Supersonic nozzle of supersonic speed rotational flow natural gas separator

A supersonic, natural gas technology, applied in the fields of processing and processing, natural gas gathering and transportation, can solve the problems of reduced nozzle efficiency, low uniformity and stability of supersonic gas flow velocity, and can not be well satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

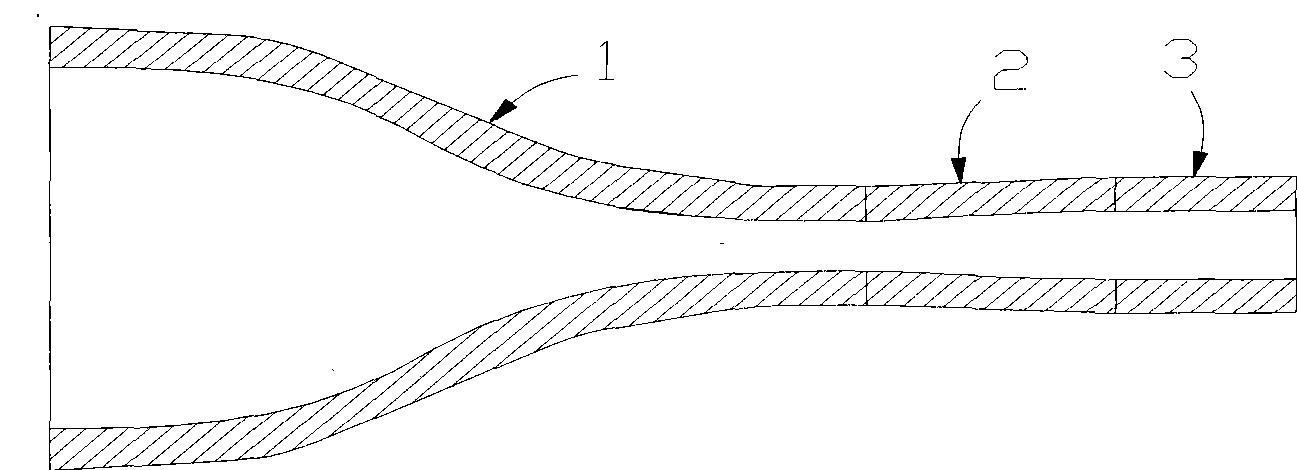

[0011] The accompanying drawing is an example of a typical supersonic nozzle designed and processed according to the purpose of the present invention. The supersonic nozzle is a cylindrical shell. figure 1 It is a sectional view of a supersonic nozzle, which is composed of a contraction pipe section (1), an expansion pipe section (2) and a rectification pipe section (3).

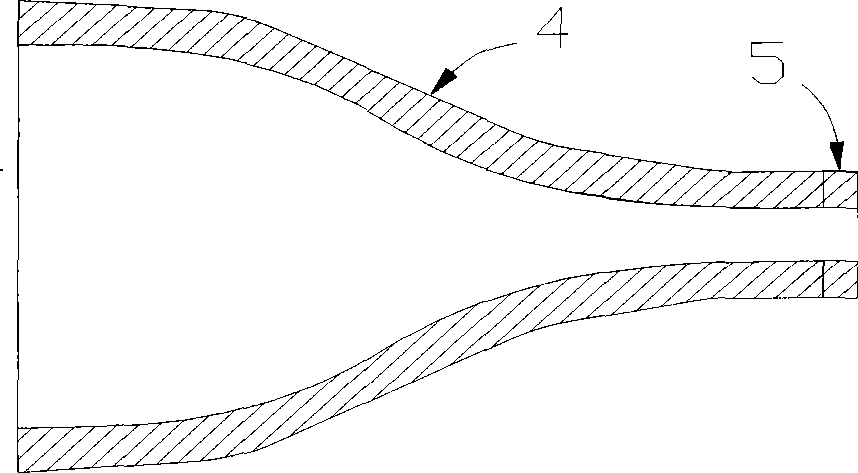

[0012] figure 2 It is a sectional view of the shrinkage section of the supersonic nozzle, and the shrinkage section of this example is composed of the shrinkage pipe (4) and the straight pipe (5). The surface curve of the shrink tube is a cubic polynomial, the diameter of the inlet is 100mm, the diameter of the outlet is 12.4mm, the length of the shrink tube is 186mm, the shrinkage angle is 15°, and the tangent of the inlet and outlet ends of the shrink tube is parallel to the axial direction. The length of the straight pipe at the end of the shrinkage pipe is 1.0 mm. This straight pipe is the throat of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com