Clearing device and method for concrete conveying pump pipe of super high-rise building

A technology for concrete delivery pumps and cleaning devices, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., which can solve problems such as difficult removal of concrete and affect construction progress, so as to improve pouring efficiency, reduce additional costs, Avoid the effect of bursting tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment takes the cleaning construction of the concrete that is bonded to the inner wall of the concrete delivery pump pipe 2 used in the construction process of a super high-rise building 1 as an example, and describes in detail the cleaning device for the concrete delivery pump pipe of a super high-rise building of the present invention. The height of 1 is about 500 meters, and the diameter of concrete delivery pump pipe 2 is 250mm.

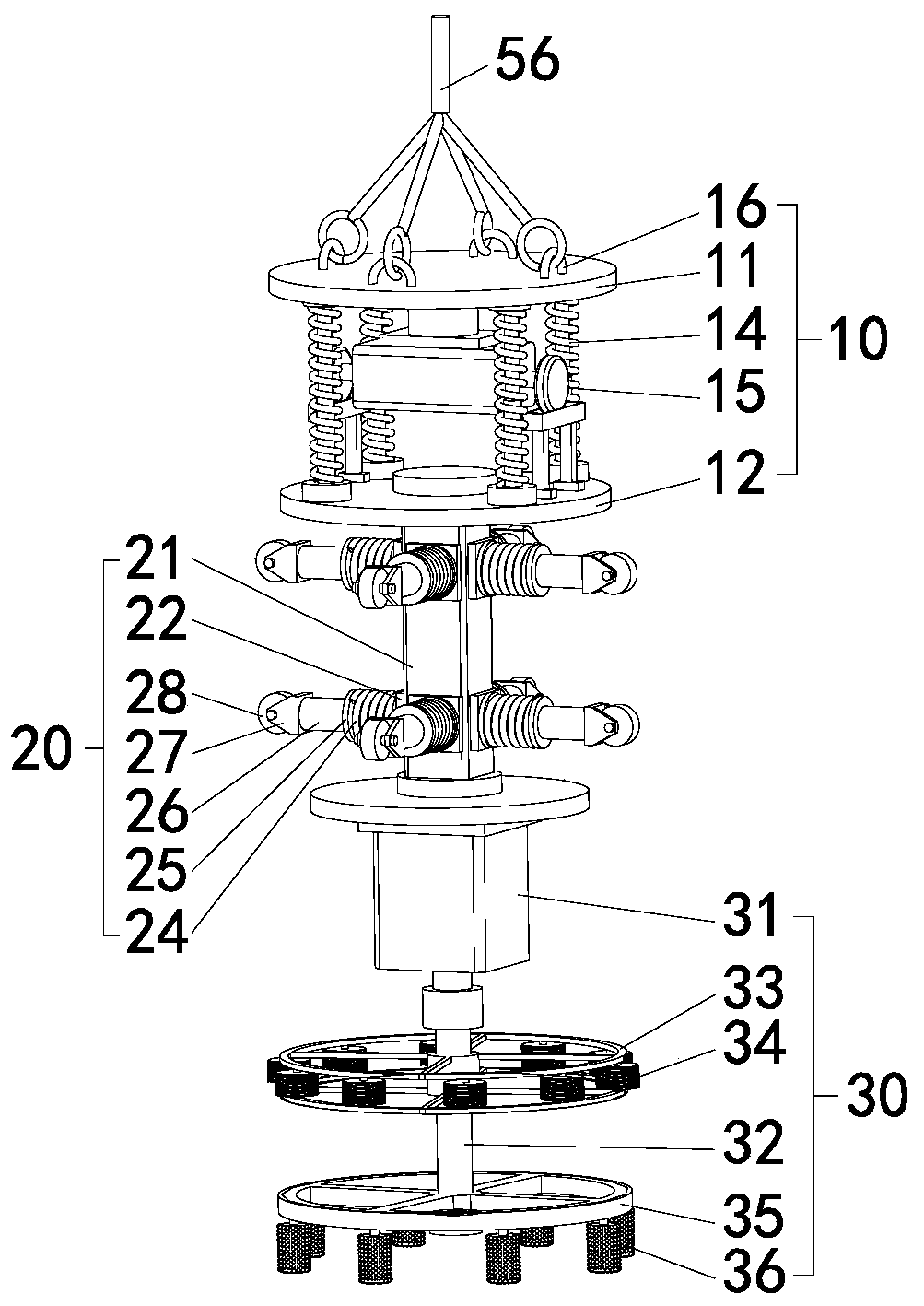

[0035] Combine below Figure 1 to Figure 4 Illustrate the cleaning device of the super high-rise building concrete delivery pump pipe of the present invention, it comprises: the vertical vibrating mechanism 10 that coaxially arranges and connects successively, lateral support positioning mechanism 20 and pump pipe dredging and cleaning mechanism 30, wherein,

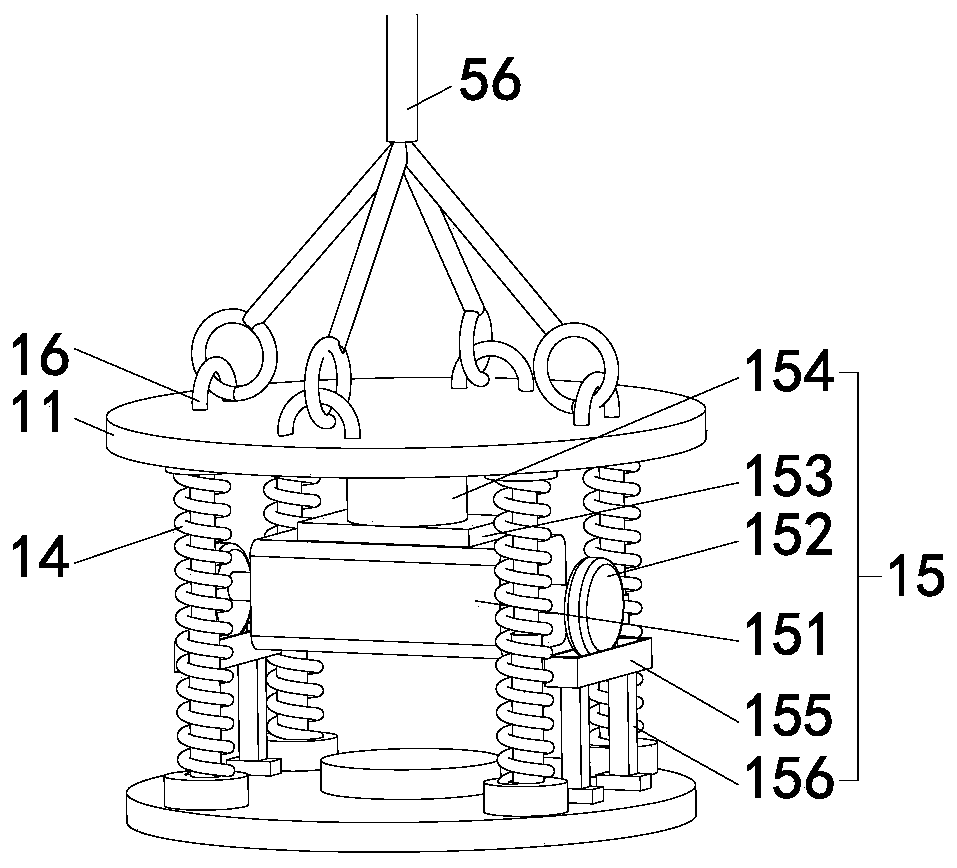

[0036] The vertical vibration mechanism 10 includes a mounting base 11 and a mounting base 2 12 arranged parallelly and at intervals up and down, a vibration motor unit 15 ...

Embodiment 2

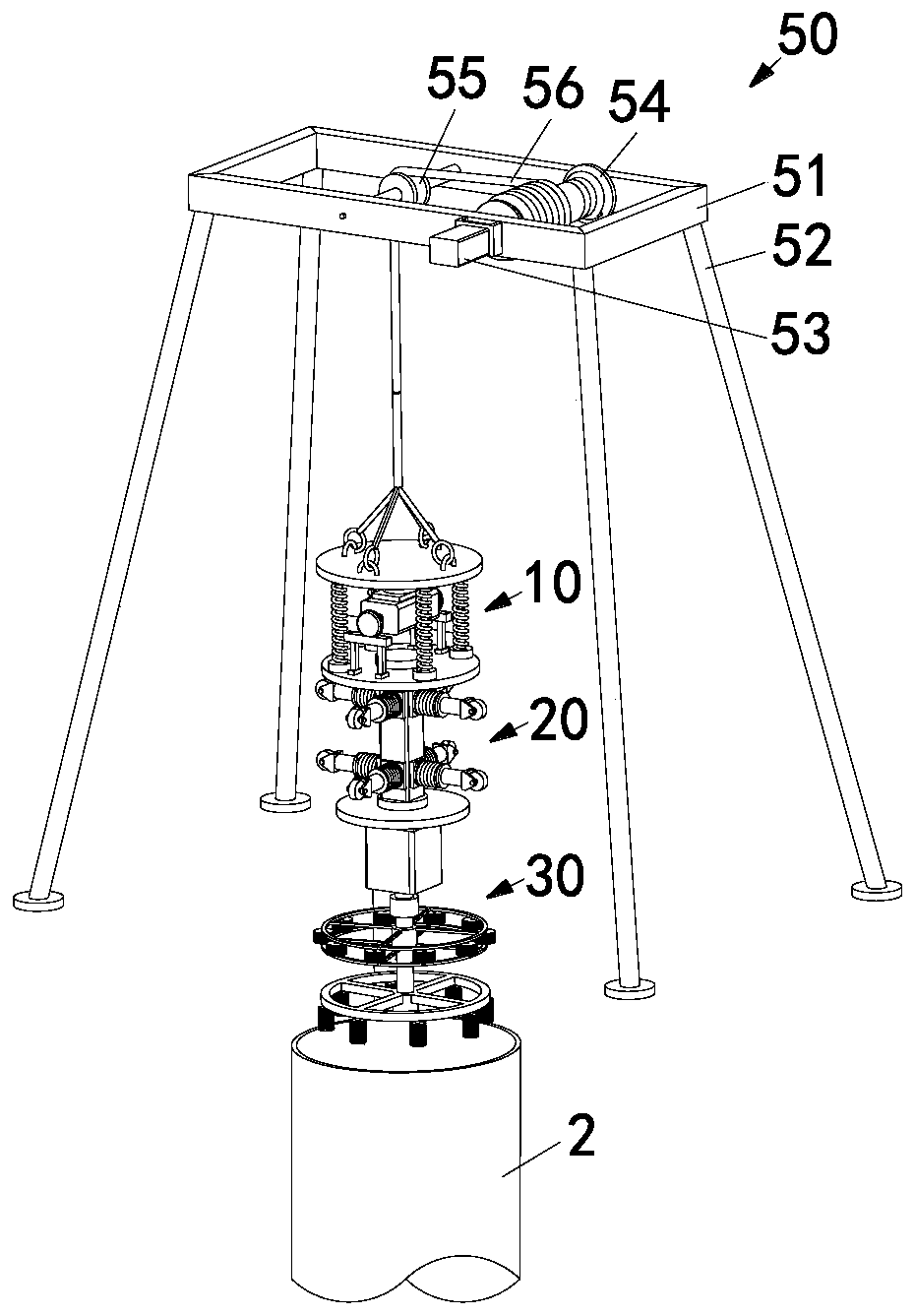

[0045] Different from Example 1, as image 3 As shown, the cleaning device of the super high-rise building concrete delivery pump pipe also includes a lifting mechanism 50, which includes a rectangular support frame 51, a lifting motor 53 fixed on the outside of the support frame 51, a rotating line fixed in the support frame 51 and arranged in parallel. Rod 54 and positioning concave wheel 55, the rotating wire rod 54 that is wound with traction steel wire rope 56 is connected with the rotating shaft of lifting motor 53, and the other end of traction steel wire rope 56 walks around positioning concave wheel 55 and is fixed on the mounting base-11 top multiple connected with a tension steel ring 16 for lifting or lowering the connected vertical vibration mechanism 10, lateral support positioning mechanism 20 and pump pipe dredging and cleaning mechanism 30. In this embodiment, the end of the traction wire rope 56 has four wire rope branches, and each wire rope branch end is co...

Embodiment 3

[0048] In this embodiment, taking the cleaning construction of the concrete that is bonded to the inner wall of the concrete delivery pump pipe 2 used in the construction process of a certain super high-rise building 1 as an example, the cleaning method of the super high-rise building concrete delivery pump pipe of the present invention is described in detail. The specific steps are as follows:

[0049] After the vertical vibrating mechanism 10, the lateral support positioning mechanism 20 and the pump pipe dredging and cleaning mechanism 30 arranged coaxially and connected in sequence are put into the inner cavity of the concrete delivery pump pipe 2, the lateral support positioning mechanism 20 enters the working state, and the multiple The reverse force generated by the pressure of the support positioning spring 24 drives the guide roller 28 against the inner wall of the concrete delivery pump pipe 2 to maintain stability, ensuring that the pump pipe dredging and cleaning mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com