Patents

Literature

190 results about "Supersonic nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

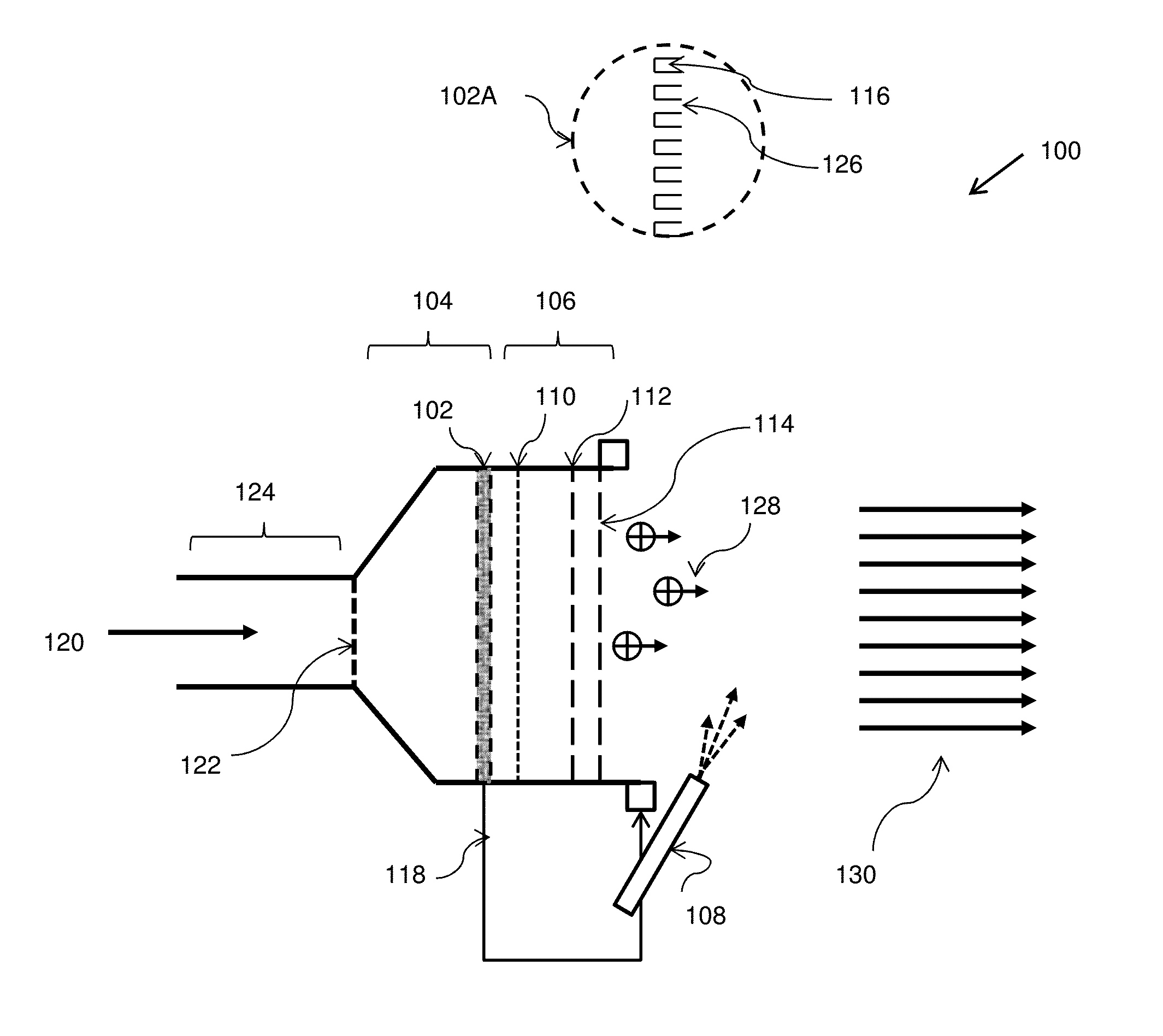

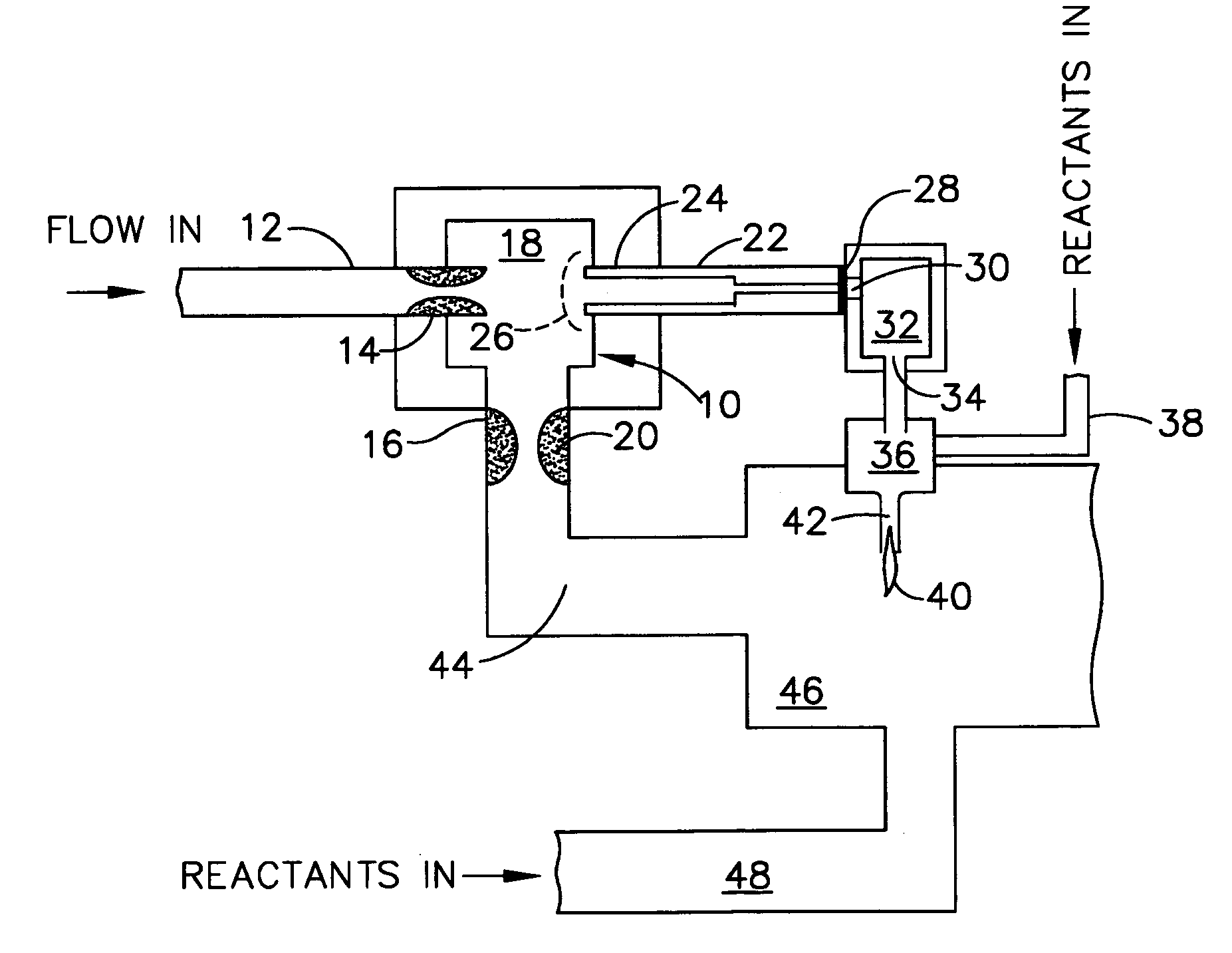

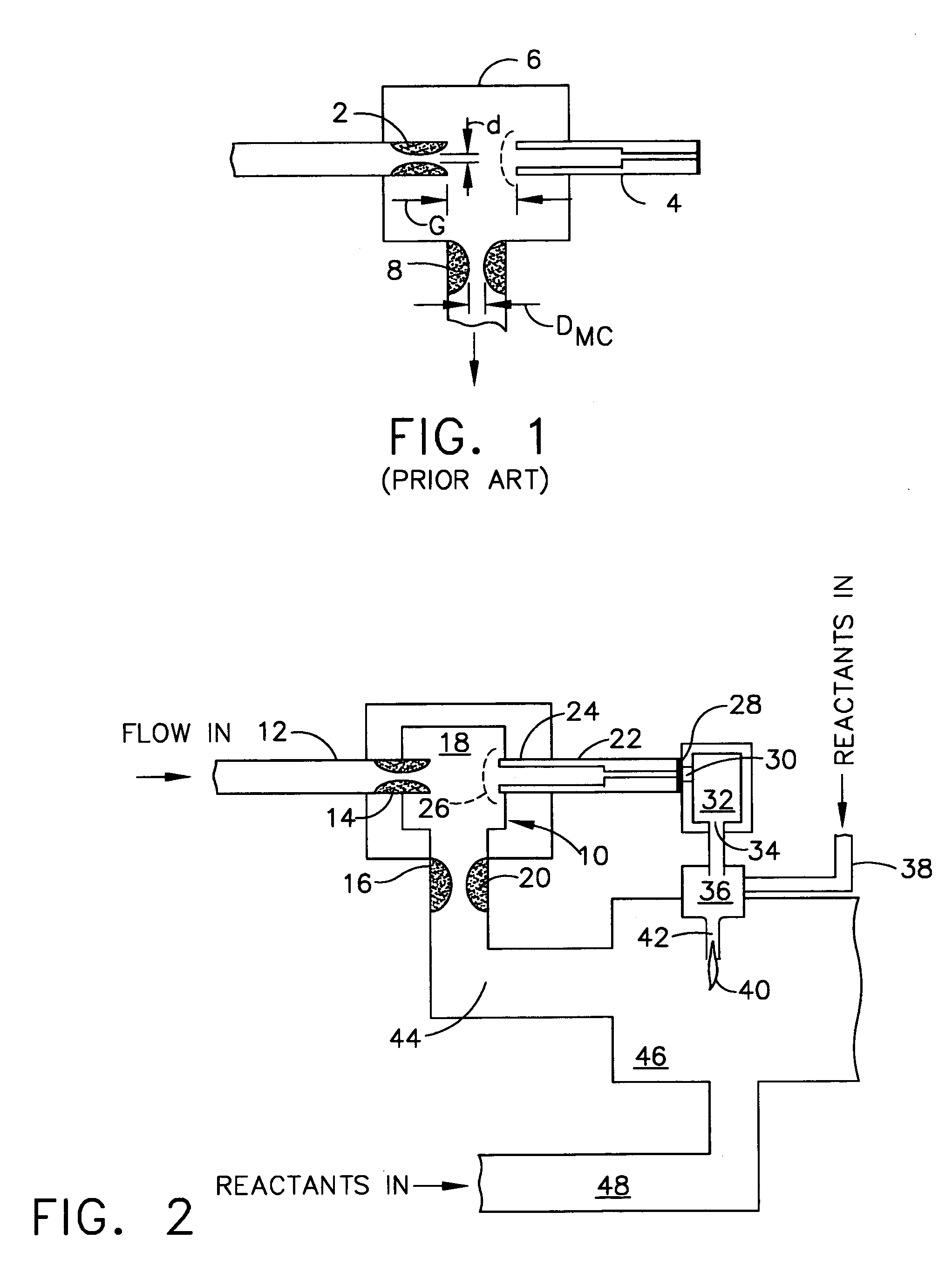

Lobed convergent/divergent supersonic nozzle ejector system

InactiveUS6877960B1Smaller length-to-entrance-diameter ratioIncrease flow pressureJet pumpsMachines/enginesDiameter ratioHigh pressure

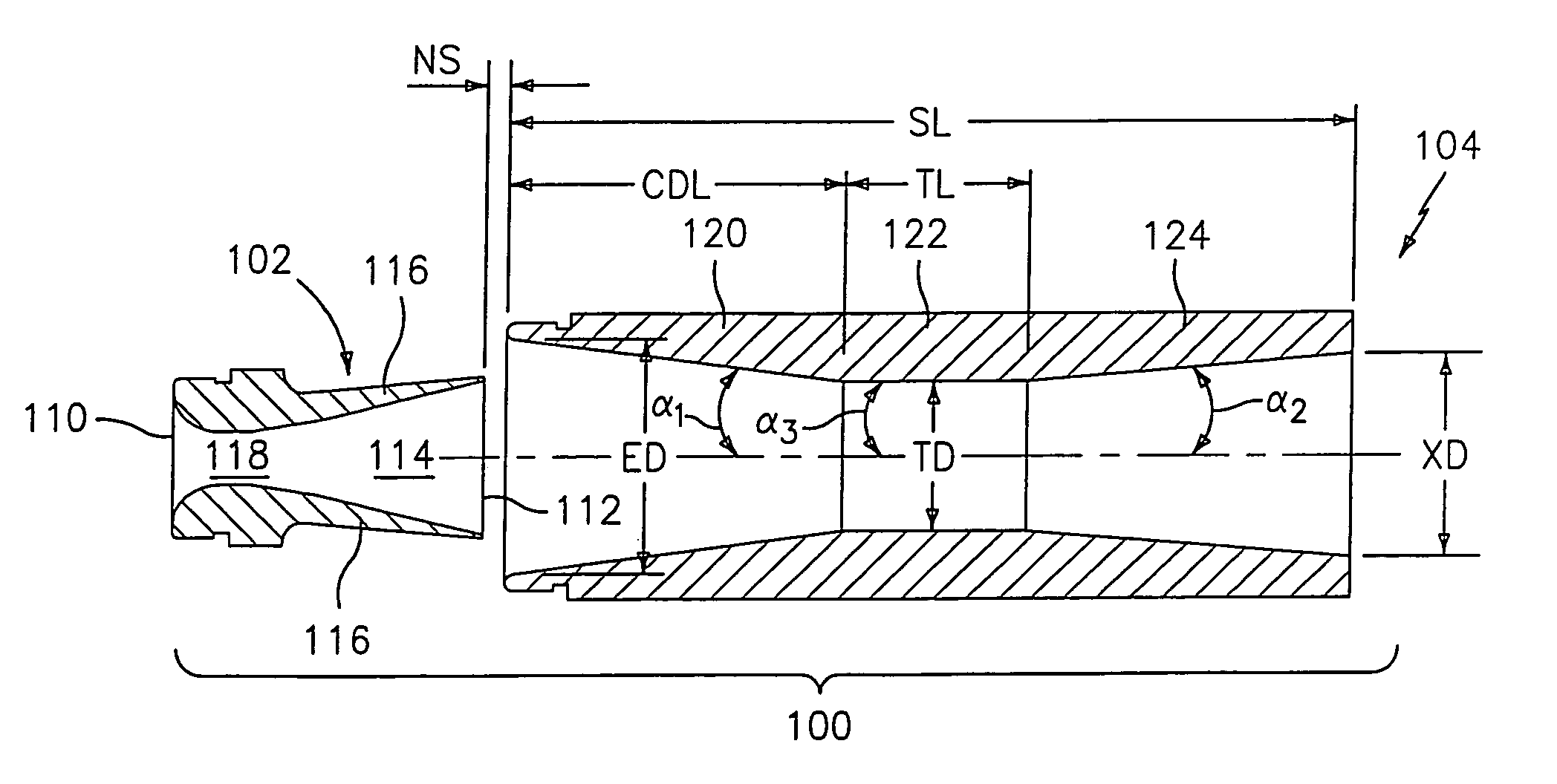

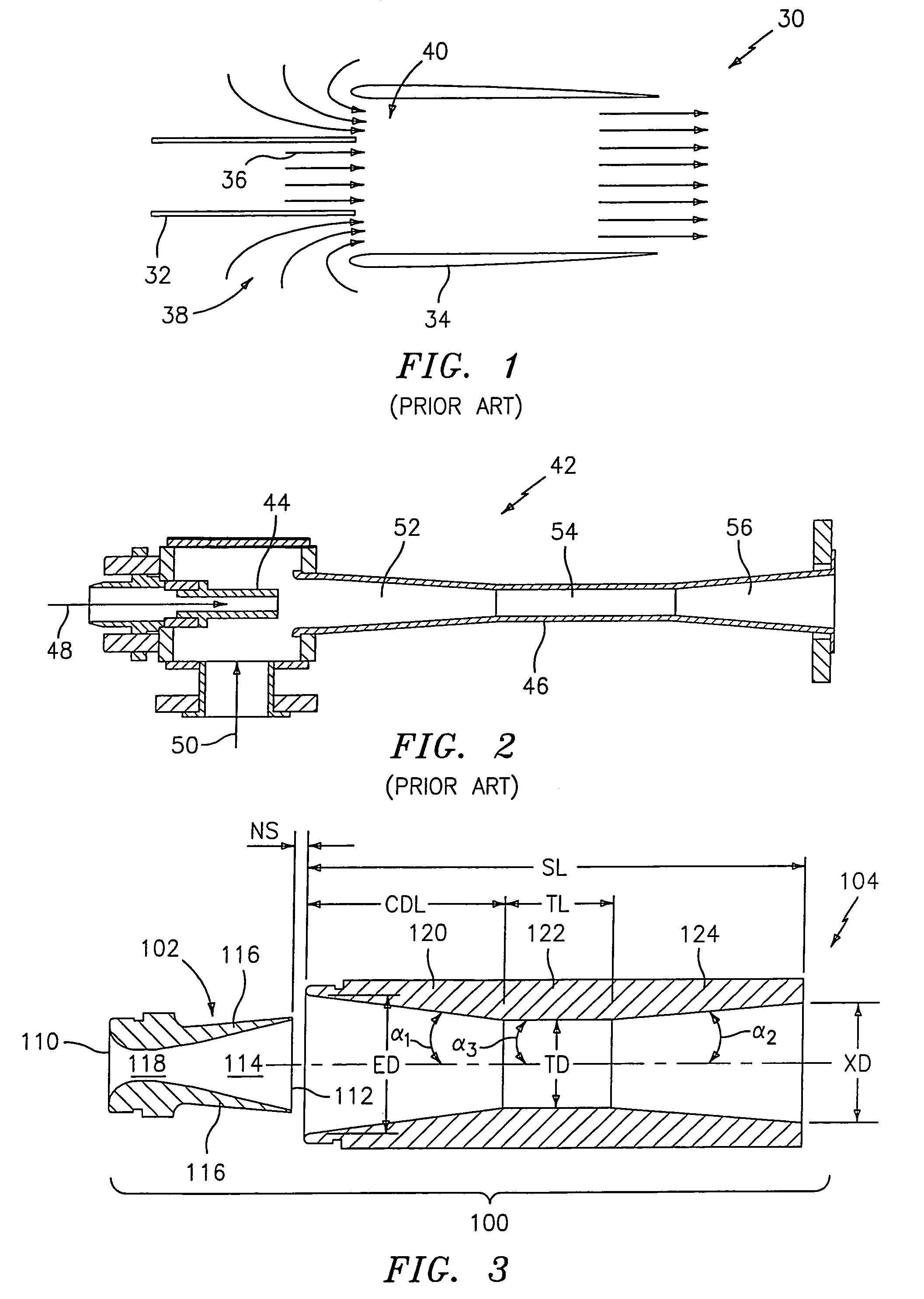

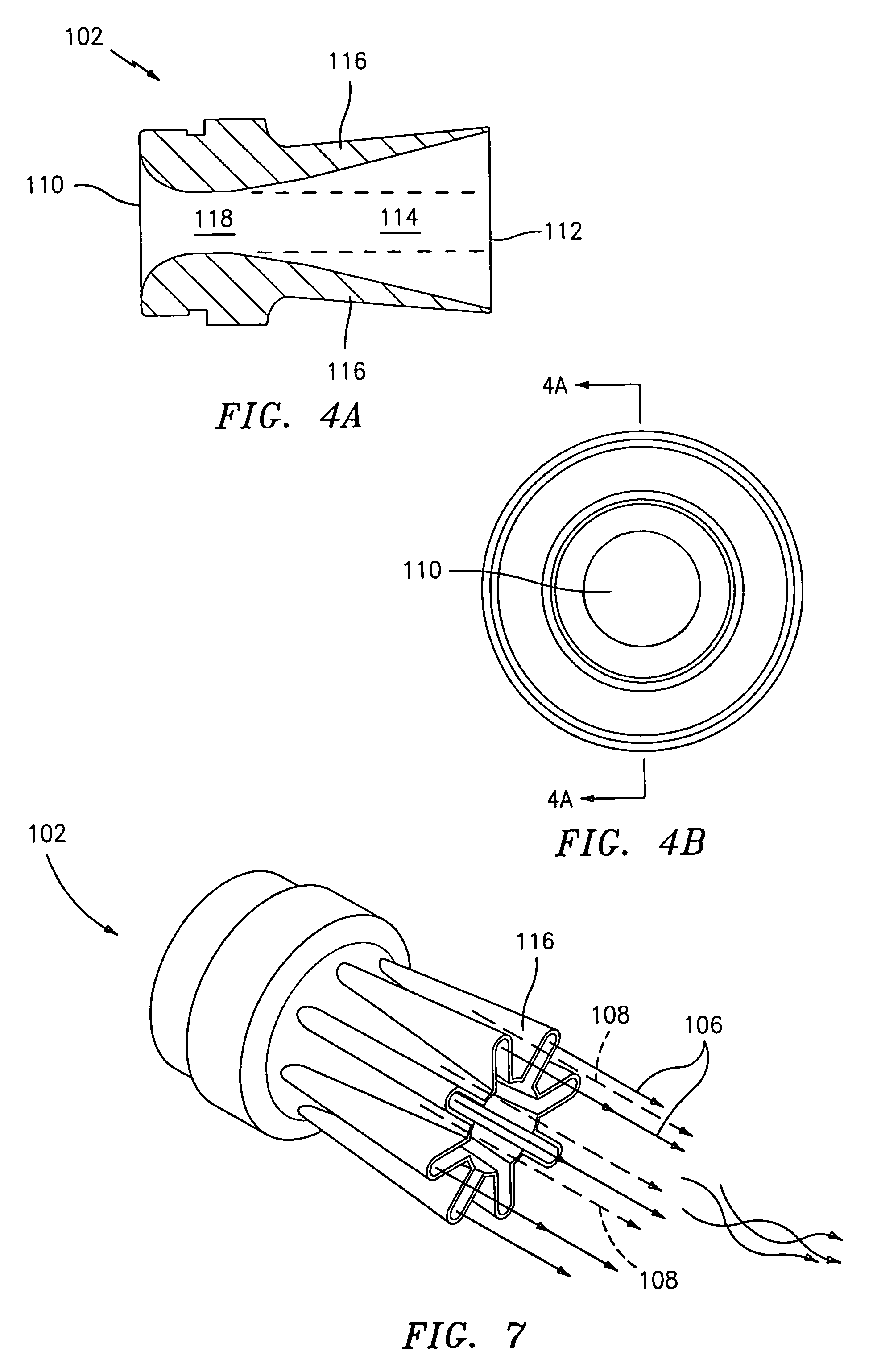

An ejector system comprises a lobed, supersonic primary nozzle and a convergent / divergent ejector shroud. The lobed nozzle is just upstream from the ejector shroud, such that there is an annular space between the nozzle and shroud for admitting a secondary flow. In operation, a primary flow of high-pressure steam or air is directed through the primary nozzle, where it is accelerated to supersonic speed. The primary flow then exits the primary nozzle, where it entrains and is mixed with the secondary flow, creating a low pressure region or vacuum. The ejector shroud subsequently decelerates the combined flow while increasing the flow pressure, which increases suction performance and reduces energy loss. Because the primary nozzle mixes the two flows, the ejector shroud is able to have a length-to-entrance-diameter ratio significantly smaller than typical shrouds / diffusers, which decreases the system's size and increases performance.

Owner:FLODESIGN WIND TURBINE

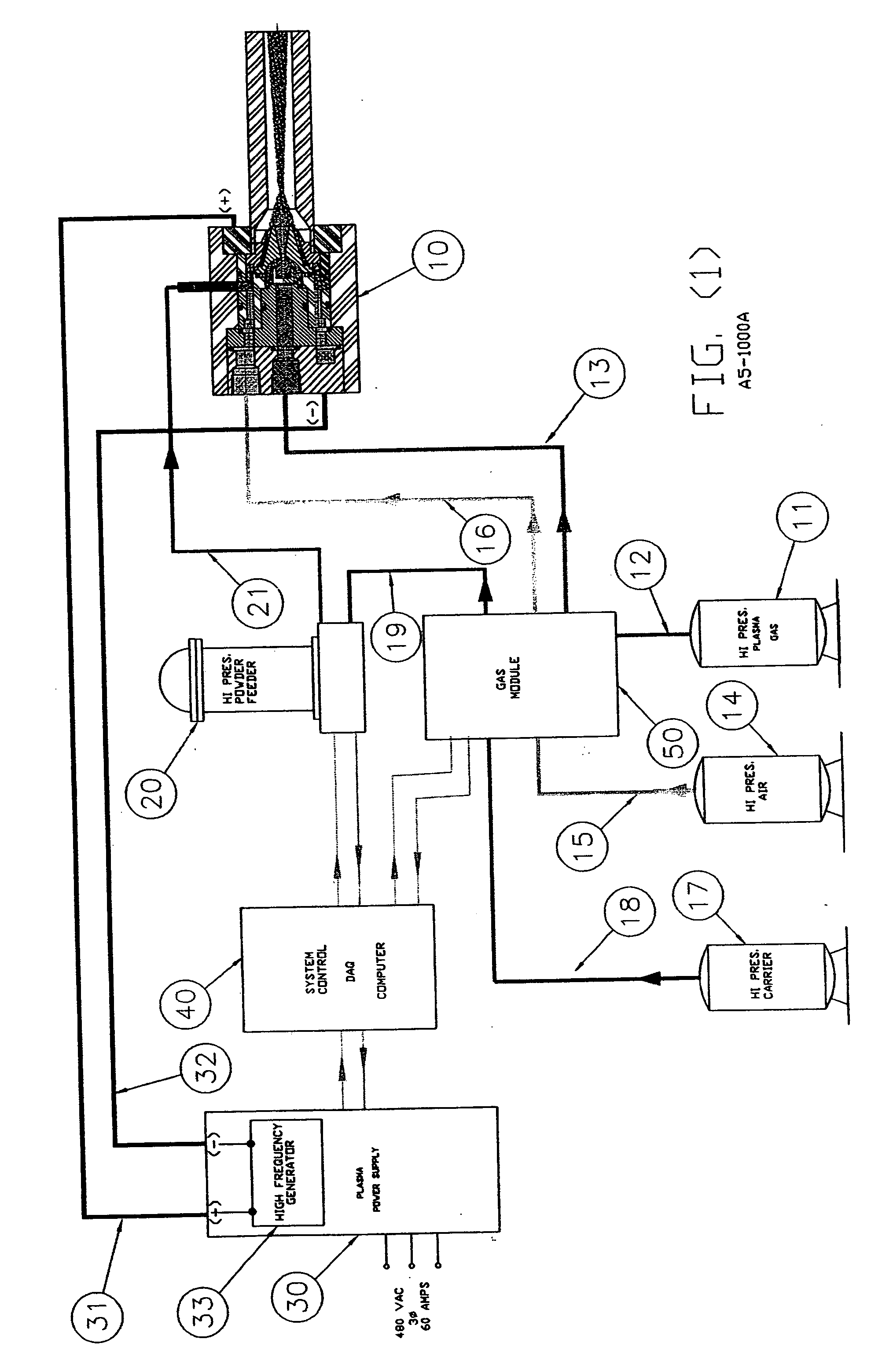

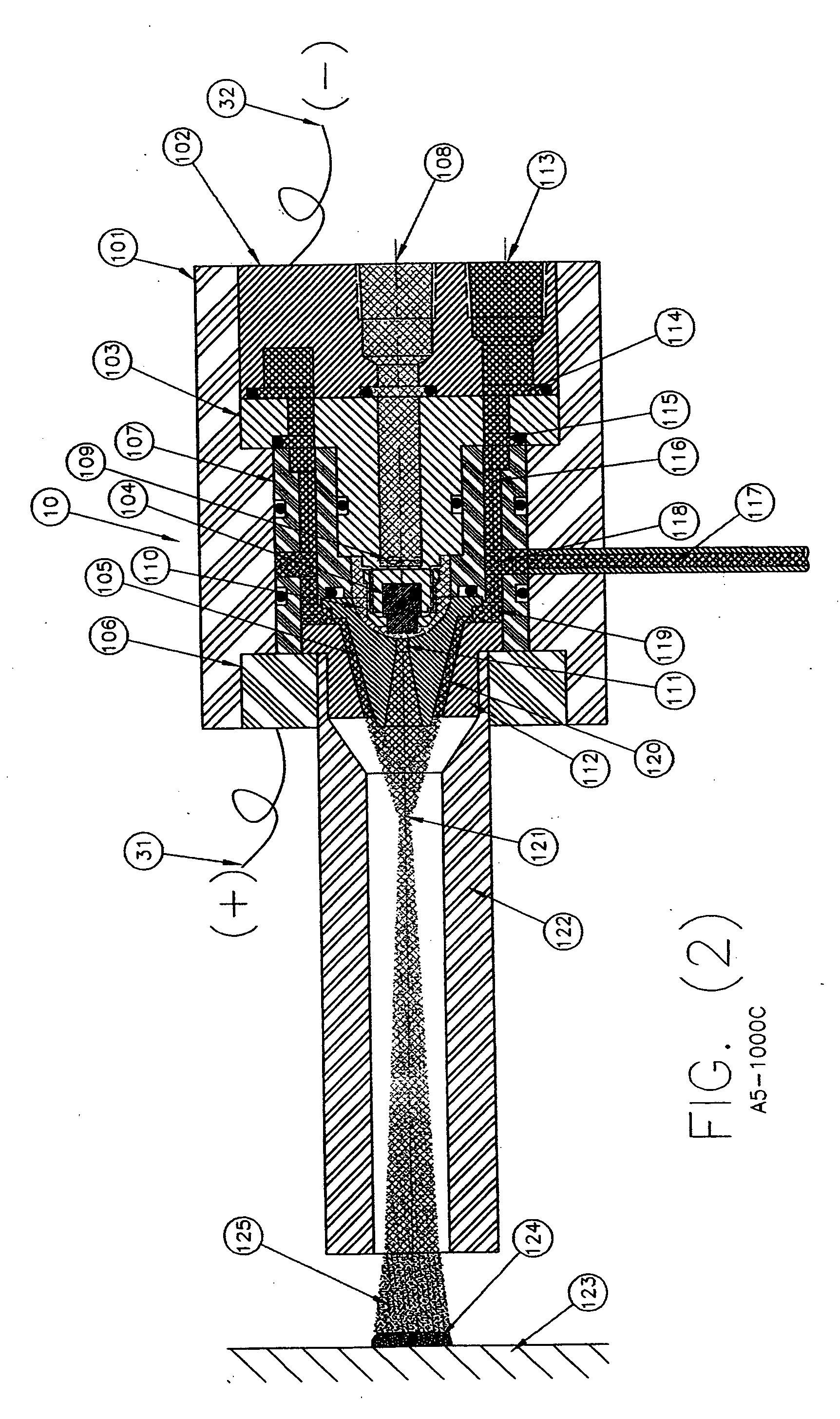

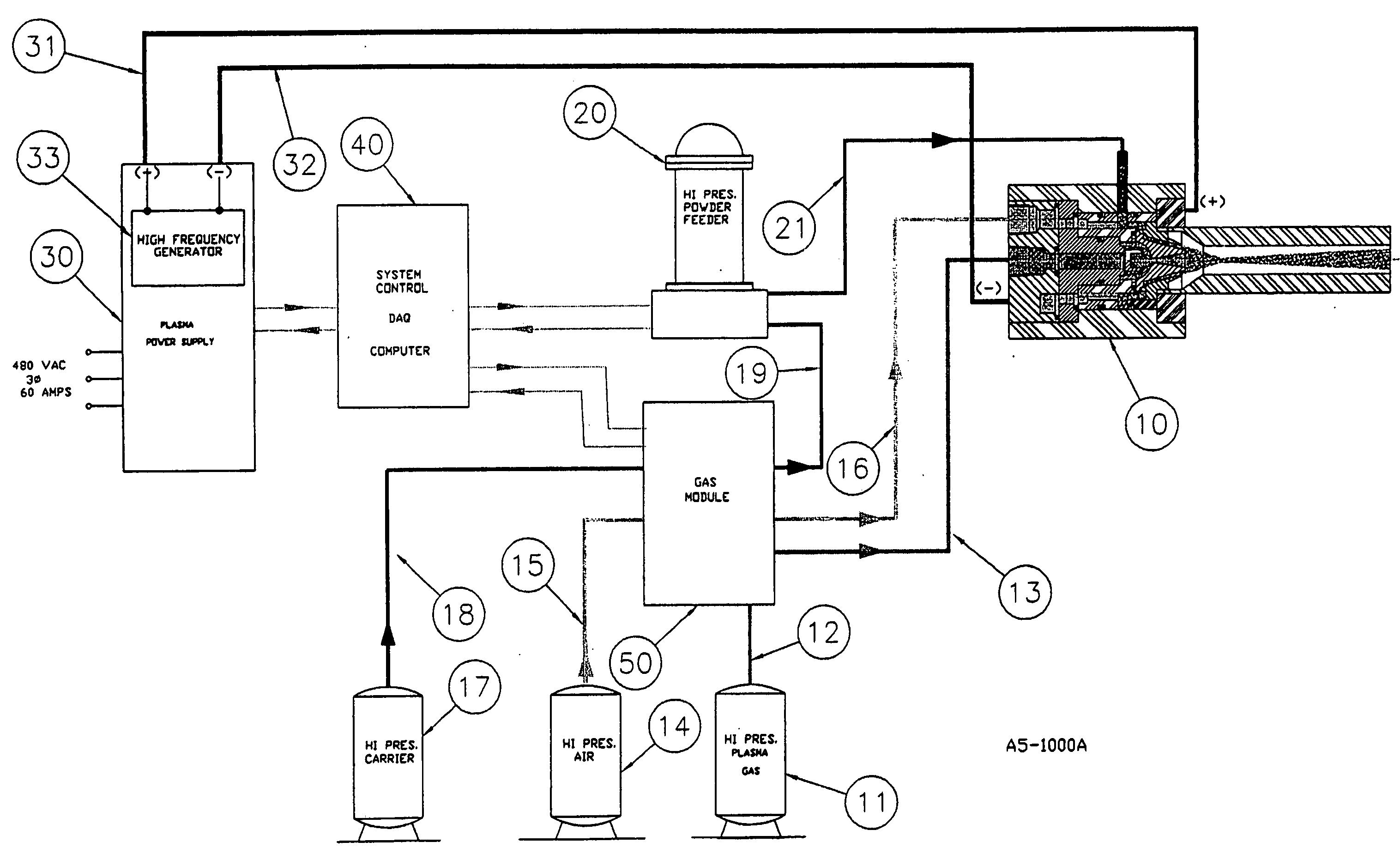

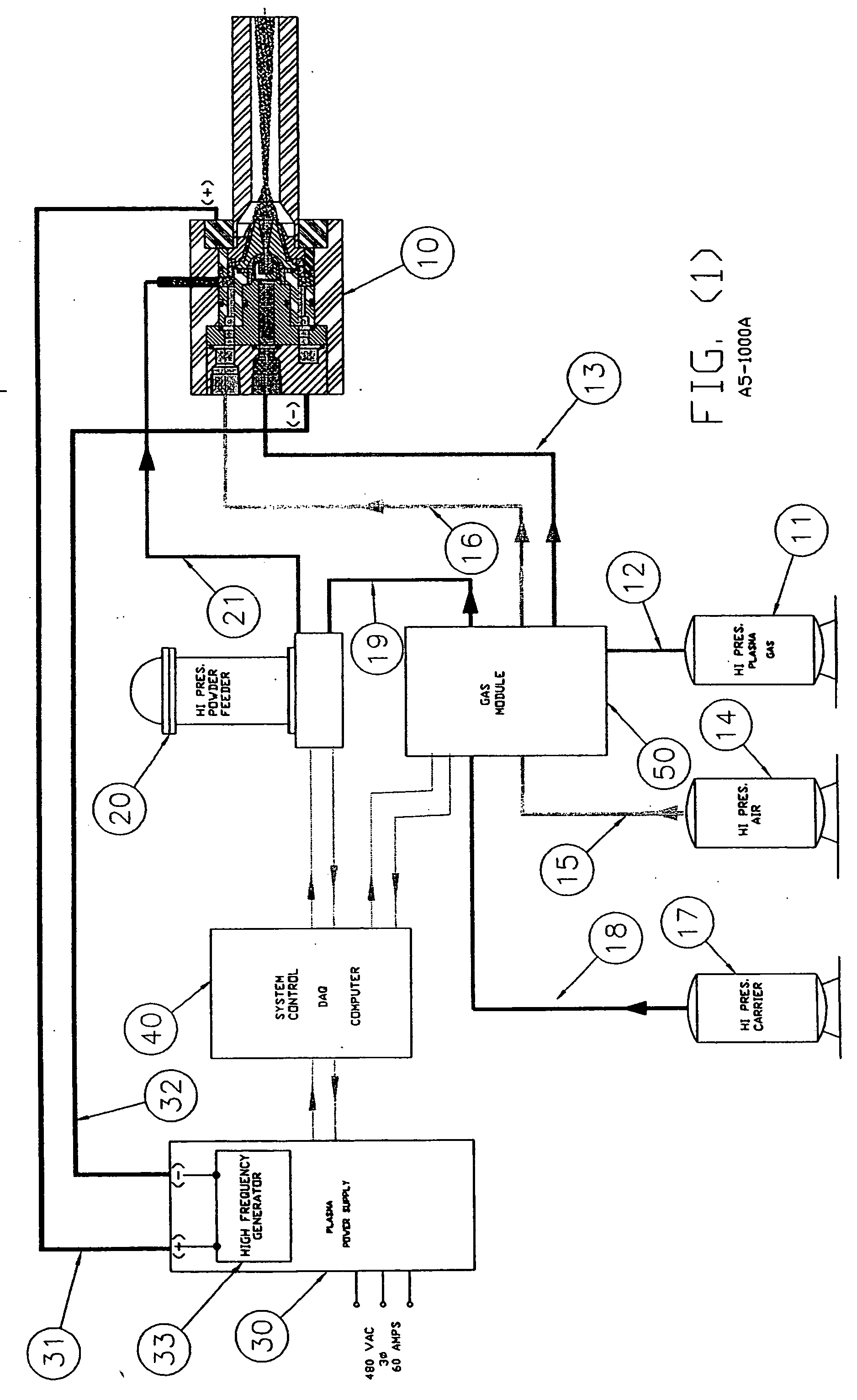

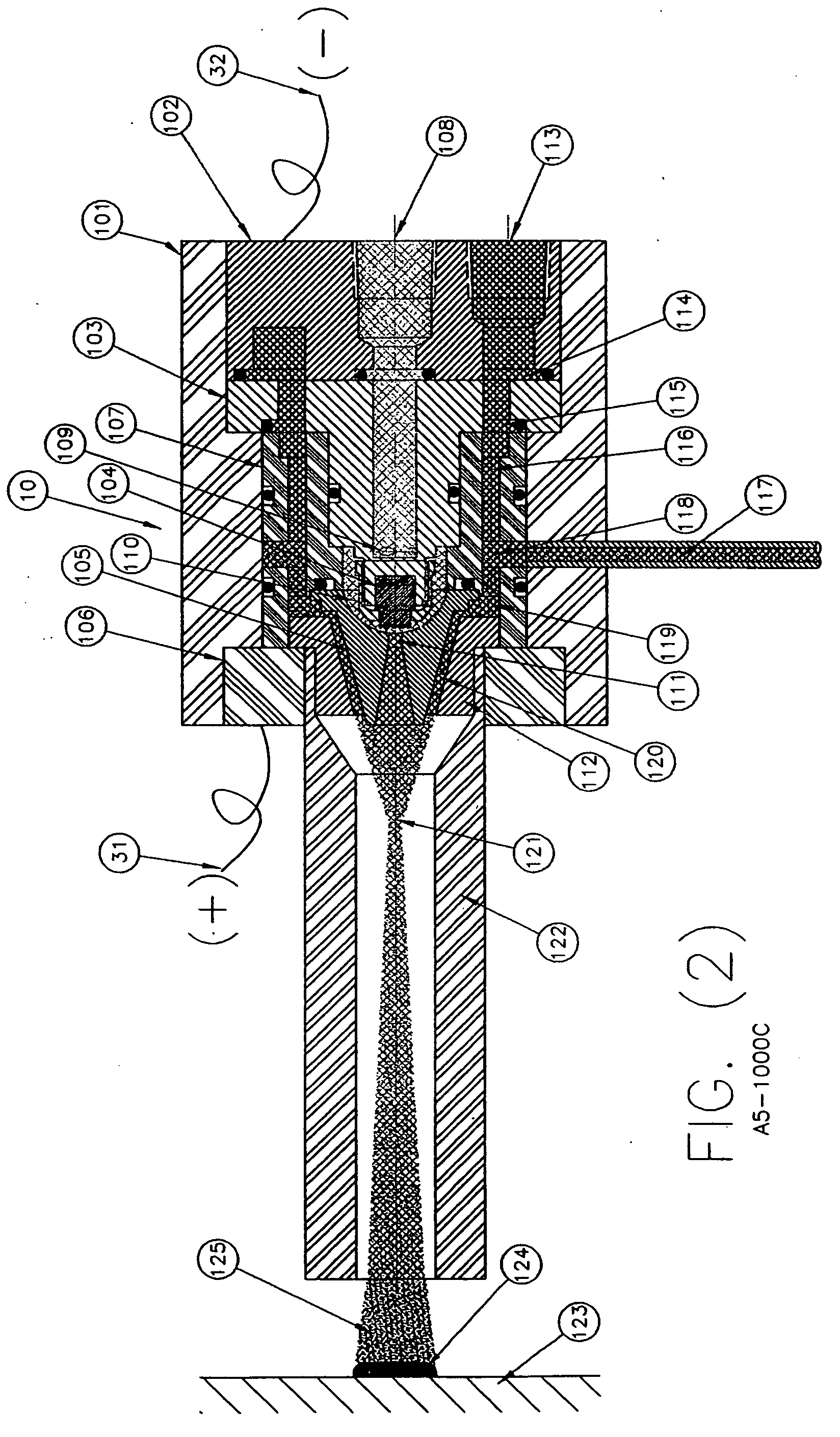

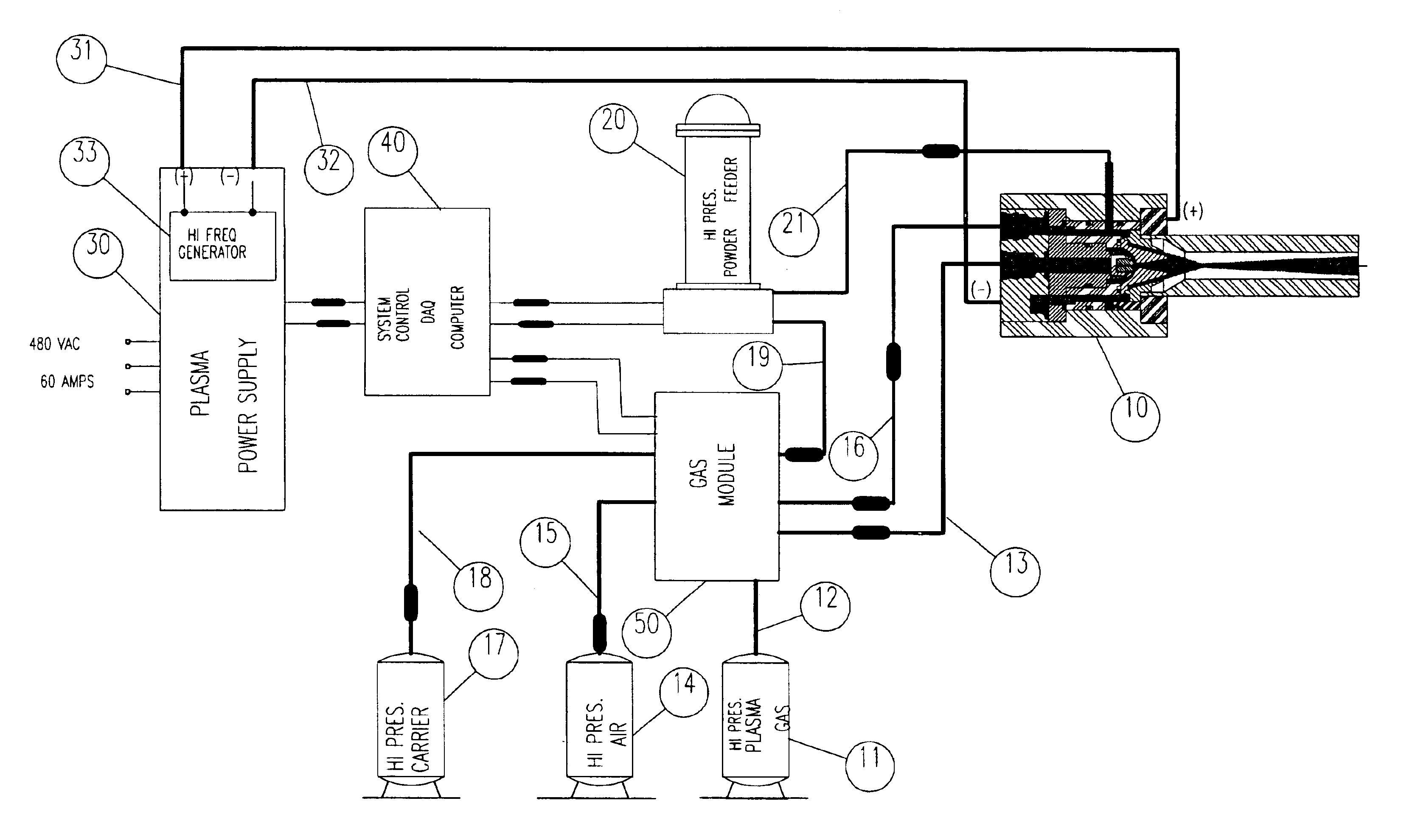

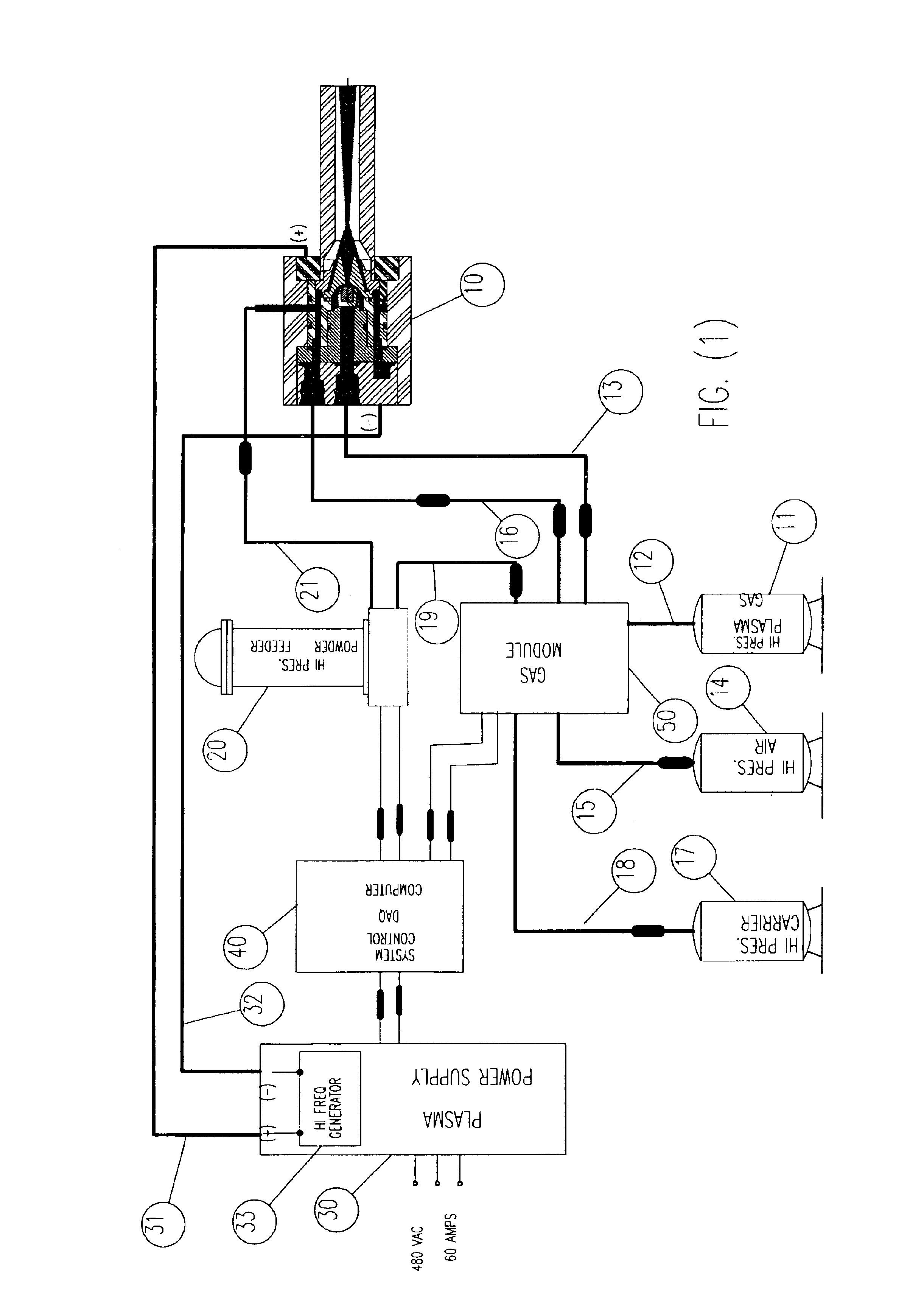

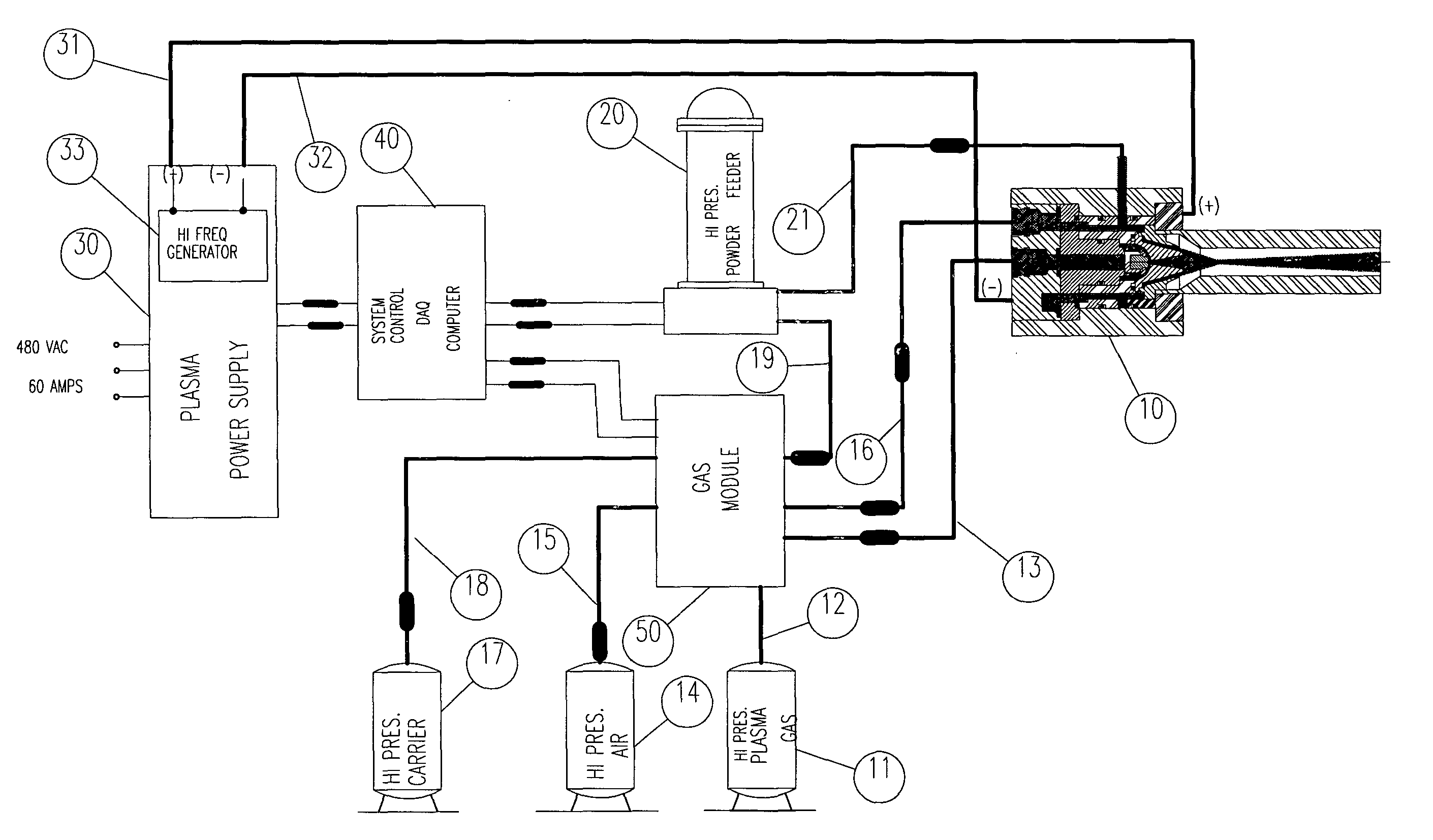

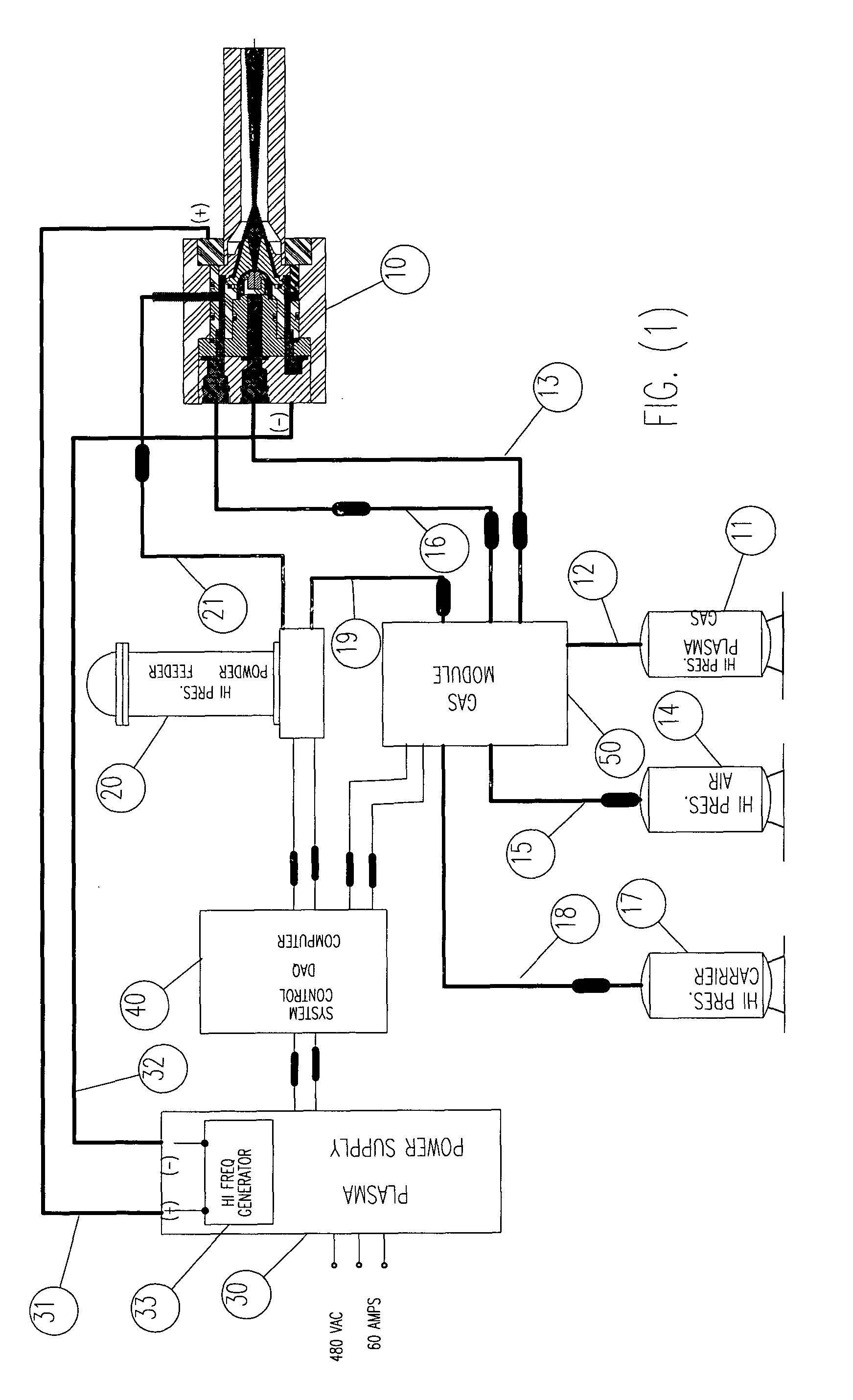

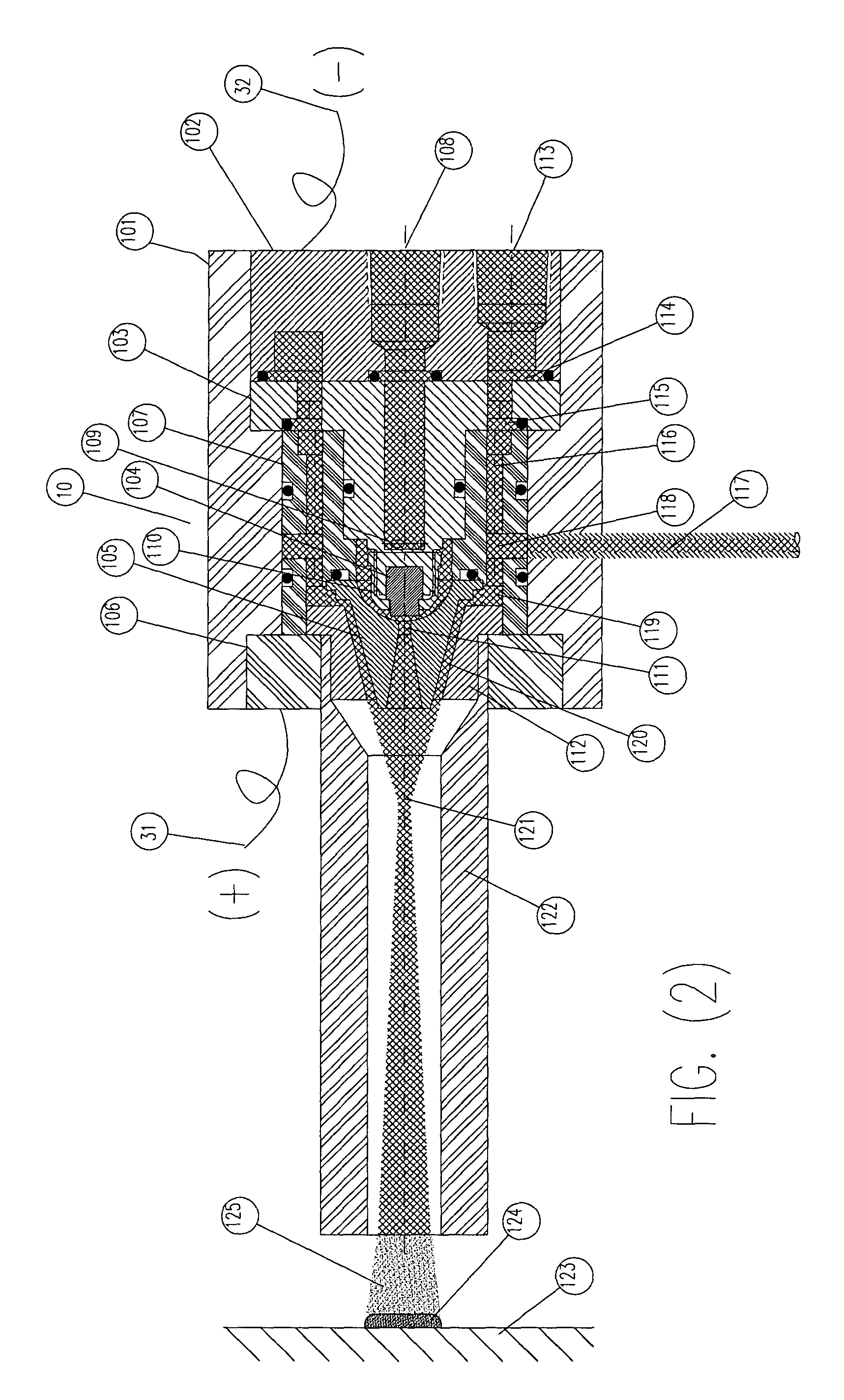

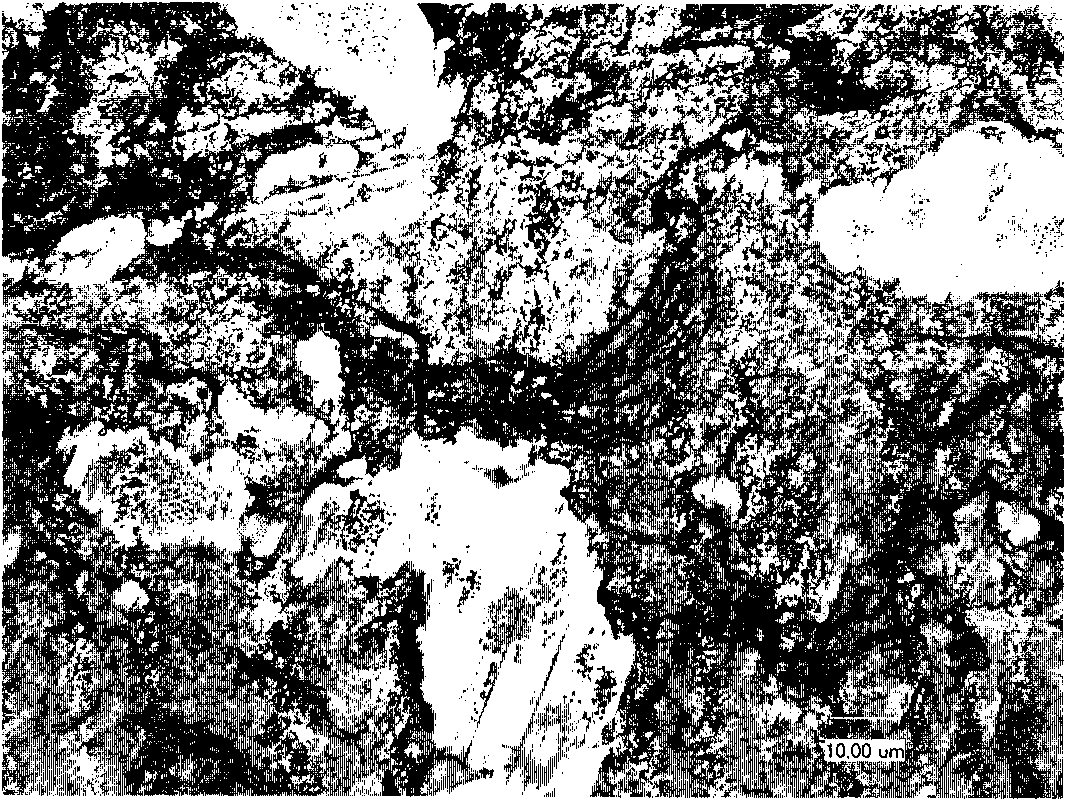

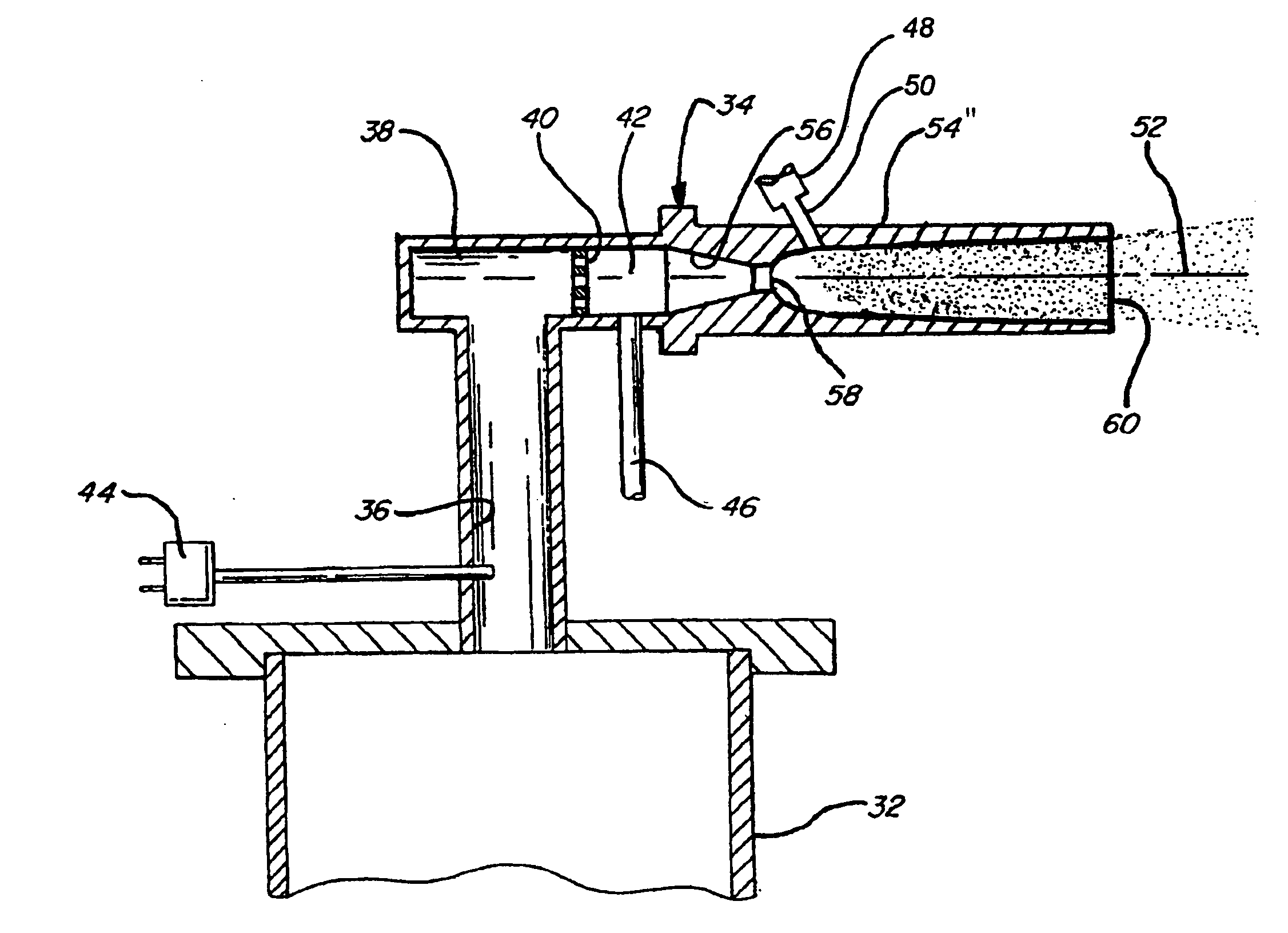

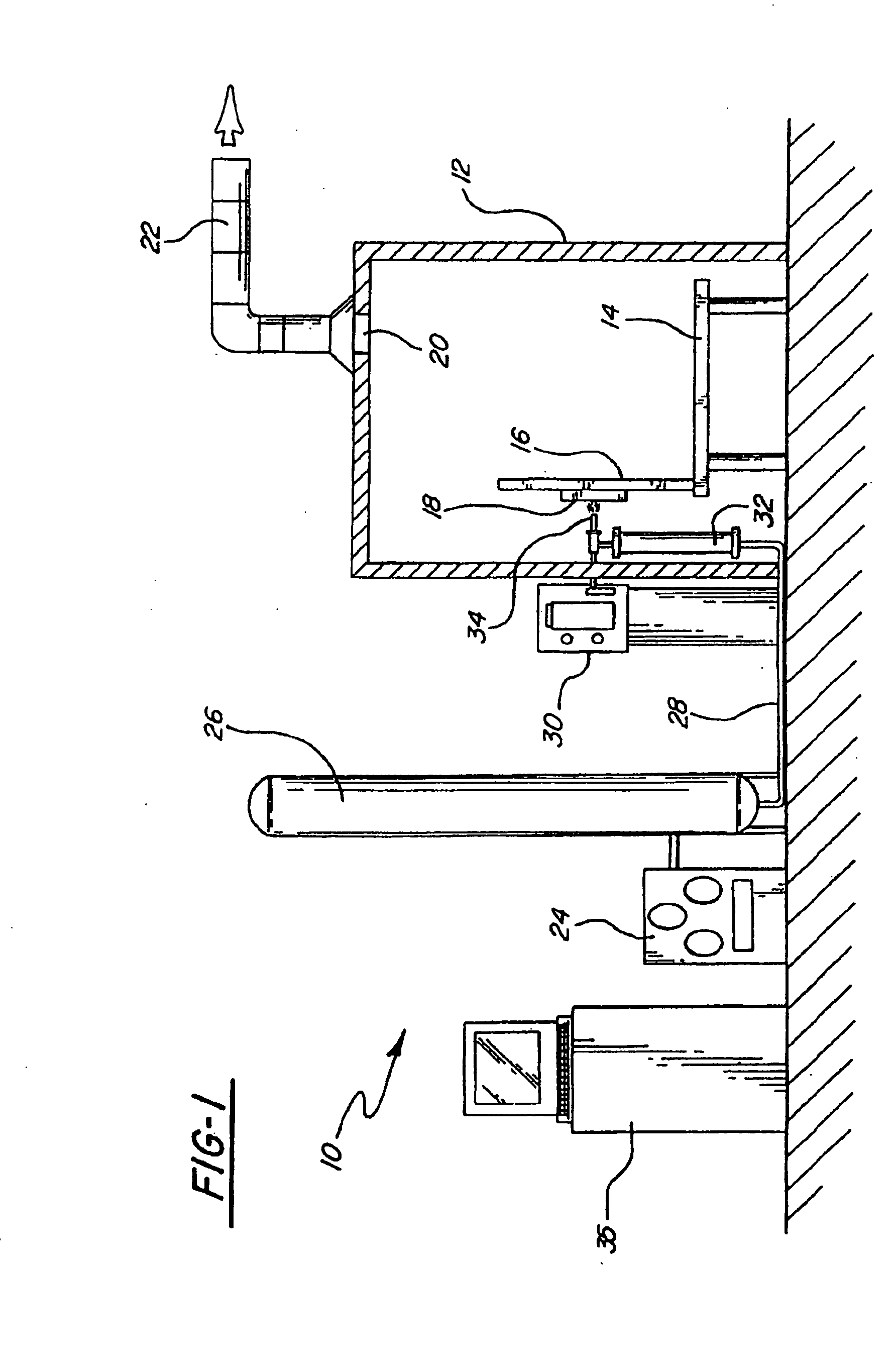

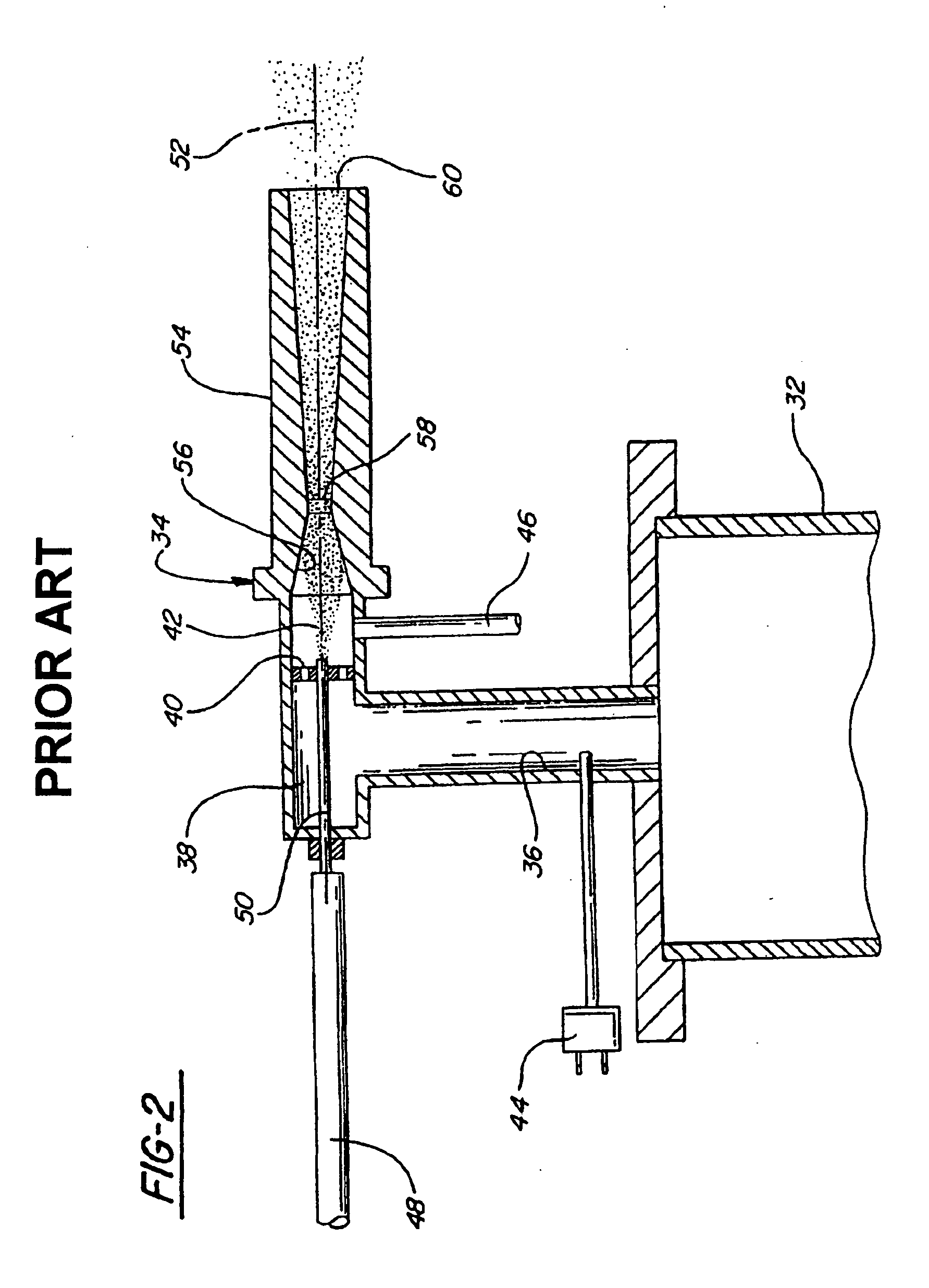

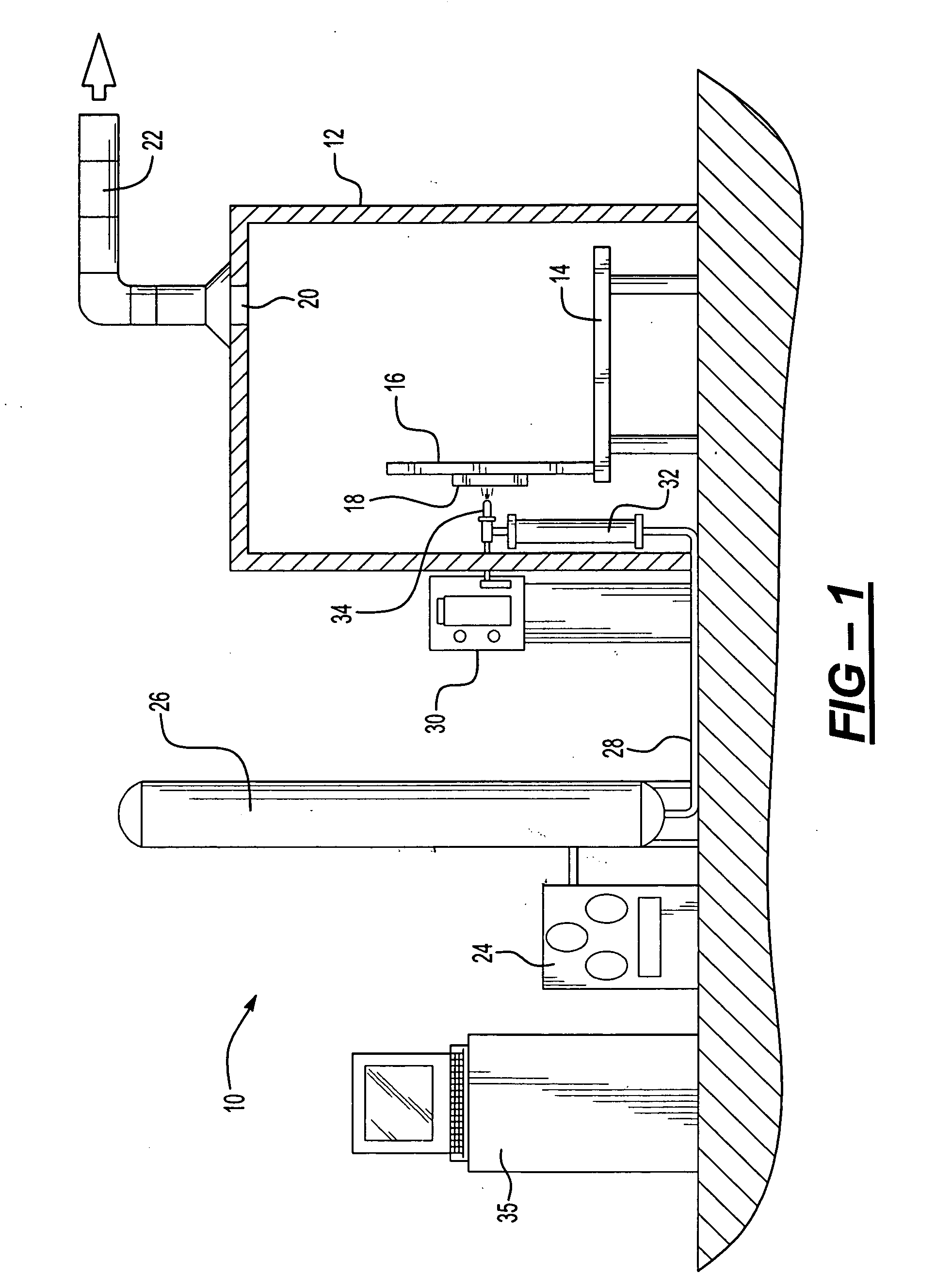

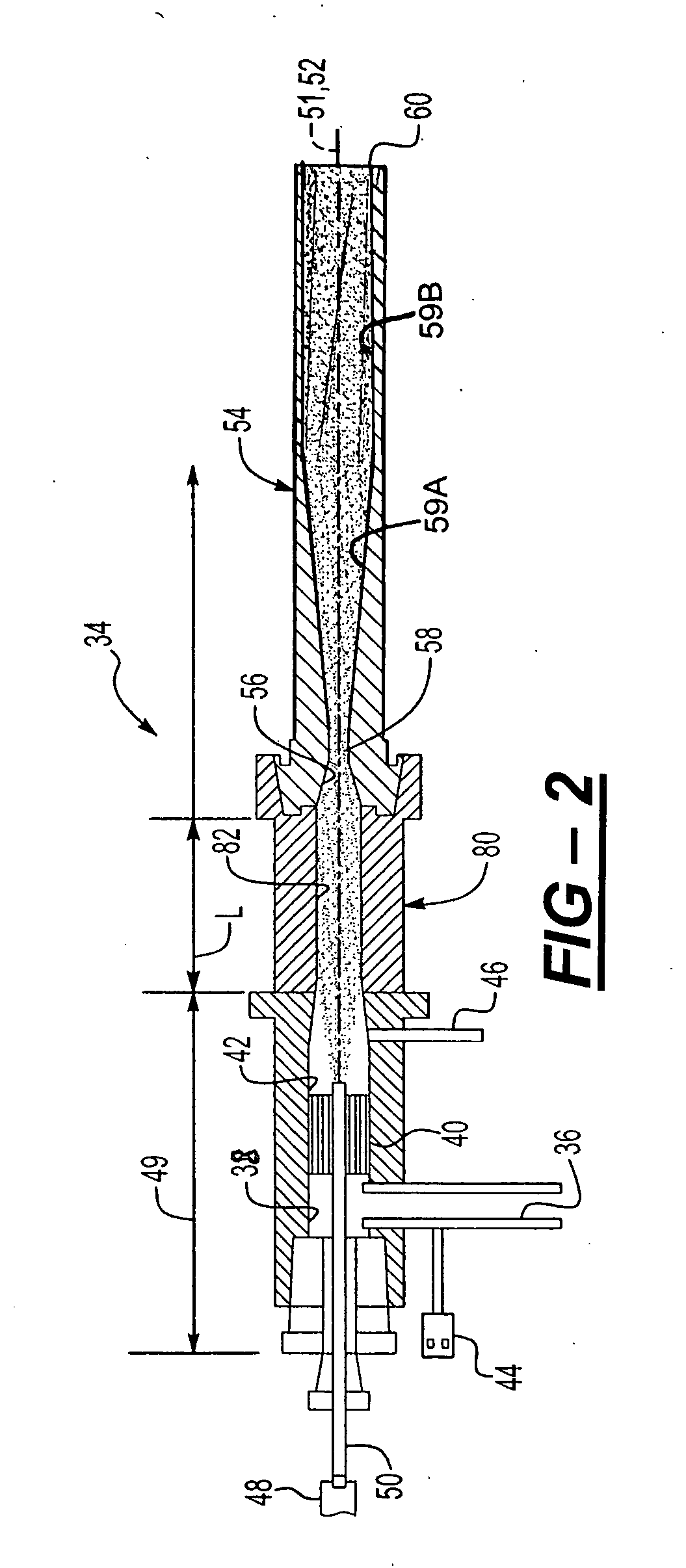

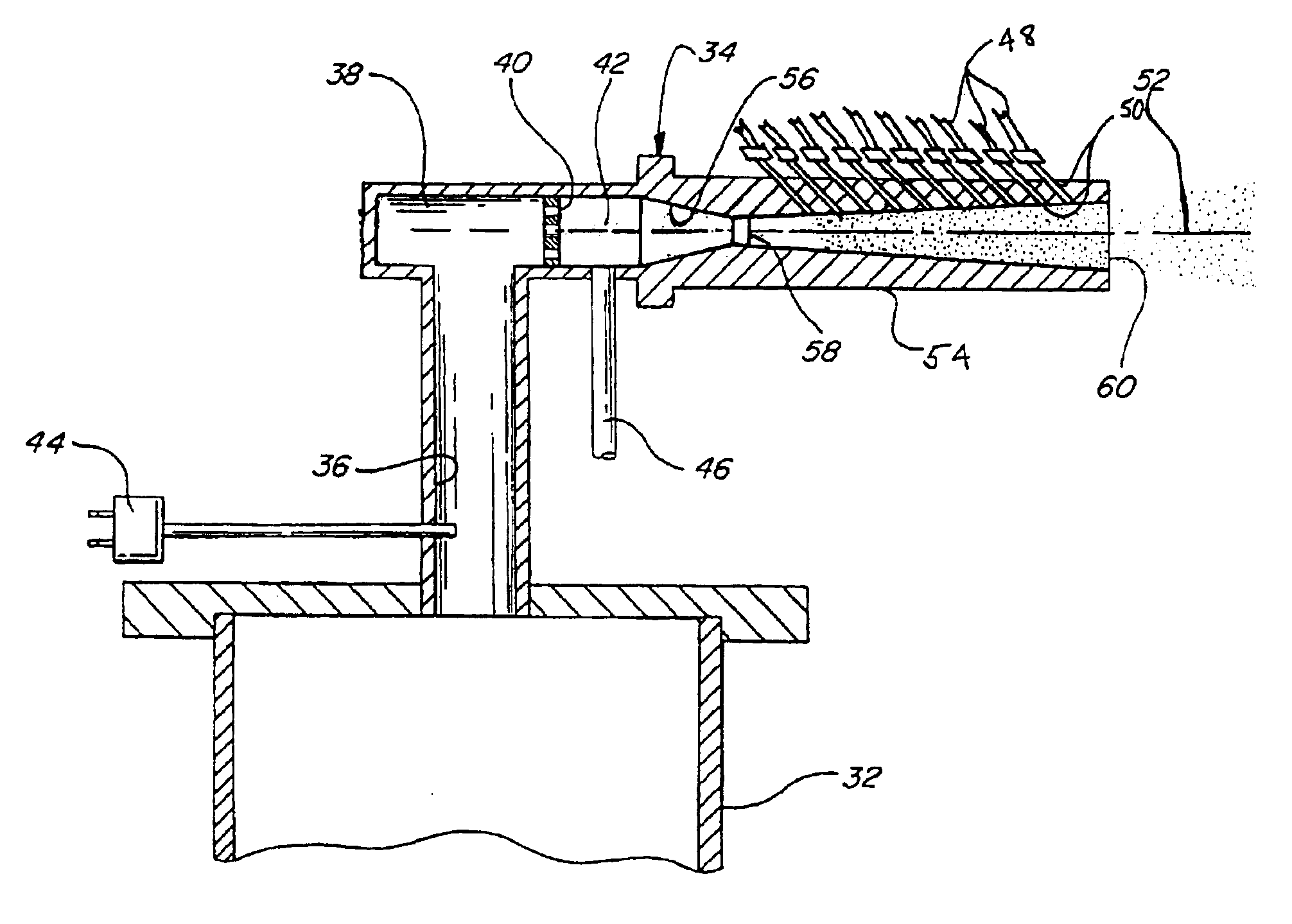

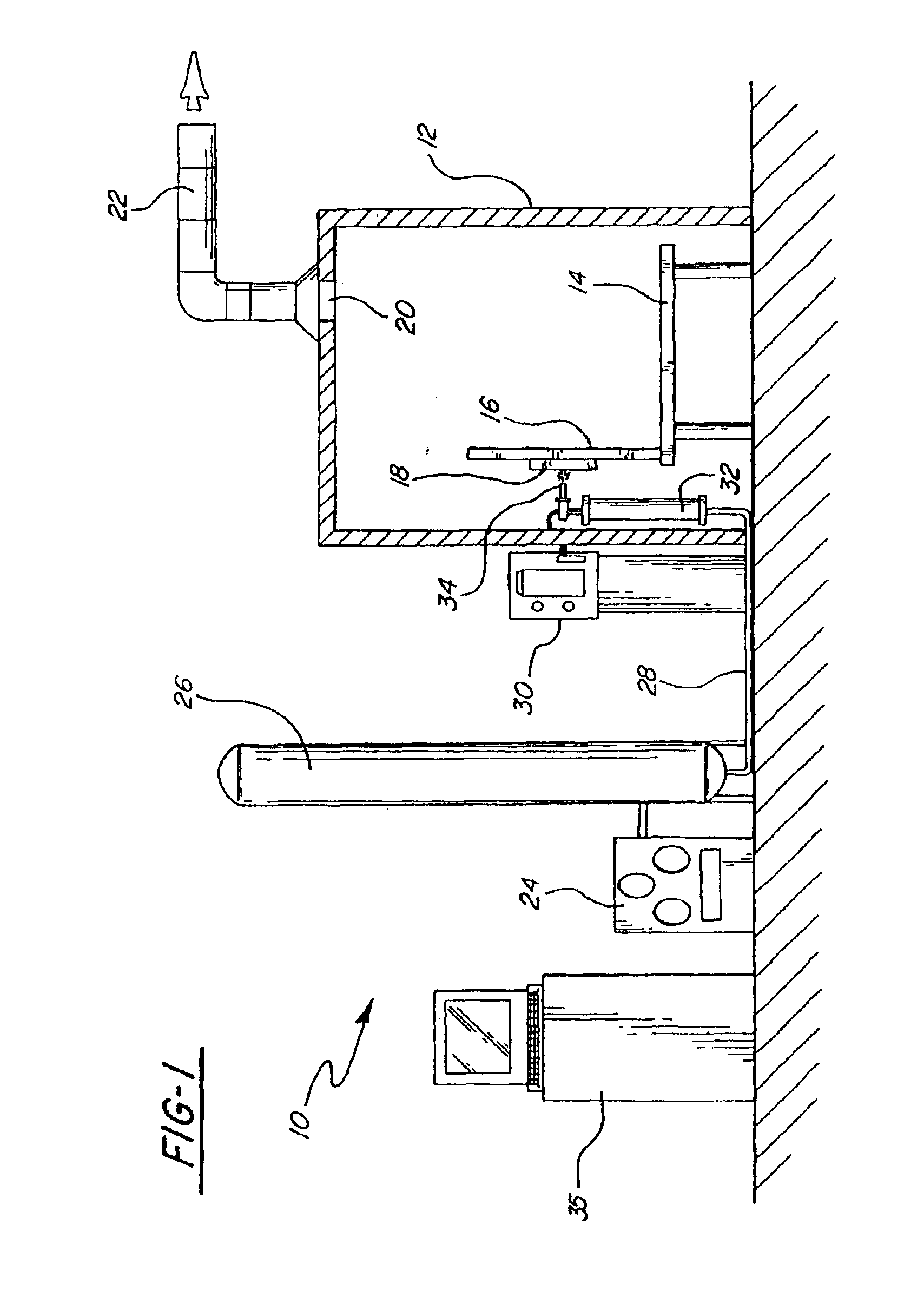

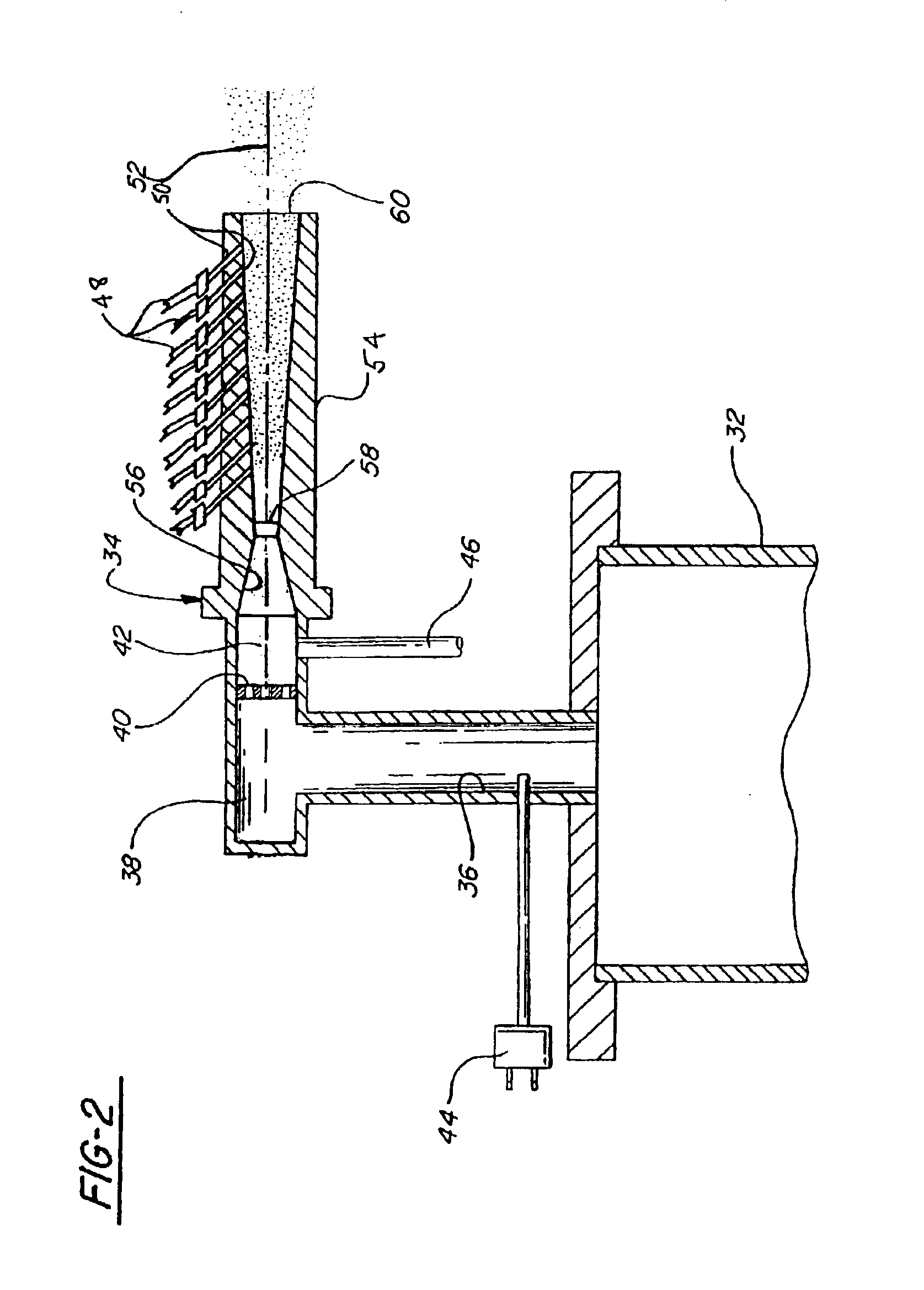

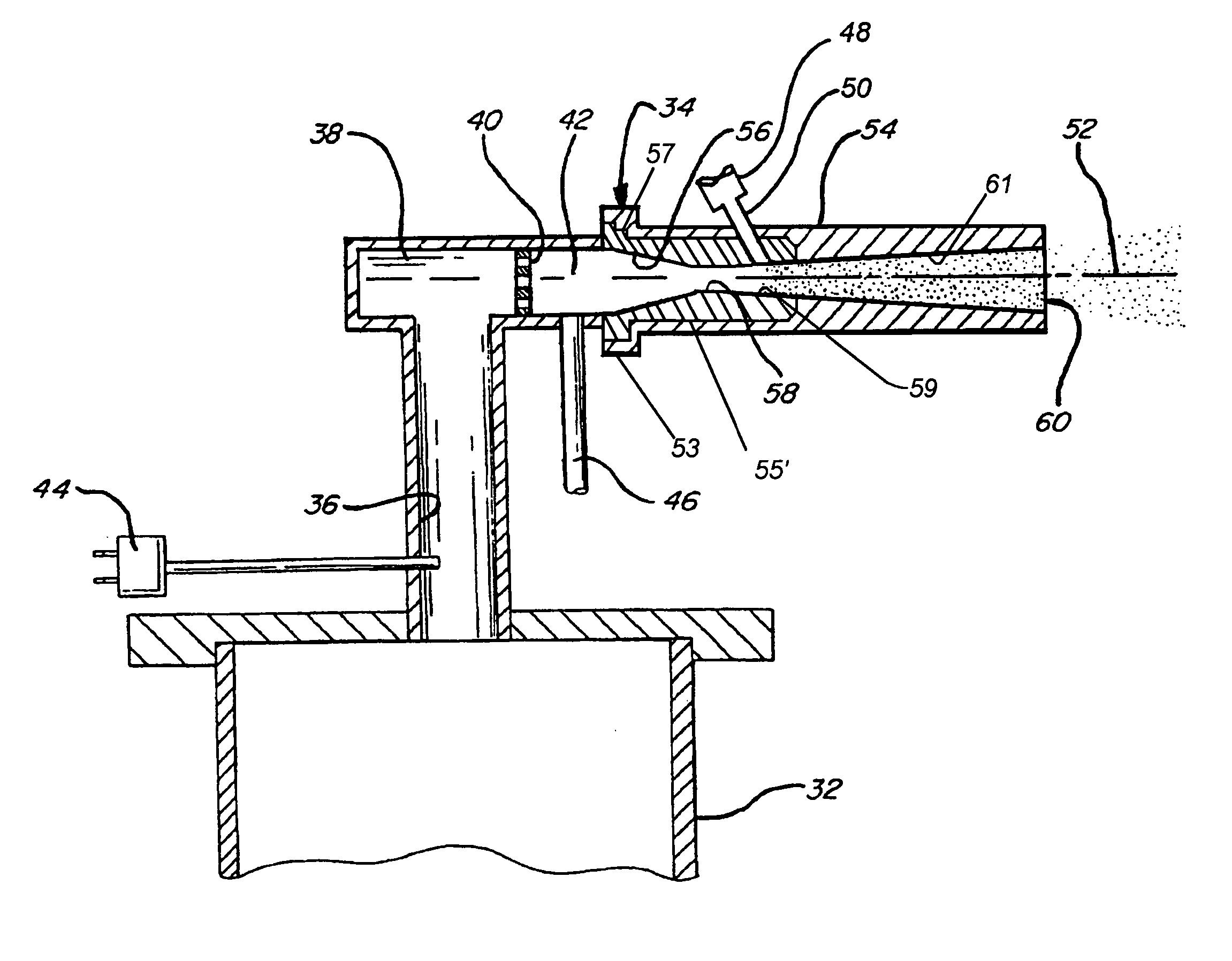

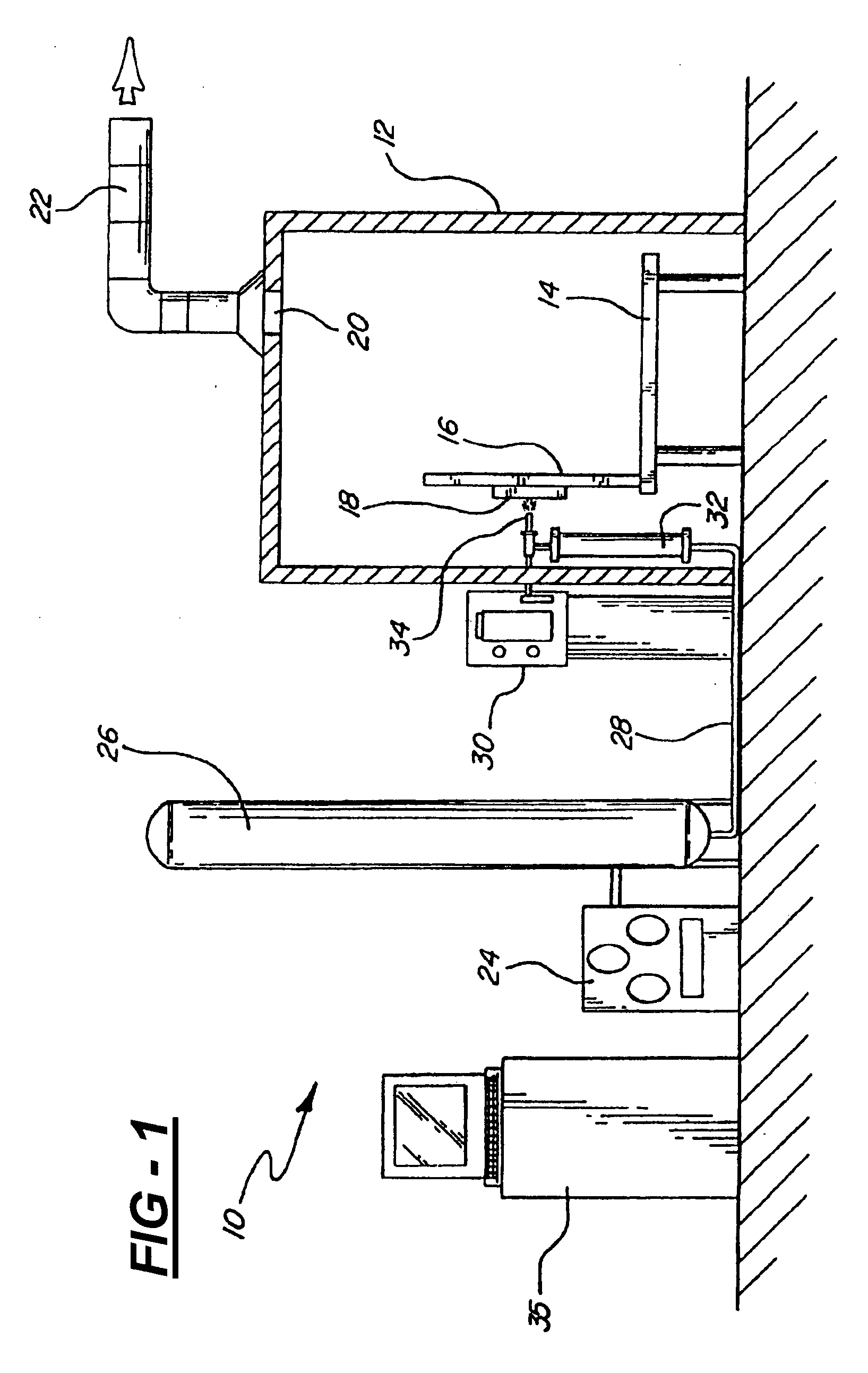

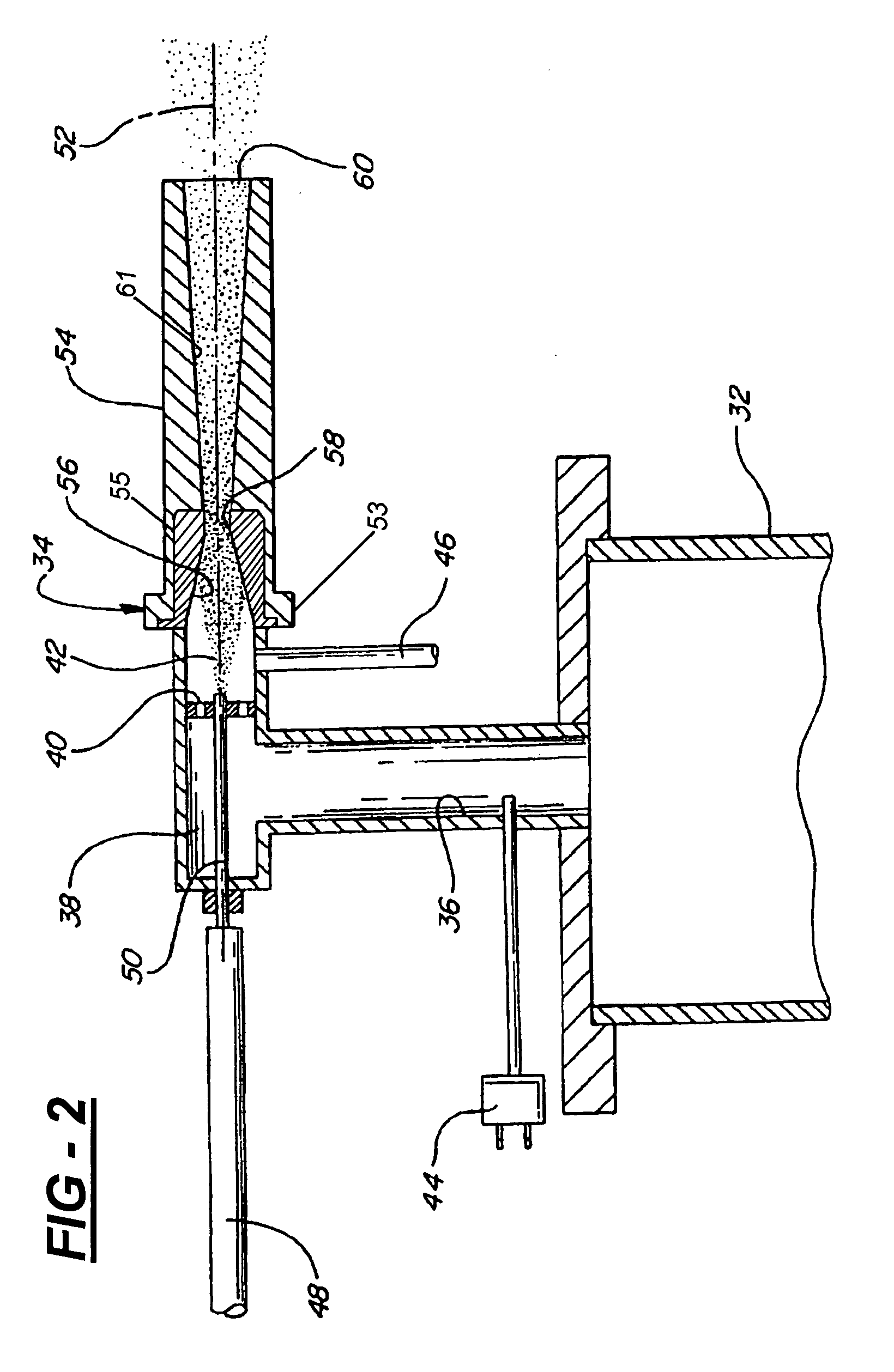

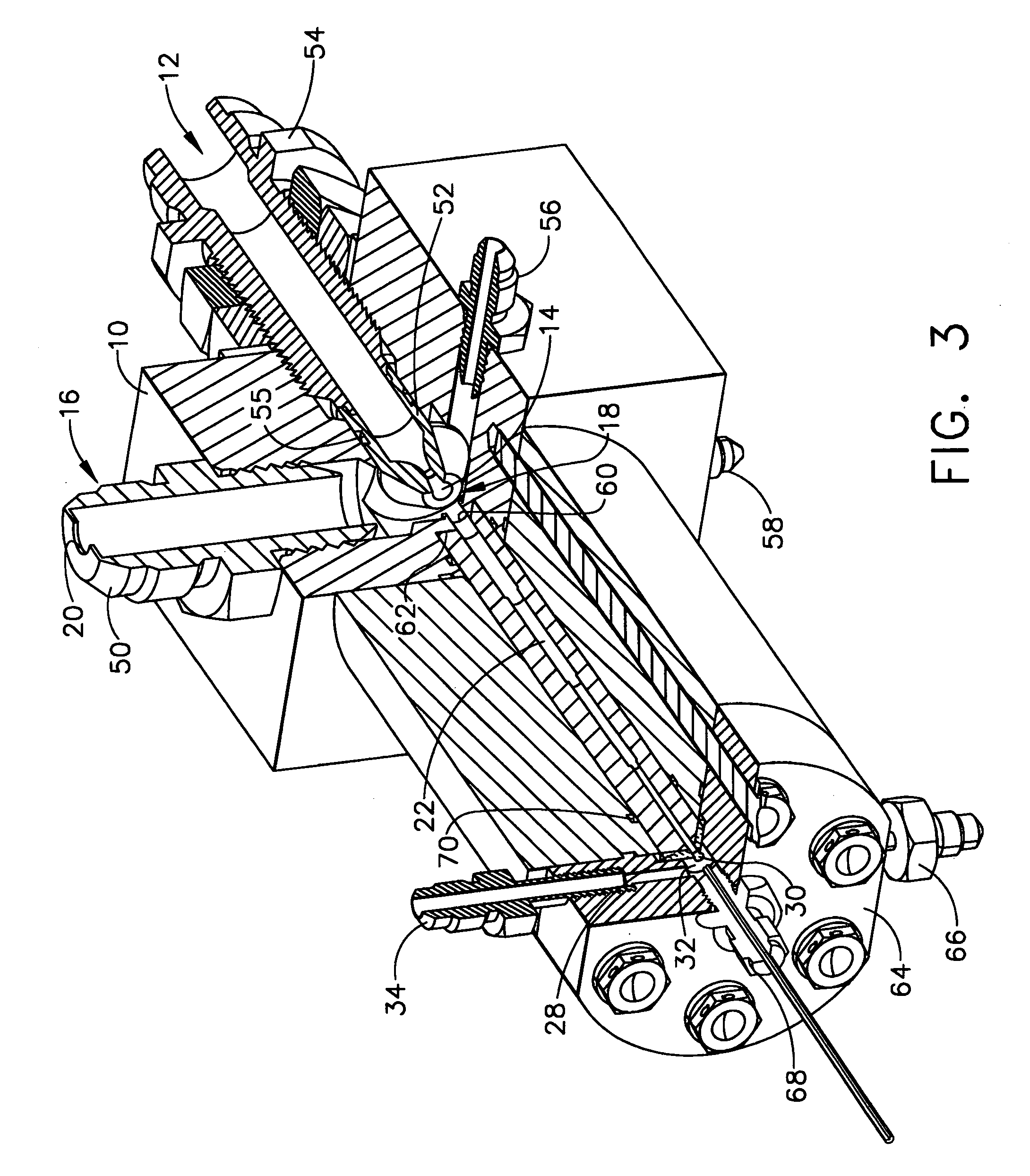

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

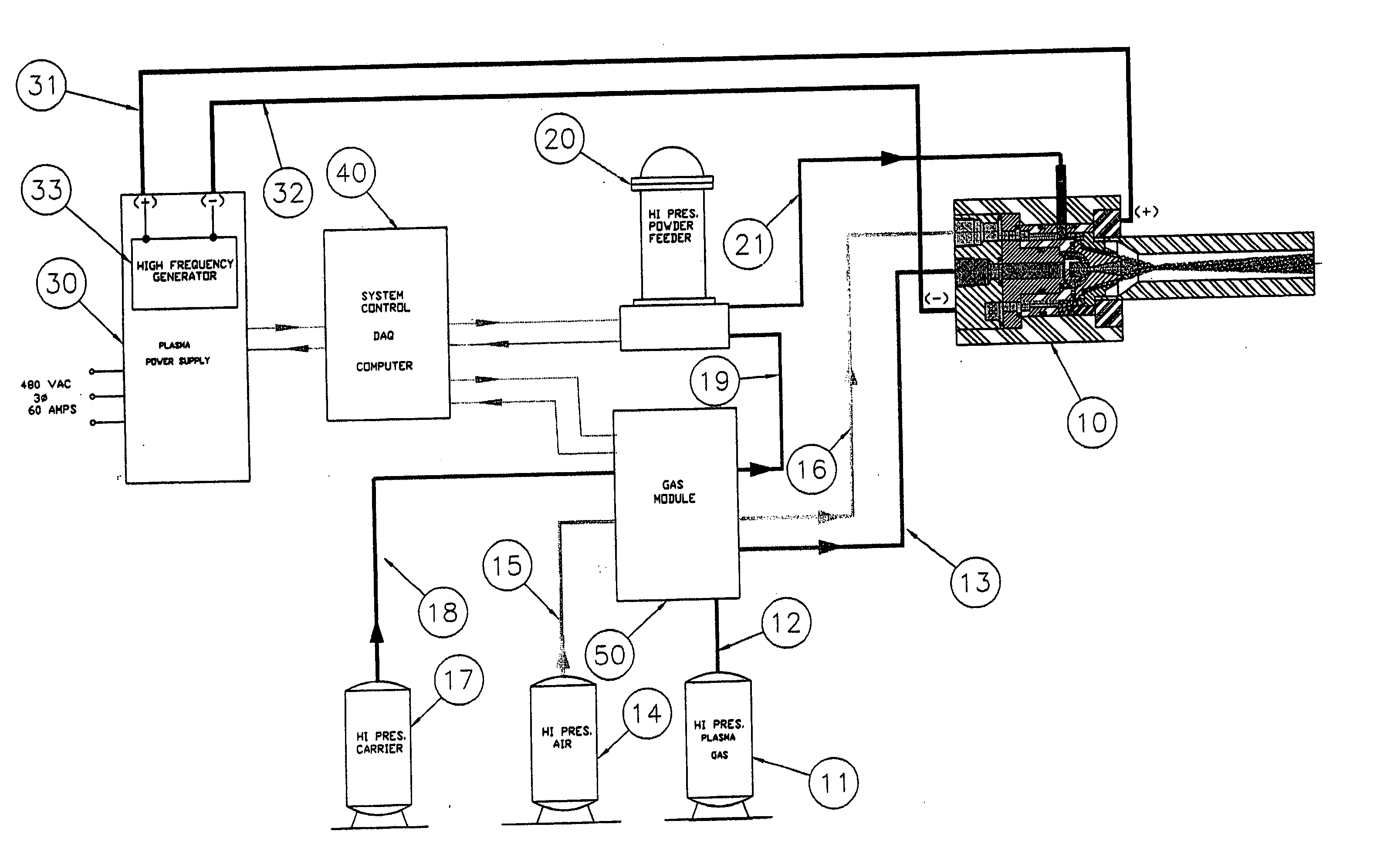

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

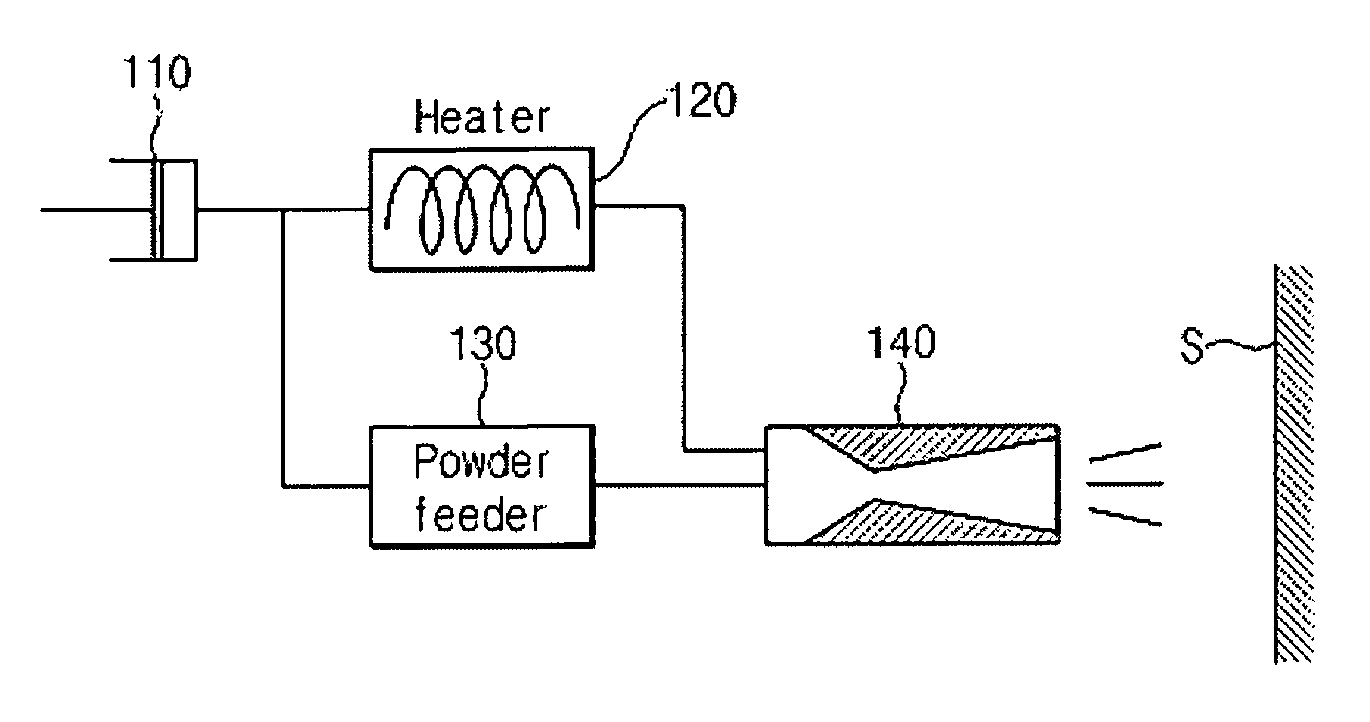

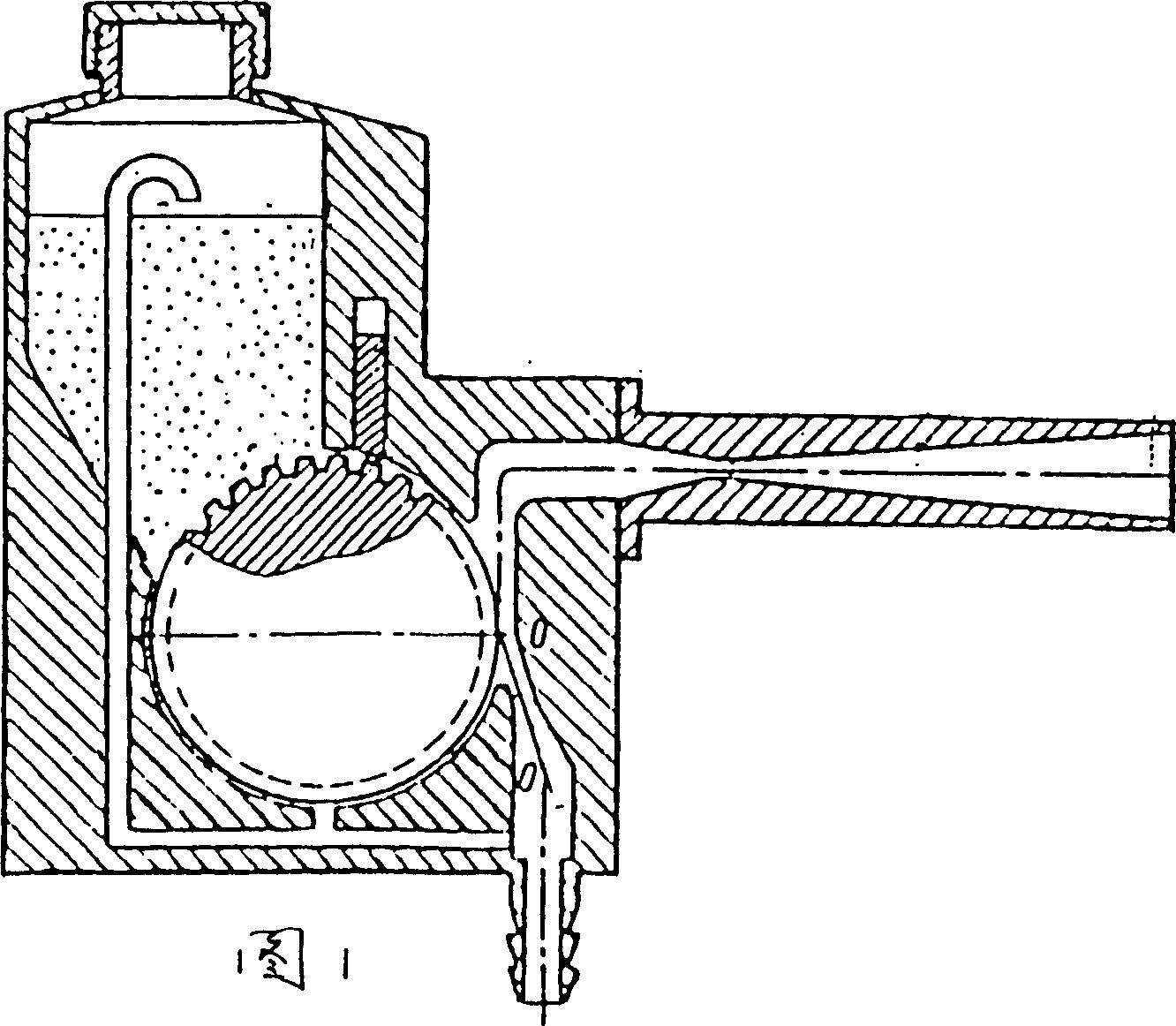

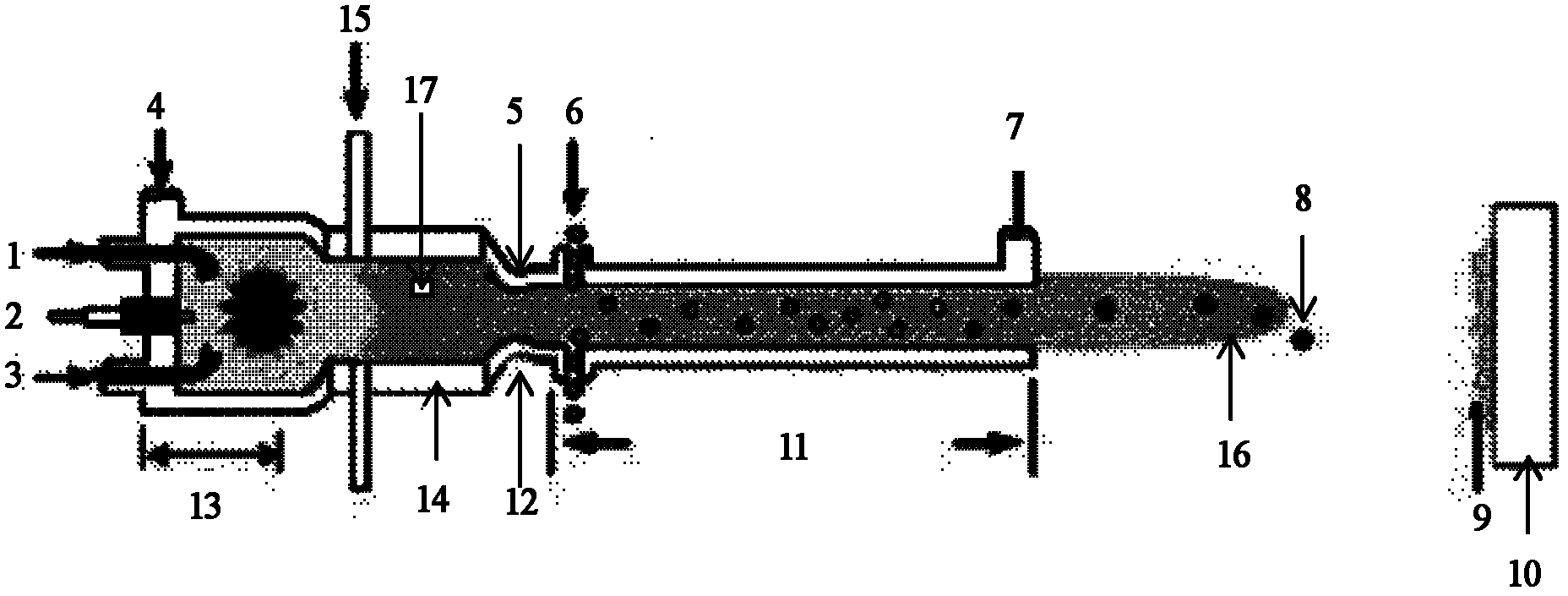

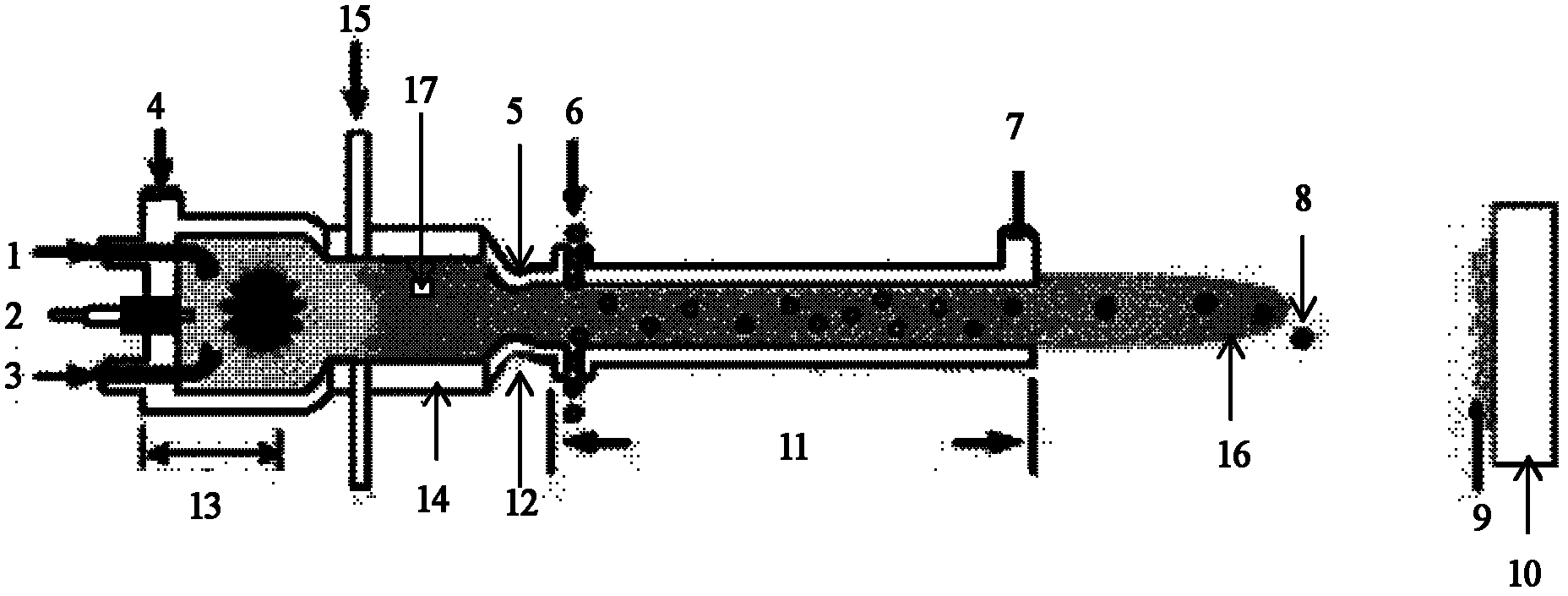

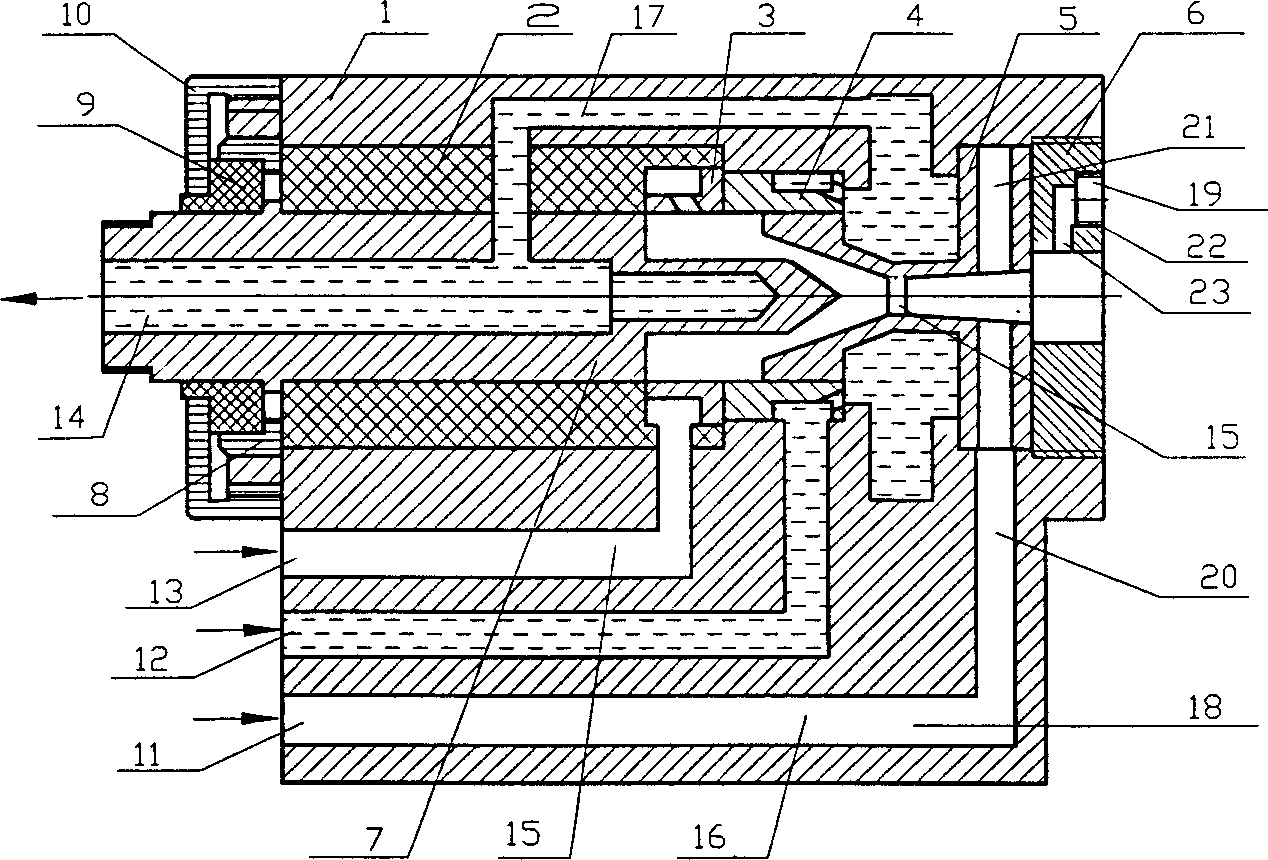

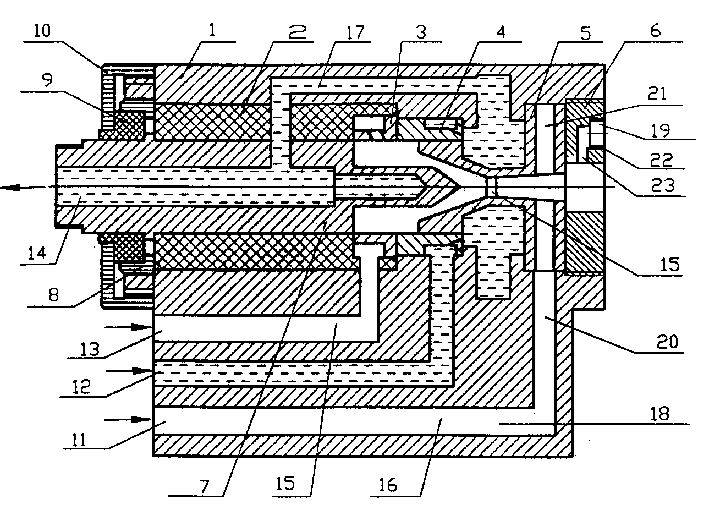

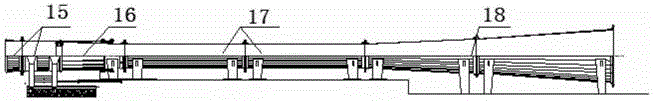

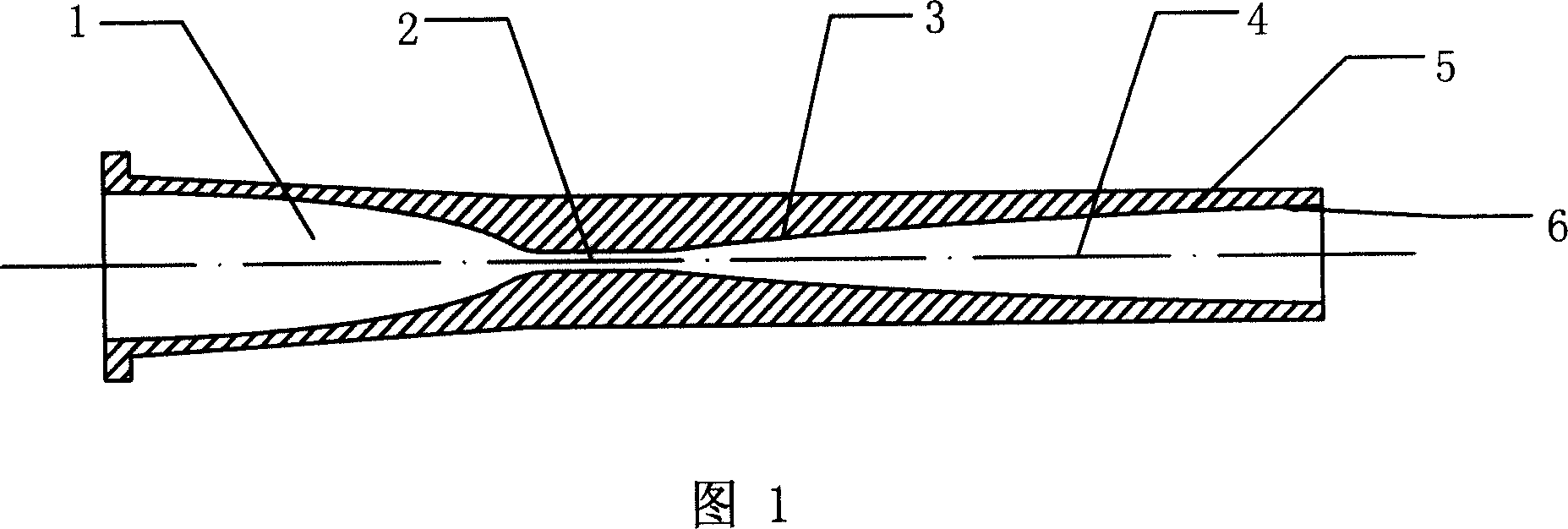

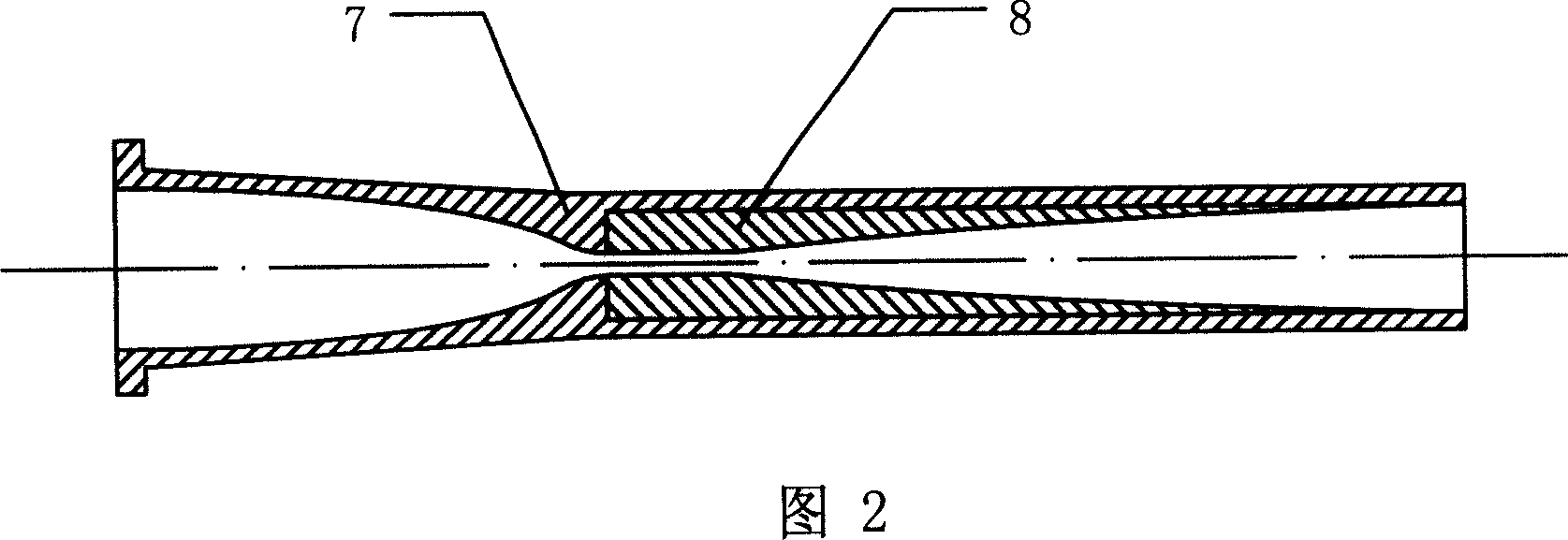

Cold air driven spray painter

InactiveCN1403210AImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

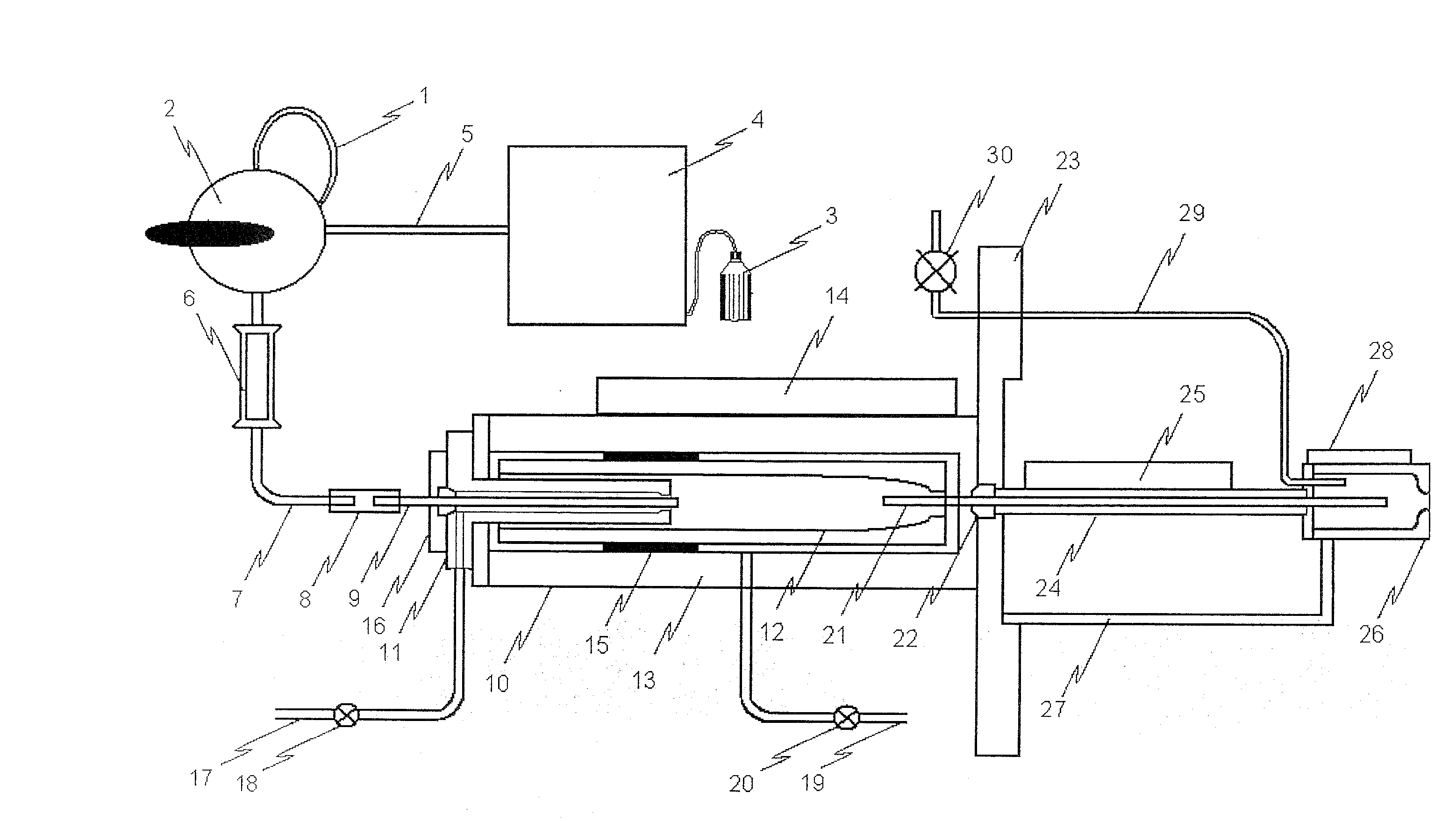

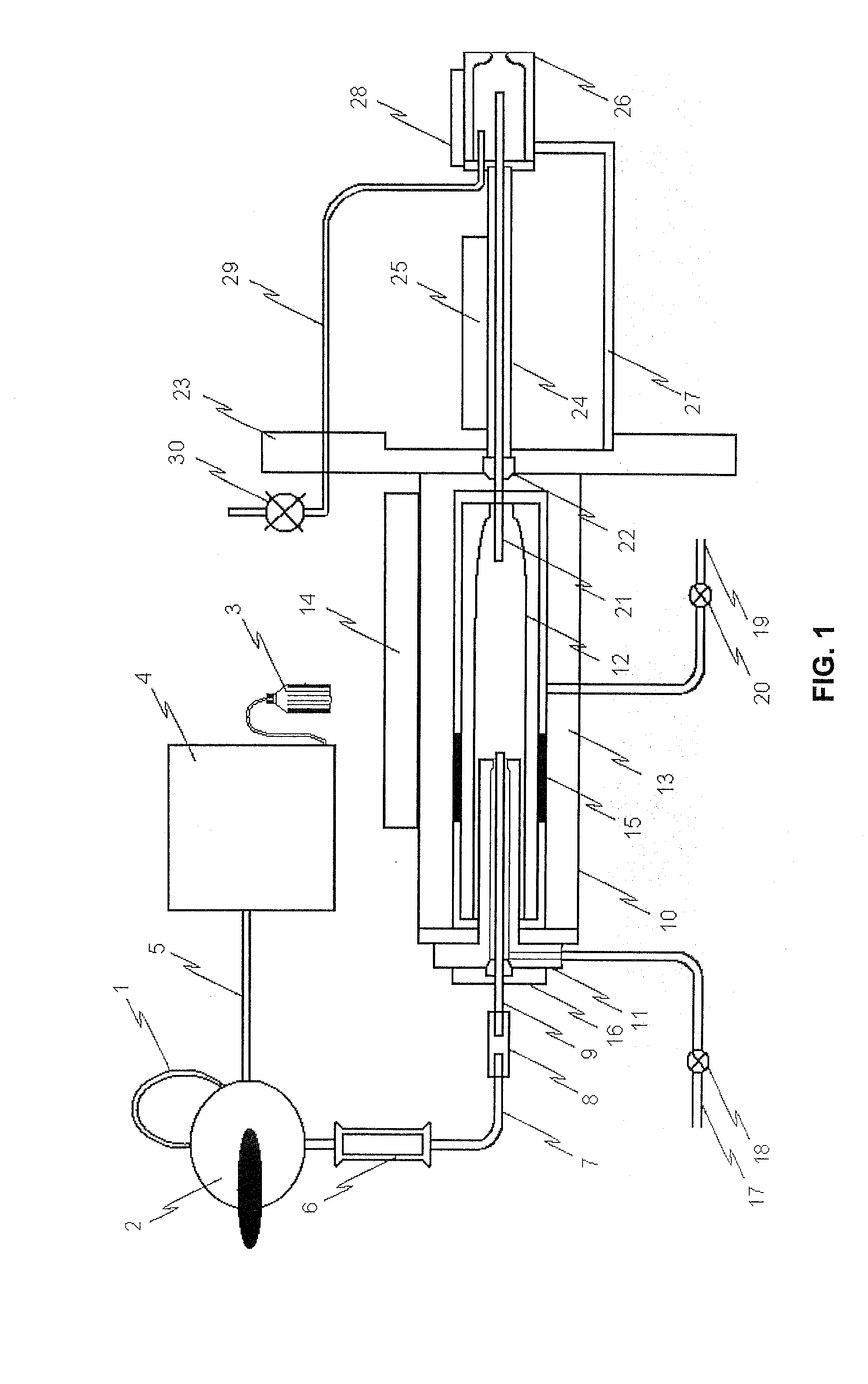

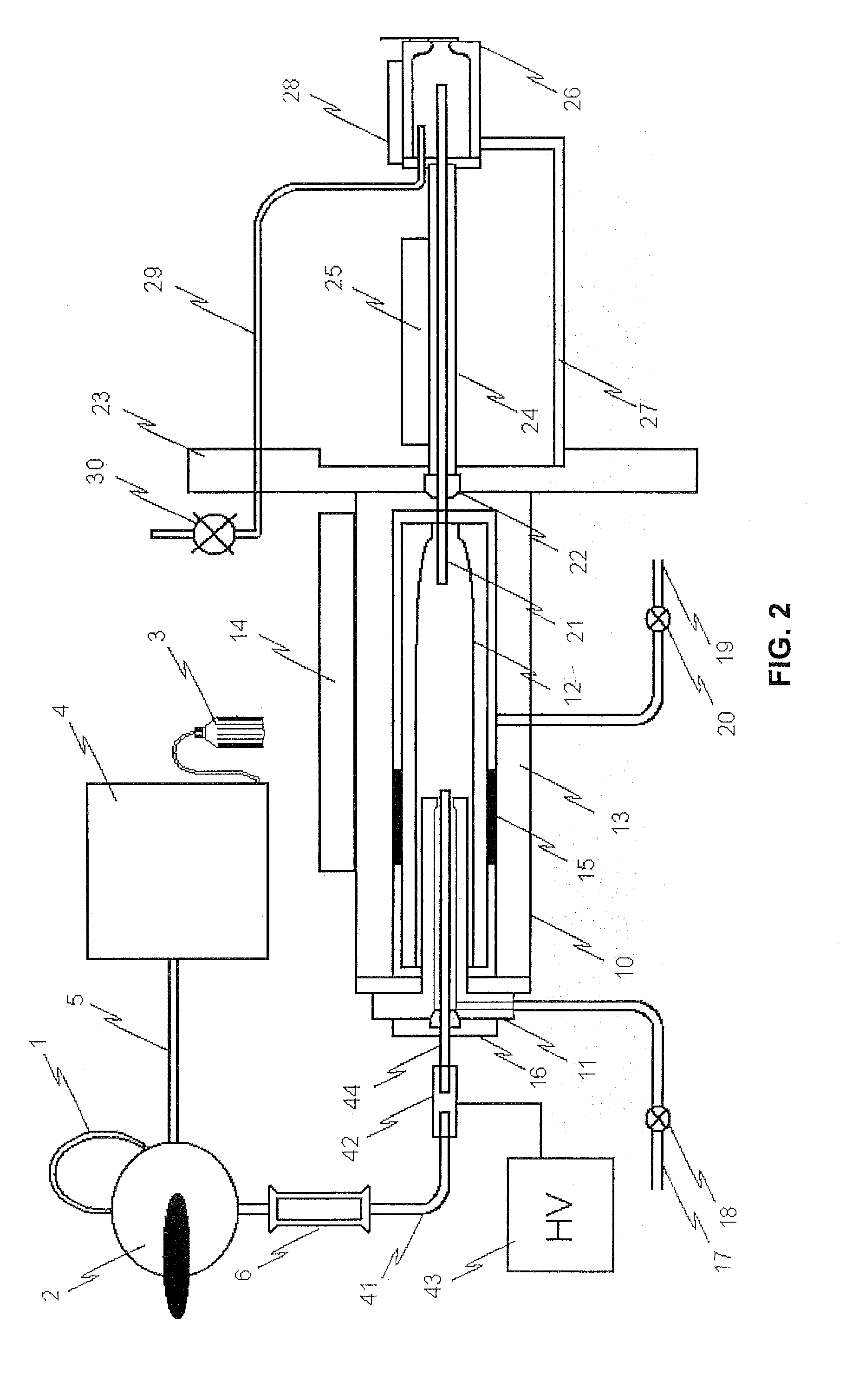

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Plasma spray method for applying a coating utilizing particle kinetics

InactiveUS6861101B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorHigh pressure

A method of operation of a plasma torch. A cold high pressure carrier gas containing a powder material is injected into a cold main high pressure gas flow and then this combined flow is directed coaxially around a plasma exiting from an operating plasma generator and converging into the hot plasma effluent, mixing with the effluent to form a gas stream with a net temperature, based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, such that the powdered material will not melt. The combined flow with entrained is directed through a supersonic nozzle accelerating the flow to supersonic velocites sufficient that the particles striking the workpiece achieve kinetic energy transformation into elastic deformation of the particles as they impact the workpiece forming a cohesive coating.

Owner:FLAME SPRAY IND

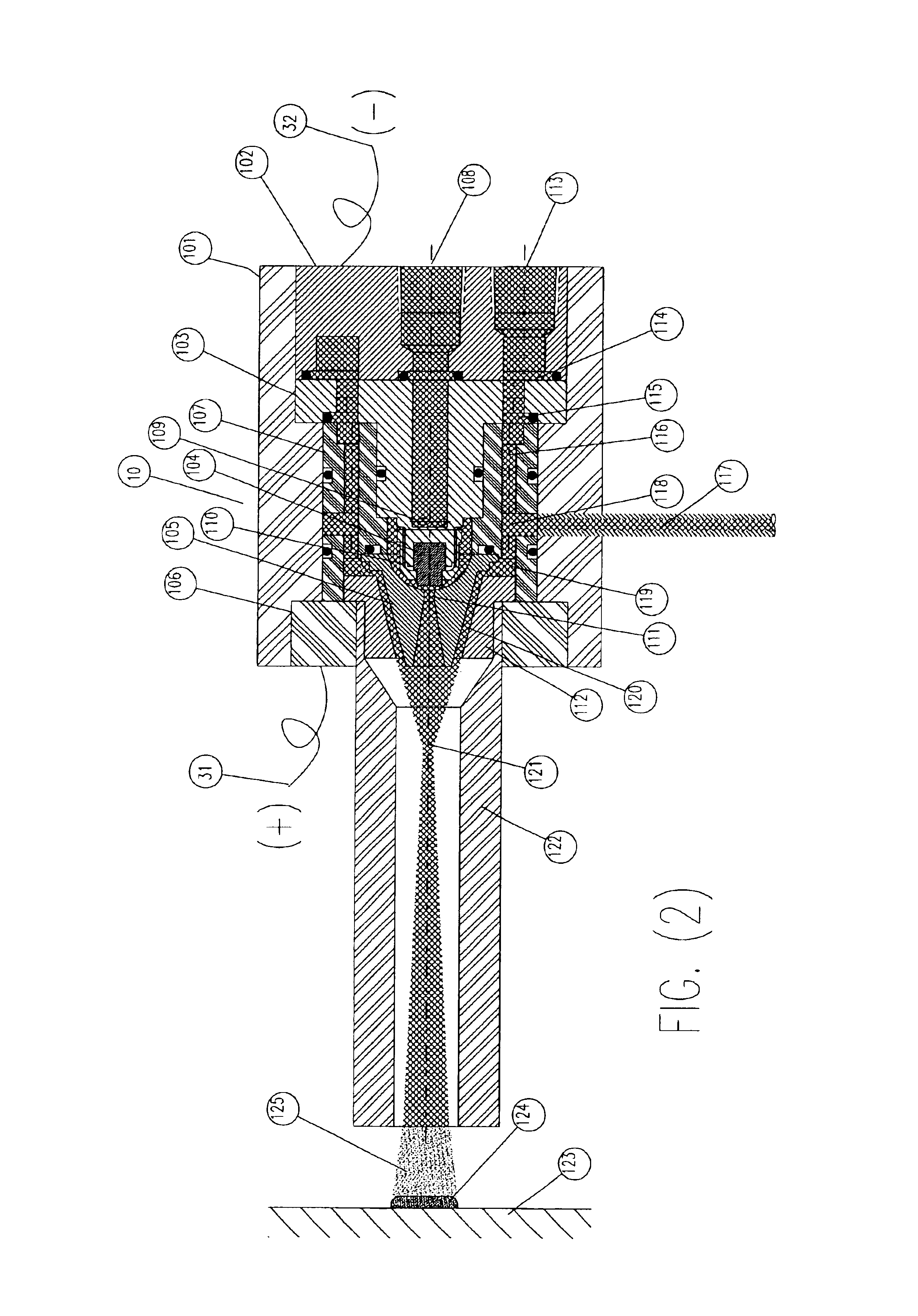

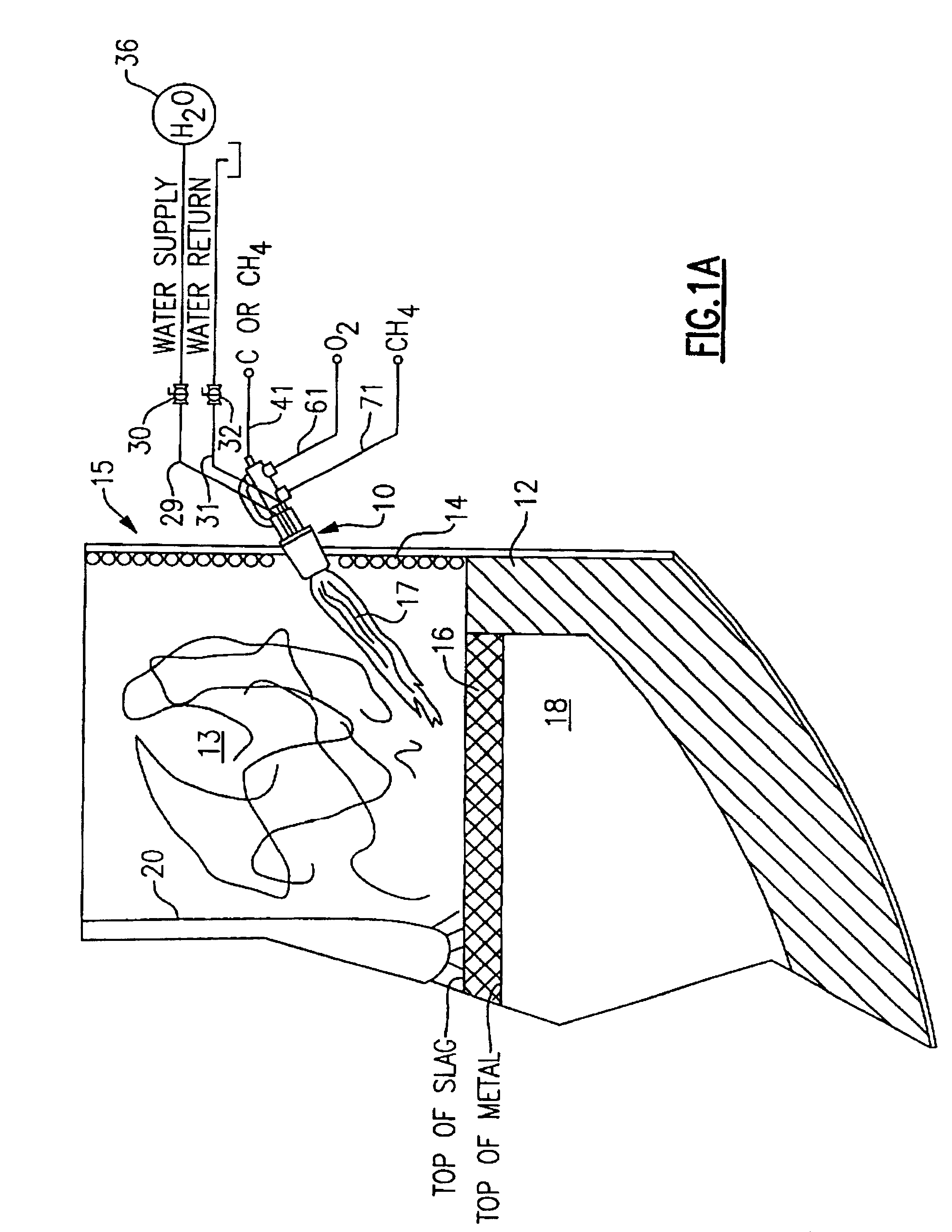

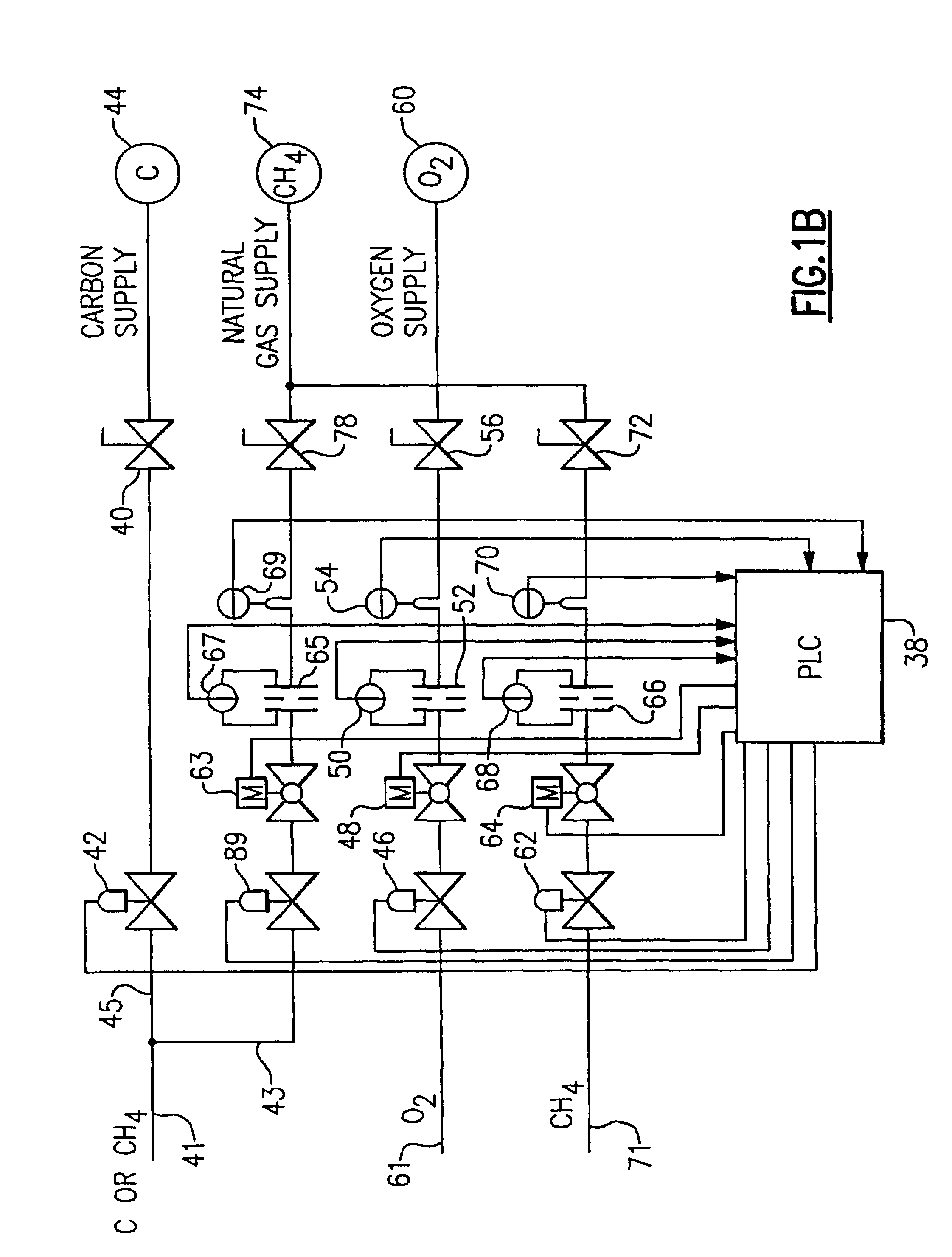

Method and apparatus for improved EAF steelmaking

An improved method and apparatus for EAF steelmaking wherein the method provides additional thermal energy to the steel making process, carbon injection for the formation of foamy slag, and oxygen injection for the decarburization of the melt, the formation of foamy slag and post combustion burning of carbon monoxide. The apparatus comprises a unique burner configuration which has a central conduit for alternatively supplying fluid hydrocarbon fuel or particulate carbon with a carrier gas which are discharged through a exit opening. The fuel or carbon is mixed with a high speed, preferably supersonic, stream of oxidizing gas. The high speed stream of oxidizing gas is provided by an annular supersonic nozzle which causes the oxidizing gas to surround the fuel or the particulates with an annular flow. The annular nozzle design can be adjusted to direct the flows of particulates and oxidizing gases in the areas and shapes desired for efficient management of the steelmaking process. Optionally, the burner can have another conduit for the secondary supply of a pressurized flow of hydrocarbon fluid fuel to a series of apertures which surround the annular flow. Further, optionally, the burner can have another conduit for the supply of a pressurized flow of a secondary oxidizing gas to a series of apertures which surround the annular flow.

Owner:PROCESS TECH INT

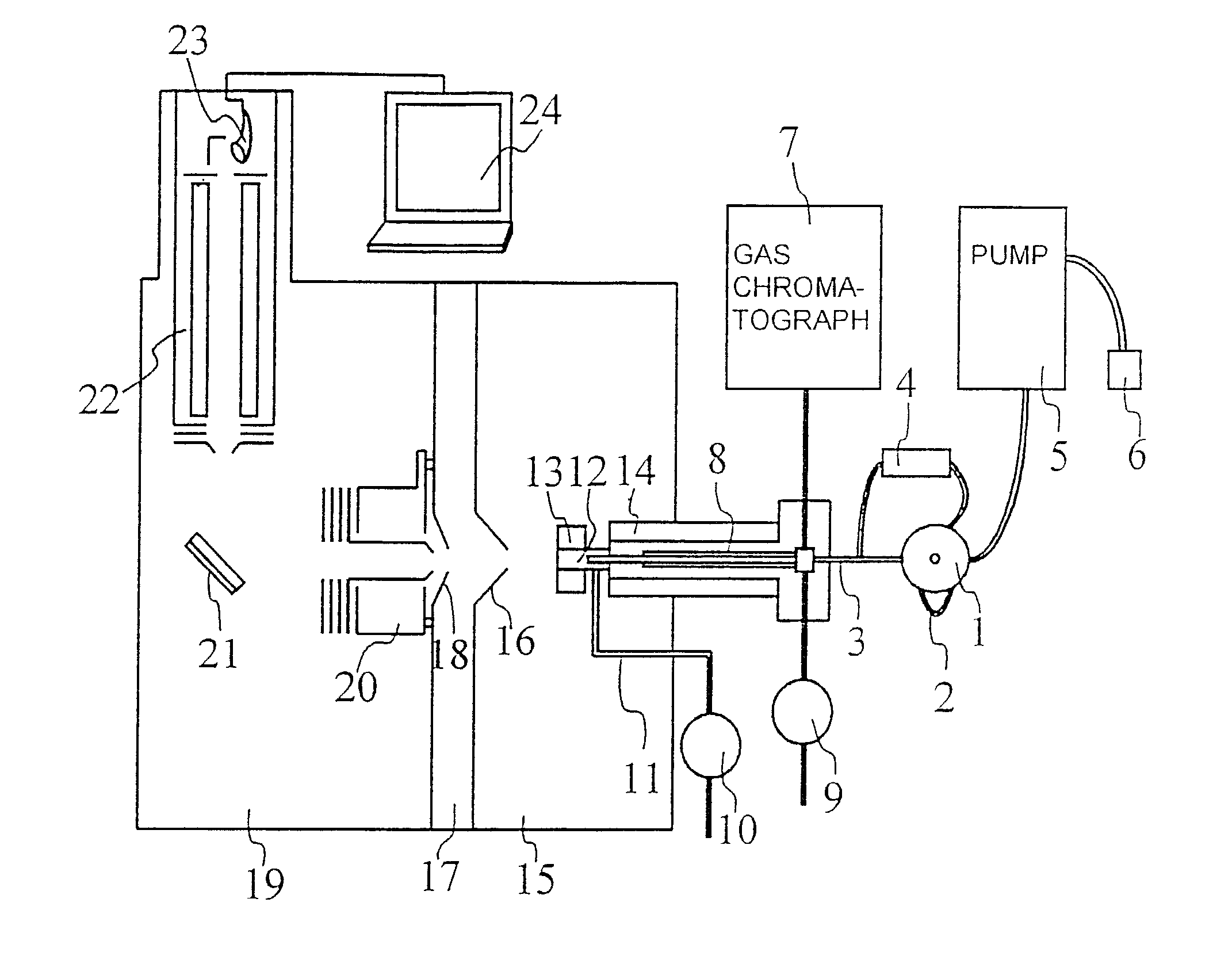

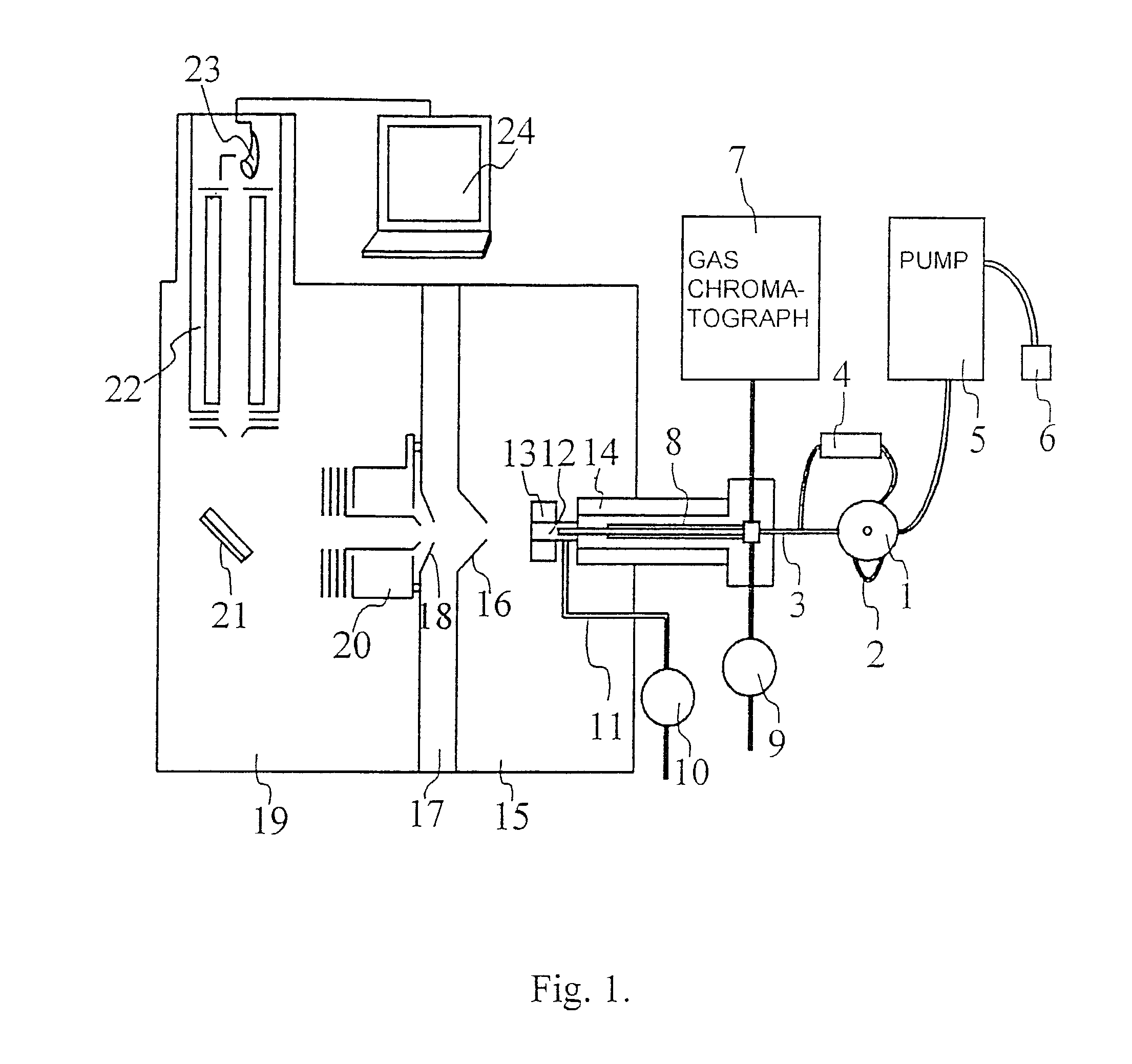

Mass spectrometer method and apparatus for analyzing a sample in a solution

InactiveUS7247495B2Fast and reliable identificationHigh sensitivityComponent separationSamples introduction/extractionSpray nozzleMass analyzer

The invention provides a mass spectrometric method for analyzing a sample in a solution, including the steps of directing a flow of a solution containing sample compounds to be analyzed towards a supersonic nozzle having an input end and an output end; vaporizing the solution and sample prior to its expansion from the output end of said supersonic nozzle; allowing expansion of the vaporized sample and solution from said supersonic nozzle into a vacuum system, forming a supersonic molecular beam with vibrationally cold sample molecules; ionizing the vaporized sample compounds with electrons while contained as vibrationally cold molecules in said supersonic molecular beam; mass analyzing the ions formed from said sample compounds; detecting said ions formed from said sample compounds after mass analysis, and processing the data obtained from the resulting mass spectral information, for identifying and / or quantifying the chemical content of said sample. The invention also provides apparatus for analyzing a sample in a solution.

Owner:AMIRAV AVIV

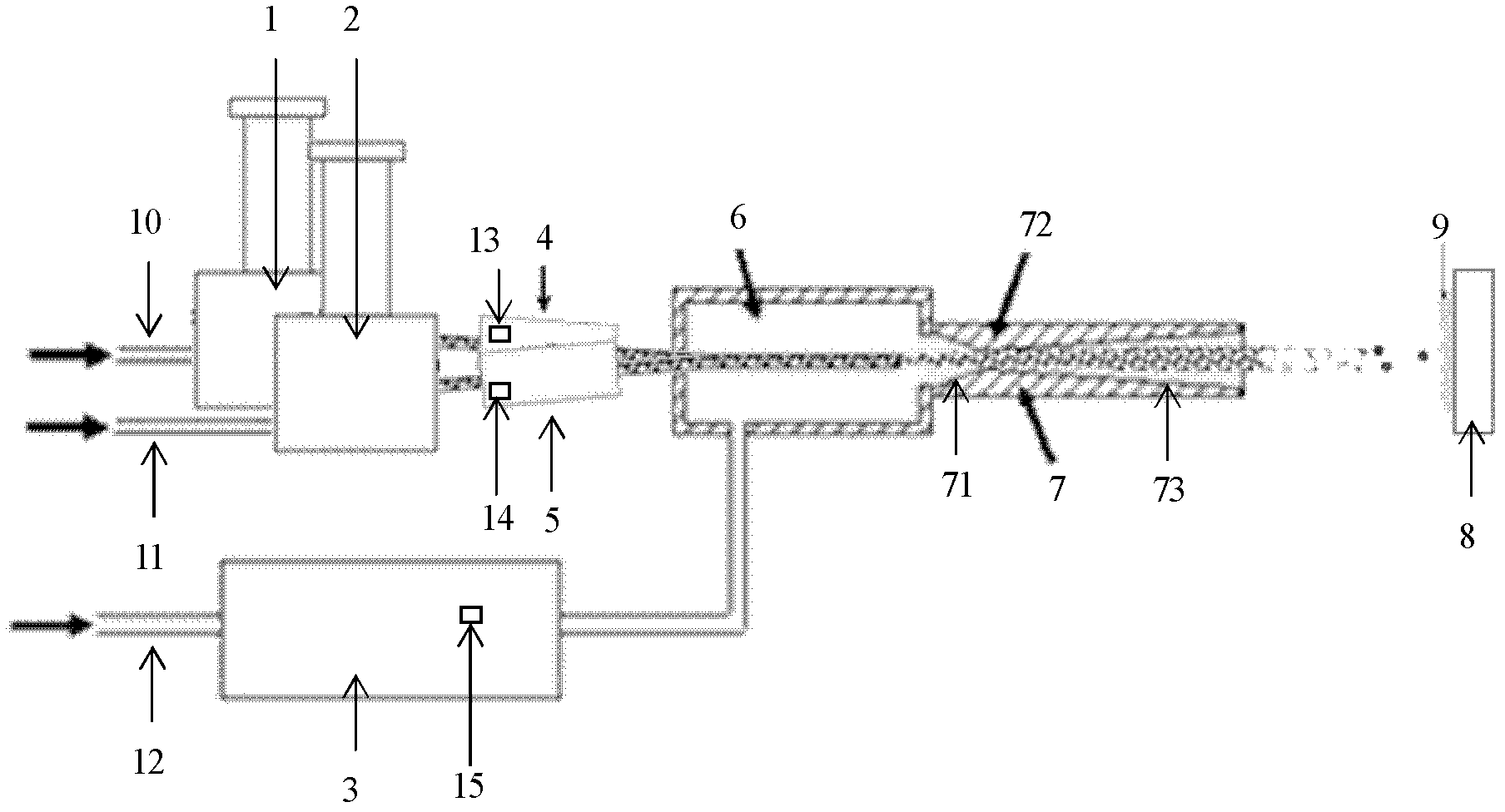

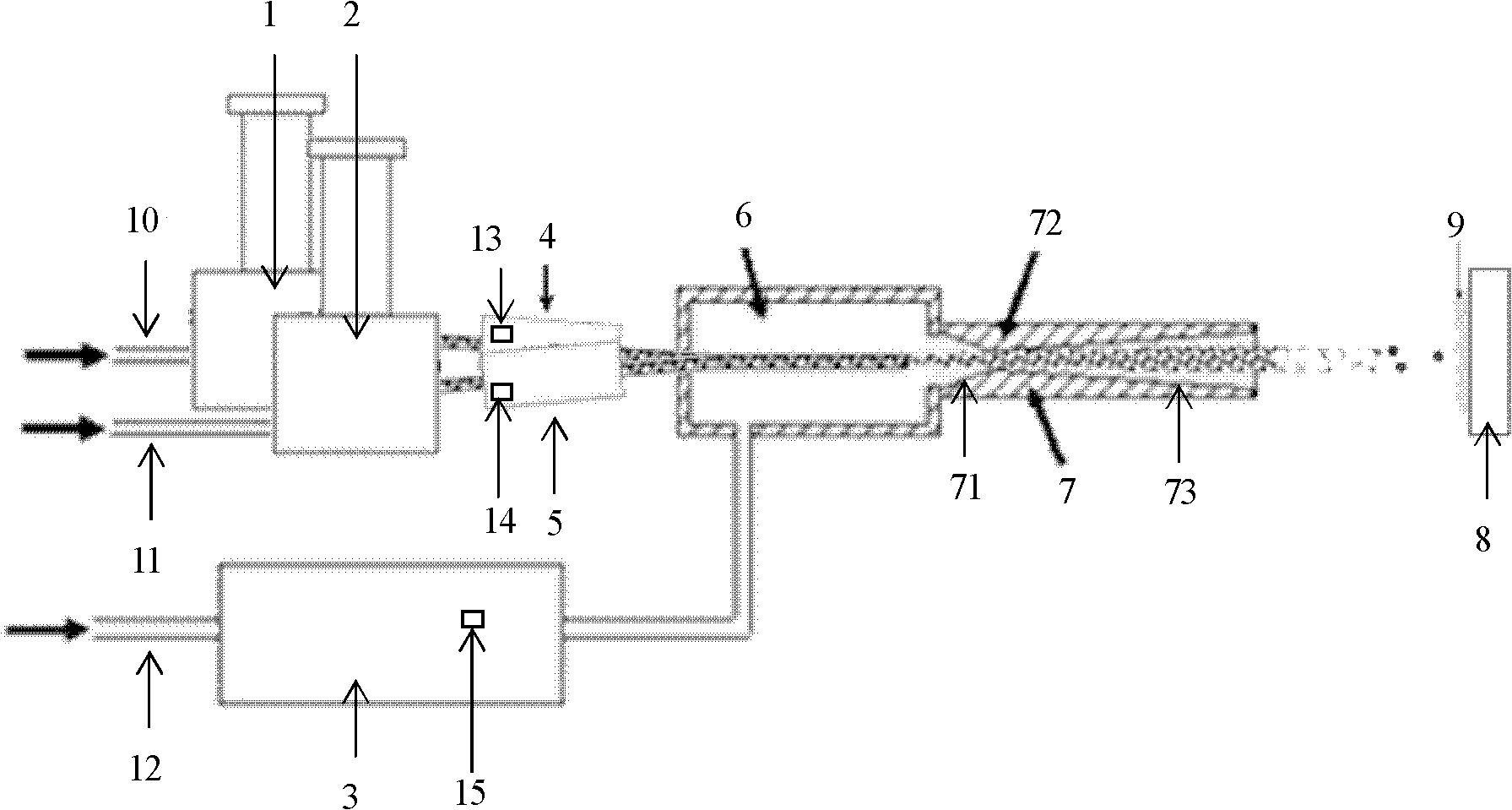

Cold spray device and method for preparing metal composite gradient quasicrystal coating

InactiveCN102527544AHigh speedLow spraying temperatureLiquid spraying apparatusSpecial surfacesForming gasGas heater

The invention relates to the field of surface coating preparation and particularly relates to a cold spray device and method for preparing a metal composite gradient quasicrystal coating. A quasicrystal powder feeder and a metal or alloy powder feeder of the device are respectively connected to a gas-solid mixing chamber through a pipeline to form a dual-channel powder feeding structure, a quasicrystal heater and a metal or alloy powder heater are respectively arranged on the pipelines, a gas heater is connected with the gas-solid mixing chamber through a pipeline and a supersonic flow nozzle is arranged at an outlet of the gas-solid mixing chamber. One path of the gas source compressed gas enters into the quasicrystal powder feeder, one path enters into the metal powder feeder, and one path enters into the heater, the gas and the powders enter into the supersonic flow nozzle via the gas-solid mixing chamber to form gas-solid dual-phase flow, solid particles in the gas-solid dual-phase flow are injected onto the surface of a workpiece and generate severe plastic deformation and finally deposit on the surface of the workpiece. The method provided by the invention can solve the problems of fragility and phase change and the like of coatings, and can be used for preparing two-component or multi-component alloy quasicrystal gradient coatings of various series.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

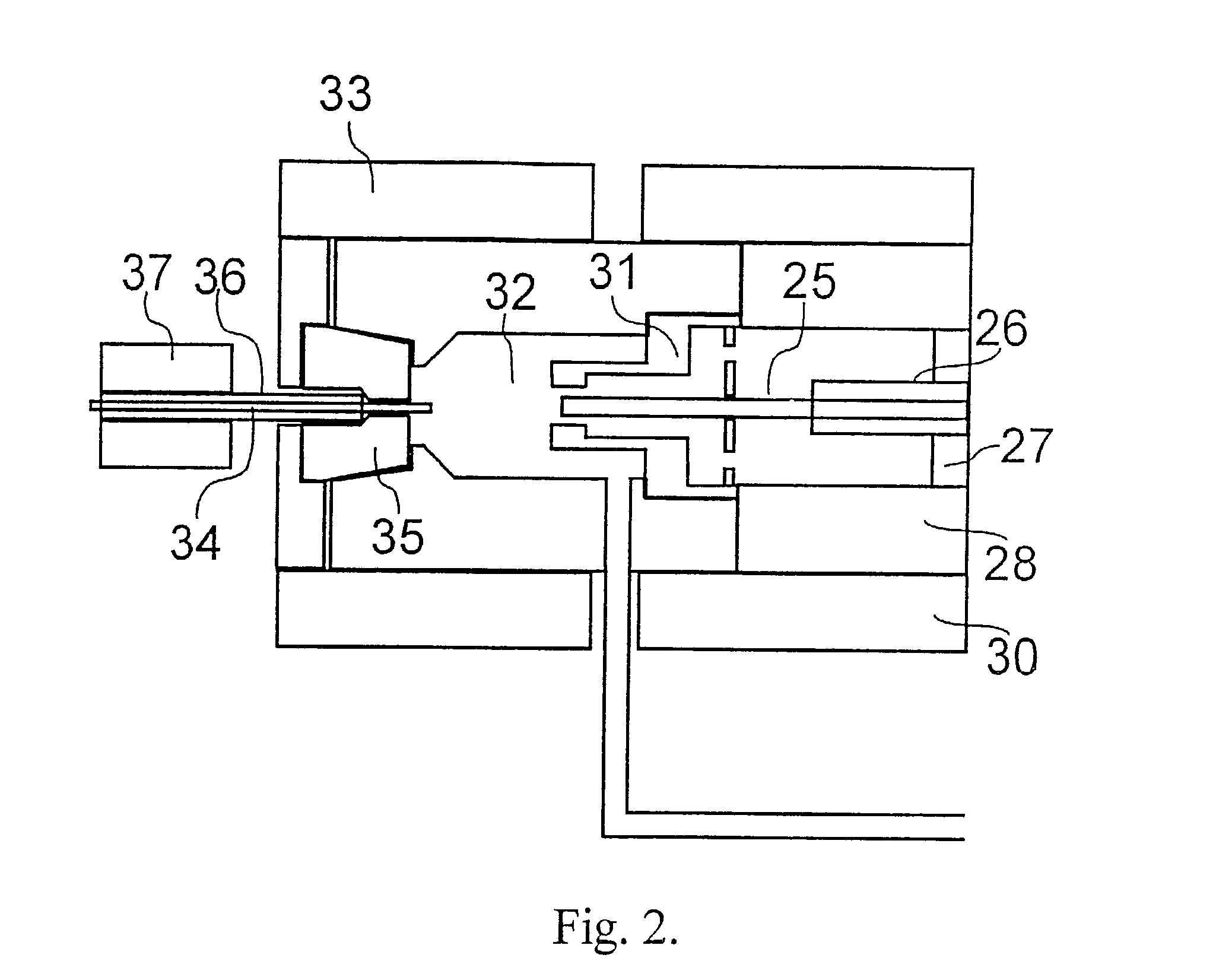

Rotary plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS6986471B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorMaterials science

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

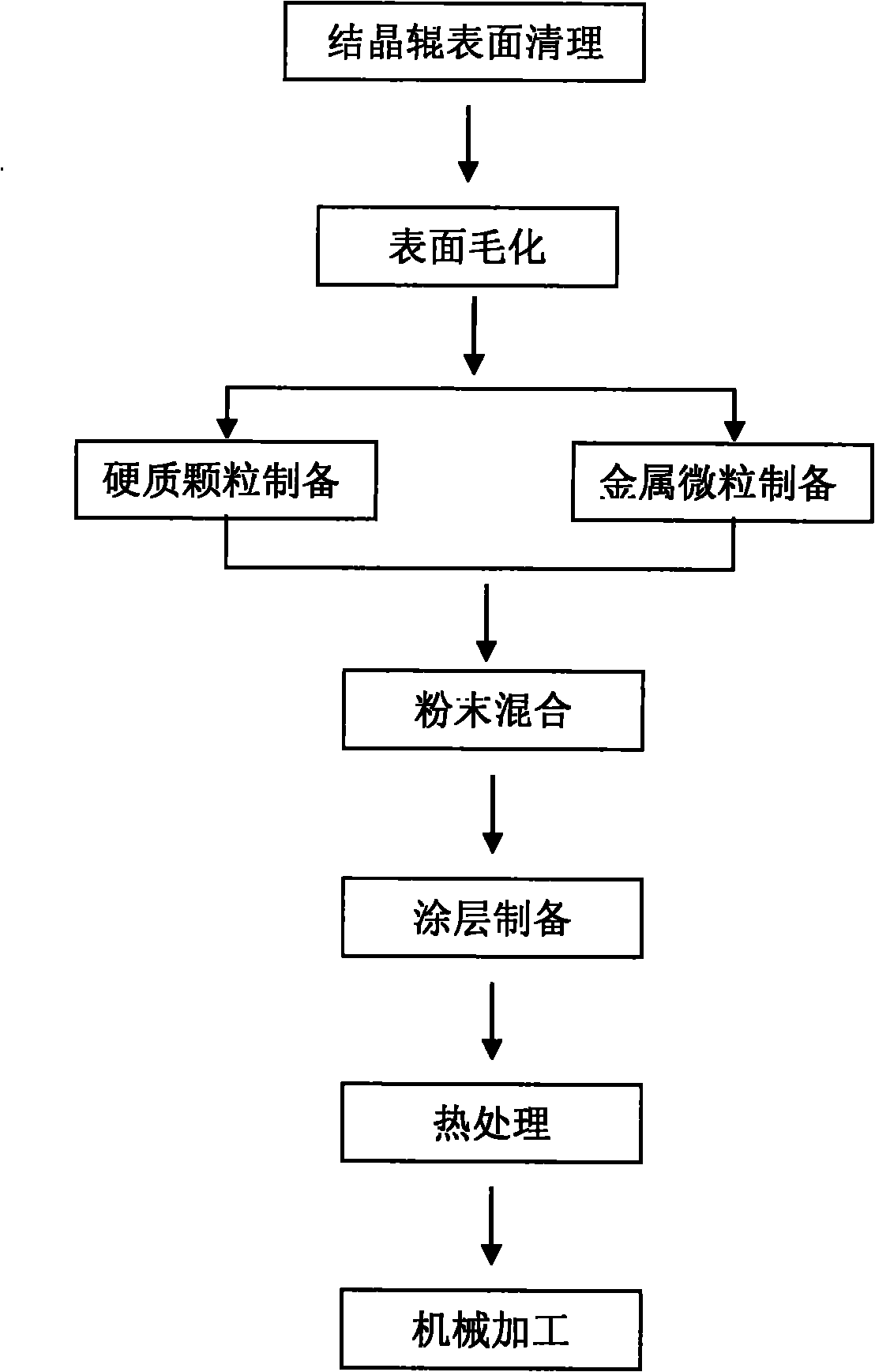

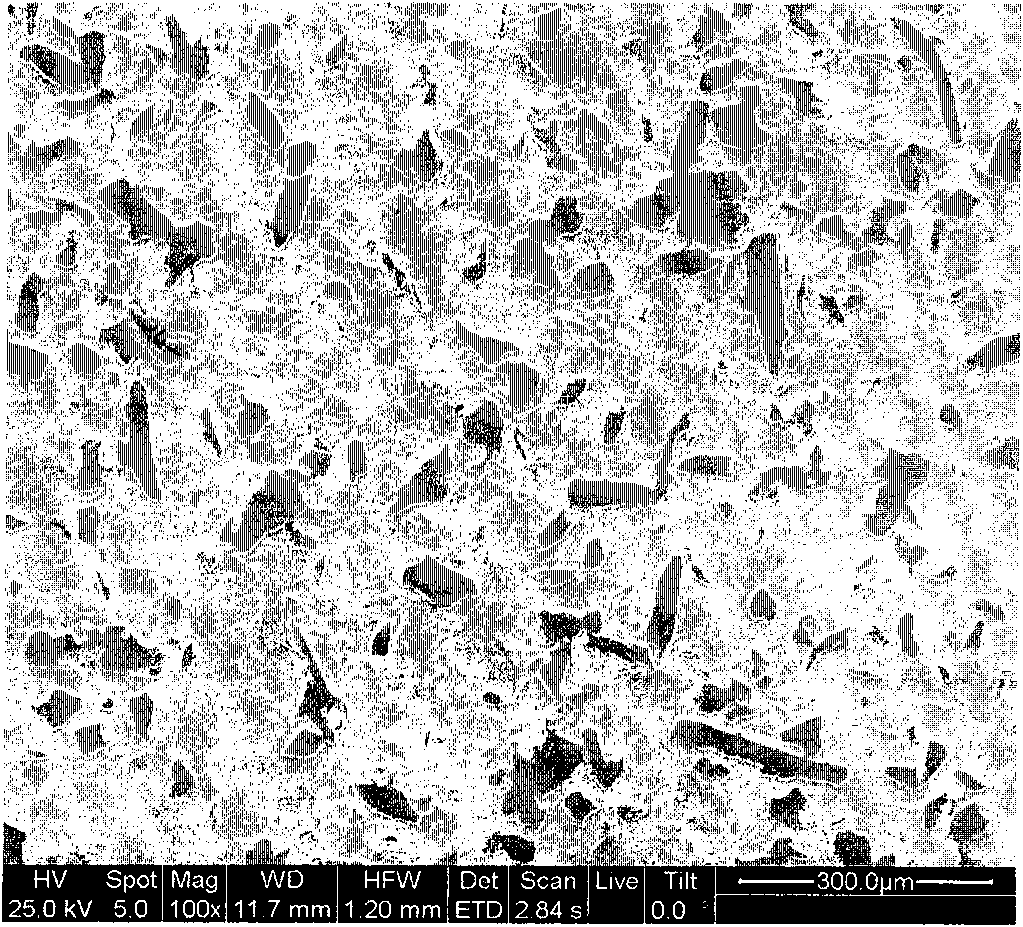

Composite coating layer on surface of high-resistant crystallizer or crystallizing roller and manufacturing method thereof

ActiveCN102039384AImprove thermal conductivityImprove wear resistancePressure inorganic powder coatingWear resistantHigh pressure

The invention relates to a manufacturing method of a composite coating layer on the surface of a high-resistant crystallizer or a crystallizing roller. The manufacturing method is as follows: adopting a preparation technology of a cold-gas dynamic spraying composite coating layer; utilizing high-pressure gas to carry metal or mixed particles of alloy matrix particles and hard reinforcement particles; increasing the speed of the metal or the mixed particles by a supersonic nozzle to be extremely high so as to collide with the surface of a copper alloy matrix of the crystallizer or the crystallizing roller; and generating strong plastic deformation by the metal or the alloy particles so as to lead the metal or the alloy particles to be bonded on the surface of the crystallizer or the crystallizing roller to form a composite coating layer. By utilizing the manufacturing method, good heat conductivity of the metal or the alloy matrix and excellent wear-resistant performance of a reinforcement are utilized comprehensively, the surface coating layer of the crystallizer or the crystallizing roller with good comprehensive performance is obtained, and the online service life of the crystallizer or the crystallizing roller is prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD

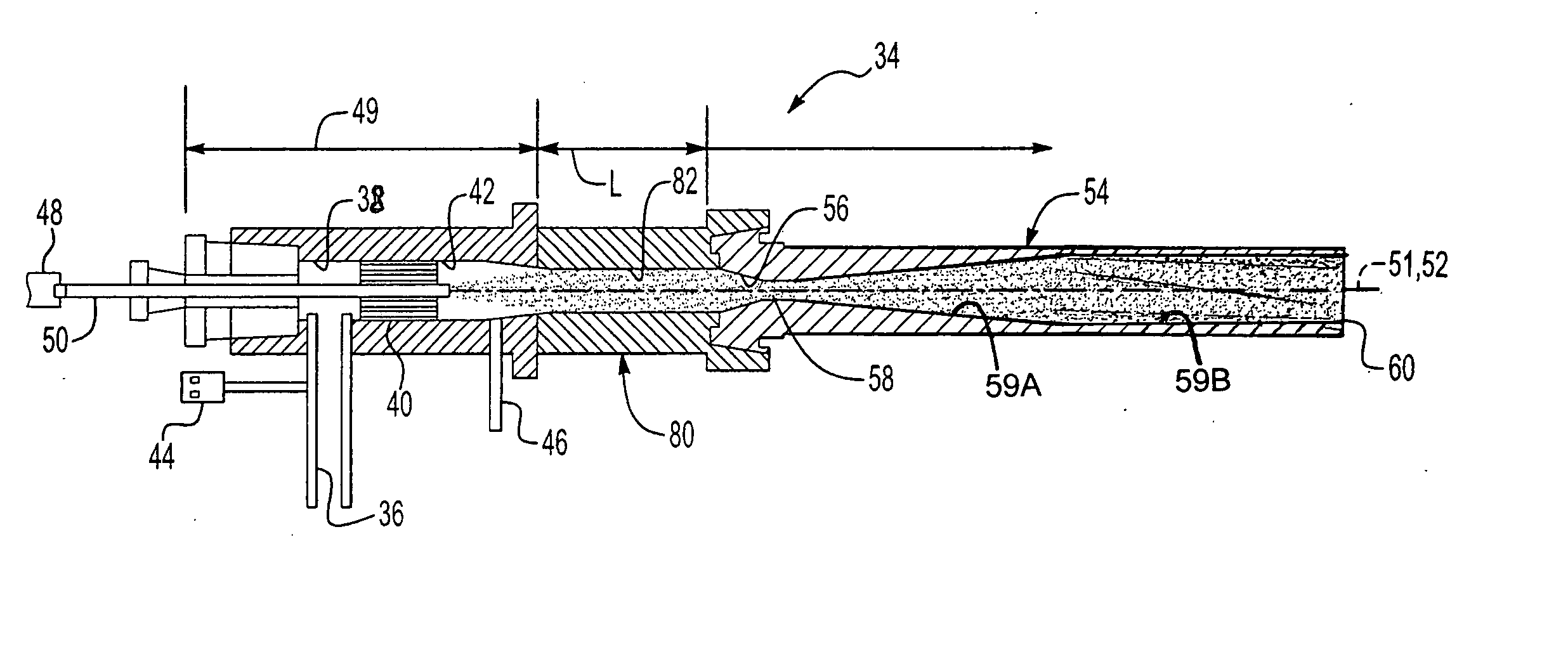

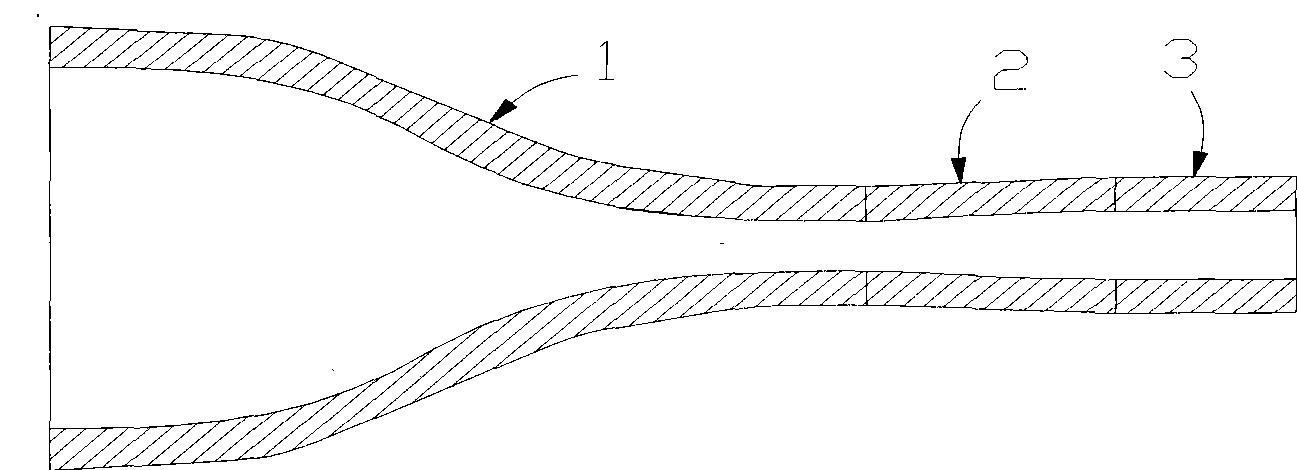

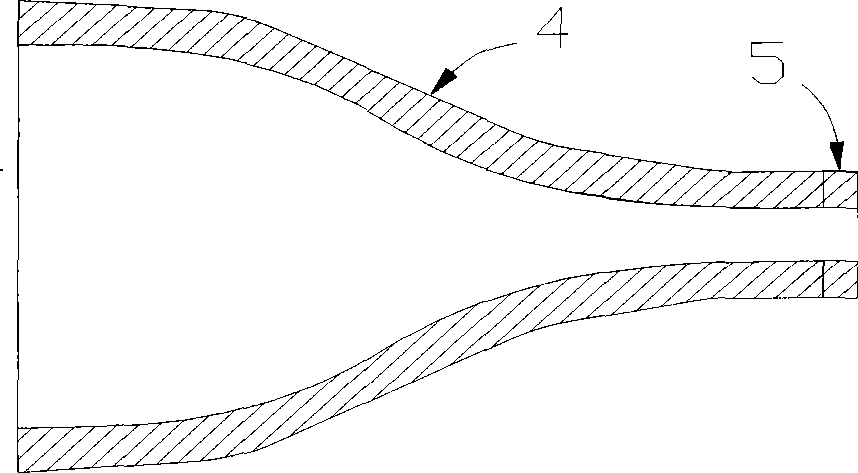

Modified high efficiency kinetic spray nozzle

A modified high efficiency kinetic spray nozzle is disclosed. The modified nozzle has a rapid expansion rate in the diverging region relative to prior art nozzles, which enables one to achieve much higher particle velocities without an increase in the main gas temperature. Preferably, the expansion rate of the supersonic nozzle in a portion of the diverging region is at least 1 mm2 per millimeter, more preferably 2 mm2 per millimeter, more preferably 5 mm2 per mm, with a most preferable expansion rate being 10 mm2 per millimeter.

Owner:FLAME SPRAY IND

Capillary separated vaporization chamber and nozzle device and method

There is provided a capillary separated vaporization chamber and nozzle method and device for improved electron ionization liquid chromatography mass spectrometry of samples in a supersonic molecular beam. The device includes a vaporization chamber located upstream of a supersonic nozzle; a capillary separating the vaporization chamber and the supersonic nozzle, means for spray formation from sample in a flowing liquid; a vacuum system into which the supersonic nozzle induces supersonic expansion of the vaporized sample compounds and solvent vapor, for forming a supersonic molecular beam with vibrationally cold sample molecules and vaporized solvent; flythrough electron ionization ion source; mass analyzer; an ion detector and means for data processing of the resulting mass spectral information, for identifying and / or quantifying the chemical content of the sample.

Owner:AMIRAV AVIV

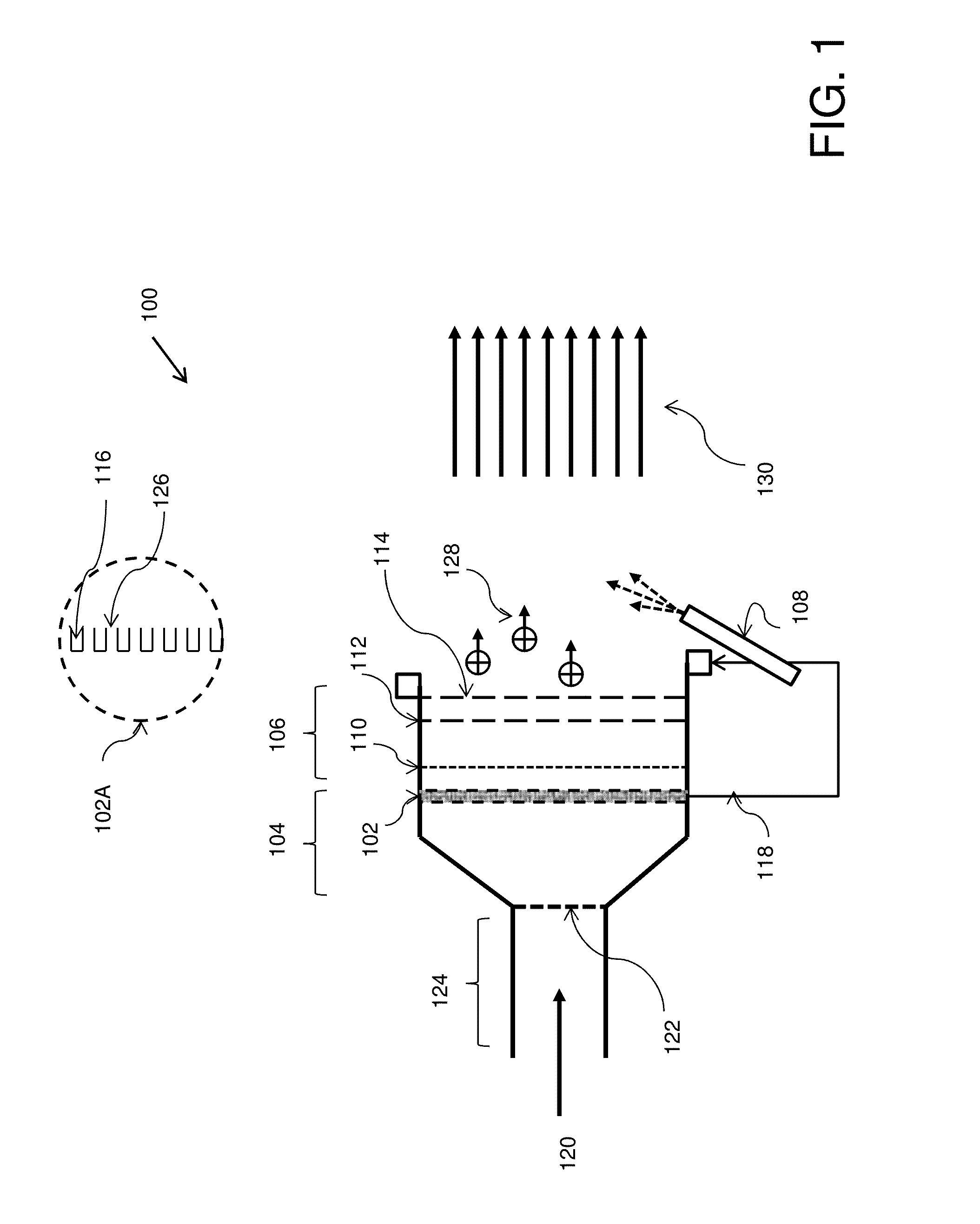

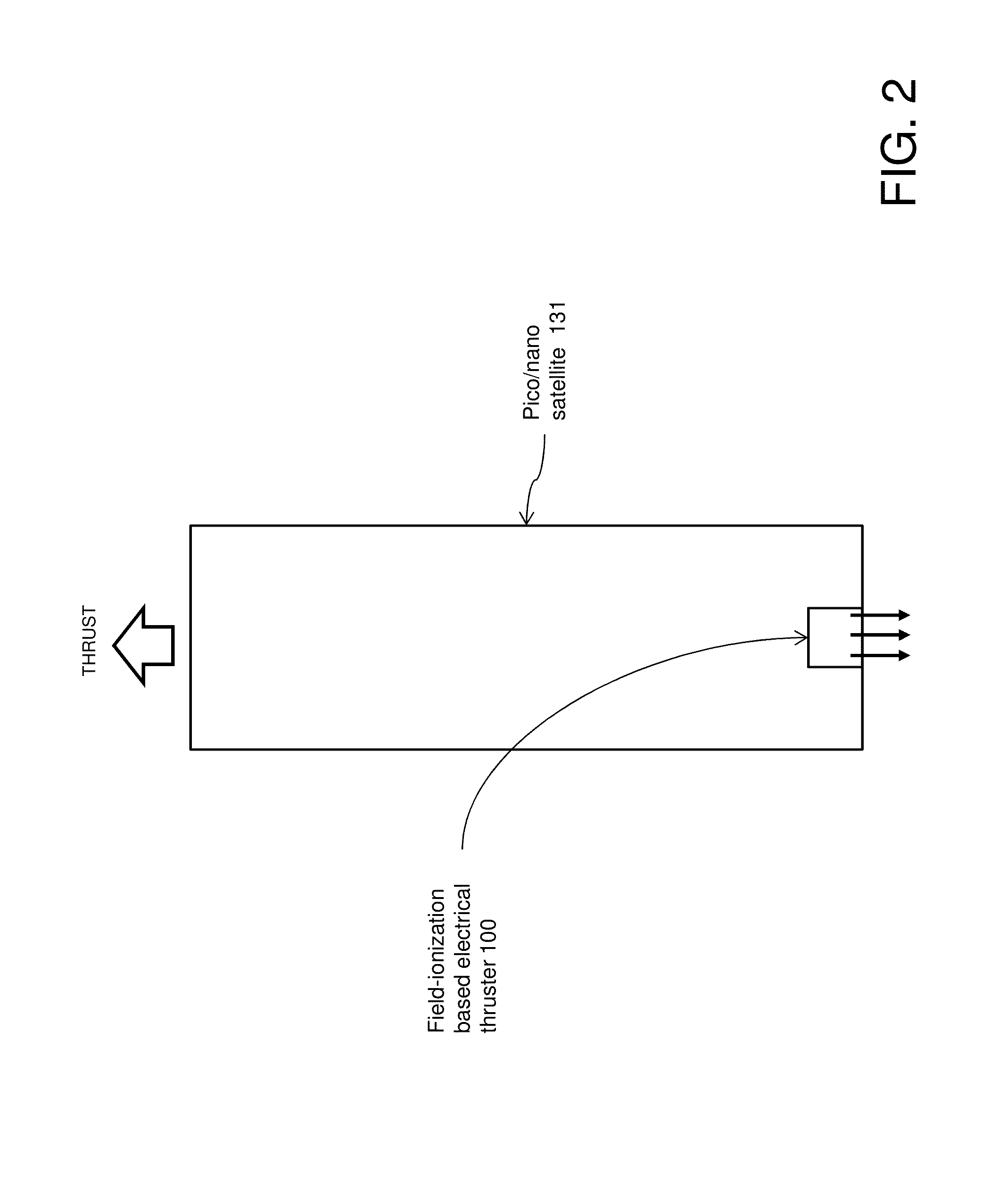

Field-ionization based electrical space ion thruster using a permeable substrate

ActiveUS9194379B1Cosmonautic vehiclesCosmonautic propulsion system apparatusField electron emissionCarbon nanotube

A field-ionization based electrical ion thruster utilizes a single propellant that can be used in either a high specific-impulse mode, i.e., ion-thruster mode, or a low-specific-impulse mode, i.e., a cold-gas thruster mode. In one embodiment, the high specific impulse mode (ion thruster mode) utilizes a miniaturized positive-ion field-ionization chamber including a permeable substrate infused with properly oriented carbon nanotubes (CNTs), which is fed propellant from a porous injection plug made from permeable carbon or equivalent material. In one embodiment, field-electron emission from a neutralizer, such as a carbon nanotube array neutralizer, positioned after one or more accelerator grids is used for ion neutralization. In one embodiment, the low specific-impulse (cold-gas mode) uses a conventional supersonic nozzle-expansion to generate thrust. In one embodiment, both the high specific-impulse mode and the low specific-impulse mode thruster embodiments share the same gas propellant, storage propellant tank, and delivery equipment.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

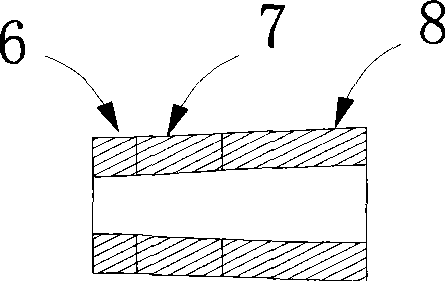

Continuous in-line manufacturing process for high speed coating deposition via a kinetic spray process

InactiveUS20060040048A1Constant cross-sectional areaMolten spray coatingPretreated surfacesSpray coatingEngineering

An improved kinetic spray system and a method for using the same in a high speed manufacturing environment are disclosed. The improved kinetic spray nozzle system comprises: a gas / powder exchange chamber connected to a first end of a powder / gas conditioning chamber having a length along a longitudinal axis of equal to or greater than 20 millimeters; a converging diverging supersonic nozzle, the supersonic nozzle having a converging section separated from a diverging section by a throat, the diverging section comprising a first portion and a second portion, with the first portion having a cross-sectional area that increases along a length of the first portion and with the second portion having a substantially constant cross-sectional area along a length of the second portion; and the converging section connected to a second end of the powder / gas conditioning chamber opposite the first end. The method includes: use of the disclosed nozzle system with the addition of hard particles that permit maximum enhancement of particle temperature while not permitting clogging of the nozzle; use of controlled particle feed rates to match the desired very high traverse speeds; and use of pre-heating of the substrate to clean it an to enhance particle bonding. With the disclosed nozzle system coupled with the disclosed methods one can apply kinetic spray coatings at traverse speeds of over 200 centimeters per second with a deposition efficiency of over 80 percent.

Owner:F W GARTNER THERMAL SPRAYING

Method for producing electrical contacts using selective melting and a low pressure kinetic spray process

A new kinetic spray process is disclosed that enables the coating to withstand severe bending and stress without delamination. The method includes use of a low pressure kinetic spray supersonic nozzle having a throat located between a converging region and a diverging region. A main gas temperature is raised to from 1000 to 1300 degrees Fahrenheit and the coating particles are directly injected into the diverging region of the nozzle at a point after the throat. The particles are entrained in the flow of the gas and accelerated to a velocity sufficient to result in partial melting of the particles upon impact on a substrate positioned opposite the nozzle and adherence of the particles to the substrate. The coating also has a desirable shinny surface. The method finds special application in coating substrates for use in formation of electrical connections.

Owner:DELPHI TECH INC

Method of maintaining a non-obstructed interior opening in kinetic spray nozzles

A method of maintaining a non-obstructed interior opening in a kinetic spray nozzle is disclosed. The method includes the steps of providing a mixture of particles including first particle population and a second particle population; entraining the mixture of particles into a flow of a gas at a temperature below the melt temperature of the particle populations; and directing the mixture of particles entrained in the flow of gas through a supersonic nozzle to accelerate the first particle population to a velocity sufficient to result in adherence of the first particle population on a substrate positioned opposite the nozzle. The operating conditions of the kinetic spray system are selected such that the second particle population is not accelerated to a velocity sufficient to result in adherence when it impacts the substrate. The inclusion of the second particle population maintains the supersonic nozzle in a non-obstructed condition and also enables one to raise the main gas operating temperature to a much higher level, thereby increasing the deposition efficiency of the first particle population.

Owner:FLAME SPRAY IND

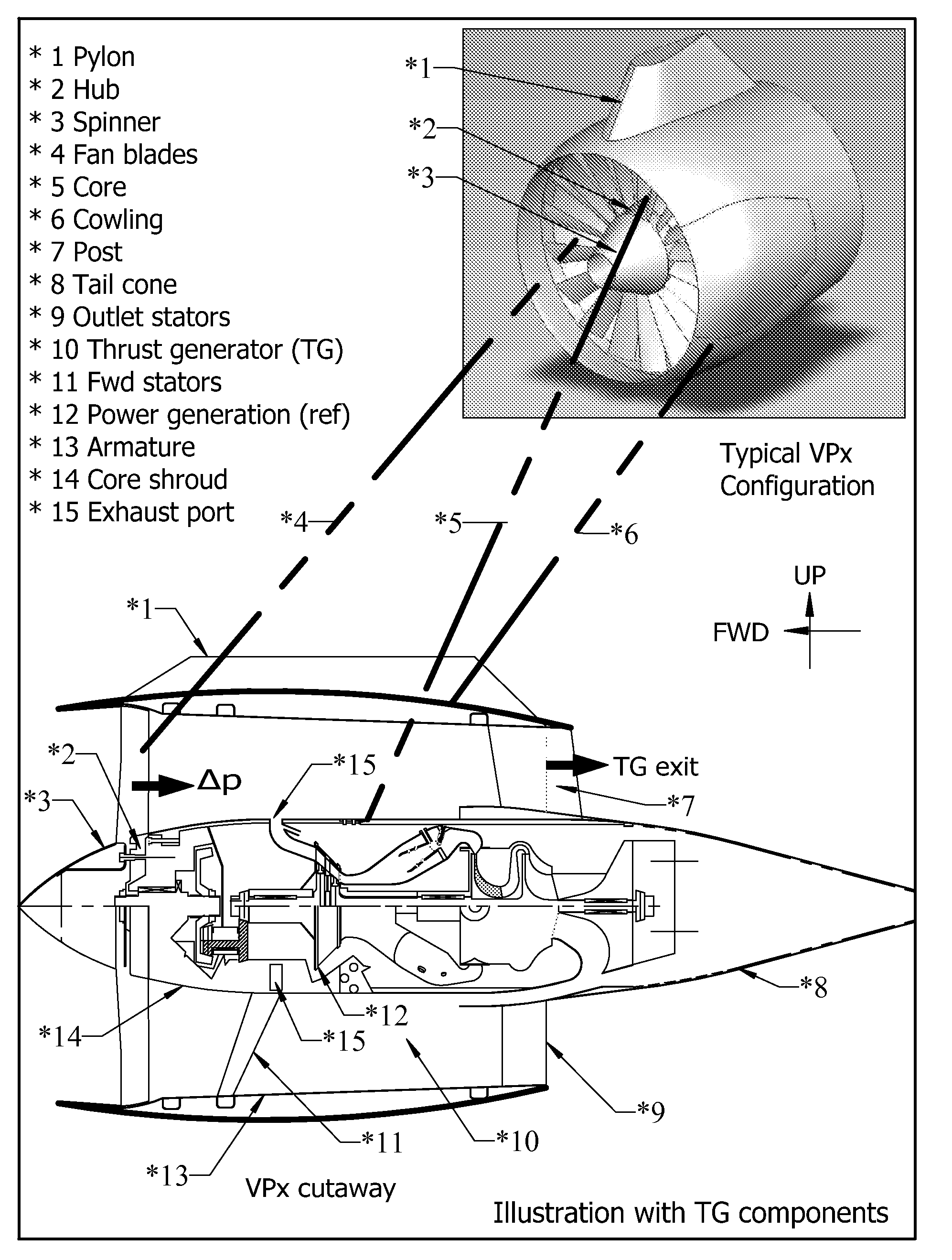

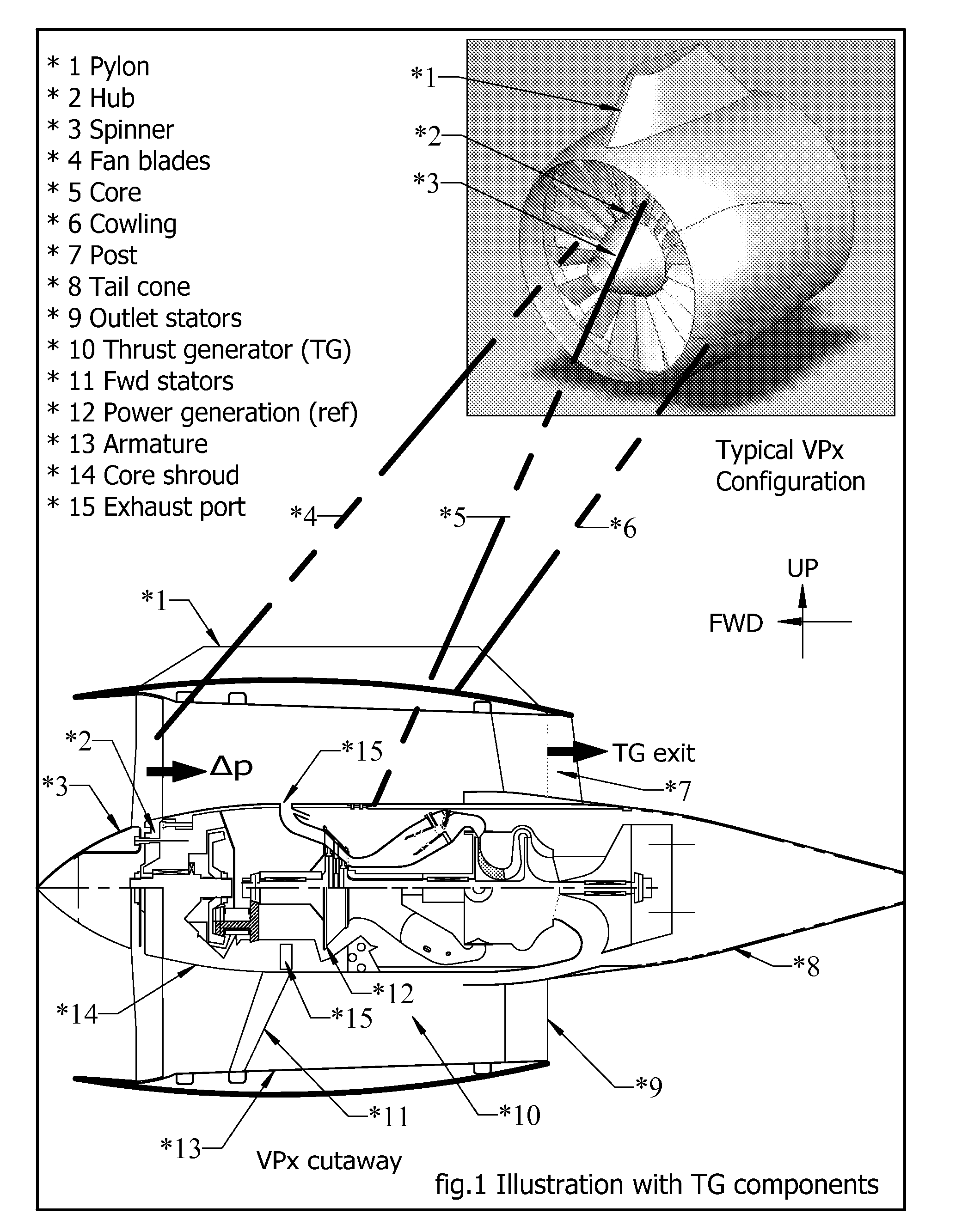

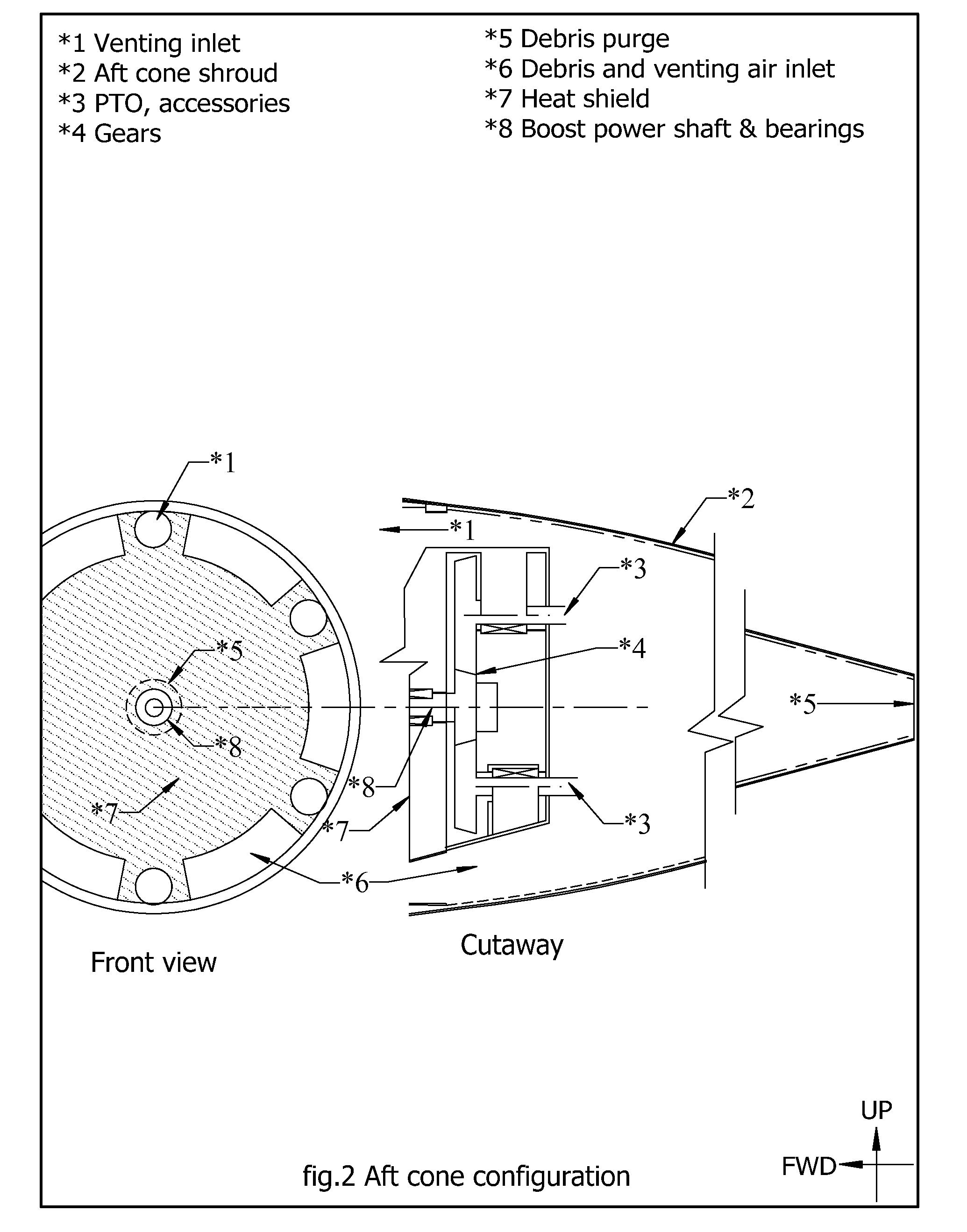

Heat regeneration for a turbofan, a Velarus Propulsion

InactiveUS20100180568A1Extend your lifeEasy to manufactureContinuous combustion chamberGas turbine plantsCombustion chamberFan blade

The invention adds details and alternate design supplementing the concept established with my patent application Ser. No. 12 / 013,431, Aircraft Propulsion System (APS). The APS ultimate fuel economy objectives requires long term design development, and this invention compromises some fuel economy for the expediency of short term implementation of a heat regeneration for turbofans via the re-arrangement of existing components and a few unique items readily designed. While this Velarus Propulsion (VPx) attains only 42% fuel economy, it retains the original APS fundamental architecture implementing heat regeneration for a turbofan engine, as well as the additional benefits of noise and emission abatement. This invention consists of the three APS technologies as follows:a) A novel arrangement of the power generation core features the turbine exhaust entering directly into the thrust chamber, thus providing heat regeneration with an appropriate configuration of the thrust chamber.b) The design of a modified combustor introduces the concept of a supersonic nozzle driving the turbines which allows for greater combustor's chamber temperature while injecting the gases at temperatures acceptable to current turbine blade metallurgy. This feature increases the engine thermal efficiency.c) The hub design allows for two options, a simpler fixed fanblade design or an advanced controllable pitch fan blade, increasing the mission and performance flexibility of a given turbofan size.In addition, this invention adds functionality to the aft cone, such as debris purge, accessories installation, and thrust reversers free from hot gases.

Owner:SACHS HUMBERTO W

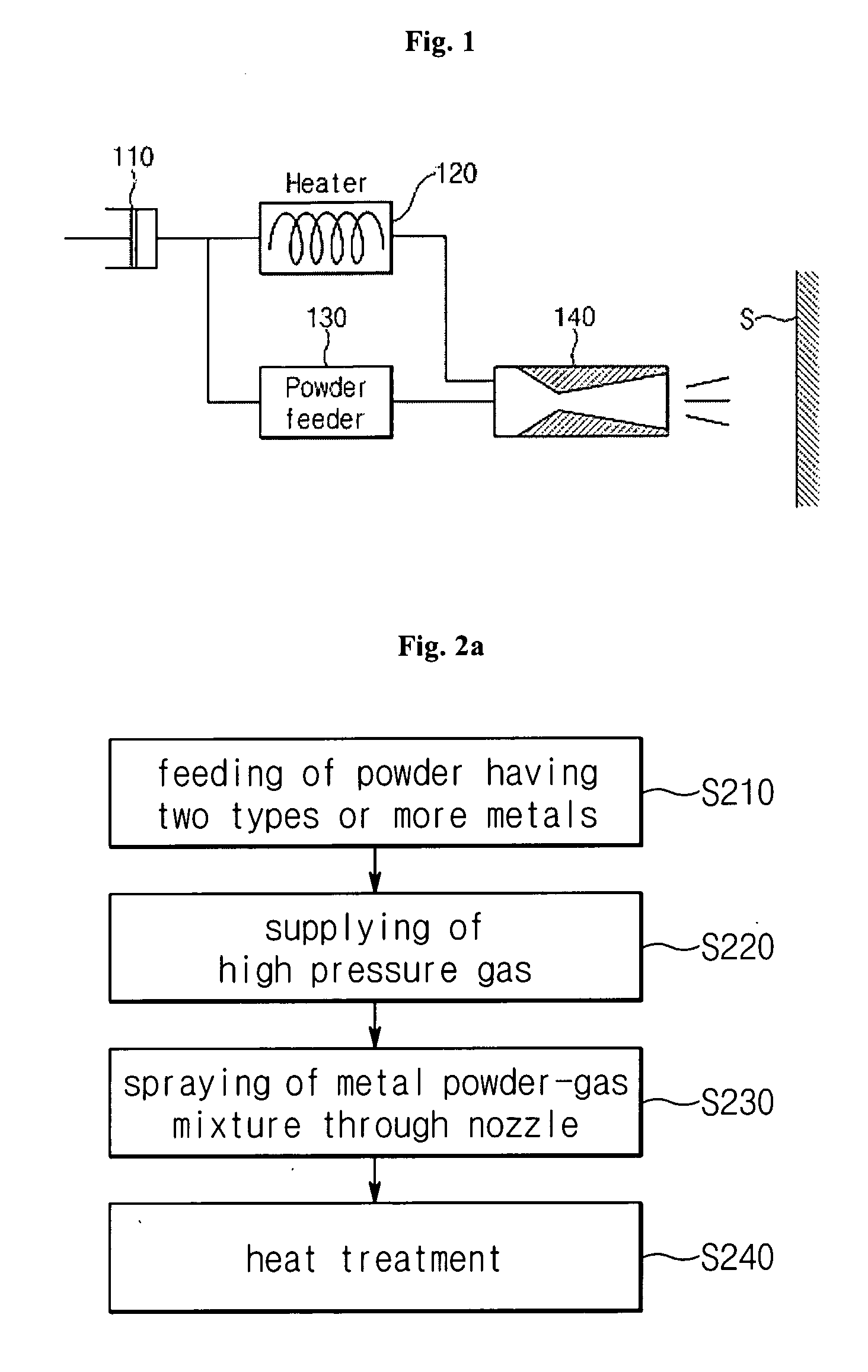

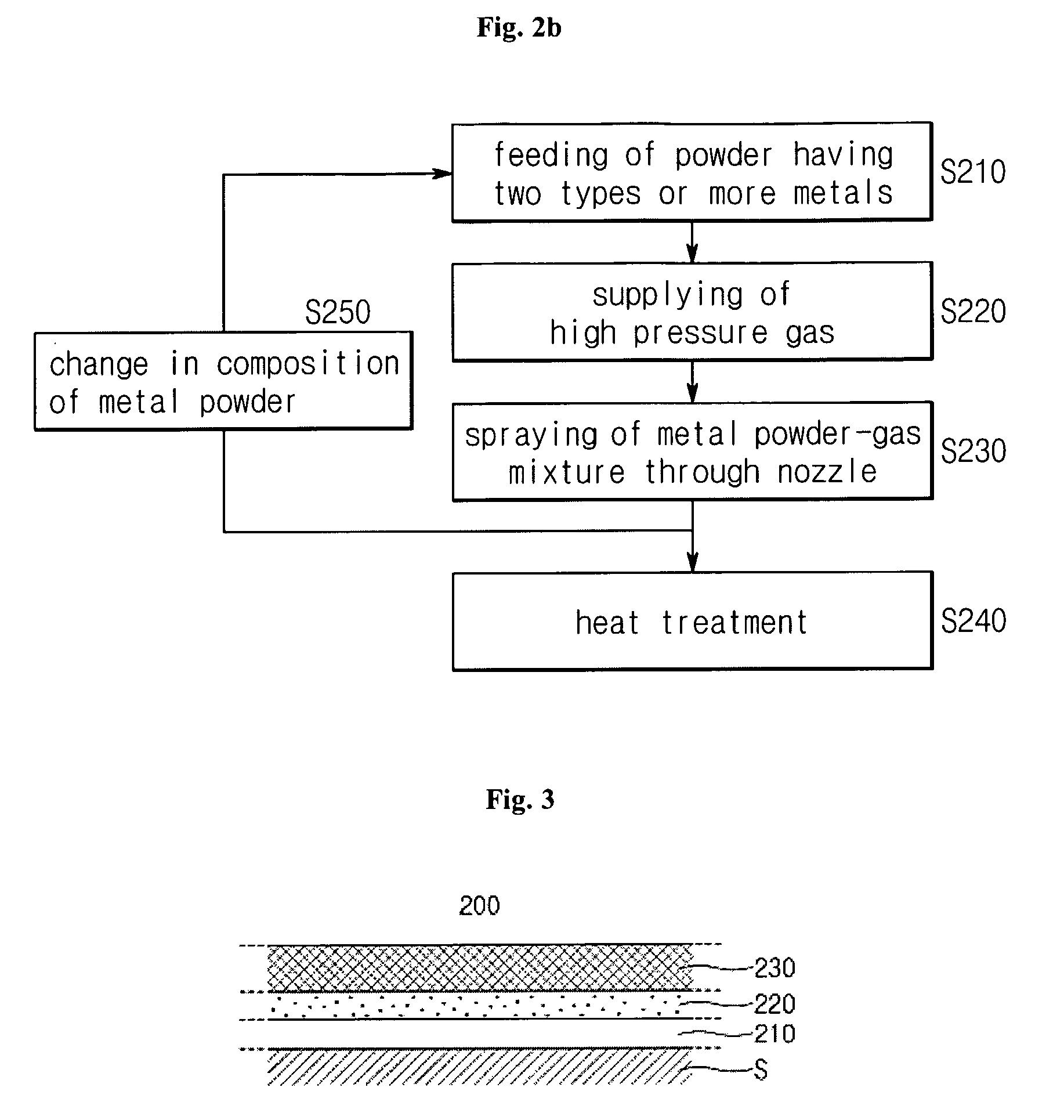

Porous Coated Member and Manufacturing Method Thereof Using Cold Spray

InactiveUS20070240603A1Damage to materialImprove thermal conductivityMolten spray coatingLighting elementsPorous coatingHigh pressure

Disclosed is a coated member on which a porous metal coating layer is formed and a method of producing the same. The method comprises providing the mother material, feeding powder having a metal composition, which includes at least two different metals selected from the group consisting of Al, Mg, Zn, and Sn and which is expressed by xA-(1−x)B (0<x<1, where x is a weight ratio of A and B), onto the mother material, supplying high pressure gas to the powder, applying the metal powder using on the mother material by spraying the metal powder using the high pressure gas through an supersonic nozzle, and heat-treating the coated mother material to form the porous coating layer. In the method, it is possible to freely control the pore size and porosity of the coated member. Accordingly, it is available to various members for thermal and mechanical applications.

Owner:SKC SOLMICS

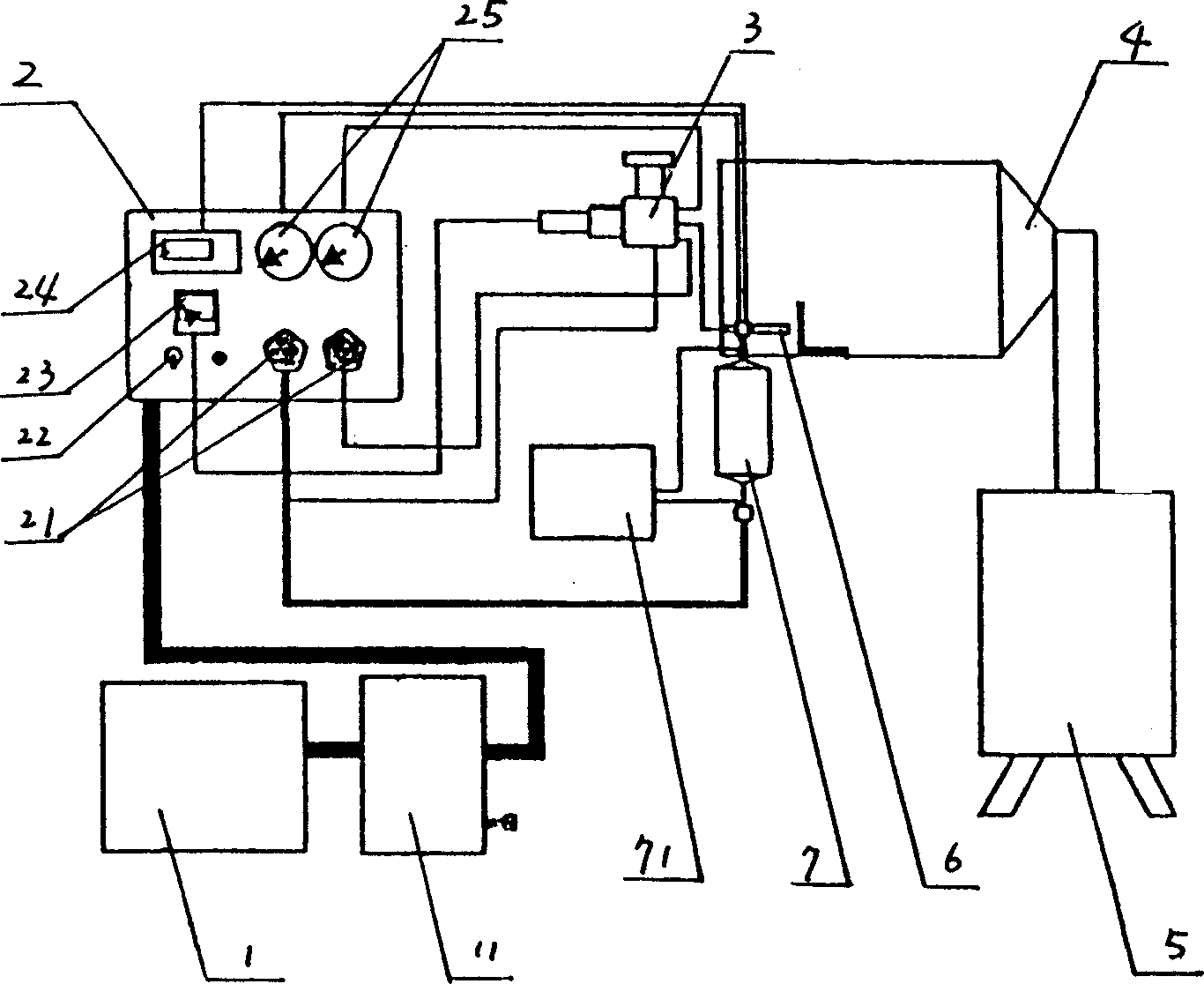

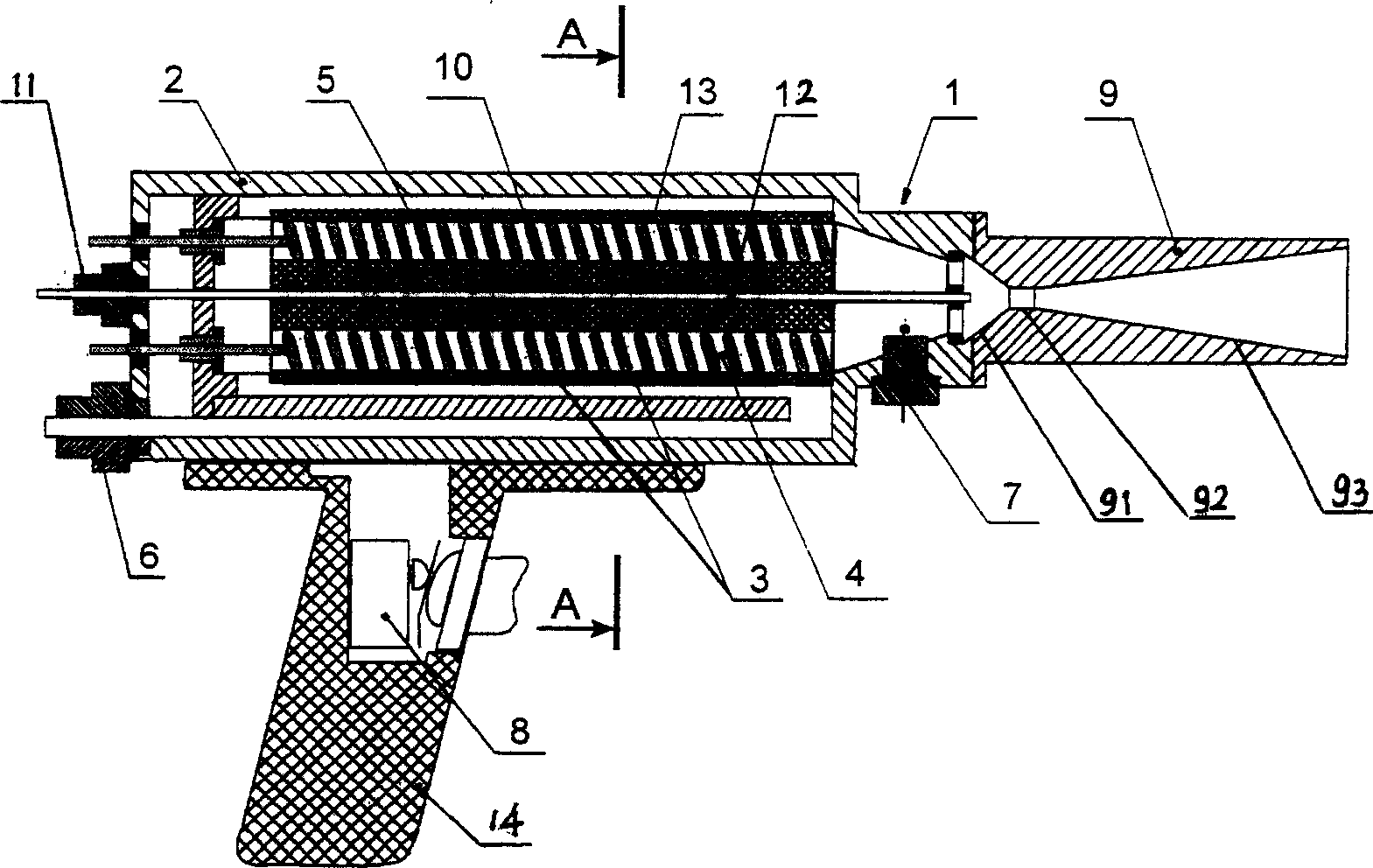

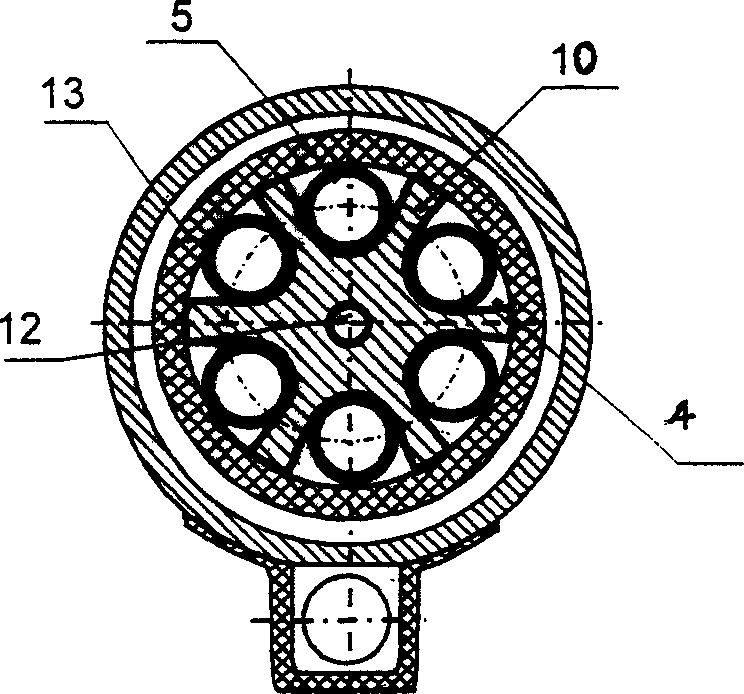

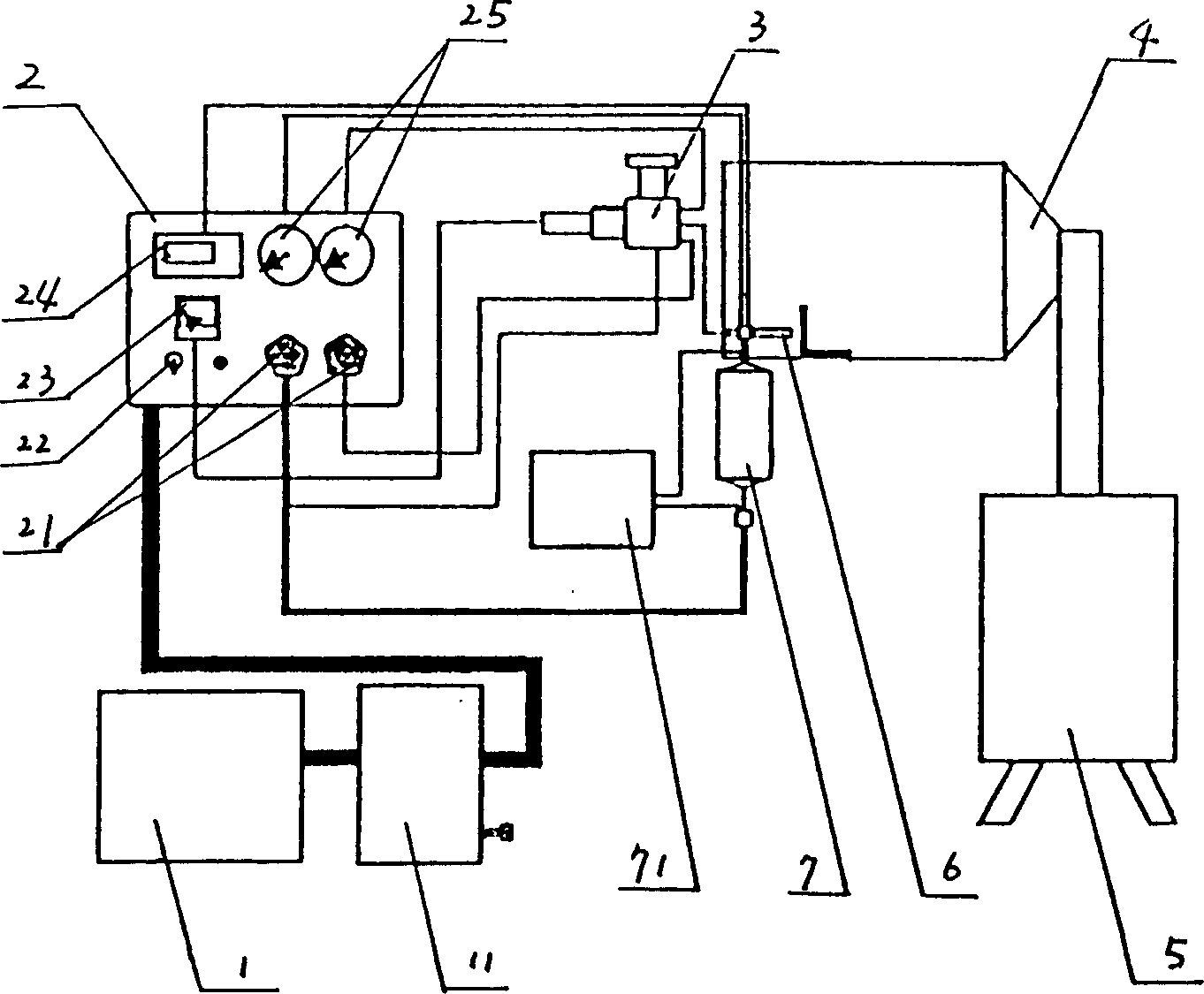

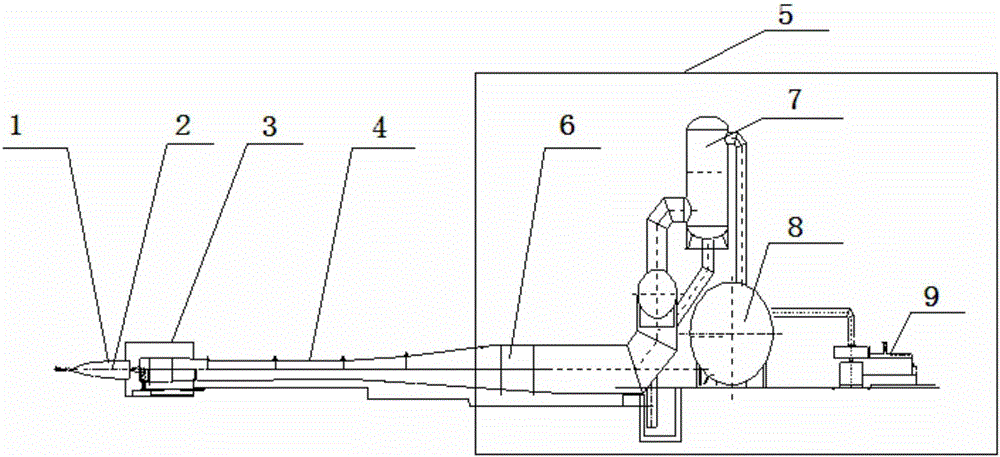

Pneumatic powder spraying apparatus

InactiveCN1603008ABroaden the scope of industrial applicationsEasy to carryLiquid spraying apparatusPressure inorganic powder coatingGas heaterMechanical energy

This invention opens one kind of gas dynamic powder spraying device which is composed with compression gas source,powder feed unit and spray mechanism.The spray mechanism includes gas heater and supersonic nozzle that is rigid linkage structure of coaxial setting.Gas heater includes metal shell,heat element and electrothermal insulator.One end of metal shell is fixed coaxial with the supersonic nozzle,the other end of metal shell is equipped with carrier gas joint and feed powder joint.The electrothermal insulator which is installed in the metal shell is composed with two coaxial emboitement internal and external tube,the center of the internal tube has a channel which two ends respectively connect powder feed unit and supersonic nozzle.In the exine of the internal tube,there are agroove gas direct channels which connect to the compress gas source,the heat element lies in the agroove gas direct channals.This invention which can be used to prepared monolayer and multi-layer coating widens industry application,reduces equipment weight,simplifies design structure and equipment maintanance and improves the spraying efficiency,being suitable for mechanical energy and metallurgy etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Replaceable throat insert for a kinetic spray nozzle

A converging diverging supersonic nozzle for a kinetic spray system is disclosed. In one embodiment, the supersonic nozzle has a first end opposite an exit end and a diverging region adjacent the exit end. A removable throat insert has an entrance cone and a throat and is received in the first end with the throat positioned adjacent the diverging region. In another embodiment, the removable throat insert has an entrance cone, a diverging region and a throat positioned between the entrance cone and the diverging region. The disclosed replaceable throat inserts address the problem of excessive wear in the throat relative to the rest of the supersonic nozzle which has plagued other kinetic spray systems. With the disclosed inserts a worn throat can rapidly and economically be replaced while saving the rest of the supersonic nozzle.

Owner:DELPHI TECH INC

Cold air driven spray painter

InactiveCN1161188CImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Thermal spraying device and method for manufacturing quasicrystalline coating

InactiveCN102560326AAvoid problems such as easy oxidationEven distribution of constituent phasesMolten spray coatingPorosityThermal spraying

The invention relates to the field of manufacturing of surface coatings, in particular to a thermal spraying device and a thermal spraying method for manufacturing a quasicrystalline coating. A fuel inlet, a spark plug and an oxygen inlet are arranged on one side of a mixing chamber of the thermal spraying device; the other side of the mixing chamber is communicated with a middle mixing chamber; a cooling gas inlet is formed on the middle mixing chamber; middle mixing chamber is communicated with a spray pipe through a supersonic nozzle; and an outlet of the supersonic nozzle and an inlet of the spray pipe are communicated with a quasicrystalline powder inlet. The middle mixing chamber for the cooling gas is added and the flame temperature is reduced, so that the powder and the gas form a gas-solid two-phase flow; solid particles in the gas-solid two-phase flow are sprayed onto the surface of a workpiece, and are plastically deformed seriously and deposited onto the surface of the workpiece; and subsequent particles with high kinetic energy repeat the process and form a quasicrystalline alloy coating. The problems that in the prior art, a crystalline phase is accompanied by a quasicrystalline phase, the porosity of the coating is high and micro-cracks exist are solved; and the thermal spraying device and the thermal spraying method can be used for manufacturing multiple series of quasicrystalline coatings.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

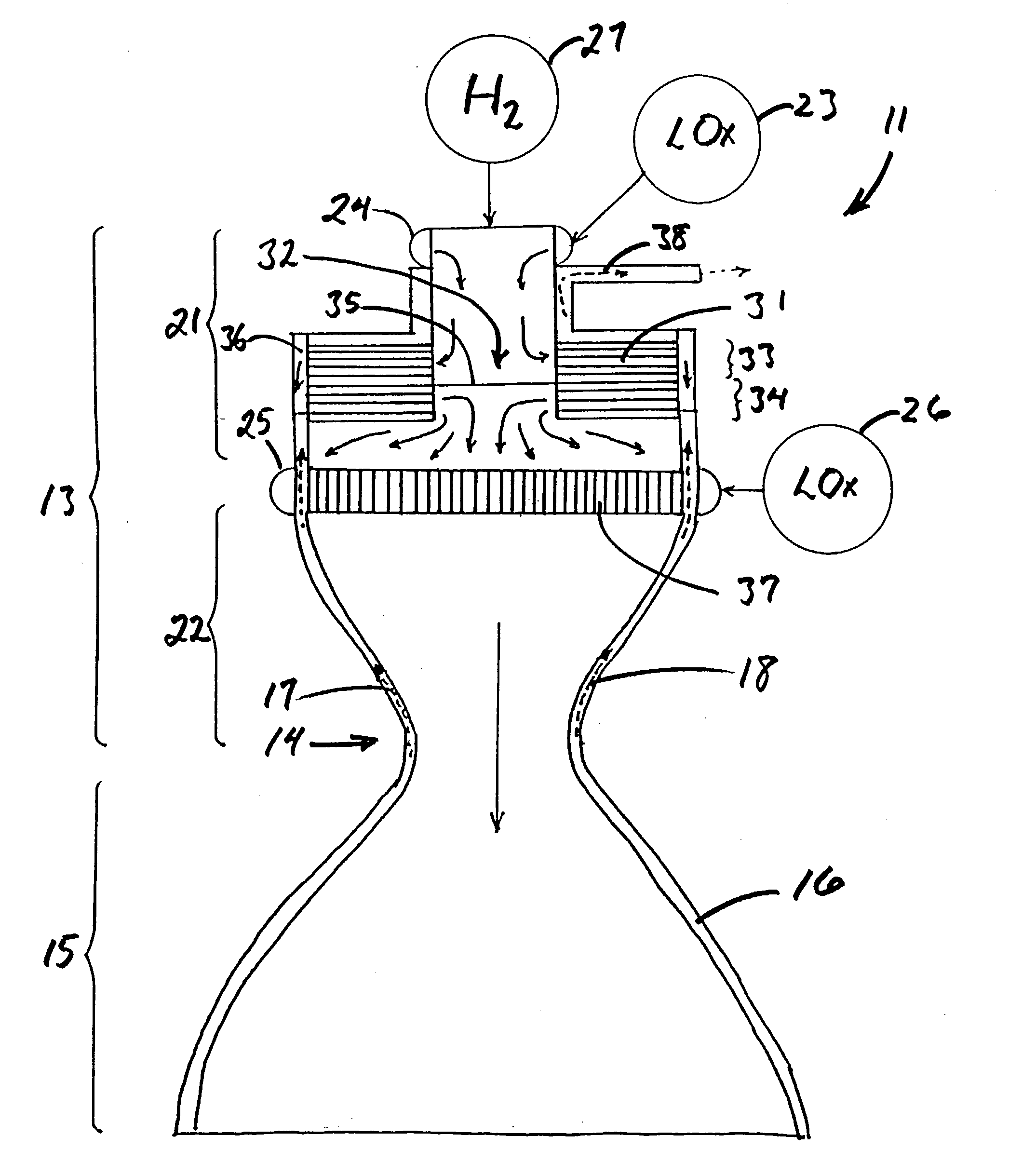

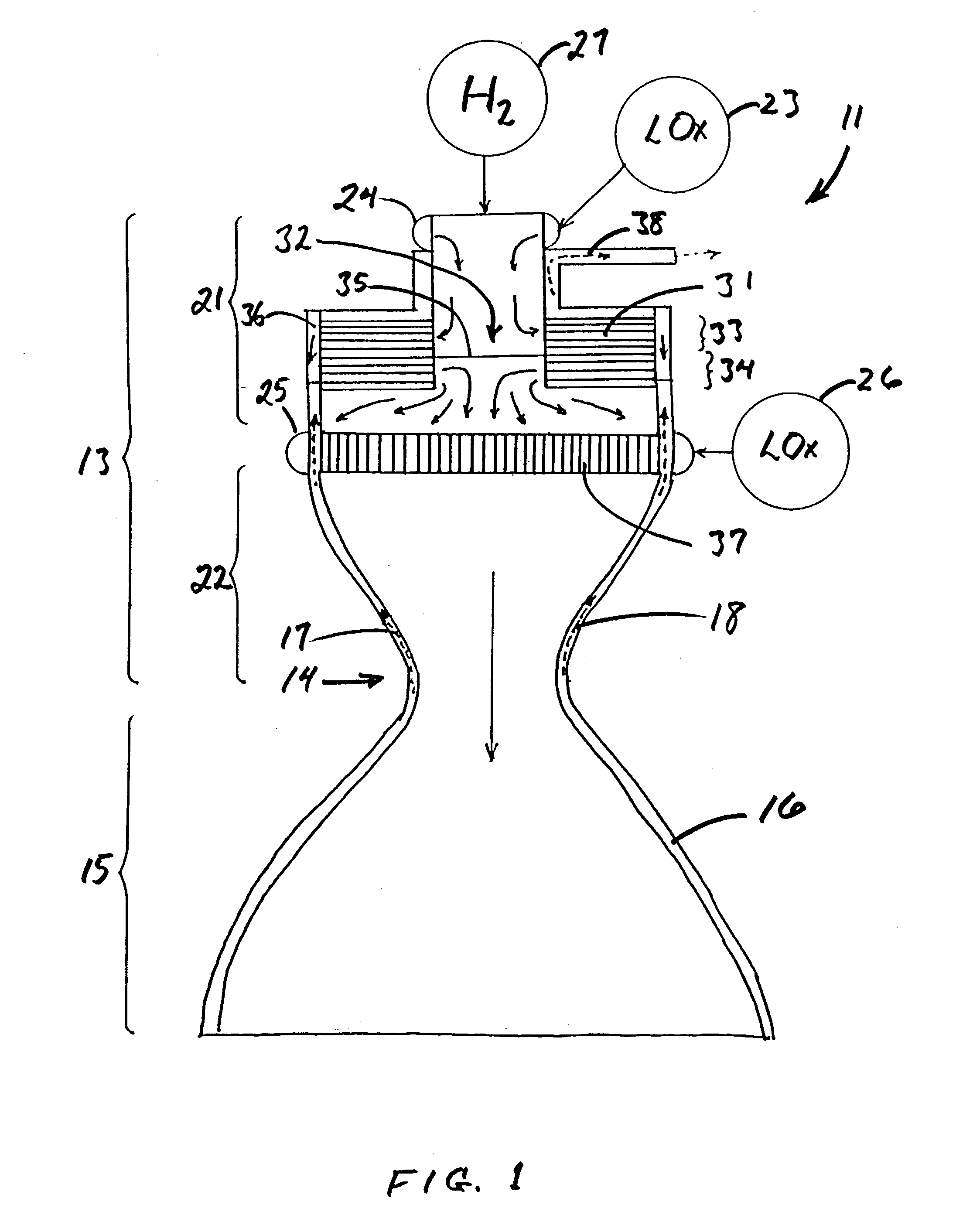

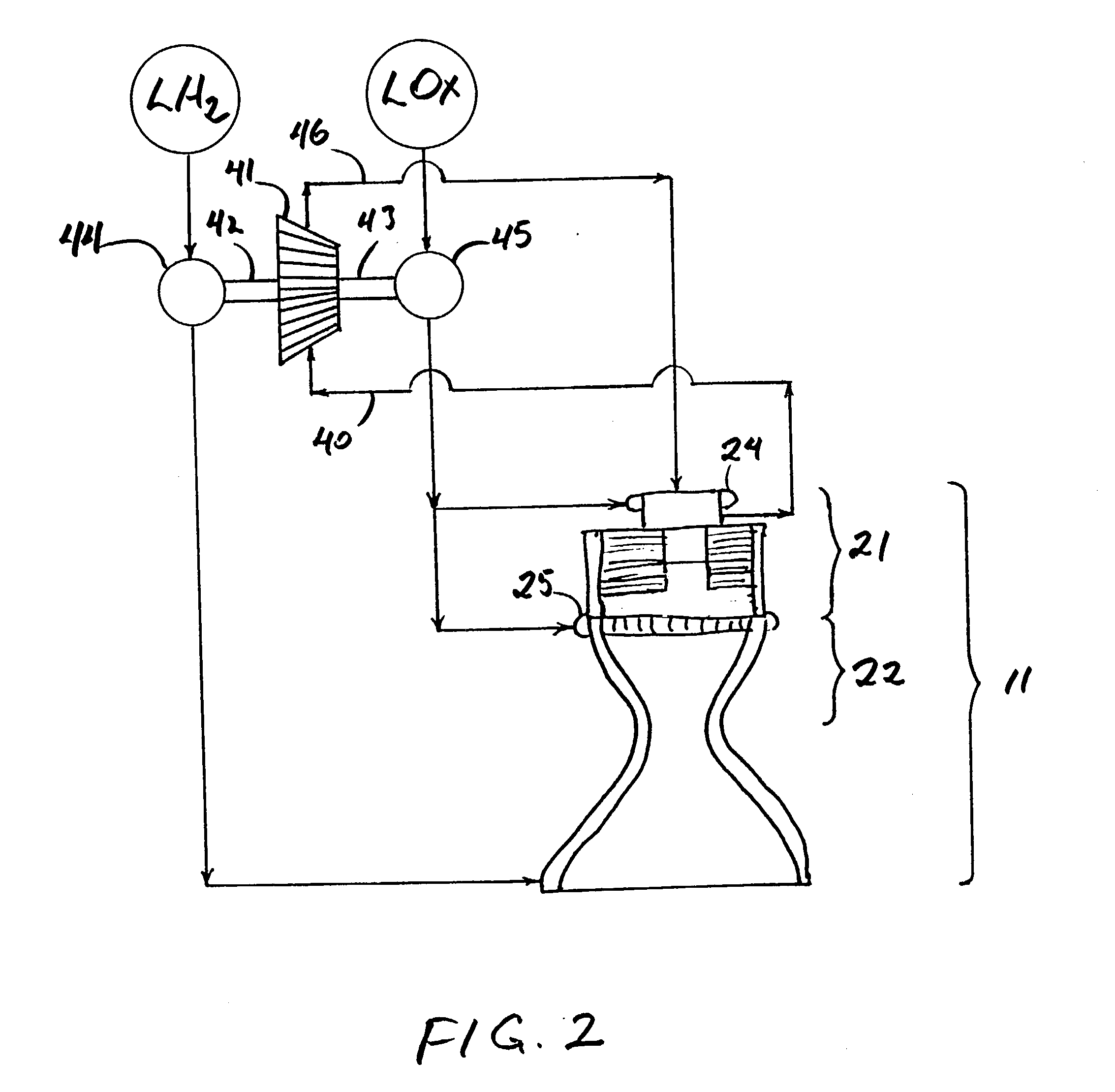

Expander cycle rocket engine with staged combustion and heat exchange

In a supersonic nozzle incorporating injectors and a combustion chamber as part of an expander cycle rocket engine, the oxidizer is injected in two streams. One of the streams, preferably a small fraction of the total, is injected into an upstream or preburner section of the combustion chamber and the other to a downstream or main section of the chamber. The preburner combustion gas is cooled in a substantially uniform manner to a moderate temperature by cooling the bulk of the gas rather than cooling only the gas in a boundary layer adjacent to the chamber wall. The combustion gas produced in the downstream section is hotter, and heat from that gas is drawn through the chamber wall into a jacket. The limited combustion in the preburner permits the use of a cooling element with highly intimate heat exchange construction, extracting a high level of energy from the preburner gas without damage to the cooling element and an overall improvement in the regenerative cooling.

Owner:AEROJET ROCKETDYNE INC

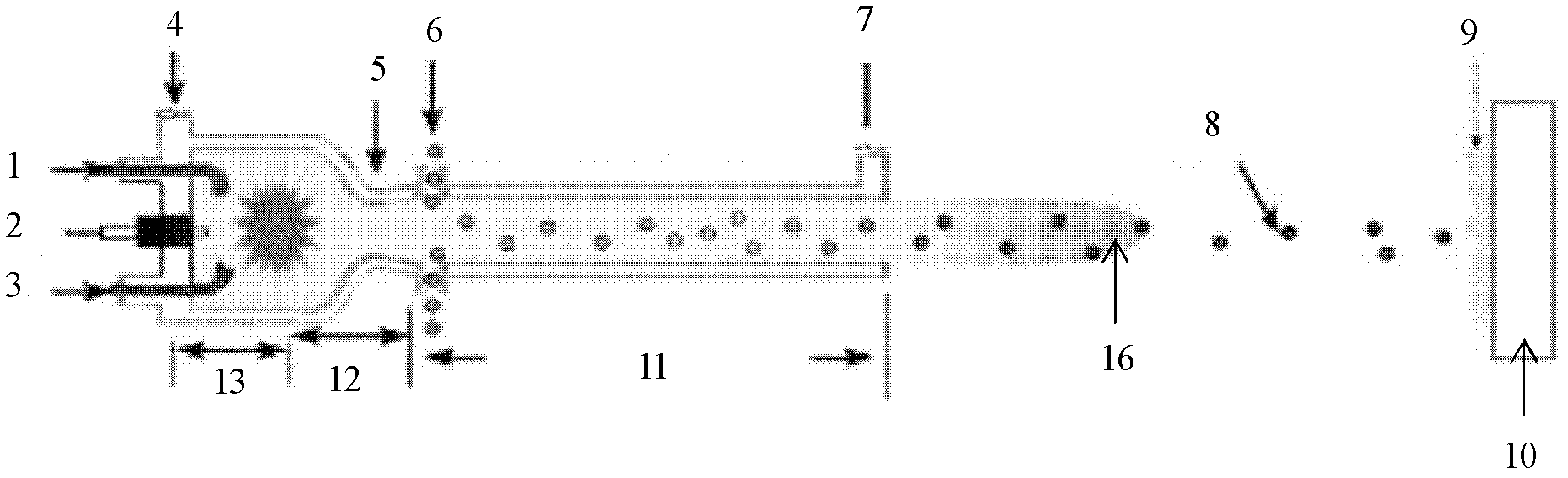

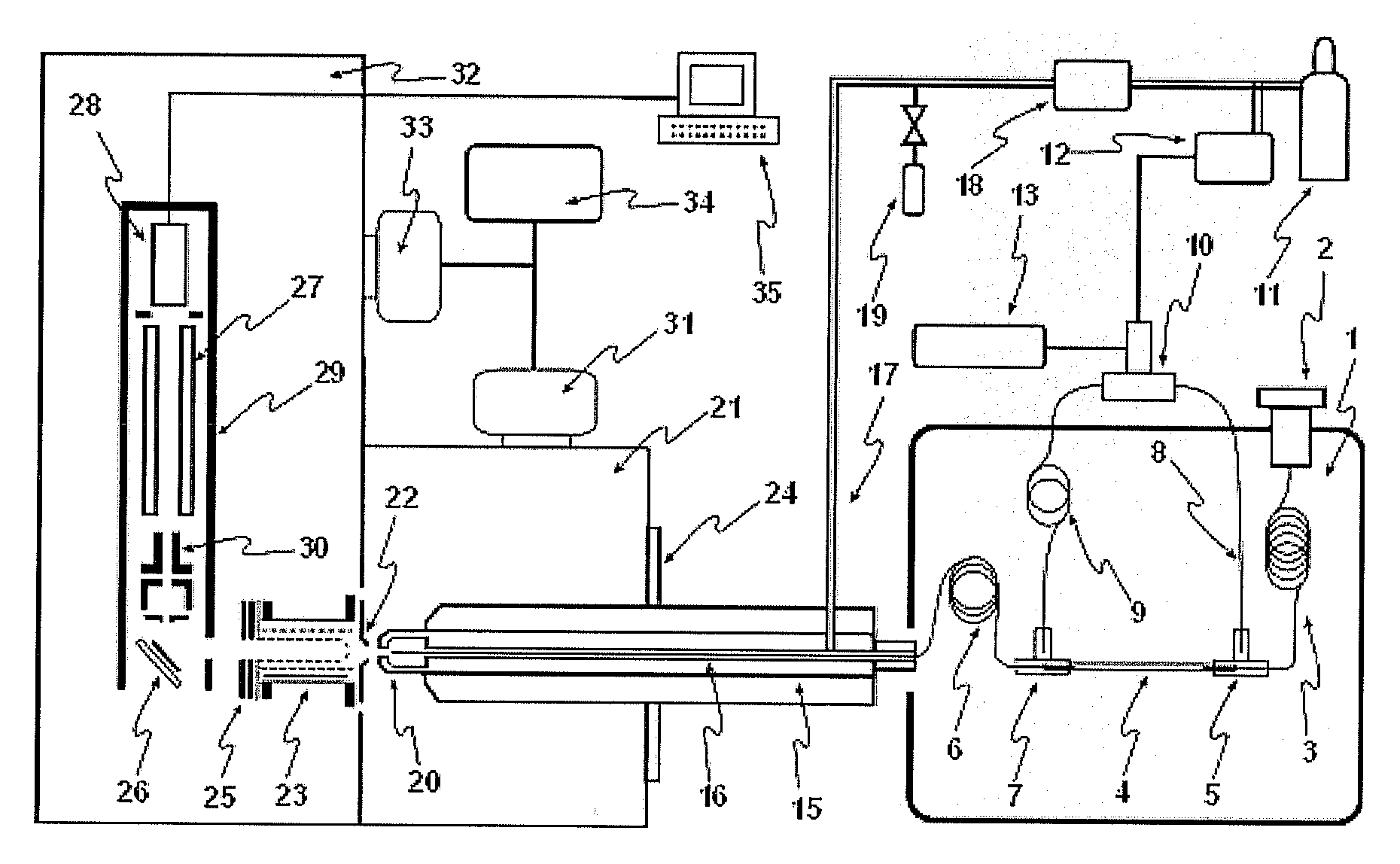

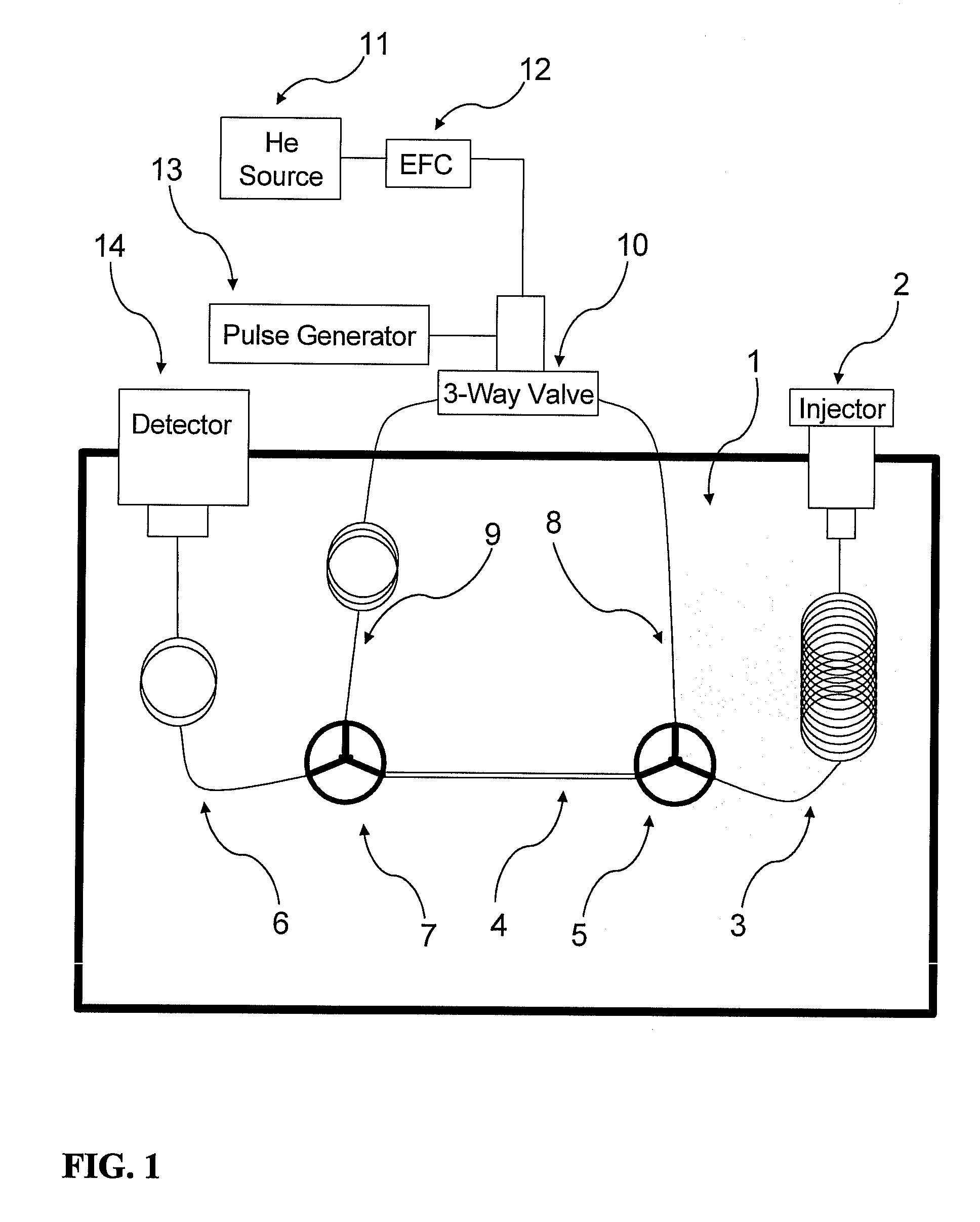

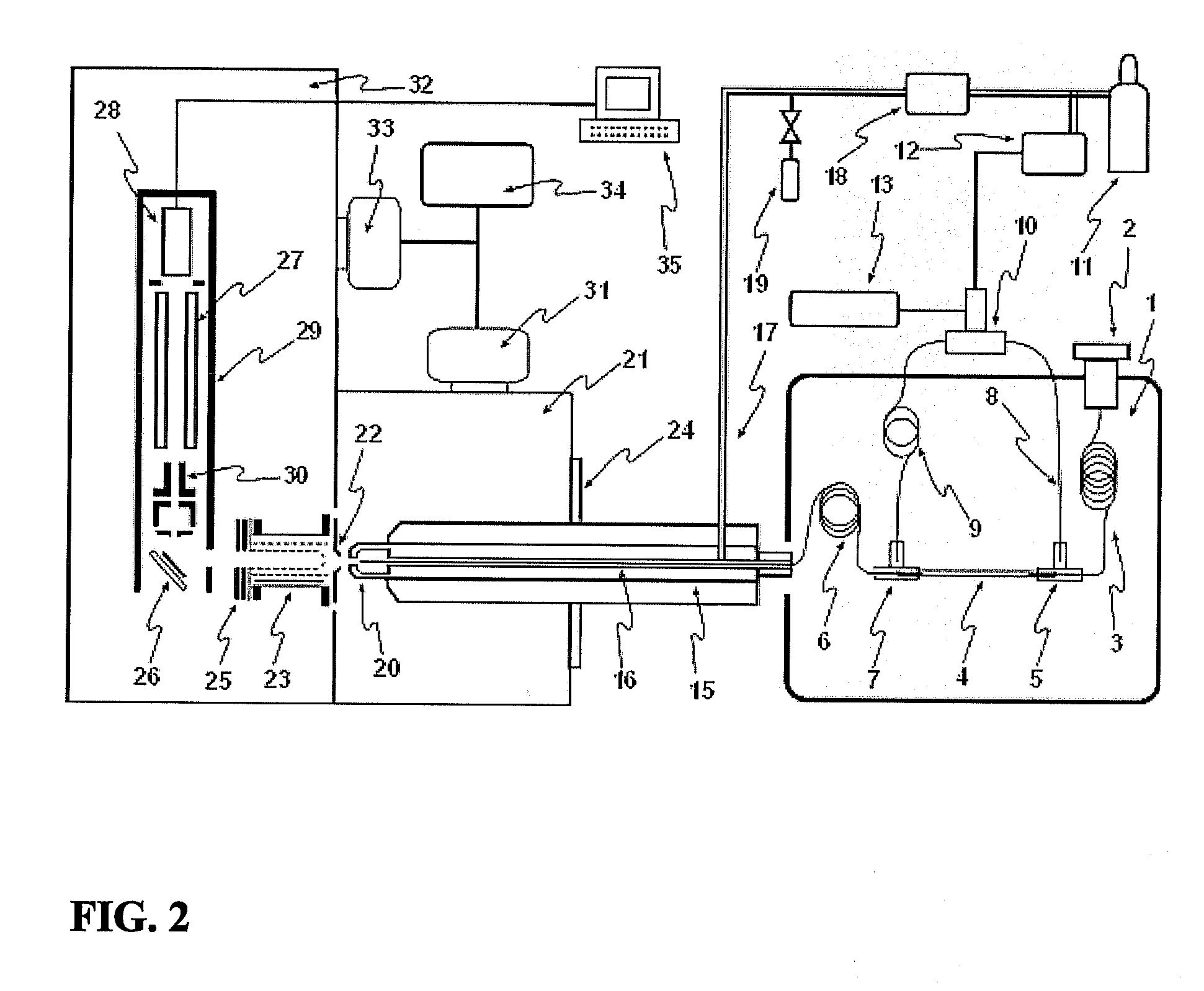

Pulsed flow modulation gas chromatography mass spectrometry with supersonic molecular beams method and apparatus

ActiveUS20080302959A1Time-of-flight spectrometersComponent separationVapor phase chromatographyMass chromatography

There is provided a pulsed flow modulation gas chromatograph mass spectrometer with supersonic molecular beams apparatus and method for improved sample analysis. The apparatus includes a gas chromatograph with an injector for the analysis of sample compounds, a first analytical column in the gas chromatograph, a sample storage, a gas pulse generator, a pressure generator, a conduit for transferring the sample compounds into a second analytical column having a different polarity than the polarity of the first analytical column, a second gas pulse generator, a transfer line for transferring the sample compounds into a supersonic nozzle, a member for adding a makeup gas to the output gas flow of the second analytical column before the supersonic nozzle, an element for reducing the flow rate of the added makeup gas, a supersonic nozzle for the expansion of the sample with the combined second analytical column and added makeup gas, a fly-through electron ionization ion source, a mass analyzer, an ion detector for the detection of the ions of the sample compounds after their mass analysis, a data processor and presenter, and a repeater for repeating the cycle of the first gas pulse of relatively high flow rate followed by the second gas pulse of intermediate flow rate.

Owner:AMIRAV AVIV

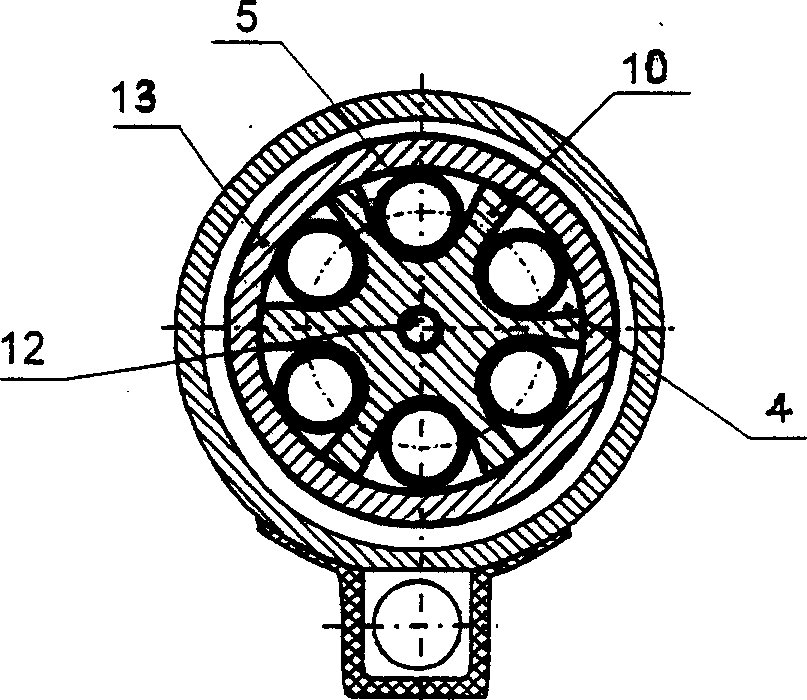

Plasma spraying gun

InactiveCN1404925ACompact and beautiful structureGuaranteed shaft alignmentElectric arc sprayingArc welding apparatusInternal pressureEngineering

The plasma spraying gun mainly comprises gun body, insulator, gas spiral-flow ring, flow divider, anode nozzle, front pressure cap, cathode body, inner pressure cap, insulating cover and outer pressure cap, in which the anode nozzle is connected with gun body by means of inner pressure cap, the flow divider is fixed in the interior of gun body by means of tight fit, the gas sprial-flow ring and insulator are connected with gun body by means of inner pressure cap,and the cathode body is fixed in the interior of gun body by means of insualting cover, outer pressure cap and in sulator. Said invention adopts integrated structure design, its structure is compact and beautiful.

Owner:SHANGHAI JIAO TONG UNIV

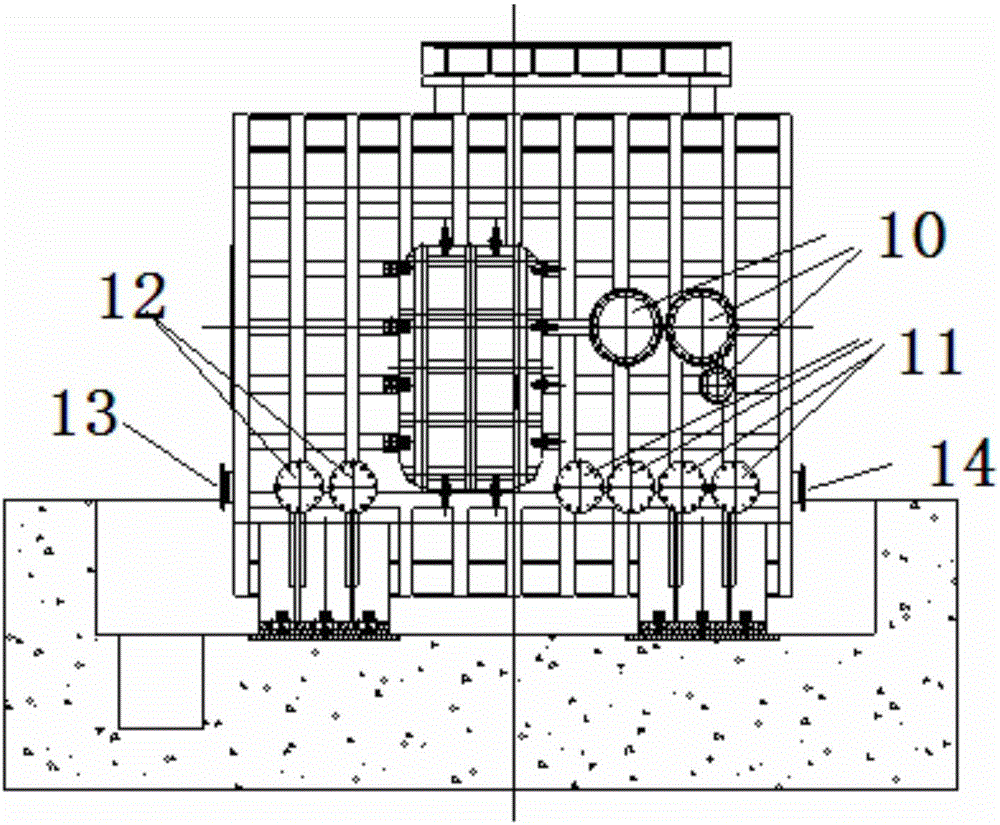

High-temperature combustion-gas flow supersonic wind tunnel test system

ActiveCN106568568AExhaust steady stateEffective use of large volumeAerodynamic testingCombustionPilot system

The invention provides a high-temperature combustion-gas flow supersonic wind tunnel test system and relates to the technical field of aircraft thermal protection ground test. The system comprises a heater, a supersonic nozzle, a test cabin, a diffuser and an exhaust system. One end of the heater is connected with an external energy system; one end of the supersonic nozzle is fixedly connected with the heater, and the other end of the supersonic nozzle is fixedly connected with the test cabin; the diffuser is fixedly arranged at one end of the test cabin; and one end of the exhaust system is fixedly connected with the diffuser, and the other end of the exhaust system is connected with the outside world directly. The high-temperature combustion-gas flow supersonic wind tunnel test system is a system having hundred-megawatt power and meter-scale jet size, and the power thereof reaches more than 200 megawatts, and the jet size reaches 1.5 m; and aircraft thermal protection system global and regional 1:1 large-size model heat check can be realized.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

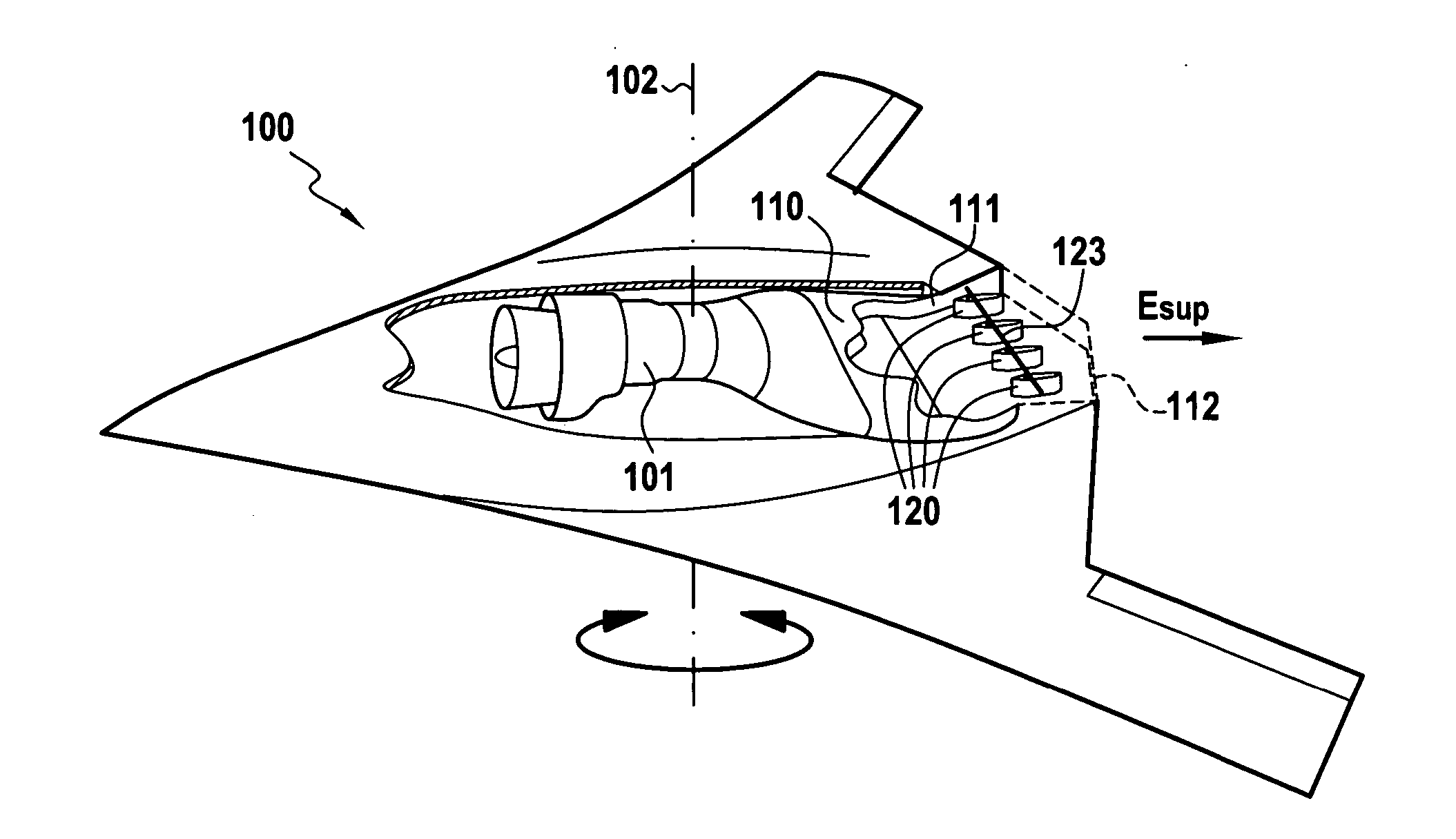

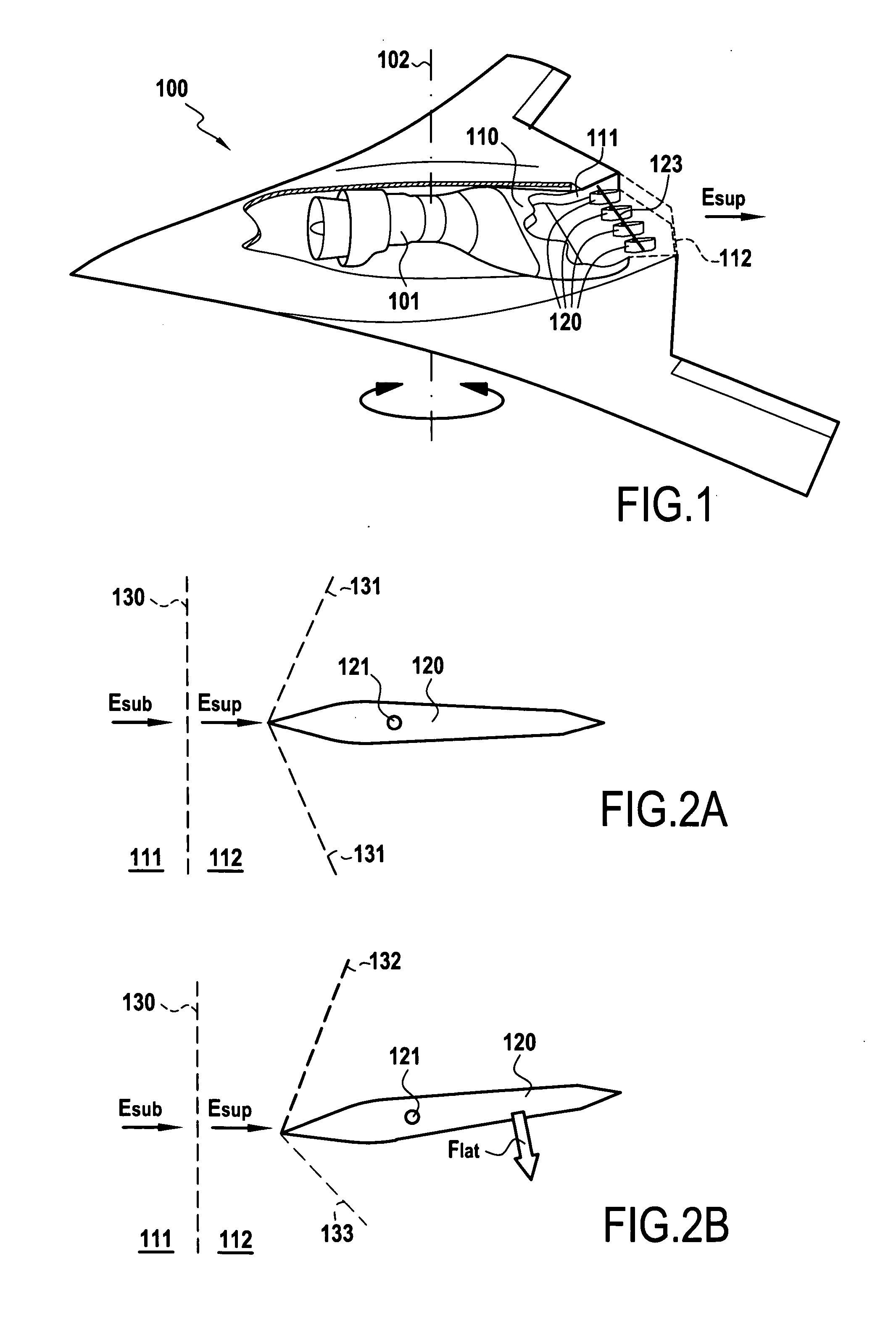

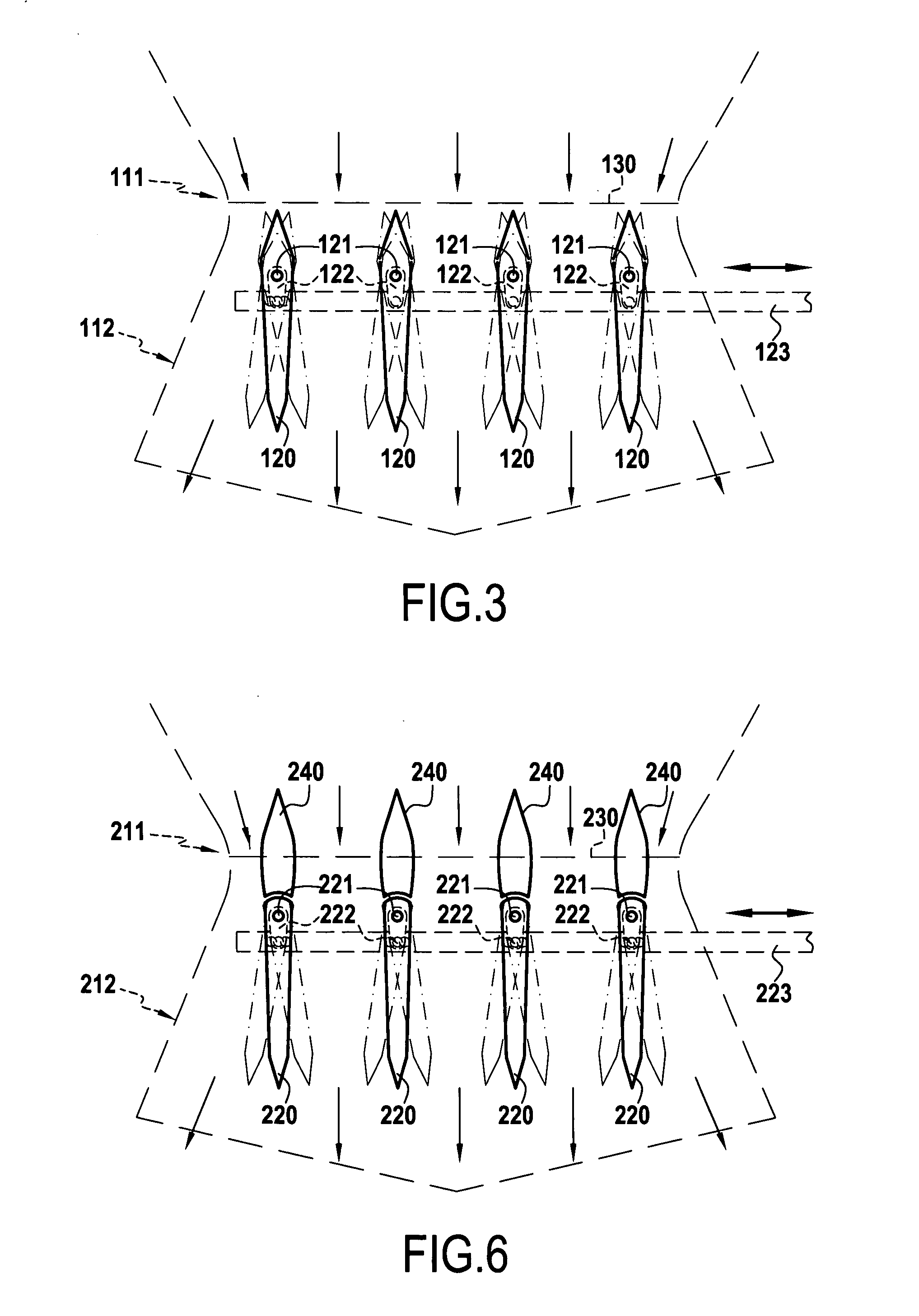

Yaw control device for a nozzle having a rectangular outlet section

InactiveUS20070095972A1Good yaw momentLimit lossAircraft navigation controlPower plant exhaust arrangementsThroatYaw control

The invention relates to a yaw control device for an aircraft fitted with a supersonic nozzle having a rectangular or flat section comprising a supersonic throat extended by a diverging portion in which supersonic flow occurs. In order to enable the aircraft to be controlled in yaw in the absence of a vertical fin, the device of the invention makes use of jet control surfaces in the form of airfoils disposed in the diverging portion of the nozzle. The control surfaces are movable about respective pivot axes in order to generate a lateral force when in a deflected position, so as to enable the aircraft to turn about its yaw axis.

Owner:SNECMA PROPULSION SOLIDE

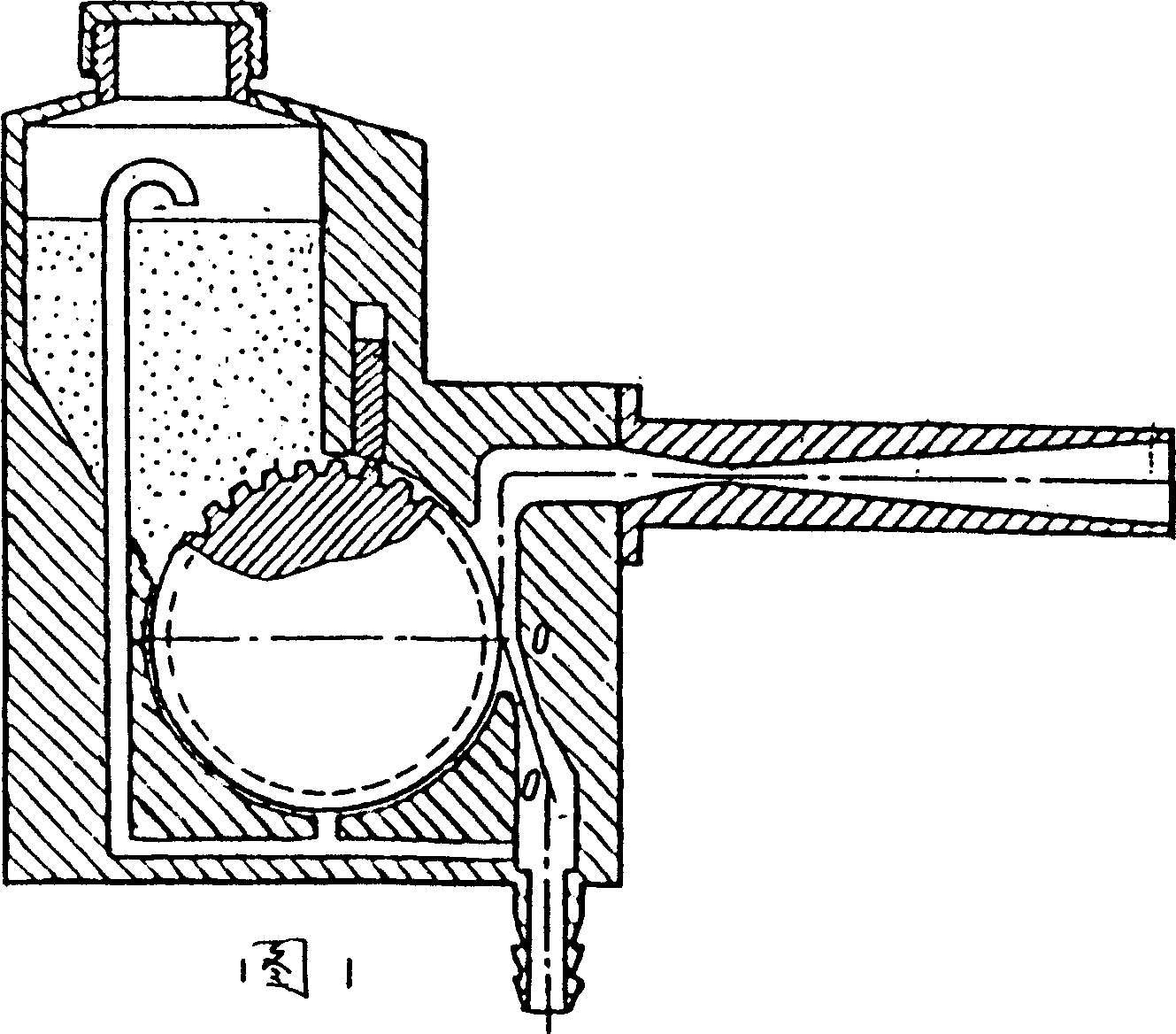

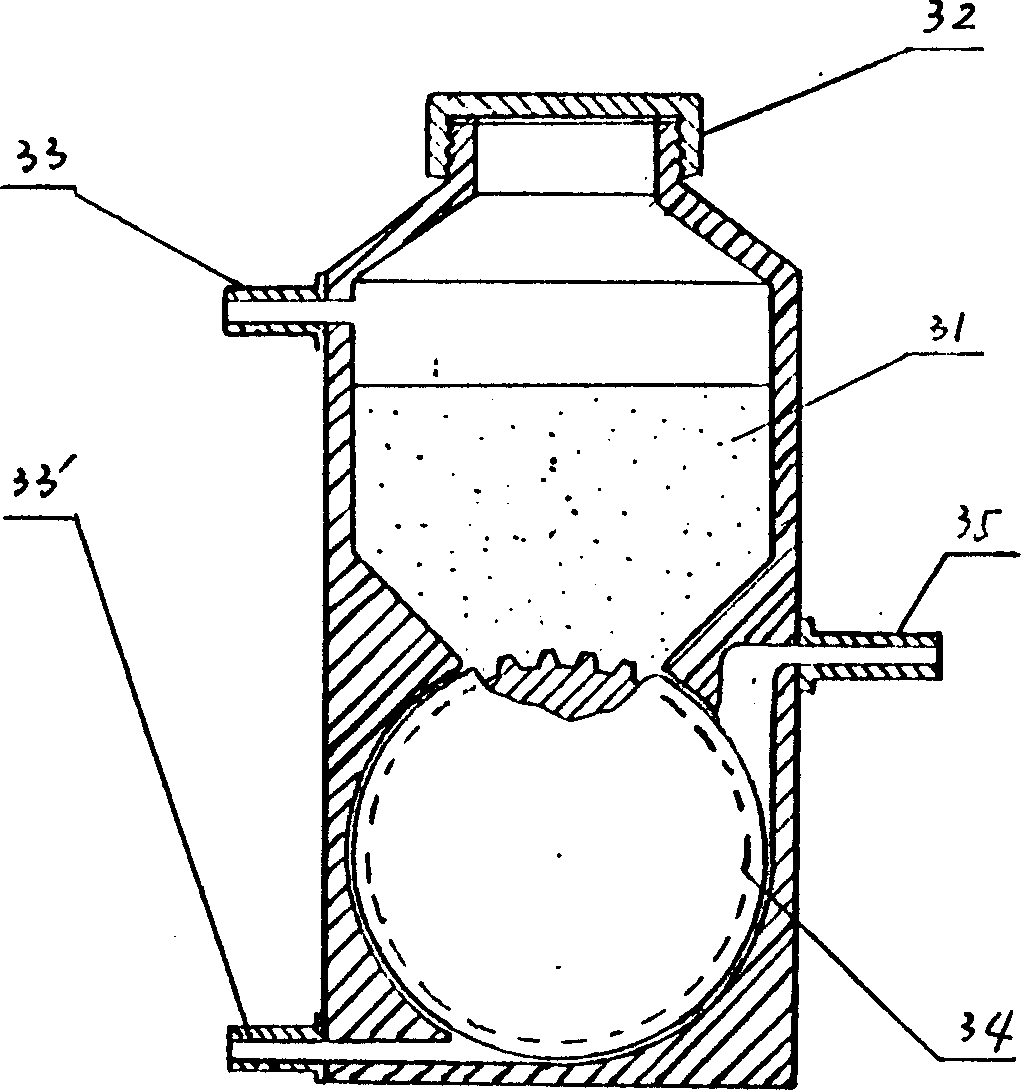

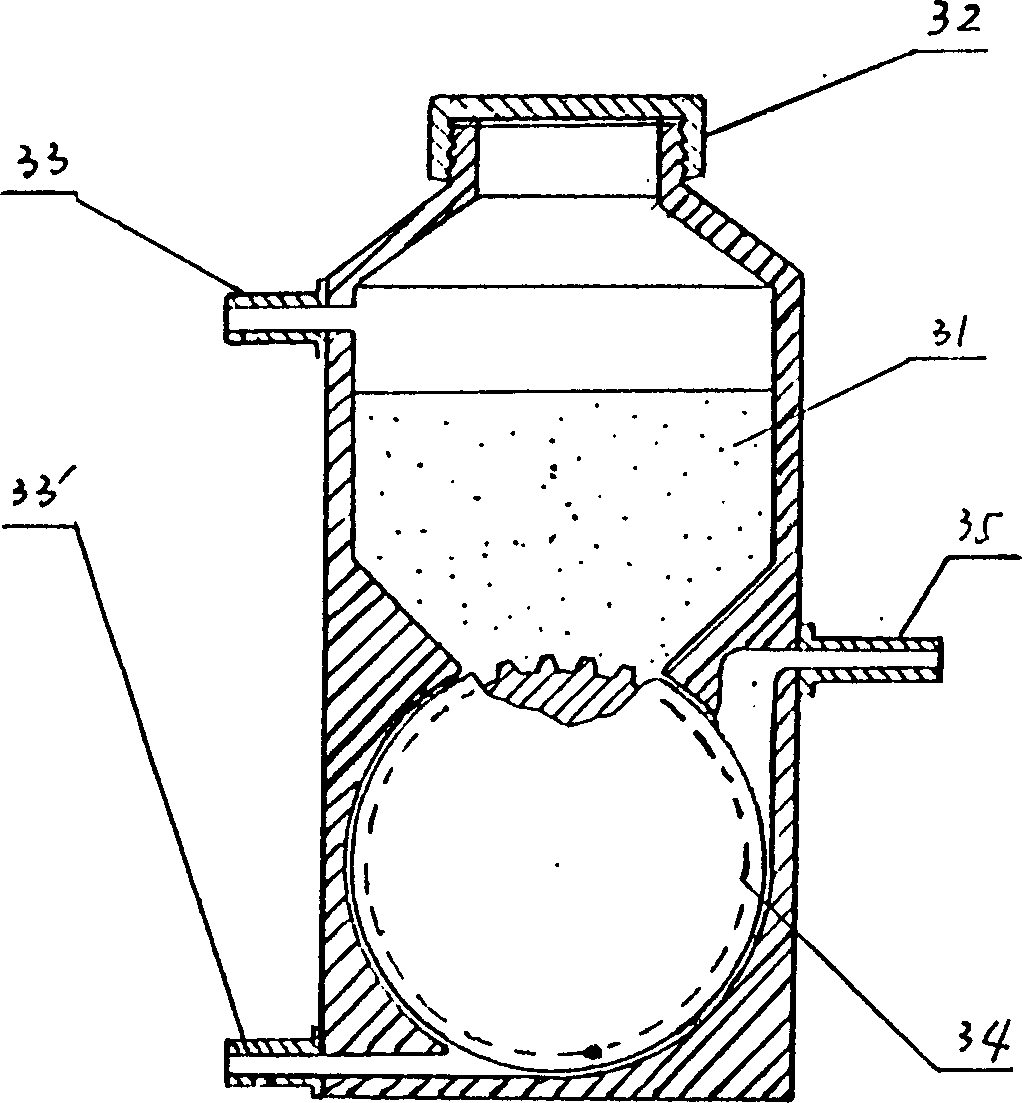

Supersonic nozzle of supersonic speed rotational flow natural gas separator

InactiveCN101387469AAchieve expansion and coolingAchieve separationSolidificationLiquefactionCycloneUltrasonic nozzle

The invention provides a supersonic jet tube used for a supersonic cyclone natural gas separator, which is a key part of the separator, and consists of a contraction tube section, an extension tube section and a rectifying tube section. A moulding surface curve of the contraction tube section is higher-order polynomial, and natural gas airflow is expanded and accelerated in the section to achieve sonic velocity so as to form a straight sonic flow. The moulding surface curve of the extension tube section consists of a plurality of sections of curve, and the sections are smoothly connected to reduce disturbance to the airflow. The moulding surface curve of the supersonic jet tube at inlet and outlet changes flatly, has small curvature change, and has weak influence on the flowing of fluid upstream and downstream without obvious inlet and outlet effect. The extension tube has smooth inlet transition with small disturbance to the fluid. The extension tube section has flat change of moulding surface curve, small airflow expansion rate and good flow speed evenness, thereby helping droplet condensation nucleus grow larger grain diameter for separating. The supersonic jet tube not only evenly accelerates the airflow, improves evenness and stability of flow field, and reduces turbulivity, so that outlet airflow has better airflow quality, and can form droplets with larger grain diameter to improve the separation efficiency of the supersonic cyclone natural gas separator.

Owner:曹学文

Gaseous oxygen resonance igniter

A gaseous oxygen resonance igniter includes a body with a first inlet for gaseous oxygen incorporating a supersonic nozzle. An outlet from the body incorporates an orifice of predetermined size to maintain a desired pressure in the body. An aperture in the body opposite the first inlet provides a port to a ceramic resonance cavity. A ceramic bleed disc is engaged at a second end of the resonance cavity. An end cap incorporates a plenum adapted to receive high temperature oxygen flow from the resonance cavity through the bleed disc. An exhaust port is connected to the plenum for the high temperature oxygen which flows to a mixing chamber which introduces pilot fuel for ignition as a combustion initiation torch.

Owner:UNITED TECH CORP +1

Composite ceramic Raoult nozzle for cold spray coating

A supersonic laval nozzle made of composite ceramic for spraying out high-speed superfine particles for cold spray coating is composed of a convergent segment based on a particular curve, a throat segment which is an isometric straight segment, and an axially symmetric clliptical segment. There is smooth transitien between adjacent two segments.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com