Cold air driven spray painter

A technology of cold air power spraying and spraying room, which is applied in the direction of spraying device, liquid spraying device, and device for coating liquid on the surface, etc. It can solve the problems of limiting the application range of thermal spraying, limiting the size of spraying workpieces, and expensive spraying equipment. To achieve the effect of improving the powder feeding method, good spraying quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

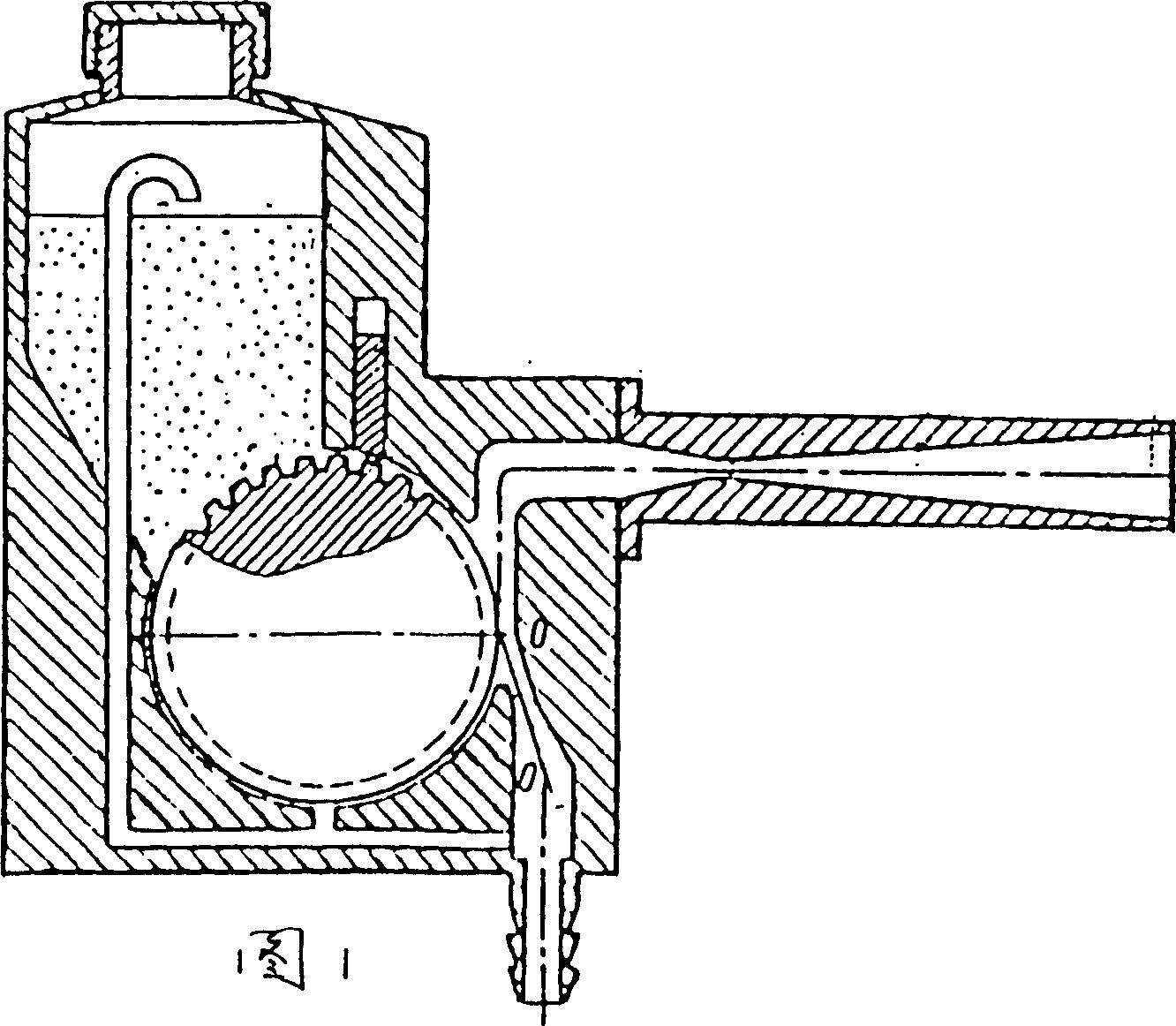

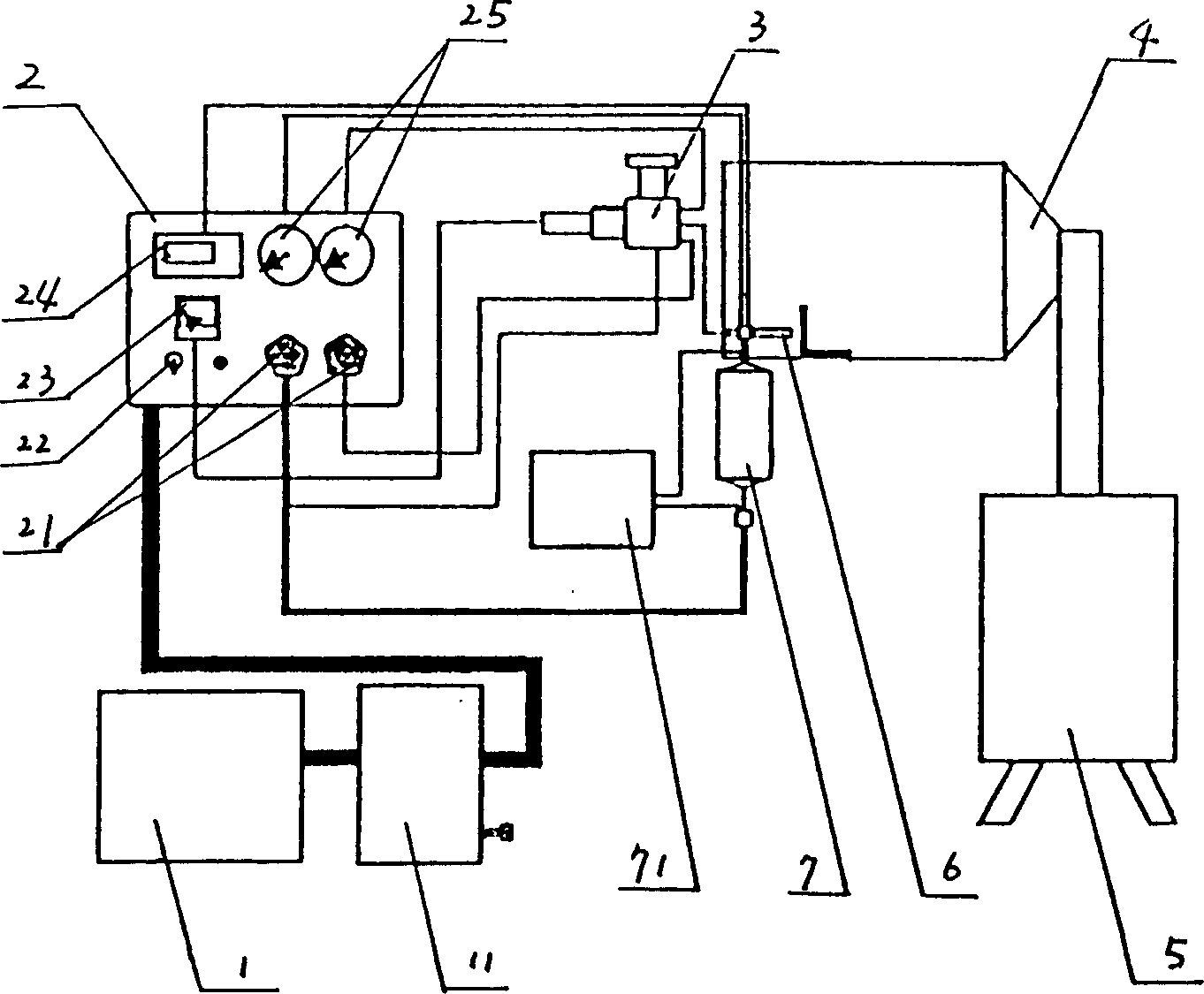

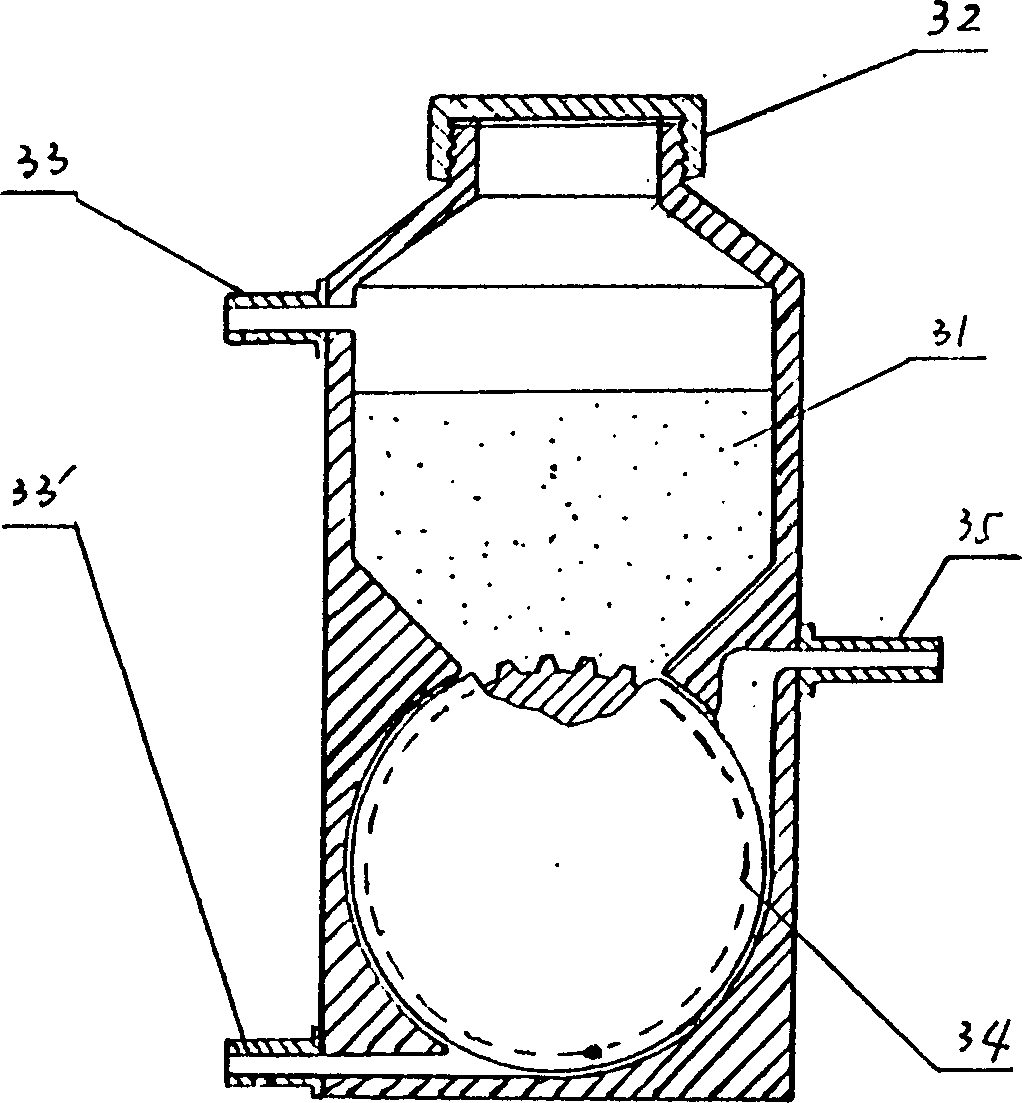

[0018] Such as figure 2 , 3 , 4, it is composed of a supersonic nozzle 6, a heater 7, a powder feeder 3, a spraying chamber 4, a powder recovery device 5, and a controller 2, wherein the supersonic nozzle 6 is installed at the entrance of the spraying chamber 4, and the controller 2. Connect with the pipeline of air compressor 1 with air storage tank 11, and connect with heater 7 and powder feeder 3 respectively through powder feeding switch 22 and pressure regulating switch 21. Heater 7 is equipped with heating power supply 71, one end To the supersonic nozzle 6, a powder recovery device 5 is installed at the outlet of the spraying chamber 4;

[0019] The supersonic nozzle 6 is connected to the powder feeder 3 through a pipeline, and consists of three parts: a contraction section 61, a throat 62, and an expansion section 63. The contraction section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com