Preparation method for ultrathin up-right graphene field emission cathode rich in wrinkle on surface

A technology that emits cathodes and graphene, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as increasing graphene surface, reducing turn-on and threshold fields, and large gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of silicon substrate:

[0034] First cut the silicon wafer into small pieces of 2cm×2cm, ultrasonically clean it in acetone, absolute ethanol, and deionized water for about 10 minutes, and the ultrasonic power is 50W, and then immerse the silicon wafer in hydrofluoric acid with a volume ratio of 4% for 5 minutes. In minutes, a silicon wafer substrate that is clean, pollution-free and free of surface oxide is obtained.

[0035] (2) Growing upright graphene:

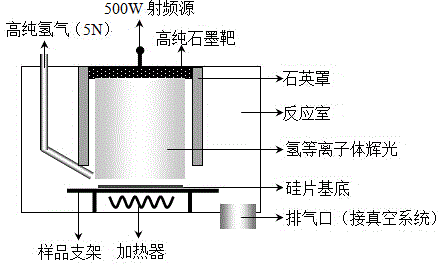

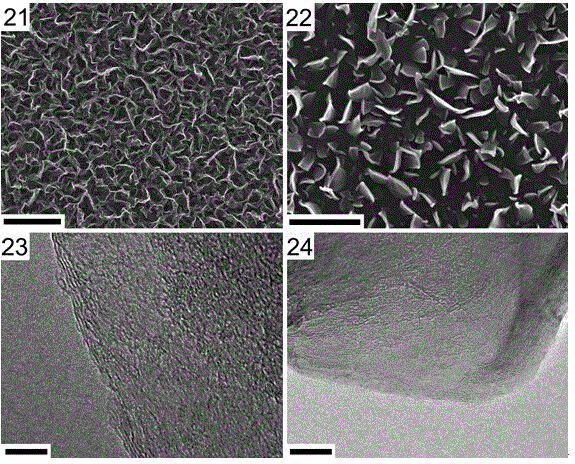

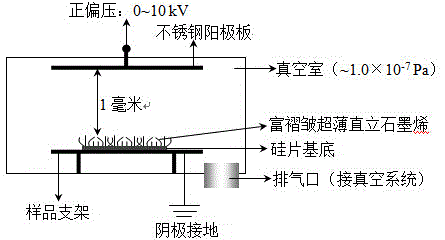

[0036] The growth of vertical graphene is completed in a radio frequency sputtering device, and the schematic diagram of the device is shown in figure 1 shown. Place the prepared silicon substrate on the sample stage in the reaction chamber, and evacuate the reaction chamber to about 8 × 10 -4 Pa; then pass high-purity hydrogen (5N) into the reaction chamber, adjust the pressure of the reaction chamber to 300Pa; heat the substrate to 1100K at a speed of about 60K / min; after the temperature and pre...

Embodiment 2

[0042] (1) Preparation of silicon substrate:

[0043] First cut the silicon wafer into small pieces of 2cm×2cm, ultrasonically clean it in acetone, absolute ethanol, and deionized water for about 10 minutes, and the ultrasonic power is 50W, and then immerse the silicon wafer in hydrofluoric acid with a volume ratio of 4% for 5 minutes. In minutes, a silicon wafer substrate that is clean, pollution-free and free of surface oxide is obtained.

[0044] (2) Growing upright graphene:

[0045] The growth of vertical graphene is completed in a radio frequency sputtering device, and the schematic diagram of the device is shown in figure 1 shown. Place the prepared silicon substrate on the sample stage in the reaction chamber, and evacuate the reaction chamber to about 8 × 10 -4 Pa; then pass high-purity hydrogen (5N) into the reaction chamber, adjust the pressure of the reaction chamber to 280Pa; heat the substrate to 1100K at a speed of about 60K / min; after the temperature and pre...

Embodiment 3

[0051] (1) Preparation of silicon substrate:

[0052] First cut the silicon wafer into small pieces of 2cm×2cm, ultrasonically clean it in acetone, absolute ethanol, and deionized water for about 10 minutes, and the ultrasonic power is 50W, and then immerse the silicon wafer in hydrofluoric acid with a volume ratio of 4% for 5 minutes. In minutes, a silicon wafer substrate that is clean, pollution-free and free of surface oxide is obtained.

[0053] (2) Growing upright graphene:

[0054] The growth of vertical graphene is completed in a radio frequency sputtering device (commercially available), and the schematic diagram of the device is shown in figure 1 shown. Place the prepared silicon substrate on the sample stage in the reaction chamber, and evacuate the reaction chamber to about 8 × 10 -4 Pa; then pass high-purity hydrogen (5N) into the reaction chamber, adjust the pressure of the reaction chamber to 320Pa; heat the substrate to 1100K at a speed of about 60K / min; afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com