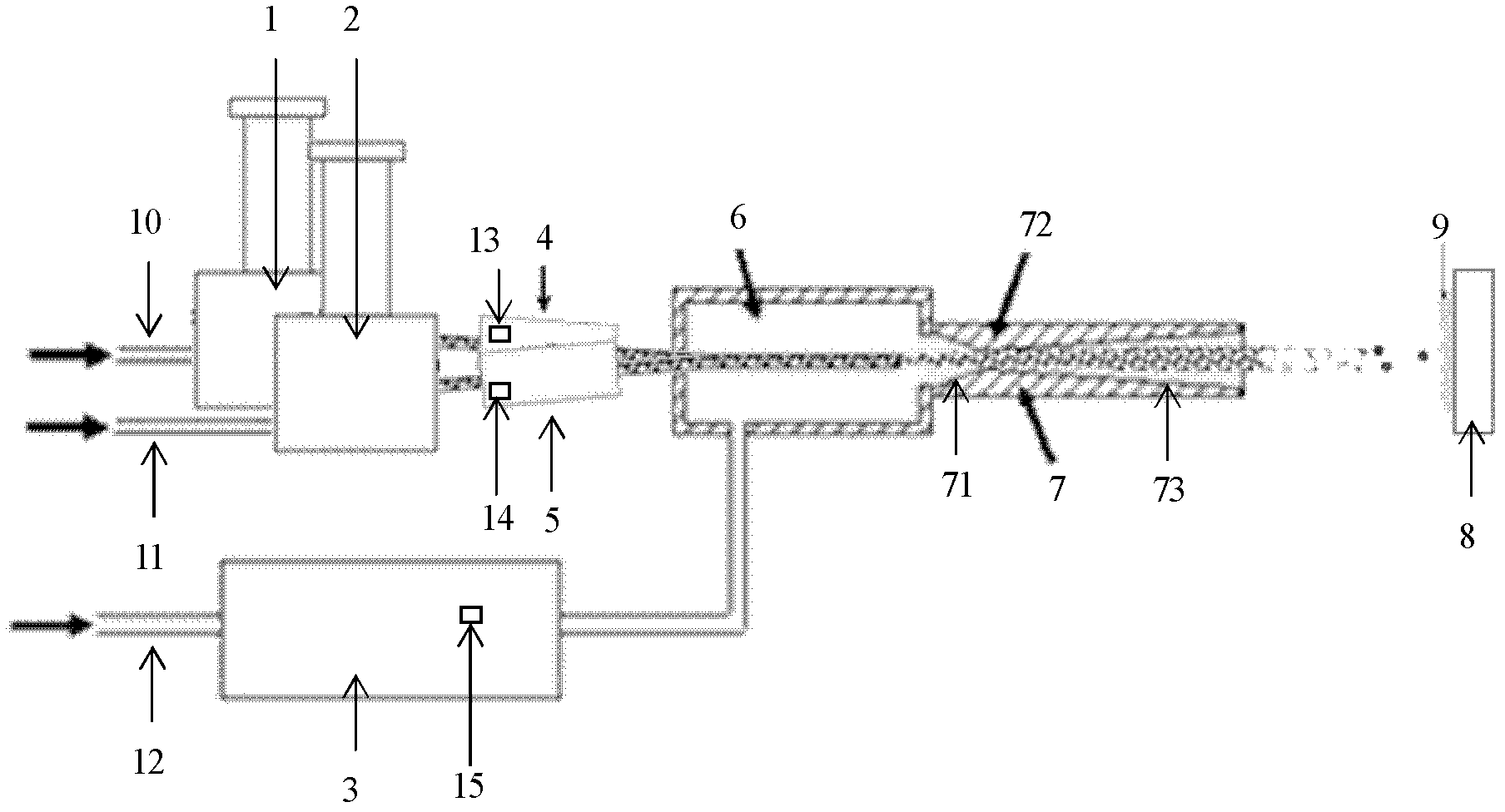

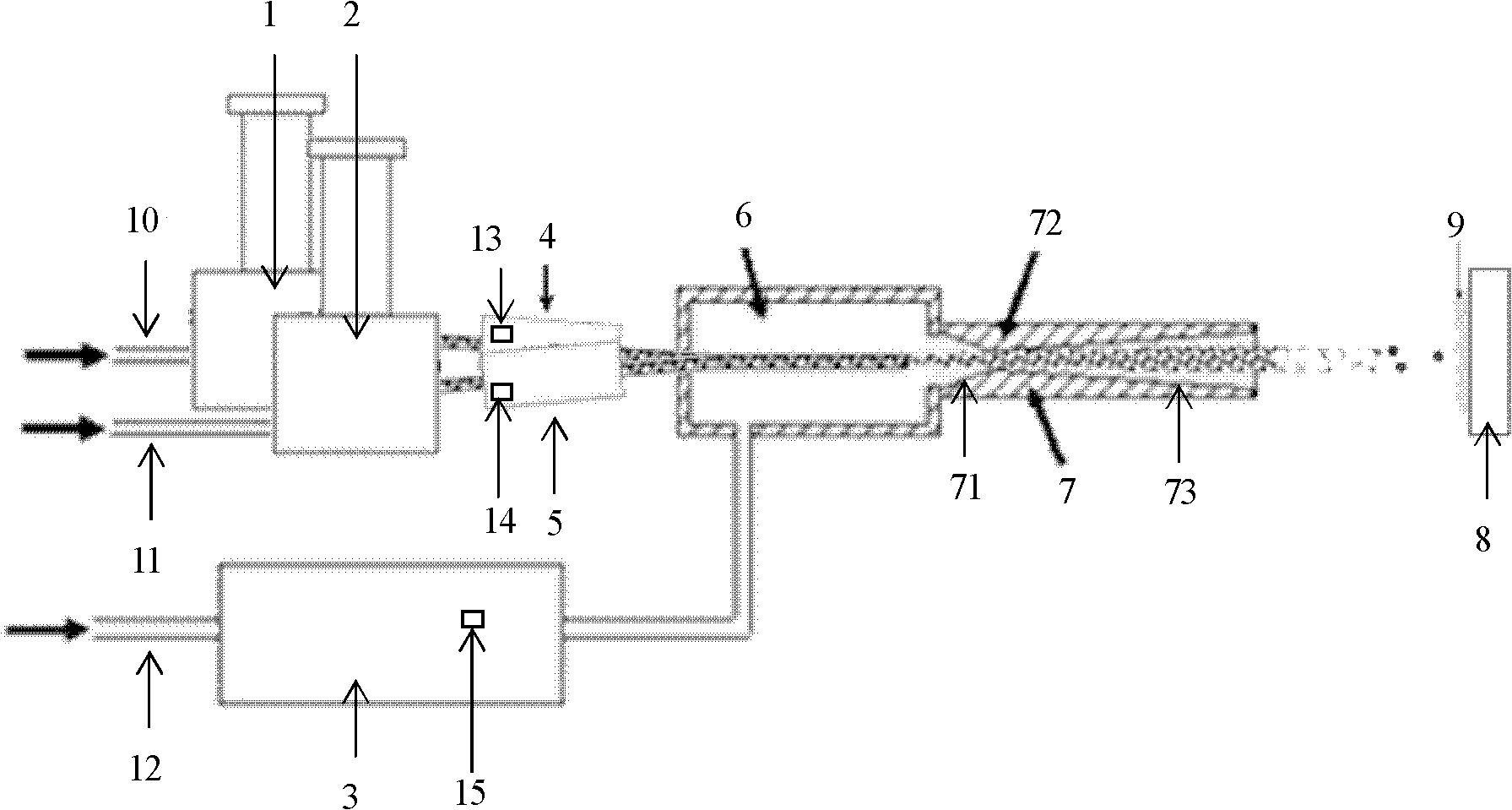

Cold spray device and method for preparing metal composite gradient quasicrystal coating

A metal composite and cold spraying technology, which is applied to the surface coating device, spray device, liquid spray device, etc., can solve the problems of coating brittleness and phase change, and achieve the effect of uniform coating gradient distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, the composite gradient quasicrystalline coating of metal Al powder and quasicrystalline Al-Cu-Fe powder is deposited on the surface of the aluminum alloy substrate, and the process parameters are as follows:

[0051] The spray distance is 10mm, the gas pressure is 3.0MPa, the gas temperature is 600°C, the air flow rate is 20g / s, the powder particle size is 30μm, the weight ratio of metal Al powder and quasicrystalline Al-Cu-Fe powder is 1:1, Al The powder heating temperature is 50°C, and the Al-Cu-Fe powder heating temperature is 600°C. During the entire spraying process, the sprayed particles remain solid, fly at a high speed of 500-1200m / s and hit the surface of the workpiece substrate, undergoing strong plastic deformation, depositing on the surface of the workpiece substrate to form a metal composite gradient quasicrystal coating, the coating thickness is 3000 microns .

[0052] In this embodiment, in the quasicrystalline powder and metal powder...

Embodiment 2

[0054] In this embodiment, the composite gradient quasicrystalline coating of metal Cu powder and quasicrystalline Al-Cu-Cr powder is deposited on the surface of the titanium alloy substrate, and the process parameters are as follows:

[0055] The spray distance is 20mm, the gas pressure is 2.0MPa, the gas temperature is 650°C, the air flow rate is 25g / s, the powder particle size is 40μm, the weight ratio of metal Cu powder and quasicrystalline Al-Cu-Cr powder is 1:3, Cu The powder heating temperature is 200°C, and the Al-Cu-Cr powder temperature is 600°C. During the entire spraying process, the sprayed particles remain solid, fly at a high speed of 500-1200m / s and hit the surface of the workpiece substrate, undergoing strong plastic deformation, depositing on the surface of the workpiece substrate to form a metal composite gradient quasicrystal coating, the coating thickness is 4000 microns .

[0056] In this embodiment, in the quasicrystalline powder and metal powder compos...

Embodiment 3

[0058] In this embodiment, the composite gradient quasicrystalline coating of metal Zn powder and quasicrystalline Al-Cu-Fe-Cr powder is deposited on the surface of the stainless steel substrate, and the process parameters are as follows:

[0059] The spray distance is 30mm, the gas pressure is 4.0MPa, the gas temperature is 700°C, the air flow rate is 30g / s, the powder particle size is 10μm, and the weight ratio of metal Zn powder and quasicrystalline Al-Cu-Fe-Cr powder is 1:5 , Zn powder is room temperature, Al-Cu-Fe-Cr powder heating temperature is 600 ℃. During the entire spraying process, the sprayed particles remain solid, fly at high speed and hit the surface of the workpiece substrate, undergo strong plastic deformation, deposit on the surface of the workpiece substrate to form a metal composite gradient quasicrystalline coating, and the coating thickness is 5000 microns.

[0060] In this embodiment, in the quasicrystalline powder and metal powder composite coating, al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com