Patents

Literature

207results about How to "Improve pouring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enzyme delivery systems and methods of preparation and use

ActiveUS20100260857A1Improve stabilityEnhanced administration propertyPowder deliveryNervous disorderDiseaseCystic fibrosis lungs

This invention relates to coated digestive enzyme preparations and enzyme delivery systems and pharmaceutical compositions comprising the preparations. This invention further relates to methods of preparation and use of the systems, pharmaceutical compositions and preparations to treat persons having ADD, ADHD, autism, cystic fibrosis and other behavioral and neurological disorders.

Owner:CUREMARK

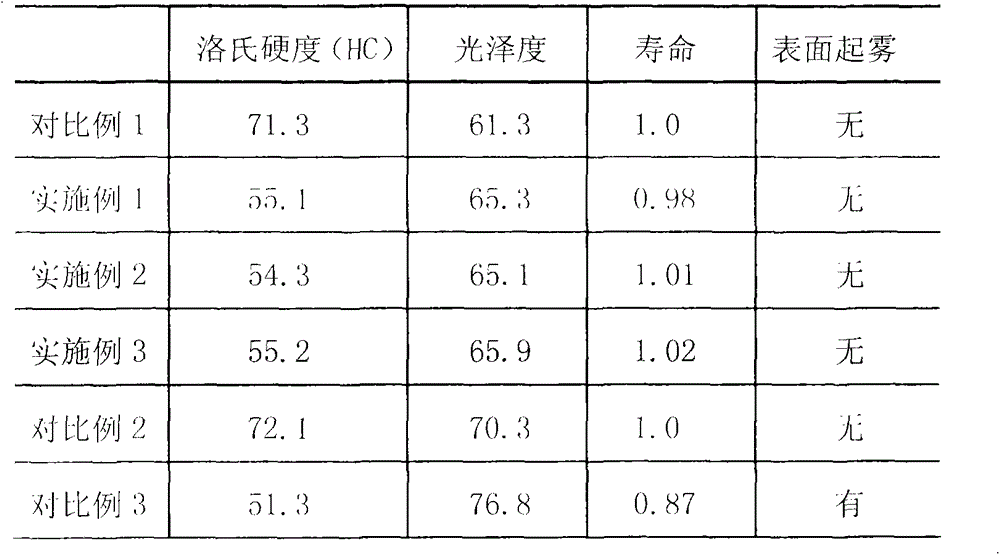

Method for preparing sharp type epoxide resin binding agent diamond abrasive tool

ActiveCN103056788AImprove bindingInhibit sheddingAbrasion apparatusGrinding devicesFirming agentEpoxide

The invention discloses a method for preparing a sharp type epoxide resin binding agent diamond abrasive tool. A working layer is mainly made of diamond abrasive, an epoxide resin binding agent, a curing agent, an auxiliary abrasive, a filler and an auxiliary assistant. The method comprises steps of uniformly mixing 5-20 parts by mass of self-sharpening diamond, 5-28 parts by mass of auxiliary abrasive, 10-40 parts by mass of filler and 0.5-10 parts by mass of auxiliary assistant through a machine; uniformly mixing the mixture, 17-25 parts by mass of liquid epoxide resin and 5-25 parts of curing agent; injecting the fluid mixture to a plastic die through a pouring mode; and obtaining the sharp type epoxide resin binding agent diamond abrasive tool after curing. Compared with the method for preparing the abrasive tool through hot press molding, the method has the advantages that the process is simple, the energy is saved, the emission is reduced, the pollution of solid powder on the environment is reduced, the method is environment-friendly, the production speed is quick, the sharpening degree is high, the self-sharpening performance is good, the polishing effect is good and the service life is long.

Owner:惠安宇信金刚石工具有限公司

Enzyme Delivery Systems and Methods of Preparation and Use

ActiveUS20120027848A1Improve stabilityImprove propertiesPowder deliveryNervous disorderDiseaseCystic fibrosis

This invention relates to coated digestive enzyme preparations and enzyme delivery systems and pharmaceutical compositions comprising the preparations. This invention further relates to methods of preparation and use of the systems, pharmaceutical compositions and preparations to treat persons having ADD, ADHD, autism, cystic fibrosis and other behavioral and neurological disorders.

Owner:CUREMARK

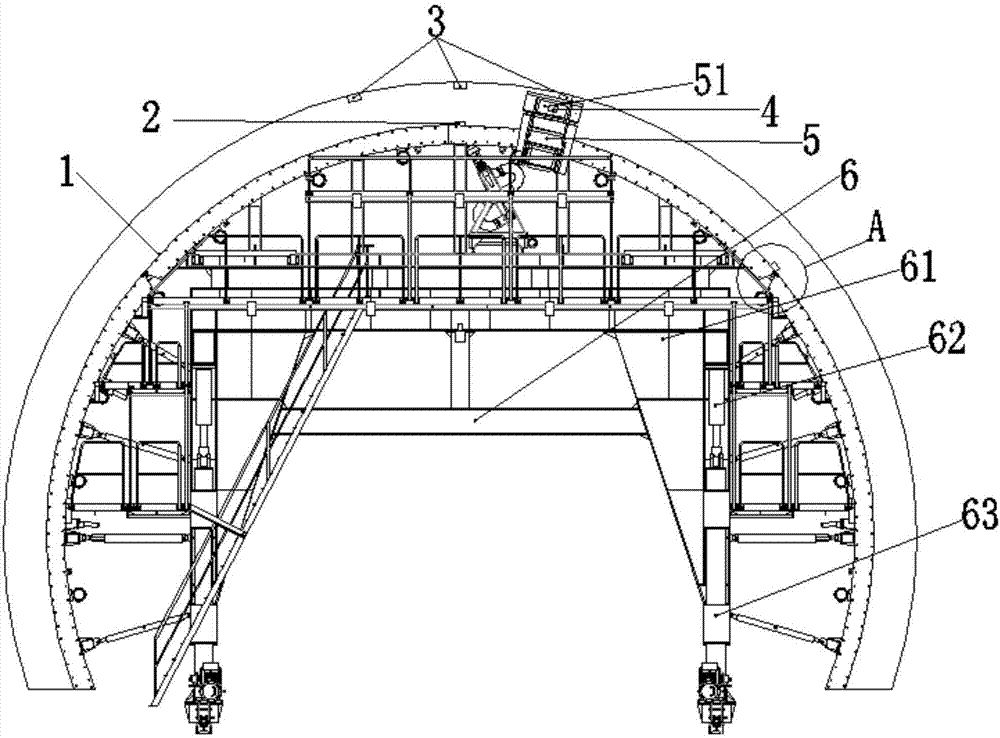

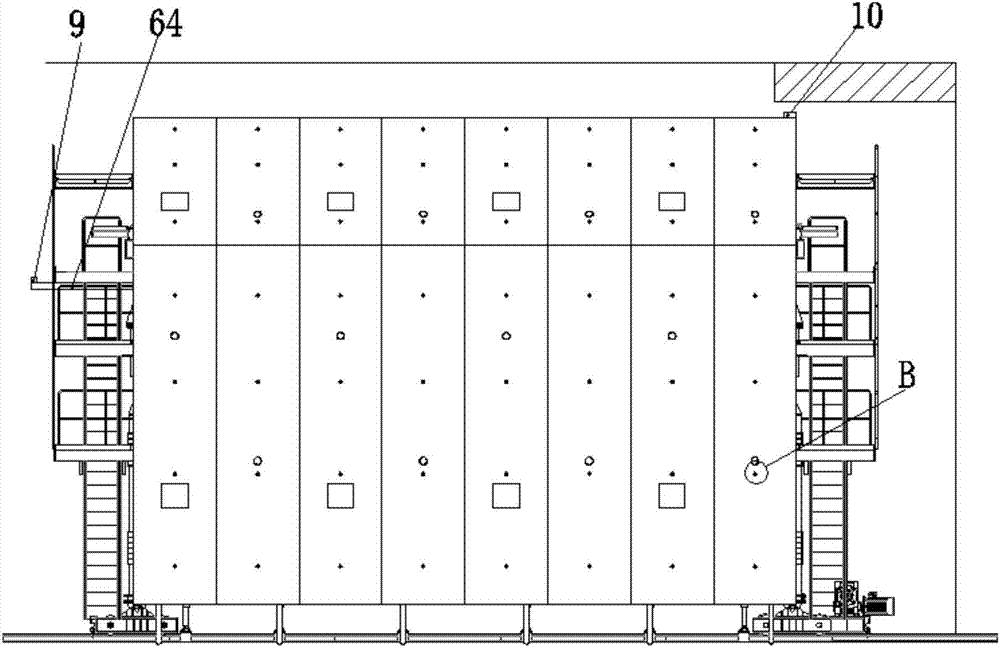

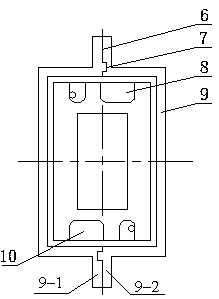

Intelligent tunnel lining trolley

PendingCN107956490AEasy loading and unloadingPlace stableUnderground chambersTunnel liningMonitoring systemSteel frame

Provided is an intelligent tunnel lining trolley, characterized by comprising a door-shaped main steel frame, a concrete pouring informationized monitoring system, an end template, a template cleaningand surface lubricating system, an automatic running gear, and a layered window-by-window pouring and cleaning system. The tunnel lining trolley is simple in structure and reasonable in design, and real-time monitoring of each parameter in a concrete pouring process is realized, automation degree of equipment is improved, cleaning and template surface lubrication operation flow are simplified. The intelligent tunnel lining trolley provides convenience for on-site management and construction, and has certain environmental protection property and very high security.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

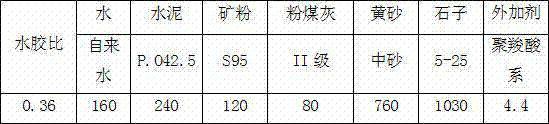

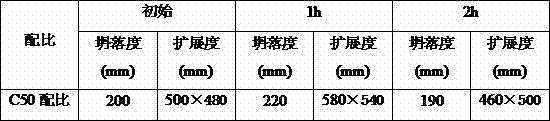

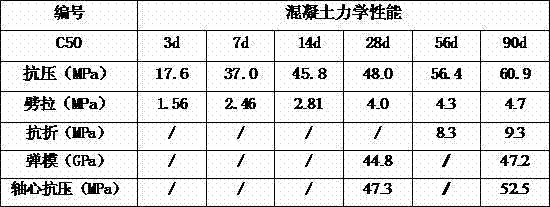

Concrete with ultra-large volume, high strength and low hydration heat

The invention relates to concrete with ultra-large volume, high strength and low hydration heat. The concrete comprises the following components in parts by weight (cube dosage kg / m3): 200-260 parts of cement, 100-160 parts of mineral powder, 80-100 parts of fly ash, 740-800 parts of fine aggregate, 1010-1050 parts of coarse aggregate, 4.0-5.0 parts of additive and 155-165 parts of water. The concrete with ultra-large volume, high strength and low hydration heat can be used to effectively reduce the hydration heat, greatly reduce the cracking risk of the large-volume concrete from the source and increase the engineering quality.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +5

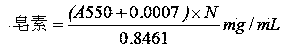

Preparation method for epoxy resin binding agent diamond grinding tool with high polishing performance

ActiveCN104057403ALow hardness valueReduce pollutionAbrasion apparatusGrinding devicesEpoxyRare earth

The invention discloses a preparation method for an epoxy resin binding agent diamond grinding tool with high polishing performance. A working layer is mainly prepared from a diamond grinding material, an auxiliary grinding material, epoxy resin, a curing agent, rare earth polishing powder, filler and a dilution agent. The preparation method comprises the steps of uniformly and mechanically mixing 5-20 parts of the diamond grinding material, 5-20 parts of the auxiliary grinding material, 5-25 parts of the rare earth polishing powder and 5-40 parts of the filler to obtain a first mixture, then uniformly mixing and stirring the first mixture with 20-40 parts of the epoxy resin, 7-15 parts of the curing agent and 0.5-10 parts of the dilution agent to obtain a final mixture, injecting the mixture with flowability into a plastic mold in a pouring manner, and curing the mixture to obtain the epoxy resin binding agent diamond grinding tool with high polishing performance. The materials are in percentage by mass. Compared with the conventional hot pressing molding method, the preparation method has the advantages that the technology is simple, the energy is saved, and the emission is reduced; the pollution, which is caused by solid dust, to the environment is reduced, and the production speed is high; compared with the conventional product in the foreign country, the epoxy resin binding agent diamond grinding tool has the advantages of good polishing effect, high polishing efficiency, few air hole defects of the grinding tool and the like.

Owner:惠安宇信金刚石工具有限公司

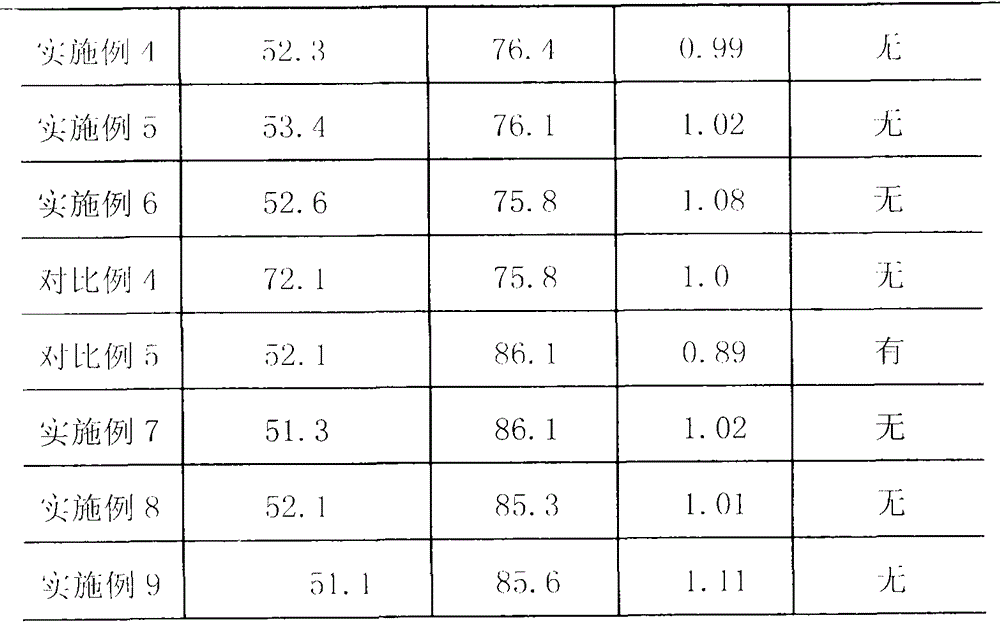

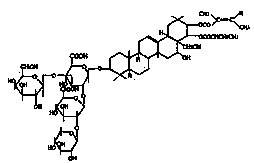

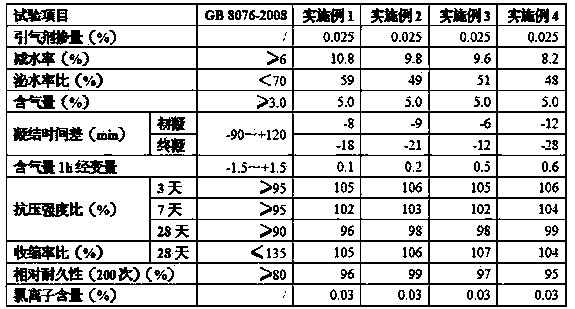

Sasanqua saponin concrete air entraining agent and preparation method thereof

The invention provides a sasanqua saponin concrete air entraining agent and a preparation method thereof. The air entraining agent is characterized by containing sasanqua saponin therein. The preparation method is characterized by extracting sasanqua as a raw material at normal temperature by hydrophilic solvent water solution, and filtering; removing large-molecule impurities from the filtrate by membrane separation under pressure, removing small-molecule impurities by membrane separation, concentrating to be concentrate with Baume degree of not lower than 10Be (60 DEG C), and spray-drying to form solid formulation; or adding a modifying agent to prepare the air entraining agent in liquid formulation. The idea is novel, the raw materials are abundant, the production efficiency is high, the energy consumption in the production is low, the production cost is low, the preparation method is simple in process, green and environment-friendly and is convenient to implement; when the air entraining agent is used in concrete engineering, the dosage of the air entraining agent is low, the air production rate is high, the aperture of the entrained air bubbles is small and the distance among the entrained air bubbles is small, and the air holes of the concrete are more even, more compact and non-communicated, therefore, the sasanqua saponin concrete air entraining agent is valuable for popularizing.

Owner:FUZHOU UNIV

Concrete preparation method

InactiveCN108214863AWell mixedExpand the scope of workDischarging arrangementCeramic shaping plantsRaw materialCivil engineering

The invention relates to the technical field of concrete preparation, in particular to a concrete preparation system and method. The concrete preparation system comprises a raw material weighing device, a raw material mixing device, a pouring-into-mold device, a curing device, a demolding device and a mold cleaning device. Through reasonable arrangement of the above processes and coordination anddistribution of responsibilities, concrete is prepared, an automatic process of concrete preparation is realized, labor is saved, work efficiency is improved, and use is convenient.

Owner:湖南道同消防工程有限公司

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

Electrolyte solution for lithium titanate battery and lithium titanate battery thereof

ActiveCN104752768AImprove stabilityImprove high temperature resistanceCell electrodesSecondary cellsPropane sultoneVinylene carbonate

The invention discloses an electrolyte solution for a lithium titanate battery and the lithium titanate battery thereof. The electrolyte solution for the lithium titanate battery comprises lithium salt, organic solvent and additive, wherein the additive is formed by the following ingredients through adopting the total weight of the electrolyte solution as the standard: 1.5-3.5 percent of dimethyl carbonate, 0.05-0.25 percent of ethylene carbonate, 0.15-0.35 percent of LiBOB, 0.1-0.45 percent of vinylene carbonate, 0.07-0.35 percent of crown ether, 0.04-0.06 percent of LiF, 0.05-0.065 percent of monofluoro ethylene carbonate, 0.05-0.25 percent of phenylcyclohexane, 0.1-0.45 percent of biphenyl, and 0.1-0.45 percent of 1,3-propane sultone. According to the electrolyte solution for the lithium titanate battery, the stability of a high-temperature SEI film under high temperature is improved, the resistance to high temperature of the electrolyte solution is improved, the cycle performance is excellent, the service life is prolonged, and meanwhile, the high-and-low temperature performance and the flame retardant property are improved.

Owner:启东市滨化供水有限公司

RH vacuum calcification furnace process treatment method

ActiveCN111575446AStable and efficient calcium treatment processImprove pouring effectCalcium handlingSlag

The invention discloses an RH vacuum calcification furnace process treatment method. The RH vacuum calcification furnace process treatment method comprises the following steps of KR molten iron pretreatment, converter smelting, RH vacuum refining and slab continuous casting, wherein the RH vacuum refining comprises decarburization, deoxidation alloying and calcium treatment; in the decarburizationprocess, a slag surface deoxidizing agent is added to the surface of furnace slag in the middle and later periods of the decarburization, the adding amount is 1.0-2.0 kg per ton of steel, and the ladle slag is modified to enable the content of (T.Fe + MnO) in the slag to be less than or equal to 5 wt%; in the deoxidation alloying process, an alloy and carbon powder are added for the deoxidation alloying; in the calcium treatment process, a seamless pure calcium wire is started to be fed for calcium treatment 5 minutes after the deoxidation alloying is finished, and the pressure of a vacuum chamber is increased to 200 mbar or above during the calcium treatment; and after the calcium treatment is finished, the pressure of the vacuum chamber is reduced to 2 mbar or below, static circulationis conducted for 6 minutes, and then vacuum breaking tapping is conducted. According to the process method, the seamless calcium wire is fed after the deoxidation alloying, and meanwhile, the Ca element is uniformly distributed in molten steel by utilizing RH molten steel circular stirring, so that the modification of Al2O3 inclusion is realized, the Ca element oxidation amount is low, the calciumyield is increased, and the calcium treatment effect is stabilized.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

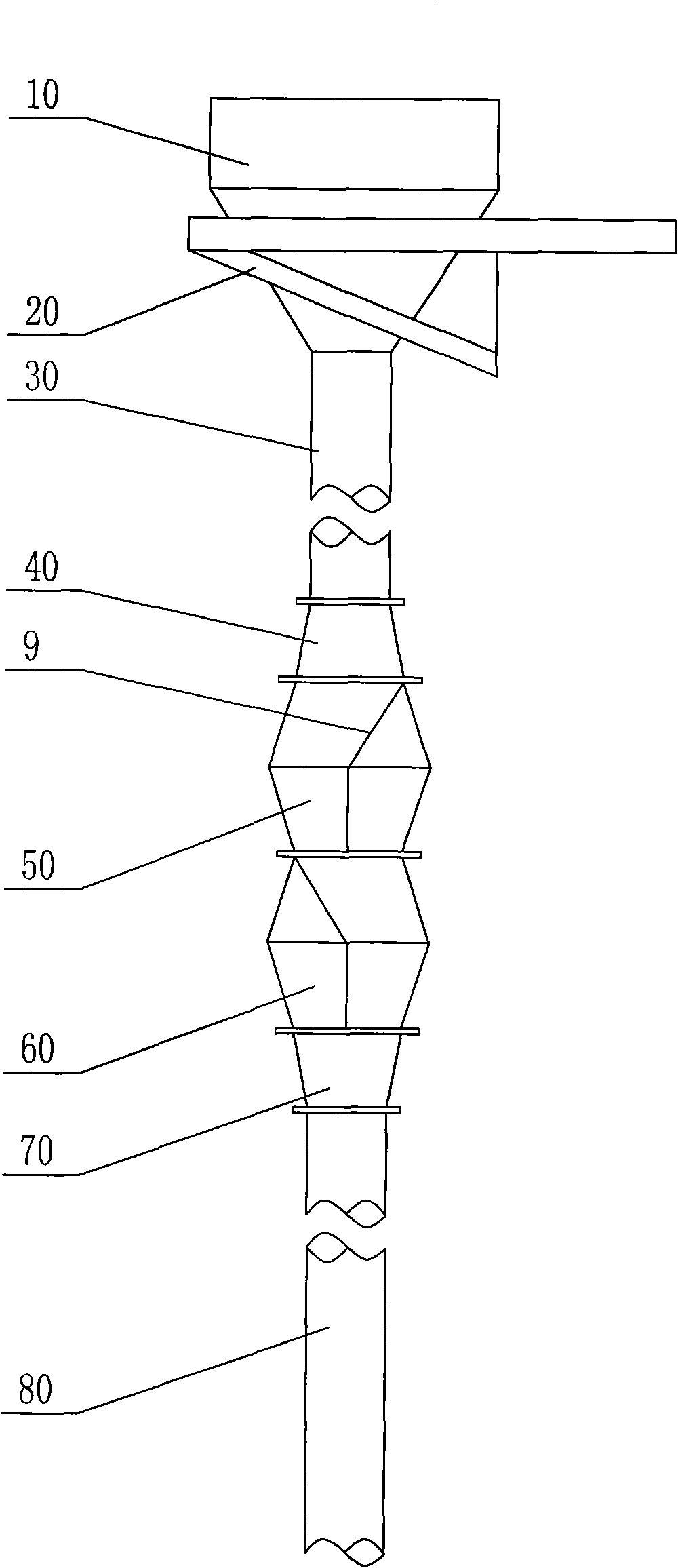

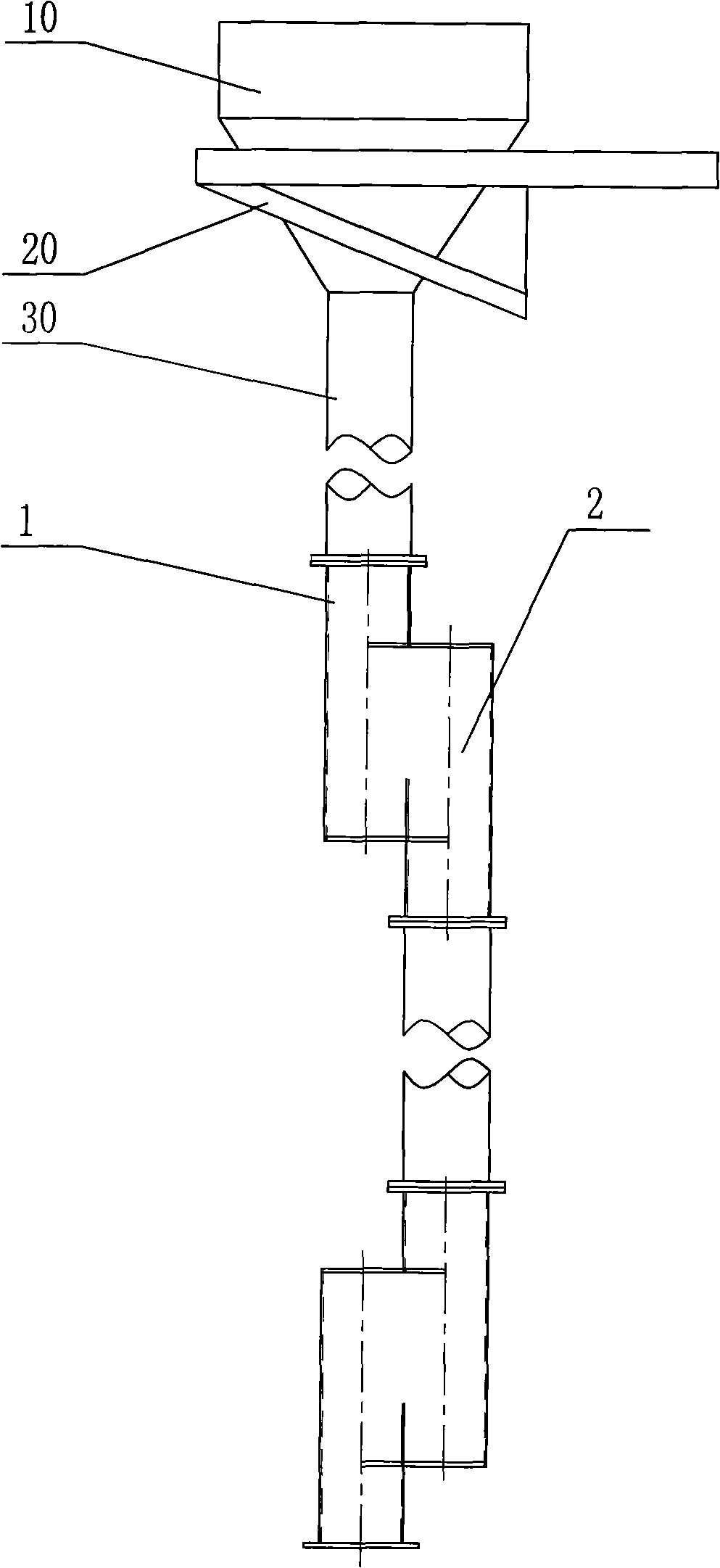

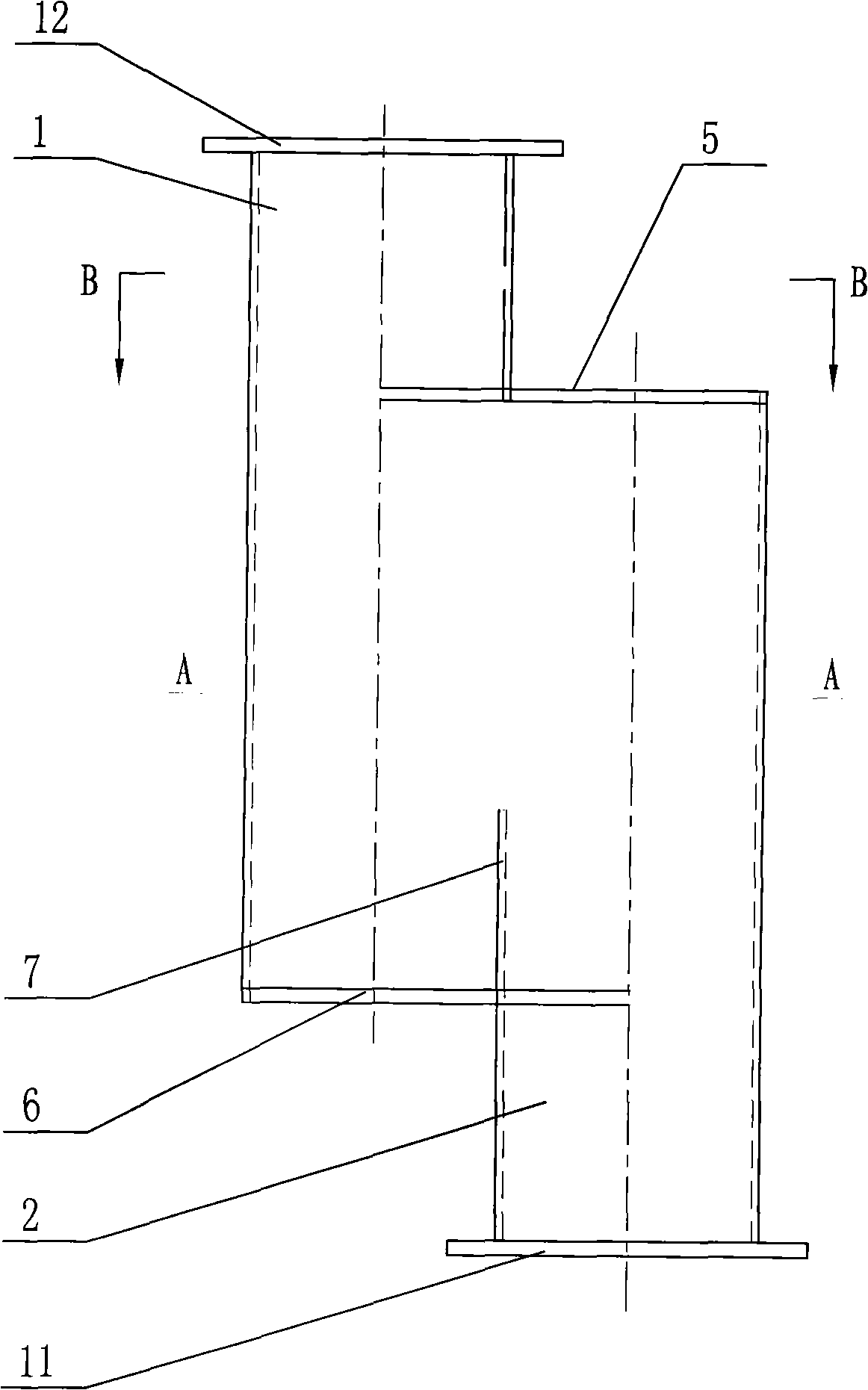

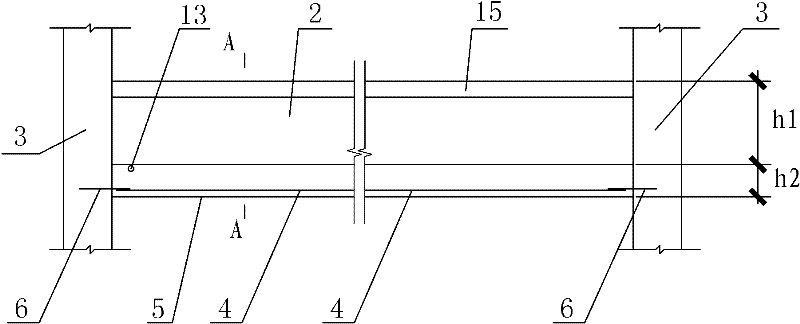

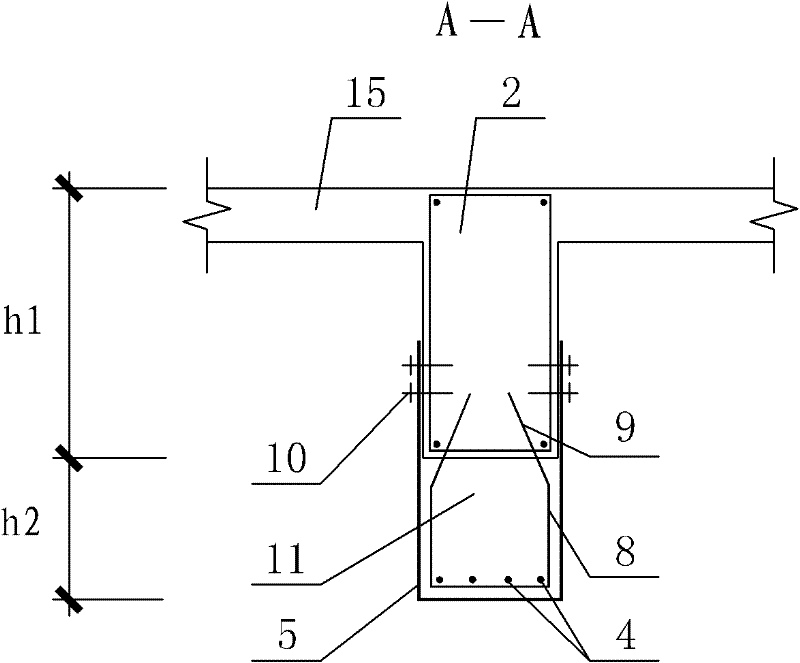

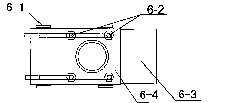

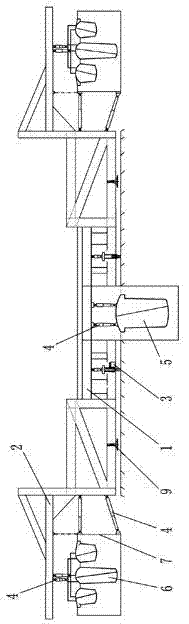

Concrete vertical conveying descent control device

InactiveCN101280627AImprove workabilityAvoid separationBuilding material handlingAerospace engineering

The invention discloses a descent control device for vertically conveying concrete, which comprises a left circular tube and a right circular tube; the central lines of the left circular tube and the right circular tube are in parallel and the left circular tube and the right circular tube are arranged alternately at the direction of height; cuts of certain length are arranged on both the left circular tube and the right circular tube; the cut on the left circular tube and the cut on the right circular tube correspond to each other at the direction of length; in addition, the front lateral sides and the rear lateral sides of the cut on the left circular tube and the cut on the right circular tube are correspond to each other and connected with each other by a front-side connecting plate and a rear-side connecting plate; the upper end parts and the lower end part of the left circular tube and the right circular tube are connected with an upper sealing board and a lower sealing board correspondingly; the left circular tube and the right circular tube form a communicated containing cavity by the corresponding connection of the front-side connecting plate, the rear-side connecting plate, the upper sealing board and the lower sealing board; the inner surface of the lower sealing board is provided with a clapboard in parallel to the central lines of the circular tubes at two sides. When used for vertically conveying concrete, the descent control device can prevent the concrete from separating, effectively improves the workability of the concrete; the descent control device has long service life, no frequent examination and repair or replacement, simple structure and low manufacturing cost.

Owner:SINOHYDRO BUREAU 14 CO LTD

Grouting material and perfusion of same into enclosed steel die for reinforcement of steel concrete beams and columns

InactiveCN102351482AGood sealing effectEasy constructionBuilding repairsRebarReinforced concrete column

The invention provides a grouting material and perfusion of the same into an enclosed steel die for reinforcement of steel concrete beams and columns, and relates to grouting materials and perfusion of the same into steel dies for reinforcement of steel concrete beams and columns. The invention is aimed to overcome the problem that compact pouring of concrete is difficult to realize when original concrete beams and columns are reinforced by using the method of enlarging sections. The grouting material is prepared by mixing P.052.5 ordinary Portland cement, a UEA expanding agent, an FDN high efficiency water reducing agent and water. According to the invention, stirrups are arranged below an original steel concrete beam and are fixedly connected with the original steel concrete beam through first connecting steel bars, loaded steel bars are fixedly connected with a bearer of the original steel concrete beam through second connecting steel bars, a U-shaped channel steel die is fixedly sleeved on the steel bars and the original steel concrete beam; anchor bolts are fixedly connected with the original steel concrete column, the loaded steel bars are arranged at external sides of the original steel concrete column and are strapped by the stirrups, the loaded steel bars are in fixed connection with an upper bearer and a lower bearer of the original steel concrete column through the first and second connecting steel bars, steel templates are cladded over the stirrups, and the grouting material is perfused into an enclosed perfusion cavity. The invention is applicable to reinforcement of steel concrete beams and columns.

Owner:HARBIN INST OF TECH

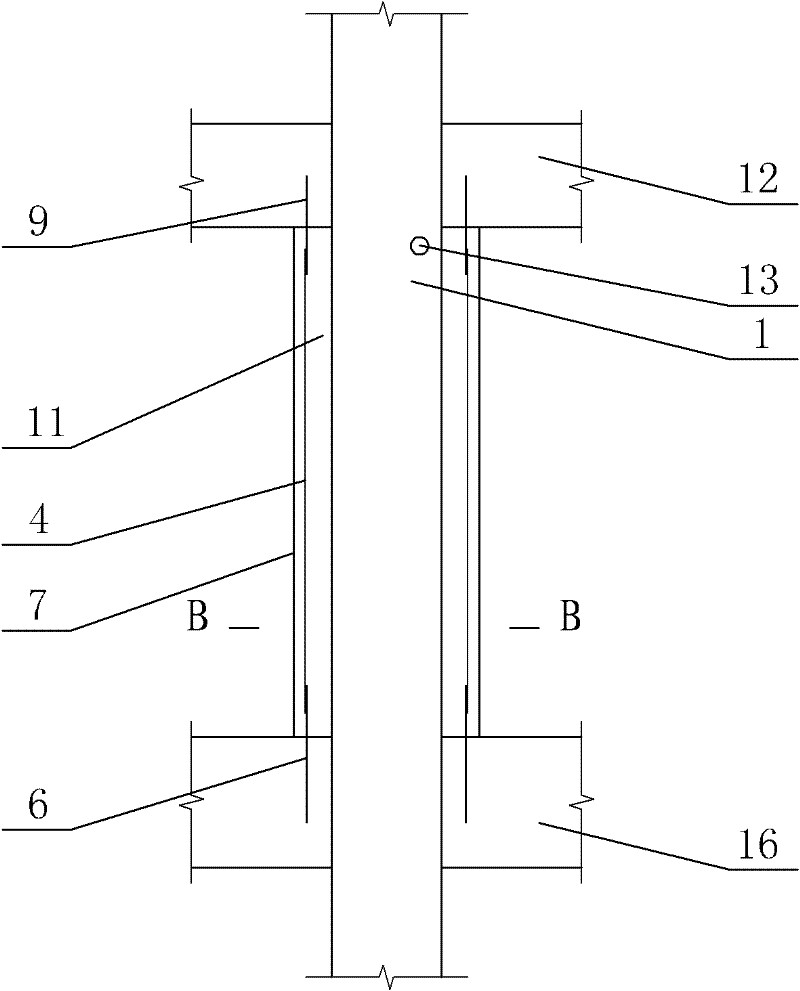

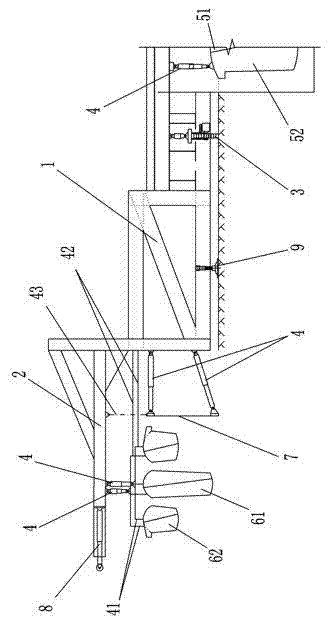

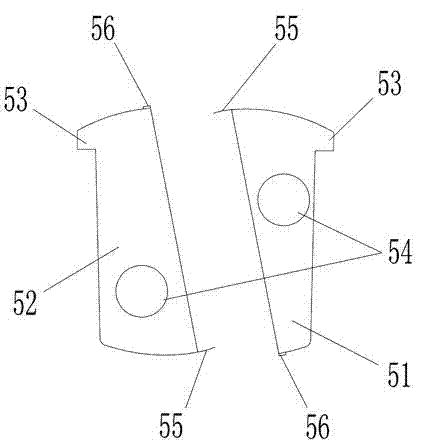

Column core concrete lift-up connecting device of steel pipe column

InactiveCN101824917APrevent backflowPrevent spillageStrutsBuilding material handlingSteel tubeGlobe valve

The invention relates to a column core concrete lift-up connecting device of a steel pipe column, belonging to the technical field of building construction. The device comprises an elbow with a horizontal port and an upwarping port. A one-way valve cover is installed at the higher side of the upwarping port of the elbow through a hinge, and the higher side of the upwarping port extends into the steel pipe column from the lower part of the steel pipe column; the horizontal port of the elbow is connected with a pumping line, and the pumping line is provided with a stop valve with a plug-in board. When the device works, the upwarping end extends into the steel pipe column, but not clings to the pipe wall of the steel pipe column, therefore, concrete is pumped out by a pipe core with favorable pouring effect; a one-way valve and the stop valve prevent the concrete from flowing backwards respectively at the inside and the outside of the steel pipe column, and therefore, the invention fulfills a function of double insurance, is reliable, also has favorable sealing effect and can keep the lift-up pressure; and when the pressure in a pipe is larger, the one-way valve firstly shares the pressure, thereby efficiency avoiding overflowing of the concrete at the stop valve, therefore, the invention is particularly suitable for pouring the higher steel pipe column.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

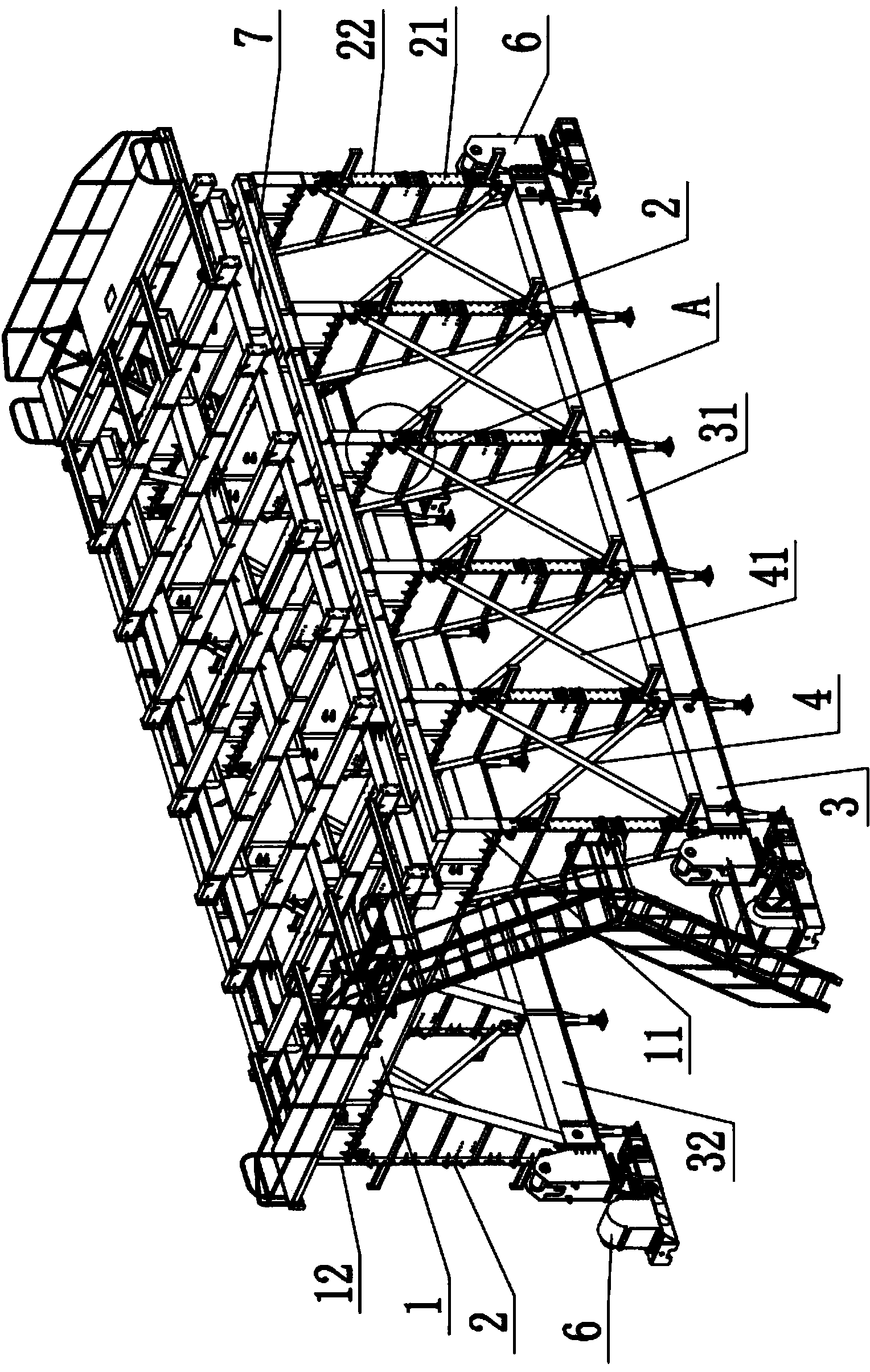

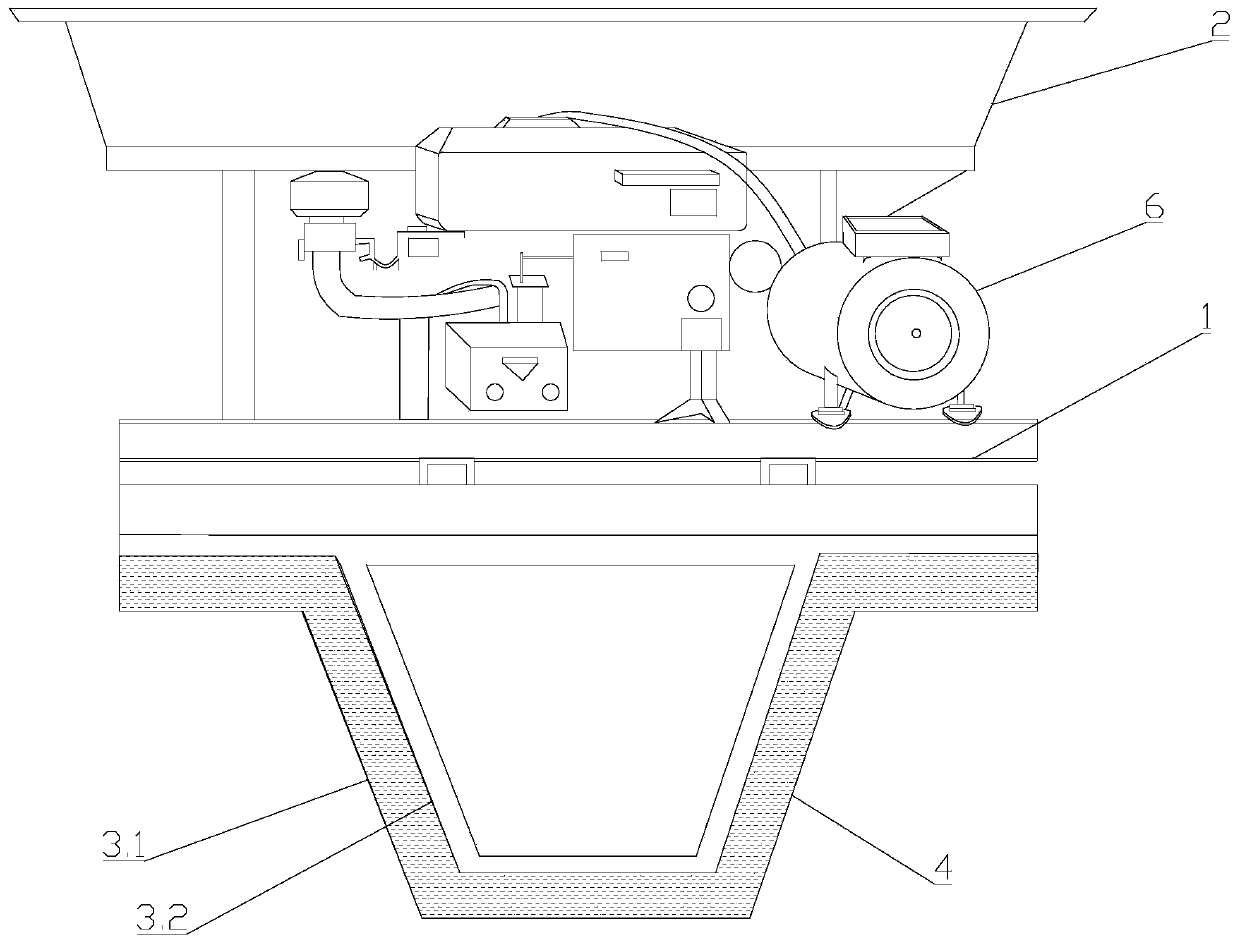

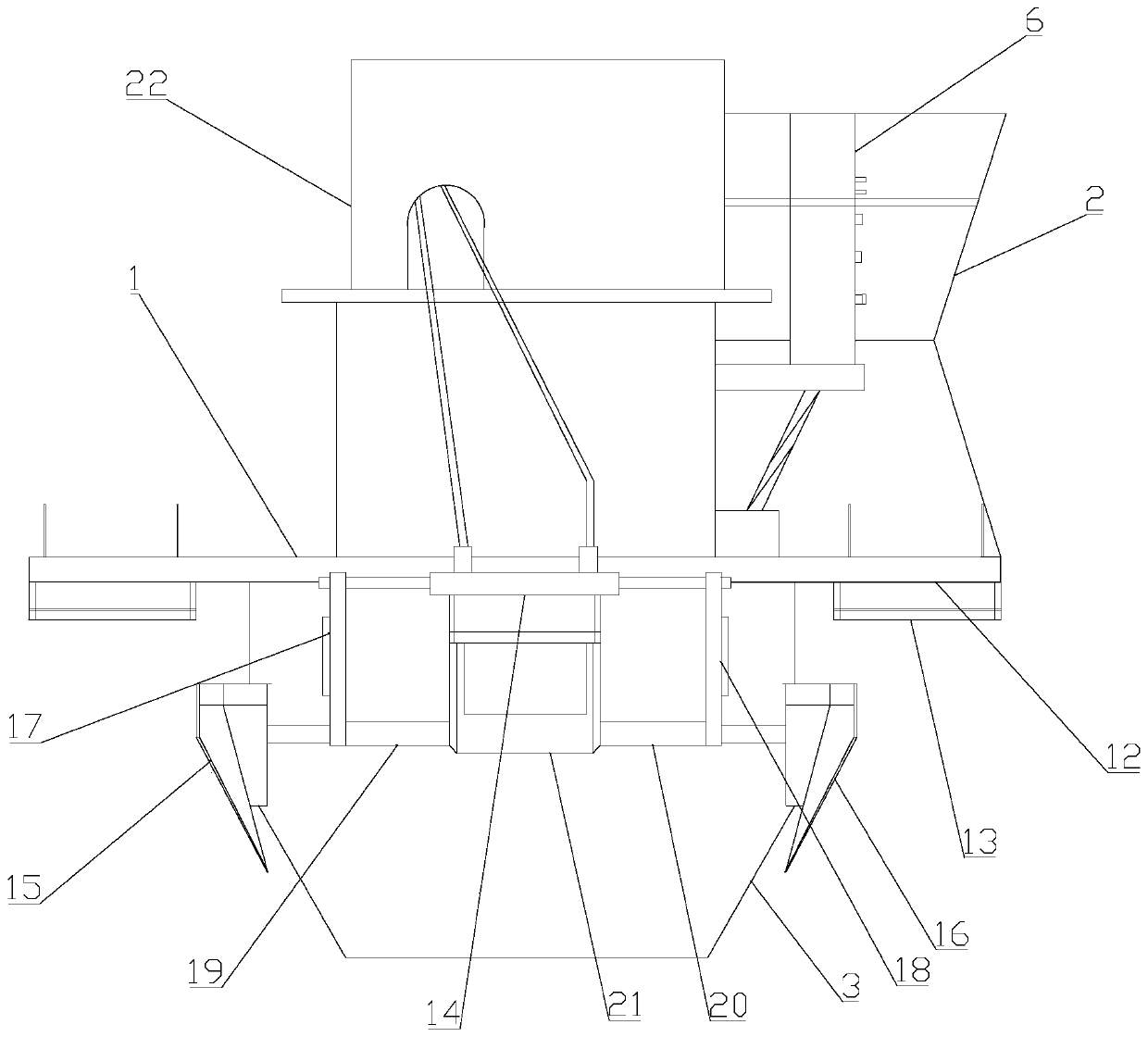

Forming device for tunnel center gutter and side ditches and forming process thereof

ActiveCN102828758AImplement automatic installationAchieve disassemblyUnderground chambersTunnel liningWorkloadForming processes

The invention relates to a forming device for a tunnel center gutter and side ditches and a forming process thereof. A used mold board is an integral type groove mold board with a complete groove shape, the forming device comprises a traveling device for driving the device to move in a tunnel, and a plurality of telescopic mechanisms are used for controlling the mold board to perform automatic installation and disassembly; and the process adopting the device to pour can simultaneously perform symmetrical pouring on the side ditches on the two sides of the tunnel, and the center gutter is also symmetrically poured from the two sides of the tunnel. According to the device and the process thereof, the tunnel center gutter and the side ditches can be poured and formed once, so that the construction workload is reduced, the mold board can be automatically installed and disassembled, the problems caused by manual installation and disassembly of the mold board can be avoided, and the construction efficiency can be improved; and when concrete is poured, symmetrical pouring is adopted, and deviation on the two sides of a table frame can be avoided.

Owner:THE 5TH ENG CO LTD OF CHINA RAILWAY 25TH BUREAU GRP +1

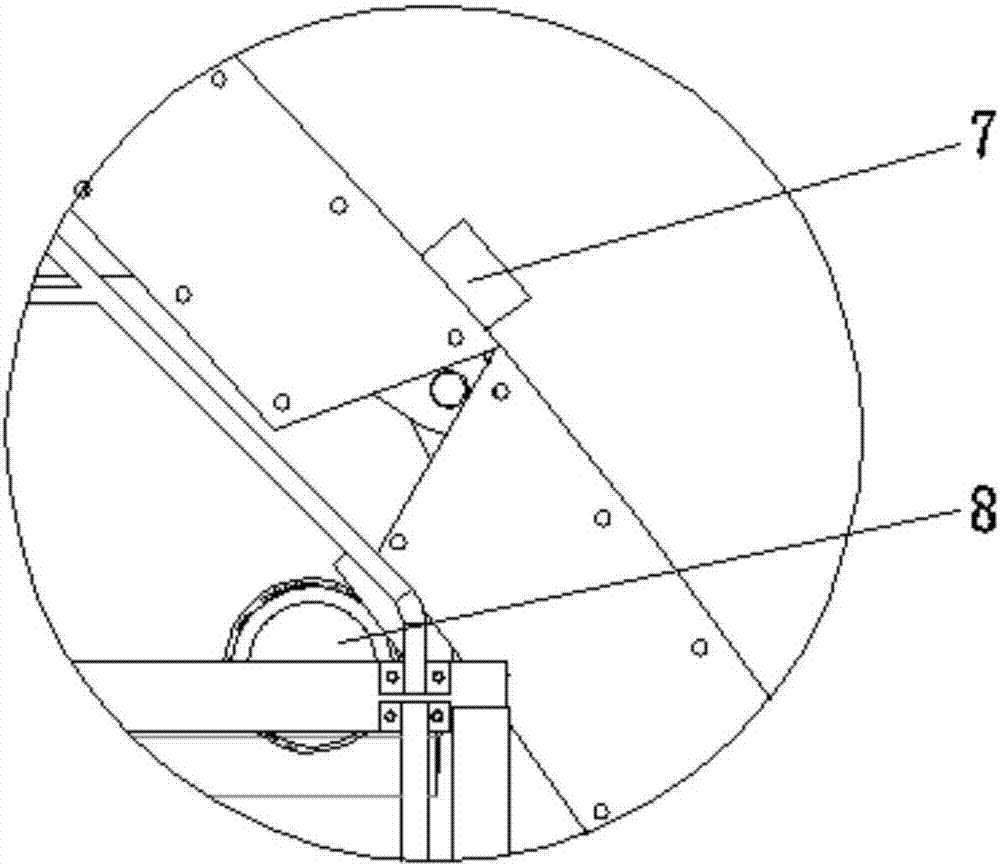

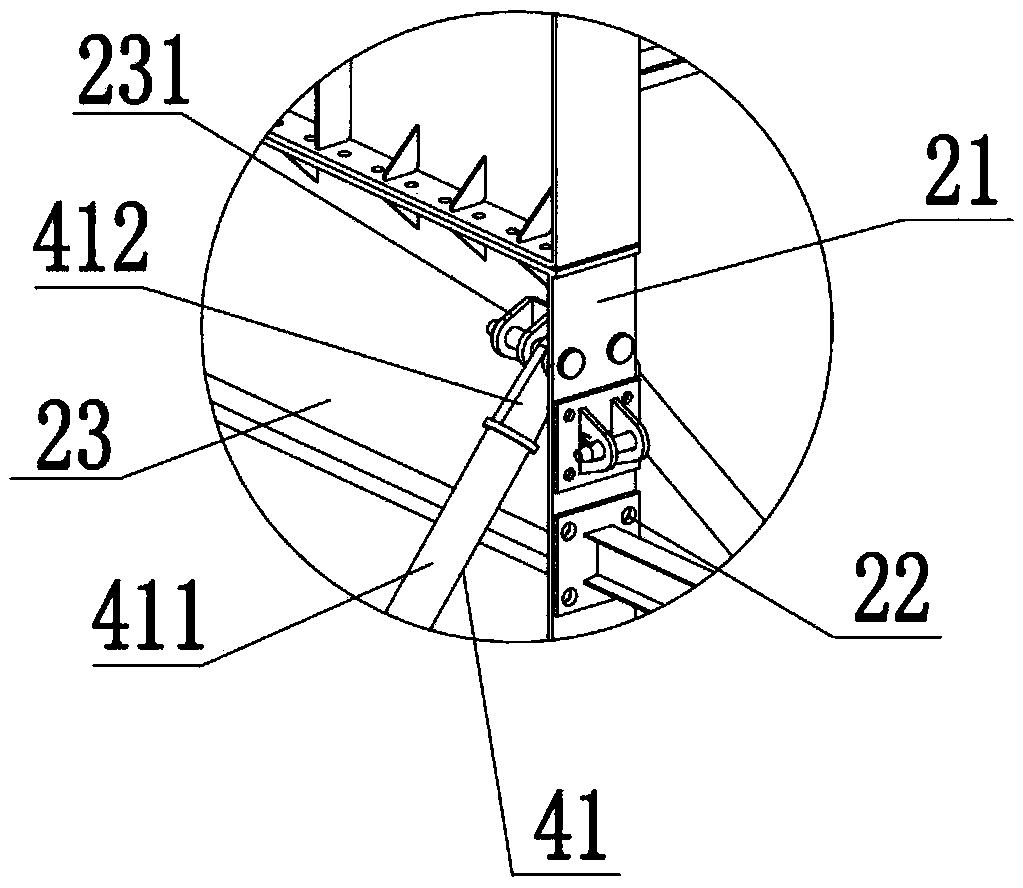

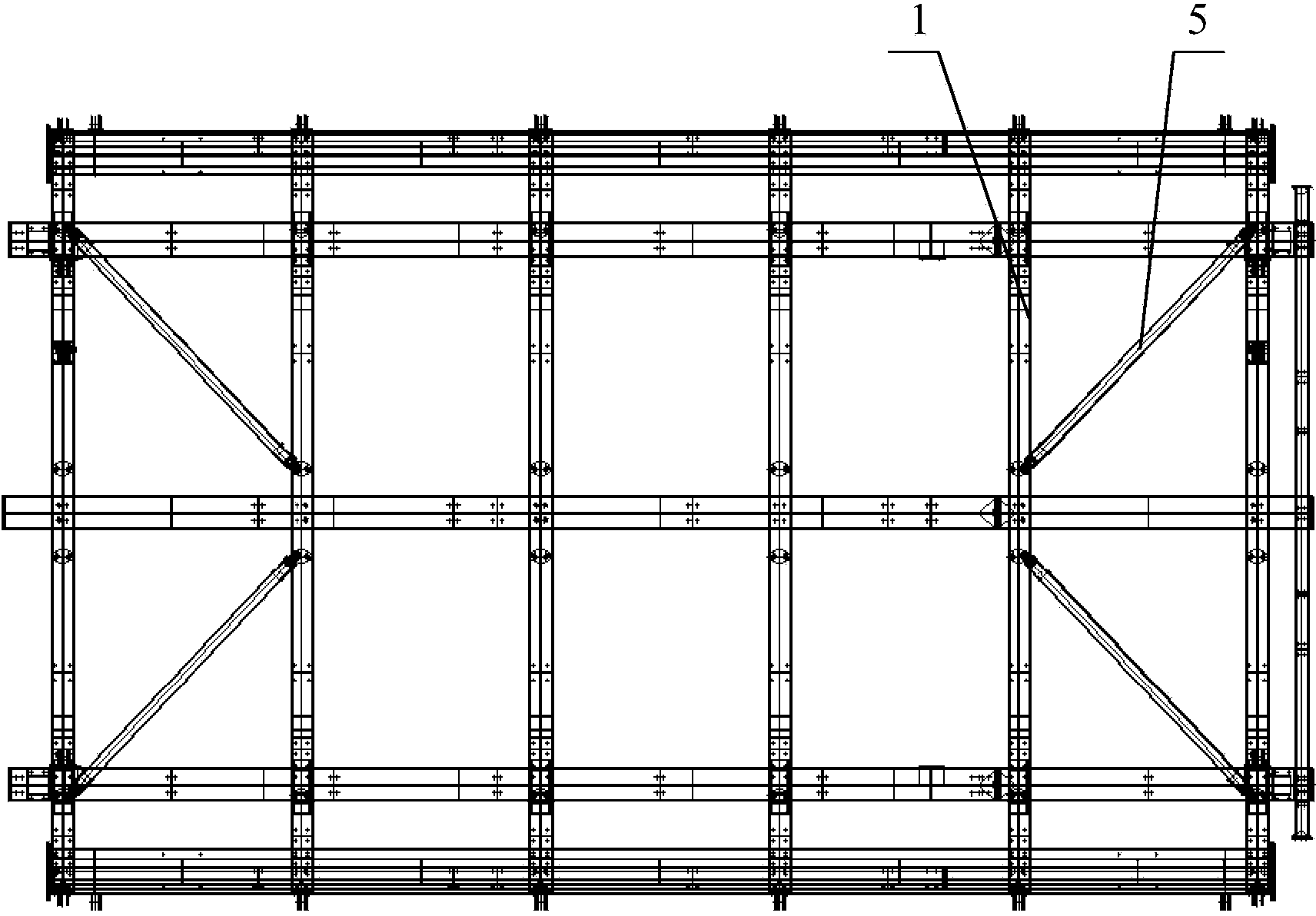

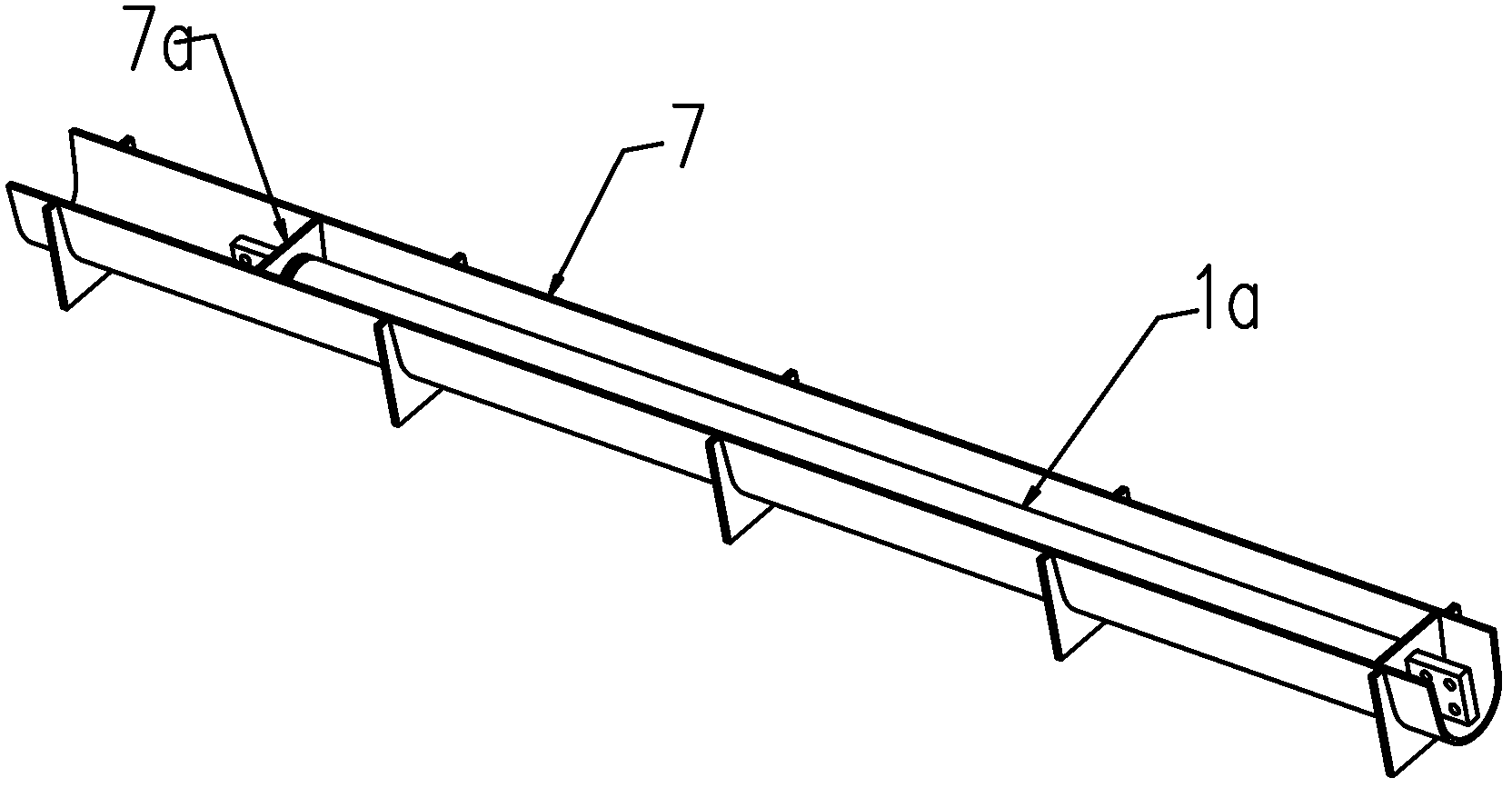

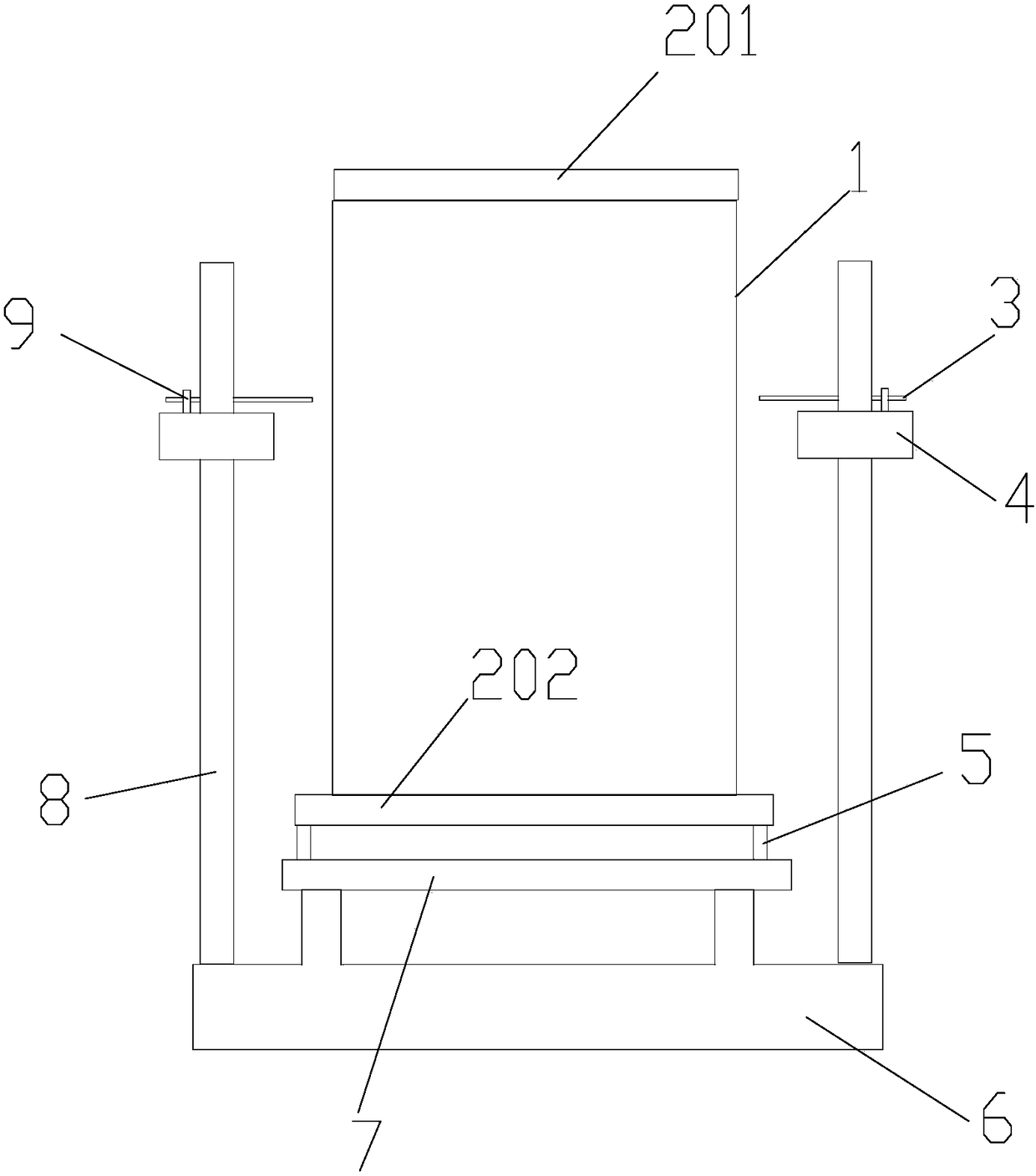

Gantry system of tunnel lining trolley

ActiveCN104033166AReduce in quantityReduce typesUnderground chambersTunnel liningSingle supportFlange

The invention provides a gantry system of a tunnel lining trolley. The gantry system comprises a support frame, a gantry longitudinal beam, jacking mechanisms and transverse beam connecting beams. The support frame comprises a plurality of single support frame bodies, each single support frame body comprises a gantry transverse beam and two gantry upright columns, the two gantry upright columns of each single support frame body are symmetrically arranged, the gantry transverse beams are perpendicular to the gantry longitudinal beam and are positioned right above the gantry longitudinal beam, and the gantry upright columns are vertically arranged among the gantry transverse beams and the gantry longitudinal beam; the transverse beam connecting beams are parallel to the gantry longitudinal beam and are arranged on the gantry transverse beams; flange plates are arranged on the side surfaces of the gantry upright columns, and two groups of through holes which are used for mounting supporting jack seats and supporting cylinder seats are equidistantly formed in each flange plate; the jacking mechanisms are arranged at two ends of the gantry longitudinal beam. The gantry system has the advantages that the gantry system is simple in integral structure; the supporting jack seats and the supporting cylinder seats can be conveniently vertically adjusted owing to the through holes, so that requirements of different working conditions can be met, and the gantry system is high in practicality; supporting jacks and supporting cylinders can be flexibly mounted and adjusted, accordingly, the construction cost can be greatly lowered, and the labor intensity can be greatly relieved.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

High-heat-insulation sandwich construction wall cement foam and preparation method thereof

Owner:大庆市碧千里科技开发有限公司

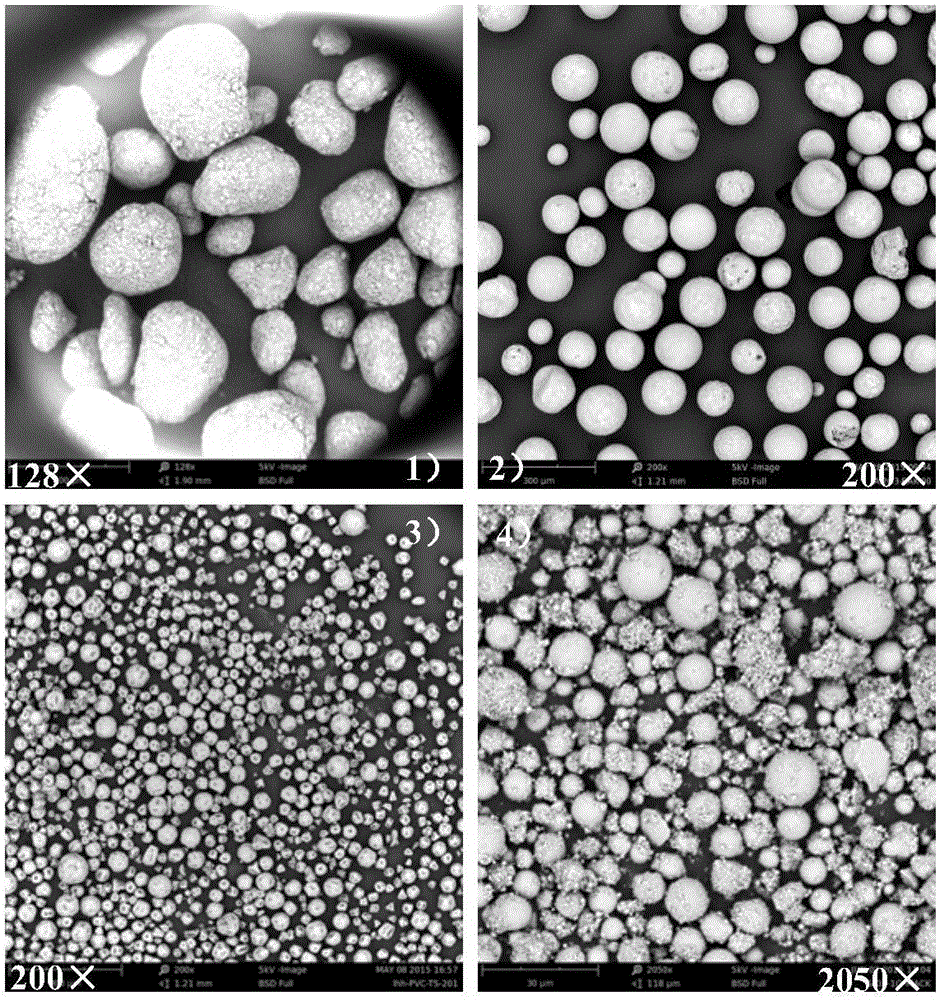

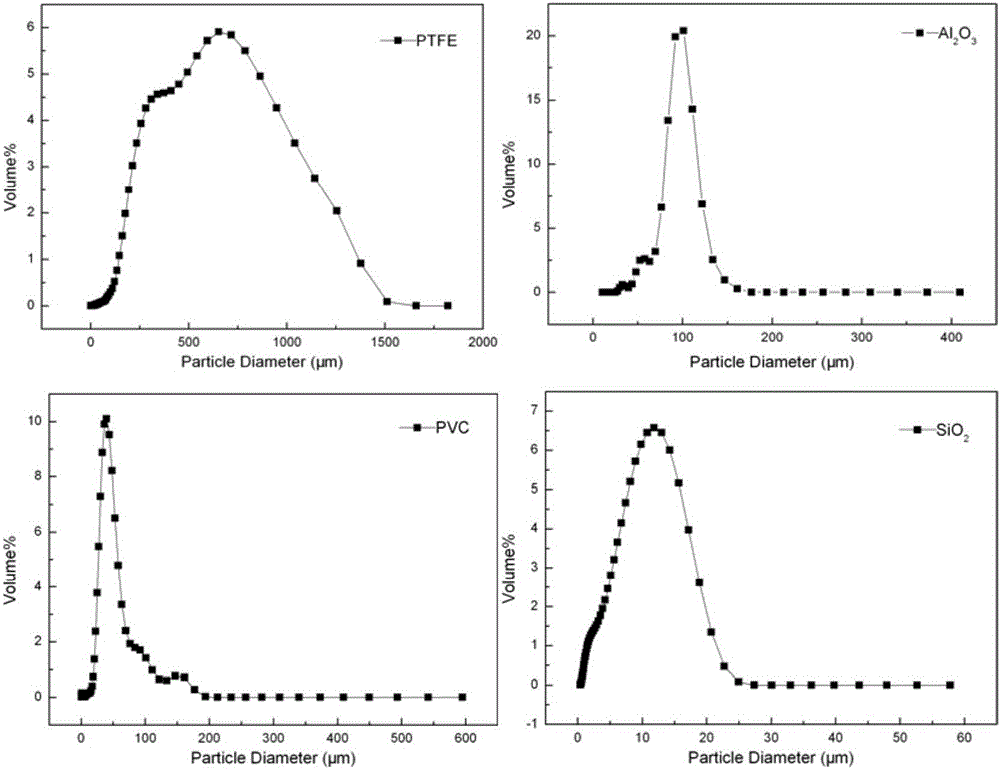

Green and environment-friendly explosive simulant material and preparation method therefor

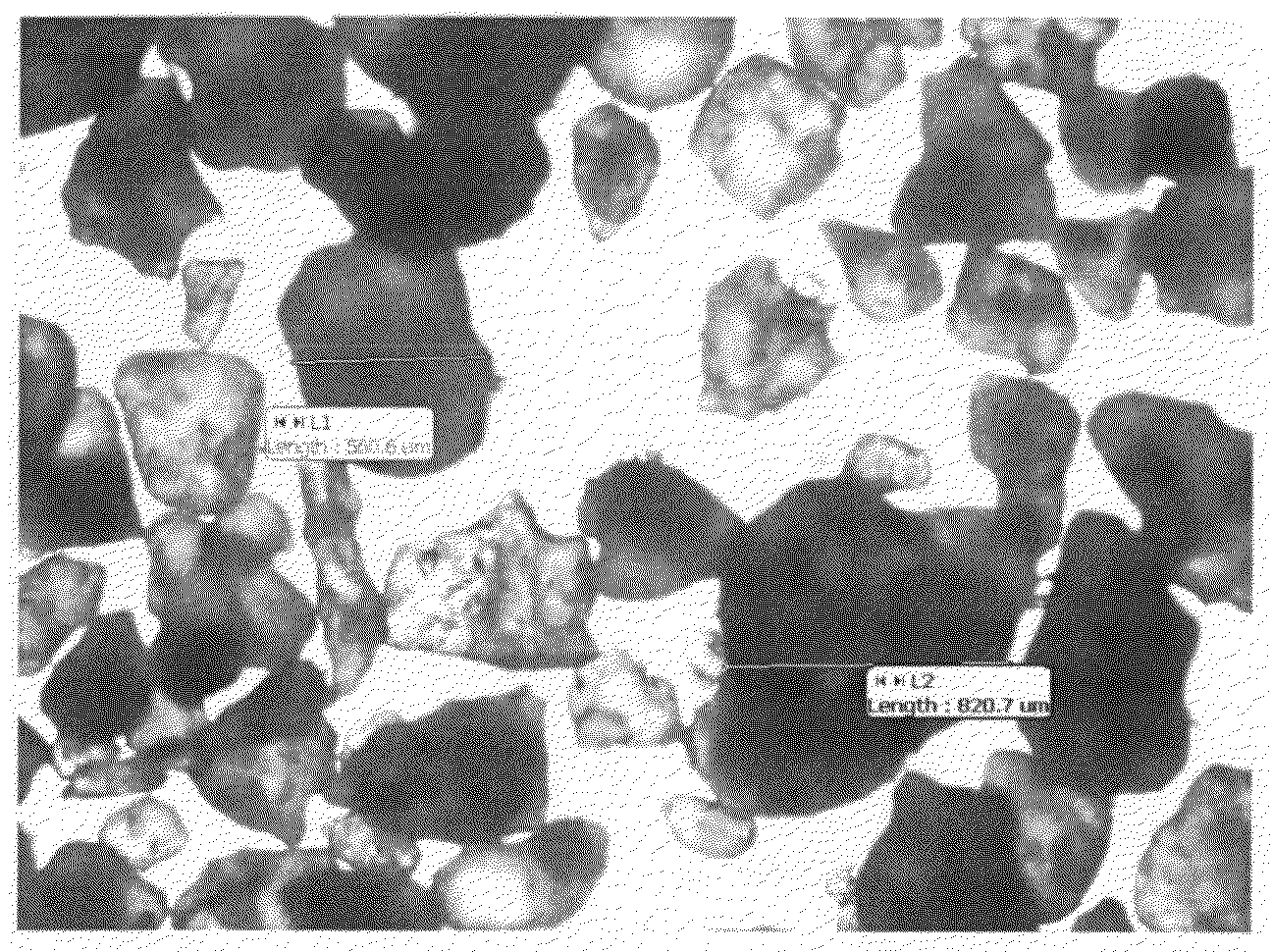

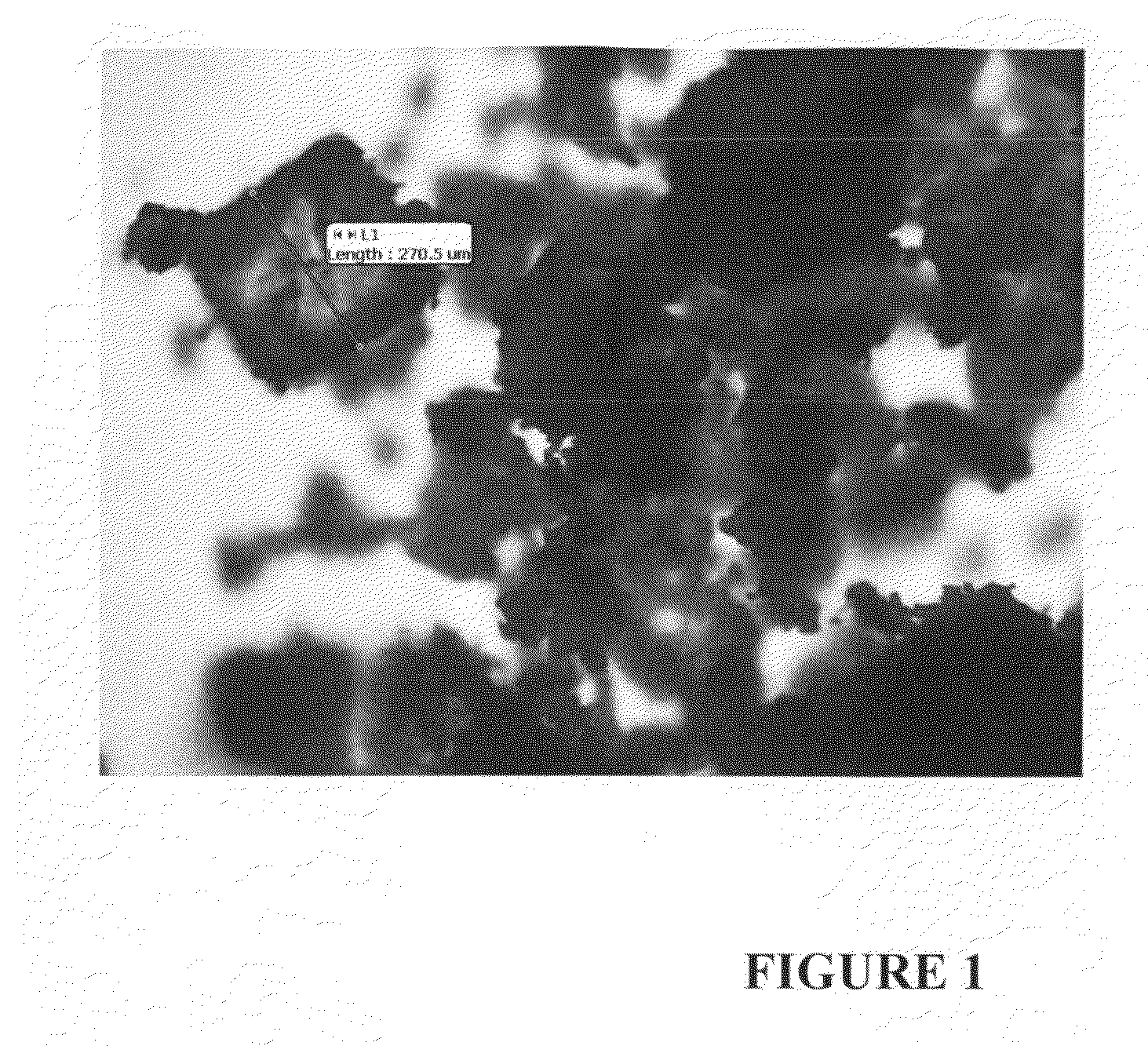

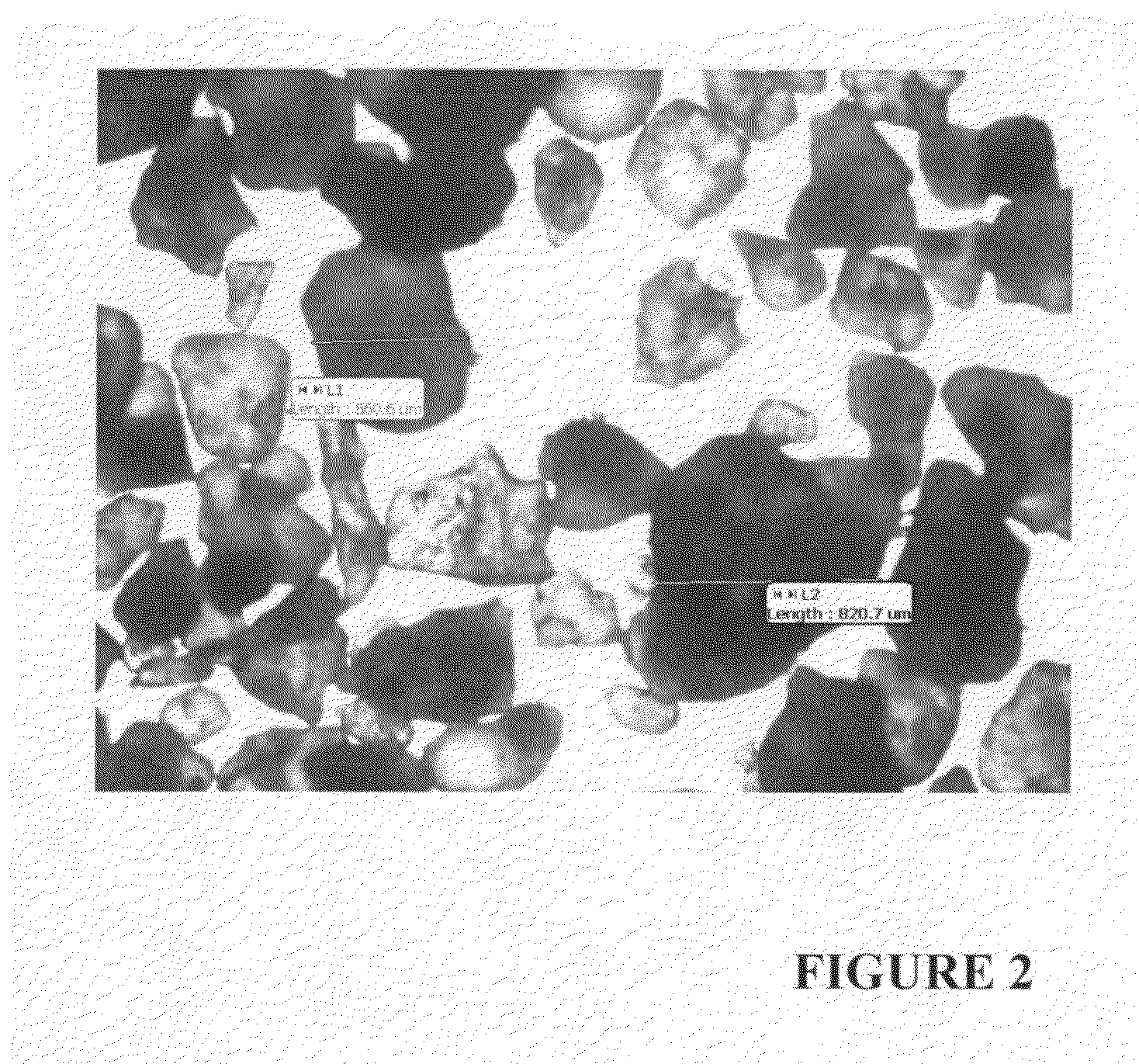

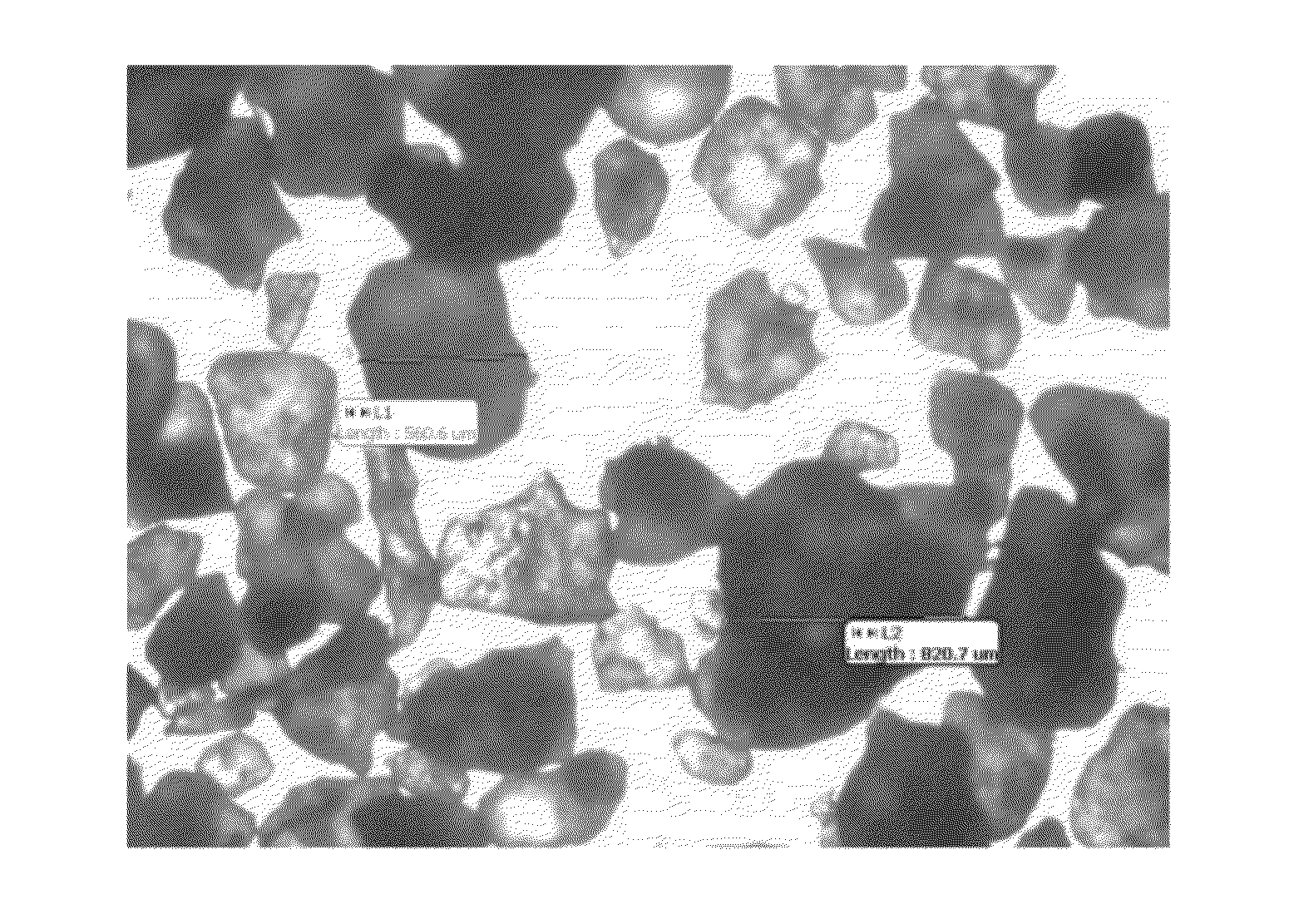

ActiveCN106083501AImprove pouring effectImprove pouring qualityExplosivesPolytetrafluoroethyleneMechanical properties of carbon nanotubes

The invention discloses a green and environment-friendly explosive simulant material. The green and environment-friendly explosive simulant material contains the following ingredients in parts by weight: 0-30 parts of polytetrafluoroethylene, 0-35 parts of aluminum oxide, 0-14 parts of polyvinyl chloride, 19-30 parts of silicon dioxide, 30-40 parts of binder, 0.4-0.8 part of curing agent, 0.01-0.1 part of colorant, 0.02-0.08 part of surfactant and 0.25-2 parts of diluent. The invention further discloses a preparation method for the green and environment-friendly explosive simulant material. According to the preparation method, through adding green and environment-friendly simulant materials into a binder system, the explosive simulant material prepared through curing is not only good in formability, good in machined dimensional stability and uniform in product interior filling, but also can be used for accurately simulating the density and mechanical properties of real explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

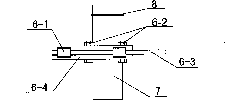

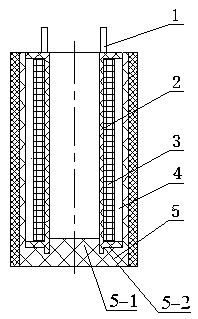

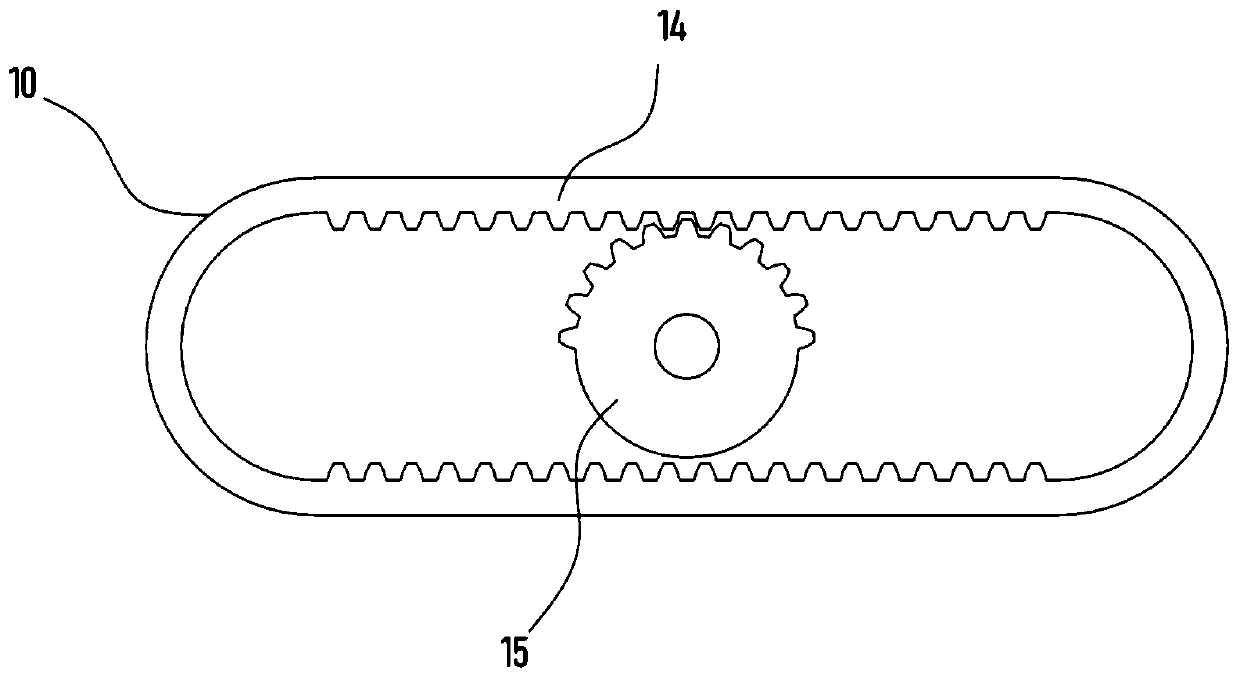

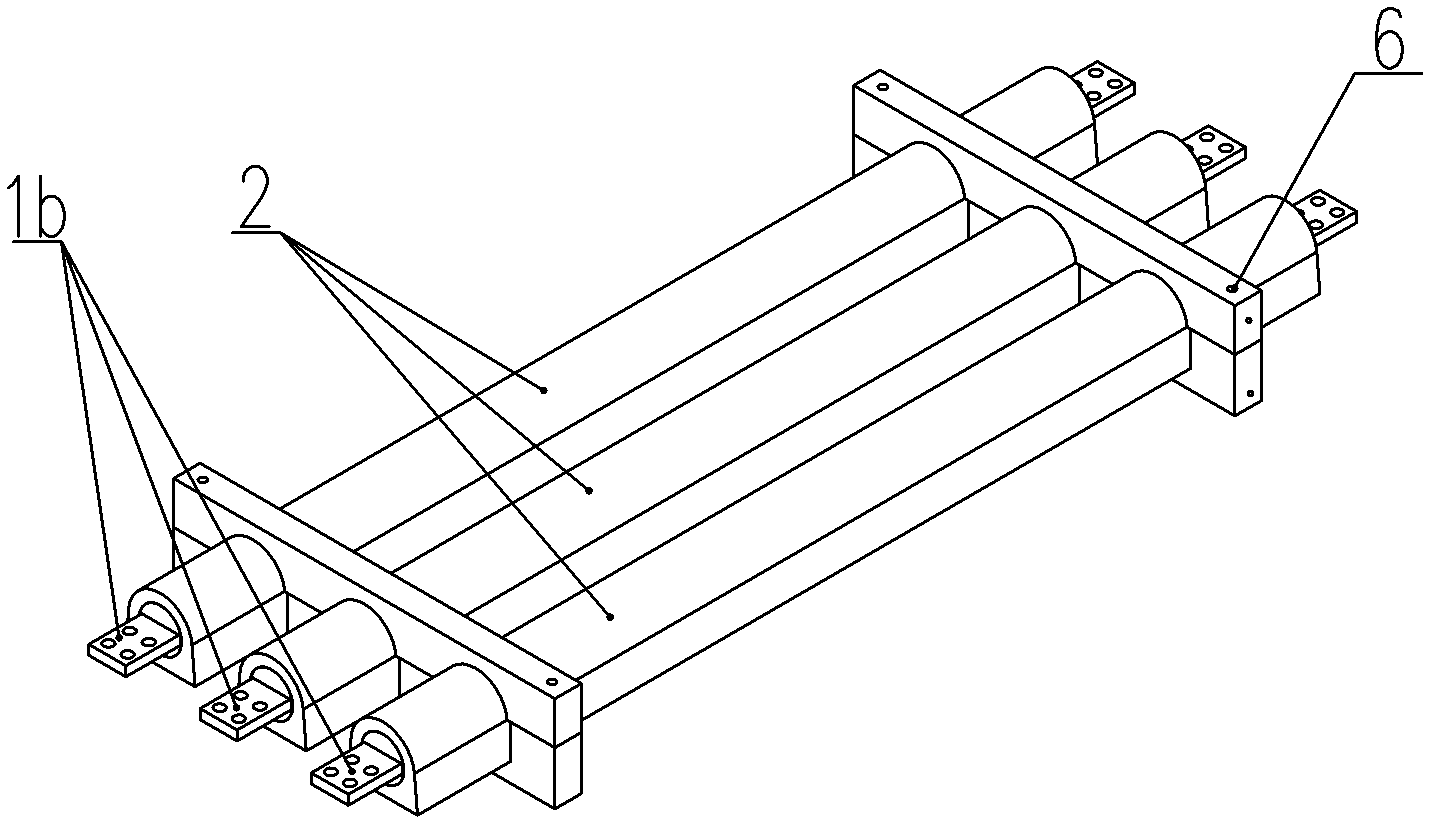

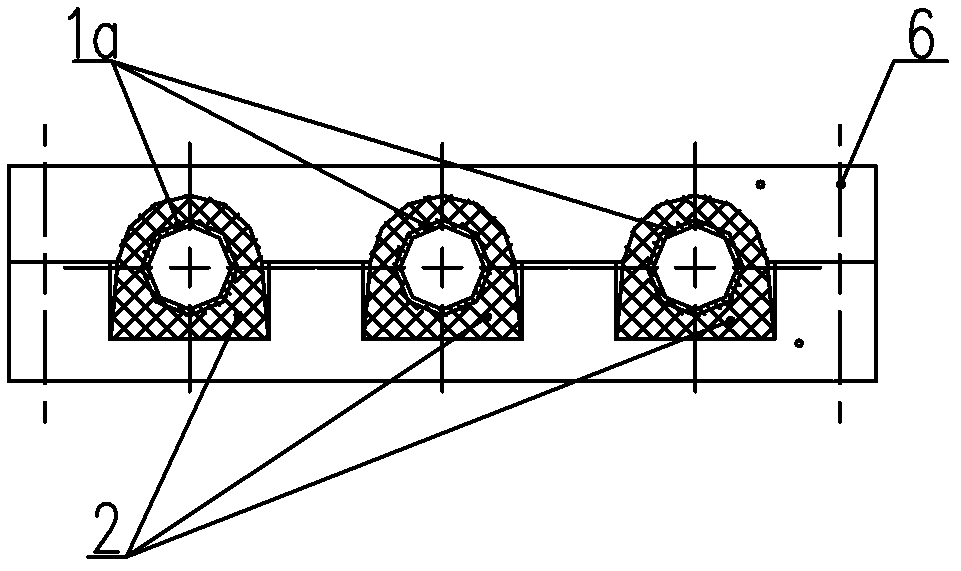

Epoxy resin pouring tooling and pouring process for skeleton coil

InactiveCN110739149ASimple structureReduce labor intensityCoils manufactureFirming agentMechanical engineering

The invention discloses an epoxy resin pouring tooling for a skeleton coil. The epoxy resin pouring tooling is characterized by comprising a rubber sleeve arranged outside the skeleton wound with thecoil, and a space to be filled with epoxy resin is arranged between the coil and the rubber sleeve. The bottom boss of the rubber sleeve is matched with the inner surface of the skeleton. The two endsof the setting and fixing shell a and the setting and fixing shell b of a setting and fixing device are provided with fixing stops, and the fixing strips of the outer side of the stops are clamped and fixed by dovetail clamps. The pouring process comprises the following steps: preheating and mixing the epoxy resin and the curing agent, vacuum inhaling the epoxy resin and the curing agent with anautomatic potting machine and vacuum defoaming; and pouring is performed from the pouring ports a and b on the skeleton; and placing on a curing platform for curing and demoulding after completion ofpoursing. The advantages are that demoulding saves time and labor, greatly improves demoulding efficiency and effectively avoids mold sticking during demoulding; the tooling can be reused so as to reduce the use cost; and the pouring process is simple, easy to operate, good in pouring effect and high in efficiency.

Owner:JIANGSU JINGJIANG INSTR TRANSFORMER FACTORY

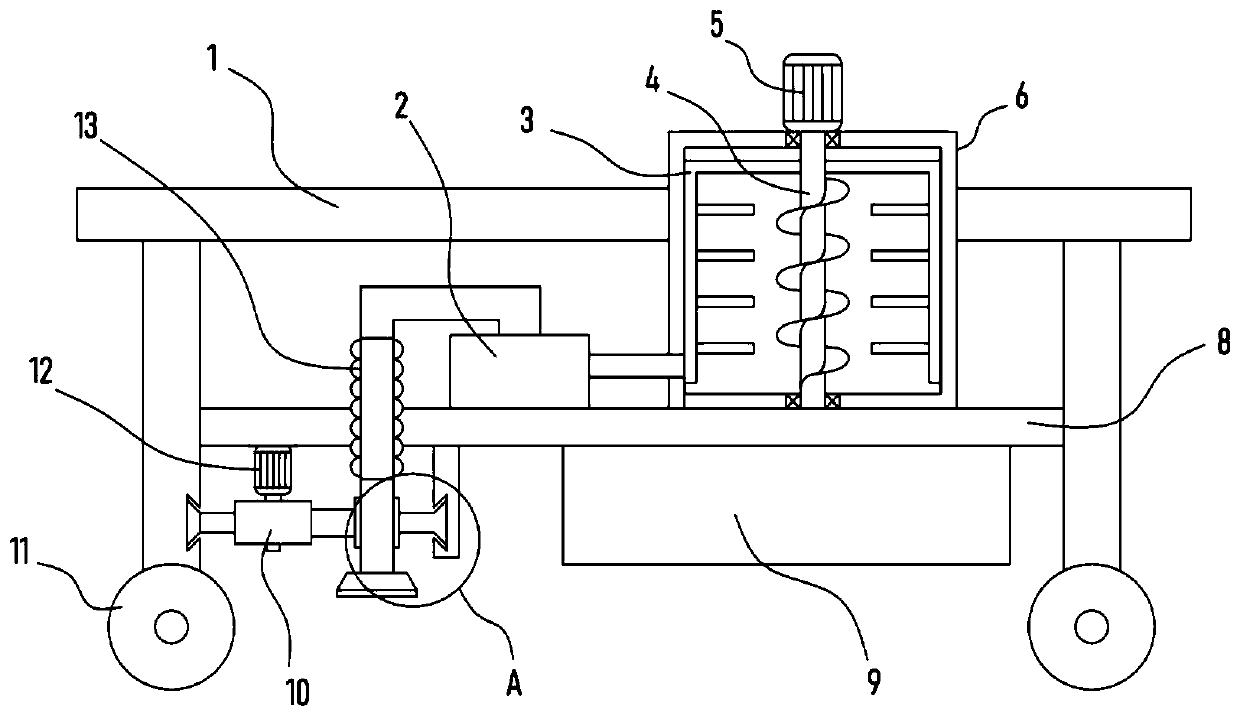

Cement terrace pouring device for water conservancy construction

ActiveCN110219464AAvoid accumulationReduce workloadBuilding material handlingArchitectural engineeringBuilding construction

The invention discloses a cement terrace pouring device for water conservancy construction, and relates to the technical field of water conservancy construction machinery. The cement terrace pouring device comprises a supporting frame, and travelling wheels are rotatably arranged at the bottom of the supporting frame; a storage barrel is fixed to the supporting frame, and a horizontal frame is fixed into the supporting frame; and the bottom of the horizontal frame is provided with a reciprocating mechanism used for driving a discharging hood to horizontally move, a storage encircling plate isfixed to the bottom of the horizontal frame, and a levelling mechanism for levelling concrete is arranged in the storage encircling plate in a lifting mode. The arranged reciprocating mechanism can drive the discharging hood to horizontally move back and forth, thus the concrete flowing out from the discharging hood can be evenly laid on different positions to be prevented from being accumulated,the workload of subsequent levelling operation is also greatly lowered, and the pouring effect of a cement terrace is better; and meanwhile, the arranged levelling mechanism can level the poured concrete in time, thus it is guaranteed that the poured concrete is not uneven, and the quality of the cement terrace is effectively improved.

Owner:GUANGDONG YUANTIAN ENG

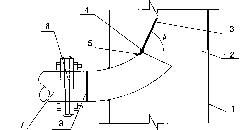

Phase isolated cast tubular bus and preparation method thereof

ActiveCN102426879AImprove rigidityReduce volumeContact member manufacturingInsulated cablesFlat jointForming gas

The invention relates to a phase isolated cast tubular bus and a preparation method thereof and belongs to the technical field of power transmission and distribution. The tubular bus is characterized in that flat joints are arranged at the two ends of a tubular bus main body; a resin insulating layer is cast outside the tubular bus main body; the section outline of the insulating layer is composed of a circular arc segment concentric with the tubular bus, extending line segments tangent with the two sides of the circular arc segment and a horizontal line segment intersecting with the two extending lines; the length of the horizontal line segment is greater than the diameter of the circular arc segment; and the circular arc segments are arranged above to form gas overflowing surfaces during casting and are arranged below to form positioning surfaces during installation. According to the invention, the convention is broken, thus an ideal casting effect can be achieved and the compact insulating casting layer can be formed, without the assistance of special equipment, thus solving the problem of insulating casting of the tubular bus; and the cast planes formed by opening casting become the ideal positioning surfaces during installation, thus achieving two aims at once.

Owner:WETOWN ELECTRIC GRP CO LTD

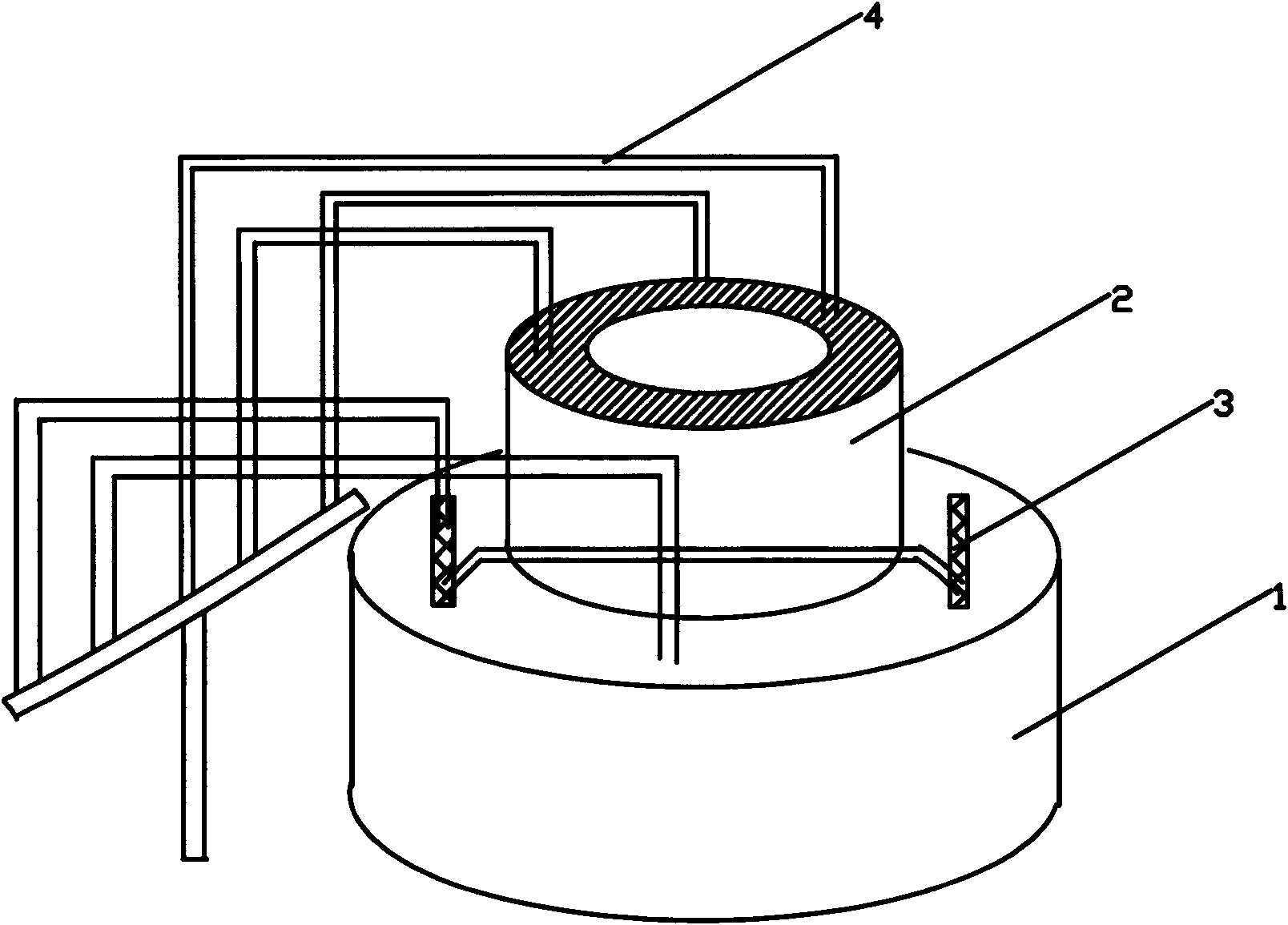

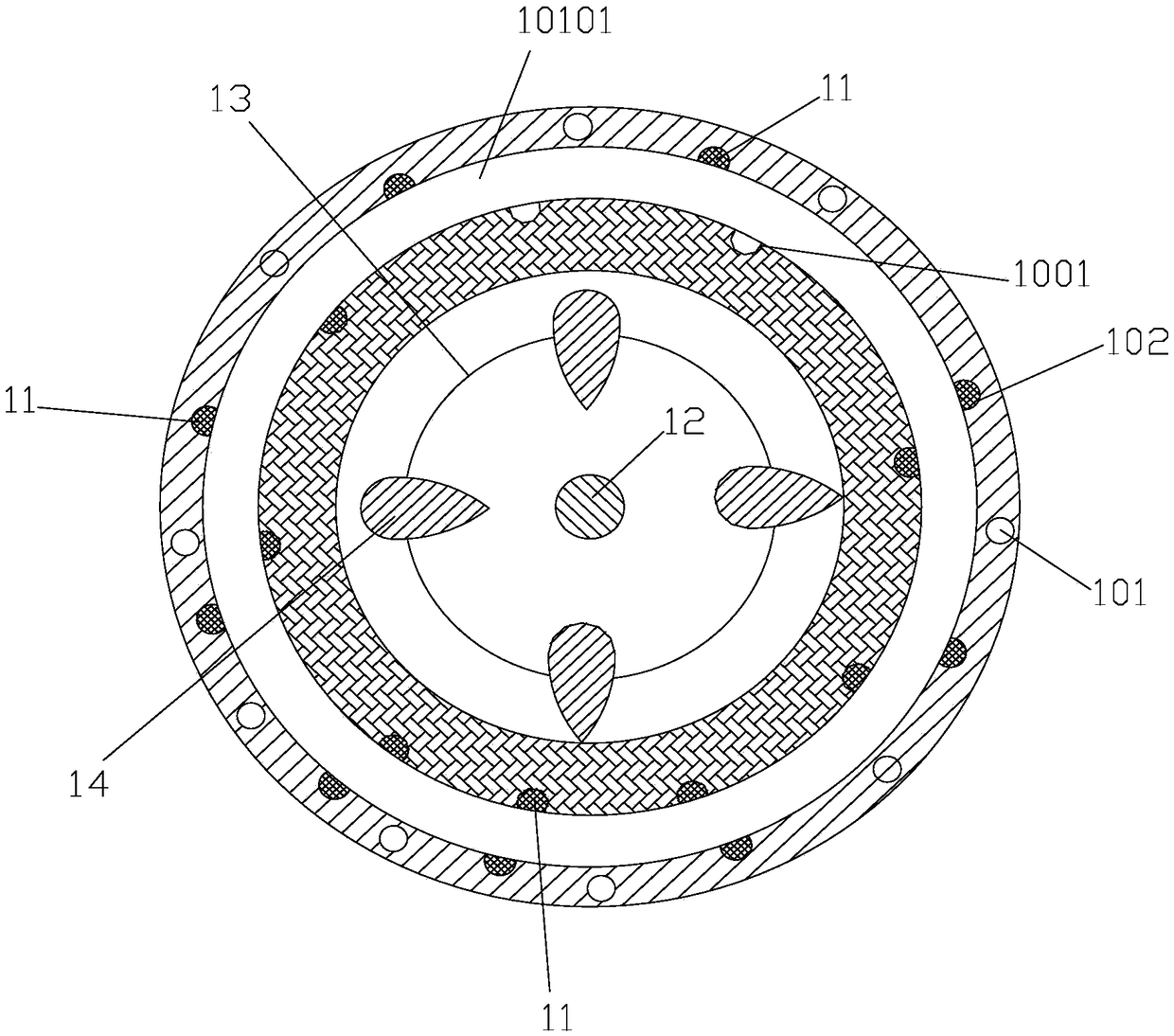

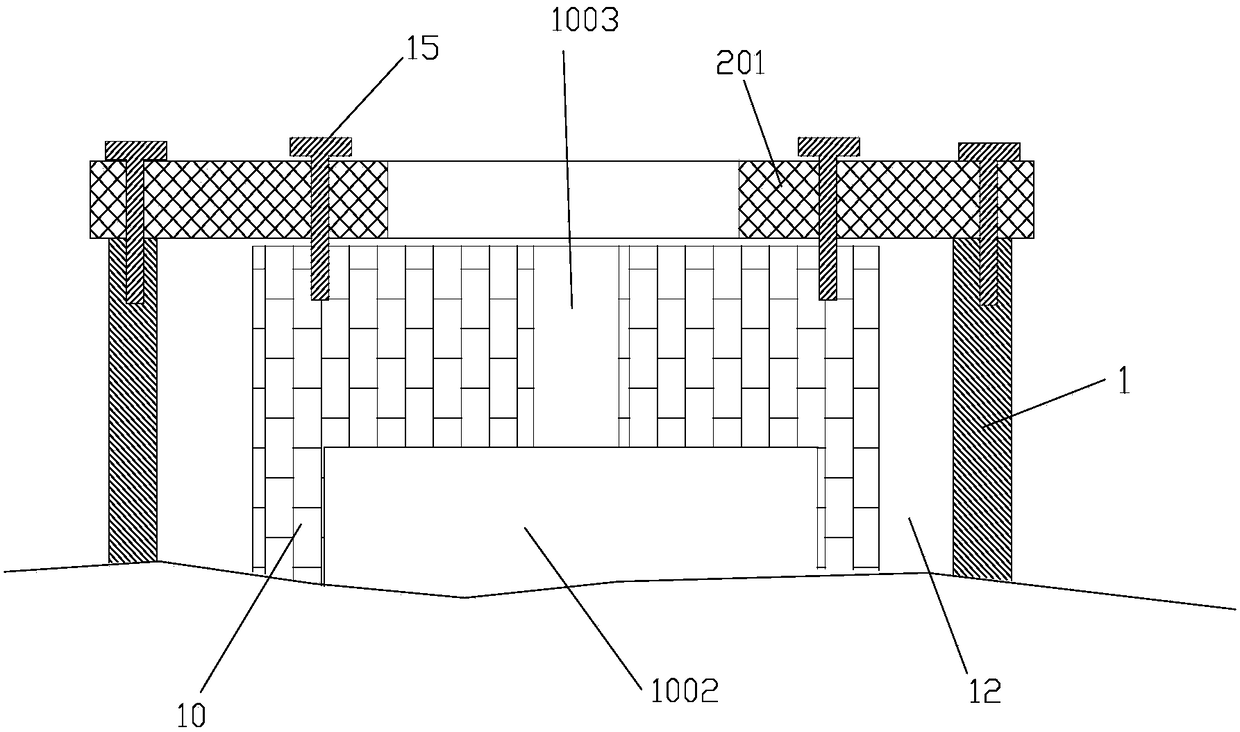

Self-heating type cement pipe pouring mould

The invention discloses a self-heating type cement pipe pouring mould which comprises at least a pair of main and auxiliary sealing end covers, a heater, an inner circular column and an outer circularsleeve; the inner circular column, the outer circular sleeve, the main sealing end cover and the auxiliary sealing end cover are detachably matched to form a pouring space; the pouring space used forcontaining a steel reinforcement cage and concrete mortar; a cavity is formed in the inner circular column; an air inlet is formed in one end face of the inner circular column; a vent hole is formedin the other end face of the inner circular column; a plurality of hot air through holes are formed in the outer circular sleeve and do not communicate with the pouring space; the vent hole in the inner circular column communicates with the hot air through holes in the outer circular sleeve through connecting pipelines; and the heater is arranged in the cavity and is used for producing heat. The self-heating type cement pipe pouring mould has the beneficial effects that the pouring efficiency is improved substantially, pouring operation can be carried out in low temperature weather, and the influence on the pouring operation by the weather is overcome.

Owner:浙江巨龙管业科技有限公司

A lithium battery

InactiveCN106058153AImprove high temperature resistanceImprove low temperature performanceCell electrodesFinal product manufactureAdhesiveEngineering

A lithium battery is disclosed. The lithium battery comprises a cathode sheet, an anode sheet, a separating membrane, an electrolyte and an outer package. The cathode sheet comprises a cathode current collector and a cathode material with which the cathode current collector is coated, and the anode sheet comprises an anode current collector and an anode material with which the anode current collector is coated. The cathode material comprises a cathode active compound, a cathode conductive agent and a cathode adhesive. The anode material comprises an anode active compound, an anode conductive agent, a thickening agent and an anode adhesive. The lithium battery has a high specific capacity and high stability. The energy density of a battery core assembled by the cathode having a high specific capacity and the lithium titanate anode in match can be 90 Wh / kg, and is obviously higher than the energy density of lithium titanate batteries at present. High-temperature resistance of the electrolyte is improved. A gas generating amount is reduced. Cyclic properties are good. The service lifetime is prolonged. High and low temperature properties and flame retardance of the electrolyte are improved. Wettability and pouring performance of the electrolyte are improved through adding 1,3-propanesultone.

Owner:YUNNAN ENERGY RES INST CO LTD

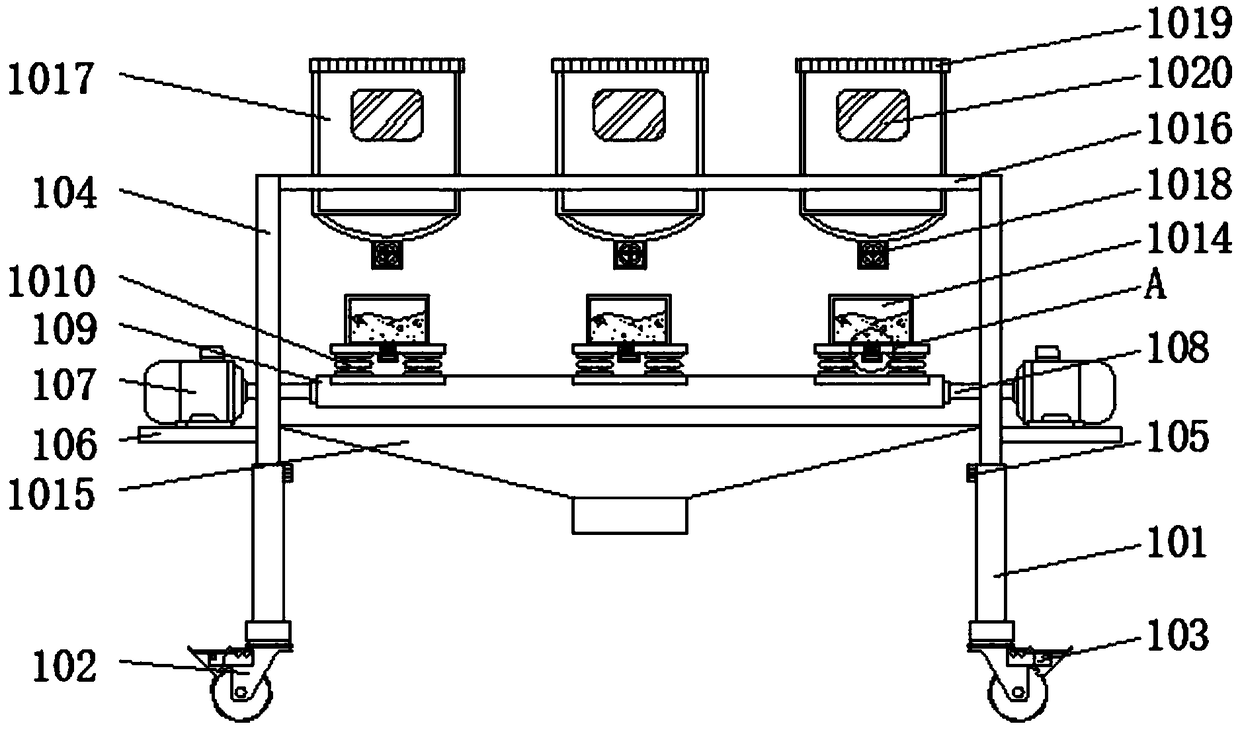

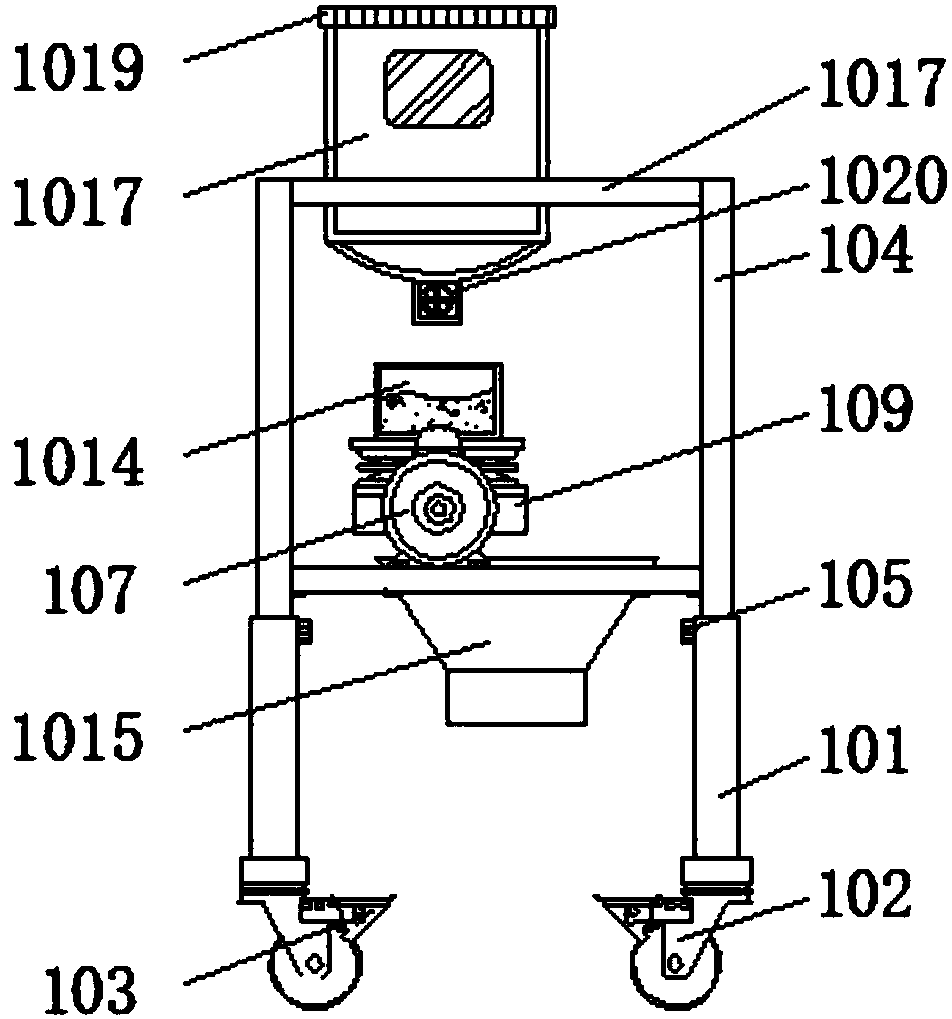

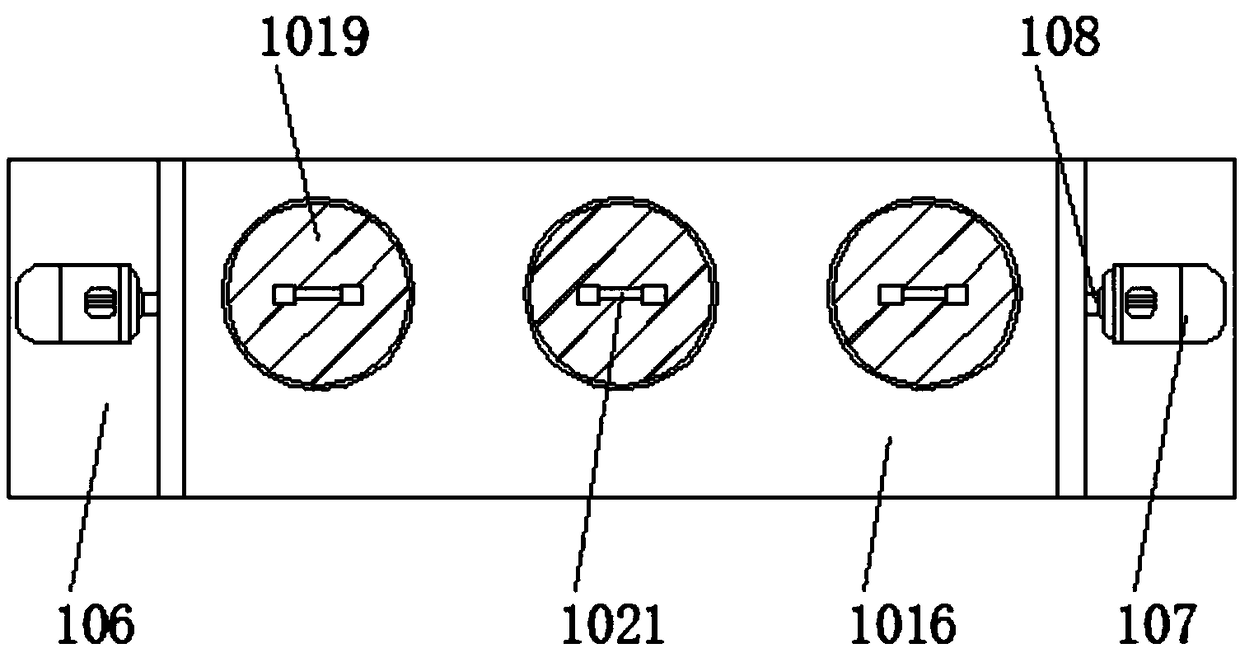

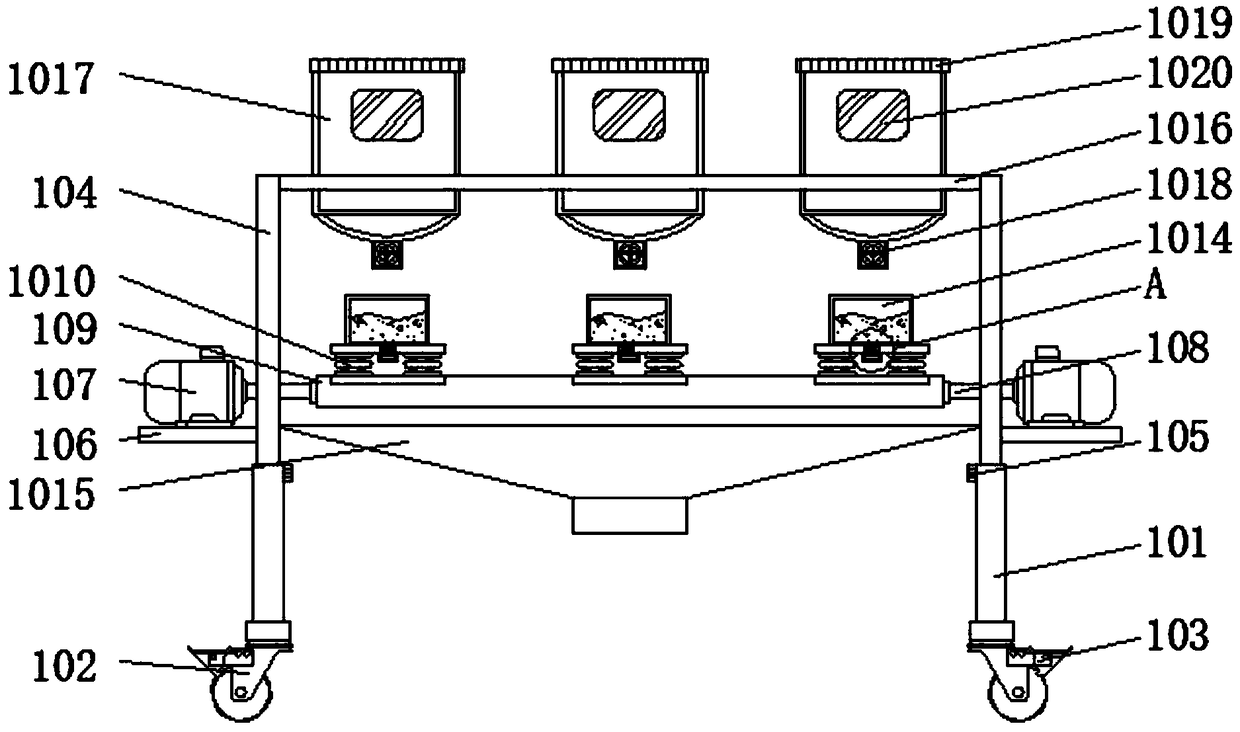

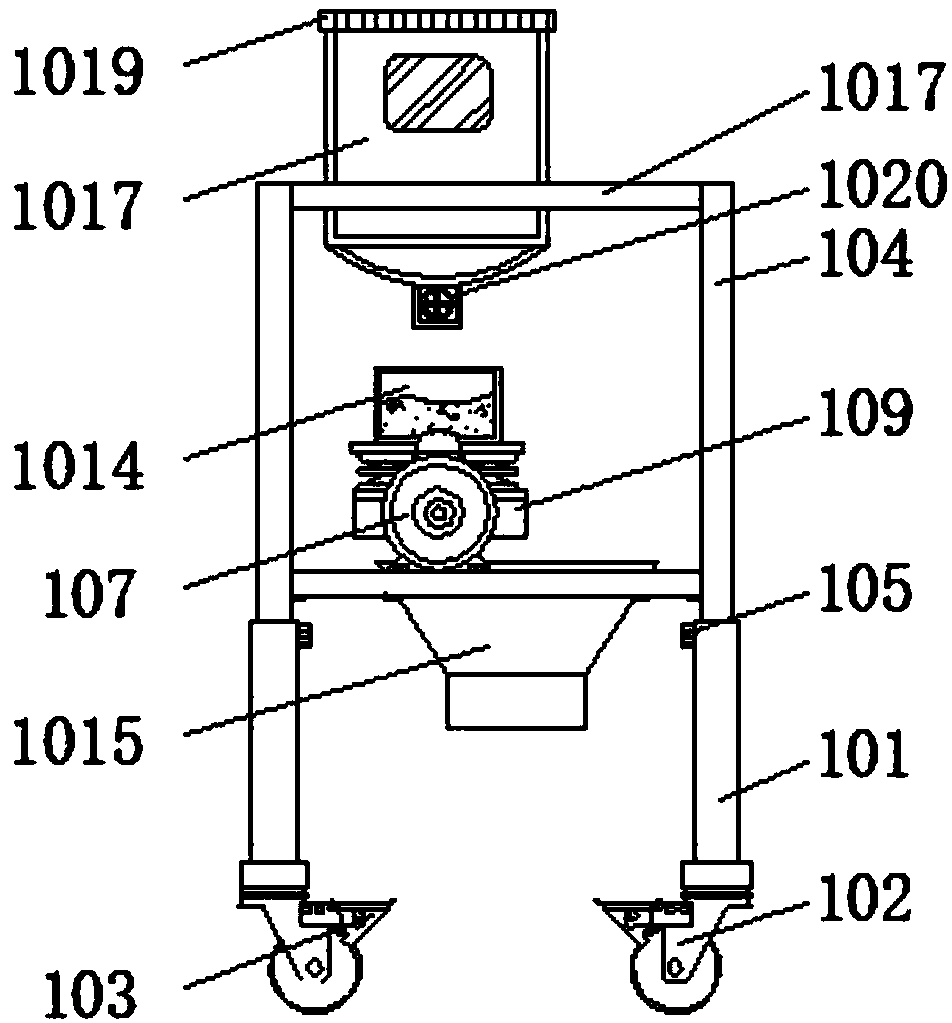

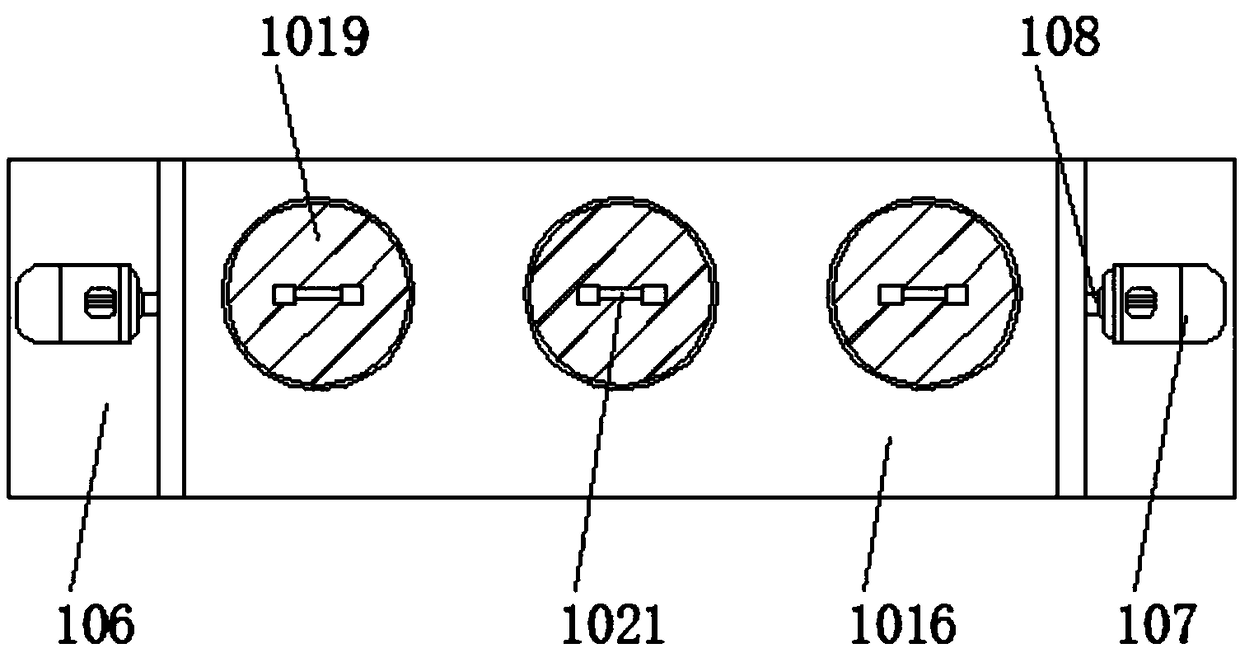

Concrete preparation system and preparation method thereof

InactiveCN108556131AWell mixedExpand the scope of workDischarging arrangementCeramic shaping plantsRaw materialCivil engineering

The invention relates to the technical field of concrete preparation, in particular to a concrete preparation system. The concrete preparation system comprises a raw material weighing device, a raw material mixing device, a pouring mold-entering device, a curing device, a demoulding device and a mold cleaning device. The concrete preparation system performs concrete preparation through the reasonable arrangement of a plurality of above processes and the division of labor and cooperation, realizes the automatic process of concrete preparation, saves manpower, improves work efficiency and is easy to use.

Owner:湖南道同消防工程有限公司

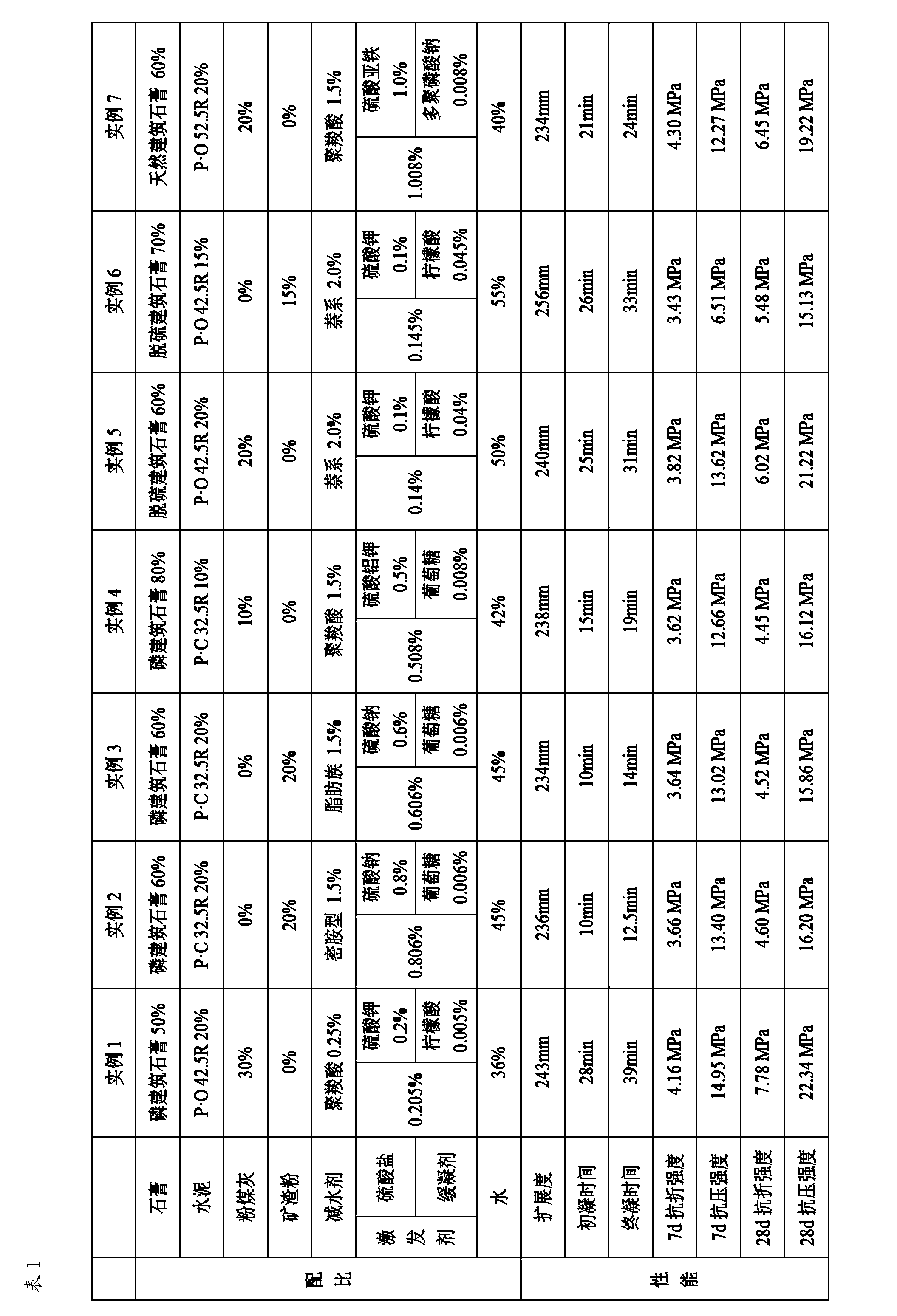

Preparation method of high-performance composite gypsum cementing slurry

A preparation method of high-performance composite gypsum cementing slurry belongs to the technical field of building materials. The composite gypsum cementing slurry comprises the components of one of building gypsum powder, coal ash or slag powder, a mixed powder comprising cementing, a water reducer and water as well as the components of an exciting agent formed by mixing a retarder and a sulphate, wherein the water, the water reducer and the exciting agent are proportionally weighed out according to the total mass of the mixed powder, and then poured into a stirring container, and uniformly stirred to obtain a mixed solution, the mixed powder are blended into the stirring container filled with the mixed solution in a stirring state, the mixed powder and the mixed solution are stirred into a slurry at a high speed after being blended so as to obtain the composite gypsum cementing slurry. The composite gypsum cementing slurry has the advantages of excellent pouring performance, adjustable settling time and high compressive strength. The preparation method can be used for producing building material products with different sizes and performances.

Owner:四川吉浦森建材有限公司

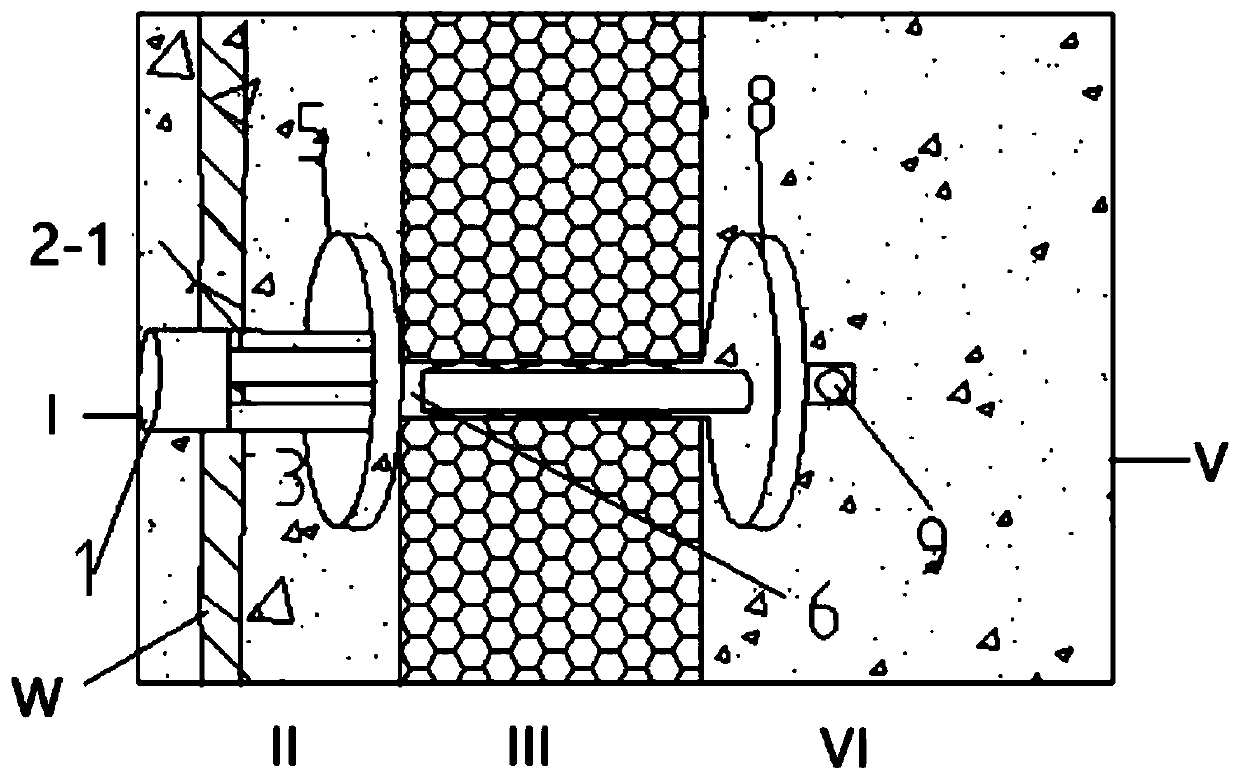

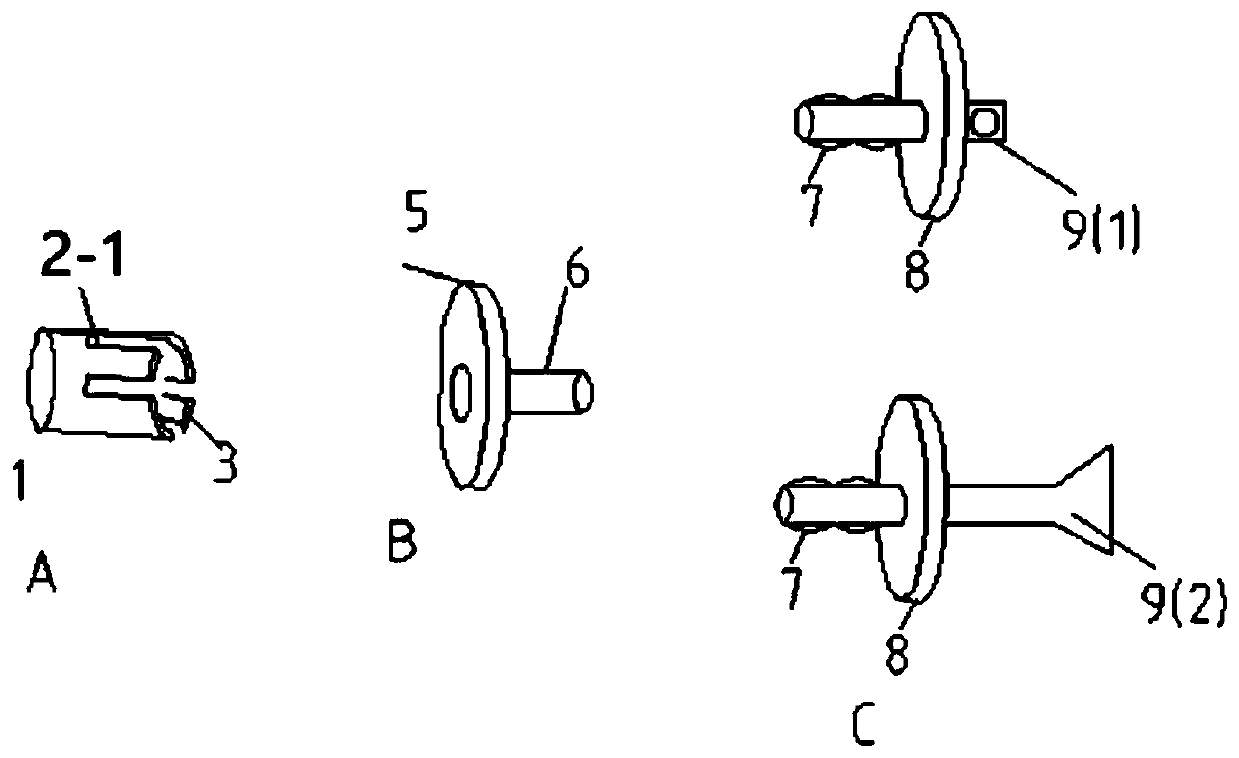

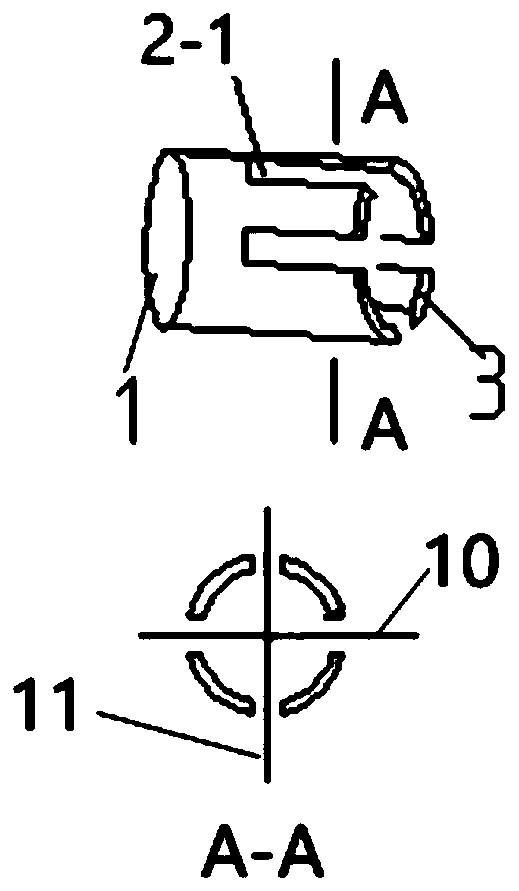

Internally-installed heat-retaining cast-in-place concrete composite shear wall and construction method thereof

PendingCN110029757ALow costSimple production processWallsHeat proofingStructure of the EarthConcrete composites

The invention provides an internally-installed heat-retaining cast-in-place concrete composite shear wall. The internally-installed heat-retaining cast-in-place concrete composite shear wall comprisesa protective layer, a heat-retaining layer and a structure layer, wherein the protective layer, the heat-retaining layer and the structure layer are sequentially arranged between an outer die plate and an inner die plate; and an anti-crack mesh piece, a first connecting piece and a second connecting piece are arranged in the protective layer, the anti-crack mesh piece is arranged between the first connecting piece and the second connecting piece, a third connecting piece is arranged in the structure layer, one end of the second connecting piece is connected with the first connecting piece, and the other end of the second connecting piece penetrates through the heat-retaining layer and is connected with the third connecting piece. The invention further provides a construction method of theinternally-installed heat-retaining cast-in-place concrete composite shear wall. The internally-installed heat-retaining cast-in-place concrete composite shear wall and the construction method thereof have the advantages that compared with other integrated materials, the construction cost is low, the production technology is simple, the production condition is low, the production efficiency is high, and the labor cost is reduced.

Owner:承德建元科技股份有限公司

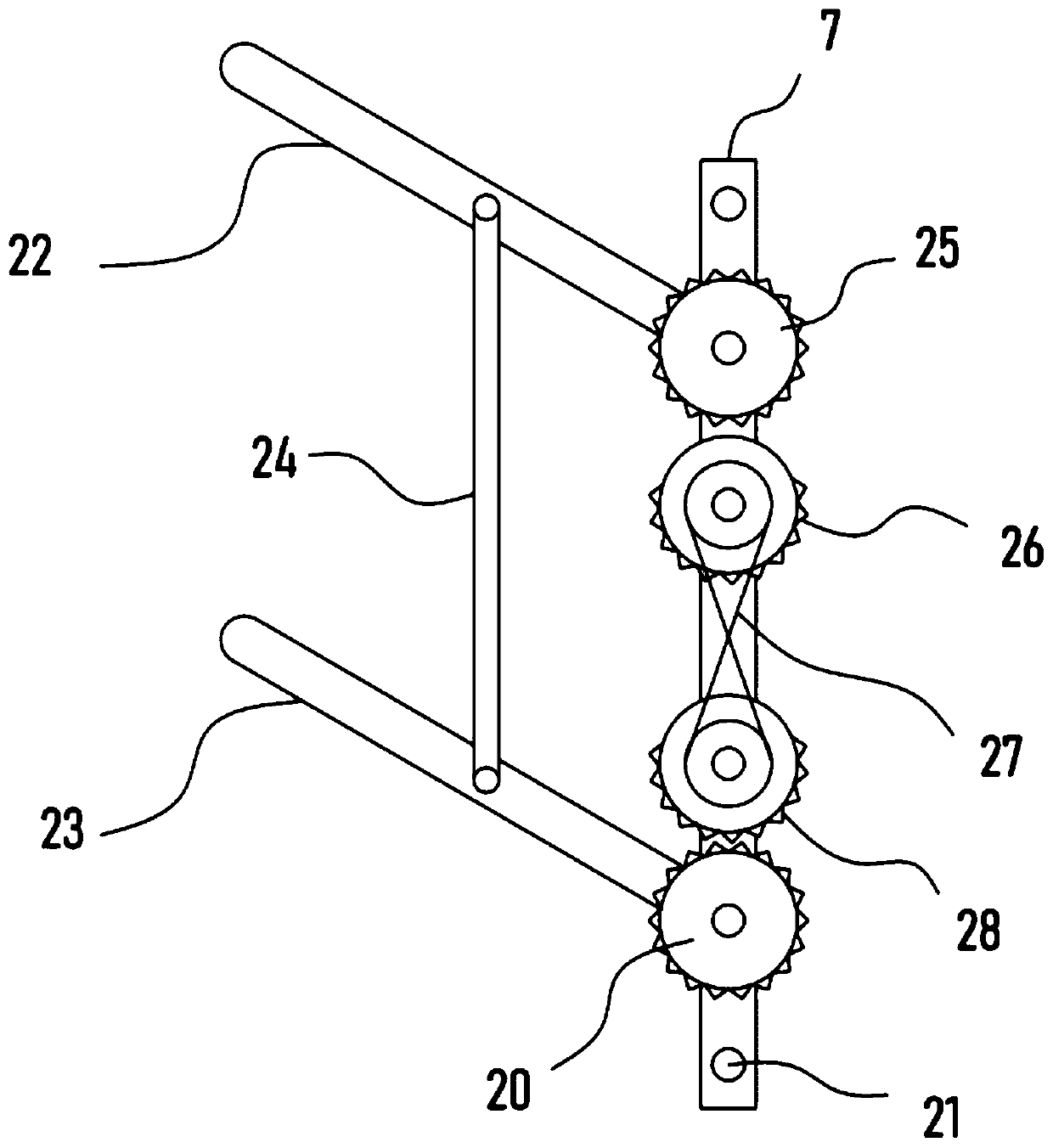

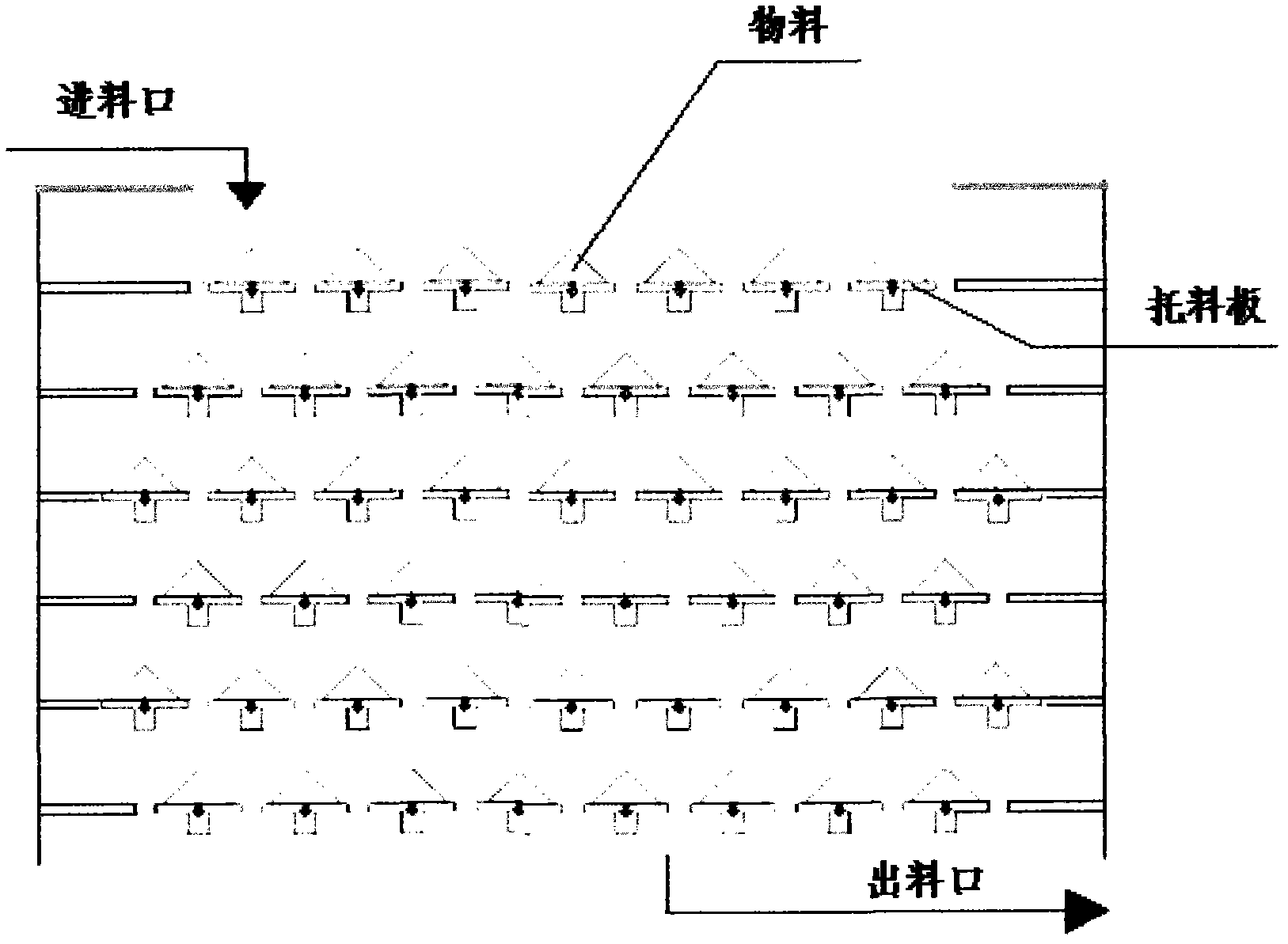

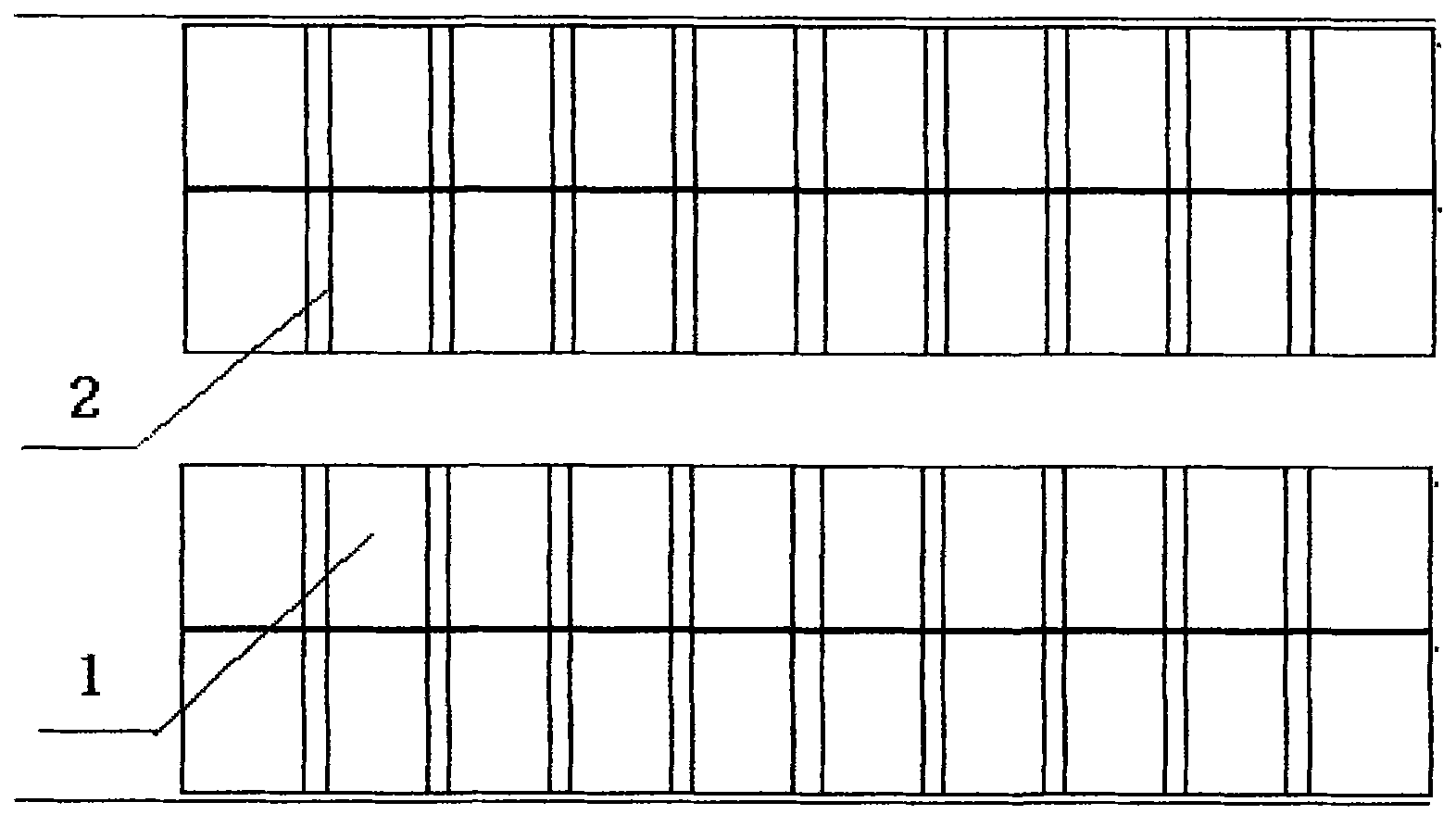

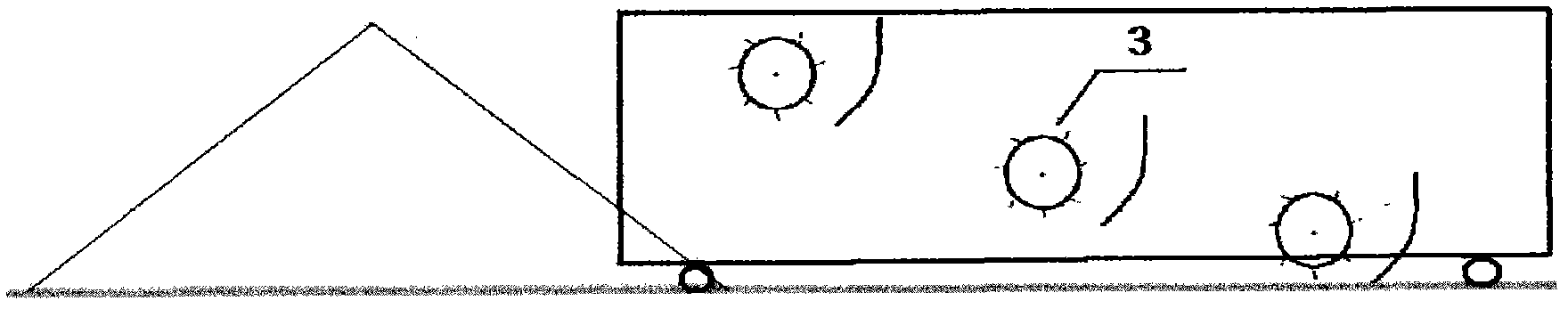

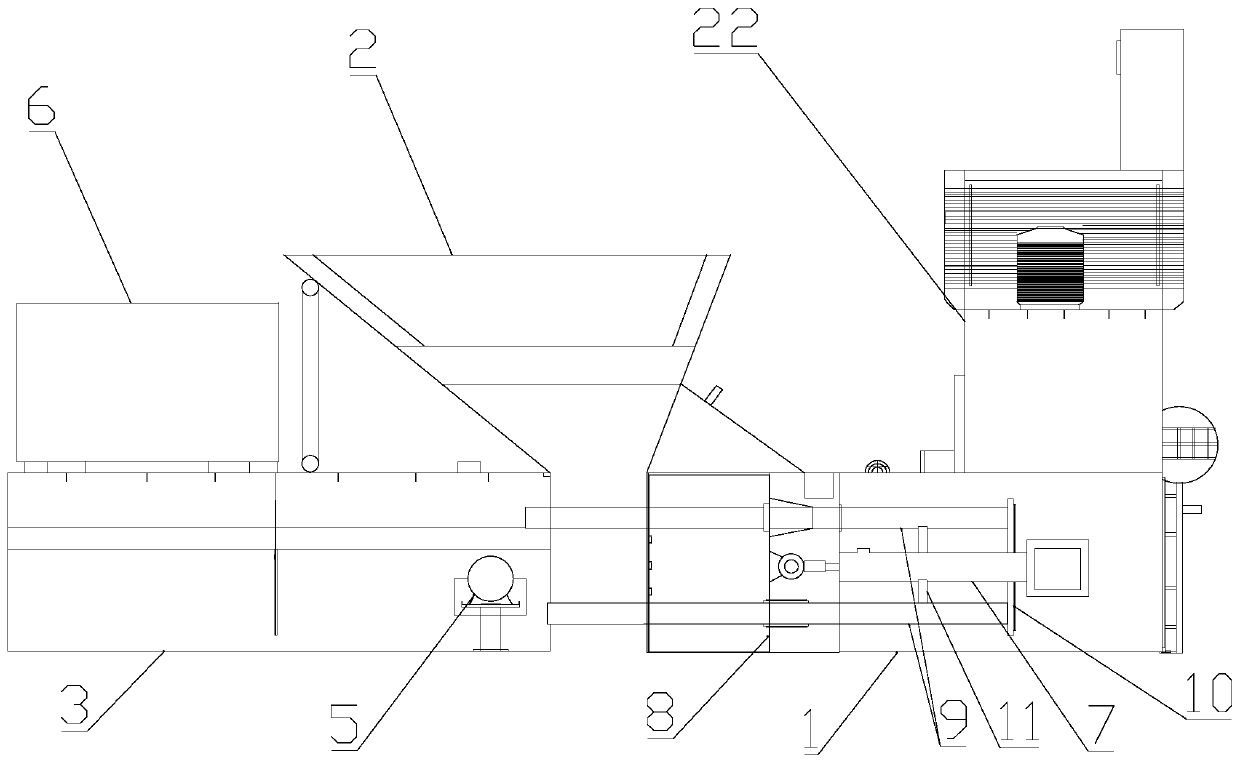

High-temperature aerobic fermentation method and device thereof

ActiveCN102311282AImprove breathabilityAchieve brokenBio-organic fraction processingClimate change adaptationEngineeringOxygen

The invention relates to a high-temperature aerobic fermentation method and a device thereof. According to the invention, materials are arranged at multiple layers in the height direction for layer by layer and step by step fermentation from bottom to up, and each layer adopts a low composting height which follows the principle that the materials have unobvious self-compaction and permeability. The materials on each layer are designed as multiple parallel strip piles, and gaps are arranged among the strip piles for circulation of air, exhaust gas generated from fermentation and the materials among layers. Due to the multiple layers of materials and low composting height of each layer, permeability of the materials is improved, fermentation time is shortened through layered fermentation, and service efficiency of a unit area is enhanced. The device has retainer plates designed as long strips, so that the materials can form strip piles on the plates, thus benefiting gas and moisture diffusion. The design of multilayer and low composting height makes the materials move conveniently with or without a reversal and pushing device, and also reduces energy consumption.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

Palladium-silver alloy material for dental department

InactiveCN103205594AImprove corrosion resistanceGuaranteed ductilityImpression capsDentistry preparationsGold alloysMechanical property

The invention discloses palladium-silver alloy for repairing an oral cavity. Alloy ingredients are optimized by an alloy material. Compared with the prior art, the obtained material has the advantages of good mechanical property, good corrosion resistance, low sensitization, and beautiful color and luster under the premise of not reducing the alloy property and clinical use effect; and the cost is just 1 / 4 to 1 / 3 of gold alloy.

Owner:SICHUAN QIHE PRECIOUS METALS CO LTD

Draining ditch forming device

PendingCN110409377AImprove molding qualityGuarantee molding qualityArtificial water canalsSewer pipelinesEngineeringDitch

The invention belongs to the technical field of civil construction and particularly relates to a draining ditch forming device. A feeding hopper of the device is fixedly arranged on a rack. A feedingopening is formed in the top of the feeding hopper. A discharging opening is formed in the bottom of the feeding hopper. A forming die is fixedly arranged at one end in the length direction of the rack. The forming die and the cross section of a draining ditch are consistent. A propelling assembly is arranged at the other end in the length direction of the rack. A discharging opening of the feeding hopper is formed between the upper end of the forming die and the propelling assembly. The output portion of the propelling assembly can contract toward the direction of the forming die. The draining ditch forming device has the characteristics that manual participation is little, the efficiency is high, time and labor are saved, and the concrete pouring effect is good, thus the forming qualityof the draining ditch is ensured, and the draining ditch forming device has very good practicality.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

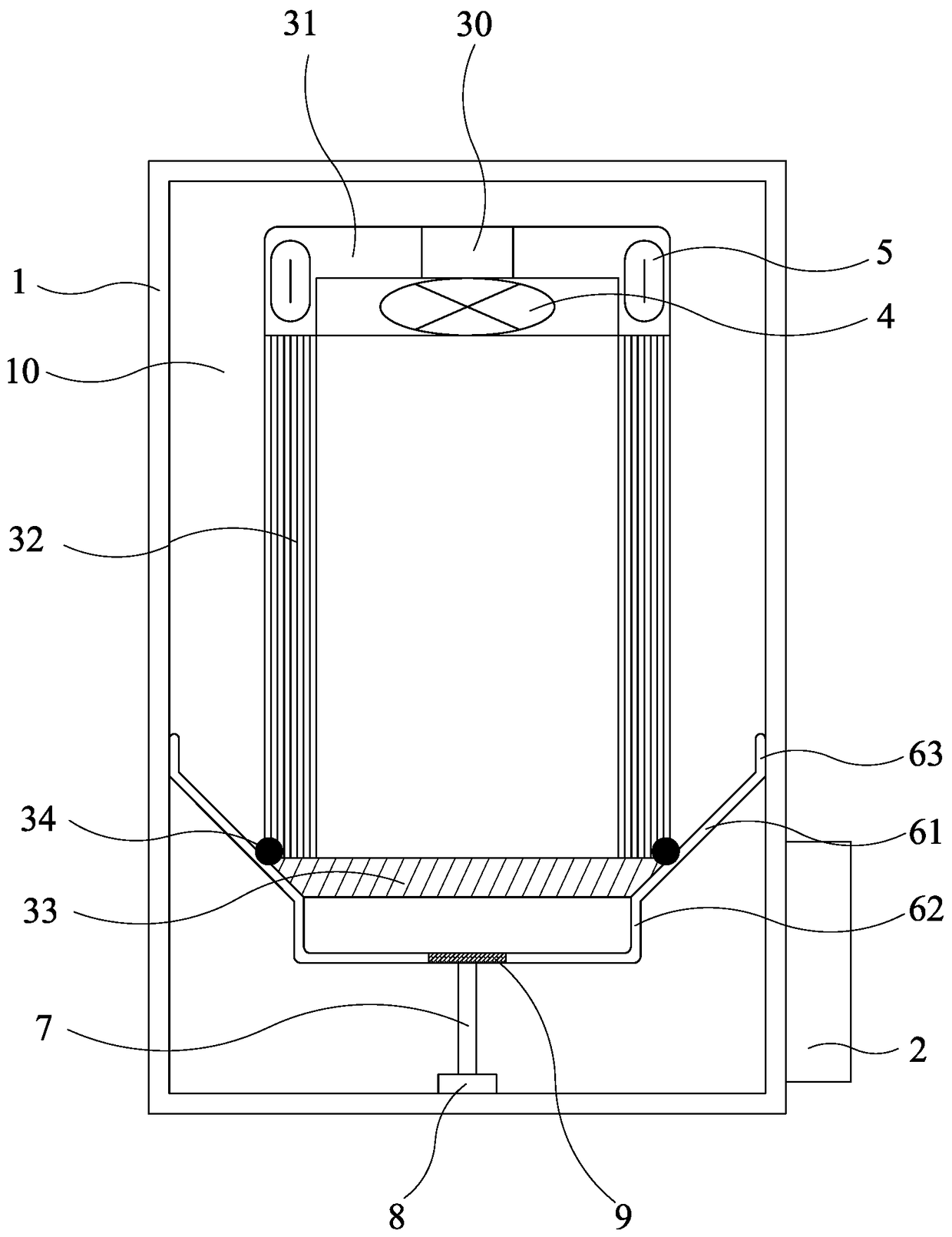

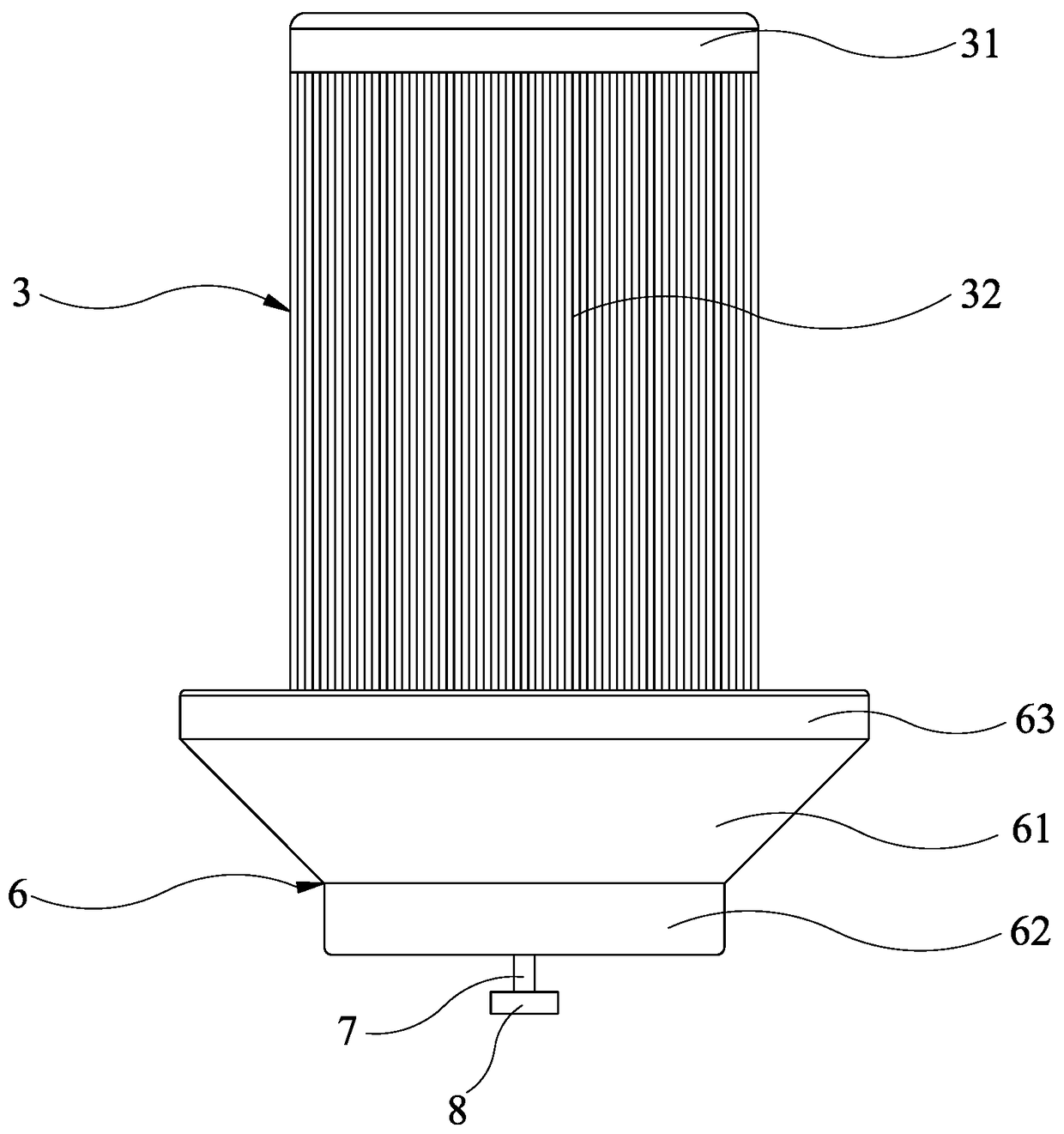

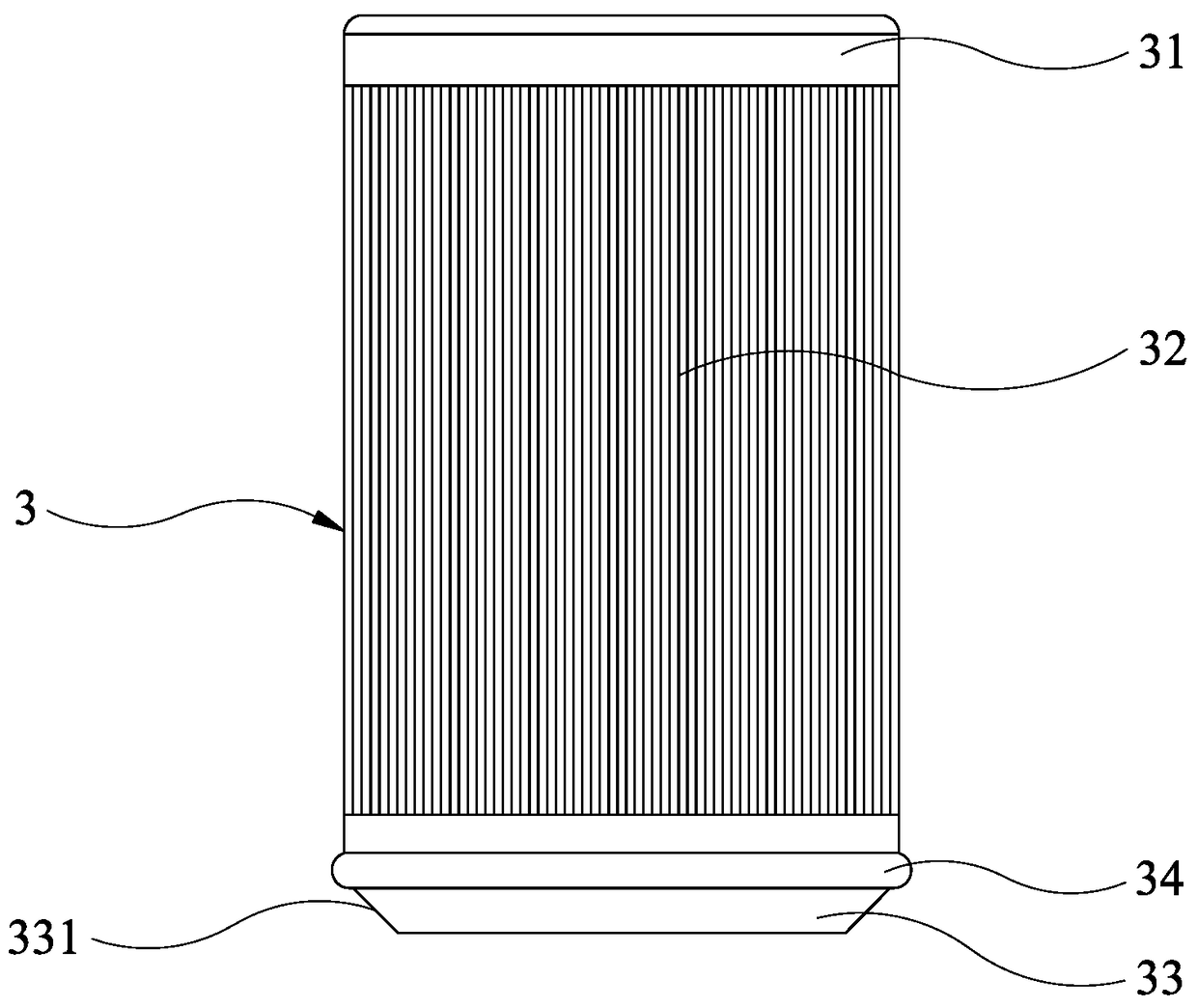

Air purifier

PendingCN109351089AEasy to collectImprove storage effectDispersed particle filtrationTransportation and packagingGrey boxEngineering

The invention discloses an air purifier. The air purifier comprises a housing, a filtering assembly, a dust collecting assembly and a control circuit board, the housing is of a hollow-out structure, the filtering assembly and the dust collecting assembly are installed in the housing, the control circuit board is fixed on the housing, the filter assembly comprises a filter tube, a turbine fan and avibration generator, the filter tube is provided with an air outlet, the turbine fan is installed on the filter tube and is electrically connected with the control circuit board, the vibration generator is installed on the filter tube and is electrically connected with the control circuit board, and the dust collecting assembly comprises a dust collecting box which is installed below the filter tube. By arranging the vibration generation on the filter tube, dust particles adhering to the outer surface of the filter tube can be automatically cleaned by the air purifier, dust particles can be collected by the dust collecting box under the action of gravitational force to prevent the problems of the accumulation of dust particles and secondary pollution, so that the service life of the air purifier is prolonged, and the trouble of frequent replacement and cleaning of filter core is prevented. The use of the air purifier is not restricted by air environment, so that the air purifier has more marketing value.

Owner:XIAMEN ZHONGCHUANG ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com