Patents

Literature

200 results about "Radio frequency sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

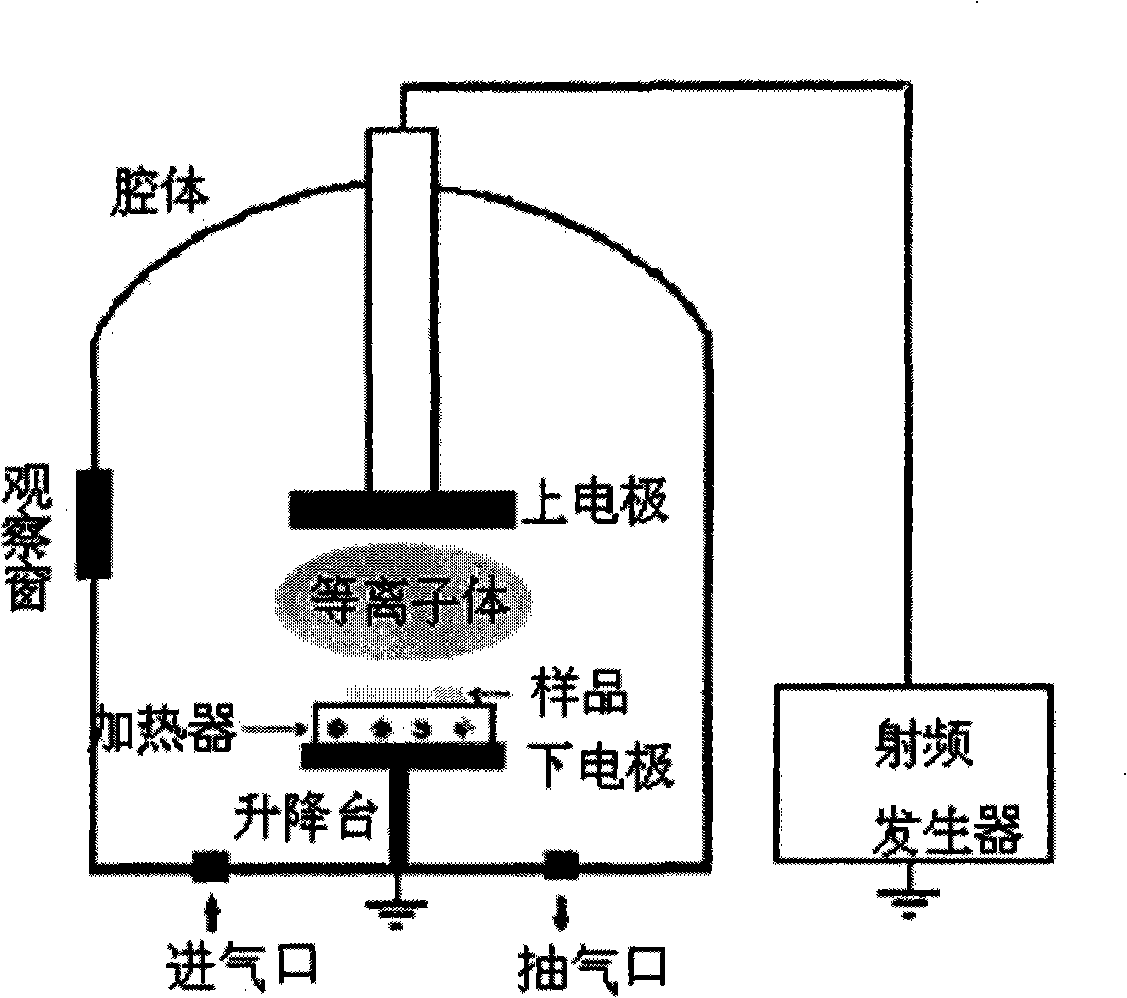

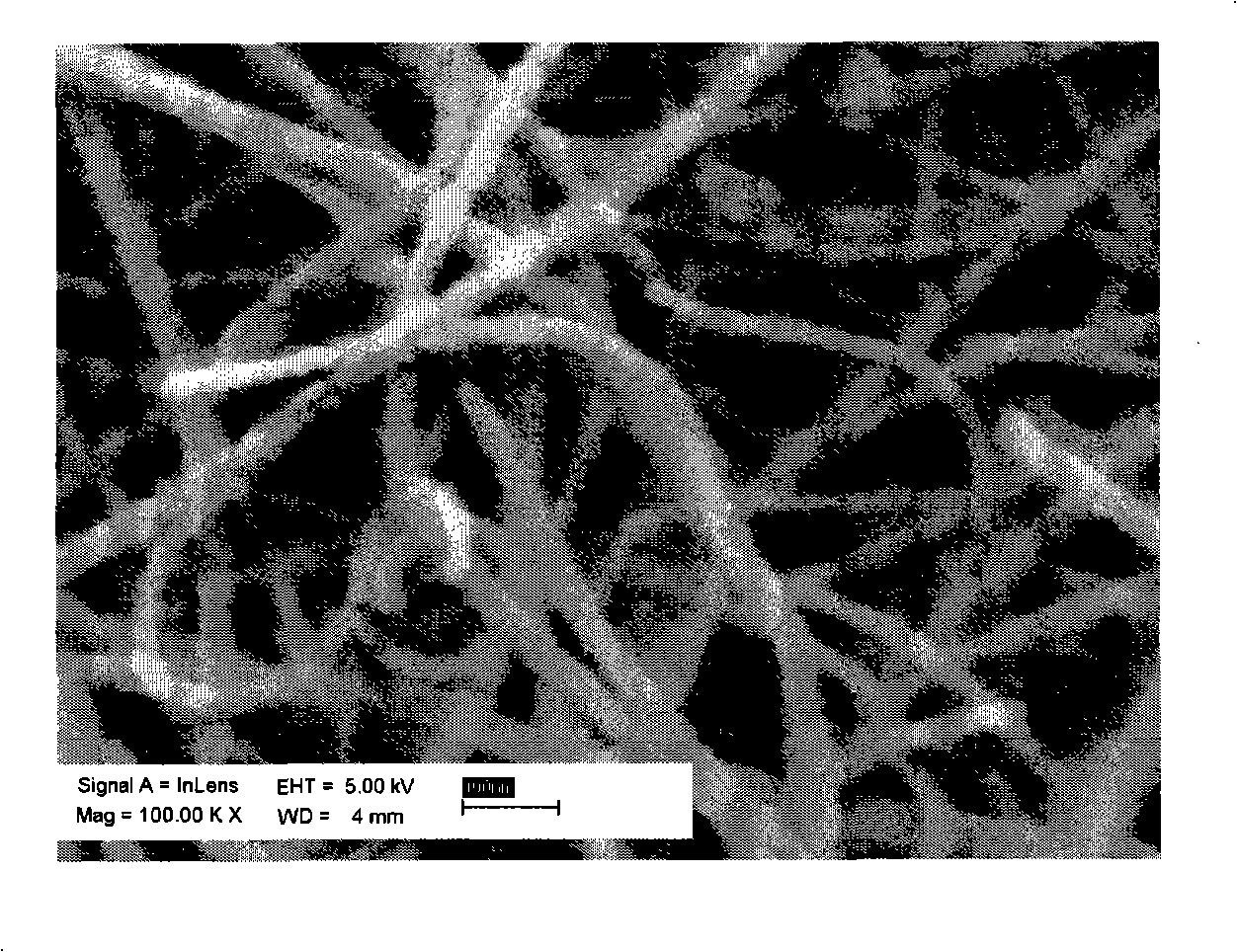

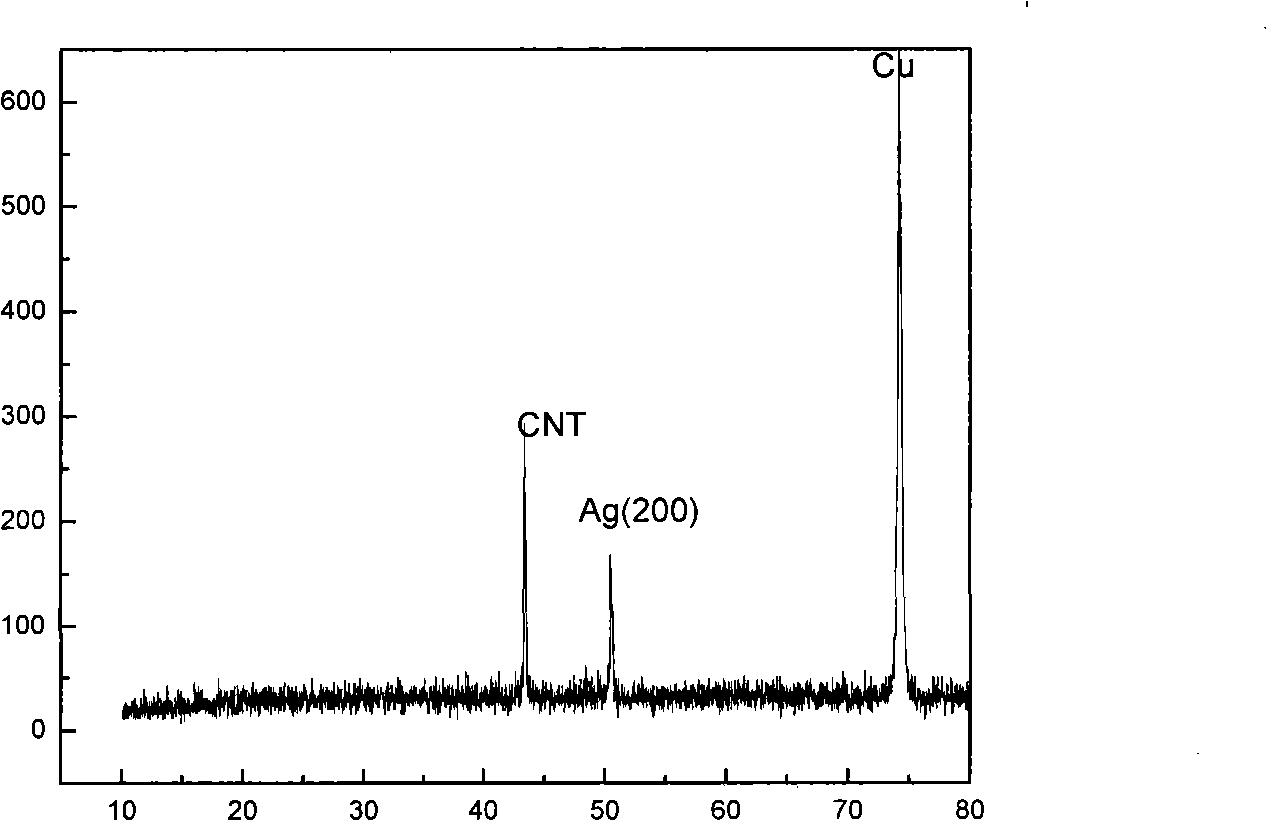

Method for preparing nano metal or metal oxide/carbon nano-tube composite material

InactiveCN101255544AShort processStable production processFrom normal temperature solutionsAfter-treatment detailsEvaporationCarbon nanotube

The invention relates to a simple practical preparation for metal or metal oxide / carbon nano-tube nano-composite, characterized in: with carbon nano-tube as the matrix, Fe, Co, Ni, Si, Ag, Au, Ti, Zn, Al, Mg, Ta, Pd, Mo, Sn and Pt as well as oxide nano-materials thereof are prepared by any method of radio frequency sputtering deposition, pulsed laser deposition, spraying schizolysis, hot evaporation or hydrothermal method, metal or metal oxide nano-grain or nano-film is formed on the surface of a carbon nano-tube. By this method, carbon nano-tube matrix composite material having multiple forms can be prepared, the process is simple, the cost is low, the carbon nana-tube matrix composite material has special optical property, electrical property, and magnetic property, thus having wide application prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

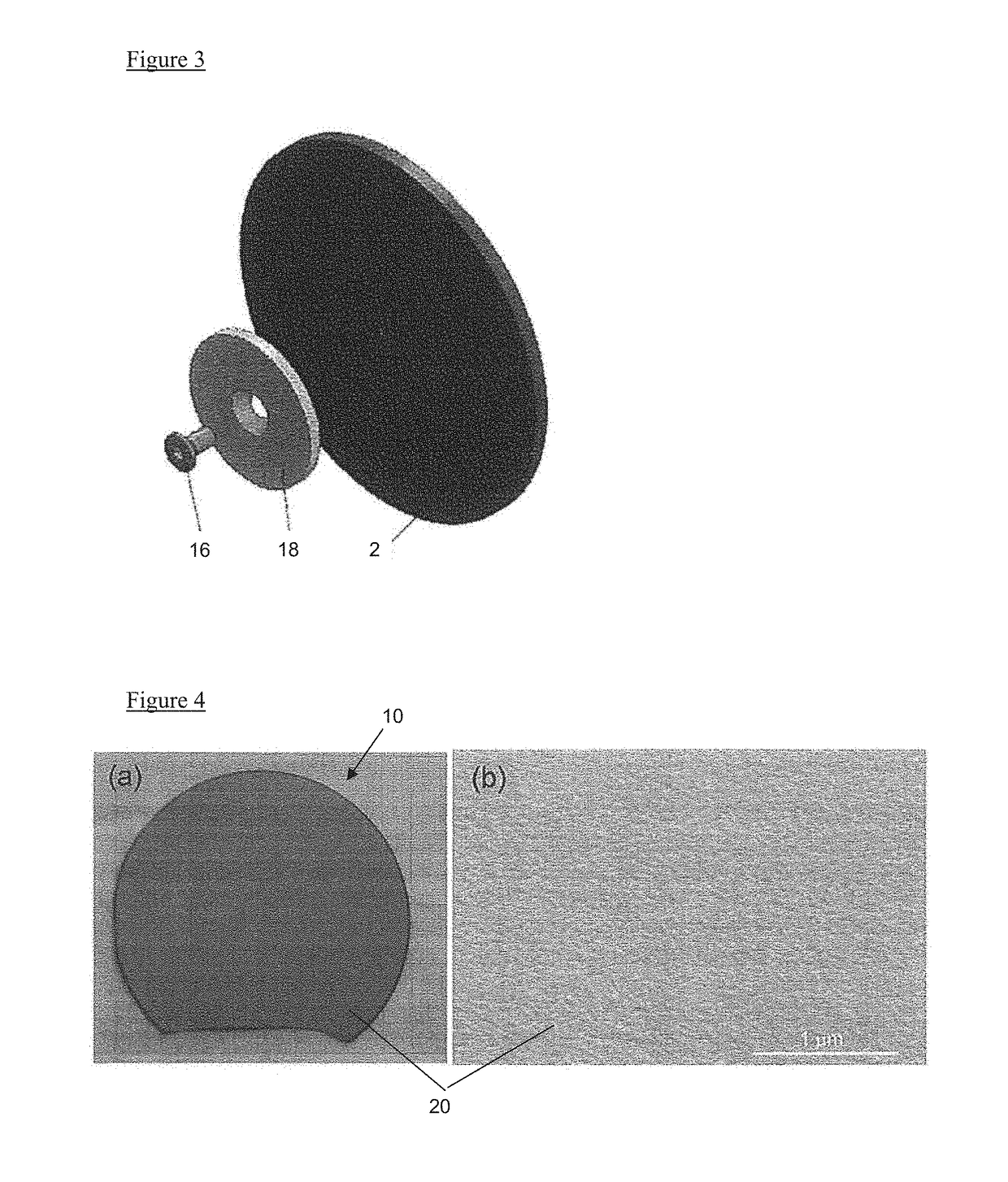

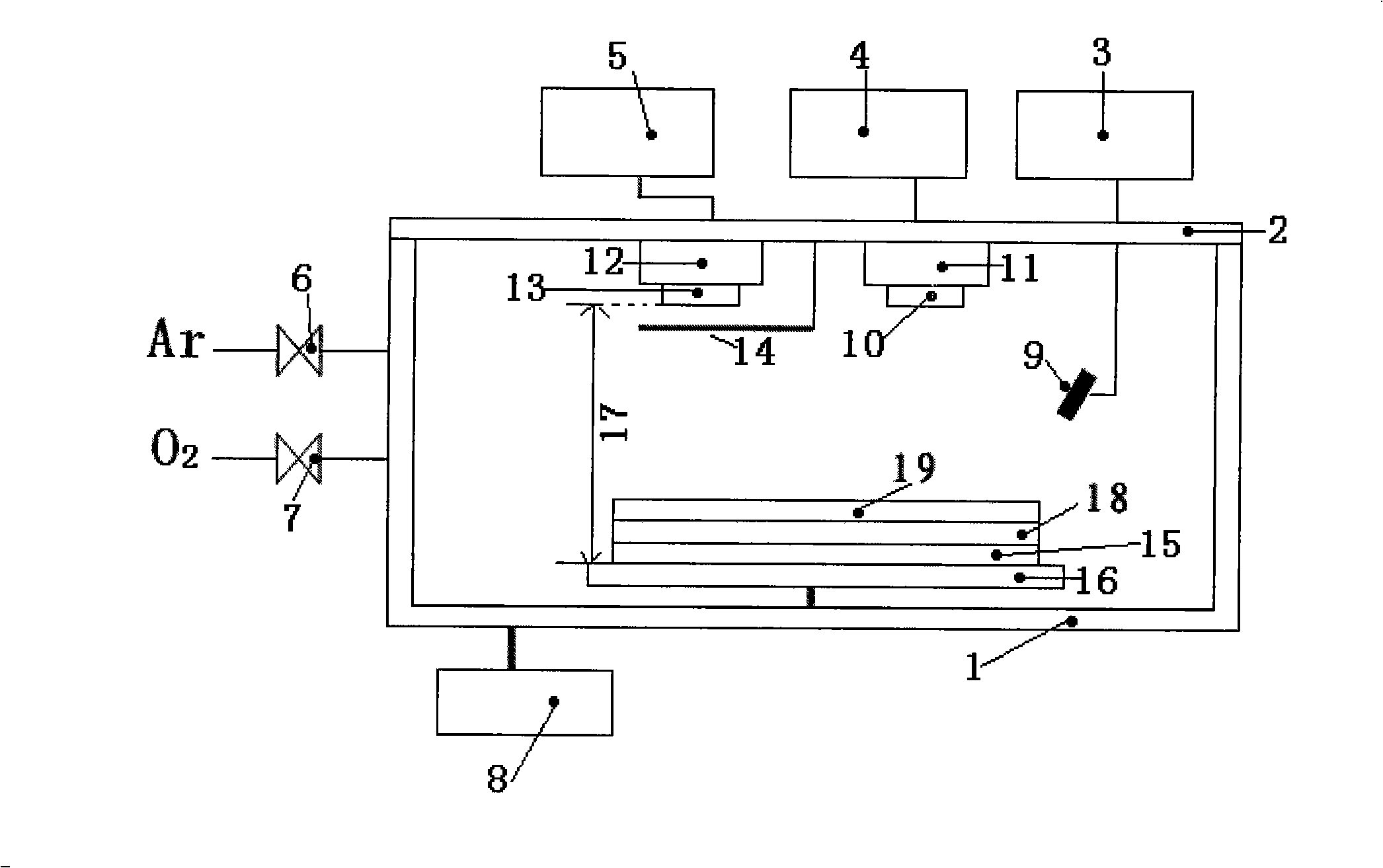

High entropy alloy thin film coating and method for preparing the same

ActiveUS20180223417A1High hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingHigh entropy alloysRadio frequency sputtering

A method for preparing a high entropy alloy thin film coating includes preparing a melt alloy by arc melting raw materials including five or more elements, casting the melt alloy into a mold to form a target, placing the target inside a vacuum chamber of a magnetron sputtering system, and rotatably fixing a substrate inside the vacuum chamber, spaced apart from the target. A high entropy alloy thin film is deposited on the substrate by high vacuum radio frequency sputtering inside the vacuum chamber.

Owner:CITY UNIVERSITY OF HONG KONG

Method for sputtering and depositing tin indium oxide transparent electroconductive film on flexible substrate at room temperature

InactiveCN101294272ALow resistivityHigh light transmittanceVacuum evaporation coatingSputtering coatingIndiumUltraviolet

The invention relates to a method for preparing the transparent and conductive indium tin oxide thin film through sputtering flexible substrates at room temperature, which belongs to the technology field of electronic material; the method comprises the following steps: cleaning, charging working gas, ultraviolet irradiating, preparing a barrier layer and sputtering an indium tin oxide film; through the on-line ultraviolet irradiation, the argon oxygen ratio is (6.0 to 7.5):0.2, by adopting radio frequency sputtering or direct current sputtering, and at the room temperature, the indium tin oxide thin film can be prepared on the organic flexible substrate coated with a silicon dioxide layer in advance and taken as the diffusion barrier layer efficiently without damage. When the thickness of the indium tin oxide thin film is 700 nm, the electrical resistivity is 3.5*10-4 omega cm, the square resistance is 5 omega, the transmissibility of the visible light is 88 percent, and the film layer is even and smooth, and cannot be crimpled nor fall off. Compared with the preparation process of the traditional flexible indium tin oxide thin film, the method has the advantages that heating is not required, the process control is simple, and no damage is caused to the basal body; the method is suitable for large-area production and has good photoelectric characteristics.

Owner:ZHEJIANG UNIV

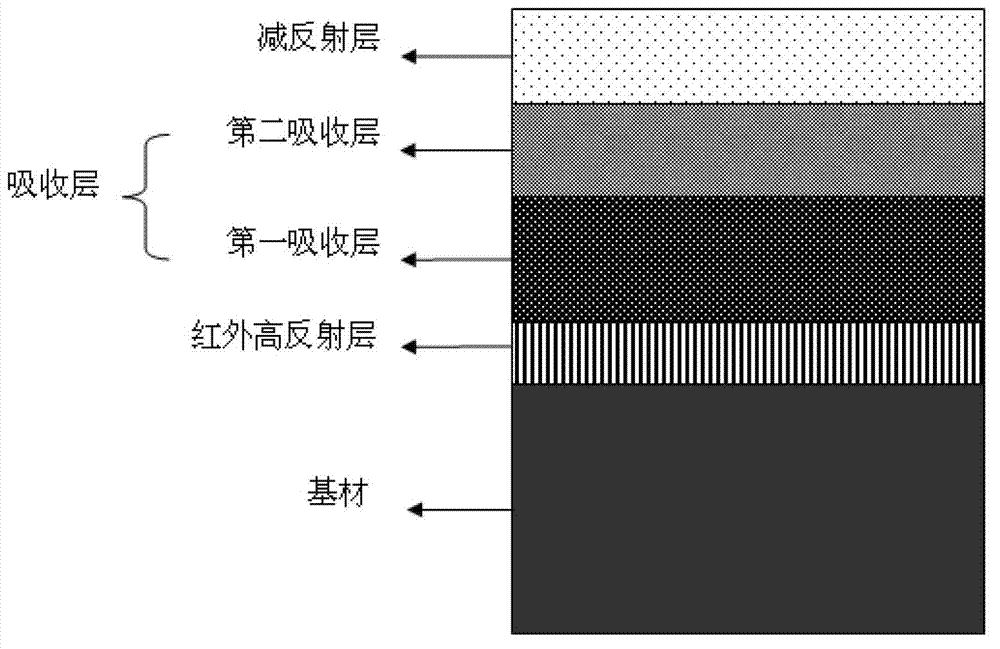

Solar intermediate-temperate high-temperature selective absorbing coating with absorbing layers composed of boron-containing compounds and preparation method of solar intermediate-temperate high-temperature selective absorbing coating

ActiveCN103398483AImprove high temperature stabilityImprove antioxidant capacitySolar heat devicesVacuum evaporation coatingEmissivityNitrogen

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

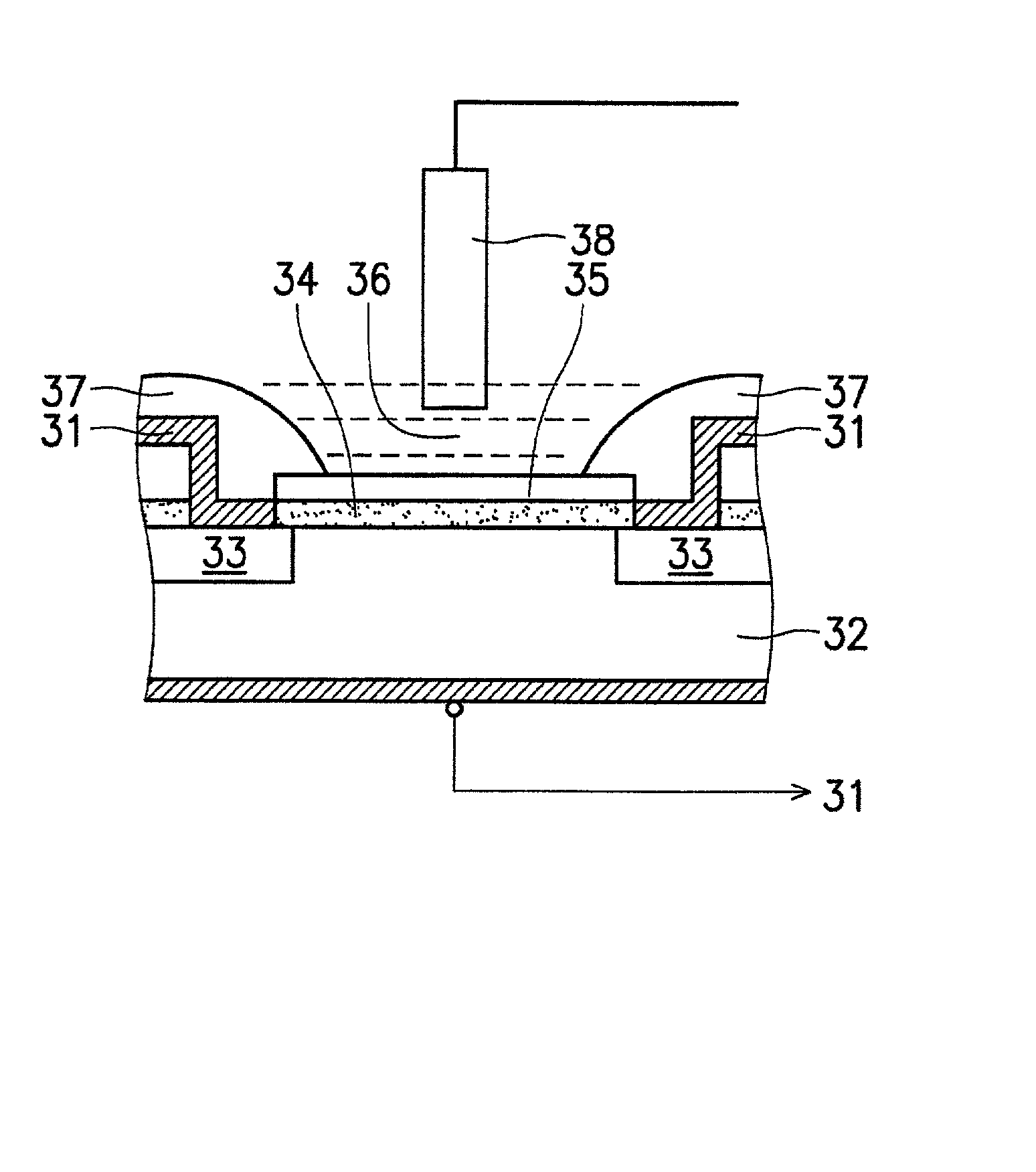

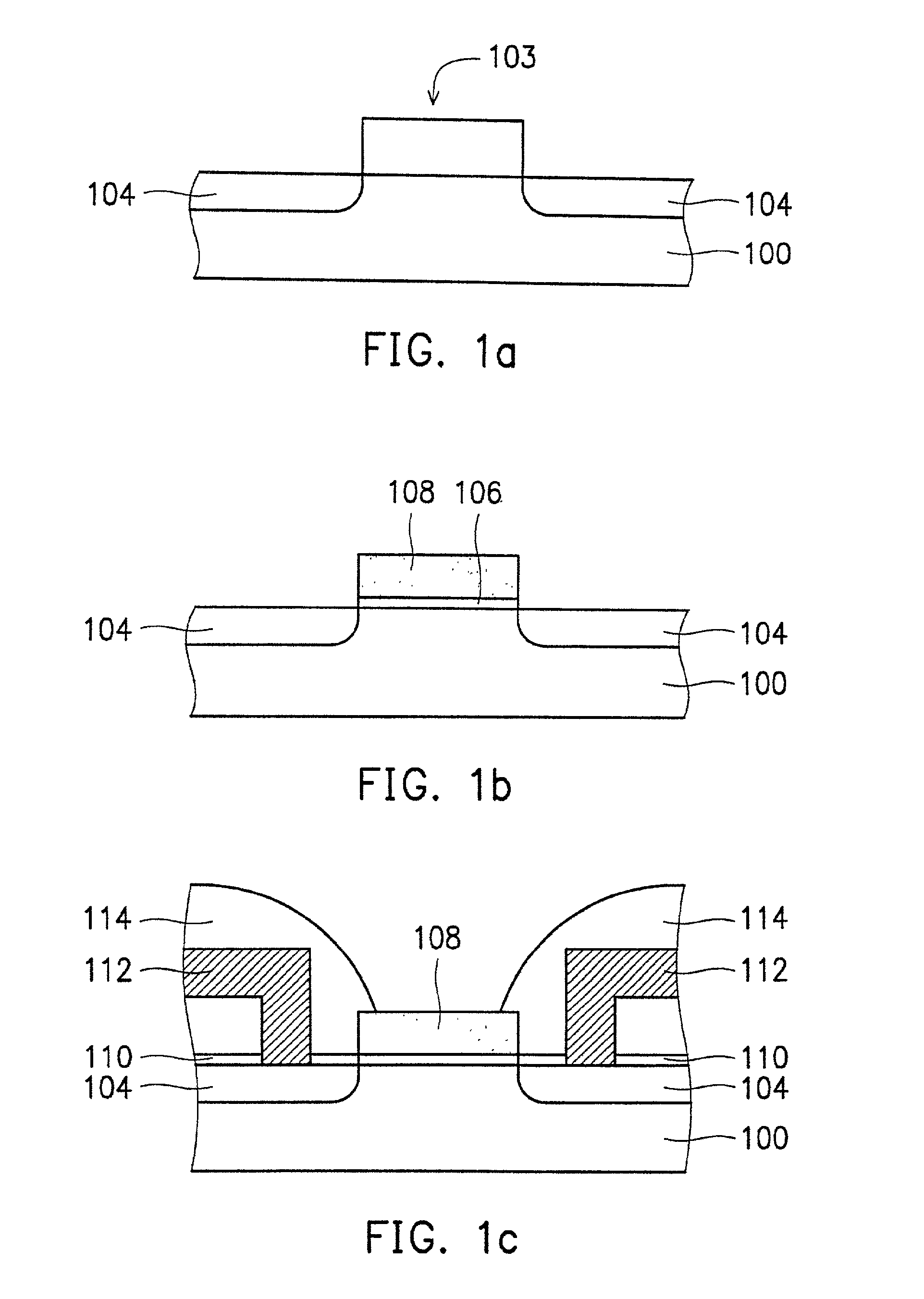

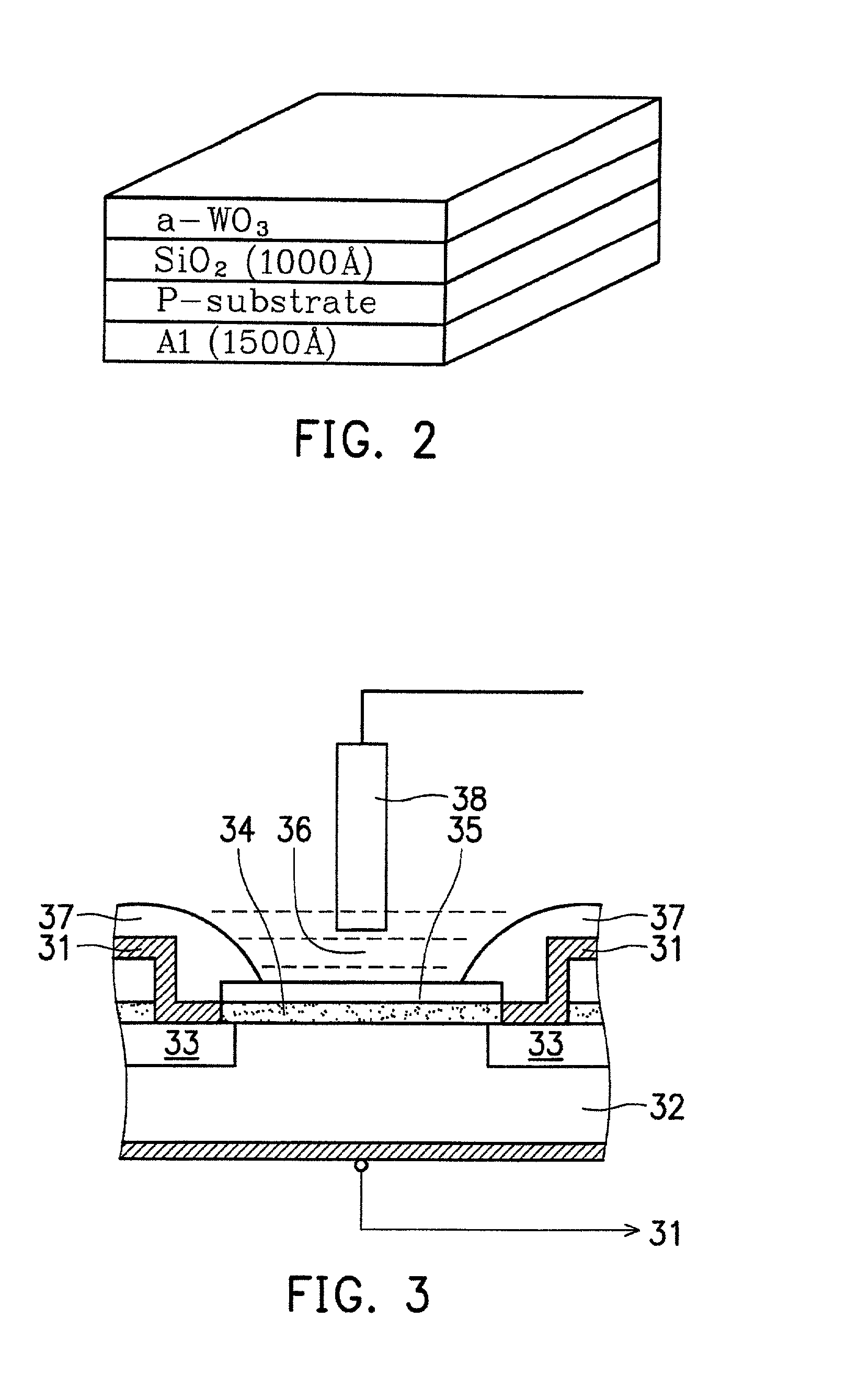

a-wo3-gate isfet devices and method of making the same

InactiveUS20020109161A1Easy to detectReduce lightSemiconductor/solid-state device detailsSolid-state devicesISFETAqueous solution

Disclosed is an ISFET comprising a H+-sensing membrane consisting of RF-sputtering a-WO3. The a-WO3 / SiO2-gate ISFET of the present invention is very sensitive in aqueous solution, and particularly in acidic aqueous solution. The sensitivity of the present ISFET ranges from 50 to 58 mV / pH. In addition, the disclosed ISFET has high linearity. Accordingly, the disclosed ISFET can be used to detect effluent.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

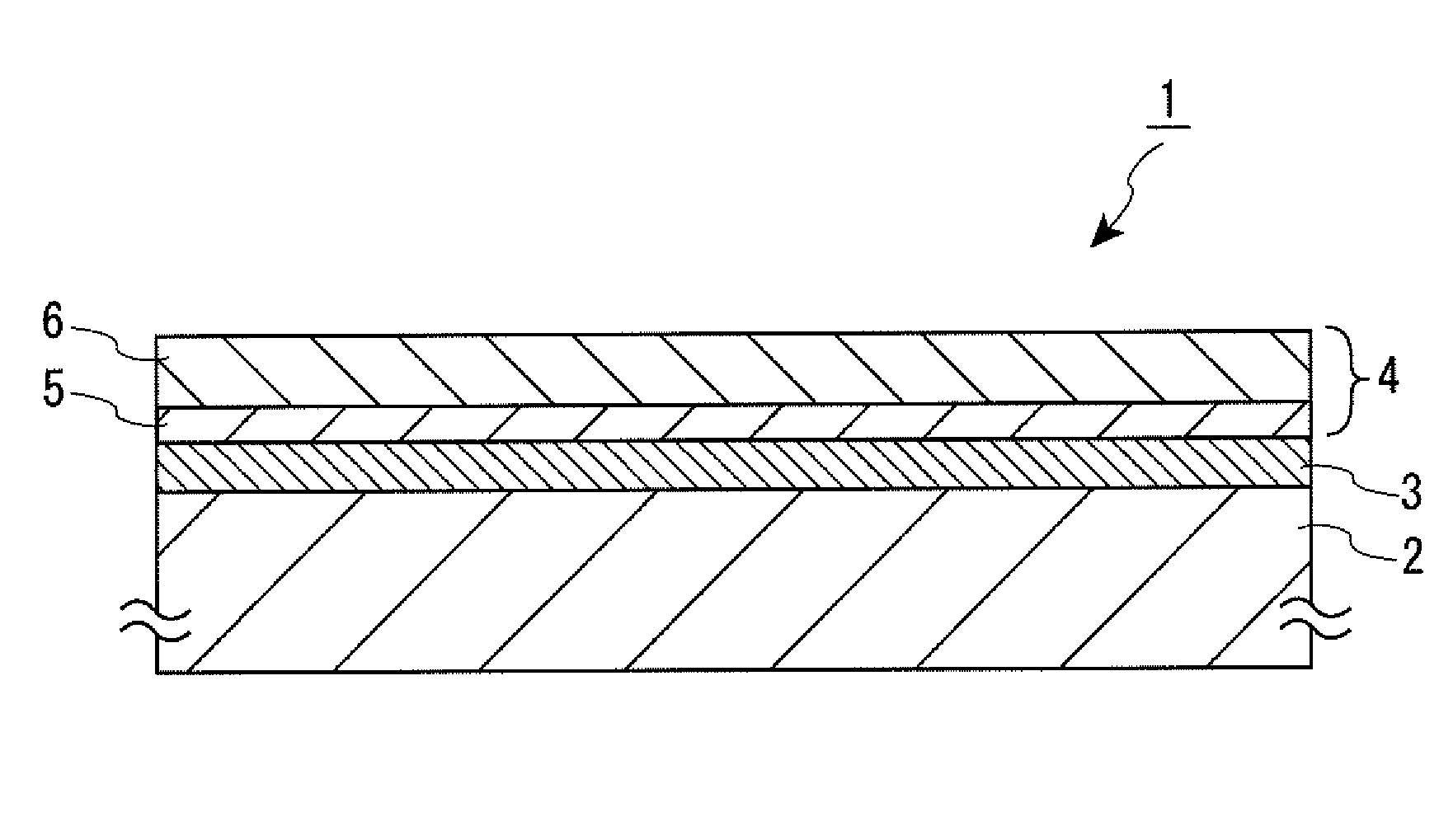

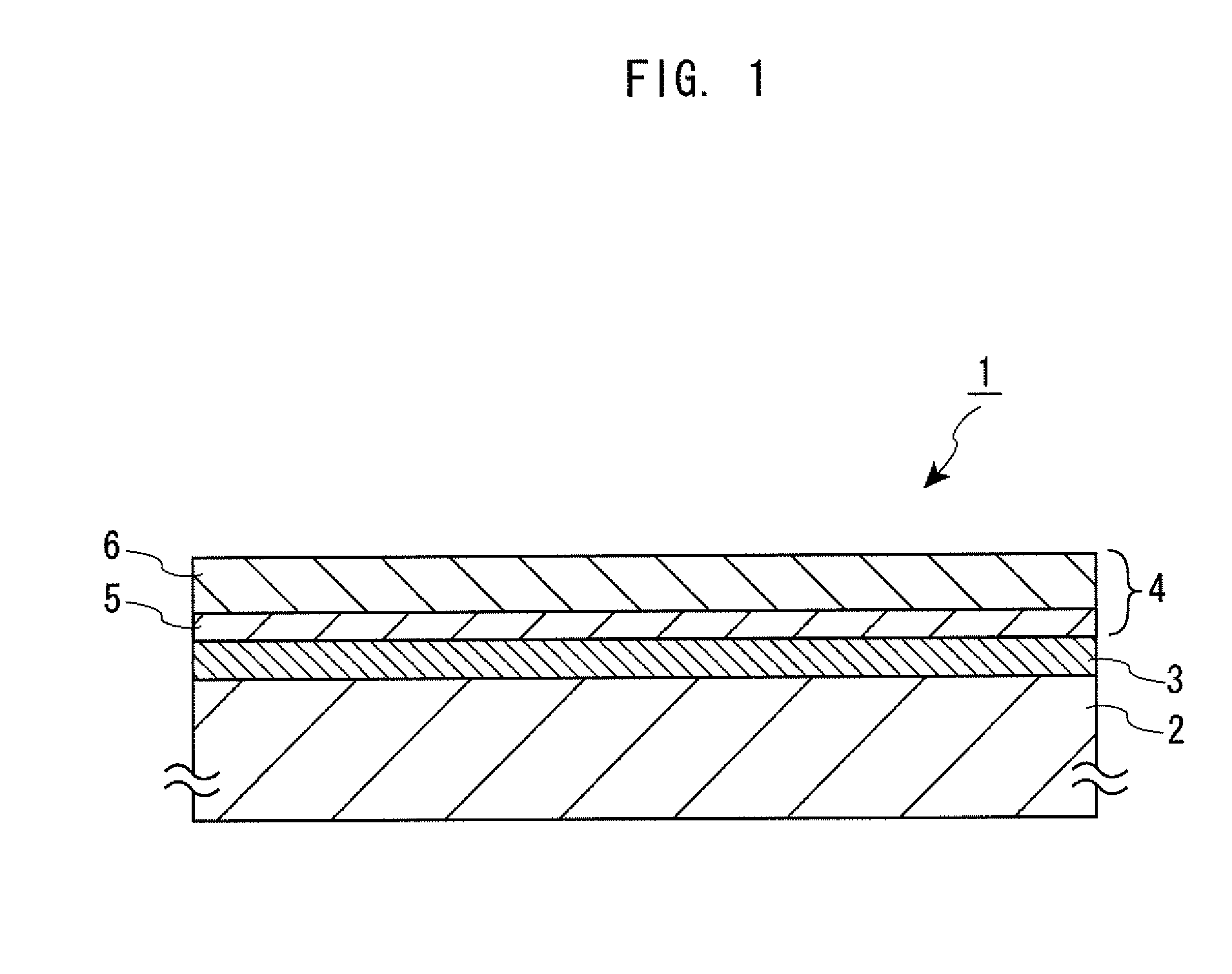

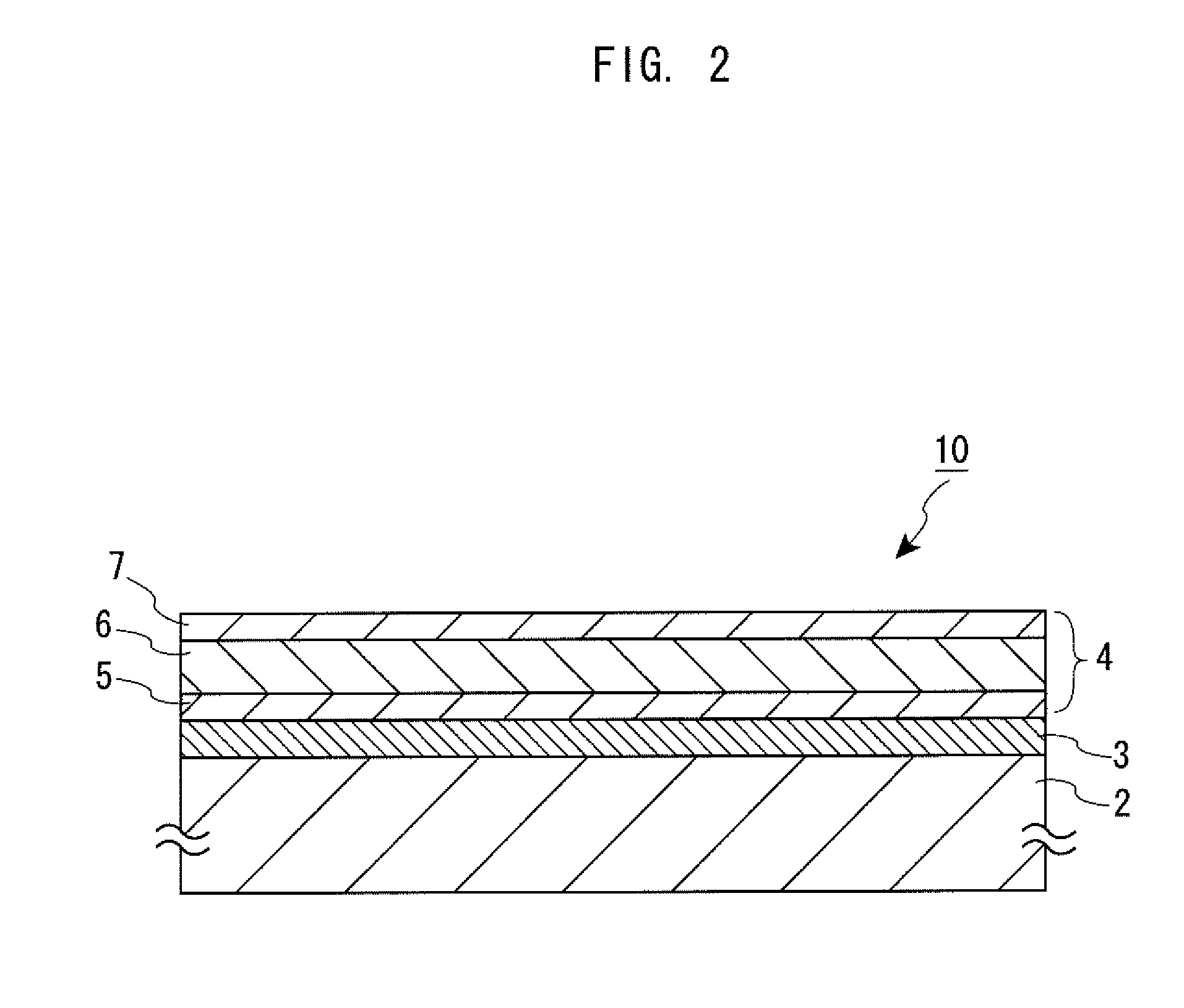

Display Substrate Having a Transparent Conductive Layer Made of Zinc Oxide and Manufacturing Method Thereof

InactiveUS20090242887A1Improve adhesionLower resistanceConductive layers on insulating-supportsVacuum evaporation coatingLiquid-crystal displayRadio frequency magnetron sputtering

A display substrate is disclosed comprising: a supporting substrate; an organic resin layer formed on the supporting substrate; and a transparent electrode formed on the organic resin layer, wherein the transparent electrode includes: a first layer containing a zinc oxide and formed in close contact with the organic resin layer; and a second layer containing a zinc oxide and which has a thickness thicker than a thickness of the first layer and is formed on the first layer, wherein the first layer is deposited by either one of a DC sputtering and a DC magnetron sputtering, and the second layer is deposited by any one of a radio frequency sputtering, a radio frequency magnetron sputtering, a radio frequency superimposing a DC sputtering, and a radio frequency superimposing a DC magnetron sputtering, and the display substrate is available, for example, as the substrate having a transparent electrode for counter electrode of liquid crystal display device.

Owner:CASIO COMPUTER CO LTD +1

Composite solid electrolyte material, preparation method thereof, and all-solid-state lithium ion secondary battery containing electrolyte material

InactiveCN106887638AOvercoming Assembly Operations ProblemsImprove stabilitySolid electrolytesSecondary cellsAll solid stateSulfur

The invention discloses a composite solid electrolyte material, a preparation method thereof, and an all-solid-state lithium ion secondary battery containing the electrolyte material. The composite solid electrolyte material comprises a core and a surface coating which covers the surface of the core, the core is inorganic chalcogenide glass ceramic state electrolyte, and the surface coating is a lithium compound which does not react with air and moisture in air. The preparation method of the composite solid electrolyte material is as follows: firstly the inorganic chalcogenide glass ceramic state electrolyte core is prepared, and then a radio frequency sputtering method or pulse laser deposition is used for coating the lithium compound which does not react with air and moisture in air on the surface of the inorganic chalcogenide glass ceramic state electrolyte. The composite solid electrolyte material has high stability in air, and can be assembled into all-solid-state batteries in the environment of common battery plant, in order to overcome the problem that prior chalcogenide electrolyte must be assembled and operated in an anhydrous condition.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

Conductive Nb2O5-x target material for magnetron sputtering coating and production method thereof

InactiveCN101851740AGuaranteed uniformityThe production process is easy to controlVacuum evaporation coatingSputtering coatingMetallurgyRadio frequency sputtering

The invention discloses a conductive Nb2O5-x target material for magnetron sputtering coating. The conductive Nb2O5-x target material comprises the following raw material powder in percentage by weight: 80 to 99 percent of ZnO, 0.1 to 10 percent of In2O3 and 0.1 to 10 percent of Ga2O3, wherein the average particle size of the powder is between 0.05 to 50 microns; and the purify of the raw material powder is more than or equal to 4N. The invention also discloses a method for producing the conductive Nb2O5-x target material. A material obtained by the method is an Nb2O5-x target material which has high conductive performance, so that niobium oxide series optical films can be produced by magnetron sputtering, film uniformity during production of the large-area niobium oxide series optical films can be ensured, the production process is easier to control and the production efficiency is improved by 30 to 50 percent compared with that of a conventional alternating current radio-frequency sputtering or vacuum evaporation coating process which takes conventional defective conductor Nb2O5 as a target source.

Owner:YIXING BAILUN OPTO ELECTRONICS MATERIAL

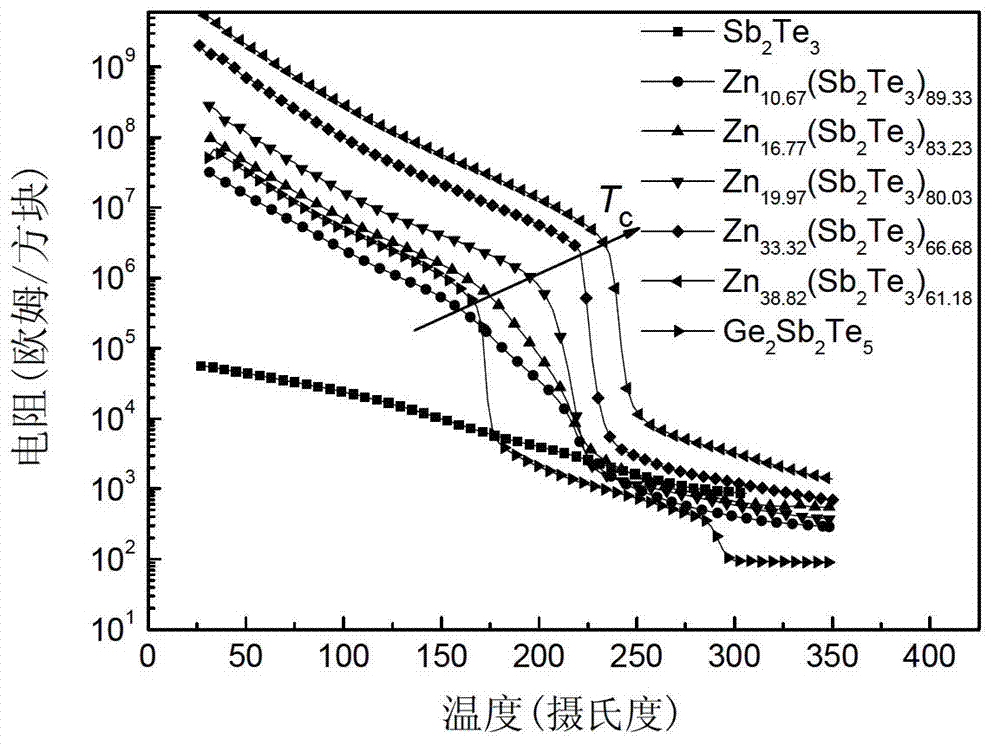

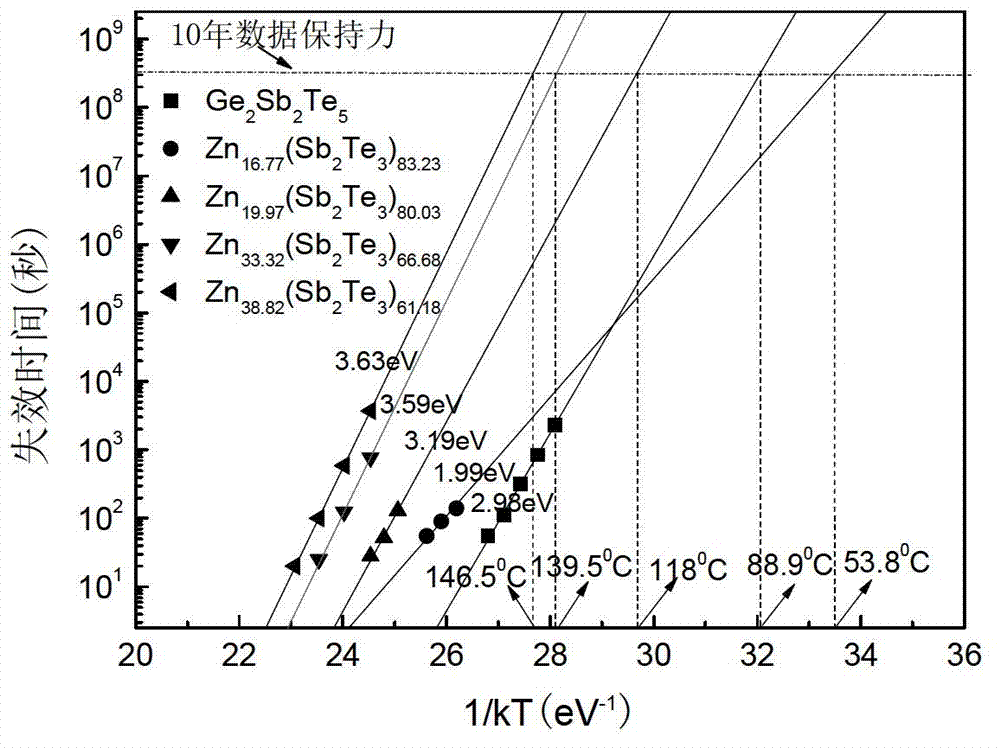

Zn (zinc)-Sb (stibium)-Te (tellurium) phase change storage thin-film material for phase change memory and preparation method of Zn-Sb-Te phase change storage thin-film material

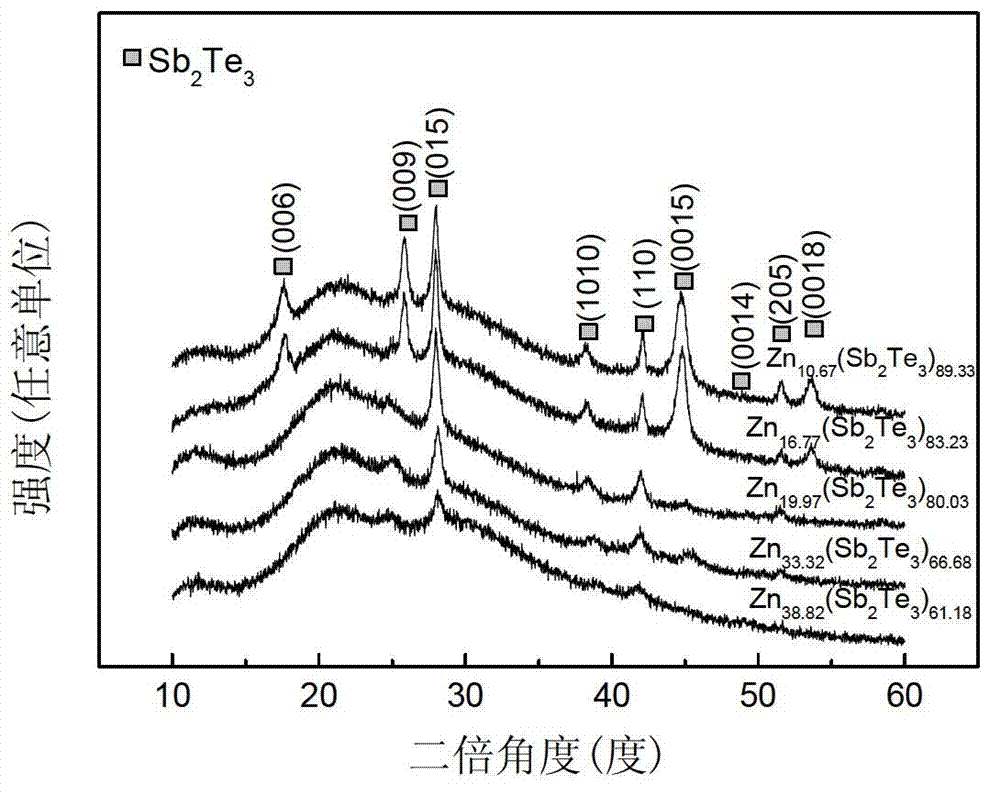

InactiveCN103247757AZn content increasedRaise the crystallization temperatureElectrical apparatusPhase-change memoryTe element

The invention discloses a Zn-Sb-Te phase change storage thin-film material for a phase change memory and a preparation method of the Zn-Sb-Te phase change storage thin-film material. The Zn-Sb-Te phase change storage thin-film material is characterized in that the material is made of three elements of Zn, Sb and Te, and the chemical structural formula of the material is ZnX (Sb2Te3)(100-X), wherein 0<x<40. The preparation process comprises the steps as follows: a zinc elemental target is mounted into a magnetic control direct current sputtering target, and an Sb2Te3 target is mounted into a magnetic control radio-frequency sputtering target; a sputtering chamber is subjected to vacuum pumping treatment until the vacuum degree inside the chamber reaches 1.6*10<-4> Pa, and then high-purity argon is fed into the sputtering chamber until the air pressure reaches 0.3 Pa; and the sputtering power of the zinc target is controlled to be 0-10 W, the sputtering power of the Sb2Te3 target is controlled to be 60-100 W, and a coating is sputtered for 200 seconds at a room temperature. The Zn-Sb-Te phase change storage thin-film material has the advantages of high crystallization speed, high crystallization temperature, lower melting point, higher crystalline state resistivity, better data retentivity and capability of stably working at high temperatures.

Owner:NINGBO UNIV

Controllable heating and defrosting capacitive type high-altitude humidity sensor and manufacturing method thereof

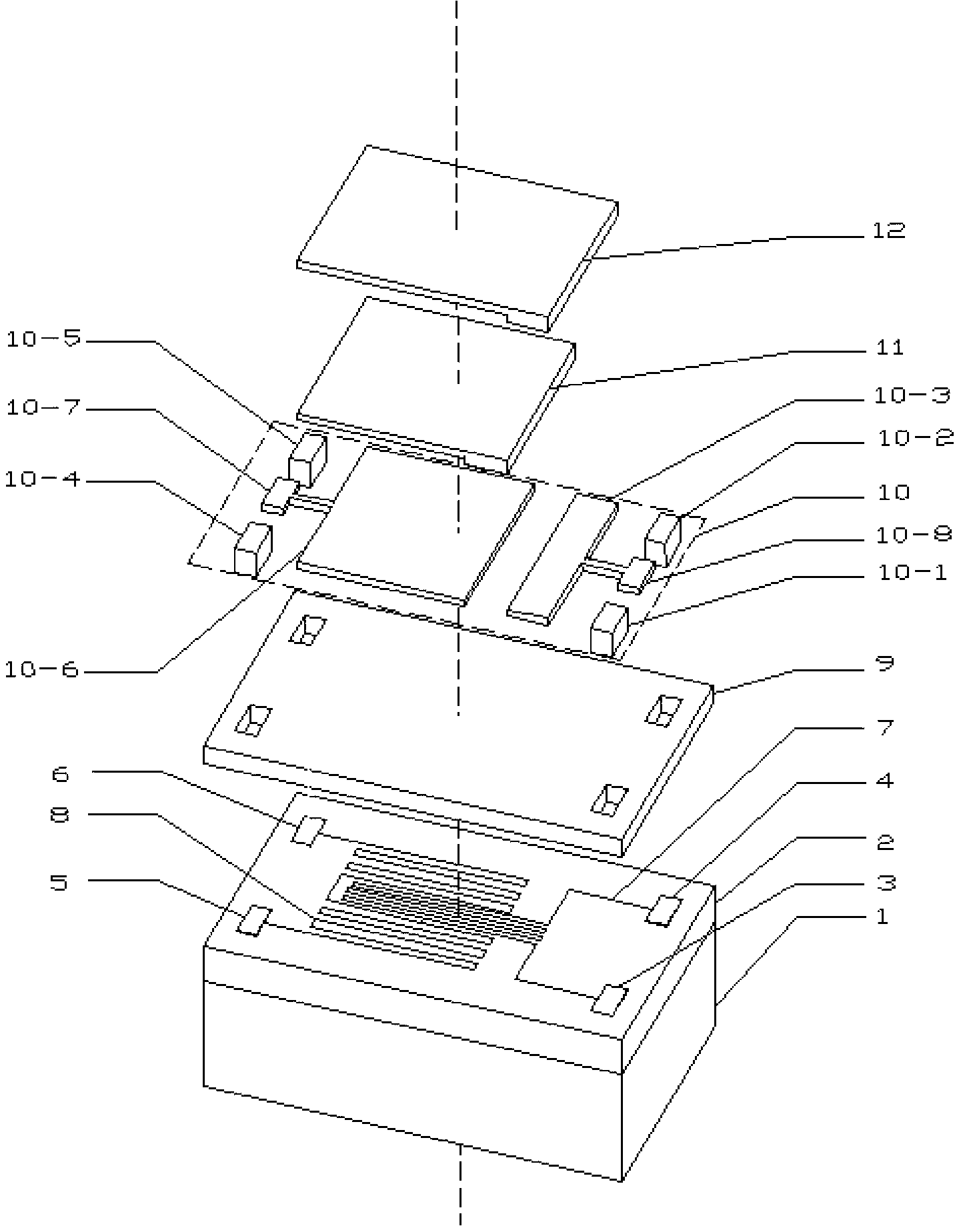

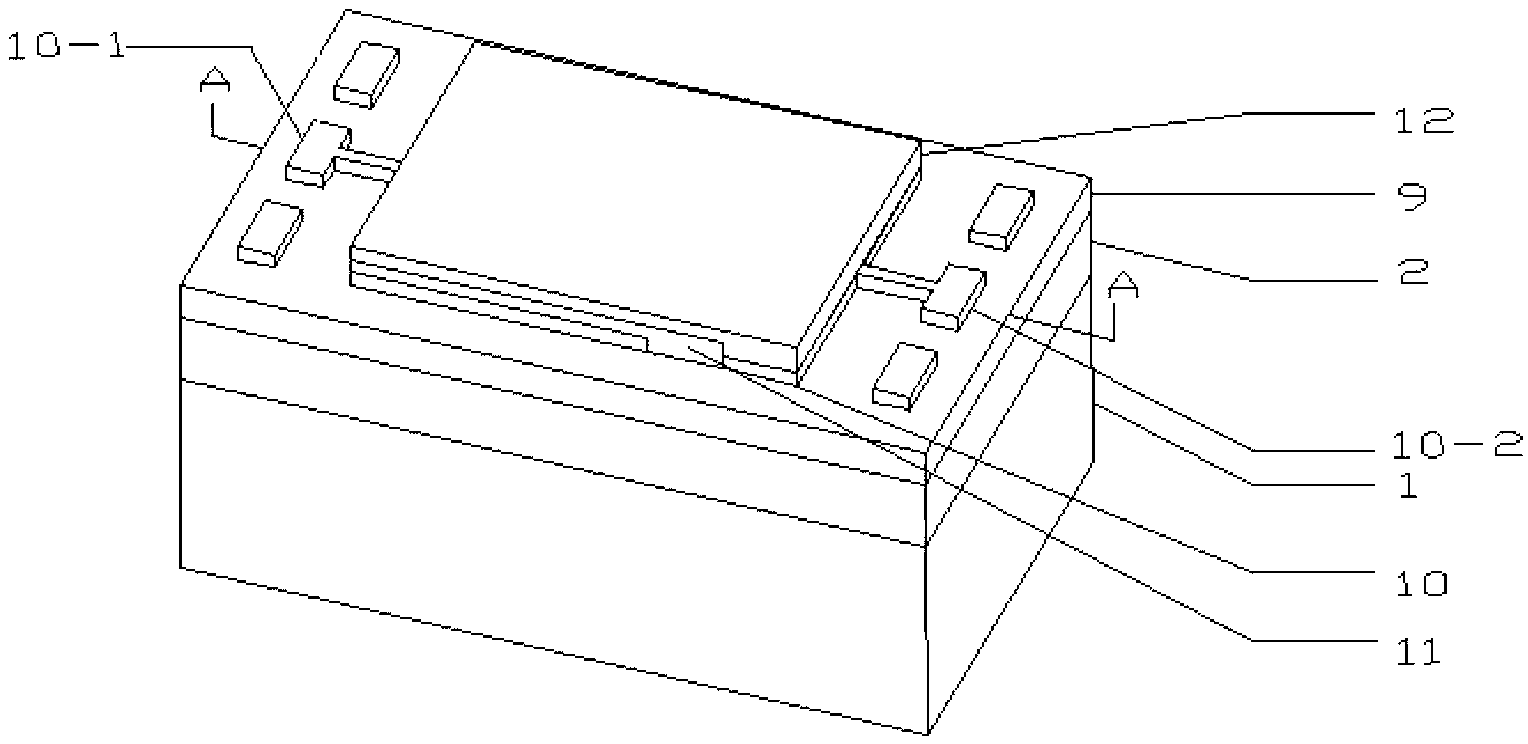

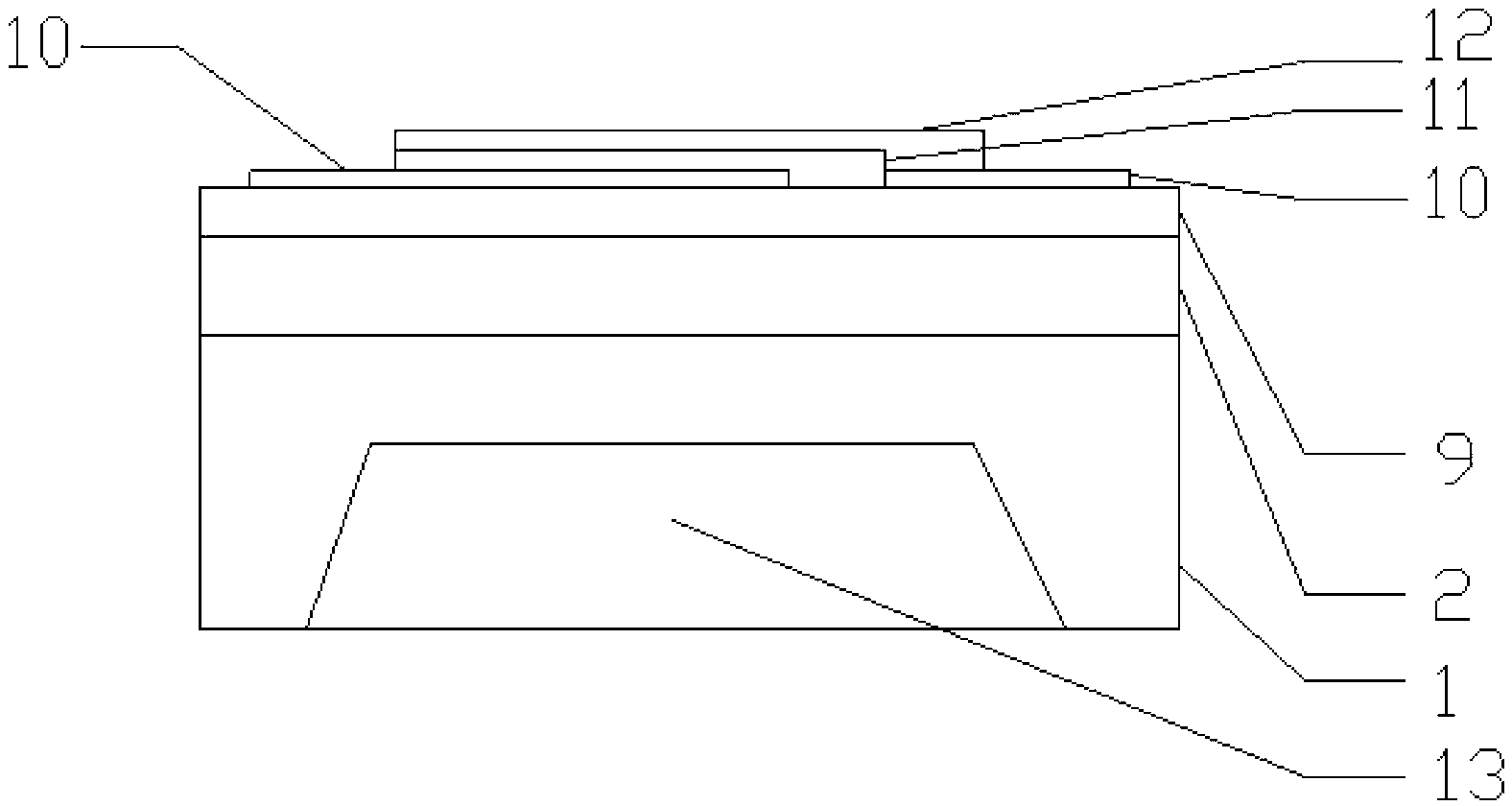

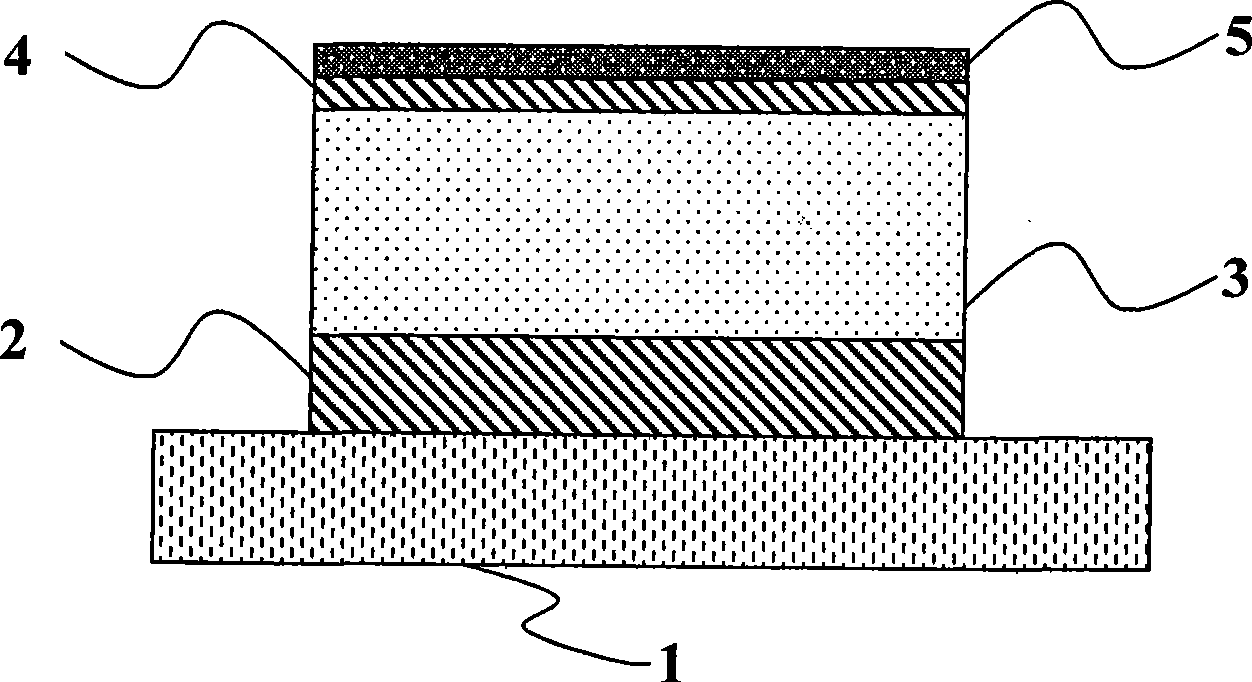

InactiveCN103018288AHigh precisionDecorative surface effectsChemical vapor deposition coatingInsulation layerData acquisition

The invention discloses a manufacturing method of a controllable heating and defrosting capacitive type high-altitude humidity sensor, relates to the field of high-altitude humidity sensors and the manufacturing method thereof, and solves the problem that the humidity data acquisition operation is seriously influenced as the surface of the conventional humidity sensor is frosted due to excessively low temperature in a high-altitude environment. The high-altitude humidity sensor is characterized by comprising a base, a first insulation layer, a first temperature sensor bonding pad, a second temperature sensor bonding pad, a first heater bonding pad, a second heater bonding pad, a temperature sensor electrode, a heater electrode, a second insulation layer, a lower electrode, a humidity sensing layer, an upper porous electrode and a groove. The manufacturing method comprises the steps as follows: manufacturing the high-altitude humidity sensor by adopting the methods of photo-etching stripping, magnetic control radio-frequency sputtering, corrosion hollowing, spin coating and evaporation coating. The high-altitude humidity sensor is suitable for the fields of climate and weather.

Owner:HARBIN UNIV OF SCI & TECH +1

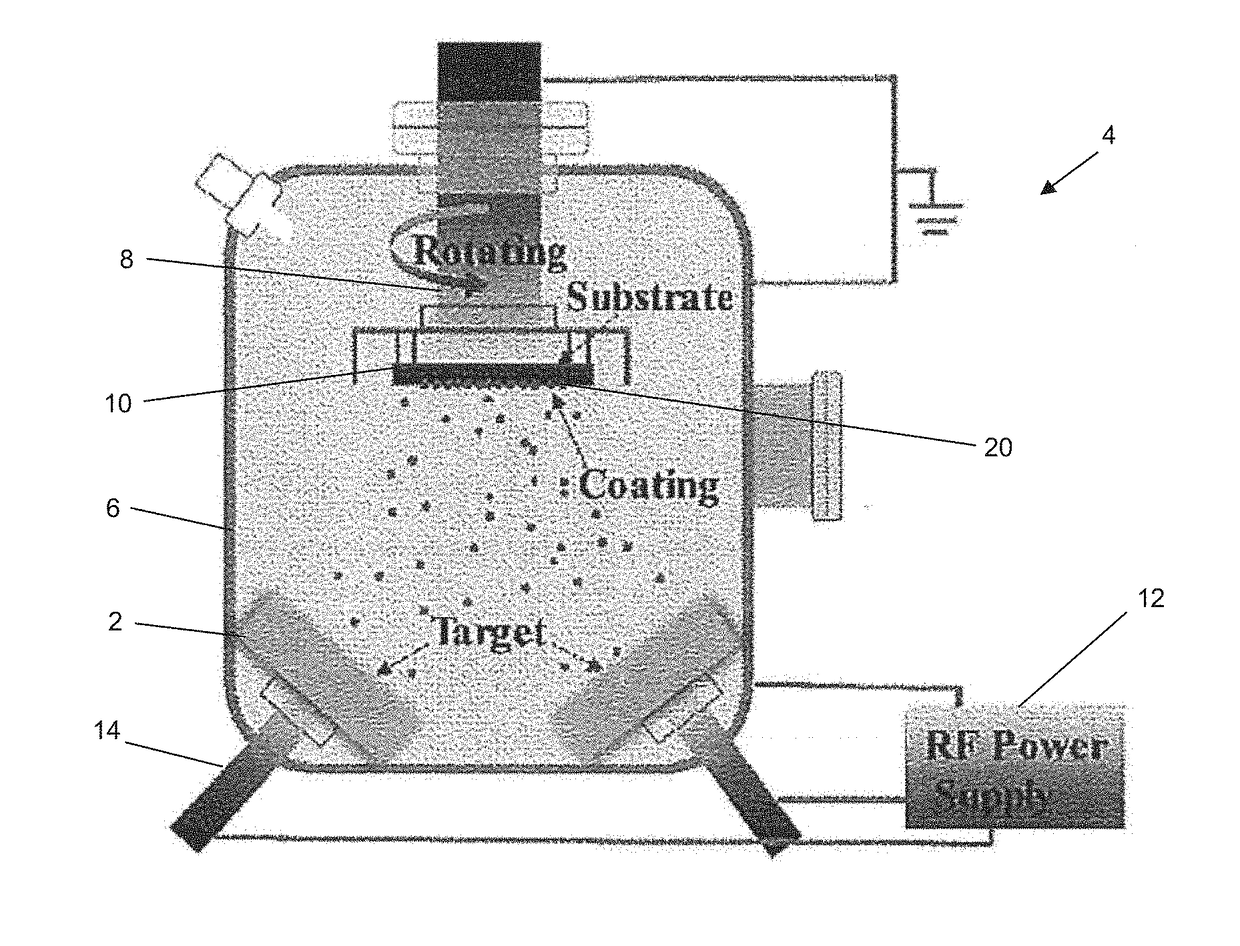

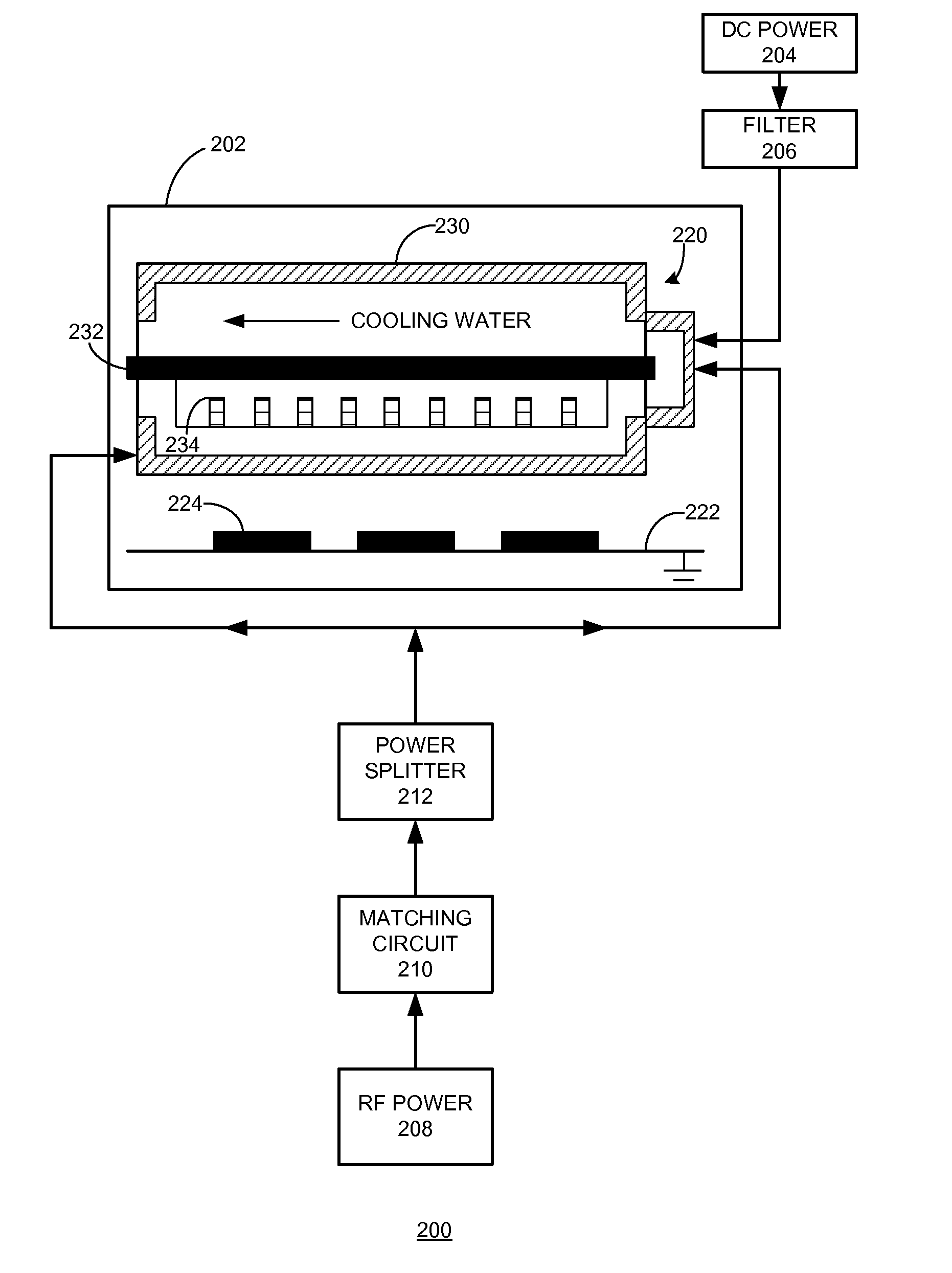

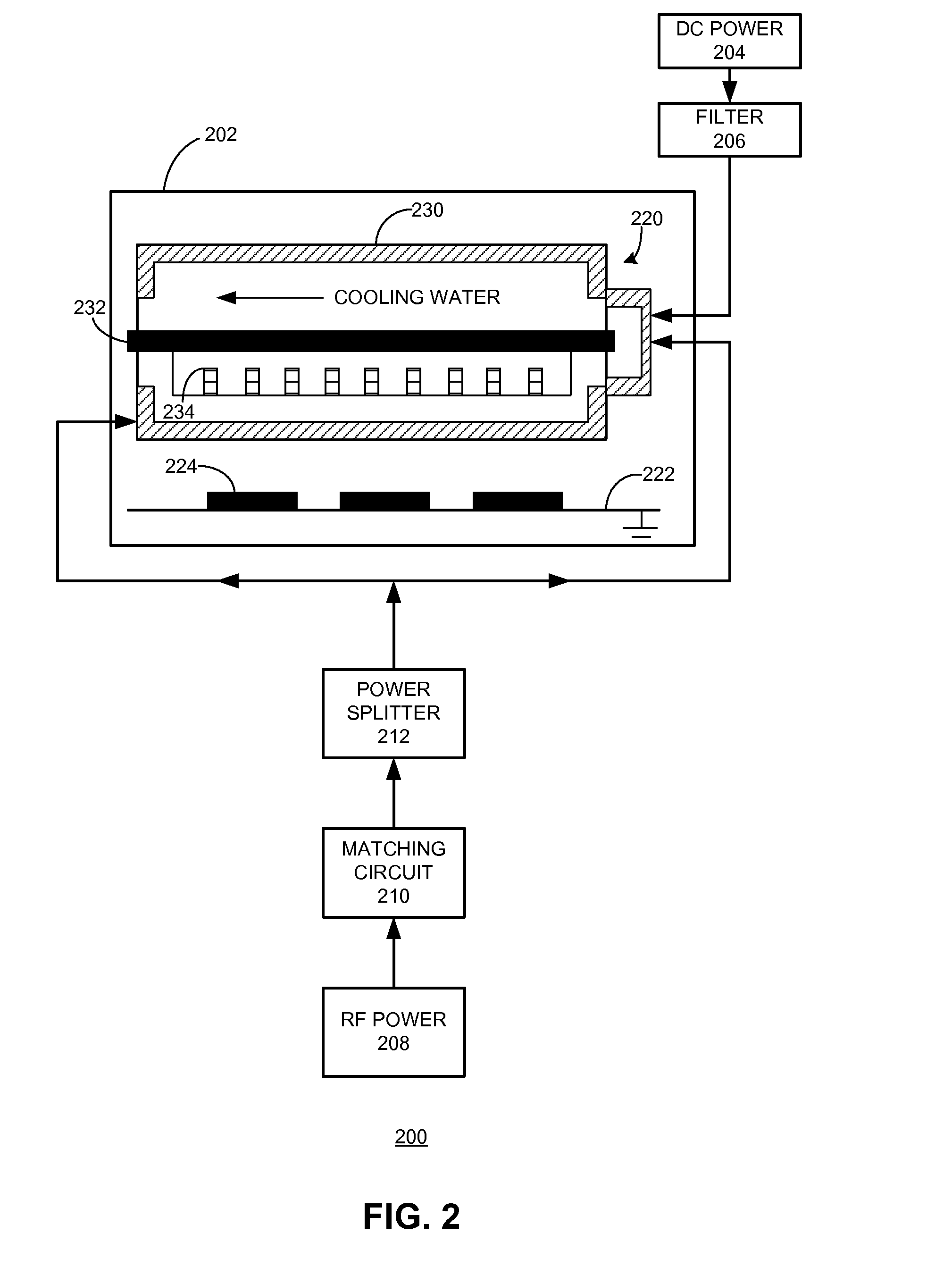

Radio-frequency sputtering system with rotary target for fabricating solar cells

One embodiment of the present invention provides a sputtering system for large-scale fabrication of solar cells. The sputtering system includes a reaction chamber, a rotary target situated inside the reaction chamber which is capable of rotating about a longitudinal axis, and an RF power source coupled to at least one end of the rotary target to enable RF sputtering. The length of the rotary target is between 0.5 and 5 meters.

Owner:TESLA INC

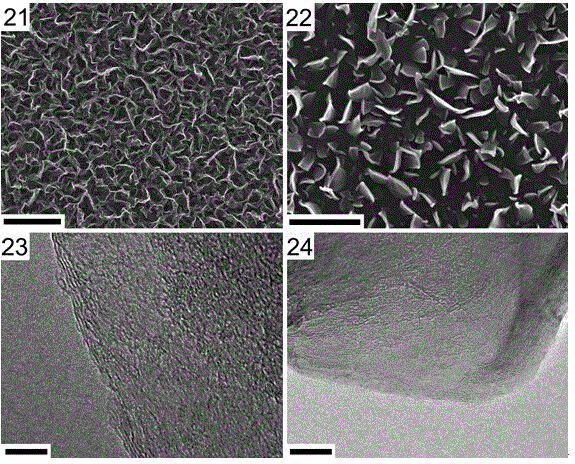

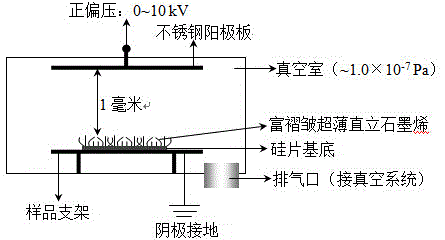

Preparation method for ultrathin up-right graphene field emission cathode rich in wrinkle on surface

InactiveCN104616944AReduce dependenceLow opening fieldDischarge tube/lamp detailsCold cathode manufactureNano structuringCarbon nanotube

The invention discloses a preparation method for ultrathin up-right graphene field emission cathode rich in wrinkle on surface and belongs to the preparation and application field of the nanometer material. The preparation method mainly comprises the following preparation technology: taking the monocrystalline silicon piece or metal piece with flat surface or carbon nanotube array or silicon nanowire array having nano structure on surface as the substrate; adopting the radio frequency sputtering for growing the ultrathin up-right graphene rich in wrinkle on surface without catalytic on the substrate; and taking the obtained ultrathin up-right graphene rich in wrinkle on surface as the cathode for assembling the field electronic emitter. The up-right graphene is very thin, the average layer number is five, much wrinkle is formed on the surface with defect, the surface of up-right graphene is flat and the up-right grapheme has lower opening field, threshold value field, good field emission stability and higher application value.

Owner:TIANJIN NORMAL UNIVERSITY

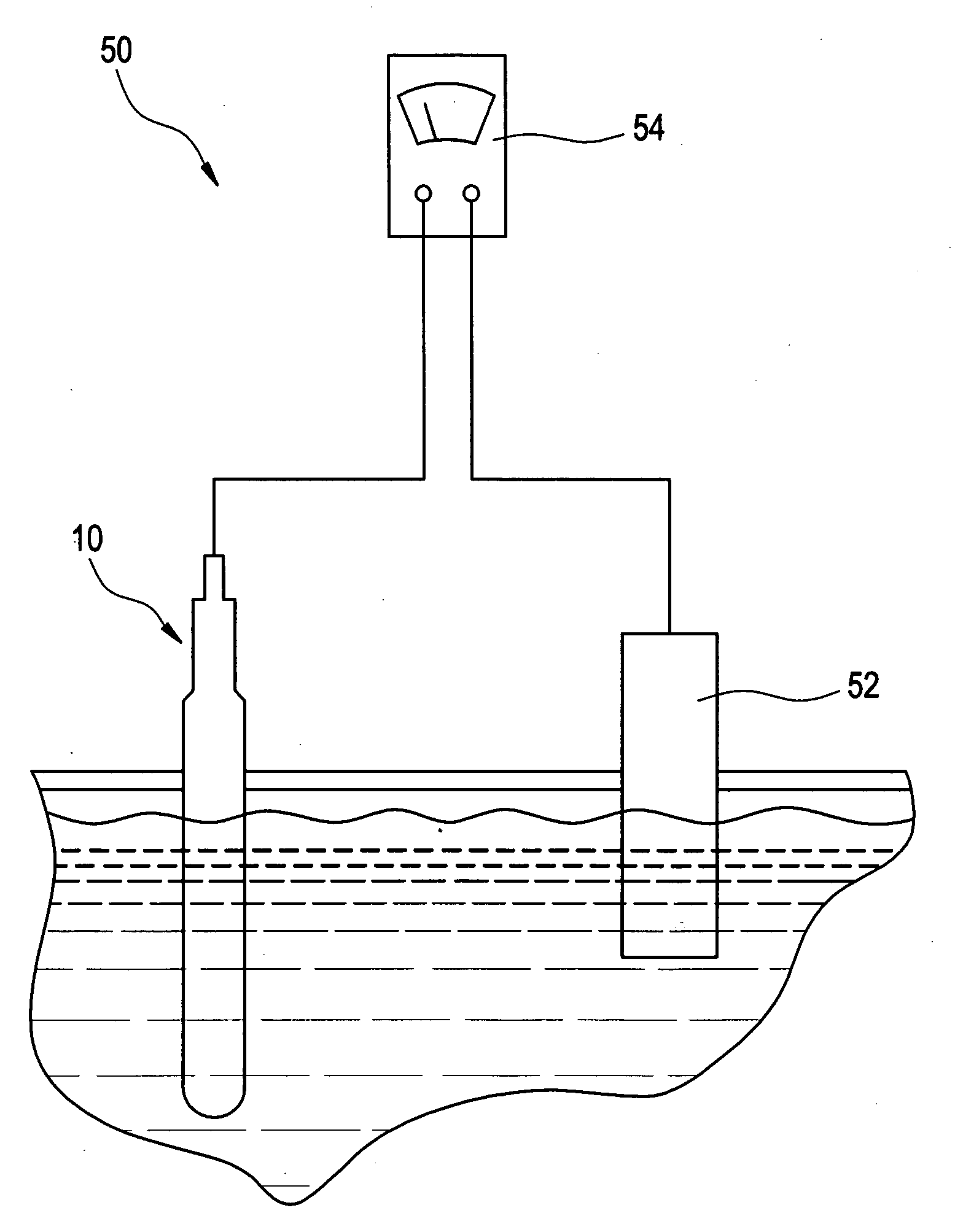

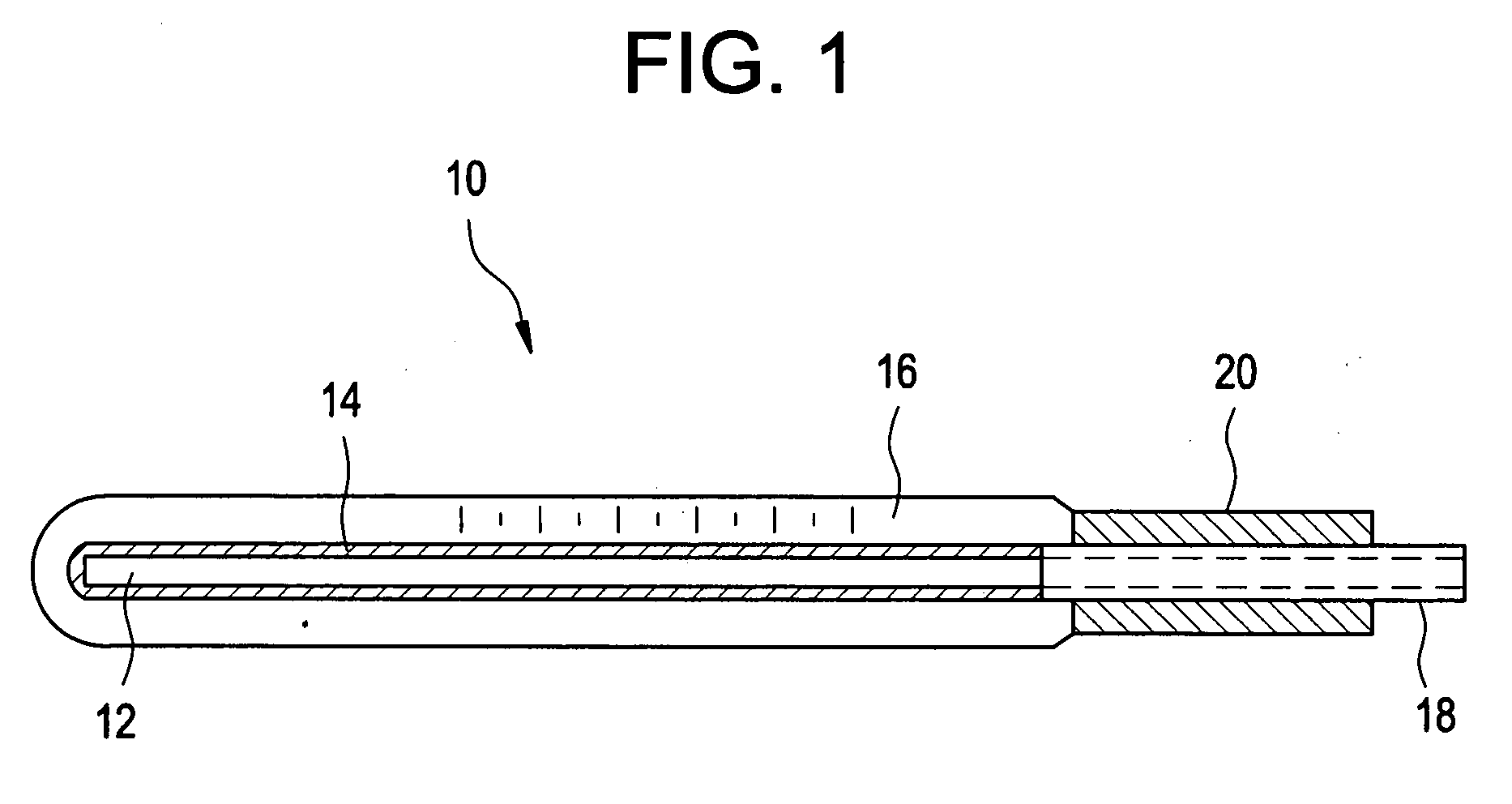

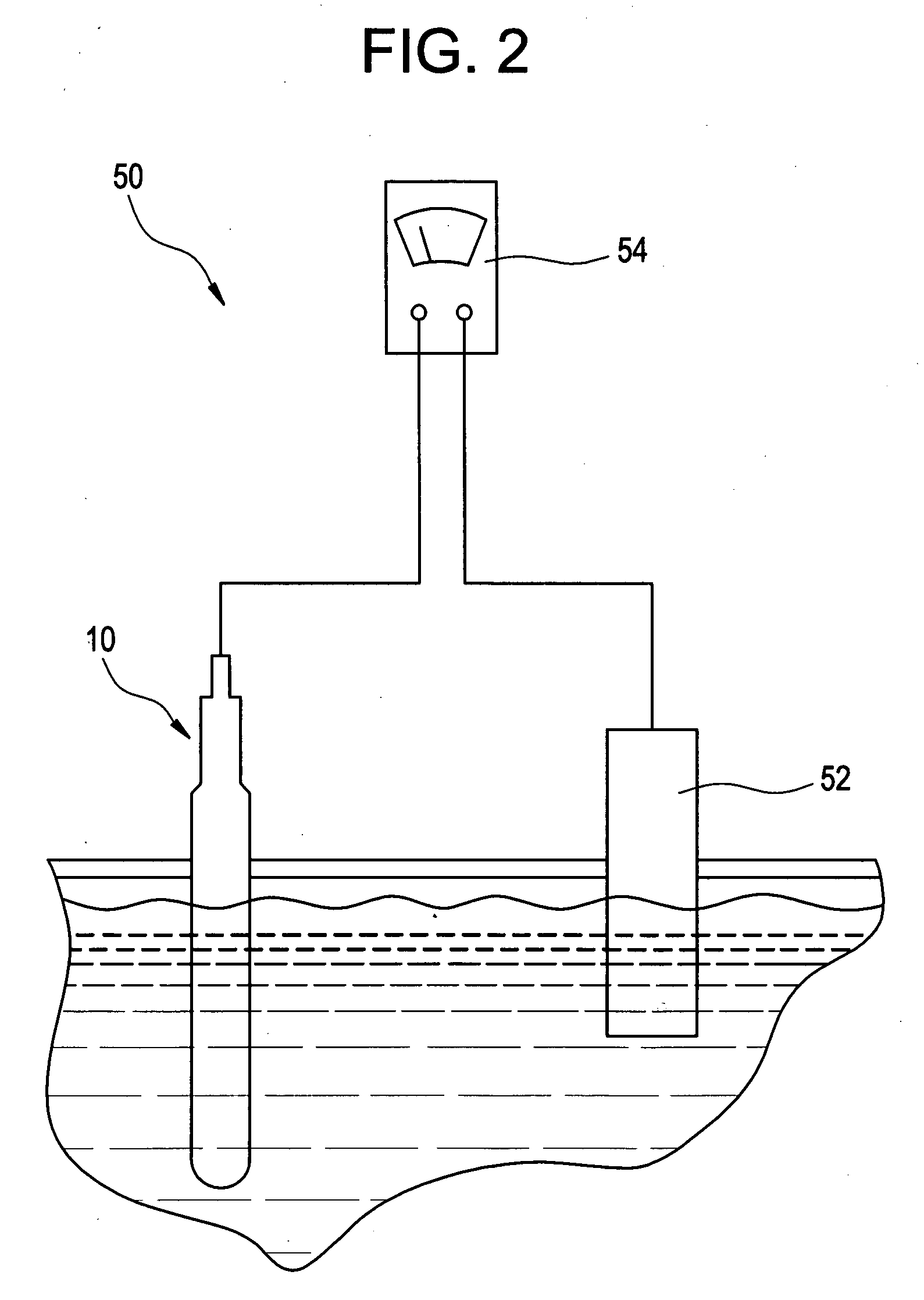

Electrochemical corrosion potential sensor and method of making

InactiveUS20080169205A1Weather/light/corrosion resistanceVolume/mass flow measurementCathodic arc depositionElectrical conductor

A sensor for measuring electrochemical corrosion potential includes an electrical conductor, a metal-oxide layer disposed on the electrical conductor, and a zirconia-containing layer disposed on the metal-oxide layer, wherein the zirconia-containing layer is disposed about the electrical conductor using thermal spraying, wire arc, ion plasma cathodic arc deposition, laser ablation, chemical vapor deposition, physical vapor deposition, electroplating, electroless plating, electrochemical oxidation, chemical oxidation, electrophoretic deposition, or radio-frequency sputtering.

Owner:BAKER HUGHES INC

High-hardness material of high-entropy alloy nitride coating and preparation method of the high-hard material

ActiveCN109338300AHigh hardnessGood abrasivenessVacuum evaporation coatingSputtering coatingHigh entropy alloysNitrogen

The invention discloses a high-hardness material of a high-entropy alloy nitride coating and a preparation method of the high-hardness material. The high-hardness material is composed of a Cr transition layer located on the surface of a substrate, a CrN transition layer located on the surface of the Cr transition layer and a nitride coating located on the surface of the CrN transition layer; the nitride coating is obtained by using a radio frequency sputtering method through deposition of nitrogen and a high-entropy alloy, and the thickness of the Cr transition layer is 80-150 nm, the thickness of the CrN transition layer is 50-100 nm, and the thickness of the nitride coating is 1.5-2.5 [mu]m. The obtained high-hardness material of the high-entropy alloy nitride coating not only has a highhardness of more than 50 GPa, but also has good abrasion performance; and the coating has the characteristics of simple production technology, high deposition speed, low costs and the like, has the advantages of high efficiency, low energy consumption and low requirements for a device, and is suitable for being used a hard cutter coating.

Owner:XIAN TECH UNIV

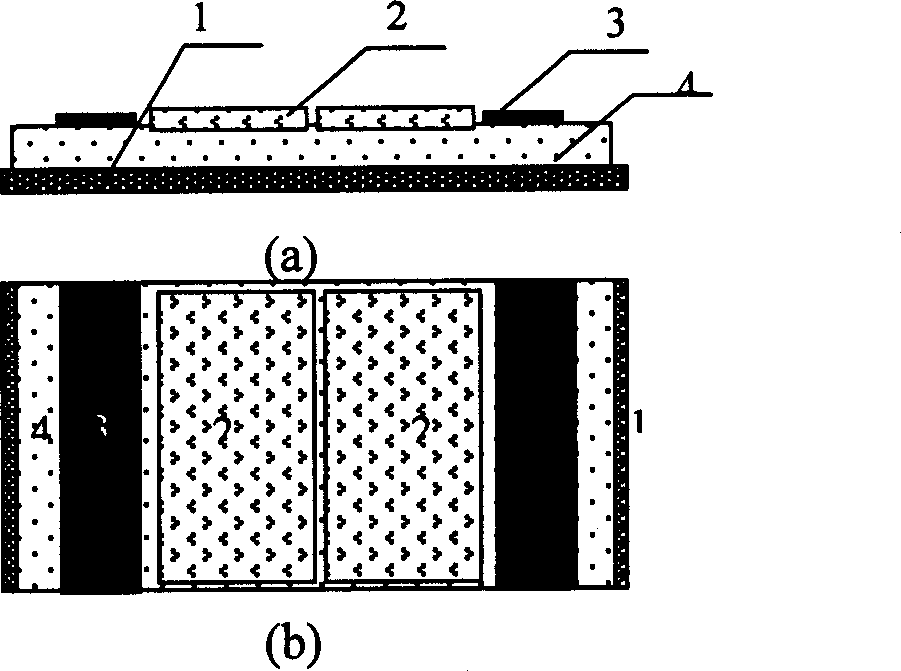

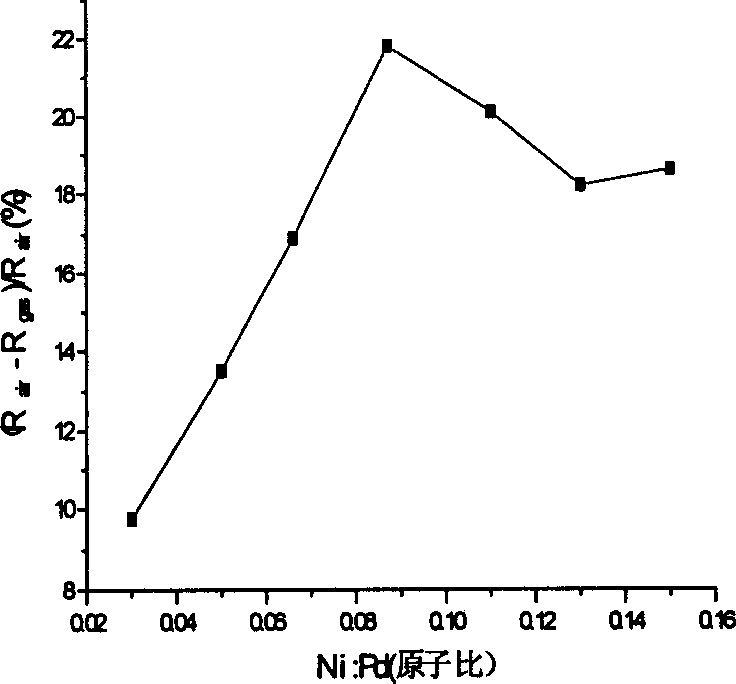

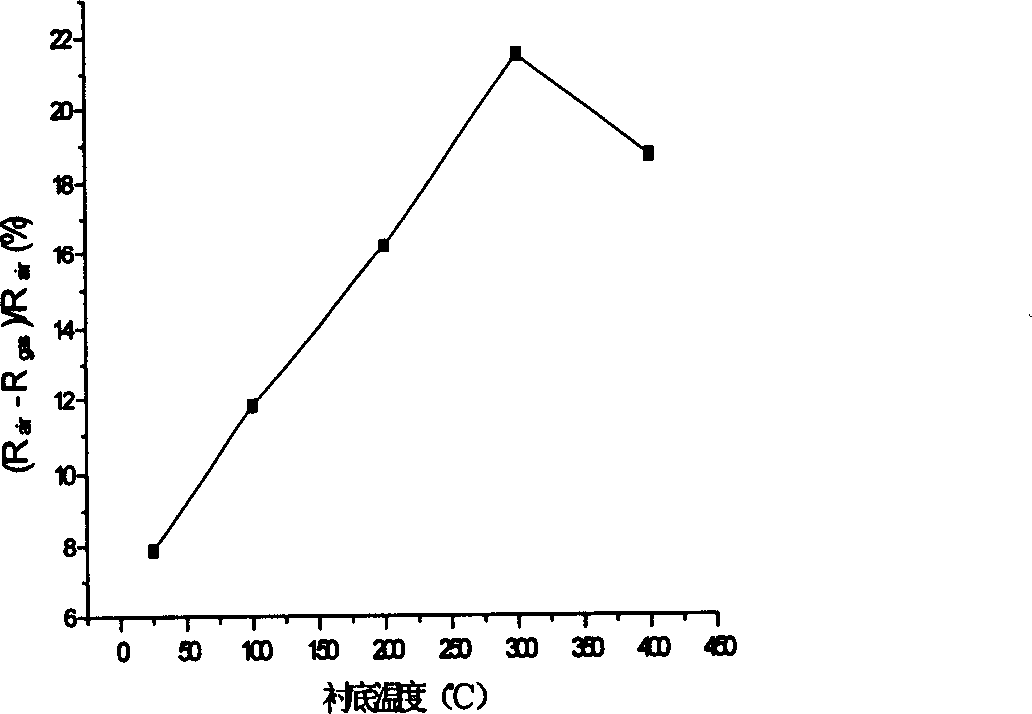

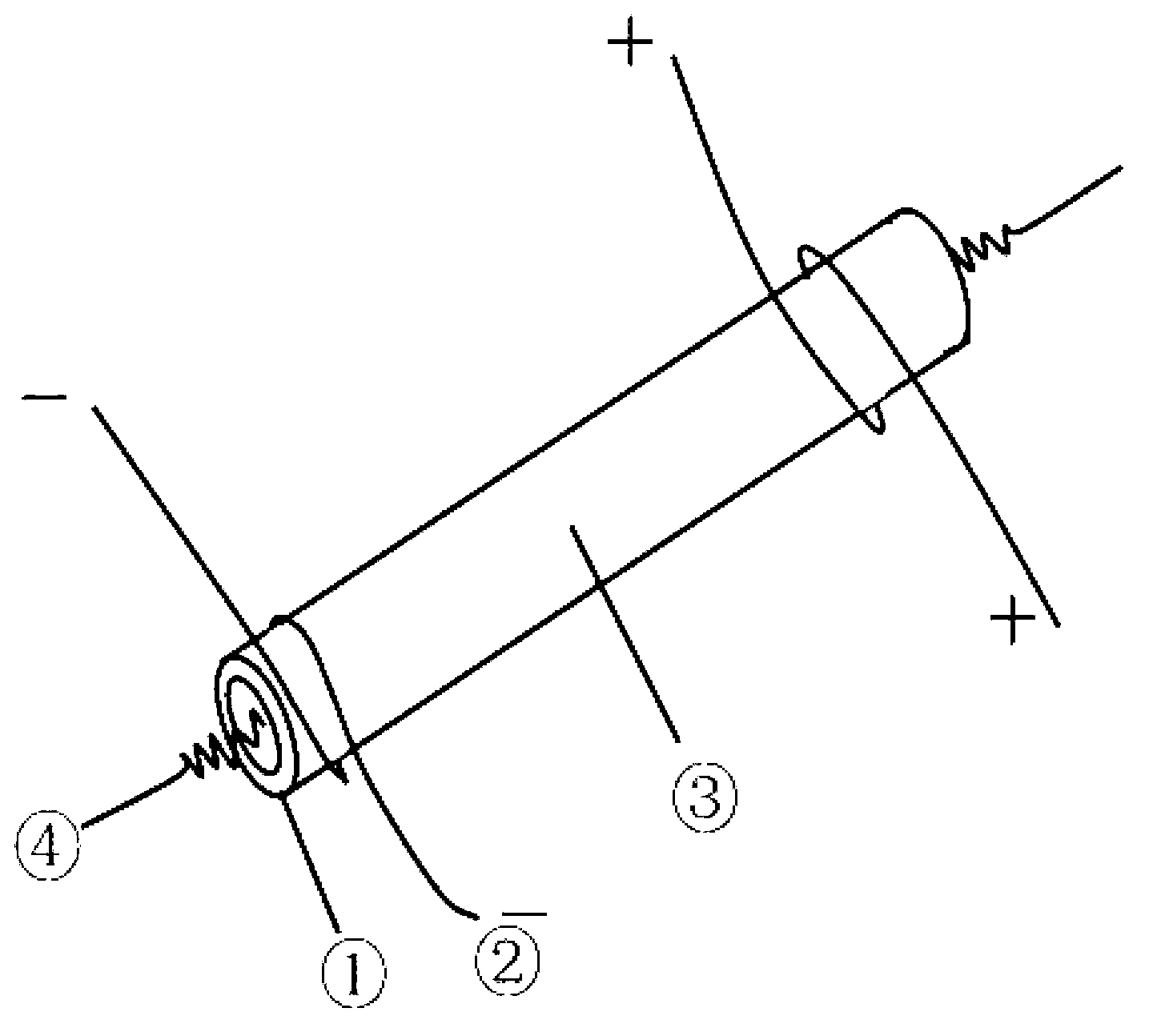

Gas sensor of hydrogen semiconductor transducer, and preparation method

ActiveCN1797806AGood choiceIncreased sensitivitySolid-state devicesMaterial resistanceTin dioxideHydrogen

Characters of the method are that n-SnO2-x thin membrane layer is prepared on Si(100) chip by using radio frequency sputtering technique; then, Pd-Ni layer is prepared on tin dioxide layer so as to form gas sensor in composite membrane of Pd-Ni / SnO2. Under environment of normal temperature, the gas sensor raises selectivity and sensibility for hydrogen. Features are: simple technique and low cost.

Owner:GRIMAT ENG INST CO LTD

Anode construction for top light emitting organic display and manufacturing process thereof

ActiveCN101459226ASave energySmall ups and downsSolid-state devicesSemiconductor/solid-state device manufacturingMetal coatingOrganic light emitting device

Disclosed are an anode structure of a top-emitting organic display and a manufacturing process thereof, and relates to a top-emitting organic light-emitting device, in particular to a low resistivity anode structure applied to a top-emitting organic display and a manufacturing process thereof. The anode structure of the top-emitting organic display includes forming an electrode via coating films on a silicon substrate, which is characterized in that four layers of films are coated on the silicon substrate, namely a high purity chromium film layer, a high purity aluminum film layer, a high purity chromium film layer and a high purity aluminum film layer from the silicon substrate layer to the top, besides radio-frequency sputtering process, PVD process is utilized, and pre-heating treatment and metal coating process are performed on the silicon substrate. The novel anode structure has high conductivity and economical property and is easy to be coated, the OLED light emitting efficiency of the novel anode structure is increased to 30% due to the relatively low absorption coefficient of light and higher reflection coefficient of light, and thereby the performance of the novel anode structure is superior to the existing anode structure.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

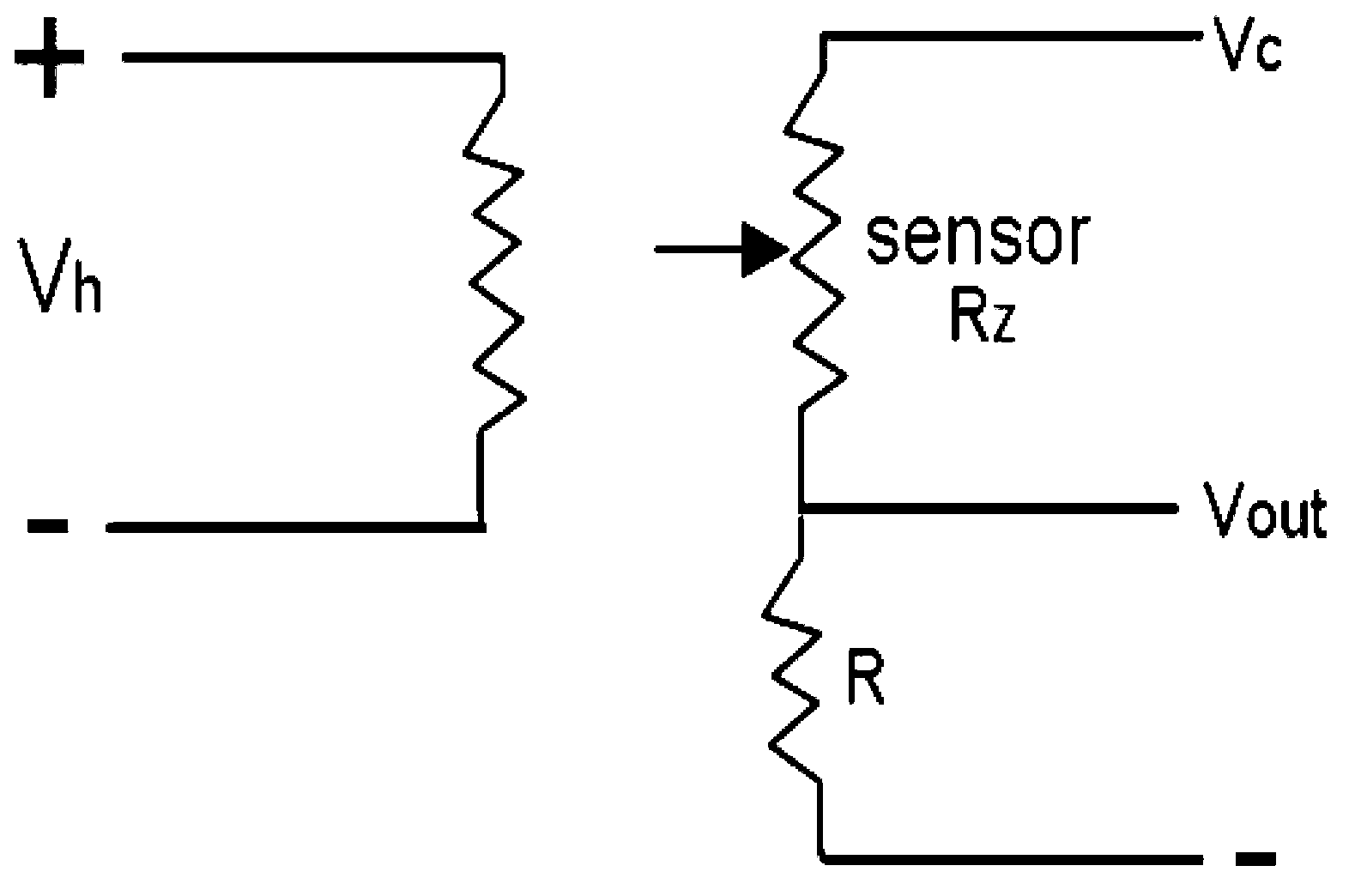

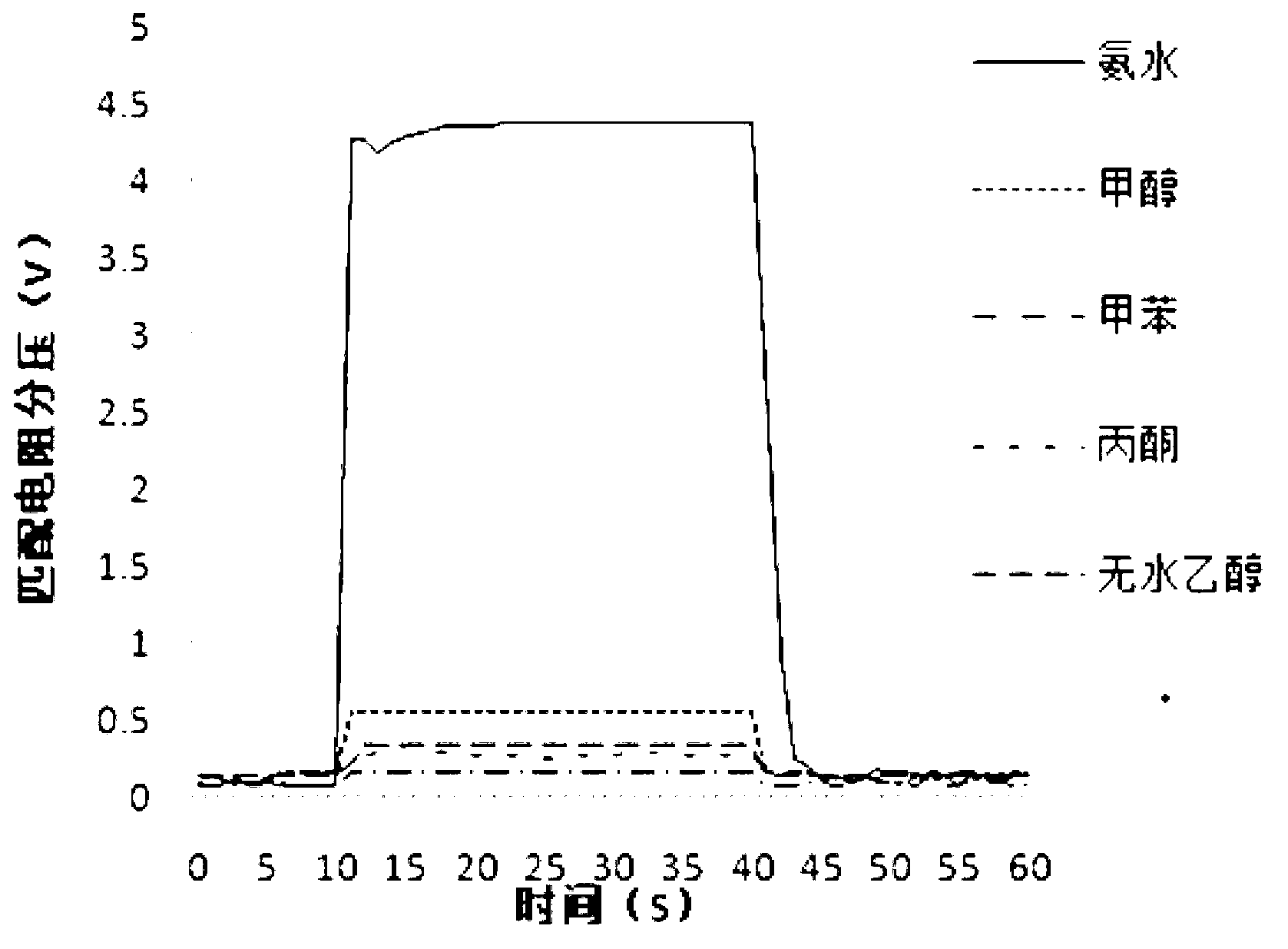

Copper oxide doped tin dioxide base ammonia gas sensitive sensor manufacturing method

InactiveCN102978578AHigh sensitivityResponse recovery time is shortVacuum evaporation coatingSputtering coatingTin dioxideVacuum pumping

The present invention discloses a copper oxide doped tin dioxide base ammonia gas sensitive sensor manufacturing method. The method comprises the following steps: sequentially placing a Cu target material with a purity of 99.99% and a Sn target material with a purity of 99.99% on two radio frequency sputtering targets, and placing a Al2O3 ceramic tube on a sample holder; carrying out vacuum pumping on the system before sputtering until air pressure of the system achieves 10<-3>-10<-5> Pa; opening gas path valves of oxygen gas and argon gas, wherein the air pressure is maintained to 6*10<0>-3*10<-1> Pa; carrying out pre-sputtering for 10 min, then removing a blocking disc, concurrently adjusting a power of the Sn target to 60-80 W, adjusting a power of the Cu target to 20-60 W, and sputtering for 45 min; opening the vacuum chamber to take the sample when the air pressure is 10<5> Pa; and carrying out annealing for 1-3 h at a temperature of 300-500 DEG C in a muffle furnace to obtain the finished product. The manufactured gas sensitive element provides good selectivity for ammonia gas, can quickly and effectively detect ammonia gas from a lot of mixing gas, and has characteristics of high sensitivity and short response recovery time.

Owner:HEBEI UNIV OF TECH

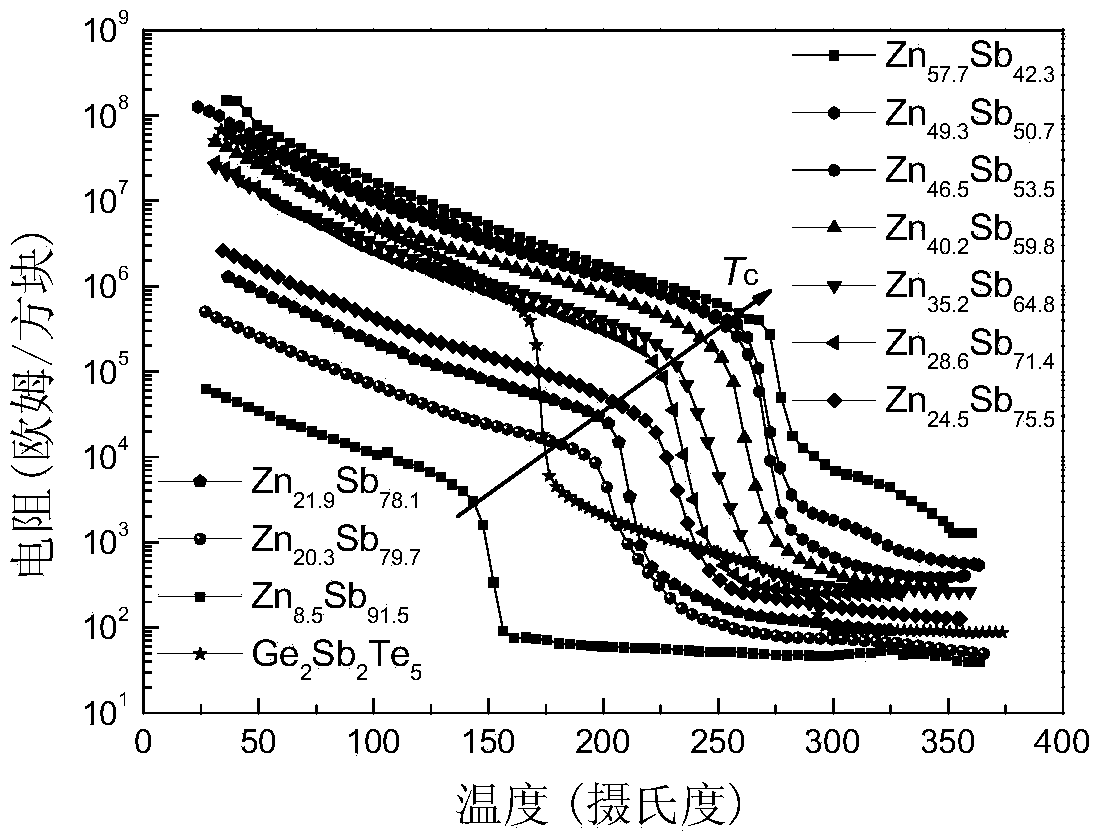

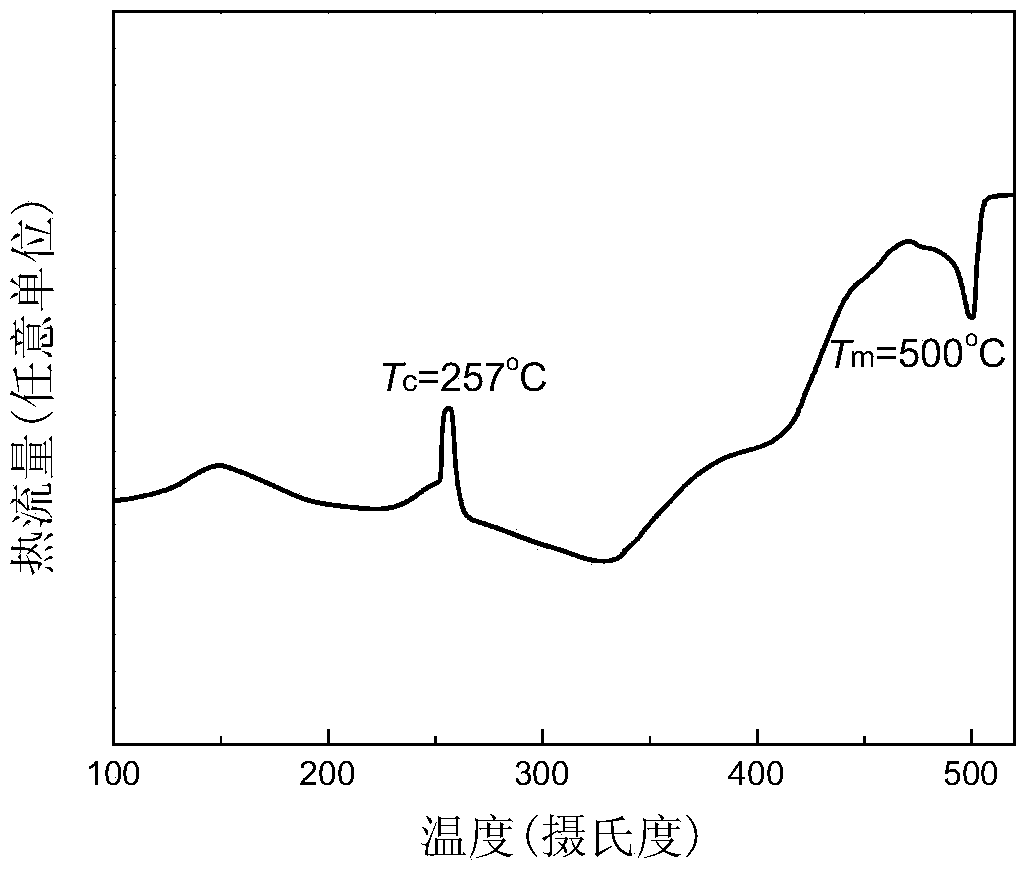

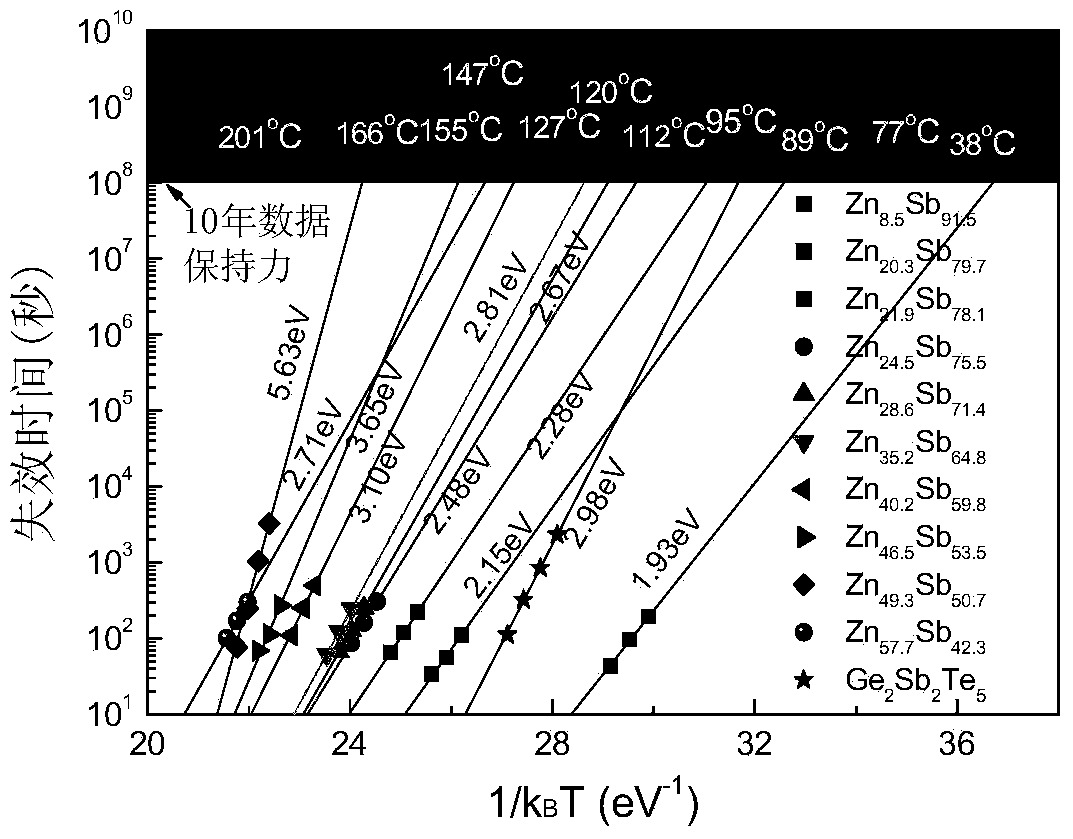

Environment-friendly Zn-Sb phase change storage thin-film material and manufacturing method thereof

InactiveCN103762309ARaise the crystallization temperatureFast and secure readElectrical apparatusRoom temperatureAlloy

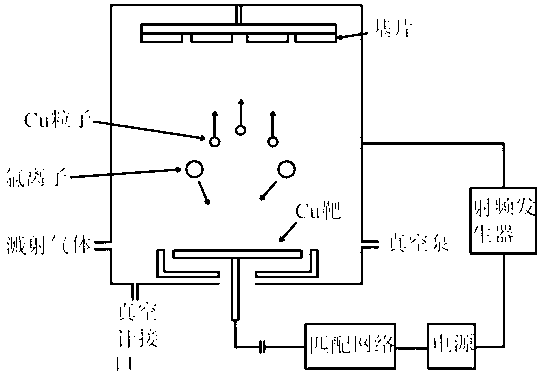

The invention discloses an environment-friendly Zn-Sb phase change storage thin-film material and a manufacturing method of the environment-friendly Zn-Sb phase change storage thin-film material. The environment-friendly Zn-Sb phase change storage thin-film material is characterized in that the chemical structural formula of the material is ZnxSb(100-x), and x is larger than 0 but smaller than 60. The manufacturing method comprises the steps of installing an elemental Sb or Zn target material in a magnetic control direct current sputtering target, installing a ZnSb alloy target material in a magnetic control radio frequency sputtering target, vacuumizing a sputtering chamber until the vacuum degree is 2.0*10<-4>Pa, feeding high-purity argon of 50ml / min into the sputtering chamber until the air pressure reaches 0.35Pa, controlling the sputtering power of the ZnSb alloy target material to be 20-50W, controlling the sputtering power of the elemental Sb or Zn target material to be 0-40W, and obtaining the finished environment-friendly Zn-Sb phase change storage thin-film material after the target materials sputter for 5 minutes at the room temperature. The environment-friendly Zn-Sb phase change storage thin-film material and the manufacturing method of the environment-friendly Zn-Sb phase change storage thin-film material have the advantages that the crystallization temperature is high, the phase change speed is high, the switch ratio is large, data retentivity is good, stability is high, and power consumption is small.

Owner:NINGBO UNIV

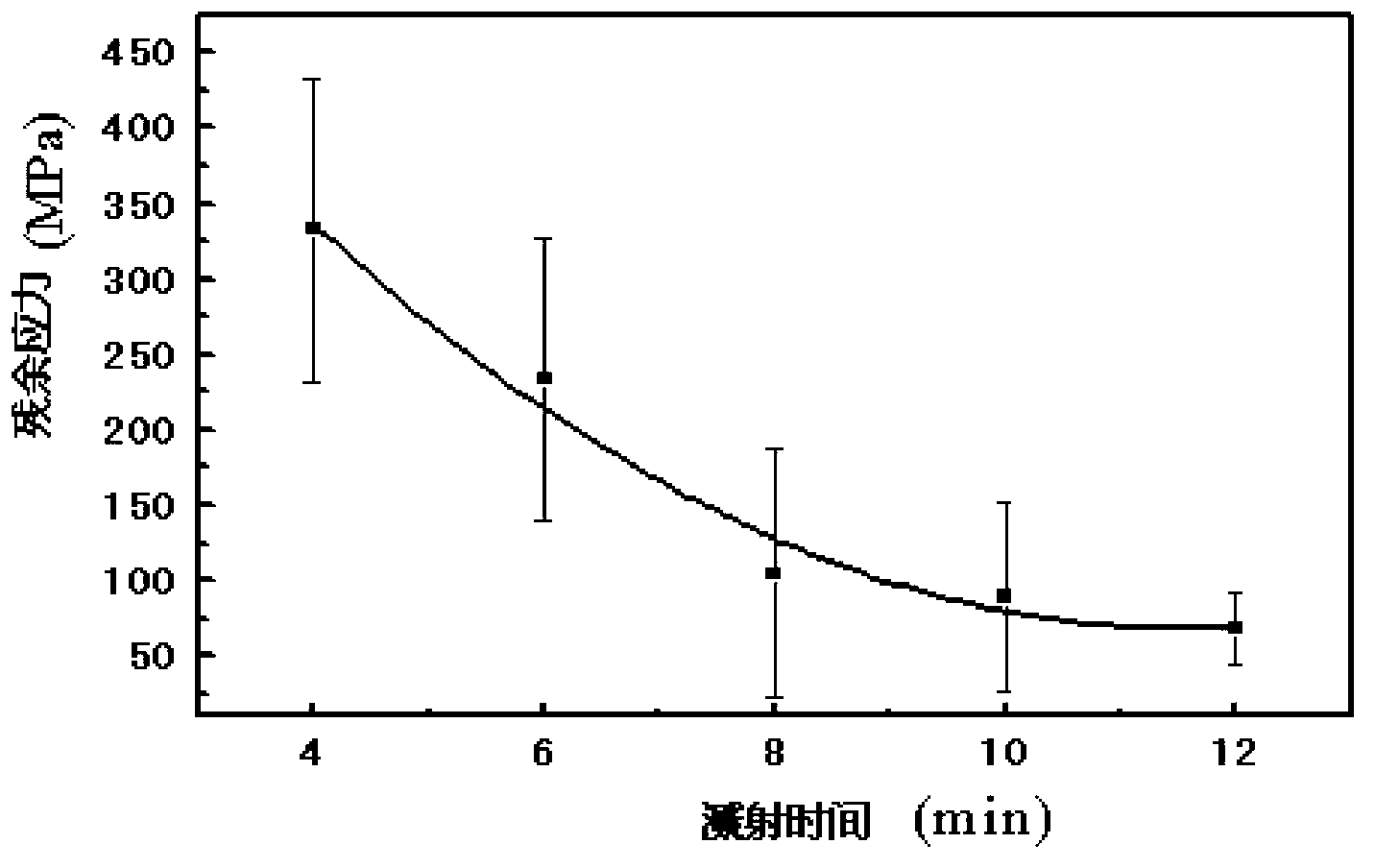

Preparation method of low-residual-stress copper film

InactiveCN102851645AImprove membrane qualityImprove performanceVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringRadio frequency sputtering

The invention relates to preparation technology of a metal film, and discloses a new simple and convenient preparation method of a copper film. The invention effectively controls the magnitude of residual stress generated in the preparation process, thereby implementing preparation of the low-residual-stress copper film material. The method is applied to a magnetron sputtering coating device, and adopts radio-frequency magnetron sputtering to prepare the copper film. The magnetron sputtering coating device is provided with a magnetron sputtering chamber, and a magnetron sputtering target is arranged in the magnetron sputtering chamber. The method comprises the following steps: a. pretreating a substrate; b. putting the pretreated substrate in the magnetron sputtering chamber; c. vacuumizing the magnetron sputtering chamber; d. introducing high-purity argon into the magnetron sputtering chamber; e. regulating the radio-frequency sputtering power and gas pressure, and sputtering the magnetron sputtering target to form the copper film on the substrate; and f. after cooling the magnetron sputtering chamber, taking out the copper film sample, and carrying out residual stress testing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

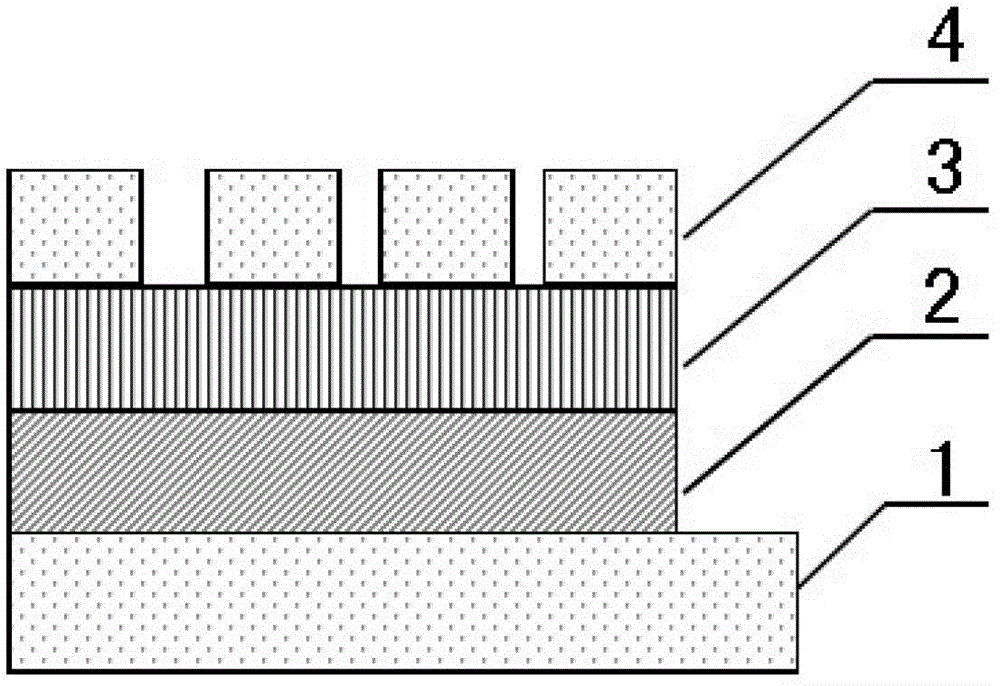

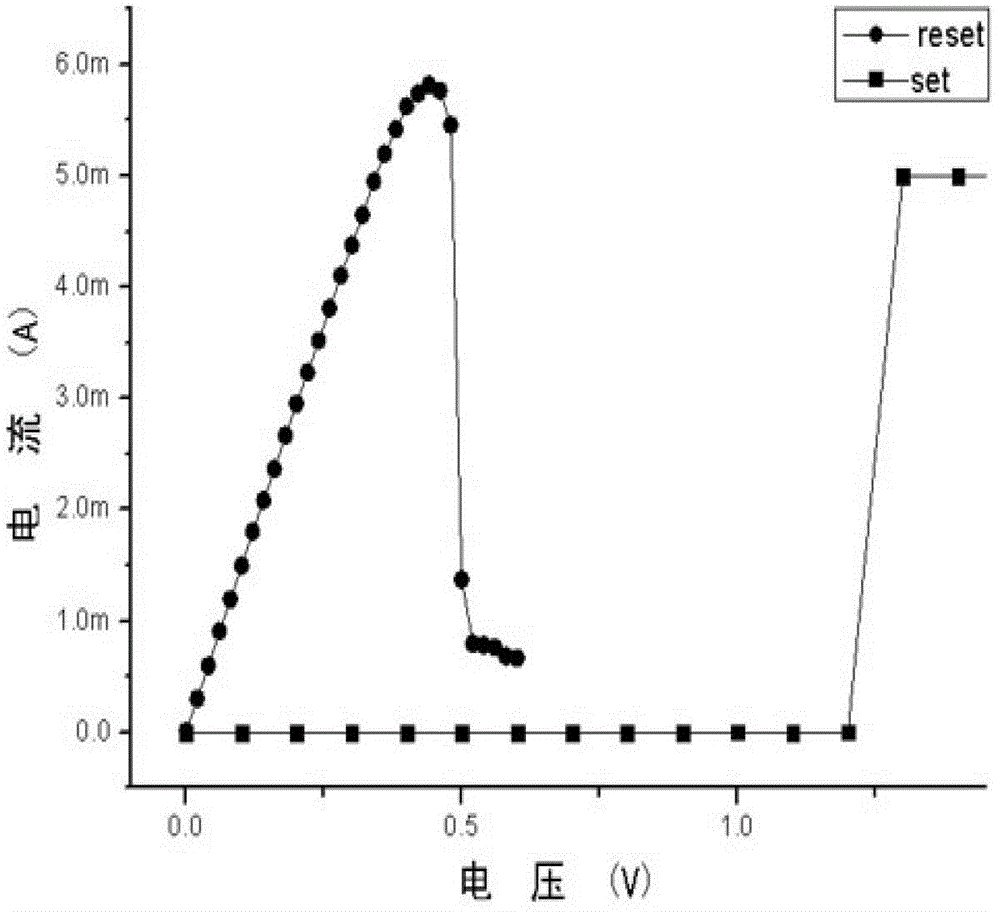

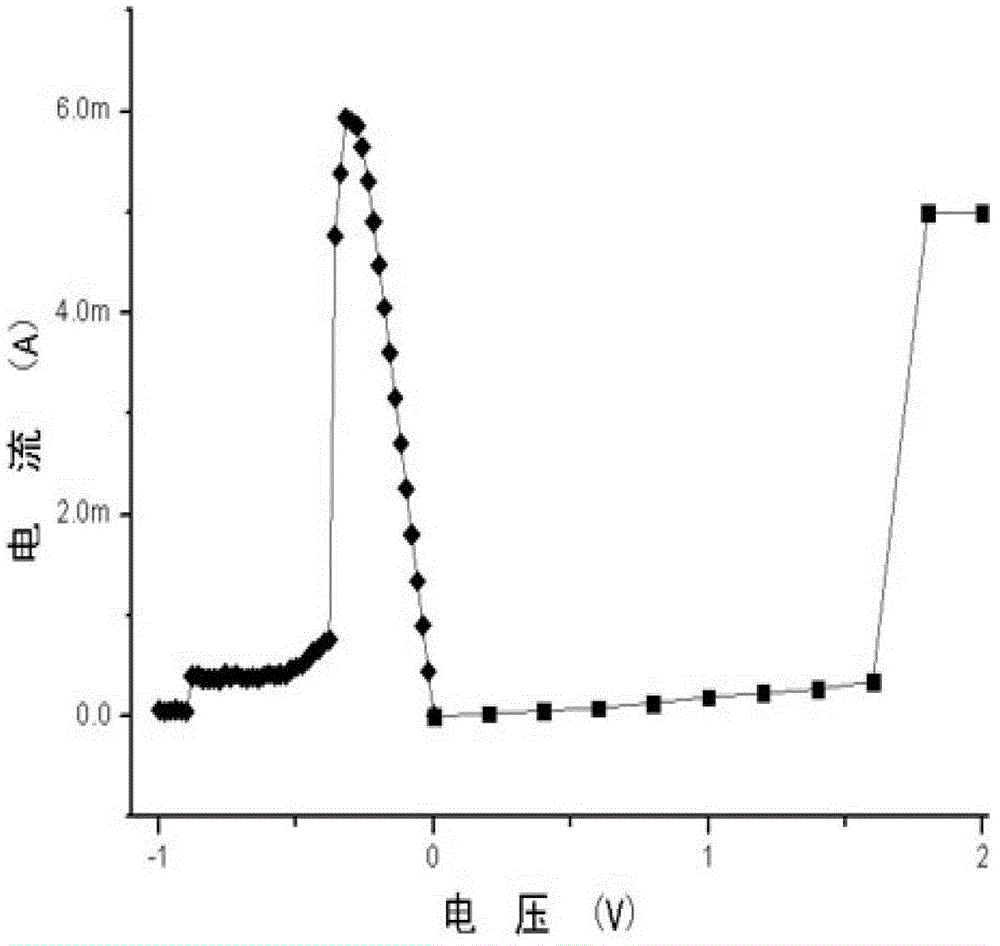

Resistance random access memory based on vanadium oxide/zinc oxide laminated structure and preparation method thereof

ActiveCN102916129AImprove consistencyGood repeatabilityElectrical apparatusDigital storageStatic random-access memoryOptoelectronics

The invention relates to a resistance random access memory based on a vanadium oxide / zinc oxide laminated structure, wherein the resistance random access memory is composed of a lower electrode, a resistance random layer and an upper electrode; the resistance random layer is the laminated structure composed of a vanadium oxide medium layer and a zinc oxide medium layer; and films of the vanadium oxide medium layer and the zinc oxide medium layer are prepared by adopting a direct-current sputtering or radio-frequency sputtering method. The resistance random access memory based on the vanadium oxide / zinc oxide laminated structure disclosed by the invention has the advantages that: the resistance random access memory is in the form of the vanadium oxide / zinc oxide laminated structure and has the advantage of controlling double polarity and single polarity of zinc oxide; consistency and repeatability of a device are increased; compared with the single-layer vanadium oxide, reset current is decreased to be below 10 mA; in the bipolar testing process, a progressive reset process exists; different high-impedance resistance can be obtained through reset voltage of different amplitude; at least three resistance values can be obtained; more than ten times of resistance value ratio between every two resistance values exists; therefore, the resistance random access memory based on the vanadium oxide / zinc oxide laminated structure can be applied to multi-value storage.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Manufacturing method of back-channel-etching oxide thin-film transistor

ActiveCN105161423ANo RF SputteringNo need for RF sputteringTransistorSemiconductor/solid-state device manufacturingPartial oxidationInsulation layer

The invention discloses a manufacturing method of a back-channel-etching oxide thin-film transistor. The method sequentially comprises the following steps: (a) manufacturing a first thin-film layer on a substrate by a direct-current sputtering method and carrying out patterning; (b) manufacturing a second thin-film layer by the direct-current sputtering method and carrying out patterning; (c) manufacturing a third thin-film layer by the direct-current sputtering method and carrying out patterning as a source-drain electrode; and (d) putting the whole semi-finished product into electrochemical oxidation equipment for electrochemical oxidation, completely oxidizing a second patterned thin-film layer to form a second oxide layer, partially oxidizing a first patterned thin-film layer, and forming an oxide layer corresponding to a first thin-film layer material on the upper surface of the first patterned thin-film layer as a first oxide layer, wherein the unoxidized part of the first thin-film layer is taken as the residual first thin-film layer; the second oxide layer is taken as an active layer; the first oxide layer is taken as a gate insulation layer; and the residual first thin-film layer is taken as a gate. According to the manufacturing method, manufacturing is carried out at room temperature; radio-frequency sputtering is not needed; the manufacturing technique is simple; the production efficiency is high; and defects are few.

Owner:王磊 +1

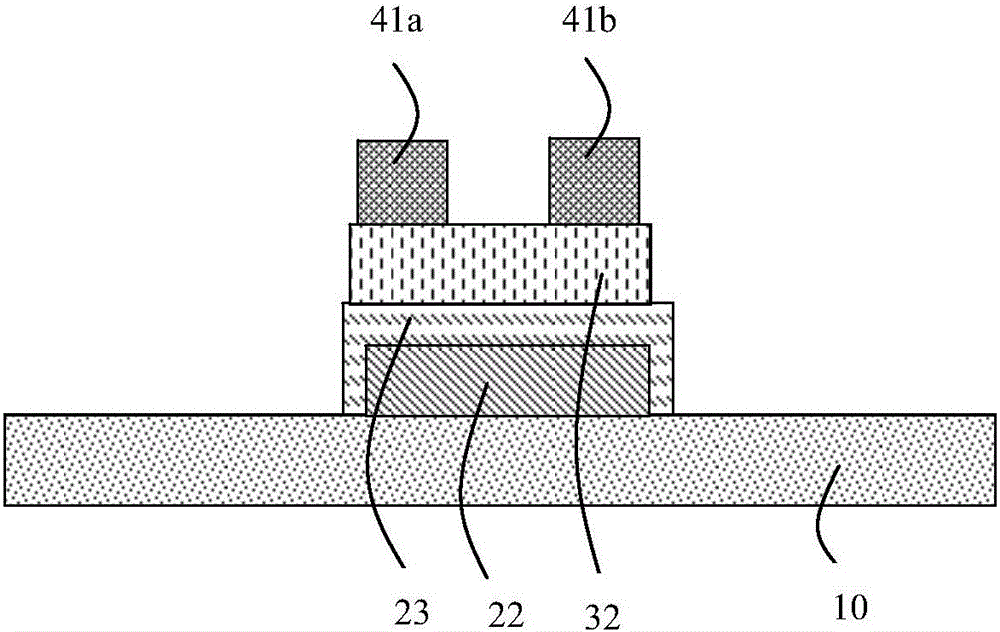

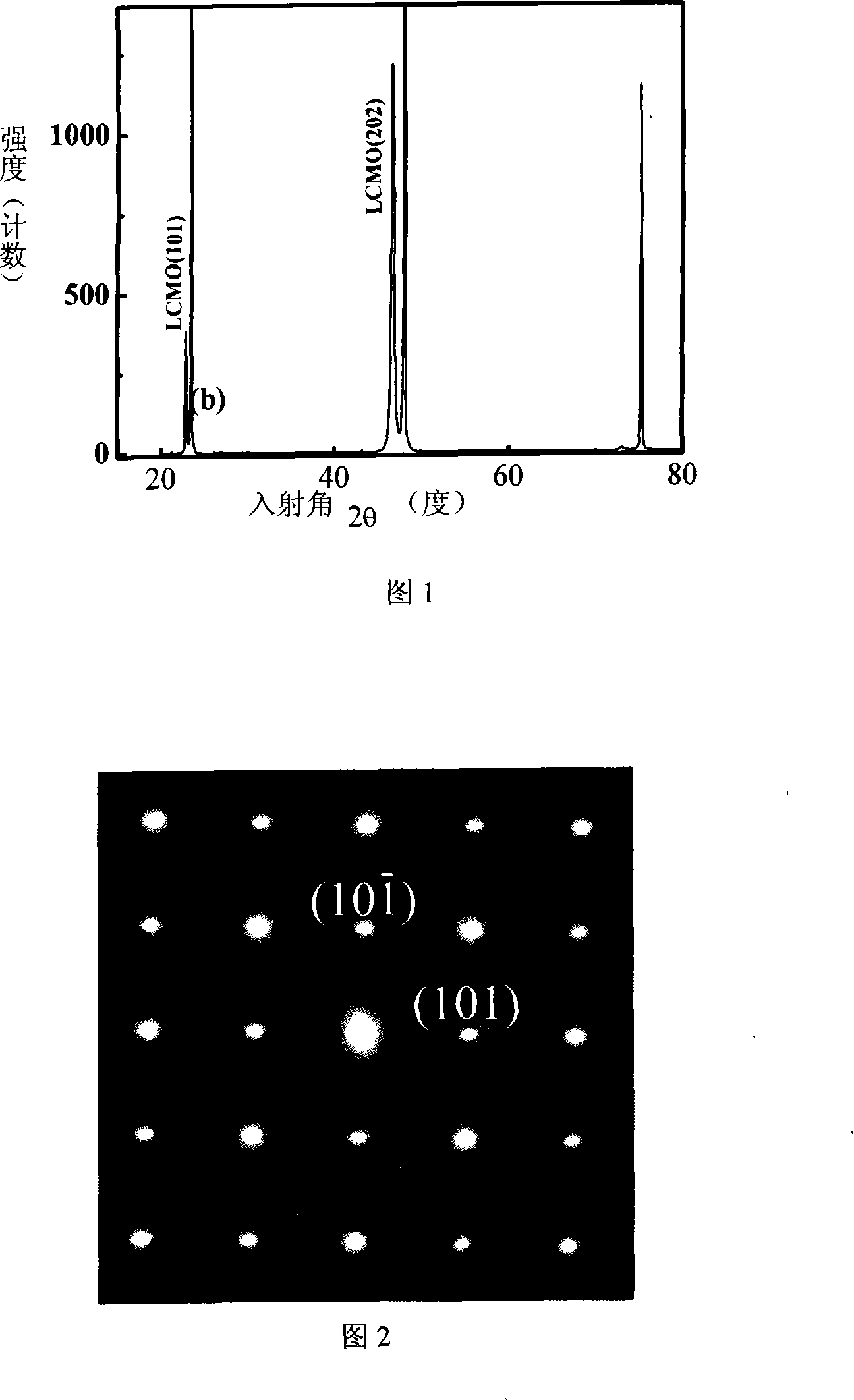

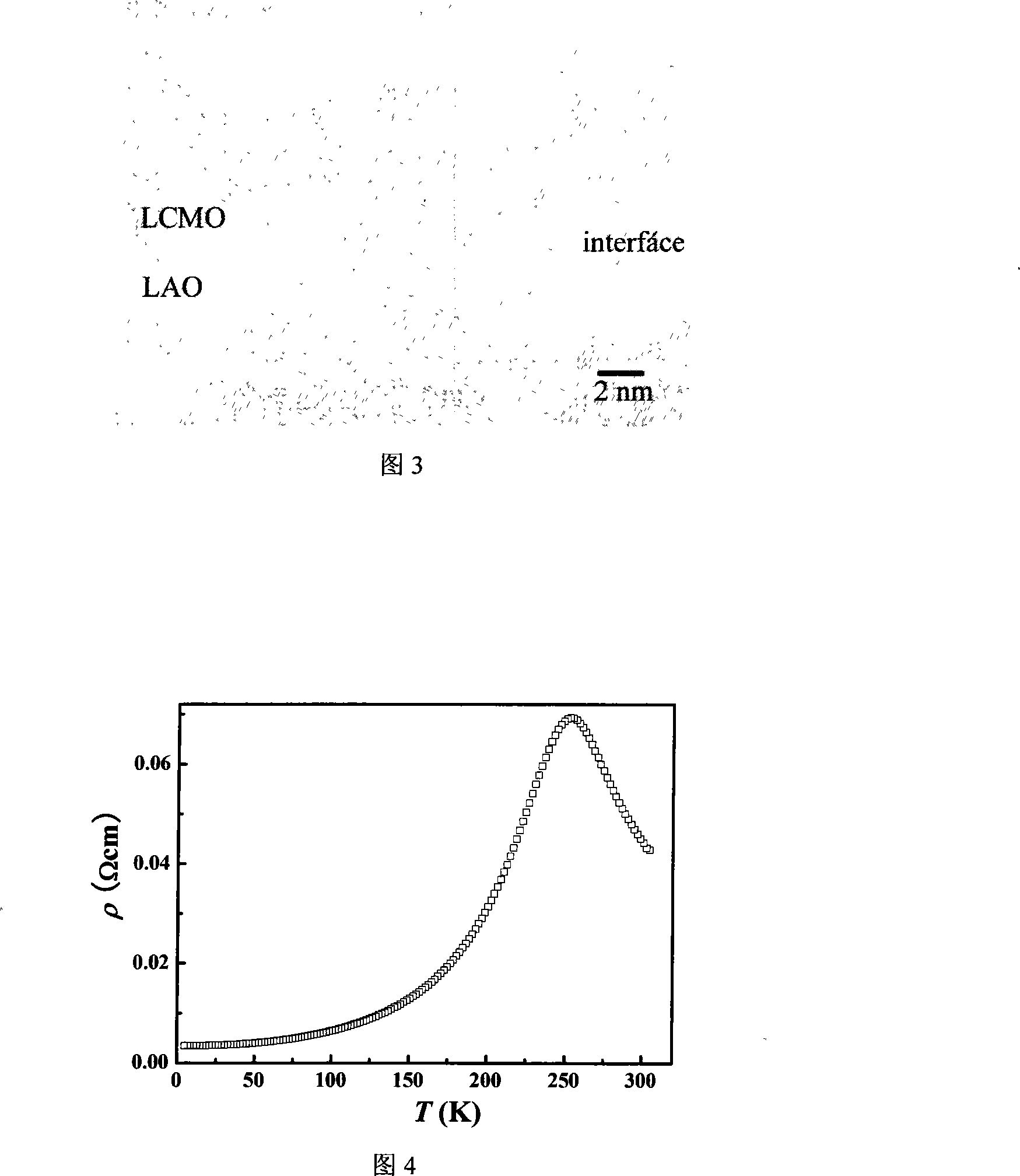

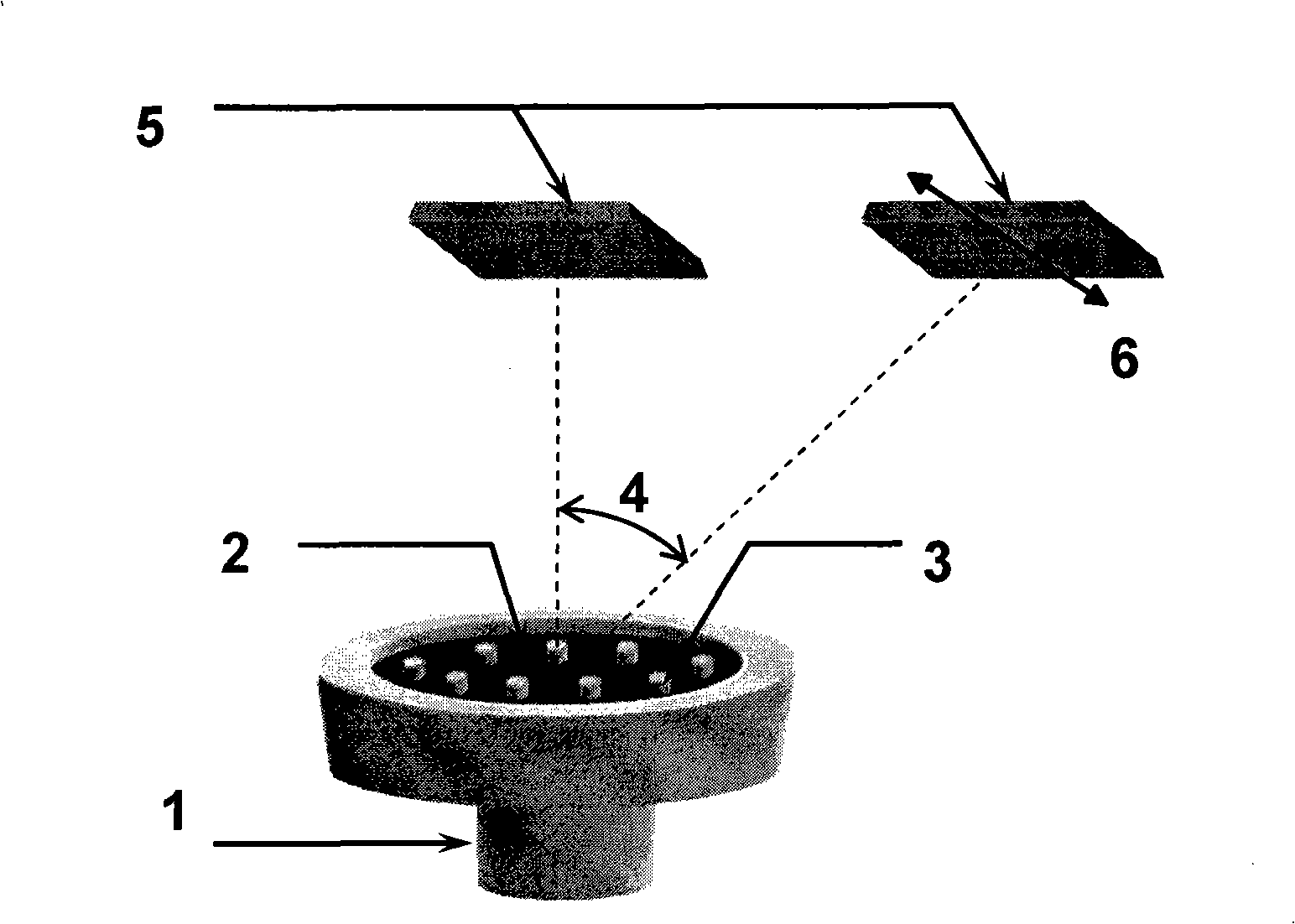

Epitaxy growing method for La1-xCaxMnO3 single crystal thin film

InactiveCN101235539AImprove uniformitySmall transition zonePolycrystalline material growthFrom chemically reactive gasesBasementRare earth

The invention relates to a method for growing La1-xCaxMnO3 single crystal thin film by a simple device, wherein the thin film is prepared by adopting the magnetic control radio-frequency sputtering method, rare-earth manganese oxide polycrystalline ceramic target which is prepared by the solid state reaction method is adopted as the target material, single crystal substrate which is matched with the rare-earth manganese oxide is adopted as the basement, the requirement of the back side vacuum degree of the sputtering device is higher than 2.0*10<-5>Pa, the temperature of the basement is between 700 DGE C and 900 DGE C, the sputtering power is between 150W and 200W, the sputtered thin film needs to be annealed under 900-1000 DEG C for 24 hours, the rare-earth manganese oxide single crystal thin film and the buffer layer of the substrate which are prepared by the preparing method are not obvious, the components of the thin film are accorded with that of the target material, the method has low cost and is convenient to grow in large area.

Owner:TIANJIN UNIV

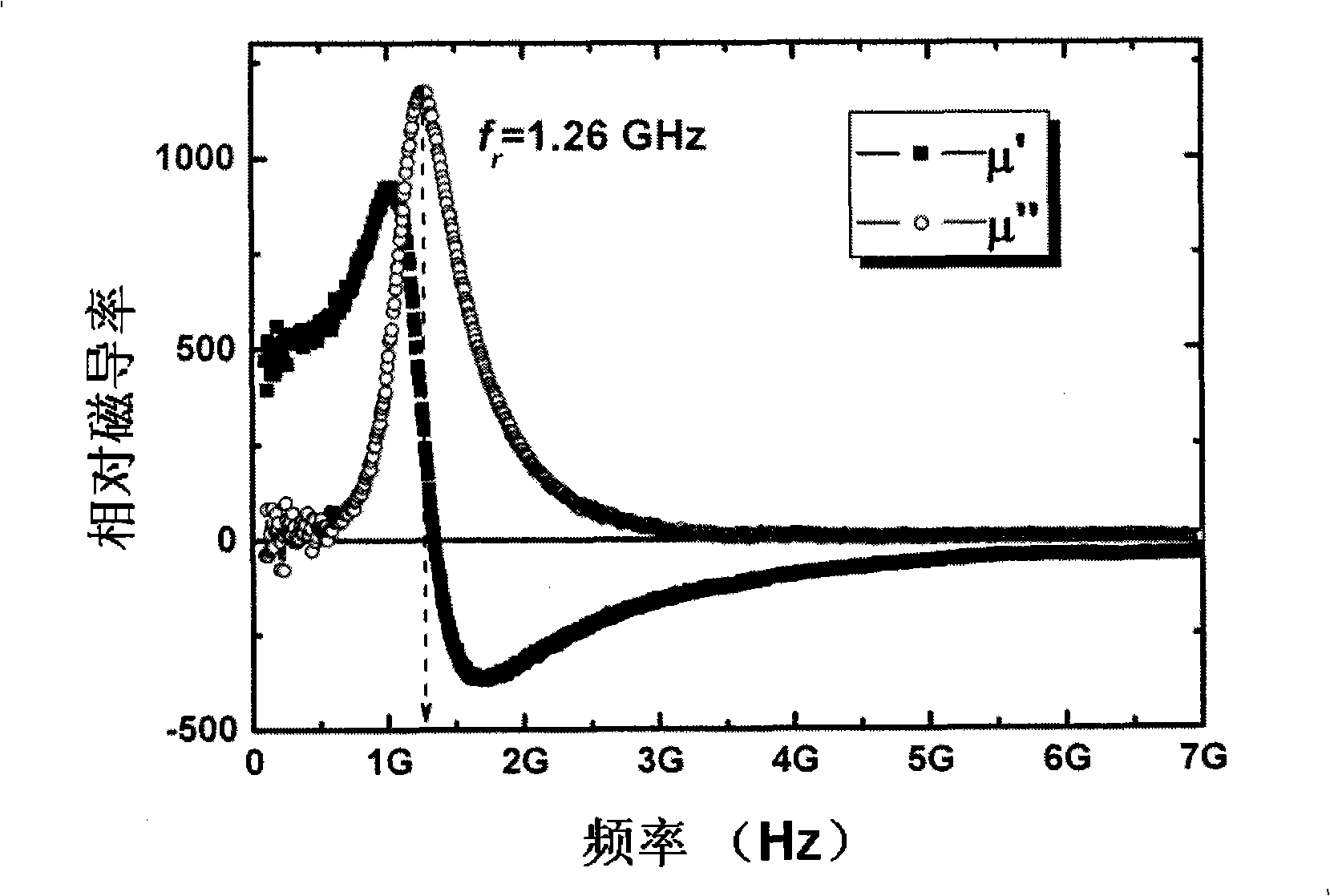

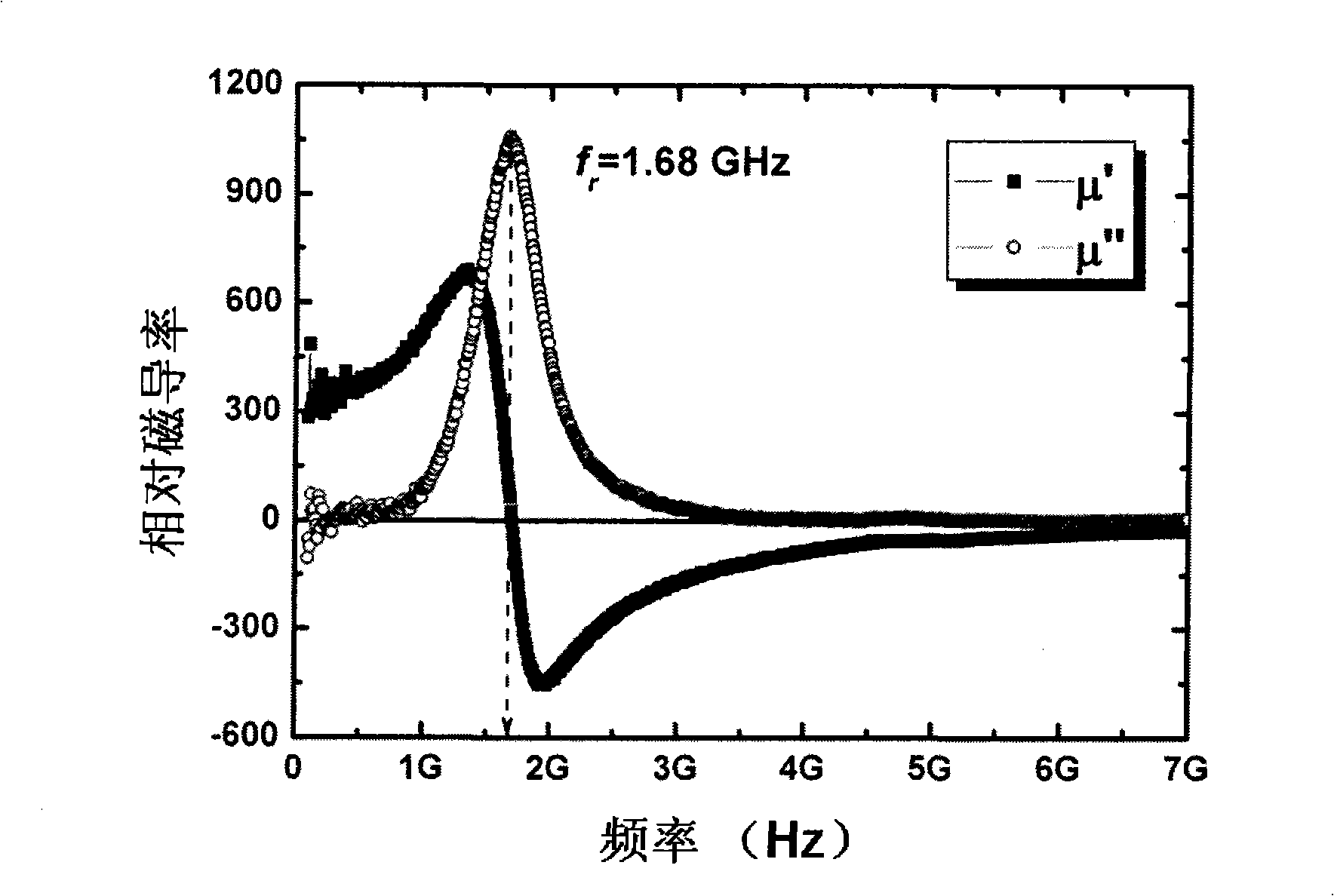

Method and device for preparing high-frequency soft magnetic thin film

InactiveCN101260514AGood high frequency characteristicsSimple methodVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringRadio frequency sputtering

The invention discloses a method and a device for in-place preparing an adjustable soft magnetic film with high-frequency property. The method adopts a radio frequency magnetron sputtering method of the prior art; a small quantity of nonmagnetic metal material is also sputtered on a substrate when magnetic metal material is sputtered. The atom percentage of nonmagnetic metal and magnetic metal sputtered on the substrate is between 3 and 20. The device is the same with the prior radio frequency sputtering device except for a sputtering target; the sputtering target material is a composite target.

Owner:LANZHOU UNIVERSITY

Method for preparing antibacterial silver-plating leather

InactiveCN101608246AImprove thermal conductivityHas broad-spectrum antibacterial propertiesSpecial leather manufactureLeather surface finishingAlloyRadio frequency sputtering

The invention discloses a method for preparing antibacterial silver-plating leather. The method is characterized in that the adopted sputtering method is magnetron sputtering and / or radio-frequency sputtering method and comprises the following steps of: removing spots on the surface of a leather material; and then putting the leather material as a substrate into a sputtering room, taking metal silver or silver alloy material as a sputtering target material, carrying out sputtering coating by adjusting technique parameters such as the temperature of the substrate and the temperature of the silver target material in the sputtering technique, and obtaining the antibacterial silver-plating leather. The method for preparing antibacterial silver-plating leather has no pollution, does not changethe performance of the raw leather materials and has high antibacterial efficiency.

Owner:XI'AN POLYTECHNIC UNIVERSITY

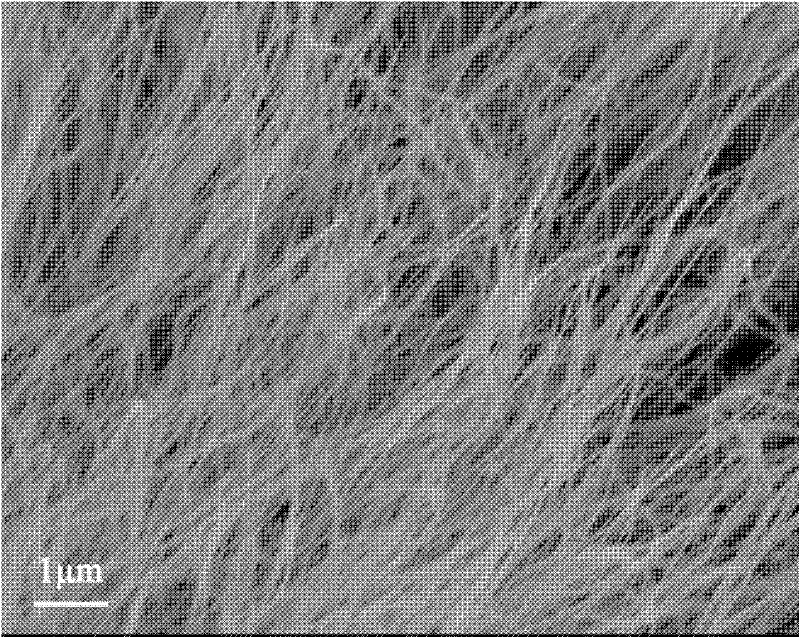

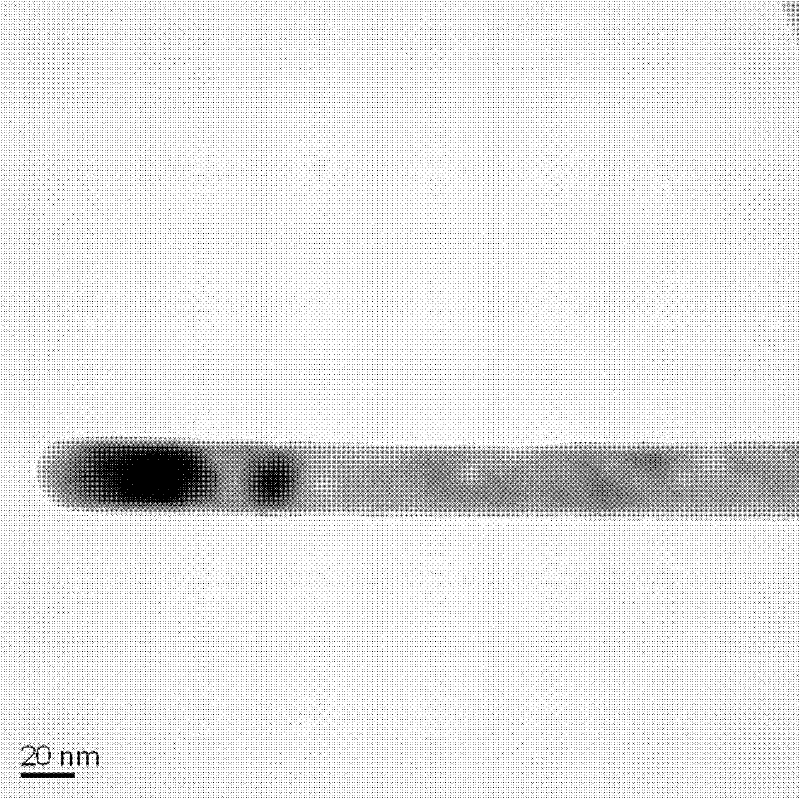

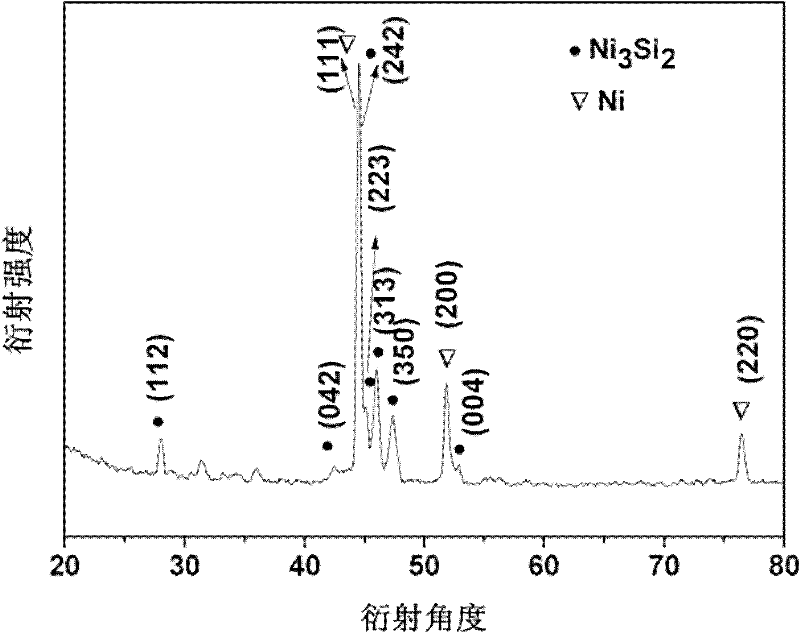

Preparation methods for arrayed nickel silicon nanowire and nickel silicon-silicon core-shell nanowire

ActiveCN102263243AAchieve high density growthControllable ratioCell electrodesNanotechnologyNanowireRadio frequency sputtering

The invention discloses preparation methods for an arrayed nickel silicon nanowire and a nickel silicon-silicon core-shell nanowire. The preparation method for the nickel silicon-silicon core-shell nanowire comprises the following steps of: washing a metal substrate for a lithium ion battery anode basal body by using a hydrochloric acid and ethanol, and drying the washed metal substrate for lateruse; growing the arrayed nickel silicon nanowire on the surface of the washed metal substrate by using a hot wire chemical vapor deposition device; and further depositing a layer of thickness-controllable silicon on the surface of the obtained arrayed nickel silicon nanowire by using a radio frequency sputtering method to obtain the arrayed nickel silicon-silicon core-shell nanowire. The metal substrate and the arrayed nickel silicon nanowire grown on the metal substrate form a lithium ion battery anode. The preparation methods provided by the invention are simple and controllable; and the prepared nanowire materials can be used for the lithium ion battery anode and high performance can be obtained.

Owner:ZHEJIANG UNIV

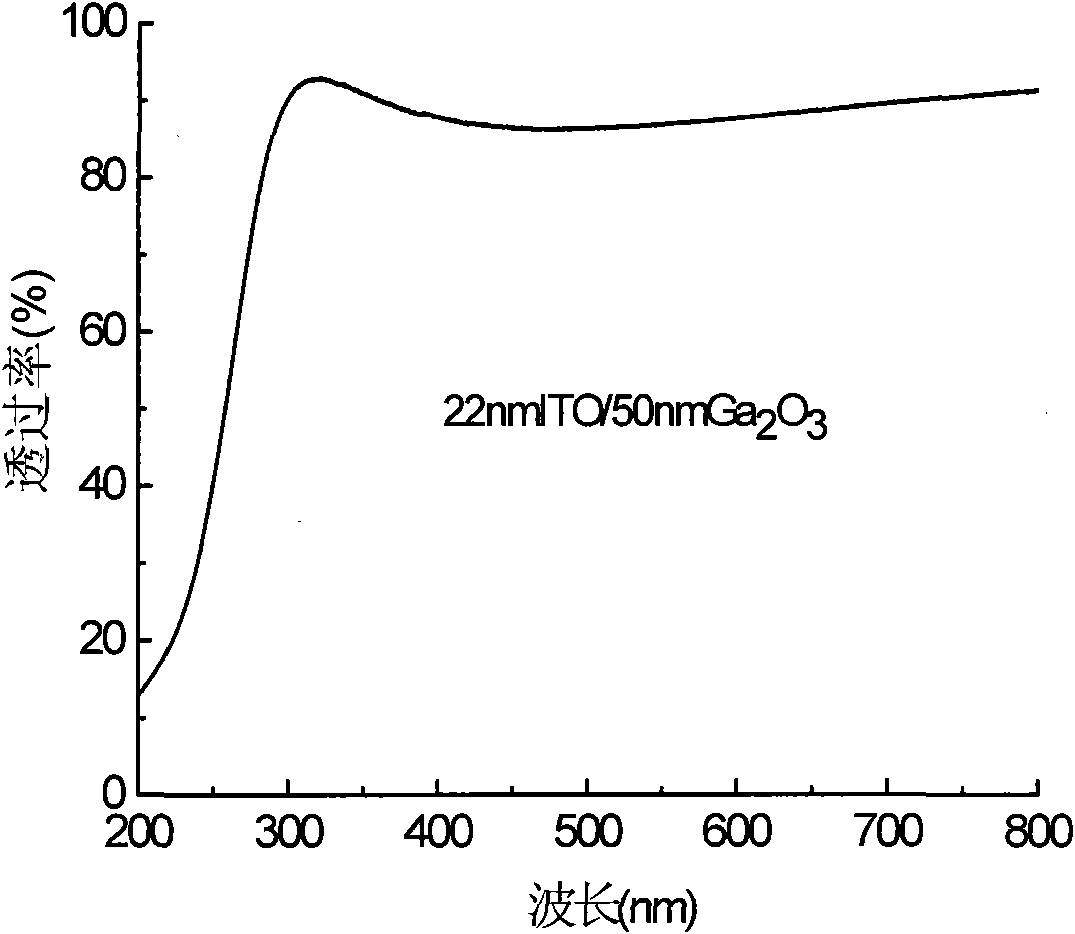

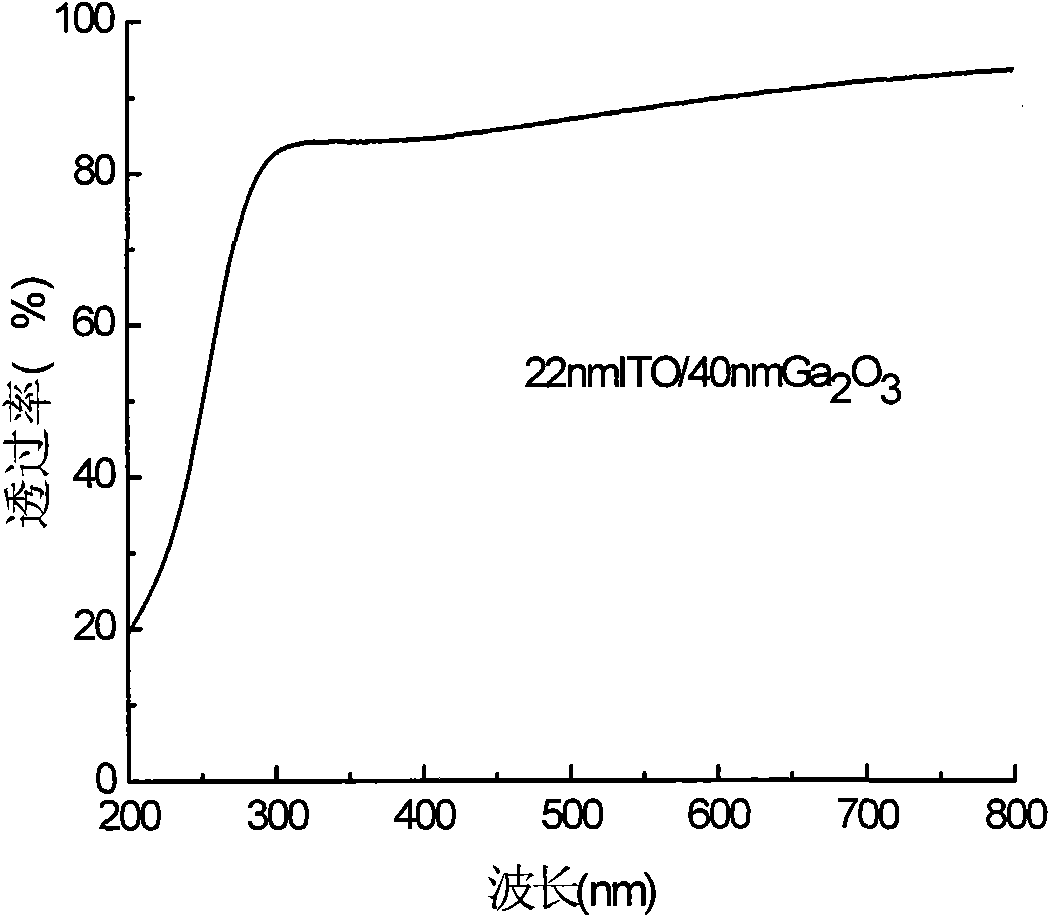

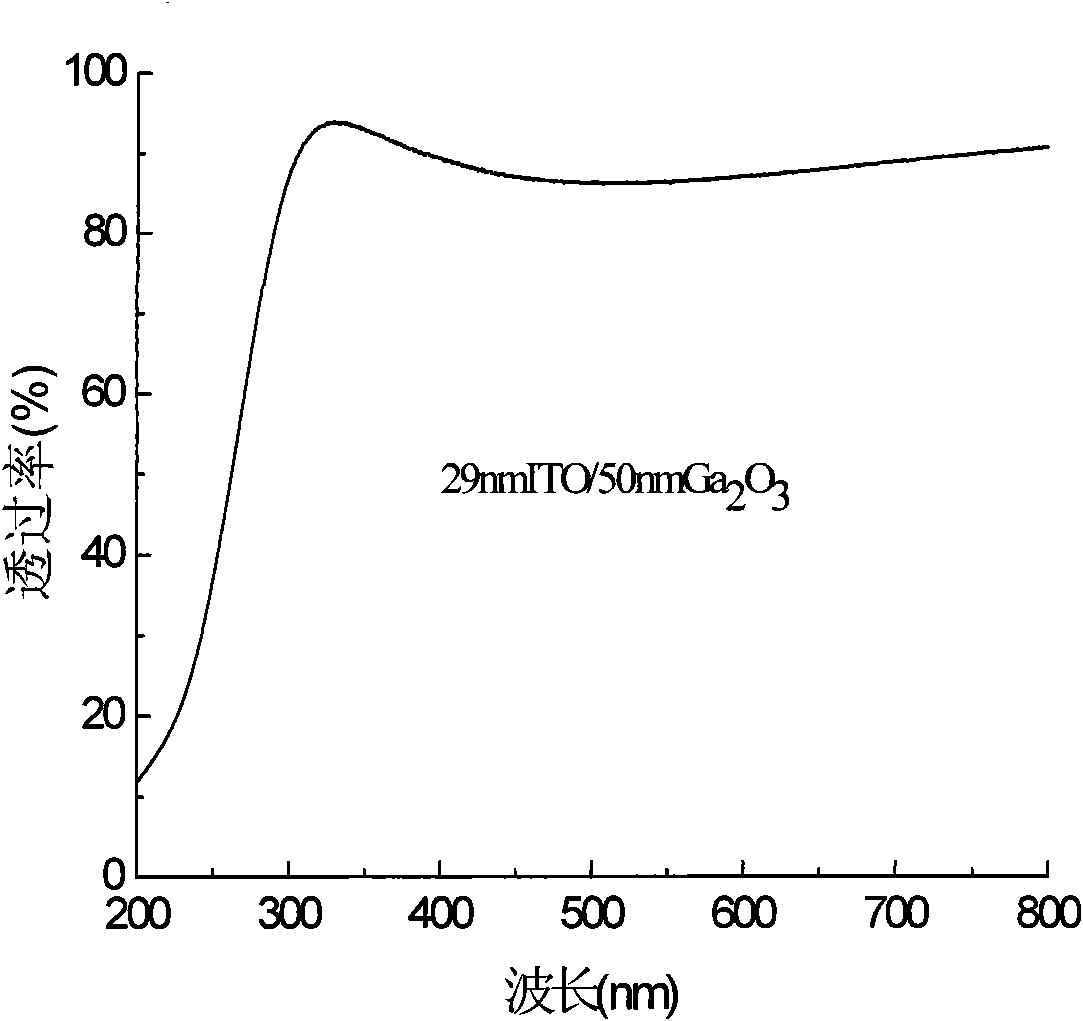

Double-layer structure deep-ultraviolet transparent conductive film and preparation method thereof

InactiveCN101841003AWith deep ultraviolet transparent optical propertiesImprove conductivitySolid-state devicesVacuum evaporation coatingIndiumRadio frequency magnetron sputtering

The invention relates to a tin-doped indium oxide (ITO) / gallium oxide (Ga2O3) double-layer structure deep-ultraviolet transparent conductive film and a preparation method thereof, and belongs to the technical field of electronic materials. The preparation method comprises the following steps: ultraviolet optical quartz glass is used as the substrate, and radio-frequency magnetron sputtering is carried out on the Ga2O3 ceramic target to prepare a Ga2O3 layer the thickness of which is 30-60 nm; and direct-current magnetron sputtering is carried out on an ITO target to prepare an ITO layer the thickness of which is 15-29 nm. The pressure intensity of argon gas for sputtering is 0.2-2 Pa, the power for radio-frequency sputtering is 50-100 W, the substrate temperature is 200-300 DEG C, the current for direct-current sputtering is 80-150 mA, and the voltage for direct-current sputtering is 200-400 V. The prepared film has the advantages of low resistivity, high transmittivity within the range of visible light, ultraviolet light and deep-ultraviolet light, and other favorable photoelectric properties. The film otained by the method of the invention has wide application prospects in the fields of ultraviolet photoelectric devices and the like.

Owner:LUDONG UNIVERSITY

Method of manufacturing metal doping ZnO film

InactiveCN101403099ADetermine the doping amountGood opticsVacuum evaporation coatingSputtering coatingSemiconductor materialsAdulterant

The invention relates to the field of semiconductor materials, in particular to a method for preparing a metal film doped with ZnO. The method is characterized by comprising the following steps: a substrate is arranged in a magnetron sputtering room after being cleaned and a reaction room thereof is pumped to vacuum with high cleanliness; high-purity metal strips are taken as adulterants and high-purity Zn are taken as materials, and metal strips are fixed on a Zn target according to a plurality of proportions; pure Ar gas and pure oxygen are taken as sputtering gas and reaction gas to be input into the vacuum reaction sputtering room by the control of a flowmeter for sputtering growth; and annealing treatment is carried out in vacuum environment after growth. The invention has the following beneficial effects: the control of metal doping content is realized, and the effect of oxidation on the metal target during the reaction sputtering is effectively reduced by the pattern of radio frequency sputtering during the reaction, thus leading the sputtering to keep continuous and stable; and finally, by being combined with the corresponding vacuum annealing technology, the optical and electrical properties of the MZO film are optimized. The preparation method simplifies technical processes, reduces the whole development procedure, shortens the period and saves the cost.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method for inorganic / organic multilayer composite separator

InactiveCN103066228AEffective control of thicknessGood electrophilic performanceVacuum evaporation coatingSputtering coatingOrganic solventPhysical chemistry

The invention discloses a preparation method for an inorganic / organic multilayer composite separator. The method comprises: soaking a separator in an organic solvent, cleaning surface of the separator by using ultrasonic vibration for 15 ~ 30min, drying in an oven, and then cutting the separator into a square separator; placing the above square separator and a target material into a RF (radio frequency) sputtering device; adjusting the air pressure of the RF sputtering device to be 0.1 ~ 1.0Pa, and then feeding in reactant gas, the sputtering power being 5 ~ 80W and the sputtering time being 5 ~ 100min; running the device, so target material plasma bombards gas molecules to form inorganic matter / organic matter which deposit on both sides of the separator to obtain an inorganic / organic multilayer composite separator. By uniformly sputtering one layer or a plurality of layers of inorganic matter / organic matter on the porous separator surface, the dimensional stability of ordinary separators is effectively improved, and the heat resistance of the separator is improved.

Owner:GUANGDONG UNIV OF TECH

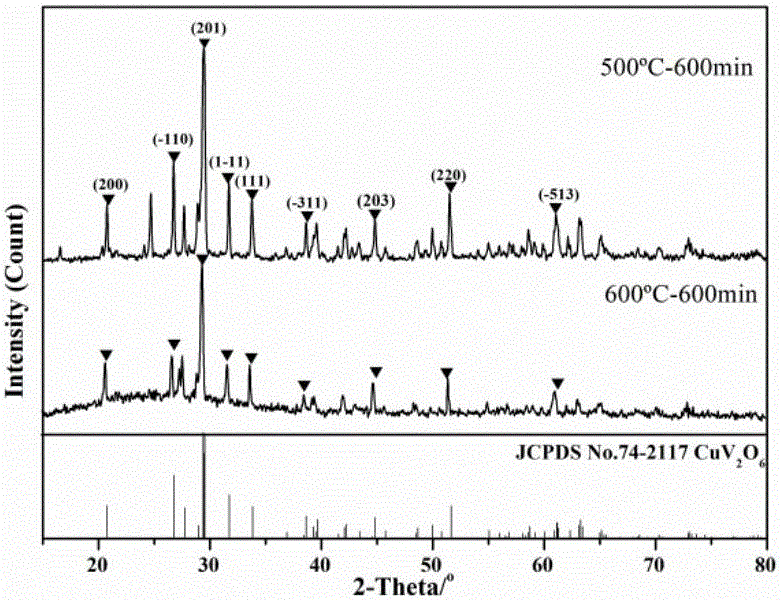

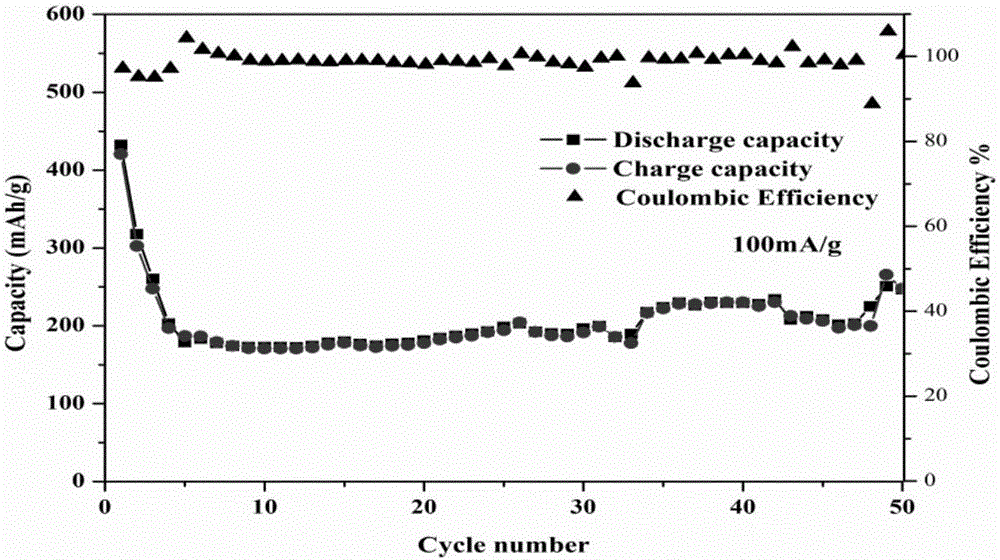

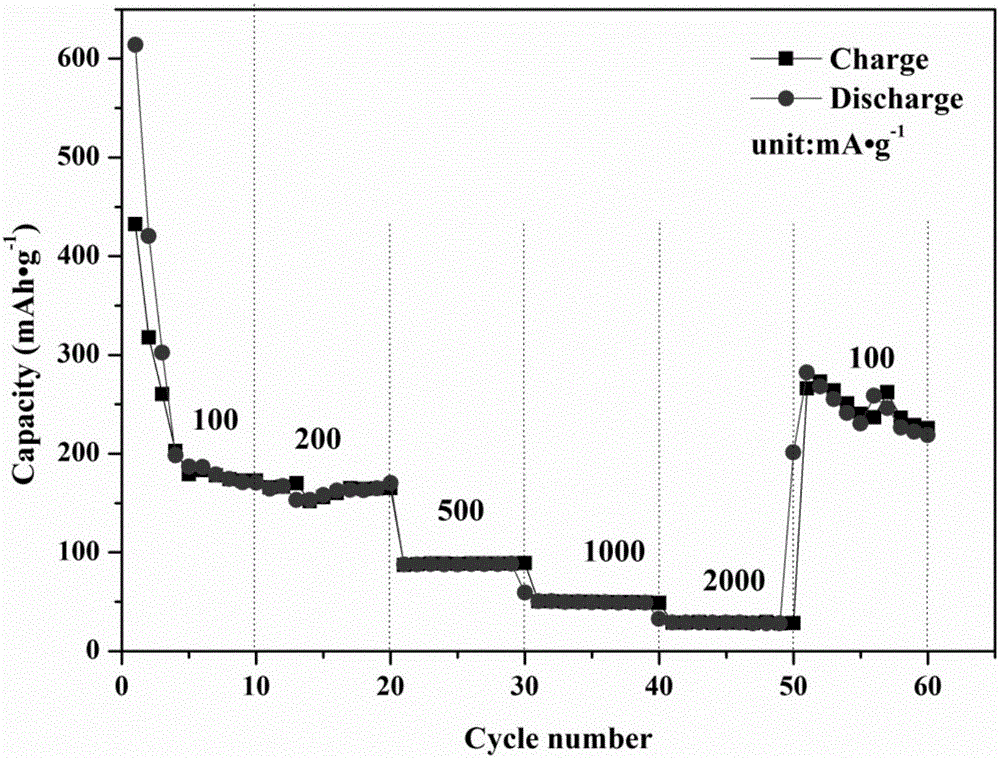

Preparation method of CuxVyOz coating for positive electrode of lithium ion battery

ActiveCN105789603AEnhance and improve performanceConditions are easy to controlSecondary cellsVanadium compoundsRadio frequency magnetron sputteringRadio frequency

A preparation method of a CuxVyOz coating for a positive electrode of a lithium ion battery comprises the following steps of placing a CuO-acetylene black target material and a V2O5 target material in two radio frequency target positions; fixing a single light aluminum foil on a film coating sample table; vacuumizing a film coating chamber and a sample chamber of a magnetron sputtering device; introducing Ar gas into the film coating chamber; setting a heating temperature of the aluminum foil to be 350-600 DEG C and the radio frequency sputtering power to be 50-400W; and starting to carry film coating on the aluminum foil, so that the mole ratio of Cu atom to V atom which are sputtered is 1:1, and the sputtering time is 10-100 minutes. A CuxVyOz thin film is synthesized on the aluminum foil at one step by radio frequency magnetron sputtering, and the prepared sample can be directly applied to the positive electrode of the lithium ion battery after stamped and cut. The method is high in reaction efficiency and high in film formation, the prepared coating is uniform in constituents, high in adhesive force and high in durability and stability, and the performance of the lithium battery is favorably enhanced and improved.

Owner:SHAANXI UNIV OF SCI & TECH

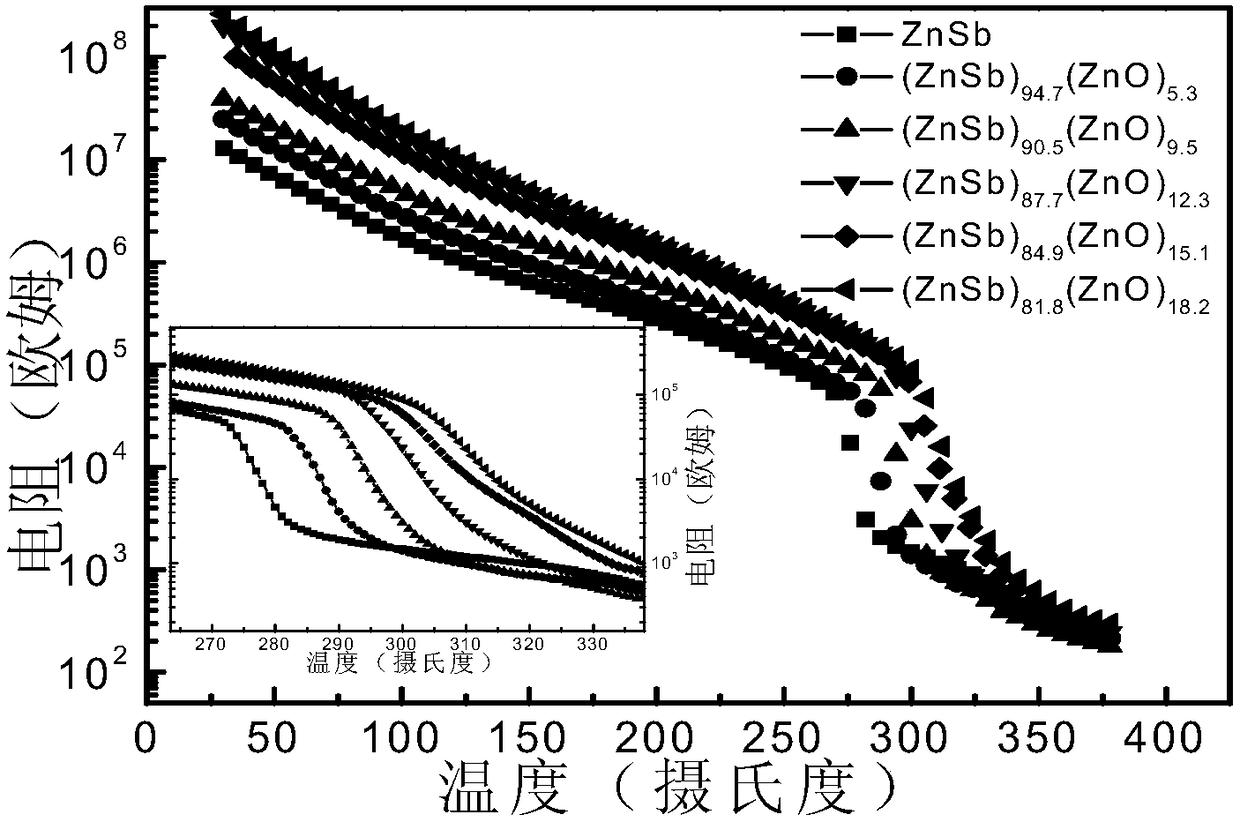

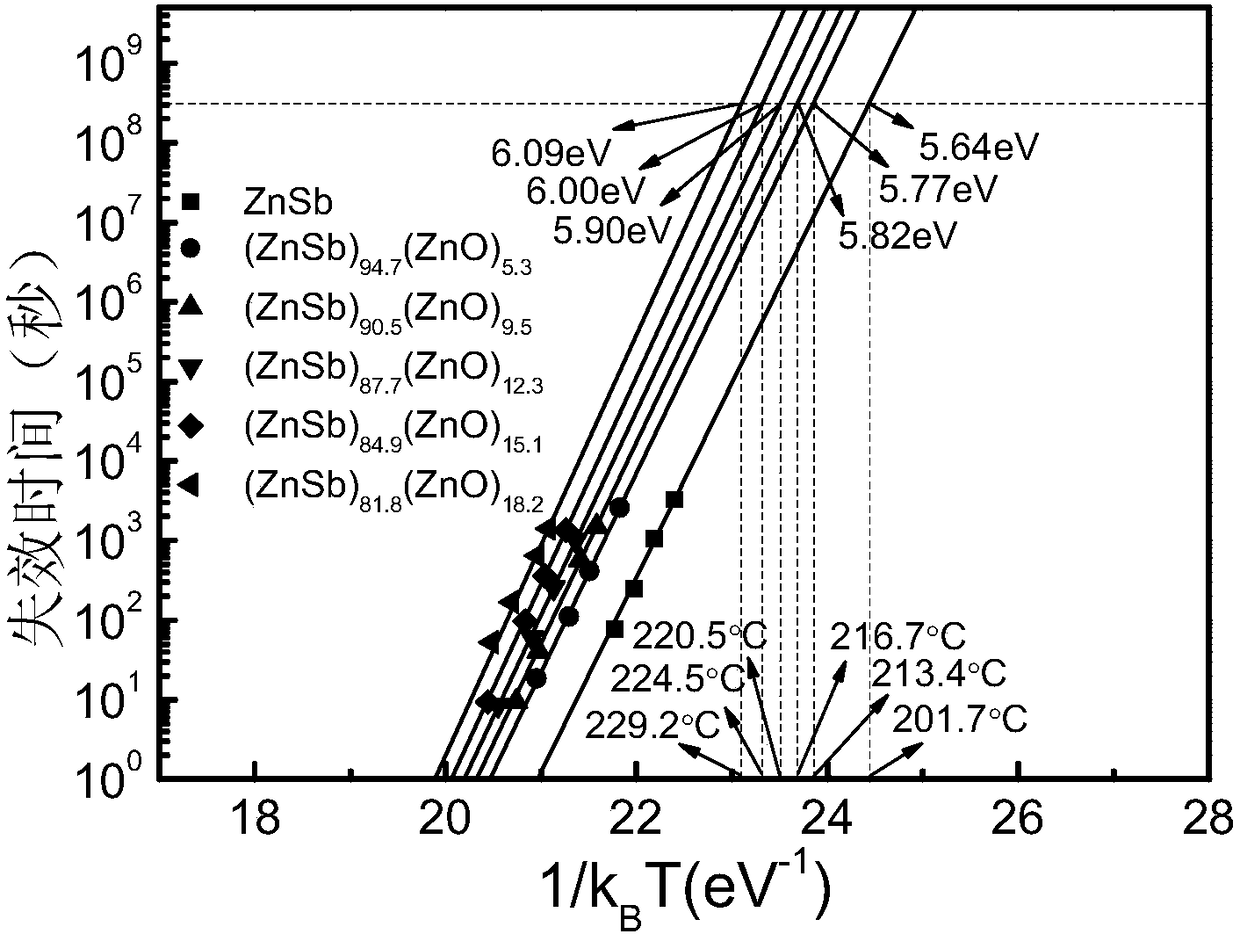

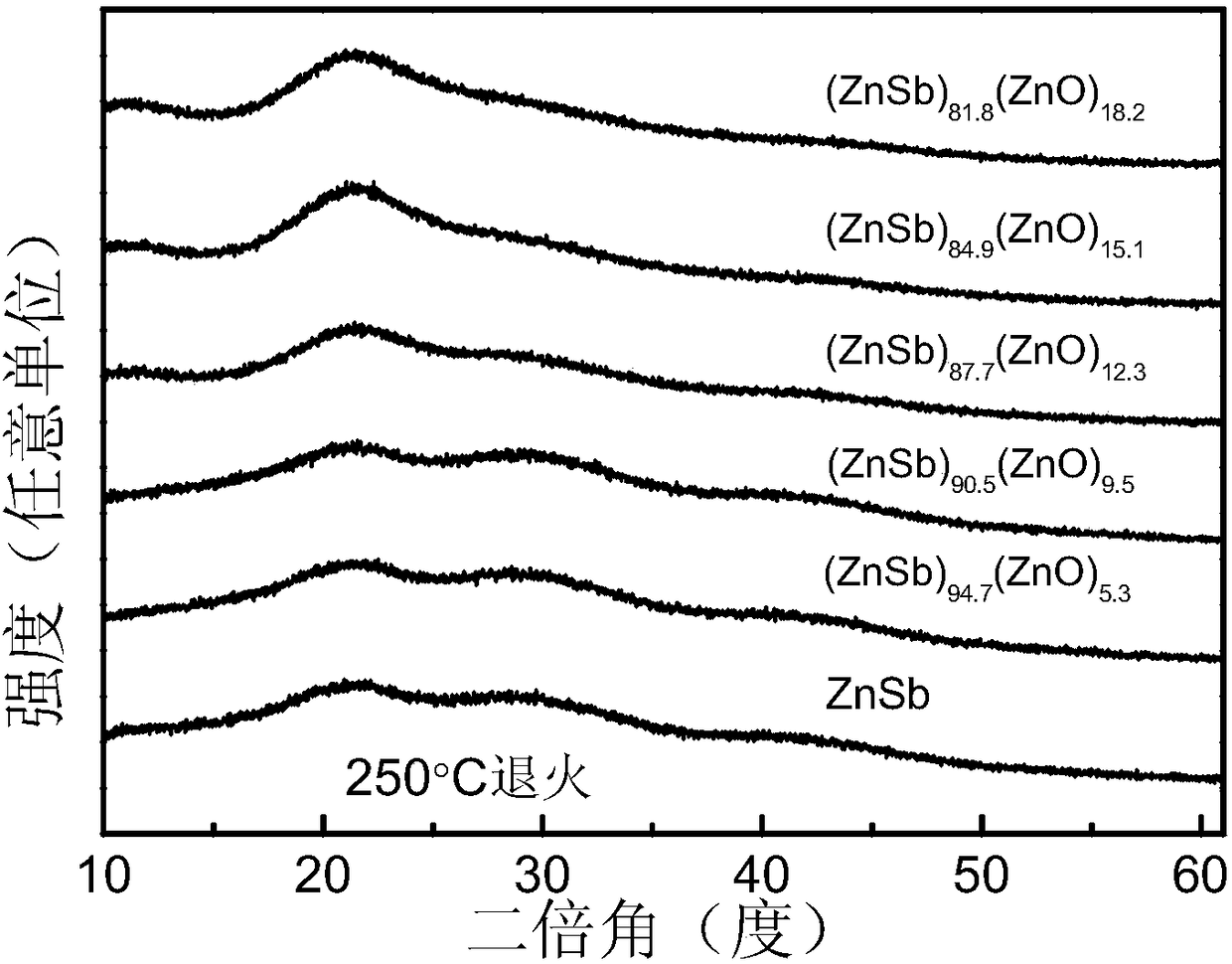

Nano-composite ZnO-ZnSb phase-change storage thin film material and preparation method thereof

ActiveCN108075039ARaise the crystallization temperatureLarge amorphous/crystalline resistance ratioElectrical apparatusCoating systemAlloy

The invention discloses a nano-composite ZnO-ZnSb phase-change storage thin film material and a preparation method thereof. The nano-composite ZnO-ZnSb phase-change storage thin film material is characterized in that the chemical structural formula of the material is (ZnSb)100-x(ZnO)x, 0<x<20. The preparation method of the material comprises the following steps: mounting a ZnO ceramic target material on a magnetron DC sputtering target; mounting a ZnSb alloy target material on a magnetron radio frequency sputtering target; vacuumizing a sputtering chamber of a magnetron sputtering coating system; then, inputting a high-purity argon gas into the sputtering chamber until the pressure of the sputtering chamber reaches luminance build-up pressure 0.30 Pa; then, fixing sputtering power of a ZnSb radio frequency target to be 35W, and adjusting and controlling the sputtering power of a ZnO DC target to be 3-21W; and carrying out dual target co-sputtering coating under the room temperature, and after sputtering thickness reaching 180 nm, obtaining a phase-change storage thin film material. The nano-composite ZnO-ZnSb phase-change storage thin film material has the advantages of high crystallization temperature, fast crystallization rate, high amorphous state / crystalline resistance ratio and being capable of realizing direct crystal phase transfer from an amorphous state to a stable state.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com