Epitaxy growing method for La1-xCaxMnO3 single crystal thin film

A single crystal thin film, epitaxial growth technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of unfavorable application, poor film uniformity, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

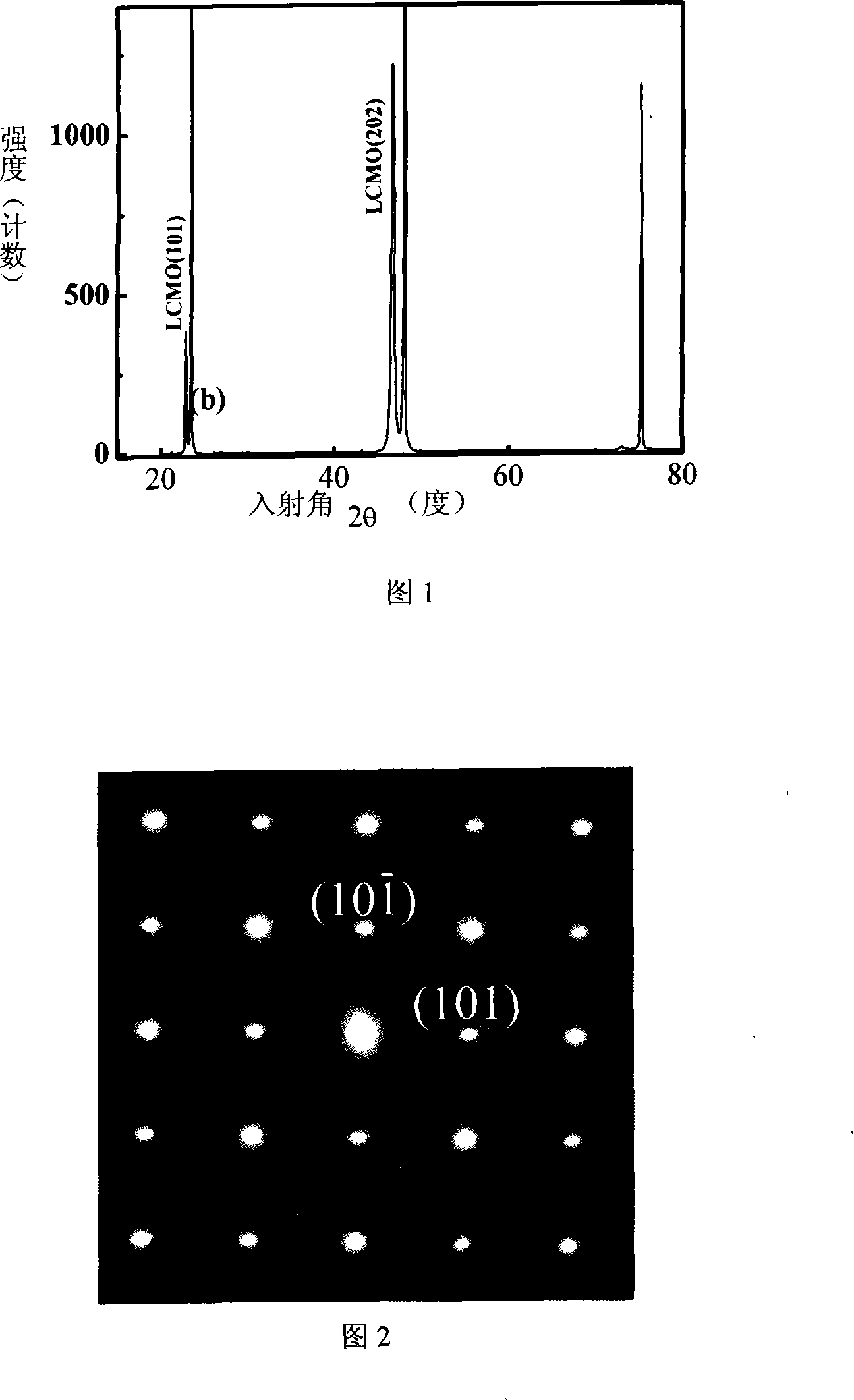

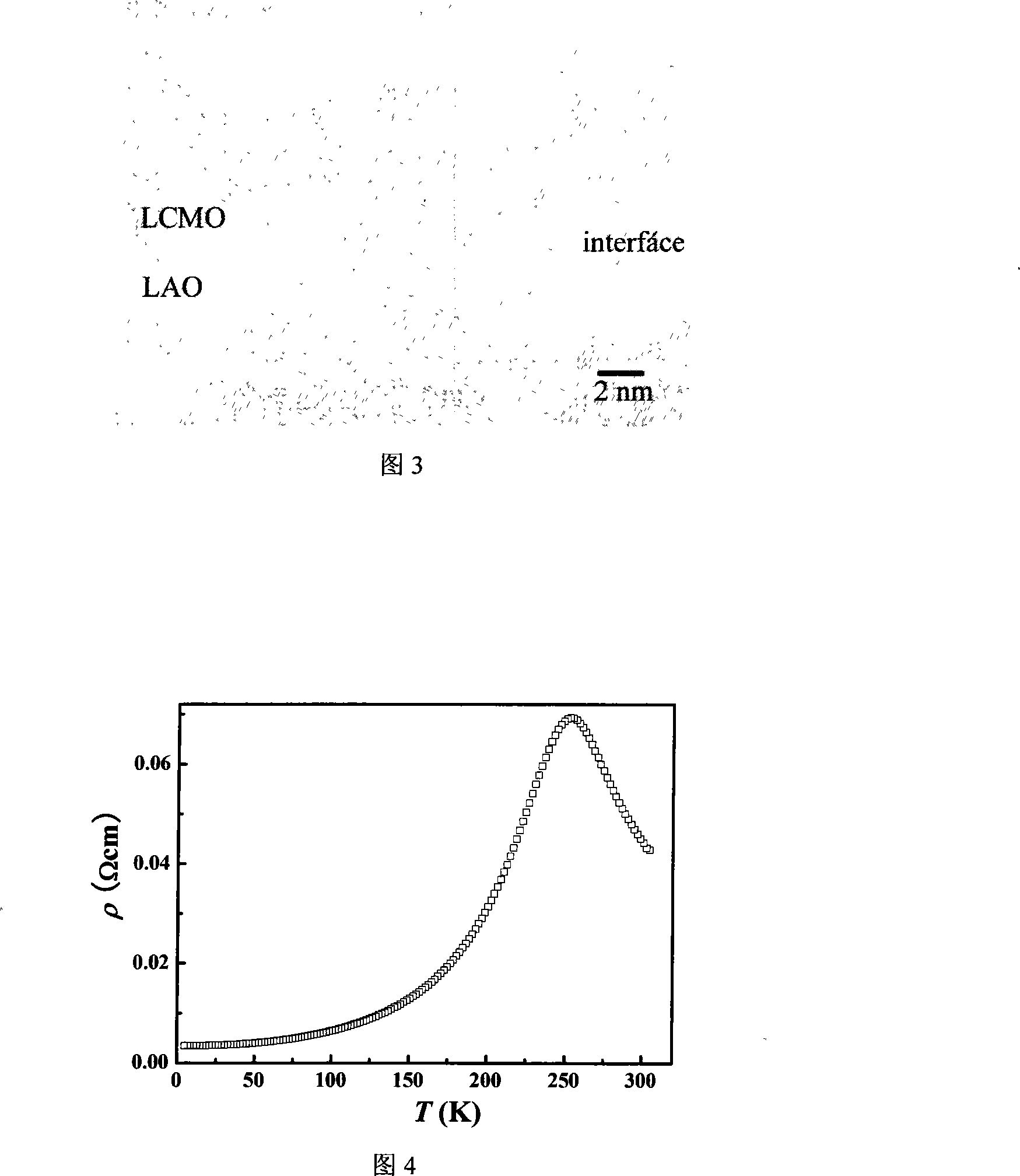

[0022] Example 1: LaAlO polished on the (100) crystal plane 3 Epitaxial growth of La on the substrate 0.67 Ca 0.33 MnO 3 single crystal film.

[0023] 1. The cleaned (100) crystal plane polished LaAlO 3 The substrate (produced by Beijing Wuke Photoelectric Technology Co., Ltd.) is placed on the sample holder of the vacuum chamber of the DPS-III ultra-high vacuum target magnetron sputtering coating machine of the Shenyang Science and Technology Center of the Chinese Academy of Sciences, and the vacuum chamber is closed;

[0024] 2. The vacuum degree at the back is 2.0×10 -5 At Pa, start heating the substrate, and finally maintain the substrate temperature at 800°C;

[0025] 3. Set the opening degree of the ultra-high vacuum gate valve to 25%, and pass high-purity Ar gas and high-purity O to the vacuum chamber 2 Gas, Ar and O 2 The volume ratio is 4:1, adjust the flowmeter to keep the vacuum chamber pressure at 0.5Pa;

[0026] 4. Close the substrate baffle and adjust the...

Embodiment 2

[0032] Example 2: LaAlO polished on (100) crystal plane 3 Epitaxial growth of La on the substrate 0.8 Ca 0.2 MnO 3 single crystal film.

[0033] 1. The cleaned (100) surface polished LaAlO 3 The substrate (produced by Beijing Wuke Photoelectric Technology Co., Ltd.) is placed on the sample holder of the vacuum chamber of the DPS-III ultra-high vacuum target magnetron sputtering coating machine of the Shenyang Science and Technology Center of the Chinese Academy of Sciences, and the vacuum chamber is closed;

[0034] 2. The vacuum degree at the back is 1.0×10 -5 At Pa, start to heat the substrate, and finally the substrate temperature is kept at 750°C;

[0035] 3. Set the opening degree of the ultra-high vacuum gate valve to 20%, and pass high-purity Ar gas and high-purity O to the vacuum chamber 2 Gas, Ar and O 2 The volume ratio is 7:3, adjust the flowmeter to keep the vacuum chamber pressure at 0.4Pa;

[0036] 4. Close the substrate baffle and adjust the radio freque...

Embodiment 3

[0042] Example 3: SrTiO polished on the (100) crystal plane 3 Epitaxial growth of La on the substrate 0.52 Ca 0.48 MnO 3 single crystal film.

[0043] 1. The cleaned (100) surface polished SrTiO 3 The substrate (produced by Hefei Kejing Material Technology Co., Ltd.) is placed on the sample holder of the vacuum chamber of the DPS-III ultra-high vacuum target magnetron sputtering coating machine of the Shenyang Keyi Center of the Chinese Academy of Sciences, and the vacuum chamber is closed;

[0044] 2. The vacuum degree at the back is 1.5×10 -5 At Pa, start heating the substrate, and finally maintain the substrate temperature at 700°C;

[0045] 3. Set the opening degree of the ultra-high vacuum gate valve to 15%, and pass high-purity Ar gas and high-purity O gas into the vacuum chamber 2 Gas, Ar and O 2 The volume ratio is 9:1, adjust the flowmeter to keep the vacuum chamber pressure at 0.3Pa;

[0046] 4. Close the substrate baffle and adjust the radio frequency power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com