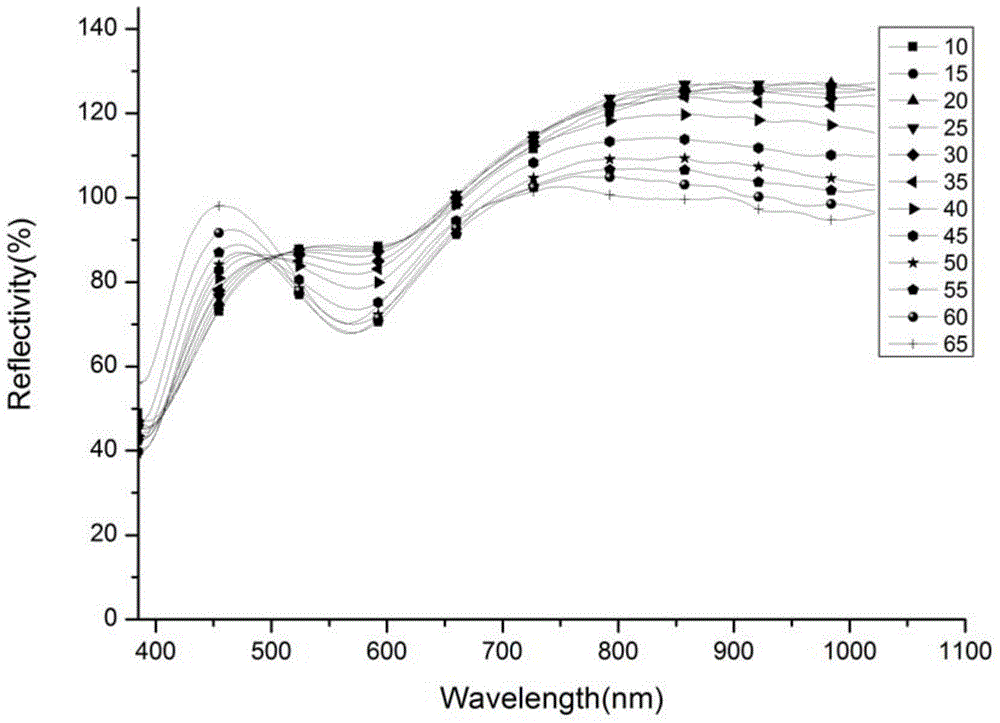

The present invention relates to a nanometer ceramic solar film. According to the nanometer ceramic solar film, a firs layer titanium dioxide film, a second layer titanium nitride film and a third titanium dioxide film are sequentially plated on a surface of a substrate PET through magnetron sputtering, wherein a thickness of the substrate PET is 23-50 mum, a thickness of the first layer titanium dioxide film is 26-38 nm, a thickness of the second layer titanium nitride film is 20-26 nm, and a thickness of the third layer titanium dioxide film is 26-38 nm. The nanometer ceramic solar film of the present invention has the following characteristics that: good spectral selective permeability, high transmittance in a visible light region, and high reflectivity in an infrared region are provided, wherein infrared rays are blocked so as to reduce heat source, such that thermal insulation is achieved while transmittance on visible light is not affected; and titanium dioxide and titanium nitride have high chemical stability at a room temperature, are not easily oxidized, and do not react with oxygen, water, steam, hydrochloric acid, sulfuric acid and the like under normal circumstances, such that performances are stable, fading and discoloration can not be generated, and a service life is long.

Owner:SOUTHWESTERN INST OF PHYSICS

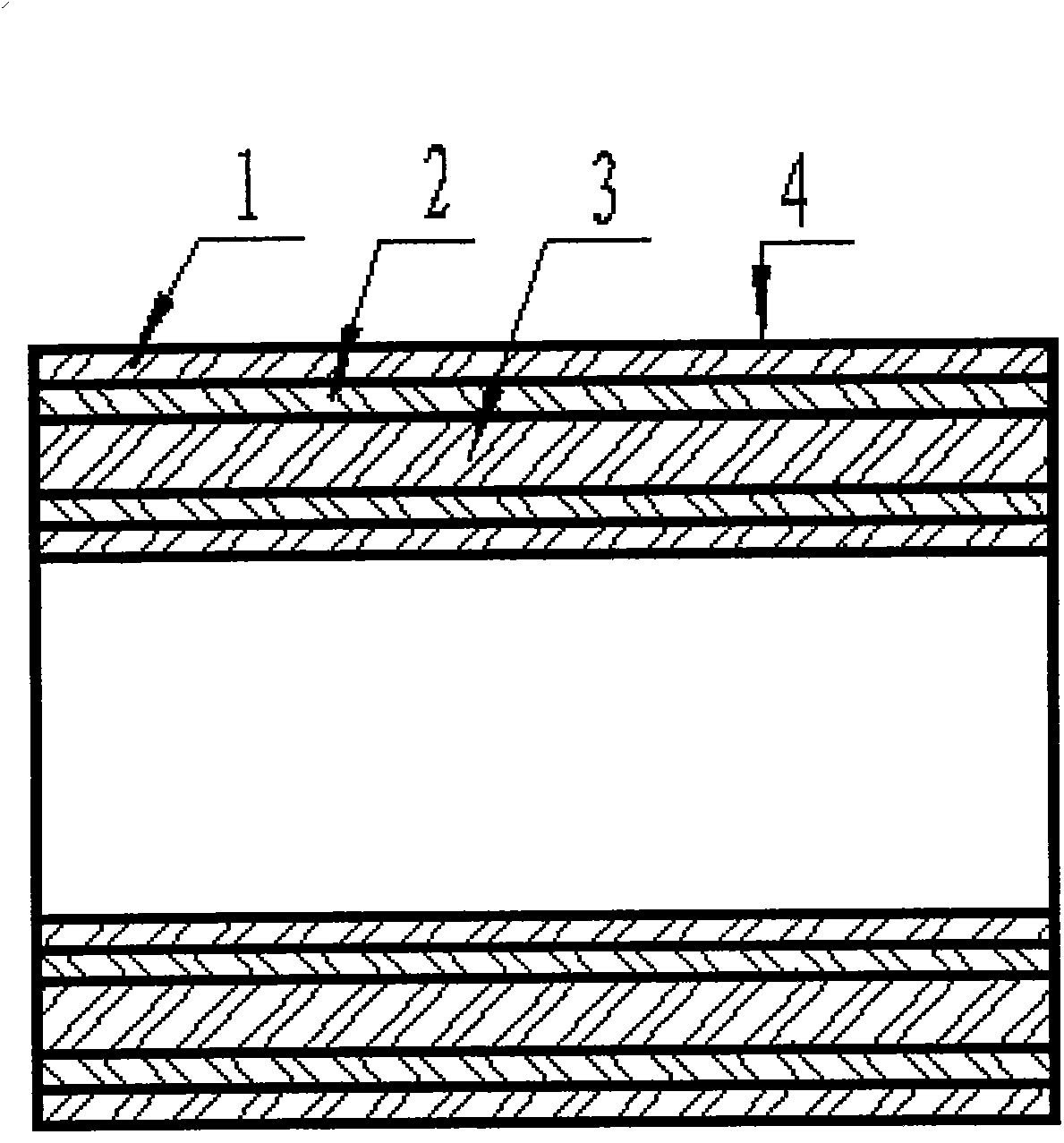

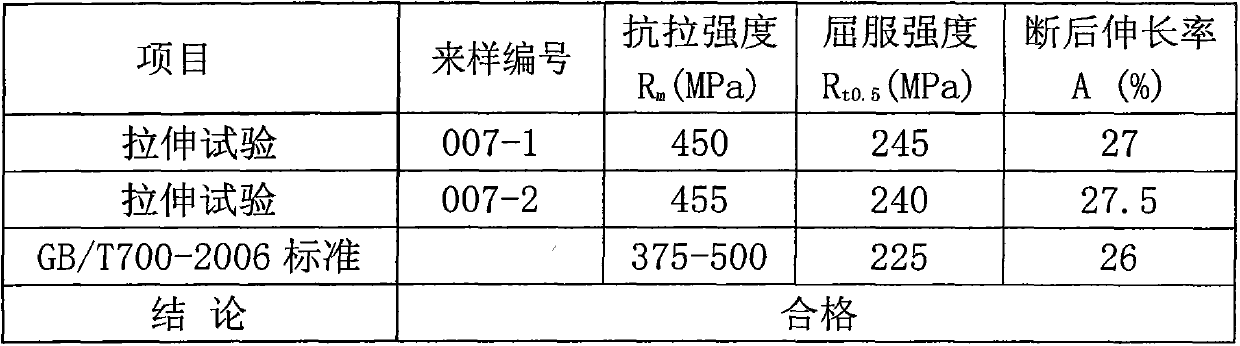

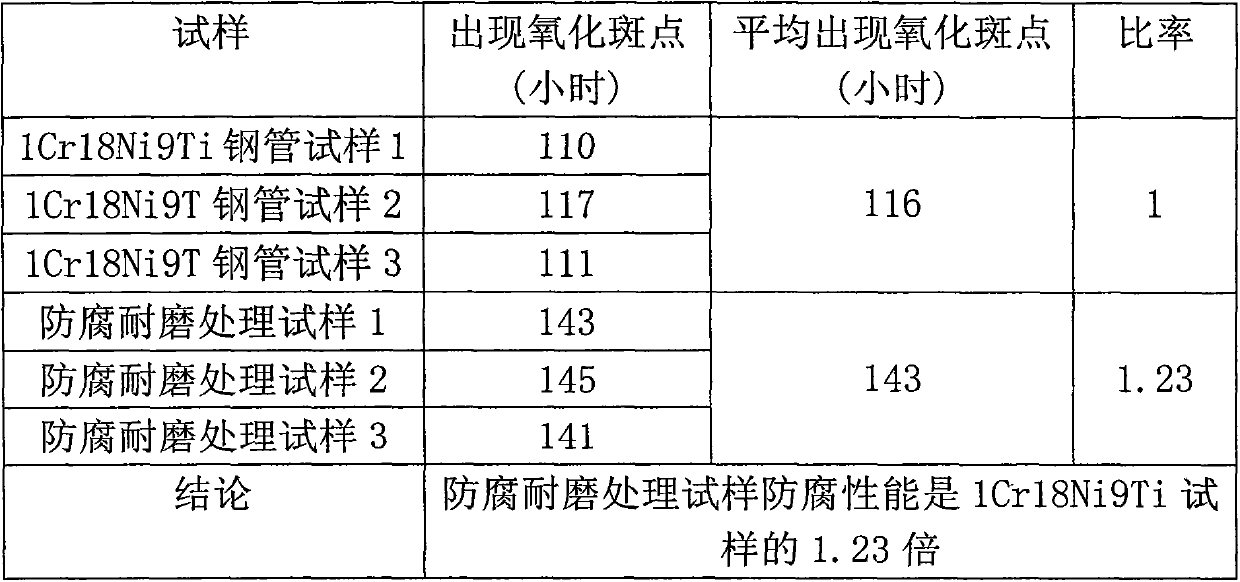

Process for preparing novel corrosion-resistant and wear-resistant color steel pipe

ActiveCN104195505AHigh hardnessImprove anti-corrosion performanceSolid state diffusion coatingWear resistantSeam welding

The invention relates to a process for preparing a novel corrosion-resistant and wear-resistant color steel pipe and belongs to the technical field of surface modification and heat treatment of steel pipes. The process is mainly characterized in that the inner and outer surfaces of the steel pipe are subjected to oil removal and cleaning treatment, steel pipe preheating treatment, steel pipe secondary polishing treatment, steel pipe third polishing treatment and liquid ion nitriding and corrosion-resistant and wear-resistant heat treatment process and then subjected to liquid ion oxidizing and coloring and fine polishing treatment and a 10mu m-100mu m corrosion-resistant and wear-resistant layer is formed on each of the inner and outer surfaces of the steel pipe, wherein the corrosion-resistant and wear-resistant layer mainly and sequentially comprises a compound layer and a nitrogen-containing austenite layer, the steel pipe is A3, Q235 or other carbon steels and the original state of the steel pipe can be a seamless steel pipe and can also be a straight-seam welded steel pipe. The steel pipe produced by the process disclosed by the invention has the advantages of relatively high corrosion resistance and wear resistance and since the outer surface of the steel pipe can show different colors, such as silver, bronze, black, and navy blue, the steel pipe can replace Cr-containing and Ni-containing stainless steel color steel pipes.

Owner:SHAANXI TIEMA FORGING

High-emulation art drawing tile copying method

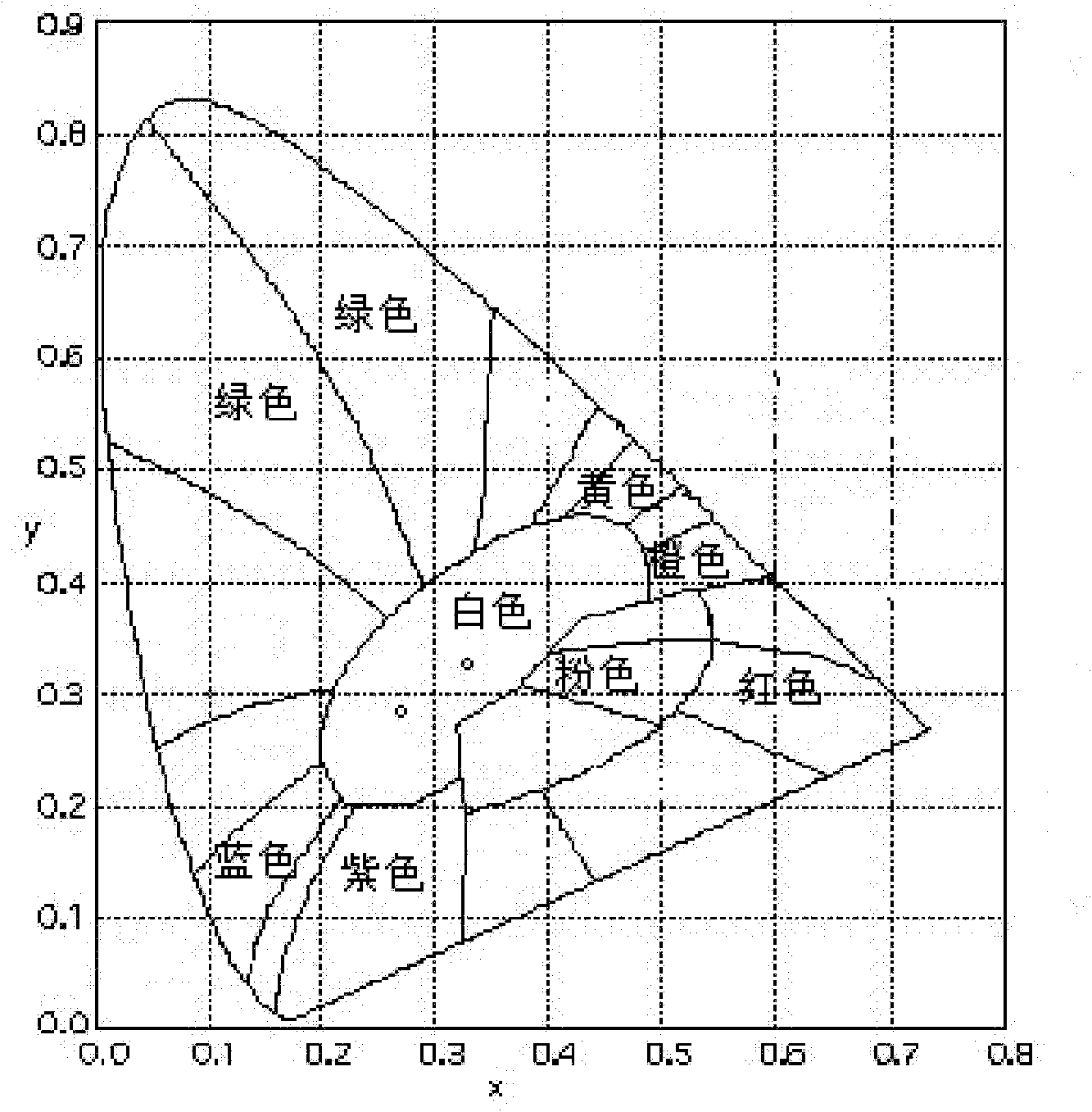

ActiveCN105082857ARealistic color effectImprove controllabilityImage analysisDecorative surface effectsColor effectComputer graphics (images)

The invention relates to a high-emulation art drawing tile copying method. The method includes the following steps that firstly, a laser radiation device is arranged on a digital scanner, an existing drawing is scanned through the digital scanner under the effect of laser radiation, and the existing drawing is converted into a digital image; secondly, color comparison and color difference management are conducted on the obtained digital image; thirdly, printed materials are selected, and printing is conducted through a high-end inkjet printer; and fourthly, high-temperature fidelity color sintering is performed, and then post-processing is conducted. Compared with the prior art, the method has the beneficial effects of being realistic in product color effect, high in controllability and the like.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

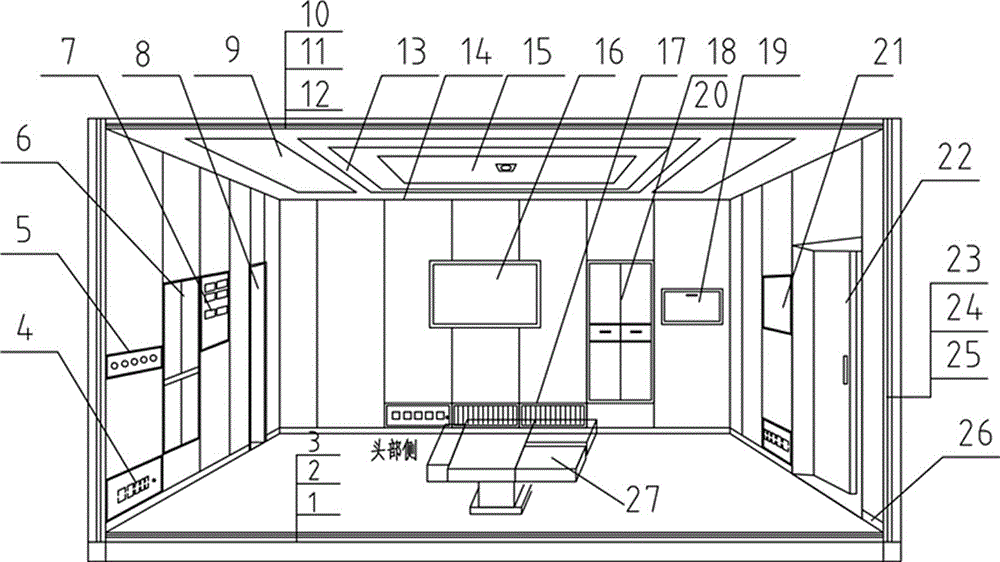

Glass operating room

InactiveCN105220907AMeet the requirements of the working environmentFireproofCovering/liningsWallsFloor slabPolyvinyl chloride

A glass operating room comprises a facade formed by assembling four walls. A ceiling integrally connected with the walls is mounted above the walls. Painted glass wall panels are spread on the outer surfaces of the walls. Painted glass top panels are spread on the outer surface of the ceiling. Seamless rubber or PVC (polyvinyl chloride) floor slabs are spread on the ground. By providing the glass operating room, the problem that an existing operating room is inconvenient to wash and poor in assembly tightness can be solved; the glass operating room is fireproof, attractive, scrub resistant, disinfection resistant, simple to construct, environment-friendly and energy-efficient and meets the requirements of operating room work environments.

Owner:JIANGSU PANASIA MEDICAL TECH GRP CO LTD

Method for producing hand-drawn wallpaper picture

InactiveCN101537768ASave labor timeReduce labor costsArtistic workSoftwareComputer graphics (images)

The invention relates to a method for producing a hand-drawn wallpaper picture. The method comprises the following steps: firstly, a proper or predesigned picture is selected, and the selected or the predesigned picture is processed by a related software; secondly, the picture is projected onto drawing materials by a projector; thirdly, images projected onto the drawing materials are directly colored, or are colored after an outline is drawn; and fourthly, the picture and color of different pieces of drawn images are spliced and colored according to the serial numbers so as to obtain the required finished product. The method has the advantages of simple technological process, low technological cost and high accuracy, can maintain the characteristics of an original works, easily change the proportion and save the labor hours , and can be widely applied to the field of producing the hand-drawn wallpaper picture.

Owner:韩波

Blue aluminum alloy

The invention relates to a blue aluminum alloy. The manufacturing process of the blue aluminum alloy comprises the following steps: (1) manufacturing an aluminum alloy into fine powder at the fineness of 120-160 meshes; (2) adding a foaming agent to the fine aluminum alloy powder obtained from the step (1), and stirring and mixing at a high speed; (3) adding a blue pigment to a mixture obtained from the step (2), and stirring and mixing at a high speed for 30 minutes; (4) heating a mixture obtained from the step (3) till the mixture starts to foam at 670-680 DEG C, and stirring; and (5) continuously stirring for 15 minutes, keeping the temperature in the step (4), stopping heating after no bubble is generated any longer, cooling to obtain the blue aluminum alloy, wherein the blue pigment is cobalt blue, and the usage amount of the blue pigment accounts for 3%-5% of the weight of the aluminum alloy. According to the invention, the internal color and external color of a metal are same; the manufactured product never fades, is low in manufacturing cost and pollution-free in production process and is a good environment-friendly product.

Owner:NANTONG ZHIBANG NEW MATERIAL TECH

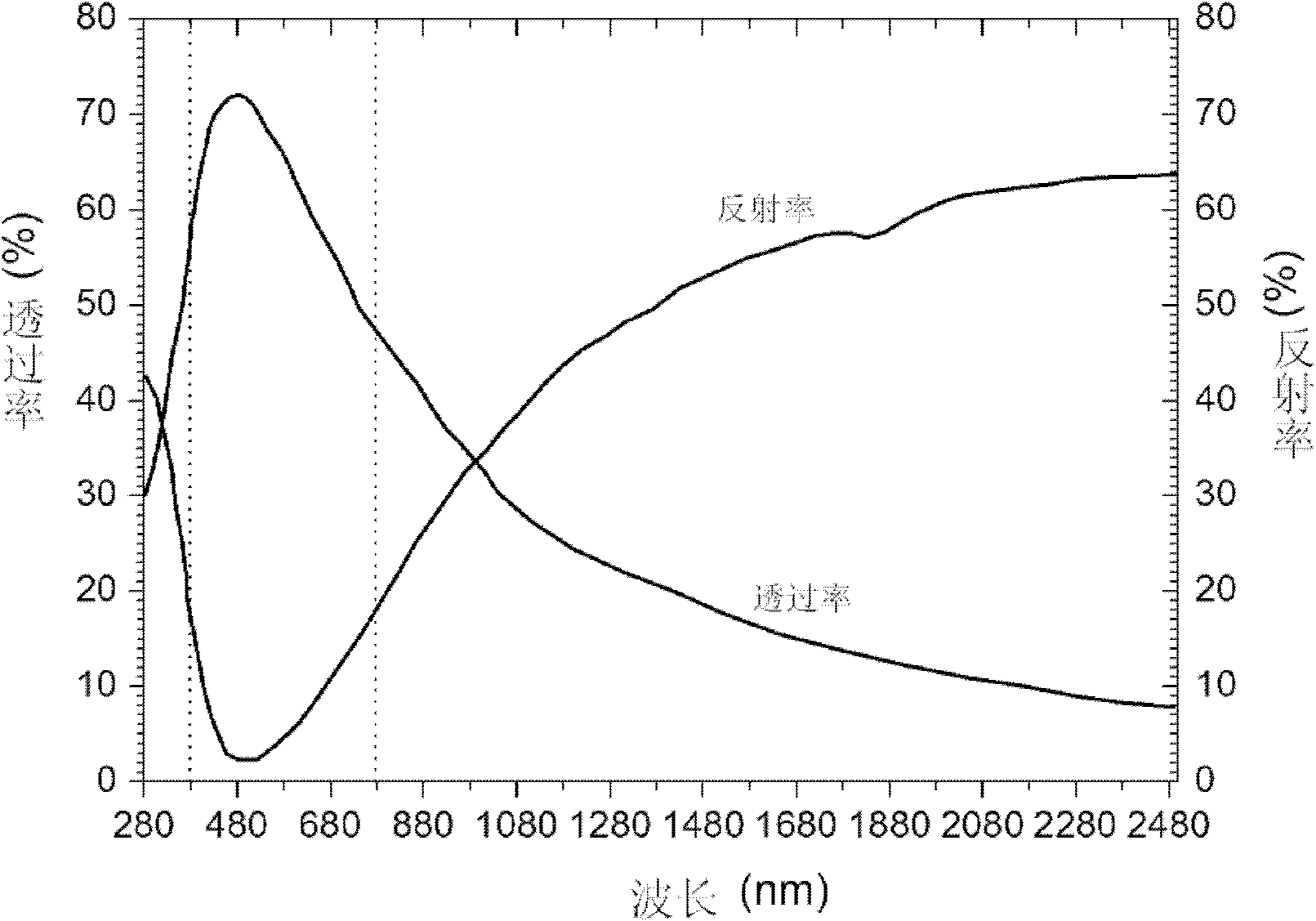

Preparation of antibacterial structural color fibers based on silk protein and antibacterial structural color fabric

InactiveCN107574676AImprove mechanical propertiesGood physical and chemical propertiesLayered productsConjugated cellulose/protein artificial filamentsRare-earth elementMicrosphere

The invention relates to a preparation method of antibacterial structural color fibers based on silk protein. The preparation method comprises the following steps: dispersing colloidal microspheres inwater to prepare colloidal emulsion with mass fraction of 6 to 15 percent, wherein the colloidal microspheres are polystyrene microspheres, polymethylmethacrylate microspheres and titanium dioxide microspheres; dissolving the silk protein, cellulose and rare earth elements in an aqueous solution of alkali, and carrying out electrostatic spinning to obtain silk protein fibers; enabling the silk protein fibers to pass through the colloidal emulsion in a lifting way from bottom to top; drying moisture by airing. The invention also provides an antibacterial structural color fabric based on the silk protein. The antibacterial structural color fabric comprises a base fabric layer and an antibacterial coloring layer, wherein the base fabric layer is formed by weaving warp yarns and weft yarns; all weft yarns are connected between every two adjacent warp yarns in an inclined manner; at least one of each warp yarn and each weft yarn is used as a wrapping yarn; the wrapping yarns are prepared from silks and bast fibers; the bast fibers are core yarns; the silks cover the surfaces of the bast fibers; the antibacterial coloring layer is prepared from the antibacterial structural color fibersbased on the silk protein.

Owner:SUZHOU BEST COLOR ENVIRONMENTAL PROTECTION NANOTECH CO LTD

Fadeless mineral pigment for painting

The invention discloses fadeless mineral pigment for painting. The fadeless mineral pigment is prepared from the following components in percentage by weight: 34.29% of mineral powder, 3.02% of epoxy resin, 0.21% of composite phosphate, 0.52% of superfine barium, 1.20% of leveling agent, 0.80% of modified starch, 0.10% of graphene, 1.2% of titanium dioxide, 0.8% of sea mud, 0.5% of wax powder, 0.5% of sepiolite powder and the balance of deionized water. In the invention, the components are relatively simple, and the preparation method is easy to realize; and by adopting the special-formula pigment, the product does not fade forever.

Owner:姜曙光

High-grade ceramic underglaze color manufacturing and decorating method

The invention discloses a high-grade ceramic underglaze color manufacturing and decorating method. The underglaze color is manufactured in a three-time firing mode. The method comprises the following steps: performing biscuit firing on the green body, performing colored firing, and finally performing glaze firing; the method is characterized in that according to the three-time firing mode, the underglaze color ceramics are manufactured by virtue of a three-times firing method comprising high-temperature biscuit firing, high-temperature colored firing and low-temperature glaze firing, wherein the high-temperature biscuit firing is performed under the temperature condition of 1150-1250 DEG C; the high-temperature colored firing is performed under the temperature condition of 1000-1250 DEG C; and the low-temperature glaze firing is performed under the temperature condition of 1000-1140 DEG C.

Owner:HUNAN NEW CENTURY CERAMICS

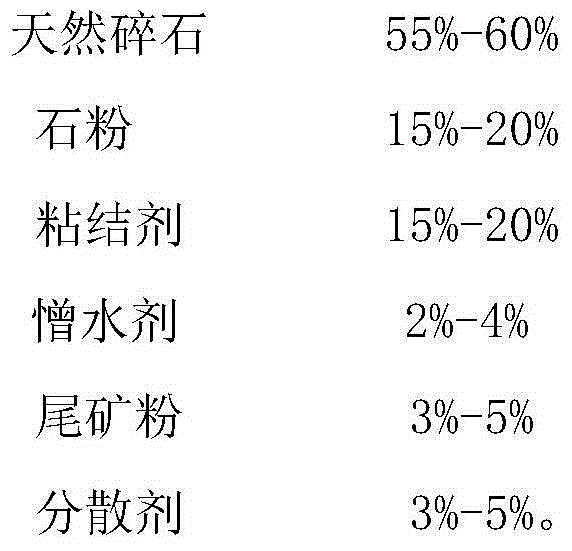

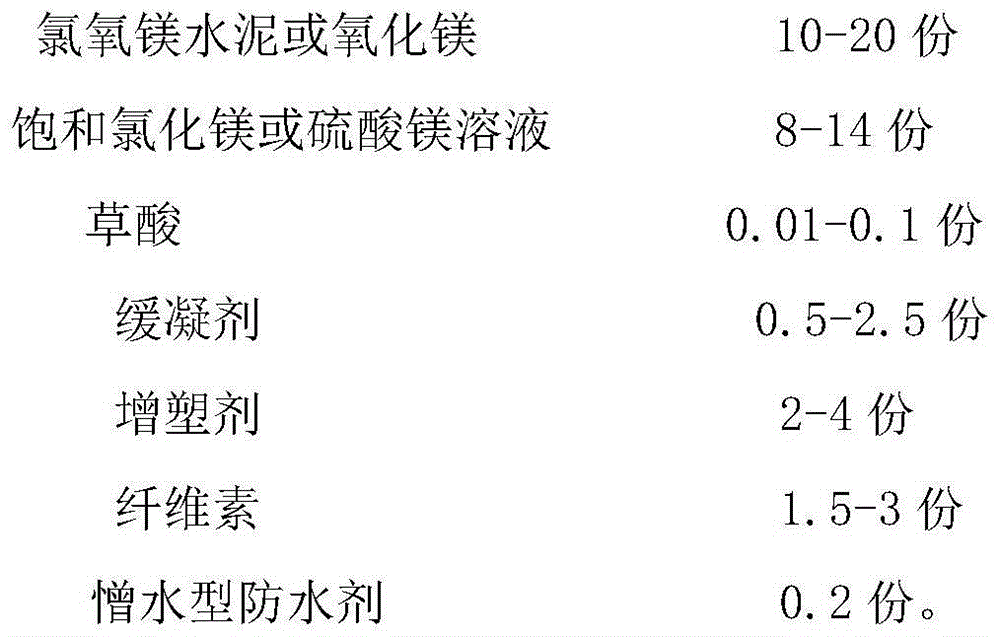

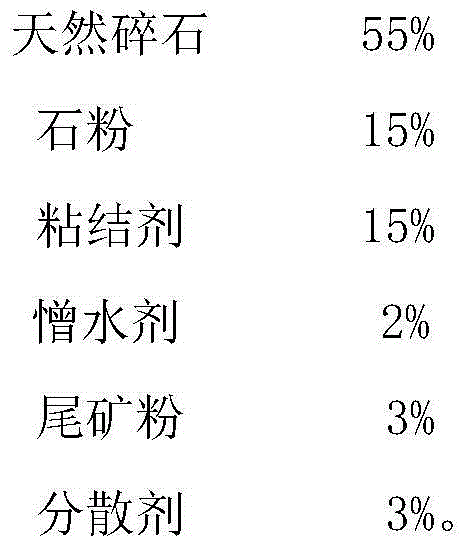

Self-cleaning type real stone lacquer and preparation method thereof

The invention discloses a self-cleaning type real stone lacquer and a preparation method thereof. The self-cleaning type real stone lacquer comprises the following components in percentage by weight: 55%-60% of natural gravels, 15%-20% of stone powder, 15%-20% of adhesion agents, 2%-4% of water repellents, 3%-5% of tailing powder and 3%-5% of dispersing agents. The self-cleaning type real stone lacquer disclosed by the invention has the characteristics of strong hydrophobic capacity and oil pollutant-resistant capacity, fire prevention, water prevention, acid-base resistance, pollution resistance, no toxicity, no odor, high adhesion power, color permanence, easiness and convenience for construction, easiness for drying, time saving, energy conservation, environmental friendliness and the like, can be used for effectively preventing the erosion of an external harsh environment on a building and prolonging the life of the building and has good adhesive power and freeze thawing resistant property, thereby being suitable for being used for various regions.

Owner:NANJING FORTUNE RECYCLING TECH

Titanium metal plate painting and manufacturing technology thereof

InactiveCN113246648AImprove the three-dimensional effectColorfulEdge grinding machinesPolishing machinesAcid etchingSurface finish

The invention belongs to the field of metal calligraphy and painting manufacturing, and particularly relates to a titanium metal plate painting and a manufacturing technology of the titanium metal plate painting. The manufacturing technology comprises the following steps of (1) manufacturing a titanium plate; (2) polishing the surface of the titanium plate to obtain a titanium plate with the surface roughness Ra ranging from 0.8 micrometers to 1.6 micrometers; (3) printing characters and patterns; (4) conducting anodic oxidation, specifically, the process comprises the steps of acid etching, neutralization, anodic oxidation and hot water cleaning; and (5) conducting surface spraying. The manufactured titanium plate painting is good in three-dimensional effect, gorgeous in color and high in surface smoothness and is free of color fading and color losing.

Owner:宝鸡市福立特工贸有限责任公司

Ceramic plate

InactiveCN106866113AImprove drying pass rateExtrusion fastCeramic materials productionClaywaresPyrophylliteToxic industrial waste

The invention provides an argil plate and belongs to the technical field of building materials. The ceramic plate is prepared from the following materials in parts by weight: 10-35 parts of illite, 0-15 parts of kaolin, 5-15 parts of pyrophyllite, 5-30 parts of chinastone, 20-50 parts of iron ore smelting tailings, 5-30 parts of coarse poor materials, 0-5 parts of plasticizers, 20-40 parts of argil dry powder, 20-30 parts of chinaclay dry powder, 10-20 parts of feldspar powder and 20-30 parts of aggregate. The aggregate is prepared by crushing waste ceramic plates, ceramic tiles, pottery tiles and leftover materials; the fineness of the aggregate is 12-60 meshes. The argil plate is free of stone radiation and harm of organic materials of artificial stone to people; after the ceramic plate is fired under high temperature, the ceramic plate is high in strength, never fades and is free of influence of climatic environment; the coarse aggregate is added into the formula, so that the surface of the ceramic plate is rough and is not slippery; the argil plate is rapid to extrude and form, high in drying qualification rate and short in firing period; the cost is reduced; the iron ore tailings are used, so that the local industrial waste residues are reused.

Owner:史晓强

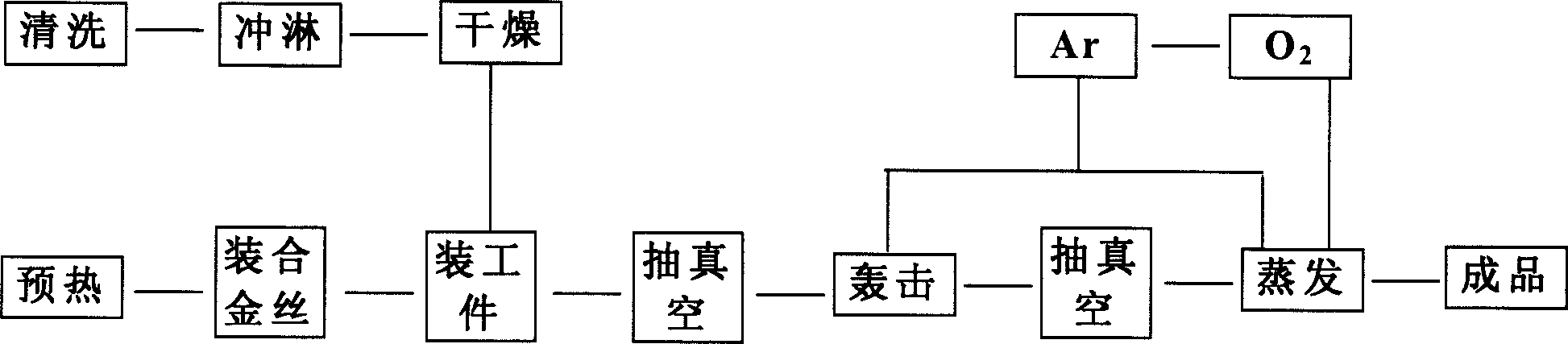

Method for producing filming decorative glass using vacuum filming machine

The present invention discloses method of making coated decorative glass with vacuum coating machine. Under the conditions of 0.1-0.5 Pa vacuum degree and O2 or O2 / Ar circumstance, gas is made to in glow discharge state, titanium wire is evaporated slowly, and titanium vapor is reacted with oxygen ion in the discharge area, so that compact, homogeneous, completely oxidized and high adhesion titania film is formed on the surface of glass workpiece. The coated decorative glass has excellent decorating effect, is durable, and has the functions of eliminating pollutant and purifying air.

Owner:钱中良

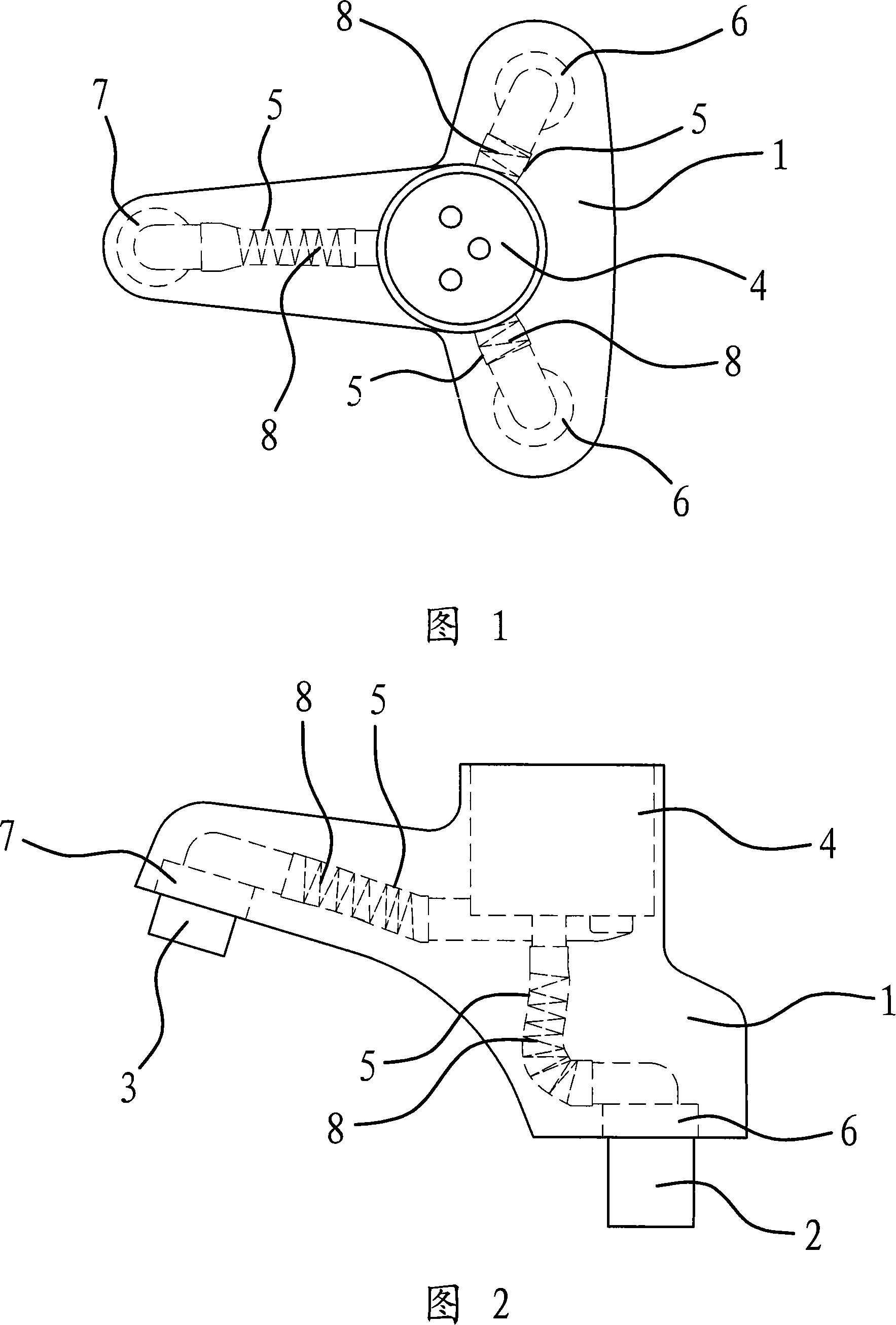

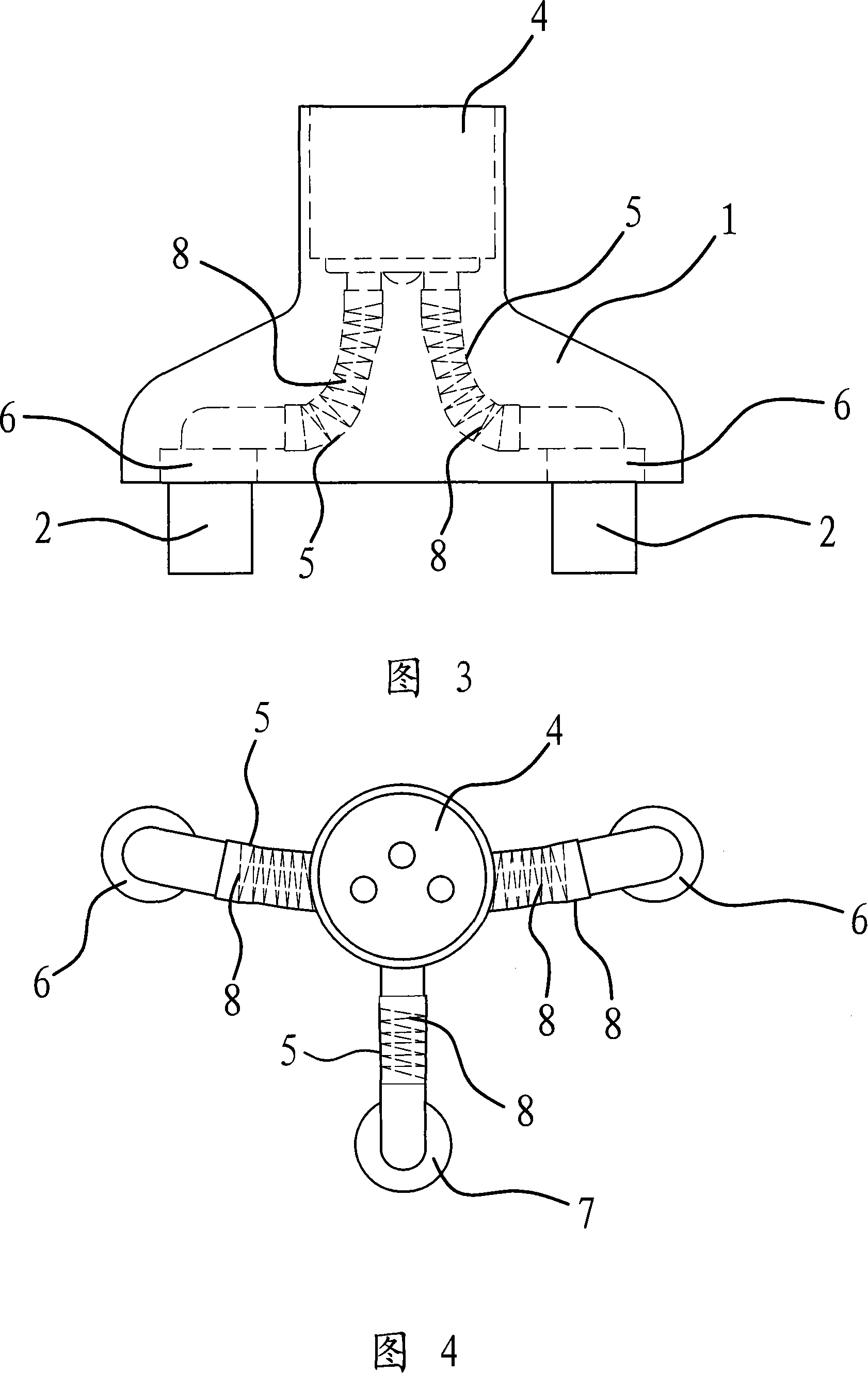

Method for manufacturing imitating jade tap and its product and mould

InactiveCN101104315AGuarantee unimpededReduce manufacturing costMultiple way valvesSlide valveMechanical engineeringSilicon

The invention provides a making method of a jade-like water tap and the product and a die thereof, relating to a water tap, which solves the problem on current water tap that water discharging amount is not agreeable. The making method of the jade-like water tap comprises the following steps: A. assembling the die; B. closing the die; C. injecting; D. assembling. The jade-like water tap comprises a body inside which a circular tube and a valve core seat are arranged. A water inlet pipe and a water outlet pipe are fixedly connected to the body and both are communicated with the valve core seat through respective connecting tubes. The body is made of resin and the connecting tubes are provided with reinforcing structures inside to strengthen the intensity of the connecting tubes. An upper die body and a lower die body of the jade-like water tap are made of plaster and the joint interface of the upper die body and the lower die body is provided with a silicon glue layer; the positioning holes of the valve core seat, the water inlet seat and the water outlet seat are provided with positioning devices. With the method, rate of finished water taps is high and the products are elegant in appearance and good in taste.

Owner:张长春

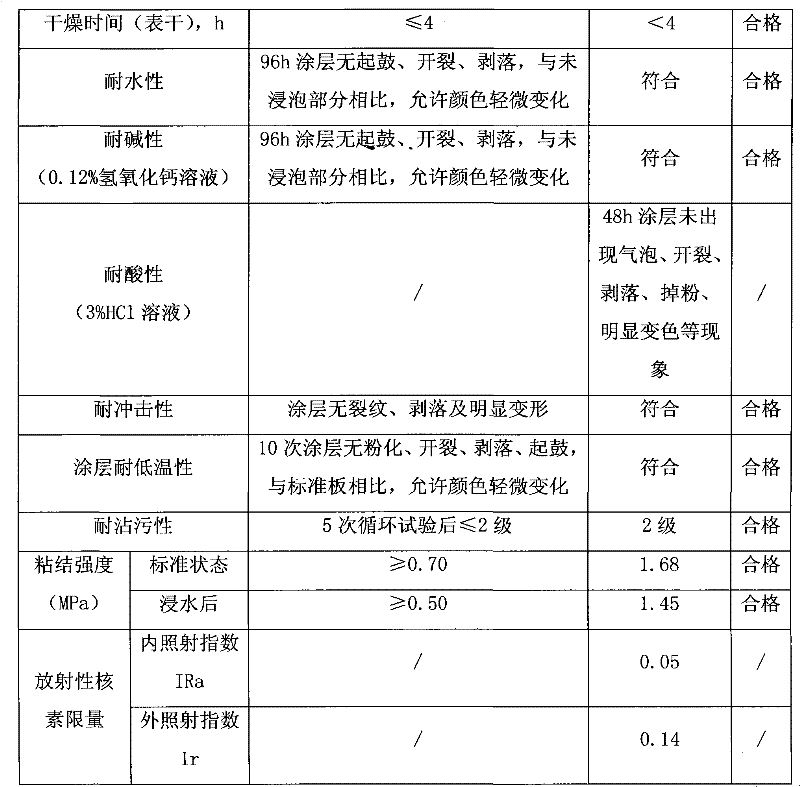

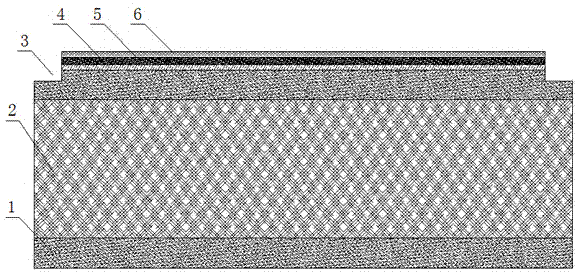

Inorganic rock-wool thermal insulation decorating plate with leveling natural stone paint surface

ActiveCN104775584ASimple structureImprove sealingCovering/liningsCoatingsCalcium silicateInsulation layer

The invention discloses an inorganic rock-wool thermal insulation decorating plate with a leveling natural stone paint surface. The decorating plate comprises a heat insulation layer made of inorganic rock-wool; calcium silicate boards which are taken as reinforced layers are respectively arranged at the upper surface and the lower surface of the heat insulation layer; the outer side surface of the calcium silicate board arranged at one side of the heat insulation layer is coated with a leveling natural stone paint finish coat; the finish coat comprises a prime coat, a natural stone paint layer and a finish paint layer; mounting sides are respectively arranged at the peripheries of the finish coat and the calcium silicate board connected with the finish coat. The inorganic rock-wool thermal insulation decorating plate integrates the functions of heat insulation, heat preservation and surface decoration, and is simple in structure, easy to install, light in self weight, high in strength and good in safety; the finish coat has the characteristics of having the true color of natural stone, being natural in color, vivid in texture, colorfast, environment-friendly, flat, smooth, high in accuracy, high in self-cleaning ability, weather-proof, cracking-resistant, anti-drop and the like; the finish coat adopts a three-layer structure including the prime coat, the natural stone paint layer and the finish paint layer, so that the decorating plate is stable and firm and does not lose paint and fade, and the product quality is guaranteed.

Owner:信阳新天意绿色建材有限公司

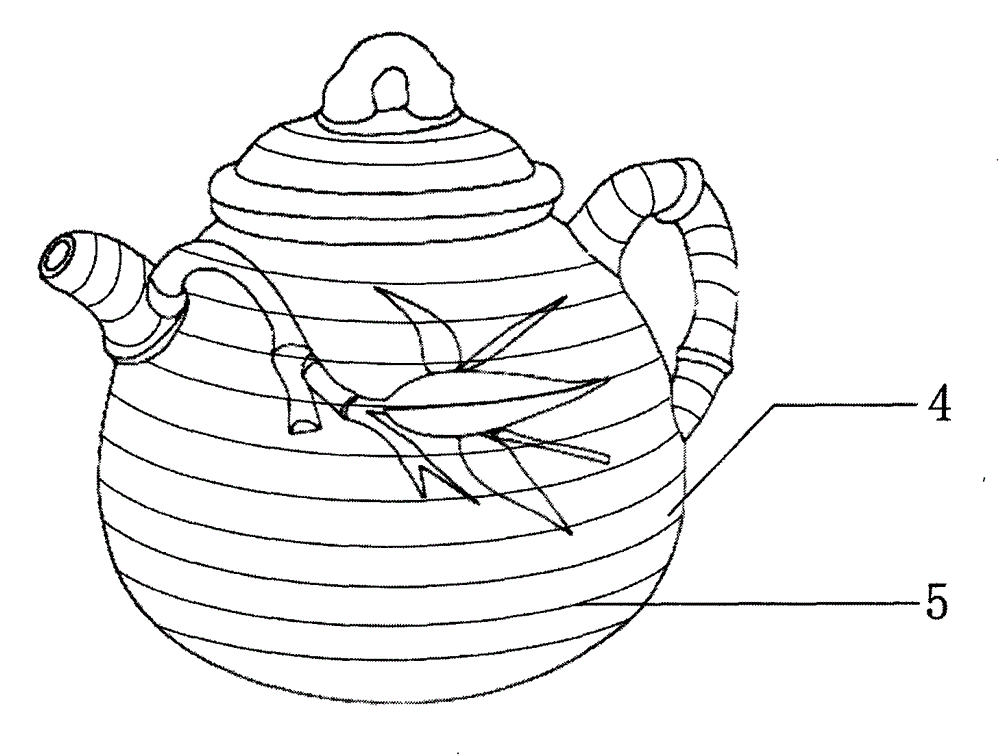

Clay and gold casting process

The invention relates to casting technical field of combining clay art ware and pure gold, in particular to a clay and gold casting process. The process comprises the following steps: fine screening of clay product, copper oil spraying, trimming, polishing, burnishing, gold cylinder electroforming, cleaning, baking, protecting agent applying, and secondary baking. The finished product prepared from the process comprises three layers, an innermost layer, actually an authentic first-class Yixing clay art ware, a middle layer, actually a copper material, and an outer layer, actually pure gold. Due to the adoption of the process, the three layers are combined together closely, unique features are provided, the technological process is fine and meticulousness, the finished products are easy to store and fast in color, and therefore, the clay products prepared from the process has super-high appreciating, collecting and use value, and is suitable for everlasting collection.

Owner:朱建华

Reflection heat insulation and preservation veneer integrated external wall panel sectional material

InactiveCN104594586ASuppresses radiant heatGood energy saving effectCovering/liningsWater-setting substance layered productFiberEmulsion

The invention relates to a reflection heat insulation and preservation veneer integrated external wall panel sectional material which is composed of a heat preservation layer and a veneer layer, wherein the heat preservation layer and the veneer layer are pressed to form a whole. The heat preservation layer is an existing external wall external heat preservation sectional material product made of inorganic mineral materials in the market. The veneer layer is formed by preparing ten raw materials of waste stone detrital materials, hollow glass micro-beads, vitrified micro-beads, rare-earth oxides, rutile, waterborne emulsion, inorganic adhesives, wood fiber, polypropylene short fiber and film formation auxiliaries and water. An overall composed, pressed and formed structure of the heat preservation layer and the veneer layer is adopted for the sectional material, the structure is used for an external wall body, safety is high, solar radiant heat absorbed by a building can be reduced, temperature rising caused by solar radiation absorbed by the surface of the building is prevented, heat transmitted into a room is reduced, the heat preservation and insulation requirement of the building outer wall body is met, and the purposes of providing comfortable indoor and outdoor environments, saving energy and lowering consumption are achieved.

Owner:信阳天意节能技术股份有限公司

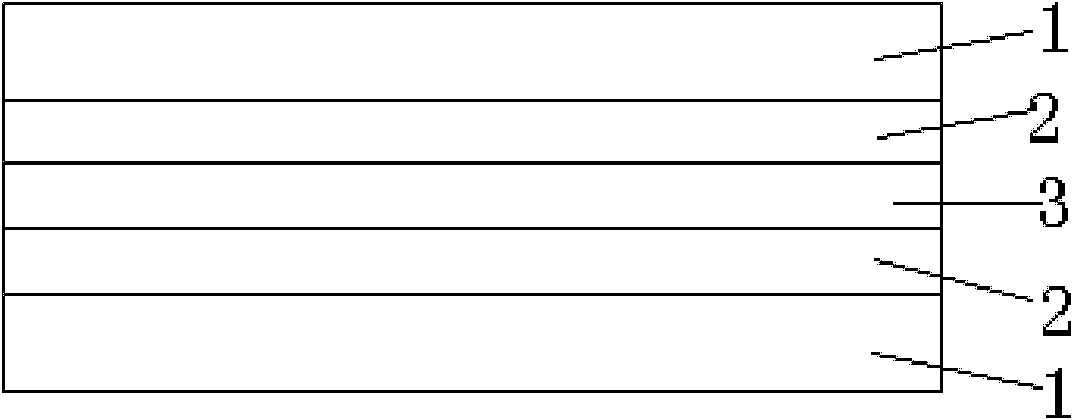

Solar control film and double layer composite solar control film

The present invention relates to a solar control film, wherein a titanium nitride film is plated on a substrate PET in a magnetron sputtering manner, a thickness of the substrate PET is 23-50 mum, a thickness of the titanium nitride film is 5-30 nm, and the titanium nitride film is plated by using a medium frequency reaction twin target magnetron sputtering method. The present invention further relates to a double layer composite solar control film, wherein two layers of solar control films are adhered through a pressure sensitive adhesive layer, and the pressure sensitive adhesive layer is positioned between the titanium nitride films of the two layers of the solar control films. The films of the present invention have the following characteristics that: infrared rays are blocked so as to reduce heat source; an anti-reflection effect can be provided in a visible light region, such that thermal insulation is achieved while transmittance on visible light is not affected; TiN has characteristics of high chemical stability at a room temperature, stable performance, no fading, no discoloration, and long service life; and glass splashing after breakage can be prevented, such that a function of explosion resistance is provided. In addition, with the double layer composite solar control film, reflected light intensity can be effectively reduced.

Owner:SOUTHWESTERN INST OF PHYSICS

Coating of bamboo and wood color painting and preparation method thereof

InactiveCN102702906AImprove antioxidant capacityNo peeling and loss of lightFireproof paintsAnti-corrosive paintsNon toxicityFire resistance

The invention relates to a coating of a bamboo and wood color painting and a preparation method thereof. The prepared coating has natural and true color and gives the elegant, harmonious and sedate aesthetic perception. The coating is suitable for indoor and outdoor decoration of the bamboo and wood color painting. The effects of vividness, lifelikeness and return to the nature can be obtained. The coating has the effects of fire resistance, waterproofness, acid and alkali resistance, pollution resistance, non-toxicity, odorlessness, strong adhesive strength, fadeless property and the like; the bamboo and wood color painting can be effectively prevented from being eroded by the outside harsh environment; and the service life of the bamboo and wood color painting is prolonged. The coating has excellent adhesive force and freeze-thaw resistance, and thus, even though the coating is used in the cold areas, the coating of the bamboo and wood color painting is also simple and convenient to spray, is easy to dry, is time-saving and is convenient to operate.

Owner:太仓市德兰树片画设备科技有限公司

Method for preparing microcrystalline glass heating plate based on in-situ crystallization technology

InactiveCN102256392AFix security issuesSolve the problem of boiling water with peculiar smellCooking-vessel materialsWater-boiling vesselsElectrical resistance and conductanceIn situ crystallization

The invention discloses a method for preparing a microcrystalline glass heating plate based on an in-situ crystallization technology and application thereof. The method comprises the following steps of: firstly, modifying 95% alumina ceramic material by adding ions, such as Ba<+> and Si<+> and the like; secondly, compounding the modified alumina ceramic material by processes, such as printing, sintering and the like; thirdly, permanently manufacturing the compounded material and a glass plate into a whole to form an inorganic conductive resistance layer; and finally, electrifying to heat and emit infrared heat energy, forming a heat radiation source and heating in a conduction and convection manner, so as to prepare the advanced microcrystalline glass heating plate. The advanced microcrystalline glass heating plate is practically applied to an electric kettle.

Owner:何小洁

Anti-freezing stone paint and preparation method thereof

The invention discloses an anti-freezing stone paint and a preparation method thereof. The anti-freezing stone paint is prepared from the following raw materials by weight: 120-140 parts of silicone-acrylic emulsion, 600-650 parts of natural manganese sand, 5-7 parts of hexylene glycol, 2-4 parts of sodium stearyl lactate, 4-6 parts of propylene glycol monoethyl ether, 60-80 parts of cellulose acetate butyrate, 20-30 parts of compound nano powder, 15-25 parts of seashell mud, 12-18 parts of germanite powder, 3-5 parts of sodium acryloyldimethyl taurate, 2-3 parts of cocoalkanoylamido propyl betaine, 1-2 parts of triethanolamine alginate, 1-2 parts of polyoxypropylene glycerol ether and 50-60 parts of water. The stone paint provided by the invention has the characteristics of anti-freezing property, water resistance, high adhesive strength, acid and alkali corrosion resistance, pollution resistance, no toxicity, environment protection and fast color, is adaptive to requirements of winter construction, particularly winter construction in the north region of China, is simple and convenient for construction, can be dried easily and save time, can be used for a plurality of base surfaces of cement and brick walls, foam, gypsum, aluminium plates and glass, and can be coated at will according to profiles of buildings.

Owner:SUZHOU ZHONGLI HEAT PRESERVATION & ENERGY SAVING MATERIAL CO LTD

Manufacturing method for brick sculpture

InactiveCN110053131AReduce manufacturing costFast productionCeramic shaping apparatusThree dimensional modelBrown iron oxide

The invention discloses a manufacturing method for a brick sculpture and relates to the technical field of building materials and building components. The manufacturing method includes the following steps that A, a drawing pattern is designed; B, a three-dimensional model is manufactured according to the drawing pattern in the first step; C, a die is manufactured according to the three-dimensionalmodel in the second step; D, brick sculpture raw materials are selected and include, by weight, 100-110 parts of sulphate aluminum cement, 130-150 parts of ceramsite, 0.5-1 part of polyester fibers,0.3-5 parts of iron oxide pigments, 36-44 parts of water, 0.2-0.5 part of an efficient water reducing agent, 3-5 parts of a penetrating type nano waterproof agent and 0.2-0.5 part of re-dispersible emulsion powder, and the raw materials are stirred evenly after being mixed; E, the brick sculpture raw materials which are stirred evenly in the fourth step are loaded into the die in the third step, and vibrating exhausting is conducted; F, die stripping curing is conducted, and the formed materials can be discharged out of the die after being solidified, and then curing is conducted; and G, the raw materials are warehoused to be stored. The manufacturing method has the beneficial effects that the production speed is high, needed manual work is small, and the cost is low; the manufacturing period is short; wear resistance, pressure resistance and folding resistance are achieved, and the anti-freezing capability is high; the brick sculpture will never fade; environment friendliness is achieved, and no pollution exists; and the pattern is exquisite.

Owner:陕西唐语景观工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com