High-temperature aerobic fermentation method and device thereof

An aerobic fermentation and high-temperature technology, which is applied in fertilization equipment, organic fertilizer, organic fertilizer preparation, etc., can solve the problems of large material transportation volume, odor residence time, and increased ventilation resistance in the plant, so as to increase utilization efficiency, Improve air permeability and reduce failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

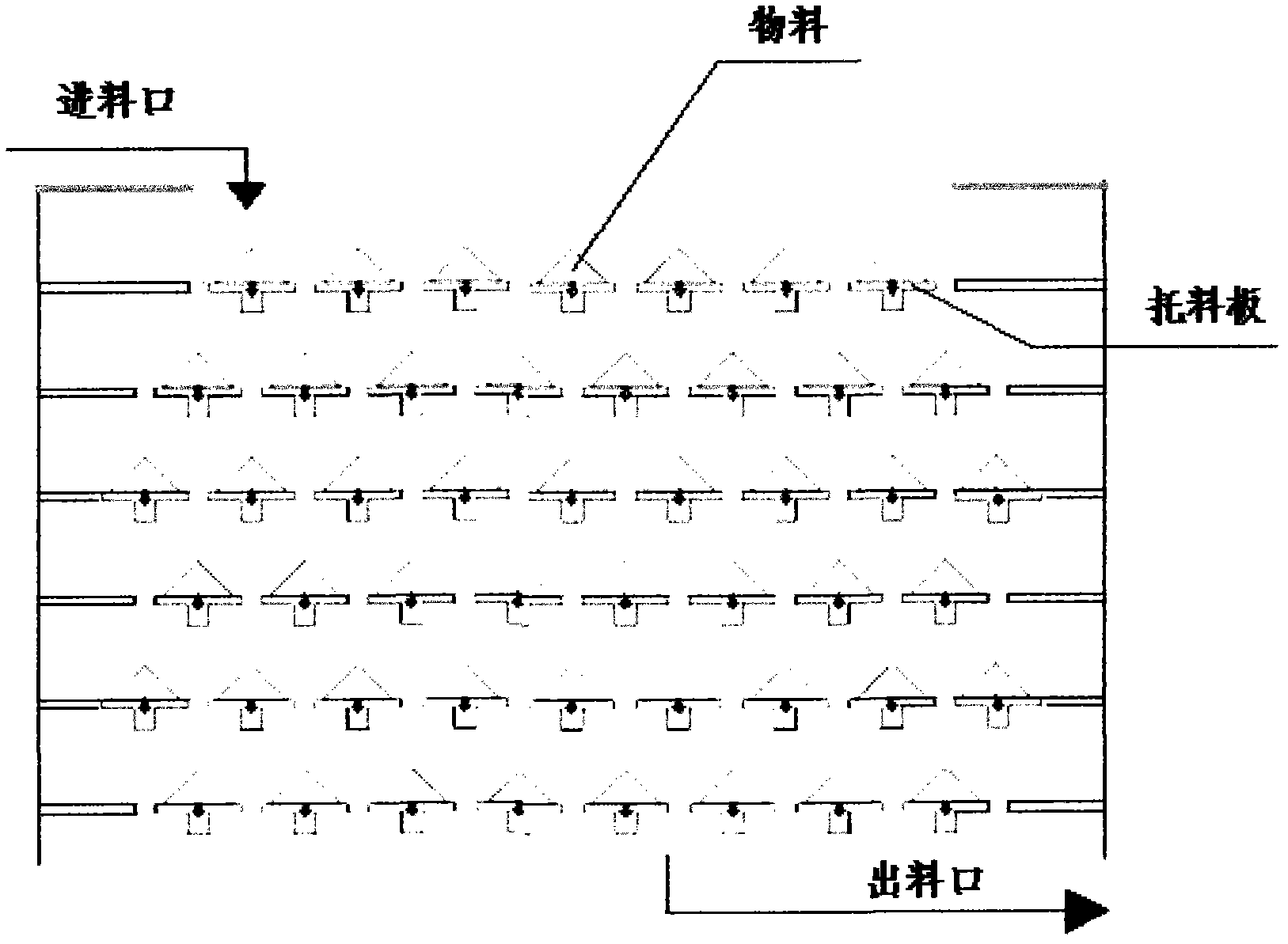

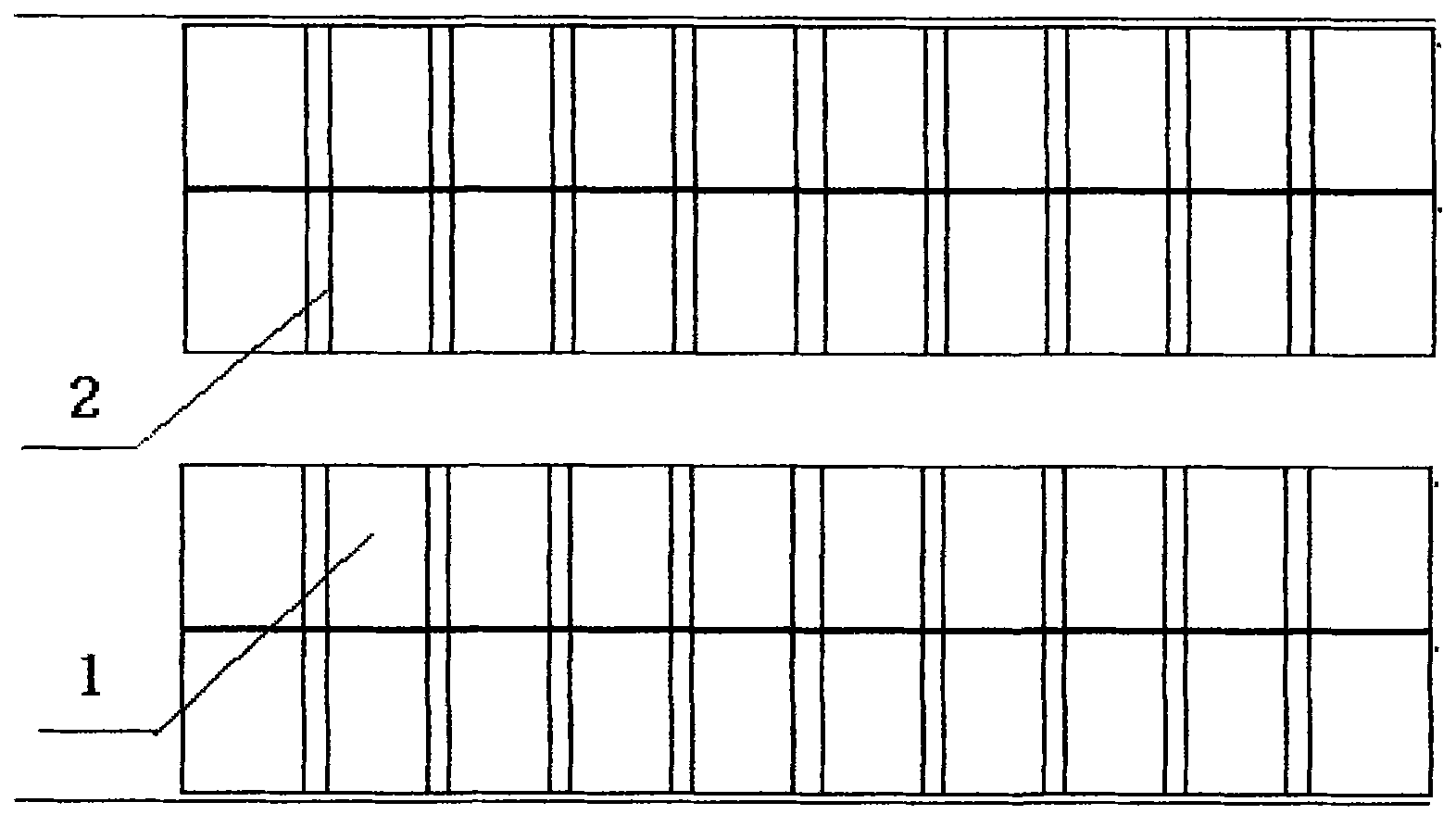

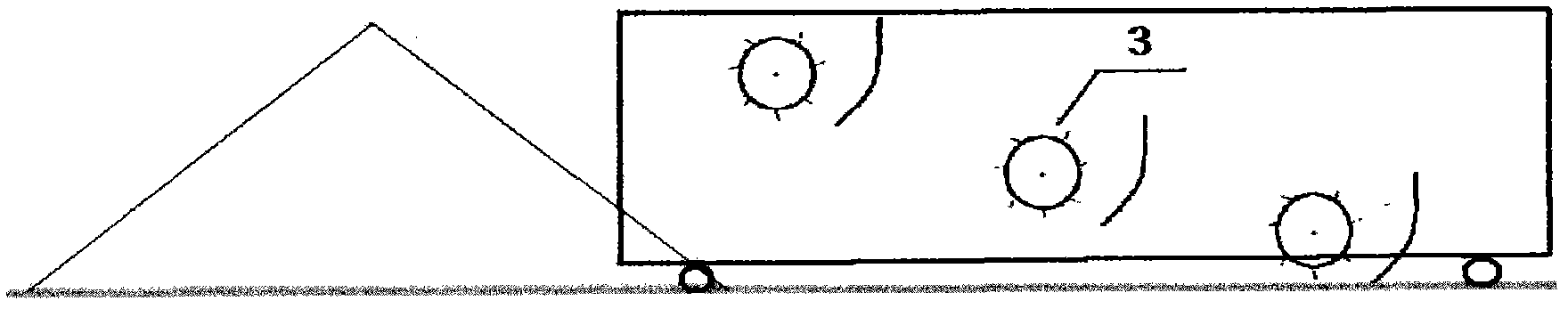

[0039] A high-temperature aerobic fermentation method, in which materials are arranged in multiple layers in the height direction, and fermentation is carried out layer by layer from top to bottom, and each layer adopts a low stacking height, and the low stacking height is determined by the self-compacting of the material. Obvious and breathable shall prevail. Generally, according to the different fermentation requirements of different materials, the maximum height that can realize the air permeability requirements can be determined, and this is the limit. Adopting the method for fermentation and composting effectively improves the utilization rate of unit space, improves the air permeability of materials, and accelerates the fermentation speed. According to different materials, the height of the stack is also different. According to the applicant's large number of experiments, for general materials, the height of each layer of materials should be between 0.4-0.6 meters, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com