Method of manufacturing metal doping ZnO film

A metal doping and thin film technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of complex preparation process of MZO thin film, not easy to control and adjust, and many research and development processes, etc. The effect of the overall R&D process, the continuous stability of sputtering, and the optimization of optical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one: prepare Al metal doped ZnO film, its step is:

[0029] (1) Substrate cleaning: take the glass substrate, clean it and put it on the sample holder of the radio frequency magnetron sputtering chamber, place the substrate to be deposited facing down, effectively avoiding contamination of the substrate by impurities.

[0030] (2) Extraction of high vacuum: the vacuum degree of the sputtering chamber is evacuated to 2×10 -4 Pa for high cleanliness vacuum.

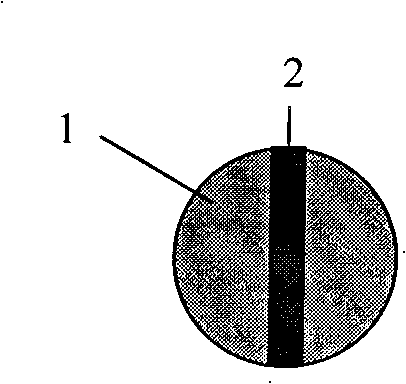

[0031] (3) Adjusting the metal and its doping amount: take two Al metal strips and fix them on the Zn target, and the fixing method of the metal strips is symmetrical and radial at the center of the circle. The area ratio of the used metal strips to the Zn target can be measured and calculated. Combined with the different sputtering yields under the same conditions, the doping amount of metal in the ZnO film can be determined, and the metal doping amount of the metal-doped ZnO film can be determined. Imp...

Embodiment 2

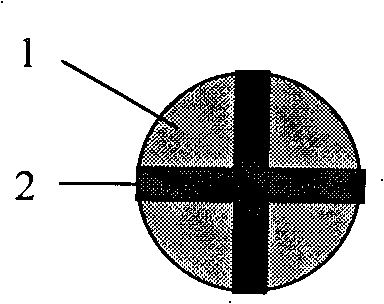

[0035] Embodiment two: (1), (2), (4) (5) (6) remain unchanged in the whole film preparation process of embodiment one, only change (3) adjust the number of Al metal strips, get 4 pieces of Al The metal strip is fixed on the Zn target in a symmetrical radial manner. In this way, thin films with different metal doping levels can be obtained.

Embodiment 3

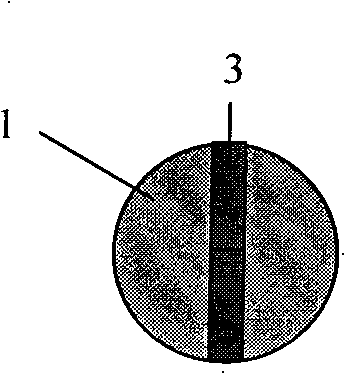

[0036] Embodiment three: (1), (2), (4) (5) (6) remain unchanged in the whole thin film preparation process of example one, only change (3) change metal strip, get 2 Ag metal strips and fix On the Zn target, the fixing method is symmetrical and radial. In this way, Ag metal-doped ZnO films can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com