Fabric structure color preparation method

A fabric structure and fabric technology, applied in animal fibers, textiles and papermaking, nanotechnology for materials and surface science, etc., can solve problems such as high free formaldehyde content, endangering human health, poor biodegradability, etc., and achieve adaptability wide, bright colors, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

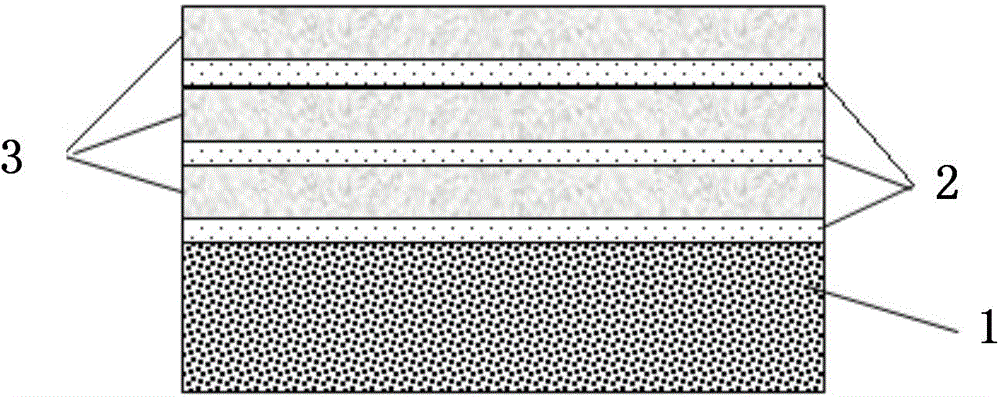

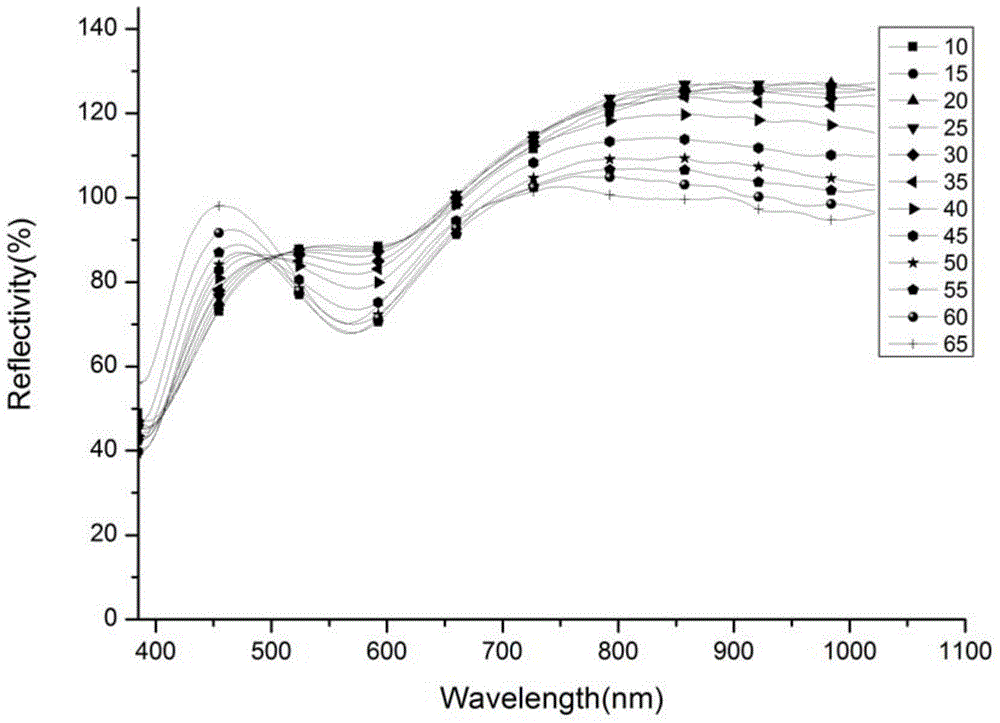

Embodiment 1

[0027] Use 30-denier 630T polyester white gray cloth as the base fabric, and pretreat it: configure 1g / L polyester softener solution at a liquor ratio of 1:50 to soak the fabric for 30 minutes of ultrasonic treatment → soak the fabric for 30 minutes of ultrasonic treatment in pure water → Rinse the fabric with pure water 3 times → dry (60°C). Put the treated fabric into a vacuum chamber, and use radio frequency magnetron sputtering technology under specific vacuum conditions to deposit nano-TiO 2 , SiO 2 Deposits on fabric surface. Specific process: target TiO 2 The purity of SiO is 99.99%. 2 The purity of argon is 99.99%, and the purity of argon is 99.95%. Using radio frequency sputtering, the sputtering process parameters are: target base distance 40mm, background vacuum 2*10 -3 Pa, the working pressure is 5Pa, the argon gas flow rate is 15sccm, the sputtering power is 84W, first sputter TiO for 2 hours 2 , and then sputtered for 4 hours on SiO 2 , this is one cycle, ...

Embodiment 3

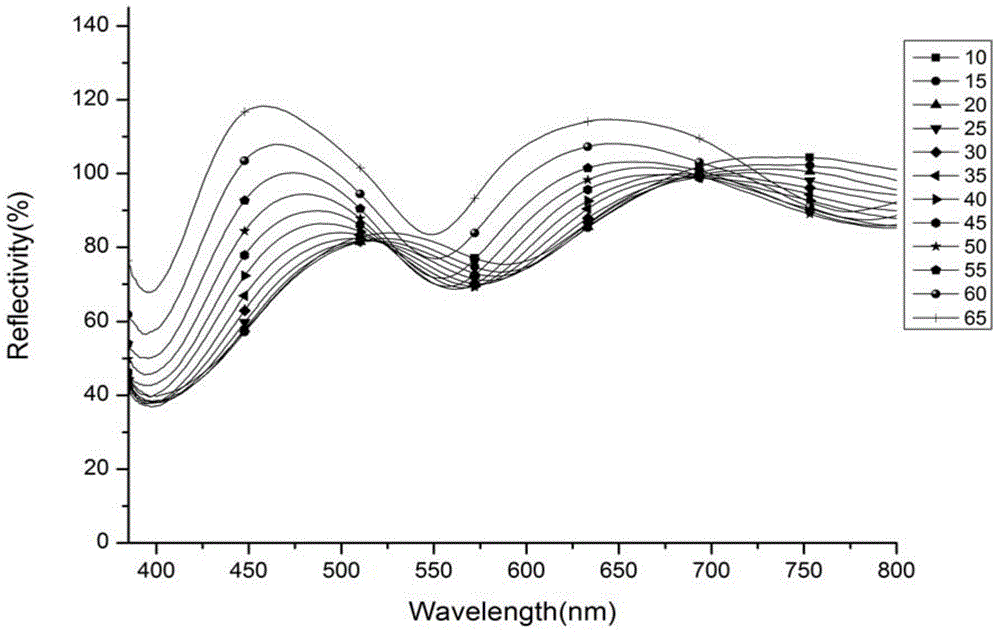

[0030] Use 30-denier 630T polyester white gray cloth as the base fabric, and pretreat it: configure 1g / L polyester softener solution at a liquor ratio of 1:50 to soak the fabric for 30 minutes of ultrasonic treatment → soak the fabric for 30 minutes of ultrasonic treatment in pure water → Rinse the fabric with pure water 3 times → dry (60°C). Put the treated fabric into a vacuum chamber, and use radio frequency magnetron sputtering technology under specific vacuum conditions to deposit nano-TiO 2 , SiO 2 Deposits on fabric surface. Specific process: target TiO 2 The purity of SiO is 99.99%. 2 The purity of argon is 99.99%, and the purity of argon is 99.95%. Using radio frequency sputtering, the sputtering process parameters are: target base distance 40mm, background vacuum 2*10 -3 Pa, the working pressure is 5Pa, the argon gas flow rate is 15sccm, the sputtering power is 84W, first sputter TiO for 2 hours 2 , and then sputtered for 4 hours on SiO 2 , this is one cycle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com