Patents

Literature

631results about How to "Solve easy blockage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

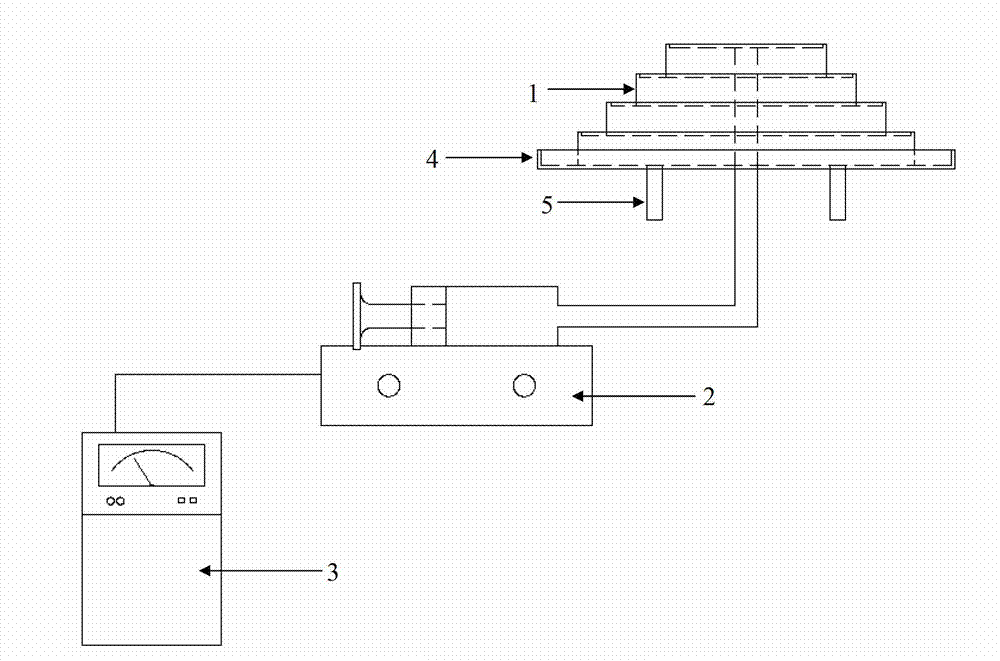

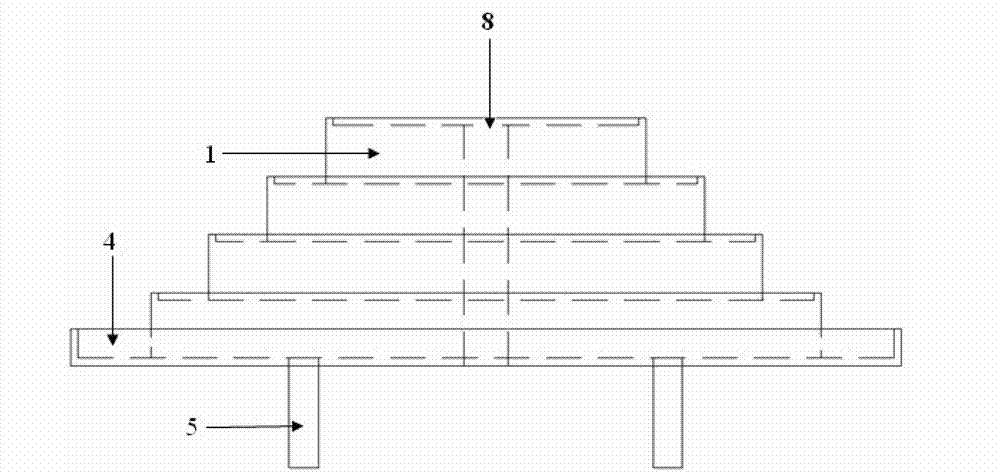

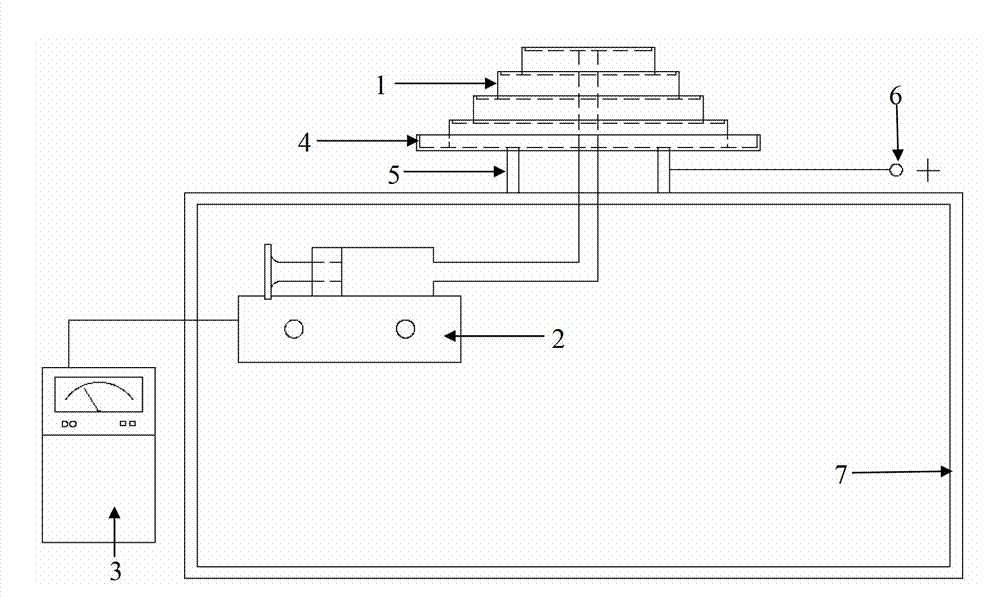

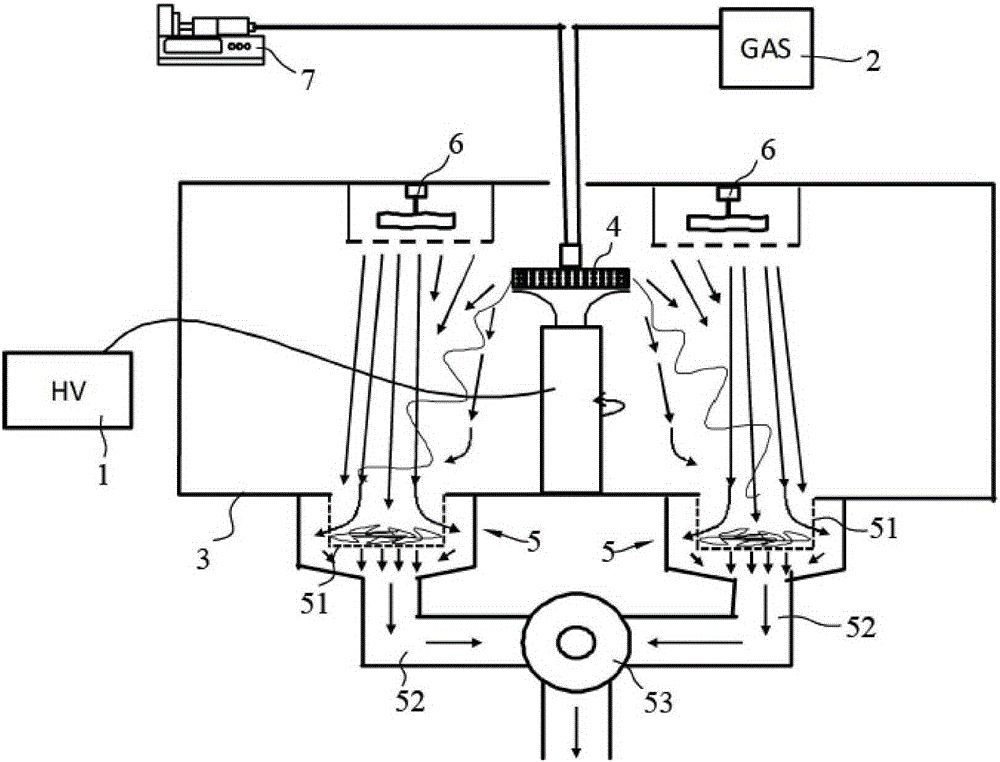

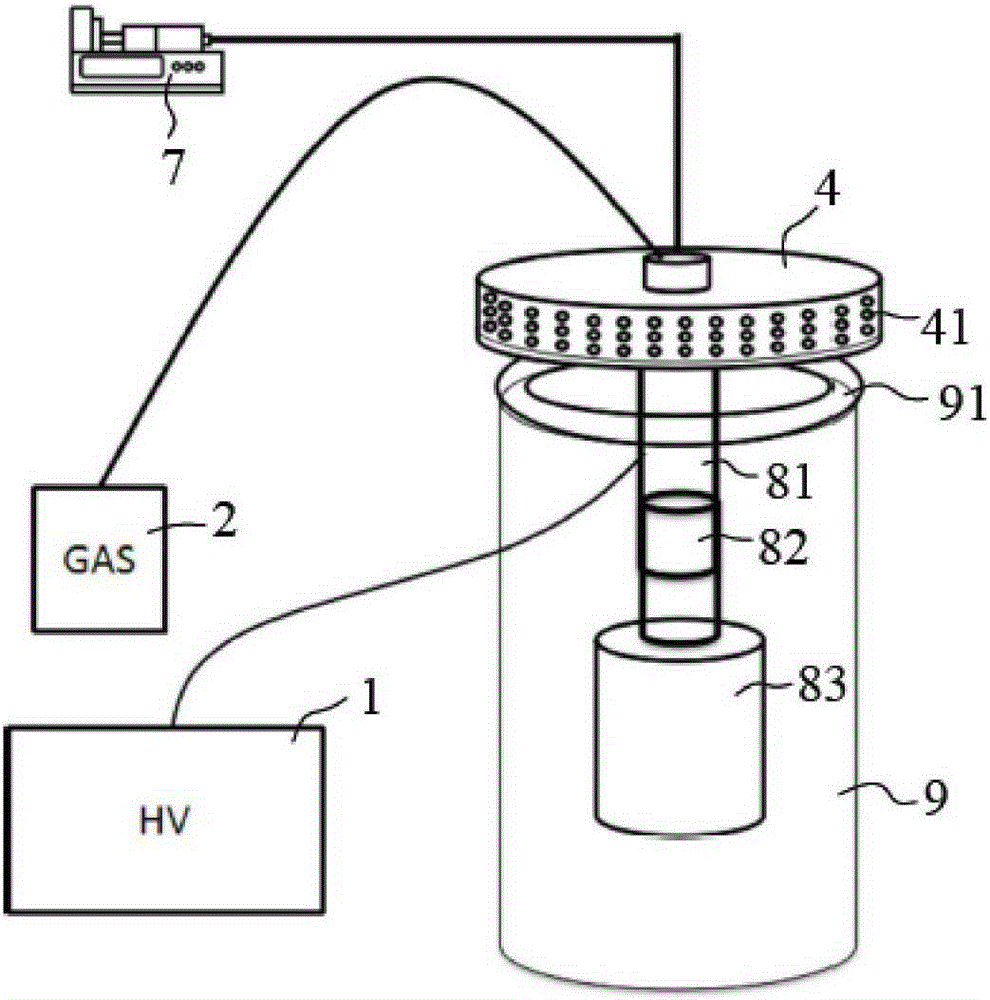

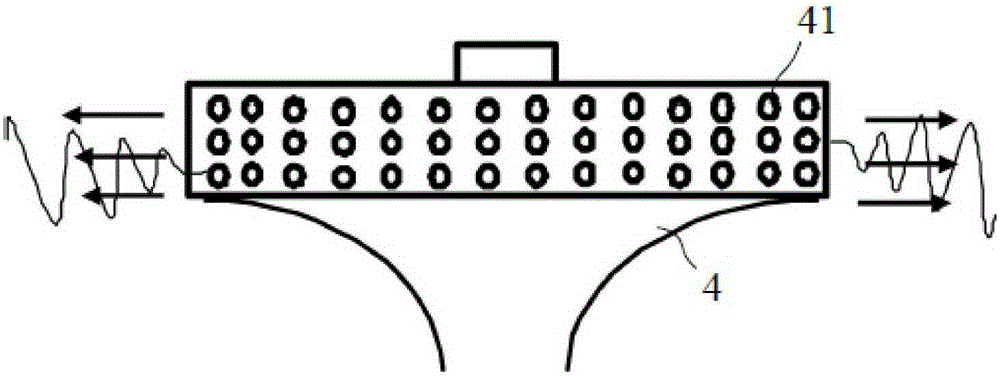

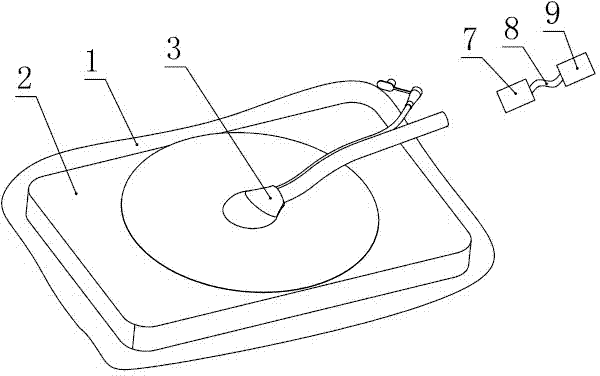

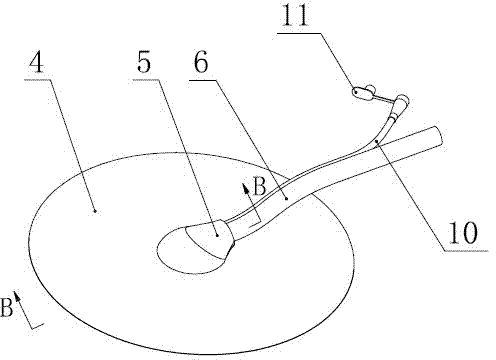

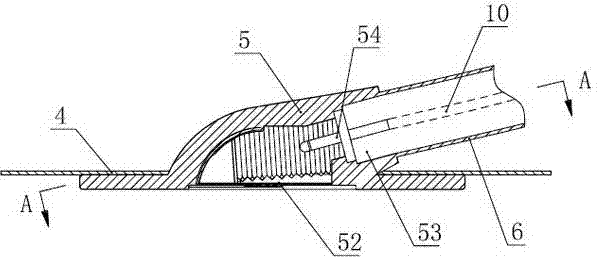

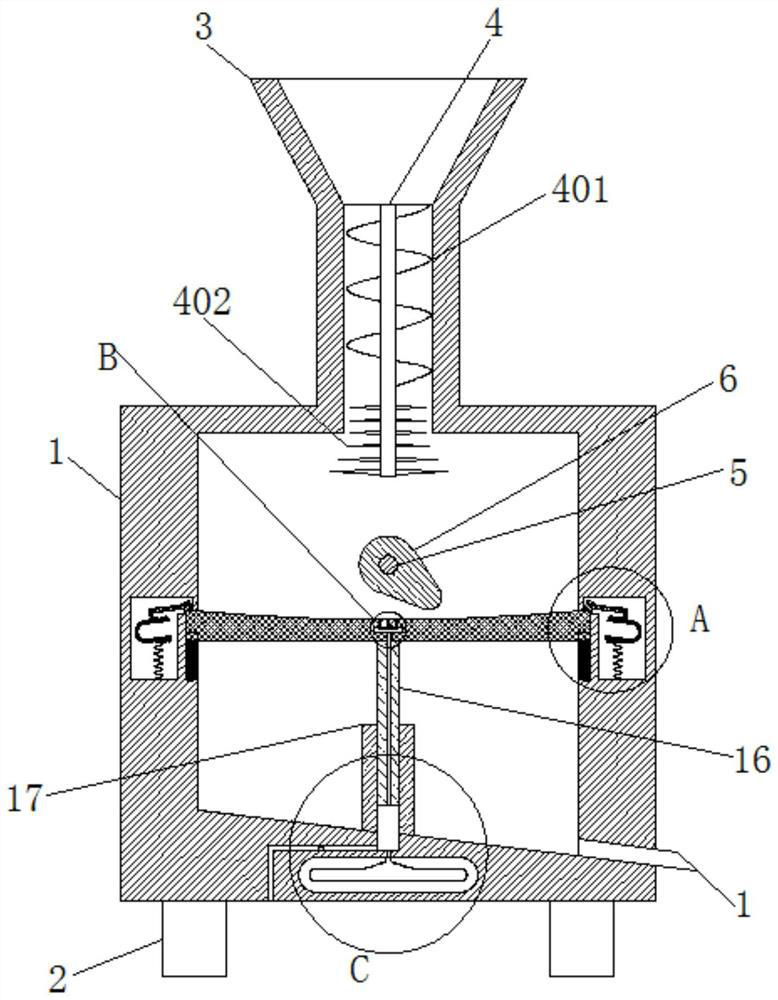

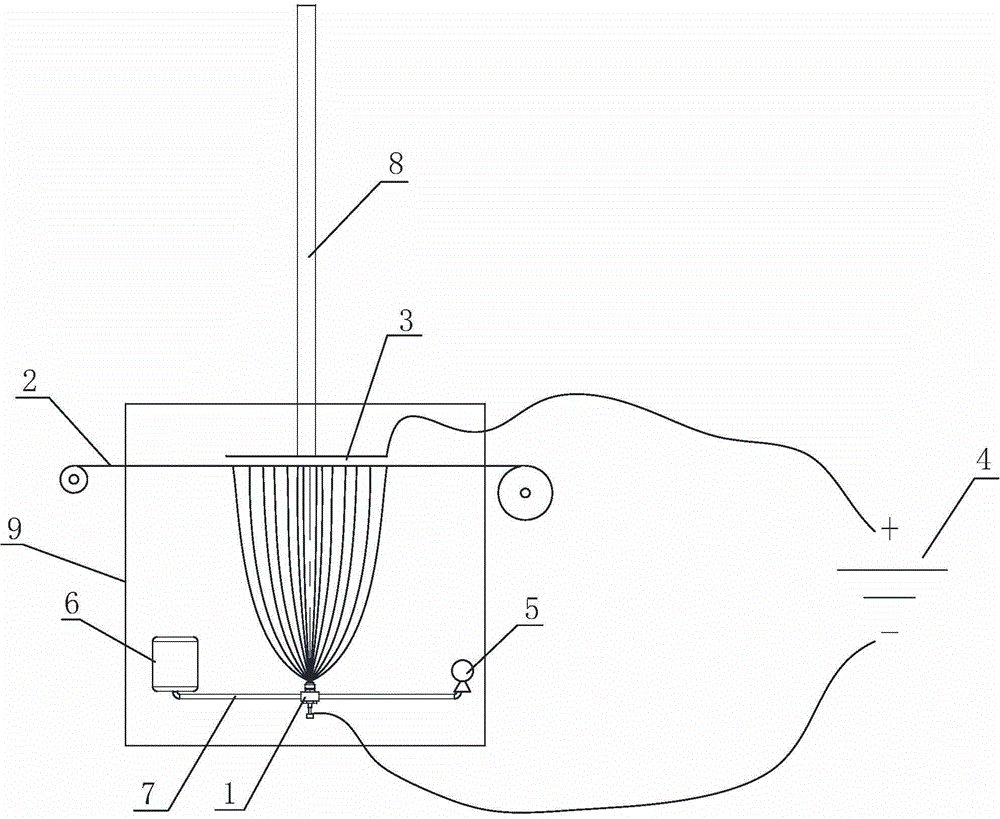

Umbrella-shaped electrostatic spinning sprayer and electrostatic spinning method

ActiveCN103088443AOvercoming easy blockageOvercome efficiencySpinnerette packsFilament/thread formingNumerical controlFiber

The invention relates to an umbrella-shaped electrostatic spinning sprayer and an electrostatic spinning method. The sprayer comprises an umbrella-shaped spinning nozzle, a numerical control type infusion device and a solution collecting groove, wherein the numerical control type infusion device mainly comprises a solution propeller and a controller; the middle of the umbrella-shaped spinning nozzle is provided with a cylindrical hollow portion, and an output end of the solution propeller is placed into the cylindrical hollow portion of the umbrella-shaped spinning nozzle; the controller controls flow velocity and flow of spinning solutions; and the solution collecting groove is placed in the bottom of the umbrella-shaped spinning nozzle. The electrostatic spinning method comprises that a binding post on the umbrella-shaped spinning nozzle is connected with a high-voltage positive electrode, conducting polymer solutions are continuously added to the umbrella-shaped spinning nozzle which is horizontally placed through the numerical control type infusion device, electrostatic spinning is started, collection is achieved through a collecting device, and nano-fibers are formed. The sprayer avoids blocking phenomena, and is easy to clean and good in stability; and the electrostatic spinning method improves production efficiency and the yield of electrostatic spinning.

Owner:DONGHUA UNIV

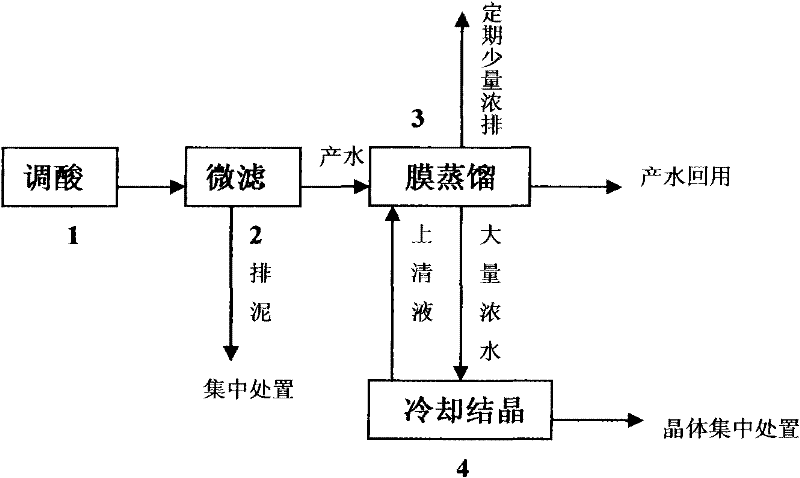

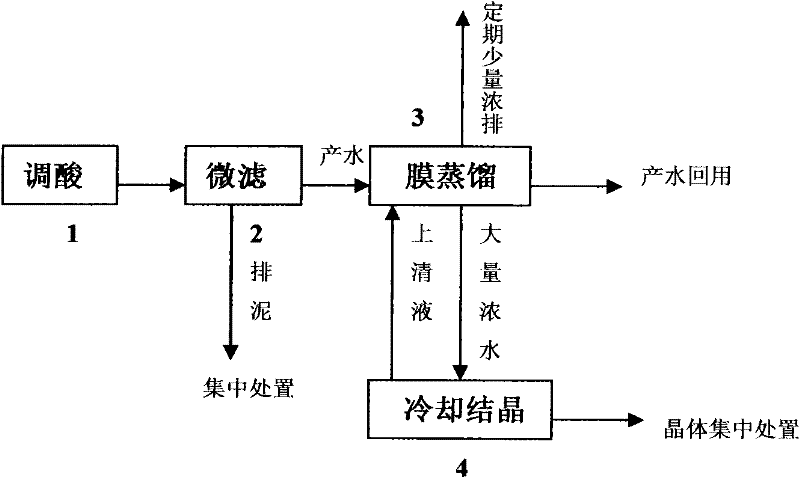

A method for the treatment and reuse of ammonia-nitrogen-containing high-salt catalyst wastewater

ActiveCN102295378ATake advantage of highly concentrated processingHigh salt contentWater contaminantsWater/sewage treatment bu osmosis/dialysisSocial benefitsSeparation technology

The invention relates to a recycling method for treating ammonia nitrogen containing high-salt catalyst wastewater by adopting a membrane separation technology. The process flow of 'acid regulation, micro-filtration, membrane distillation, cooling and crystallization' is adopted in the method. By adopting the process flow, salts, ammonia nitrogen and metal ions in the wastewater can be effectively removed, and deep treatment and recycle of the ammonia nitrogen containing high-salt catalyst wastewater are realized. The process flow makes full use of the technical advantages of membrane distillation, solves the problem that the discharge of high salts, ammonia nitrogen and metal ions of the ammonia nitrogen containing high-salt catalyst wastewater does not reach the standards, and realizes recycle of the produced water. After the ammonia nitrogen containing high-salt catalyst wastewater is treated by the process flow, the reclamation rate of the wastewater is more than 90 percent, and high recycle of the ammonia nitrogen containing high-salt catalyst wastewater is realized; and the method accords with the development strategies of energy conservation and emission reduction, and has remarkable social benefit and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

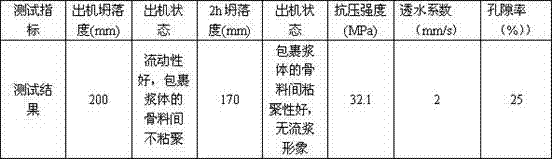

Specialadmixture for pervious concrete and application ofspecialadmixture

The invention discloses a specialadmixture for pervious concrete and application of the specialadmixture. Thespecial admixture comprises the following materials in weight percent: 5 to 15 percent (solid content) of a water reducing agent; 0.1 to 1 percent of a retarder; 0.1 to 1 percent of a thickener; 15 to 25 percent of an early strength agent; 25 to 50 percent of a water-repellent agent; 25 to 50 percent of rubber powder. The admixture overcomes the problem that the existing pervious concrete is not easy to transport bya tanker, and ensures that the phenomenon of blocking cannot occur when the pervious concrete is put into a tanker after the admixture is used, has excellent service behavior after the pervious concrete is discharged from the tanker, and has excellent cohesiveness, without phenomena of bottom sealing and hole blocking.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

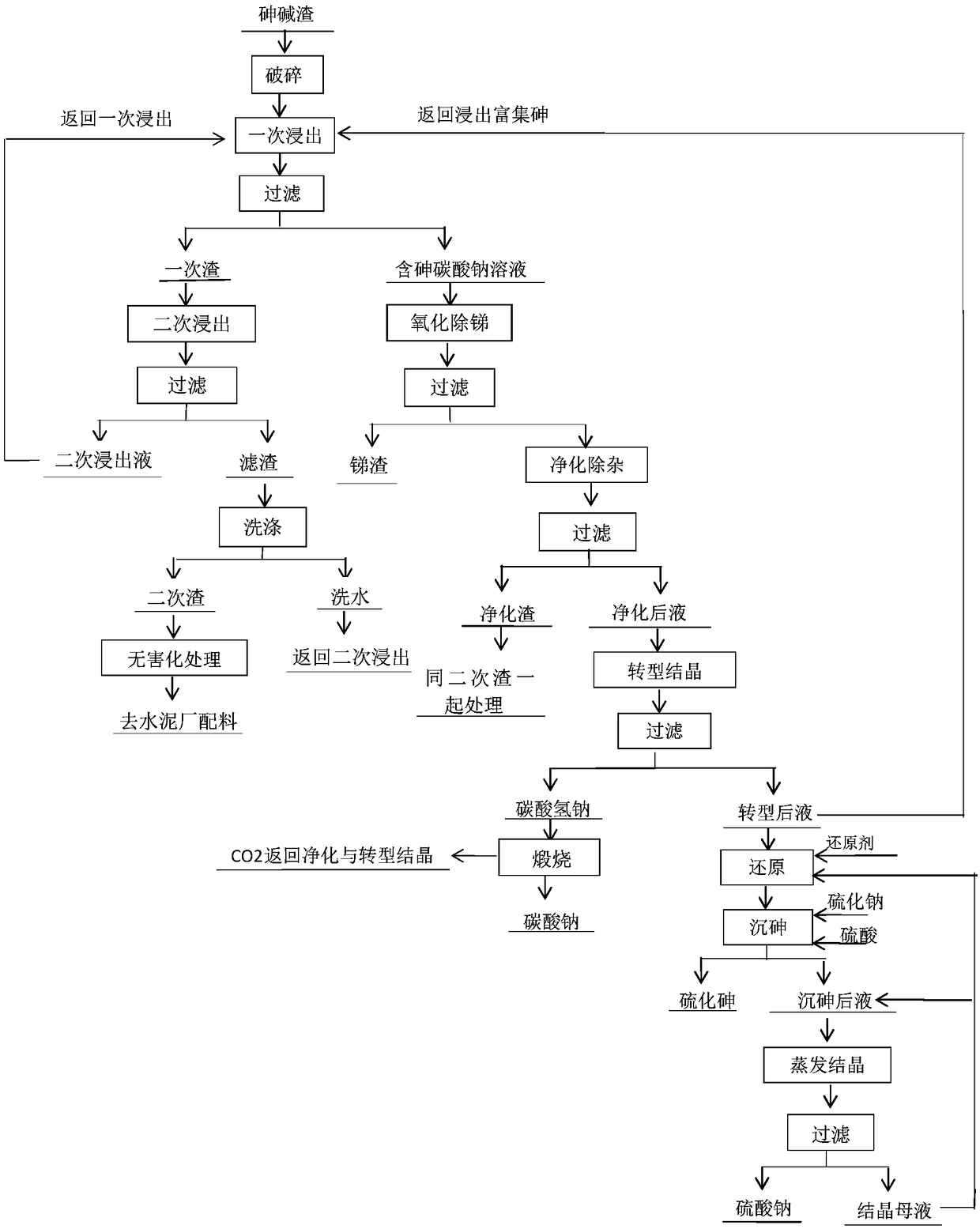

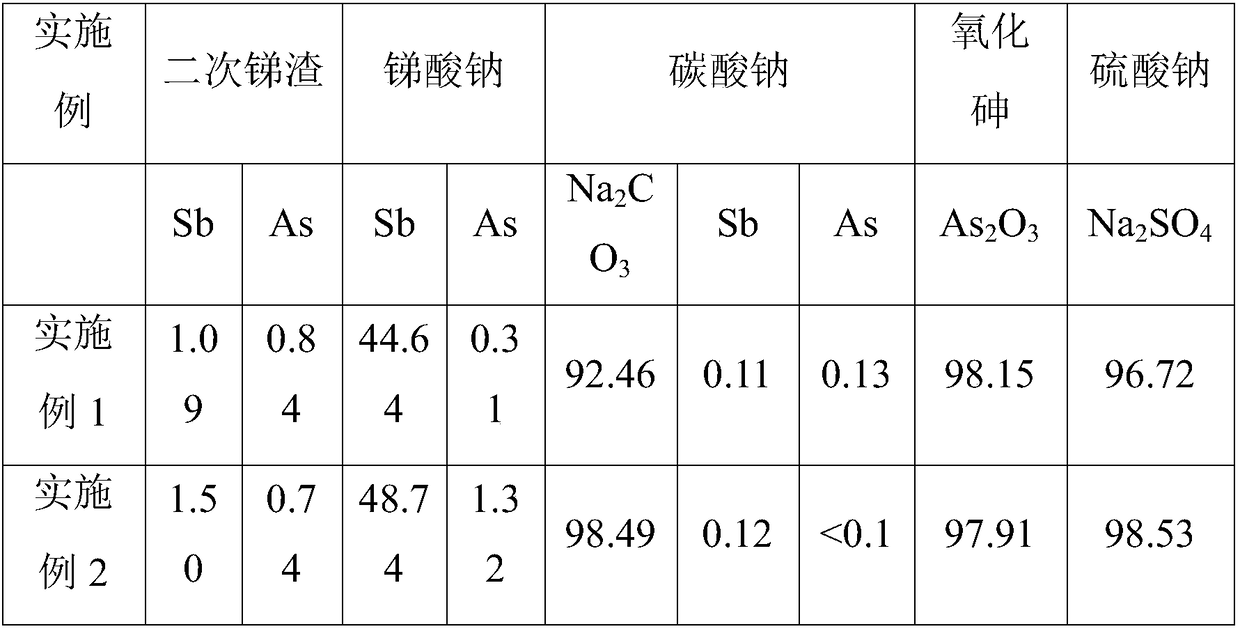

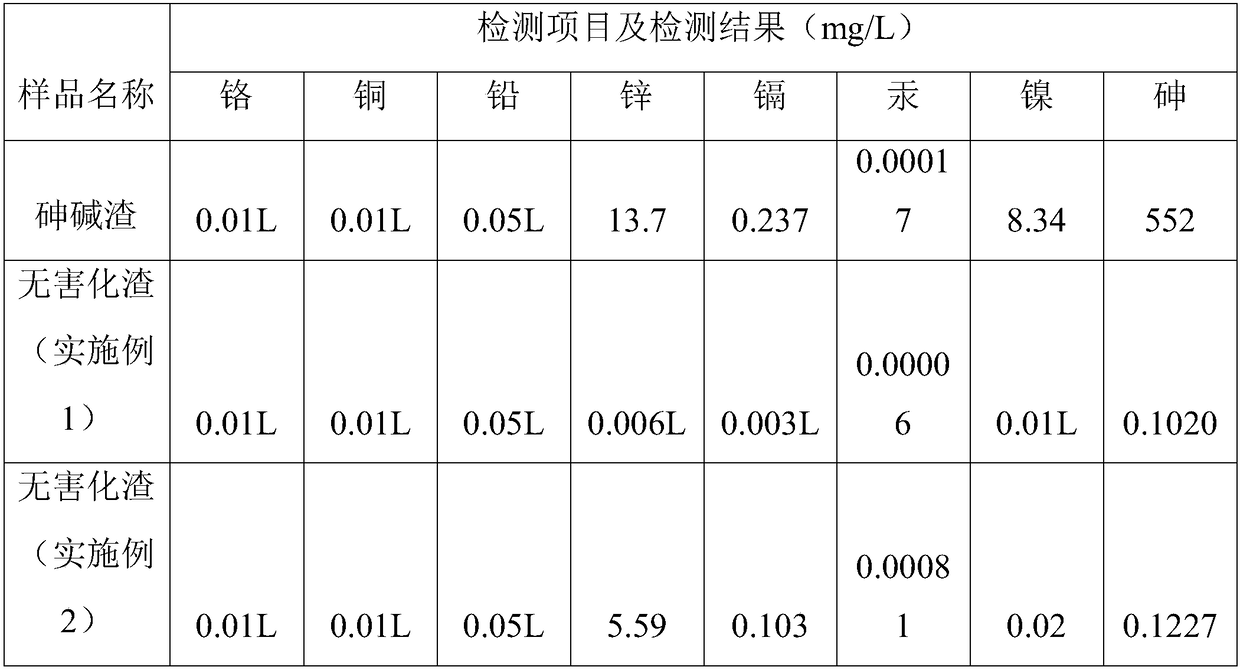

Wet-method recycling and harmless treatment process for antimony smelting arsenic alkali residue

PendingCN108441642ARealize green and clean cycle productionHigh recovery rateSolid waste disposalAlkali metal sulfite/sulfate purificationWastewaterImpurity

The invention belongs to the field of antimony smelting arsenic alkali residue treatment and particularly discloses a wet-method recycling and harmless treatment process for antimony smelting arsenicalkali residue. The process adopts a whole-wet-method treatment process and mainly comprises the eight working procedures of breaking, dissolving for leaching, oxidation for antimony outlet, purification for impurity removing, transition for crystallizing, reduction for arsenic sinking, evaporative crystallization and secondary residue harmless treatment. Recycling and harmless treatment of the arsenic alkali residue, zero emission of waste residue and waste water and up-to-standard discharge of exhaust gas are thoroughly achieved, the long-term plagued arsenic alkali residue environmental pollution problem in the antimony smelting industry in China is thoroughly solved, and the environmental risk caused by stacking the arsenic alkali residue is eliminated; and meanwhile, separation, enrichment and effective recovering of valuable elements are achieved.

Owner:CHENZHOU YANGTAO CHEM

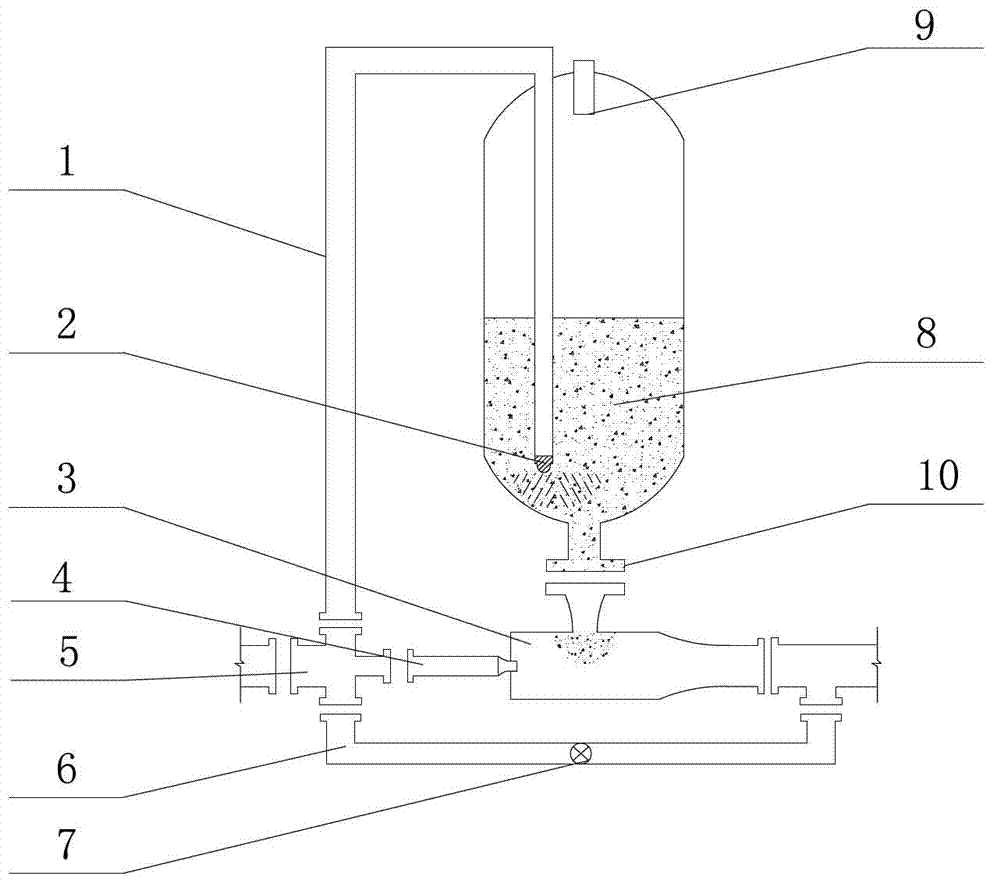

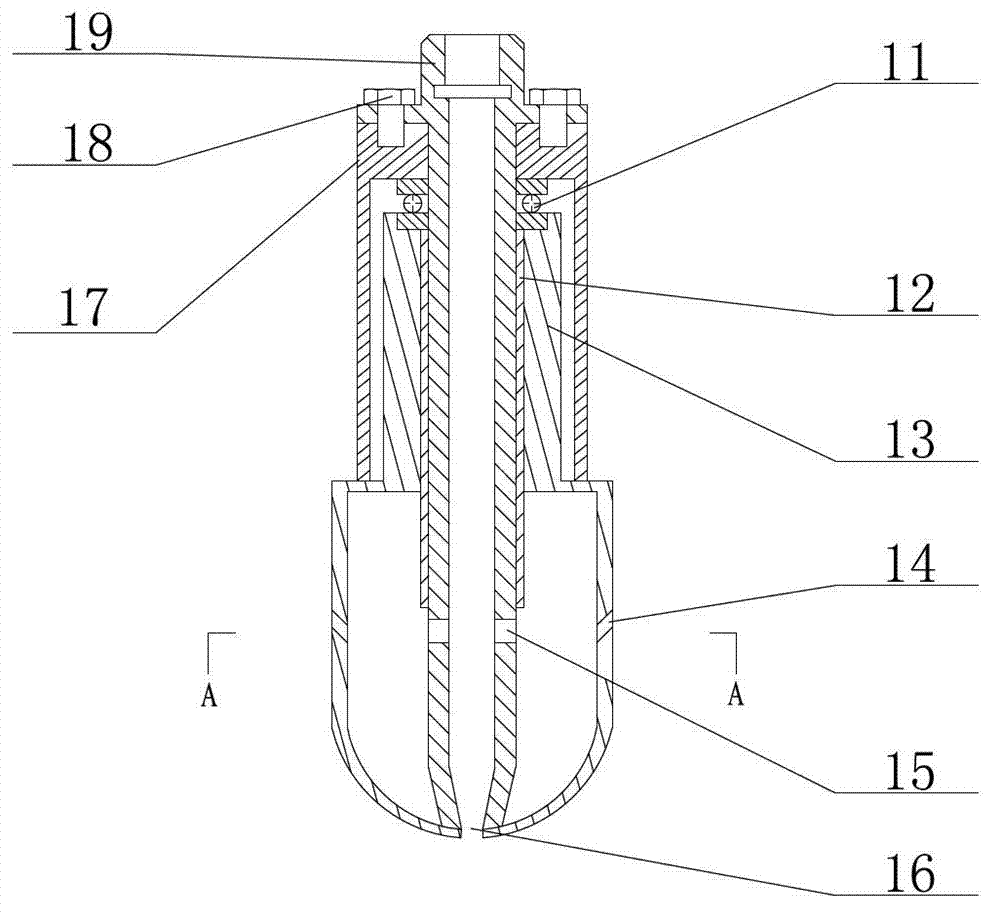

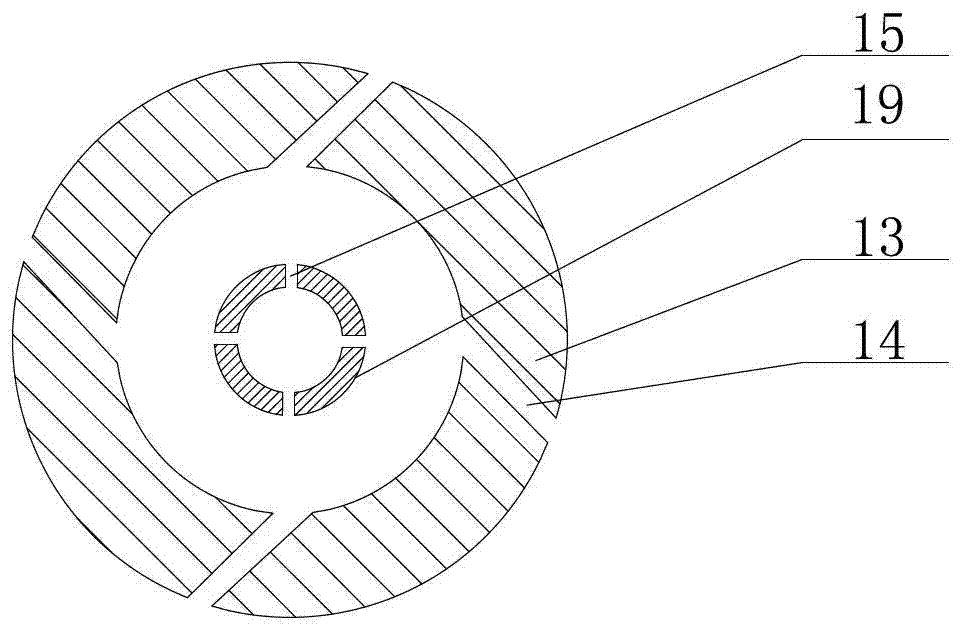

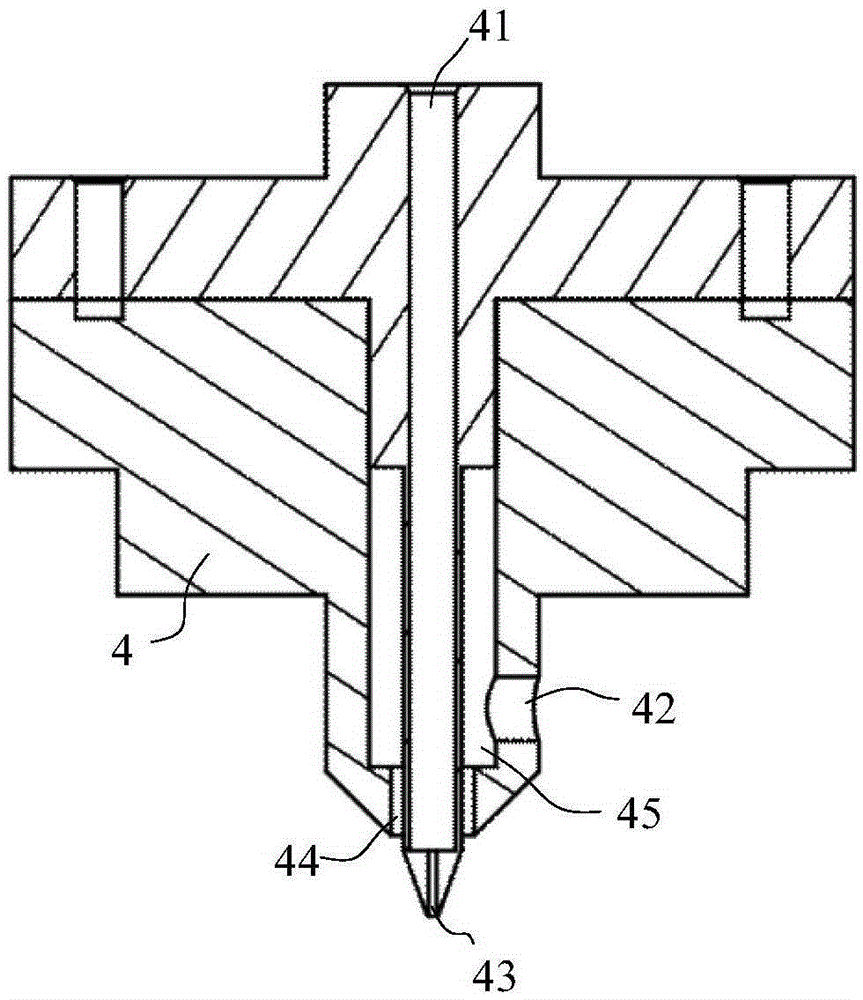

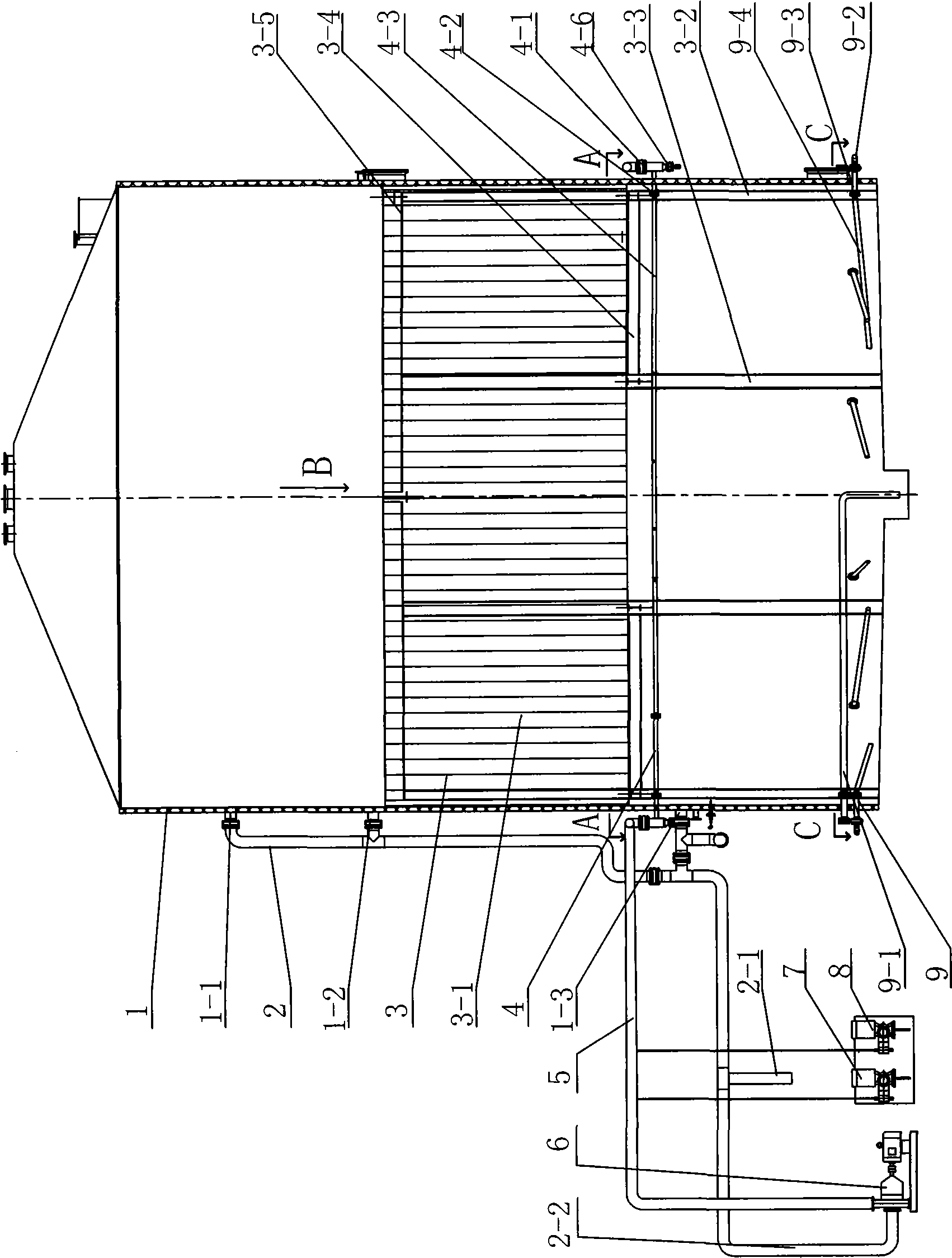

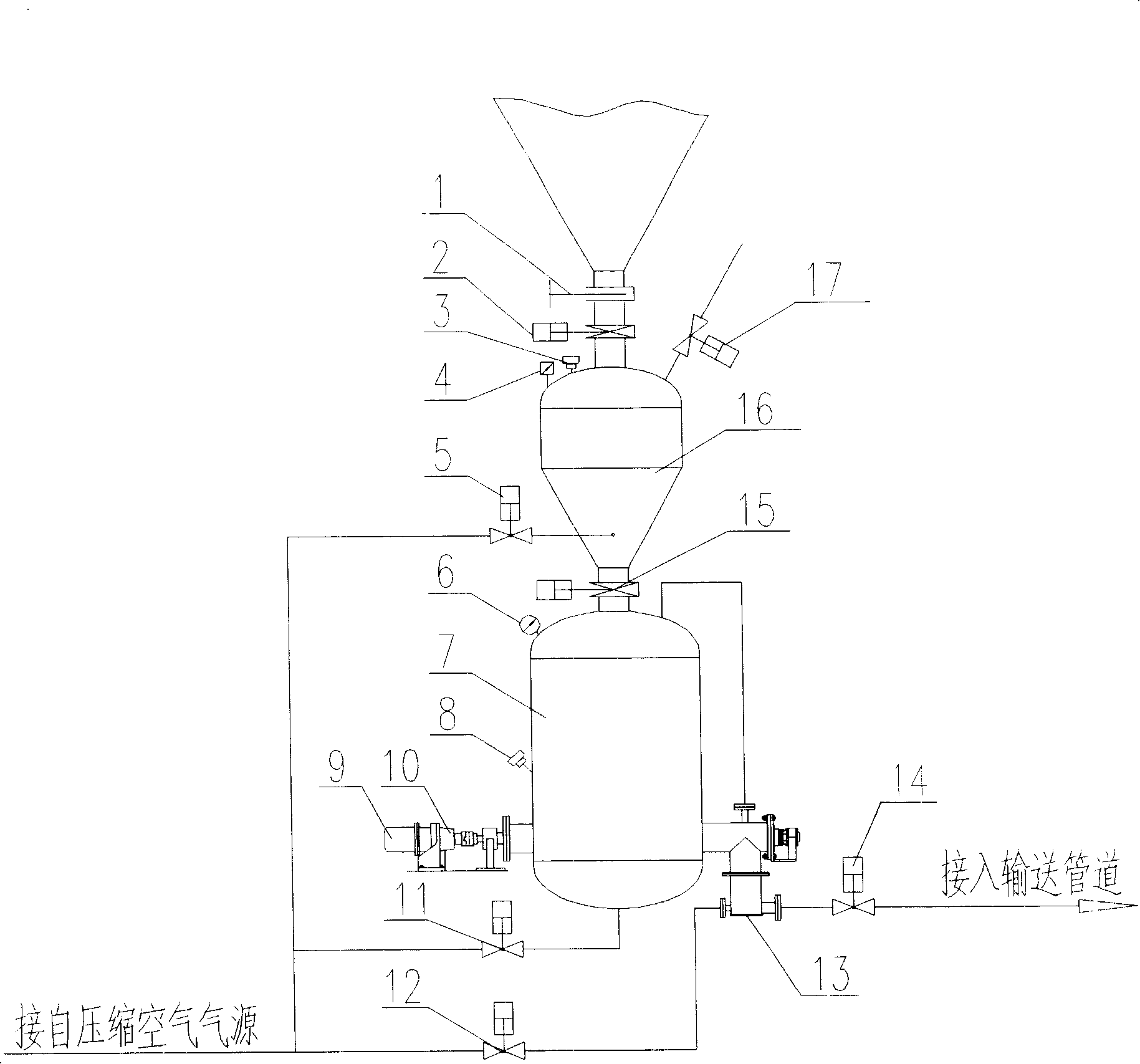

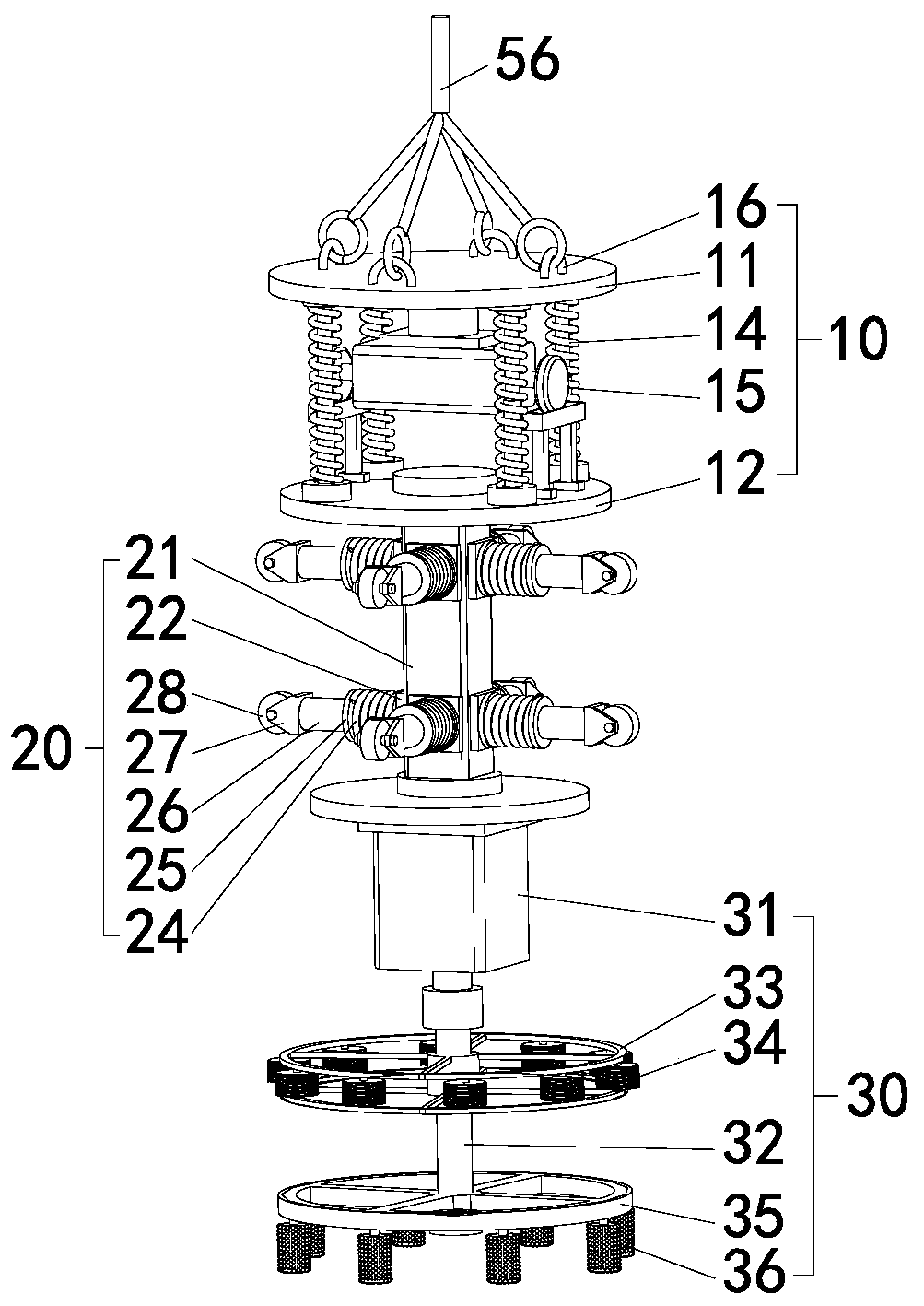

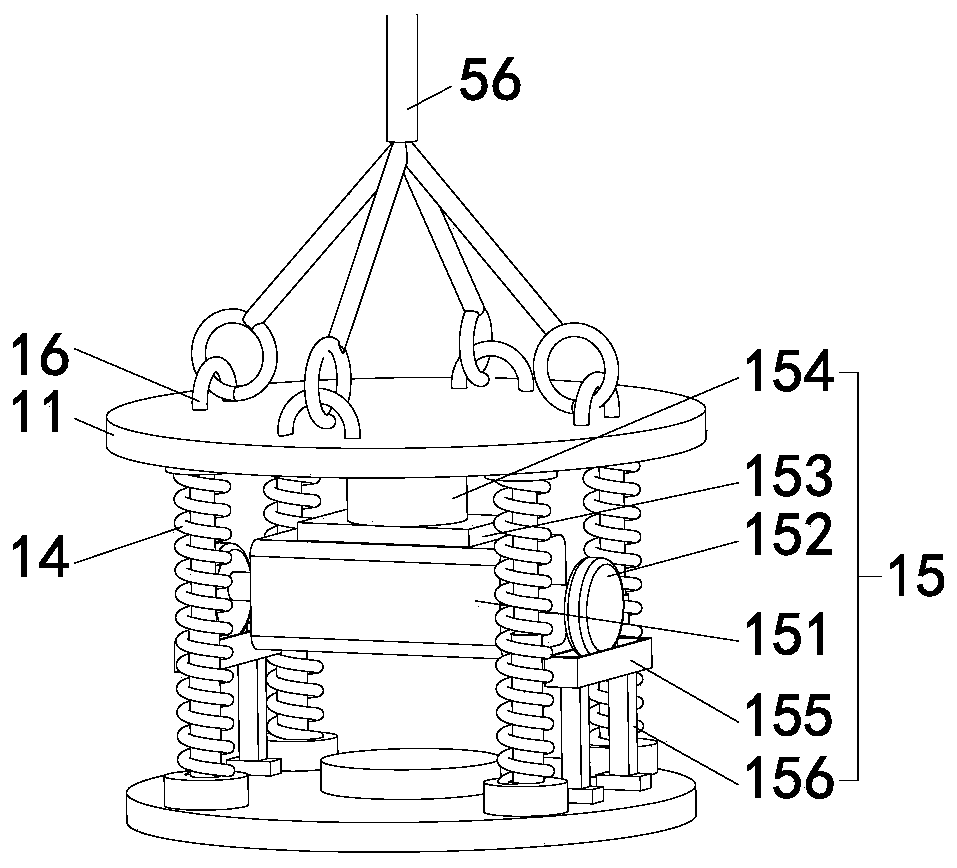

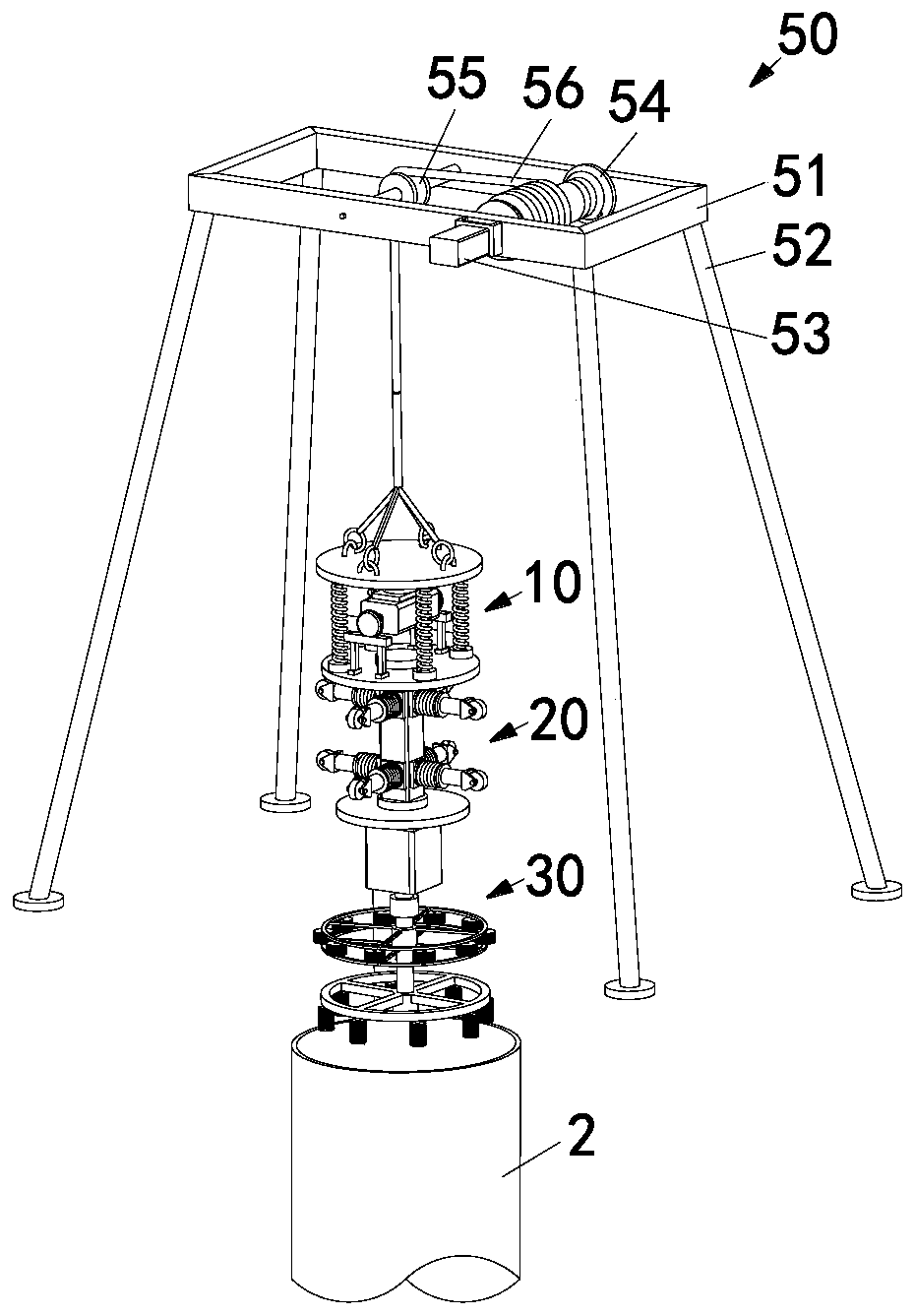

Negative-pressure jet-type particle impact drilling injection device

InactiveCN103195363AGood effectSolve easy blockageSpray nozzlesDrilling machines and methodsPetroleumHigh pressure

The invention belongs to the technical field of petroleum drilling engineering and particularly relates to a negative-pressure jet-type particle impact drilling injection device. A balanced-pressure jet pipe is installed on one side of a material inlet at the top of a high-pressure particle injection tank, a jet anti-blocking sprayer is arranged at one end of the balanced-pressure jet pipe, the other end of the balanced-pressure jet pipe is arranged at the top of a main pipe manifold, the jet anti-blocking sprayer is arranged at the bottom of the high-pressure particle injection tank, a negative-pressure particle injection pipe is arranged at the bottom of a material outlet, a nozzle is arranged at one end of the negative-pressure particle injection pipe and communicated with the main pipe manifold, a regulating pipe is arranged at the bottom of the main pipe manifold, the tail end of the regulating pipe is communicated with an outlet of the negative-pressure particle injection pipe, and a regulating valve is arranged in the regulating pipe. The negative-pressure jet-type particle impact drilling injection device adopts the self-rotating type jet anti-blocking sprayer, achieves omnibearing and multi-angle stirring on the material outlet of the high-pressure particle injection tank, is easy, convenient and safe to operate, serves as one of three core systems of the particle impact drilling new technology, and is simple in processing and manufacturing, convenient to detach, stable in performance and capable of remarkably improving the drilling speed of extra-hard wear-resisting stratum of deep well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

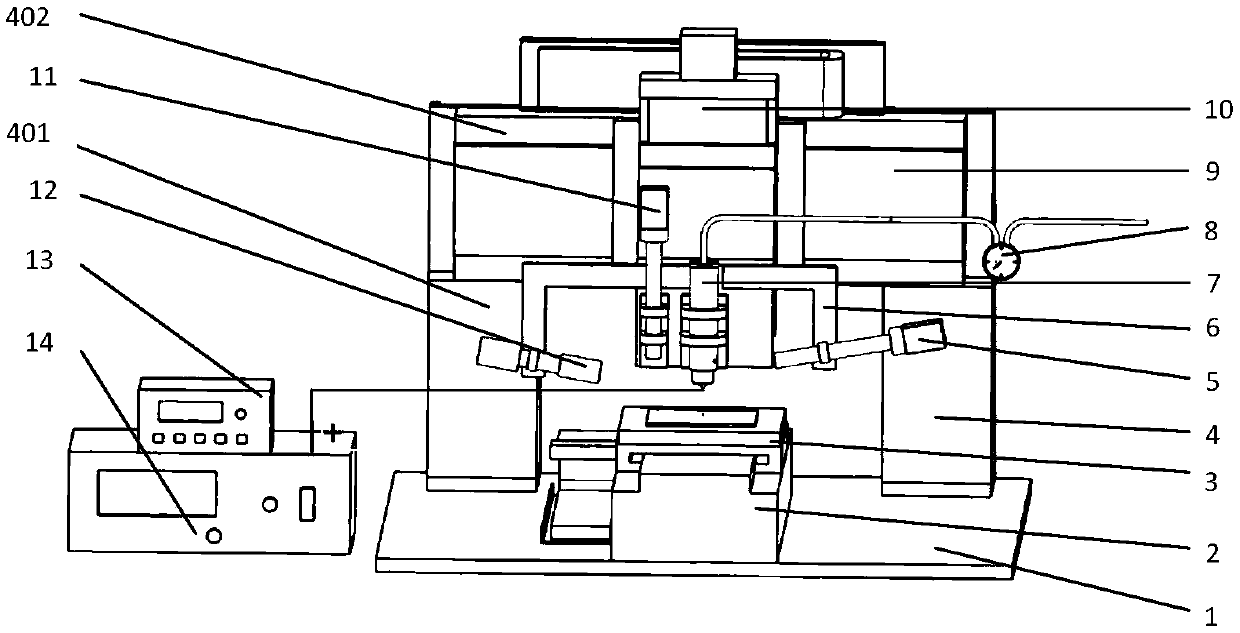

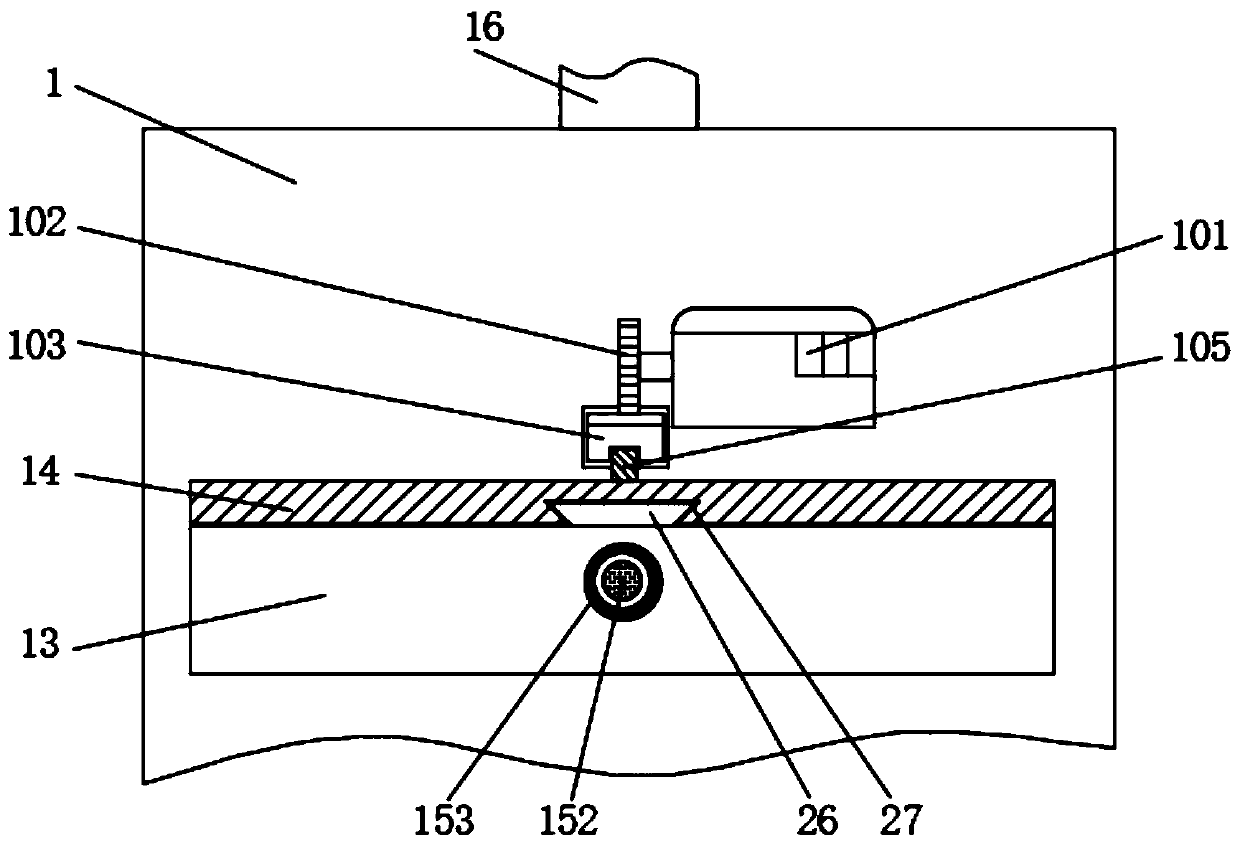

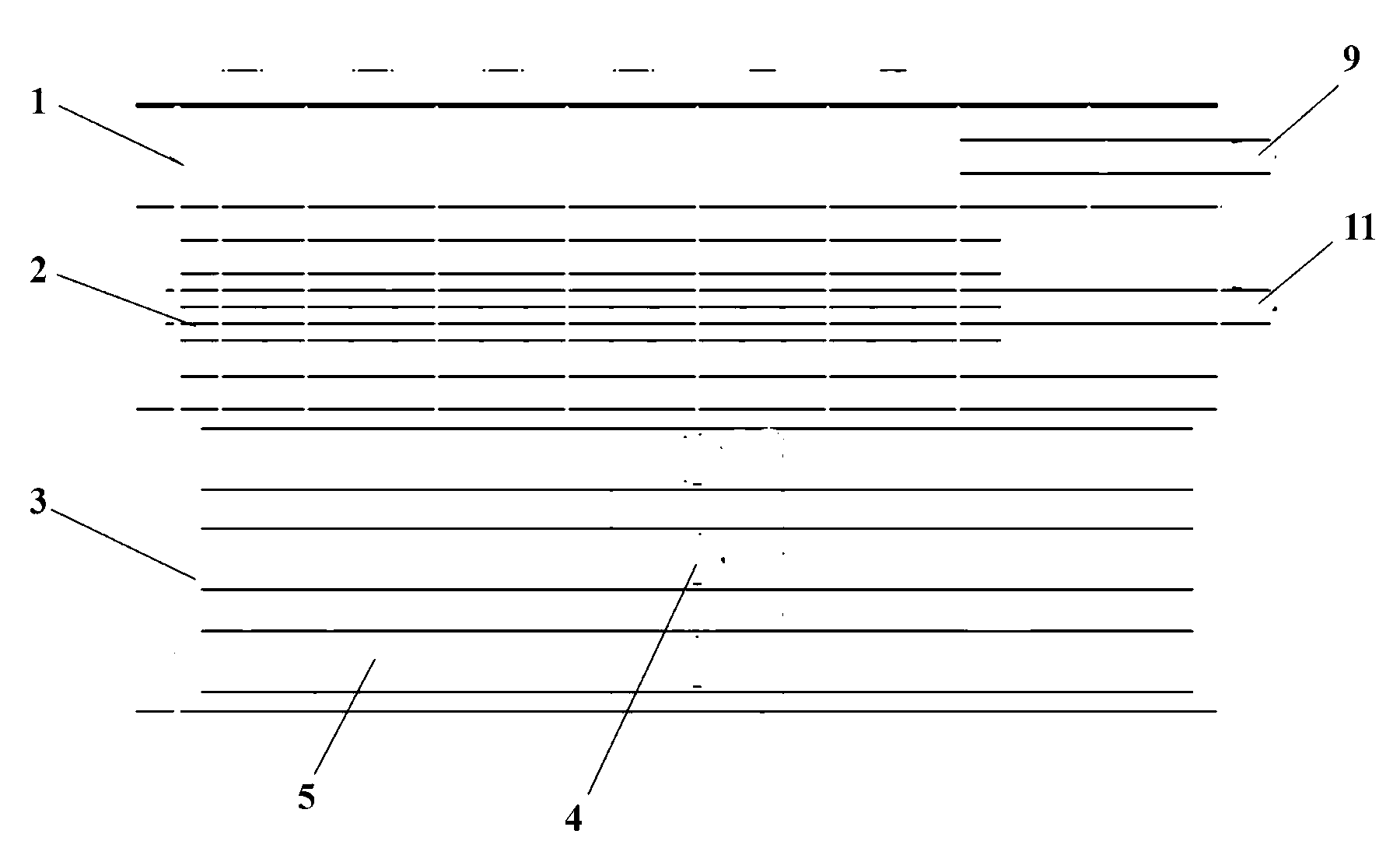

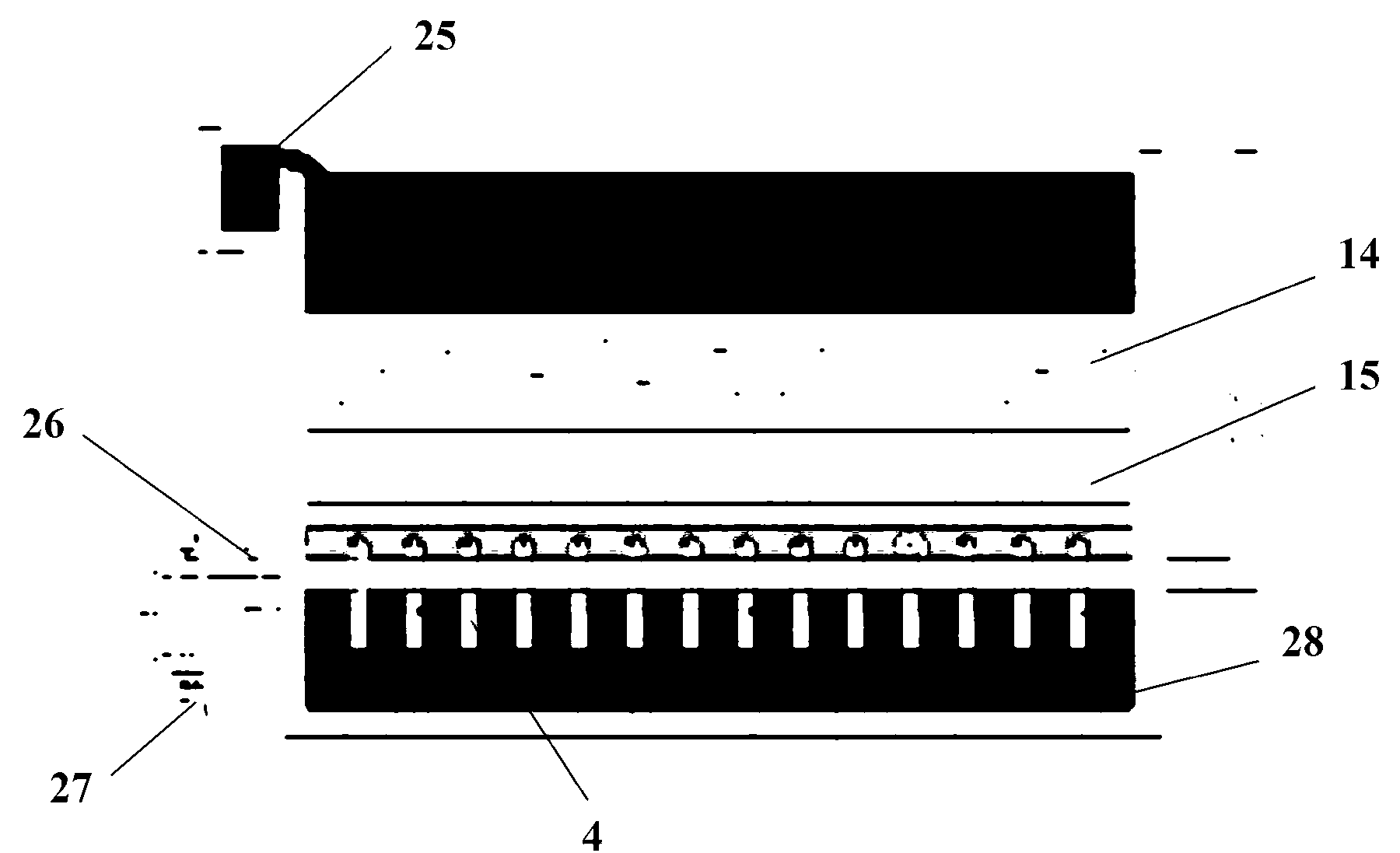

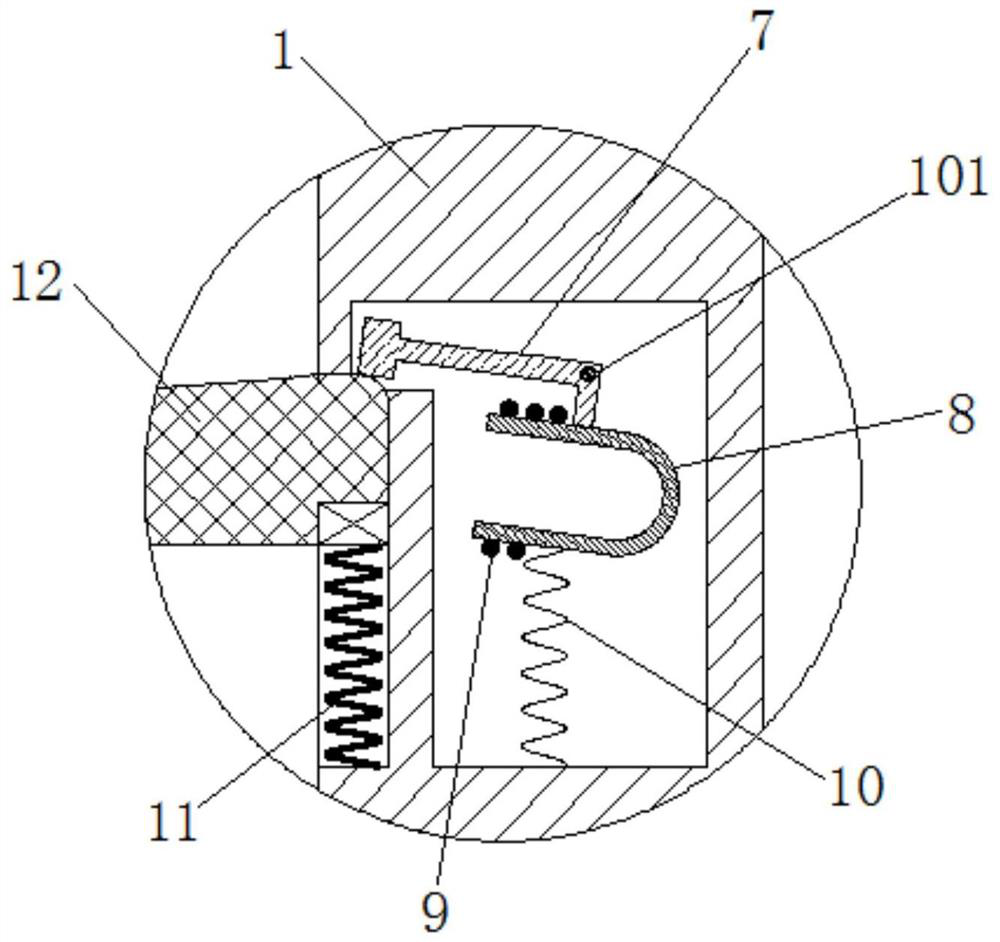

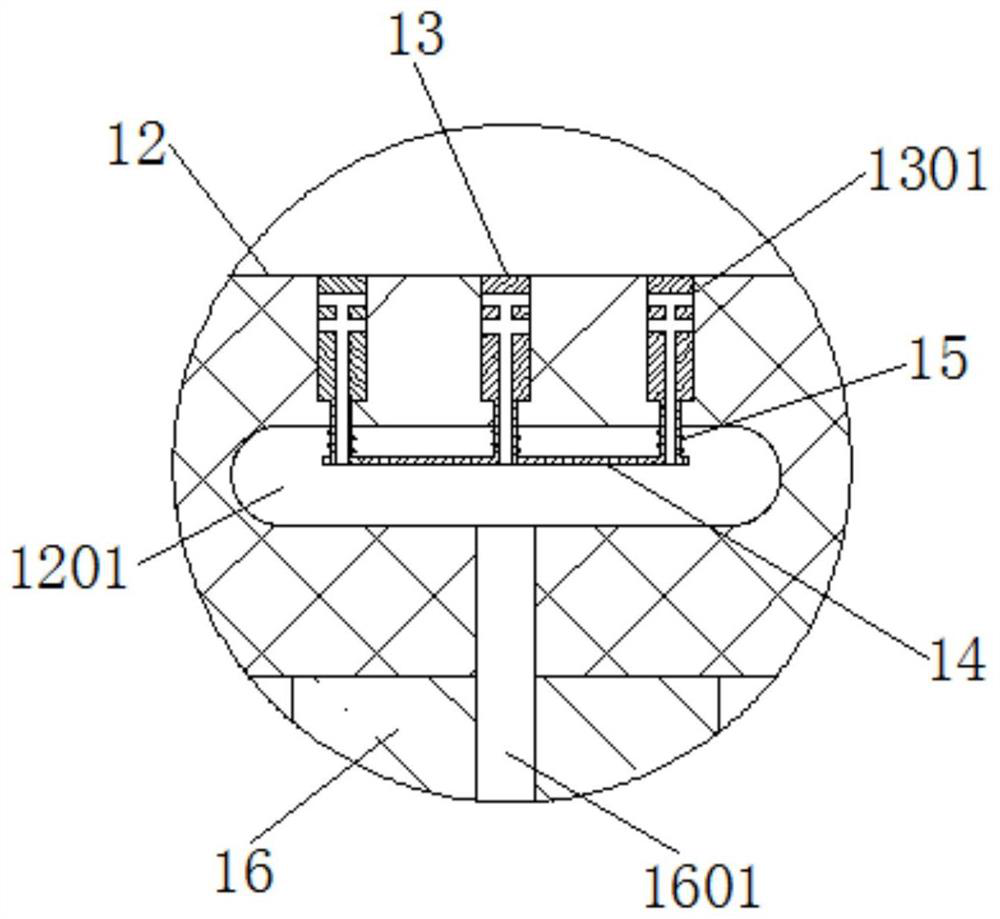

Electric field driven fusion spraying deposition 3D printer and working method thereof

PendingCN107932898ASolve easy blockageRealize real-time monitoringManufacturing platforms/substratesManufacturing heating elementsSpray nozzleElectric field

The invention discloses an electric field driven fusion spraying deposition 3D printer and a working method thereof. By means of the electric field driven fusion spraying deposition 3D printer and theworking method thereof, the fusion deposition 3D printing resolution is low, printing materials are limited, sprayers are likely to be blocked, and high-resolution and micro-scale structure printingis difficult. A novel sprayer structure is introduced to the electric field driven fusion spraying deposition 3D printer, and low-cost and high-resolution fusion deposition forming is achieved. According to the technical scheme, the electric field driven fusion spraying deposition 3D printer comprises a bottom plate, a Y-axis workbench is arranged on the bottom plate, a printing platform is fixedto the Y-axis workbench, a sprayer module and a vertical observing camera are correspondingly arranged above the printing platform, the sprayer module and the vertical observing camera are connected to a Z-axis workbench, and the Z-axis workbench is fixed to an X-axis workbench; and a squinting observing camera is correspondingly arranged on one side of a printing nozzle, and an LED light source is correspondingly arranged on the other side of the printing nozzle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

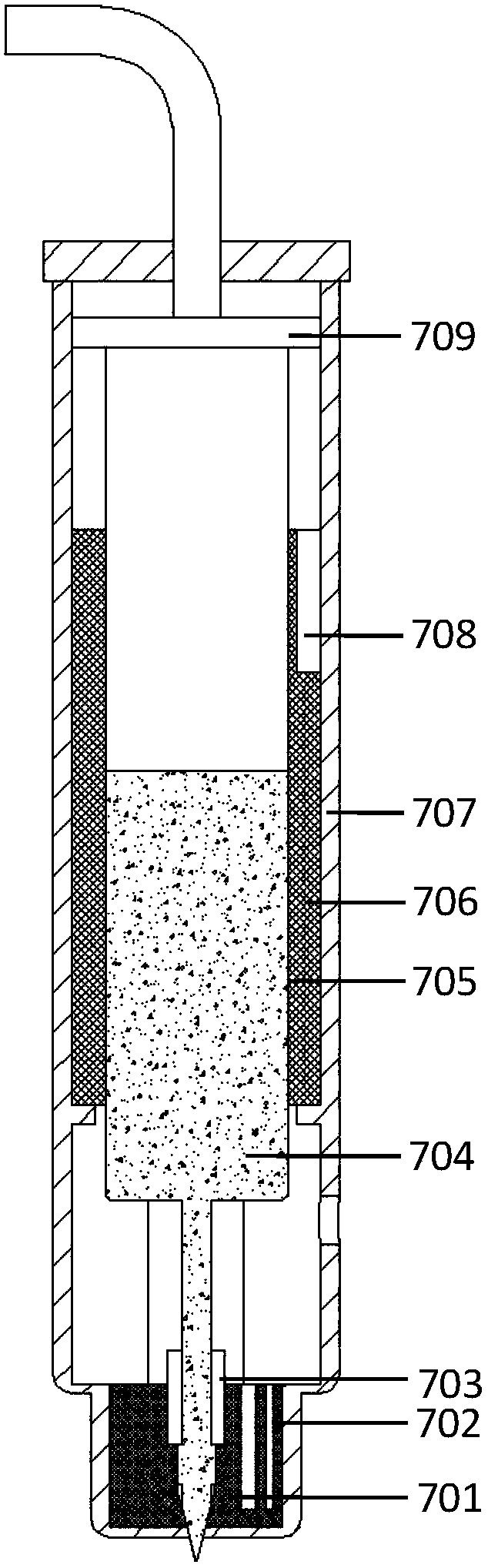

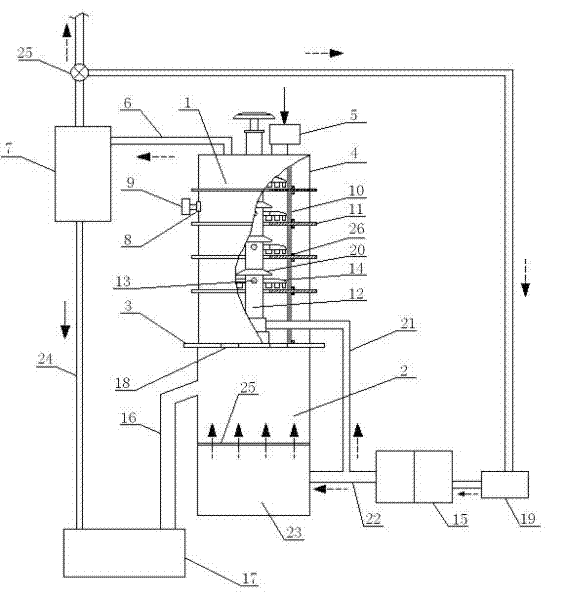

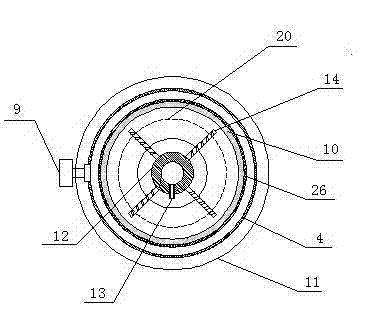

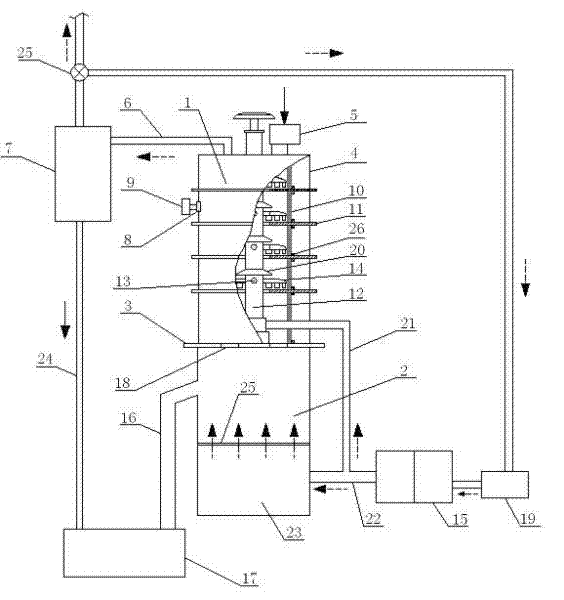

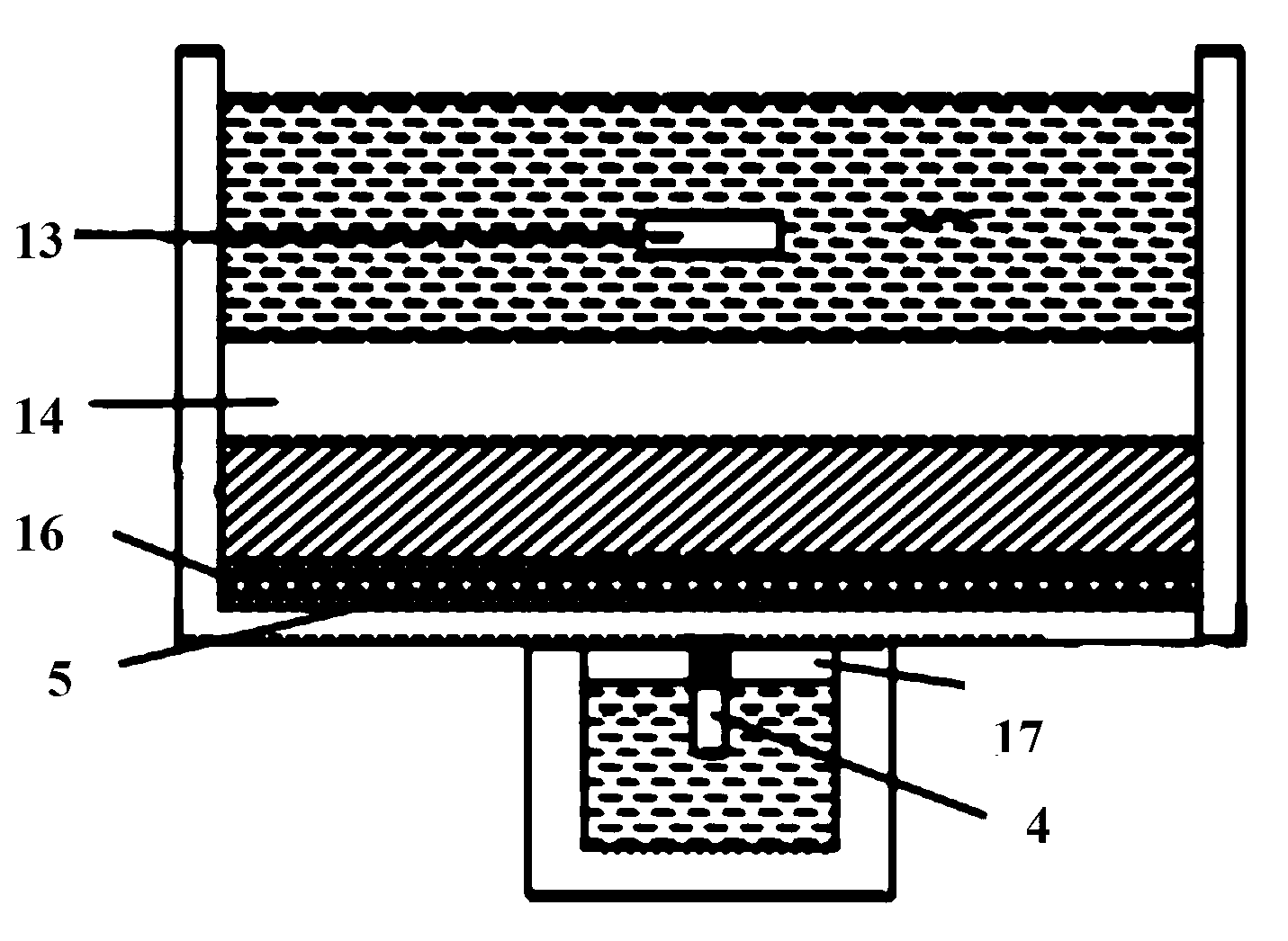

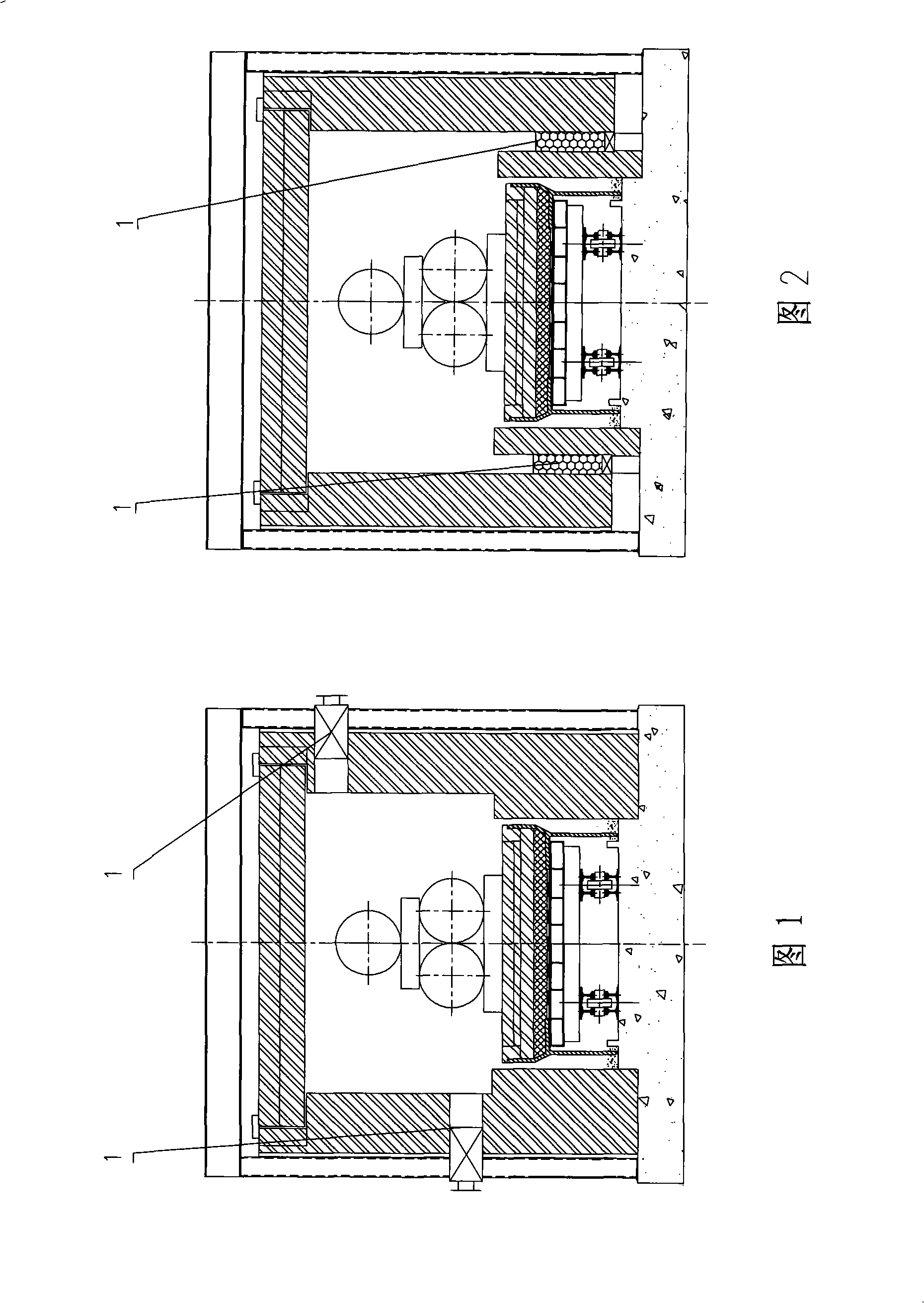

RH vacuum refining bottom blowing powder injection device

ActiveCN102560009ASolve easy blockageImprove product qualityCharge manipulationMetallurgyWater circulation

The invention relates to an RH vacuum refining bottom blowing powder injection device. The device comprises a driving gas system, a vacuum chamber, a steel ladle and a bottom blowing powder injection member, wherein the vacuum chamber is formed above the steel ladle; the driving gas system comprises a driving gas channel and an air compressor connected with the driving gas channel; an ascending pipe and a descending pipe are arranged at the bottom of the vacuum chamber and stretch into molten steel; the driving gas channel is communicated with the ascending pipe; the bottom blowing powder injection member comprises a powder injection element and a gas storage chamber; a steel sleeve is sleeved outside the powder injection element; the gas storage chamber is fixed below the powder injection element; a powder gas flow conveying pipe at the port of the gas storage chamber is connected with a powder injection system; a gap is formed on the powder injection element; one or two bottom blowing powder injection members are arranged at the bottom of the steel ladle; the distance between the bottom blowing powder injection member and the center of the bottom of the steel ladle is 0 to 0.9 time the radius of the bottom of the steel ladle; and the powder injection element penetrates through the bottom of the steel ladle. The device enhances a stirring effect and improves the quality of steel by combining vacuum refining, molten steel circular flow and bottom blowing powder injection refining.

Owner:NORTHEASTERN UNIV

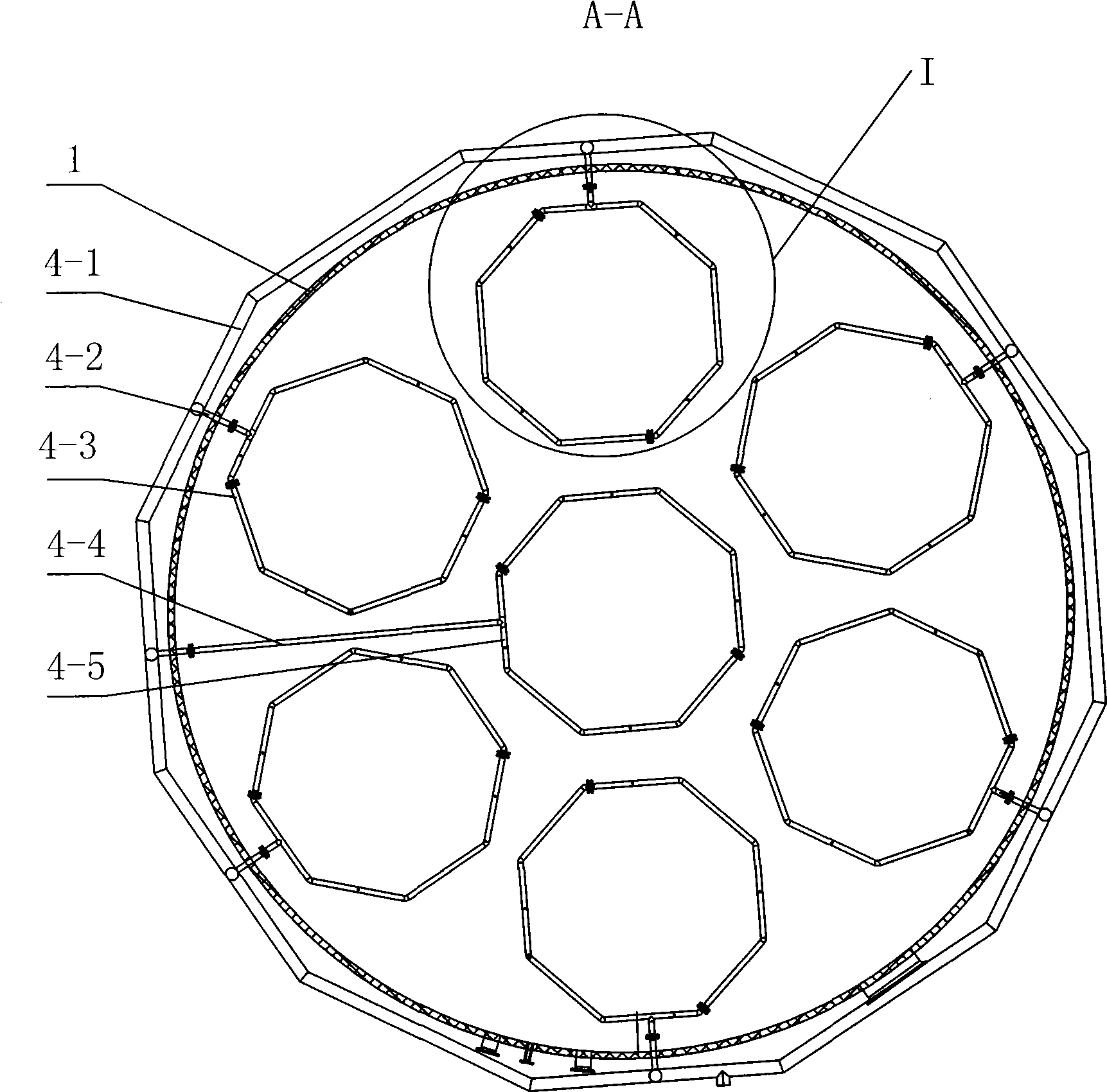

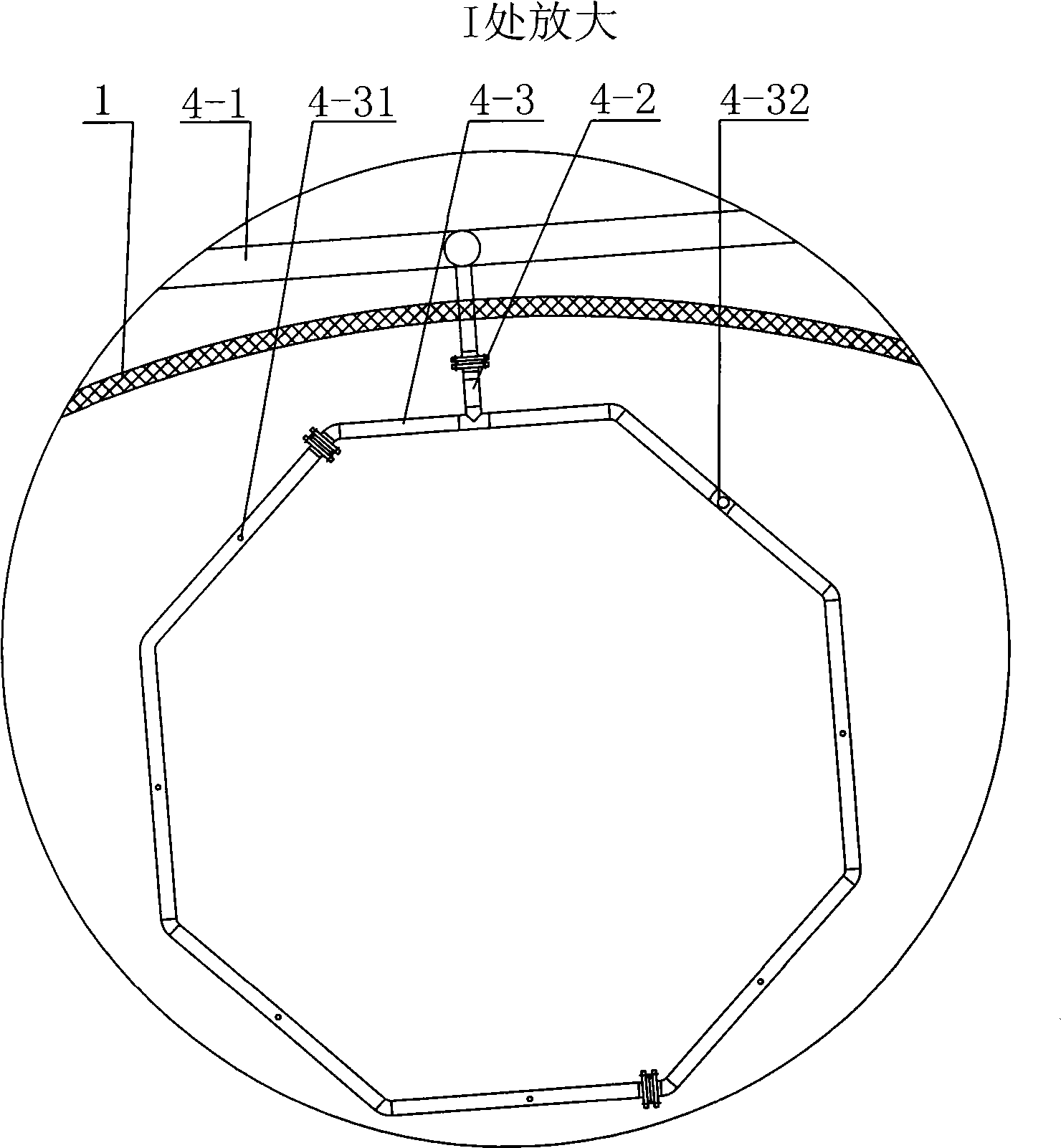

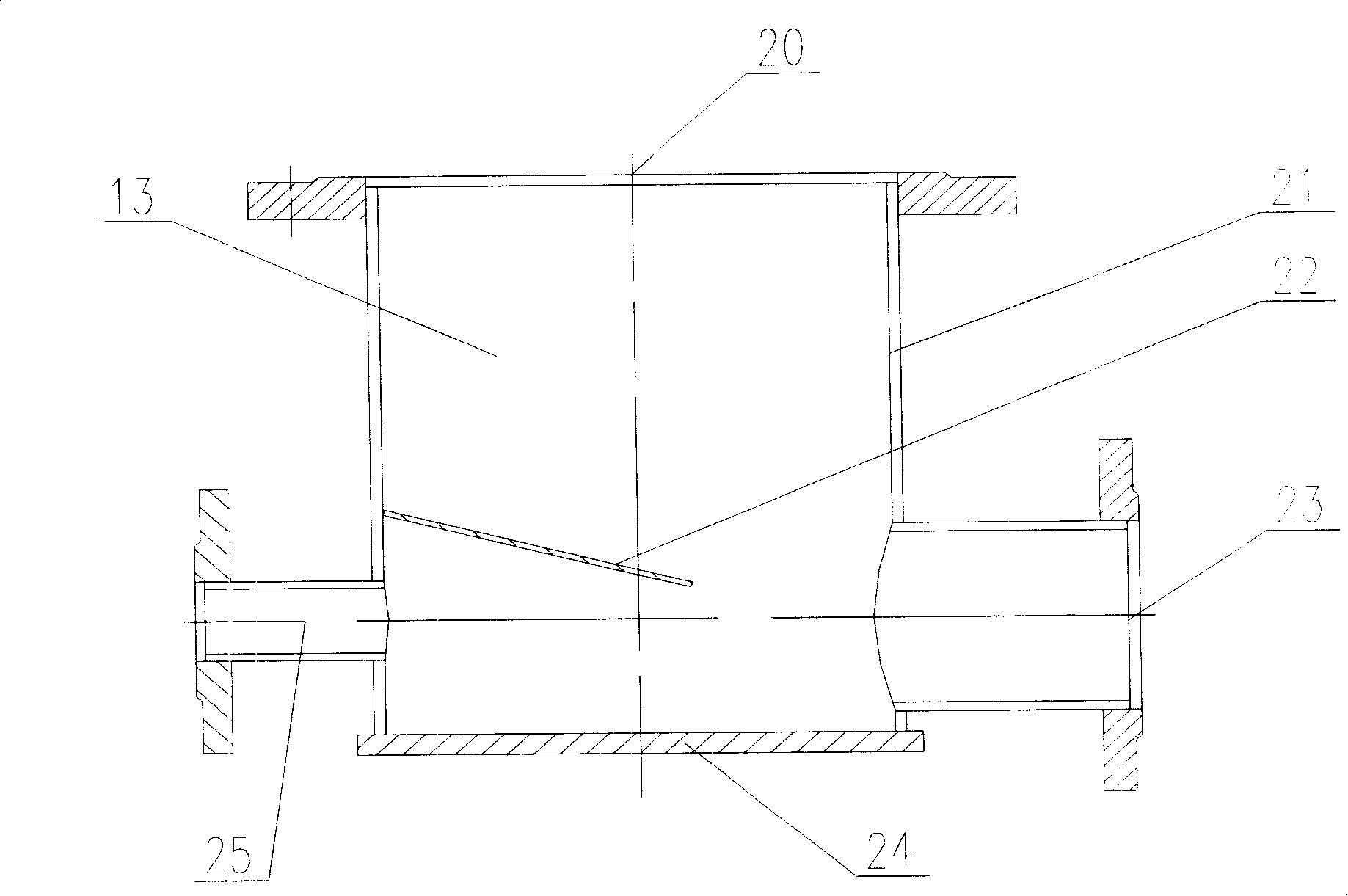

A device for microwave fluidized drying lignite

InactiveCN102261822ALow drying temperatureImprove energy utilizationDrying solid materials with heatHearth type furnacesEngineeringMicrowave

The invention discloses a device for drying lignite by microwave fluidization. The device comprises a microwave heating chamber and a fluidized bed, wherein the fluidized bed is arranged at the bottom of the microwave heating chamber and communicated with the microwave heating chamber; the microwave heating chamber comprises a metal furnace shell capable of shielding microwaves, a material inlet and a smoke gas exhaust port are arranged at the top of the furnace shell, at least one microwave generation device is arranged on the side surface of the furnace shell, a cylindrical ceramic furnace tube through which microwaves can penetrate is further arranged in the furnace shell, a plurality of layers of annular metal baffle plates are arranged along the inner wall of the ceramic furnace tubefrom top to bottom, a rotating shaft is arranged at the center of the ceramic furnace tube, a plurality of rake-shaped structural members which correspond to the metal baffle plates respectively are fixedly arranged on the rotating shaft along the axial direction, and a tapered material guide disc is fixedly arranged on each rake-shaped structural member; and the fluidized bed is in vertical structure, an air chamber of the fluidized bed is connected with a hot air furnace through a first hot air inlet pipe and an overflow pipe connected with a finished product warehouse is arranged at the upper part of the fluidized bed. By adopting the device, the large-scale, fast, low-energy-consumption and deep-drying production of the lignite can be realized.

Owner:KEDA INDUSTRIAL GROUP CO LTD

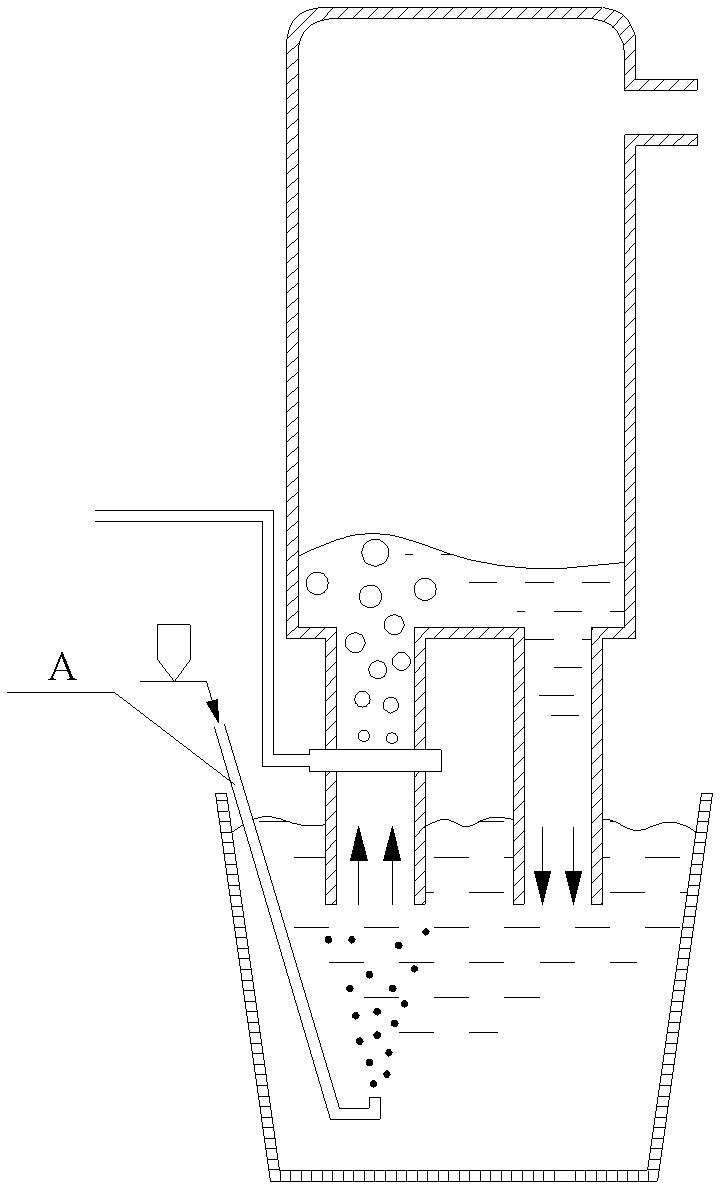

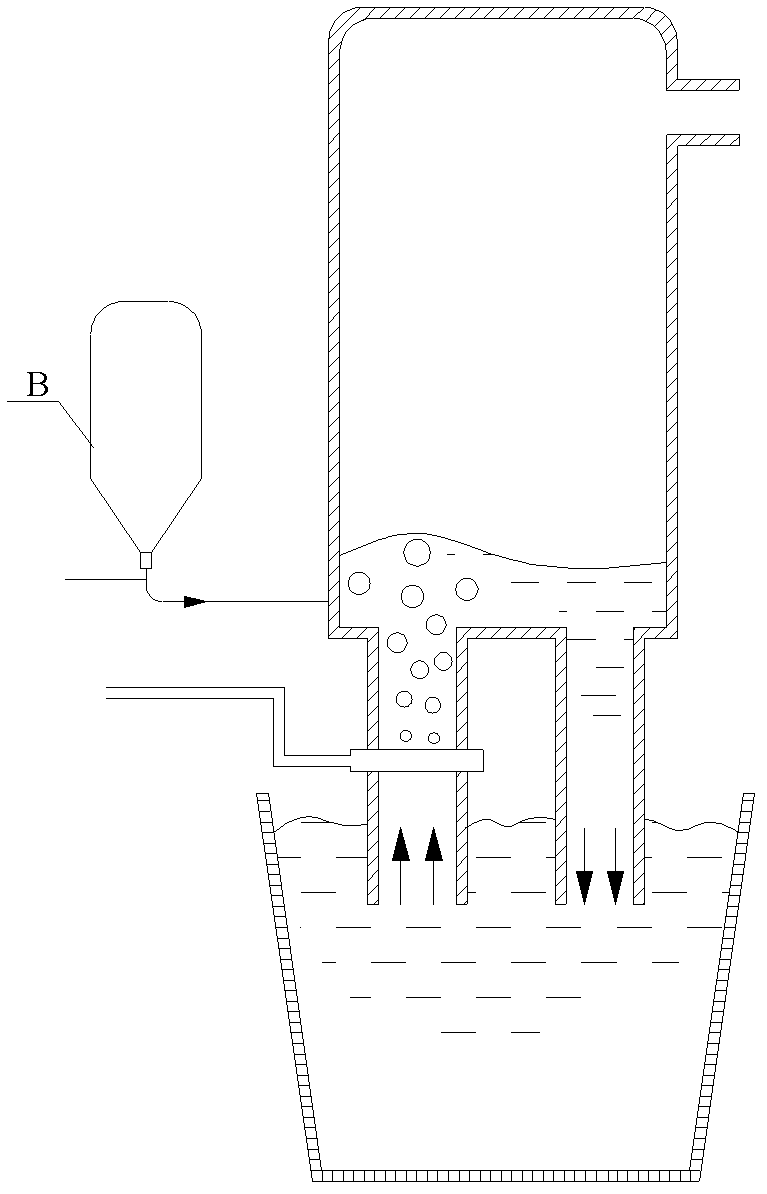

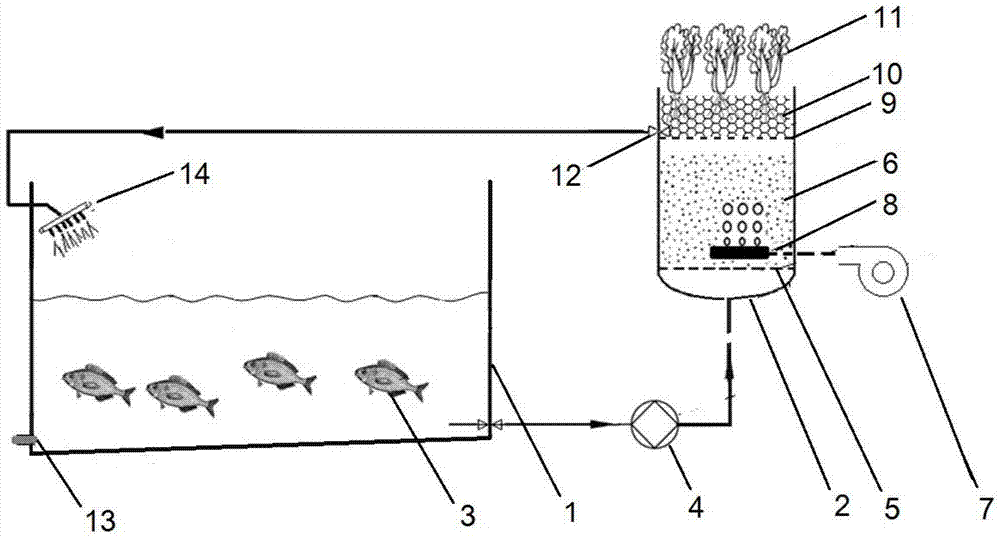

Construction and running method of plant microbial fluidized bed enhanced fish-vegetable symbiotic system

ActiveCN104705227ASolve easy blockageImprove processing efficiencyClimate change adaptationAgricultural fishingWater deliveryZero emission

The invention relates to a construction and running method of a plant microbial fluidized bed enhanced fish-vegetable symbiotic system. The construction and running method comprises the following steps: excavating a fish pond, constructing a plant microbial fluidized bed and arranging a water delivery system and aeration systems. The fish pond is excavated in natural earth or is constructed through concrete pouring, the bottom of the fish pond is a slope surface, the plant microbial fluidized bed consists of a fluidized bed and a water culture bed, the fluidized bed part is positioned at the lower part of the plant microbial fluidized bed and is filled with fluidized filler for purifying fish farming wastewater; the water culture bed is positioned at the upper part of the plant microbial fluidized bed, matrix and a floating bed are used for fixing plant so as to culturing hydroponic plant; the two parts are separated through a slit type bearing layer; the water delivery system consists of a water pump and a water delivery pipeline and is used for communicating the fish pond and the plant microbial fluidized bed together; and an aeration system is arranged in each of the fish pond and the plant microbial fluidized bed. The constructed fish-vegetable symbiotic system can effectively purify the fish farming wastewater, and by culturing the plant with fish farming waste water, the yield increase and income increase can be realized on the basis of zero emission.

Owner:SHANDONG UNIV

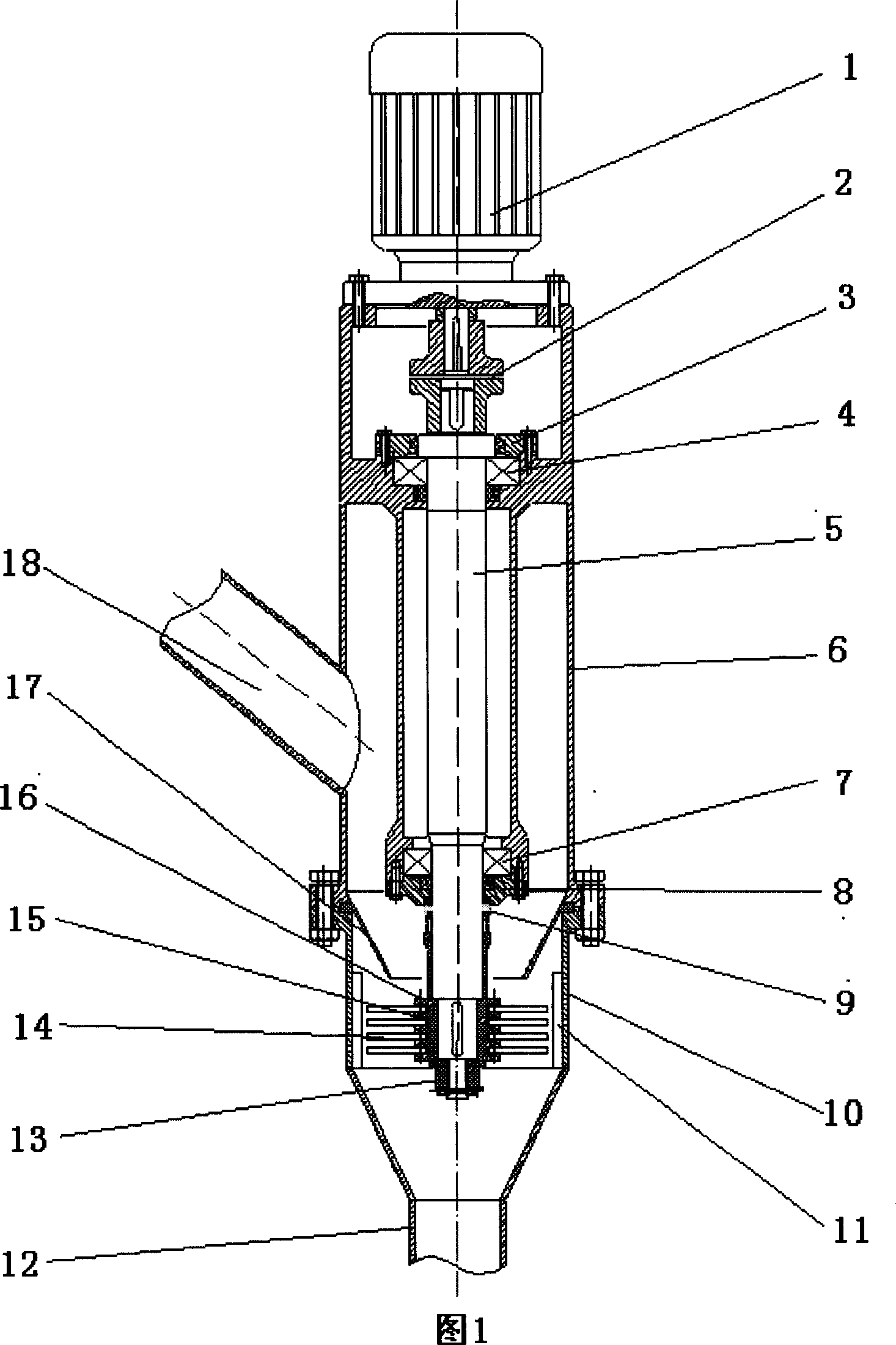

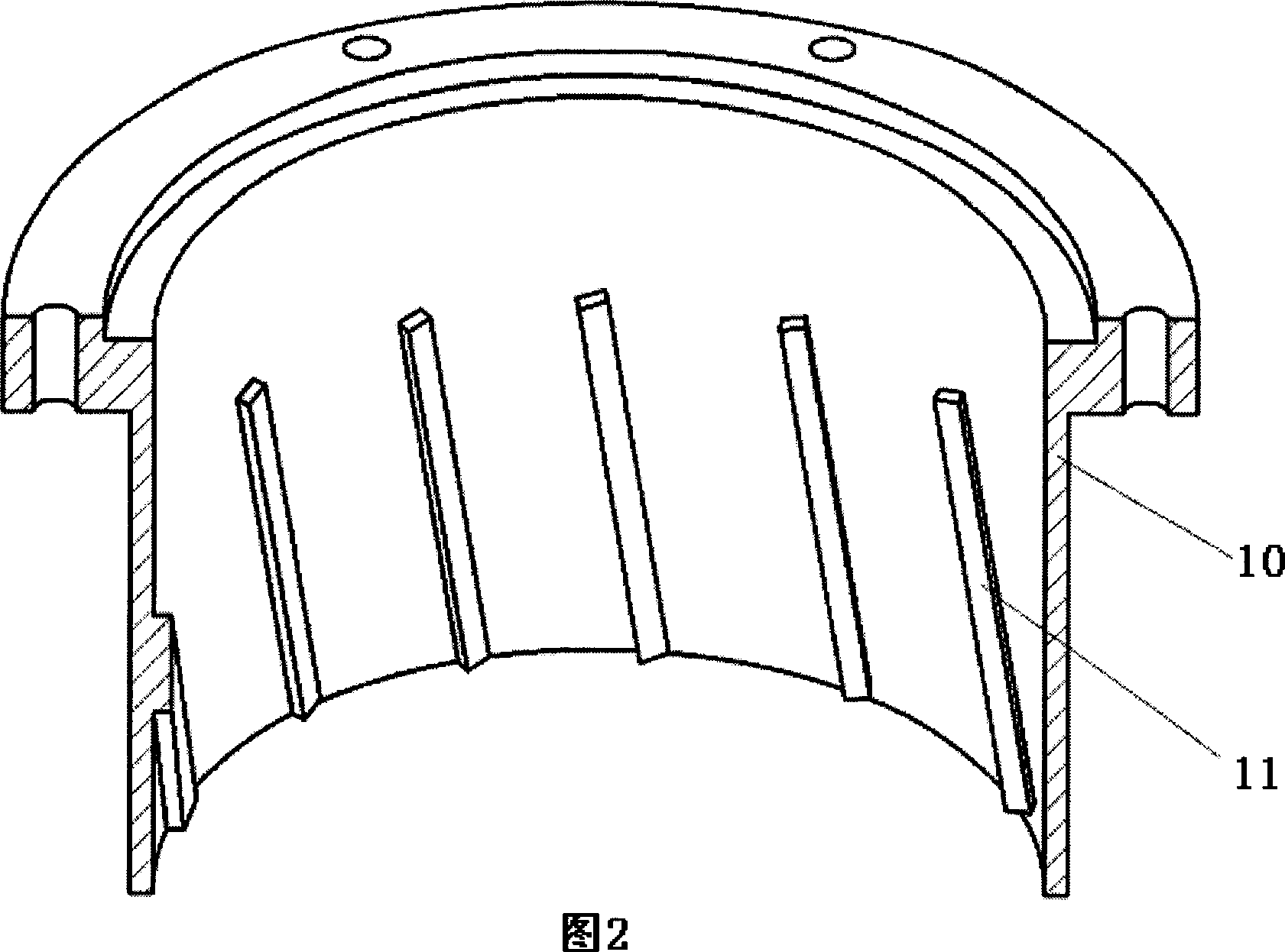

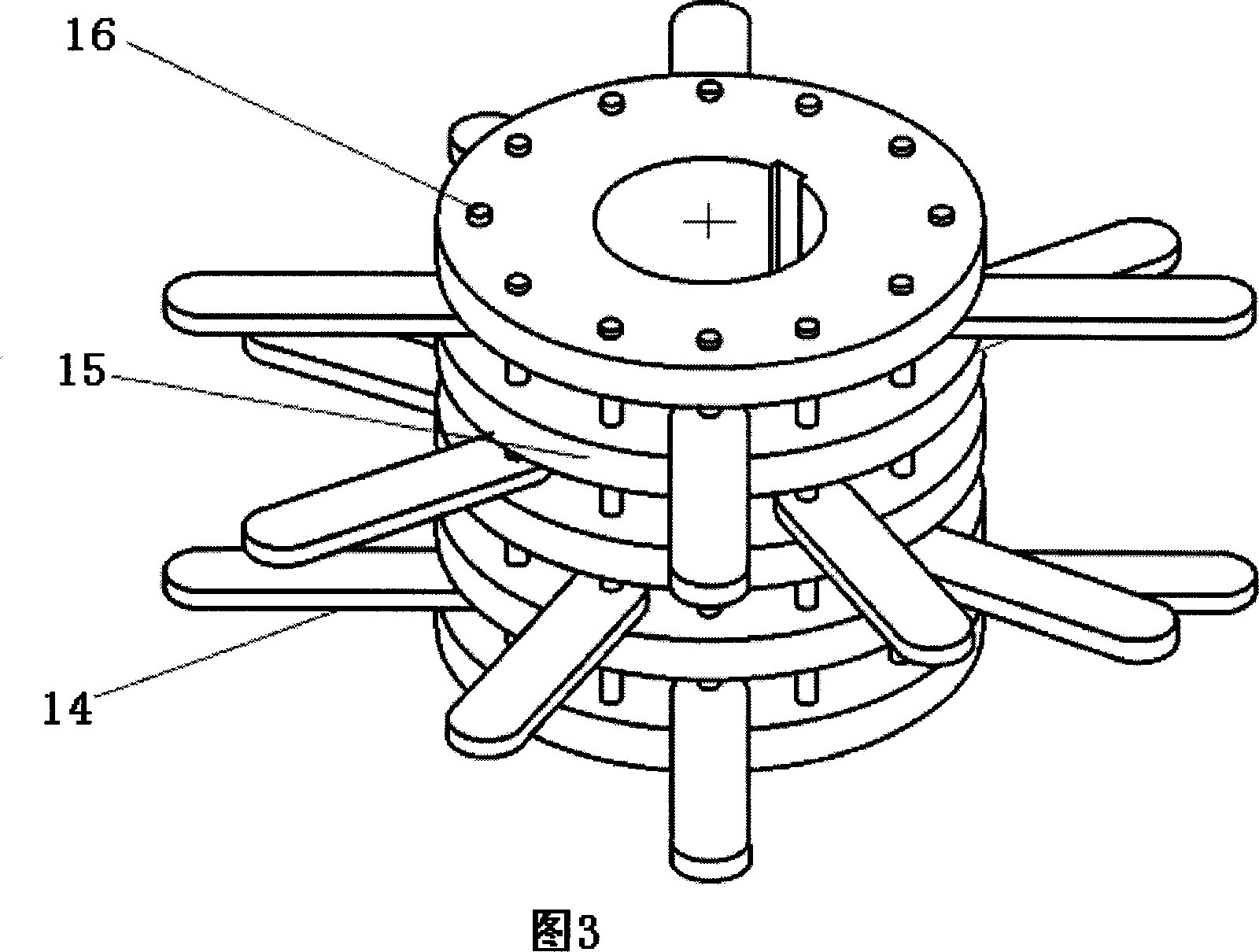

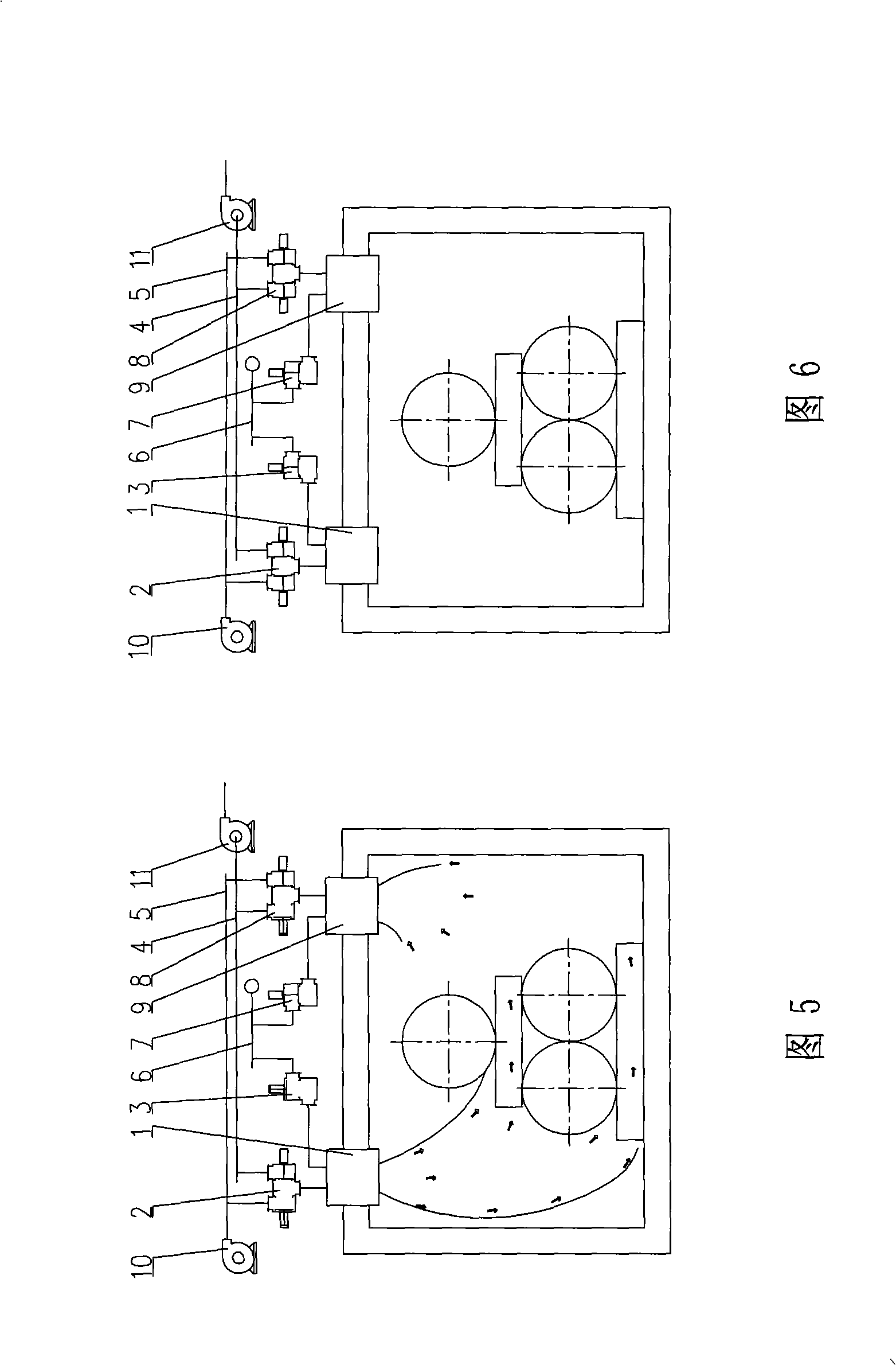

Centrifugal gas-electric spinning device by utilizing negative-pressure array

InactiveCN105350093AAirflow path controllableSimple structureNew-spun product collectionFilament/thread formingFiberEngineering

The invention discloses a centrifugal gas-electric spinning device by utilizing a negative-pressure array. The centrifugal gas-electric spinning device comprises a high-voltage alternating-current generator, an air supply device, a box body, a centrifugal sprayer, a centrifugal driving mechanism and negative-pressure receiving devices. The interior of the centrifugal sprayer is provided with a liquid storage cavity. Filament outlet holes are arranged in the centrifugal sprayer. Each negative-pressure receiving device comprises a collector, a negative-pressure pipe and a negative air-pressure generator. Negative-pressure pipe openings are formed by negative-pressure pipes in the bottom of the box body. Collectors are nested into the negative-pressure pipe openings. The multiple negative-pressure receiving devices are arrayed in an annular array with the centrifugal sprayer as the center. The high-voltage alternating-current generator is formed for generating an electric field. Airflow spraying out of the filament outlet holes is formed by the air supply device. The centrifugal gas-electric spinning device by utilizing the negative-pressure array has following beneficial effects: nanofibers are formed by sprayed polymers under airflow, an electric field, negative pressure and centrifugal force such that a three-dimensional structure is formed by nanofibers on the negative-pressure receiving devices; thickness of fiber disposition is increased; biological materials are better compatible and the application scope of technology materials is broad; and a support structure obtained is beneficial for cell growth of tissue engineering.

Owner:GUANGDONG UNIV OF TECH

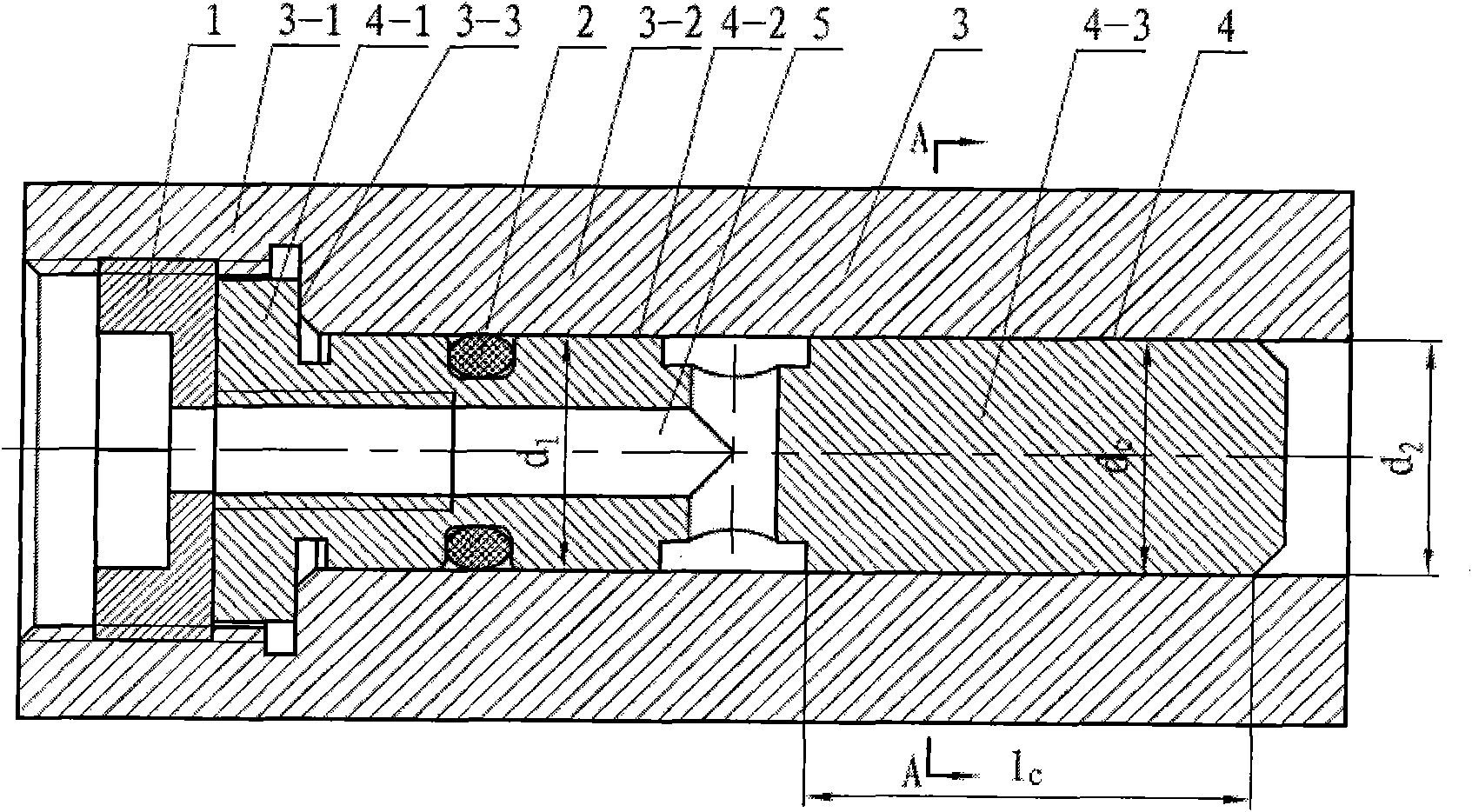

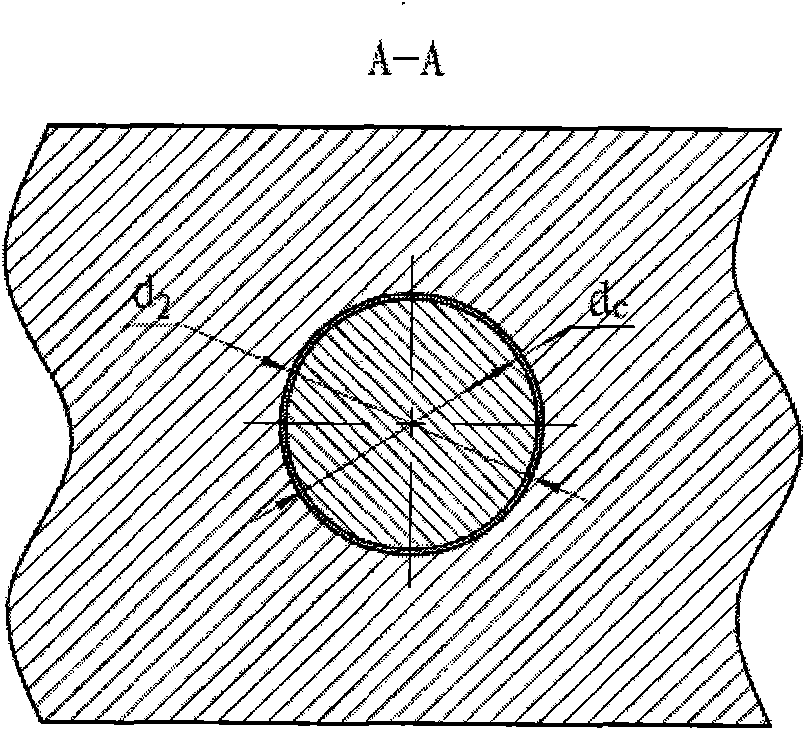

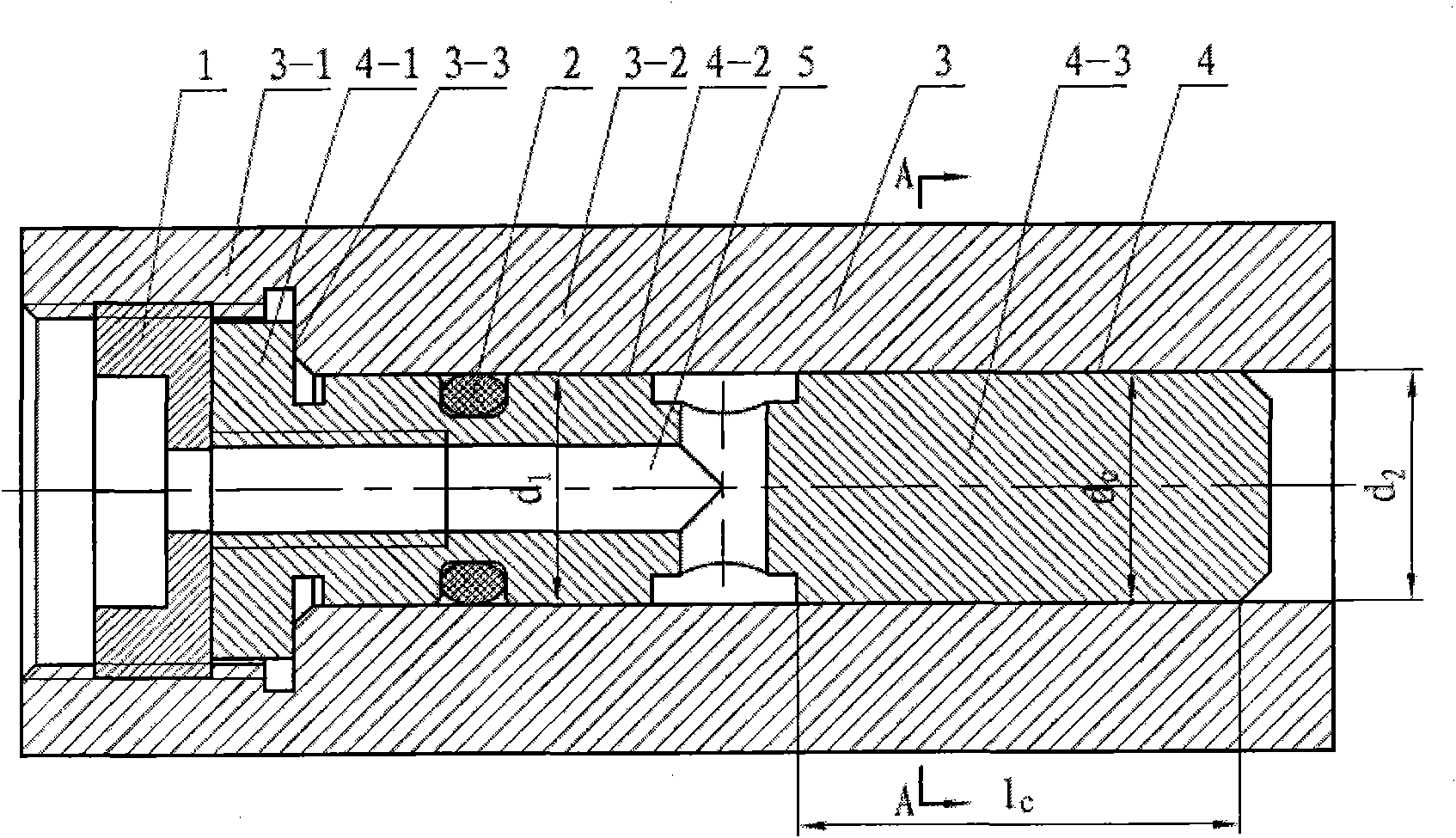

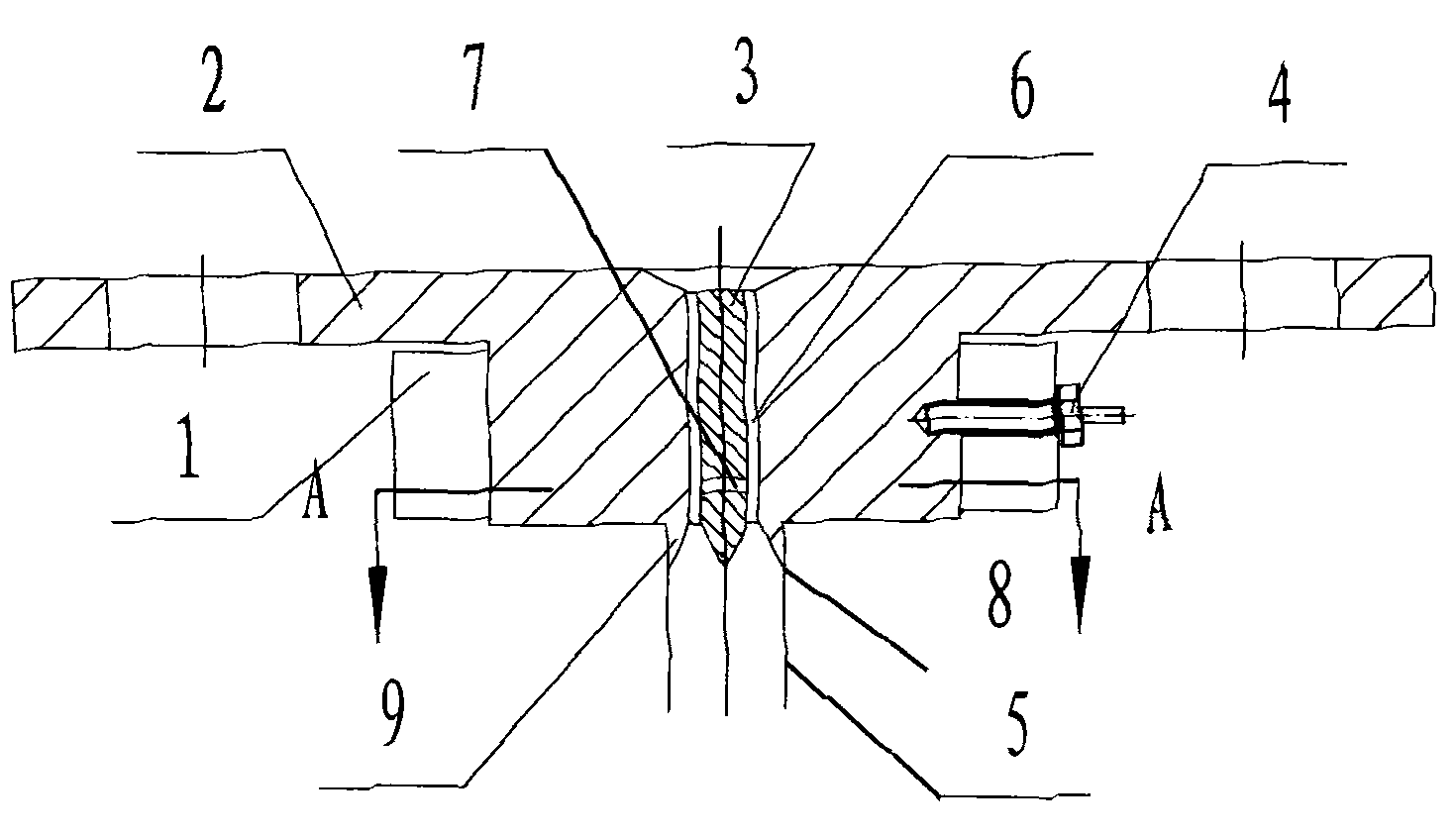

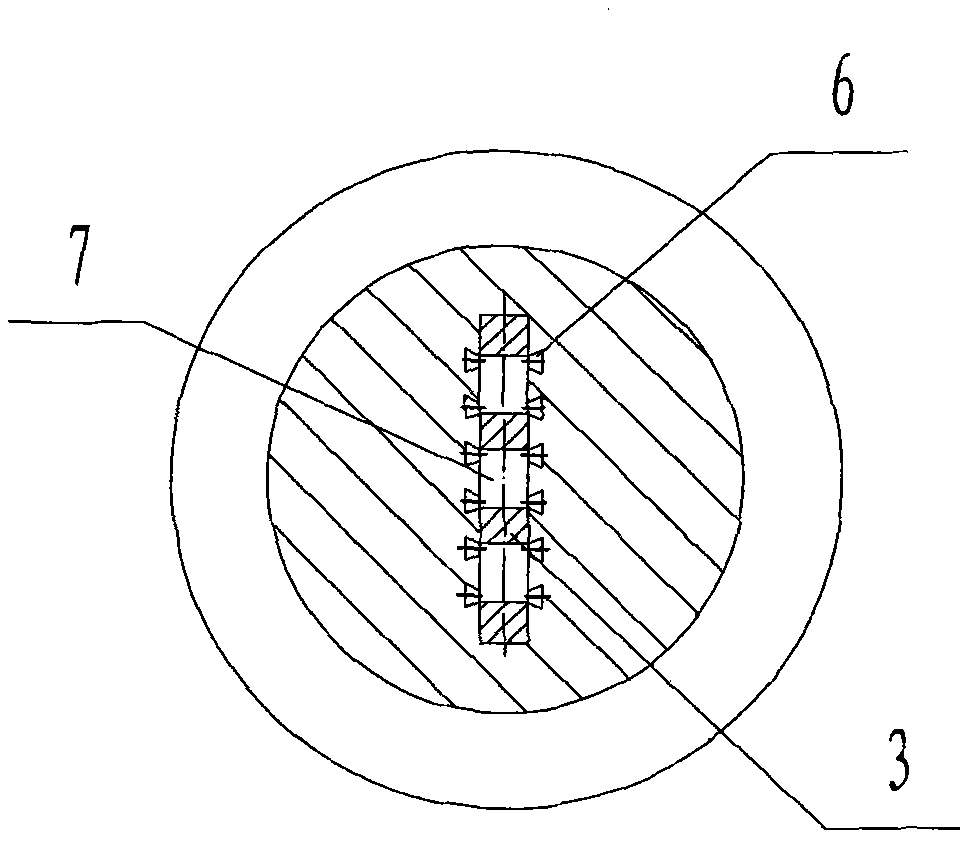

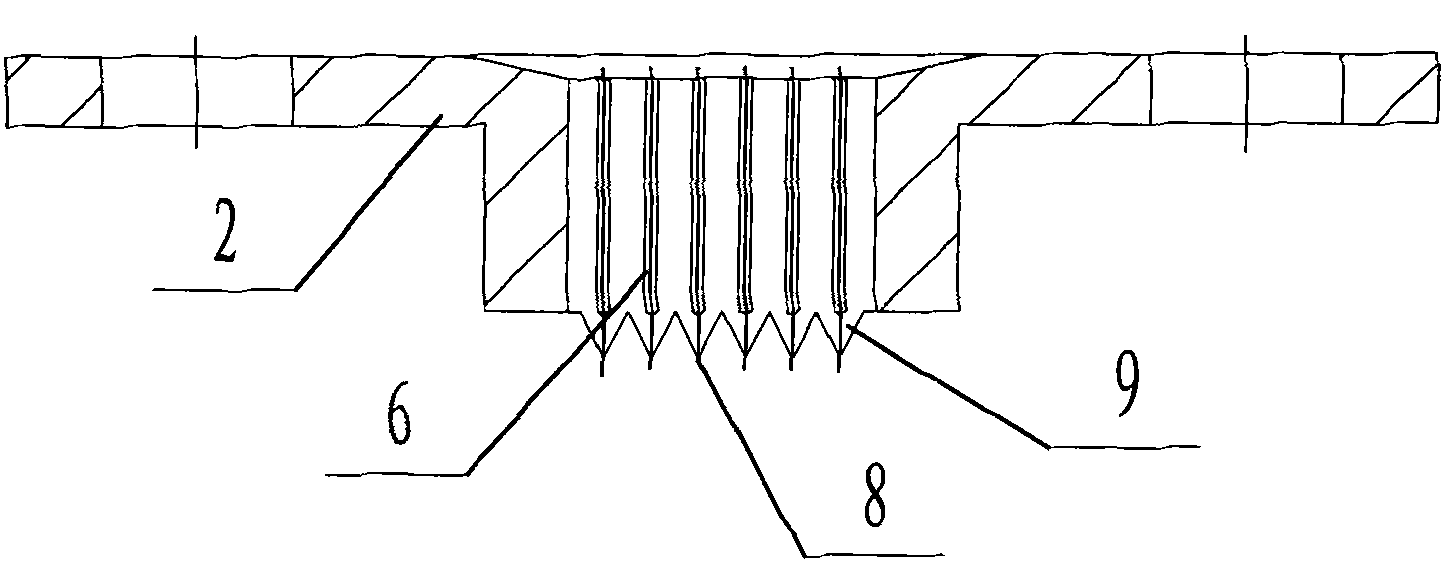

Annular slit restrictor

InactiveCN101832340ASolve easy blockageCompact structureBearing assemblyBearingsWork zoneMechanical engineering

The invention relates to annular slit restrictor comprising a restrictor mounting body and a restrictor body. The restrictor body is arranged in the restrictor mounting body; the restrictor mounting body comprises a step-shaped front end cavity and a step-shaped rear end cavity; the restrictor body comprises a step-shaped front end part, a step-shaped middle part and a step-shaped rear part, wherein the front end part is axially positioned by hole shoulder of the restrictor mounting body, and the middle part and the rear part are arranged in the rear end cavity of the restrictor mounting body; the middle part of the restrictor body is axially matched with the rear end cavity of the restrictor mounting body; the diameter of the rear part of the restrictor body is smaller that that of the rear end cavity of the restrictor mounting body; the slit between the rear part of the restrictor body and the rear end cavity of the restrictor mounting body forms the working zone of the annular slit restrictor; and the front end part and the middle part of the restrictor body are provided with through holes which are communicated with the working zone. The annular slit restrictor meets the requirement of compact structure, convenient assembly and disassembly, easy adjustment, stable performance and less susceptibility to block.

Owner:XI AN JIAOTONG UNIV +1

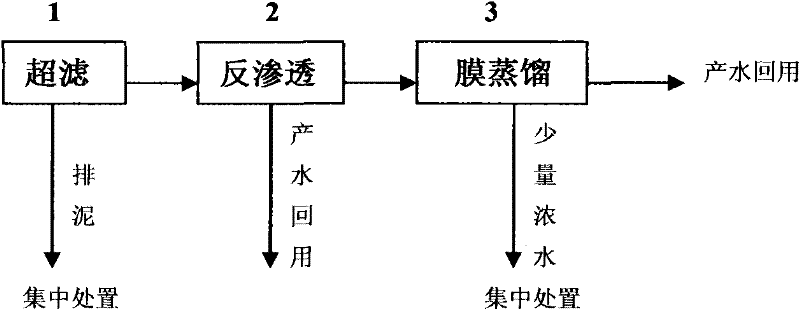

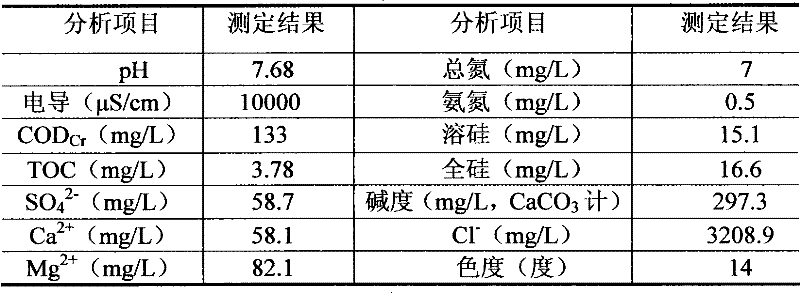

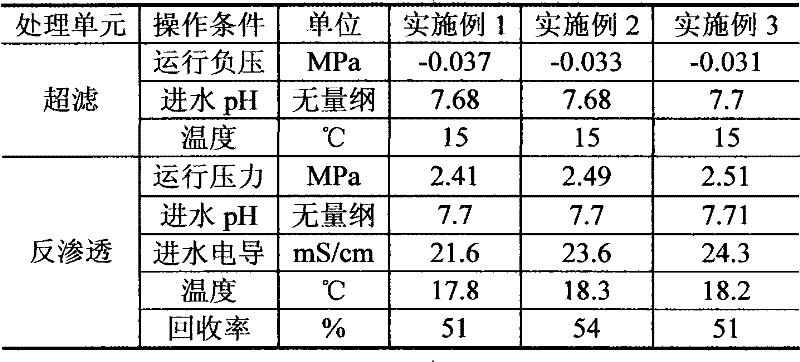

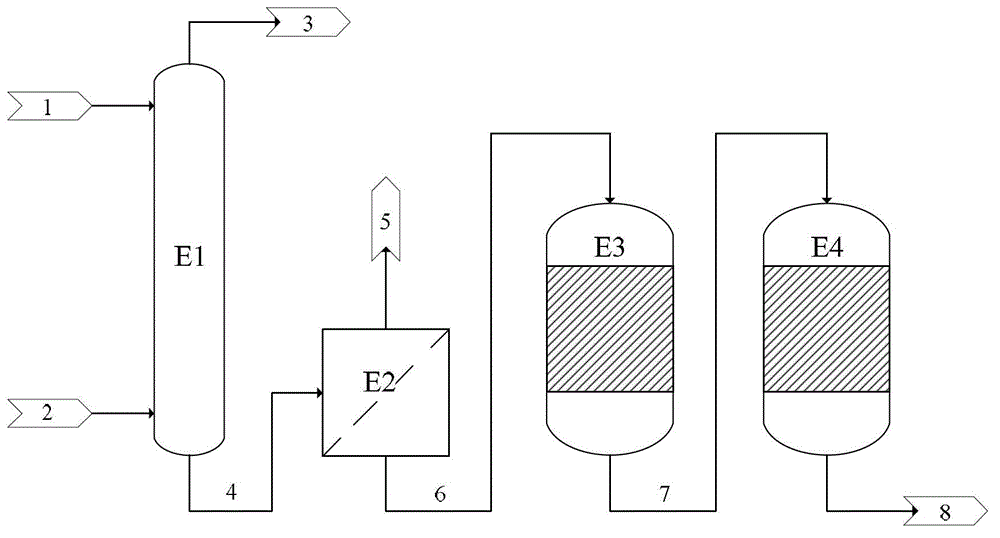

A kind of advanced treatment and reuse method of olefin polymerization catalyst production wastewater

ActiveCN102295377AHigh desalination rateEnhanced couplingGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisSocial benefitsUltrafiltration

The invention relates to an advanced treatment and reuse method of wastewater in olefin polymerization catalyst production. In the method, a coupled process flow comprising ultrafiltration, reverse osmosis and membrane distillation is adopted; by using the process flow, the advanced treatment and reuse of biochemical effluent of wastewater in the olefin polymerization catalyst production can be achieved; and produced water by reverse osmosis and membrane distillation of the biochemical effluent treated by the process flow of wastewater in the olefin polymerization catalyst production can meetthe process water requirement. According to the invention, the recovery rate of the whole system is up to above 90%, thereby realizing the reuse of the biochemical effluent of the wastewater in the olefin polymerization catalyst production and realizing the advanced treatment and reuse of high-salt sewage. Thus, the method provided by the invention has obvious social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

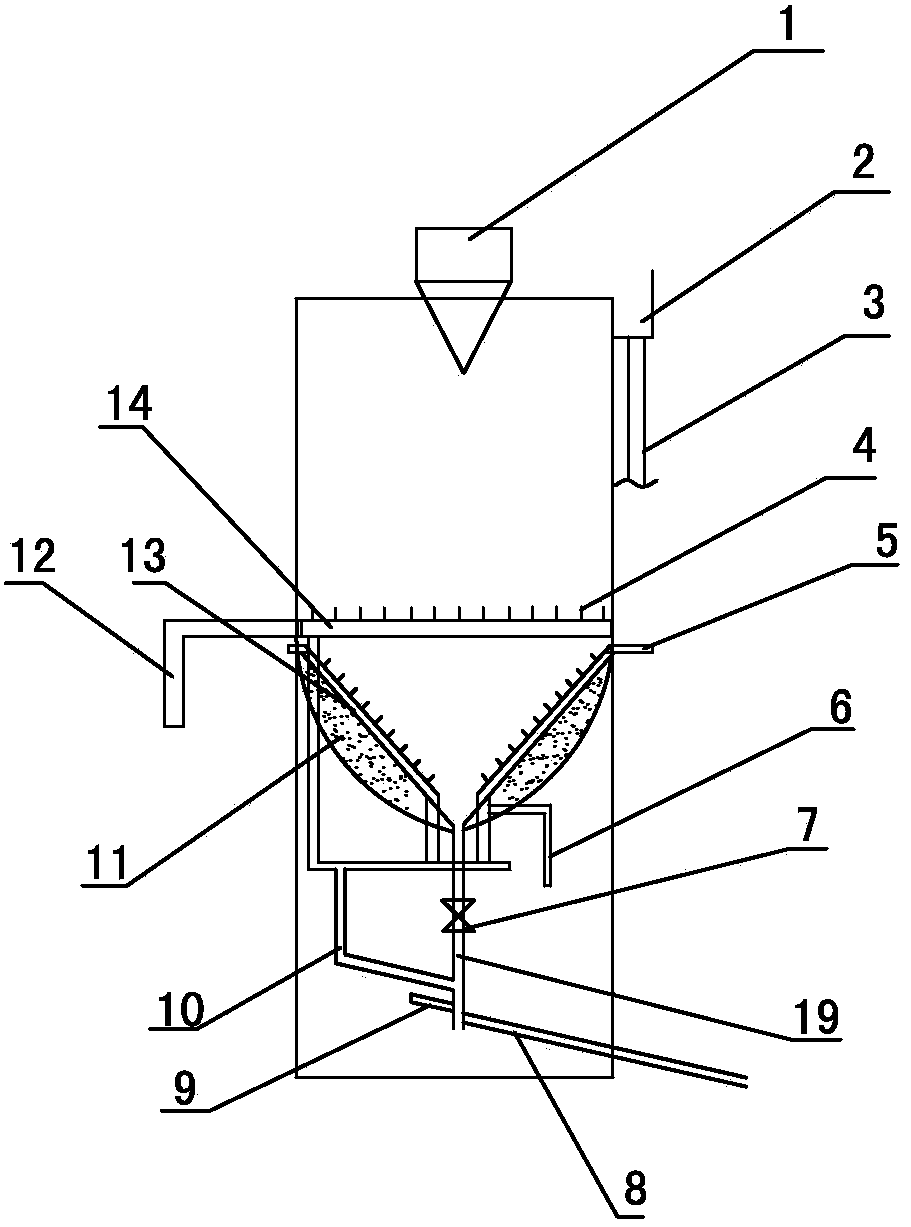

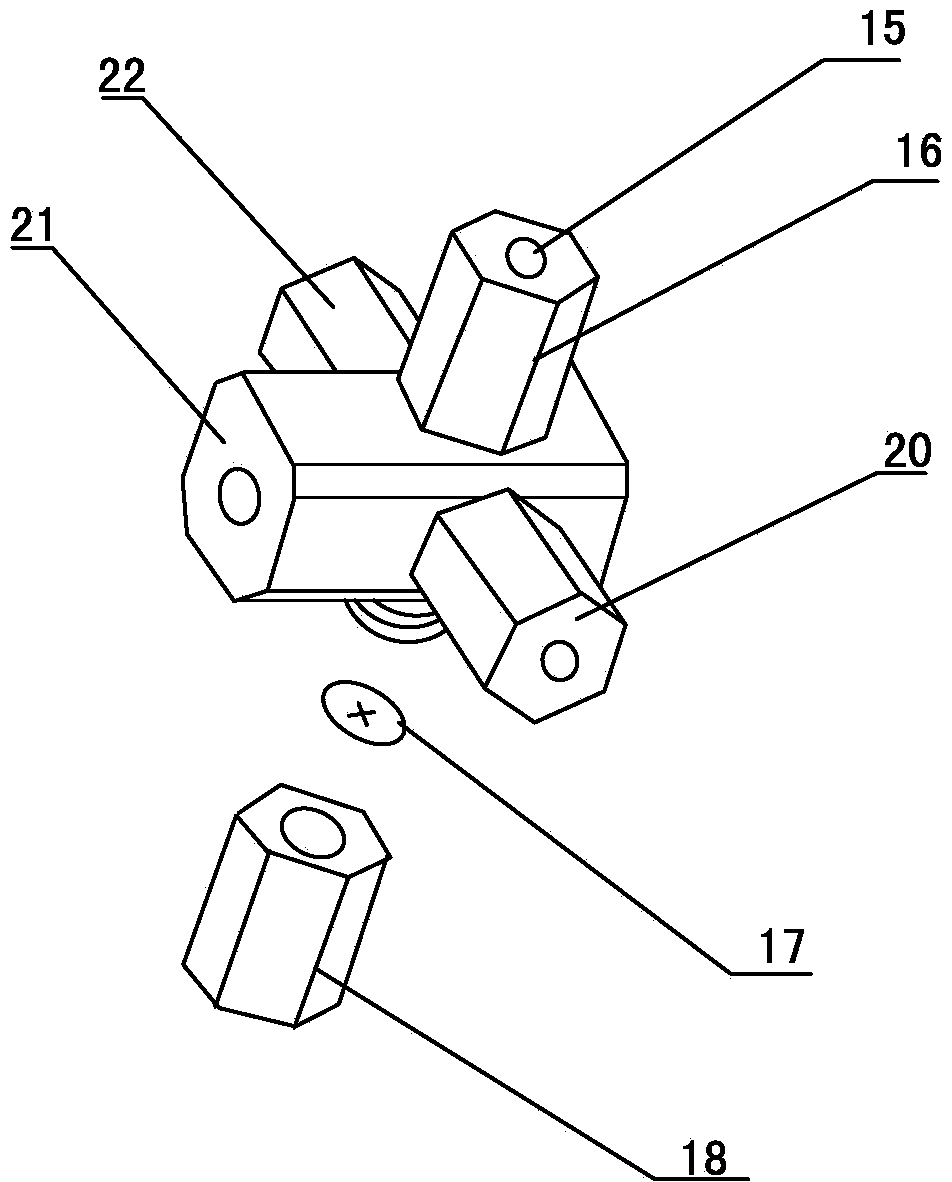

Vertical sand silo mud-making device

ActiveCN103963162ASolve easy blockageFix damageLarge containersCement mixing apparatusSpray nozzleEngineering

The invention relates to a sand silo used for backfilling a mine, and in particular relates to a vertical sand silo mud-making device. The vertical sand silo mud-making device comprises a silo body, wherein an annular mud-making pipe and two oblique mud-making pipes are arranged in the silo body; one end of the circular mud-making pipe is provided with a first high-pressure air pipe; upper ends of the two oblique mud-making pipes are both provided with second high-pressure air pipes; nozzles are evenly distributed in the annular mud-making pipe and the two oblique mud-making pipes; the nozzles comprise air inlet pipes and first jet pipes; the air inlet pipes are hollowed; the first jet pipes are sleeved on the air inlet pipes; rubber cushions are inset in the connection parts of the first jet pipes and the air inlet pipes; nozzle holes are formed in the central axes of the first jet pipes. The vertical sand silo mud-making device provided by the invention solves the problem that the nozzles are easy to block and damage when a vertical sand silo backfilling system releases mill tailings, has high sand-releasing concentration, and is stable.

Owner:SHANDONG HUALIAN MINING

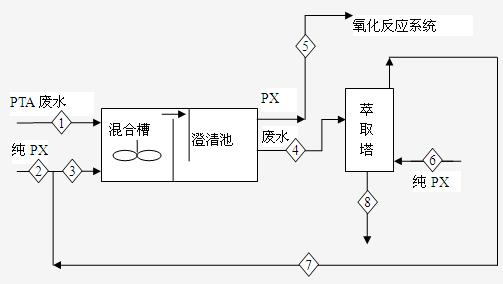

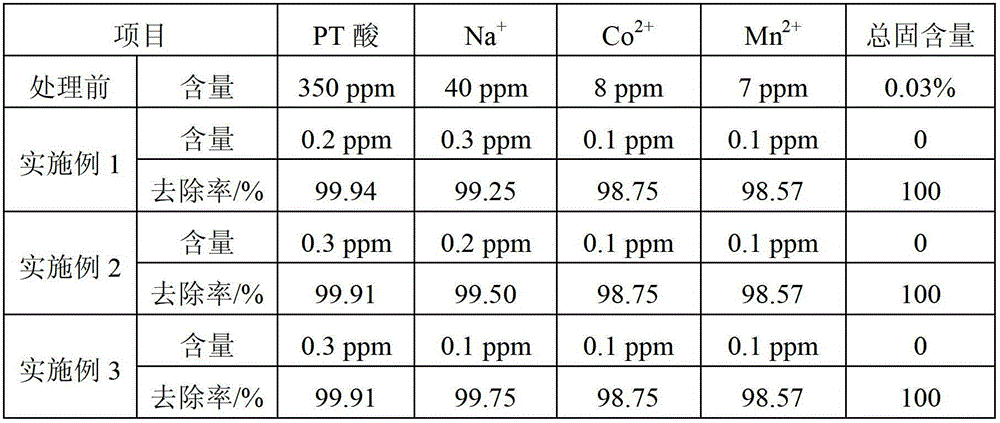

Method for recycling mother solid in PTA-refining wastewater

ActiveCN101941901AAvoid wastingSolve easy blockageMultistage water/sewage treatmentCarboxylic compound separation/purificationRecovery methodSingle stage

The invention discloses a method for recycling mother solid in PTA-refining wastewater, comprises the following steps: mixing PTA-refining wastewater and paraxylene in a prepositioned mixing tank, carrying out single-stage extraction and cooling on the wastewater, dissolving and extracting the solid in mother liquor into a PX phase, returning the extract phase PX discharged from a clarification tank to an oxidizing reaction system, and delivering the wastewater to an extraction tower to be subject to multistage countercurrent extraction; delivering the wastewater discharged from the bottom ofthe extraction tower to be subject to further treatment; and returning the extraction phase discharged from the top of the extraction tower to serve as extract liquor for single-stage extraction. By adopting the method in the invention, most of organic matters, such as p-toluic acid, terephthalic acid and the like in the wastewater can be recycled, thus the purpose of recycling wastes is achieved, and wasting of resources is avoided; and the invention omits the conventional filtering unit, saves the filter cloth-replacing cost, ensures that the extraction tower can operate at appropriate operating temperature, and has the advantages of investment saving, low energy consumption, high resource recovery rate and the like.

Owner:FUZHOU UNIV

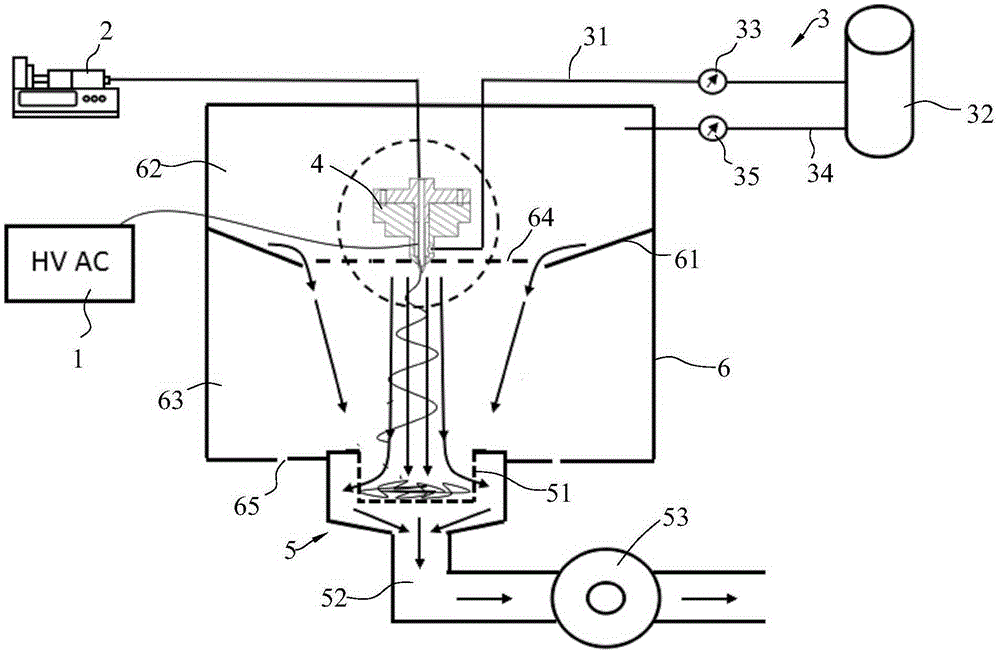

Preparation method and device for three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection

ActiveCN105350089ASimple structureSimple processFilament/thread formingEngineeringAlternating current

The invention discloses a preparation method and device for a three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection. A device comprises an alternating-current high-voltage generator, a liquid supply device, a gas liquid device, a coaxial sprayer and a negative-pressure collecting device. The coaxial sprayer is provided with a liquid outlet and a gas outlet. The gas supply device is used for conveying a spinning solution or melts to the coaxial sprayer and enabling melts to flow out of the liquid outlet. The gas liquid device can generate air flow blowing from the liquid outlet to the negative-pressure collecting device via the liquid outlet. The alternating-current high-voltage generator can form an alternating electric field between the coaxial sprayer and the negative-pressure collecting device. The negative-pressure collecting device comprises a collector, a negative-pressure pipe and a negative-pressure generator. The spinning solution or melts form solution jet flow or melt jet flow in the coaxial sprayer and the collector under effect of airflow and the alternating electric field.The preparation method and device for the three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection have following beneficial effects: by adoption of spinning technology based on the negative-pressure collector, the nanofiber three-dimensional support featuring a broad range of preparation material, small fiber diameters, uniformly-distributed filament diameters, a loose structure, great thickness and superior mechanical properties is obtained and has great technological universality.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

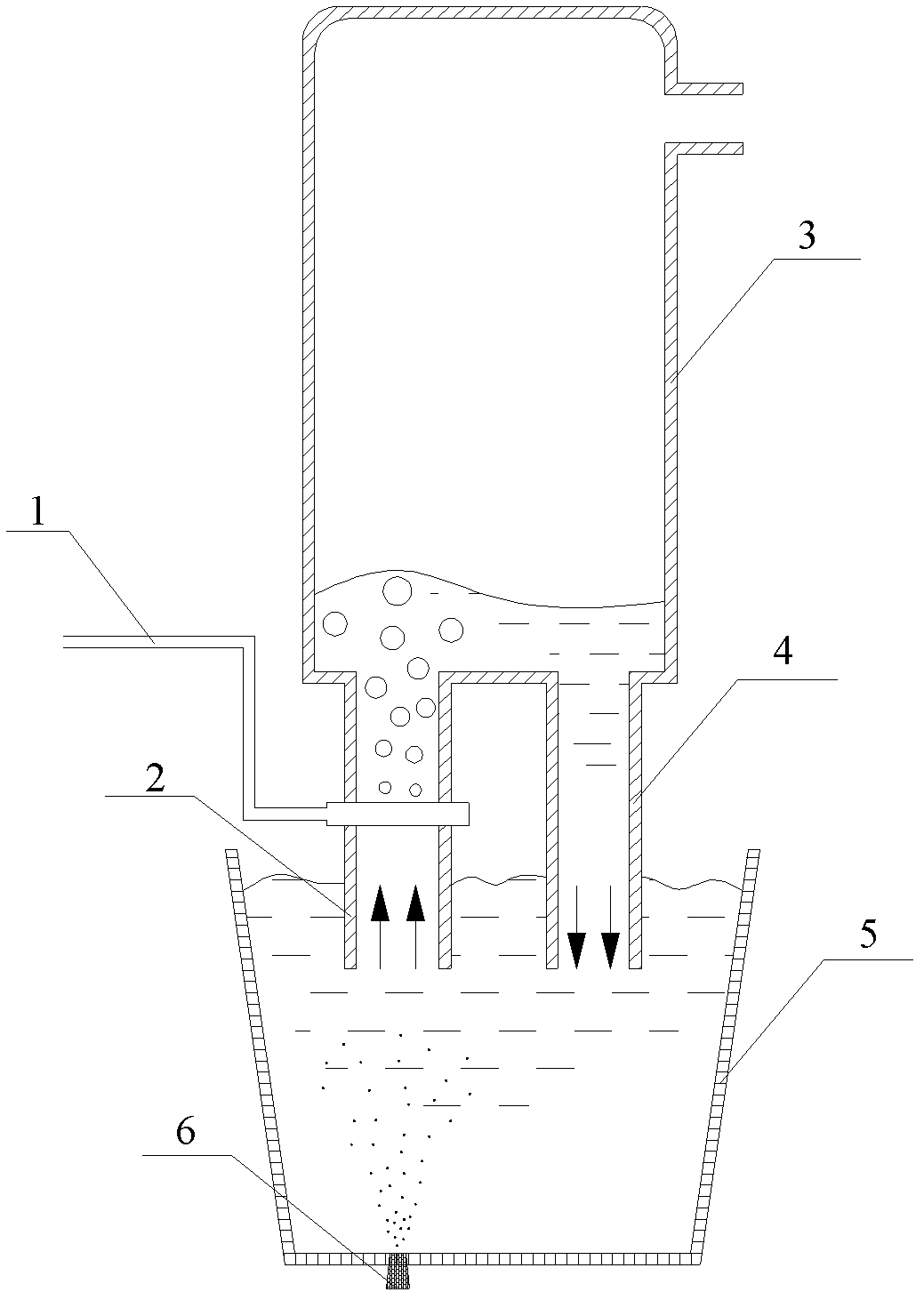

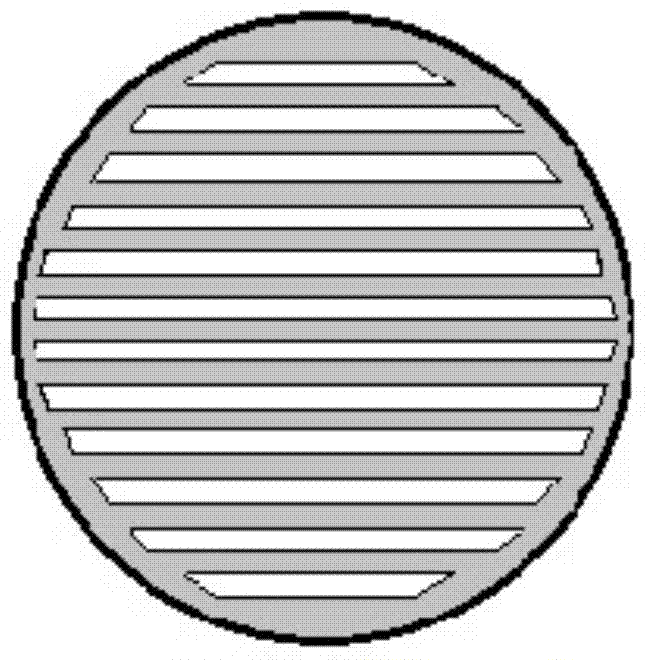

Anaerobic reactor

ActiveCN101497476ASolve easy blockageReduce foulingTreatment with anaerobic digestion processesAnaerobic reactorCirculating pump

The invention relates to an anaerobic reactor. The anaerobic reactor comprises a cylinder body, a water inlet pipe, a water outlet pipe, a filling device on the middle part of the water outlet pipe, a water distribution device at the bottom of the filling device and a sludge discharge device at the bottom of the water distribution device; the water distribution device comprises a water distribution main pipe and more than four closed annular water distribution branch pipes; water outlet holes of the water distribution branch pipes are alternately arranged along more than three concentric circumferences; the cylinder body is positioned on the upper part of the filling device; the lower part of each water distribution branch pipe is provided with more than two water outlets; the water outlets are connected with the water outlet pipe; a reflowing pipe of the water outlet pipe is mixed with the water inlet pipe by a circulating pump and is communicated with the water distribution main pipe; a first medicating device and a second medicating device are communicated with the water inlet pipe respectively through connecting pipes; the filling device comprises a filling rack, a membrane hanging rack and a zonal biomembrane strip; the biomembrane strip is hung on the membrane hanging rack; and the sludge discharge device comprises a sludge discharge main pipe and six sludge discharge branch pipes arranged in length alternation along radial direction. The anaerobic reactor has the characteristics of reasonable water distribution, compact structure and stable operation of the reactor.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

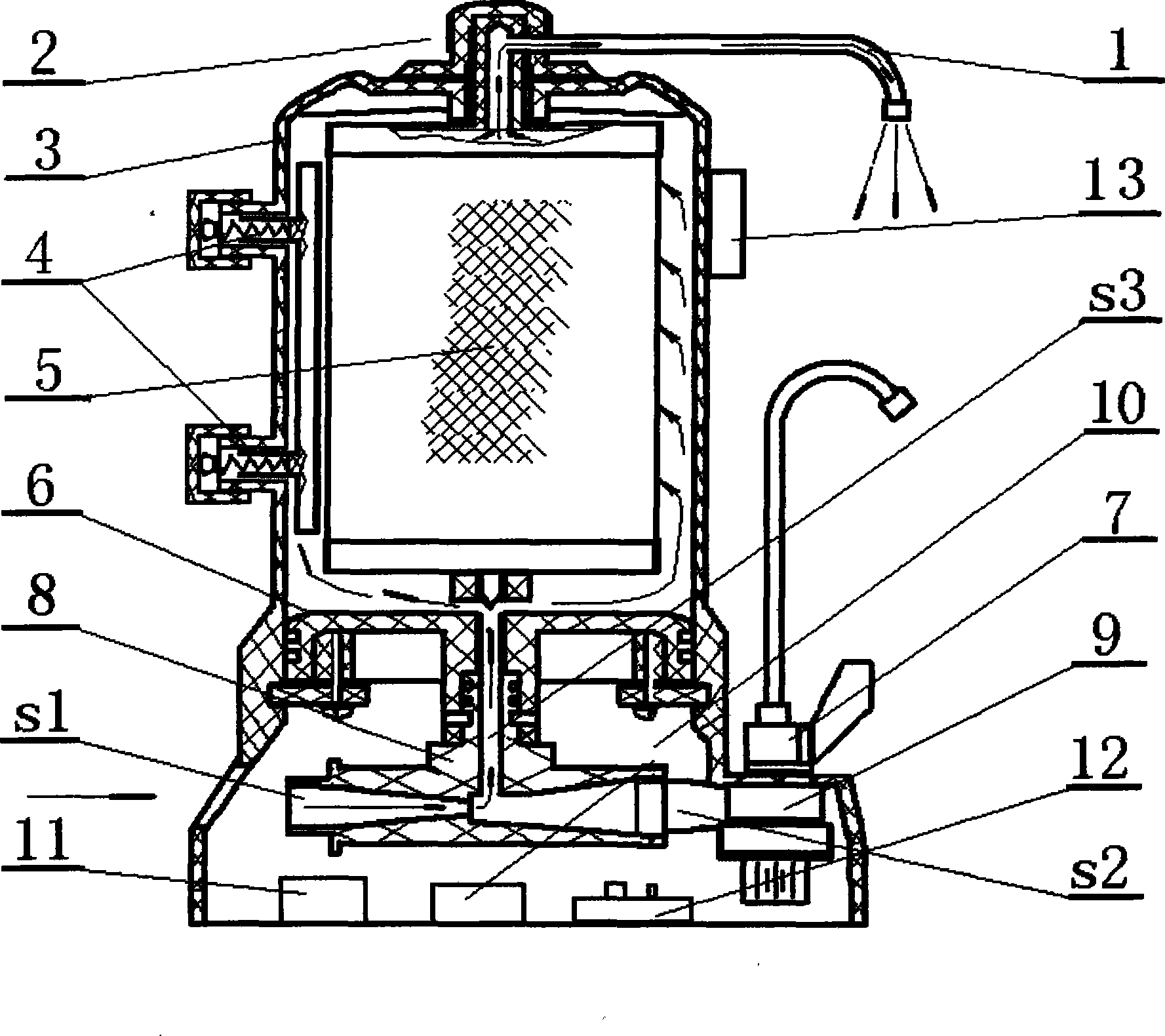

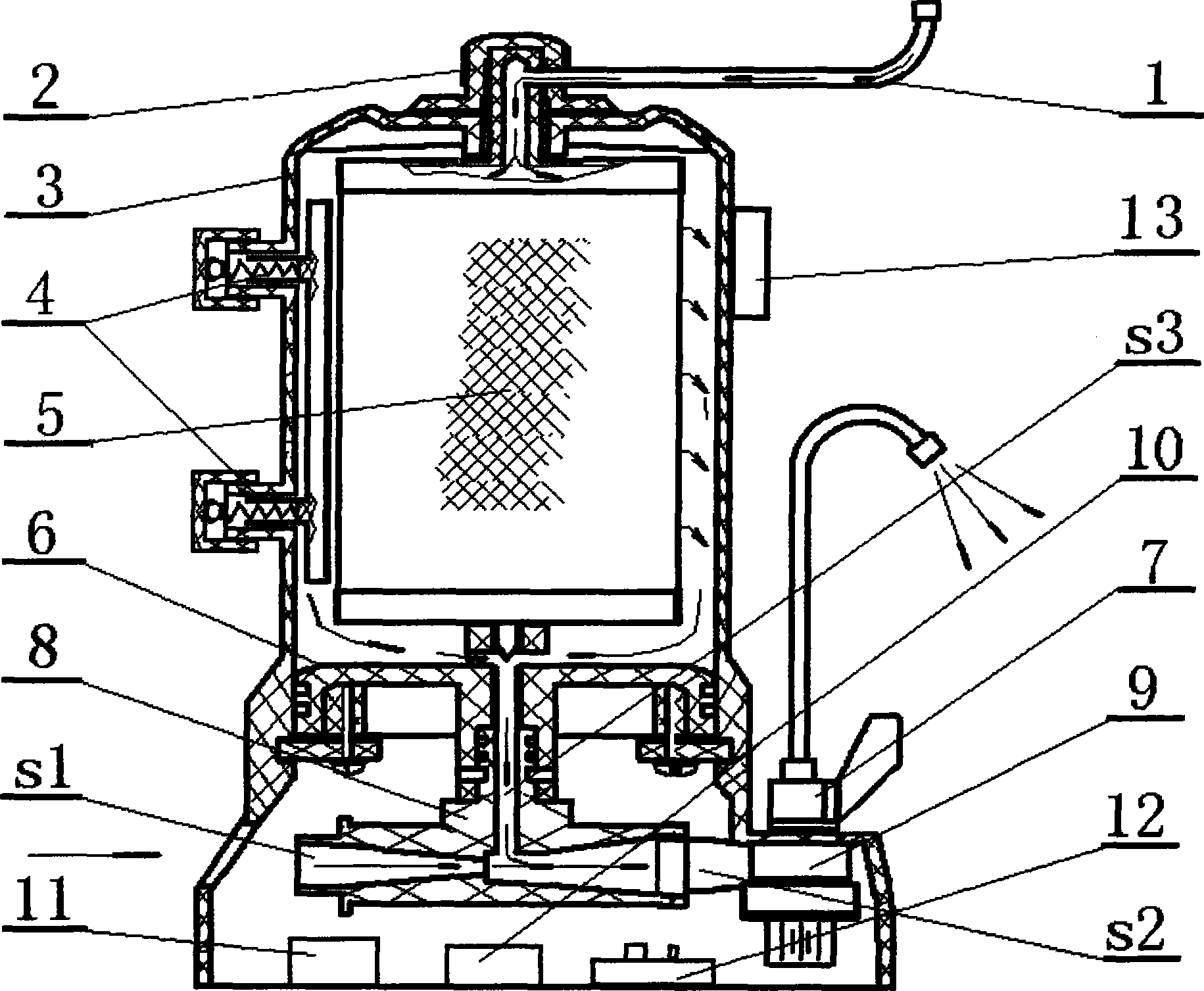

Self-generating multifunctional self-cleaning water purifier

InactiveCN101503256ASolve easy blockageSolve cleaningBatteries circuit arrangementsMultistage water/sewage treatmentOzone generatorWater wheel

The invention discloses a method of a multifunctional self-generating and self-cleaning water purifier and a device. The device comprises an outer casing, a cleaning handwheel, a cleaning brush and a support frame, a ceramic filter element, various water purifying filter materials, a lower blanking cover, an ejector, a water wheel generator, a discharge cock, a water purifying cock, a storage battery, an ozone generator and a switch, an illuminating lamp and a switch, a control circuit and an external socket. The water purifying function is achieved by adopting the ceramic filter element and the water purifying filter materials which can enable tap water to pass through the device; the self-cleaning function of normally and reversely pumping and cleaning is achieved by the ejector; the disassembly-free, the friction and the self-cleaning functions are achieved by the strip-shaped emery stick of the cleaning brush through mutually rotating the ceramic filter element; and the flow speed of water flow is improved by the ejector, so that the generator works to achieve the self-generating function, the illuminating function, the function of disinfecting the water purifier, the ozone water function and the power supply function, thereby solving the problems that the ceramic filter element carries out water purification and the self-cleaning is achieved without disassembly; and moreover, the invention has the advantages of simple structure and convenient operation and simultaneously can also achieve the multifunction.

Owner:黄光智

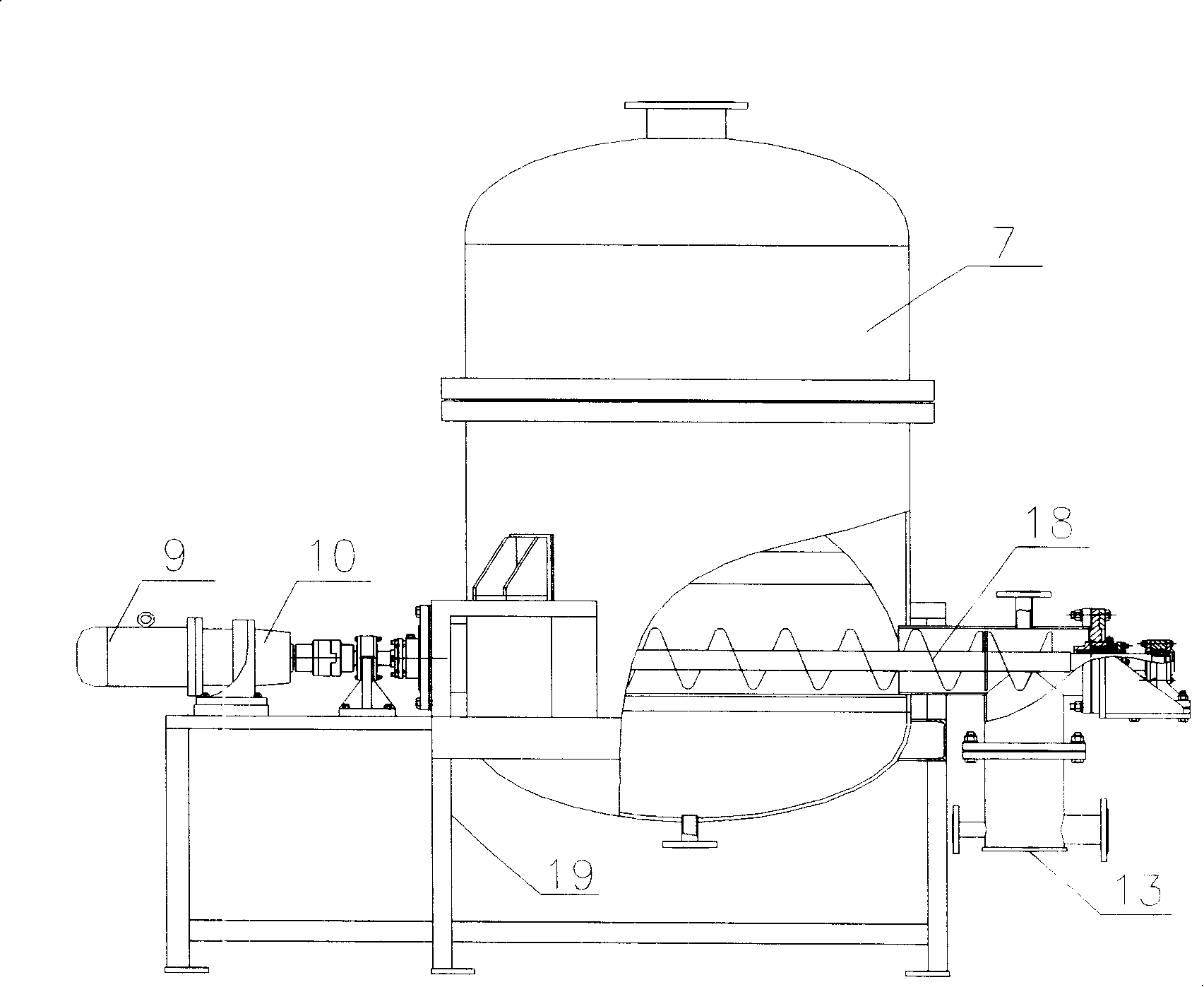

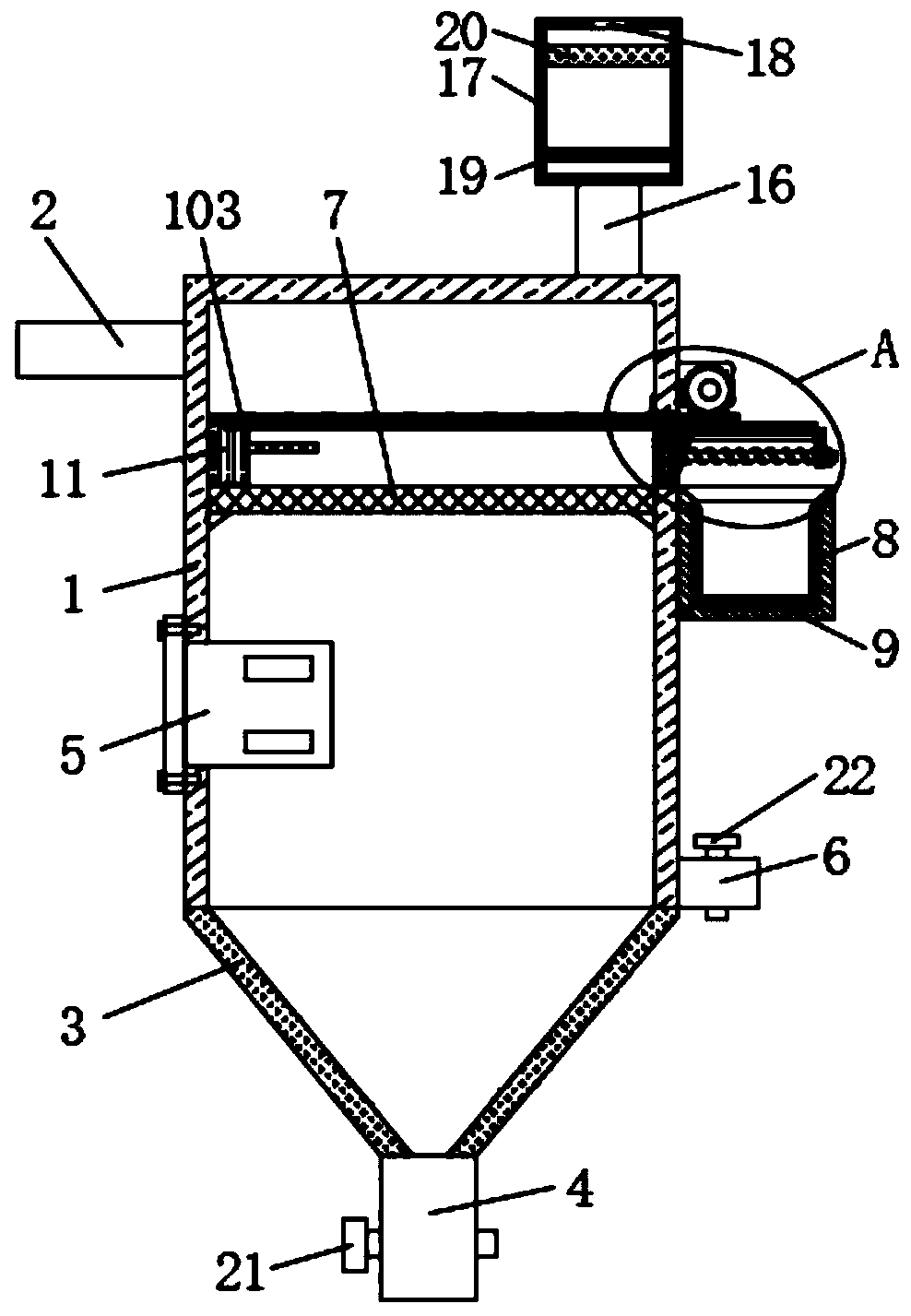

Cabin type helix transporting device

ActiveCN101205020ASolve easy blockageFully fluidizedLarge containersBulk conveyorsHigh energyScrew conveyor

The invention discloses a spiral delivery device of storehouse type to solve the problems of easy pipe blocking and high energy consumption in the prior device. The invention adopts a spiral conveyor (18) installed in a lower hopper (7). A discharge hole of the spiral conveyor (18) is connected with an inlet orifice (20) of a material and gas mixing cavity (13). An air inlet (25) and a discharge orifice (23) are respectively arranged at the lower part of the material and gas mixing cavity (13). The air inlet (25) of the material and gas mixing cavity (13) is connected with compressed air. The discharge orifice (23) of the material and gas mixing cavity (13) is connected with a delivery pipe. Therefore, the invention has the advantages of few occurrences of blockage and can reduce energy consumption.

Owner:FUJIAN LONGKING

Vertical hammer piece breaking mixing apparatus

InactiveCN1947846ASolve easy blockageImprove work efficiencyMaterial granulationGrain treatmentsEngineering

A breaking mixer with vertical hammer plate for the mixture of fused chemical and solid powder is composed of a casing with feeding pipe and discharge pipe, a motor, and a breaking chamber with a mainshaft driven by motor, a hammer plate holder fixed to lower end of mainshaft and with at least two radial slots and the hammer plates (2-8 hammer plates in each slot). When the mainshaft is rotating at high speed, said hammer plates can play their breaking role.

Owner:孔亦周

Double-hole type sucker negative pressure drainage device

ActiveCN103495259ASolve easy blockageEasy to block and not easyWound drainsAdhesive dressingsWound dressingSemipermeable membrane

The invention provides a double-hole type sucker negative pressure drainage device which is suitable for large-area wound therapy in a human body or the body surface of the human body. The double-hole type sucker negative pressure drainage device comprises multi-hole wound dressing, an integral external sucker and a biological semipermeable membrane, wherein the integral external sucker comprises a sucker body, a sucker connecting membrane, a drainage outer pipe and a washing pipe, an attraction hole is formed in the bottom of the sucker body, a drainage channel and a washing channel are arranged inside the sucker body, and the sucker body is placed on the biological semipermeable membrane provided with a through hole; the sucker connecting membrane covers the sucker body, and a position, stretching out of the sucker body, of the sucker connecting membrane is pasted with the biological semipermeable membrane; the drainage channel is communicated with the drainage outer pipe, and the drainage pipe is connected with a drainage container and a negative pressure source; the washing channel is communicated with the washing pipe, and the tail end of the washing pipe is further provided with a sealing cover. The double-hole type sucker negative pressure drainage device has the advantages that the problem that the drainage outer pipe and the washing pipe are easily blocked is thoroughly resolved, negative drainage effects and washing effects are improved, and wound concrescence can be well promoted.

Owner:SUZHOU & SCI & TECH DEV

Recycling processing device for electroplating wastewater

InactiveCN110372146ANot easy to clog gas treatment effectImprove anti-blocking effectDispersed particle filtrationSpecific water treatment objectivesSlagProduct gas

The invention discloses a recycling processing device for electroplating wastewater. The recycling processing device comprises a processing barrel, a water inlet pipe communicates with the top of theleft side of the processing barrel, and a sludge hopper is welded to the top of the processing barrel. According to the recycling processing device for the electroplating wastewater, waste gas is filtered through an air filtering box, the situation that unpleasant odor generated by the waste gas influences a user is avoided, the user drive a scrapping plate through a transmission mechanism to moverightwards, impurities at the top of a filtering plate is removed, meanwhile a sealing plate is rightwards pushed to be opened by the scrapping plate, thus waste slag conveniently falls into a collecting box, after the scraping plate moves leftwards and restores, restoring of the sealing plate is conducted through a restoring mechanism to seal the processing barrel, and the problems that a filtering plate is prone to being blocked and the unpleasant odor is large after blocking in an existing recycling processing device for the electroplating wastewater after a long time using are solved. Therecycling processing device for the electroplating wastewater has the advantages that the filtering plate is not prone to being blocked, and the gas processing effect is good, and the anti-blocking effect and the unpleasant odor processing effect are improved.

Owner:ANHUI QIMING SURFACE TECH

Integrated water purification device and water purification method

InactiveCN103007625ASolve easy blockageSolve the dirty cleaning of the filter materialMultistage water/sewage treatmentFiltration circuitsFlocculationPurification methods

The invention relates to an integrated water purification device and a water purification method. The device comprises a flocculation basin, an inclined plate sedimentation basin and a non-overflowing double-layered filter material filtering tank which are sequentially connected in series, wherein the filtering tank comprises a filter material layer, a supporting layer, a water distribution and gas distribution assembly and a water distribution water channel which is vertically arranged along the middle part of the filtering tank; the water distribution and gas distribution assembly comprises a water collection pipe row which is horizontally arranged, and a vertical pipe row which is vertically arranged; the upper ends of all vertical pipes are communicated with water collection pipes in the water collection pipe row and the lower ends of all the vertical pipes are communicated with the water distribution water channel; a water discharging hole is formed in the bottom of each water collection pipe, and an air exhausting hole and a washing air hole are sequentially formed in the middle part and the top of each water collection pipe; and an air inlet small hole is formed in the lower middle part of each vertical pope. According to the integrated water purification device and the water purification method, the problems that a filtering head of a double-layered filter material filtering tank is easy to block, a filter material cannot be washed, a mud ball is deposited, the filtering material is lost, the construction cost is high, the maintenance is complicated ant the like can be solved; the construction period is short, a land is saved and the construction cost is low; and the water supply requirements of countryside villages and towns, and industrial and mining enterprises, and beauty spots, which are far away from cities can be met.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

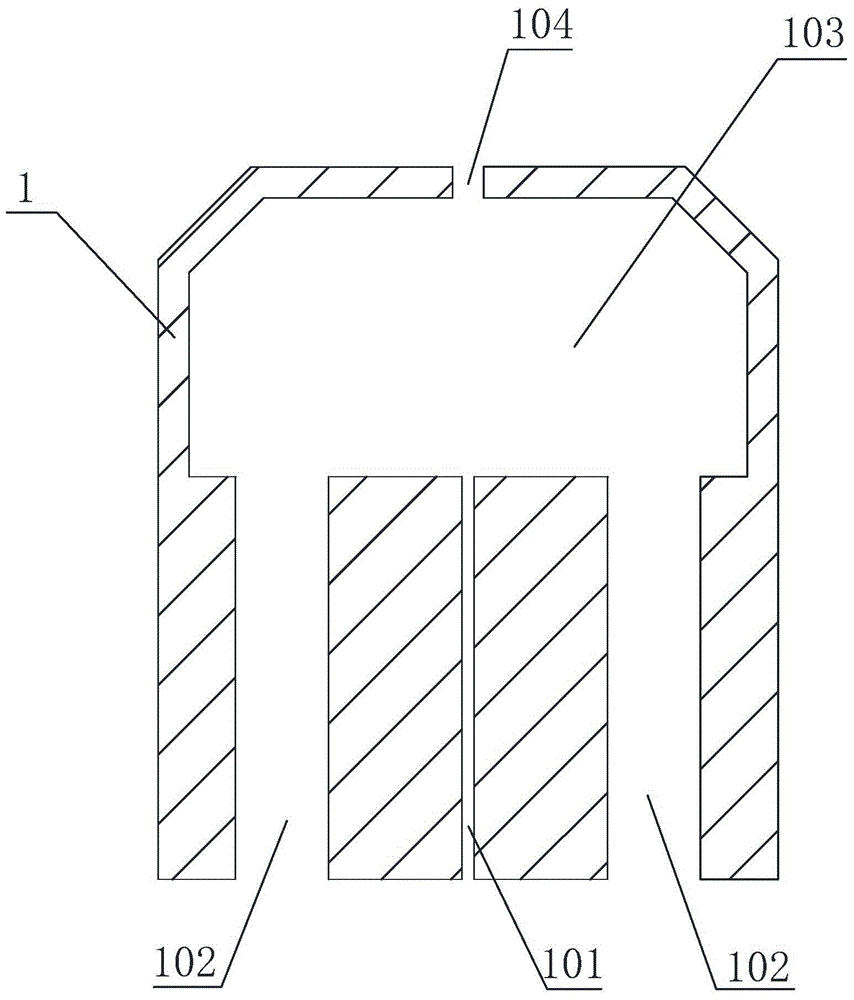

Multi-row electrostatic spinning spray head

InactiveCN101967687AReduce depthSolve easy blockageSpinnerette packsFilament/thread formingYarnTemperature control

The invention discloses a multi-row electrostatic spinning spray head, which belongs to the field of electrostatic spinning. The spray head comprises a connecting piece, a flow guide core and an independent temperature control device, wherein the connecting piece is connected with the flow guide core in a matching way and provided with a trapezoidal open flow channel and a bump for guiding a material; the bump is provided with a spinning tip for jet flow molding; the flow guide core is provided with a balancing groove for balancing the material in each open flow channel, a flow guide bump and a spinning tip for forming spinning; and when the spinning tip is provided with solution or melt and an electrostatic field is formed, a plurality of rows of jet flow is formed at the spinning tip. The conventional electrostatic spinning changes from a single yarn discharging way to a multi-yarn and multi-row parallel strip form and a spliced open flow channel is adopted, so that the flow guide core can be extracted directly when an experiment ends, the open flow channel is opened truly and the problems of easy blocking and difficult cleaning of a capillary tube are solved.

Owner:BEIJING UNIV OF CHEM TECH

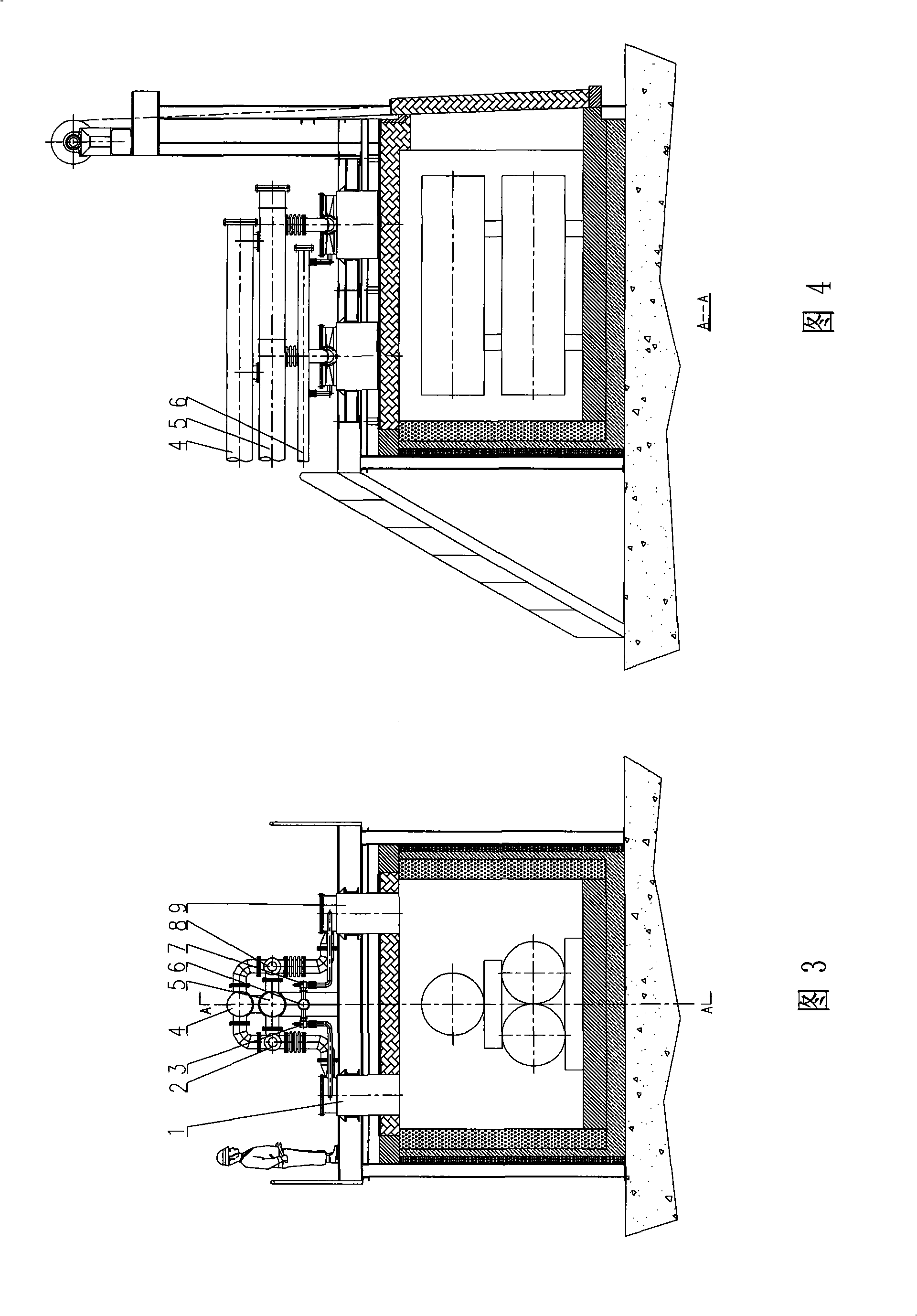

Cell-type car-type heating stove highly effective combustion system

InactiveCN101261089AImprove uniformitySolve easy blockageMechanical apparatusFurnace componentsFurnace temperatureHigh energy

The invention relates to an efficient combustion system of a chamber and car bottom heating furnace, belonging to the energy-saving and environment-protecting heating furnace technique field. The invention comprises a plurality of pairs of heat accumulating left and right sides combustion nozzles which are arranged on the two sides of the furnace top of the heating furnace, wherein, the heat accumulating left side combustion nozzles are connected with a smoke pumping main and an air main through a left side reversing valve and are connected with a gas main through a left side gas quick-switch valve; the heat accumulating right side combustion nozzles are connected with the smoke pumping main and the air main through a right side reversing valve and are connected with the gas main through a right side gas quick-switch valve; the air main is connected with a combustion air fan; the smoke pumping main is connected with a smoking machine. The efficient combustion system forms the high kinetic energy U-shaped air steam inside the furnace, thereby improving the uniformity of the furnace temperature; all the flue gas generated by the combustion of half of the combustion nozzles of the whole furnace is discharged from the other half of the combustion nozzles, thereby abolishing the tail gas duct with high energy consumption and complicated structure of the prior chamber and car bottom heating furnace; the energy consumption is reduced by 40 to 60 percent and the furnace output and the blank heating quality are improved.

Owner:WUXI LONGSHAN TECH

Automatic sand screening device for building material synthesis production and sand screening method thereof

ActiveCN112474311AAvoid settingTo achieve the effect of automatic disintegrationSievingScreeningMaterial synthesisReciprocating motion

Owner:GUIZHOU QINENG THERMAL INSULATION MATERIAL ENG CO LTD

Combined process for treatment of PTA (pure terephthalic acid) refined waste water

InactiveCN102874955AEmission reductionSolve easy blockageMultistage water/sewage treatmentNature of treatment waterFiltration membraneIon exchange

A combined process for treatment of PTA (pure terephthalic acid) refined waste water comprises the following steps: firstly, aromatic acid in the PAT refined waste water is extracted in an extraction column by using para-xylene into an extract phase, and the extract phase is conveyed to an oxidation unit to serve as a reaction raw material; a raffinate phase is conveyed to a micro-filtration membrane separation device, so that solid suspension particles in the raffinate phase are removed; and a penetrating fluid enters a resin adsorption device and an ion exchange device, so that residual aromatic acid and metal ions in the penetrating fluid are removed, and treated water meets the water standard of a PAT refining unit. According to the method, the water and the aromatic acid therein are recycled, so as to reduce the unit consumption of products and water consumption, and bring remarkable economic benefits.

Owner:NANJING UNIV OF TECH

Electrostatic spinning device

The invention discloses an electrostatic spinning device. The electrostatic spinning device comprises a spraying nozzle, a collecting device, an electrode and a high-voltage power source. Wherein the spraying nozzle is provided with a gas flow channel in the direction of the axis of the spraying nozzle, liquid flow channels are arranged around the gas flow channel in parallel, an atomizing cavity is formed in the spraying nozzle, an outlet of the gas flow channel and outlets of the liquid flow channels are all communicated with the atomizing cavity, one end of the spraying nozzle is provided with a spraying nozzle hole communicated with the atomizing cavity, the spraying nozzle hole is located on the center axis of the spraying nozzle which is made of metal materials, and the electrode and the spraying nozzle are connected with the positive electrode and the negative electrode of the high-voltage power source respectively. The spraying nozzle adopted in the device is of an inner mixed structure, compared with an outer mixed spraying nozzle without an atomizing cavity, discharged liquid particles are more uniform and smaller due to the mode that spinning liquid and compressed air are mixed in the atomizing cavity, and therefore the diameter of nanofiber obtained through stretching in a high-pressure electric field is smaller, and the nanofiber is more uniform.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

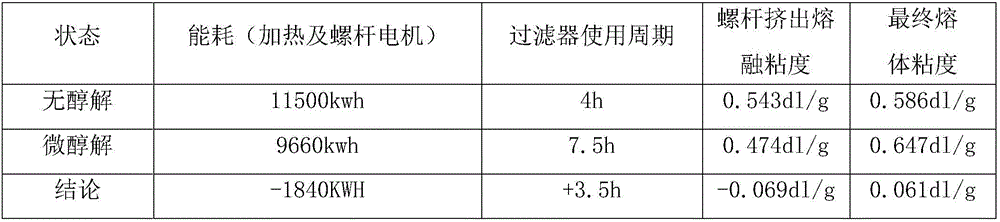

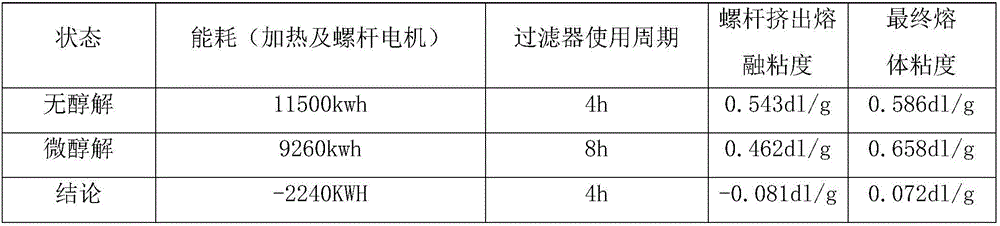

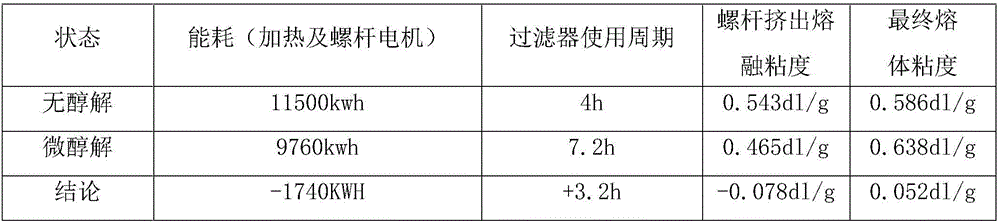

Method for preparing high-quality fusant from waste polyester textiles

InactiveCN106283226ARapid alcoholysisHigh intrinsic viscositySpinning solution de-aeratingFilament forming substance formingPolyesterPolymer science

The invention relates to high-value cycling and reusing techniques of waste polyester and particularly relates to a method for preparing a high-quality fusant from waste polyester textiles. The method comprises the following steps: adding 1-8% of alcohol into the raw material according to the mass of the raw material, and carrying out blending and melt extrusion by virtue of a screw extruder, wherein the melt viscosity of the fusant from the screw extruder is 0.40dl / g-0.50dl / g; and then adding the material into a tempering and viscosity-regulating device, wherein the melt viscosity of the fusant from the tempering and viscosity-regulating device is 0.620dl / g-0.685dl / g. According to the method, by adding a proper amount of glycol, the melt viscosity is increased, meanwhile, the problems that the cycle of a filter is short, and the maintenance quantity of a vacuum system is great are further effectively solved, the production cost is lowered, and the additional value of products is further increased.

Owner:NINGBO DAFA CHEM FIBER

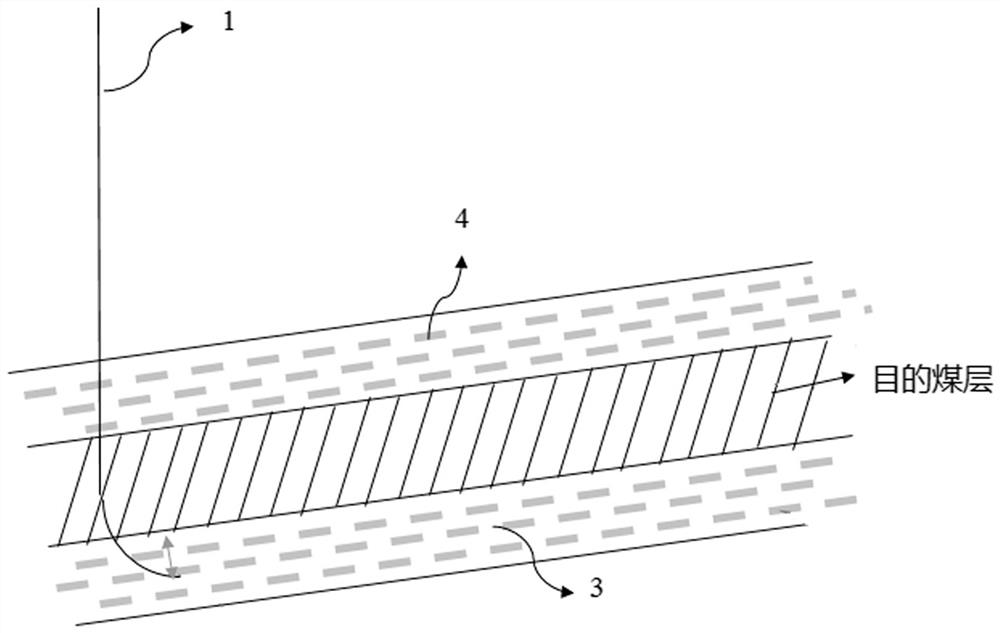

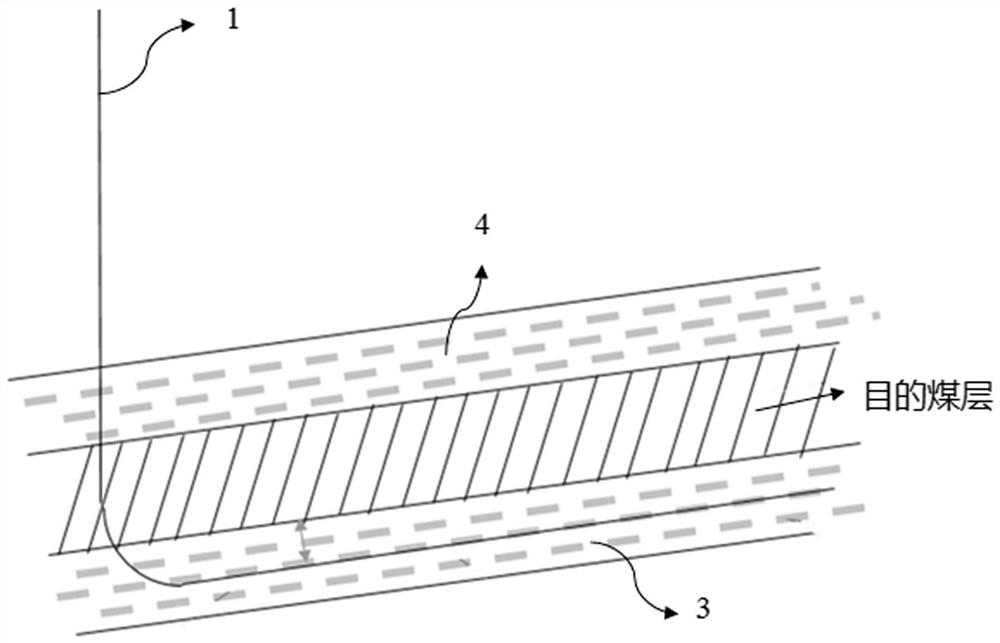

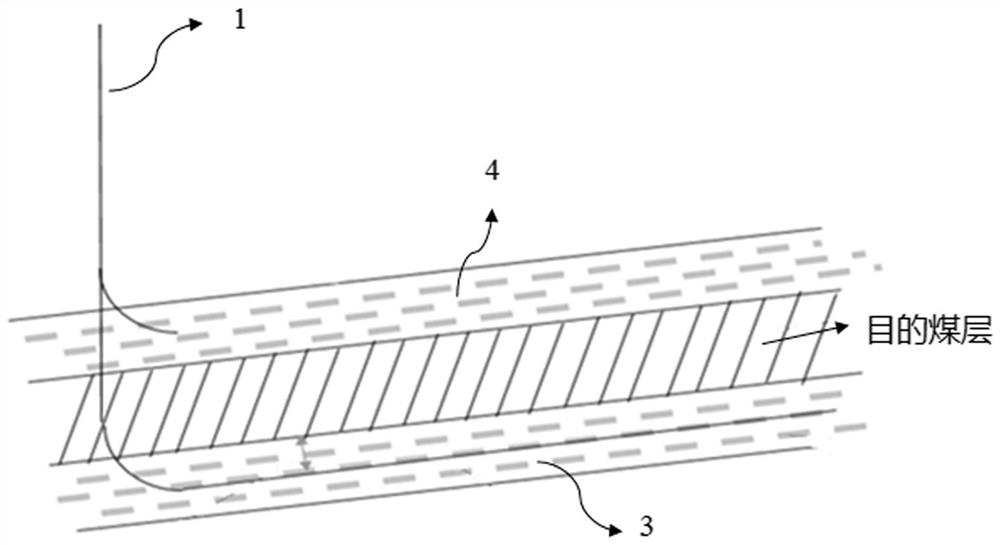

Method for transforming coal bed gas horizontal well system

PendingCN112855087AAvoid complex situations such as collapseImprove stabilityFluid removalSealing/packingMining engineeringHorizontal wells

The invention discloses a method for transforming a coal bed gas horizontal well system. The method comprises the following steps that a low-rank coal bed or a construction coal bed is selected for transformation; a first horizontal well track drills through a lower bottom plate of a target coal bed, and then drilling is carried out in the horizontal direction according to the coal bed track; cement is adopted for well cementation in the first horizontal well track; windowing sidetracking is carried out on the first horizontal well track at the upper boundary portion of the target coal bed and the position with the well deviation angle being 45-75 degrees to form a second horizontal well track, and then drilling is carried out in the horizontal direction; production casing pipes are put from the horizontal section of the first horizontal well track to the well bottom and from the windowing sidetracking point of the second horizontal well track to the well bottom respectively to form a first horizontal well and a second horizontal well; directional perforation is carried out on the second horizontal well downwards, and large-scale staged fracturing or dragging fracturing is carried out; directional perforation is carried out on the first horizontal well upwards, and hydraulic jetting or small fracturing seam forming is carried out; and an oil pipe is put to the lower boundary of coal bed gas for water drainage and pressure reduction gas recovery. The development efficiency of the coal bed gas on construction coal and low-rank coal is improved.

Owner:河北佐和佑石油技术发展有限公司

Clearing device and method for concrete conveying pump pipe of super high-rise building

ActiveCN111054708AImprove pouring efficiencyClean up thoroughlyHollow article cleaningVertical vibrationElectric machine

The invention discloses a clearing device and method for a concrete conveying pump pipe of super high-rise building. The problems that concrete bonded to the inner wall of the concrete conveying pumppipe cannot be difficultly and thoroughly cleaned up through an existing water clearing mode, and the construction progress is influenced are solved. The device comprises a vertical vibration mechanism, a lateral supporting and positioning mechanism and a pump pipe dredging and clearing mechanism which are coaxially and sequentially connected, wherein a coarse grinding wheel support and a fine grinding wheel support of the pump pipe dredging and clearing mechanism are driven by a rotating motor to do circular motion along the inner wall of a pipeline, and the concrete on the inner wall of thepipeline is removed through rotating grinding of the coarse grinding wheel and vertical vibration impact of the fine grinding wheel; two installing bases of the vertical vibration mechanism are flexibly connected through a spring type connecting piece arranged between the two installing bases, and a vibration motor set drives the pump pipe dredging and clearing mechanism to vibrate back and forthalong the axis of the pipeline; and a plurality of support positioning springs and guide rolling wheels are uniformly distributed on a guiding rod of the lateral supporting and positioning mechanism in the radial direction, and the guide rolling wheels are driven to prop against the inner wall of the pipeline by reverse acting force generated by pressing the support positioning springs.

Owner:SHANGHAI CONSTRUCTION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com