A touch control display panel

A touch display panel, touch position technology, applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc. Thin, good optical effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

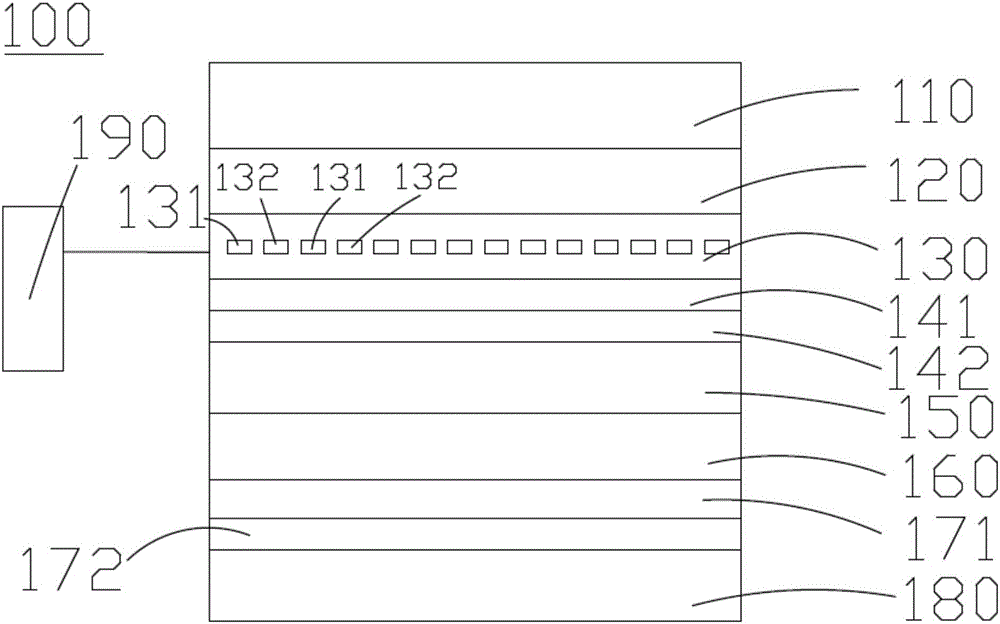

[0033] figure 1 It is a schematic diagram of an embodiment of the touch display panel of the present invention, figure 2 It is a timing diagram of an embodiment of the touch display panel of the present invention, please refer to figure 1 The touch display panel 100 includes a first electrode layer 130, a common electrode layer 160, and a control circuit 190. The first electrode layer 130 includes a plurality of first sensing electrodes 131 and a plurality of second sensing electrodes 132. The control circuit 190 is coupled to connected to the first electrode layer 130.

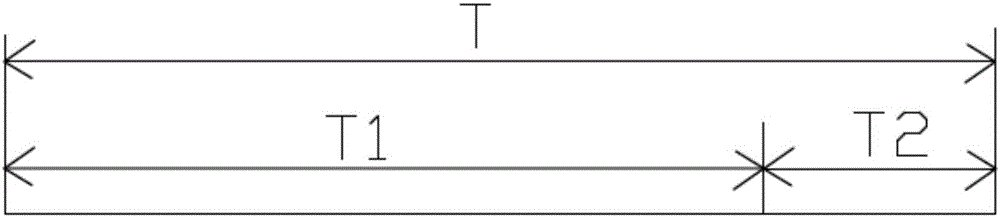

[0034] Refer again figure 2 , this embodiment is divided into the first period T1 and the second period T2 to drive the touch display panel 100 differently. In the first period T1, the control circuit 190 detects the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com