Patents

Literature

366 results about "Field electron emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

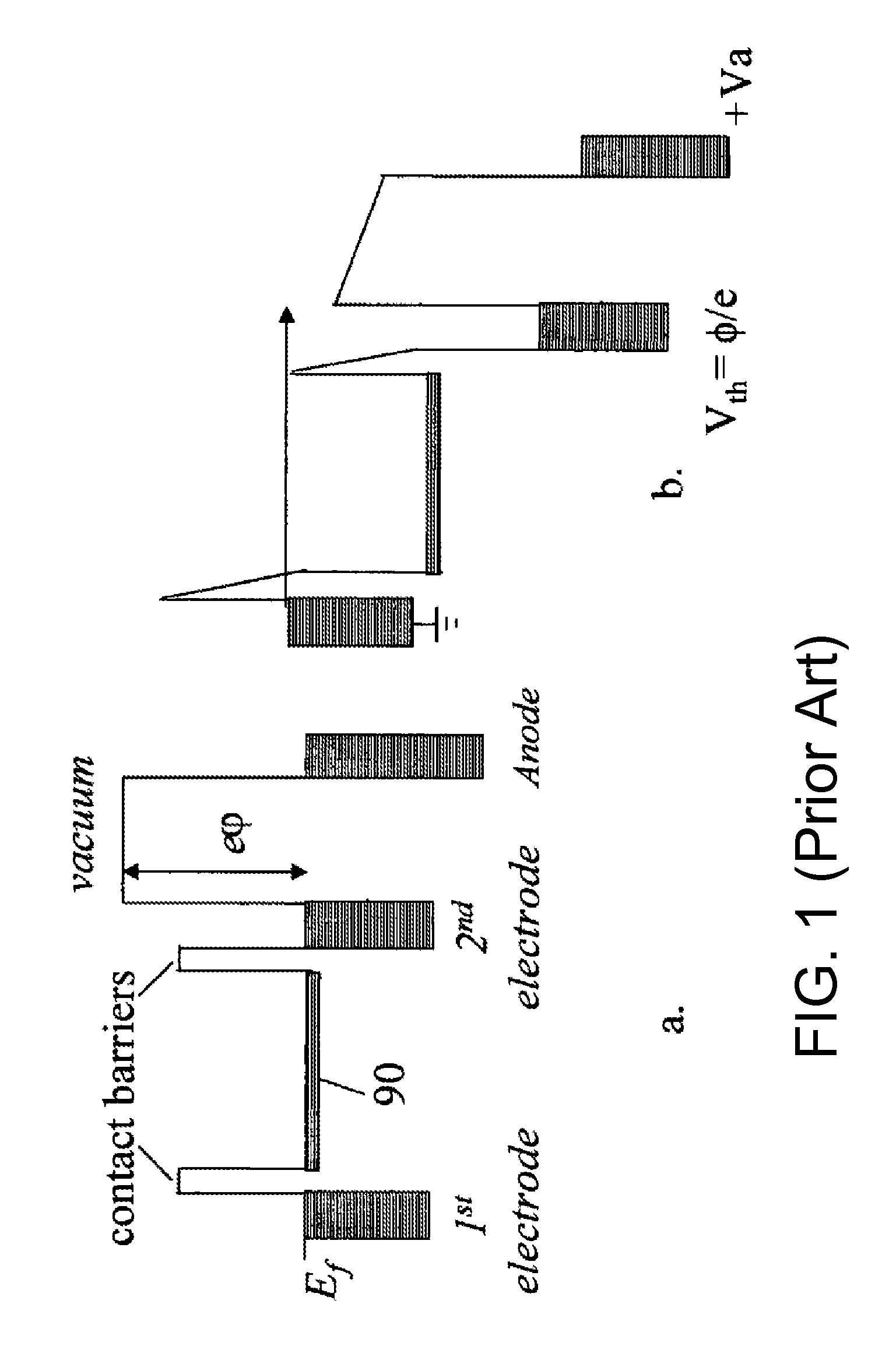

Field electron emission (also known as field emission (FE) and electron field emission) is emission of electrons induced by an electrostatic field. The most common context is field emission from a solid surface into vacuum. However, field emission can take place from solid or liquid surfaces, into vacuum, air, a fluid, or any non-conducting or weakly conducting dielectric. The field-induced promotion of electrons from the valence to conduction band of semiconductors (the Zener effect) can also be regarded as a form of field emission. The terminology is historical because related phenomena of surface photoeffect, thermionic emission (or Richardson–Dushman effect) and "cold electronic emission", i.e. the emission of electrons in strong static (or quasi-static) electric fields, were discovered and studied independently from the 1880s to 1930s. When field emission is used without qualifiers it typically means "cold emission".

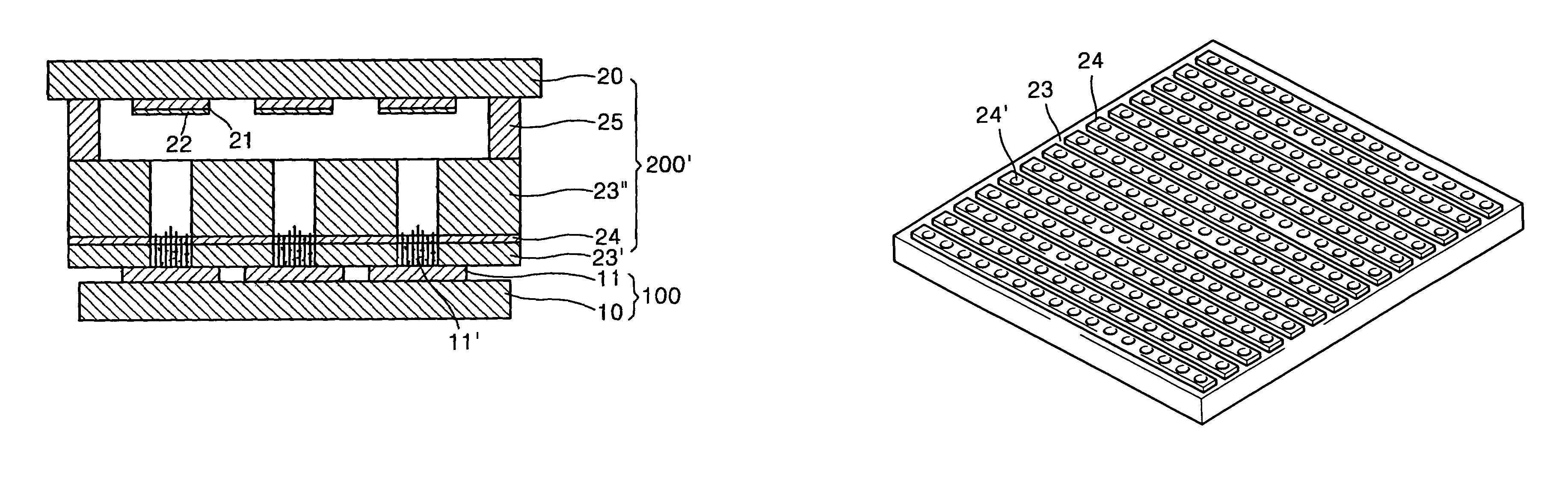

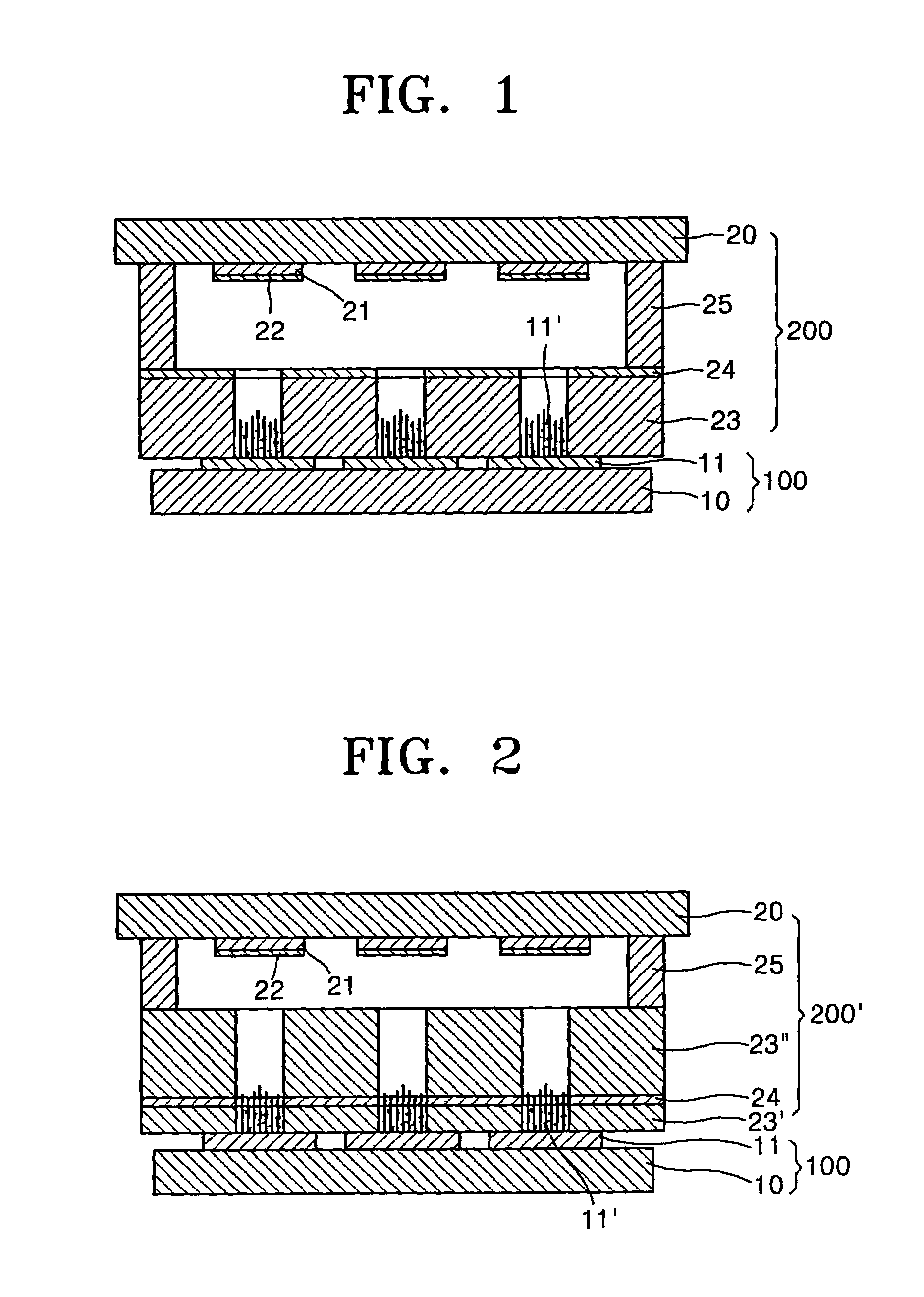

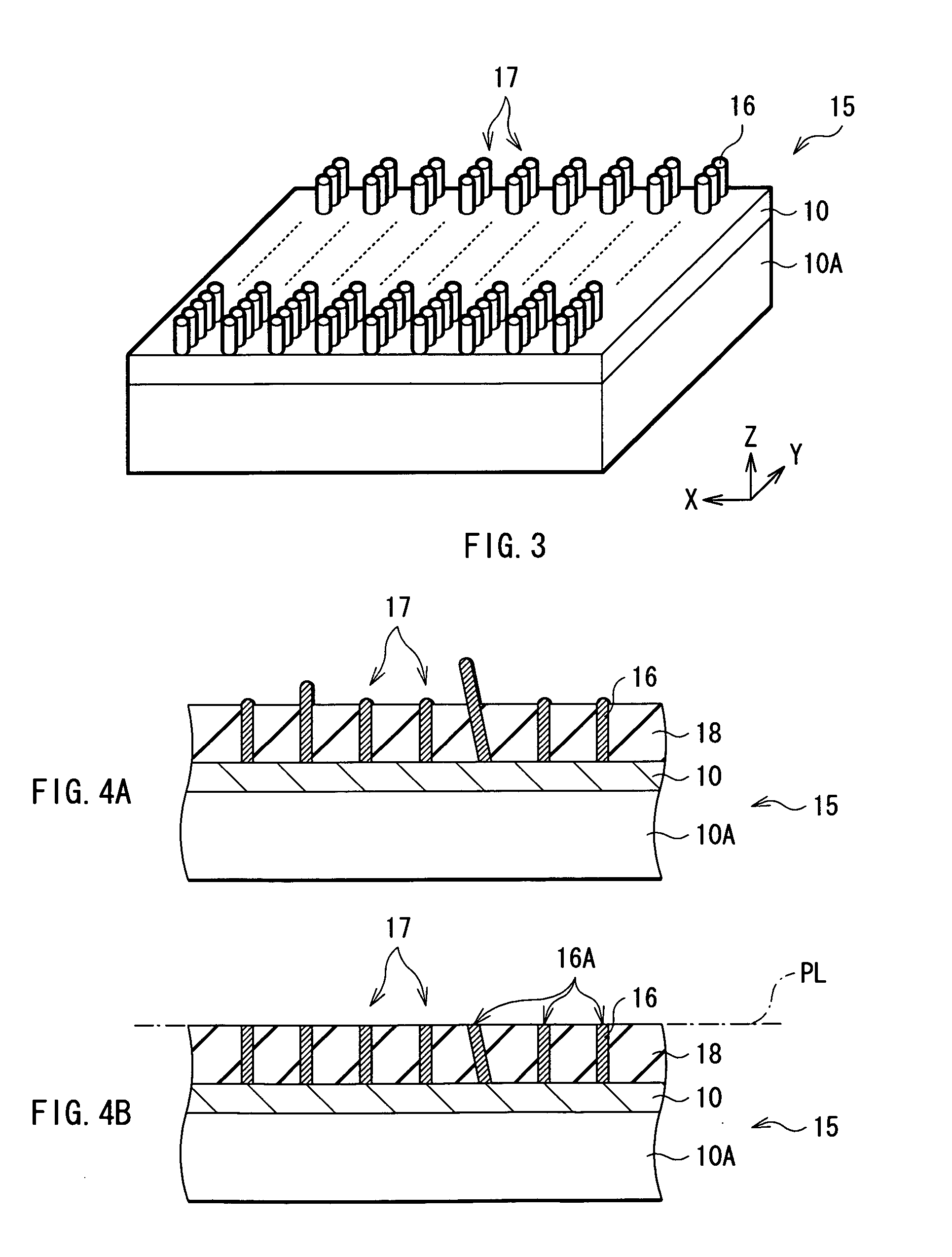

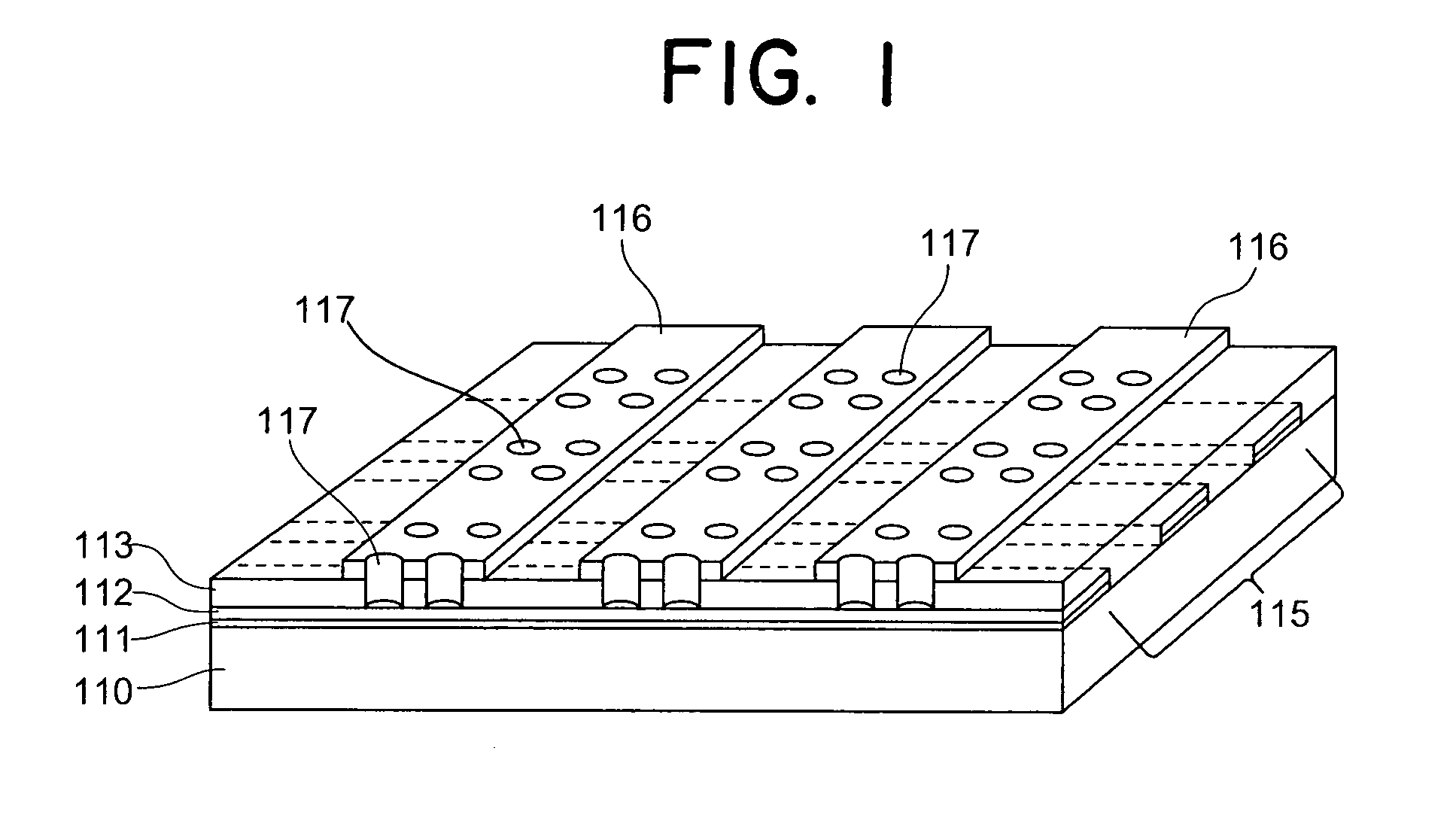

Field emission array with carbon nanotubes and method for fabricating the field emission array

InactiveUS6976897B2Simple film formationTube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersPhosphorCarbon nanotube

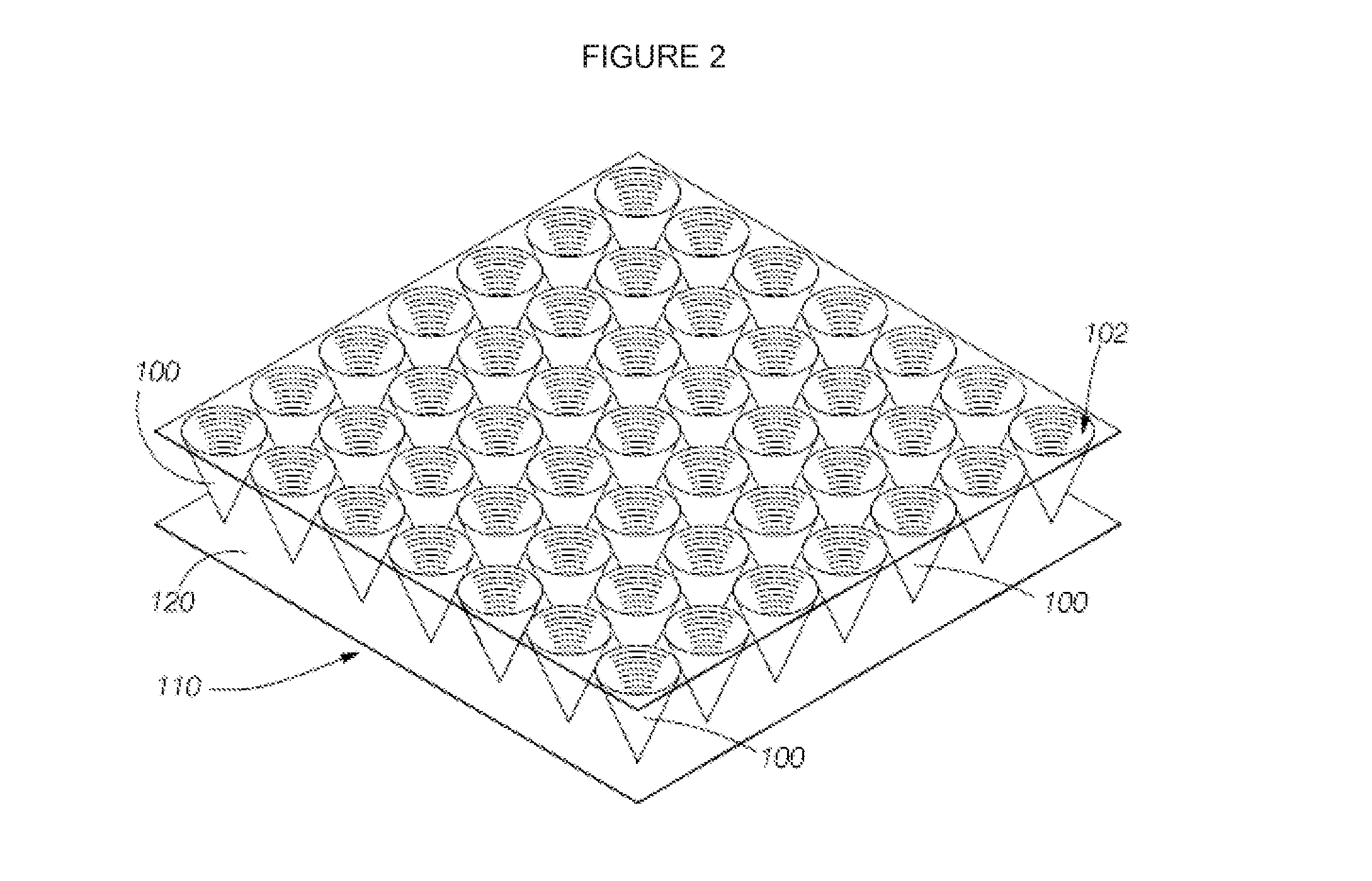

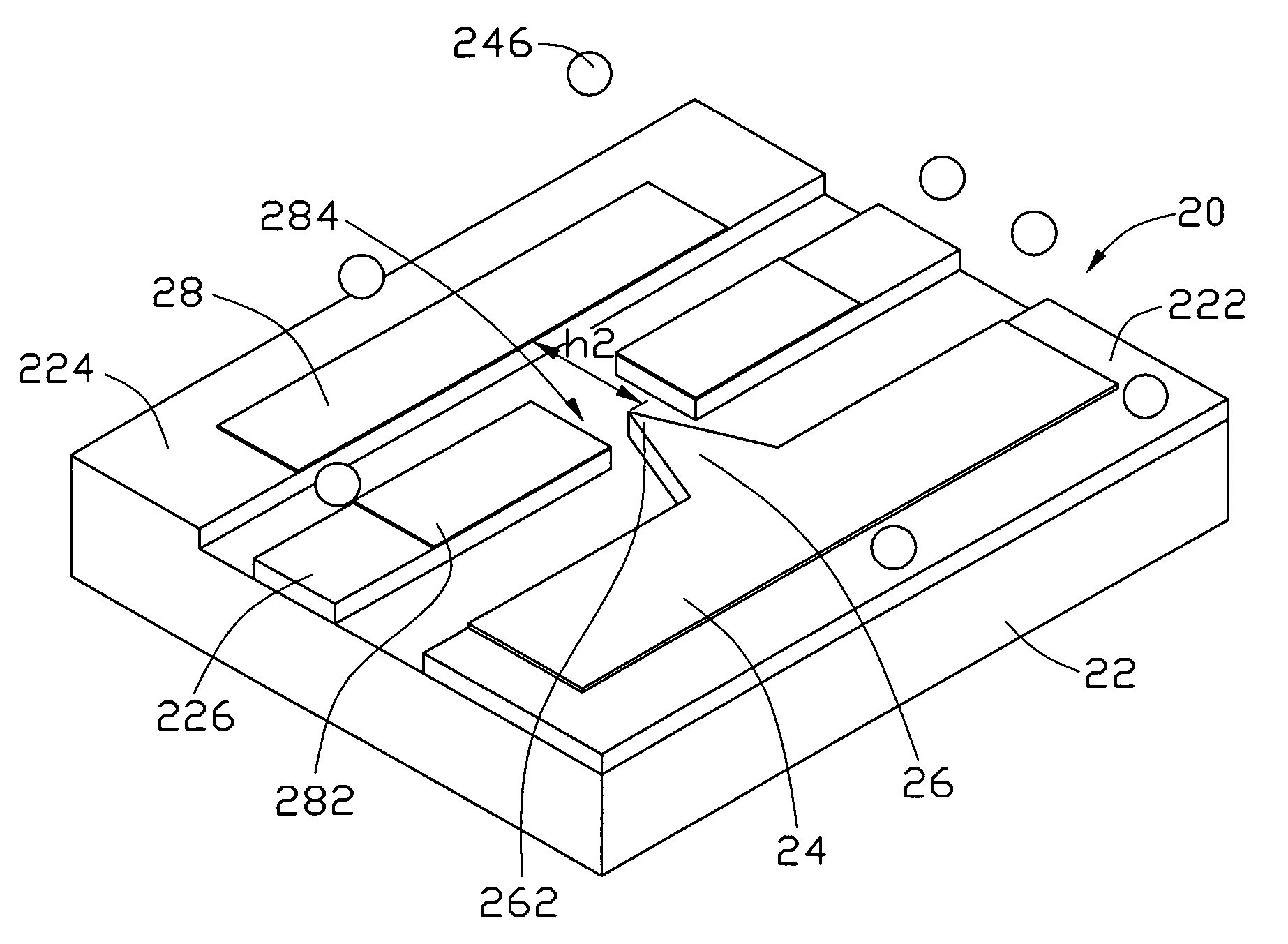

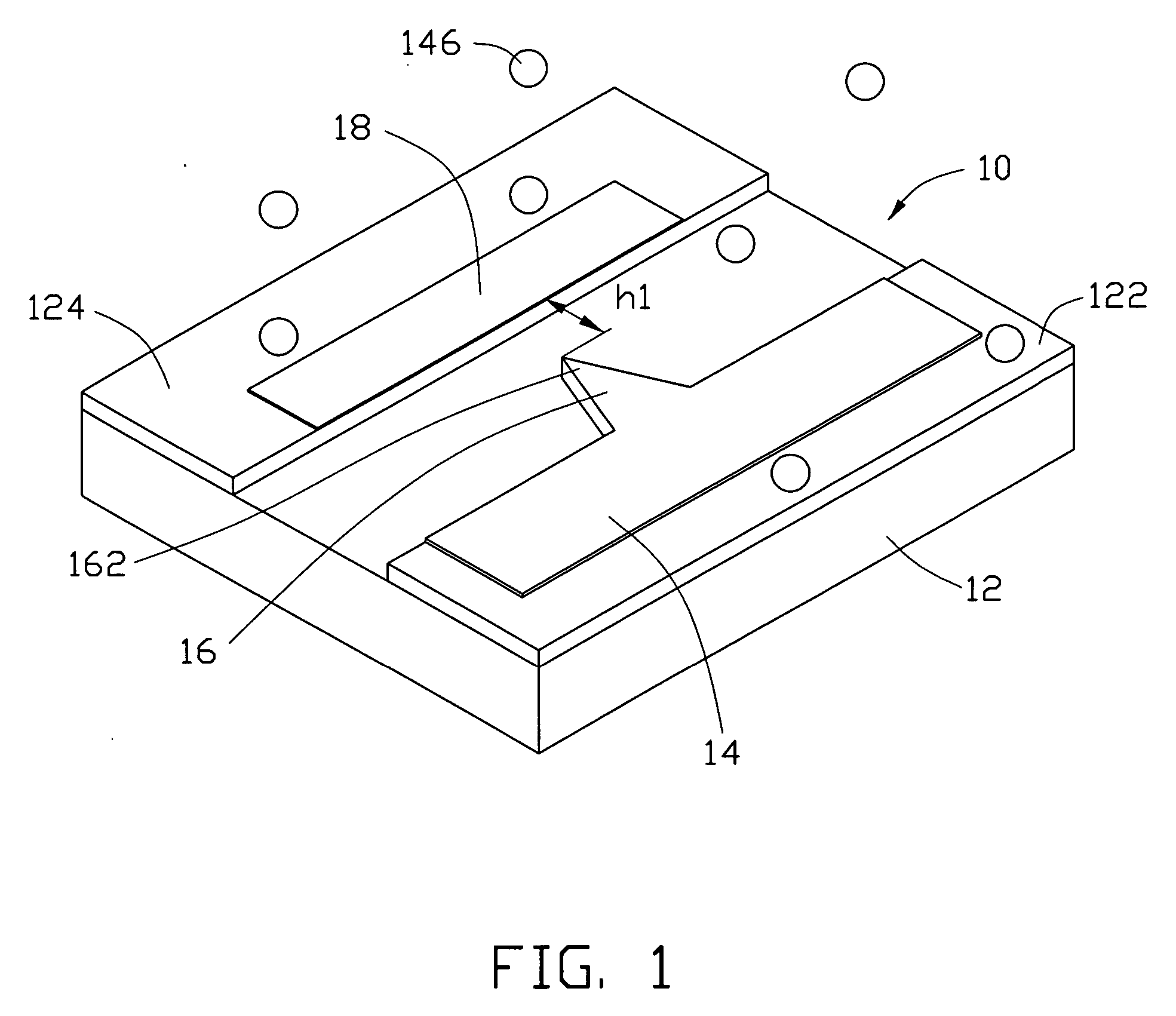

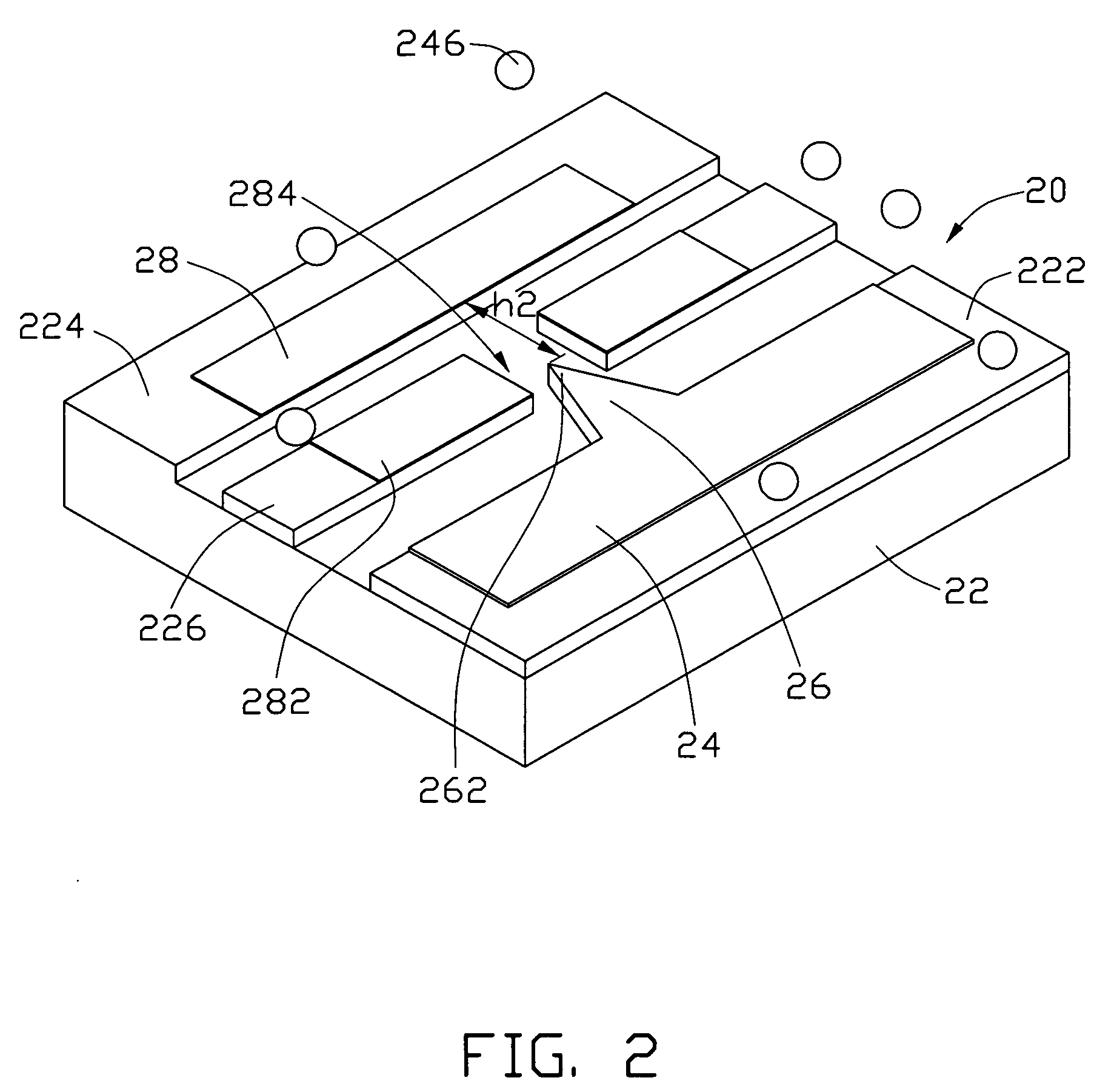

A field emission array adopting carbon nanotubes as an electron emitter source, wherein the array includes a rear substrate assembly including cathodes formed as stripes over a rear substrate and carbon nanotubes; a front substrate assembly including anodes formed as stripes over a front substrate with phosphors being deposited on the anodes, a plurality of openings separated by a distance corresponding to the distance between the anodes in a nonconductive plate, and gates formed as stripes perpendicular to the stripes of anodes on the nonconductive plate with a plurality of emitter openings corresponding to the plurality of openings. The nonconductive plate is supported and separated from the front substrate using spacers. The rear substrate assembly is combined with the front substrate assembly such that the carbon nanotubes on the cathodes project through the emitter openings.

Owner:SAMSUNG SDI CO LTD

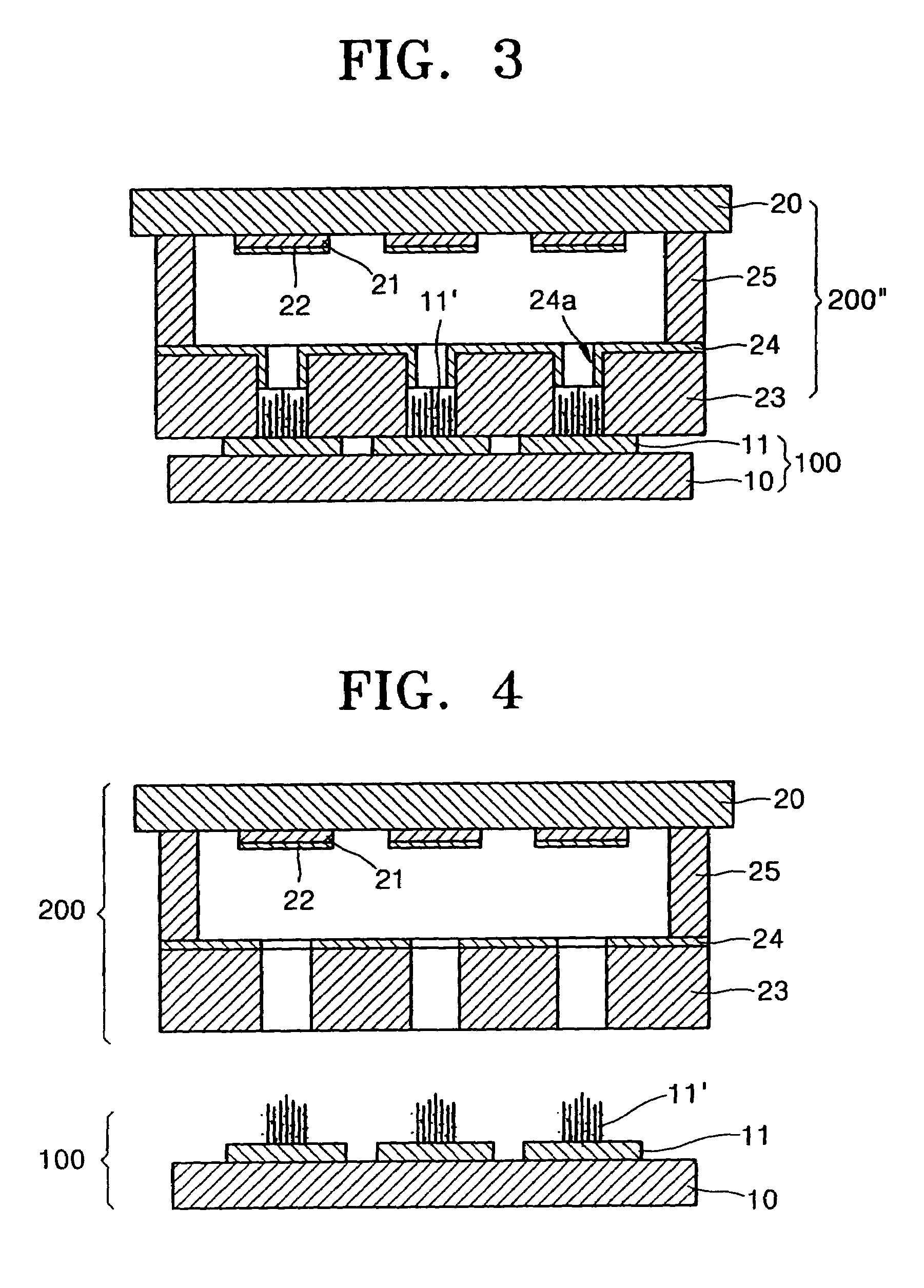

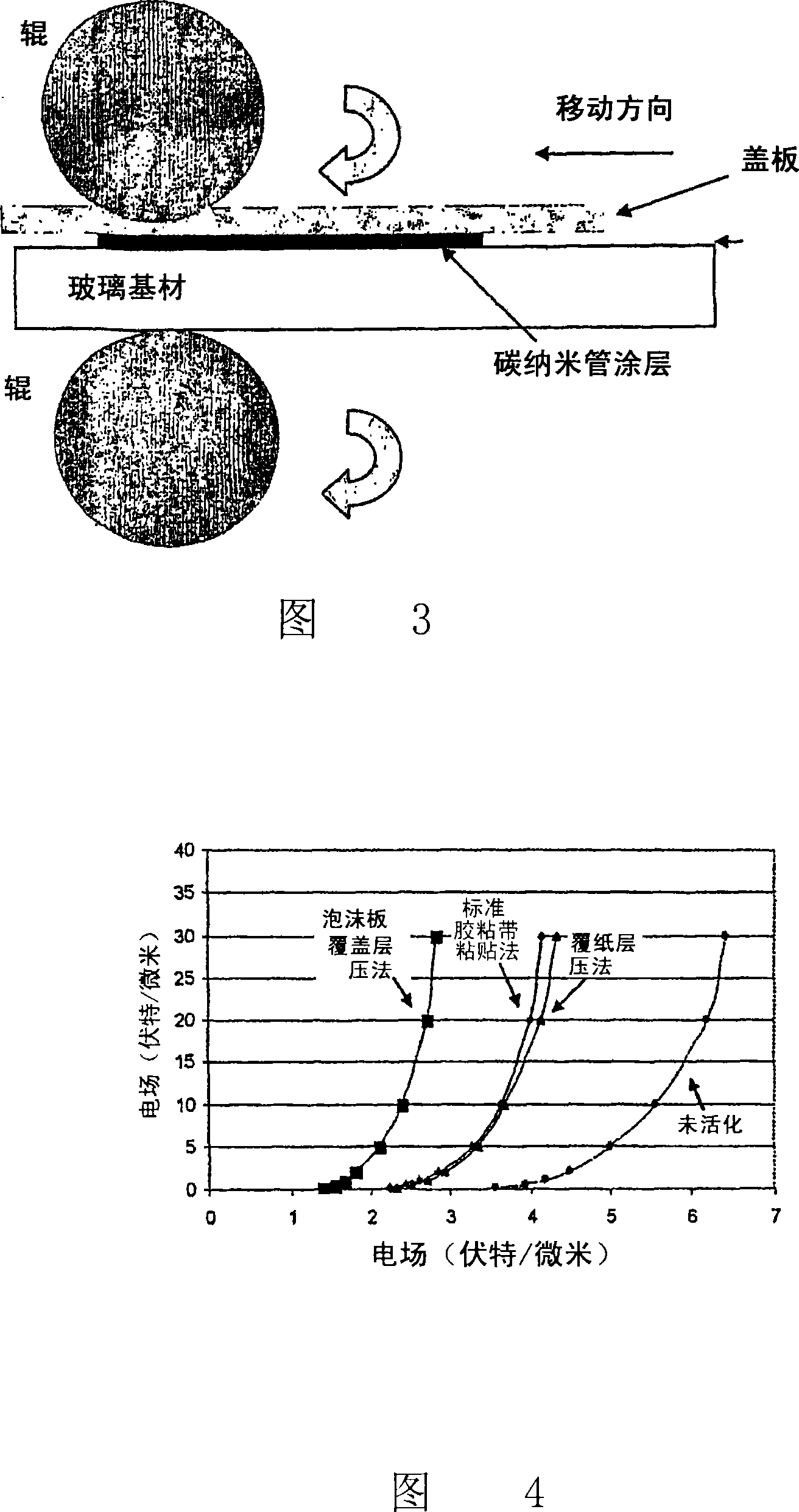

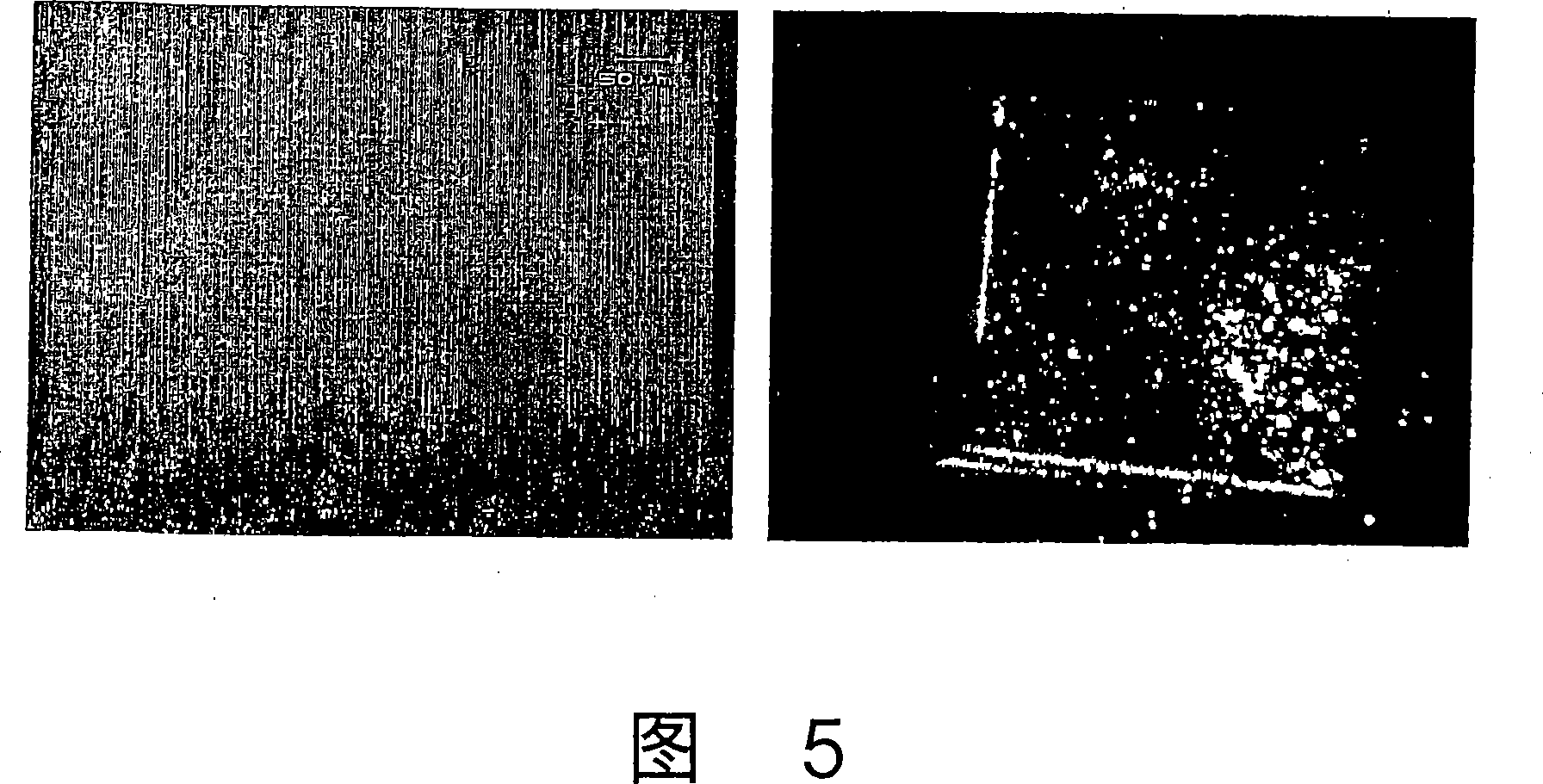

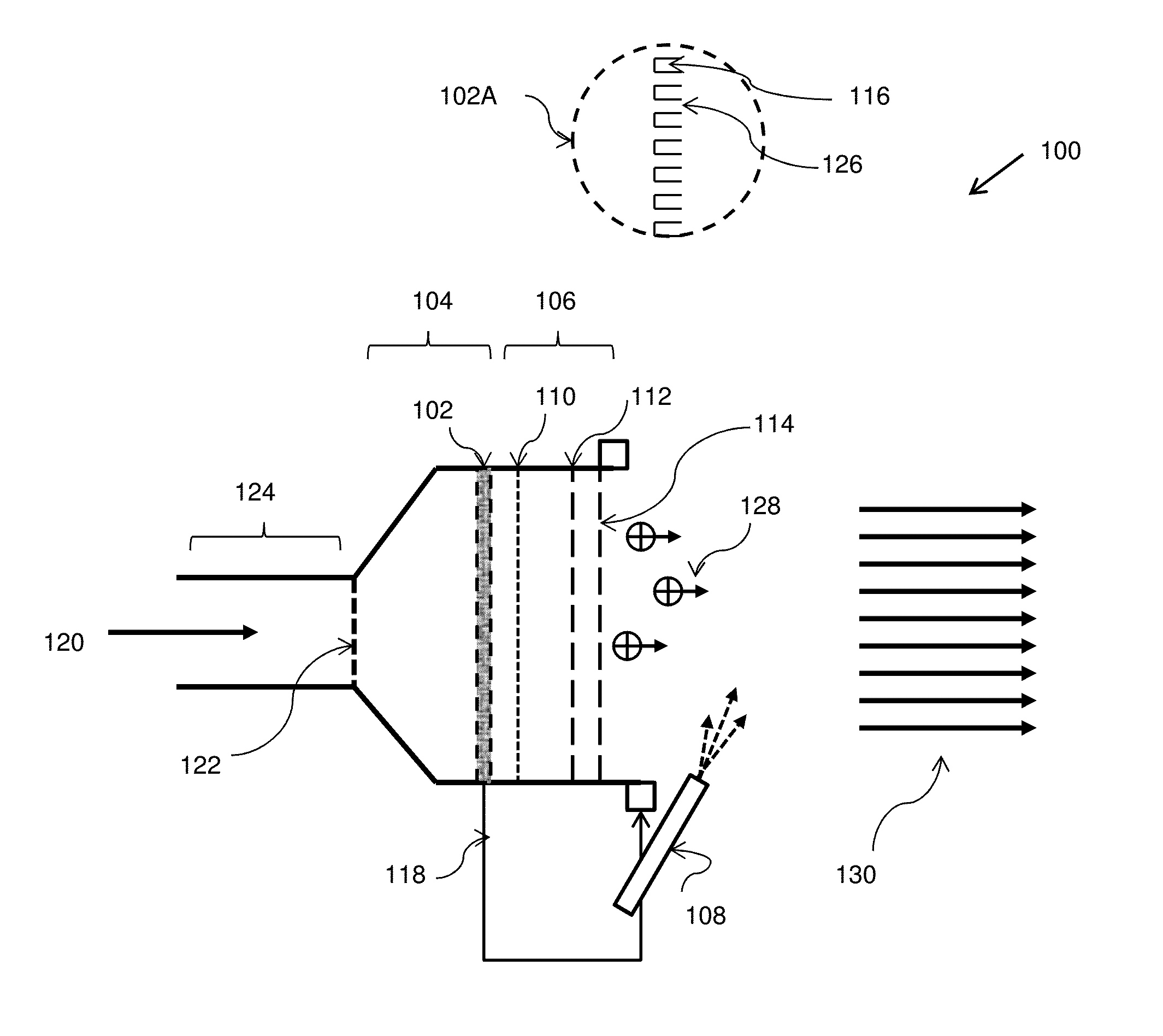

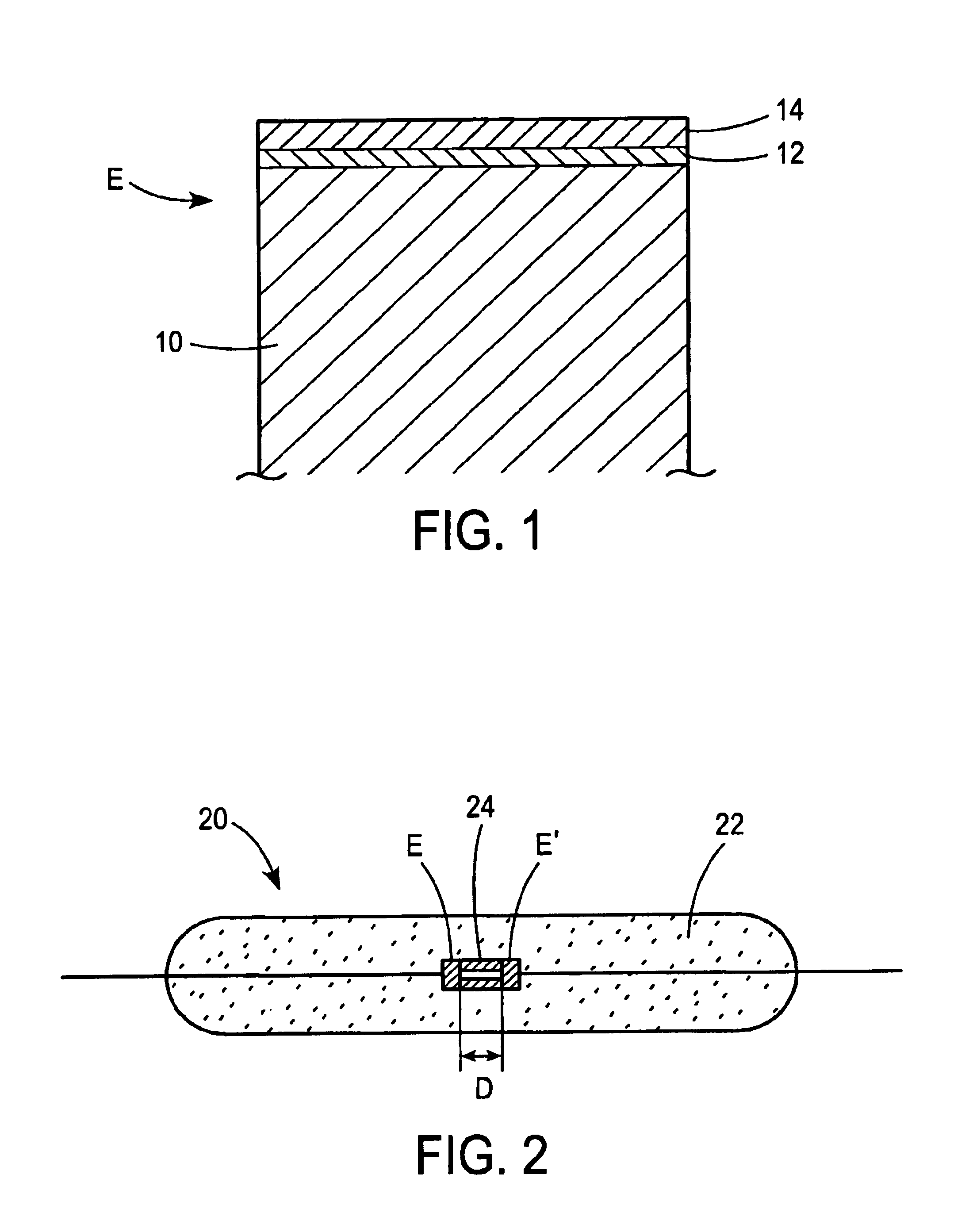

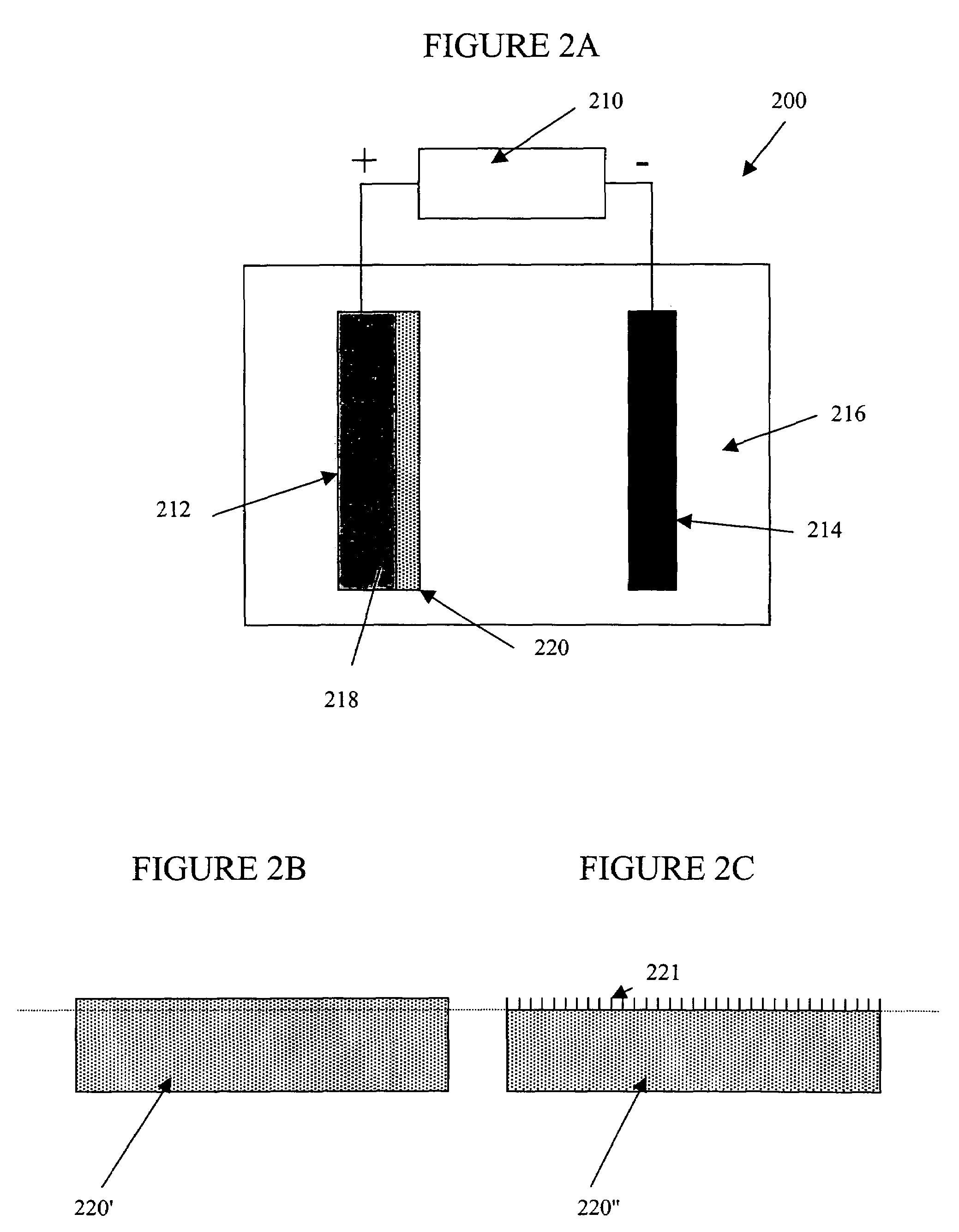

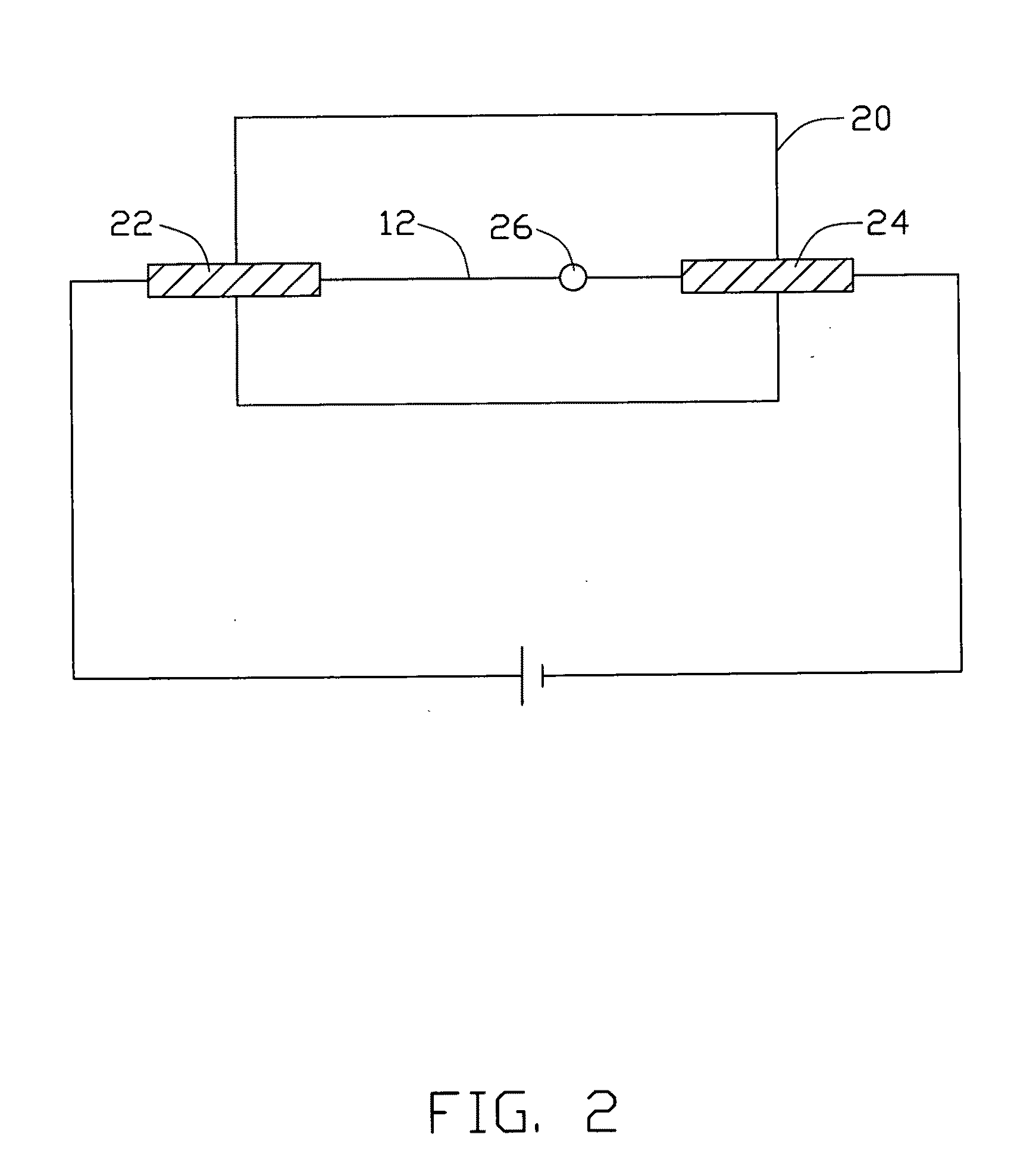

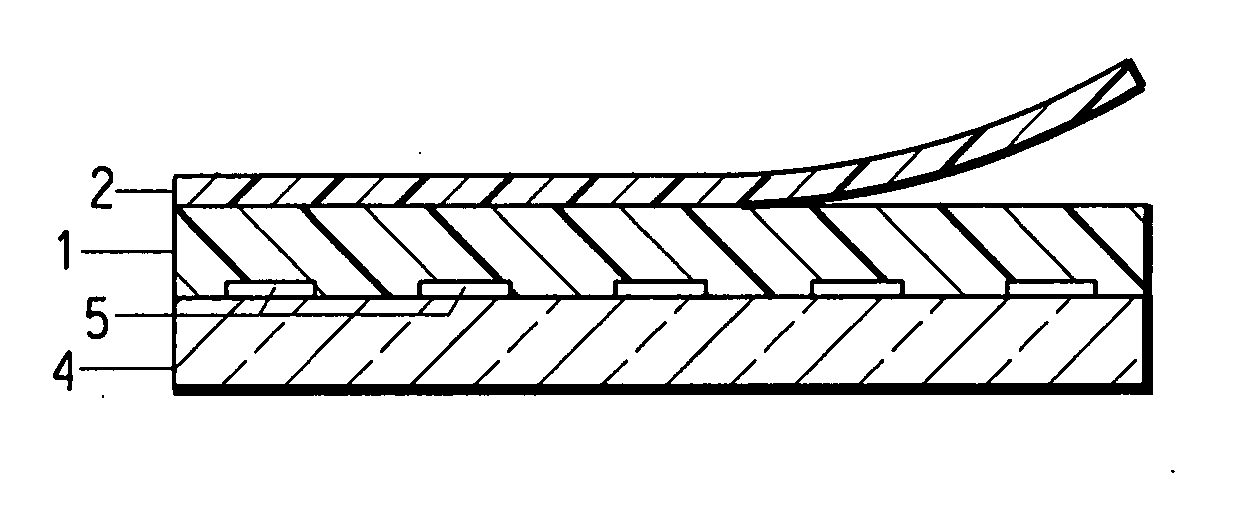

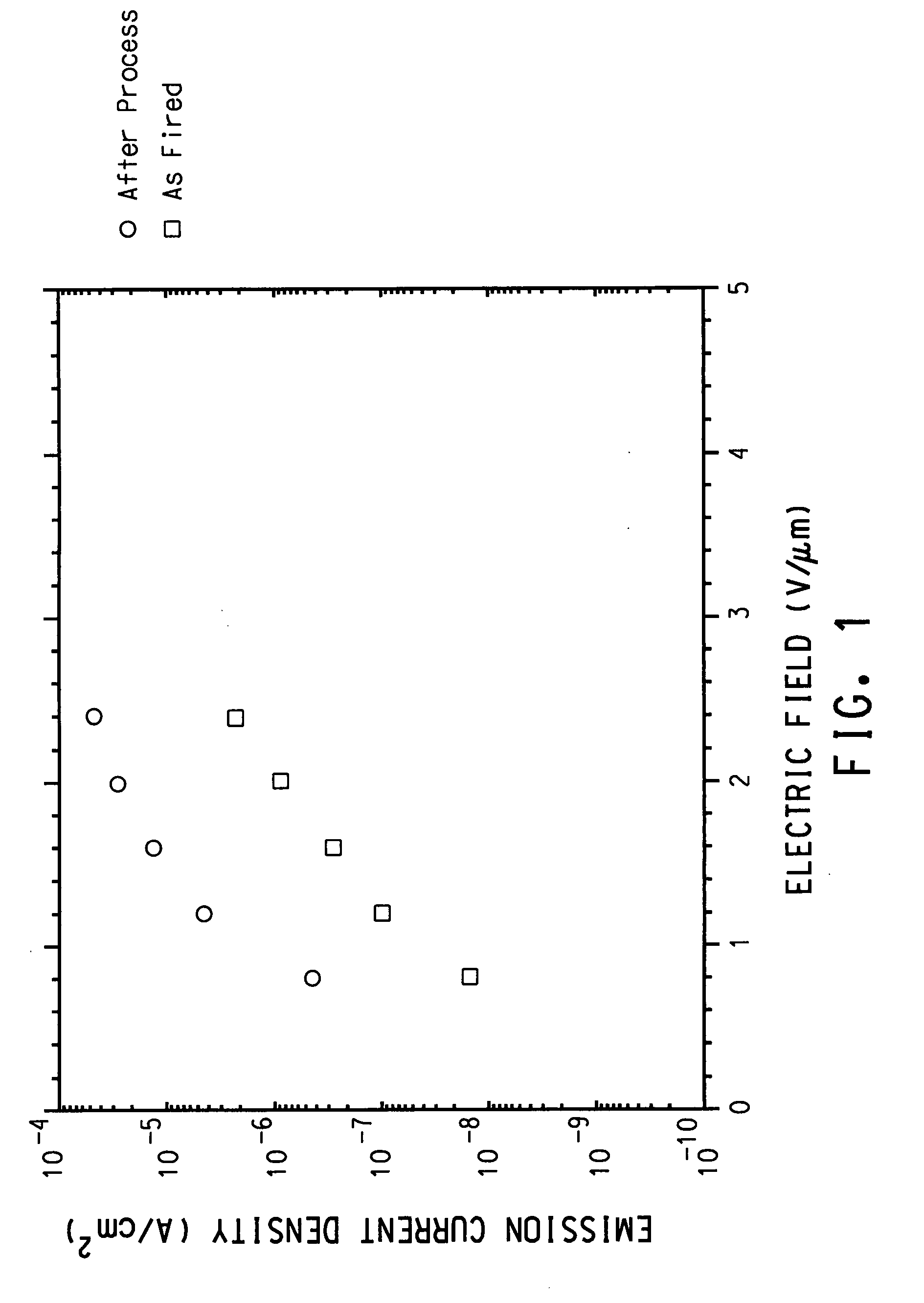

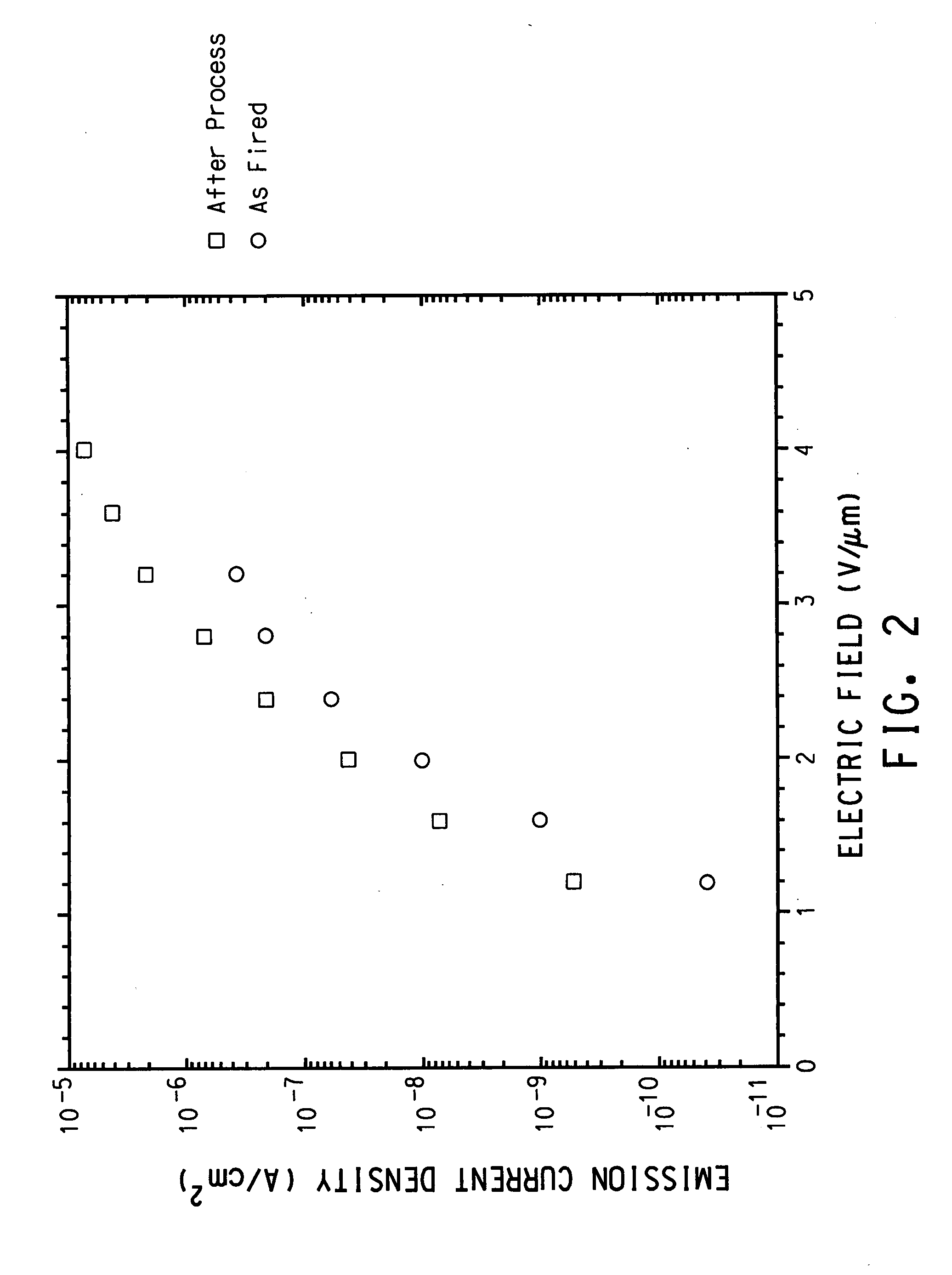

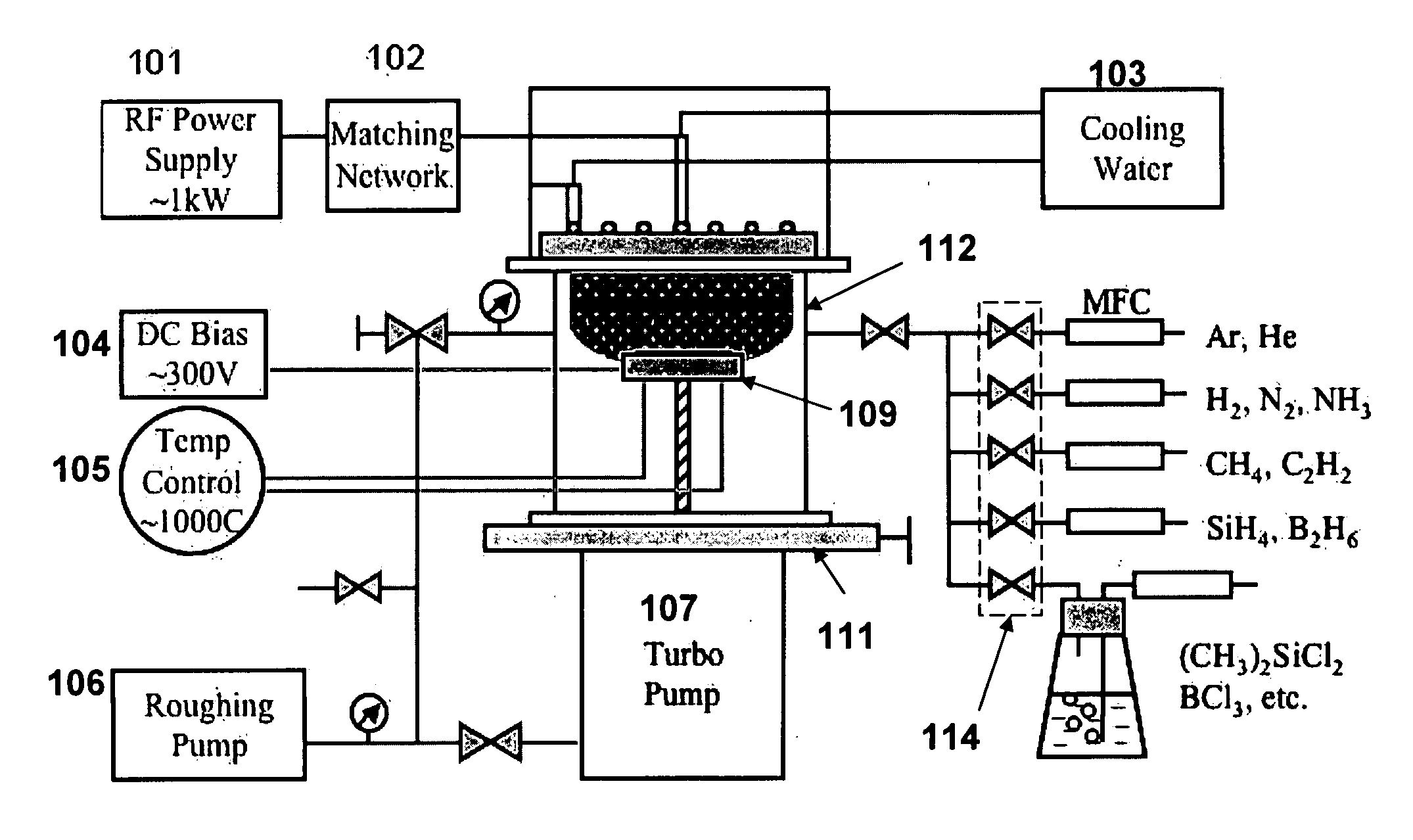

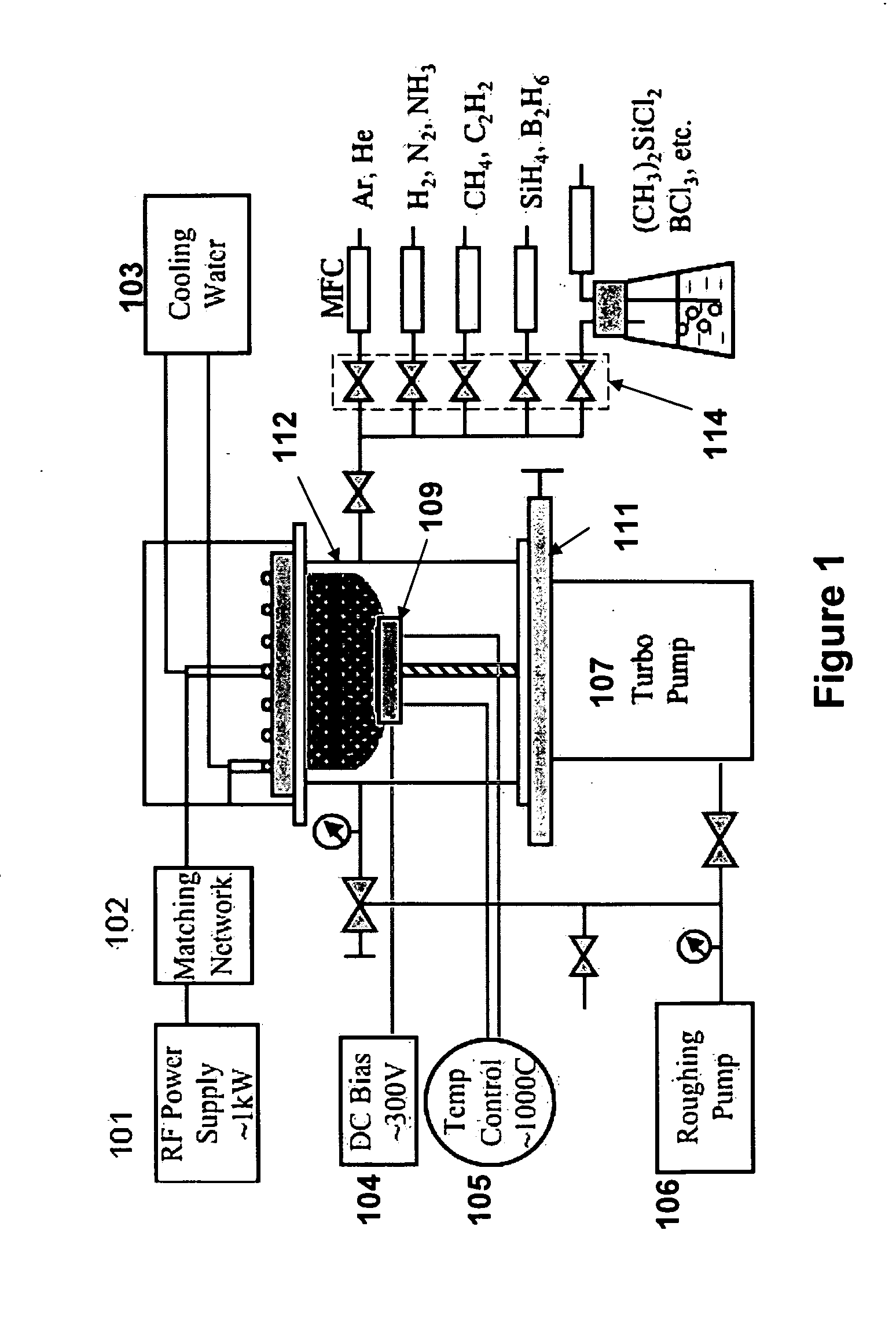

Activation of carbon nanotubes for field emission applications

InactiveCN1998067AEasy to handleLow costSemiconductor/solid-state device manufacturingCarbon nanotubeField electron emission

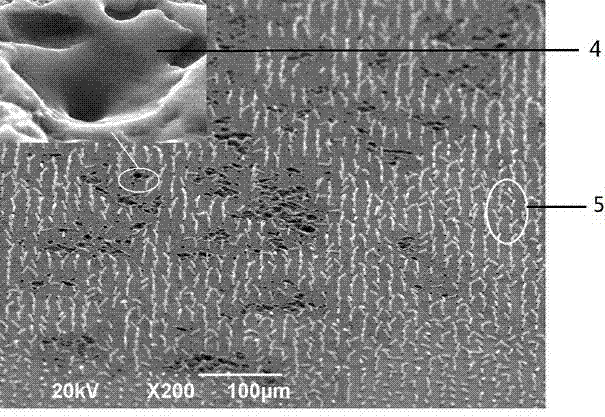

Substantially enhanced field emission properties are achieved by using a process of covering a non-adhesive material (for example, paper, foam sheet, or roller) over the surface of the CNTs, pressing the materiel using a certain force, and removing the material.

Owner:NANO

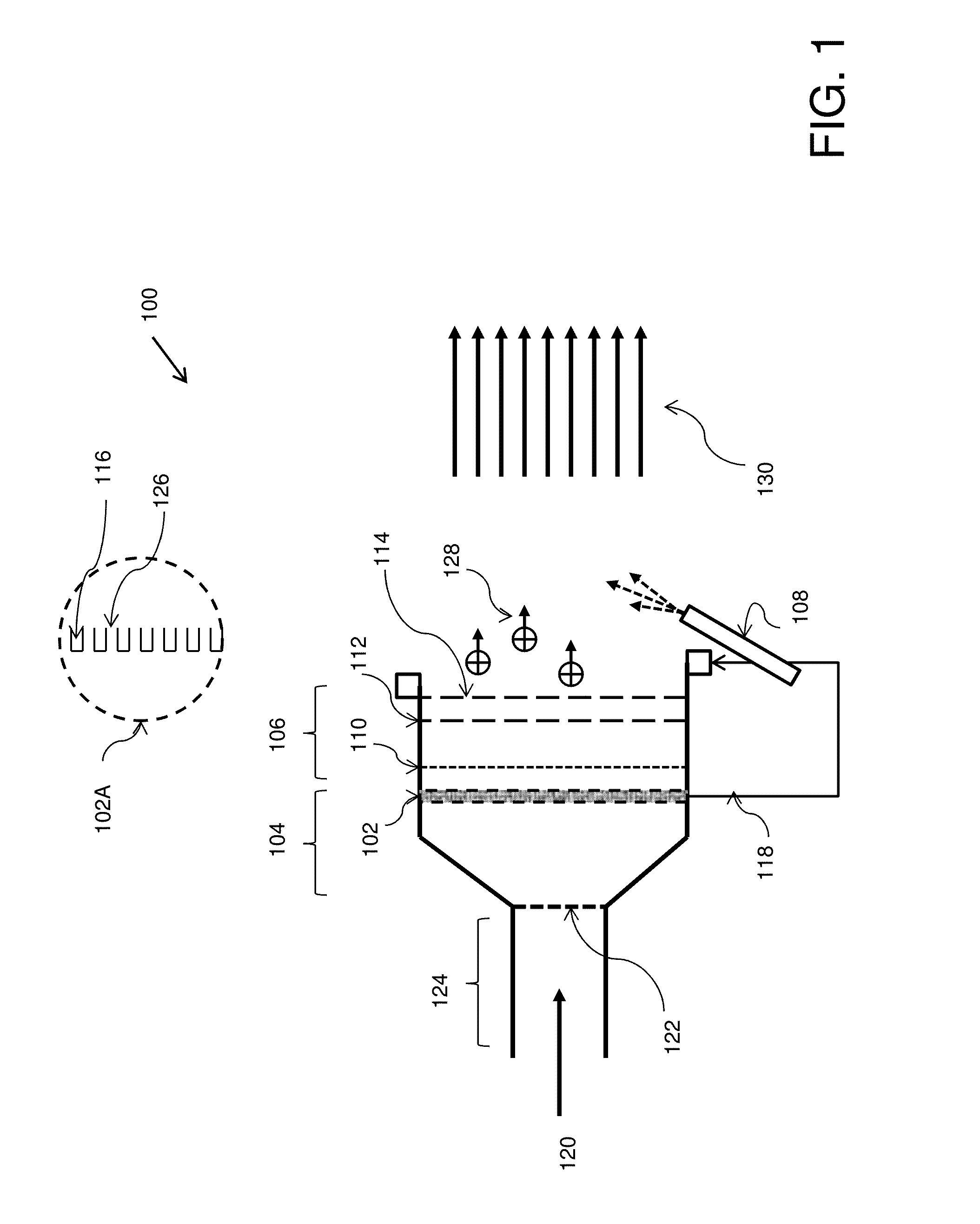

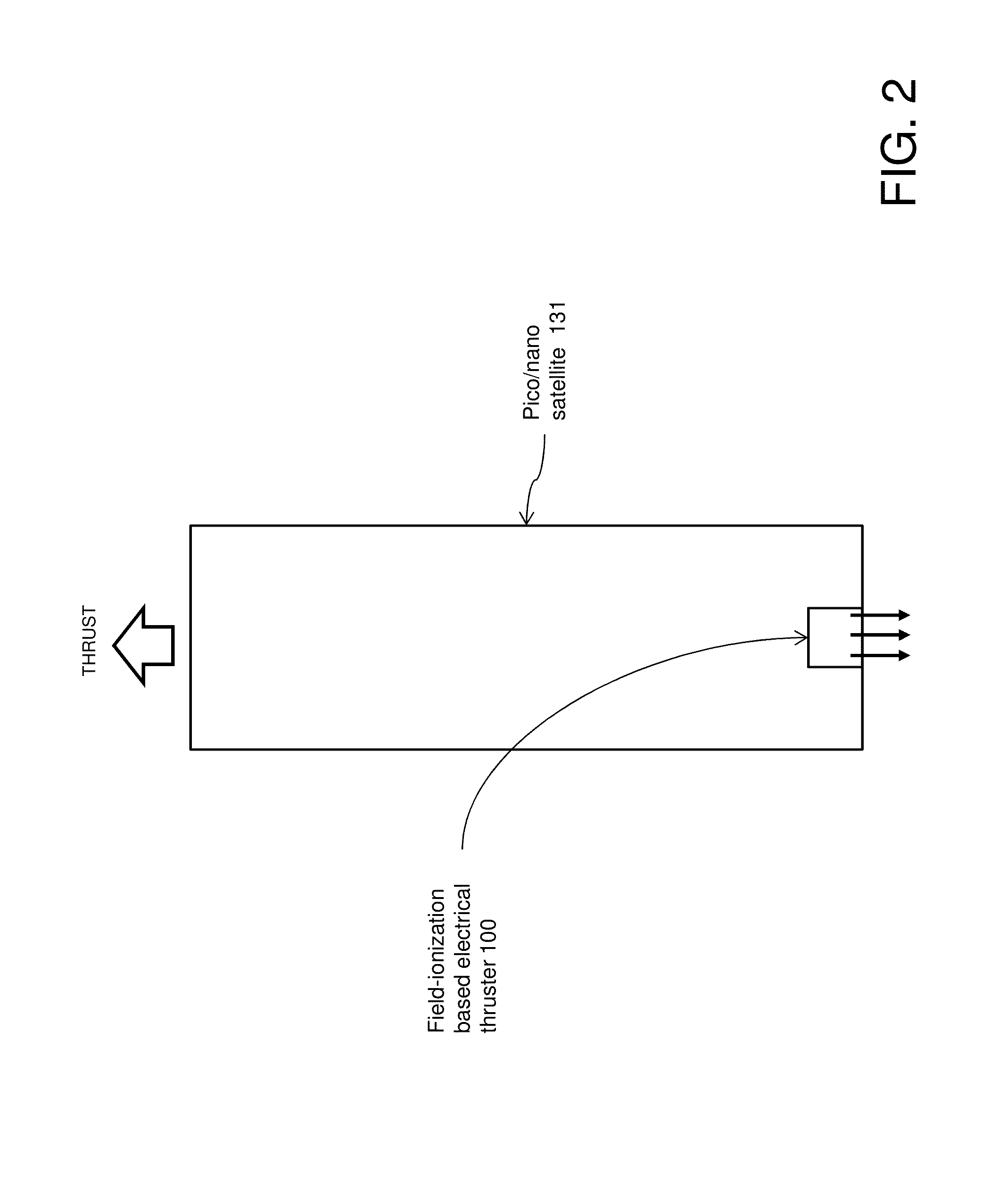

Field-ionization based electrical space ion thruster using a permeable substrate

ActiveUS9194379B1Cosmonautic vehiclesCosmonautic propulsion system apparatusField electron emissionCarbon nanotube

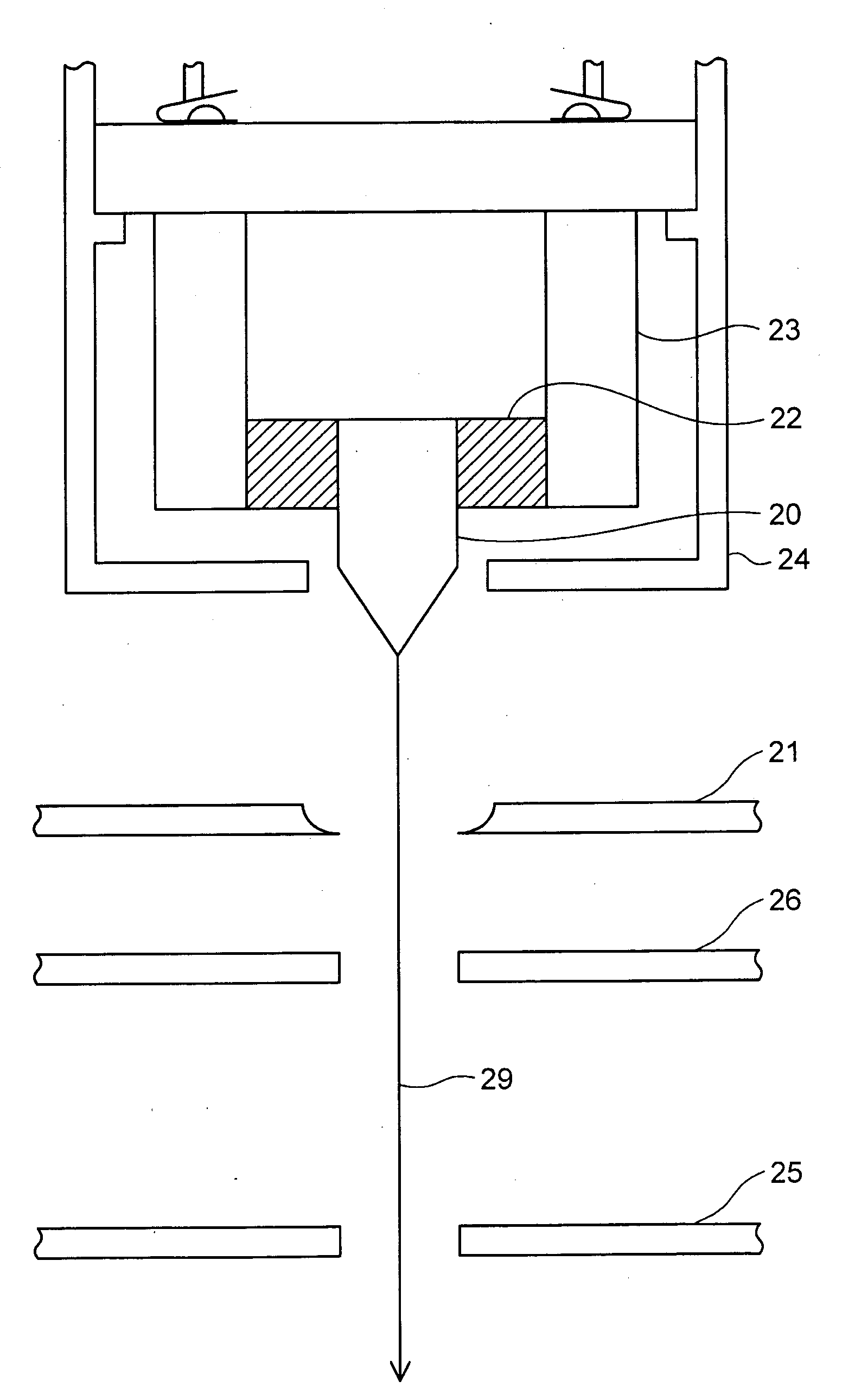

A field-ionization based electrical ion thruster utilizes a single propellant that can be used in either a high specific-impulse mode, i.e., ion-thruster mode, or a low-specific-impulse mode, i.e., a cold-gas thruster mode. In one embodiment, the high specific impulse mode (ion thruster mode) utilizes a miniaturized positive-ion field-ionization chamber including a permeable substrate infused with properly oriented carbon nanotubes (CNTs), which is fed propellant from a porous injection plug made from permeable carbon or equivalent material. In one embodiment, field-electron emission from a neutralizer, such as a carbon nanotube array neutralizer, positioned after one or more accelerator grids is used for ion neutralization. In one embodiment, the low specific-impulse (cold-gas mode) uses a conventional supersonic nozzle-expansion to generate thrust. In one embodiment, both the high specific-impulse mode and the low specific-impulse mode thruster embodiments share the same gas propellant, storage propellant tank, and delivery equipment.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

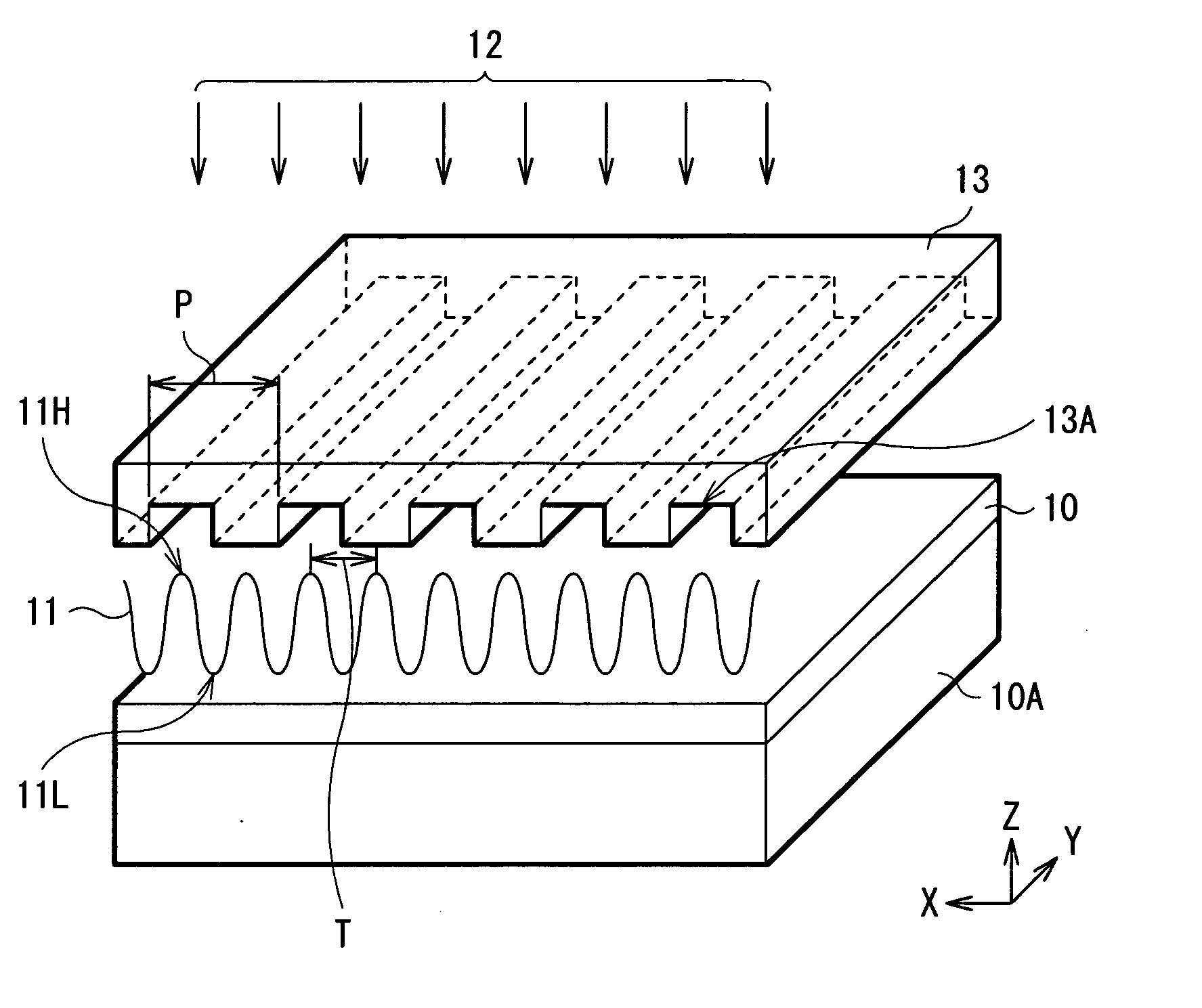

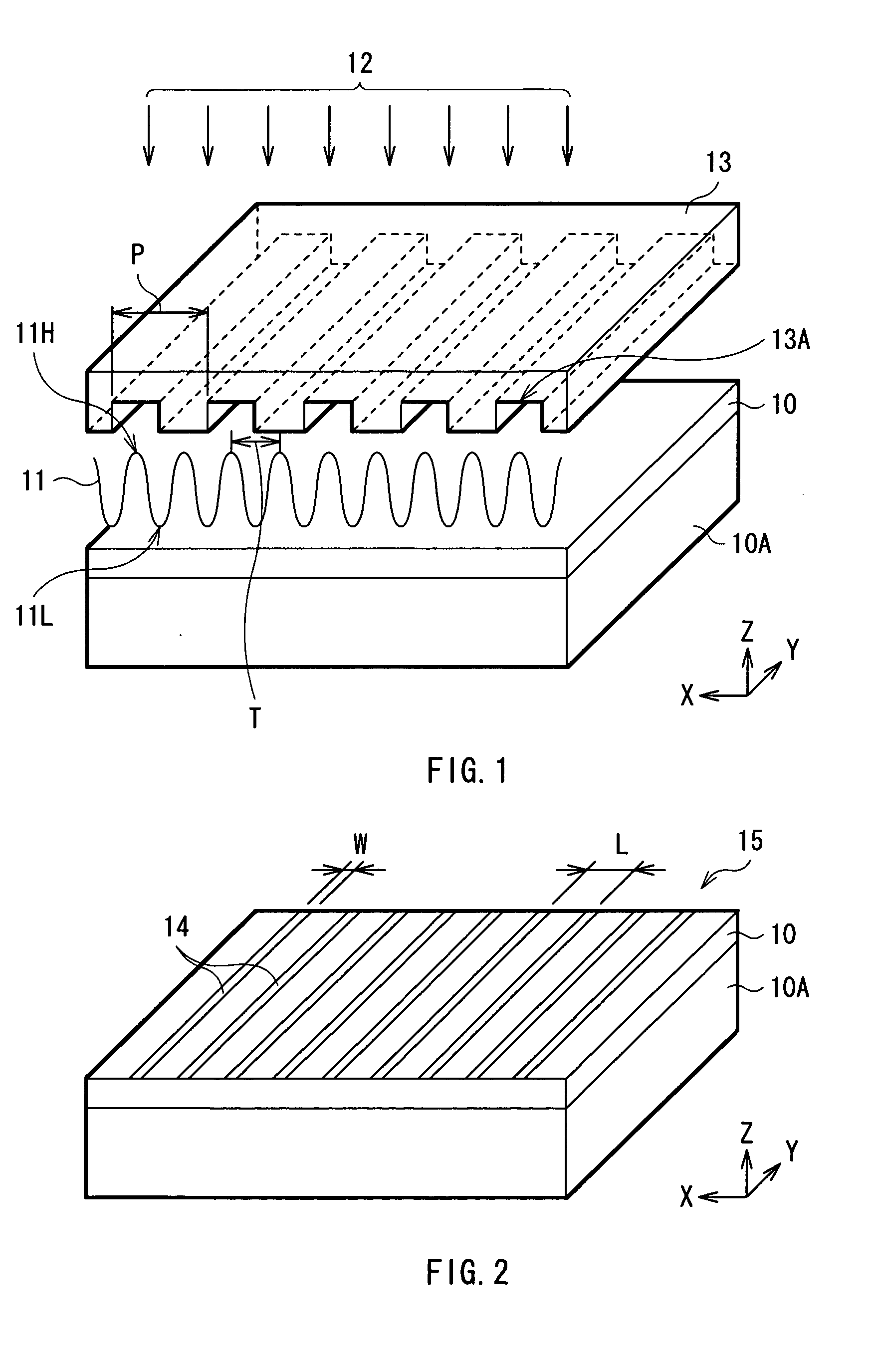

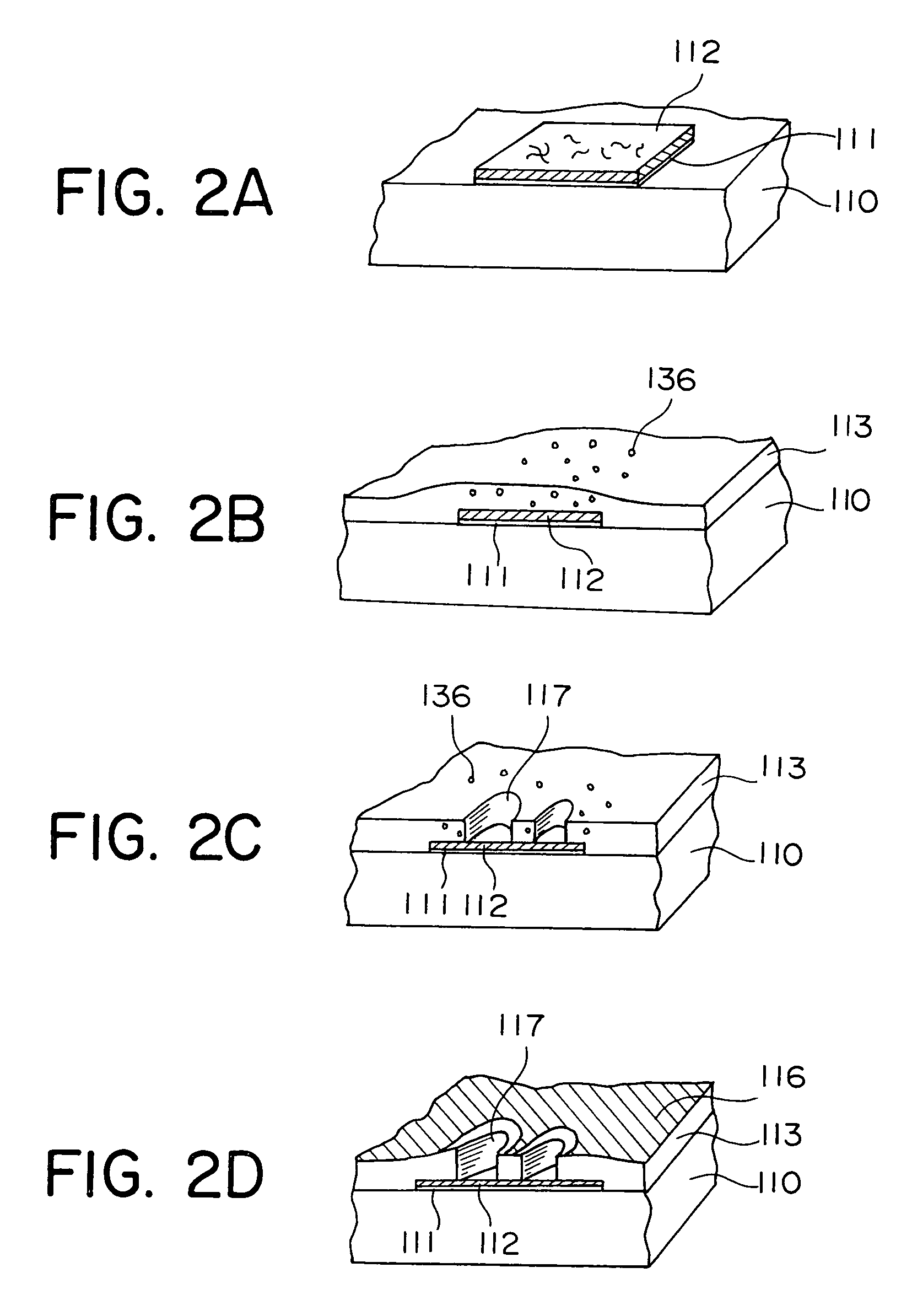

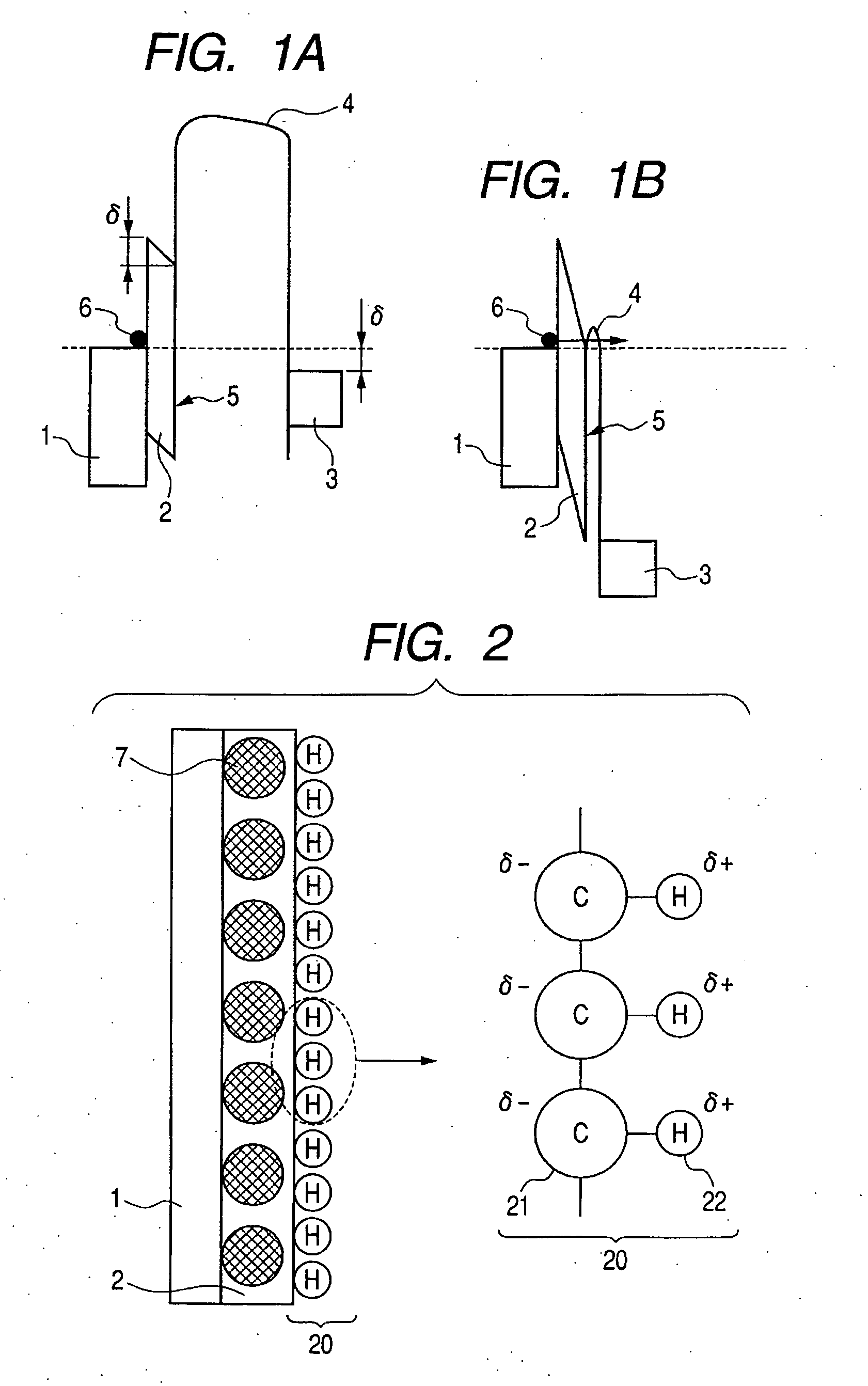

Production method for tubular carbon molecule and tubular carbon molecule, production method for recording device and recording device, production method for field electron emission element and field electron emission element, and production method for display unit and display unit

InactiveUS20060108906A1Display clearImprove recording densityMaterial nanotechnologyDischarge tube luminescnet screensCarbon nanotubeField electron emission

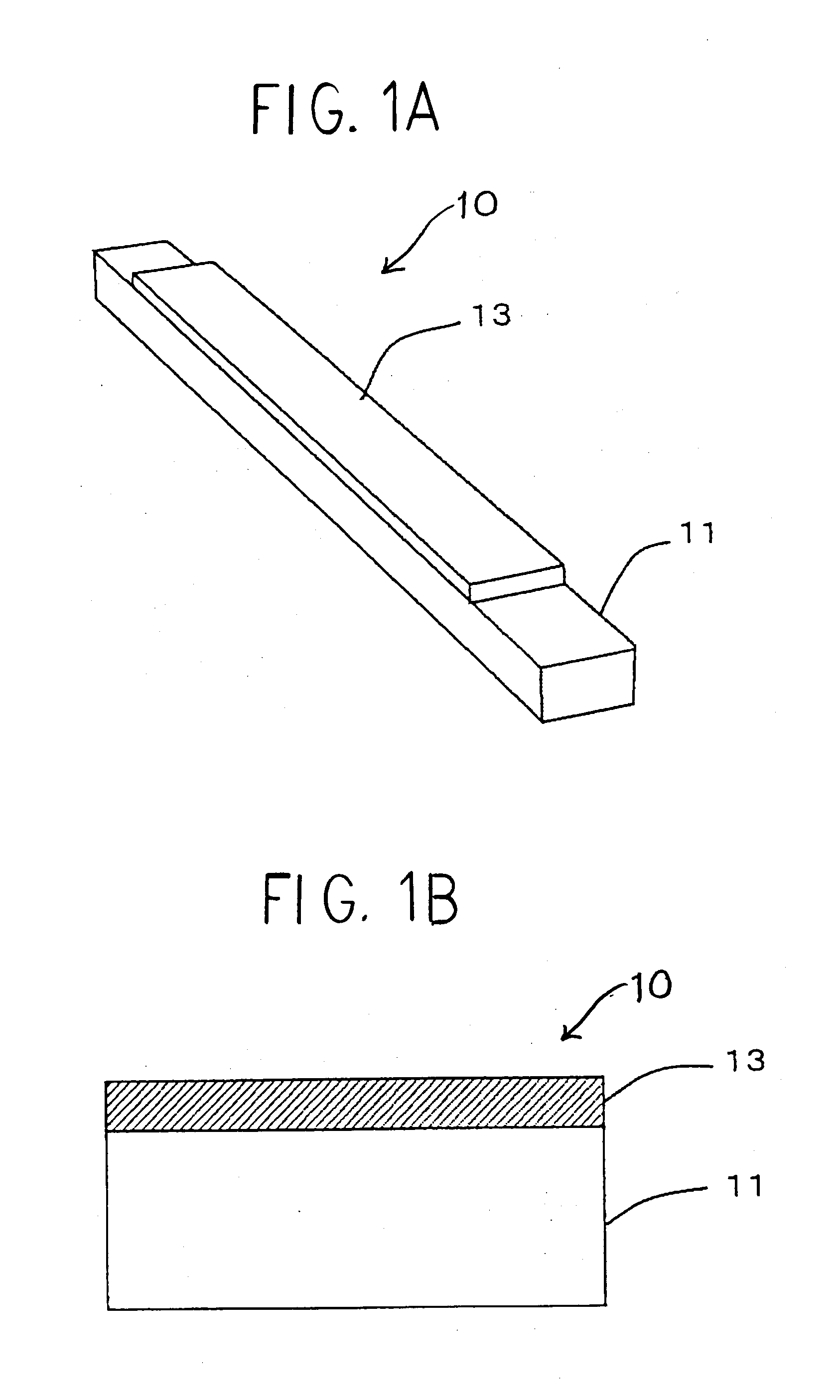

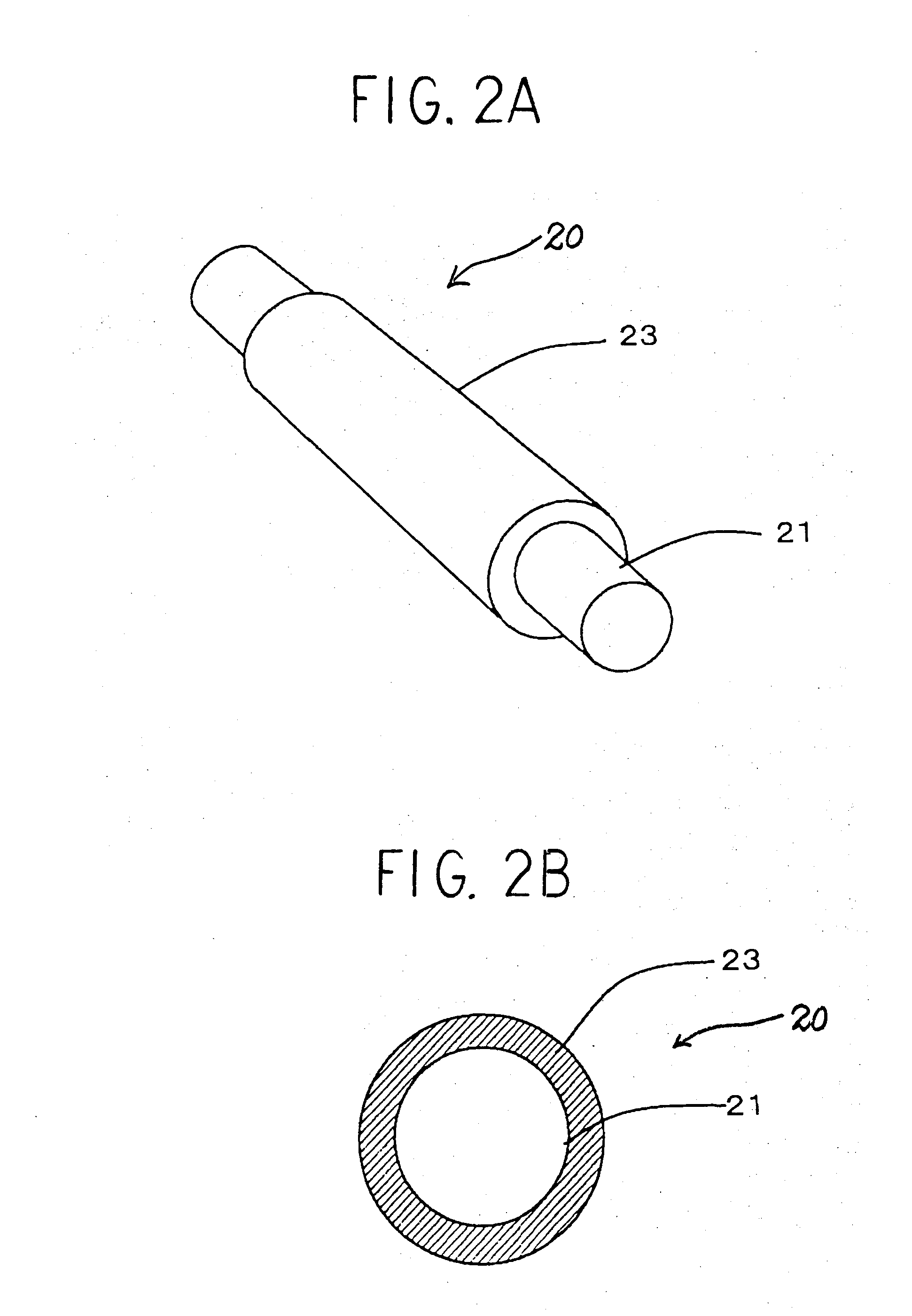

A method of manufacturing a tubular carbon molecule capable of regularly aligning a carbon nanotube with a finer spacing is provided. A catalyst is arranged on a material substrate (10) made of a semiconductor such as silicon (Si) and including iron (Fe) as a catalyst through the use of melting according to a modulated heat distribution (11). The heat distribution (11) is formed, for example, through diffracting an energy beam (12) by a diffraction grating (13). As a method of arranging the catalyst, for example, iron may be deposited in a planar shape or a projection shape in a position corresponding to the heat distribution (11), or the deposited iron may be used as a master to be transferred to another substrate. A carbon nanotube is grown through the use of the arranged catalyst. The grown carbon nanotube can be used as a recording apparatus, a field electron emission device, an FED or the like.

Owner:SONY CORP

Double-walled carbon nanotubes and methods for production and application

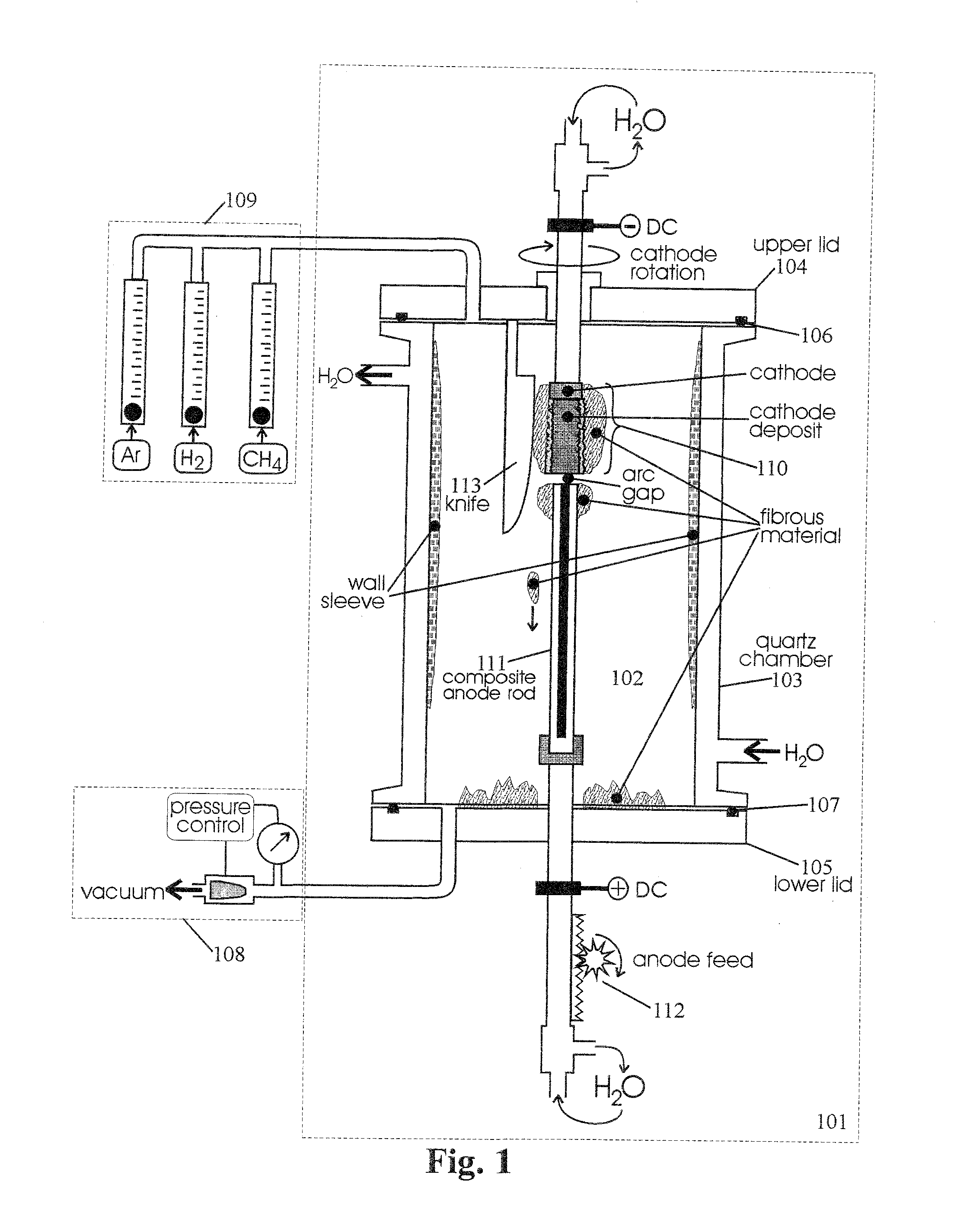

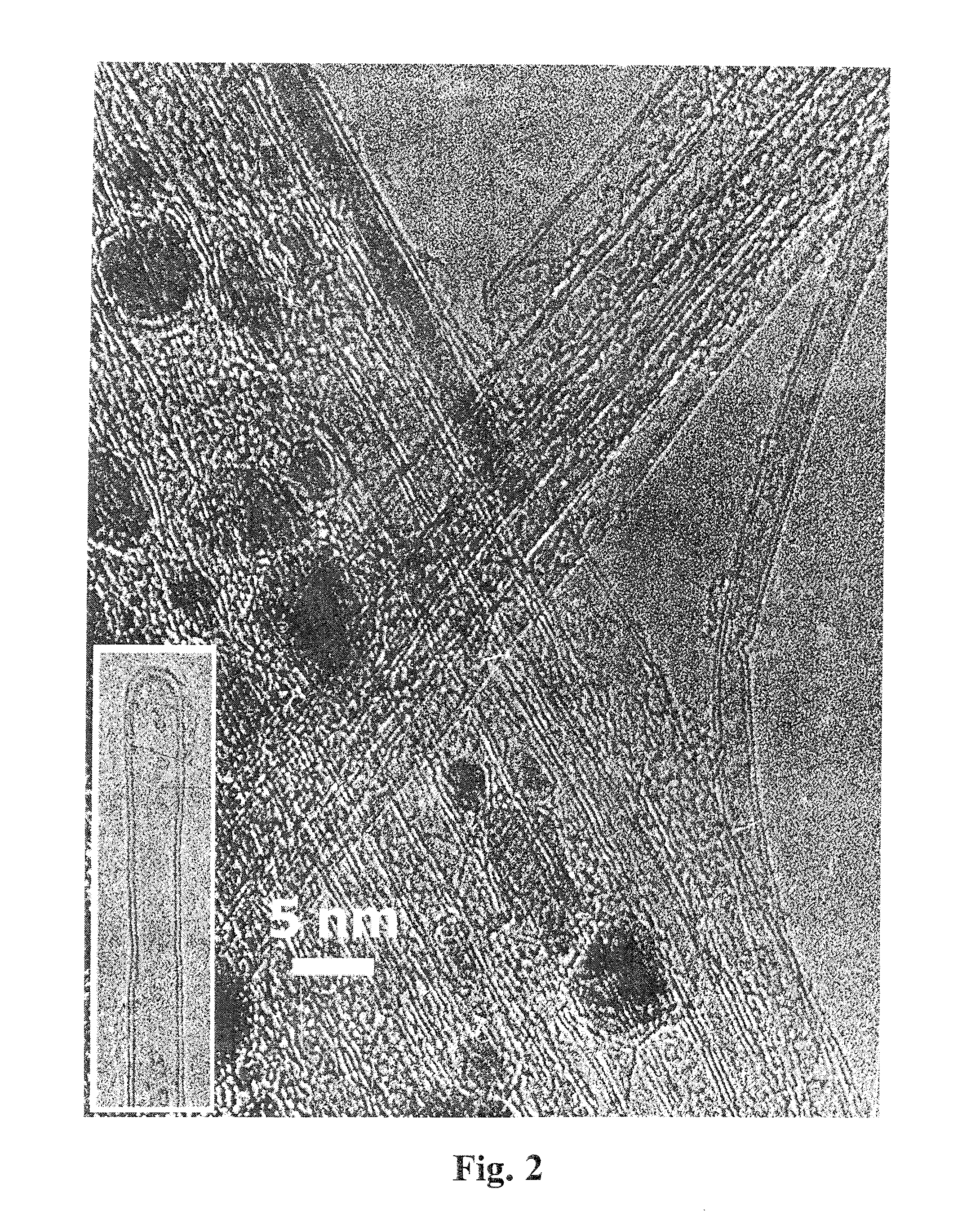

The present invention relates to fullerene carbon nanotubes having a cylindrical wall comprising a double layer of carbon atoms and methods for the production and application of these double-wall carbon nanotubes; and, more particularly, to nanotubes with controlled number of carbon layers and methods for the production of macroscopic amounts of these nanotubes and there application as cathode materials in the cold field electron emission devices, notable such devices comprising light emitting CRT's.

Owner:ATS MER LLC

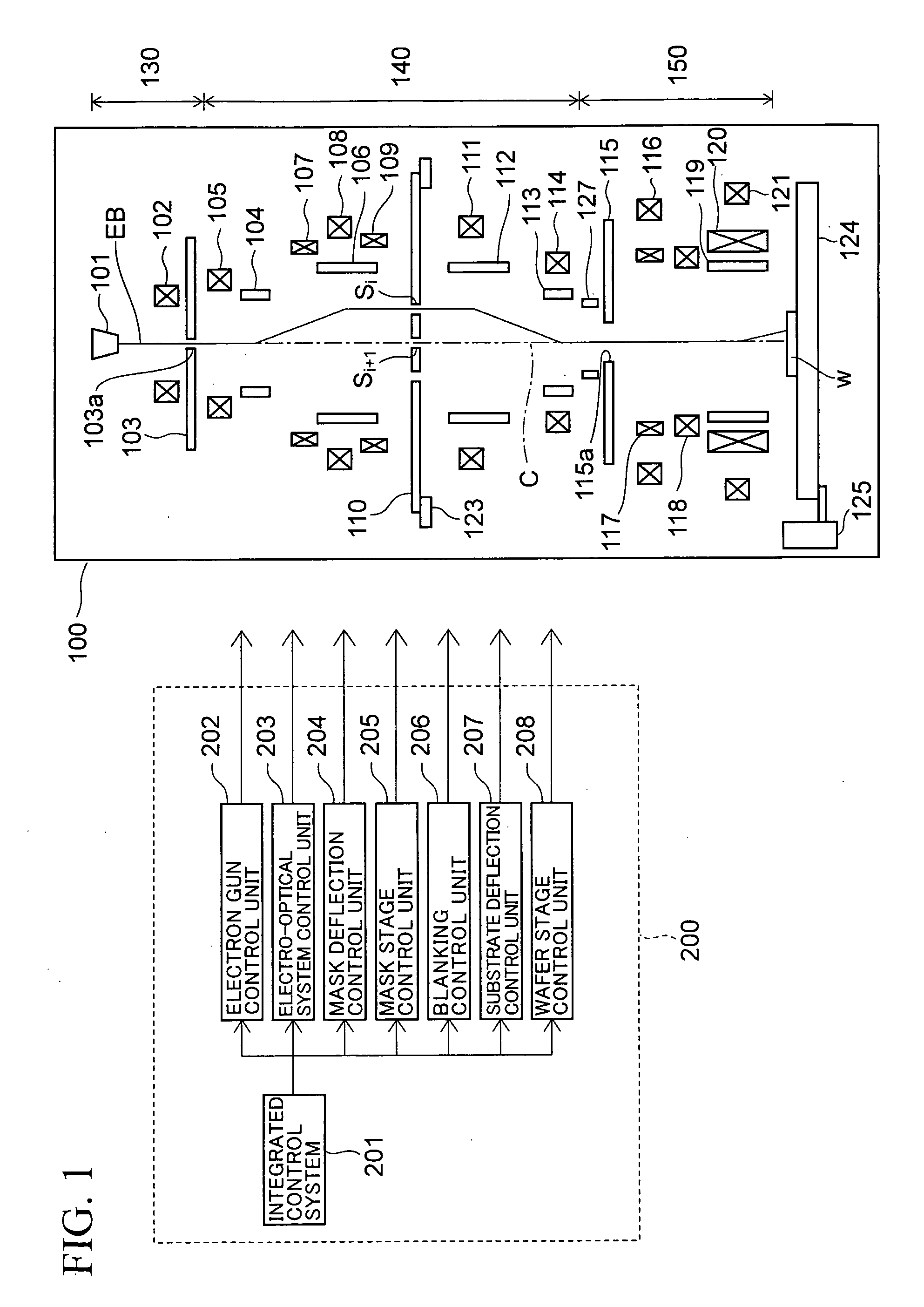

Electron gun, electron beam exposure apparatus, and exposure method

InactiveUS20080211376A1Avoid damageEasy to useNanoinformaticsElectrode and associated part arrangementsElectron sourceOptical axis

An electron gun having an electron source emitting electrons includes: an acceleration electrode which accelerates the electrons; an extraction electrode which has a spherical concave surface having the center on an optical axis and facing the electron emission surface, and which extracts an electron from the electron emission surface; and a suppressor electrode which suppresses electron emission from a side surface of the electron source. In the electron gun, an electric field is applied to the electron emission surface while the electron source is kept at a low temperature in such an extent that sublimation of a material of the electron source would not be caused, to cause the electron source to emit a thermal field emission electron.

Owner:ADVANTEST CORP

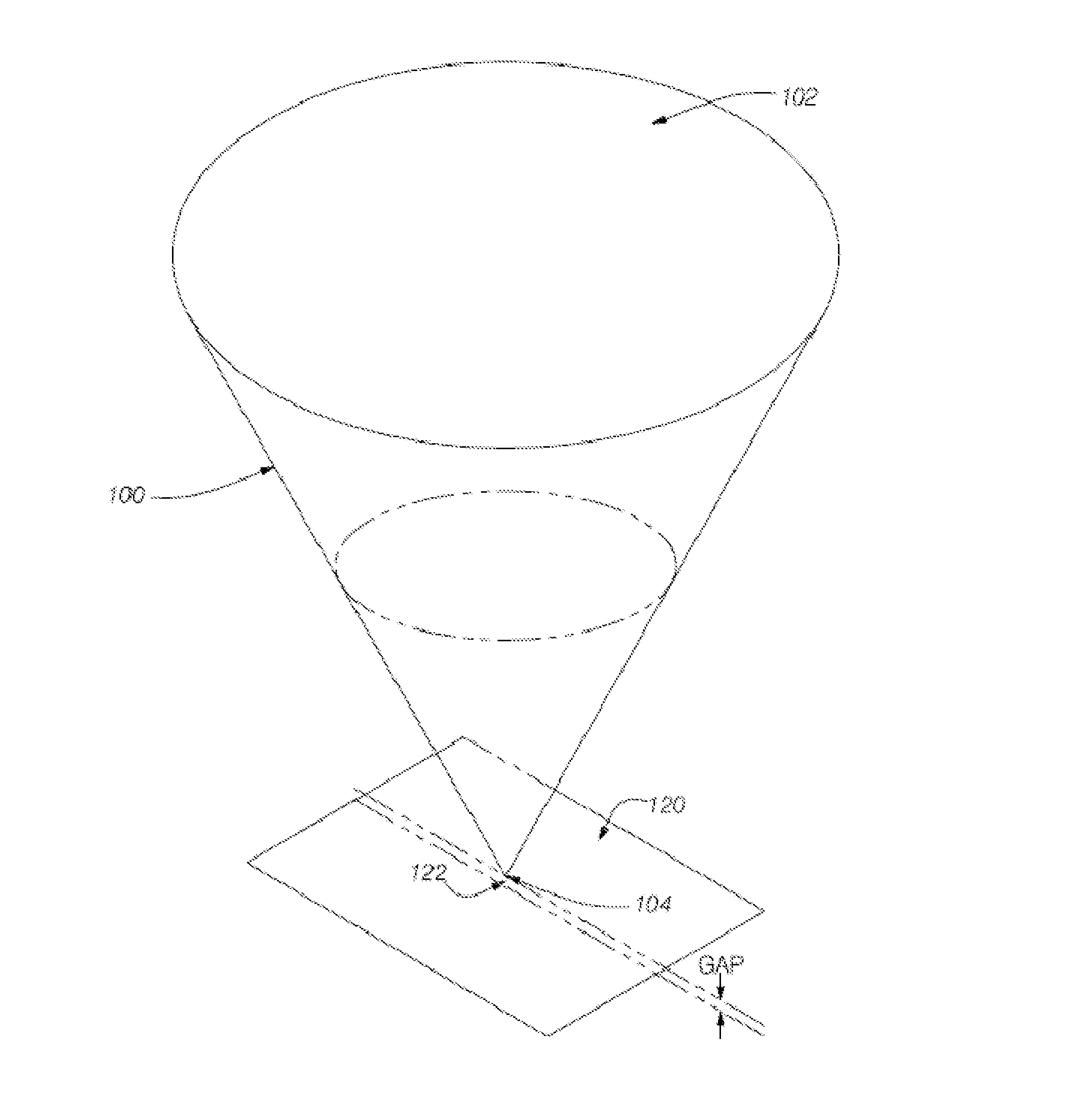

Optical antennas with enhanced fields and electron emission

ActiveUS20130294729A1Convenient lightingStrong local field enhancementAntenna arraysNanoopticsElectrical conductorField electron emission

Owner:PACIFIC INTEGRATED ENERGY

Field emission electron source and preparation method of carbon nanotube graphene composite structure thereof

ActiveCN103050346AImprove launch performanceImprove stabilityMaterial nanotechnologyDischarge tube/lamp detailsPower flowElectron source

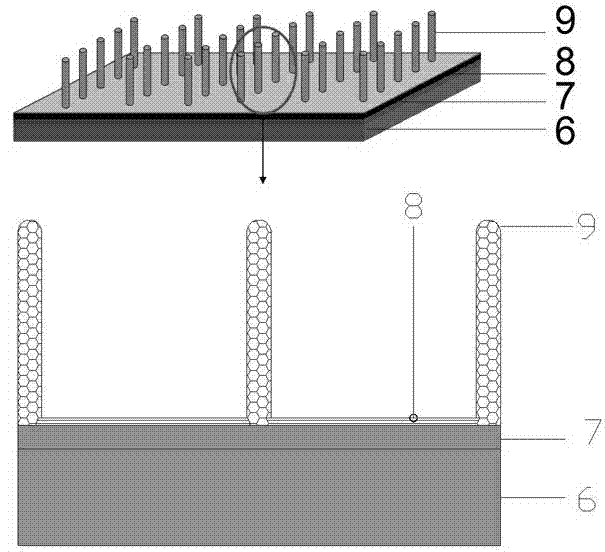

The invention discloses a field emission electron source and a preparation method of a carbon nanotube graphene composite structure thereof. The field emission electron source comprises a conductive substrate, a graphene film layer and a carbon nanotube array which is directionally perpendicular to the graphene film layer, wherein the graphene film layer is adhered onto the conductive substrate, and one end of each carbon nanotube in the carbon nanotube array is connected with the graphene film layer to form an integrated structure. The emission capacity and stability of the carbon nanotube array field emission electron source are greatly improved, so that the electron source obtains highly efficient and stable emission current, and can bear extremely high emission current density.

Owner:广州市昊志影像科技有限公司

Coated electrode with enhanced electron emission and ignition characteristics

InactiveUS6965199B2Improved breakdown reliabilityIncrease current densityNanotechDischarge tube luminescnet screensHigh current densityTelecommunications network

An improved electrode capable of smaller variances and mean breakdown voltage, increased breakdown reliability, smaller electron emission turn-on requirements, and stable electron emissions capable of high current densities include a first electrode material, an adhesion-promoting layer disposed on at least one surface of the first electrode material, and a nanostructure-containing material disposed on at least a portion of the adhesion promoting layer. An improved gas discharge device is provided incorporating an electrode formed as described above. An improved circuit incorporating an improved gas discharge tube device as set forth above is also provided. Further, an improved telecommunications network, incorporating an improved gas discharge tube device as set forth above can also be provided. An improved lighting device is also provided incorporating an electrode constructed as described above.

Owner:COMMSCOPE TECH LLC +1

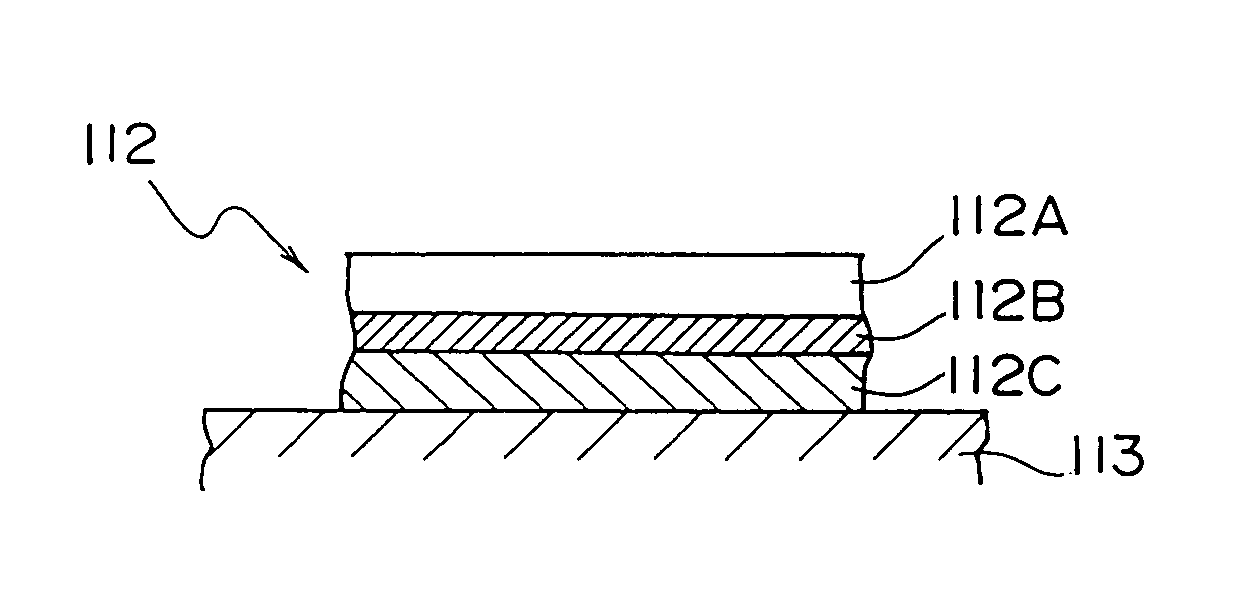

CNT film and field-emission cold cathode comprising the same

InactiveUS7161285B2Improve emission characteristicsUniform and stable emission currentNanoinformaticsThermionic cathodesCarbon nanotubeCold cathode

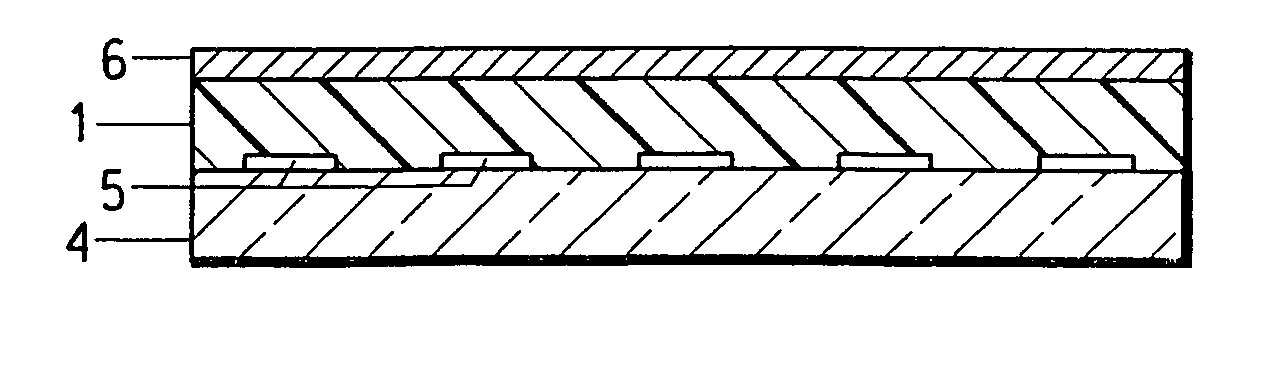

A fabrication method for an emitter includes the steps of forming on a glass substrate a CNT film which contains a plurality of carbon nanotubes (CNTs) and constitutes an emitter electrode, forming a gate electrode via an insulating film on the CNT film, forming a plurality of gate openings in the gate electrode and the insulating film, and aligning upright the CNTs in the gate opening. The upright alignment generates a stable uniform emission current and provides excellent emission characteristics.

Owner:NEC CORP

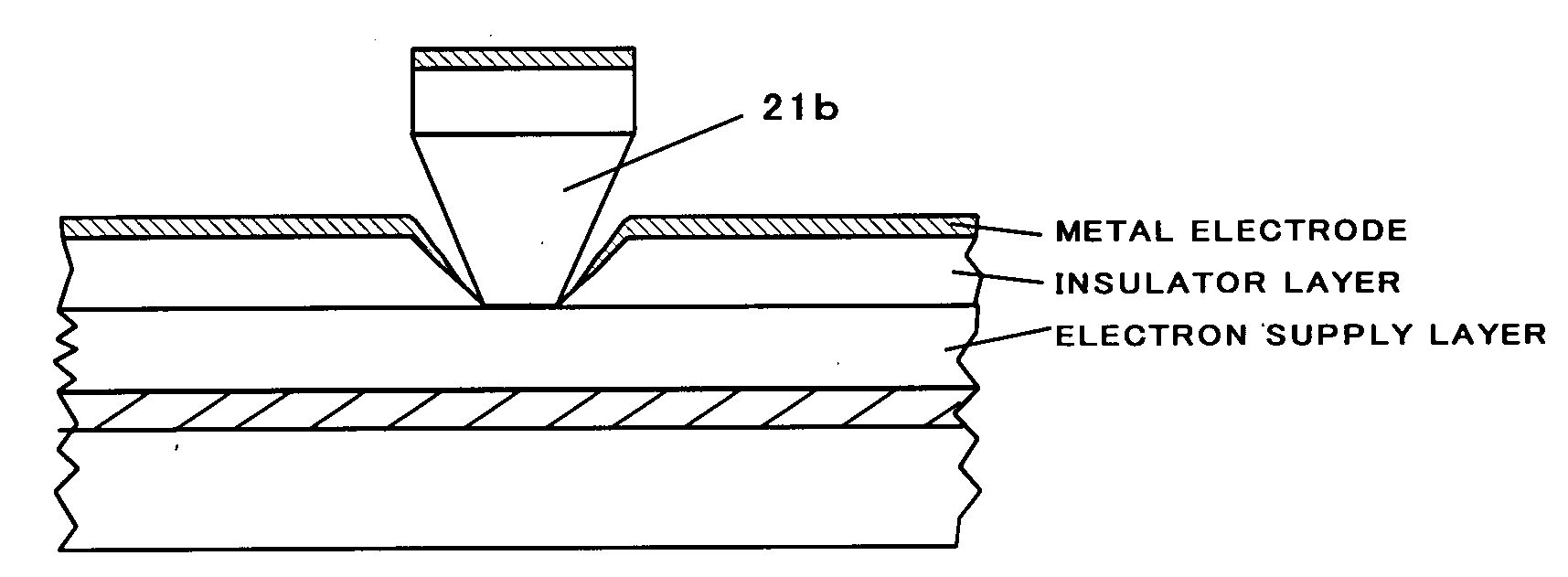

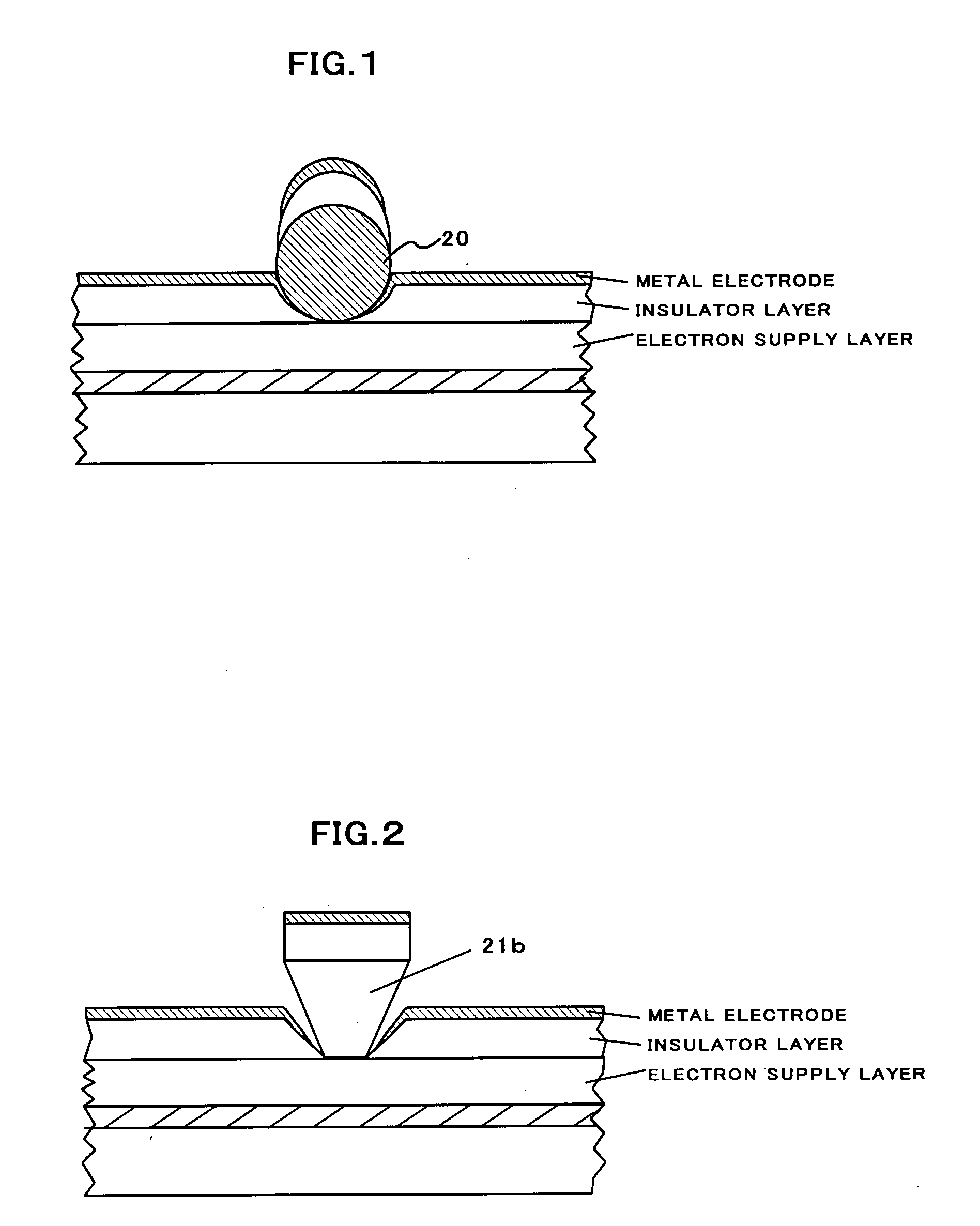

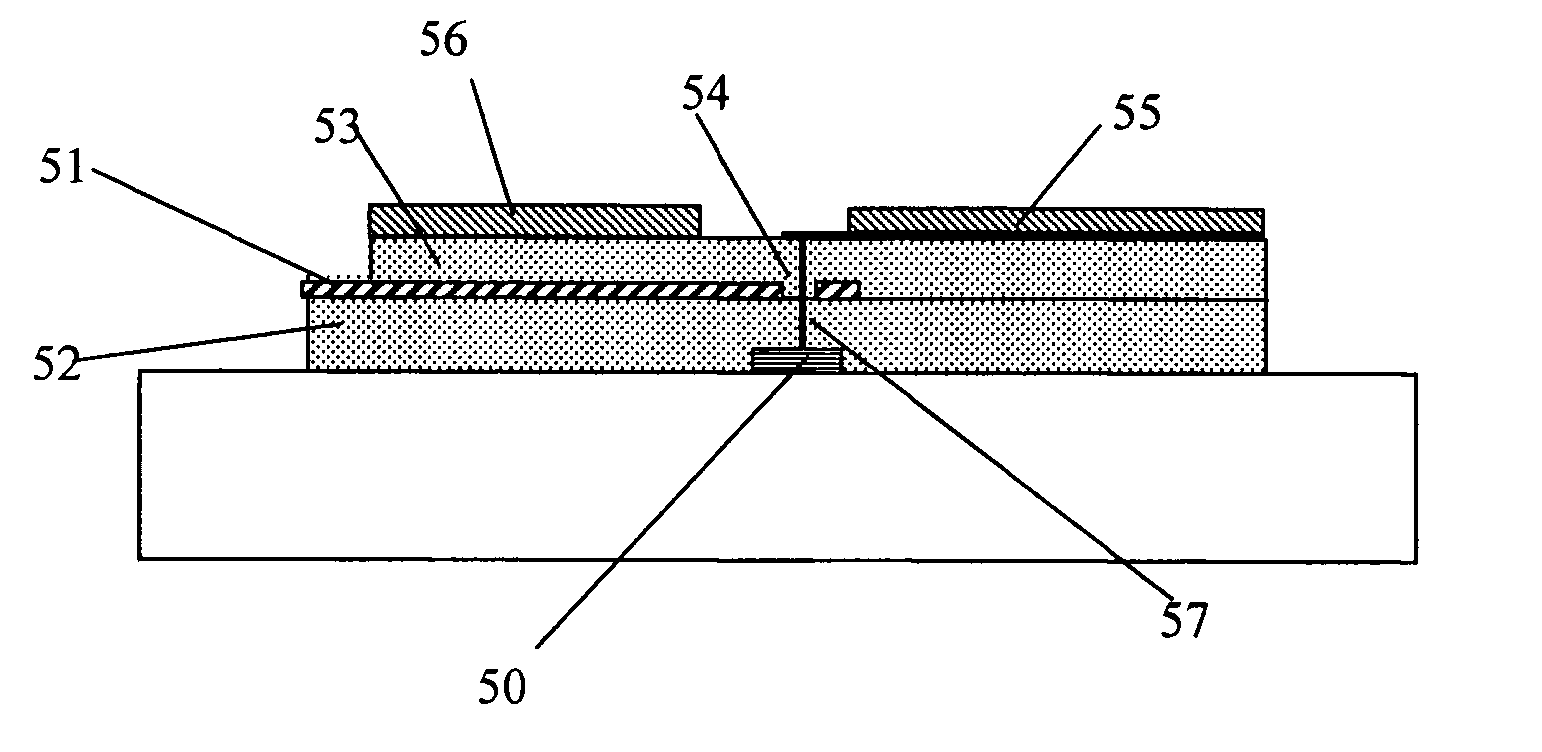

Electron Emission Device And Manufacturing Method Of The Same

InactiveUS20080211401A1Reduce thicknessDischarge tube luminescnet screensElectric discharge tubesField electron emissionOptoelectronics

An electron emission device including a lower electrode on a near side to a substrate and an upper electrode on a far side to the substrate and an insulator layer and an electron supply layer stacked between the lower electrode and the upper electrode and emitting an electron from the upper electrode side at the time of applying a voltage between the lower electrode and the upper electrode, which includes an electron emission part provided with an opening formed by an inner wall of a stepped shape in which a thickness of the insulator layer decreases stepwise; and a carbon-containing carbon region which is connected to the upper electrode side and which is brought into contact with the insulator layer and the electron supply layer.

Owner:PIONEER CORP

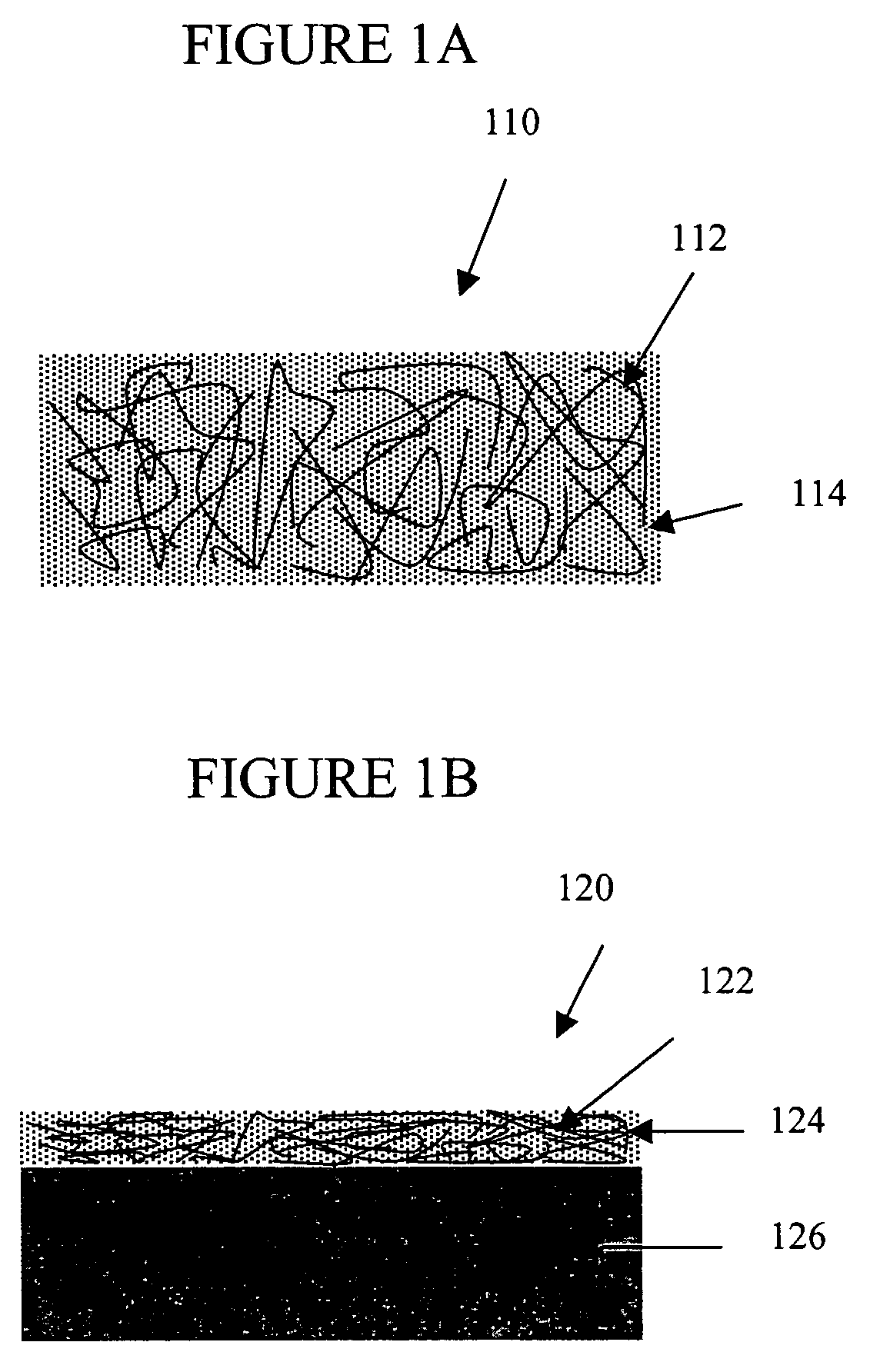

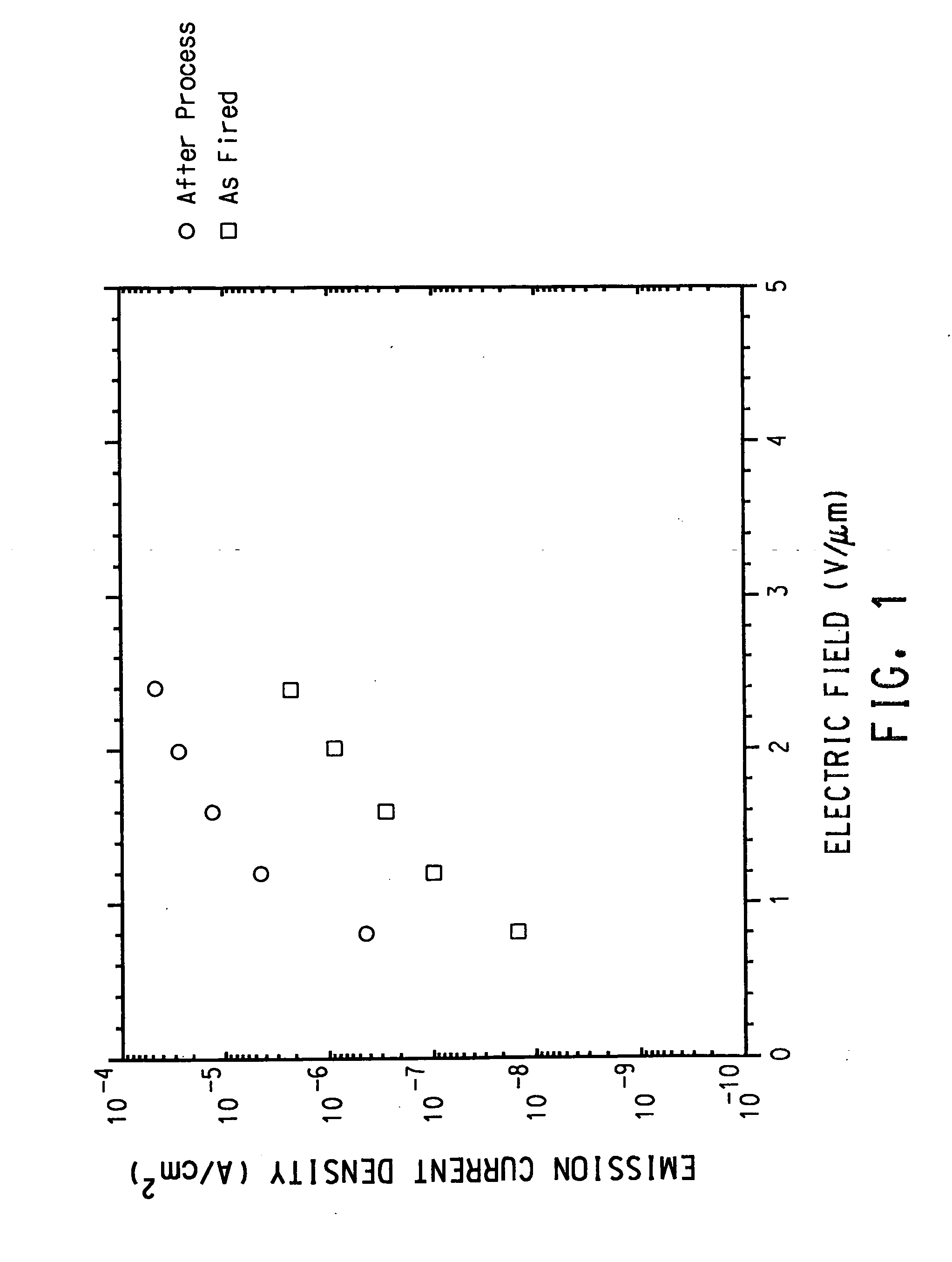

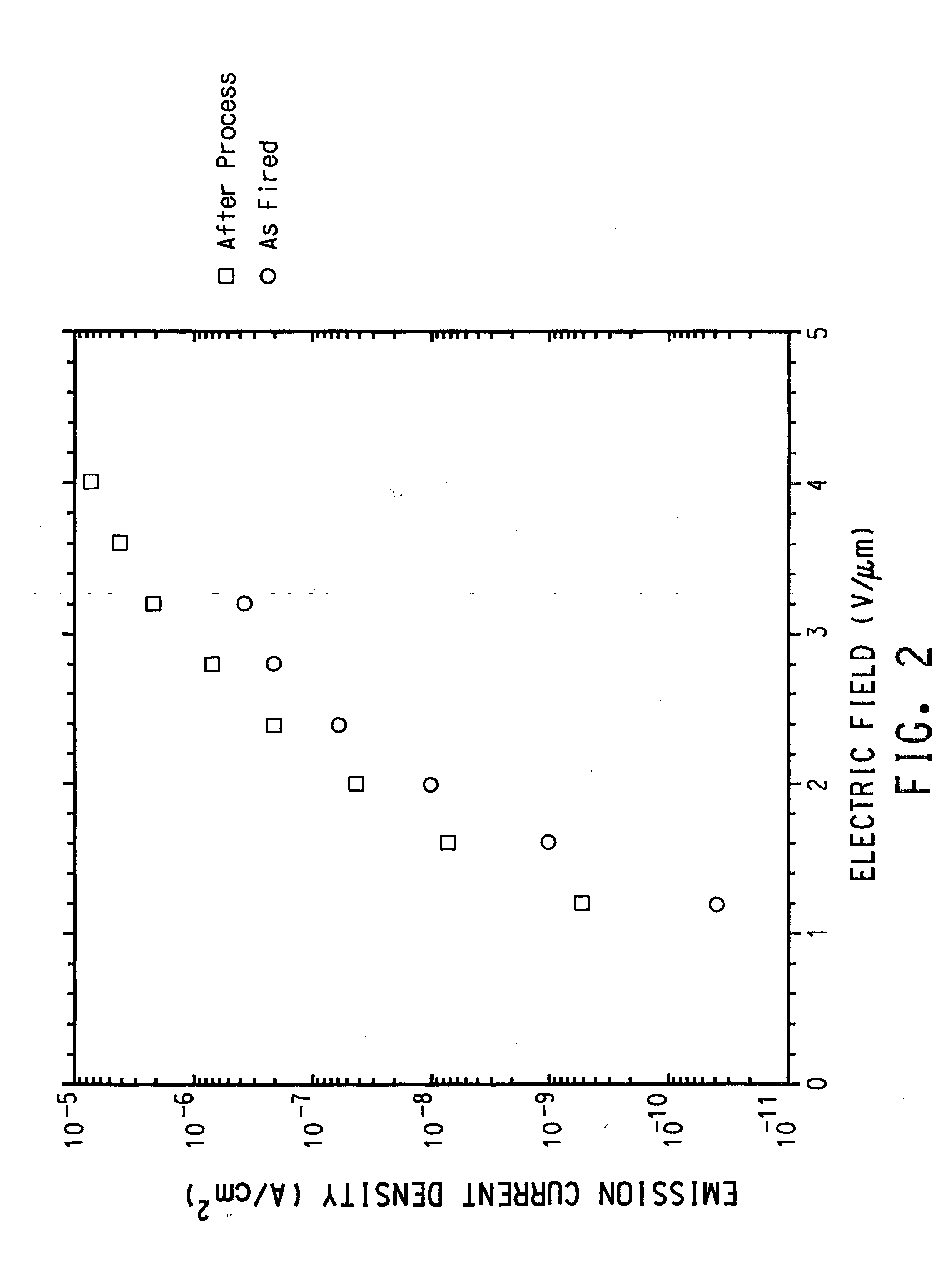

Process for improving the emission of electron field emitters

InactiveUS20050231091A1Improve launch performanceImprove adhesionLamp incadescent bodiesNanoinformaticsField electron emissionParticle physics

This invention provides a process for improving the field emission of an electron field emitter comprised of an acicular emitting substance such as acicular carbon, an acicular semiconductor, an acicular metal or a mixture thereof, comprising applying a force to the surface of the electron field emitter wherein the force results in the removal of a portion of the electron field emitter thereby forming a new surface of the electron field emitter.

Owner:EI DU PONT DE NEMOURS & CO

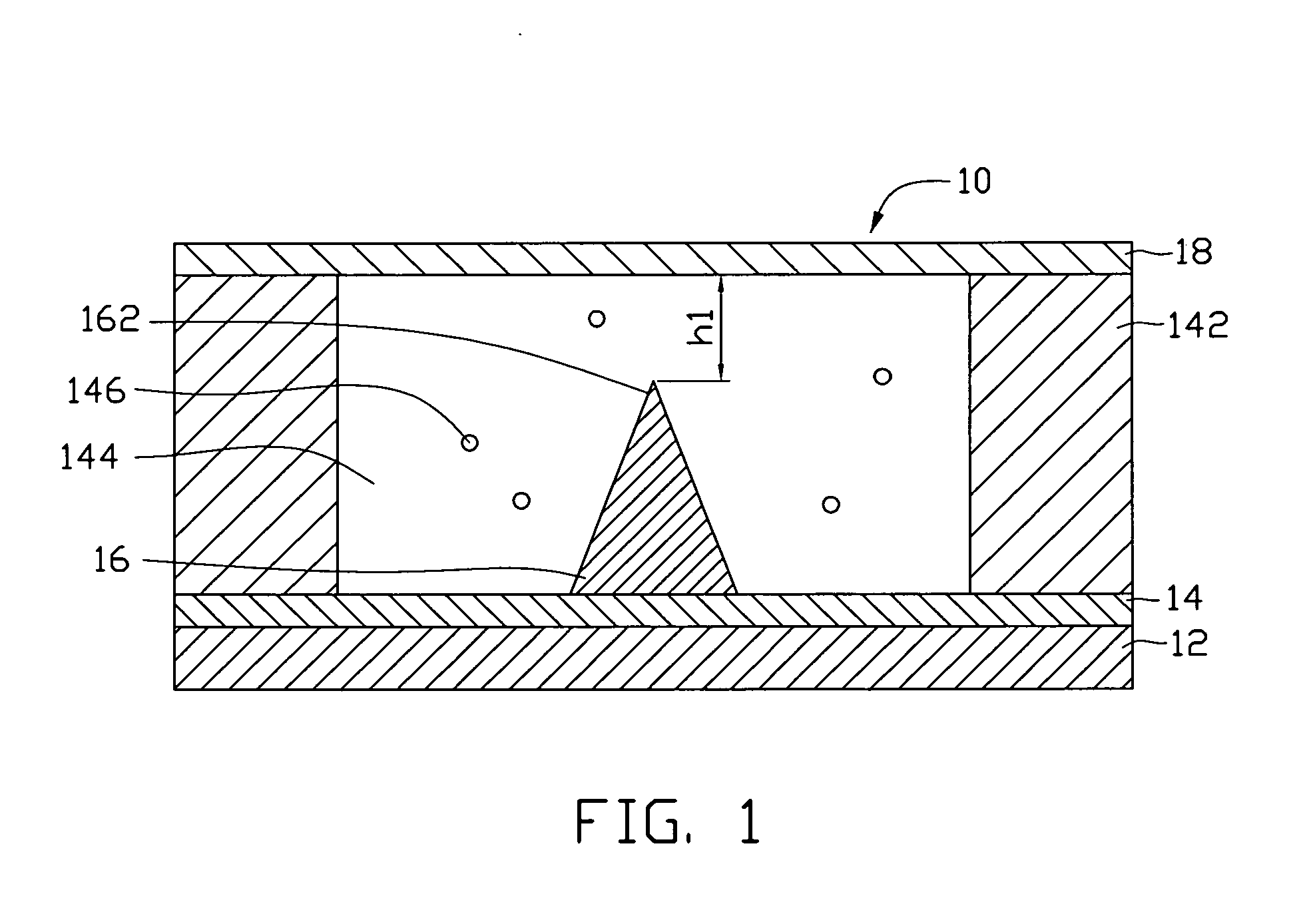

Field emission microelectronic device

InactiveUS20080001513A1Discharge tube main electrodesTubes without control meansMean free pathField electron emission

A nano-scaled field emission electronic device includes a substrate, a cathode electrode, and an anode electrode. The cathode electrode is placed on the substrate and has an emitter. The anode electrode is positioned opposite to and spaced from the cathode electrode. The nano-scaled field emission electronic device further has at least one kind of inert gas filled therein. The following condition is satisfied: h<λe, wherein h indicates a distance between a tip of the emitter and the anode electrode, and λe indicates an average free path of an electron in the inert gases. More advantageously, the following condition is satisfied:h<λe_10.

Owner:TSINGHUA UNIV +1

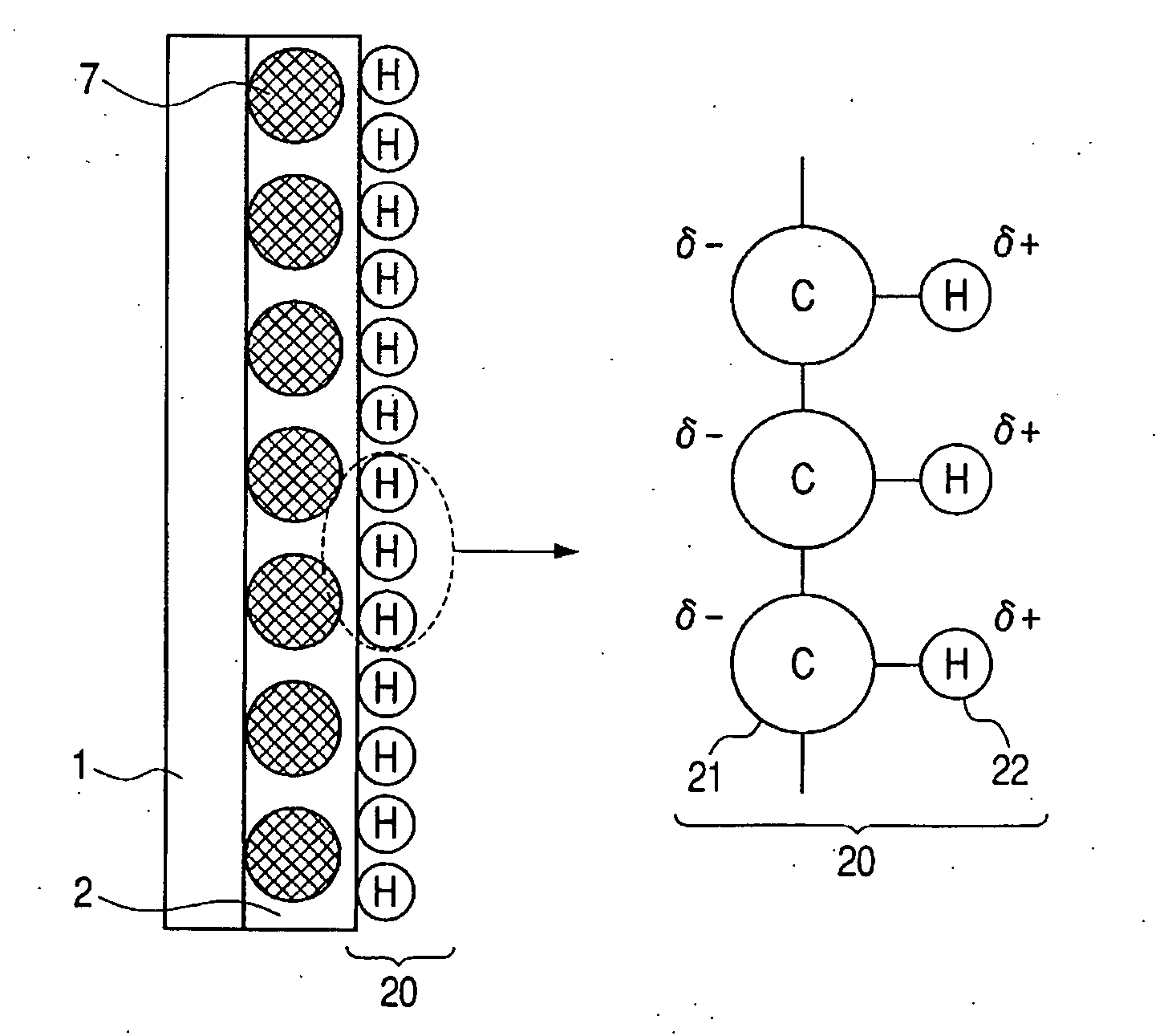

Producing method for electron-emitting device and electron source, and image display apparatus utilizing producing method for electron-emitting device

InactiveUS20060125370A1Easy to prepareSufficient on/off characteristicDischarge tube luminescnet screensCathode ray tubes/electron beam tubesElectron sourceLow voltage

The invention is to provide a producing method for an electron emitting device of field emission type, having sufficient on / off characteristics and capable of efficient electron emission at a low voltage. There is provided a producing method for an electron emitting device including steps of preparing a plurality of electroconductive particles each covered with an insulation material having a thickness of 10 nm or less at least on a part of a surface of the particle, and forming a dipole layer on a surface of the insulation material covering each of the plurality of electroconductive particles.

Owner:CANON KK

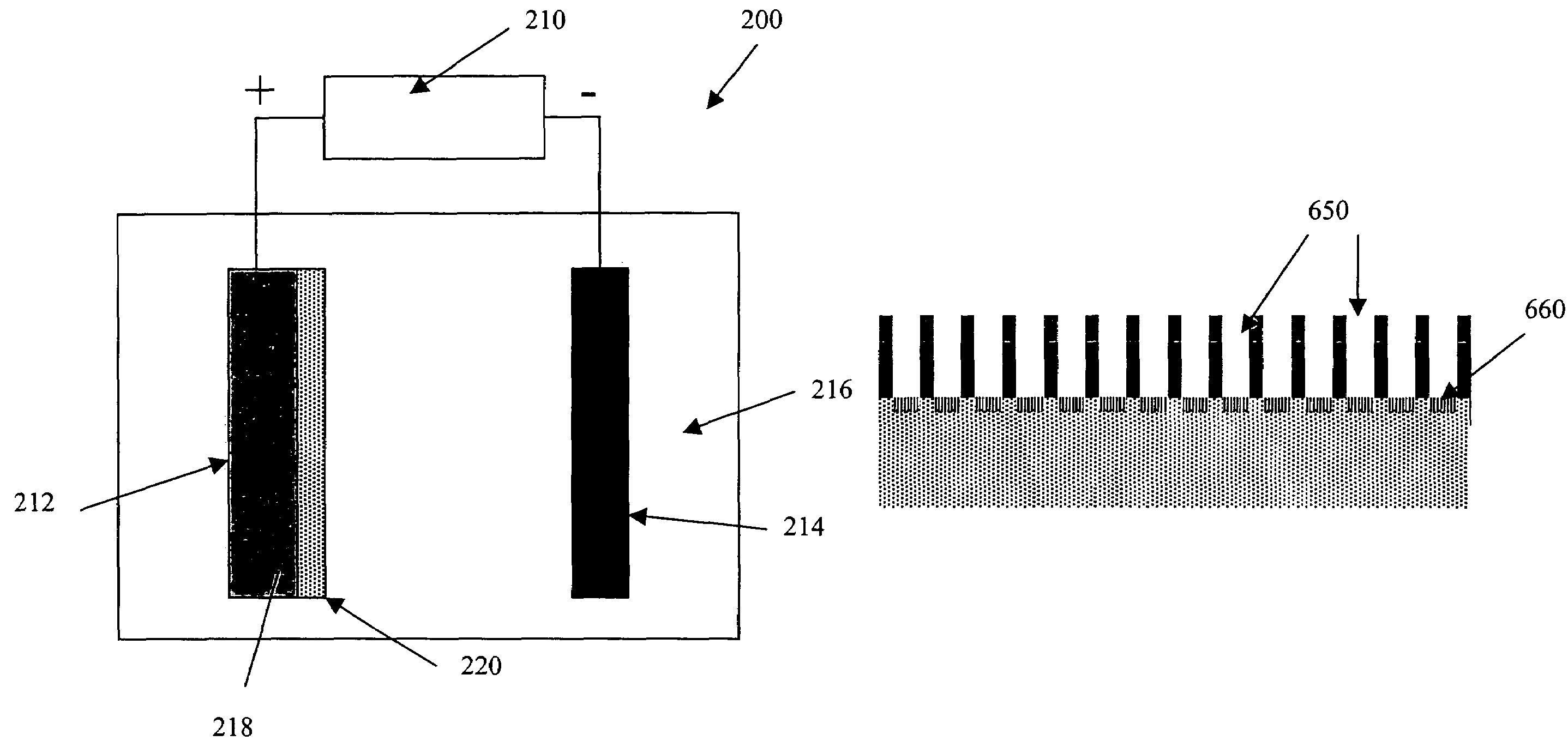

Fabrication and activation processes for nanostructure composite field emission cathodes

ActiveUS7294248B2Improve adhesionImprove conductivityVolume/mass flow measurementNanoinformaticsComposite fieldMetallurgy

A method of forming an electron emitter includes the steps of: (i) forming a nanostructure-containing material; (ii) forming a mixture of nanostructure-containing material and a matrix material; (iii) depositing a layer of the mixture onto at least a portion of at least one surface of a substrate by electrophoretic deposition; (iv) sintering or melting the layer thereby forming a composite; and (v) electrochemically etching the composite to remove matrix material from a surface thereof, thereby exposing nanostructure-containing material.

Owner:NURAY TECH

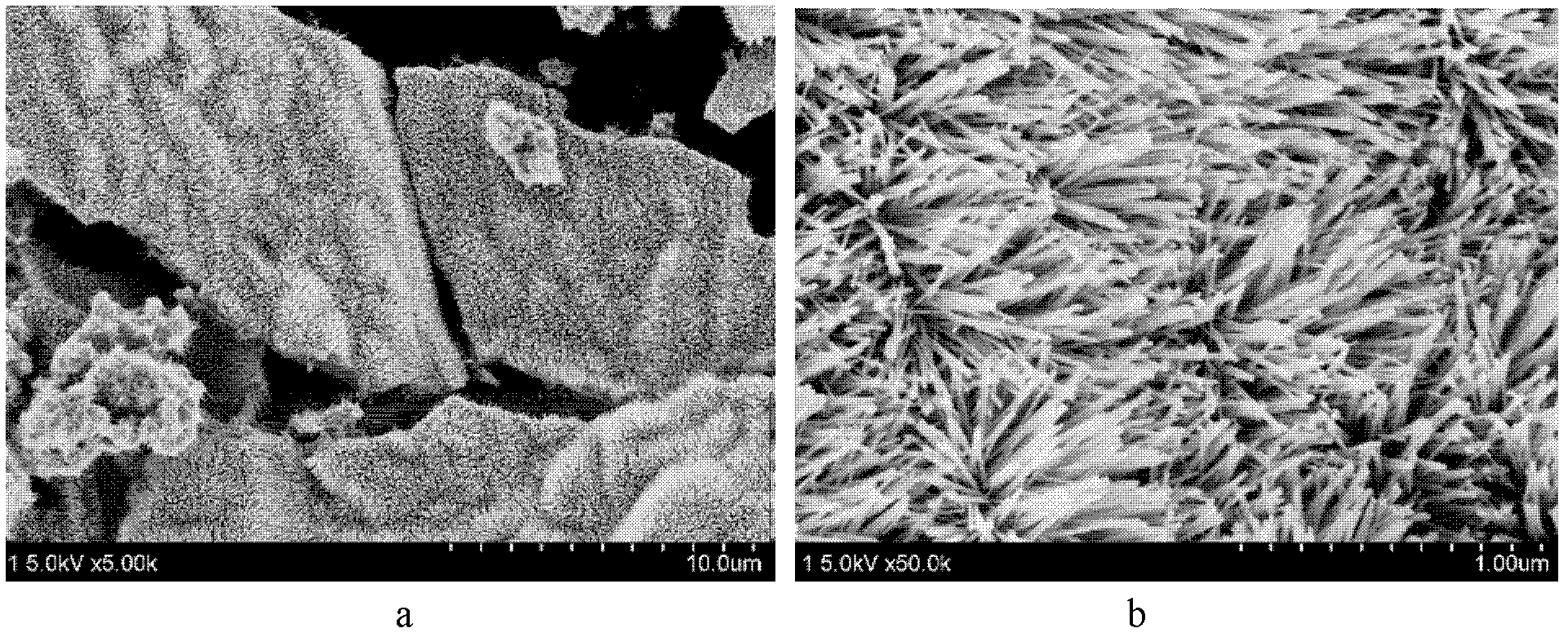

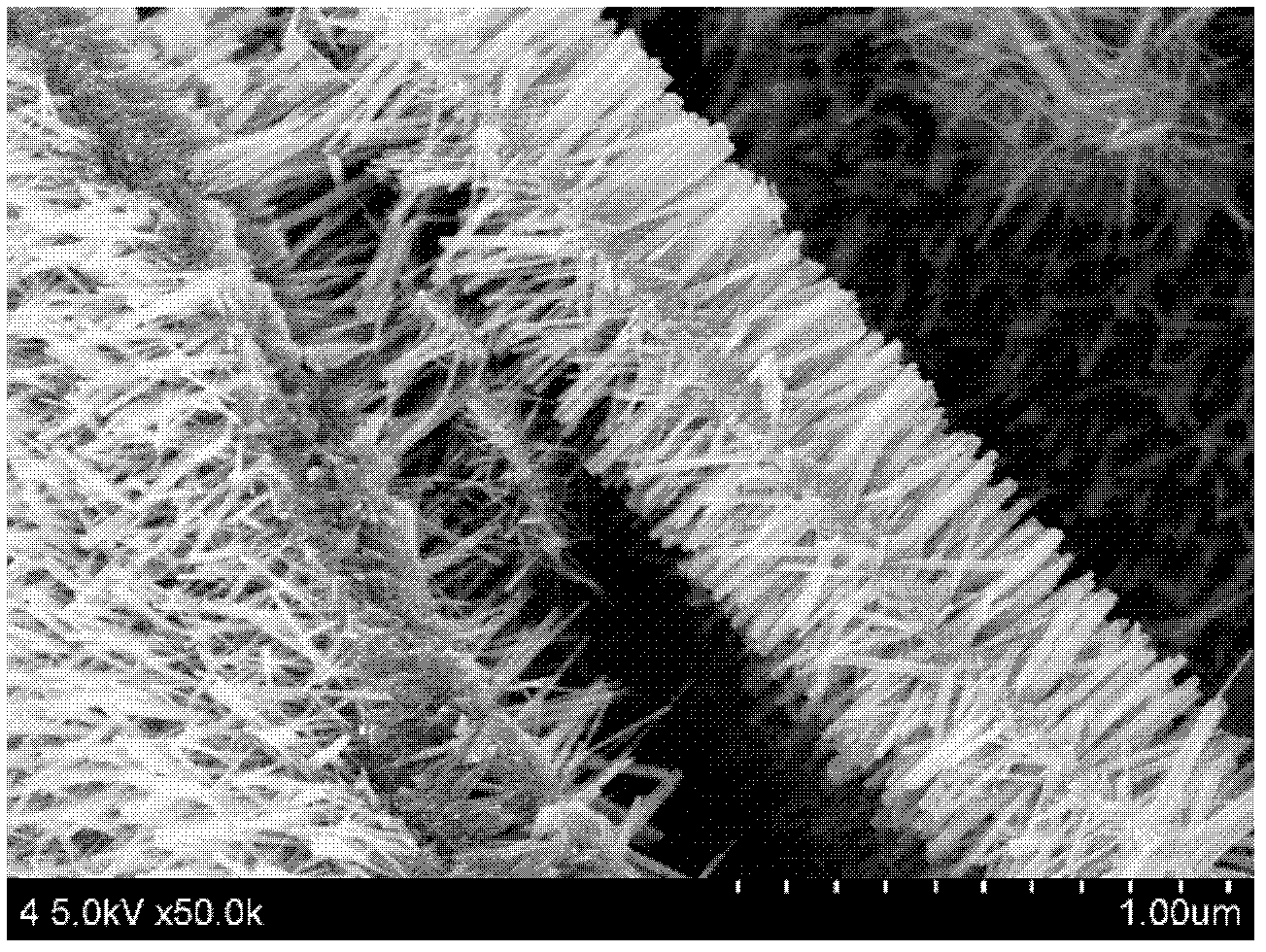

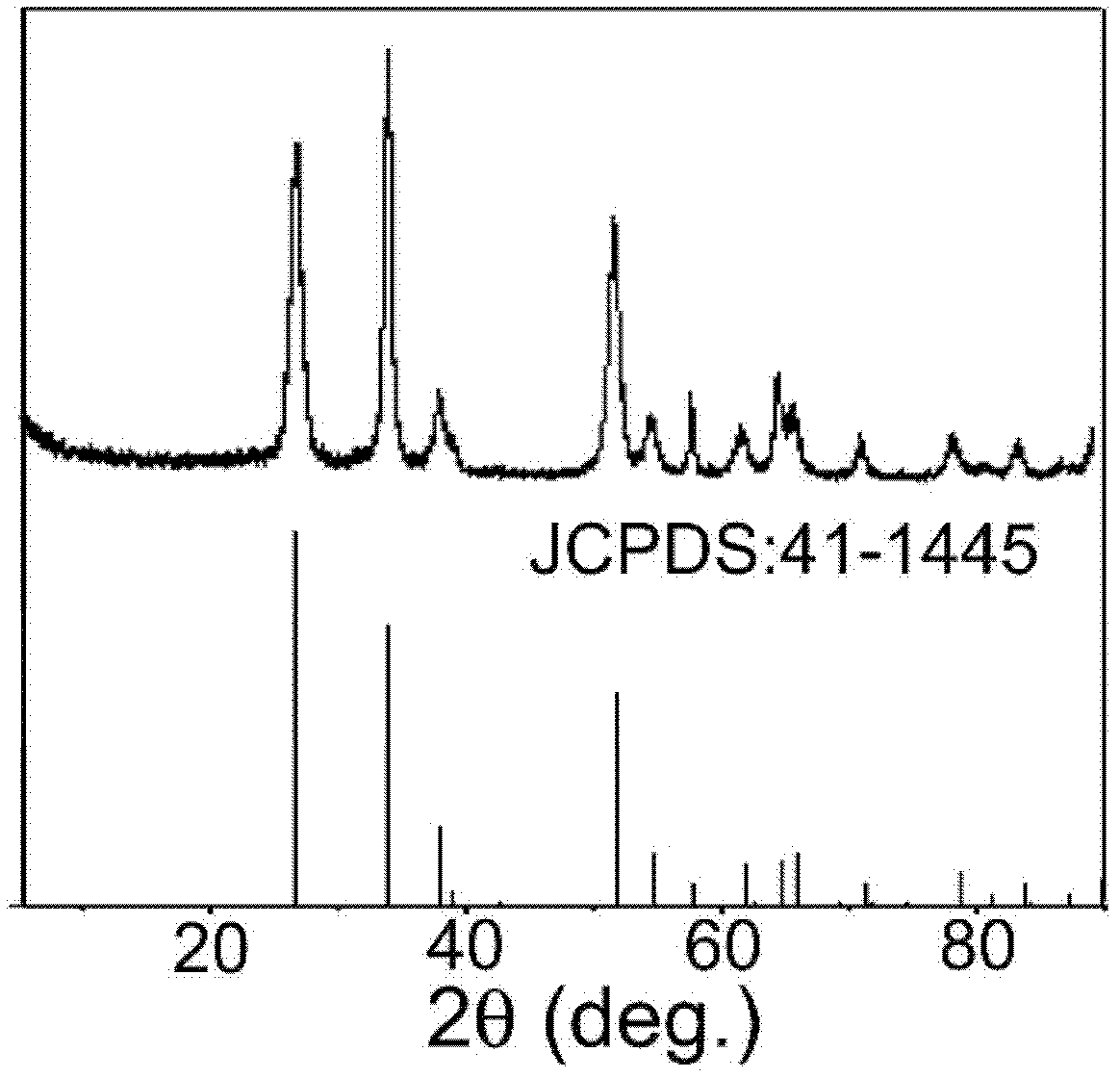

A method for preparing self-substrated sno2 nanorod arrays

InactiveCN102275981ANothing producedLow equipment requirementsNanotechnologyTin oxidesField electron emissionSolvent

The invention relates to a preparation method of a self-substrate SnO2 nanorod array, and the preparation method comprises: dissolving a tin source and sodium hydroxide in water, then adding an organic solvent containing a surfactant, uniformly mixing, then stirring for 10-50 minutes, and then carrying out hydrothermal reaction at the temperature of 100-300 DEG C for 1-50 hours; and after the reaction is finished, naturally cooling to room temperature, filtering, washing and drying to obtain the self-substrate SnO2 nanorod array. The preparation method provided by the invention has the advantages that: the hydrothermal synthesis method has relatively low equipment requirement, is relatively simple to operate and is easy to scale; the used solvents are environmentally-friendly and no toxicmaterials are produced; and the prepared self-substrate SnO2 nanorod array has excellent gas-resistance sensitivity and has broad application prospects in the aspects of gas detection, field emissionmicroelectronic devices, lithium ion battery electrodes and solar cells.

Owner:DONGHUA UNIV

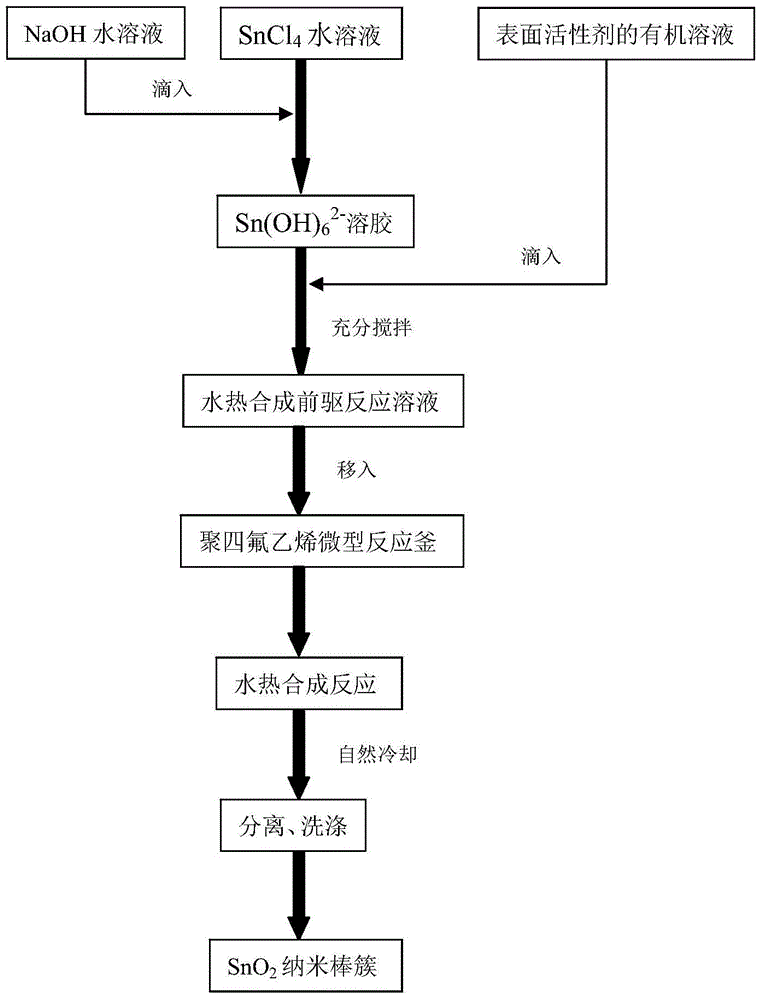

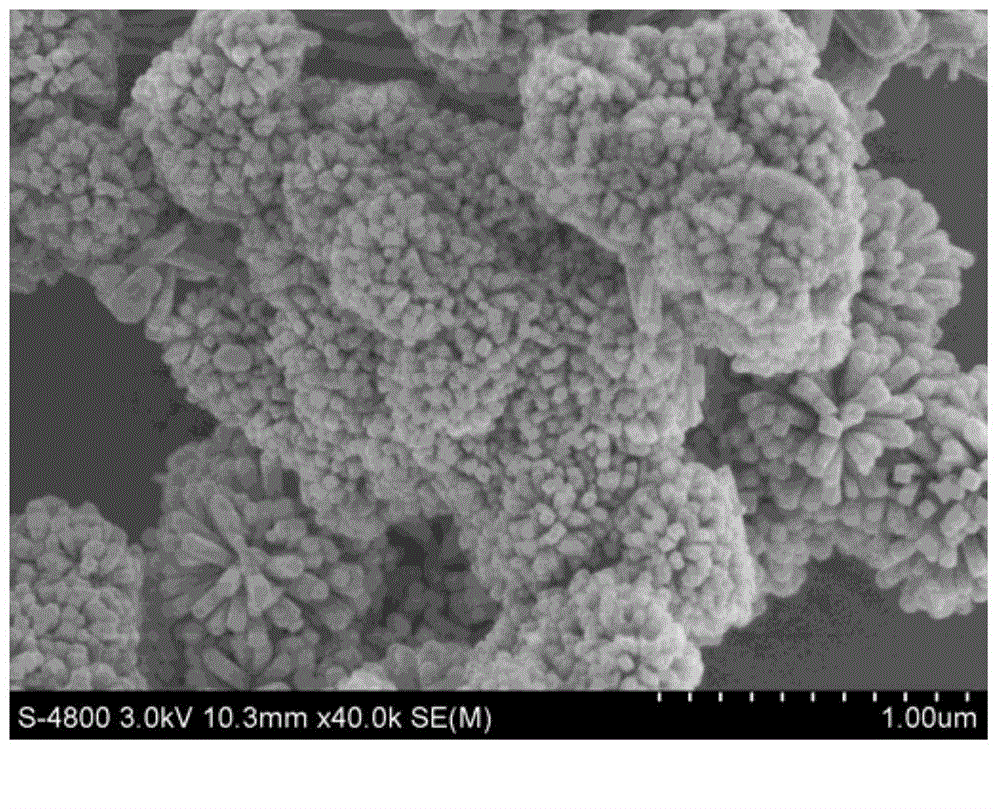

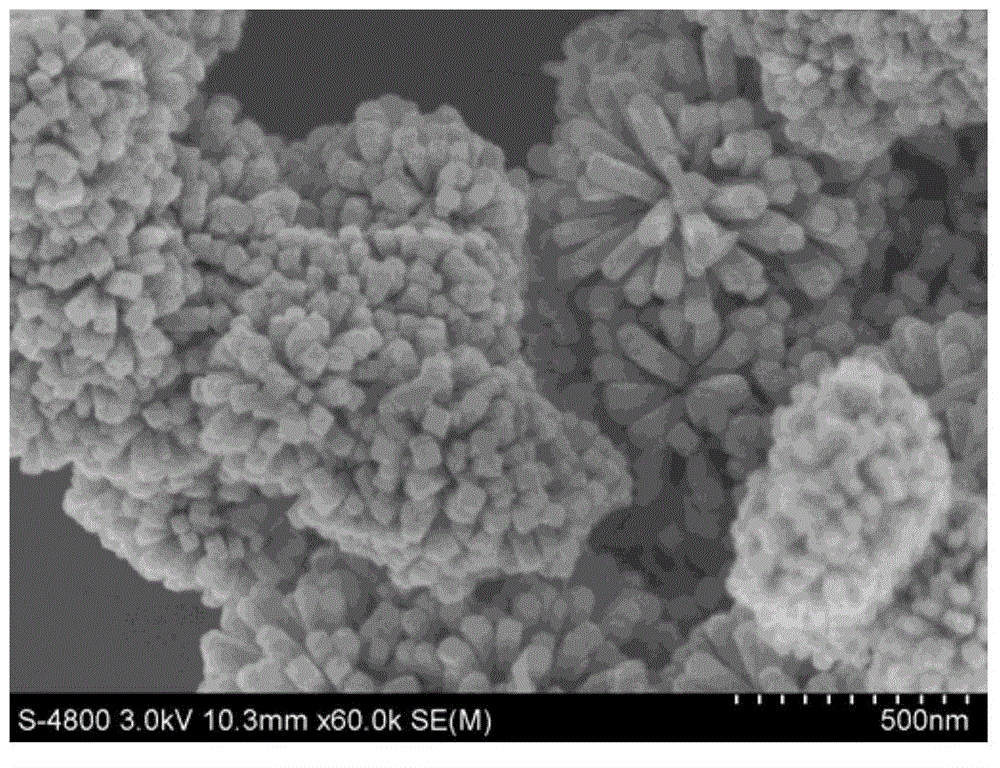

Preparation method for preparing stannic oxide nanorod cluster by using one-step hydrothermal method

InactiveCN104528810ANothing producedLow equipment requirementsMaterial nanotechnologyTin oxidesCrystal orientationField electron emission

The invention relates to a preparation method for preparing a SnO2 nanorod cluster by using a one-step hydrothermal method. The method comprises the following steps: respectively dissolving a stannum source and an alkali in deionized water, dissolving a crystal growth guide agent in a mixed solution of deionized water and ethanol, uniformly mixing the stannum solution and alkali solution, dripping the crystal growth guide agent for stirring so as to form Sn(OH)62-sol; carrying out a hydrothermal reaction at the temperature of 120-260 DEG C, so that the crystal center grows according to a certain crystal orientation; and naturally cooling to room temperature after the reaction is ended, filtering, washing, drying, thereby obtaining the product. The hydrothermal synthesis method disclosed by the invention is low in equipment requirement, easy to operate and easy for large-scale production. The various used solvents are environmentally friendly, and toxic substances are not produced; and the prepared SnO2 nanorod cluster has the properties of large specific surface area and high orientation and has wide application prospects in the aspects of catalyst carriers, gas detection, field emission microelectronic devices and lithium ion battery electrodes.

Owner:TIANJIN UNIV

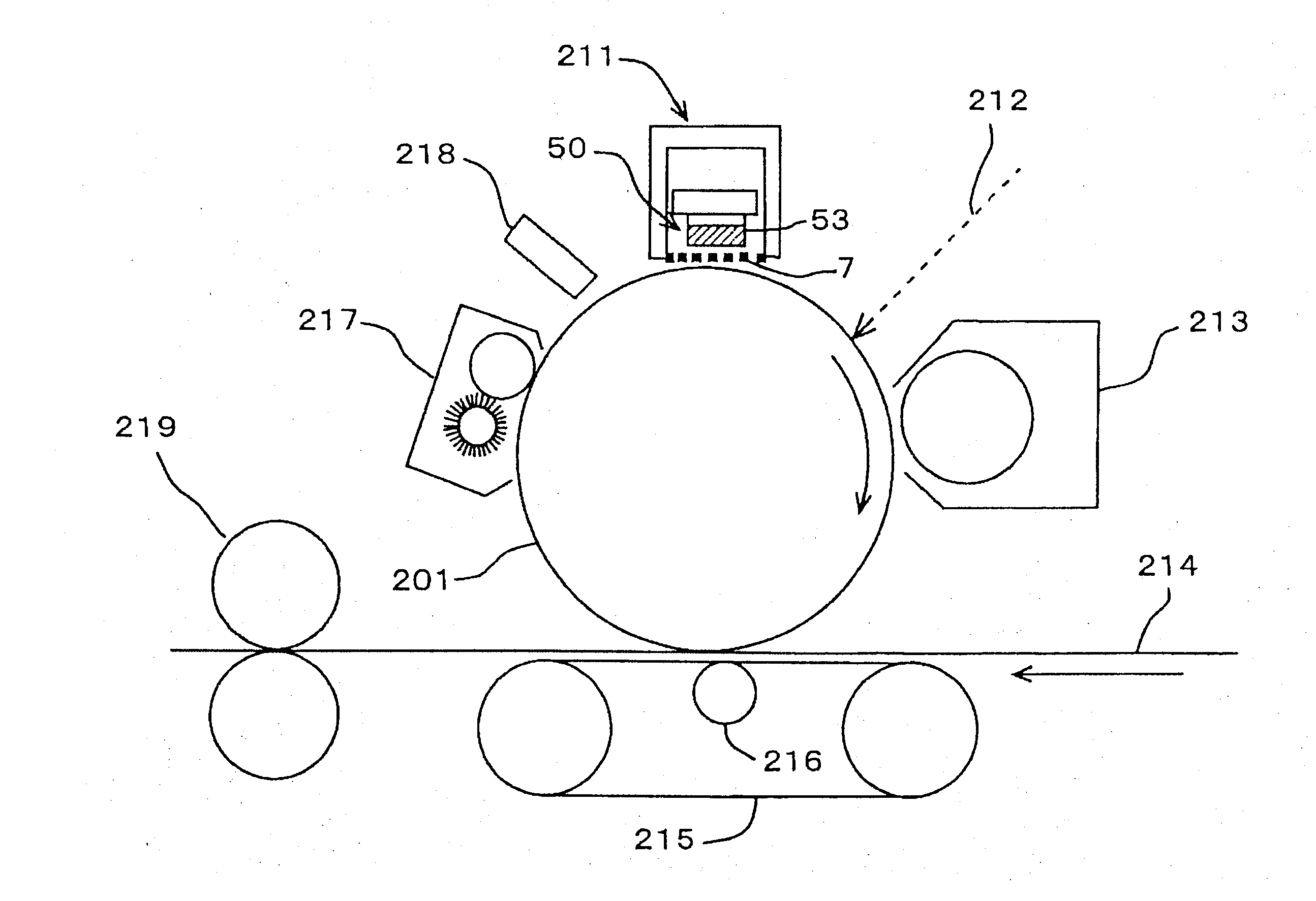

Electron emission element, charging device, process cartridge, and image forming apparatus

InactiveUS20070231010A1Emission reductionReduce deteriorationDischarge tube luminescnet screensLamp detailsSemiconductor materialsMetallic materials

An electron emission element according to the present invention is compact, thin and low cost, and has a structure and constitution in which deterioration of the electron emission material itself is low. In the electron emission element, boron nitride material is used as the electron emission material, and a metal material or a semiconductor material is used as a substrate for forming the boron nitride material. In this way it is possible to obtain good quality boron nitride material on the substrate. Also, a voltage can be applied to the material to emit electrons, also electrons can be supplied. Moreover, by using Sp3-bonded boron nitride as the boron nitride material, and using Sp3-bonded 5H—BN material or Sp3-bonded 6H—BN material as the Sp3-bonded boron nitride, a field electron emission element can be achieved for which high efficiency electron emission characteristics unprecedented in conventional art can be obtained.

Owner:RICOH KK

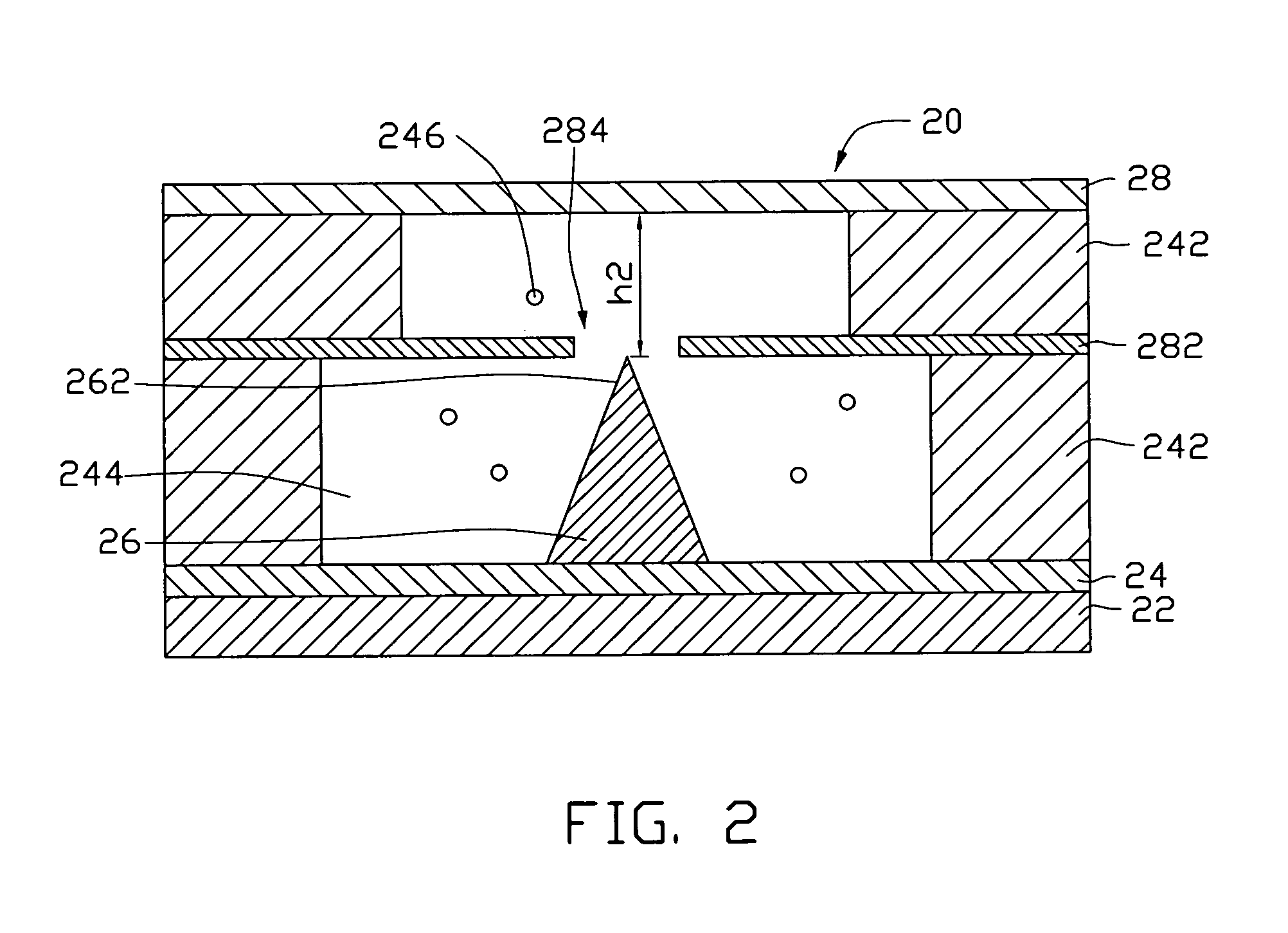

Field emission microelectronic device

InactiveUS20080030117A1Discharge tube luminescnet screensLamp detailsMean free pathField electron emission

A nano-scaled field emission electronic device includes a substrate, a first insulating layer, a second insulating layer, a film of cathode electrode, and a film of anode electrode. The second insulating layer is positioned spaced from the first insulating layer. The cathode electrode is placed on the first insulating layer and has an emitter. The anode electrode is placed on the second insulating layer and positioned opposite to the cathode electrode. The nano-scaled field emission electronic device further has at least one kind of inert gas filled therein. The following condition is satisfied: h<λe, wherein h indicates a distance between a tip of the emitter and the anode electrode, and λe indicates an average free path of an electron in the inert gases. More advantageously, the following condition is satisfied: h<λe_10.

Owner:TSINGHUA UNIV +1

Cold field emitter

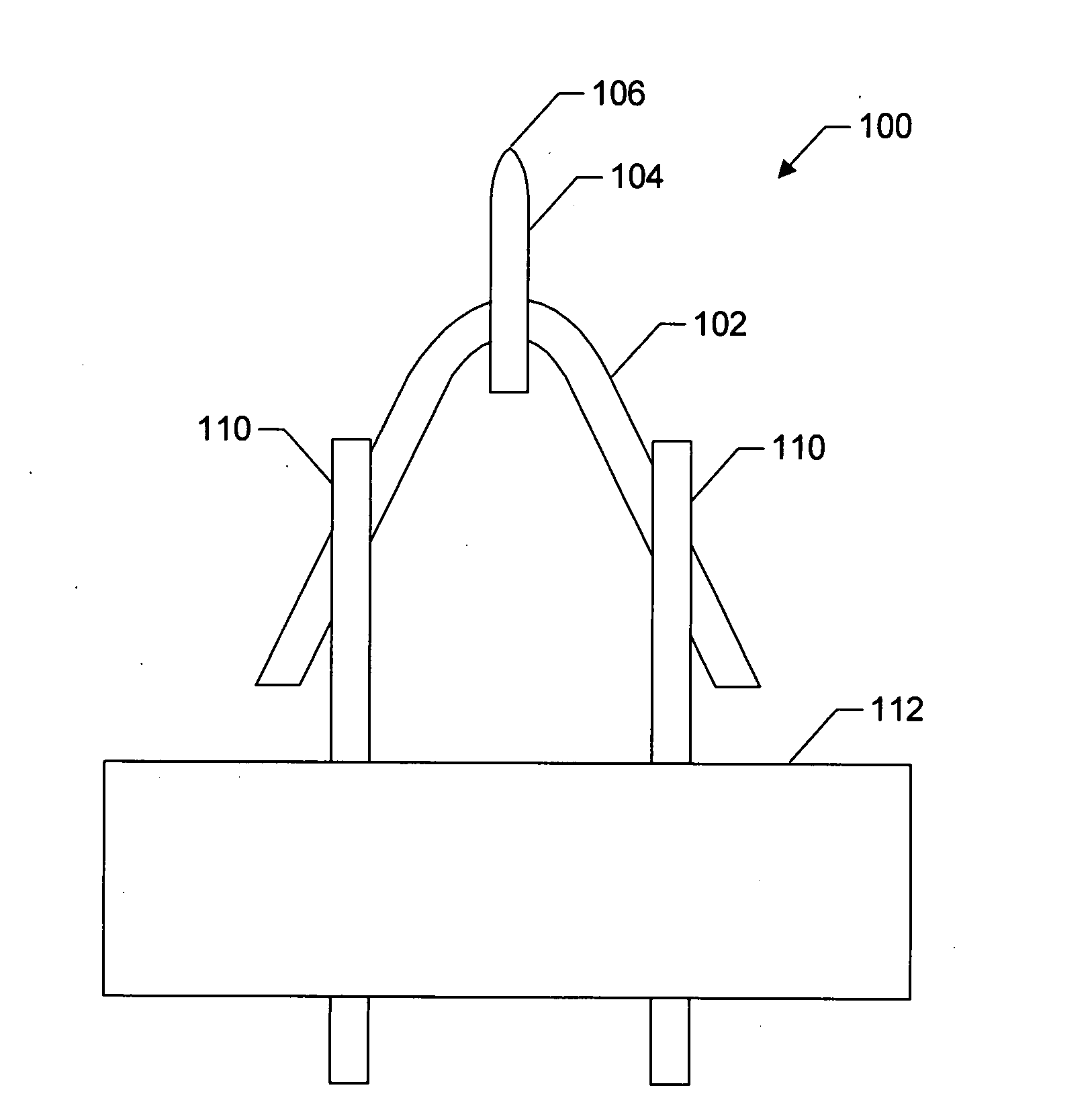

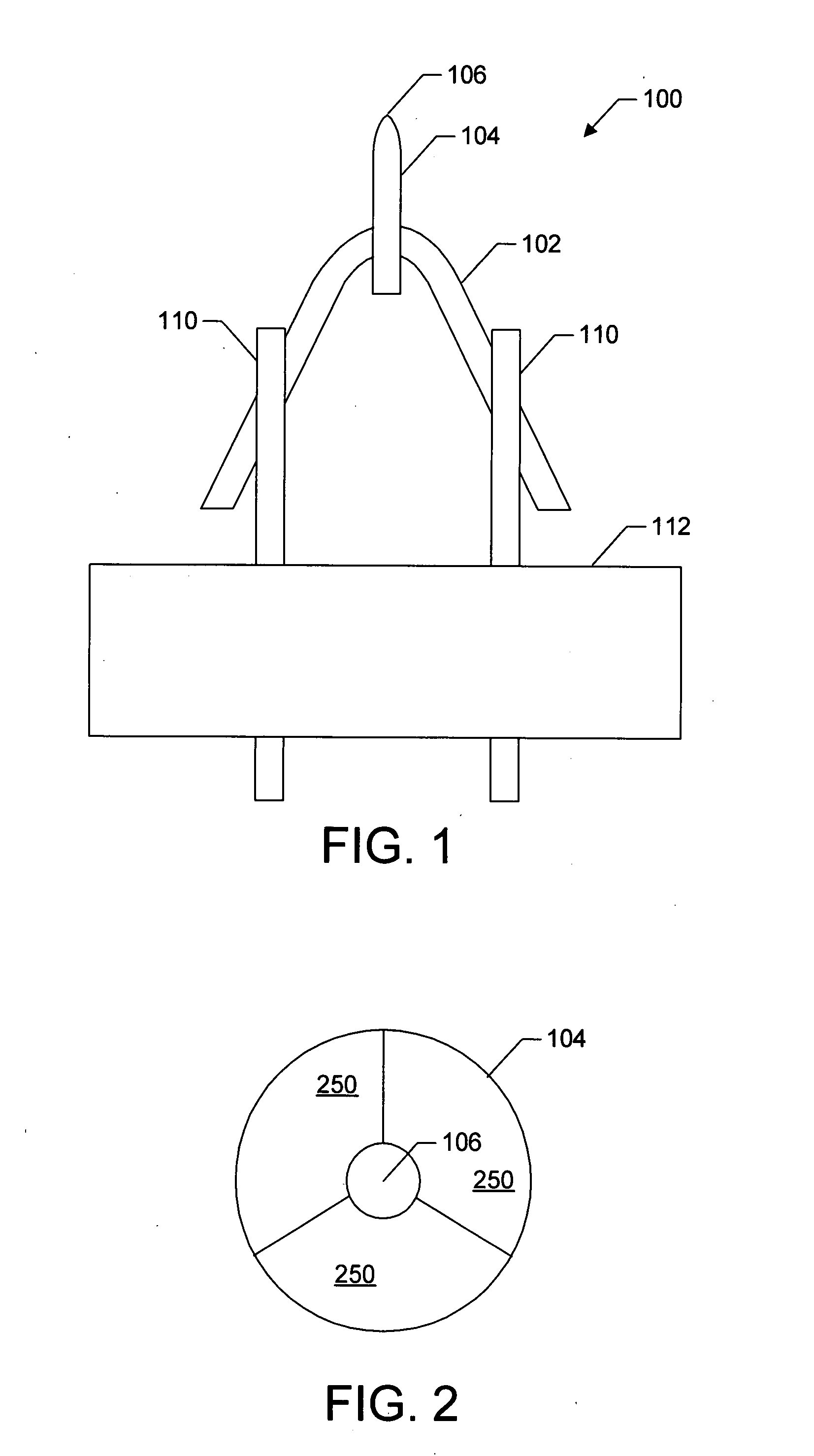

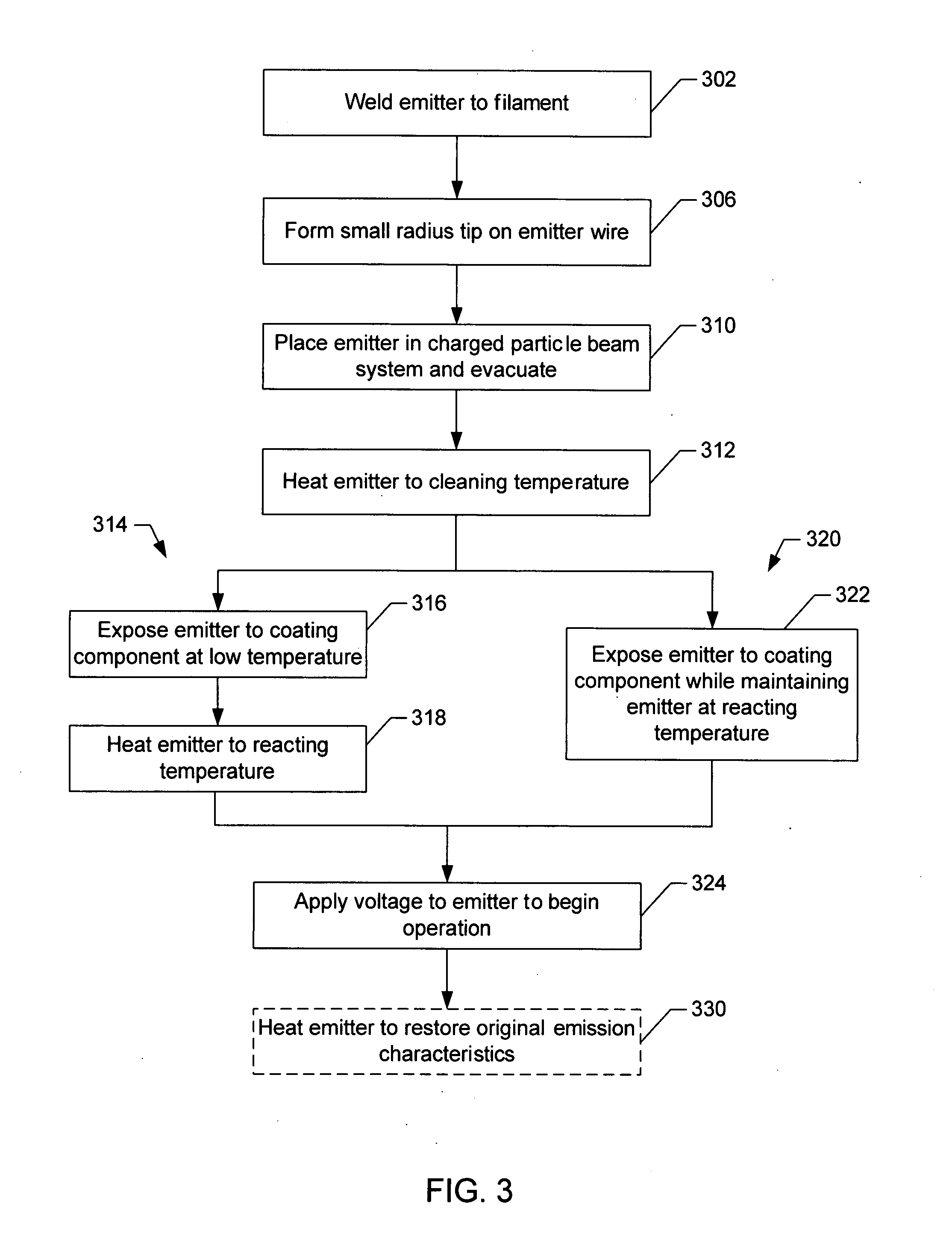

ActiveUS20080174225A1Improve stabilityReduce adsorptionMaterial analysis using wave/particle radiationThermionic cathodesField electron emissionHigh pressure

A stable cold field electron emitter is produced by forming a coating on an emitter base material. The coating protects the emitter from the adsorption of residual gases and from the impact of ions, so that the cold field emitter exhibits short term and long term stability at relatively high pressures and reasonable angular electron emission.

Owner:FEI CO

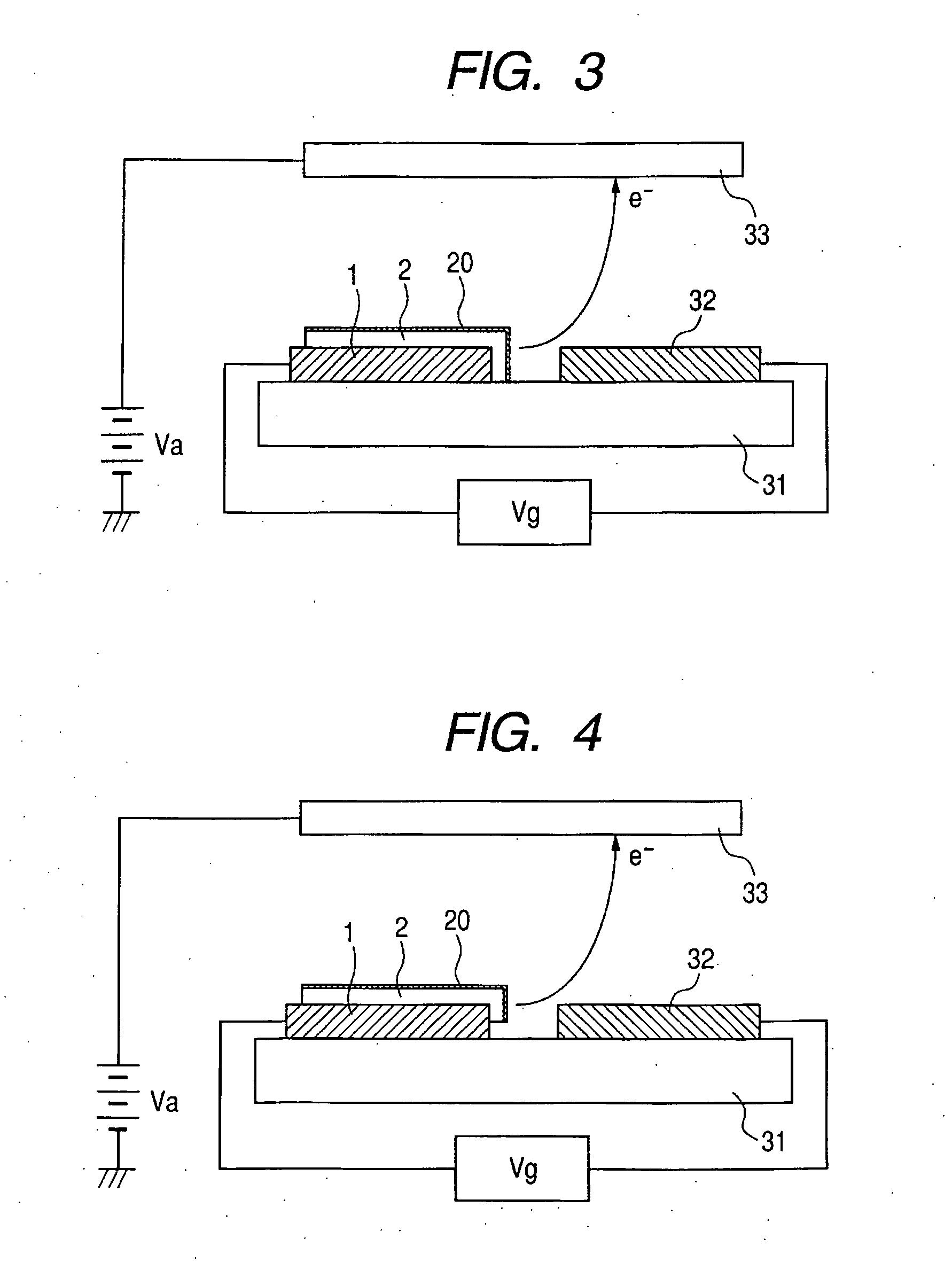

Nanotube array electronic devices

InactiveUS7851784B2Promote growthStrong quantum size effectNanoinformaticsSolid-state devicesFluorescenceField electron emission

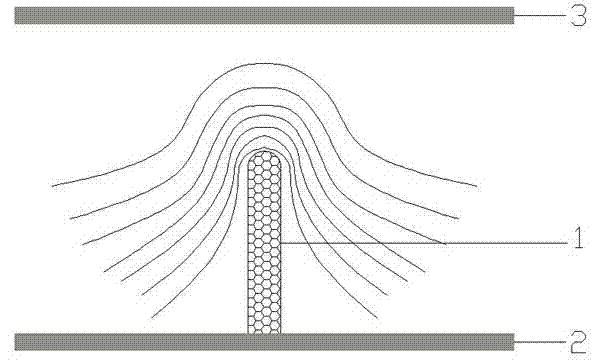

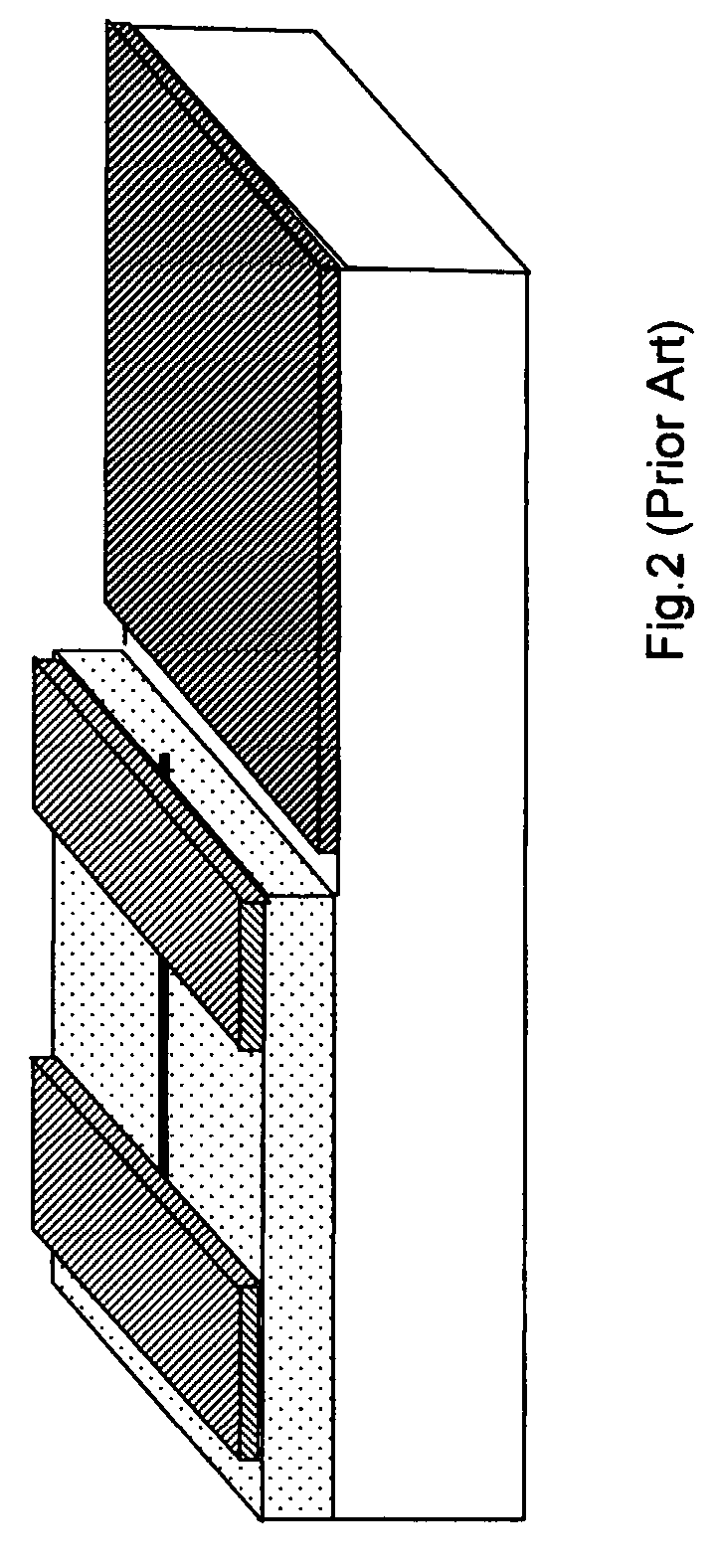

The Nanotube Array Ballistic Transistors are disclosed, wherein the ballistic (without collisions) electron propagation along the nanotubes, grown normally to the substrate plane on the common metal electrode, is used for a new class of hybrid (solid state / vacuum) electronic devices. In the disclosed transistors, the array of nanotubes emits electrons into vacuum when electrons gain sufficient energy inside the nanotubes due to ballistic electron movement under the voltage applied to the nanotube ends.In the disclosed devices, planar layer deposition technology is used to form multilayer structures and attach two electrodes to the nanotubes ends.The ballistic transistor can also be used for making a new type of electron-emission display when a phosphor layer is deposited on the anode electrode.The non-ballistic nanotube array transistor, employing field-induced electron emission and the same planar layer deposition technique, is also disclosed, the device being considered to be a transistor approaching terahertz frequency range of operation.

Owner:NANO ELECTRONICS & PHOTONIC DEVICES & CIRCUITS

Process for improving the emission of electron field emitters

InactiveUS20060049741A1Improve launch performanceImprove adhesionNanoinformaticsThermionic cathodesField electron emissionSemiconductor

This invention provides a process for improving the field emission of an electron field emitter comprised of an acicular emitting substance such as acicular carbon, an acicular semiconductor, an acicular metal or a mixture thereof, comprising applying a force to the surface of the electron field emitter wherein the force results in the removal of a portion of the electron field emitter thereby forming a new surface of the electron field emitter.

Owner:EI DU PONT DE NEMOURS & CO

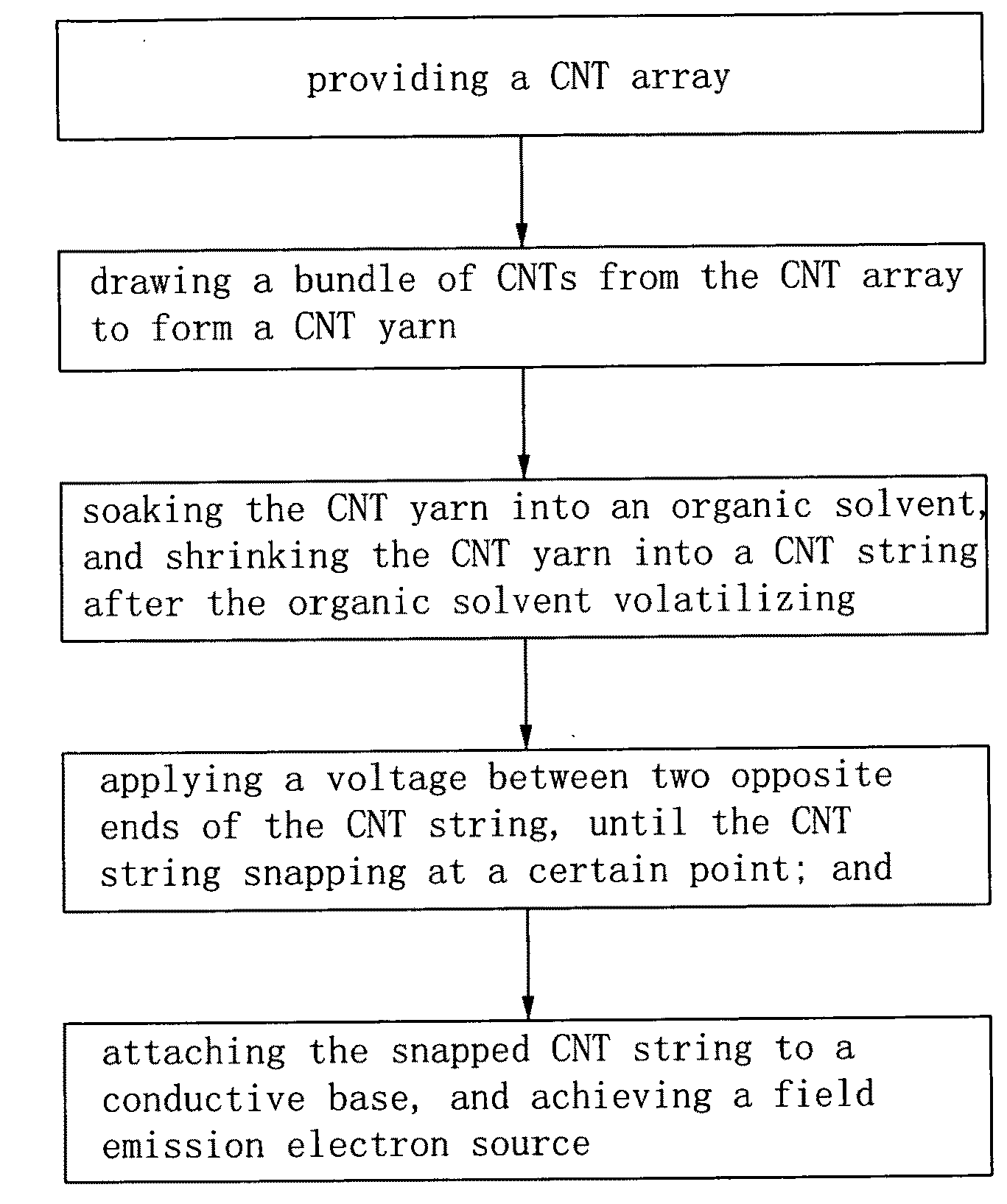

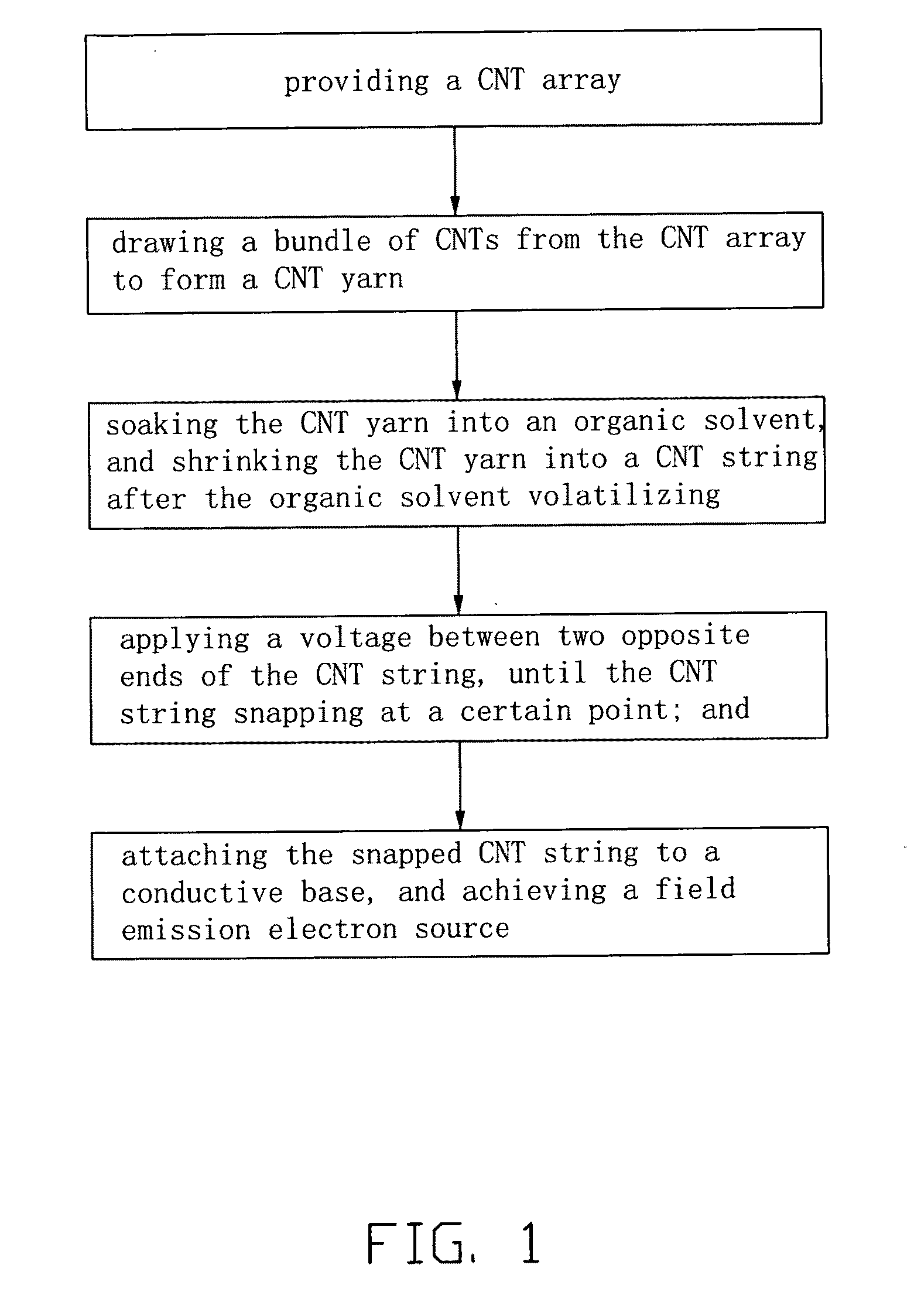

Method for manufacturing field emission electron source having carbon nanotubes

ActiveUS20090117674A1Simple control processHigh mechanical strengthElectric discharge tubesSemiconductor/solid-state device manufacturingYarnOrganic solvent

A method for manufacturing a field emission electron source includes: providing a CNT array; drawing a bundle of CNTs from the CNT array to form a CNT yarn; soaking the CNT yarn into an organic solvent, and shrinking the CNT yarn into a CNT string after the organic solvent volatilizing; applying a voltage between two opposite ends of the CNT string, until the CNT string snapping at a certain point; and attaching the snapped CNT string to a conductive base, and achieving a field emission electron source. The field emission efficiency of the field emission electron source is high.

Owner:TSINGHUA UNIV +1

Process for improving the emissions of electron field emitters

InactiveUS20070160758A1Improve launch performanceImprove adhesionNanoinformaticsCold cathodesField electron emissionSemiconductor

This invention provides a process for improving the field emission of an electron field emitter comprised of an acicular emitting substance such as acicular carbon, an acicular semiconductor, an acicular metal or a mixture thereof, comprising applying a force to the surface of the electron field emitter wherein the force results in the removal of a portion of the electron field emitter thereby forming a new surface of the electron field emitter.

Owner:EI DU PONT DE NEMOURS & CO

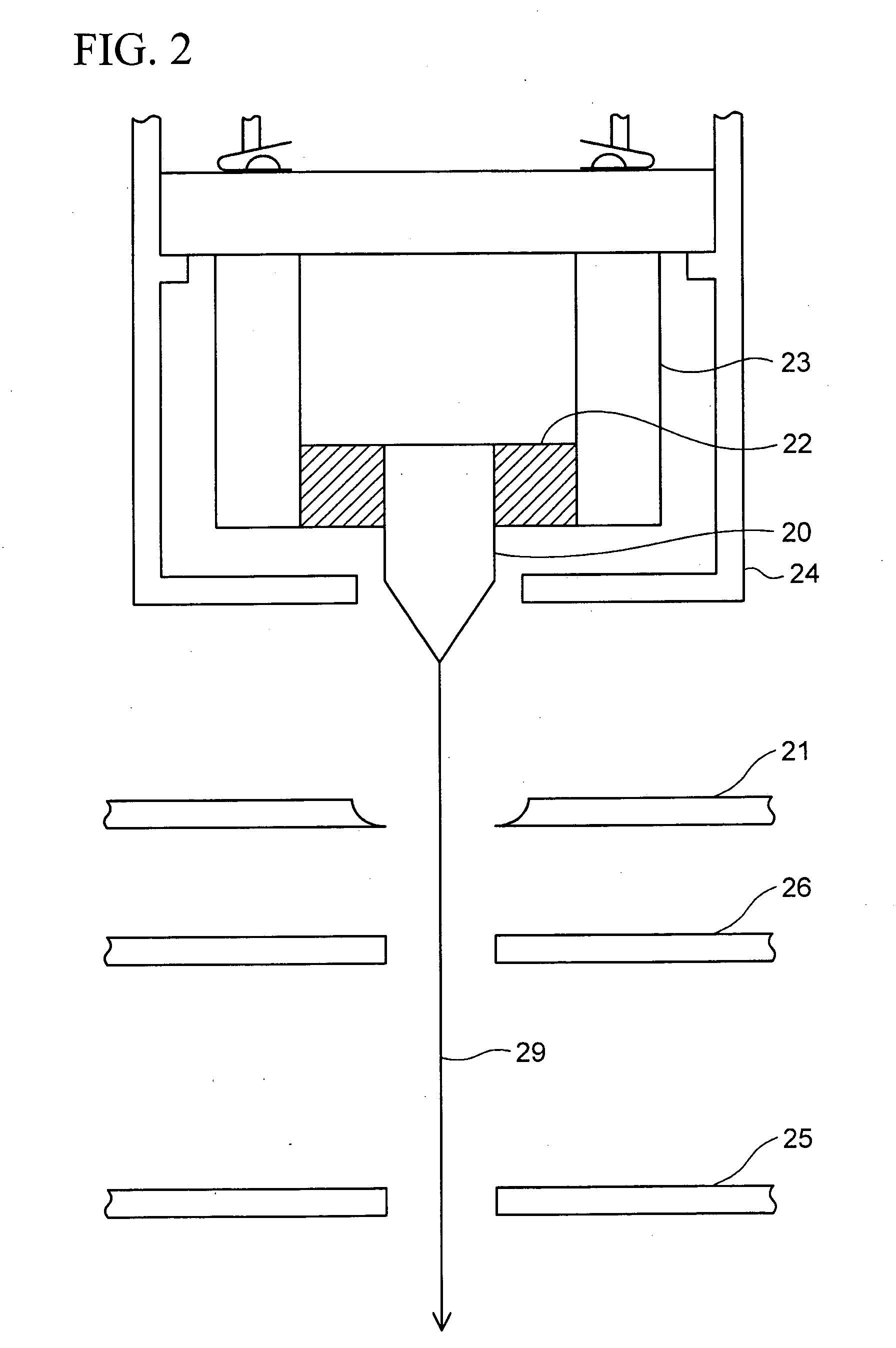

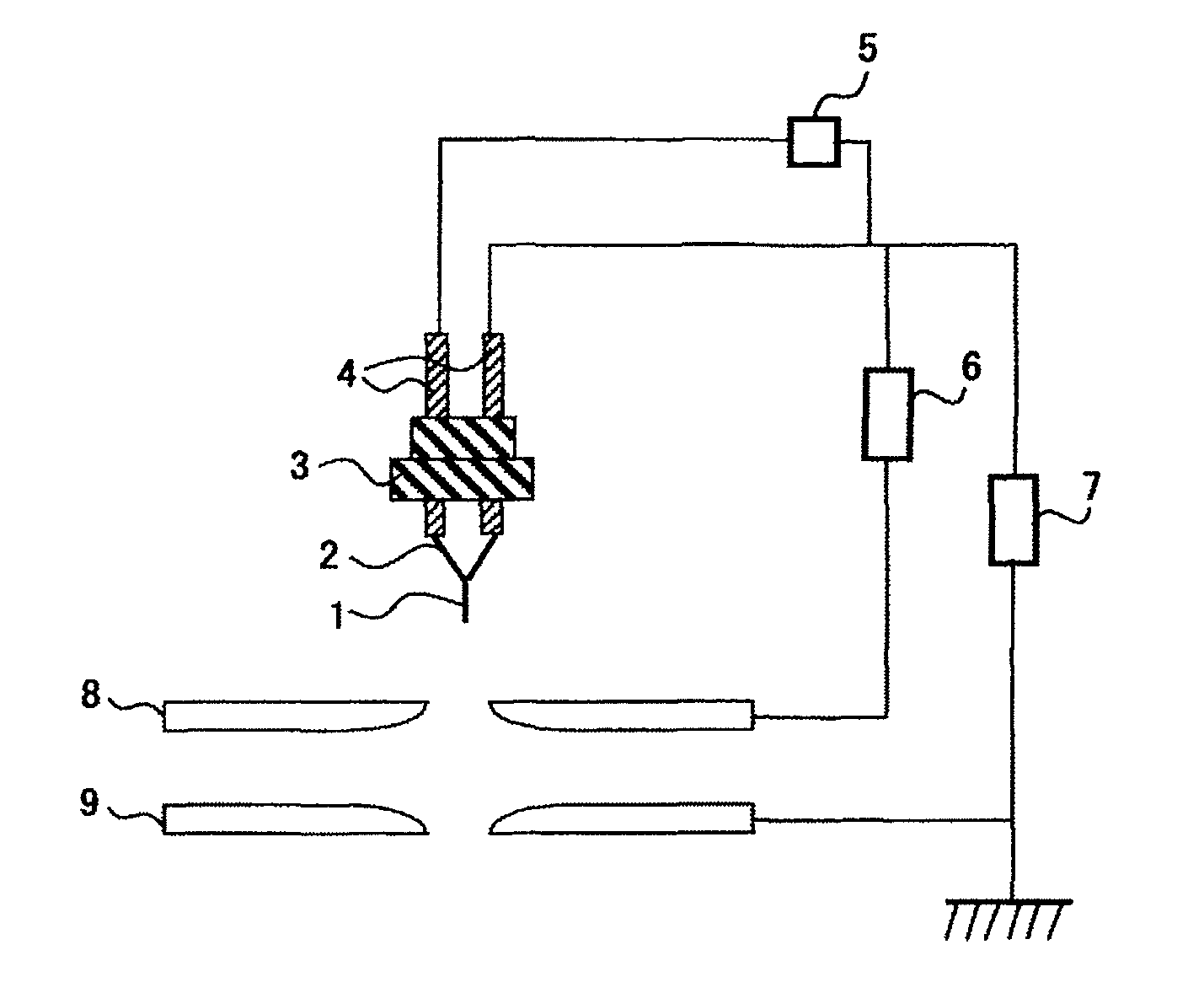

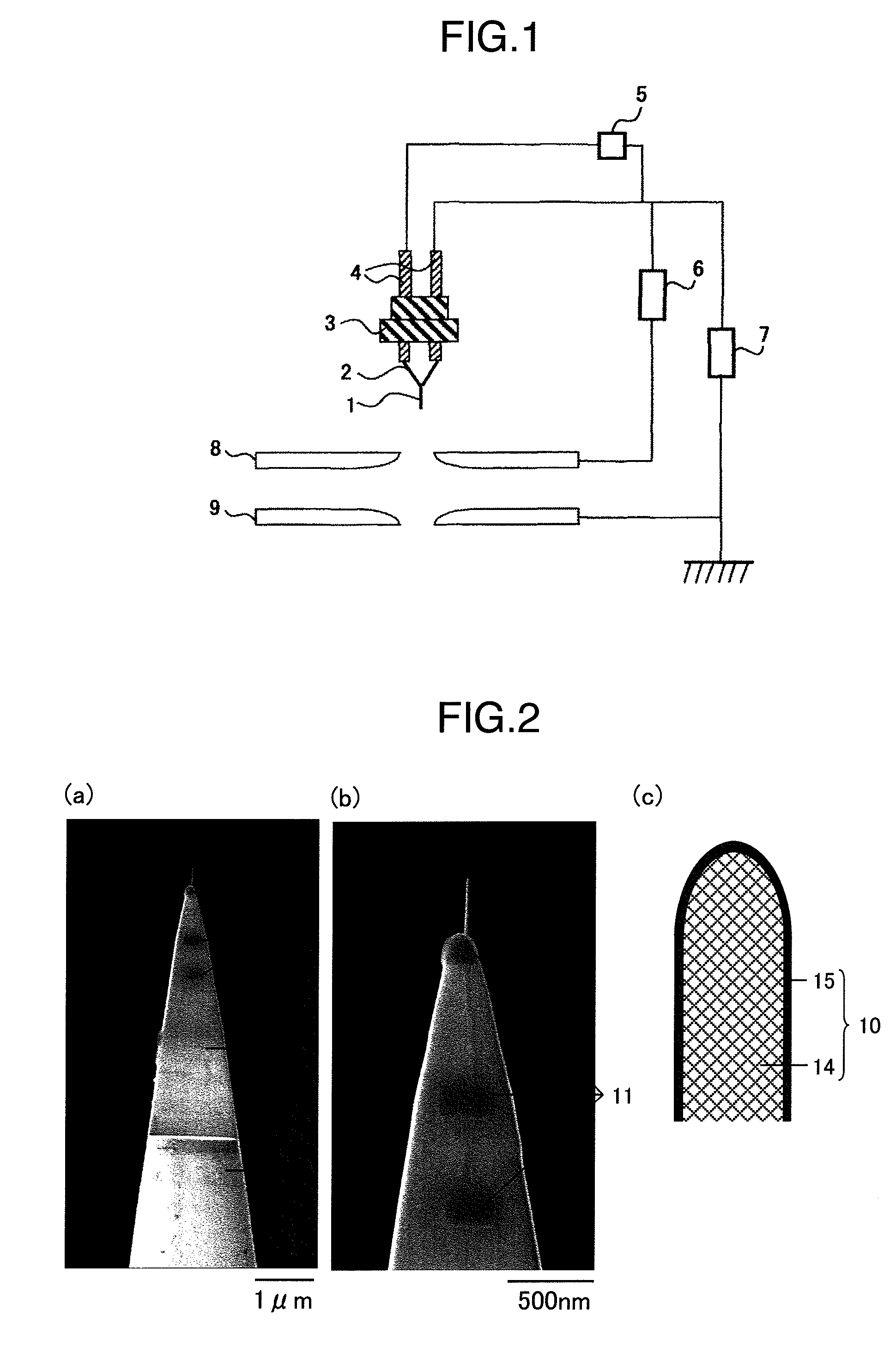

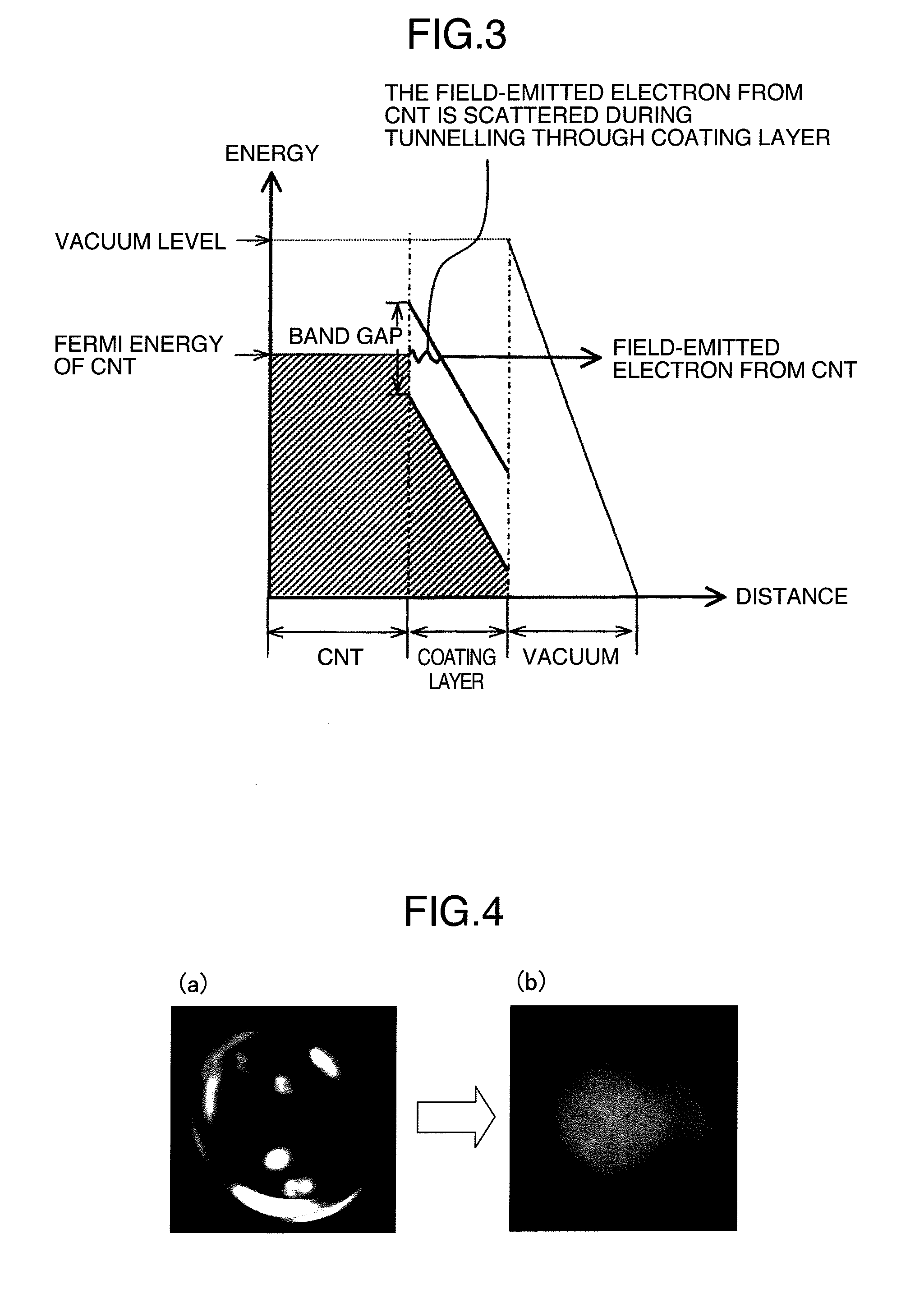

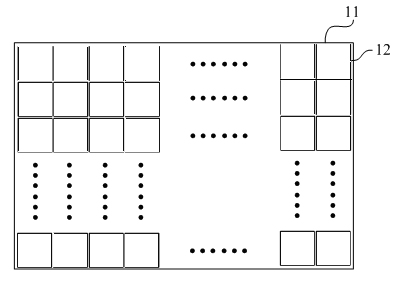

Field emission electron gun and electron beam applied device using the same

InactiveUS20080029700A1Sufficient image contrastReduce resolutionMaterial analysis using wave/particle radiationElectric discharge tubesElectron sourceOptical axis

The object of the present invention is to enable the optical axis of an electron beam of a field emission electron gun mounting thereon an electron gun composed of a fibrous carbon material to be adjusted easily. Moreover, it is also to obtain an electron beam whose energy spread is narrower than that of the electron gun. Further, it is also to provide a high resolution electron beam applied device mounting thereon the field emission electron gun. The means for achieving the objects of the present invention is in that the fibrous carbon material is coated with a material having a band gap, in the field emission electron gun including an electron source composed of a fibrous carbon material and an electrically conductive base material for supporting the fibrous carbon material, an extractor for field-emitting electrons, and an accelerator for accelerating the electrons. Moreover, it is also to apply the field emission electron gun to various kinds of electron beam applied devices.

Owner:HITACHI LTD

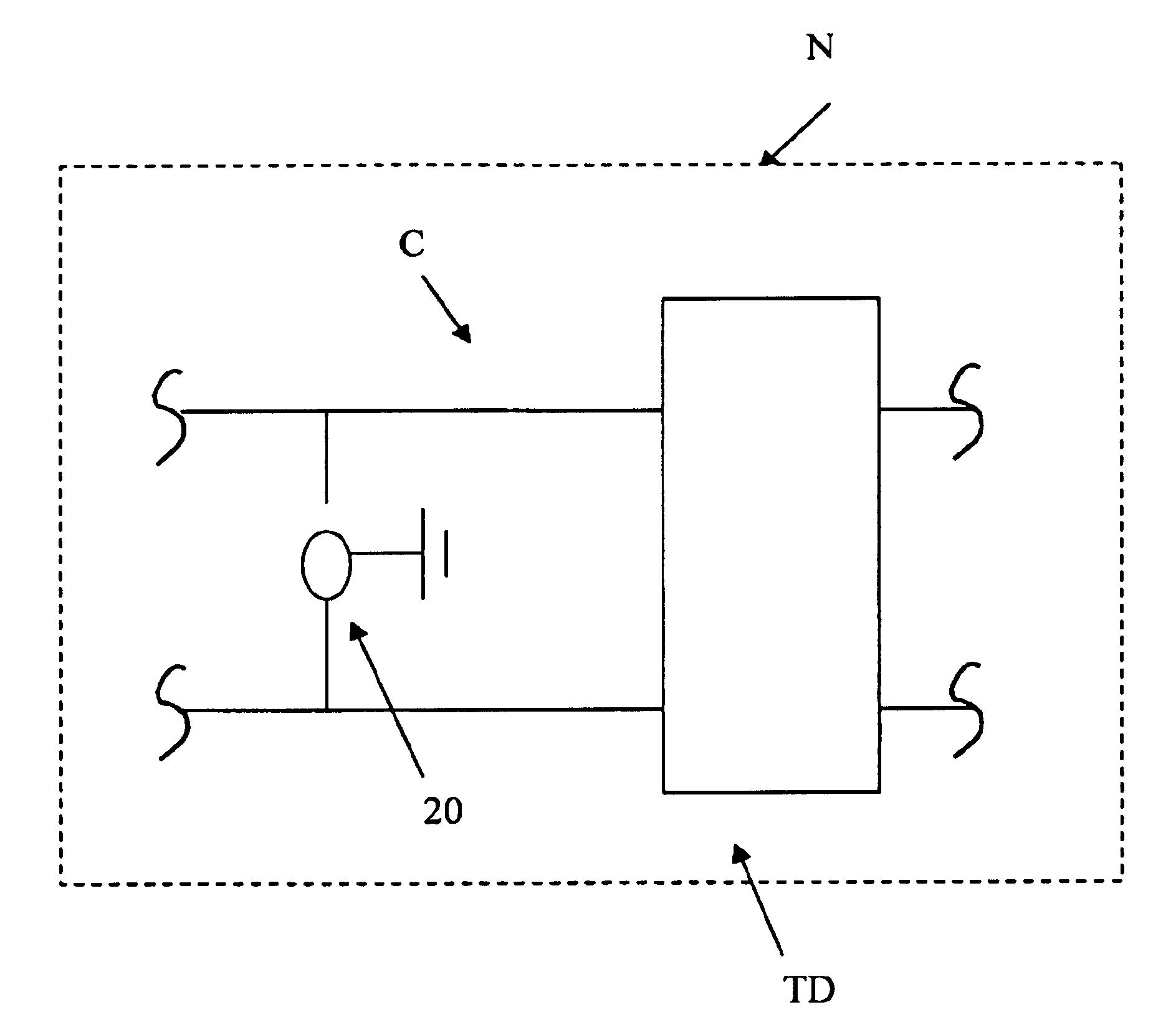

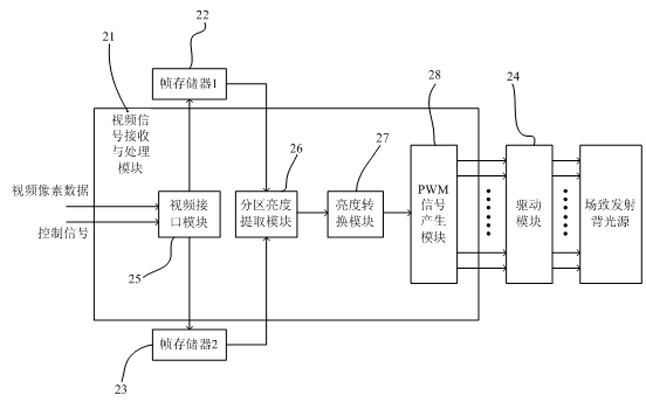

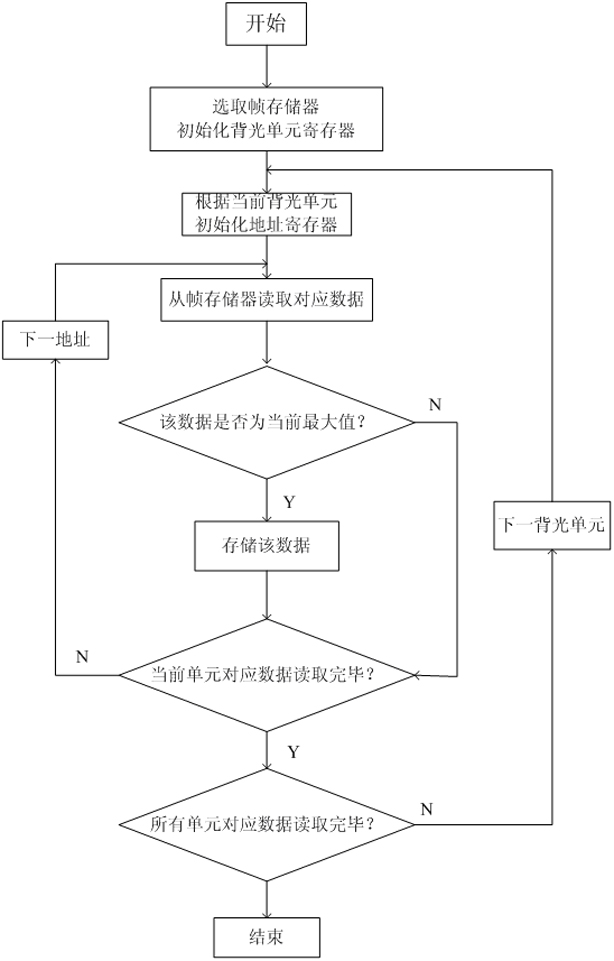

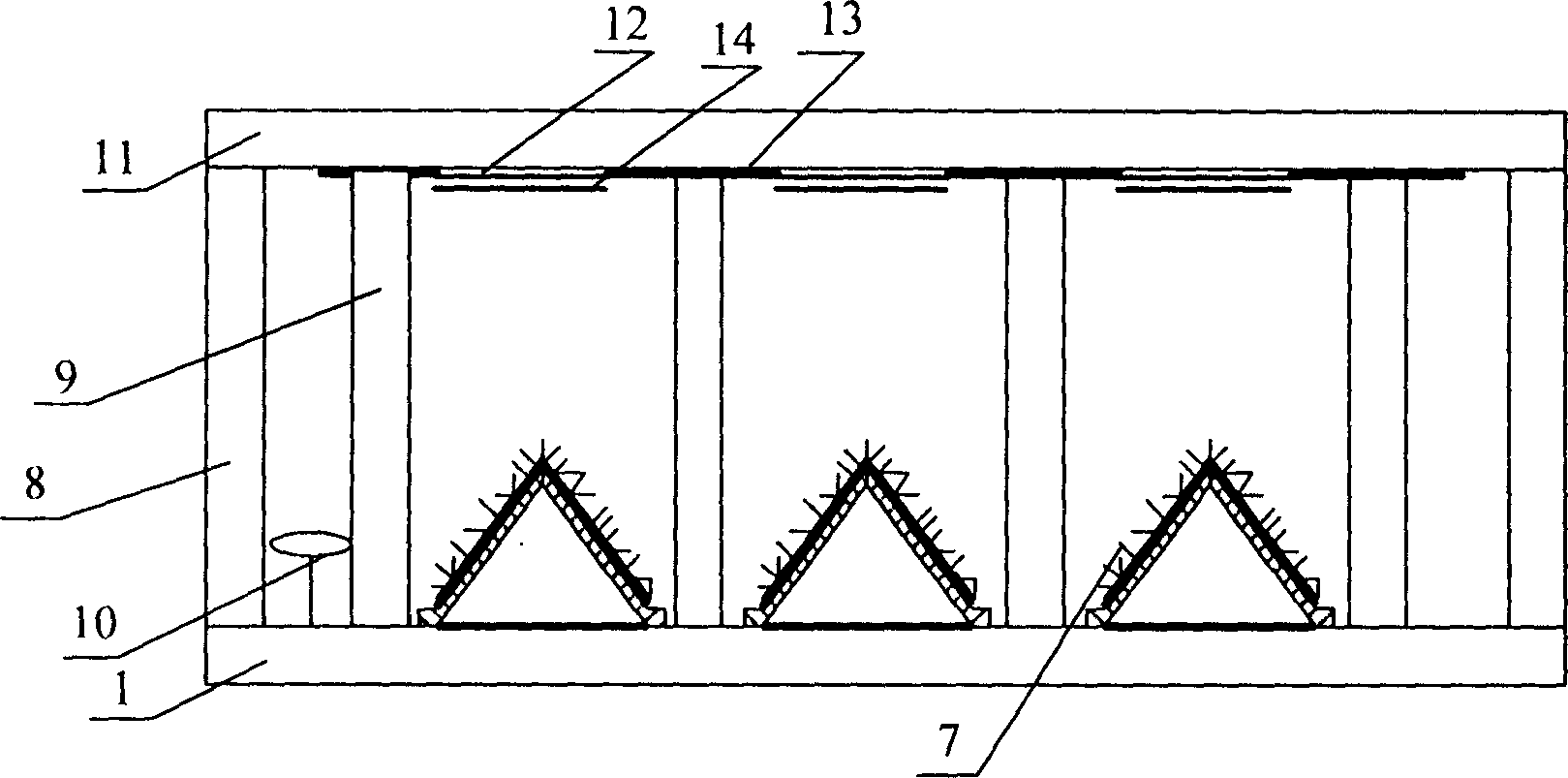

Dynamic dimming circuit for splicing large-area field emission backlight

ActiveCN101976549ARealization of dynamic dimmingReduce energy consumptionStatic indicating devicesControl signalComputer module

The invention relates to a dynamic dimming circuit for splicing large-area field emission backlight. The backlight is formed by splicing a plurality of triode field emission backlight units with certain regular shapes, wherein each backlight unit is relatively independent. The dynamic dimming circuit is characterized by comprising a video signal receiving and processing module, a frame storage module and a driving module, wherein the video signal receiving and processing module generates a luminance control signal of each field emission backlight unit according to the received video signal; the frame storage module is used for storing video image data and has a data caching effect; and the driving module performs current and voltage amplification on the luminance control signals so as to drive the field emission backlight.

Owner:FUZHOU UNIV

Rare-earth doped tantalic acid salt transparent luminous thin-film and preparation thereof

InactiveCN1613960AEasy to getSynthesis temperature is lowLuminescent compositionsField electron emissionRare earth

The invention relates to a transparent-shining film of rare-earth choleric acid salt and its production method. The chemical formula is (Ln1-xREx)TaO4(0<x<0.1); Ln=Gd,Lu; RE=Eu,Tb. The process is low cost, simple, and convenience. The film is of transparent, compact and good adhesion. It simplifies conditions of experiment and shortens preparation period. It can be used for the microradiology imaging screen of high space resolution factor and screen of high resolution factor cathode-ray, field emission, plasma display.

Owner:TONGJI UNIV

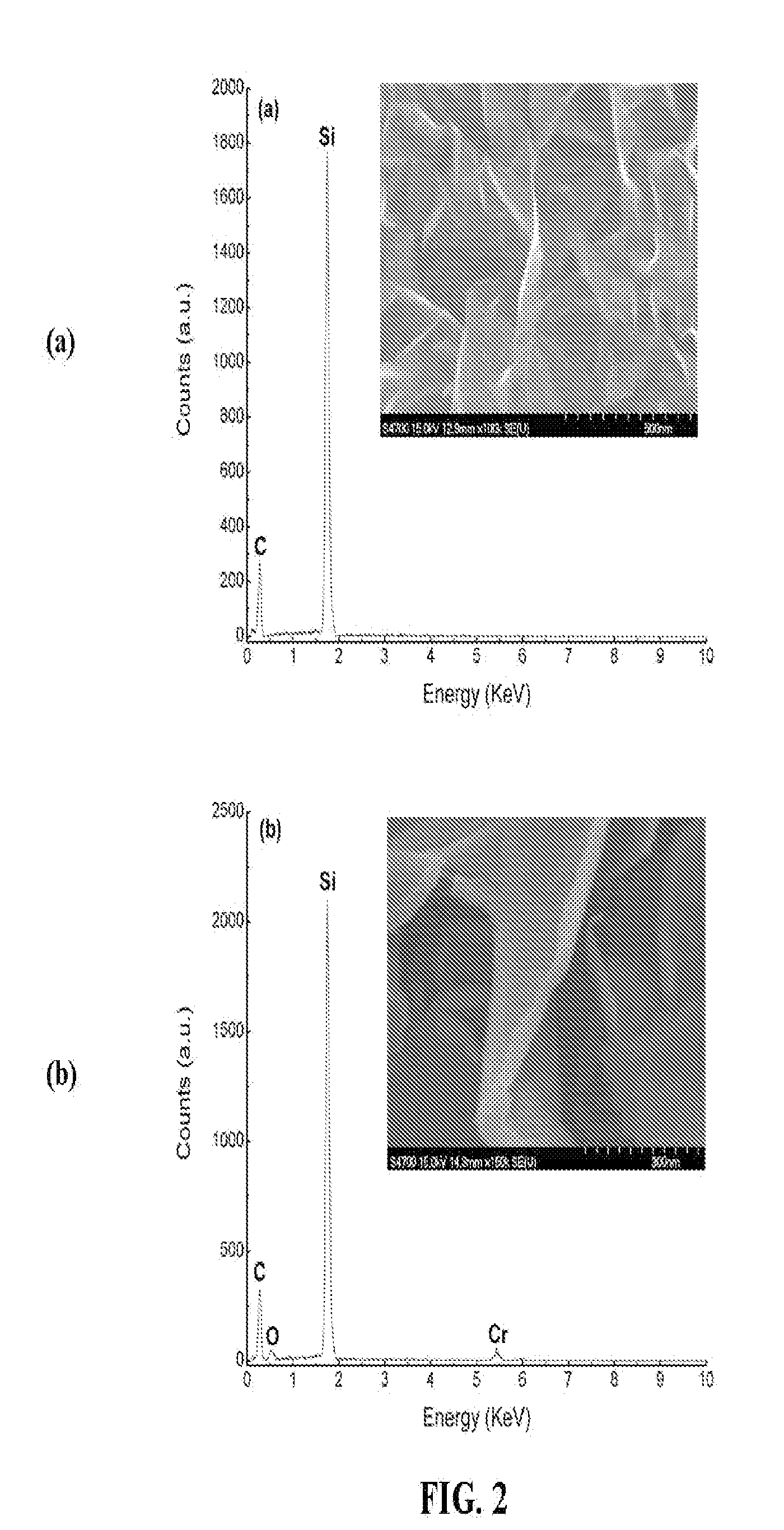

Coated carbon nanoflakes

InactiveUS20110175038A1Effective electron emissionEfficient emissionsMaterial nanotechnologyConductive materialMetallurgyField electron emission

Compositions of carbon nanoflakes are coated with a low Z compound, where an effective electron emission of the carbon nanoflakes coated with the low Z compound is improved compared to an effective electron emission of the same carbon nanoflakes that are not coated with the low Z compound or of the low Z compound that is not coated onto the carbon nanoflakes. Compositions of chromium oxide and molybdenum carbide-coated carbon nanoflakes are also described, as well as applications of these compositions. Carbon nanoflakes are formed and a low Z compound coating, such as a chromium oxide or molybdenum carbide coating, is formed on the surfaces of carbon nanoflakes. The coated carbon nanoflakes have excellent field emission properties.

Owner:COLLEGE OF WILLIAM & MARY

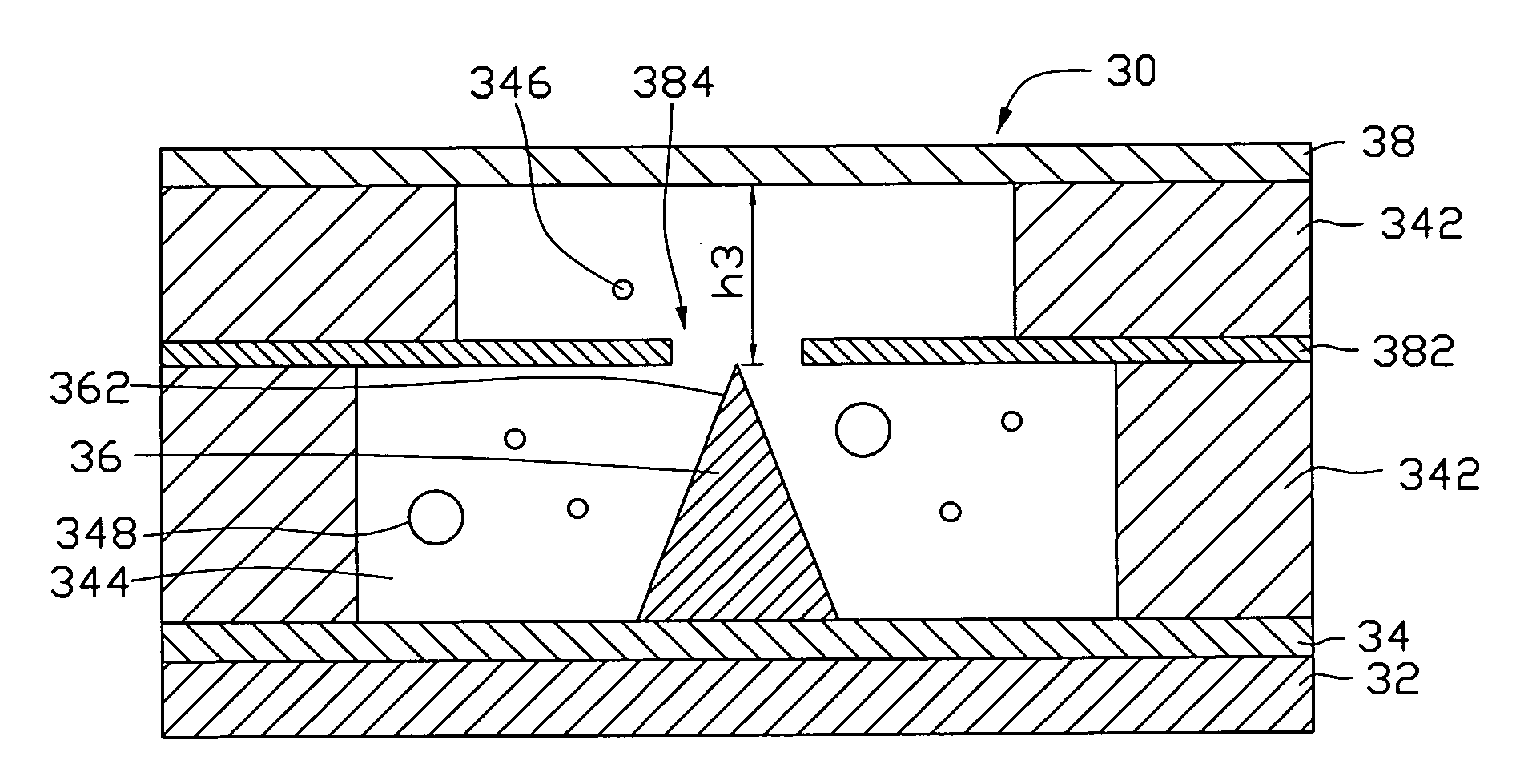

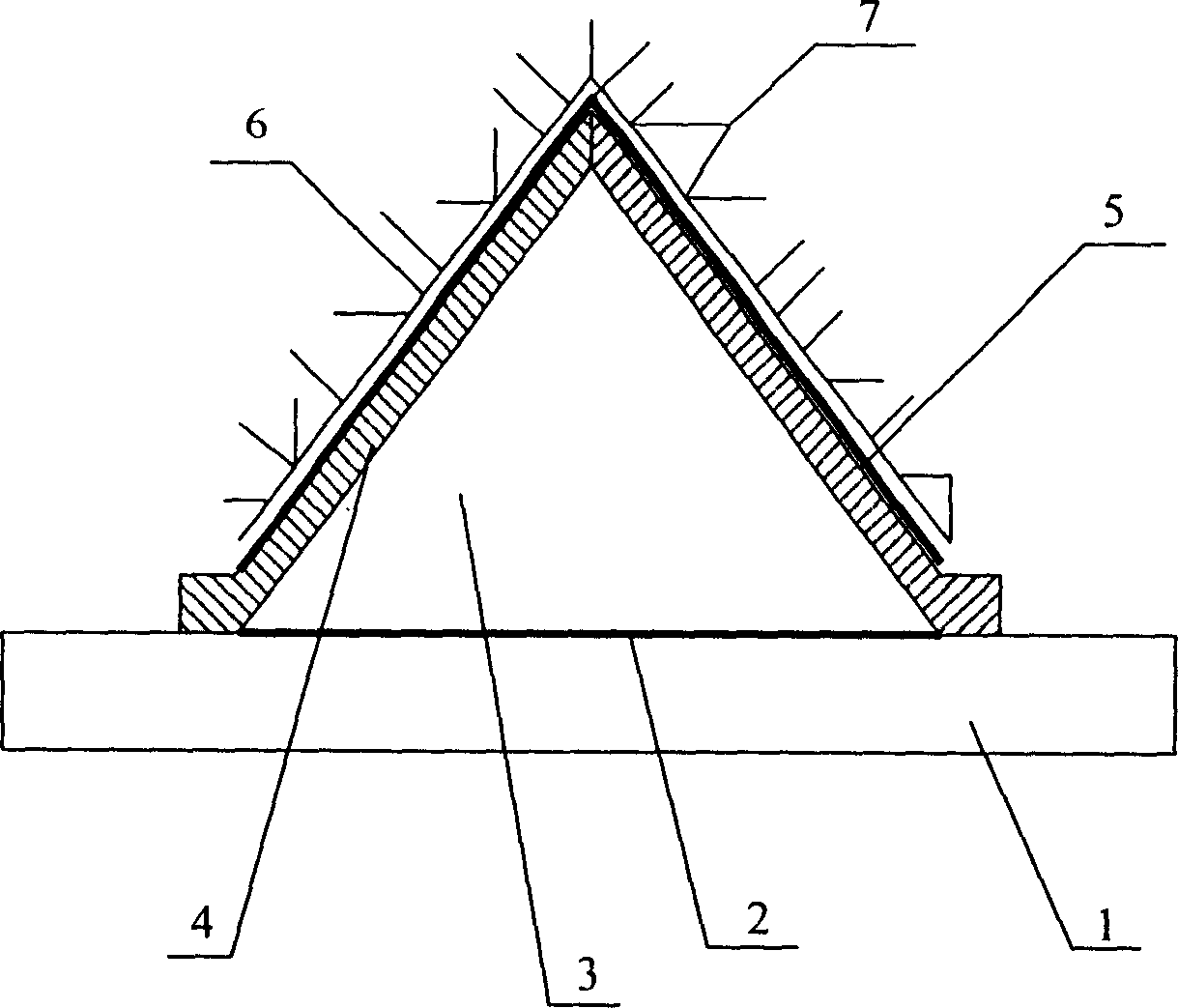

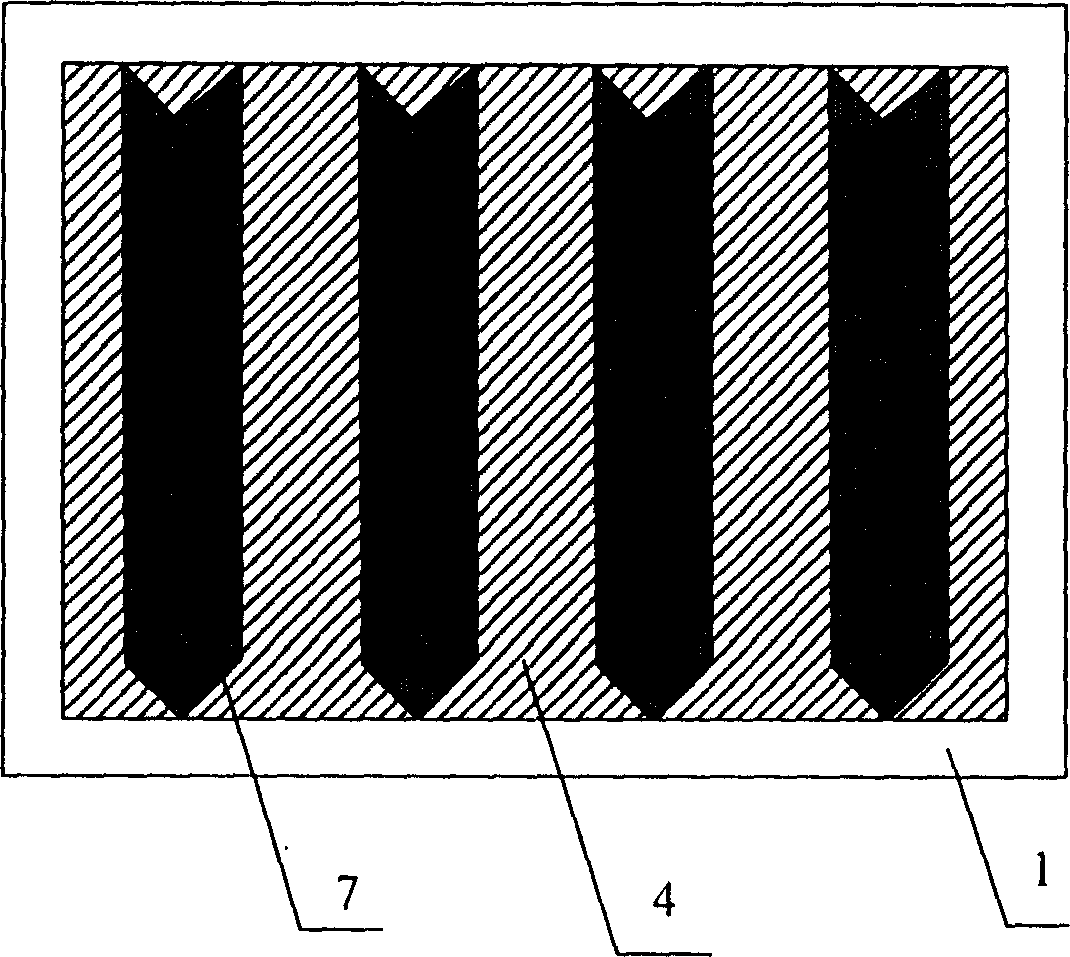

Panel display with integrated triangle tapered grid cathode structure and its making process

InactiveCN1790599AIncrease the launch areaImprove electron emission efficiencyImage/pattern display tubesCold cathode manufactureDisplay deviceCarbon nanotube

The invention relates to a flat panel display with integrated triangular sharp-cone grid cathode structure, which comprises: a seal vacuum cavity constructed by cathode and anode glass panel and round glass, a fluorescent powder layer on anode electrode layer on anode glass panel, a control grid for nano carbon tube emission, an integrated triangular sharp-cone grid cathode structure under the nano carbon tube cathode to control its electron emission, a support wall structure and air-detrainer accessory. This invention enlarges emission area, uses fully of well field-emission property of nano carbon tube cathode, and has reliable manufacture process with low cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Deep Ultraviolet Semiconductor Optical Device

InactiveUS20100289435A1Discharge tube luminescnet screensLamp detailsRare earthField electron emission

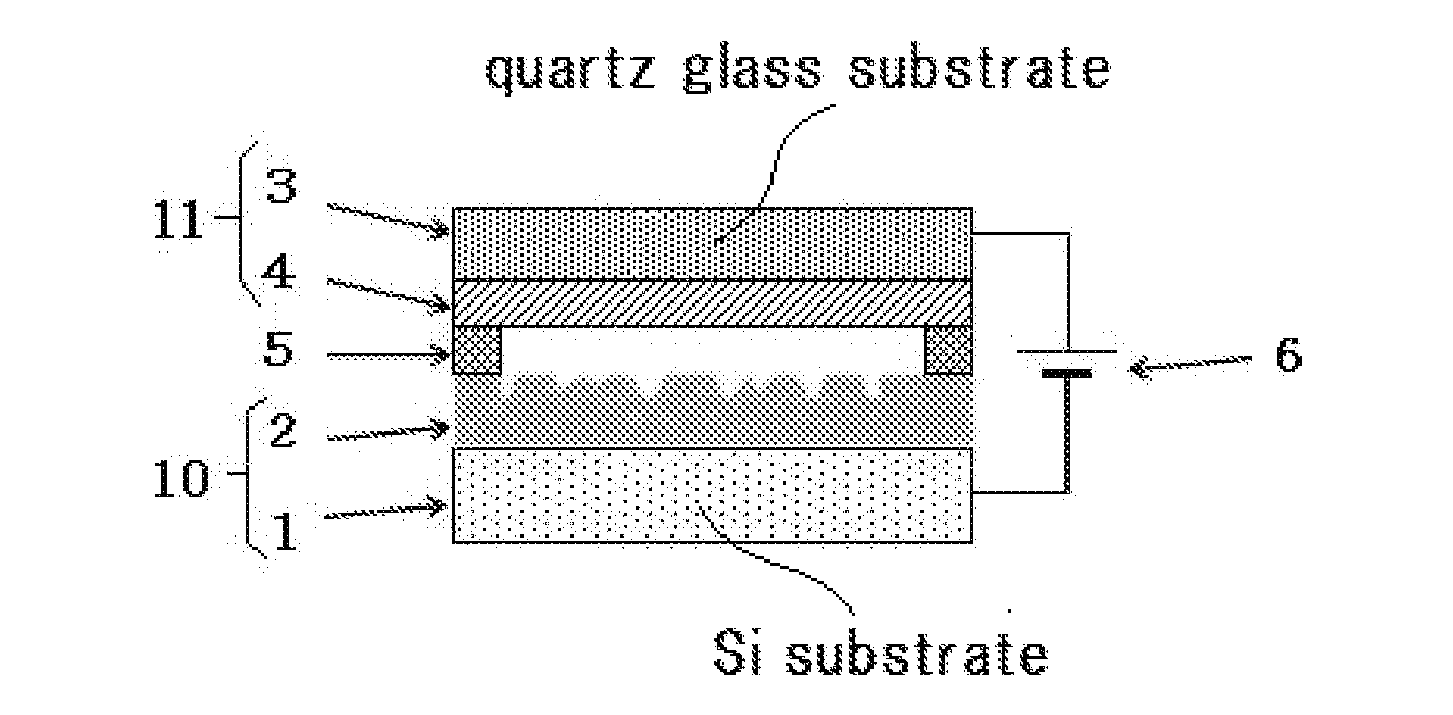

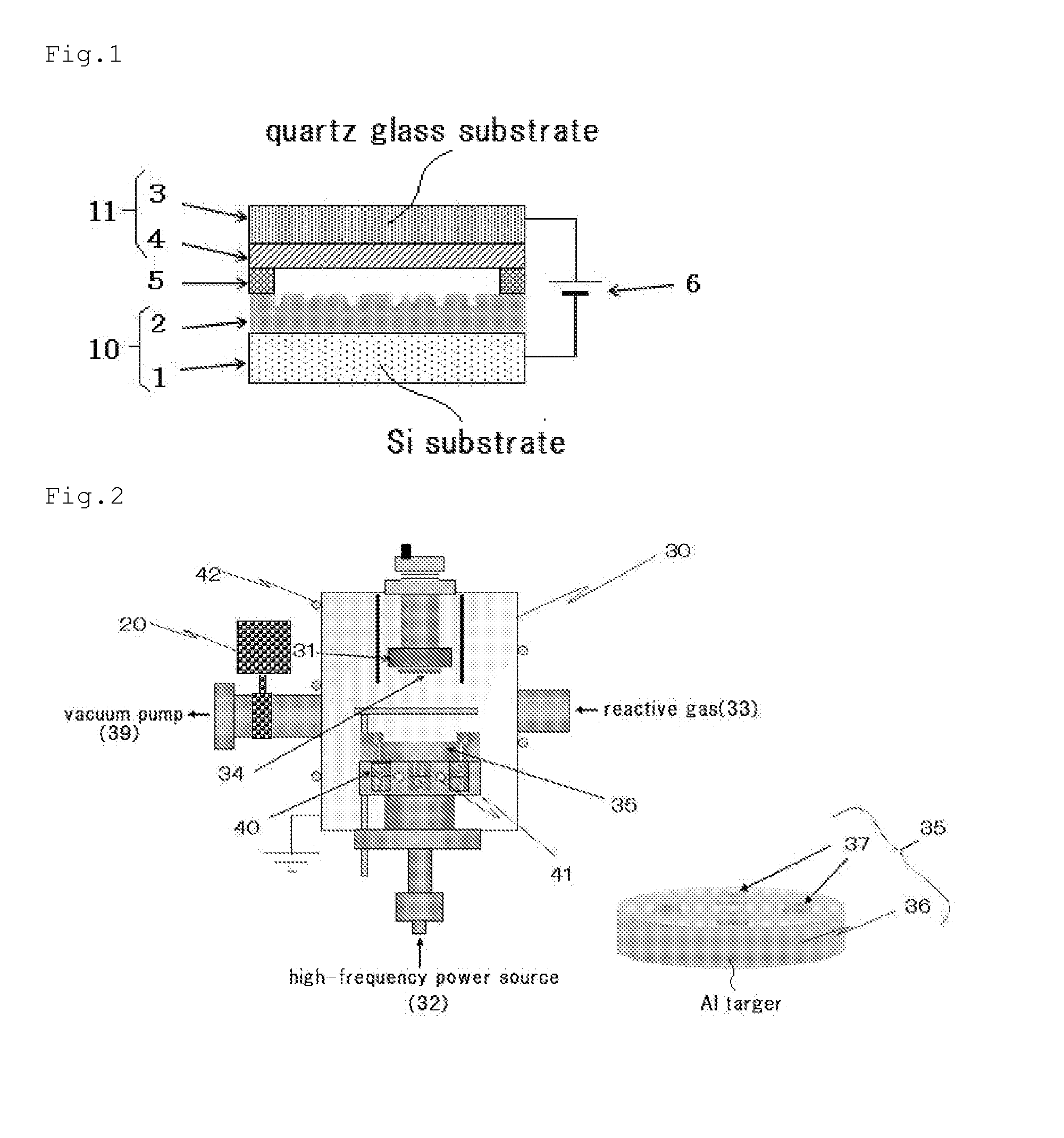

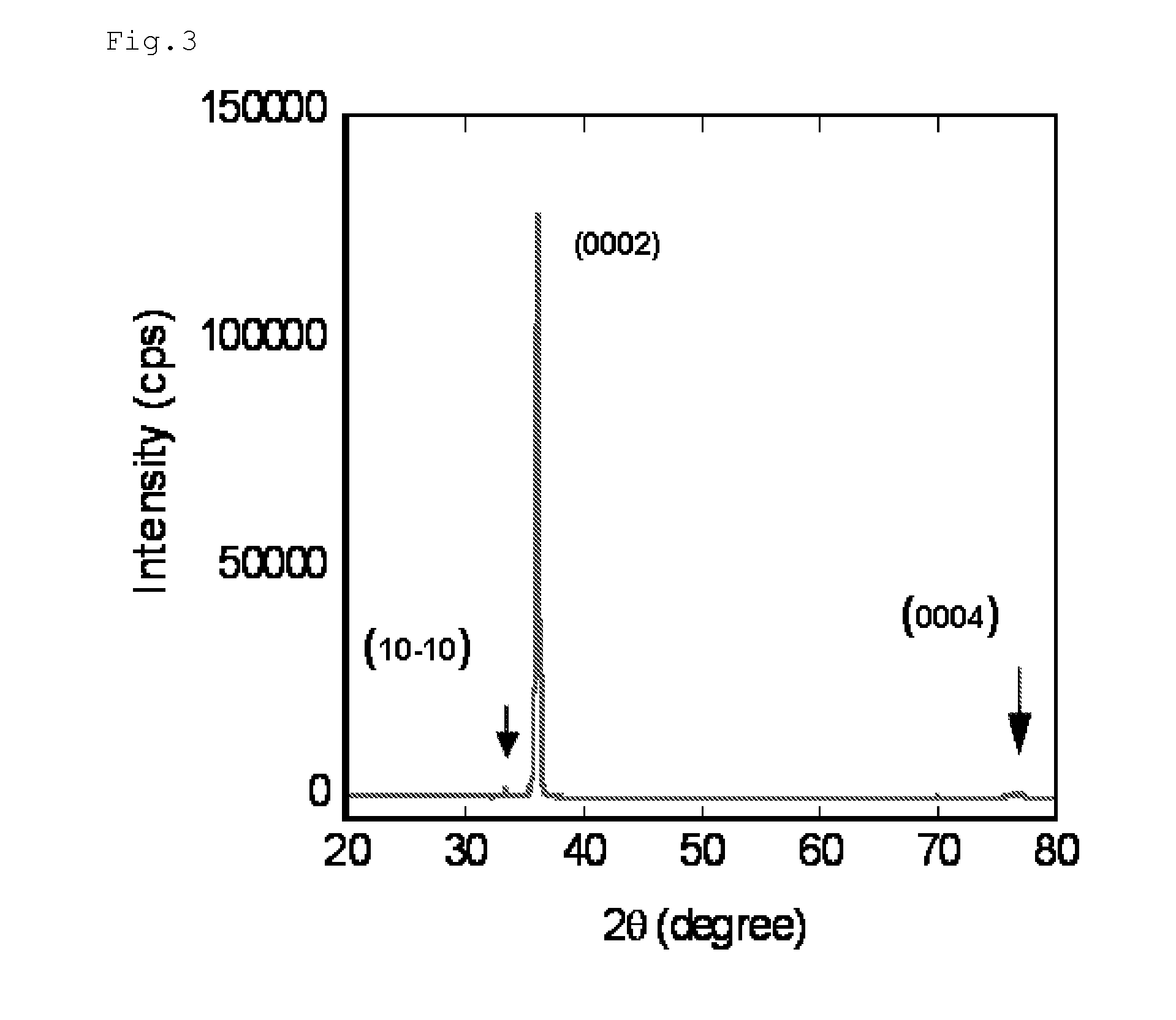

A large-area and high-luminance deep ultraviolet light source device is provided under circumstances where the scales of existing mercury lamps used as ultraviolet light sources cannot be reduced and light-emitting diodes of 365 nm or less do not reach the practical level. The deep ultraviolet light source device comprises at least an anode substrate having an ultraviolet phosphor thin film doped with rare-earth metal ions such as gadolinium (Gd) ions and containing with aluminum nitride as the host material, a cathode substrate having a field electron emission material thin film, a spacer for holding the anode substrate and the cathode substrate opposite to each other and maintaining the space between the substrates in a vacuum atmosphere, and a voltage circuit for applying an electric field to the space between the anode substrate and the cathode substrate. Light is emitted by injecting electrons from the field electron emission material thin film into the ultraviolet phosphor thin film by applying the electric field to the space between the substrates and maintaining the space between the anode substrate and the cathode substrate as a vacuum channel region.

Owner:YUMEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com