Process for preparing novel corrosion-resistant and wear-resistant color steel pipe

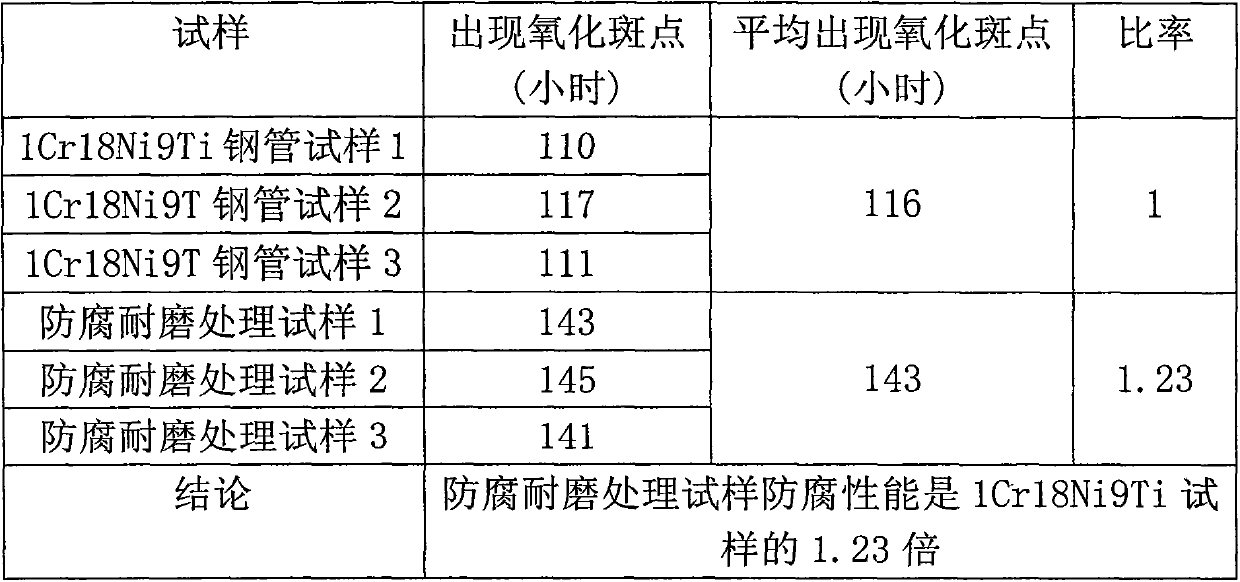

A technology of anti-corrosion and wear-resisting and preparation technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor anti-corrosion and wear resistance, low surface finish and hardness, single color, etc., to achieve Good mechanical properties, high hardness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

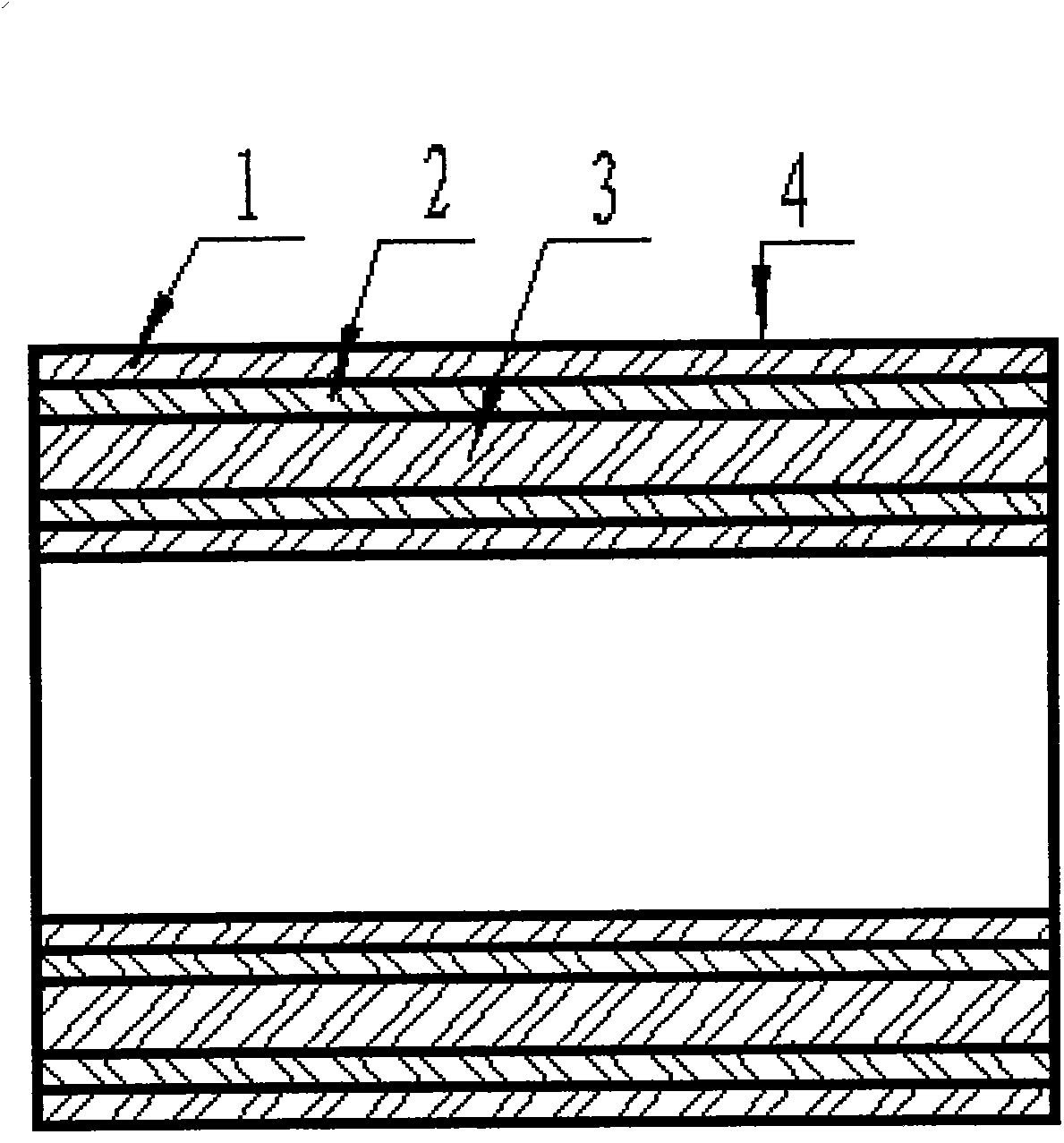

[0028] A new anti-corrosion and wear-resistant color steel pipe preparation process, the method and steps of making the color surface 4 of the steel pipe 3 into a silver-white steel pipe are:

[0029] 1. The inner surface of the steel pipe 3 is degreased, cleaned and dried; the outer surface is shot blasted and polished;

[0030] 2. Steel pipe 3 preheating treatment, preheating in a resistance furnace, the temperature is 350 ° C, and the time is 50 minutes;

[0031] 3. Soaking treatment of the steel pipe 3, the steel pipe 3 is heated evenly and kept warm in the intermediate frequency induction heating liquid ion nitriding furnace (model XIAN-TM-001), and the steel pipe is soaked at a temperature of 450°C for 30 minutes;

[0032] 4. Steel pipe 3 polishing treatment;

[0033] 5. Liquid ion nitriding treatment of steel pipe 3. Steel pipe 3 is heated in an intermediate frequency induction heating liquid ion nitriding furnace (model XIAN-TM-002) at a temperature of 650°C for 50 mi...

Embodiment 2

[0039] A new anti-corrosion and wear-resistant color steel pipe preparation process, the method and steps of making the steel pipe 3 into an antique color steel pipe are:

[0040] 1. The inner surface of the steel pipe 3 is degreased, cleaned and dried; the outer surface is shot blasted and polished.

[0041] 2. Preheating treatment of steel pipe 3: Preheat in a resistance furnace at a temperature of 350°C for 50 minutes.

[0042] 3. Soaking treatment of the steel pipe 3: The steel pipe 3 is uniformly heated and kept warm in a medium-frequency induction heating liquid ion nitriding furnace (model XIAN-TM-001), and the steel pipe 3 is soaked at a temperature of 470°C for 30 minutes.

[0043] Four, steel pipe 3 polishing treatment:

[0044] 5. Steel pipe 3 liquid ion nitriding treatment: the steel pipe is heated in an intermediate frequency induction heating liquid ion nitriding furnace (model XIAN-TM-002) at a temperature of 670°C for 50 minutes to form Fe 3 N, Fe 4 N, Fe 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com