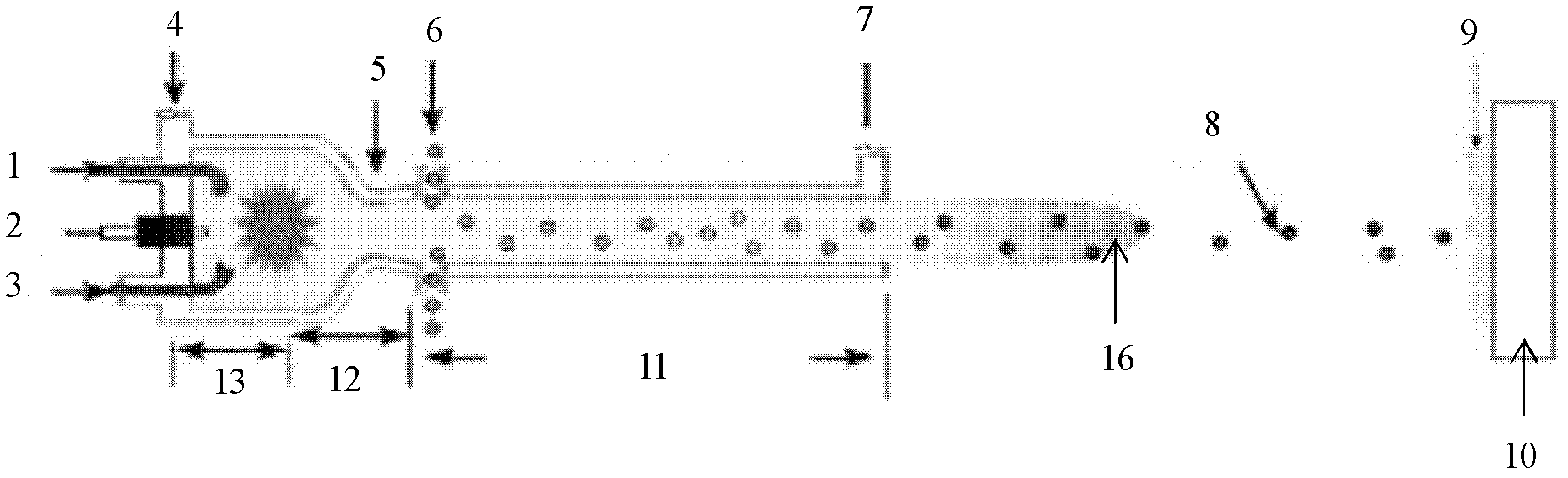

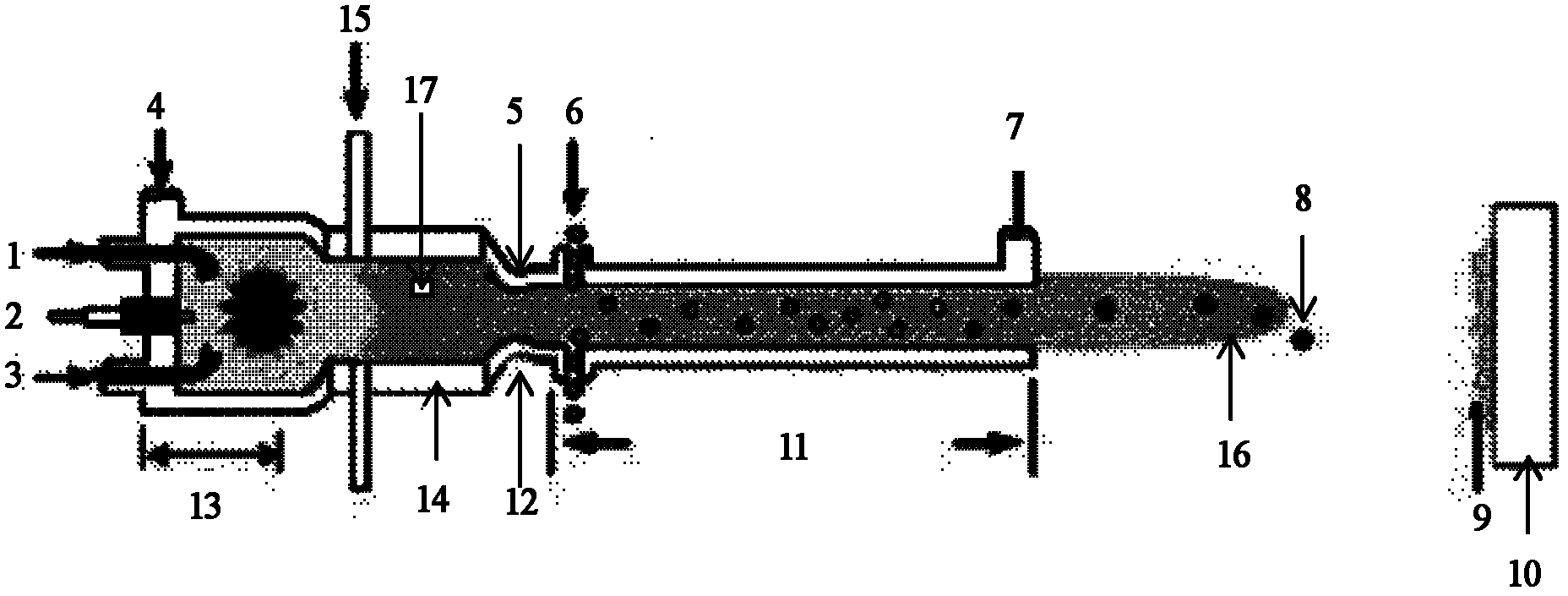

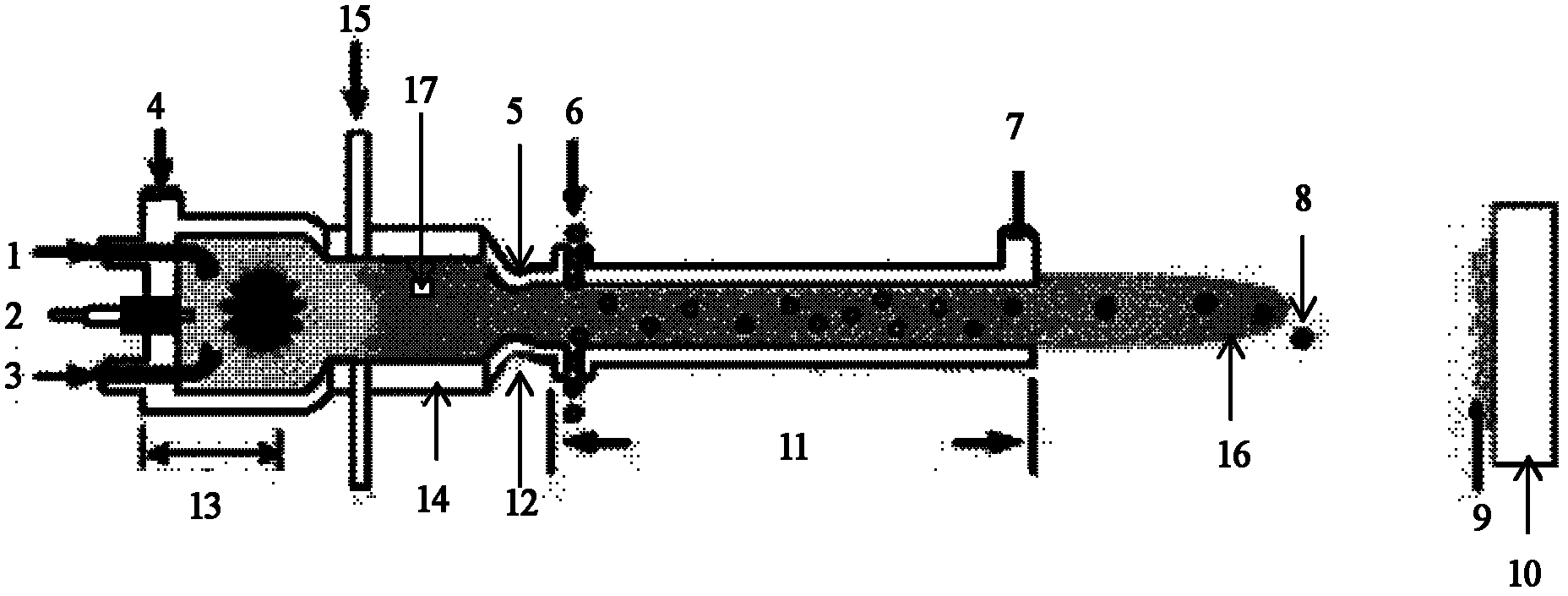

Thermal spraying device and method for manufacturing quasicrystalline coating

A spraying device and quasicrystal technology, which is applied in coating, metal material coating process, molten spraying, etc., can solve the problems of microcracks, quasicrystal phase accompanied by crystal phase and high porosity of the coating, and achieve the composition phase Uniform distribution, high quasi-crystal purity, and the effect of avoiding changes in crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the quasicrystalline Al-Cu-Fe powder coating is deposited on the surface of the aluminum alloy substrate, and the process parameters are as follows:

[0047] The spraying distance is 100mm, the oxygen pressure is 0.5MPa, the oxygen flow rate is 200L / mm, the nitrogen pressure is 0.4MPa, the nitrogen flow rate is 200L / mm, the gas C 3 h 8 The pressure is 0.5MPa, the gas flow rate is 50ml / min, the spraying temperature is 1000°C, the particle velocity is 900-1600m / s, the particle size of the quasicrystalline powder is 30-50μm, the powder feeding rate is 20g / min, and the coating thickness is 500μm.

[0048] In this embodiment, the quasicrystalline coating is evenly distributed and compact in structure. The tensile strength of the coating and the substrate is 60MPa, the shear strength is 35MPa, and the purity of the quasicrystalline phase is 98wt%.

Embodiment 2

[0050] In this embodiment, the quasicrystalline Al-Cu-Cr powder coating is deposited on the surface of the titanium alloy substrate, and the process parameters are as follows:

[0051] Spraying distance is 50mm, oxygen pressure is 0.25MPa, oxygen flow rate is 400L / min, nitrogen pressure is 0.15MPa, nitrogen flow rate is 50L / min, gas C 3 h 8 The pressure is 0.25MPa, the gas flow rate is 20ml / min, the spraying temperature is 500°C, the particle velocity is 900-1600m / s, the particle size of the quasicrystalline powder is 10-30μm, the powder feeding rate is 10g / min, and the coating thickness is 1000μm.

[0052] In this embodiment, the quasicrystalline coating is evenly distributed and has a compact structure. The tensile strength of the coating and the substrate is 80 MPa, the shear strength is 50 MPa, and the purity of the quasicrystalline phase is 96 wt%.

Embodiment 3

[0054] In this embodiment, an Al-Cu-Fe-Cr quasicrystalline coating is deposited on the surface of a stainless steel substrate, and the process parameters are as follows:

[0055] The spraying distance is 300mm, the oxygen pressure is 0.75MPa, the oxygen flow rate is 600L / min, the nitrogen pressure is 0.55MPa, the nitrogen flow rate is 300L / mm, the gas C 3 h 8 The pressure is 0.65MPa, the gas flow rate is 100ml / min, the spraying temperature is 1500°C, the particle velocity is 900-1600m / s, the particle size of the quasicrystalline powder is 50-80μm, the powder feeding rate is 30g / min, and the coating thickness is 1500μm.

[0056] In this embodiment, the quasicrystalline coating is evenly distributed and dense in structure, the tensile strength of the coating and the substrate is 70 MPa, the shear strength is 40 MPa, and the purity of the quasicrystalline phase is 97 wt%.

[0057] The results of the examples show that the device of the present invention is simple, easy to operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com